Process for producing fired dry-cured beef

A production process and drying technology, which is applied in the production process of roasted beef, can solve the problems of single taste, monotonous variety, production and sales constraints, etc., and achieve the effect of high protein content, pure taste and low fat content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

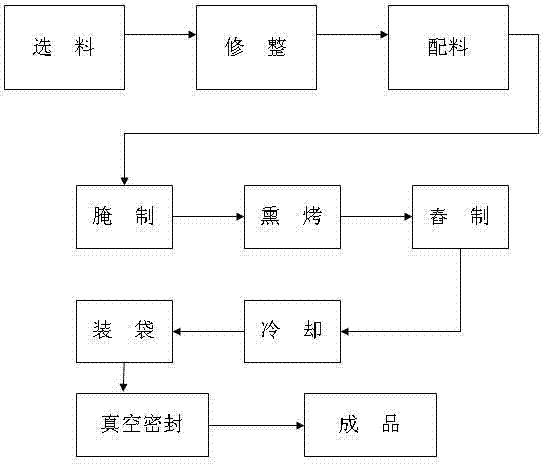

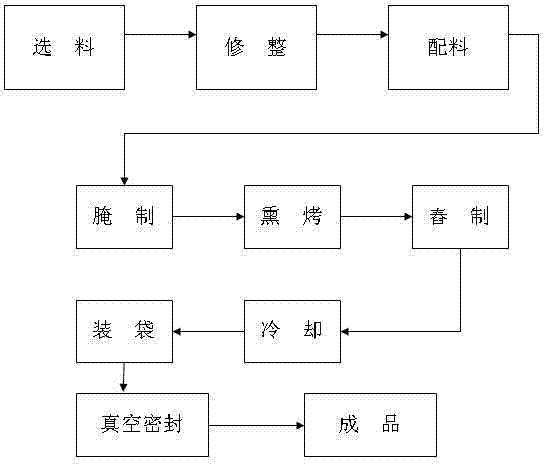

Image

Examples

Embodiment

[0015] 1. Material selection. Raw materials must be purchased according to the standard, and must be purchased in the market that has passed the inspection of the animal husbandry department's designated slaughtering and food hygiene supervision department. It is not allowed to purchase sick and dead beef, water-injected beef and abnormal beef.

[0016] Second, trimming. Remove tendons, skin, fat and other sundries from the purchased fresh beef, keep the meat, and cut into strips with dimensions of about 20×1×10cm or 30×1.5×15cm.

[0017] Three, the ingredients are marinated. Mix the strip-shaped fresh beef with refined salt and monosodium glutamate, use 11.5 grams of salt, 1.6 grams of monosodium glutamate, 2.3 grams of peppercorns and 11 grams of chili powder per kilogram of fresh meat, mix well and marinate in a marinating tank for 4-5 Hours, pay attention to indoor temperature can not be too high, generally 10-25 degrees. When the temperature is high, cooling measures ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com