Halogen-free flame-retardant PET (polyethylene terephthalate) material and preparation method thereof

A flame retardant and catalyst technology, applied in the field of halogen-free flame retardant PET material and its preparation, can solve the problems of inability to achieve a higher flame retardant grade, unstable flame retardant effect, poor flame retardant effect, etc., and achieve excellent physical properties. Performance and mechanical properties, low production cost, outstanding effect of electrical insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

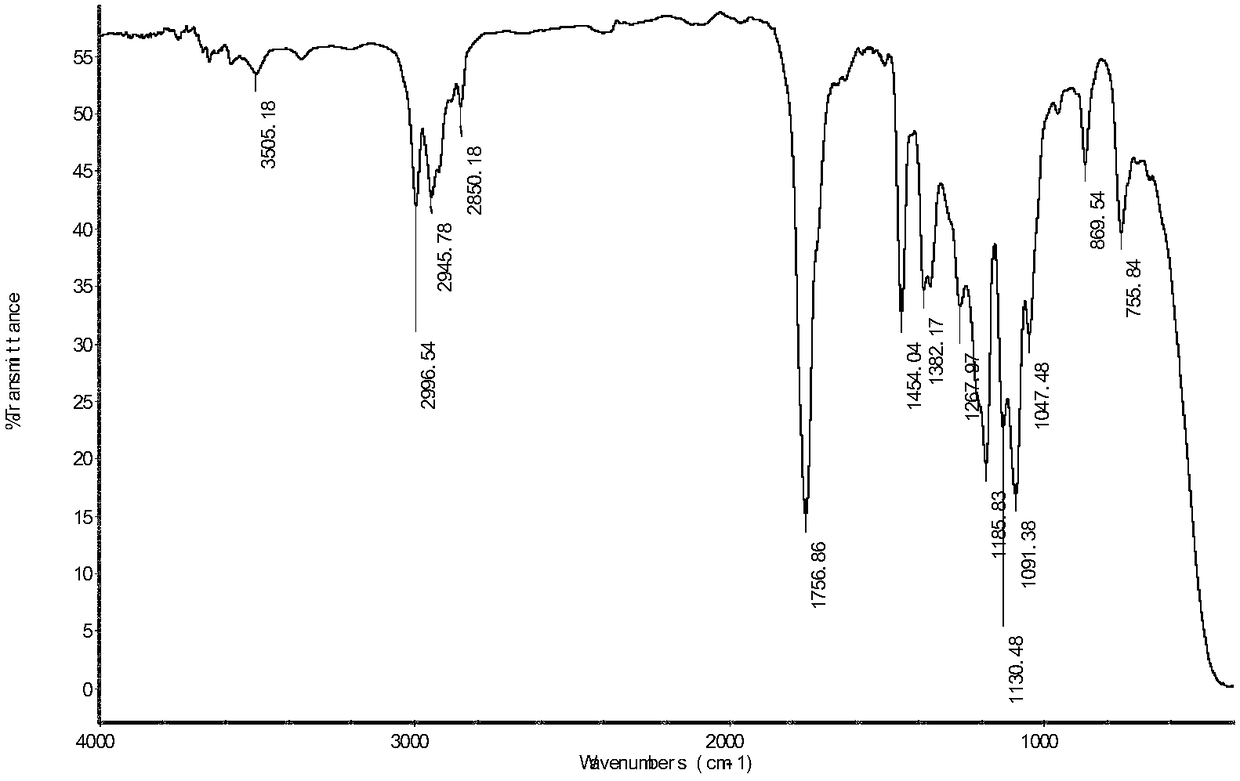

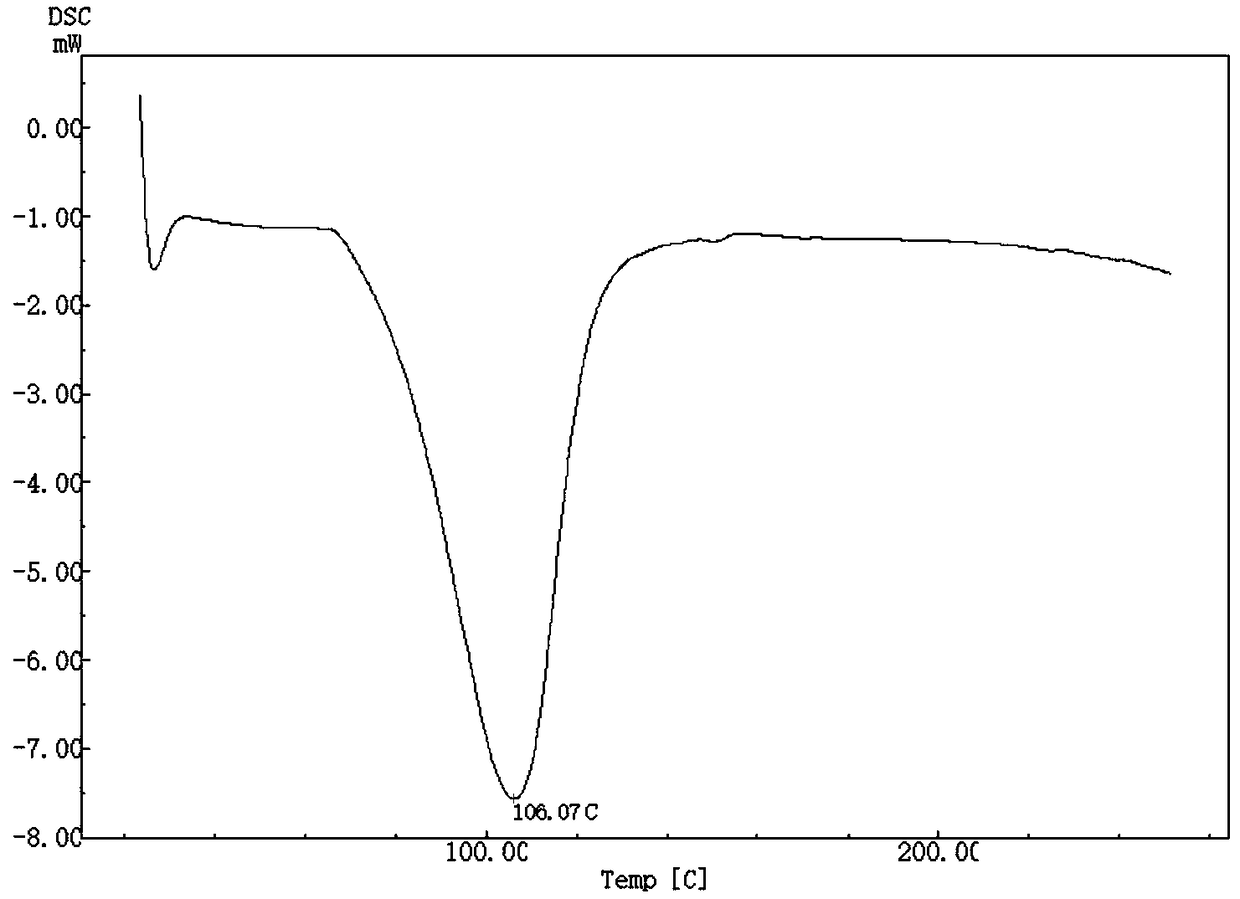

Image

Examples

preparation example Construction

[0074] The present invention also provides a preparation method of the halogen-free flame-retardant PET material described in the above technical solution, comprising the following steps:

[0075] Mix PET, halogen-free phosphorus copolyester flame retardant, auxiliary flame retardant, glass fiber, compatibilizer, coupling agent and antioxidant II to obtain a mixture;

[0076] The compound is extruded, drawn, water-cooled, pelletized and dried in sequence to obtain the halogen-free flame-retardant PET material.

[0077] The invention mixes PET, non-halogen phosphorus copolyester flame retardant, auxiliary flame retardant, glass fiber, compatibilizer, coupling agent and antioxidant II to obtain a compound.

[0078] In the present invention, the glass fiber is preferably added from the glass fiber adding port; the mixing is preferably to mix all the pellets in the raw material uniformly first, then add the liquid material for high-speed mixing, and finally add the powder material...

Embodiment 1

[0087] Under the protection of nitrogen, add 6mol (1164g) dimethyl terephthalate into a 10L reaction kettle, add 18mol (1116g) ethylene glycol, heat up while stirring, adjust the system temperature to 170°C, Under the action of diantimony, the first transesterification reaction was carried out, and the amount of methanol removed reached a theoretical value of 384g, and the transesterification product system I was obtained;

[0088] Reduce the system temperature of transesterification product system I to 145°C, add 6mol (744g) dimethyl methylphosphonate (DMMP) and 0.38g antimony trioxide, stir evenly, and carry out the second transesterification reaction at 185°C until The amount of methanol produced exceeds 25% of the theoretical value to reach 480g, and the transesterification product system II is obtained;

[0089] Add 3.77g epoxy chain extender REPAIR CE-3, 2.83g triethyl phosphate and 0.75g tetrabutyl titanate to the transesterification product system II, press Slowly ev...

Embodiment 2

[0096] Under the protection of nitrogen, 6mol (1164g) of dimethyl terephthalate was added to a 10L reactor, followed by 19.8mol (2060g) of pentanediol, and the temperature was raised while stirring to adjust the temperature of the system to 160°C. Under the action of cobalt octoate, the first transesterification reaction was carried out, and the amount of methanol removed reached a theoretical value of 384g, and the transesterification product I system was obtained;

[0097] Lower the system temperature of transesterification product system I to 145°C, add 7.2mol (893g) dimethyl methylphosphonate (DMMP) and 0.78g cobalt octanoate, stir well, and carry out the second transesterification reaction at 170°C until the The amount of methanol exceeds 25% of the theoretical value to reach 576g, and the transesterification product system II is obtained;

[0098] Then add 2.59g epoxy chain extender REPAIR CE-3, 2.59g tris[2,4-di-tert-butylphenyl] phosphite and 0.51g tetrabutyl titanate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com