Preparation method of solar cell back plate

A technology for solar cells and backsheets, applied in the field of preparation of solar cell backsheets, can solve problems such as complex processes, and achieve the effects of increased tensile fracture strength and excellent mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment relates to the preparation of a solar battery back sheet, comprising the following steps:

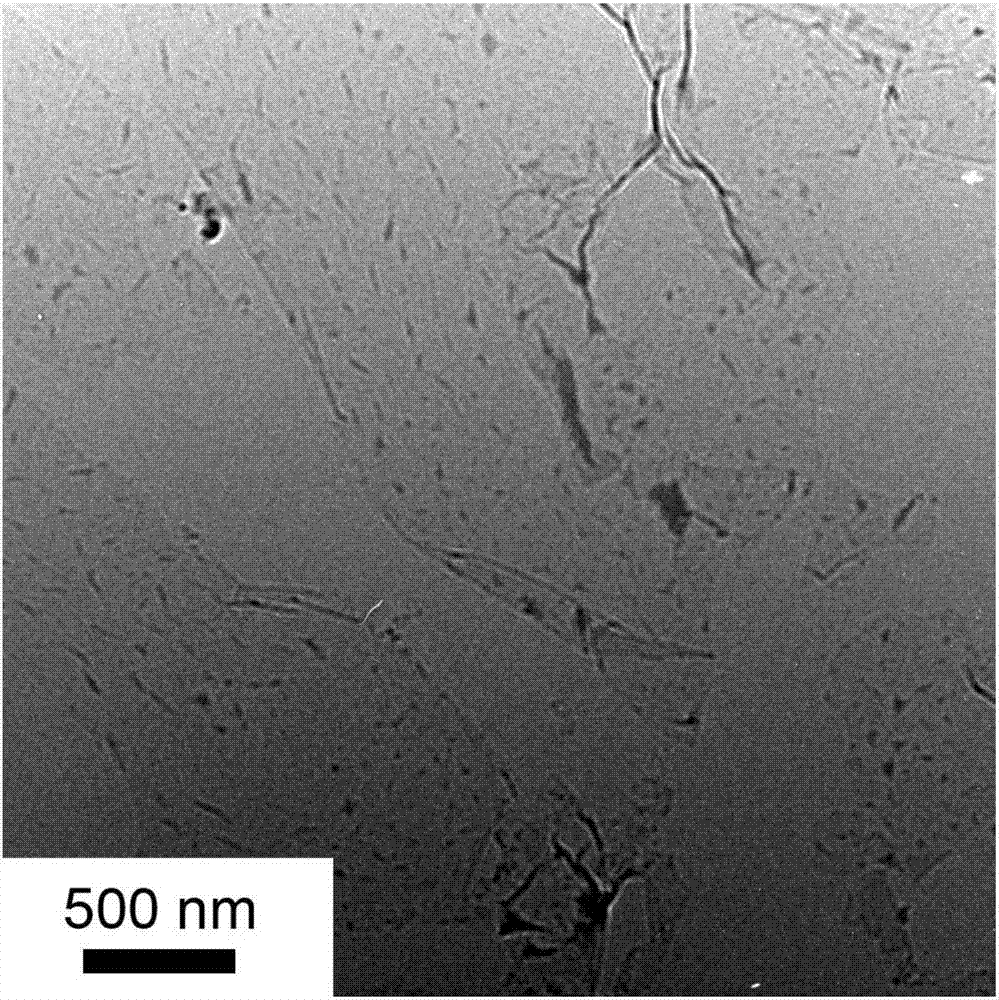

[0039] 1. Large-scale preparation of graphene oxide (optimized Hummers method for large-scale preparation of graphene oxide, washing 3 to 5 times and then ultrasonicating under acidic conditions, which simplifies the washing process, greatly reduces the degree of pollution and reduces the cost);

[0040] The method for preparing graphene oxide by Hummers method after optimization is:

[0041] 1) Add 460mL of concentrated sulfuric acid into a 2L beaker, and the temperature of the ice bath is 0°C;

[0042] 2) Add graphite powder, and add 60g of KMnO after the dispersion is uniform 4 , during which the temperature is kept below 10°C;

[0043]3) Raise the temperature of the solution to 35°C. After 2h, add another 920mL of distilled water for another 1.5h (add 30mL in equal portions to keep the temperature below 50°C, that is, add in batches, add 30mL in each batch),...

Embodiment 2

[0052] This embodiment relates to the preparation of a solar battery back sheet, comprising the following steps:

[0053] 1. Large-scale preparation of graphene oxide (optimized Hummers method for large-scale preparation of graphite oxide, washing 3 to 5 times and then ultrasonicating under acidic conditions, which simplifies the washing process, greatly reduces the degree of pollution and reduces the cost);

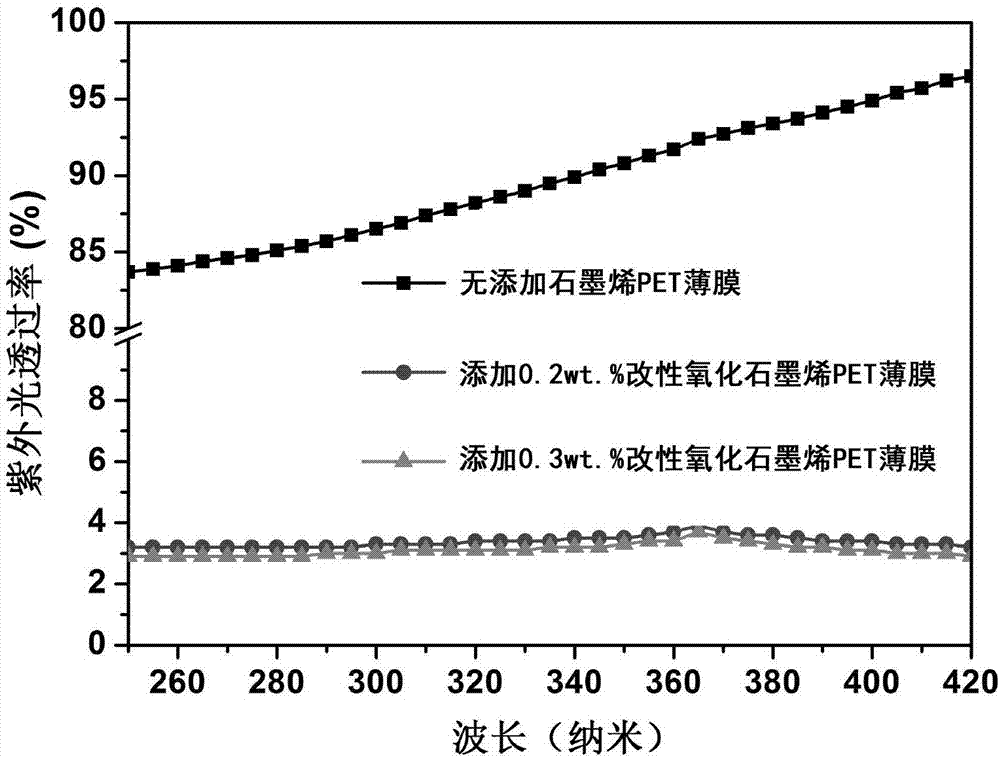

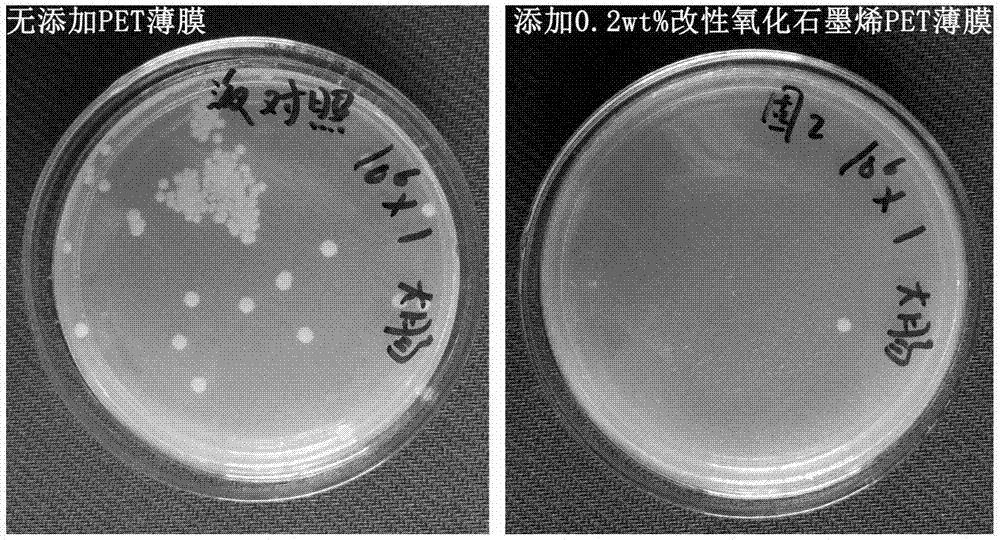

[0054] 2. The acidic graphene oxide dispersion and modifiers (such as silane coupling agent, titanate coupling agent, aluminate coupling agent, phosphate ester coupling agent, dodecyl dimethyl oxide, etc.) Amine, cetyl dimethyl amine oxide, octadecyl dimethyl amine oxide, dodecyl bromide, hexadecane bromide, octadecyl bromide, octadecyl ammonium bromide, imidazole morpholine, morpholine guanidine, triazine derivatives, etc.) molecules for reaction grafting, under acidic conditions, the grafting of the above-mentioned modifiers on graphene oxide sheets can be catalyzed, a...

Embodiment 3

[0058] This embodiment relates to the preparation of a solar battery back sheet, comprising the following steps:

[0059] 1. Large-scale preparation of graphene oxide (optimized Hummers method for large-scale preparation of graphite oxide, washing 3 to 5 times and then ultrasonicating under acidic conditions, which simplifies the washing process, greatly reduces the degree of pollution and reduces the cost);

[0060] 2. The acidic graphene oxide dispersion and modifiers (such as silane coupling agent, titanate coupling agent, aluminate coupling agent, phosphate ester coupling agent, dodecyl dimethyl oxide, etc.) Amine, cetyl dimethyl amine oxide, octadecyl dimethyl amine oxide, dodecyl bromide, hexadecane bromide, octadecyl bromide, octadecyl ammonium bromide, imidazole morpholine, morpholine guanidine, triazine derivatives, etc.) molecules for reaction grafting, under acidic conditions, the grafting of the above-mentioned modifiers on graphene oxide sheets can be catalyzed, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com