Patents

Literature

189results about How to "Improve tensile strength at break" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

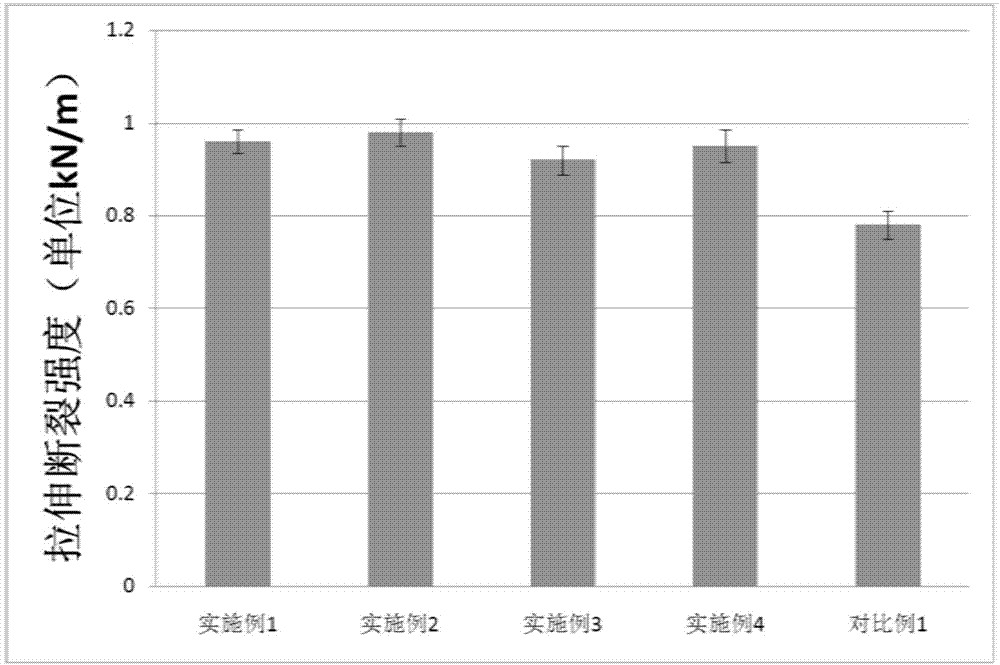

Preparation method of reinforced electrostatic spinning nano-fiber lithium-ion battery separator

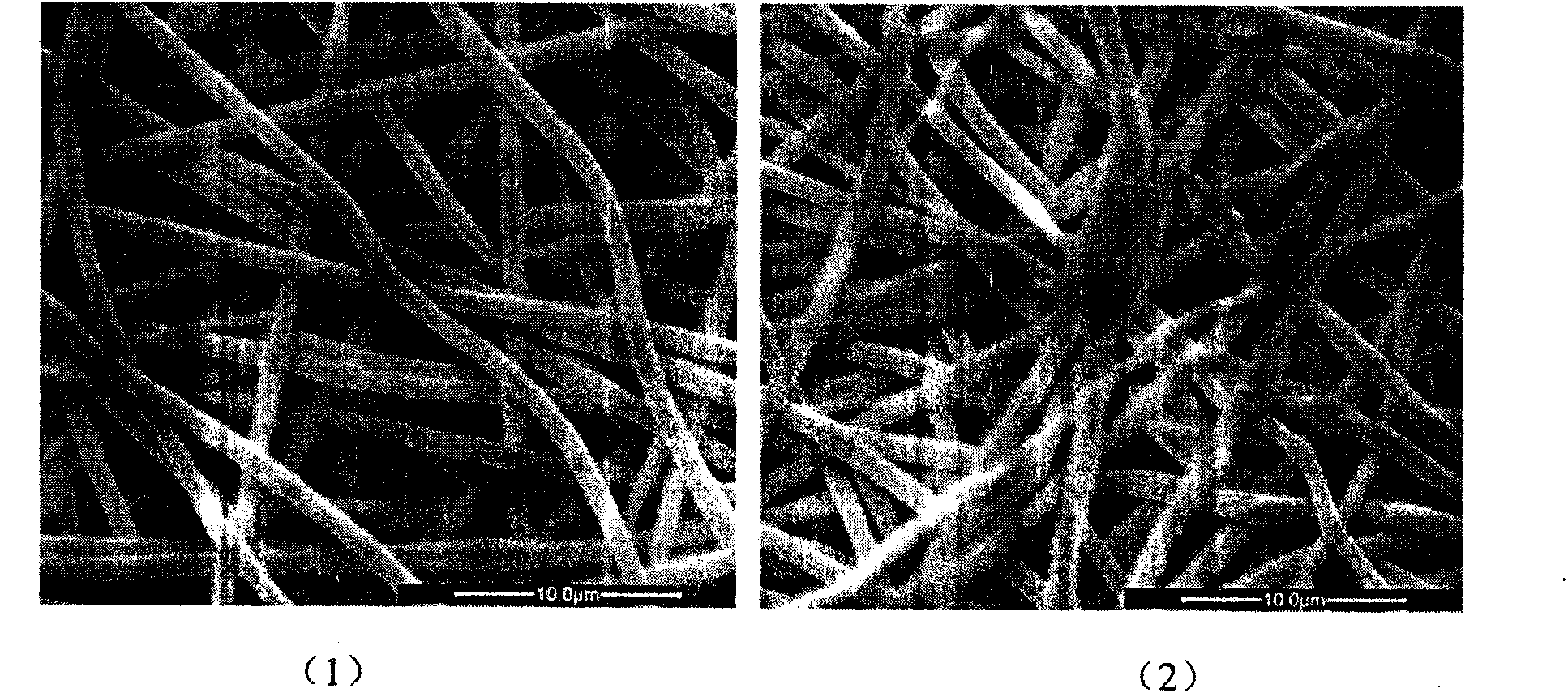

The invention provides a preparation method of a reinforced electrostatic spinning nano-fiber lithium-ion battery separator. The preparation method is characterized in that the reinforced electrostatic spinning nano-fiber lithium-ion battery separator is a composite film formed by two polymers with the differences of melting temperatures being more than 30 DEG C, the composite film is a nano-fiber film which is prepared from a spinning solution system formed by two polymers with the differences of melting temperatures being more than 30 DEG C through an electrostatic spinning technique, the fiber film is stilled for 10 hours under normal temperature under the negative pressure so as to evaporate organic solvents left in the fiber film, then the fiber film is subjected to hot-pressing treatment for a certain time under a certain pressure intensity, the hot-pressing temperature is between the melting temperature of the low-melt-point polymer and the melting temperature of the high-melt-point polymer, the low-melt-point polymer is fused to enable nano-fibers in the fiber film to be mutually bonded, so that the mechanical strength of the fiber film is greatly improved. The method is easy and convenient to operate, the prepared separator reserves the advantages of high porosity and high pick-up rate of an electrostatic spinning separator, and the defects of poor dynamic performance and non-existence of effective bonding points between fibers of the electrostatic spinning separator are also overcome.

Owner:TIANJIN POLYTECHNIC UNIV

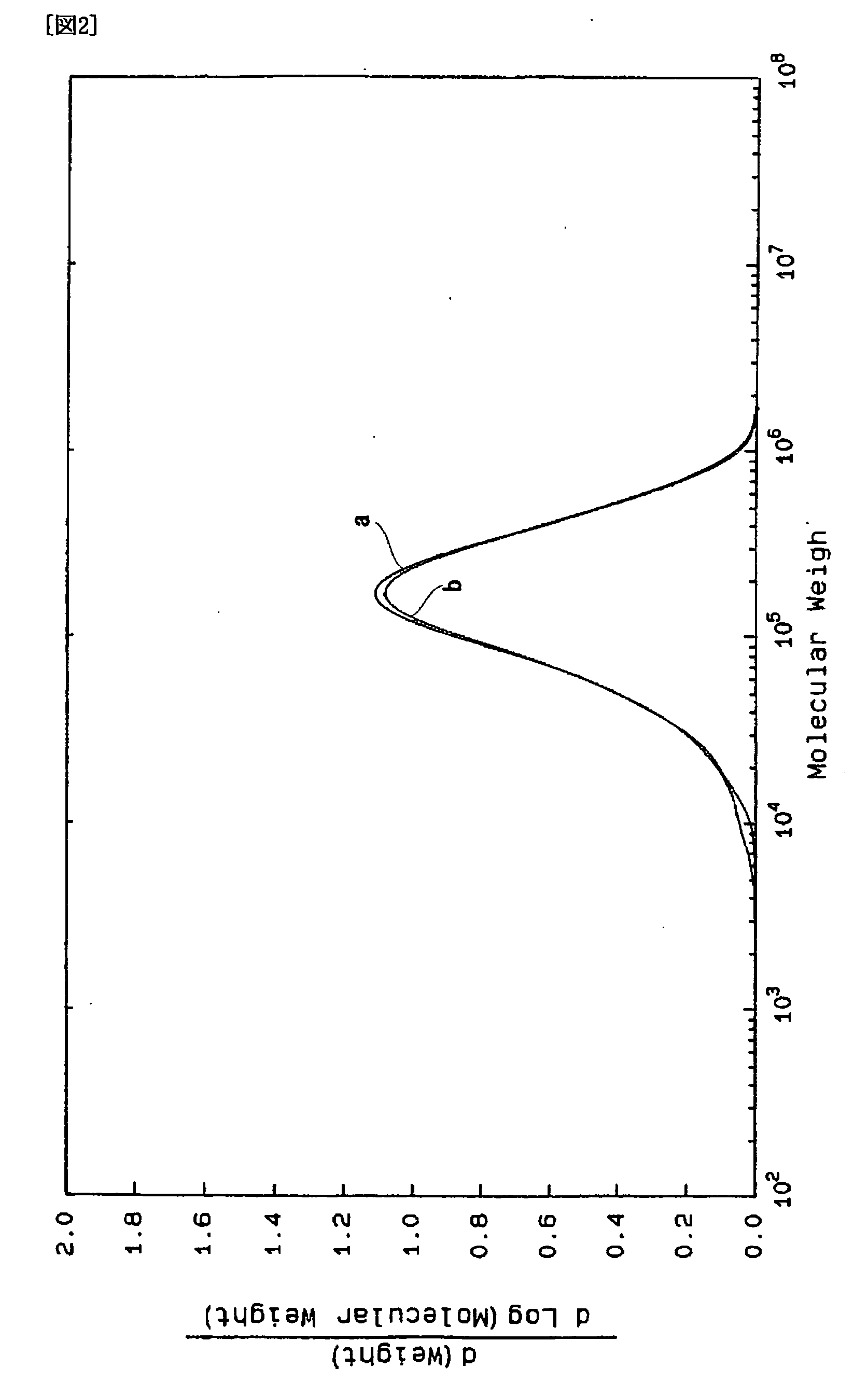

Acrylonitrile copolymer, preparation and use thereof

InactiveCN101323656AReduce pollutionLow costMonocomponent synthetic polymer artificial filamentMelt spinning methodsPolymer scienceNitrogen

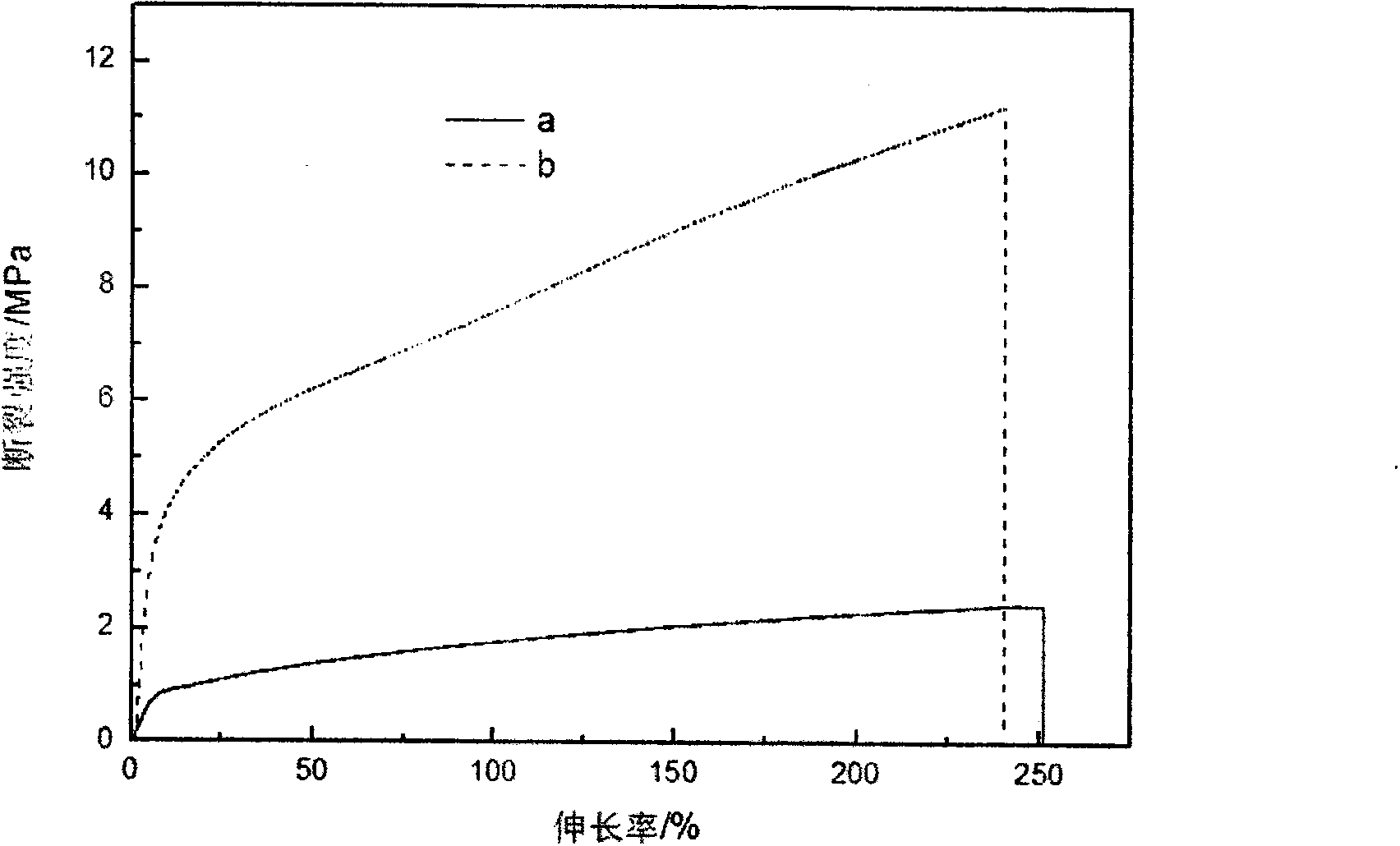

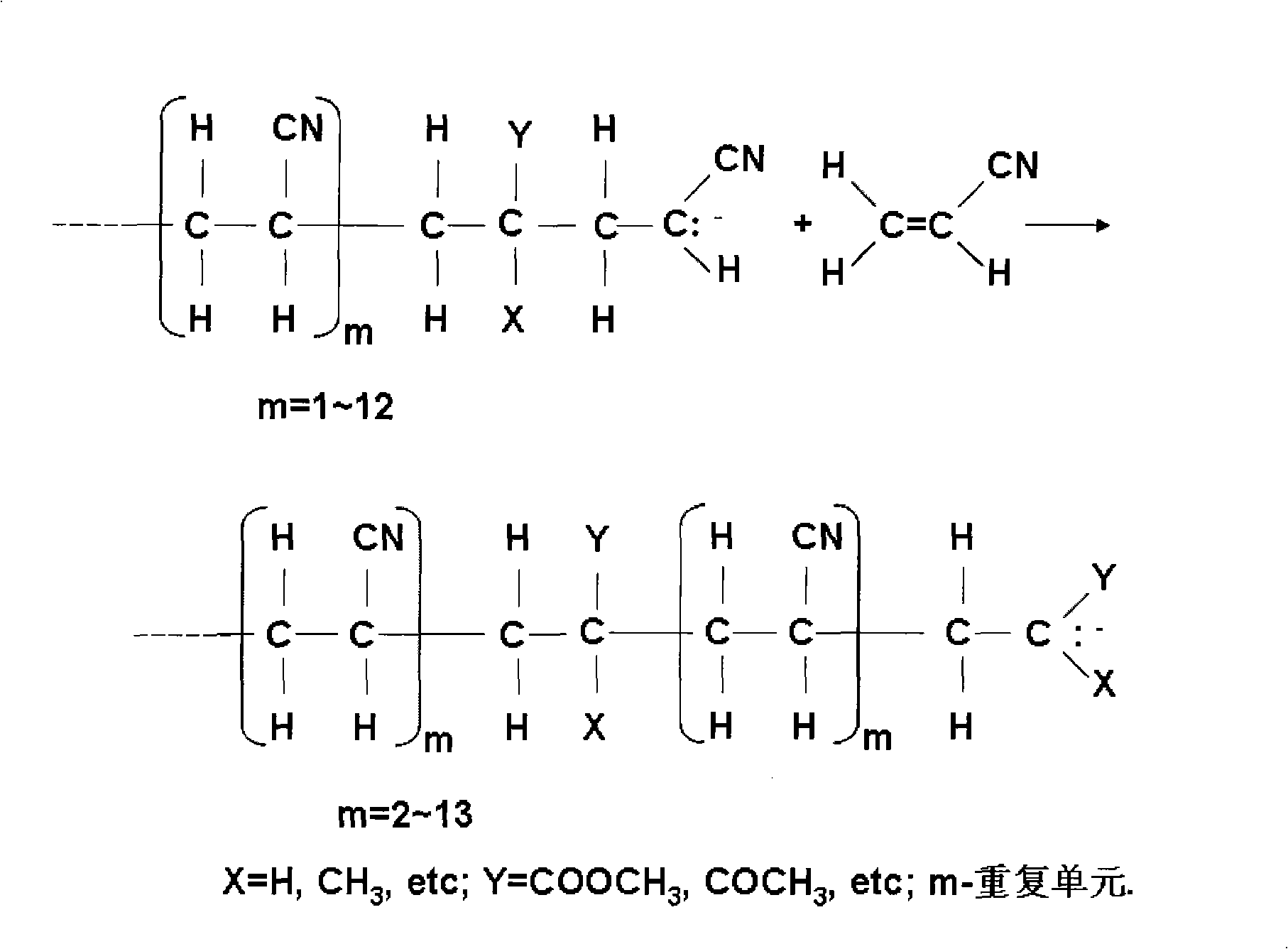

The invention relates to an acrylonitrile copolymer and a preparation method and an application thereof, wherein, the mole ratio of an acrylonitrile on a molecular chain of the acrylonitrile copolymer to a second monomeric unit is 2:1 to 19:1; the formula of the acrylonitrile copolymer is that: 70.0 mol percent to 90.0 mol percent of the acrylonitrile monomer, 10.0 mol percent to 30.0 mol percent of the second monomeric unit, an evocating agent and a chain-transferring control agent respectively taking up 0.1 mol percent to 16.2mol percent and 0.05 mol percent to 5.0mol percent of the total quantity of monomers. The preparation method adopts the formula of the acrylonitrile copolymer and the following technique: a proper amount of deionized water is put in a reaction vessel and cleaned with nitrogen for 5 minutes to 400 minutes at a temperature of 0 DEG C to 70 DEG C; the evocating agent and the chain-transferring control agent are added in one time; the acrylonitrile monomer and the second monomer are put into a blending container, evenly blended and the dropped slowly into the reaction vessel; and then all reactants continue to be stirred for 20minutes to 40 minutes and the product is obtained after being filtered, cleaned with the deionized water for three times and dried in vacuum. The acrylonitrile copolymer of the invention can be produced into acrylic fiber or film with good performance through a fusion processing method.

Owner:TIANJIN POLYTECHNIC UNIV

Water-soluble biodegradable material, and its preparing method and membrane product

The invention relates to water solubility biodegradable material. The material contains the outcome formed by mixture fusing which contains starch, polyhydric alcohol, and aqueous polyvinyl alcohol which has hydrophilicity. Using the mixture total weight as the criterion, the content of the polyhydric alcohol is 19-40wt%. Its fusing temperature is 140-190 degree centigrade; decomposition temperature is 250-400 degree centigrade. Thus it can be made into film products by blow molding forming which is biodegradable, has high tensile break strength reached to 65 megapascal, 398% percentage elongation at rupture at the condition of high starch content.

Owner:李小鲁

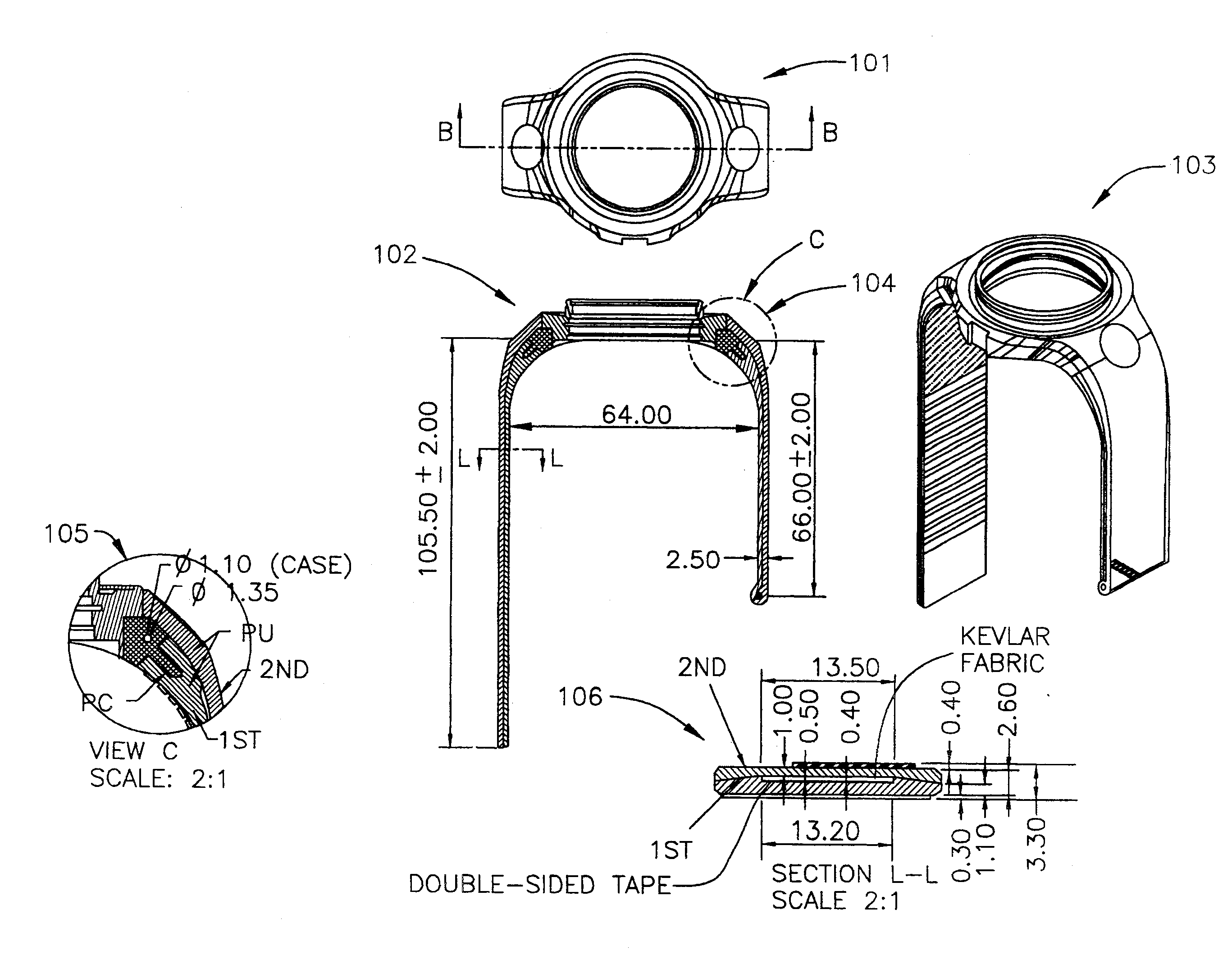

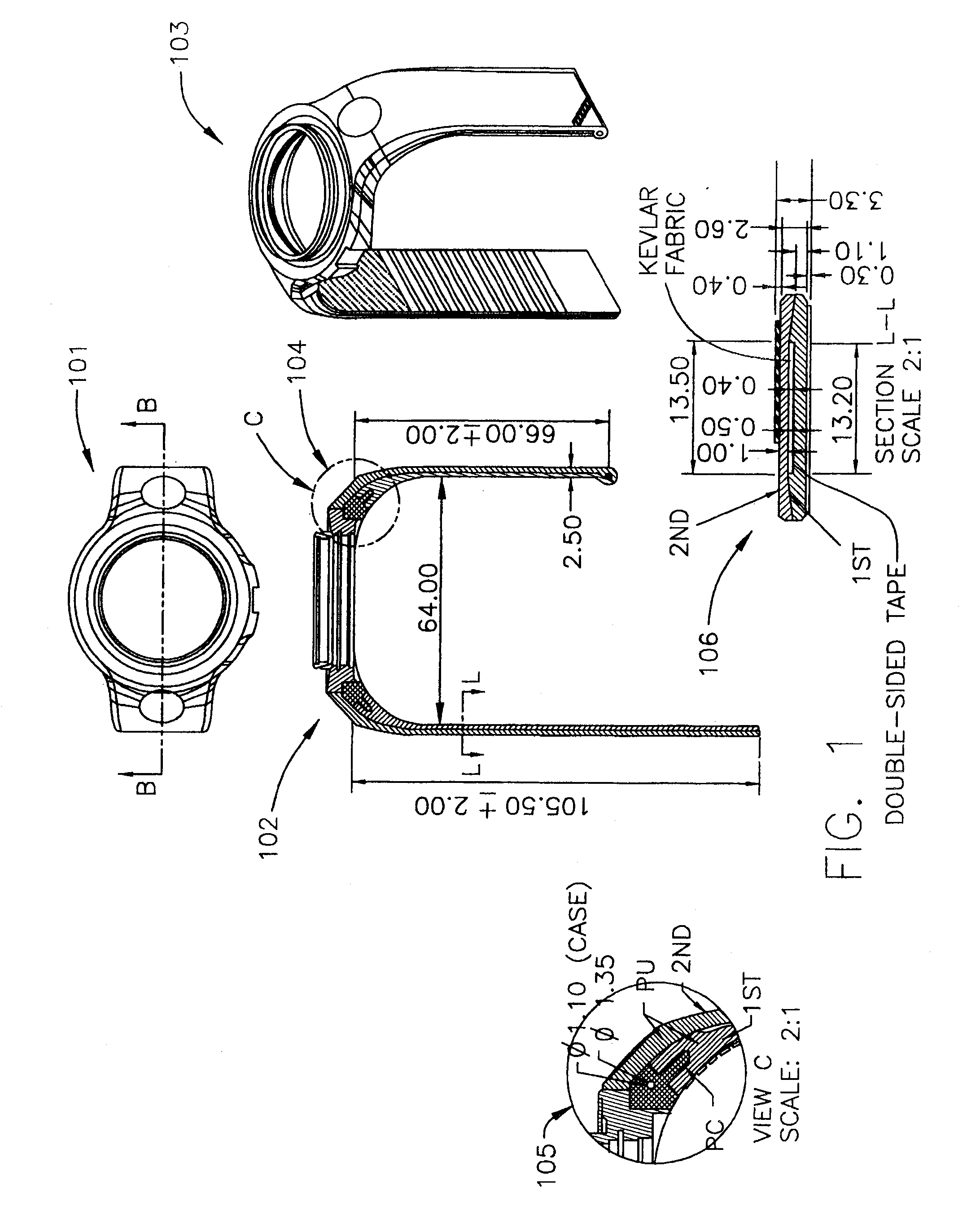

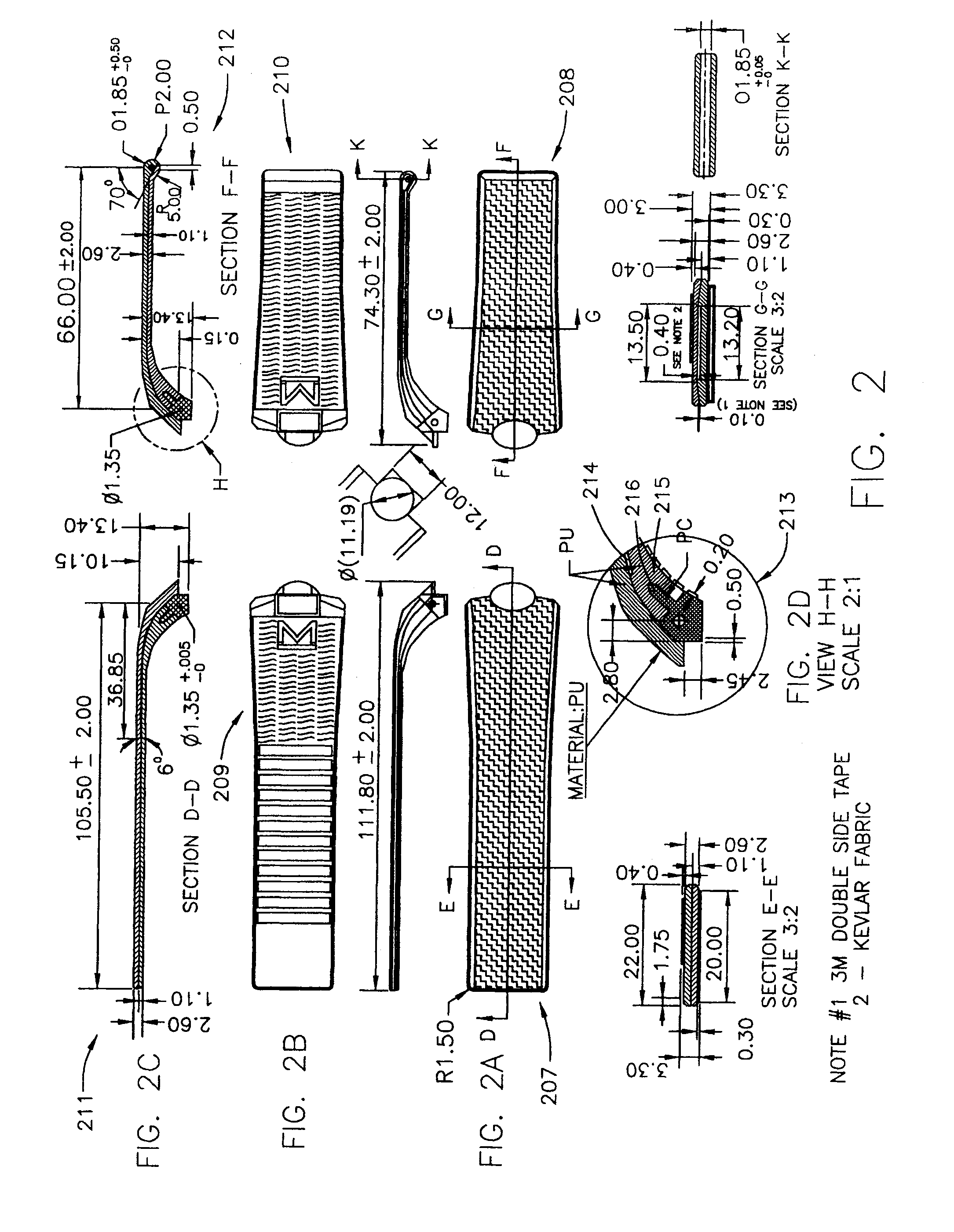

Integrated watch band and methods therefor

InactiveUS20090175135A1Increase tensile break strengthFacilitate formationWood working apparatusClockwork casesFrequency bandInjection molding process

The present invention includes an integrated (composite) watchband and process for making a watchband that integrates a high tensile strength fabric (e.g. an aramid fabric) within the watchband via an injection molding process. The resultant integrated watchband exhibits greatly increased strength while maintaining all the necessary characteristics of a conventional band.

Owner:MOVADO

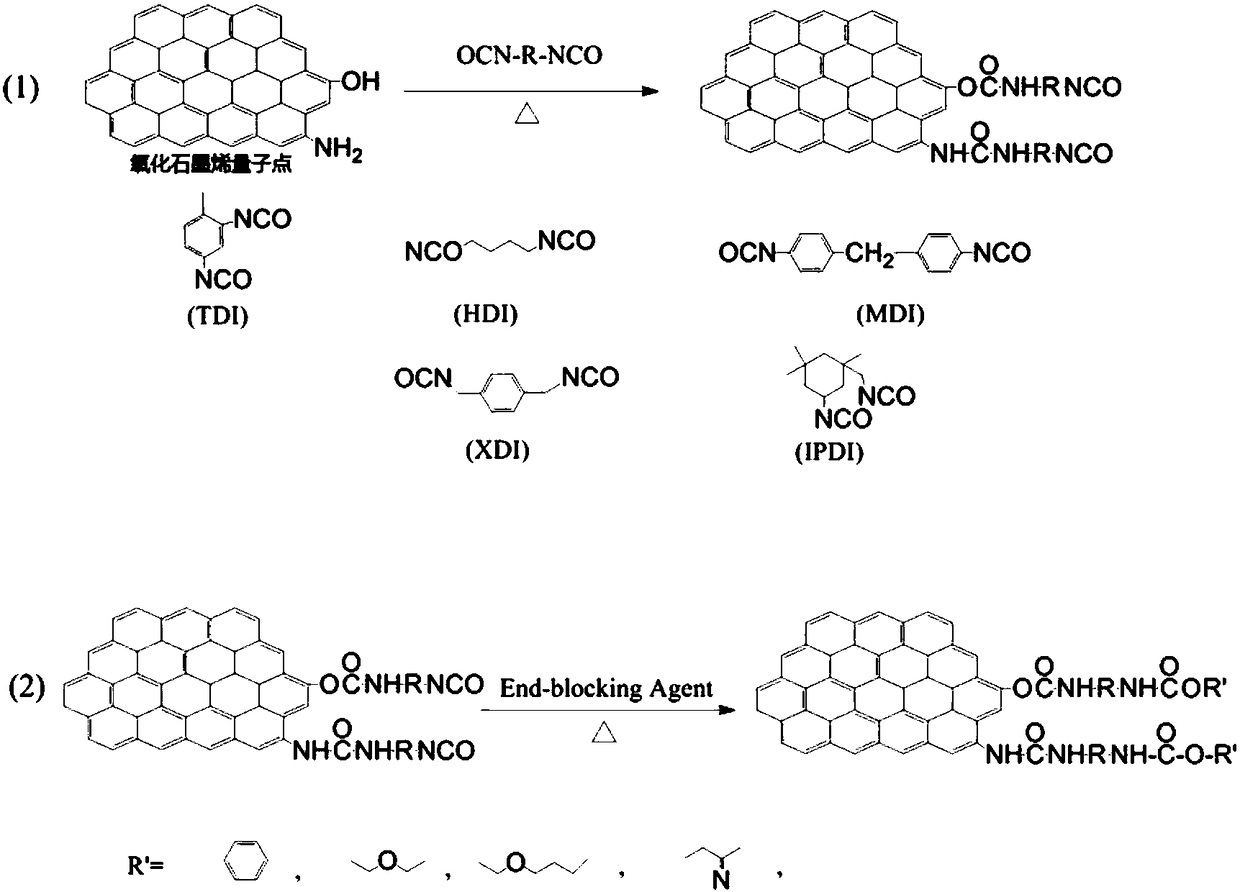

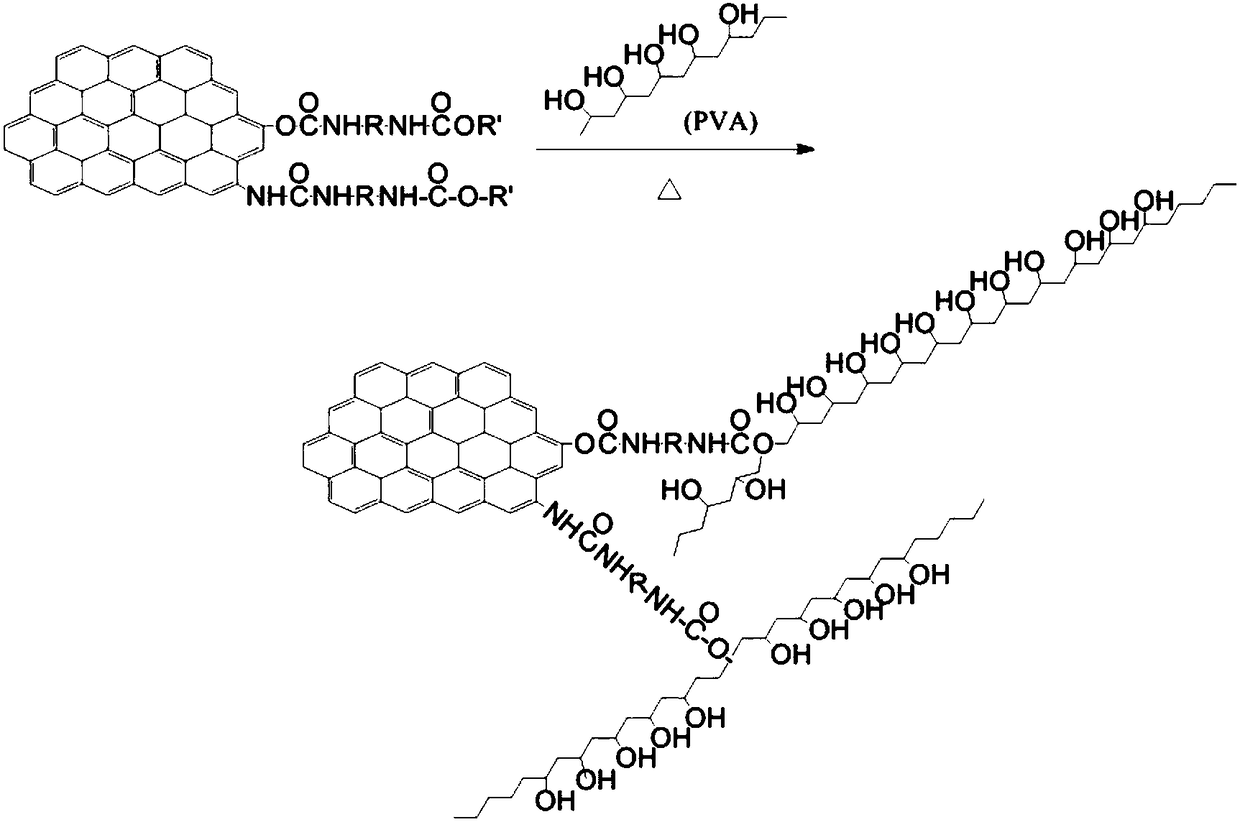

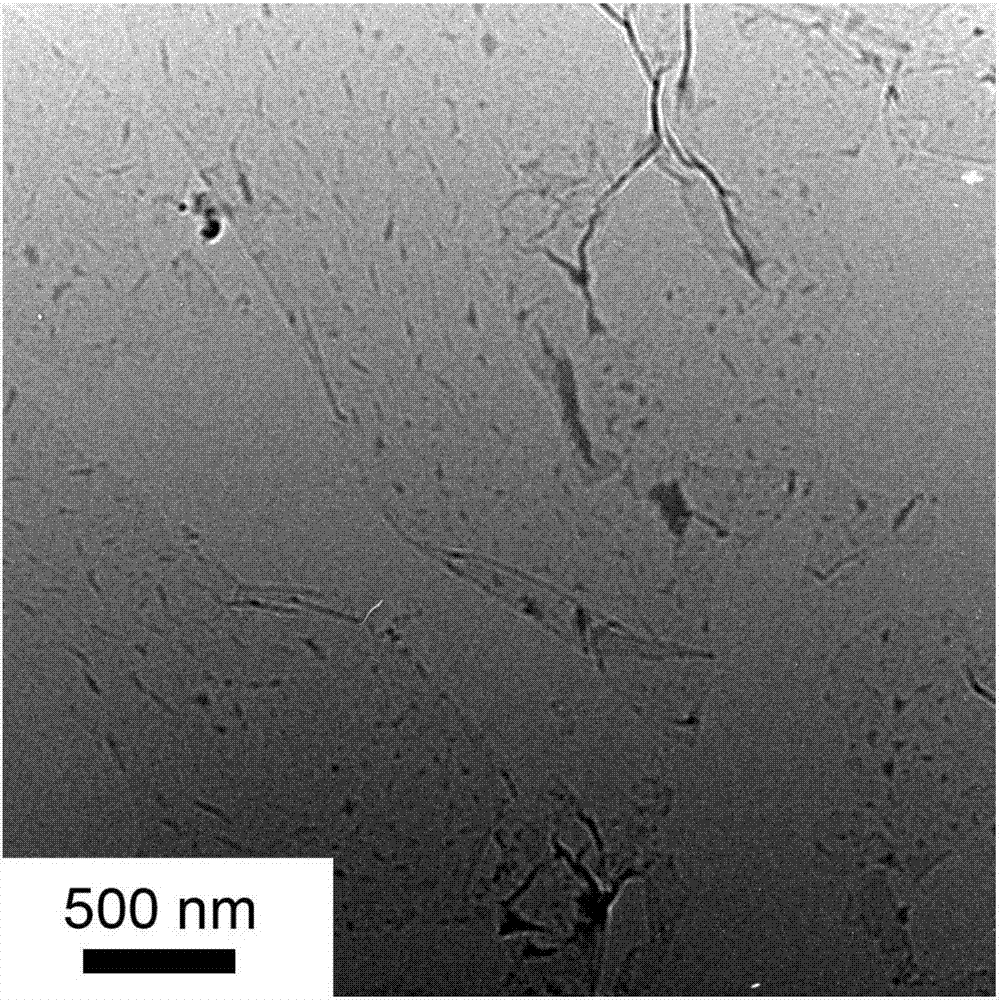

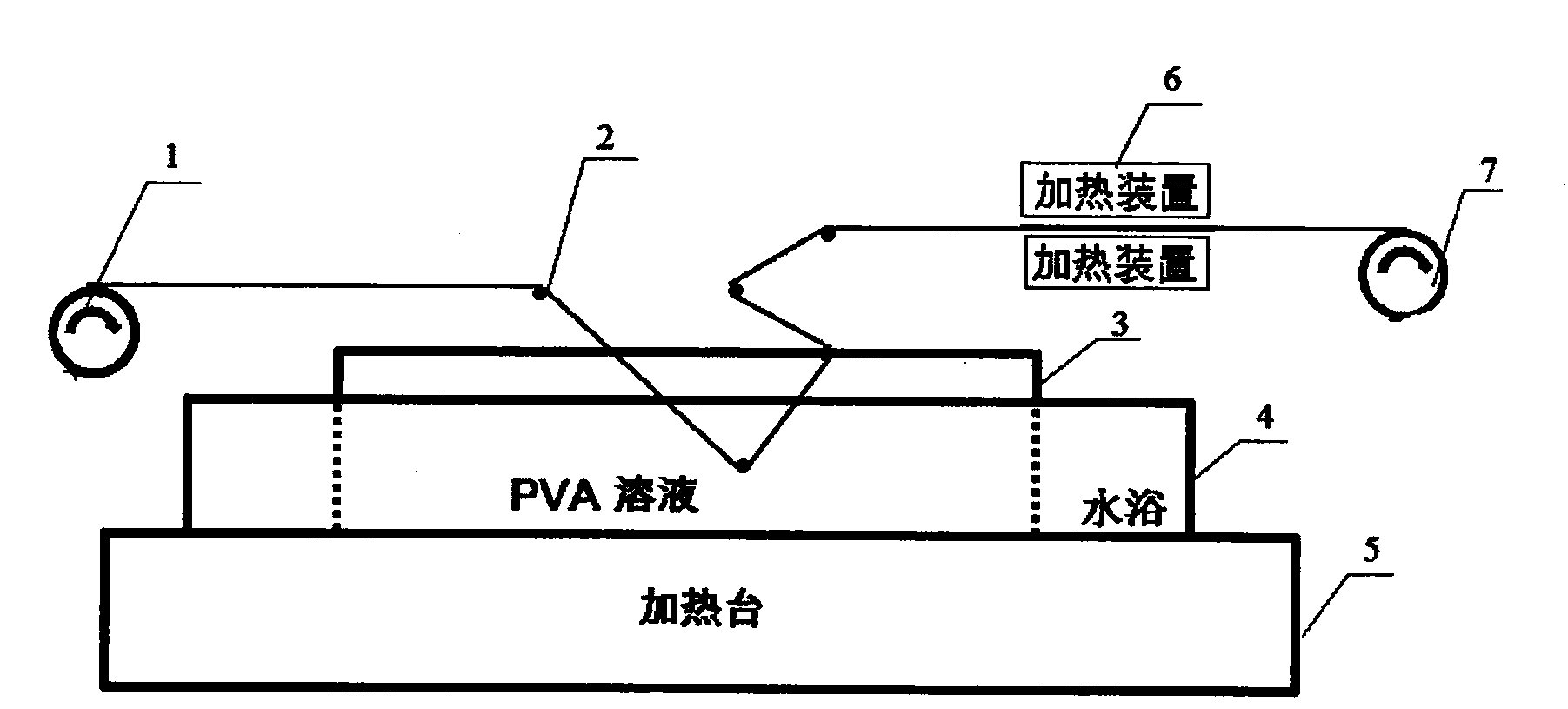

Method for preparing high performance graphene-polyvinyl alcohol composite fiber

InactiveCN108251907AImprove tensile strength at breakHigh strengthMonocomponent synthetic polymer artificial filamentArtifical filament manufactureFiberProcess equipment

The invention discloses a method for preparing high performance graphene-polyvinyl alcohol composite fiber, the method comprises the following steps: 1) functionalization of blocked isocyanate groupsof graphene quantum dots; 2) preparation of a spinning solution of polyvinyl alcohol-graphene quantum dots (PVA-GQD); 3) wet spinning; 4) post-treatment of nascent fibers; the method is simple, shortin process, low in cost and suitable for large-scale production, and does not require modification of existing polyvinyl alcohol wet spinning process equipment, and the prepared PVA-GQD fiber not onlyhas excellent mechanical properties and easy dispersibility, but also has a metallic luster, and is an ideal concrete reinforcement material, packaging material and clothing fabric.

Owner:重庆中科烯维科技有限公司

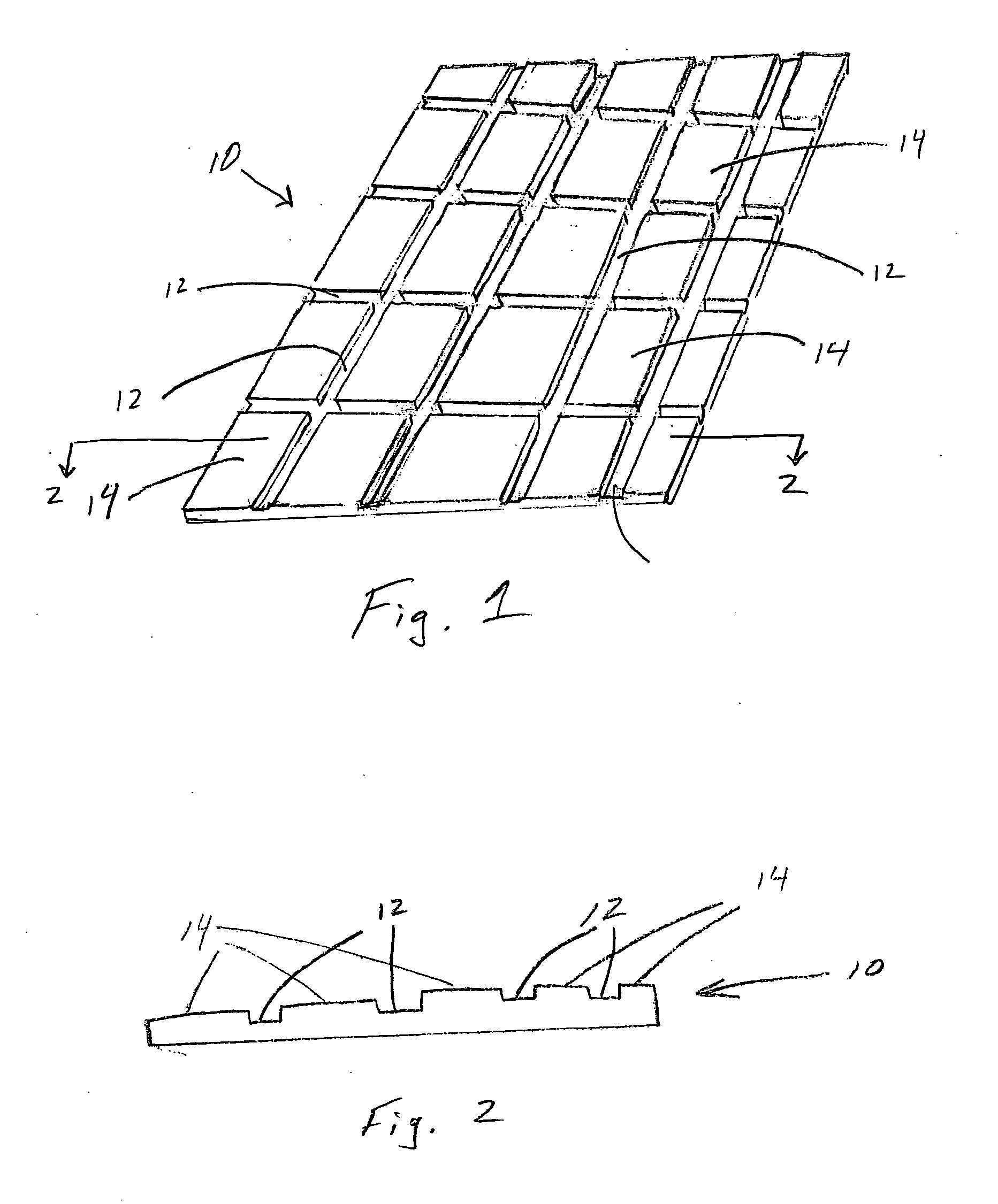

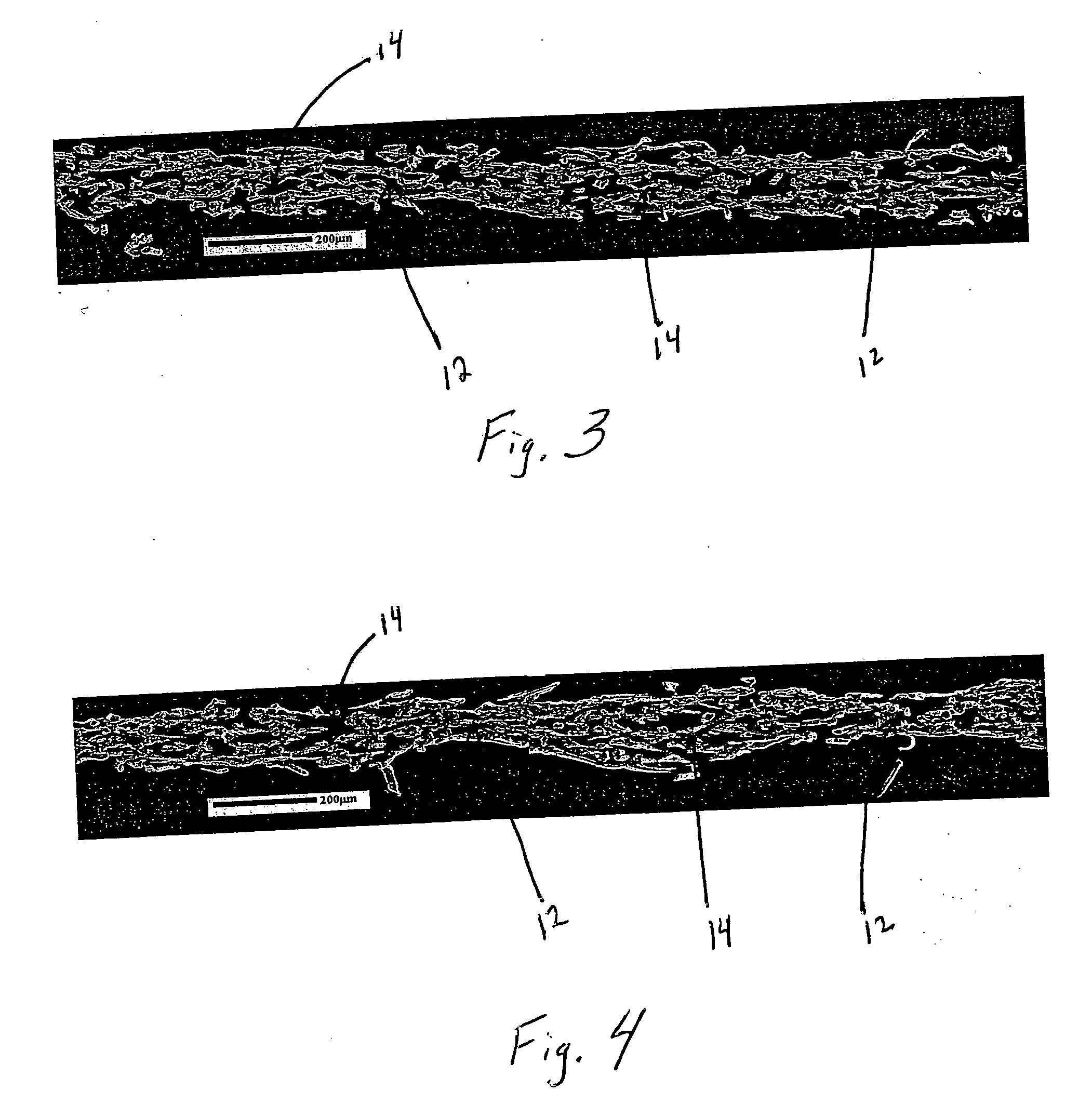

Densified fibrous structures and methods for making same

ActiveUS20070074833A1Improve tensile strength at breakNon-fibrous pulp additionMechanical working/deformationPolymer scienceFiber structure

Owner:THE PROCTER & GAMBLE COMPANY

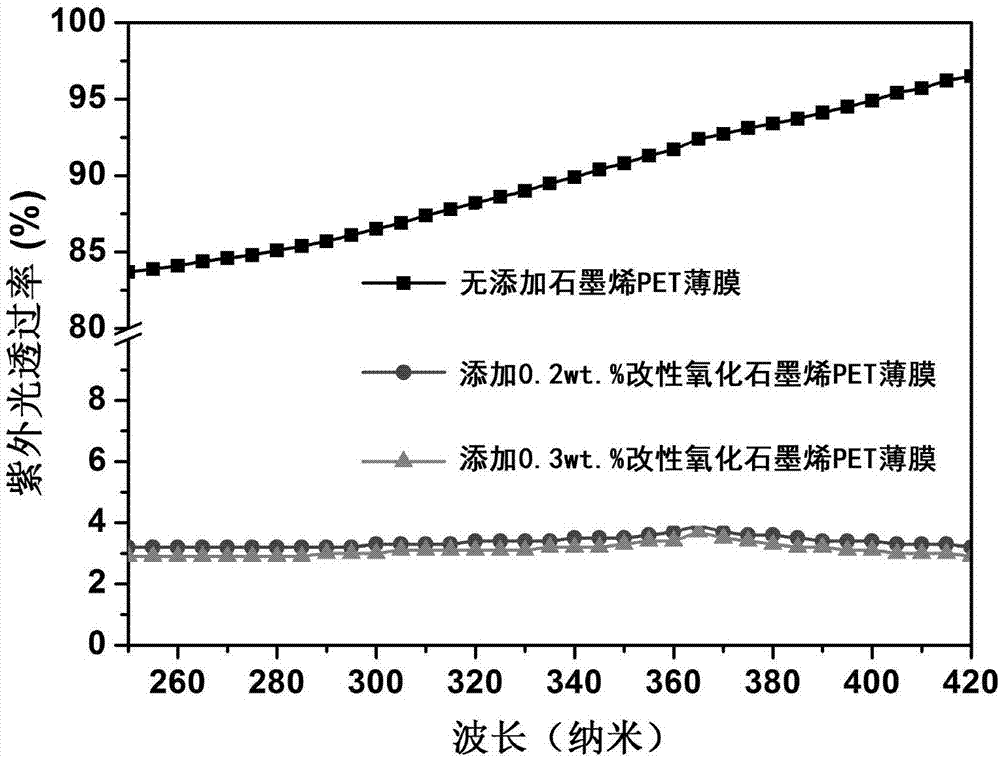

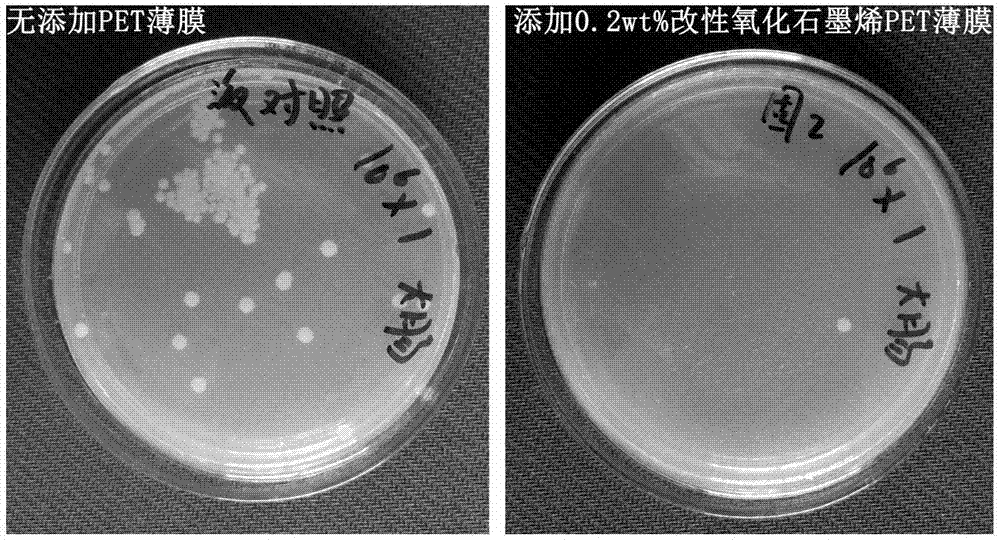

Coating composition for solar cell backboards and solar cell backboards which are coated by coating composition

InactiveCN107236378AHigh efficiencyHigh temperature resistantFireproof paintsAntifouling/underwater paintsPolyethylene terephthalateWeather resistance

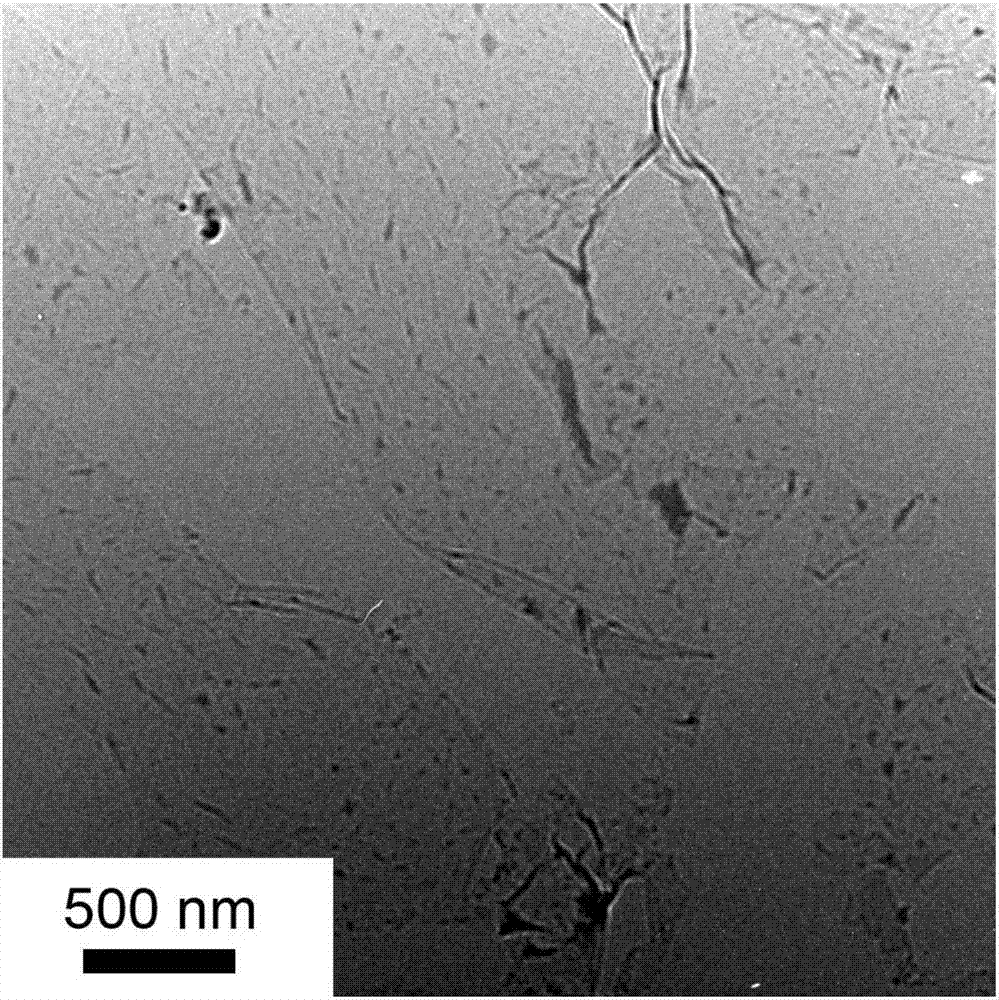

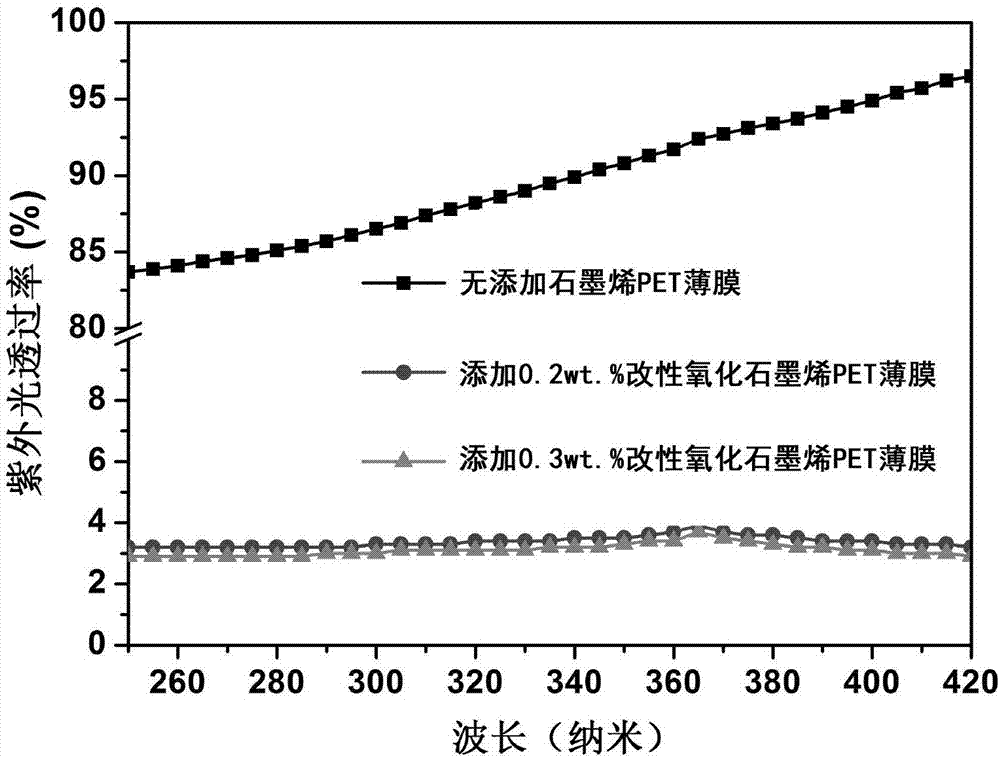

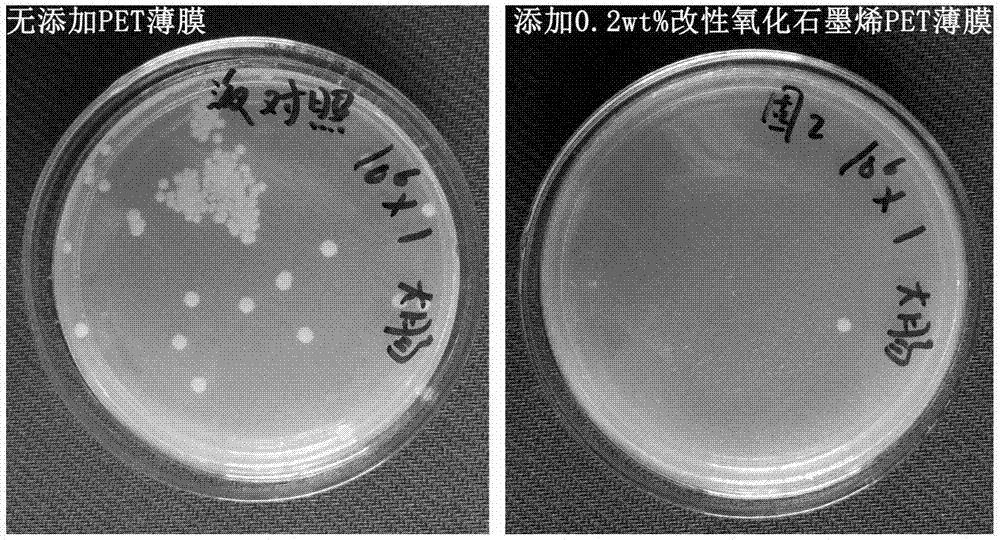

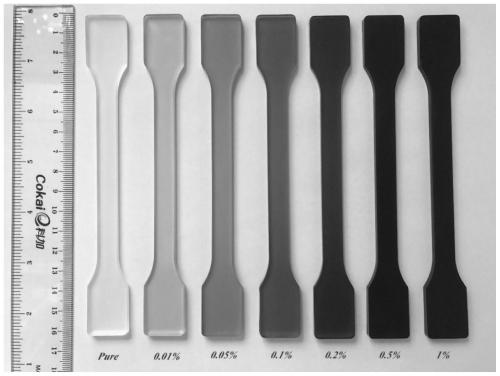

The invention provides a coating composition for solar cell backboards and the solar cell backboards which are coated by the coating composition. The coating composition comprises the following components: a graphene-like filler, resin, titanium dioxide, a solvent, a curing agent, and an auxiliary agent. A preparation method of the solar cell backboards which are coated by the coating composition comprises the following steps: a graphene-like filler and PET (polyethylene terephthalate) slices are uniformly mixed, and then mixing, extruding, rotation-drum sizing and biaxial stretching are successively performed, so that the solar cell backboards are obtained; surfaces of the solar cell backboards are treated to produce low-temperature plasma, and the coating composition coats the surfaces of the solar cell backboards; and drying solidification is performed, so that the solar cell backboards which are coated by the coating composition are obtained. According to the invention, by using graphene as an additive of the coating composition of the solar cell backboards, the solar cell backboards which are coated by the coating composition have the advantages of good mechanical performance, good ultraviolet resistance (aging resistance and weather resistance are enhanced), good heat conductivity (rapid heat dissipation, high-temperature resistance, high safety, improved cell efficiency and service life and the like) and the like, and an extensive application in all kinds of environmental climates.

Owner:NANTONG QIANGSHENG PHOTOVOLATIC TECH

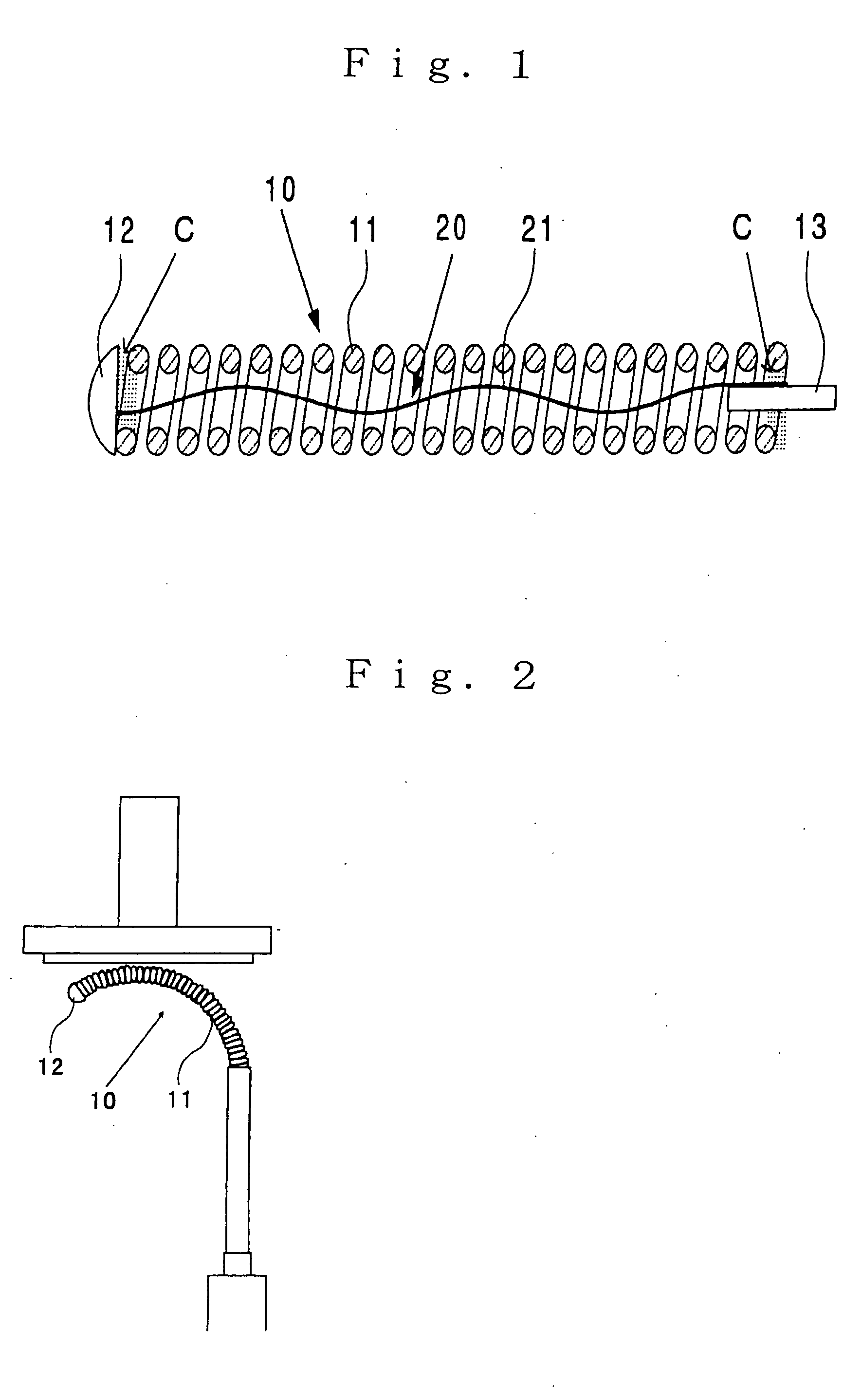

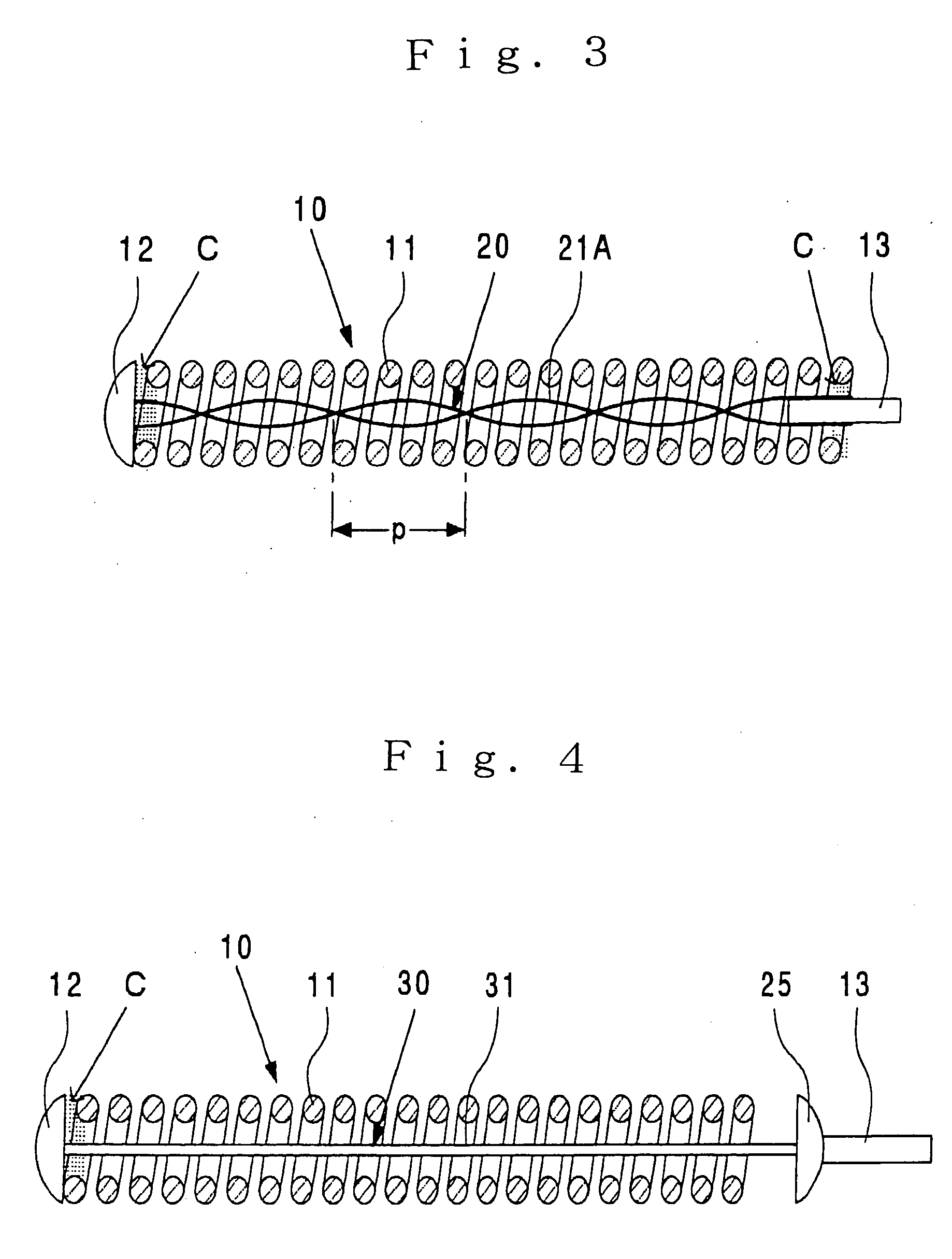

Indwelling instrument for forming embolus

InactiveUS20060173488A1Increase flexibilityFlexibility is impairedDilatorsOcculdersBreaking strengthWire rod

Disclosed herein is an intracorporeally indwelling device for embolization, which is capable of being placed surly in an appointed site, capable of permiting surely performing a replacing operation of the intracorporeally indwelling device arranged once, and thus has high safety and high operating ability. The intracorporeally indwelling device for embolization of the invention comprises a flexible coiled body and an axial extension-controlling member having specified tensile break strength and provided in the interior of the coiled body so as to extend in an axial direction of the coiled body. The axial extension-controlling member is made up of a wire material having tensile break strength of at least 700 N / mm2 in the axial direction of the coiled body and a diameter of at most 25 μm.

Owner:KANEKA MEDIX +1

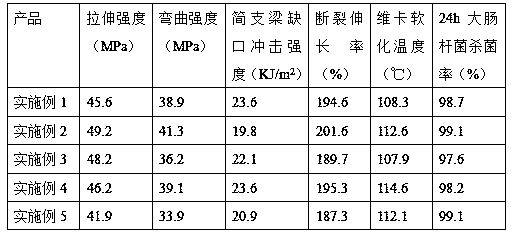

Modified calcium carbonate filled PVC tubular product and preparation method thereof

InactiveCN108504001AStrong impact resistanceStrong antibacterial and antibacterial propertiesCoatingsPipe protection against damage/wearMaleic anhydrideAntioxidant

The invention discloses a modified calcium carbonate filled PVC tubular product and a preparation method thereof. The PVC tubular product contains the following raw materials in parts by weight: 100 parts of PVC resin, 5-10 parts of bismaleimide, 3-5 parts of an acrylic acid-maleic anhydride copolymer, 1-3 parts of polyurethane propyl methyl semisiloxane, 1-2 parts of maleic acid ricinoleate, 15-30 parts of modified nano-calcium carbonate, 3-5 parts of asbestos fibers, 1-3 parts of a coupling agent, 0.5-2 parts of a cross-linking agent, 0.5-1.5 parts of an antioxidant, 0.5-1.5 parts of a stabilizer, 1-2 parts of an antibacterial agent and 3-5 parts of a processing aid. By virtue of a special raw material formula and the coordination effect of the components, the PVC tubular product provided by the invention has the advantages of high strength and tenacity, strong shock resistance, heat resistance, strong bacteriostatic and antibacterial effects, ageing resistance, good stability and the like and is unlikely to be deformed, a processing process is simple, and the PVC tubular product is relatively low in cost and has wide market prospects.

Owner:钦州市宝业坭兴陶厂

Modification method of calcium carbonate and application of modified calcium carbonate in PVC pipes

InactiveCN108948793AGood compatibilityGood dispersionPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsPhosphateSurface modification

The invention discloses a modification method of calcium carbonate and application of modified calcium carbonate in PVC pipes. The method includes: firstly conducting surface modification on calcium carbonate with disodium cocamidopropyl sulfosuccinate monoester and nonylphenol polyoxyethylene ether, and then using octa(aminophenyl)silsesquioxane and sodium laureth-4 phosphate for second surface modification. The modified calcium carbonate obtained by the invention has the characteristics of high dispersibility, high toughness, weather resistance, heat resistance, high strength, high toughness, etc, as the filler of the PVC pipe system, the modified calcium carbonate can endow pipes with high strength, high toughness, corrosion resistance, good heat resistance, strong impact resistance andother performance, prolongs the service life of the pipes and widens the application fields of the pipes.

Owner:贺州钟山县双文碳酸钙新材料有限公司

Method for preparing humidity-sensitive switch flexible sensing material

The invention provides a method for preparing a humidity-sensitive switch flexible sensing material. The method for preparing the humidity-sensitive switch flexible sensing material is characterized by specifically comprising the following steps: preparing at least one polymer solution, pouring the polymer solution into at least one composite tank, performing water bath heating on the composite tank, unwinding a carbon nano tube fiber or carbon nano tube membrane from a winding roller, leading through a leading needle, and feeding into the composite tank for combination; after the combination, performing grouting treatment through the guide needle, guiding, feeding into a heating area for drying so as to cure the polymer on the surface and inside the carbon nano tube fiber or carbon nano tube membrane, thereby obtaining the humidity-sensitive switch flexible sensing material. The humidity-sensitive switch flexible sensing material can be wound on a wire shaft connected with a motor. The humidity-sensitive switch flexible sensing material has the advantages of being low in cost, good in flexibility, good in conductivity, fiber-like, capable of being embedded into a monitored environment to be in contact with the monitored environment in all directions, and the like.

Owner:DONGHUA UNIV

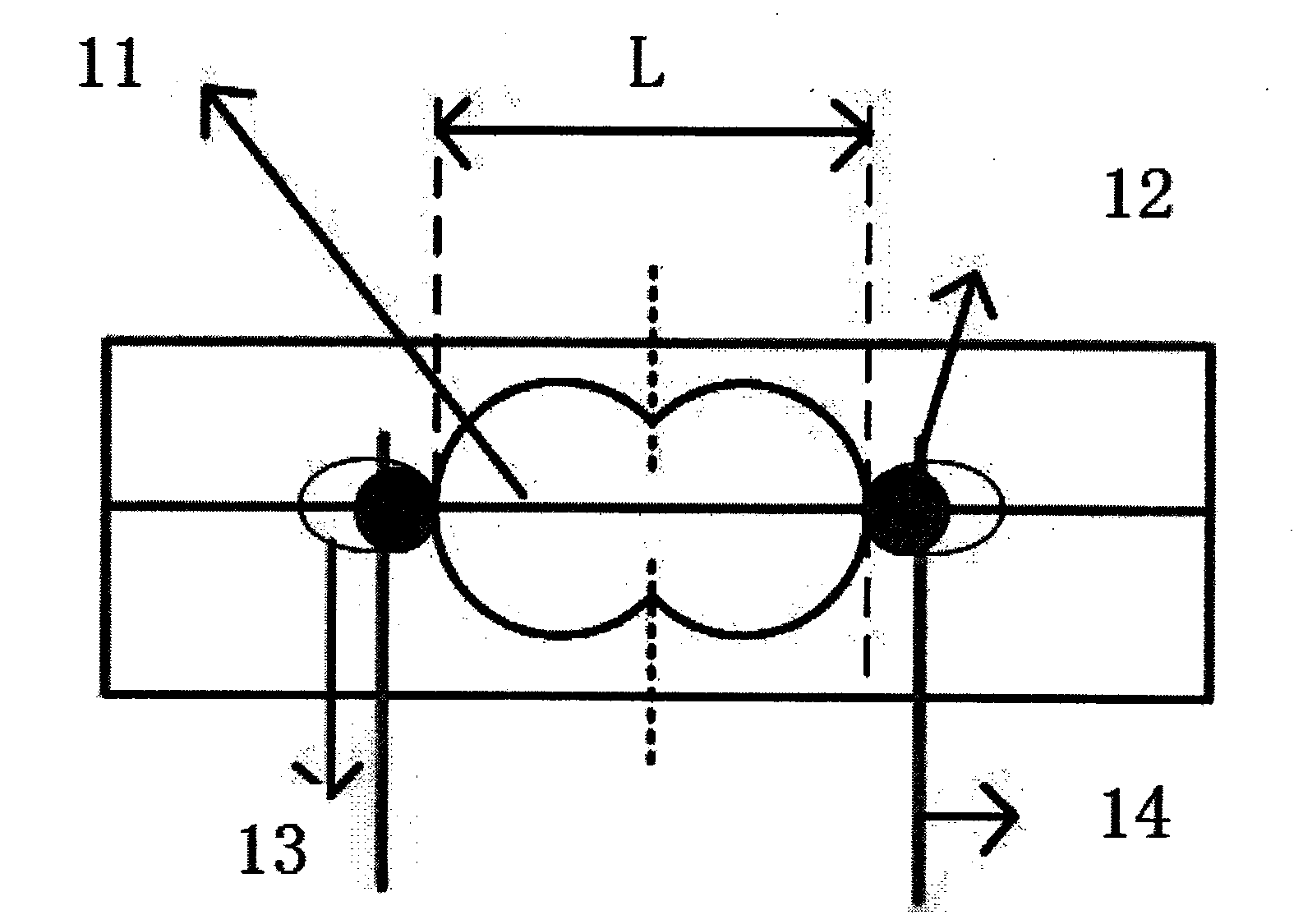

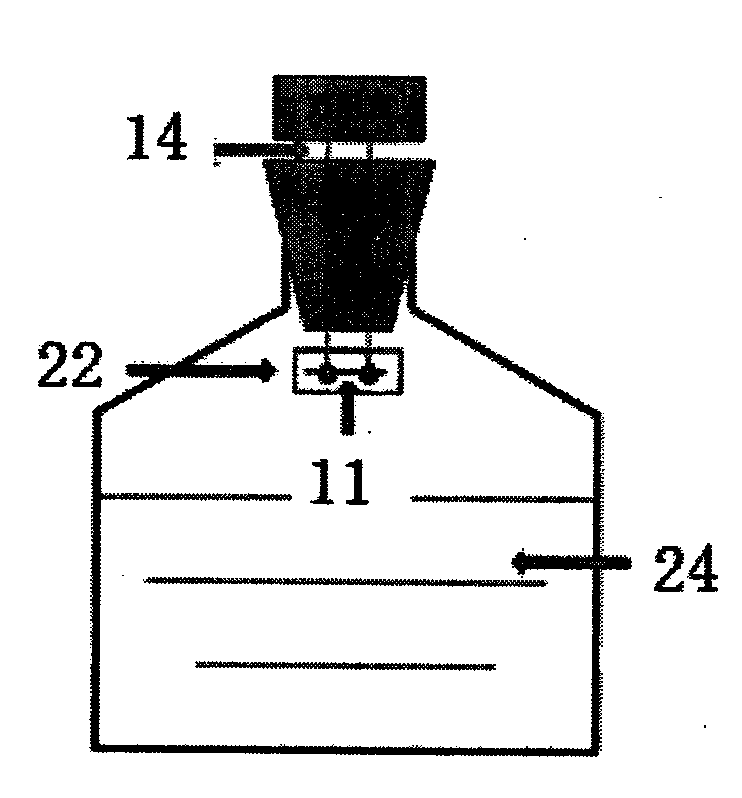

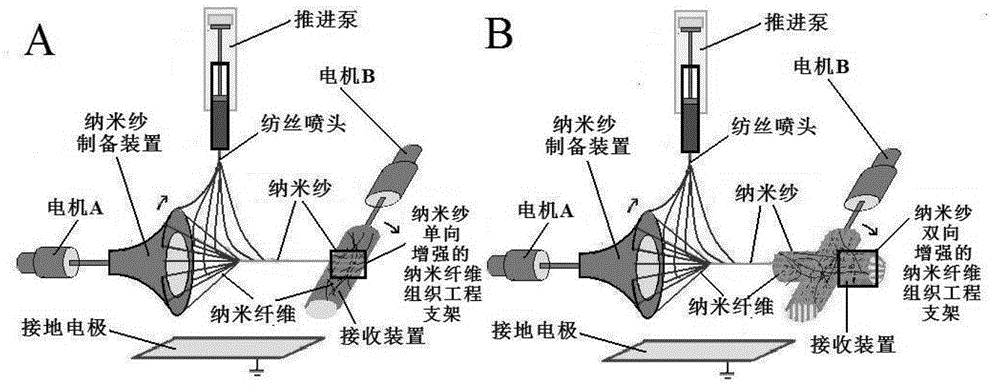

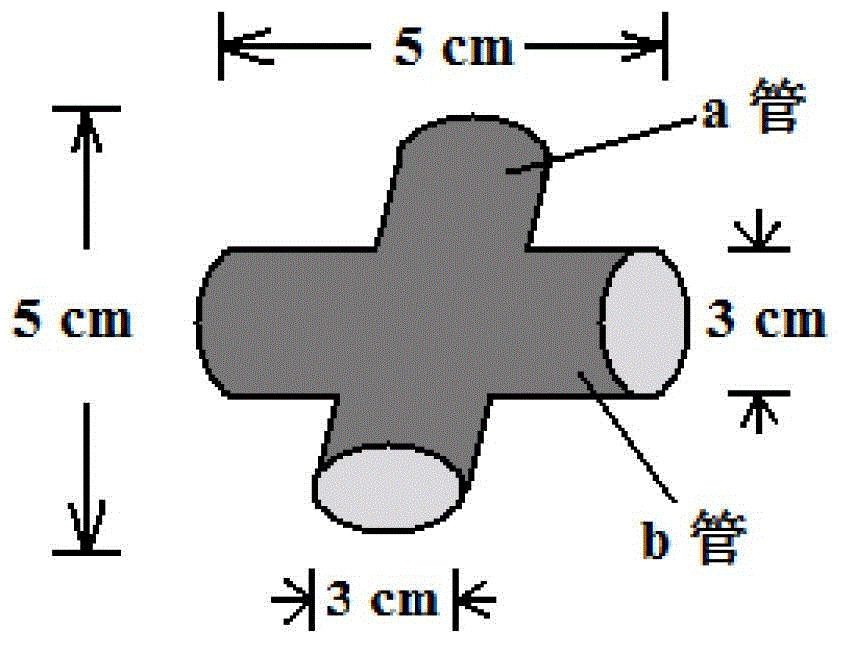

Nano yarn reinforcement electrostatic spinning fiber texture engineering scaffold and method for producing same

ActiveCN102973333AImprove tensile strength at breakComplete structureFilament/thread formingProsthesisFiberYarn

The invention relates to a nano yarn reinforcement electrostatic spinning fiber texture engineering scaffold and a method for producing the same. The method comprises the processes of building a production device, preparing poly-L-lactic acid / hexafluoroisopropanol electrostatic spinning solution, connecting with high pressure to carry out electrostatic spinning, combining nano fibers to form yarns, collecting nano yarns and nano fibers and the like. The texture engineering scaffold has good tensile mechanical property and is beneficial to keeping the integral structure of the scaffold during the material processing and texture regenerating processes; and the scaffold has large pores to facilitate cells to move into the texture. In addition, the scaffold also has the characteristics of simplicity in producing method and convenience in operation, and is expected to be applied to industrial production. The method is convenient to operate and is low in cost, the tensile mechanical property and pore size of a common electrostatic spinning nano fiber scaffold can be effectively improved, and the method is expected to be applied to the fields of tissues and organs of tendon, ligament, mules, vessel and the like which have high requirements on the tensile mechanical property.

Owner:SHANGHAI DIVINE MEDICAL TECH

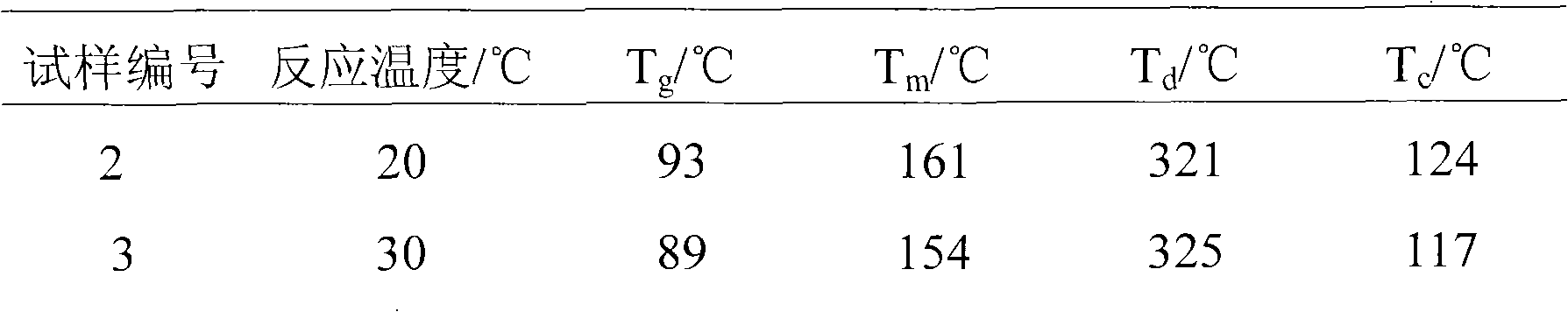

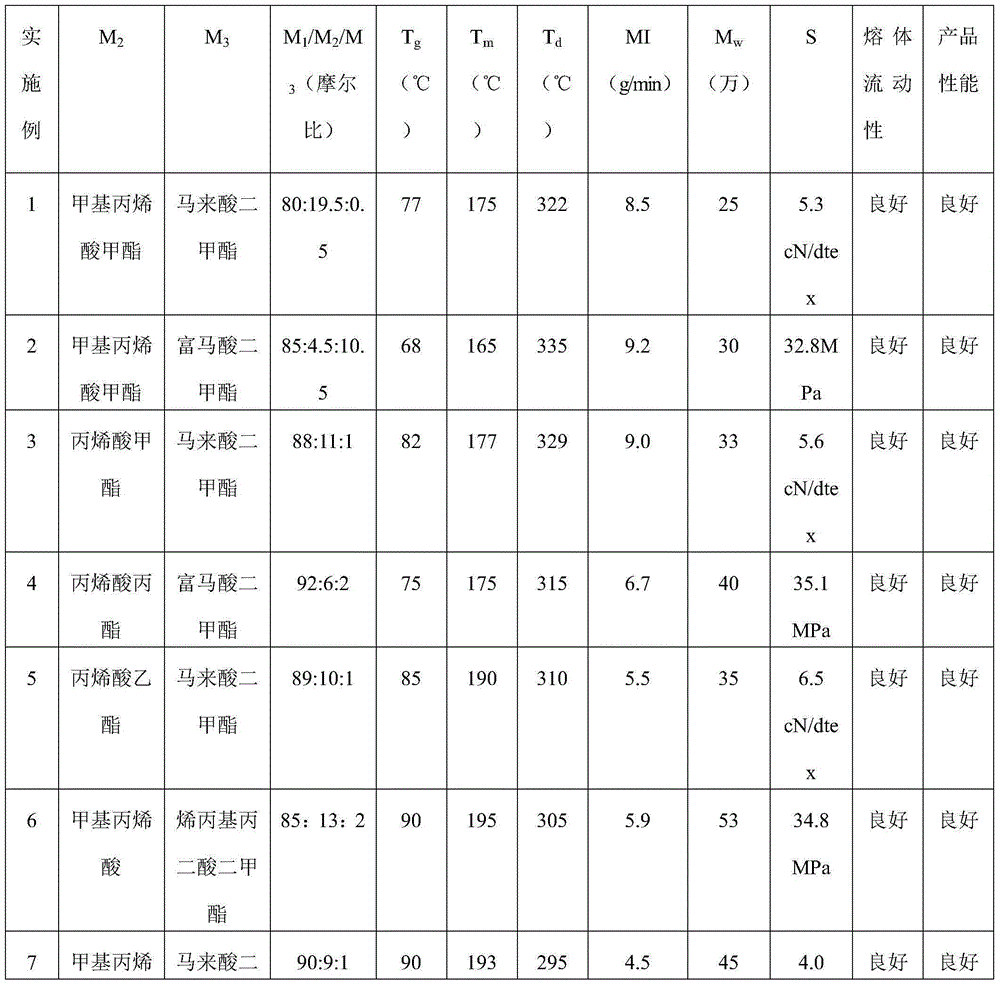

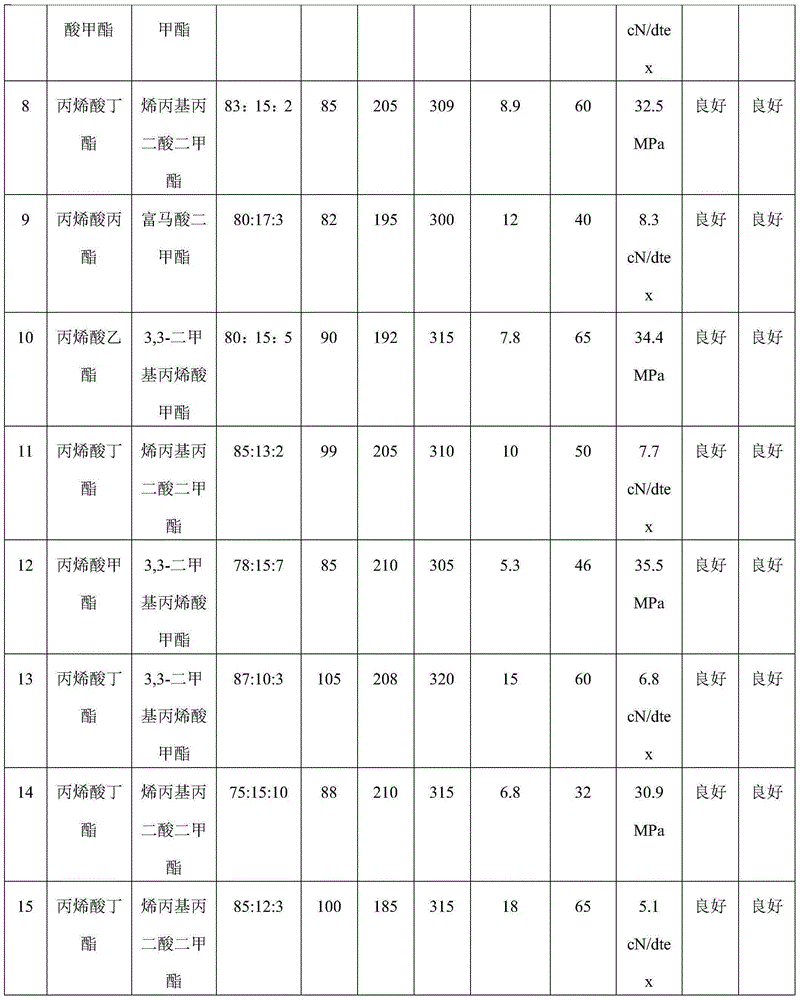

Preparation method and application of thermoplastic acrylonitrile-based terpolymer

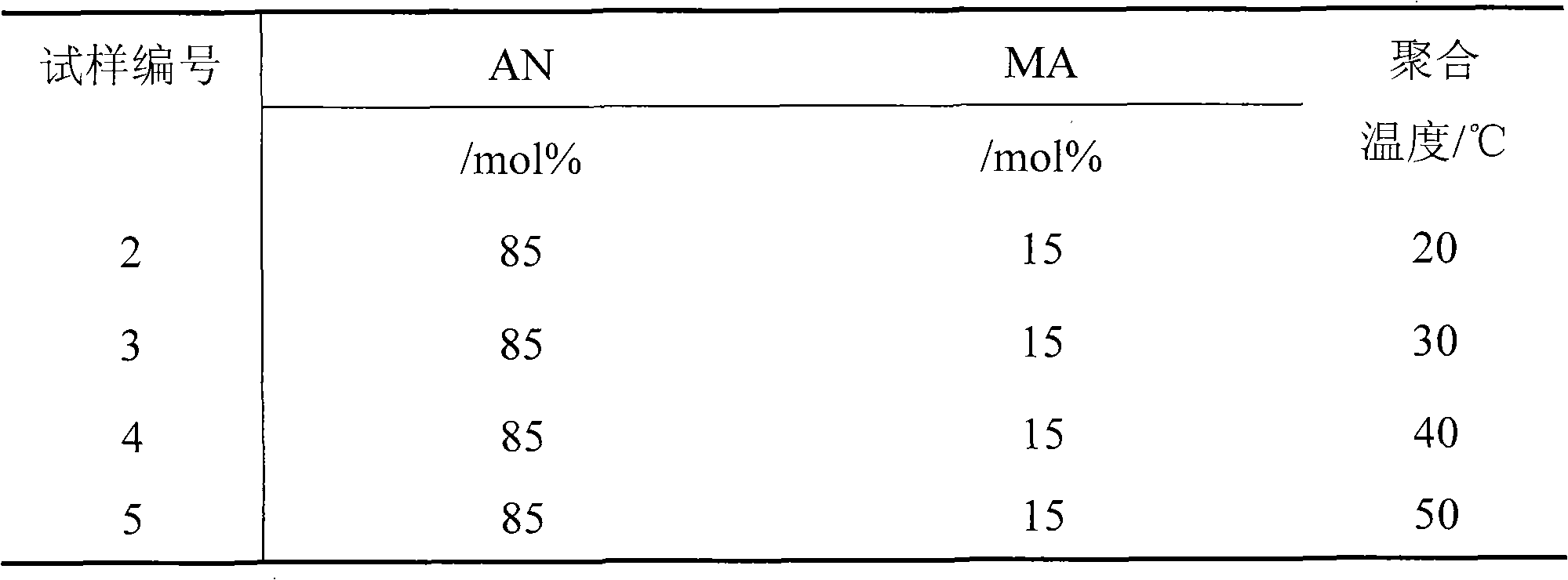

ActiveCN105199042AImprove melt fluidityThe polymerization process is simple and easy to controlMonocomponent synthetic polymer artificial filamentThermoplasticPolymer science

The invention discloses a preparation method and an application of a thermoplastic acrylonitrile-based terpolymer. In the preparation method, a selected reactive monomer consists of an acrylonitrile monomer, a second monomer and a third monomer. A method for preparing the thermoplastic acrylonitrile-based terpolymer with the reactive monomer comprises the following steps: adding an emulsifying agent into a reaction container filled with deionized water under an oxygen-free condition; adding a chain transfer agent, an initiator and the reactive monomer; reacting at a temperature being 20 to 90 DEG C for 3 to 16 hours to obtain an emulsion; demulsifying the emulsion and standing; performing suction filtration in vacuum to collect a solid; washing the solid with acetone; washing with the deionized water; finally drying in vacuum to obtain powder, namely, the thermoplastic acrylonitrile-based terpolymer. An obtained product can be directly processed into polyacrylonitrile fibers or a polyacrylonitrile film with a melt spinning method, has high performance, and is low in cost.

Owner:TIANJIN POLYTECHNIC UNIV

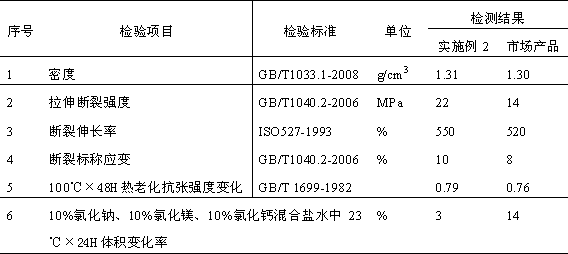

Trielement ethyl propylric rubber waterproofing coiled material and production process thereof

InactiveCN1793215ALarge specific surface areaHigh tensile strengthOther chemical processesWaxPolymer science

The invention discloses tri-ethylene-propylene rubber water proof coiled material that uses tri-ethylene-propylene rubber EP35 or 4045, carbon, fine particle calcium carbonate, ZnO, stearic acid, Rhine wax, anti-aging agent, accelerating agent, vulcanizing agent as raw material. The advantage of the invention is that it is water proof, damp proof, mould proof, pressure proof, acid, alkali, and salt resistant, strong adhesive force, good extension, and strong ageing resistance.

Owner:何霖

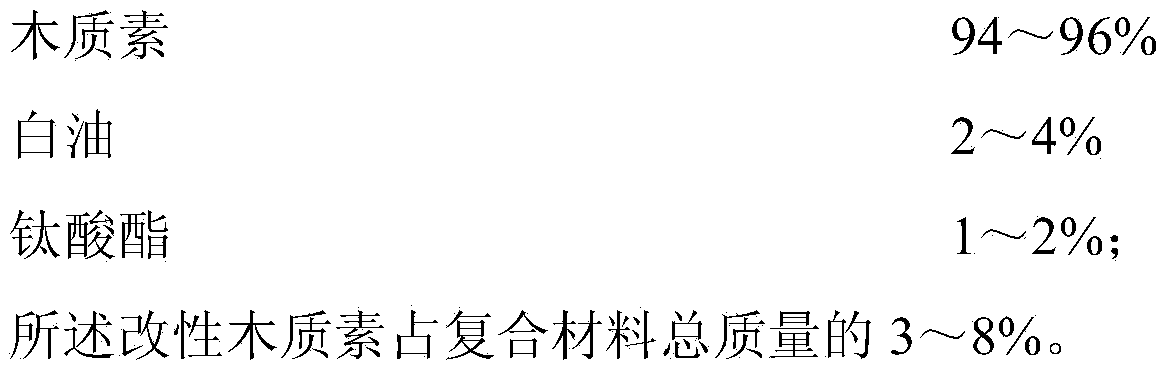

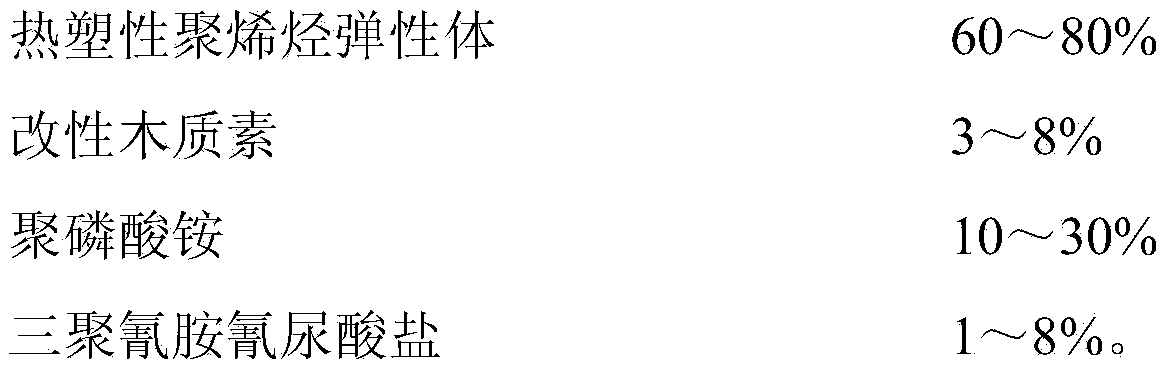

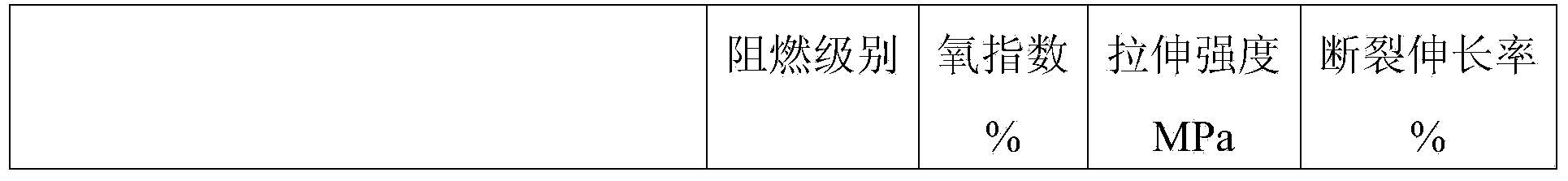

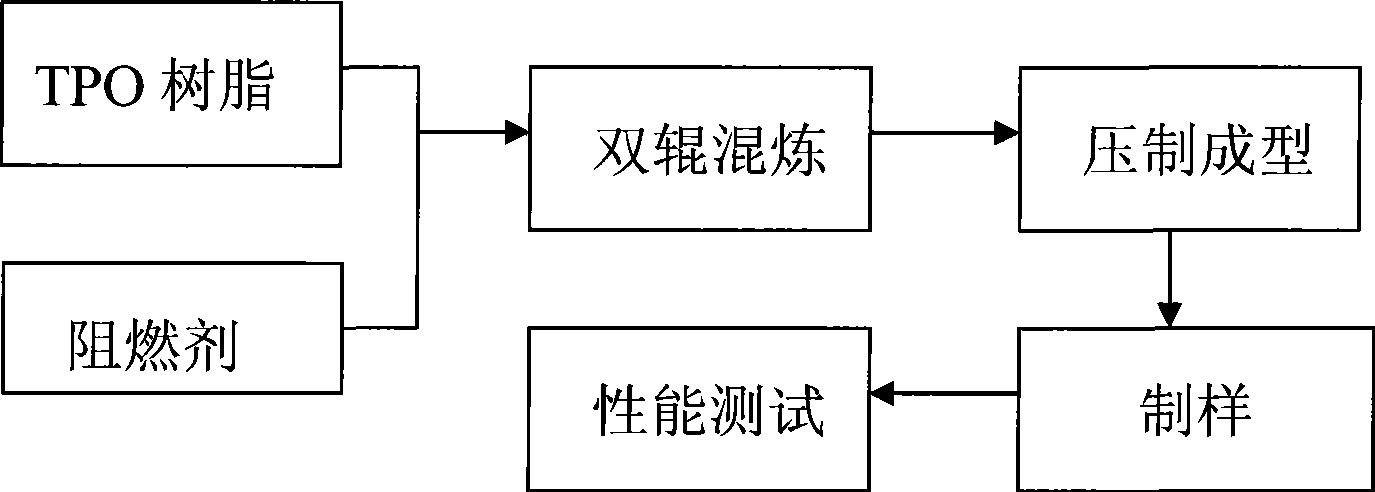

Modified lignin intumescent flame retardant TPO composite material as well as preparation method and application of composite material

InactiveCN103834107APromote environmental protectionHigh char formation ratePolyolefinAging resistance

The invention relates to a modified lignin intumescent flame retardant thermoplastic polyolefin (TPO) composite material as well as a preparation method and an application of the composite material. The composite material contains modified lignin, wherein the modified lignin consists of the following components in percentage by mass: 94-96% of lignin, 2-4% of white oil and 1-2% of titanate; and the modified lignin accounts for 3-8% in terms of total mass of the composite material. The prepared modified lignin intumescent flame retardant TPO composite material disclosed by the invention has the beneficial effects of being high in tensile strength at break, high in elongation at break, low in heating expansion amount, good in low temperature flexibility, good in penetration resistance and strong in chemical corrosion resistance; and the composite material is excellent in weather aging resistance, applicable to damp, hot and cold natural environments in a long term, and low in performance change.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Modified white graphene composite polypropylene tubular product, and preparation method thereof

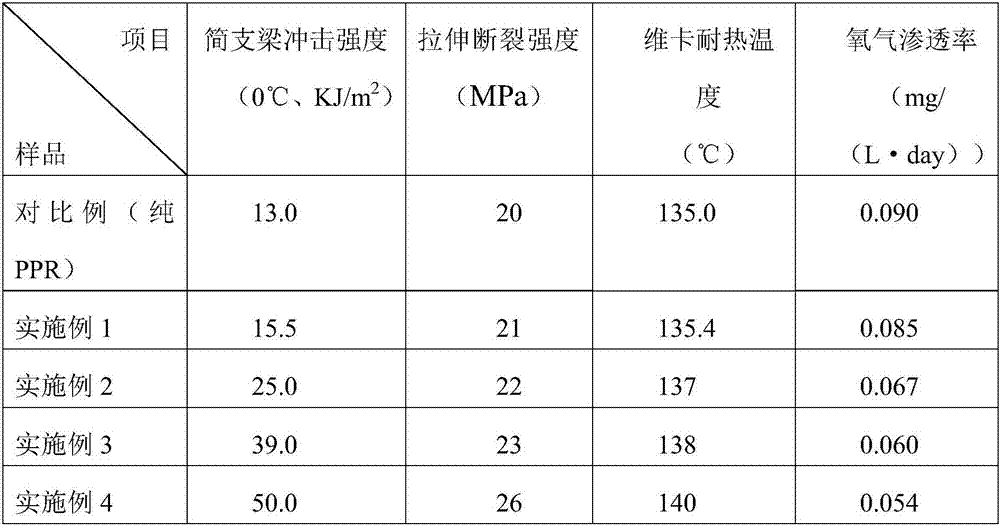

InactiveCN107446243AExcellent gas barrierHigh strengthNon-macromolecular adhesive additivesOther chemical processesBreaking strengthPolymer science

The invention belongs to the technical field of plastic tube, and more specifically discloses a modified white graphene composite polypropylene tubular product. The modified white graphene composite polypropylene tubular product is composed of, by weight, 100 parts of polypropylene resin, 0.1 to 10 parts of modified white graphene, 0.05 to 1 part of an anti-oxidant, 0.05 to 1 part of a dispersant. The invention also discloses a preparation method of the modified white graphene composite polypropylene tubular product. The preparation method comprises following steps: preparation of modified white graphene, blending of modified white graphene and polypropylene resin, preparation of modified white graphene polypropylene master batch, and extrusion moulding. Compared with conventional polypropylene tubular product, the modified white graphene composite polypropylene tubular product possesses following advantages: 0 DEG C low temperature impact resistance is improved by 350% or higher, tensile break strength is increased by 30%, Vicat softening point is increased by 5 DEG C, oxygen permeability is reduced by 40%, both thermal conductivity and corrosion resistance are excellent, processing is convenient, cost is relatively low, and practicality is high.

Owner:GUANGDONG NANOLUTION SCI & TECH CO LTD

Preparation method of solar cell back plate

InactiveCN107230732AThermally stableSelf-cleaningPhotovoltaic energy generationSemiconductor devicesEngineeringSolar cell

The invention provides a preparation method of a solar cell back plate. The method comprises the following steps of uniformly mixing a graphene filler and resin sections, performing mixing, extrusion, drum sizing and bidirectional stretching in sequence to obtain a solar cell back plate, carrying out the low-temperature plasma treatment on the surface of the solar cell back plate, coating the surface of the back plate of the solar cell by using a coating, and drying and solidifying to obtain the product. Compared with the same type of patents, through the grapheme modification of the PET slice, the invention can realize thermal stability, self-cleaning performance, anti-aging performance, gas / water resistance, and ultraviolet resistance of the PET substrate of the back plate of the solar cell.

Owner:NANTONG QIANGSHENG PHOTOVOLATIC TECH

Preparation method of epoxy resin/MXene composite material

The invention provides a preparation method of an epoxy resin / MXene composite material. The preparation method comprises the following steps: preparing a single-layer MXene, determining the addition amount of the single-layer MXene, compounding the single-layer MXene and an epoxy resin material, and the like. The preparation method is simple in process, short in time, high in efficiency and low incost, and the prepared epoxy resin / MXene composite material is remarkably improved in tensile breaking strength and good in mechanical property.

Owner:HOHAI UNIV

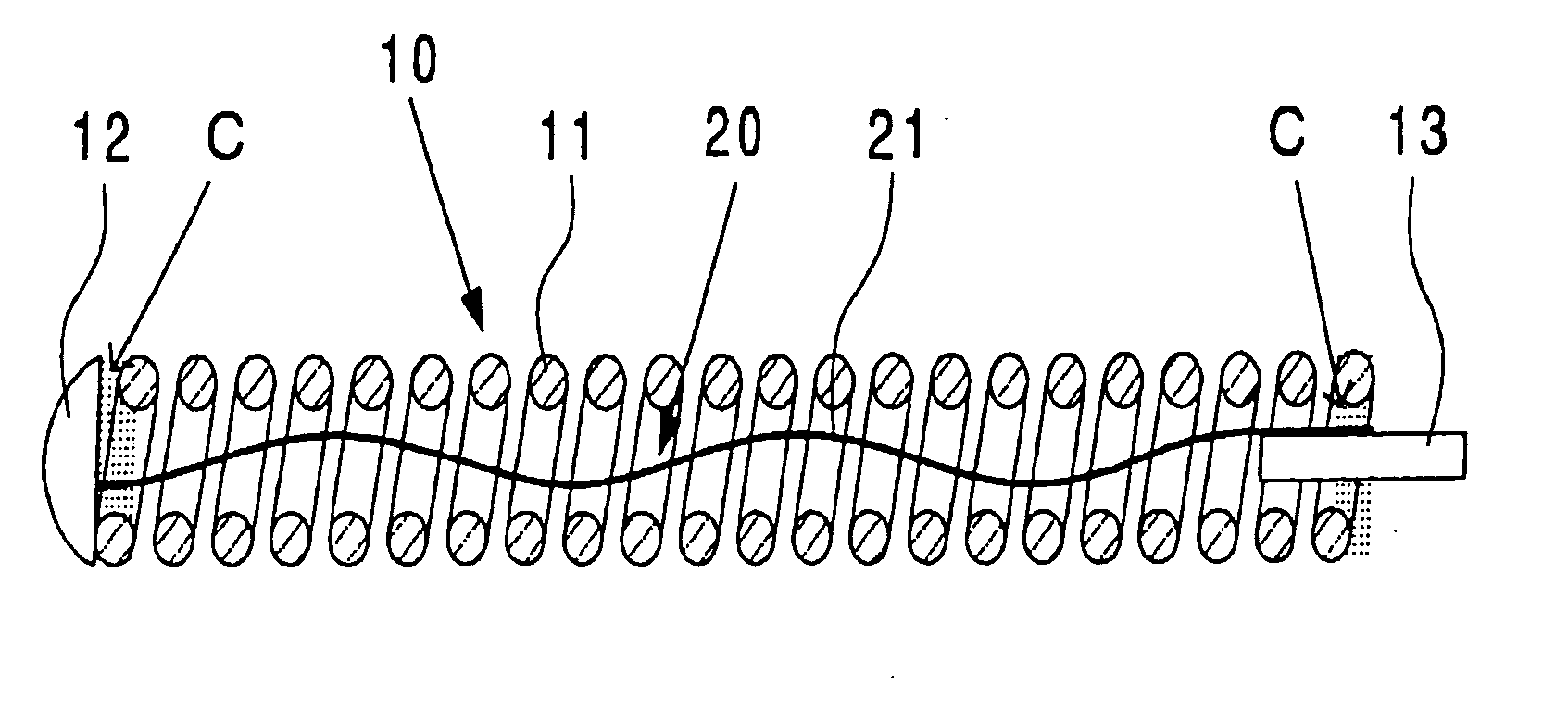

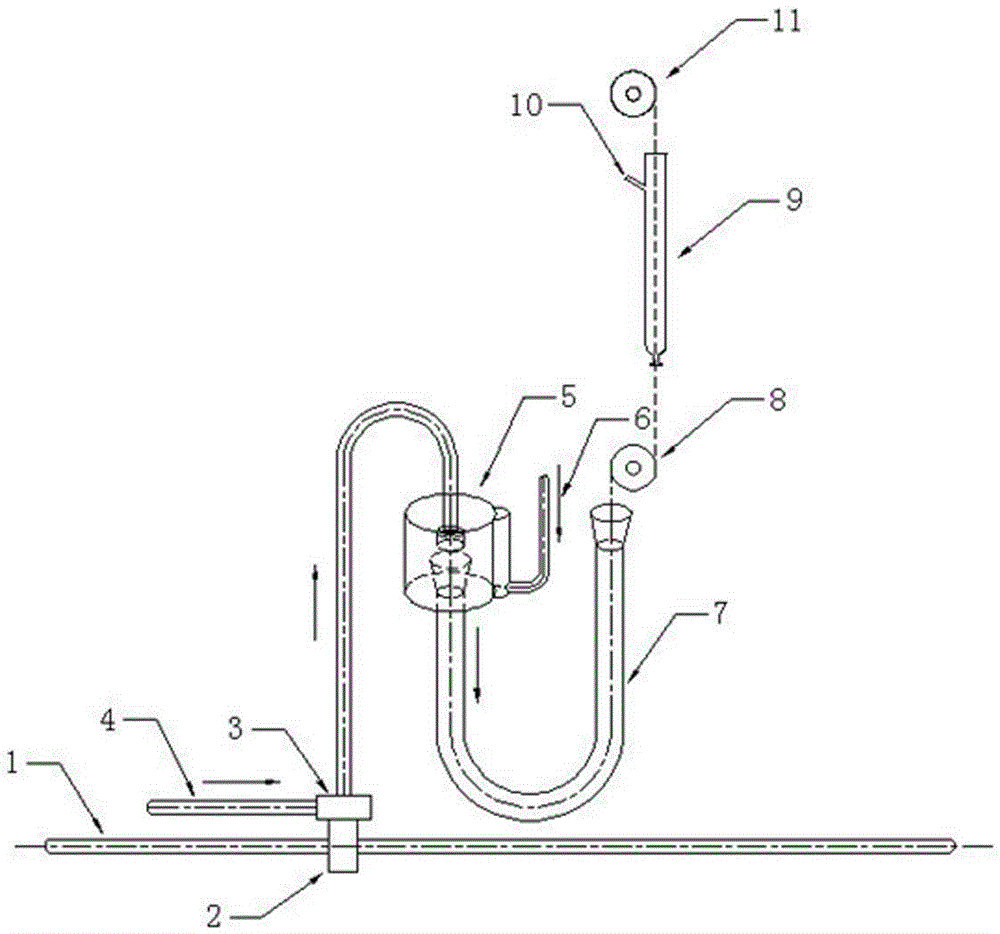

Vertical type wet spinning method and device

ActiveCN105420827AMolecular Structure Orientation ConcentrationImprove tensile strength at breakWet spinning methodsEngineeringFiber drawing

The invention belongs to the technical field of specialty fibers, and particularly relates to a vertical type wet spinning method and device. The device comprises a pump shaft (1), a pump shaft clutch (2), a metering pump (3), a stock solution header pipe (4), a coagulation bath tank (5), a first-level coagulation liquid pipeline (6), a U-shaped coagulation bath pipe (7), a first draw-off godet (8), a straight coagulation bath pipe (9), an overflow port (10) and a second draw-off godet (11). The device is characterized in that the pump shaft (1) is provided with the pump shaft clutch (2), the stock solution header pipe (4) is connected with the coagulation bath tank (5) through the metering pump (3) arranged on the pump shaft clutch (2), and the first-level coagulation liquid pipeline (6) is communicated with the coagulation bath tank (5). According to the vertical type wet spinning method and device, longitudinal drawing is performed on nascent fibers through gravity by adopting the vertical type special wet spinning method, the nascent fiber drawing direction and the coagulation liquid flowing direction are consistent with the gravity direction, therefore, the influence of the gravity on molecular structure orientation is avoided, and the molecular structure orientation is more concentrated.

Owner:四川辉腾科技股份有限公司

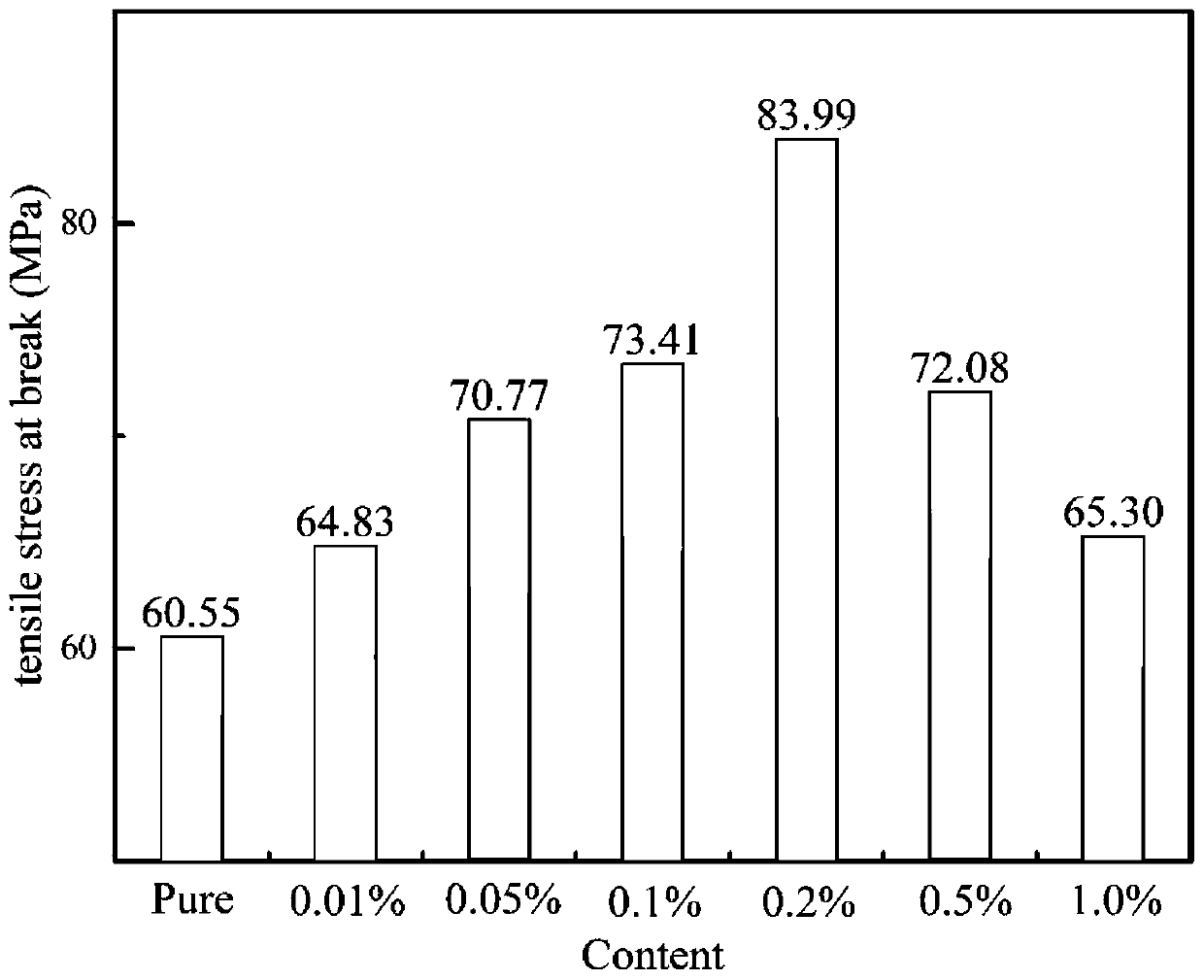

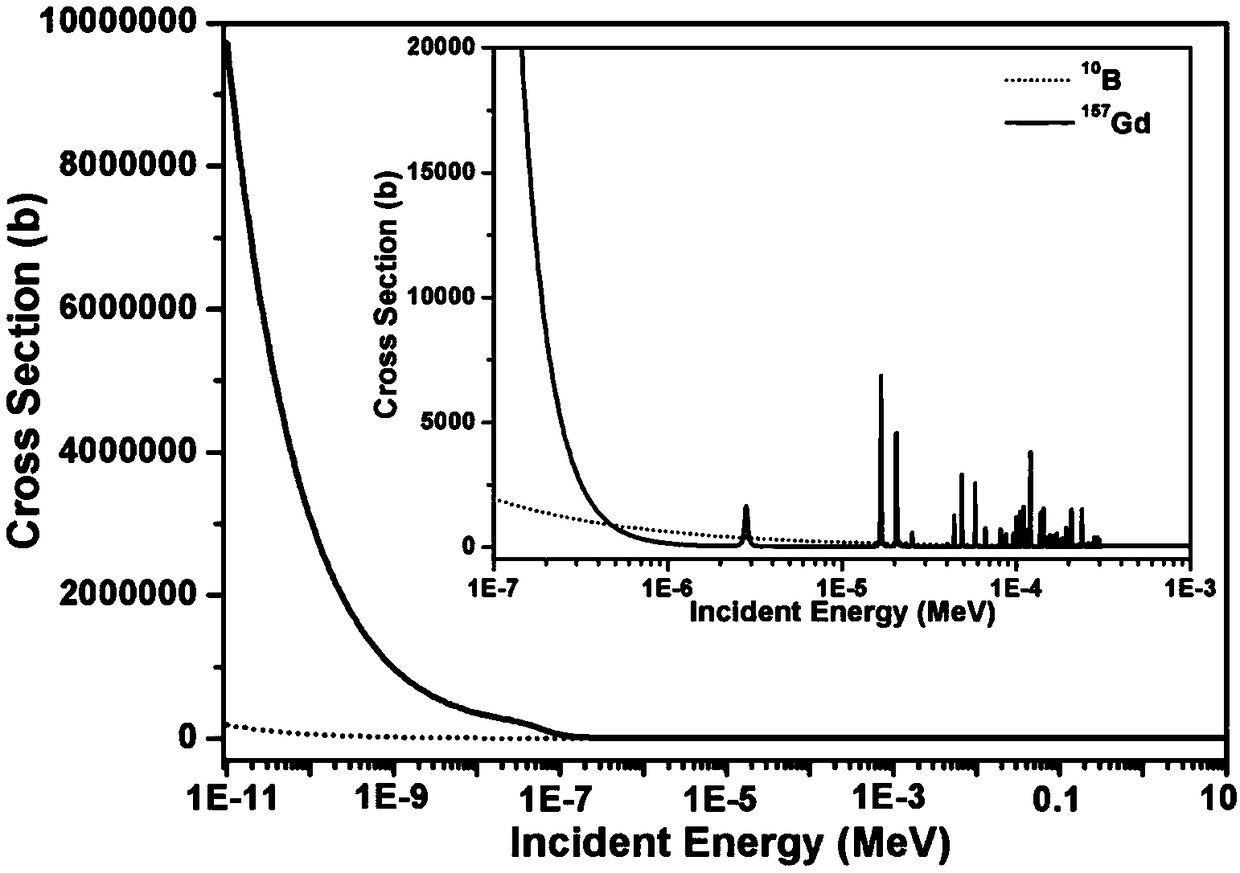

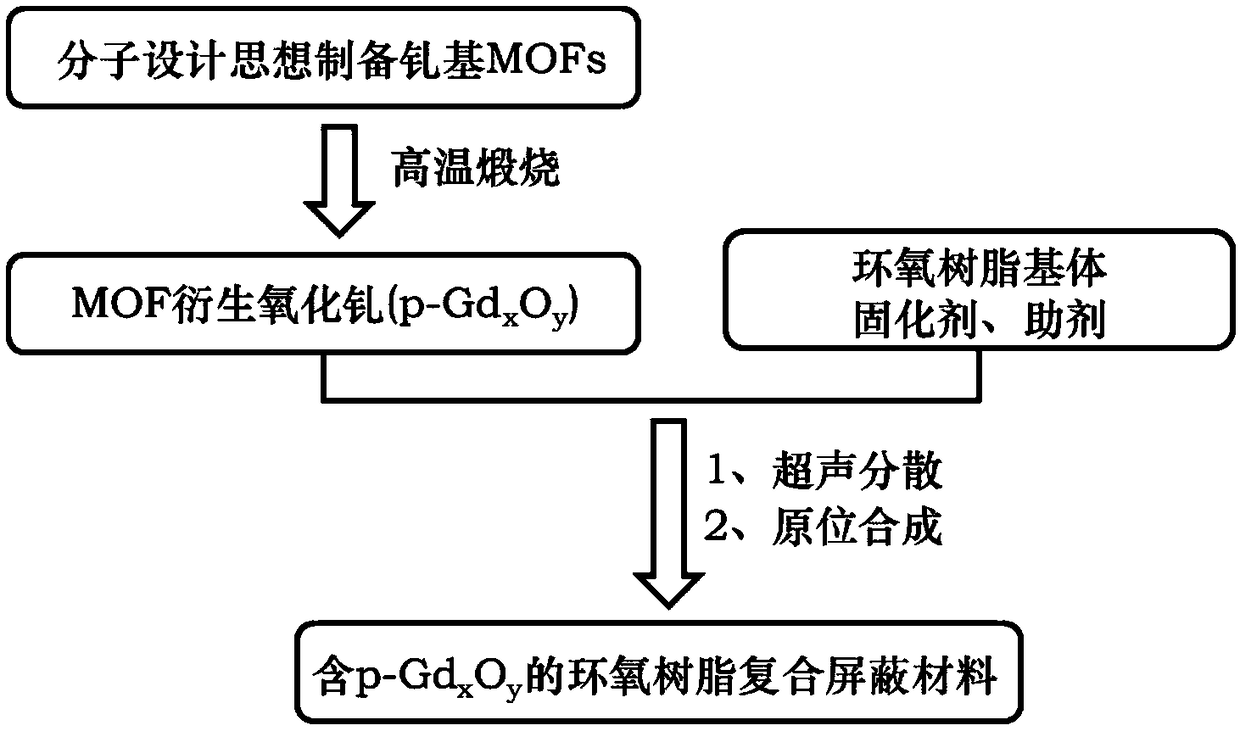

Compound shielding material containing MOF derivative porous gadolinium oxide and preparation method

The invention discloses a compound shielding material containing MOF derivative porous gadolinium oxide and a preparation method and relates to the field of neutron radiation protection. The compoundshielding material is prepared from the following raw materials in parts by weight: 1-100 parts of epoxy resin, 1-10 parts of curing agent, 1-100 parts of auxiliaries and 1-100 parts of MOF derivativegadolinium oxide, wherein the porous gadolinium oxide is acquired from the process of high-temperature calcination and pyrolysis of gadolinium-based metallic organic framework material. Epoxy resin is a neutron slowing material; gadolinium element is a neutron absorbing material; the porous feature of MOF derivative gadolinium oxide is beneficial to strong interaction with an epoxy resin substrate. The compound shielding material containing MOF derivative porous gadolinium oxide provided by the invention has excellent thermal neutron shielding capacity, high thermal stability and high mechanical stability.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Anti-bacterial and flame-retardant PVC composite board and processing method thereof

The invention discloses an anti-bacterial and flame-retardant PVC composite board and a processing method thereof, wherein the anti-bacterial and flame-retardant PVC composite board includes the following raw materials in parts by weight: 100 parts of PVC resin, 5-10 parts of an acrylic acid-maleic anhydride copolymer, 40-60 parts of wood meal, 40-60 parts of modified calcium carbonate, 5-10 partsof shell powder, 3-5 parts of boron nitride, 1-3 parts of aramid fibers, 2-4 parts of a foaming agent, 1-2 parts of a flame retardant, 1-2 parts of an antibacterial agent, 1-3 parts of a plasticizer,0.5-1.5 parts of a stabilizer, 0.5-1.5 parts of an antioxidant, 2-4 parts of a modifier and 3-5 parts of a processing aid. The modifier consists of octaaminophenyl cage-like silsesquioxane and vegetable oil fatty acid alkanolamide borate with a mass ratio of (1-3):1. The prepared PVC composite board has the advantages of high strength, strong impact resistance, no fission, good flame retardancy,strong antibacterial property, low water absorption rate, wear resistance, weather resistance, heat resistance, difficult deformation, aging resistance, good processing performance, simple process, low cost, and good social and economic benefits.

Owner:钦州市宝业坭兴陶厂

Conductive polymeric material and preparation method therefor

InactiveCN106633338AImprove conductivitySmall particle sizeNon-conductive material with dispersed conductive materialAntioxidantBarium titanate

The invention discloses a conductive polymeric material. The conductive polymeric material is prepared from the following ingredients in parts by weight: 50-80 parts of base resin, 2-10 parts of carbon nano-tubes, 10-15 parts of conductive carbon black, 1-2 parts of polyethylene glycol, 2-5 parts of lignin, 0.1-1 part of stearic acid, 0.1-1 part of epoxy oil, 1-2 parts of barium titanate, 0.1-0.5 part of antioxidant and 0.1-0.5 part of polydimethylsiloxane. In addition, the invention further provides a preparation method for the conductive polymeric material. The conductive polymeric material provided by the invention is good in electric conductivity, high in tensile strength at break and high in elongation at break; and the material is good in low-temperature flexibility and good in aging resistance, thereby having superior mechanical properties and processability.

Owner:PINGDINGSHAN UNIVERSITY

Partition plate of lead storage battery and lead storage battery

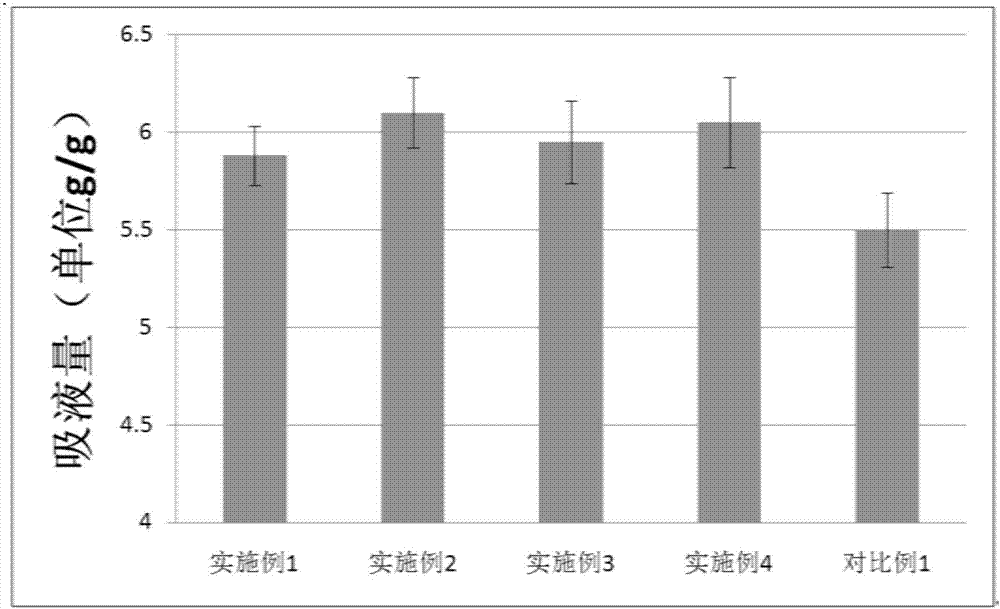

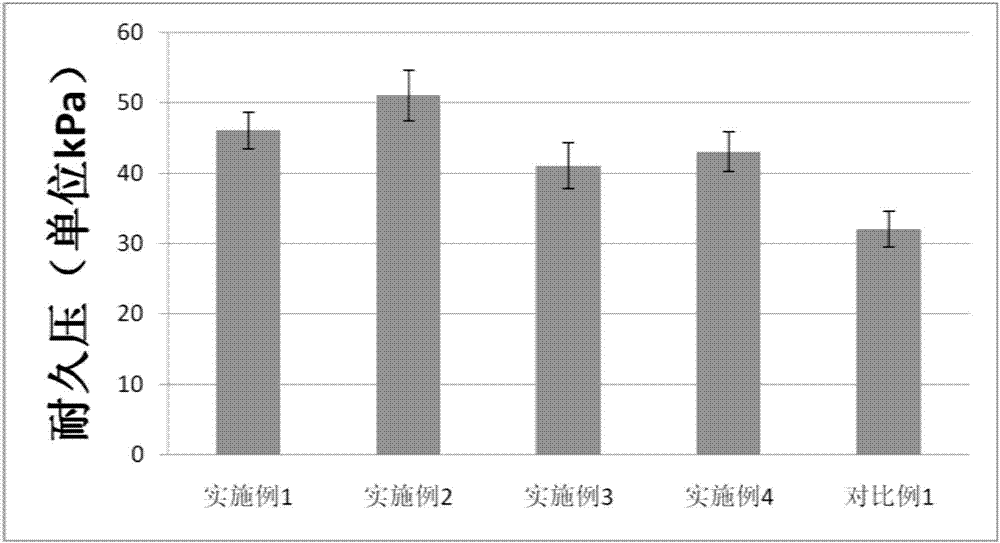

ActiveCN106981609AHigh acid absorptionDurable pressureLead-acid accumulatorsCell component detailsEngineeringFiber

The invention discloses a partition plate of a lead storage battery and the lead storage battery. The constituent of the partition plate of the lead storage battery comprises glass fiber and a COPET sea-island filament, wherein the COPET sea-island filament is obtained by dissolving a PA / COPET sea-island fiber in sea. During fabrication of the partition plate of the lead storage battery, the COPET sea-island filament is added and obtained by dissolving the PA / COPET sea-island fiber in the sea; after the sea-island fiber is separate, the filament number is relatively slim, conventional spinning cannot be achieved, and thus, the partition plate has characteristic which ordinary fiver cannot possess; and compared with an ordinary AGM partition plate, the partition plate of the lead storage battery has the advantages of high acid absorption quantity, large durability, large tensile breaking strength and the like and has good application prospect.

Owner:TIANNENG BATTERY GROUP

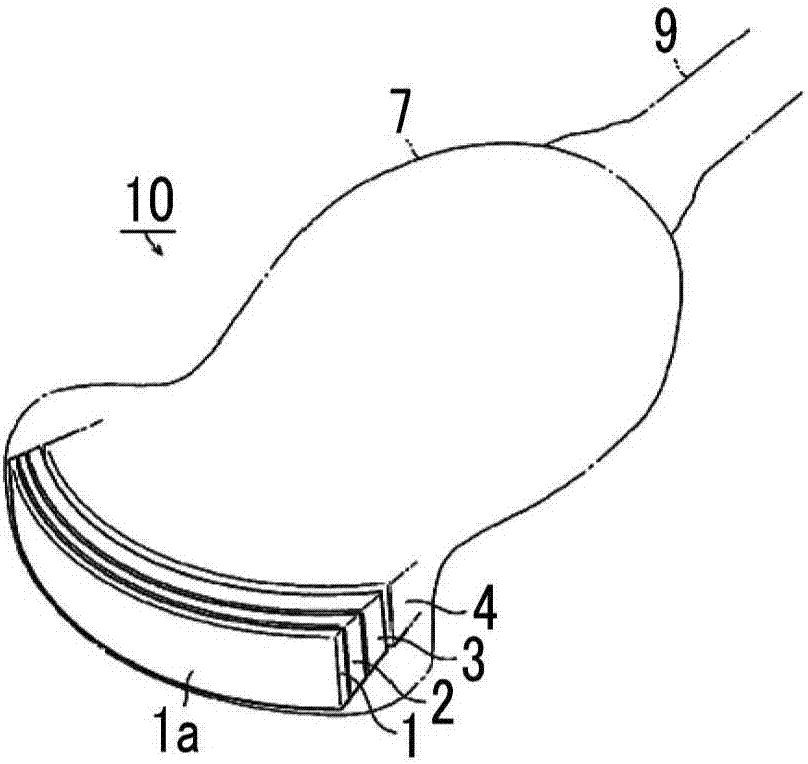

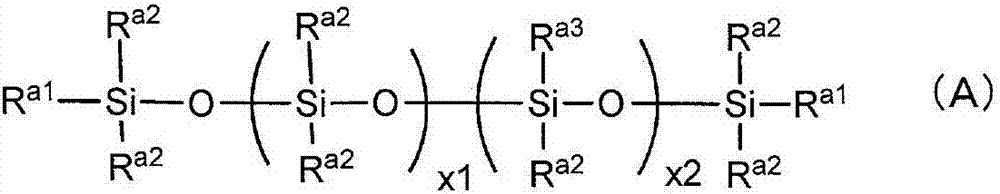

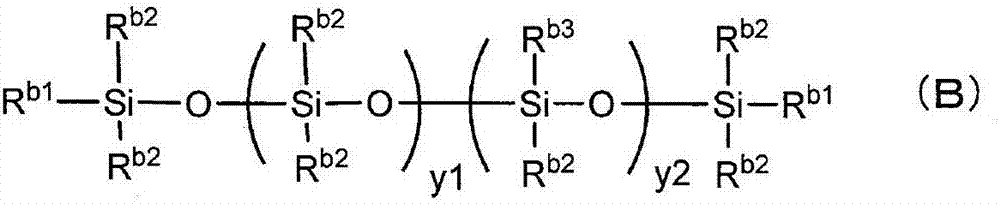

Composition for acoustic wave probe, silicone resin for acoustic wave probe using same, acoustic wave probe, ultrasonic probe, acoustic wave measurement device, ultrasonic diagnostic device, photoacoustic wave measurement device, and ultrasonic endoscope

ActiveCN107005770AHigh hardnessHigh mechanical strengthUltrasonic/sonic/infrasonic diagnosticsSurgeryYTTERBIUM OXIDEMeasurement device

Provided is a composition for an acoustic wave probe, a silicone resin for acoustic wave probe using same, an acoustic wave probe, an ultrasonic probe, an acoustic wave measurement device, an ultrasonic diagnostic device, a photoacoustic wave measurement device, and an ultrasonic endoscope, said composition containing a polysiloxane mixture comprising: a polysiloxane having a vinyl group; a polysiloxane having at least two Si-H groups in the molecular chain thereof; and at least one type of inorganic compound particles. The inorganic compound particles have an average primary particle size of less than 25 nm, and are selected from the group consisting of magnesium oxide, titanium oxide, iron oxide, zinc oxide, zirconium oxide, barium oxide, tin oxide and ytterbium oxide. With this composition for an acoustic wave probe, the silicone resin for acoustic wave probe using same, the acoustic wave probe, the acoustic wave measurement device and the ultrasonic diagnostic device, it is possible to greatly enhance the hardness and mechanical strength (tensile fracture strength, tensile fracture elongation, tear strength and wear resistance) of silicone resins while keeping acoustic wave attenuation low. Moreover, the present invention is capable of enhancing the sensitivity of ultrasonic probes, photoacoustic wave measurement devices and ultrasonic endoscopes using a cMUT as a transducer for ultrasonic diagnosis.

Owner:FUJIFILM CORP

Pressure-sensitive adhesive composition and infrared transparent black adhesive tape, preparation method thereof and application thereof

InactiveCN106032458AHave optical propertiesWith low hazeNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer sciencePressure sensitive

The invention relates to a pressure-sensitive adhesive composition and an infrared transparent black adhesive tape, a preparation method thereof and application thereof. In particular, the invention relates to the technical field of bonding, relates to an infrared transparent black pressure-sensitive adhesive, and also relates to an adhesive tape containing the pressure sensitive adhesive, especially an infrared transparent black adhesive tape. The pressure-sensitive adhesive and the adhesive tape have transparency in the visible light area of 400 to 780nm significantly lower than that in the 780 to 1000nm near infrared region. In addition, the invention relates to the preparation method and application of the pressure-sensitive adhesive and adhesive tape, such as application in many fields of optoelectronics.

Owner:TESA SE

High-strength slurry pump rubber lining

The invention discloses a high-strength slurry pump rubber lining which is characterized in that the rubber raw material comprises the following components: 70-90 parts of 1# natural rubber, 30-50 parts of 21-type chloroprene rubber, 2-3 parts of stearic acid, 1-2 parts of paraffin, 22 parts of 1500-type styrene butadiene rubber, 43 parts of 3707-type nitrile butadiene rubber, 37 parts of argil, 2-5 parts of vaseline, 15-25 parts of hard carbon black, 20-30 parts of calcium carbonate, 3-5 parts of zinc oxide, 4-5 parts of magnesium oxide, 0.3-0.5 part of accelerator DM (Chinese name: 2,2'-dithiodibenzothiazole, molecular formula: C14H8N2S4), 1.1-1.3 parts of accelerator TT (Chinese name: tetramethylthiuram disulfide, molecular formula: C6H12N2S4), 0.9-1.1 parts of anti-aging agent 4010 (N-cumene-N-phenylenep-phenylenediamine) and 0.9-1 part of anti-aging agent D (Chinese name: N-phenyl-2-naphthylamine, molecular formula: C16H13N). Through the invention, the tensile breaking strength of the slurry pump rubber lining is improved by changing the proportion of the polar material and polysulfur bond of the rubber material.

Owner:XIAN ZHITAI RUBBER & PLASTIC IND

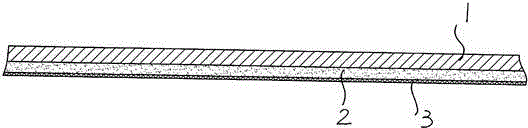

Waterproof roll free of folds and easy to weld

ActiveCN104531000AIncrease elasticityIncreased tensile strength at breakFilm/foil adhesivesMarine site engineeringPolyolefinEngineering

The invention belongs to the technical field of waterproof materials used in water conservancy projects and building projects and particularly discloses a waterproof roll free of folds and easy to weld. According to the technical scheme, the waterproof roll free of folds and easy to weld comprises a sheet, non-asphalt self-adhesive flue layers and isolating films, wherein the non-asphalt self-adhesive flue layers are attached to one side face or two side faces of the sheet, and the self-adhesive flue layers are coated with the isolating films. The sheet comprises, by weight, 65-70 parts of polyethylene, 15-18 parts of POE, 10-12 parts of EVA, 5-7 parts of polyethylene flexibilizer, 4-6 parts of maleic anhydride compatilizer and 1-2 parts of polyolefin aging-proof agent. The waterproof roll free of folds and easy to weld has the advantages that the hot melting temperature is low, both welding and construction are easy, and compared with ordinary materials, on the premise that the excellent welding effect is guaranteed, the welding temperature is lowered by 50-80 DEG C, and power consumption of a welding device is greatly reduced; meanwhile, the tensile strength at break is high, the elongation at break is high, the tearing strength is high, and chemical corrosion resistance is achieved, and the requirement for conduction in a low-temperature environment is met.

Owner:河北创隆工程橡塑有限公司

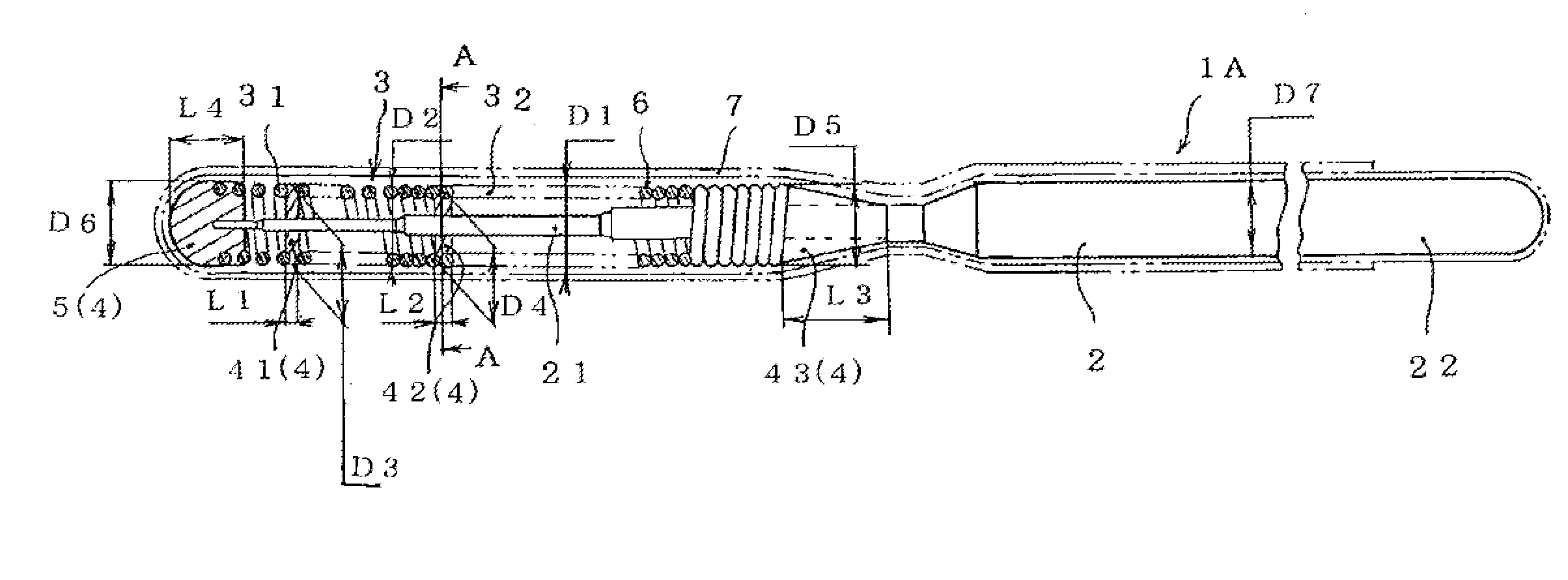

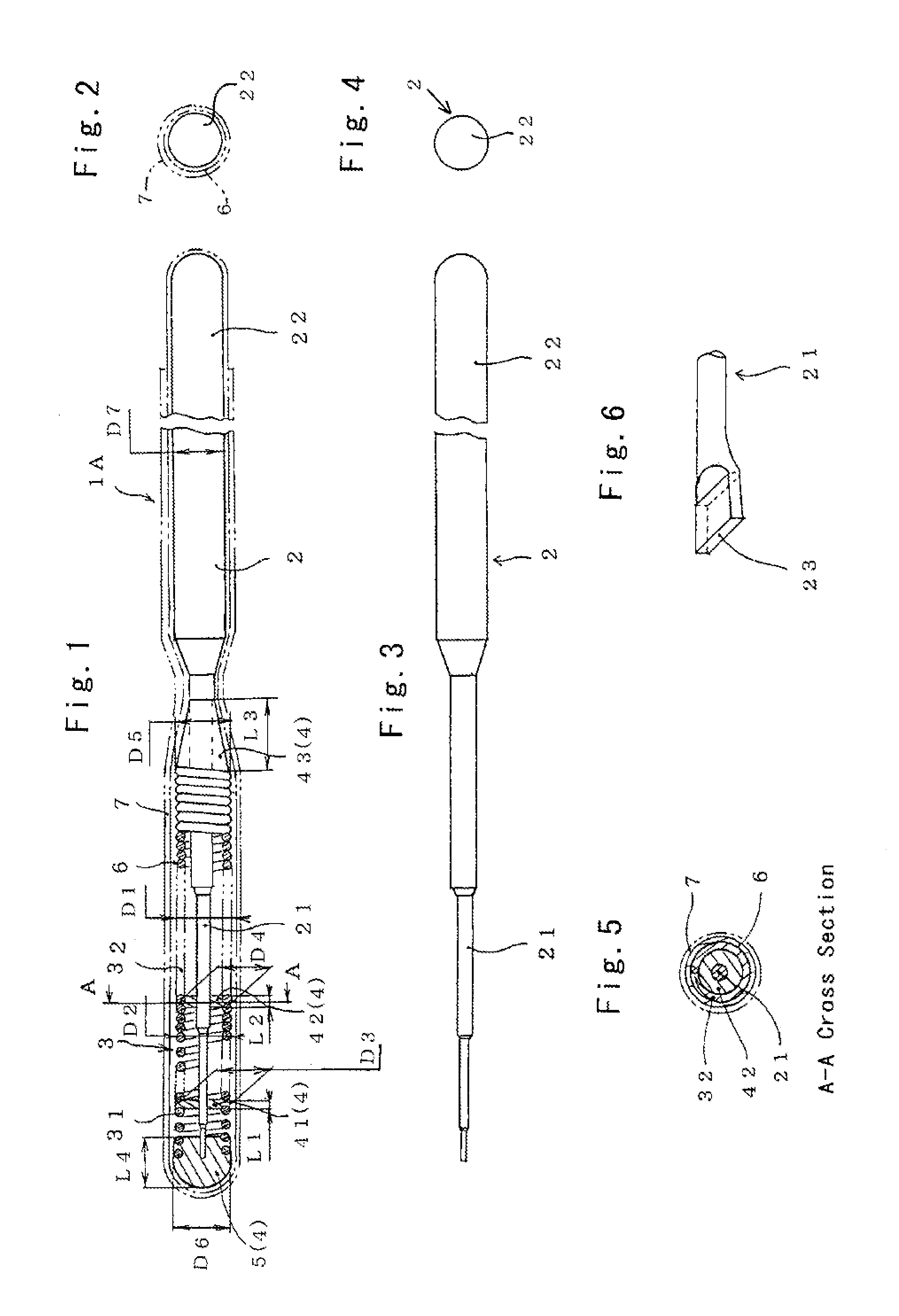

medical guide wire, an assembly of microcatheter and guiding catheter combined with the medical guide wire, and an assembly of ballooncatheter and guiding catheter combined with the medical guide wire

ActiveUS20120123329A1Improve welding strengthReduce vertical sizeStentsBalloon catheterAusteniteGuide wires

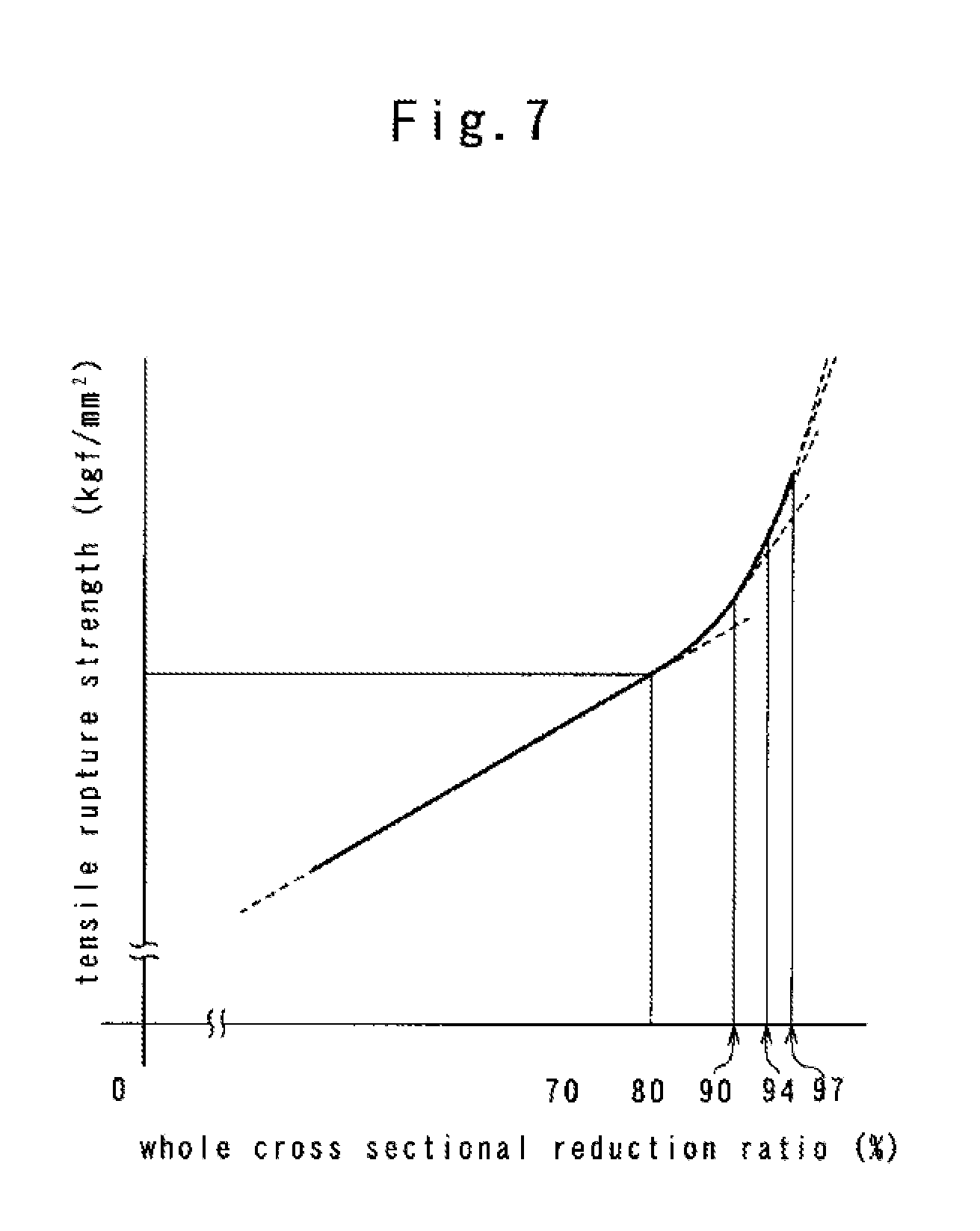

In a medical guide wire 1, a helical spring body 3 is made of austenitic stainless steel wire treated with a solid-solution procedure, and tightly drawn with a whole cross sectional reduction ratio as 90%-99.5%. A metallic wire element of the helical spring body 3 is heat treated at low temperature within a range in which a tensile rupture strength of the helical spring body 3 rapidly increases by partly or totally making use of a conductive heat generated when a core wire 2 and the helical spring body 3 are in part bonded by means of a welding member 4. This makes it possible to improve a mechanical strength property, especially a fatigue-resistant property against a repetitive bending action of the helical spring body 3.

Owner:ASAHI INTECC CO LTD

Method of Modifying Liquid Crystal Polymers

ActiveUS20090048362A1High degree of polymerizationIncrease modulusLiquid crystal compositionsPretreated surfacesCrystallographyLaser beams

A method of modifying liquid crystal polymers, which involves a step of irradiating a liquid crystal polymer with the laser beam having a pulse width of 10−12 seconds or less. Using the invention method, the physical strength of the liquid crystal polymers can be improved as compared with the conventional liquid crystal polymers.

Owner:LEF TECH

Halogen-free flame retardant weldable elastic water proof building sheet material

InactiveCN101362843AOvercome expensiveImprove flame retardant performanceBuilding insulationsFire proofingProof constructionElastomer

The invention relates to a halogen-free inflaming retarding water-proof construction sheet of a weldable elastomer; TPO is taken as a matrix resin; the matrix resin is mixed with flame retardants according to a proportion; the mixed material is plasticated by two rollers under the temperature of 130 to 150 DEG C and is shaped in a hot-press way by a flat vulcanizing machine under the temperature of 160 to 170 DEG C to obtain the sheet; wherein, the flame retardants are divided into an inorganic flame retardant and an expansion flame retardant; the inorganic flame retardant is modified magnesium hydrate; expansion flame retardant is mixed and compositely prepared by monoammonium phosphate, faecula and magnesium hydrate. The halogen-free inflaming retarding water-proof construction sheet of the weldable elastomer has the advantages of effective flame retardation and excellent comprehensive mechanical property as well as being capable of improving the durability and the weatherability.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com