Preparation method of polyester polyol for laminated film adhesive

A technology of polyester polyol and composite film, applied in the field of polyester polyol preparation, can solve the problem of less disclosure of polyester polyol and the like, and achieve the effect of excellent bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

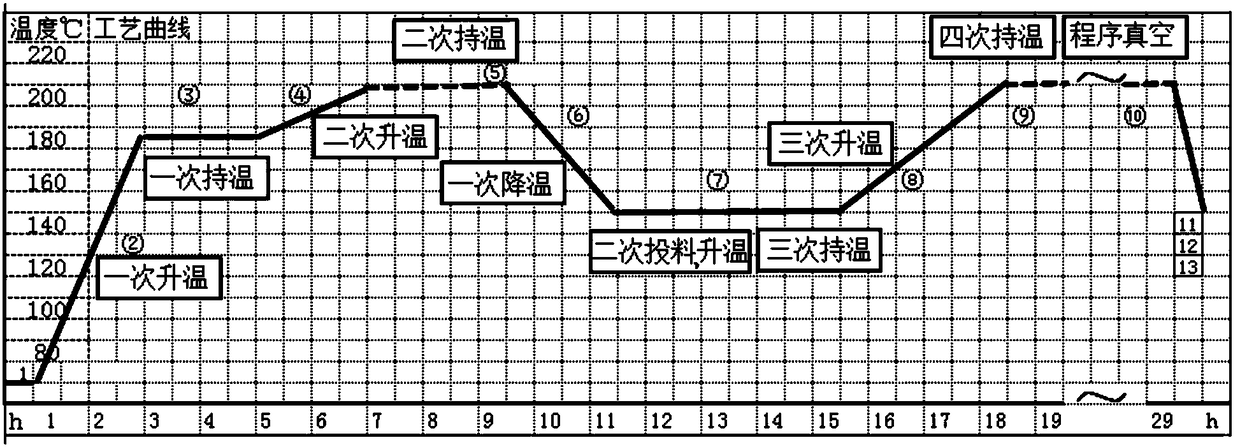

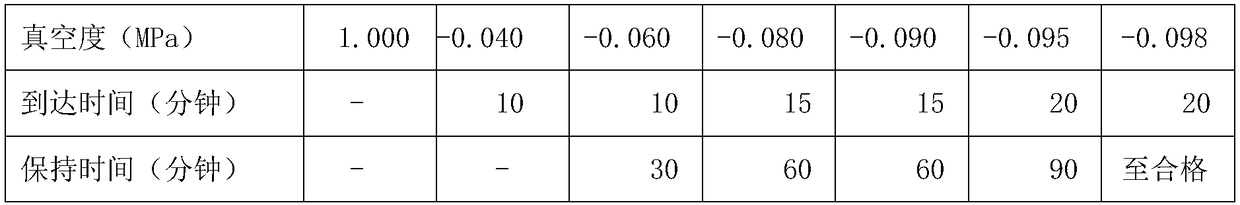

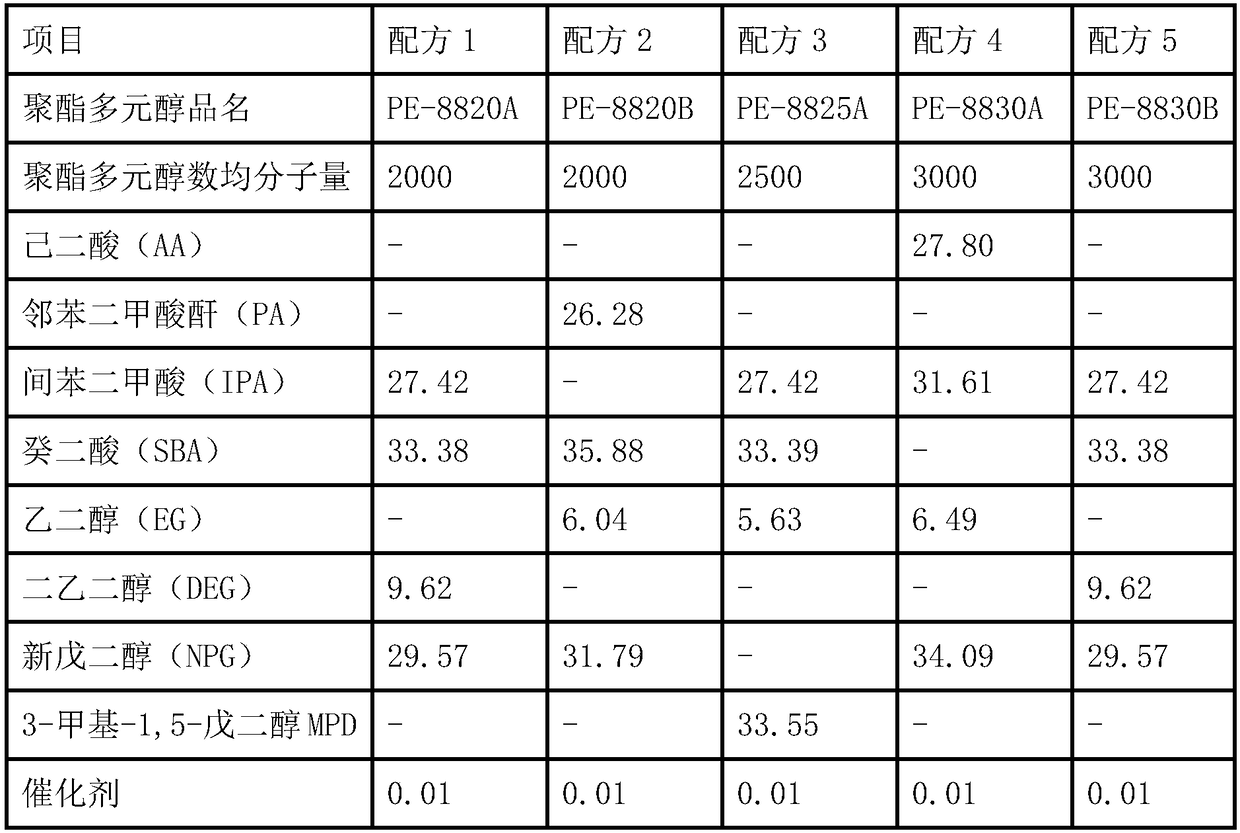

[0030] Example 1: Add 27.42% of isophthalic acid (IPA) and 29.57% of liquid neopentyl glycol NPG (except water) to the reactor by weight percentage, and feed nitrogen at 5-20 L / min, start stirring and heating , a program to raise the temperature to 180-190°C, hold at this temperature for 1-3 hours; then set the temperature to rise slowly to 210-230°C within 2-4 hours, and hold at this temperature for 2-4 hours. In the above process, water mainly occurs from esterification reaction. Pay attention to control the heating rate and the temperature at the top of the distillation tower within 100-105°C to prevent excessive loss of small molecule alcohol. During the temperature-holding process at 210-230°C, as the esterification reaction progresses, the acid value of the system gradually decreases, and the acid value is measured by sampling. When the acid value reaches 10-30mgKOH / g, the temperature can be lowered to 150-160°C , and then enter the second feeding reaction stage. The se...

Embodiment 2

[0031] Embodiment 2: In percent by weight, phthalic anhydride (PA) 26.28%, liquid neopentyl glycol NPG (except water) 31.79% are added in the reactor, and logical nitrogen 5~20L / min, start to stir and Heating, the temperature is raised to 180-190°C in one stage, and the temperature is maintained at this temperature for 1-3 hours; after that, the temperature is slowly raised to 210-230°C within 2-4 hours, and the temperature is maintained at this temperature for 2-4 hours. In the above process, water mainly occurs from esterification reaction. Pay attention to control the heating rate and the temperature at the top of the distillation tower within 100-105°C to prevent excessive loss of small molecule alcohol. During the temperature-holding process at 210-230°C, as the esterification reaction progresses, the acid value of the system gradually decreases, and the acid value is measured by sampling. When the acid value reaches 10-30mgKOH / g, the temperature can be lowered to 150-160°...

Embodiment 3

[0032] Example 3: In terms of weight percentage, 27.42% of isophthalic acid (IPA) and 33.55% of 3-methyl-1,5-pentanediol (MPD) were added to the reactor, and nitrogen gas was passed at 5 to 20 L / min , start stirring and heating, and heat up to 180-190°C in a one-step program, and hold at this temperature for 1-3 hours; then set the temperature to slowly rise to 210-230°C within 2-4 hours, and hold at this temperature for 2-4 hours. In the above process, water mainly occurs from esterification reaction. Pay attention to control the heating rate and the temperature at the top of the distillation tower within 100-105°C to prevent excessive loss of small molecule alcohol. During the temperature-holding process at 210-230°C, as the esterification reaction progresses, the acid value of the system gradually decreases, and the acid value is measured by sampling. When the acid value reaches 10-30mgKOH / g, the temperature can be lowered to 150-160°C , and then enter the second feeding re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com