Patents

Literature

107results about How to "Excellent gas barrier" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Edible food package film and method for preparing same

InactiveCN1827672AImprove mechanical propertiesExcellent gas barrierFlexible coversWrappersPolymer sciencePullulan

The invention provides an edible packaging film for foodstuff and its process for preparing. The components and percentages by weight of this edible packaging film for foodstuff are as below: 20-50% of pullulan; 20-50 % of gelatin; 1-17 % of auxiliary membraneagne; 0.05-2 % of emulsifier; 0-1 % of pigment; and 0.1-10 % of water. The process for preparing the packaging film includes the following steps: preparing the raw materials for intimate mixing materials, then making the obtained materials pass the colloid mill, homogenize and degass, molding by disgorging and strickling through the film forming machine, then drying them to form the film. The edible packaging film provided by this invention has super mechanical property, gas resistivity, scent retention, water resistivity, oil resistivity and tasty retention, is capable of printing and heat-sealing, and is suitable for automatic operation of appliances of packaging film for foodstuff; and the said packaging film is edible and its wastes can be degraded without pollution to the environment. The preparation technology provided by this invention is of simple process and low factory cost, and there is no discharge of harmful substances in the industrial process, so it is of high safety.

Owner:林玉惠

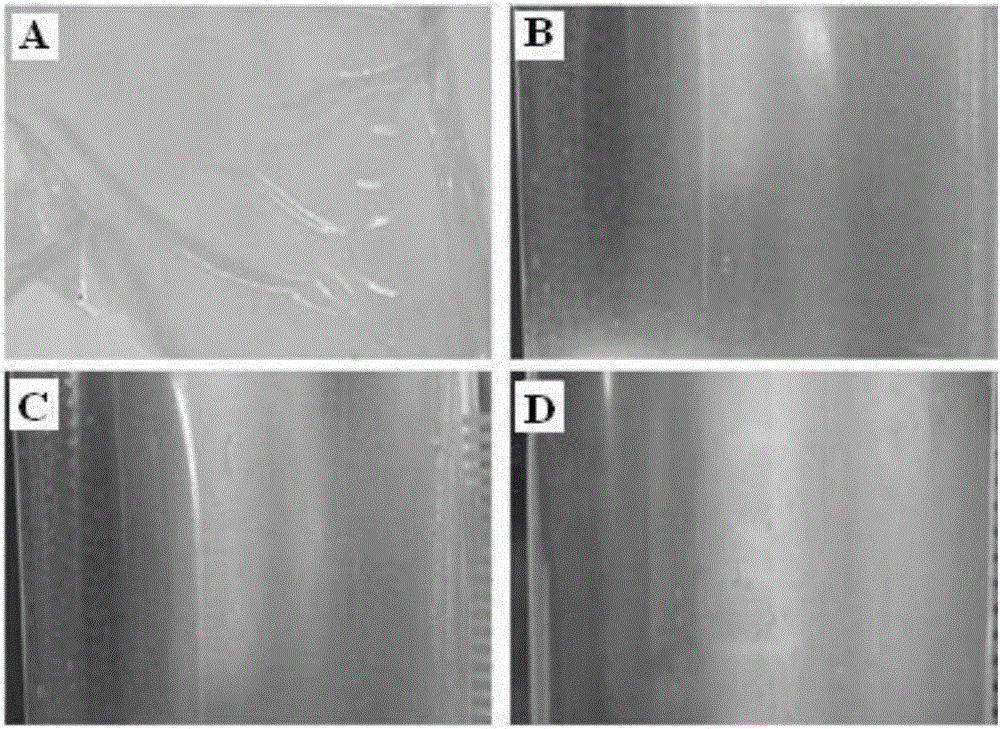

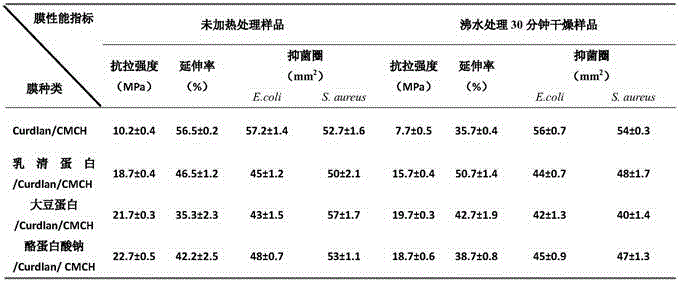

Edible protein/polysaccharide composite membrane and preparation method and application thereof

ActiveCN105802249AWide variety of sourcesGood film formingFlexible coversWrappersCross-linkProtein solution

The invention discloses an edible protein / polysaccharide composite membrane and a preparation method and application thereof.The composite membrane is prepared through the method that a Curdlan solution, a carboxymethyl chitosan solution and plasticizer glycerinum are added into a protein solution including one of soybean protein, casein and whey protein, the pH value of the mixed liquid is adjusted to be 5-8; ultrasonic degassing is conducted, MTG is added, and membrane-forming liquid is acquired; the membrane-forming liquid is poured into a polyfluortetraethylene plate, a reaction is conducted for 30-60 minutes at the temperature of 55-65 DEG C, sizing and sterilization are conducted, 4-DEG C cooling is conducted for 10-20 minutes, drying is conducted under the conditions that RH is 30-50% and the temperature ranges from 20 DEG C to 30 DEG C, and then membrane uncovering is conducted.The heat stability of the membrane is improved by adding Curdlan into the common edible protein solution, chitosan is added so that the membrane can have the antibacterial performance, microorganism source transglutaminase is added to catalyze the protein and cross linking between the protein and chitosan, and the chemical performance of the membrane is improved.

Owner:TAIXING DONGSHENG FOOD TECH

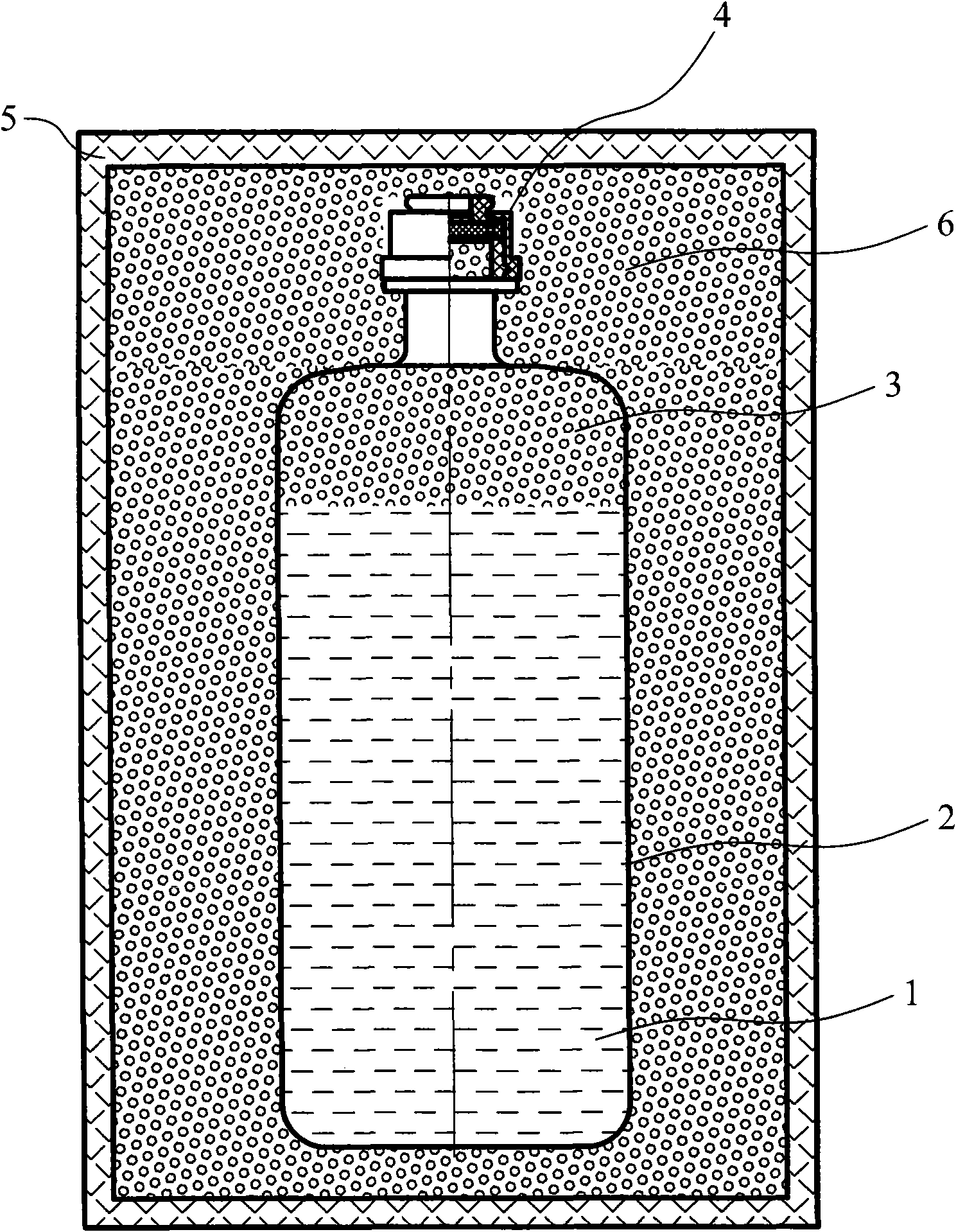

Packaging method of sodium bicarbonate injection

ActiveCN101618770AExcellent gas barrierReduce manufacturing costLiquid fillingPharmaceutical containersProduct gasBiomedical engineering

The invention discloses a packaging method of a sodium bicarbonate injection, which comprises the following steps: filling the sodium bicarbonate injection into a plastic container; charging carbon dioxide gas into the plastic container; sealing the plastic container filled and charged with the sodium bicarbonate injection and the carbon dioxide gas; sterilizing the sealed plastic container; and sealing the sterilized sealed plastic container in a choke protection bag. The manufacturing cost of a packaging bag manufactured by the packaging method is greatly reduced.

Owner:HUNAN CHINASUN PHARMA MASCH CO LTD

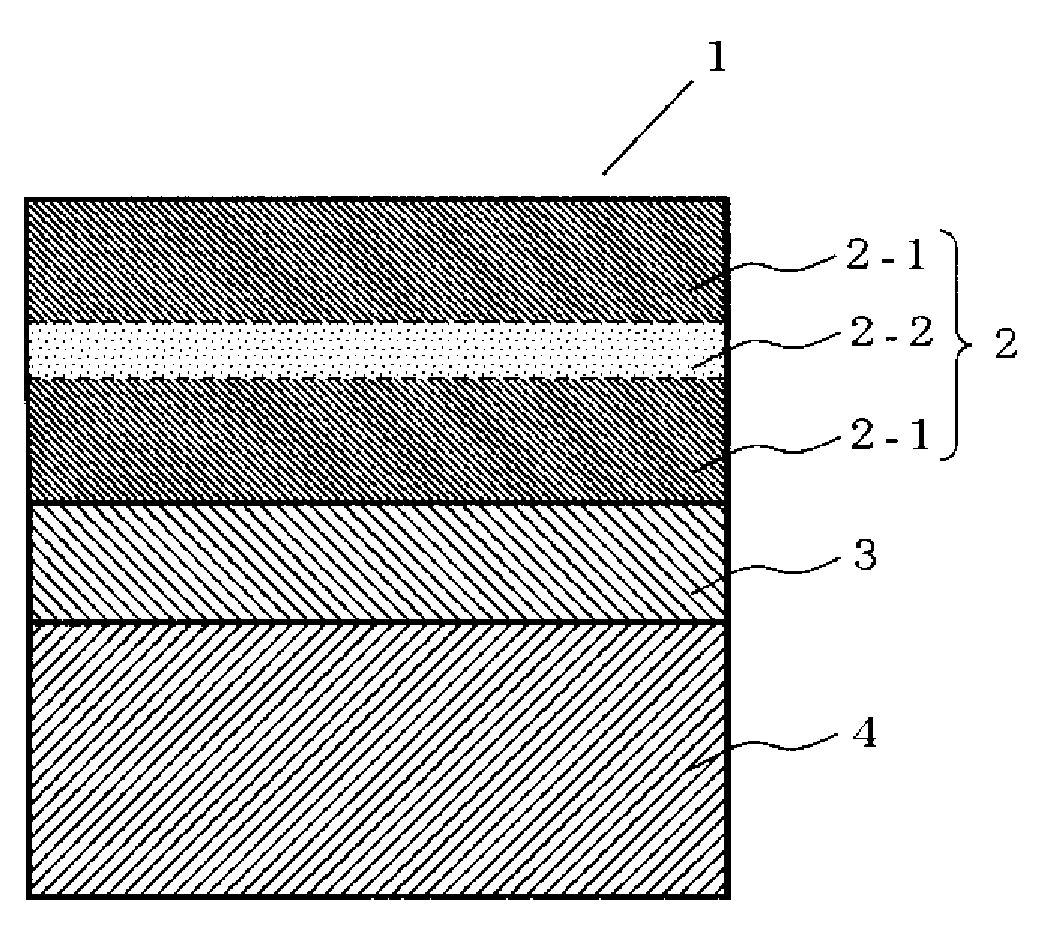

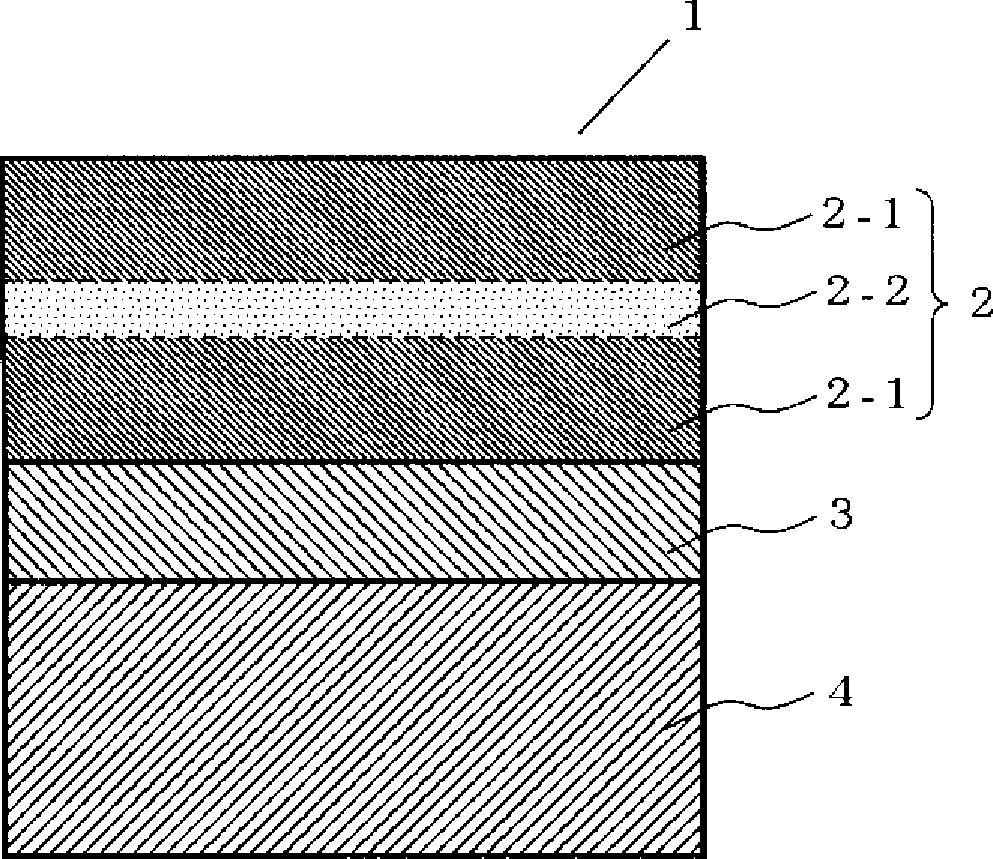

Film for vacuum heat insulating material, and vacuum heat insulating material

InactiveCN102667298AExcellent gas barrierImprove reliabilityThermal insulationSynthetic resin layered productsPolymer scienceHermetic packaging

Provided are a film for a vacuum heat insulating material, said film being superior in gas barrier properties to the existing films for vacuum heat insulating materials and capable of sustaining the excellent gas barrier properties even after folding or deforming, and a vacuum heat insulating material wherein a core material is hermetically sealed and packaged in said film. The film for a vacuum heat insulating material is characterized by comprising a protective layer formed of a co-extruded and stretched film, which is composed of a nylon-based resin, an ethylene / vinyl alcohol copolymer and a nylon-based resin being layered in this order, a gas barrier layer, and a heat-fusible layer.

Owner:OKURA IND

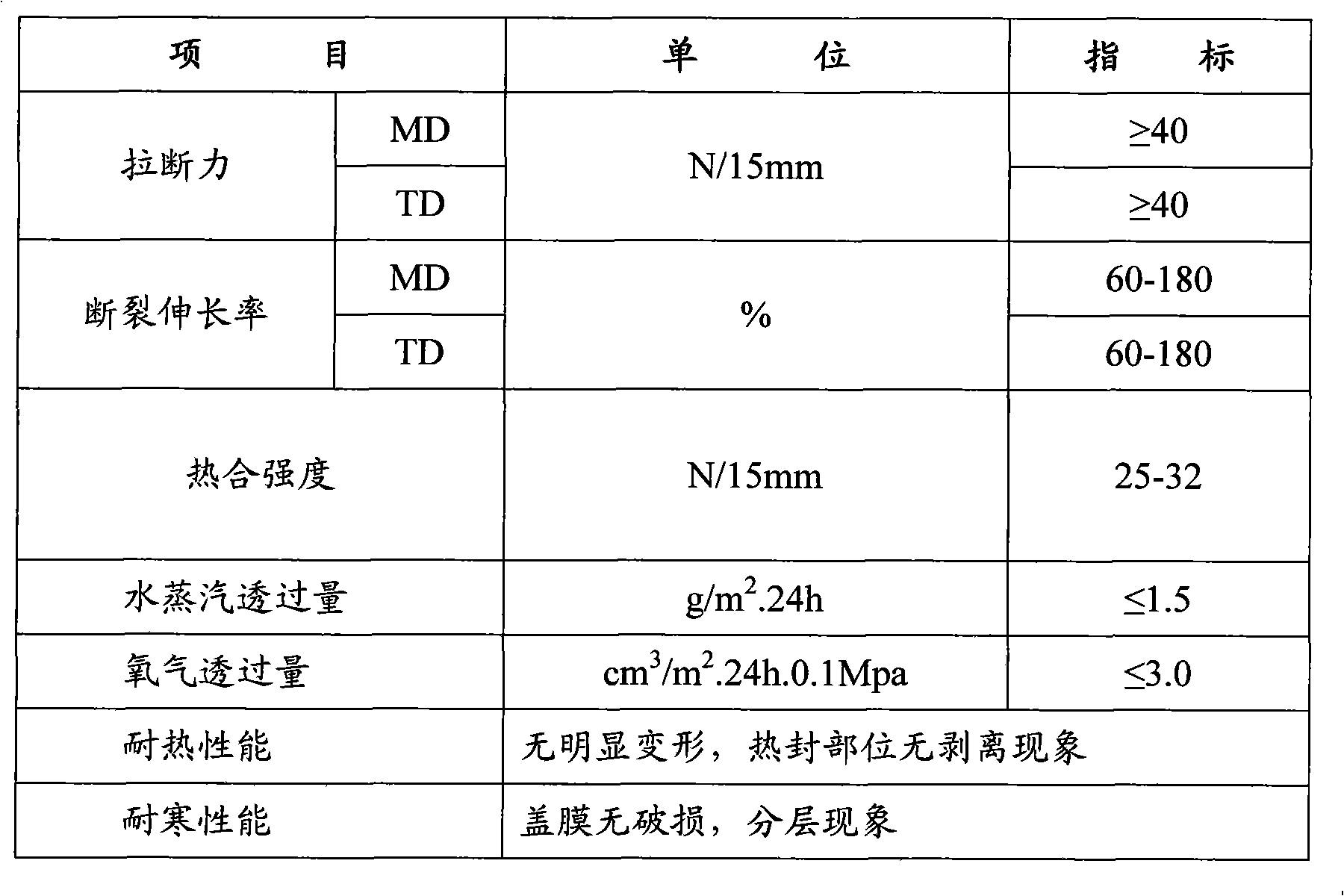

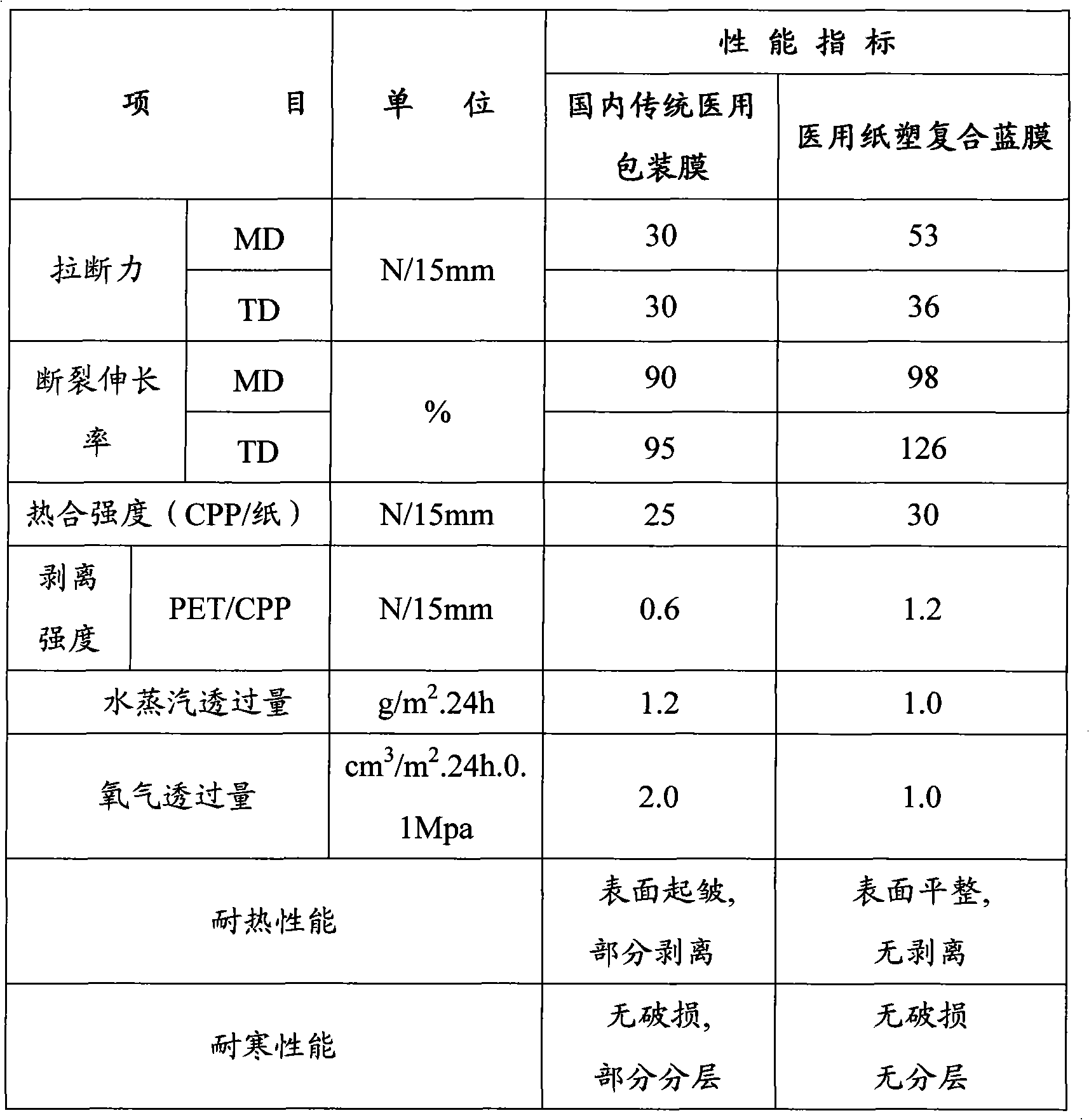

Medical paper-plastic composite blue film and preparation method thereof

ActiveCN101607458AImprove mechanical propertiesImprove folding resistanceNon-macromolecular adhesive additivesLamination ancillary operationsButenePolyester

The invention discloses a medical paper-plastic composite blue film and a preparation method thereof, the medical paper-plastic composite blue film is formed by combining a biaxially orientated polyester film which is printed and coated and a cast polypropylene film, the cast polypropylene film is divided into three layers of a corona layer, an intermediate layer and a heat seal layer, the raw material component of the corona layer is additive-free binary copolymer propylene resin RF401, the raw material components of the intermediate layer are 85-95% of binary random copolymer polypropylene resin F800E and 5-15% of ethylene-butene elastomer A-4085S, and the raw material components of the heat seal layer are 85-90% of binary copolymer propylene resin RF402 containing anti-sticky slipping agent, 5-15% of ethylene-butene elastomer A-4085S, 1-2% of inorganic anti-sticky agent ABPP10S and 0.5-1.5% of slip modified masterbatch SE07PP. The preparation method comprises the steps of printing, preparation of the cast polypropylene film, combination of the biaxially orientated polyester film and the cast polypropylene film and cutting. The medical paper-plastic composite blue film is matched with medical packing paper which can carry out heat sealing, steam sterilization and air infiltration blocking for carrying out packing of medical items, thereby reducing the packing cost and realizing safety performance of packing applications and environment-friendly treatment of packing wastes.

Owner:HUANGSHAN NOVEL

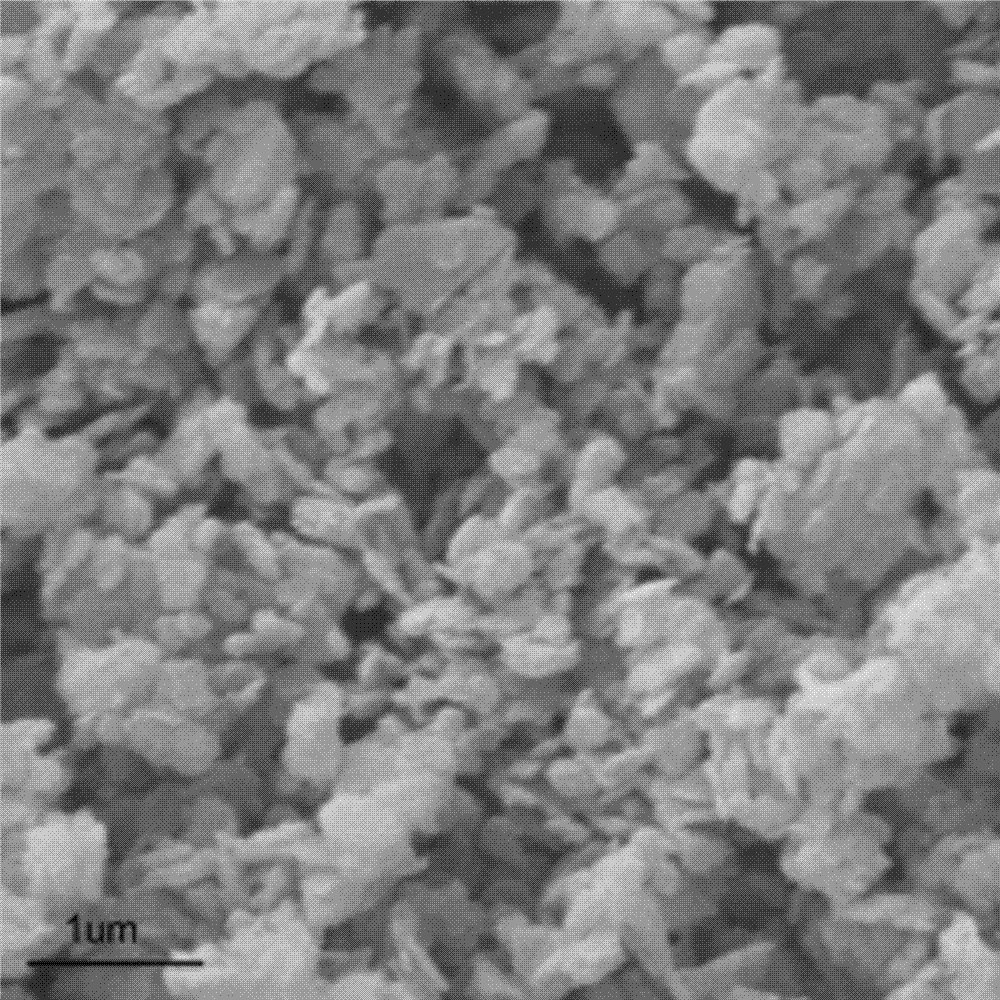

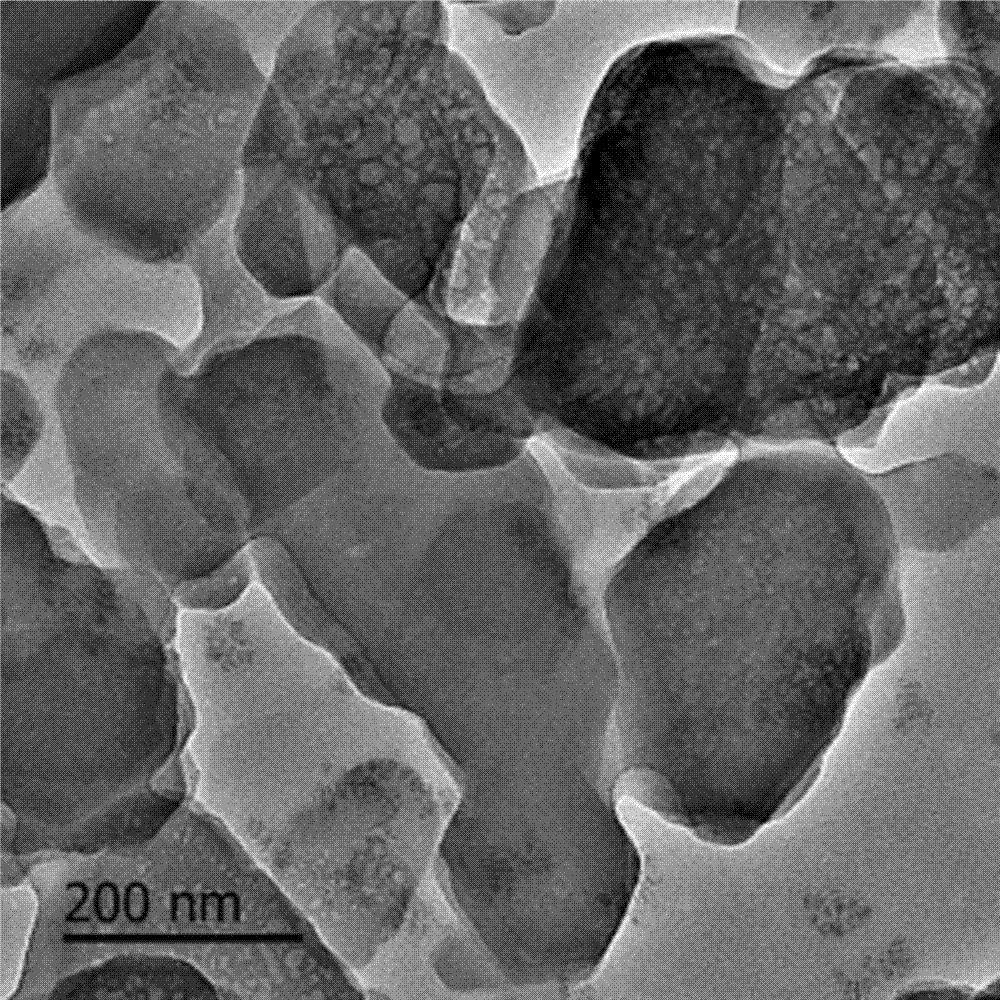

Preparation method of nanometer organic modified zirconium phosphate/MC nylon composite material

The invention provides a preparation method of a nanometer organic modified zirconium phosphate / MC nylon composite material, wherein organic zirconium phosphate, a caprolactam monomer, a catalyst, an initiator and a silane coupling agent are subjected to a reaction to obtain the nanometer organic modified zirconium phosphate / MC nylon composite material. According to the preparation method, alpha-zirconium phosphate is modified with n-butylamine and a Gemini surfactant, and then a co-precipitation method is performed to obtain the organic zirconium phosphate; the organic zirconium phosphate is subjected to high speed dispersion with the caprolactam monomer; the silane coupling agent and the catalyst are added; operations such as heating, high speed stirring and thermal insulation are performed, the obtained material is mixed with the caprolactam monomer added with the initiator after the melting, the obtained mixture is transferred into a mold, the mold is placed into an oven, the temperature is adjusted, and a thermal insulation reaction is performed; and cooling demolding is performed to obtain the nanometer organic modified zirconium phosphate / MC nylon composite material.

Owner:HUNAN UNIV OF TECH

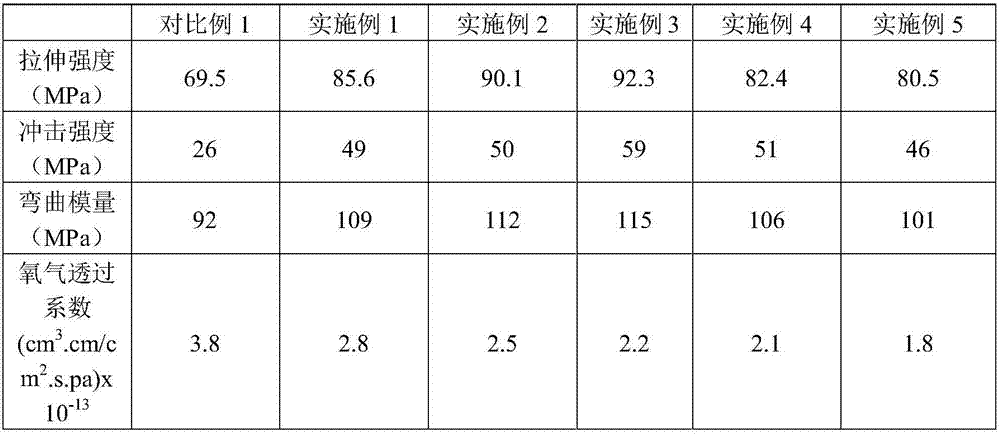

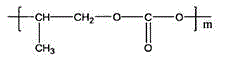

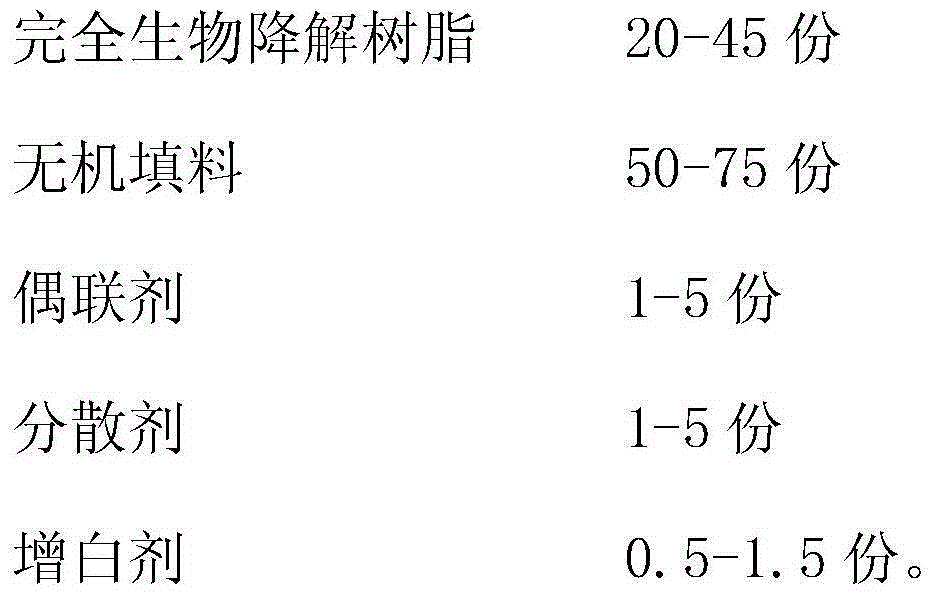

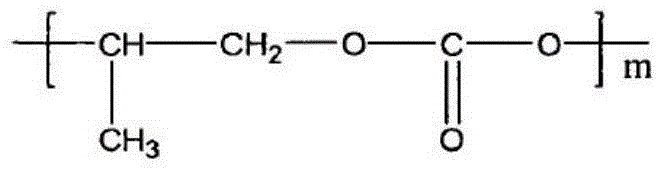

Biodegradable stone paper and preparation method thereof

InactiveCN104693710ASolve the problem of non-biodegradableTo achieve the purpose of environmental protectionFolding endurancePapermaking

The invention discloses biodegradable stone paper and a preparation method thereof, and belongs to the technical field of light industrial papermaking. Main ingredients of the stone paper comprise, 50-75 parts of inorganic filler, 20-45 parts of full biodegradable resin, 1-5 parts of coupling agent, 1-5 parts of dispersing agent and 0.5-1.5 parts of brightening agent, wherein the full biodegradable resin is a mixture of carbon-dioxide-based full-degradable plastic and biodegradable polyester. The stone paper prepared by the preparation method is a full-degradable material, and the problem that existing stone paper regards polyethylene as a base body, and resin is not degradable is solved. The stone paper has a series of advantages that the strength is higher, the folding endurance is high, and the whiteness is high.

Owner:SUN YAT SEN UNIV +1

Thermoplastic elastomer composition and pneumatic tire using the same

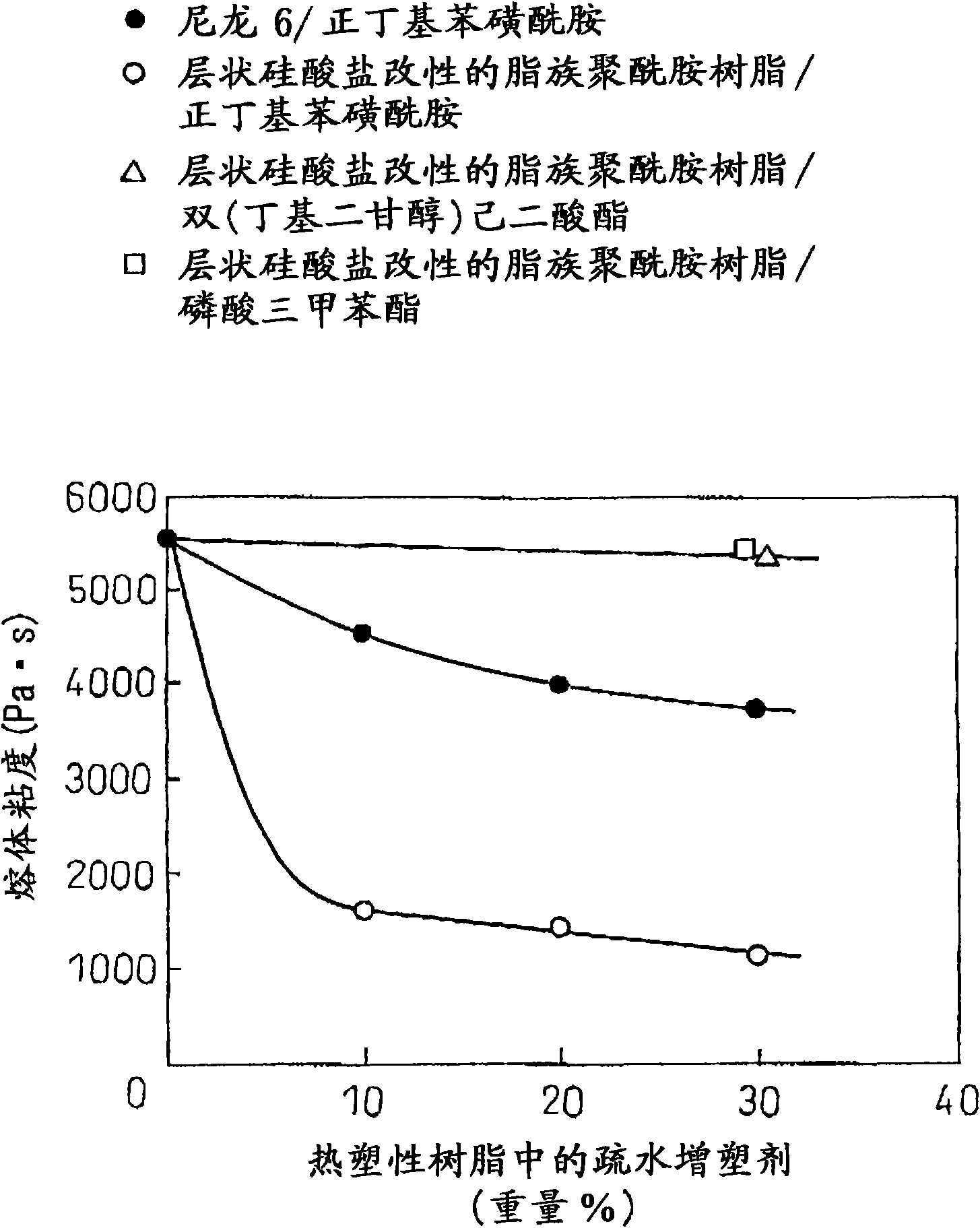

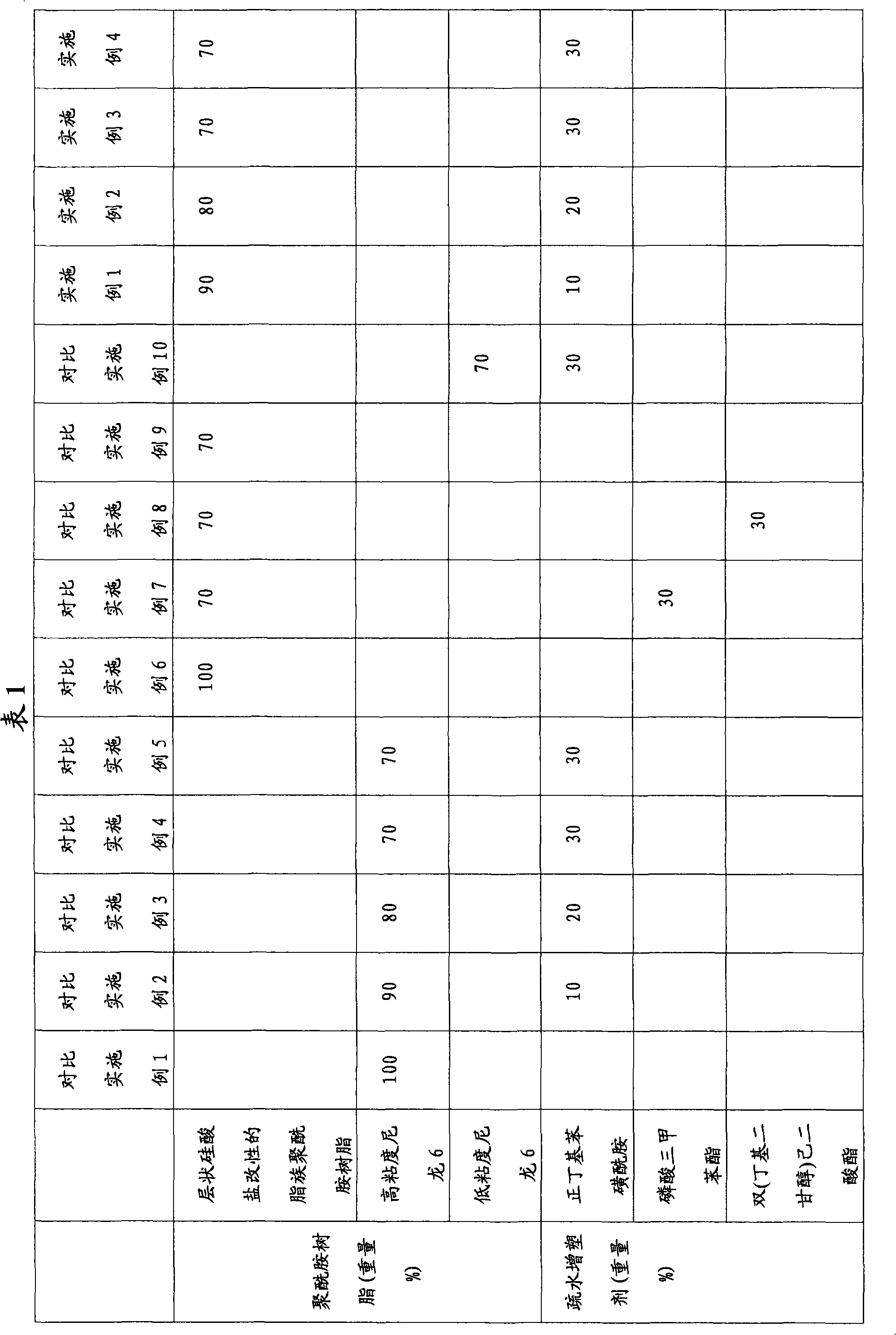

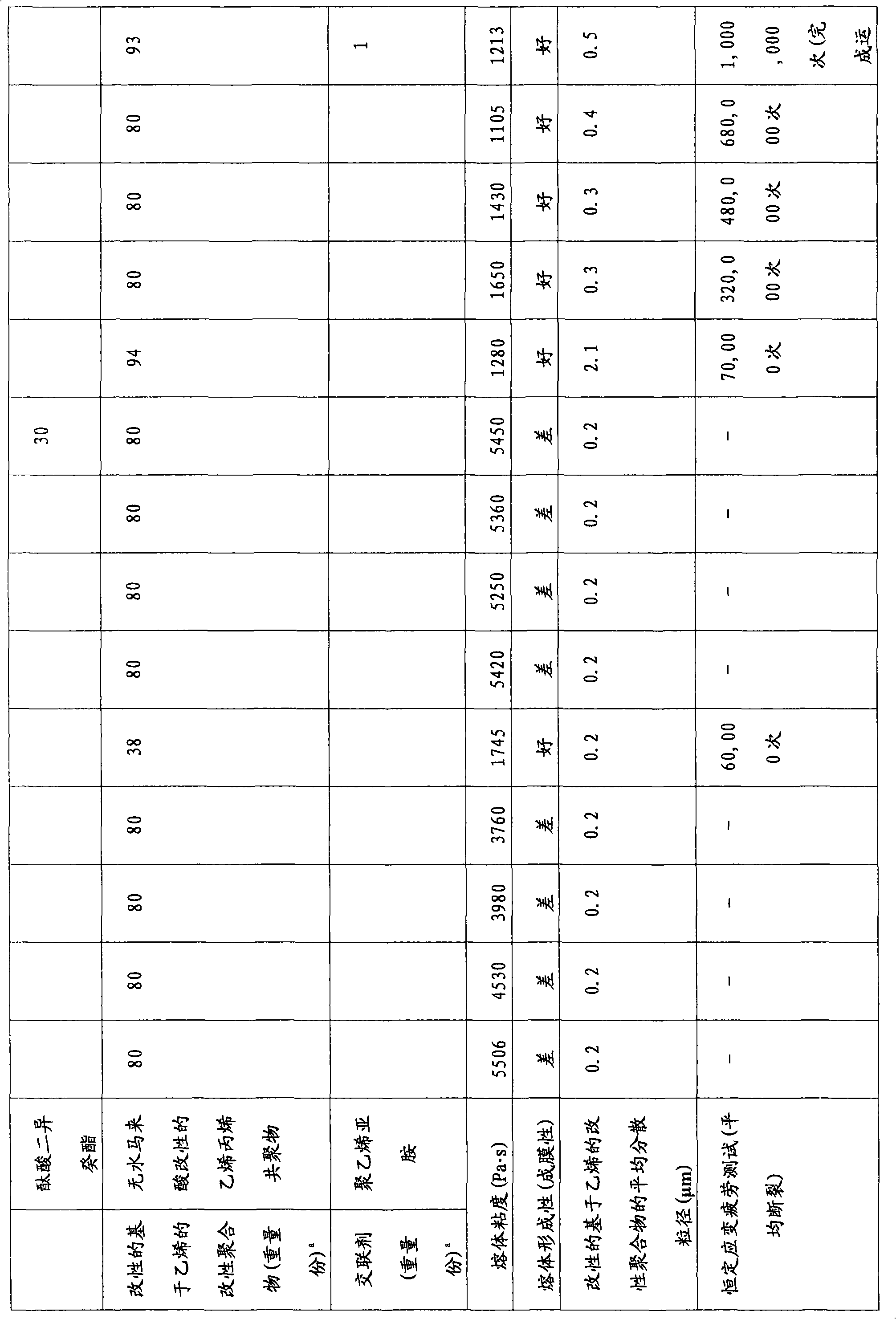

The invention aims to improve the balance of the low temperature durability, gas barrier property, and melt processability of a thermoplastic elastomer composition comprising an aliphatic polyamide resin in which an ethylene-based modifying polymer is dispersed, a thermoplastic elastomer composition comprising a thermoplastic resin composition (A) and a modified ethylene-based modifying polymer (B) graft modified with acid anhydride groups, wherein the thermoplastic resin composition (A) comprises 60 to 90 percent by weight of a layered silicate modified aliphatic polyamide resin (A1) prepared by an interlayer polymerization method and 10 to 40 percent by weight of a hydrophobic plasticizer (A2) having a solubility parameter (SP value) of 10 to 12 (cal / cm<2>)<1 / 2>, the modified ethylene-based modifying polymer (B) is 70 of 120 parts by weight based on 100 parts by weight of the thermoplastic elastomer composition, and the modified ethylene-based modifying polymer (B) forms a dispersedparticle phase.

Owner:YOKOHAMA RUBBER CO LTD

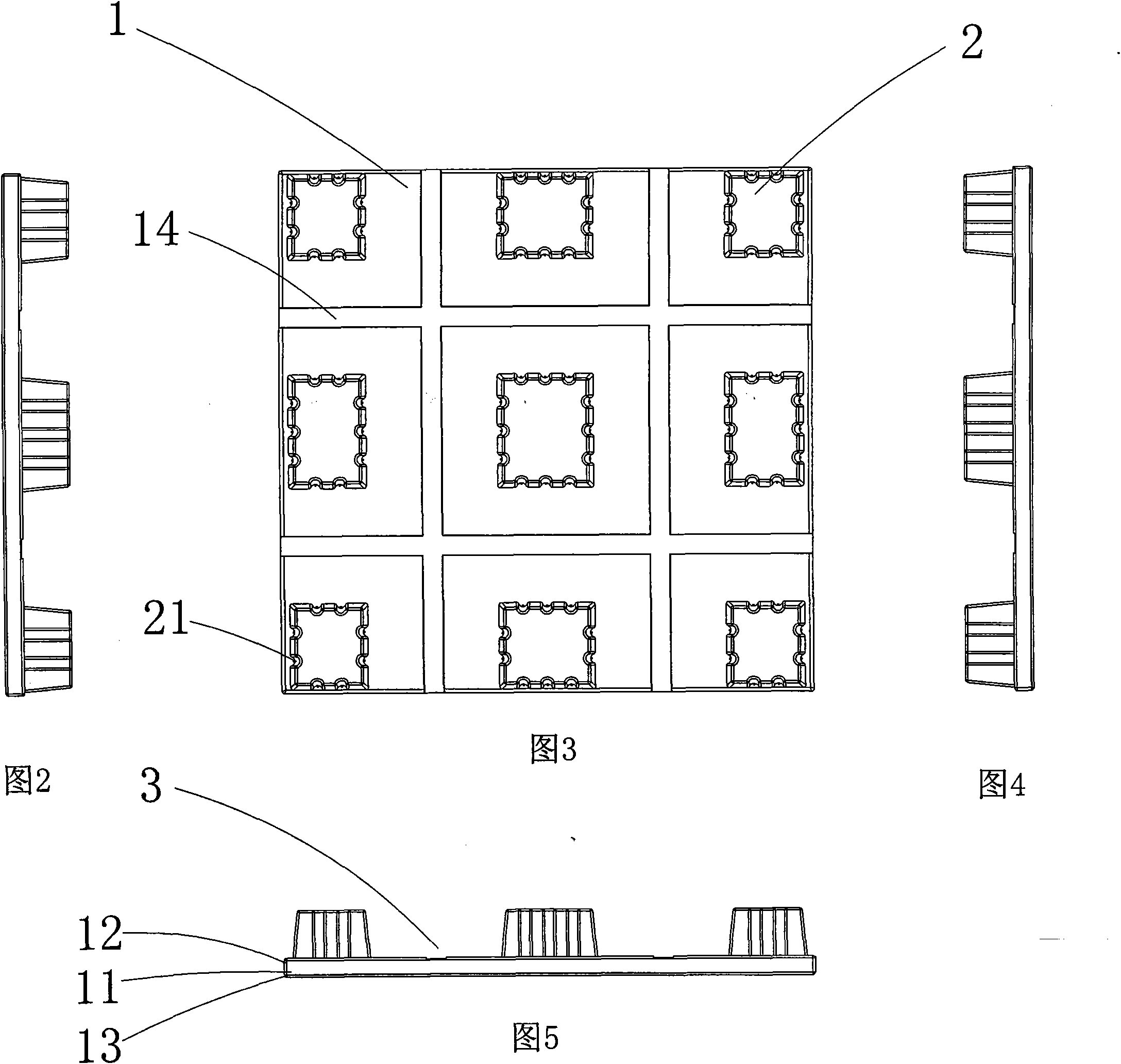

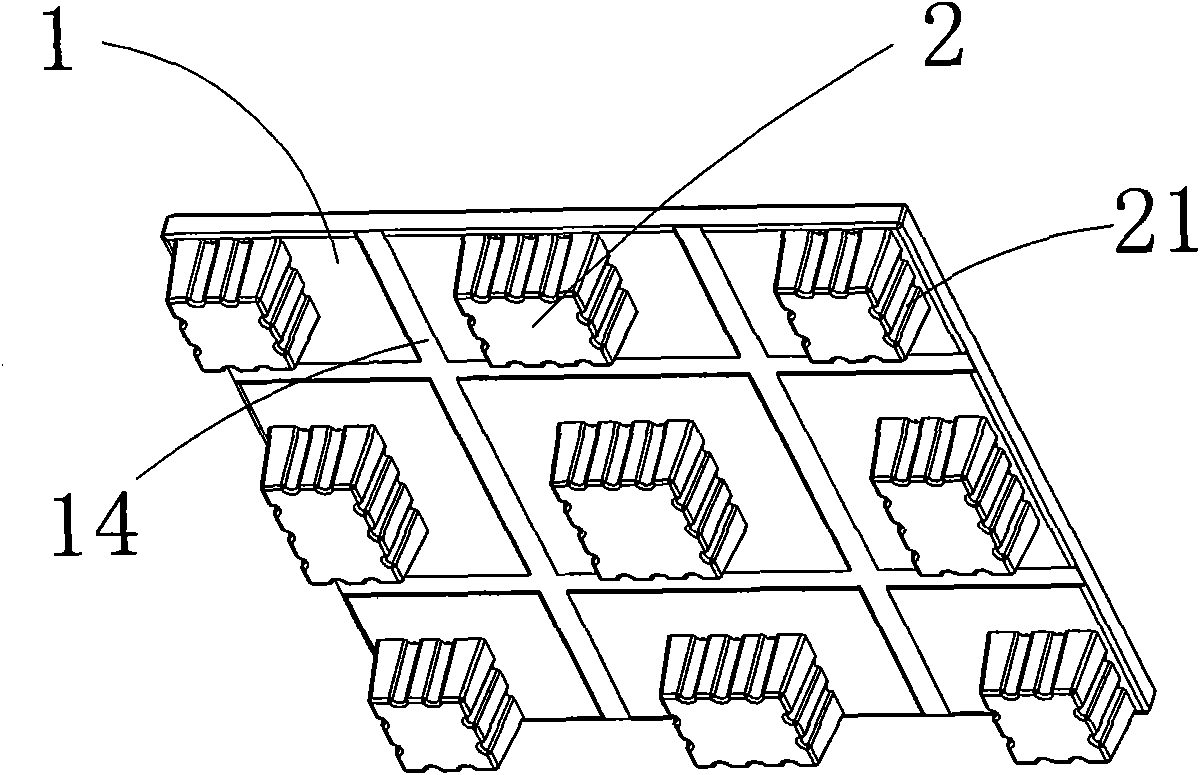

Aviation tray and manufacturing method thereof

InactiveCN101983897ALight in massGood heat insulationSynthetic resin layered productsAdhesivesAviationPolyethylene terephthalate

The invention discloses an aviation tray and a manufacturing method thereof. The aviation tray comprises a bearing panel, the main body of the bearing panel is an integrated EPS (expandable polystyrene) plate, the bottom of the EPS plate is provided with nine EPS supporting posts, PET (polyethylene terephthalate) films are stuck on the surfaces of the bearing panel and the EPS supporting posts, a jack is formed between the EPS supporting posts, the surface of the EPS plate is stuck with the PET films through an EVA (acrylate-vinyl acetate) glue layer, and the nine EPS supporting posts are distributed in 3*3 matrix. The manufacturing method comprises the steps of main body formation, film spraying, heating and cutting, vacuum plastic sucking and cooling formation. The PET films are stuck on the EPS plate so that the aviation tray has the advantage of light weight of the EPS plate, overcomes the defects of poor impact resistance and tension resistance of the EPS plate and has good mechanical property of the PET films; and the tray has the advantages of good folding resistance, capability of tolerating most solvents, good high and low temperature resistance, no toxicity, no taste, sanitation and good safety.

Owner:黄祖良

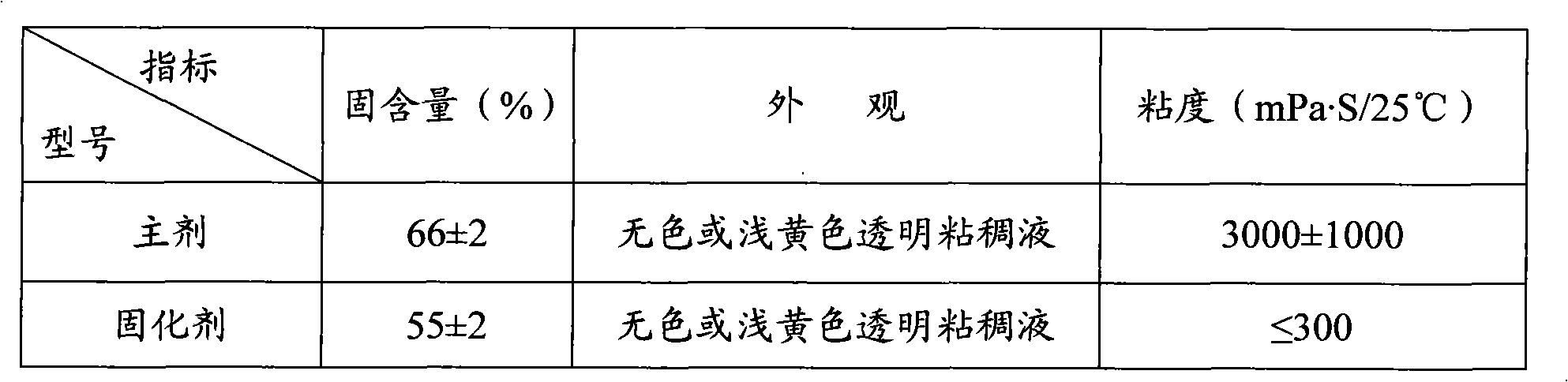

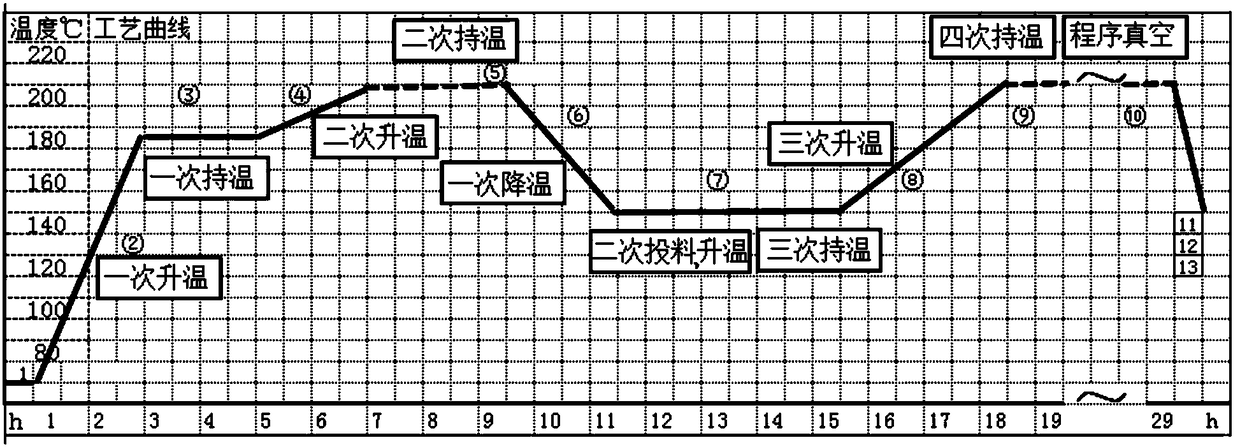

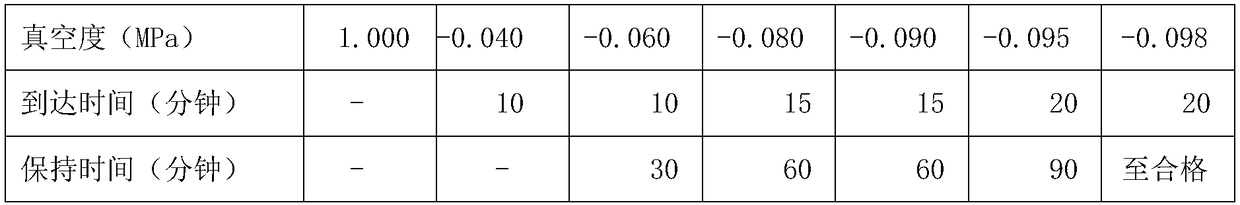

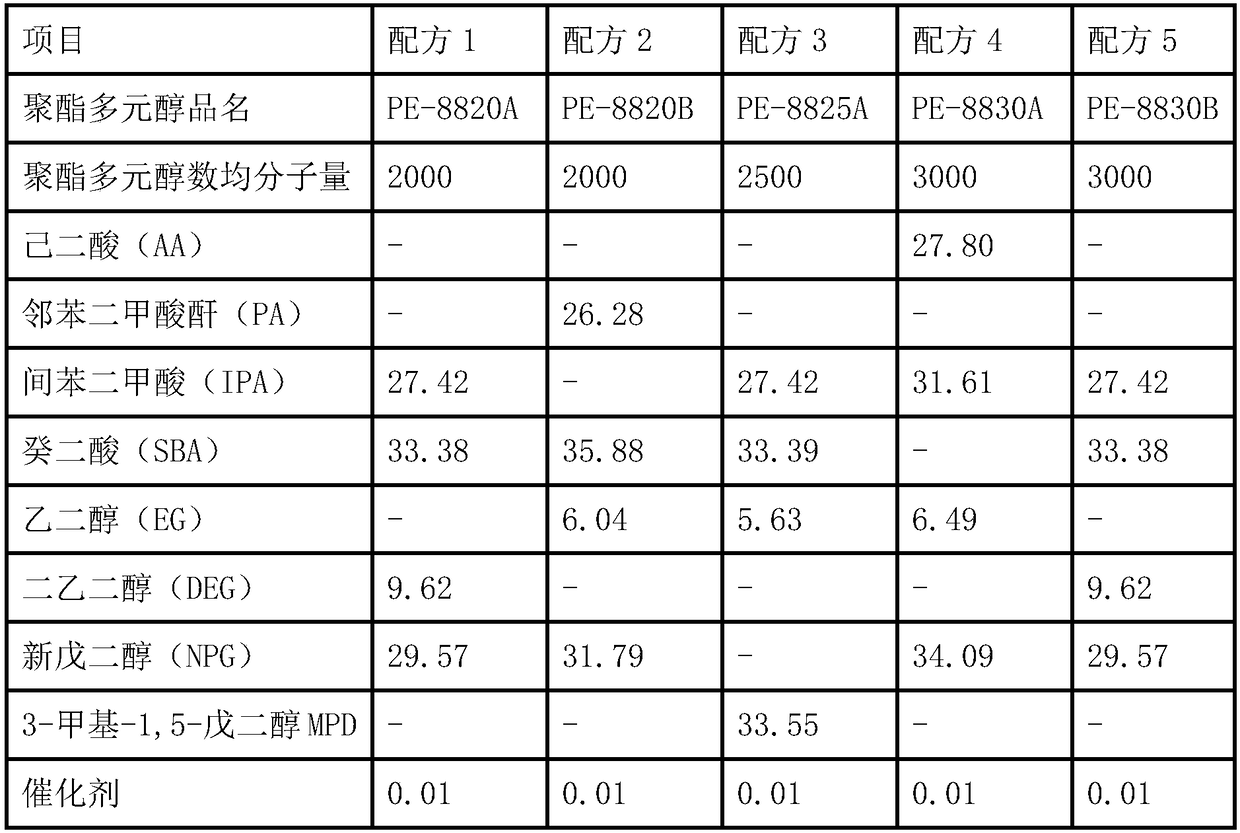

Preparation method of polyester polyol for laminated film adhesive

InactiveCN108424510AHigh bonding strengthHigh reactivityPolyureas/polyurethane adhesivesPolyesterPolyurethane adhesive

The invention provides a preparation method of polyester polyol for a laminated film adhesive. The preparation method comprises steps as follows: primary feeding is performed, 25.0%-35.0% of aromaticbinary carboxylic acid and 25.0%-40.0% of small-molecular diol are fed into a reaction kettle, programed heating is executed to promote esterification reaction, and after an acid value is reduced to 10-30 mgKOH / g, cooling is performed for secondary feeding; 25.0%-40.0% of aromatic binary carboxylic acid and 5.0%-15.0% of small-molecular diol are subjected to secondary feeding, the temperature is increased again, the esterification reaction is performed, water is produced, a tetrabutyl titanate or stannous octoate catalyst is added, programed heating and programmed vacuum are controlled, and atarget polyester polyol product containing both benzene ring aromatics and aliphatic hydrocarbon is obtained; the target polyester polyol product is primary hydroxyl terminated difunctional polyol andhas higher reactivity with isocyanate groups. The polyurethane adhesive prepared from polyester polyol as a main soft segment through polymerization is suitable for adhesion of food packaging laminated films which meet the high-temperature requirement and have steaming resistance for sterilization.

Owner:SHANGHAI LIANJING MATERIAL ASSETAB

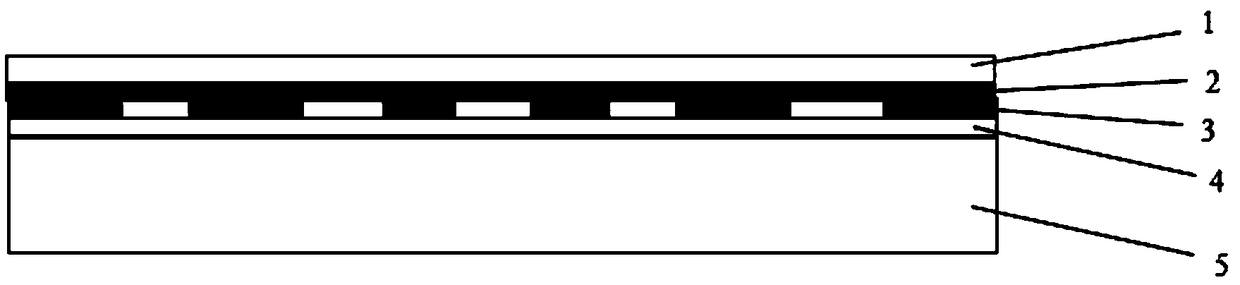

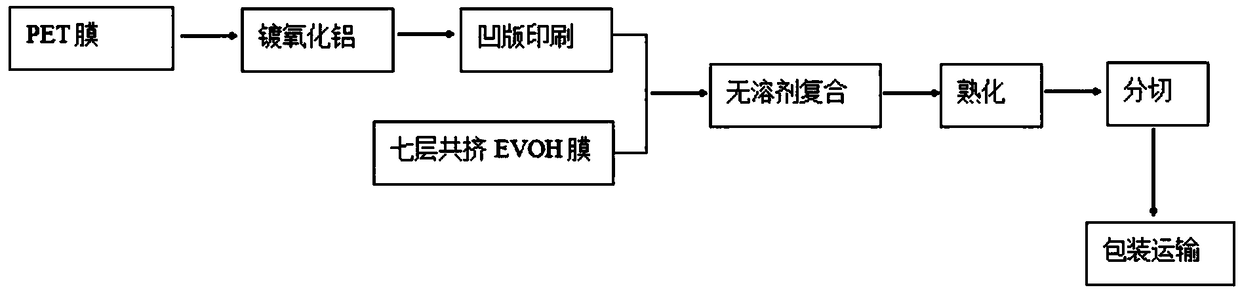

High-transparent high-barrier and easy-taking opening sealing cover membrane and production technology thereof

ActiveCN109263211AEasy to displayIncrease the fragranceSynthetic resin layered productsLaminationPolybutyleneDouble barrier

The invention relates to a high-transparent high-barrier and easy-taking opening sealing cover membrane and a production technology thereof. The membrane layer structure of the membrane sequentially comprises a PET membrane layer, an alumina coating layer, an oil ink layer, an adhesive layer and an EVOH co-extrusion membrane layer from outside to inside; and the EVOH co-extrusion membrane layer comprises a compound layer A, a sub outer layer B, a binding layer C, a middle layer D, a binding layer E, a sub outer layer F and a hot sealing layer G. The high-transparent high-barrier and easy-taking opening sealing cover membrane is obtained through innovation on the EVOH co-extrusion membrane layer formula. The membrane product has the high transparency and low haze, can well display the packed content and attracts consumers. The alumina coating PET and the EVOH co-extrusion membrane layer jointly form a double-barrier layer, so that the membrane has the outstanding moisturizing, air barrier and fragrance preserving functions, and provides safety guarantee to food. A polybutylene easy-taking layer in the hot sealing layer G can be well sealed with various kinds of materials such as PP,PE and PS, the controllable peeling strength can be guaranteed, and the user experience of the consumers is greatly improved.

Owner:HUANGSHAN NOVEL

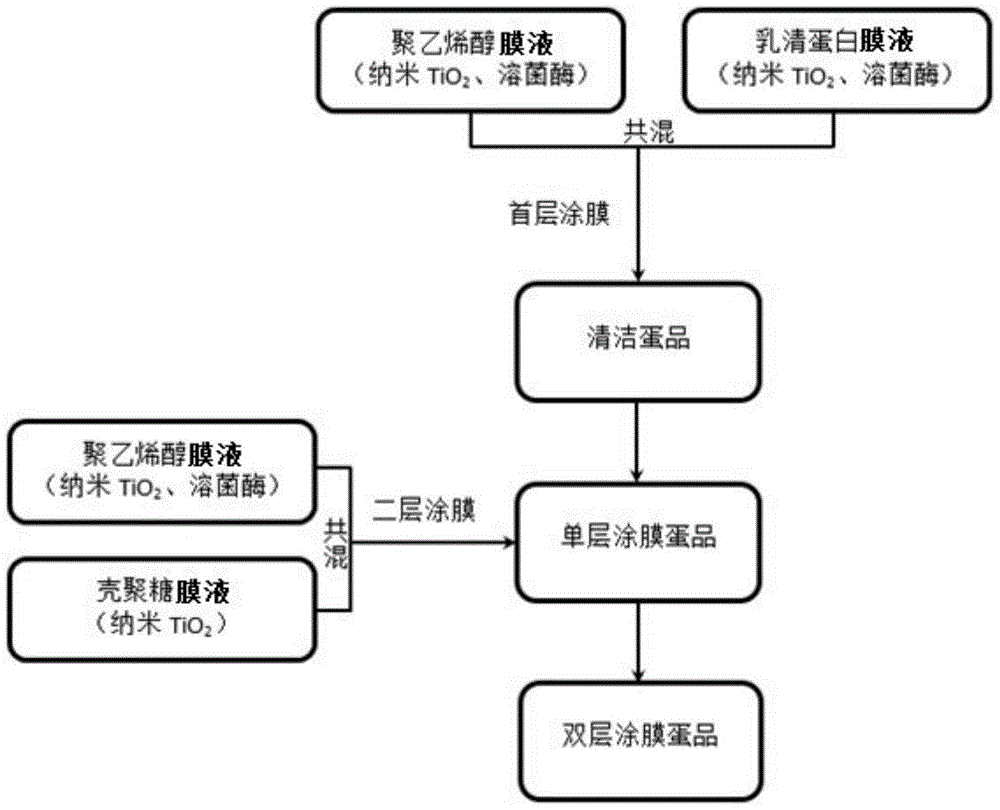

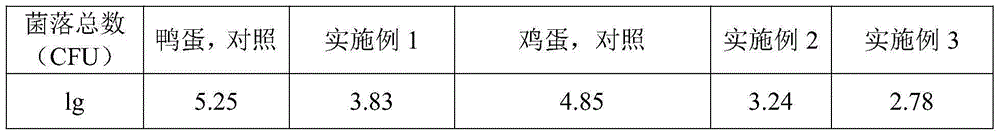

Egg product freshness keeping method by means of double layers of nano-antibacterial coating films

ActiveCN105166010AExtended shelf lifeExcellent gas barrierEggs preservation by coatingWhey proteinEconomic benefits

The invention provides an egg product freshness keeping method by means of double layers of nano-antibacterial coating films. The method comprises the steps that a PVA-whey protein nano-antibacterial coating film solution and a chitosan-PVA nano-antibacterial coating film solution are prepared separately; egg products are steeped in the prepared PVA-whey protein nano-antibacterial coating film solution, naturally air-dried, steeped in the prepared chitosan-PVA nano-antibacterial coating film solution, air-dried and then packaged for storage. According to the egg product freshness keeping method by means of double layers of the nano-antibacterial coating films, safe, nontoxic and degradable materials serve as coating film freshness keeping substrates to perform double-layer film coating treatment on the egg products, therefore, the safety of the product is improved, and the shelf life of the egg products is effectively prolonged. The method is beneficial for improving the quality of the egg products and increasing the economic benefits of egg product industry, easy and convenient to operate and low in production energy consumption and has a good application prospect.

Owner:SHANGHAI JIAO TONG UNIV

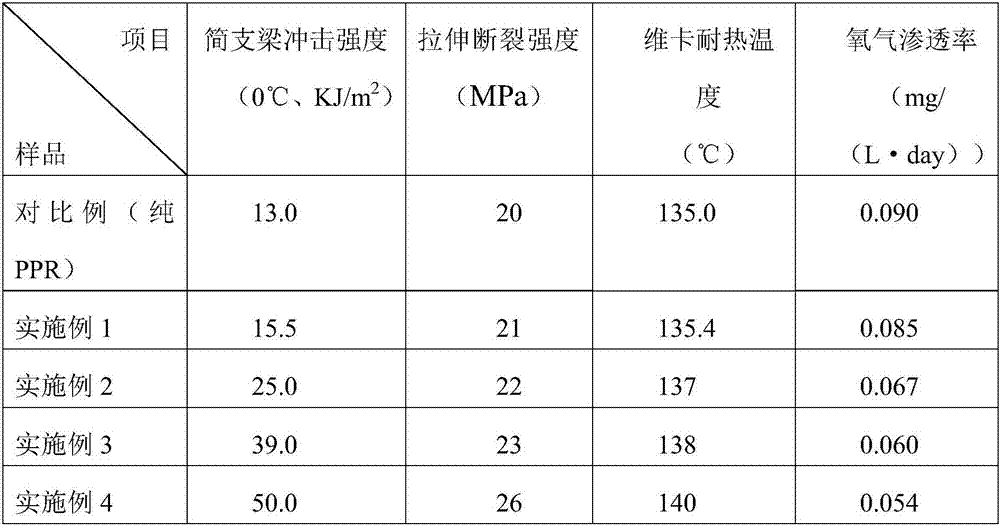

Modified white graphene composite polypropylene tubular product, and preparation method thereof

InactiveCN107446243AExcellent gas barrierHigh strengthNon-macromolecular adhesive additivesOther chemical processesBreaking strengthPolymer science

The invention belongs to the technical field of plastic tube, and more specifically discloses a modified white graphene composite polypropylene tubular product. The modified white graphene composite polypropylene tubular product is composed of, by weight, 100 parts of polypropylene resin, 0.1 to 10 parts of modified white graphene, 0.05 to 1 part of an anti-oxidant, 0.05 to 1 part of a dispersant. The invention also discloses a preparation method of the modified white graphene composite polypropylene tubular product. The preparation method comprises following steps: preparation of modified white graphene, blending of modified white graphene and polypropylene resin, preparation of modified white graphene polypropylene master batch, and extrusion moulding. Compared with conventional polypropylene tubular product, the modified white graphene composite polypropylene tubular product possesses following advantages: 0 DEG C low temperature impact resistance is improved by 350% or higher, tensile break strength is increased by 30%, Vicat softening point is increased by 5 DEG C, oxygen permeability is reduced by 40%, both thermal conductivity and corrosion resistance are excellent, processing is convenient, cost is relatively low, and practicality is high.

Owner:GUANGDONG NANOLUTION SCI & TECH CO LTD

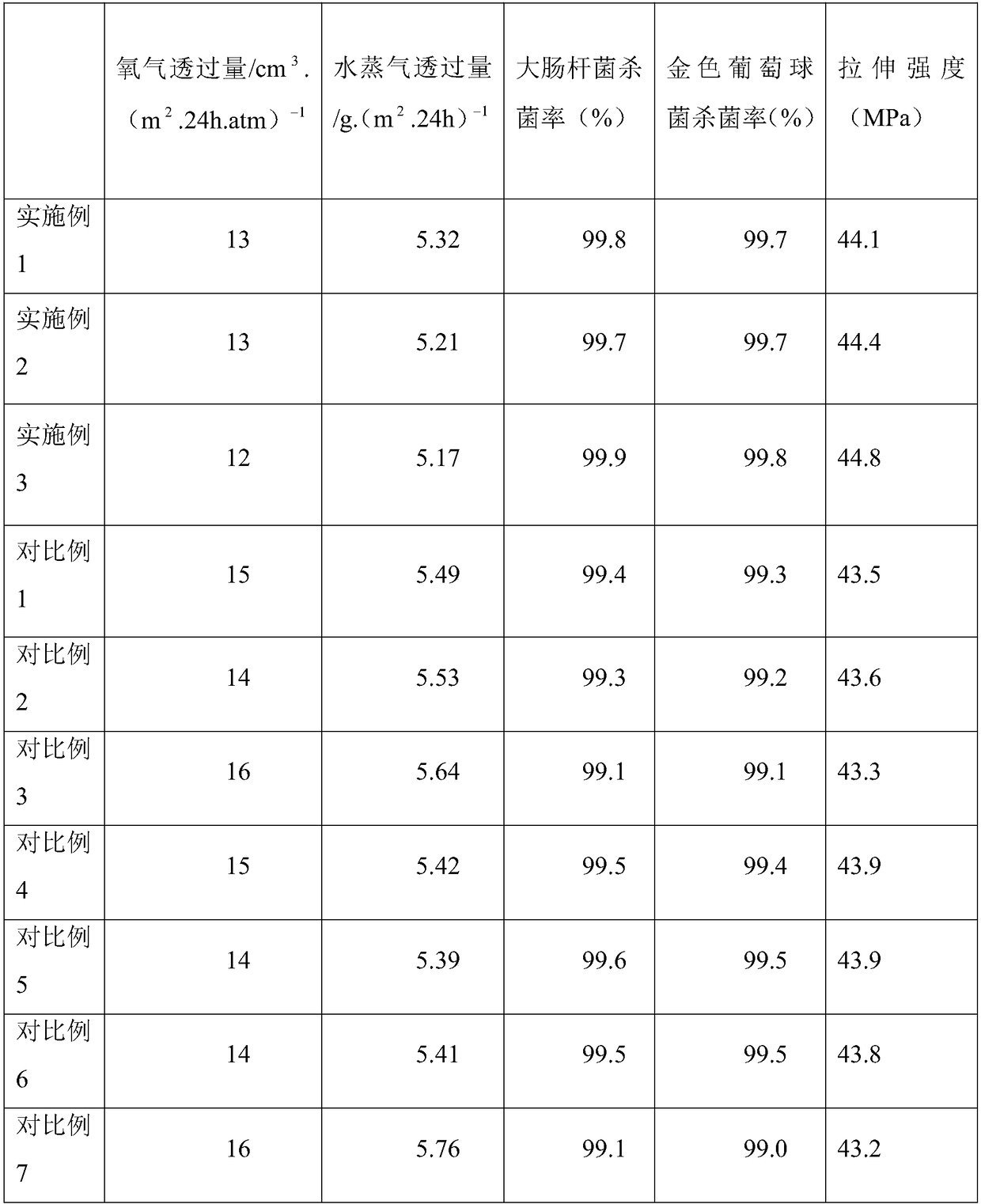

Antibacterial high barrier food wrapping film and preparation method thereof

The invention discloses antibacterial high barrier food wrapping film and a preparation method thereof. The film is prepared from ethylene vinyl alcohol copolymer, polyurethane, polyvinyl acetal, a compound silicate mineral additive and a silane coupling agent KH-550. The antibacterial high barrier food wrapping film takes the ethylene vinyl alcohol copolymer, the polyurethane, the polyvinyl acetal and the compound silicate mineral additive as materials of the wrapping film, based on the ethylene vinyl alcohol copolymer, the polyurethane, the polyvinyl acetal, the compound silicate mineral additive and other materials are added, the blending technology is adopted, and the wrapping film is obtained through an extrusion mechanism, so that the antibacterial performance, barrier performance and other performance of the wrapping film are greatly improved.

Owner:CHANGDE JINDE NEW MATERIAL TECH CO LTD

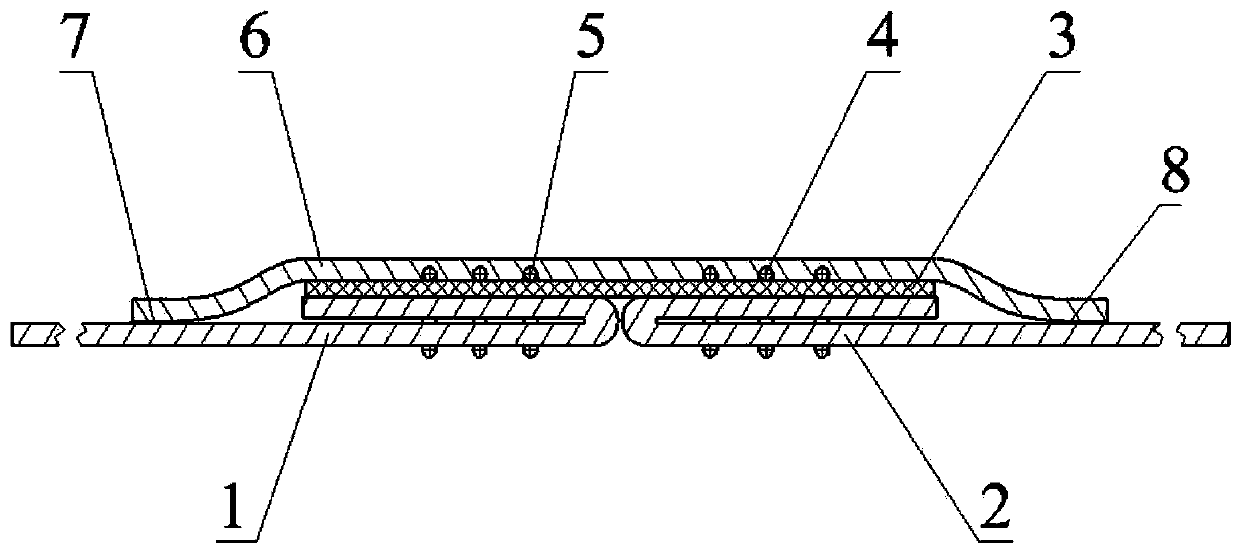

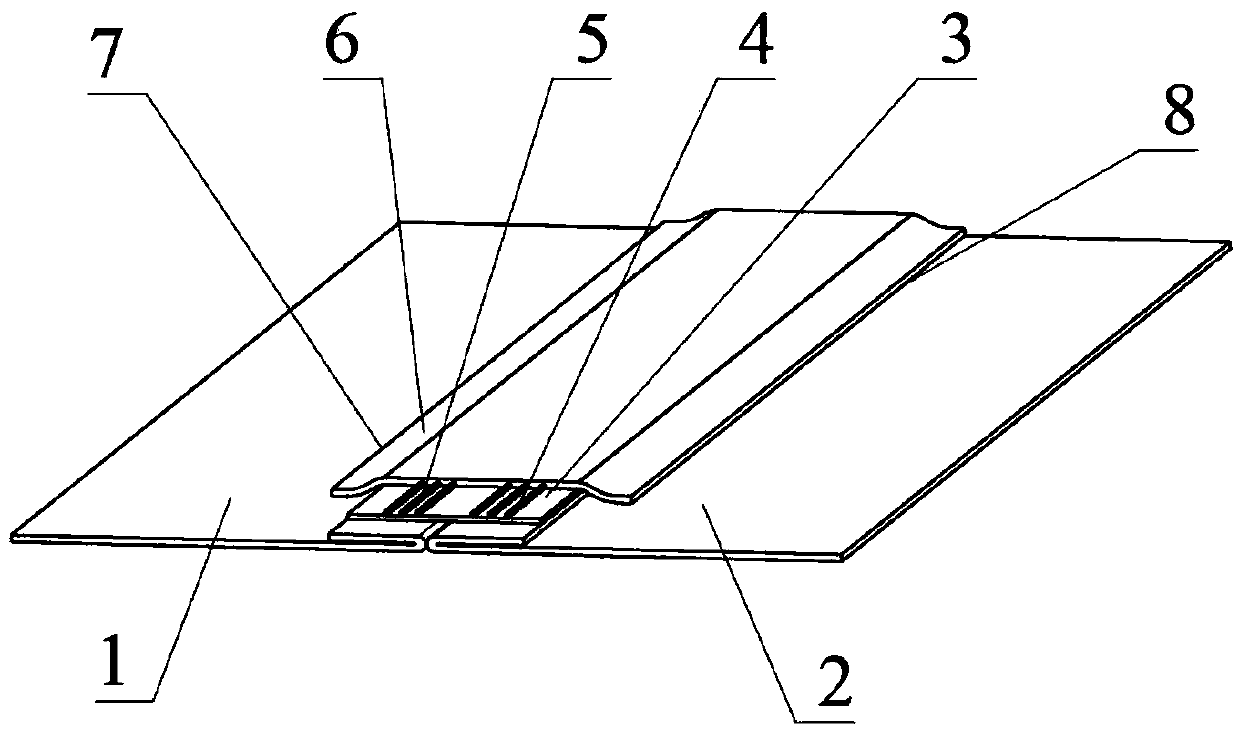

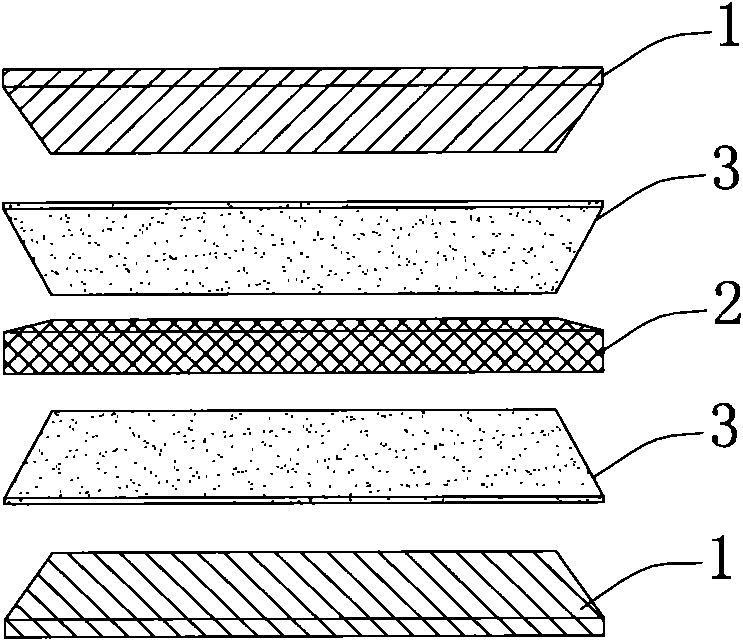

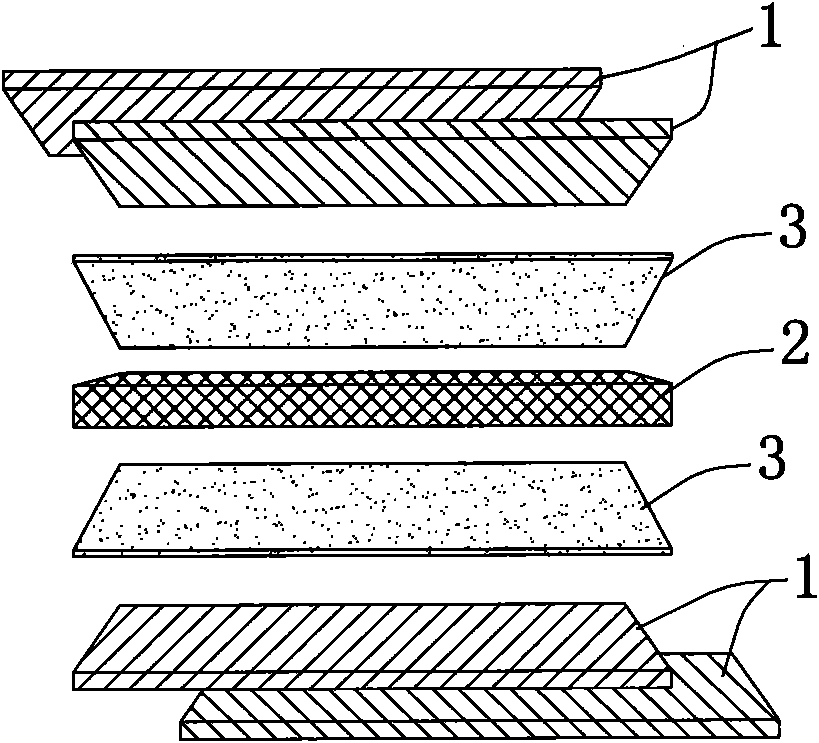

High-strength fiber reinforcement thin film sealing butt-joint structure universal for high altitude airship

Disclosed is a high-strength fiber reinforcement thin film sealing butt-joint structure universal for a high altitude airship. The high-strength fiber reinforcement thin film sealing butt-joint structure universal for the high altitude airship comprises left and right side butt-joint high-strength fiber reinforcement lamination composite universal skins, namely the left side skin and the right side skin, a middle reinforcement bearing layer, left side connecting sewing threads, right side connecting sewing threads, an inner side sealing film layer, a left side film layer sealing glue layer and a right side film layer sealing glue layer. The left side skin and the right side skin become the bottommost layers of the butt-joint structure. The middle reinforcement bearing layer, the left side skin and the right side skin are connected together through the left side connecting sewing threads and the right side connecting sewing threads. The inner side sealing film layer is the topmost layer of the butt-joint structure, covers connectors and then is in glue connection with the left side skin and the right side skin through the left side film layer sealing glue layer and the right side film layer sealing glue layer on the two sides, namely adhesive agents. According to the high-strength fiber reinforcement thin film sealing butt-joint structure universal for the high altitude airship, the technical difficult problems that in the butt-joint process of skin materials of the high altitude airship, the skin materials are high in welding intensity, and the helium leakage character is good are solved, the risk that the skin materials of the airship are torn and damaged at the butt joints of the skins in the high-altitude overpressure flying process of the high altitude airship is reduced, and the influence on the whole intensity of the airship in the skin high-frequency welding process is reduced.

Owner:BEIHANG UNIV

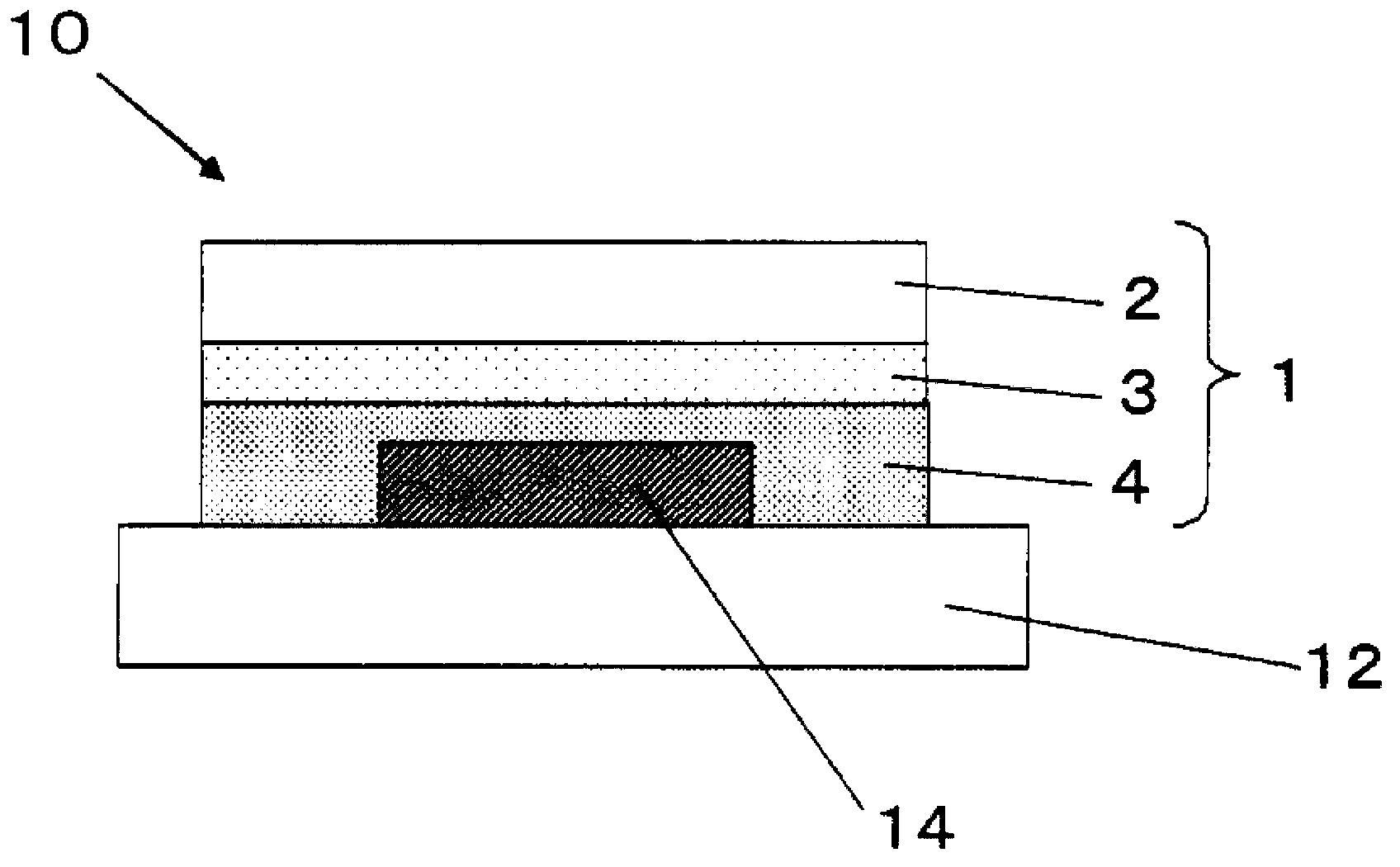

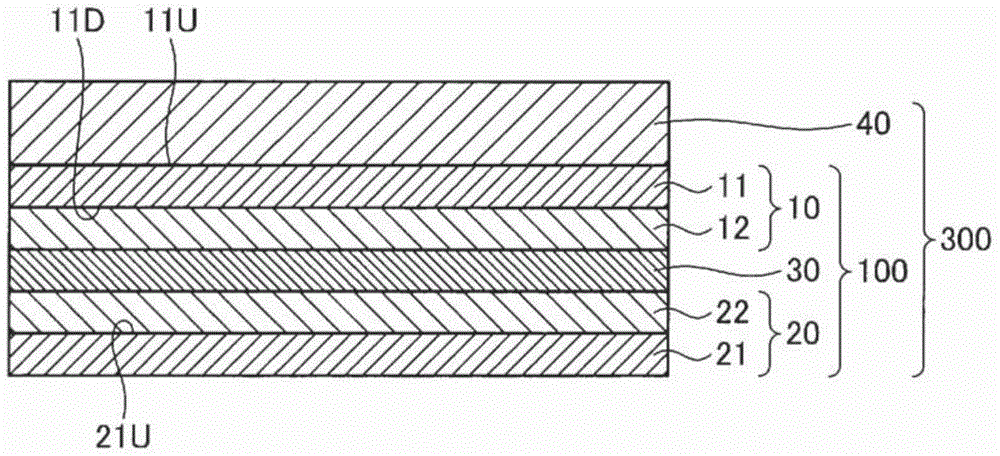

Adhesive sheet and electronic device

ActiveCN103154172AExcellent gas barrierImprove bending resistanceFilm/foil adhesivesEster polymer adhesivesSurface layerNitrogen

Owner:LINTEC CORP

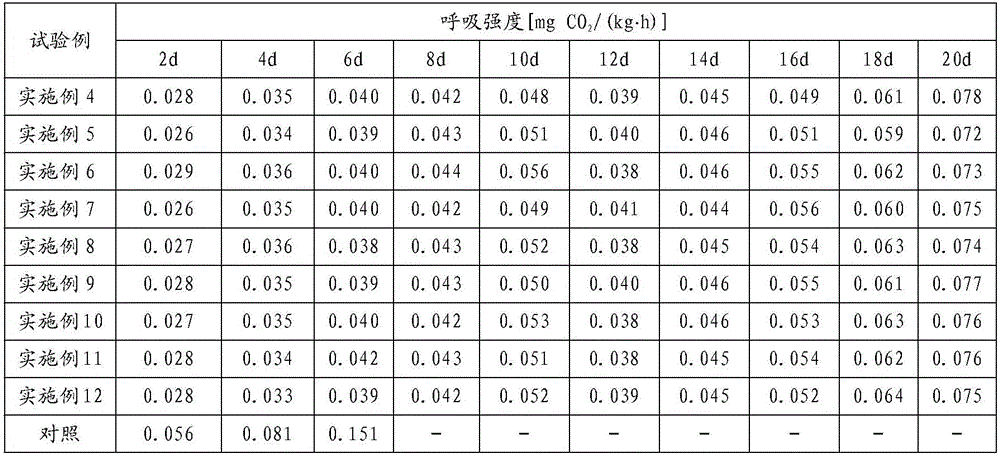

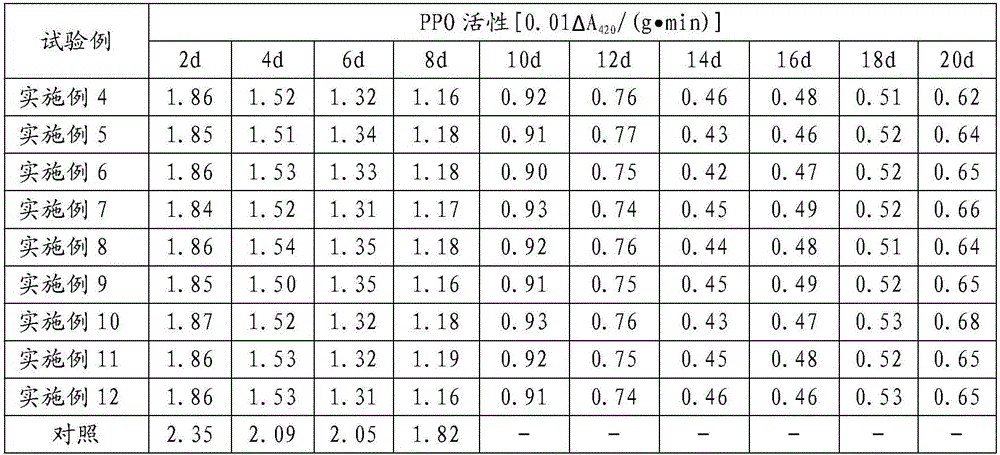

Method for coating preservation of Litchi chinensis bacterium by phellinus igniarius polysaccharide

InactiveCN106578029AExtended shelf lifeReduce the metabolic intensity of breathingFruits/vegetable preservation by coatingEvaporationPhellinus igniarius

The invention discloses a method for coating preservation of Litchi chinensis bacterium by phellinus igniarius polysaccharide. The method comprises the following steps: classifying the harvested Litchi chinensis bacterium, picking the Litchi chinensis bacterium consistent in maturity and sizes and free of mechanical damage and plant diseases and insect pests, and soaking in a phellinus igniarius polysaccharide solution of which the concentration is 0.8 to 1.2% for 2 to 6min, carrying out air drying by cold air until the surfaces of the Litchi chinensis bacterium are dried and formed by films and then performing preservation at the temperature of 4 DEG C. The invention further discloses a preservation method of the Litchi chinensis bacterium by fumigating the phellinus igniarius polysaccharide solution on the surfaces of the Litchi chinensis bacterium, and further discloses a method for extracting the phellinus igniarius polysaccharide solution. In addition, the invention has the beneficial effects of lowering the respiration rate of the Litchi chinensis bacterium, inhibiting the activity of polyphenol oxidase of the Litchi chinensis bacterium, reducing internal moisture evaporation, delaying aging and having low cost and long preservation time; furthermore, the phellinus igniarius polysaccharide is high in nutritional values and has a variety of biological activities of oxidation resistance, immunity enhancement, tumor resistance and the like, and the films are coated on the surfaces of the Litchi chinensis bacterium, and free of any toxic and side effects to human bodies, thereby being natural and environment-friendly.

Owner:GUANGZHOU JUCHAN MODERN AGRI RES INST CO LTD

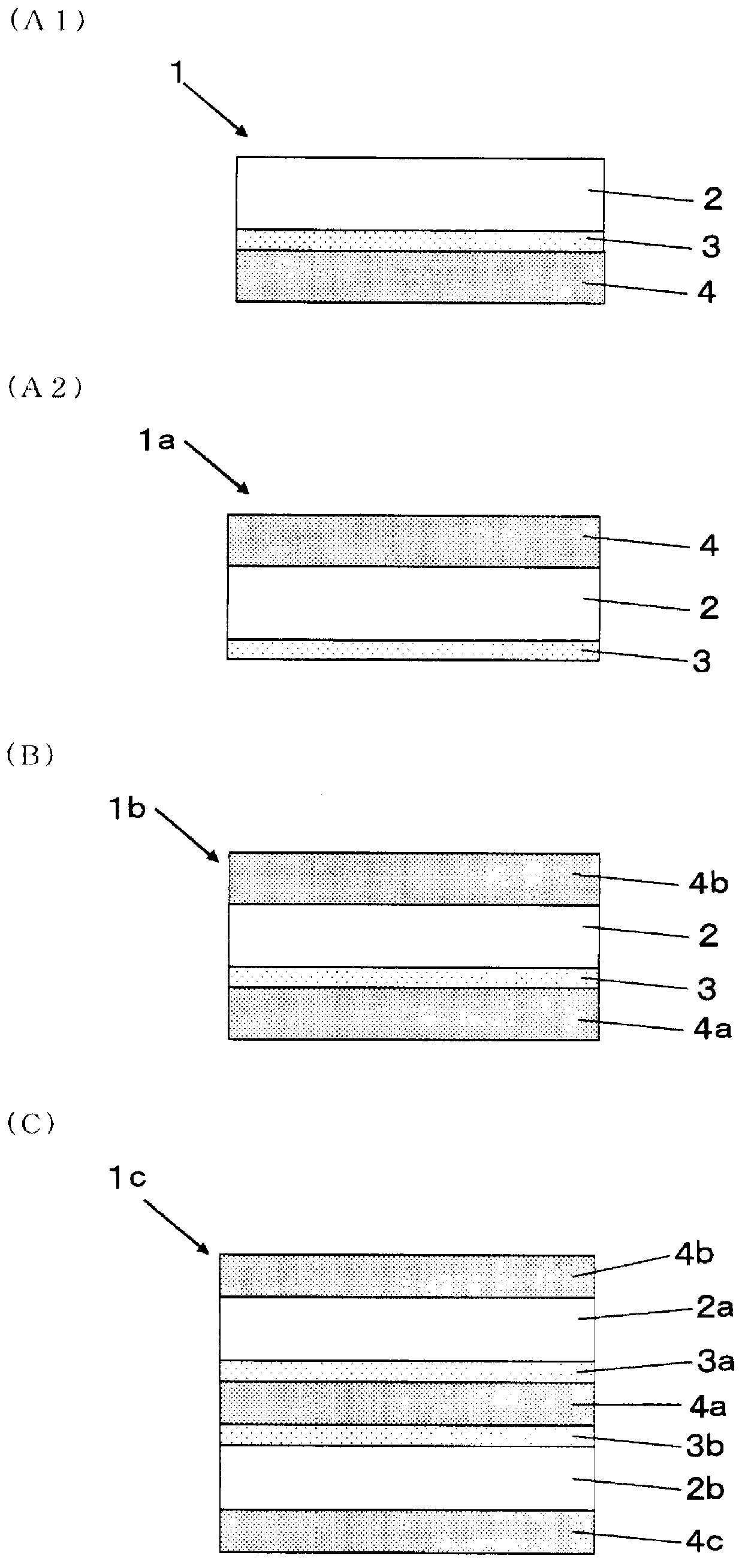

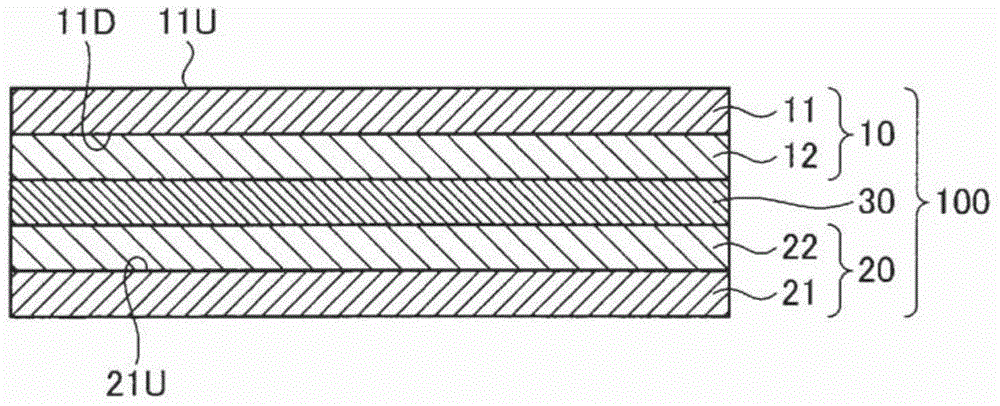

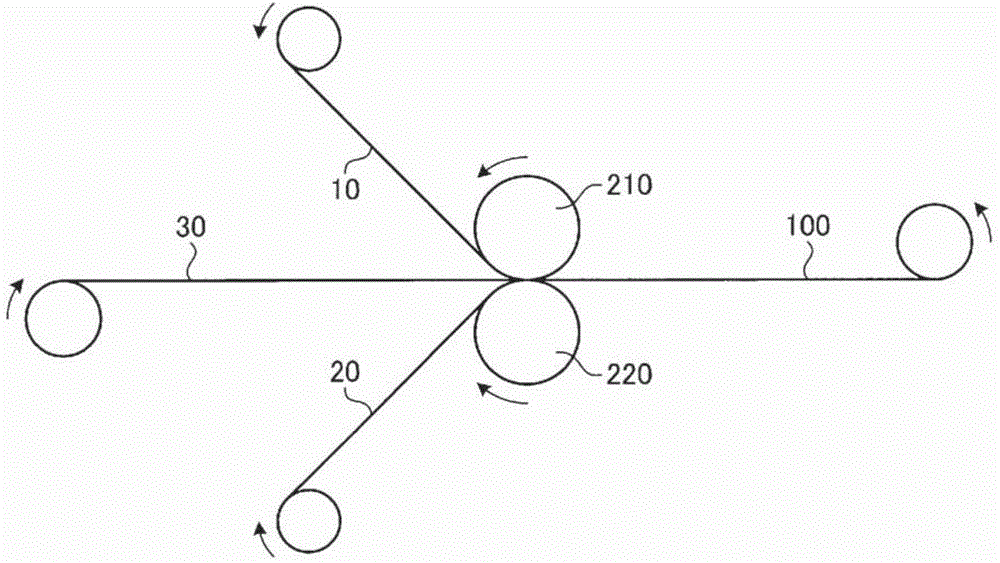

Composite gas barrier laminate and method for producing same, and composite electrode

ActiveCN104619485AExcellent gas barrierSoft and flexibleSolid-state devicesSemiconductor/solid-state device manufacturingPolyolefinChemistry

This composite gas barrier laminate is formed by bonding a gas barrier laminate (A) provided with an alicyclic polyolefin resin film (a) and an inorganic layer (a) formed on at least one surface of the film (a), and a gas barrier laminate (B) provided with an alicyclic polyolefin resin film (b) and an inorganic layer (b) formed on at least one surface of the film (b), via a styrene thermoplastic elastomer resin layer in such a manner that the inorganic layer (a) and the inorganic layer (b) face each other.

Owner:ZEON CORP

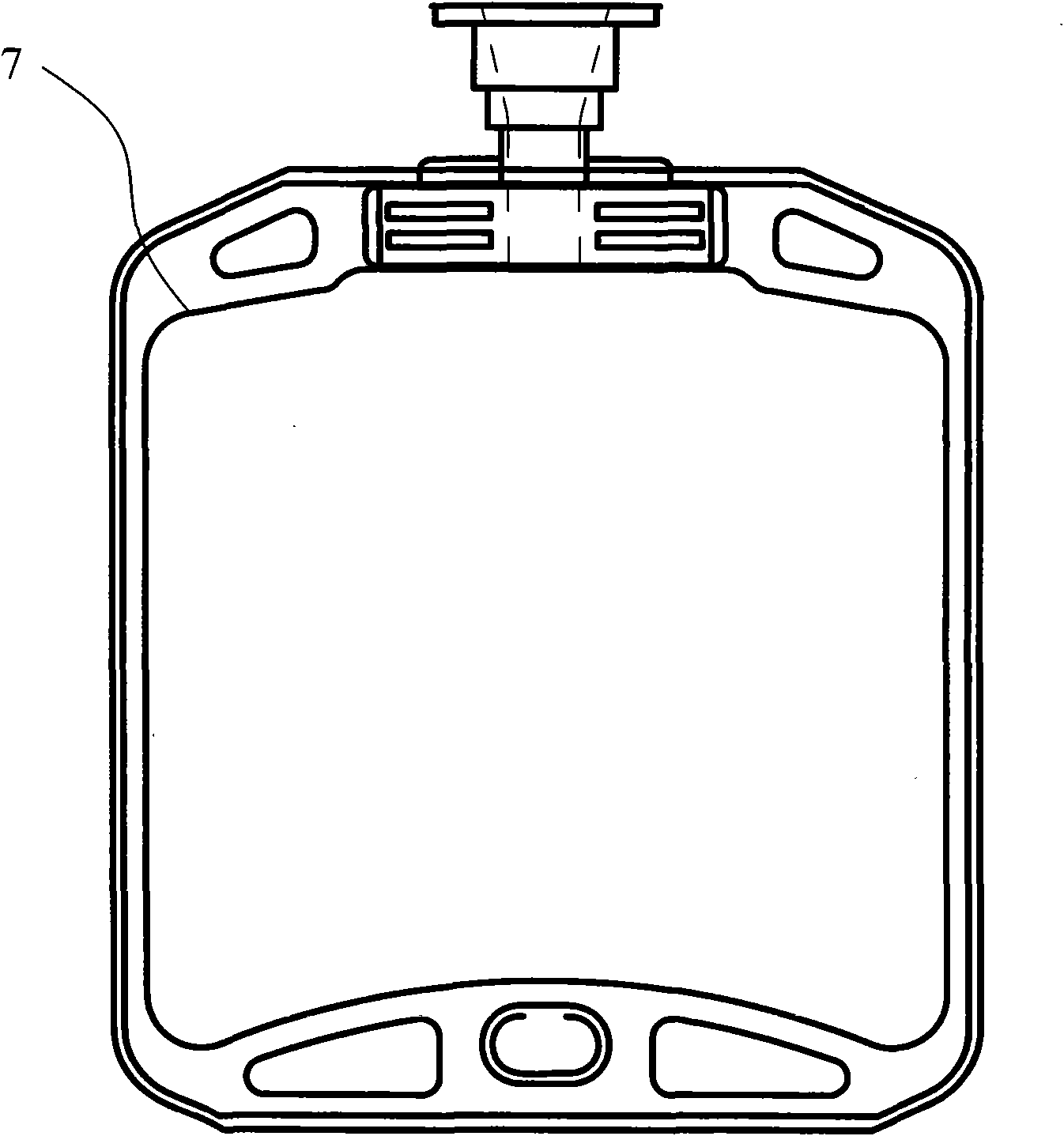

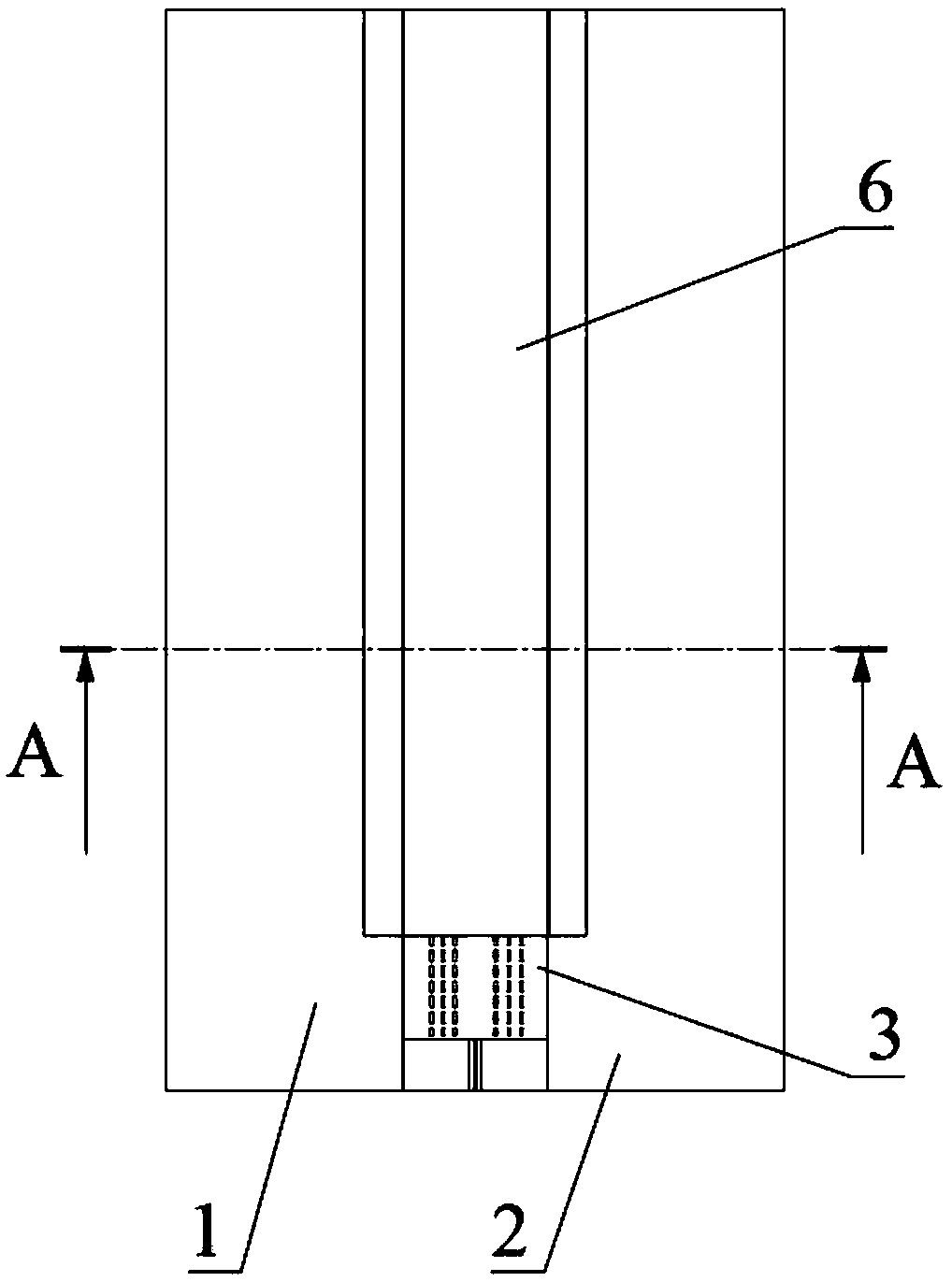

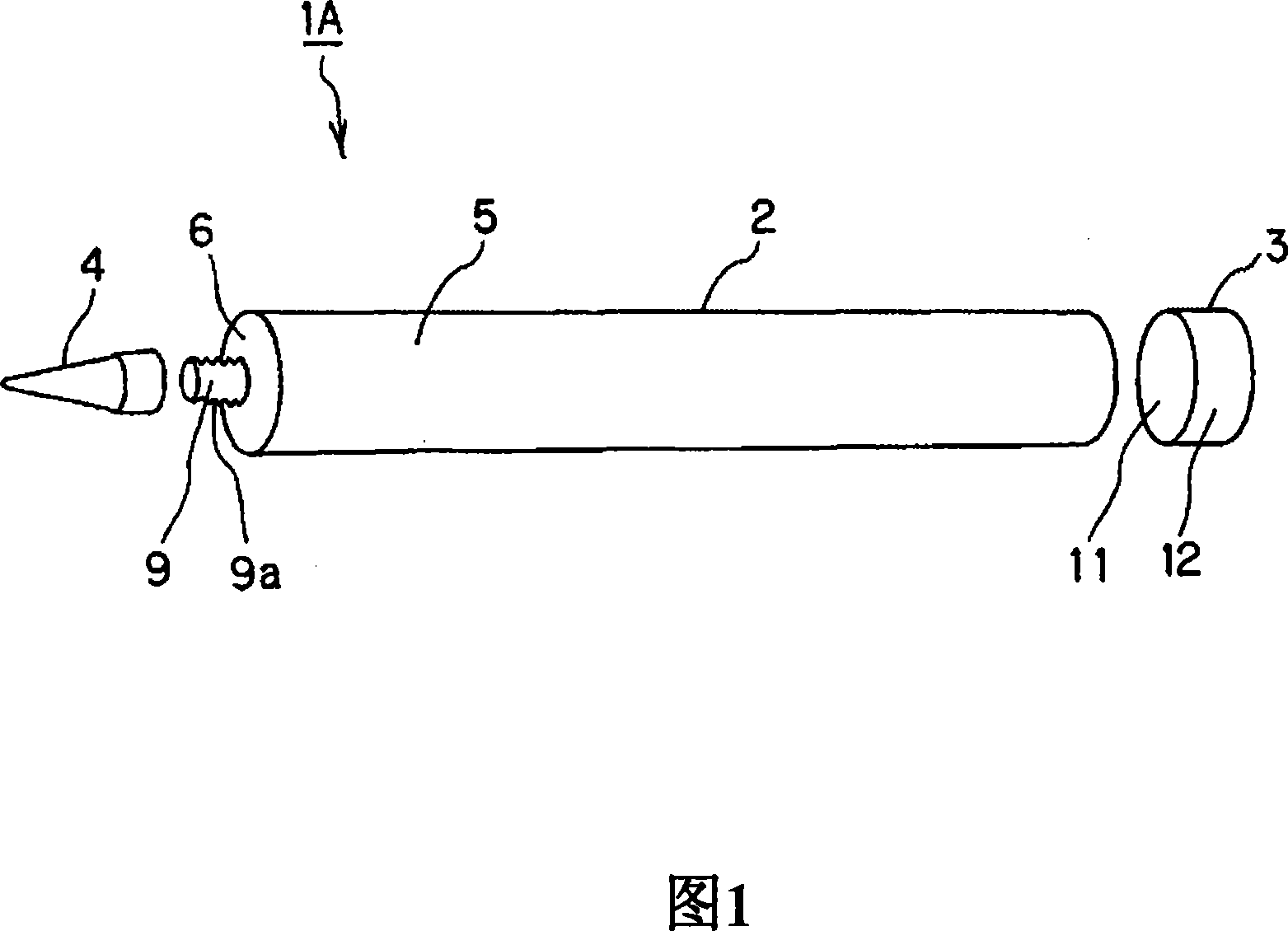

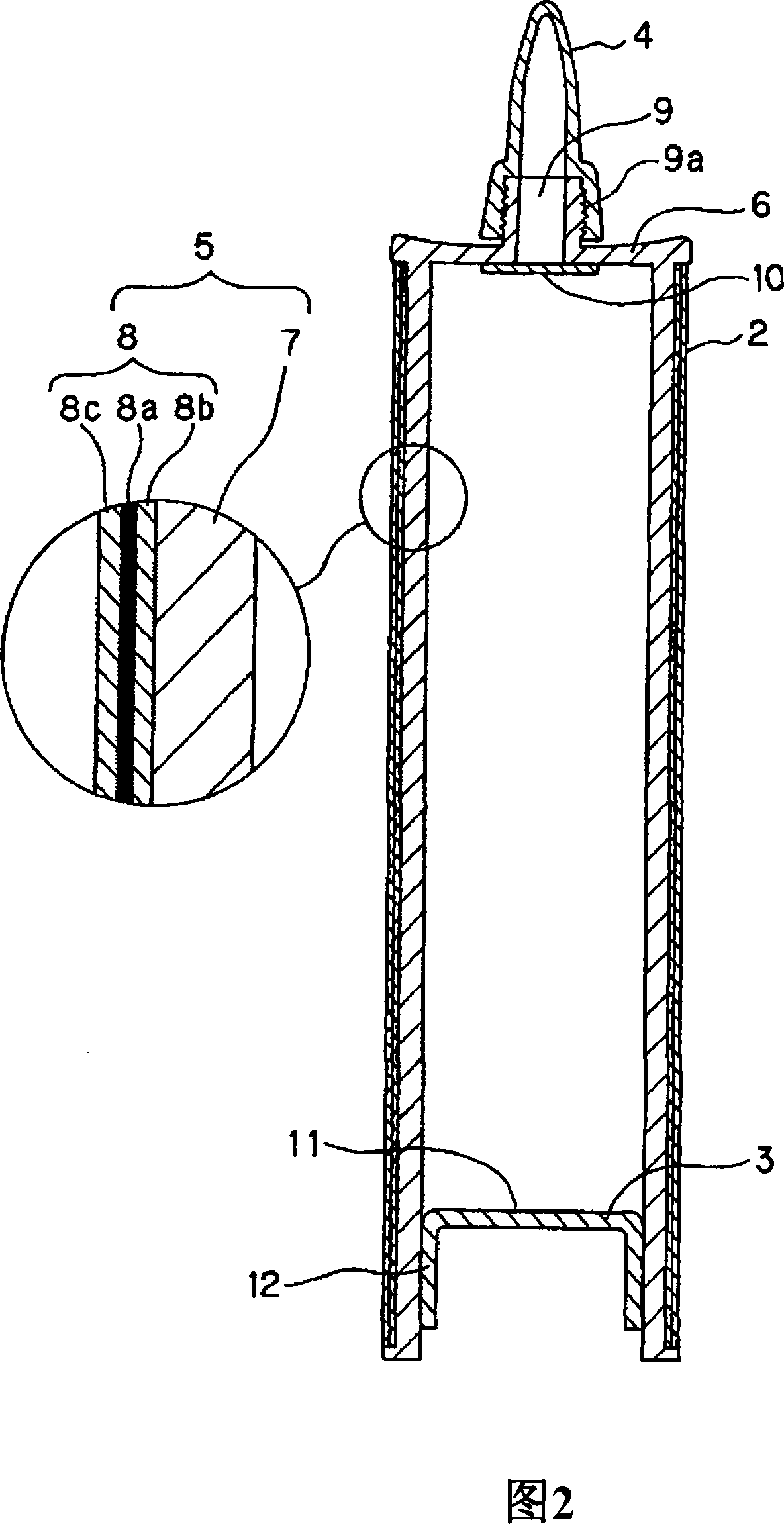

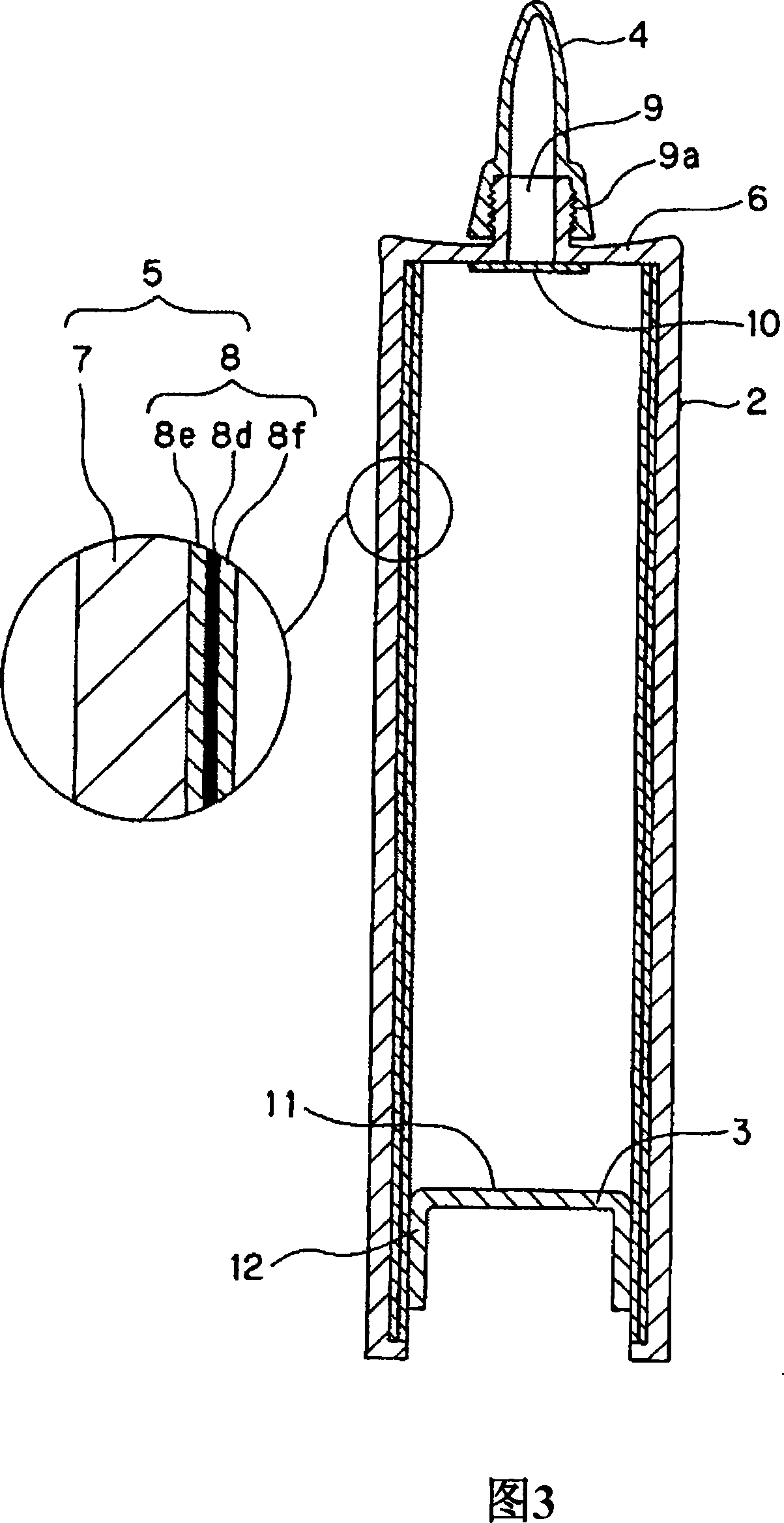

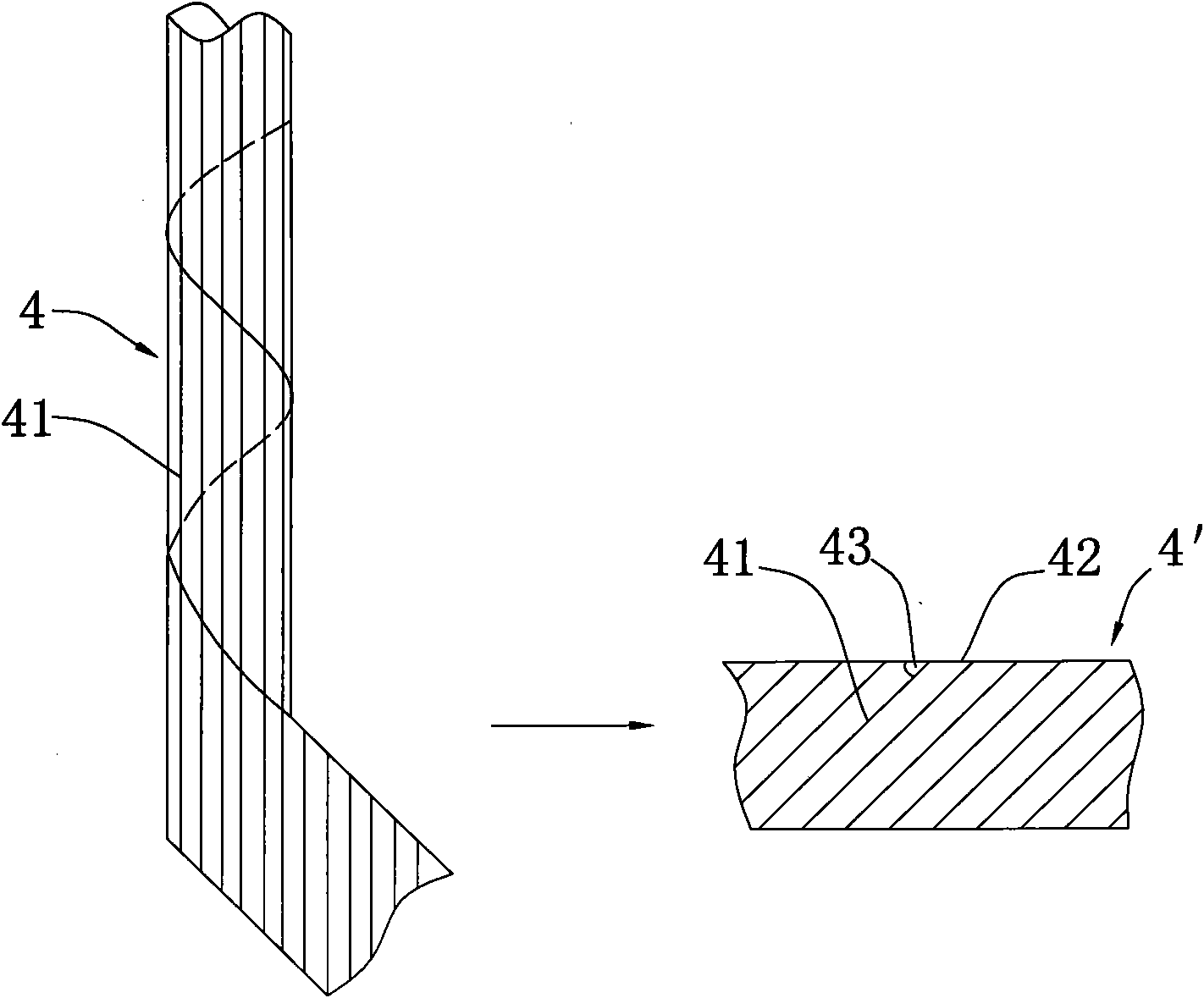

Cartridge for viscous fluid object

ActiveCN101124127AImprove productivityExcellent gas barrierLiquid surface applicatorsDispensing apparatusProduction rateThin layer

A cartridge for storing and dispensing viscous fluid materials providing excellent productivity and gas barrier properties and free from external appearance defects at the site of film wrapping. The inventive cartridge for viscous fluid materials has a plunger 3 inserted into the bottom portion of a cartridge body 2 fabricated using insert injection molding by integrally molding a cylindrical barrel portion 5 of a multilayer structure produced by laminating a gas barrier layer 8 including a metal thin layer 8a on the exterior periphery or interior periphery of a plastic layer 7, and a lid 6 covering the top of said cylindrical barrel portion.

Owner:DOW CORNING TORAY CO LTD

Polyester-based resin composition

The polyester-based resin composition of the present invention comprises a polyamide resin, a polyester resin containing an antimony compound and a compound selected from the group consisting of inorganic acid salts and hydroxides of group-1 or -2 metals of the periodic table and transition metals. In the polyester-based resin composition, the phosphorus atom concentration, the antimony atom concentration, and the blending ratio of the inorganic acid salt or hydroxide to the phosphorus compound are regulated so as to satisfy the specific relationships to effectively prevent the darkening due to the deposition of antimony metal, thereby providing the polyester-based resin composition having excellent gas barrier properties and a good appearance with minimized darkening.

Owner:MITSUBISHI GAS CHEM CO INC

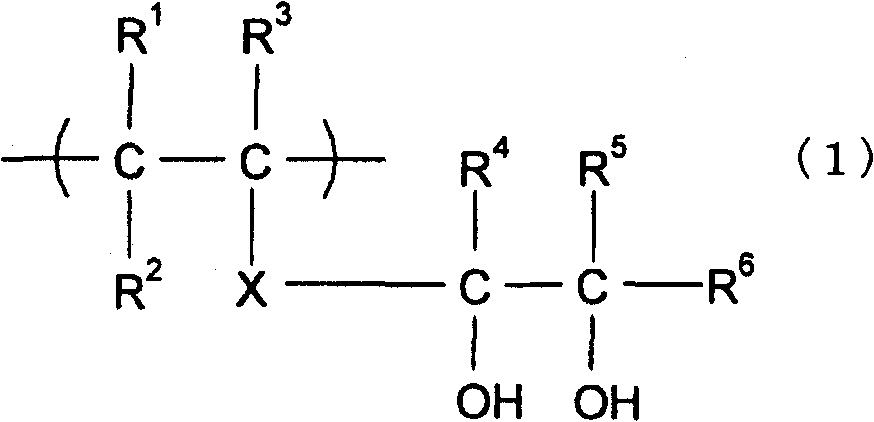

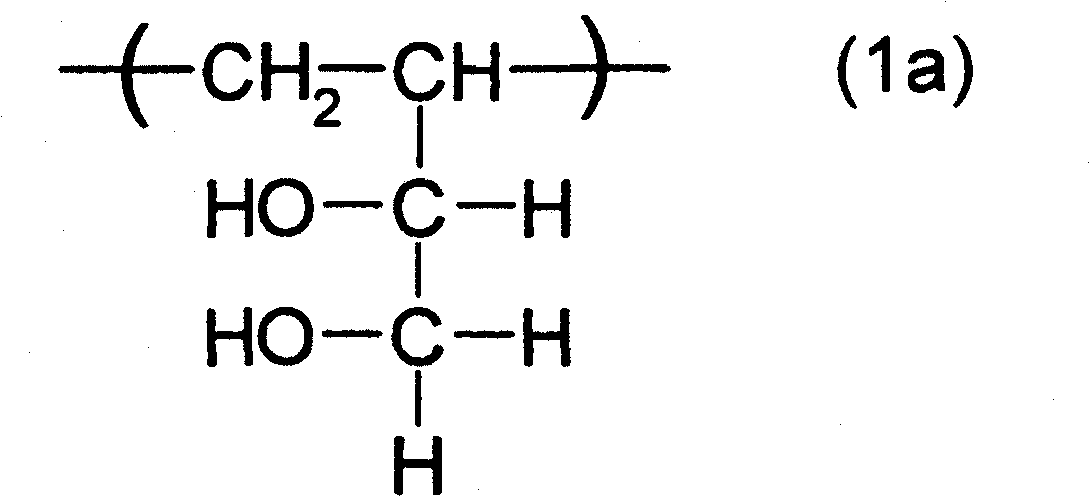

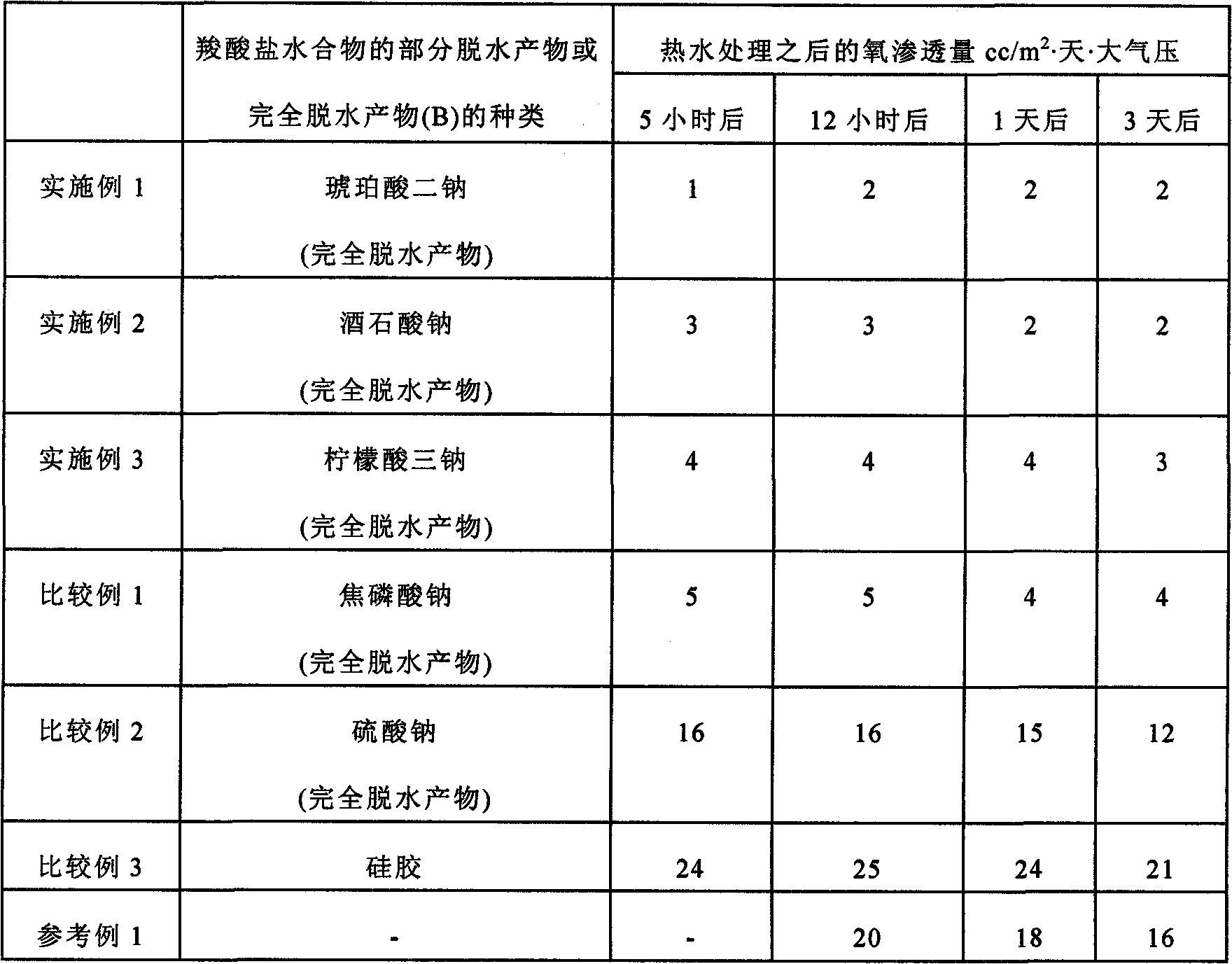

Resin composition, melt-molded article, multi-layered structure, and process for production of resin composition

Disclosed is a resin composition which exhibits excellent gas barrier properties after the treatment with hot water, does not cause the increase in viscosity thereof in a melt-kneading step employed in a molding process, and has excellent handling properties. The resin composition comprises (A) a thermoplastic resin and (B) a partly dehydrated product or a completely dehydrated product of a hydrate of a carboxylic acid salt.

Owner:MITSUBISHI CHEM CORP

Novel crossed composite membrane

InactiveCN101830094ASmall water absorptionImprove insulation performanceSynthetic resin layered productsLow-density polyethyleneFiber

The invention discloses a novel crossed composite membrane which is provided with an upper outer layer, a lower outer layer and an intermediate core layer, wherein the core layer and the outer layers are compounded into a whole through an adhesive layer, and at least one outer layer is an orientation membrane layer which is arranged between the fiber direction and the membrane edge and provided with an orientation angle; the core layer is made of polyethylene glycol terephthalate (PET), wherein the density of the core layer is 1.395 to 1.405g / cm<3>, and the thickness thereof is 10 to 50mu m; an adhesive in the adhesive layer is one of a one-component polyurethane adhesive, a double-component polyurethane adhesive, an alcohol-soluble polyurethane adhesive and a water-soluble polyurethane adhesive; the two outer rings are made of one material selected from low-density polyethylene (LDPE), high-density polyethylene (HDPE) and casting polypropylene (CPP) and also can be made by mixing two or more than two materials selected from the LDPE, the HDPE, the CPP and metallocene polyethylene (mPE). Except for wide heat-sealing temperature range as well as favorable barrier property, tensile strength and printing effect, the composite membrane has the most remarkable tearing resistance property.

Owner:徐建学

Application of water transport plate to integrated renewable proton exchange membrane fuel cell

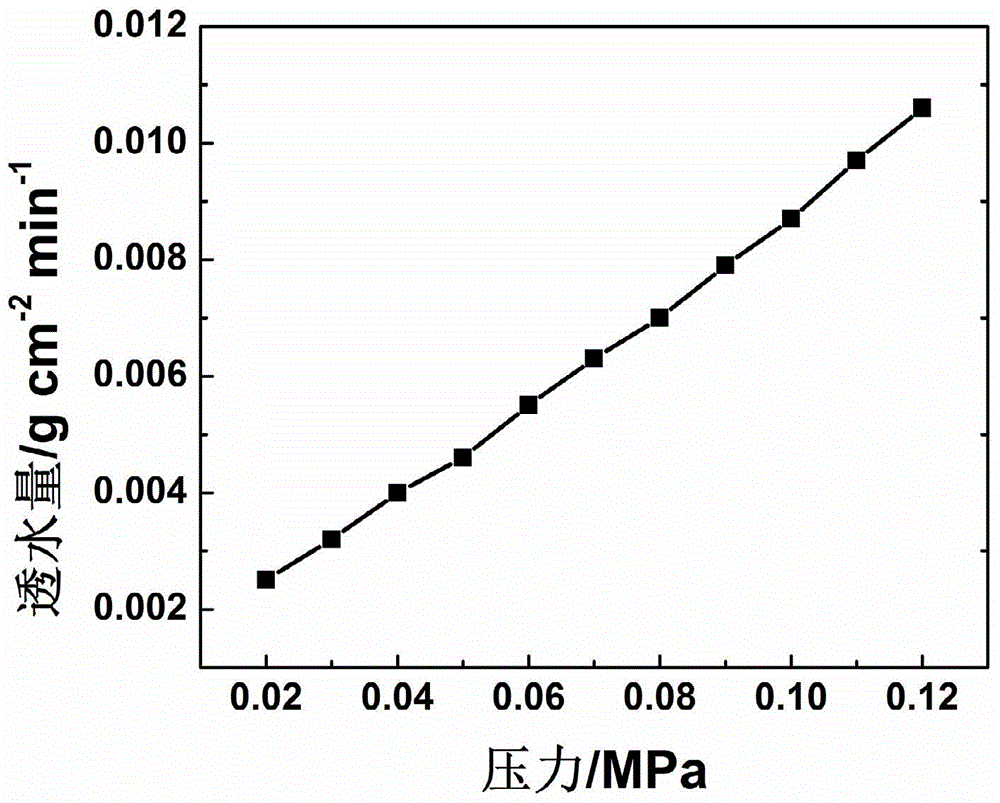

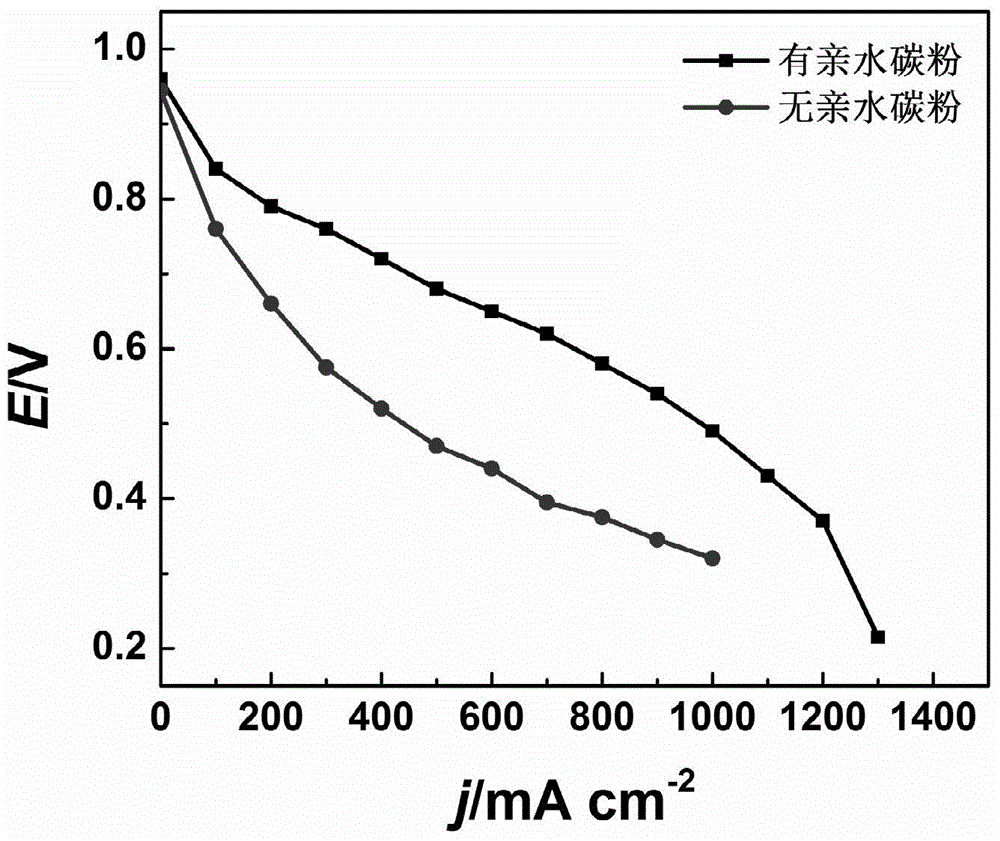

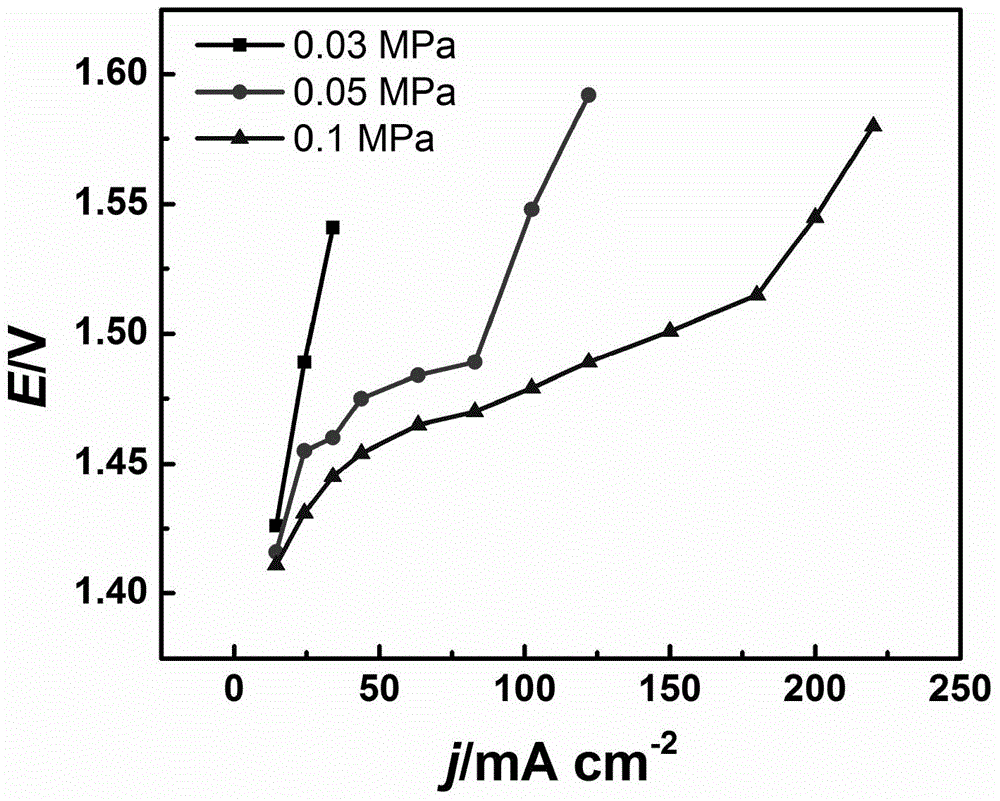

ActiveCN105633427AAlleviate water shortageMitigationFuel cell auxillariesFuel cell detailsFiberCarbon fibers

The invention discloses a hydrophilic water transport plate for an integrated renewable proton exchange membrane fuel cell and a preparation method for the water transport plate. The method comprises the steps of firstly hydrophilically treating a carbon nanomaterial; secondly uniformly mixing the hydrophilically treated carbon nanomaterial, a conductive additive, a reinforced carbon fiber and a resin adhesive; and finally performing thermoforming in a mould to obtain the hydrophilic water transport plate, wherein the hydrophilic carbon nanomaterial achieves the effect of promoting water transport. The water transport plate serving as a bipolar plate for the integrated renewable proton exchange membrane fuel cell has good water-penetrating property; and the situations of water shortage and flooding in a working mode of the fuel cell can be effectively relieved, the performance of the fuel cell can be improved, the static water supply can be realized directly by utilizing cooling water in a working mode of an electrolytic tank, the anodic concentration polarization phenomena can be reduced, the electrolytic performance under high electric density can be improved, a system can be simplified, and the energy consumption can be reduced.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

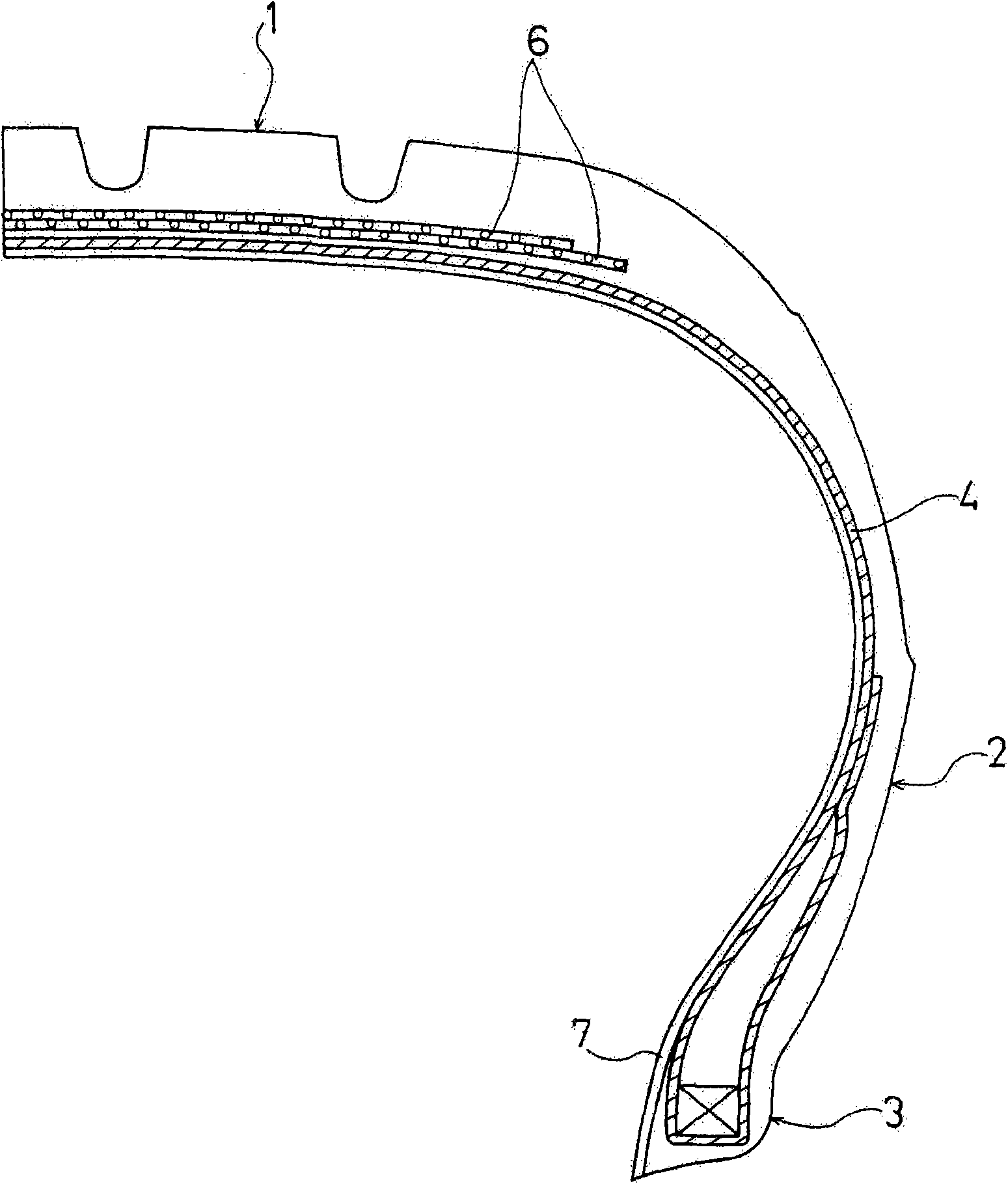

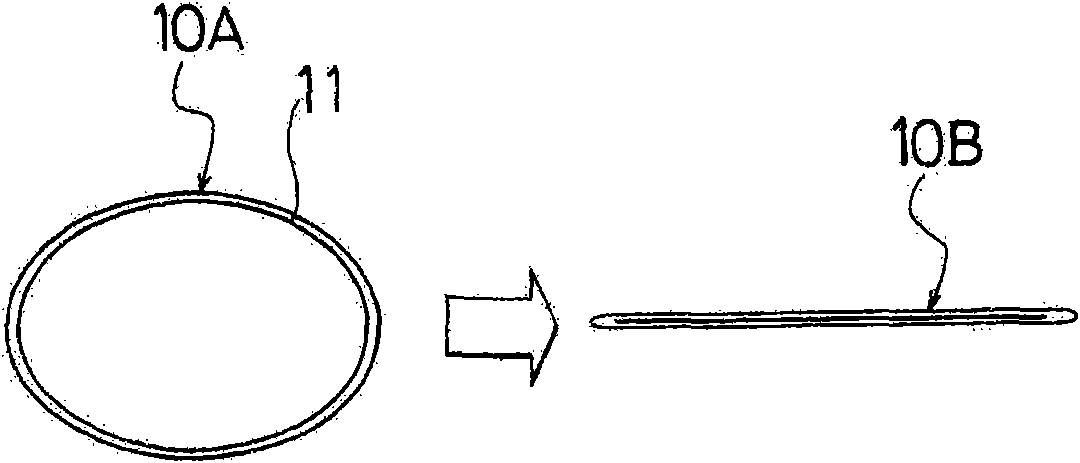

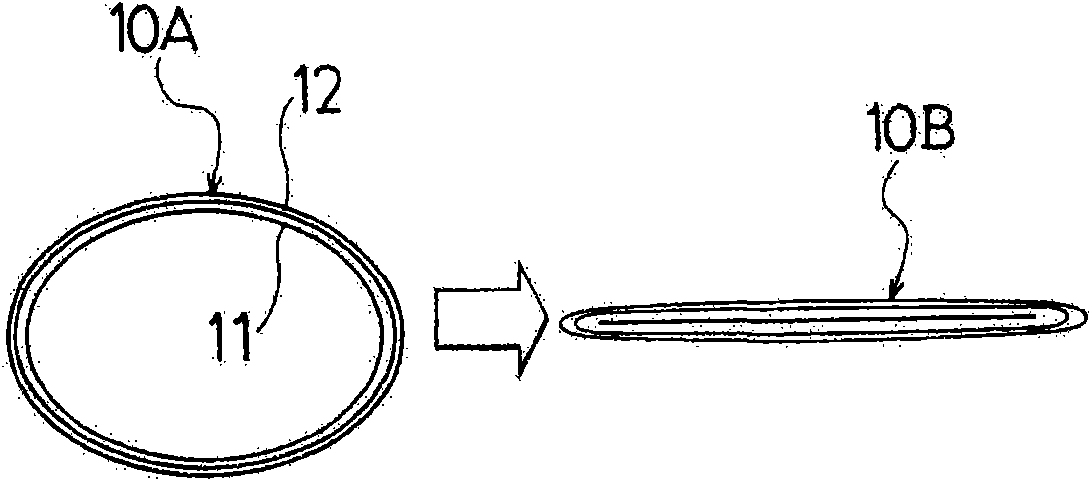

Pneumatic tire and process for manufacturing the same

InactiveCN101674947AExcellent plane orientationExcellent gas barrierWithout separate inflatable insertsTyresElastomerThermoplastic elastomer

A pneumatic tire and process for manufacturing the same that realize, in the use of a film of thermoplastic resin or thermoplastic elastomer composition composed of a blend of thermoplastic resin andelastomer as an air permeation preventive layer, formation of an air permeation preventive layer excelling in gas barrier performance and molding of a tire through simple molding operation without thegeneration of any unnecessary scraps. In the pneumatic tire, a cylindrical molding of a film of thermoplastic resin or thermoplastic elastomer composition composed of a blend of thermoplastic resin and elastomer is crushed into a sheet laminate, and the sheet laminate is used as an air permeation preventive layer. In the manufacturing operation, the sheet laminate is wrapped around a molding drumto thereby obtain an unvulcanized tire having the sheet laminate as an air permeation preventive layer, and the unvulcanized tire is vulcanized.

Owner:THE YOKOHAMA RUBBER CO LTD

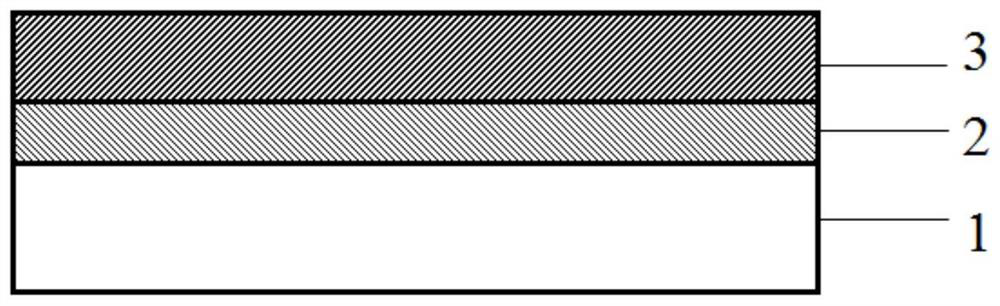

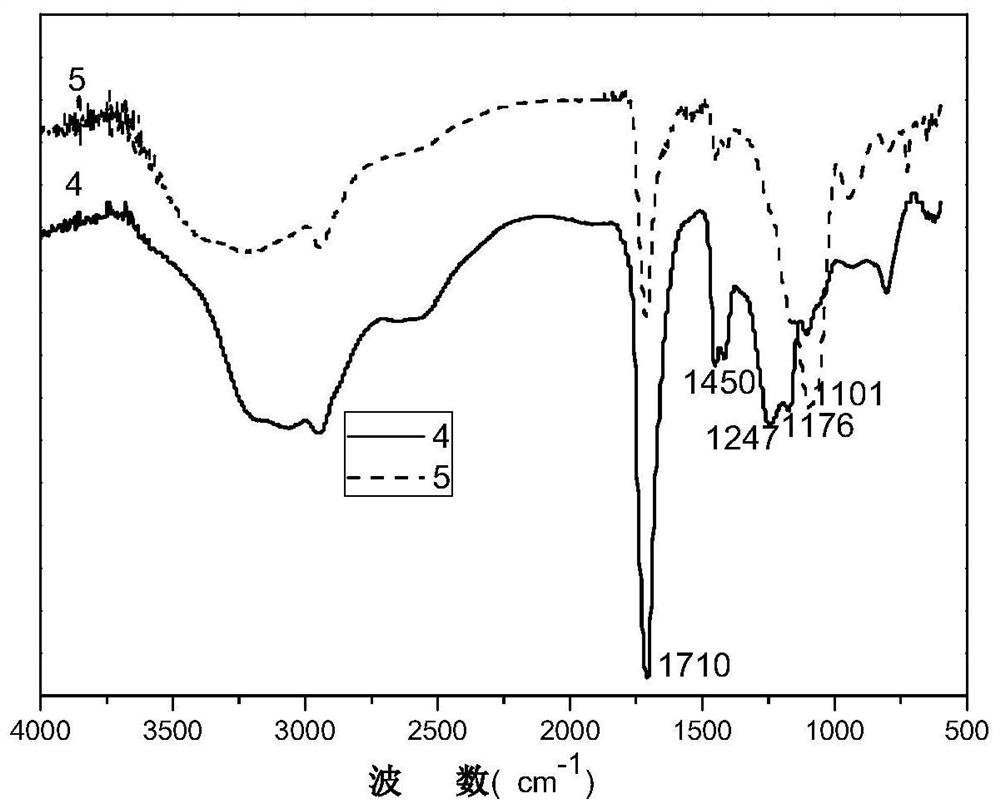

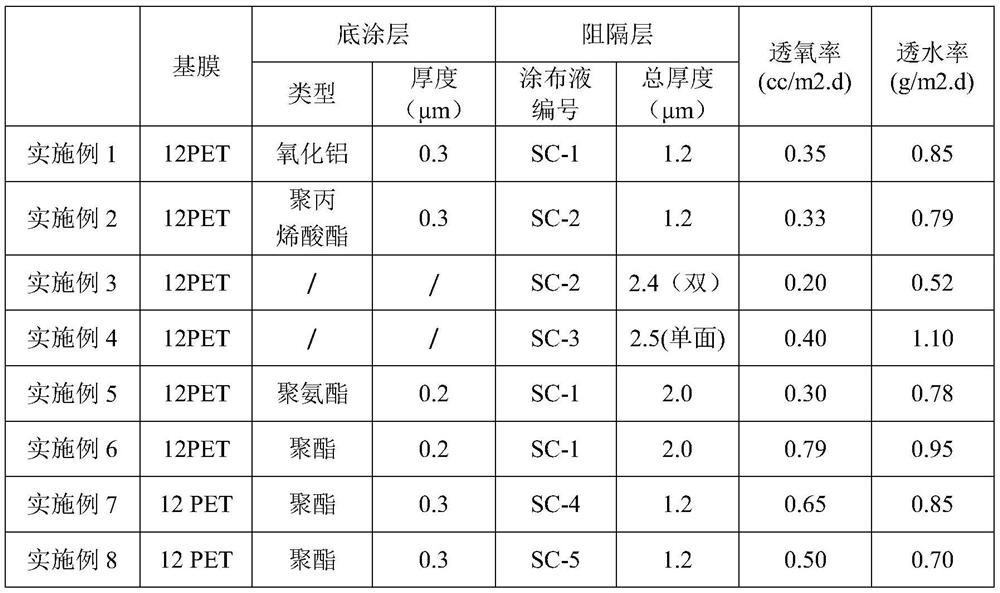

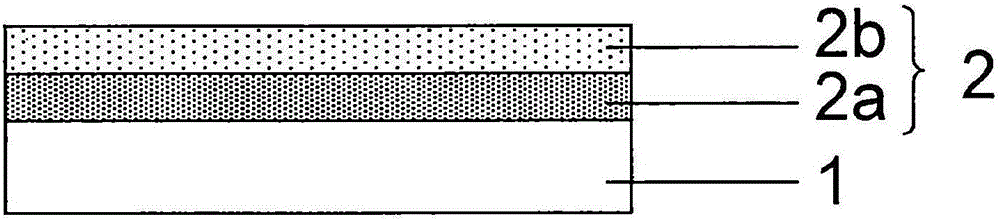

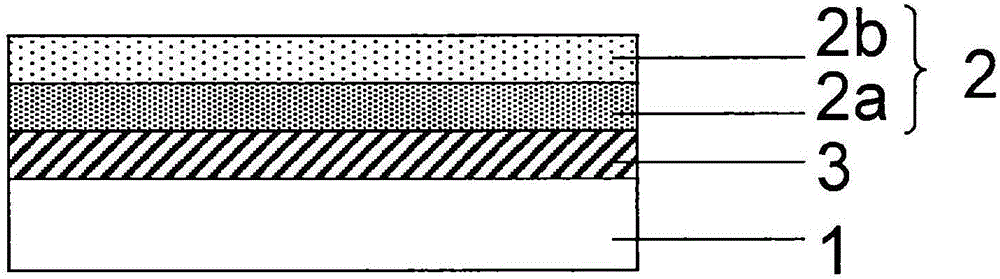

Coating liquid for barrier layer, preparation and barrier film thereof

ActiveCN112063244AExcellent gas barrierImprove water resistanceCoatingsPolymer scienceFood packaging

The invention discloses a coating liquid for a barrier layer, preparation and a barrier film thereof. The coating liquid comprises the following components in parts by mass: 0.4-20 parts of a carboxyl-containing polymer (A), 0.20-5.0 parts of a hydroxyl-containing water-soluble polymer (B), 0.01-3 parts of a coupling agent (C) with carboxyl reactive groups, 1.7-13 parts of a hydrolytic condensateof metal alkoxide (L) and 30-95 parts of a solvent. According to the invention, a carboxyl-containing polymer (A) is used as a main agent, and excellent gas-blocking and water-blocking properties areshown after two-step modification of ester crosslinking and inorganic hybridization; and the barrier film disclosed by the invention is realized through coating, is simple in preparation process, highin production efficiency and low in cost, and can be applied to the fields of food packaging, medicine packaging, flexible packaging of photoelectric devices and the like.

Owner:CHINA LUCKY FILM CORP

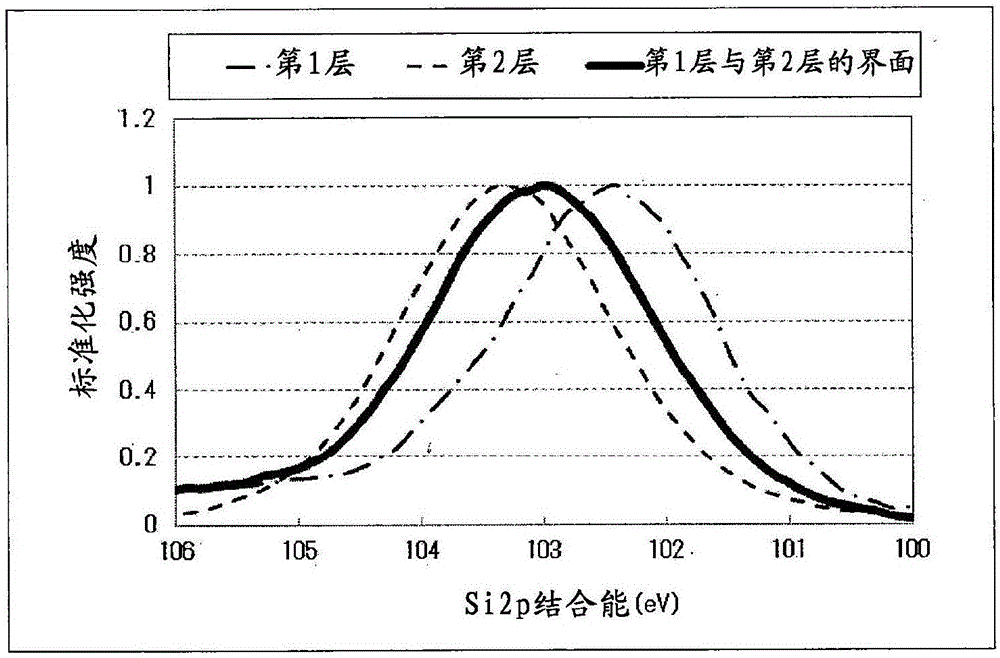

Gas barrier film

The purpose of the invention is to provide a gas barrier film having excellent gas barrier characteristics. This gas barrier film includes, on at least one surface of a polymer base material, a gas barrier layer in which a first layer including zinc oxide and silicon dioxide and a second layer including a silicon compound are arranged in contact with one another in this order from the polymer base material, wherein the binding energy of the Si 2p orbit at the interface between the first layer and the second layer as measured by X-ray photoelectron spectroscopy is greater than the binding energy of the Si 2p orbit in the first layer and is smaller than the binding energy of the Si 2p orbit in the second layer.

Owner:TORAY IND INC

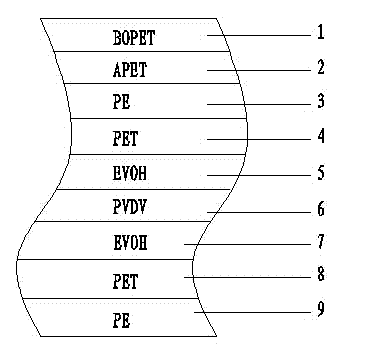

Coextrusion-lamination obstructing packaging film

InactiveCN104494262AImprove barrier propertiesImprove ductilityFlexible coversWrappersBoPETEngineering

The invention discloses a coextrusion-lamination obstructing packaging film and belongs to the technical field of packaging materials. According to the coextrusion-lamination obstructing packaging film, the problems that an intermediate layer of an existing coextrusion film is relatively high in water absorption, the permeability resistance of barrier layers is reduced, the effective expiration date of a product is short, and meanwhile, due to structure arrangement of the intermediate layer PA of the coextrusion film and the single barrier layers at two sides of the intermediate layer, high barrier property and high coextrusion malleability property of the packaging film can not be simultaneously realized are solved. The packaging film comprises a BOPET (biaxially-oriented polyethylene terephthalate) film, an APET shading film, a first PE polyethylene film, a first PET polyester film, a first EVOH barrier layer, a PVDC gas barrier film, a second EVOH barrier layer, a second PET polyester film and a second PE polyethylene film, wherein the BOPET film, the APET shading film, the first PE polyethylene film, the first PET polyester film, the first EVOH barrier layer, the PVDC gas barrier film, the second EVOH barrier layer, the second PET polyester film and the second PE polyethylene film are co-extruded and compounded from outside to inside to form the packaging film. The packaging film disclosed by the invention is especially suitable for packaging fresh seafood, beef and dried tofu.

Owner:哈尔滨隆华艺达包装制品有限公司

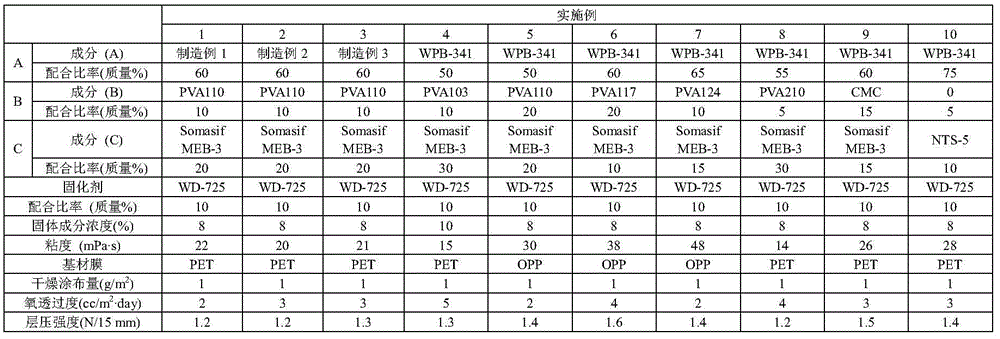

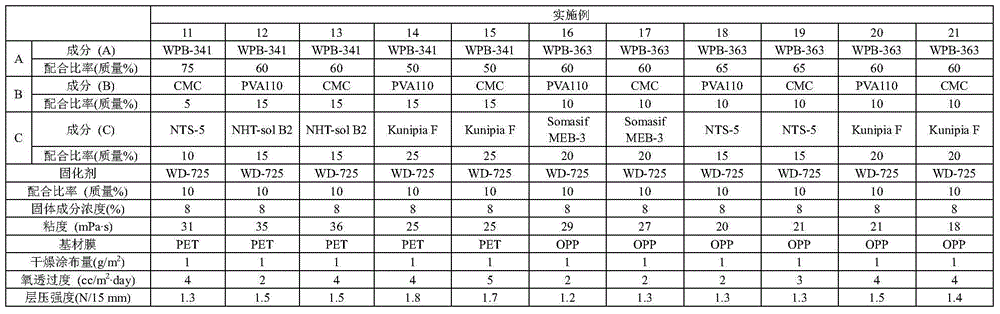

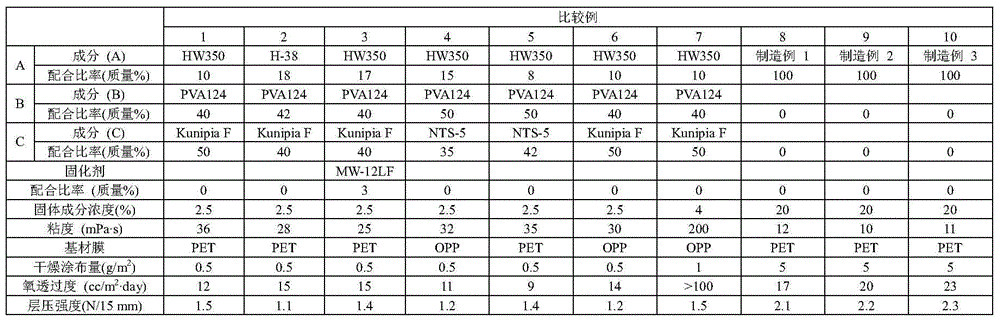

Aqueous coating agent and gas barrier film

InactiveCN104136560AExcellent gas barrierImprove quality retentionSynthetic resin layered productsPolyurea/polyurethane coatingsAcid groupChemistry

This aqueous coating agent contains as primary constituent components: an aqueous polyurethane resin (A) containing a polyamine compound and a polyurethane resin having an acid group; an aqueous polymer (B); and an inorganic lamellar mineral (C). Of the entirety of the solid components the share contained of the aqueous polyurethane resin (A) is 50-80 mass%, of the aqueous polymer (B) is 5-20 mass%, and of the inorganic lamellar mineral (C) is 10-30 mass%. The concentration of the entirety of the solid components is at least 5 mass%, and the viscosity at 23°C is no greater than 50 mPa·s.

Owner:TOPPAN PRINTING CO LTD

Halogen-free flame-retardant PET (polyethylene terephthalate) material and preparation method thereof

ActiveCN109370172AImprove melt strengthGood physical propertiesGlass fiberPolyethylene terephthalate glycol

The invention provides a halogen-free flame-retardant PET (polyethylene terephthalate) material. The halogen-free flame-retardant PET material contains the following components in parts by weight: 40-60 parts of PET, 25-40 parts of halogen-free phosphorus-based copolyester flame retardant, 3-7 parts of auxiliary flame retardant, 5-20 parts of glass fiber, 1-3 parts of compatibilizer, 0.1-1 part ofcoupling agent and 0.5-2 parts of antioxidant II. A high-efficiency P-containing flame retardant is synthesized through polymerization reaction; and the presence of a P flame retardance element can improve the flame retardance of the polymer in a mode of changing the thermal degradation process of a polymer matrix and the like; the flame retardance stability of the polymer is further improved through the compounding of the P-containing flame retardant, and P and N flame retardance auxiliaries; and then the halogen-free flame-retardant PET material is prepared through the selection and dosagecontrol of reaction auxiliaries and the like. The halogen-free flame-retardant PET material prepared by the method has an excellent flame retardance effect, excellent mechanical property, high and lowtemperature resistance, chemical resistance and excellent resistance to gas, water, oil, peculiar smell and the like.

Owner:BEIJING CO FOUND HIGH TECH INCUBATOR

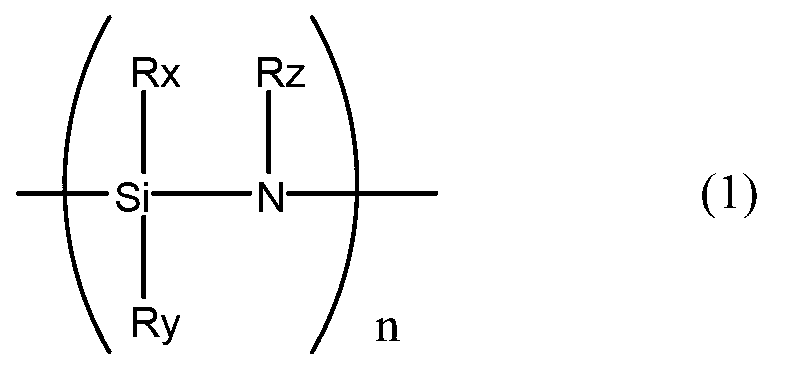

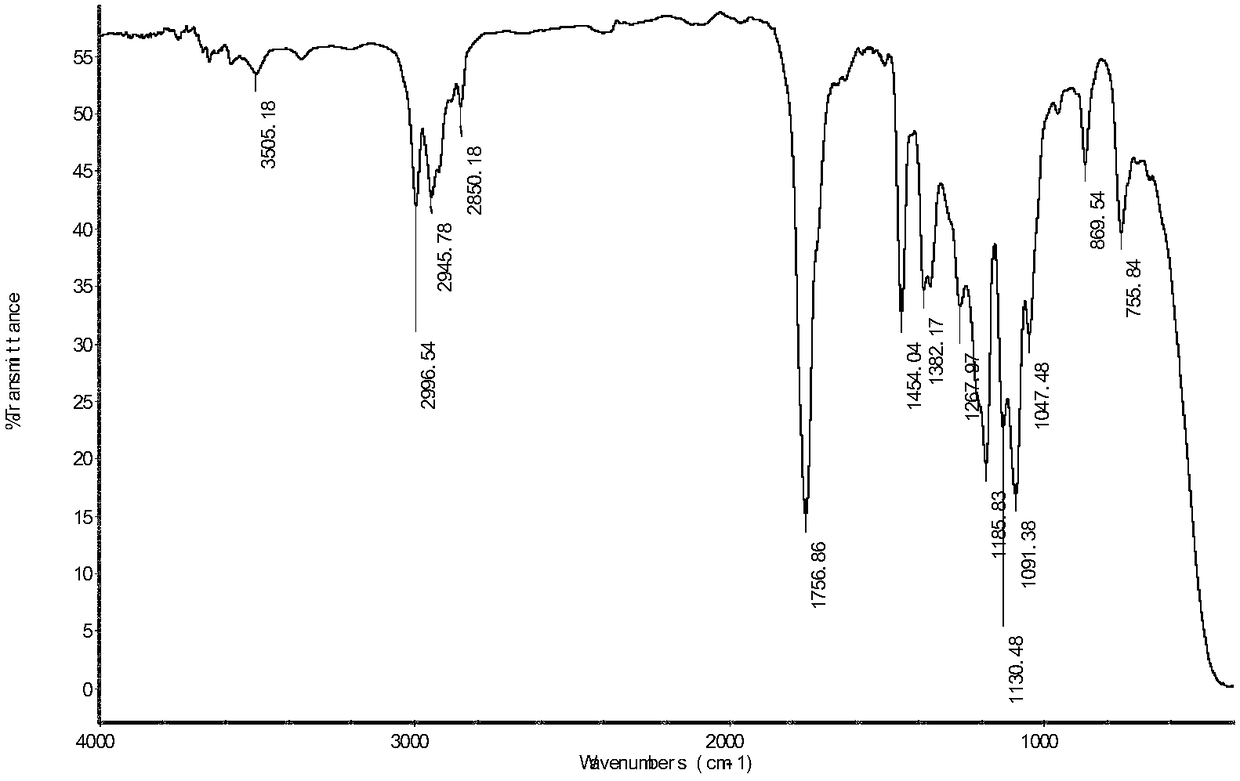

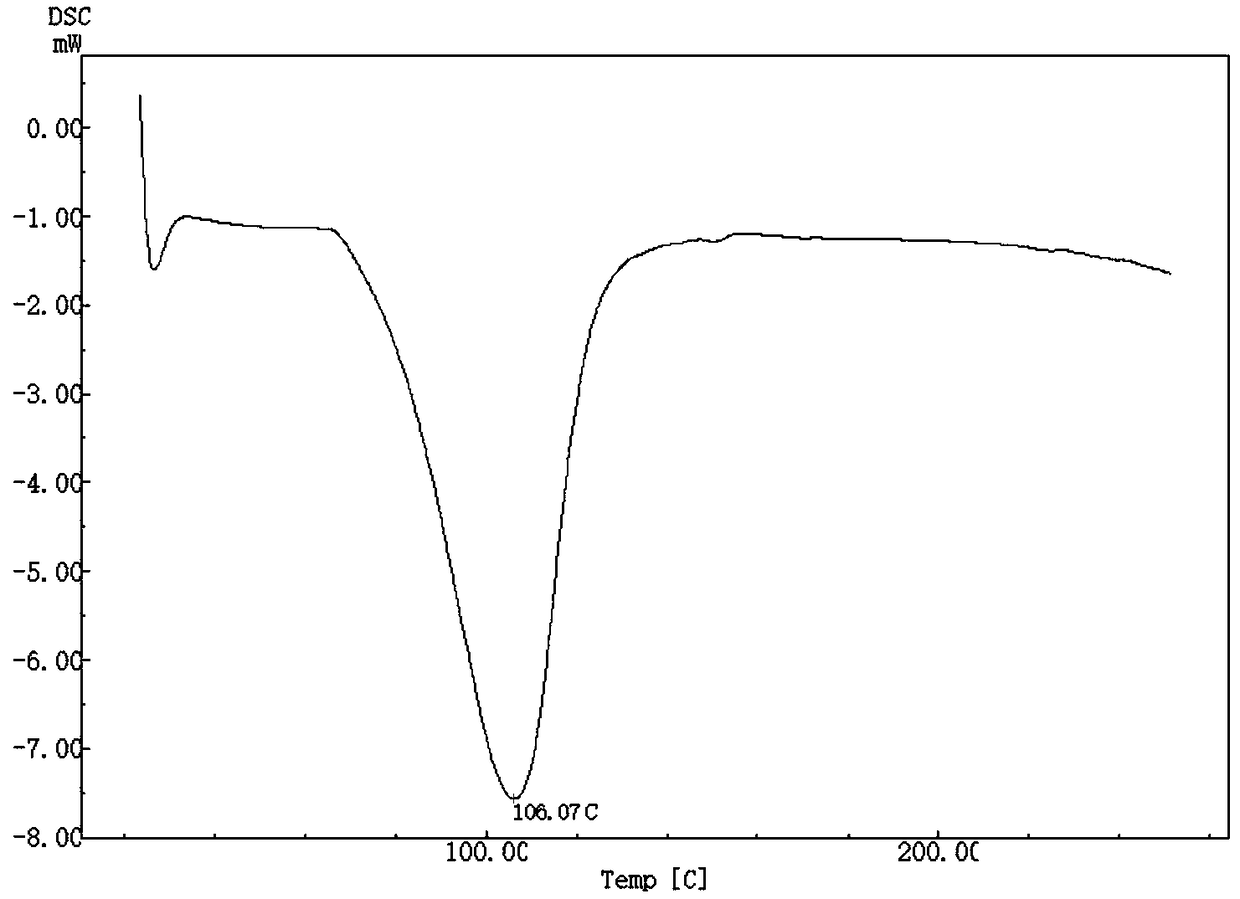

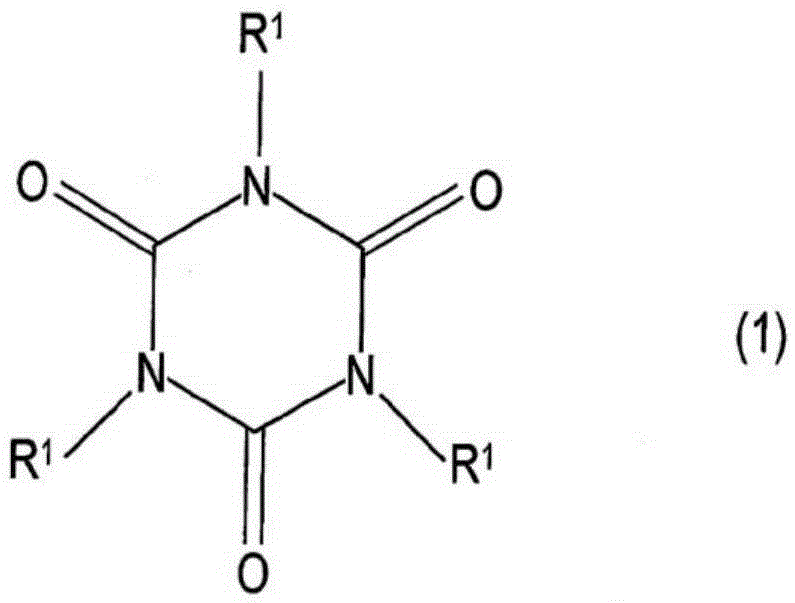

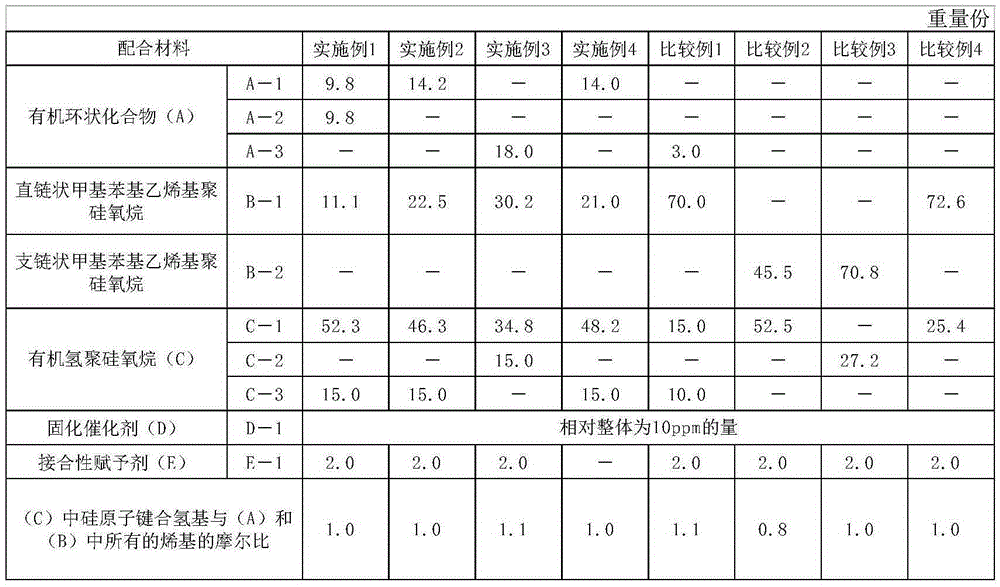

Addition reaction cured resin composition and photosemiconductor device

InactiveCN105623271ALow oxygen permeabilityExcellent gas barrierSemiconductor devicesArylHydrosilylation

Provided is an addition reaction cured resin composition characterized by comprising an organic cyclic compound (A) each molecule of which contains more than two functional groups reacting with SiH base through hydrosilylation reaction; a straight chain organic organopolysiloxane (B) each molecule of which contains at least two silicon bonding alkenyl reacting with the SiH base and having at least one silicon bonding aryl; organic polysiloxane (C) each molecule of which contains at least two SiH base and at least having branch chain organic polysiloxane; and a curing catalyst (D) required by addition reaction.

Owner:AICA KOGYO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com