Aviation tray and manufacturing method thereof

一种制造方法、航空的技术,应用在化学仪器和方法、容器、刚性容器等方向,能够解决耐热老化性差、吸水性小、环境应力敏感等问题,达到耐折性好、耐稀酸、透明度高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

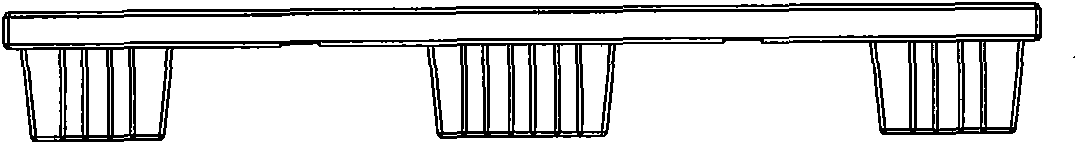

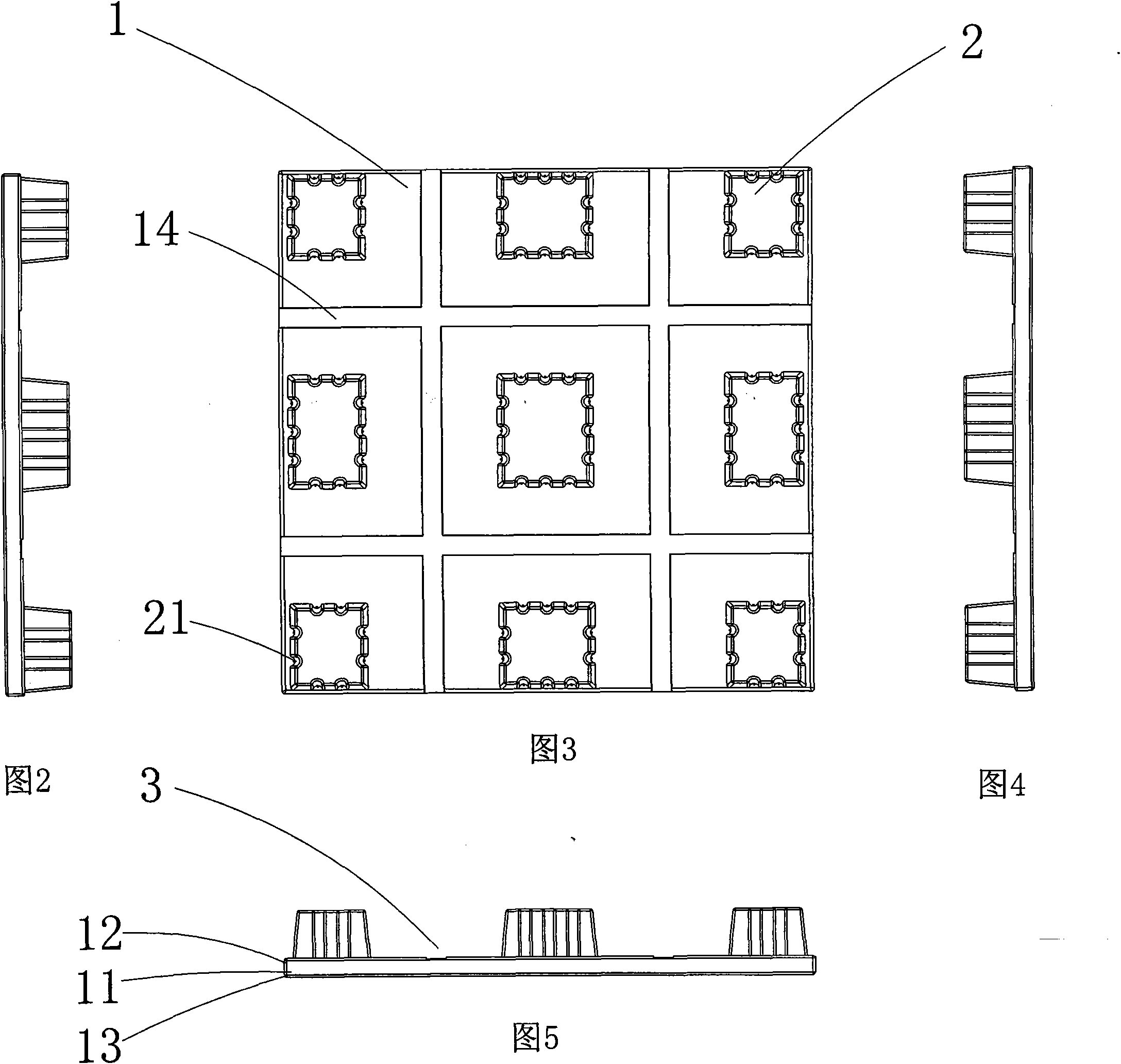

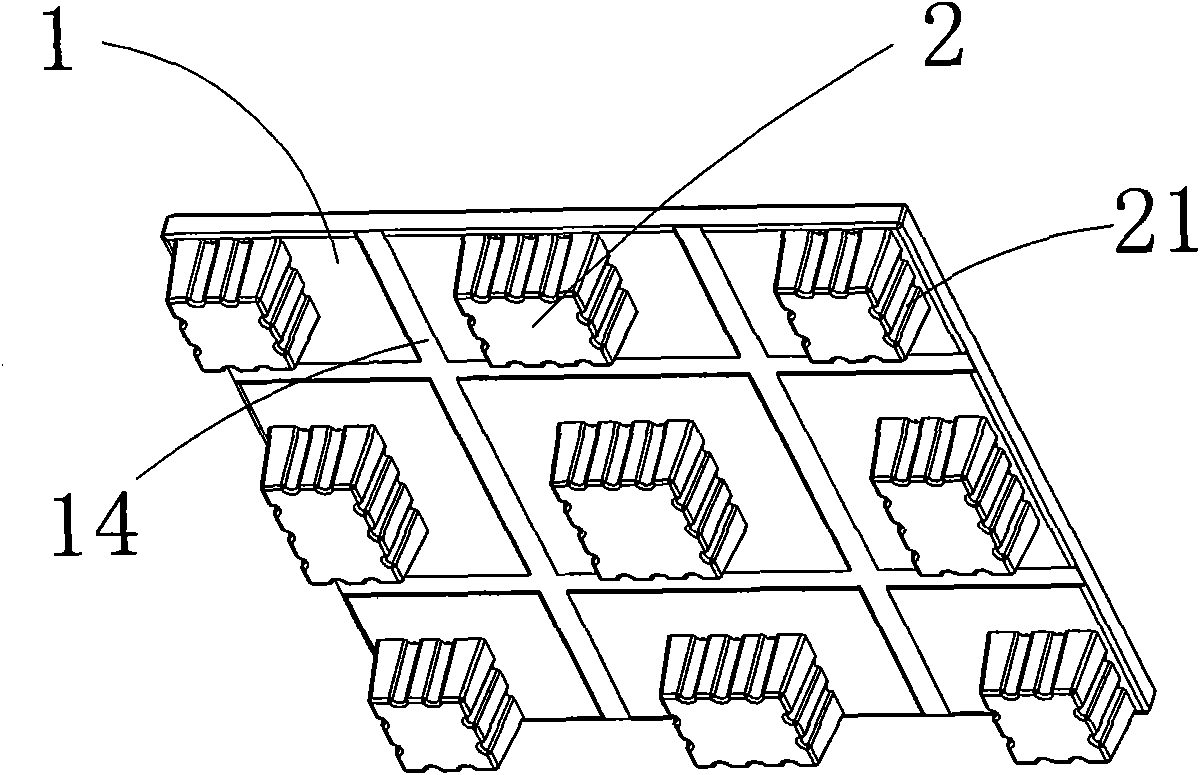

[0030] Such as Figure 1 to Figure 9 As shown, the reference numbers are as follows: bearing panel 1, EPS board 11, PET film 12, EVA adhesive layer 13, groove 14, EPS support column 2, wave-shaped groove 21, socket 3.

[0031] The aviation pallet of the present invention comprises a load-bearing panel 1, an EPS board 11 formed integrally with the main body of the load-bearing panel 1, and nine EPS support columns 2 are formed on the bottom of the EPS plate 11, and a PET film 12 is bonded on the surface of the load-bearing panel 1 and the EPS support columns , between each EPS supporting column 2 is a jack 3 .

[0032] The surface of the EPS board 11 is bonded to the PET film 12 via the EVA adhesive layer 13 .

[0033] The bearing panel 1 has a length of 1000 mm, a width of 900 mm, and a thickness of 40 mm.

[0034] The length of the EPS sup...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com