Pneumatic tire and process for manufacturing the same

一种充气轮胎、制造方法的技术,应用在充气轮胎、轮胎零部件、没有单独的充气垫等方向,能够解决阻气性差等问题,达到提高密合性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

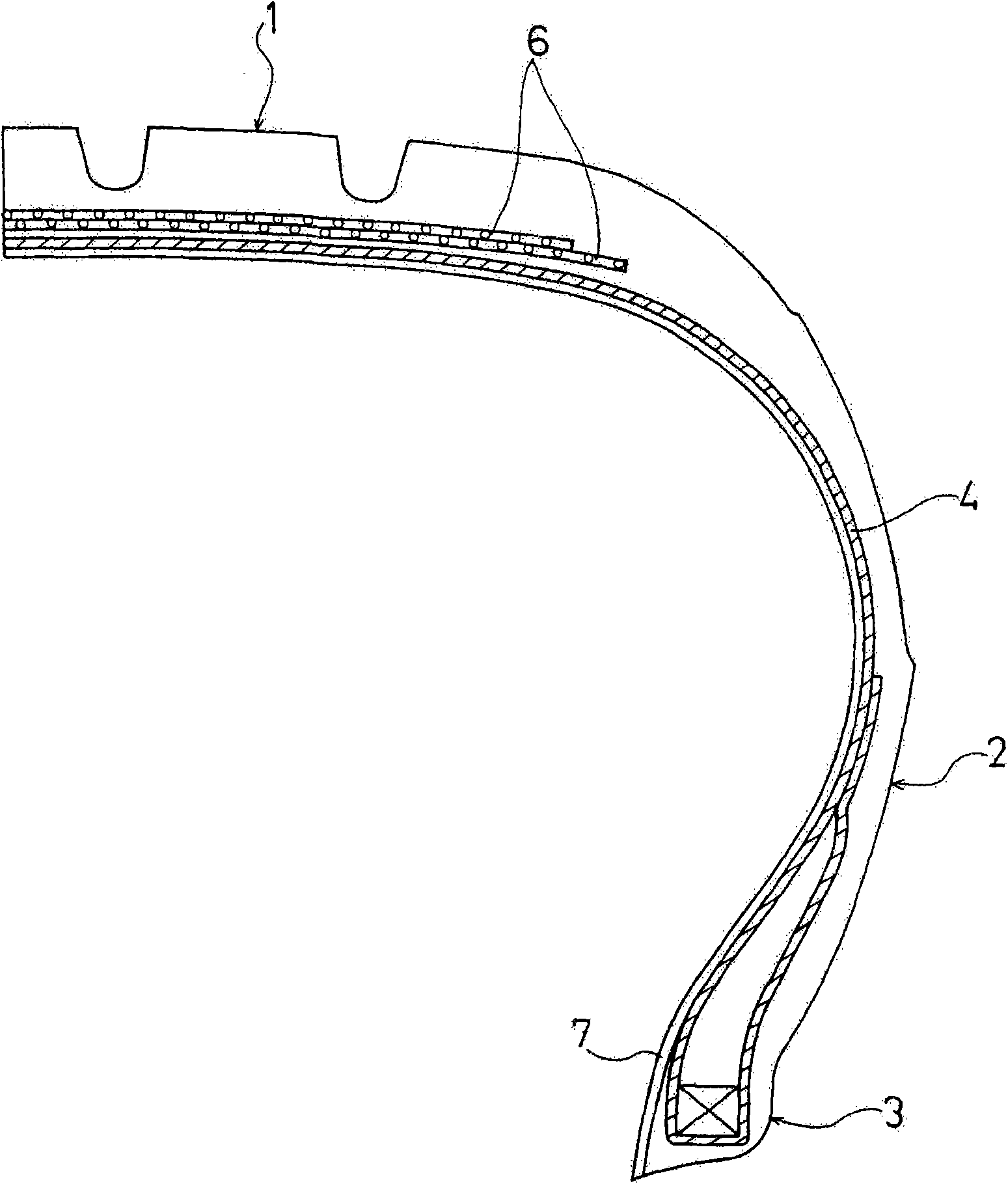

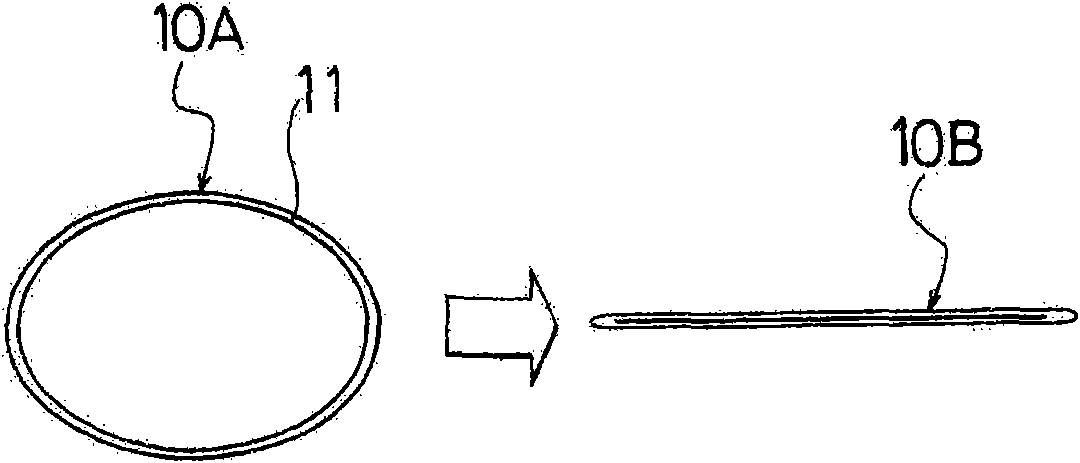

[0082] A cylinder with a circumference of 900 mm and a thickness of 20 μm (the outermost layer containing the adhesive: 5 μm, a film of a thermoplastic elastomer composition: 15 μm) was produced at a pull-out speed of 10 mm / min using a double-layer cylinder molding device. The molded product, followed by flattening the cylindrical molded product with nip rolls, yields a sheet-like laminate. An unvulcanized rubber composition sheet having a thickness of 0.2 mm was bonded to the sheet-like laminate from the vertical direction to produce a rubber laminate. Using this rubber laminate as an inner liner material, an unvulcanized tire is molded by a known method, and the unvulcanized tire is vulcanized. In this case, since the same material supply device as in the case of using an existing inner liner material formed of a rubber sheet can be used, and the sheet-like laminate does not require a cutting process for adjusting the lateral dimension, it can be achieved by Easy building p...

Embodiment 2

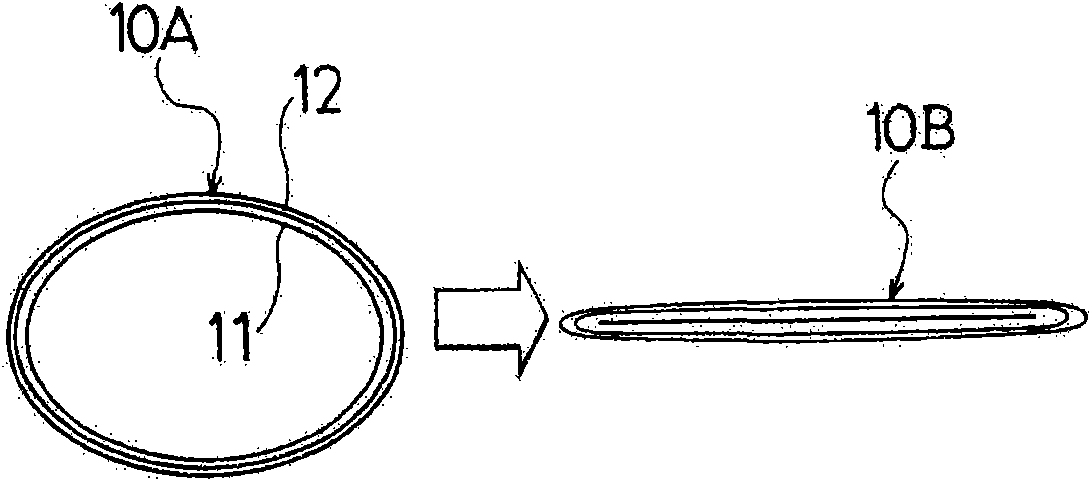

[0084] A cylinder with a circumference of 900 mm and a thickness of 20 μm (the outermost layer containing the adhesive: 5 μm, a film of a thermoplastic elastomer composition: 15 μm) was produced at a pull-out speed of 10 mm / min using a double-layer cylinder molding device. The molded product, followed by flattening the cylindrical molded product with nip rolls, yields a sheet-like laminate. In addition, in the above-mentioned cylindrical molding, a liquid containing an adhesive is sprayed on the inner side of the film to form the innermost layer on the inner side of the film. An unvulcanized rubber composition sheet having a thickness of 0.2 mm was bonded to the sheet-like laminate from the vertical direction to produce a rubber laminate. Using this rubber laminate as an inner liner material, an unvulcanized tire is molded by a known method, and the unvulcanized tire is vulcanized. In this case, since the same material supply device as in the case of using an existing inner l...

Embodiment 3

[0086] Using a double-layer cylinder molding device, a cylindrical molding with a circumference of 900 mm and a thickness of 20 μm (the outermost layer containing the adhesive: 5 μm, and a thermoplastic resin film: 15 μm) was produced at a pulling speed of 10 mm / min. Next, a sheet-like laminate is obtained by flattening the cylindrical molding with nip rolls. In addition, in the above-mentioned cylindrical molding, a liquid containing an adhesive is sprayed on the inner side of the film to form the innermost layer on the inner side of the film. An unvulcanized rubber composition sheet having a thickness of 0.2 mm was bonded to the sheet-like laminate from the vertical direction to produce a rubber laminate. Using this rubber laminate as an inner liner material, an unvulcanized tire is molded by a known method, and the unvulcanized tire is vulcanized. In this case, since the same material supply device as in the case of using an existing inner liner material formed of a rubber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com