Patents

Literature

73results about How to "Increased tensile elongation at break" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

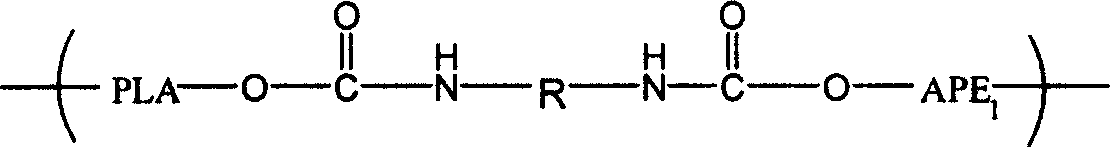

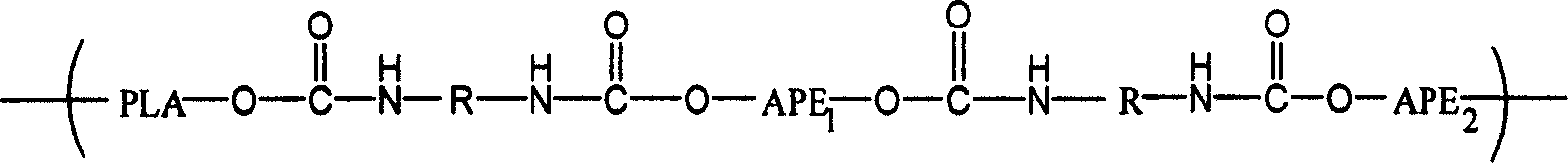

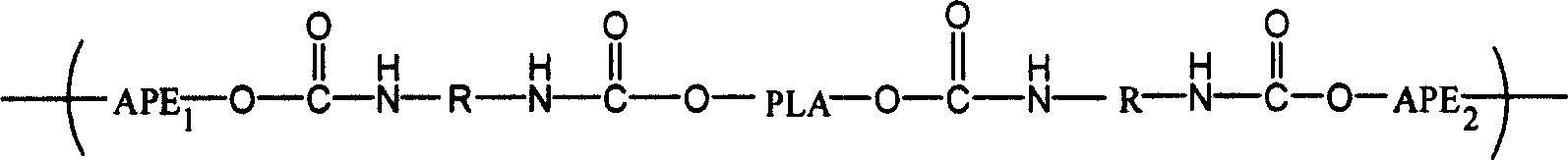

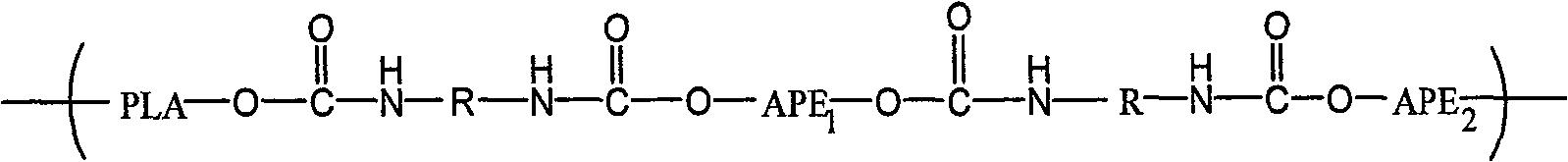

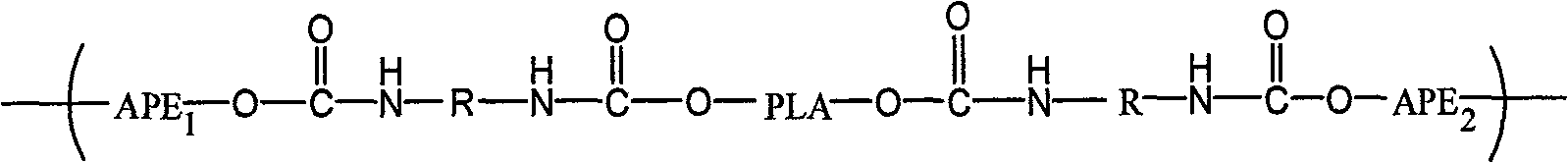

Polylactic-acid block copolymer and its preparing method

ActiveCN101024696ALow costAvoids a host of problems associated with ring-opening polymerization processesPolyesterPolymer science

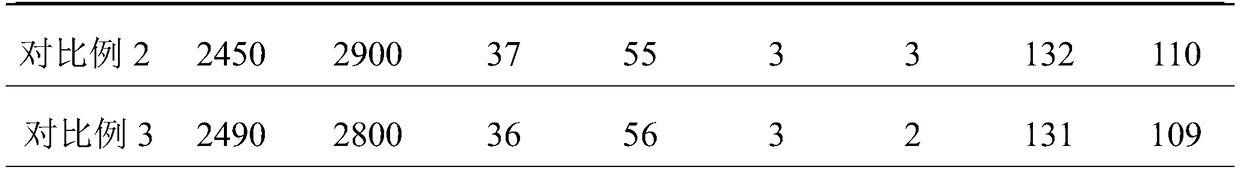

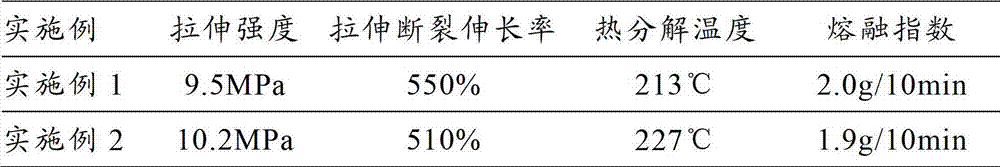

The invention discloses a poly-lactic acid block copolymer. The feature is that it is made from the end hydroxyl poly-lactic acid with intrinsic viscosity of 0.05-0.5dL / g and aliphatic polyester glycol with intrinsic viscosity of 0.1-1.0dL / g taking fusion reaction under existing of diisocyanate. The intrinsic viscosity of the copolymer is 0.7-2.5dL / g, and tensile strength is 10-40MPa, elongation at break is 100-800%. The invention also discloses the manufacturing method for the copolymer. It has the advantages of good toughness, strong tensile strength, high tensile fracture elongation, etc.

Owner:SICHUAN UNIV

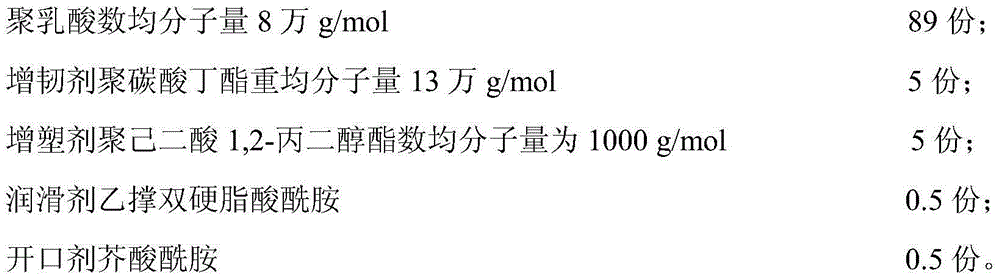

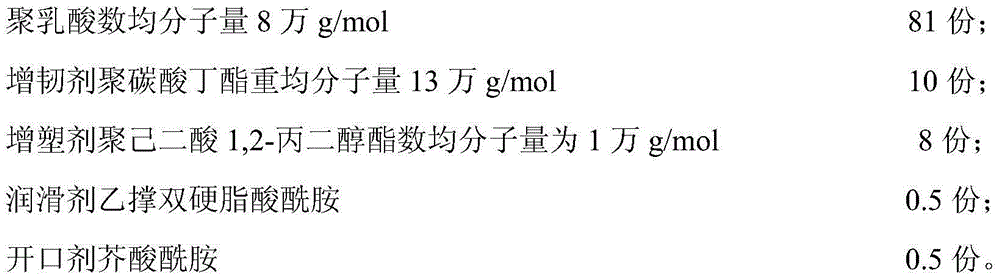

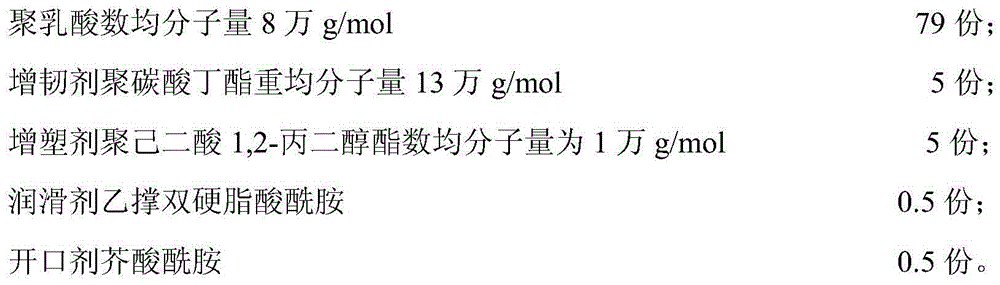

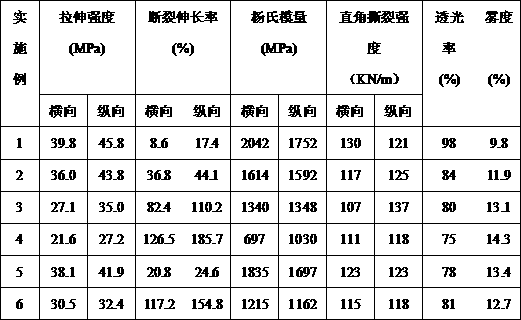

Transparent, tear-resistant and biodegradable polylactic acid thin film and preparation method thereof

InactiveCN104387732AIncreased tensile elongation at breakHigh tear strengthPolymer sciencePlasticizer

The invention provides a transparent, tear-resistant and biodegradable polylactic acid thin film and a preparation method thereof, belonging to the field of high molecular material and solving the technical problem of high brittleness, poor tear resistance and poor flexibility of the polylactic acid thin film in the prior art. The transparent, tear-resistant and biodegradable polylactic acid thin film comprises a mixture of polylactic acid, a toughening agent, a plasticizer, a lubricant and a plastic lubricant. The preparation method comprises the following steps: mechanically mixing polylactic acid, the toughening agent, the plasticizer, the lubricant and the plastic lubricant to obtain a premix at first; feeding the premix from the feeding opening of a twin-screw extruder; metering the plasticizer and adding the metered plasticizer from the liquid feeding opening of the twin-screw extruder; and pelleting by melt extrusion to finally obtain the transparent, tear-resistant and biodegradable polylactic acid thin film. The elongation at break and tearing strength of the polylactic acid thin film provided by the invention are improved obviously, the transparency of polylactic acid is retained, the brittleness defect of the polylactic acid thin film is solved, the rheological behavior of the material is improved obviously, the tensile strength is 43.2MPa at most, the elongation at break is 48%, and the right angle tear strength is 127KN / m.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

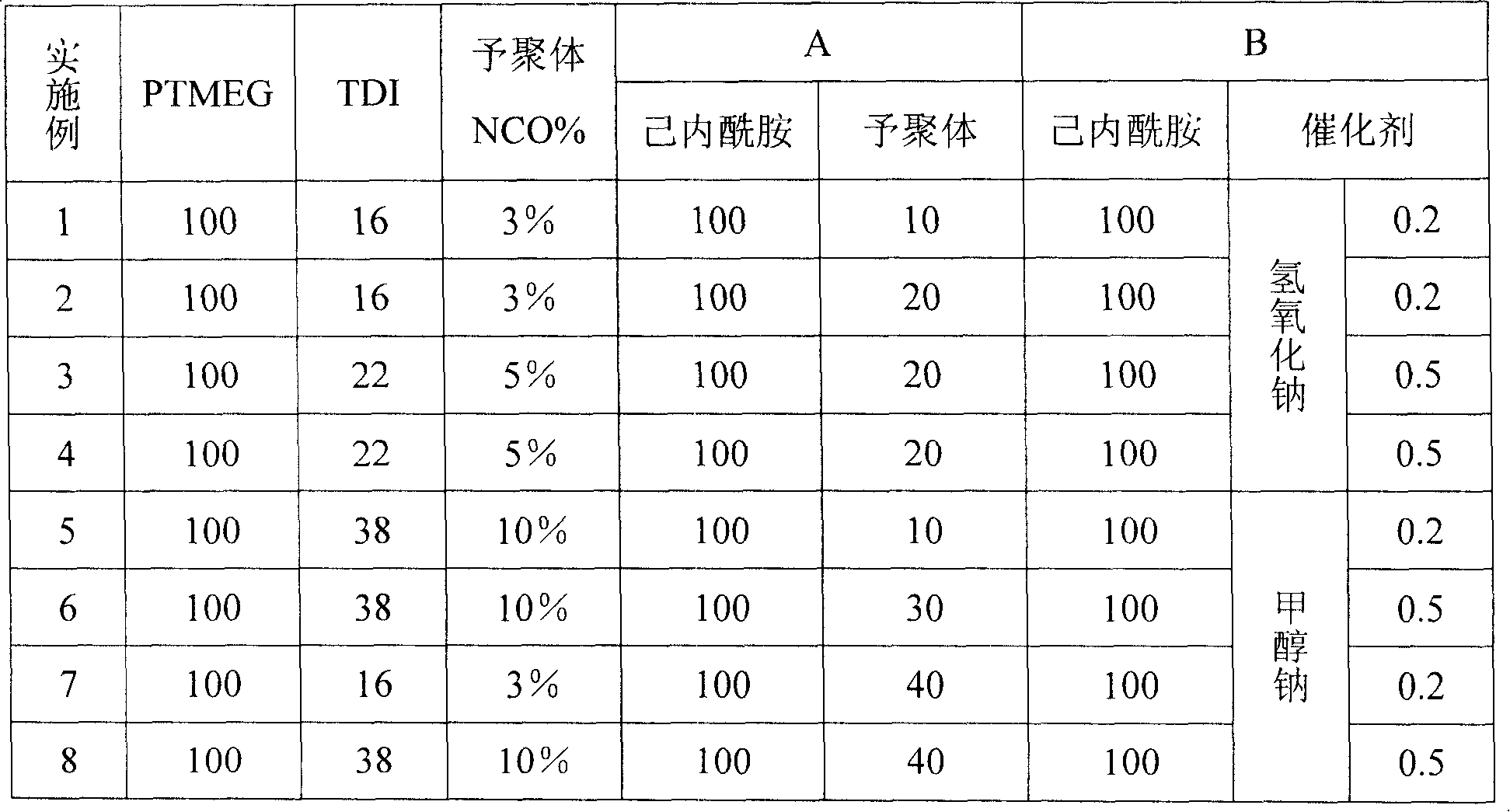

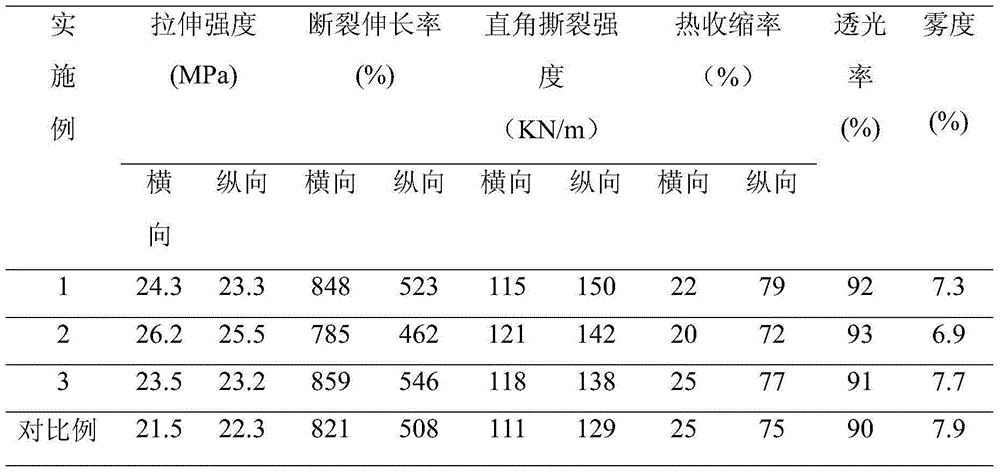

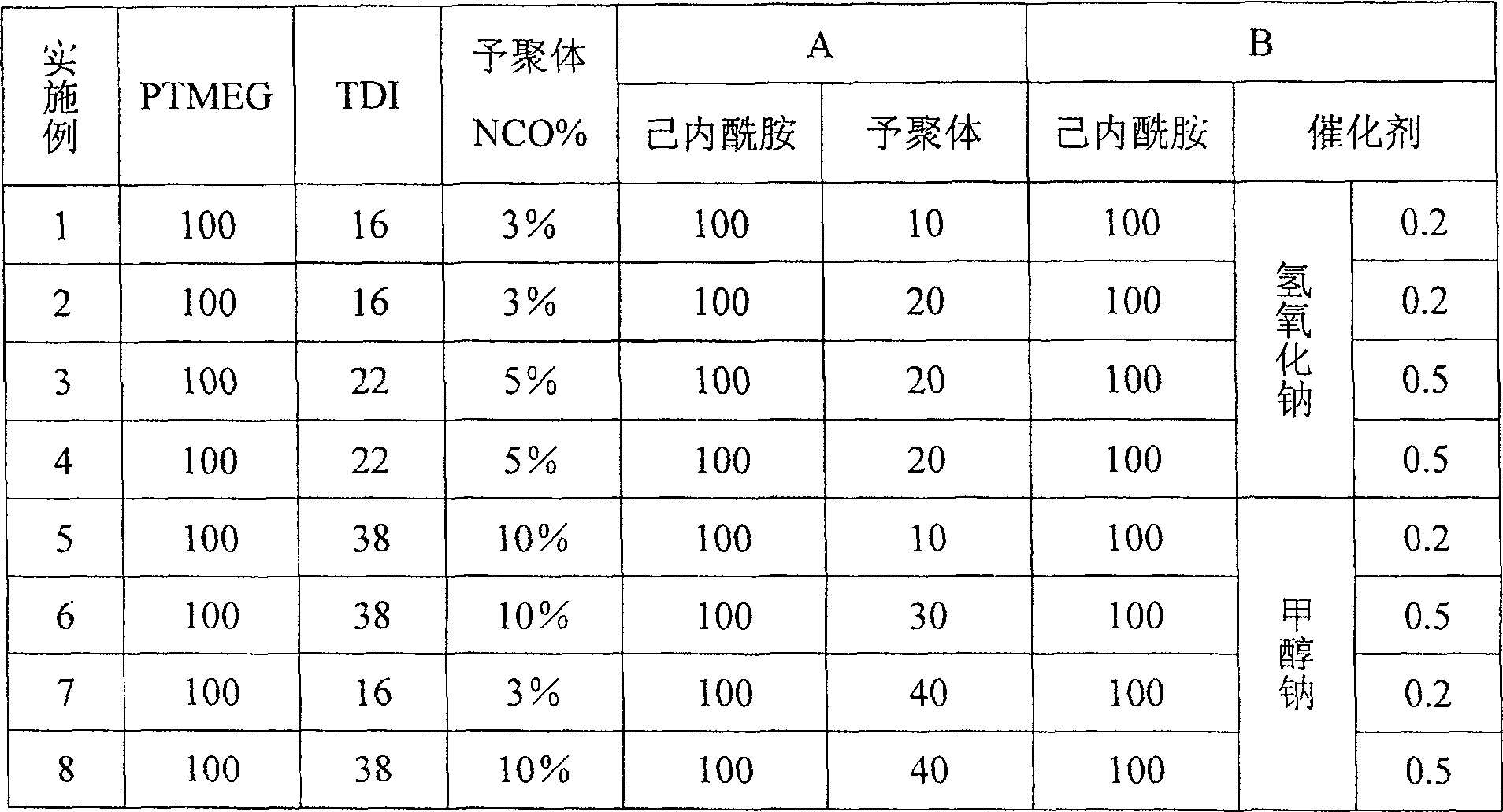

Method for producing polyurethane toughness-reinforcing cast form nylon composite material

InactiveCN101195706AHigh mechanical strengthIncreased tensile elongation at breakNylon materialToughness

The invention relates to a preparation method of polyurethane plasticizing monomer casting nylon compound material. The material is made through pouring the raw material of polyurethane prepolymer, and caprolactam, etc. The main performance of the material is characterized in that the mechanical strength is improved, the tensile fracture elongation rate is increased along with increasing of the use amount of the polyurethane prepolymer, the impact strength is enhanced along with the increasing of the use amount of the polyurethane prepolymer, and the tribology performance and the antistatic performance are improved remarkably.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Transparent and toughening polylactic acid resin and method for preparing the same

The invention provides a transparent and toughening polylactic acid resin and method for preparing the same. The polylactic acid resin consists of polylactic acid, methyl methacrylate-butyl acrylate copolymer as the flexibilizer, citrate plasticizer, pentaerythritol toltetranitrate (Benzenepropanoic acid, 3,5-bis(1,1-dimethylethyl)-4-hydroxy-) as the antioxidant and tris (2,4-ditert-butylphenyl) phosphate. First, premix is prepared by mixing polylactic acid, flexibilizer, plasticizer and antioxidant mechanically. Then the premix is subject to melt extrusion and granulation by utilizing double-screw extruder. The above method has the advantages of increasing the anti-impact strength, tensile strength and elongation at break of polylactic acid and maintaining the transparency thereof. In addition, the viscosity of the blends is decreased, thereby remedying the defects of brittleness of polylactic acid and improving the rheological behavior of materials obviously. The impact strength is up to 60.1KJ / M2.The light transmittance and the haze of the products are 89% and 8.5% respectively when the thickness thereof is 0.04mm.The above polylactic acid resin, instead of PE and PVC, is applicable to the preparation of films, plates, sheet materials, foamings and injection moulding plastics.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

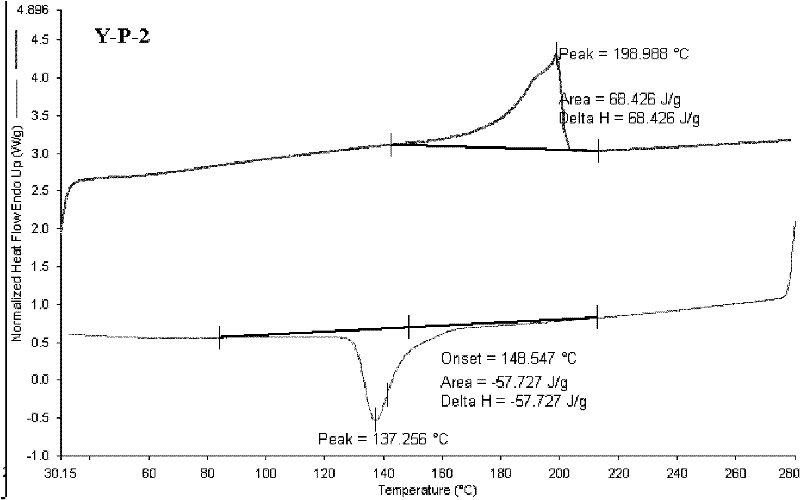

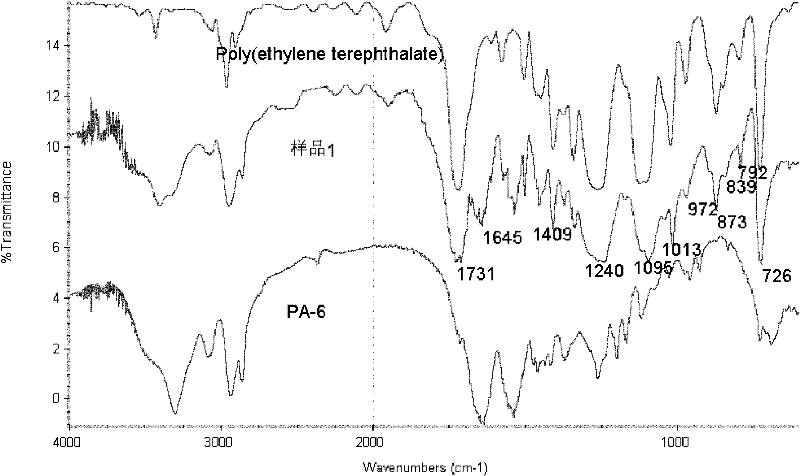

Polyester-polyamide copolymer and synthetic preparation method thereof

The invention relates to a polyester-polyamide copolymer and a synthetic preparation method thereof. The polyester-polyamide copolymer is composed of polyester and nylon 6 with relative viscosity of 1.5-2.2, intrinsic viscosity thereof is 0.80-0.90dL / g, tensile strength thereof is 40-80MPa, elongation at break thereof is 10-80%, content of a terminal carboxyl group thereof is less than 18mol / t and diglycol content thereof is less than 1.0%. In the invention, the nylon 6 with the relative viscosity of 1.5-2.2 is added during the polyester polymerization process, so that a polyester prepolymer performs copolymerization with the nylon 6 to obtain a polyester copolymer with an acid dyeable amide group which has affinity to acid dyes, thus further processing and preparing polyester chips and fibers, which can be subject to acid dyeing; and the method thoroughly solves the problem of poor compatibility between the nylon and the polyester, and overcomes the problems of low spinning strength, poor dyeing uniformity and easy occurrence of color difference of the copolymer obtained in the prior art.

Owner:CHINESE TEXTILE ACAD

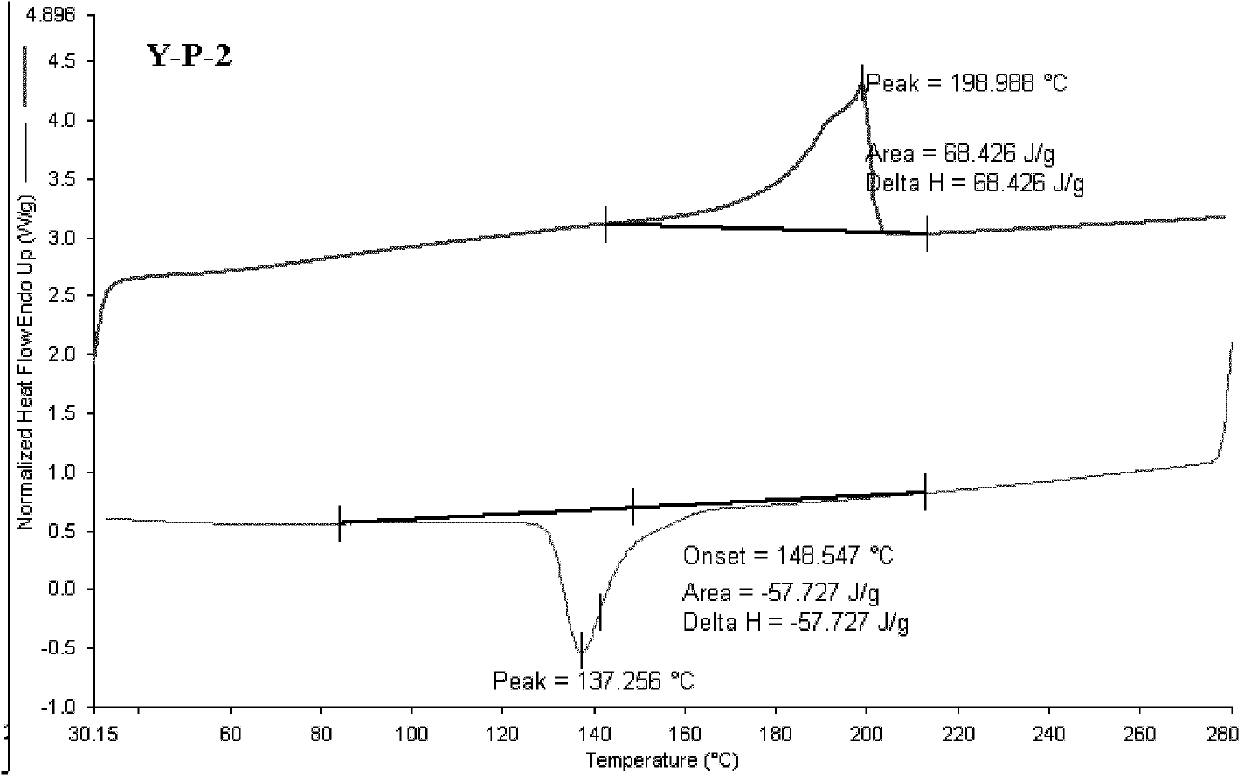

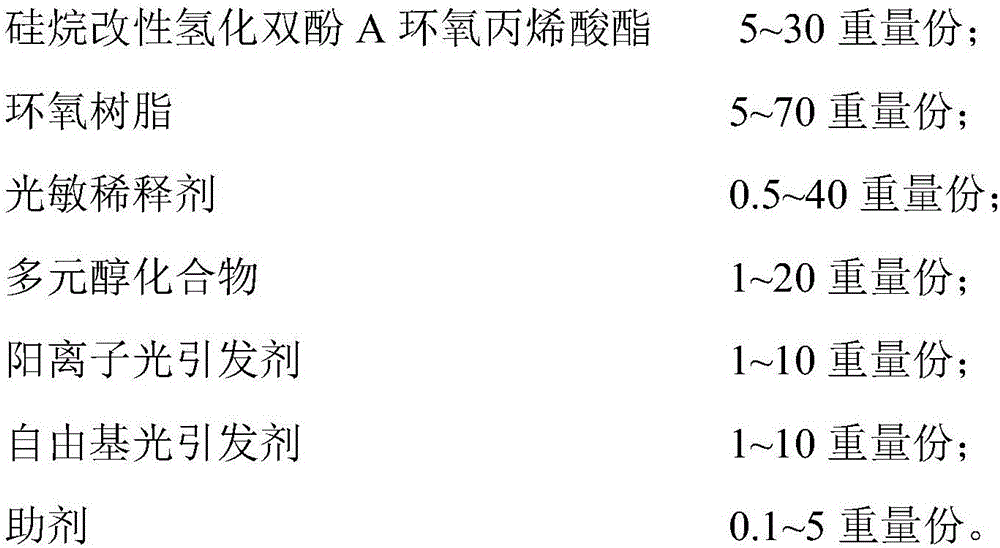

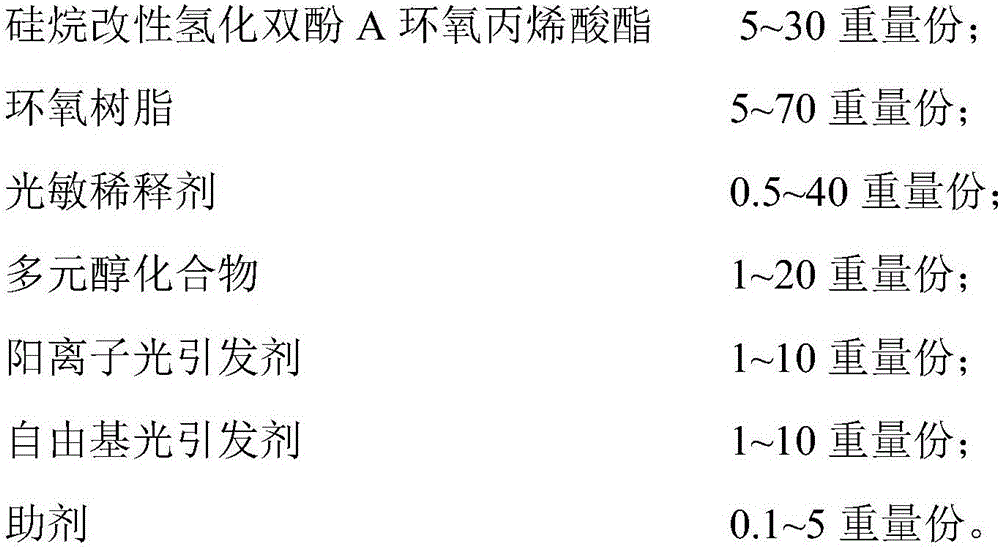

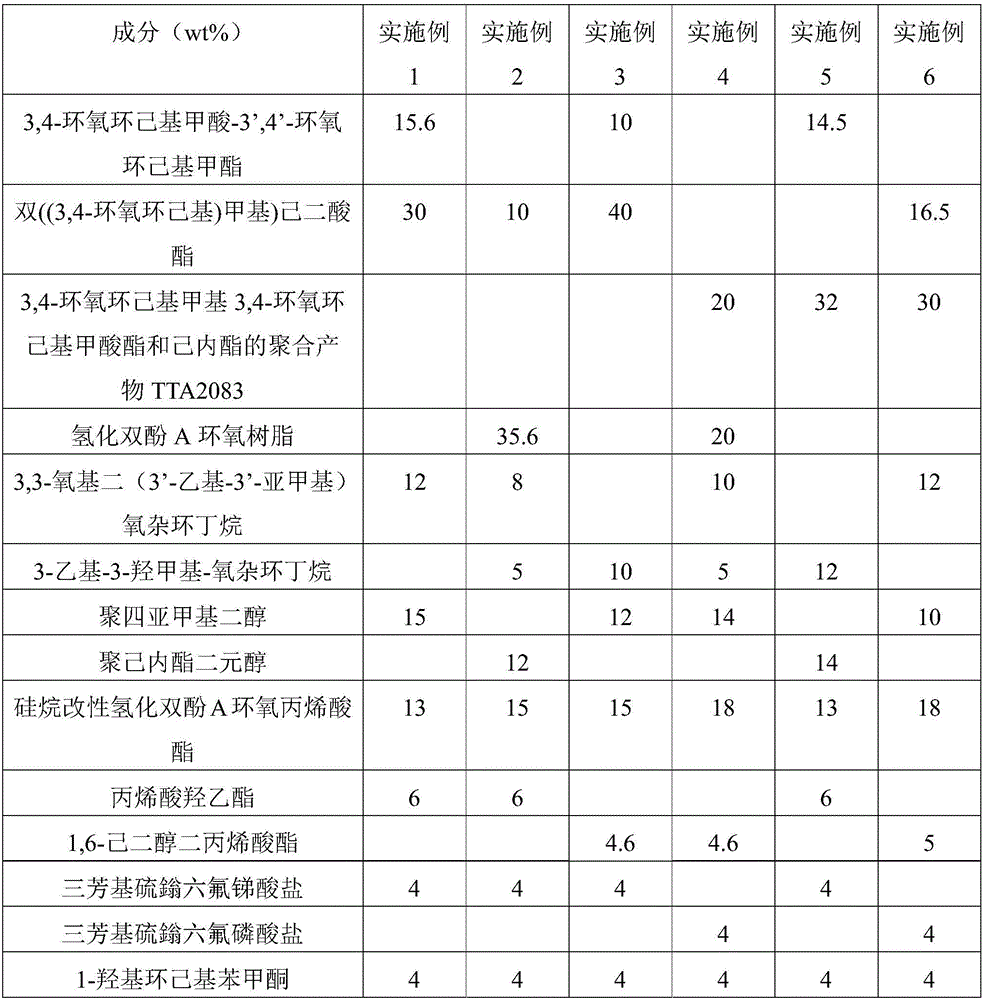

Rubber-type light curing 3D printing material and preparation method thereof

The invention discloses a rubber-type light curing 3D printing material and preparation method thereof. The rubber-type light curing 3D printing material is prepared from the following raw materials: silane-modified hydrogenated bisphenol A epoxy acrylate, epoxy resin, a photosensitive diluent, a polyol compound, a cationic photoinitiator, a free radical photoinitiator and an auxiliary agent. Compared with the prior art, the silane-modified hydrogenated bisphenol A epoxy acrylat as a prepolymer is added into the 3D printing material, so that the tensile elongation at break of the light curing 3D printing material is greatly improved, and the light curing 3D printing material has excellent elasticity, toughness and softness. In addition, the hardness of the light curing 3D printing material can be adjusted through the change of the ratio of the raw materials, different products with the Shore A hardness of 30 to 95 are obtained, and different requirements can be met. The rubber-type light curing 3D printing material has the advantages of high elasticity, high toughness, low hardness, high flexibility, high forming precision and high gloss.

Owner:HANGZHOU LEYI NEW MATERIAL TECH CO LTD

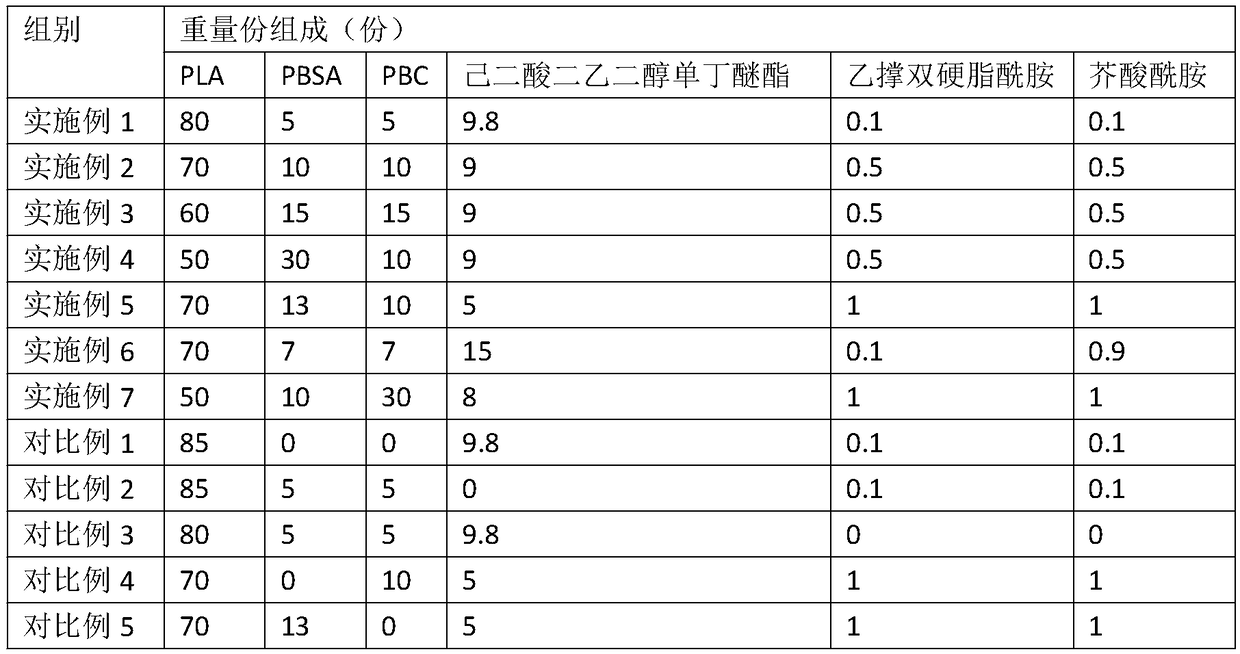

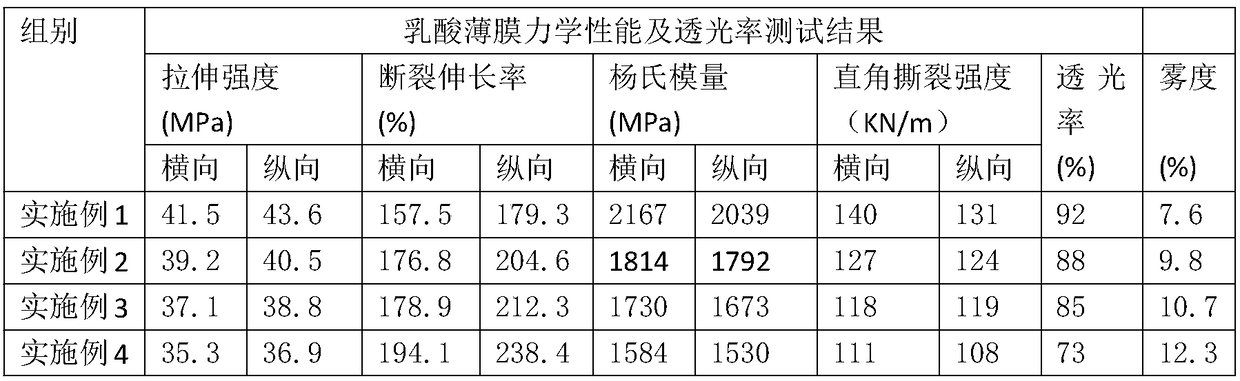

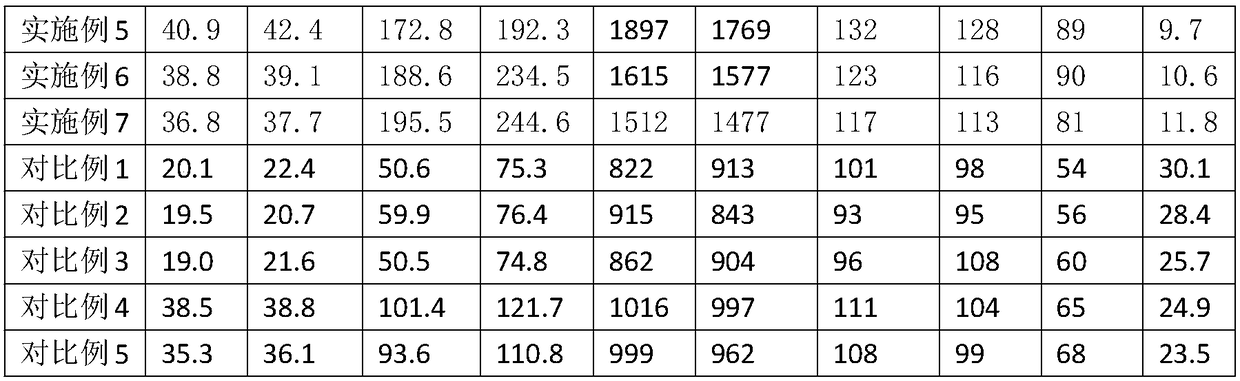

Completely-biodegradable polylactic acid-based blow molding thin film and preparation method thereof

The invention belongs to the field of polymer materials, and particularly relates to a PLA (polylactic acid) biodegradable thin film and a preparation method thereof. The PLA biodegradable thin film is prepared from the following components of PLA, PBSA (poly(butylene succinate-co-adipate)), PBC (polypropylene carbonate), a plasticizer, a lubricant and a pore forming agent. The preparation methodcomprises the following steps of mechanically mixing the PLA, the PBSA, the PBC, the lubricant and the pore forming agent; adding the mixed raw materials into a material hopper of a double-screw extruder; metering the plasticizer by a metering pump, adding via a liquid adding port of the extruder, starting the solid charge and liquid charge, smelting, extruding and granulating, so as to obtain thePLA resin material; performing blow molding and film forming on the PLA resin material, so as to obtain the PLA-based thin film. The PLA-based thin film has the advantages that the mechanical property is better, and the transparency is good; the complete biodegradable effect is realized; the PLA-based thin film can be used for replacing PE (polyethylene), PP (polypropylene), PVC (polyvinyl chloride) and the like to prepare thin films and sheets.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP +1

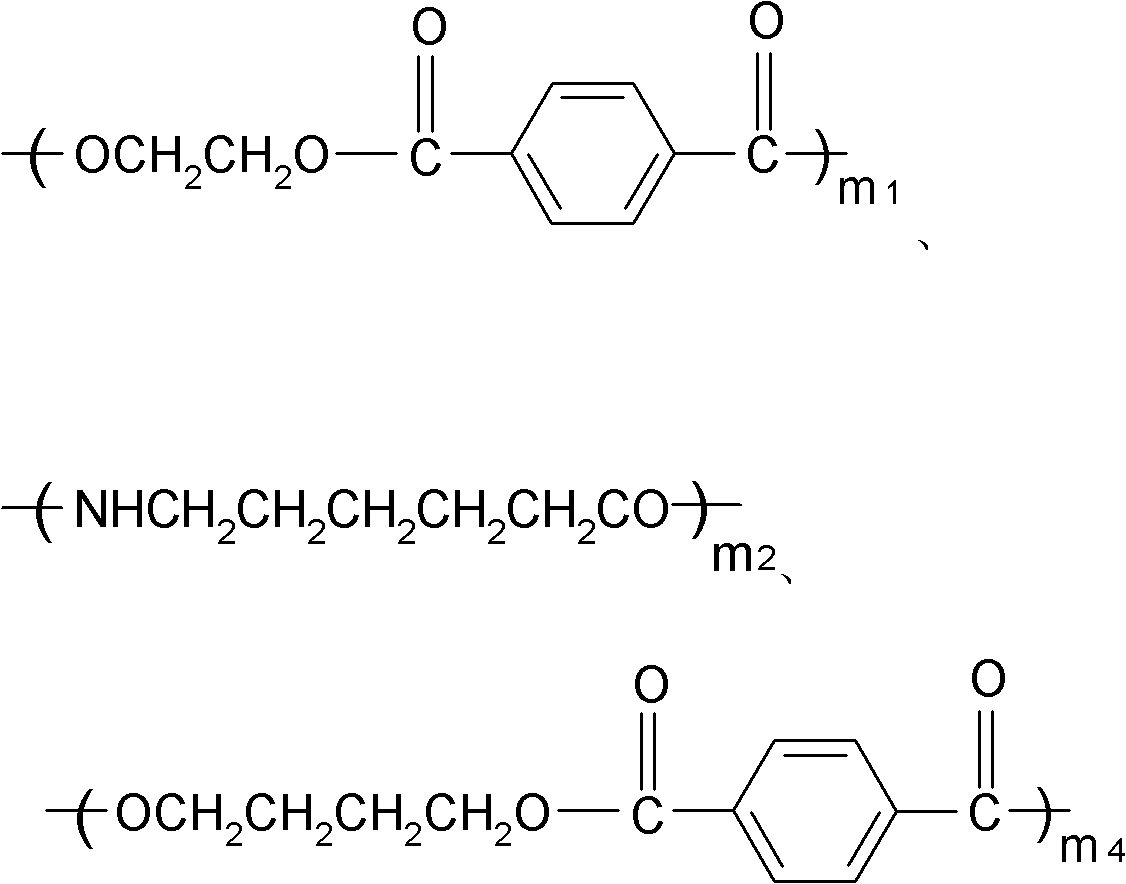

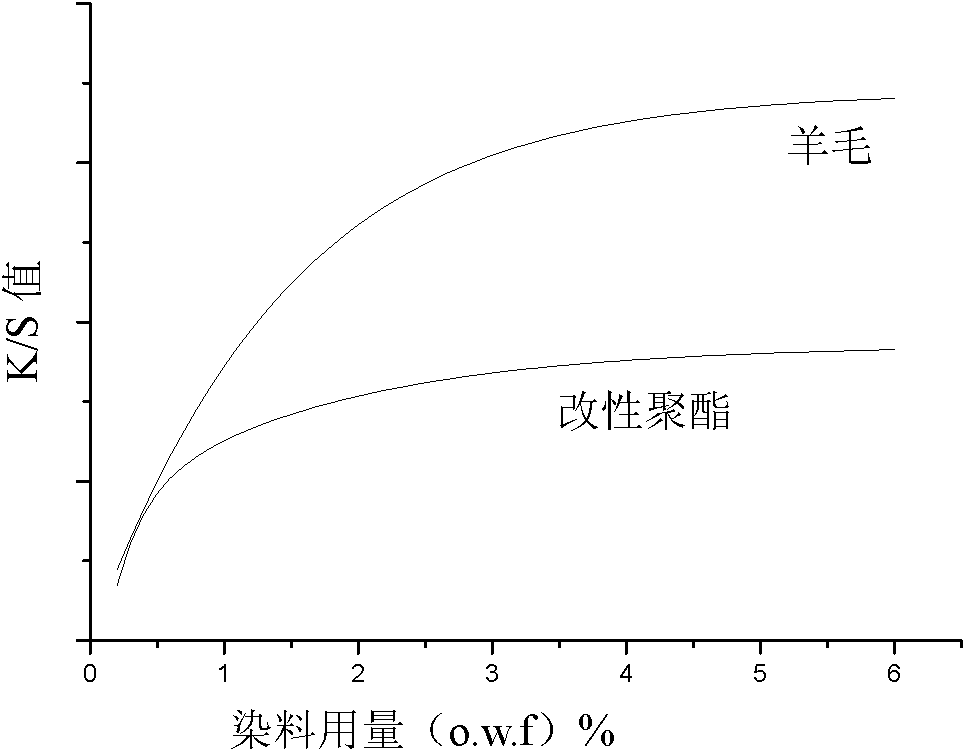

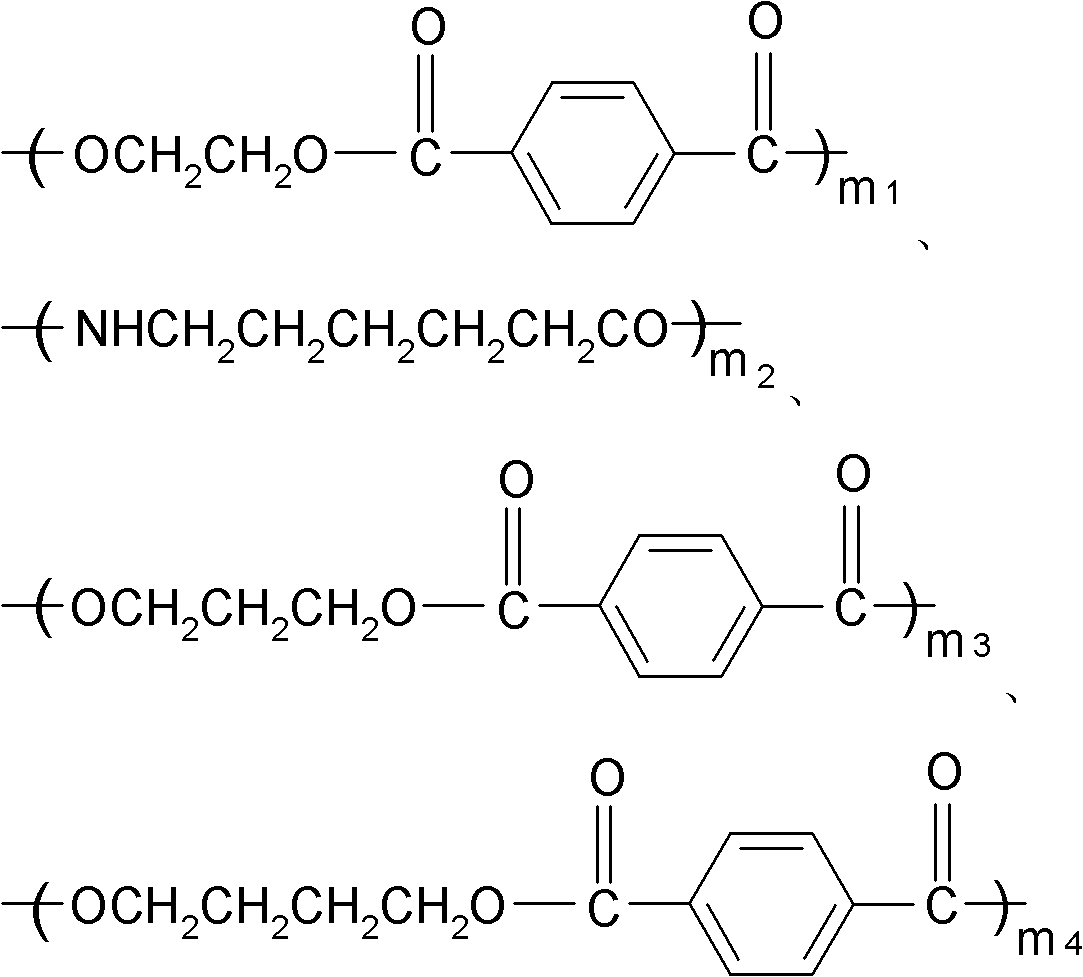

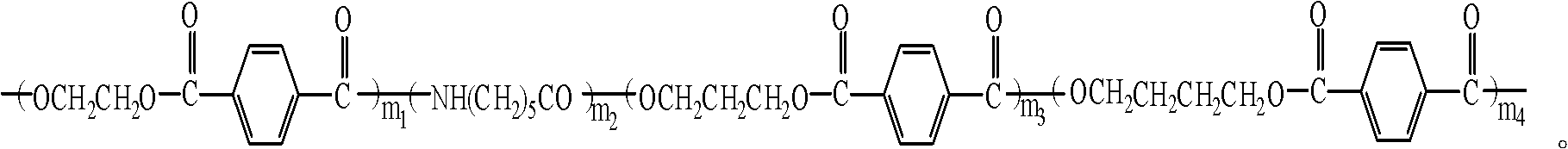

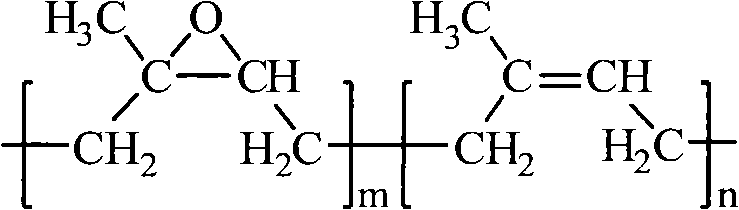

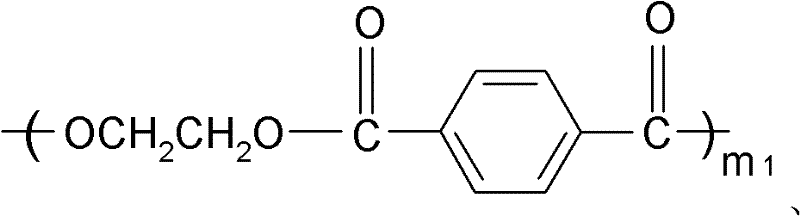

One-bath dyeing method of modified polyester/wool blended fabric

ActiveCN101899788AIncreased tensile elongation at breakEvenly distributed sequenceDyeing processWoolChemistry

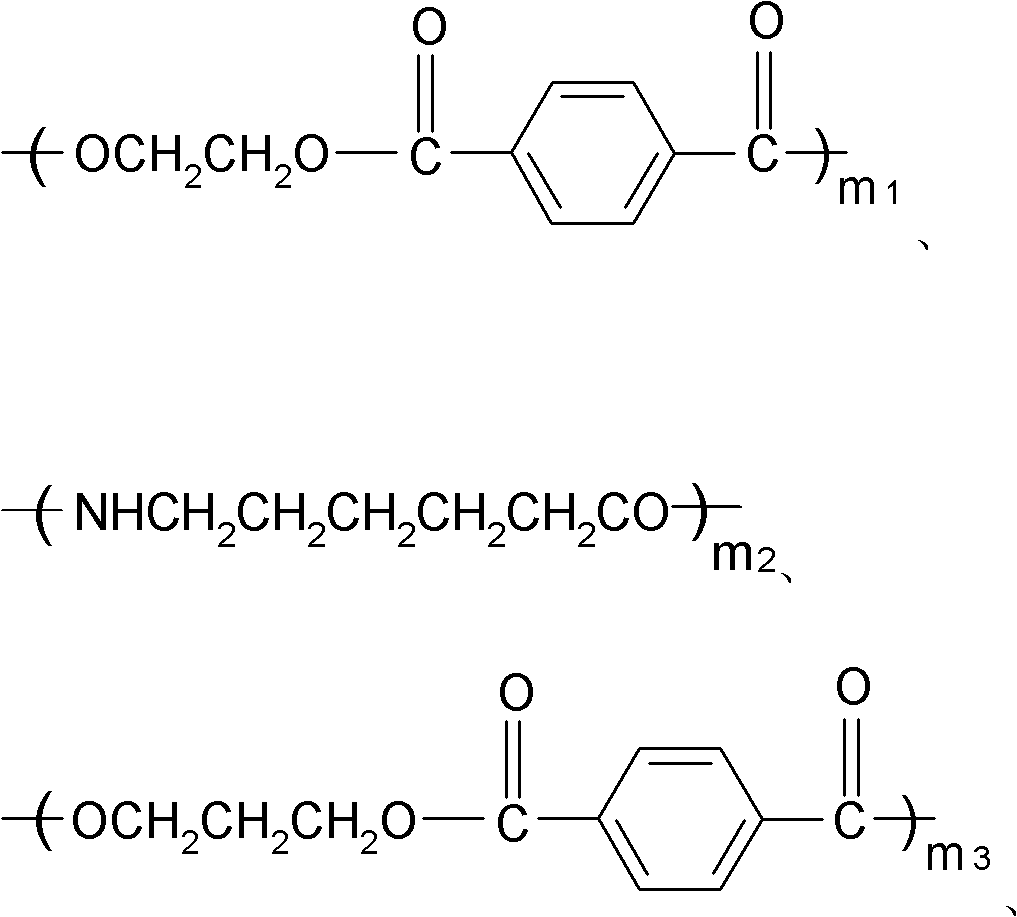

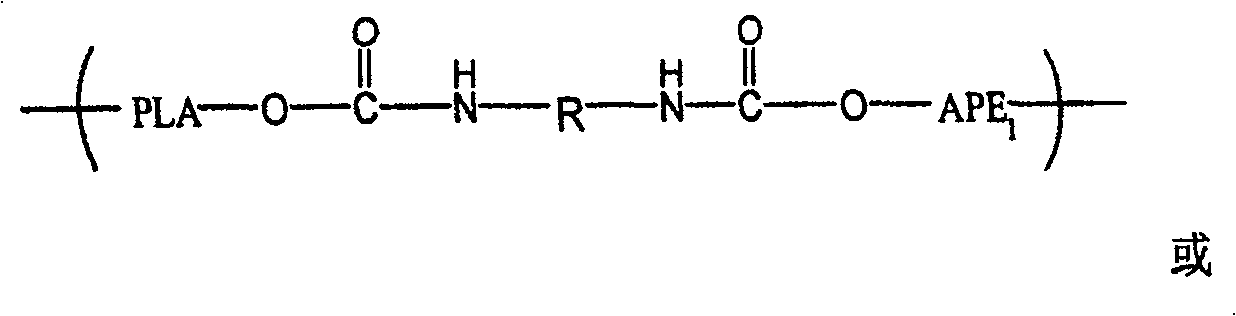

The invention provides a modified polyester / wool blended fabric, which is formed by blending modified polyester and wool. The modified polyester structurally comprises the following structural units:, wherein m1 is more than 1 but less than 160; m2 is more than 1 but less than 70; m3 is not less than 0 but less than 20; and m4 is not less than 0 but less than 20; the blended fabric can be one-bath dyed with acidic dye or acidic dye and disperse dye, thus dyeing procedures are simplified, energy conservation and pollution reduction is saved, and energy consumption can be prominently reduced owing to the dyeing temperature below 100 DEG C.

Owner:CHINESE TEXTILE ACAD

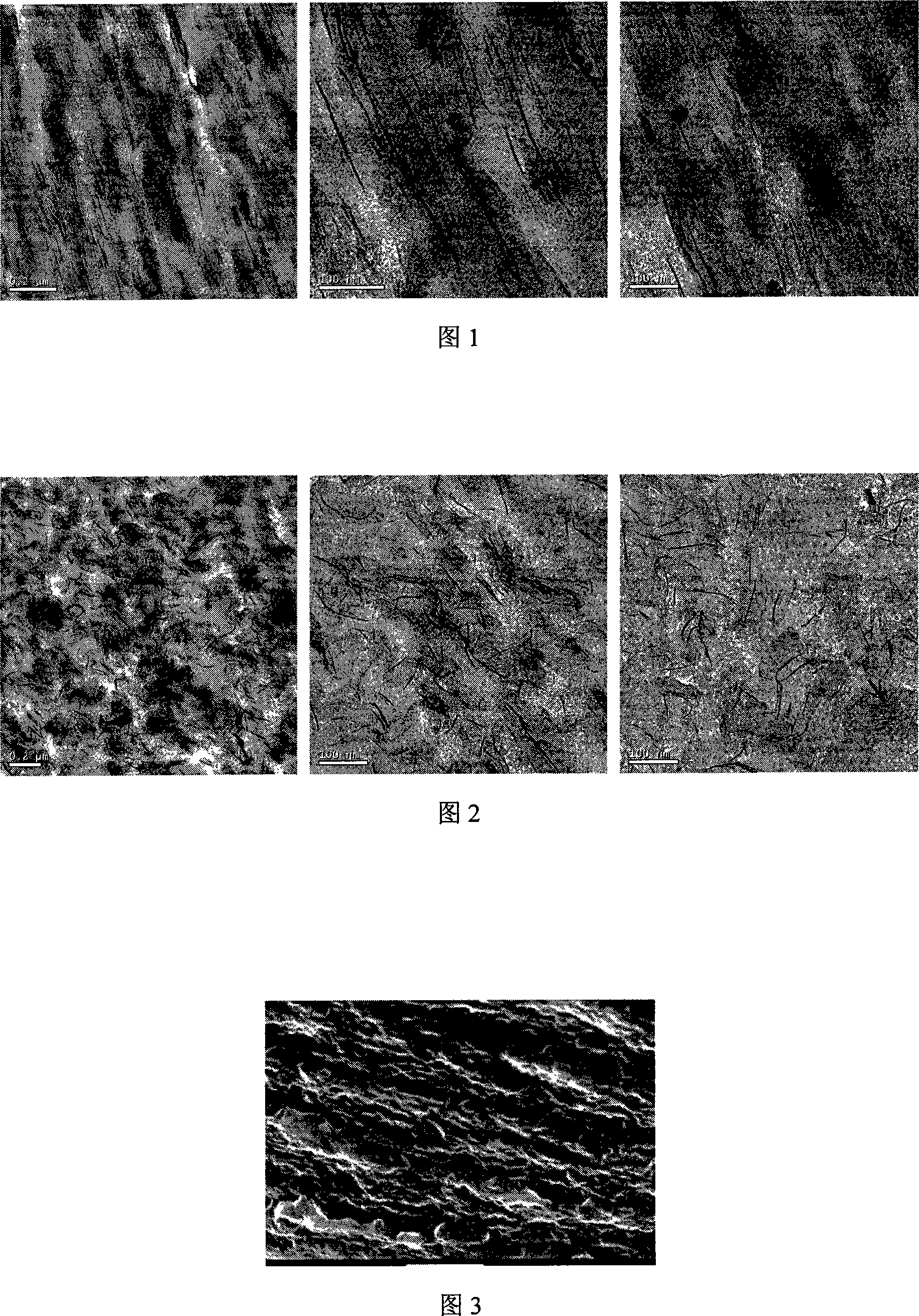

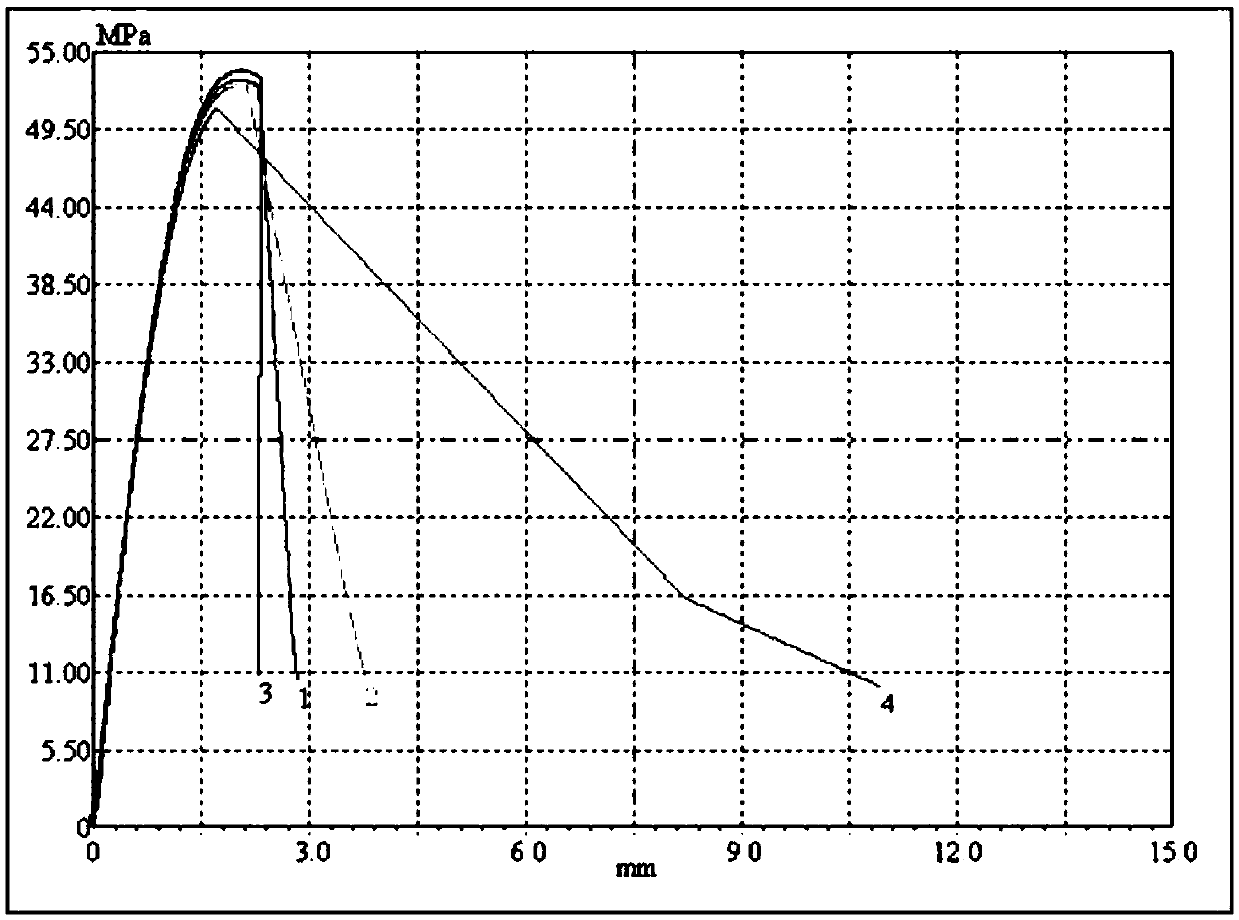

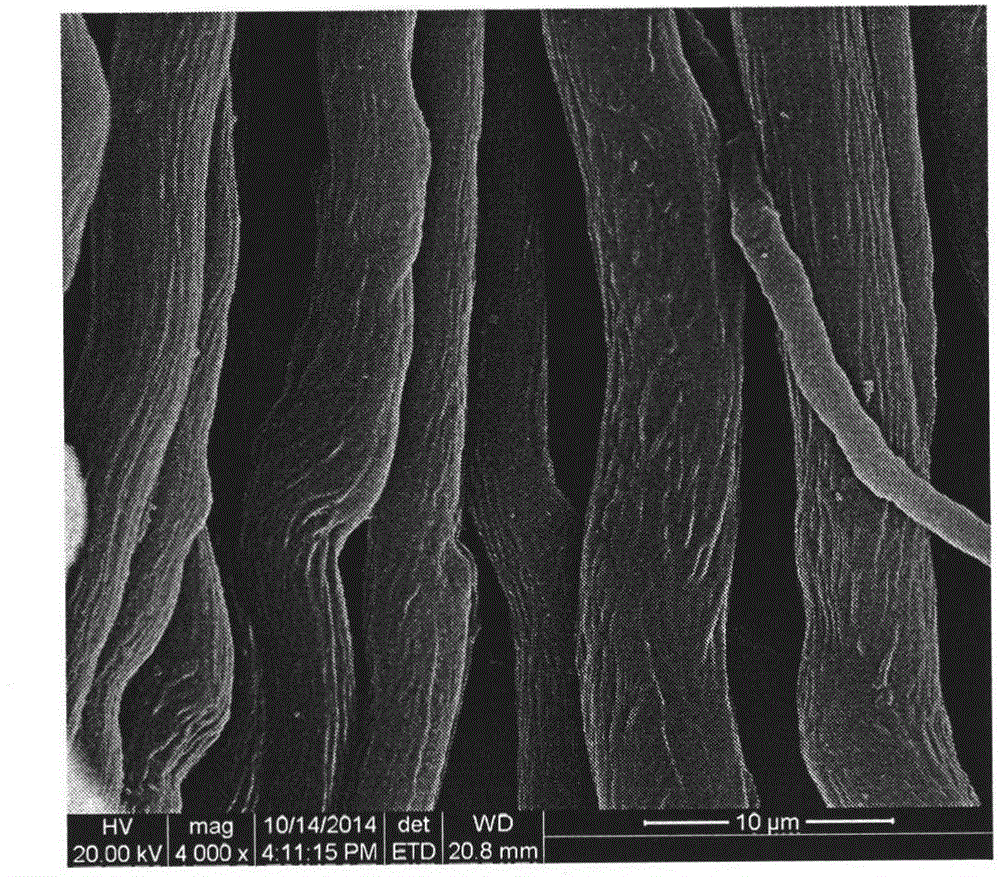

Montmorillonite layered nylon6/montmorillonite nano composite material and preparation thereof

The invention relates to a nanocomposite of nylon 6 / montmorillonite in the shape of a montmorillonite laminiplantation and a preparation method thereof. The nanocomposite is made up of 100 shares of nylon 6, 1 to 10 shares of modified montmorillonite and 0.1 to 1 share of antioxidizer; the nanocomposite is a stripping material obtained by melting intercalation. The nylon 6 / montmorillonite nanocomposite with special micro morphostructure is manufactured sequentially by realizing melting intercalation by means of twin-screw extrusion, by injection premolding, and by exerting high pressure from a flat vulcanizing machine with a temperature ranging between 20 DEG C and 100 DEG C thus producing solid flow. The montmorillonite, dispersing in polymeric matrix of the nanocomposite, is in a high parallel alignment. The nanocomposite is internally provided with micro laminated structure similar with the internal structure of seashell, and has larger elongation fracture tensile rate than common material of the same components. This is the first time to introduce bionics in macromolecule / montmorillonite nanocomposite.

Owner:DONGHUA UNIV

High-performance polylactic acid blow molding thin film and preparation method thereof

The invention relates to a high-performance polylactic acid blow molding thin film and a preparation method thereof, belongs to the technical field of biodegradable polymeric materials, and solves thetechnical problem of poor pure polylactic acid blow molding film-forming performance in the prior art. According to the high-performance polylactic acid blow molding thin film, polylactic acid with crystallization capacity serves as a raw material and is crystallized and blow-molded to form the thin film. The thin film can simultaneously have high strength, modulus, tensile breaking elongation and tearing strength in a horizontal direction and a vertical direction. The thin film overcomes the shortcoming of severe brittleness of the polylactic acid thin film and retains transparency and completely biodegradable environmental protection performance of the polylactic acid, so that a polylactic acid thin film product is widely used. Experimental tests show that the horizontal breaking elongation and the vertical breaking elongation of the thin film are 73% and 135%, and the horizontal tearing strength and the vertical tearing strength of the thin film reach up to 223KN / m and 183KN / m.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

PLA-PBSA blown film and preparation method thereof

InactiveCN108017887AIncreased tensile elongation at breakHigh tear strengthFlat articlesDiethylene glycol monobutyl etherPolymer science

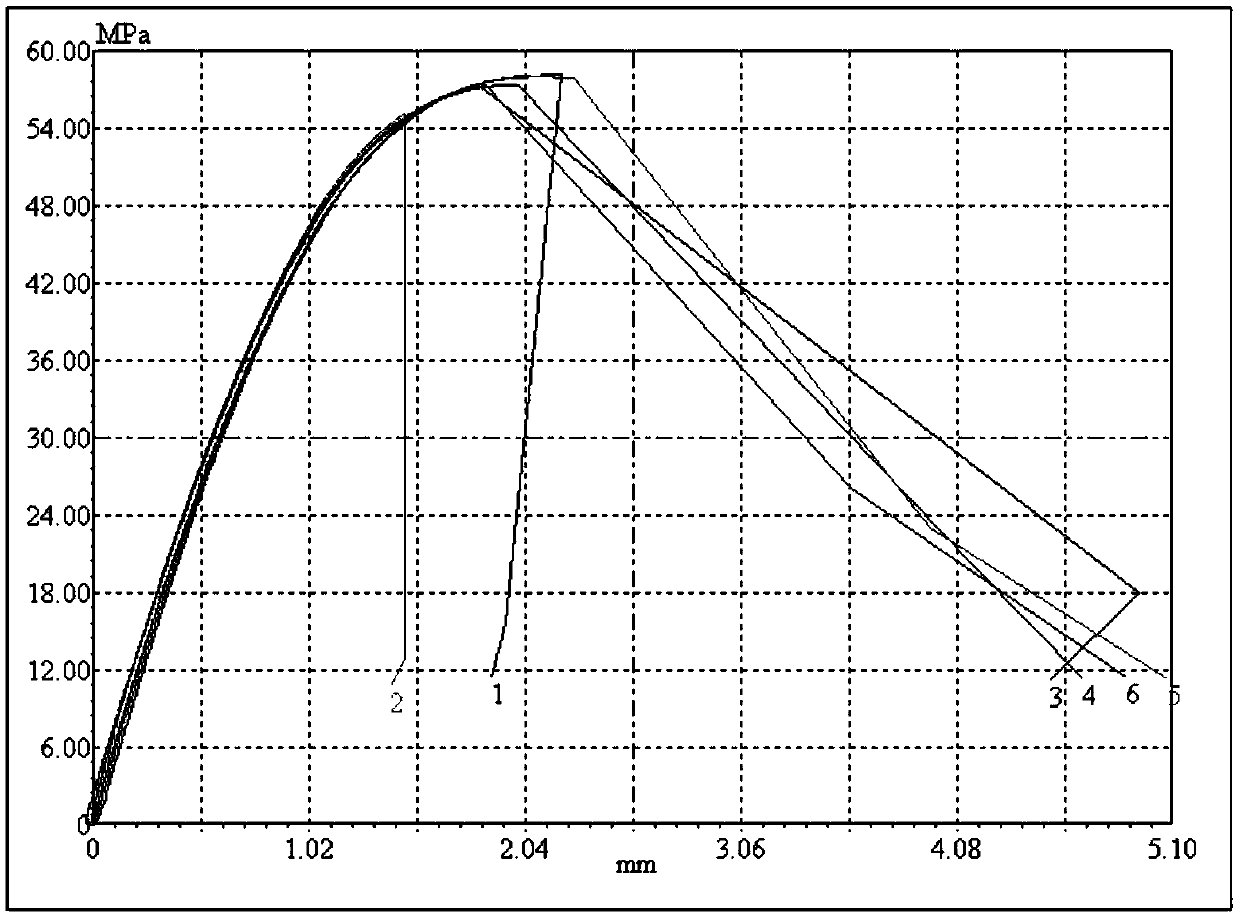

The invention provides a polylactic acid (PLA) / poly(butylene succinate-butylene adipate) (PBSA) blown film and a preparation method thereof. The blown film comprises a mixture of PLA, PBSA, plasticizer diethylene glycol monobutyl ether adipate, a lubricant, a plastic lubricant and an antioxidant. The PLA, the PBSA, the lubricant, the plastic lubricant and the antioxidant are first mechanically mixed into a premix, the premix is added through a feeding port of a twin-screw extruder, meanwhile the plasticizer diethylene glycol monobutyl ether adipate is metered and added in through a liquid feeding port of the twin-screw extruder, modified polylactic acid blown film special resin is prepared by melt-extruding, water-cooling, pelletizing and drying, the modified polylactic acid blown film special resin is blown by a film blowing machine to form a transparent tear-resistant biodegradable film. The PBSA, the plasticizers, the lubricant, the plastic lubricant and the antioxidant can effectively increase the tensile elongation at break and tear strength of polylactic acid films, maintains the transparency of the polylactic acid, and solves the brittleness defects of the polylactic acid films. The polylactic acid (PLA) / poly(butylene succinate-butylene adipate) (PBSA) blown film has good mechanical properties and excellent transparency, and can replace PE, PP, PVC and the like for preparation of films and sheets.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP +1

Method for producing high-purity micro-silica plastics anti-block agent

InactiveCN101423216AImprove the premium rateIncreased tensile yield strengthSilicon compoundsSilicic acidSilica gel

The invention provides a production method of a high-purity micro-powder silica plastic anti-block agent; high-purity water glass reacts with sulfuric acid to gain sodium sulfate and silicic acid; the sodium sulfate is washed by water to gain silicious colloid which is centrifugally dehydrated, and dried by micro-wave to gain pure SiO2 powder which is crushed by an airflow crusher to gain the high-purity micro-powder silica plastic anti-block agent. The production method of the high-purity micro-powder silica plastic anti-block agent has simple process, high purity and small particle size of the gained products, is suitable for the production and use of top-class plastic films, can obviously improve the top-grade product rate, reduces the cost of the product, improves the tensile yielding strength of the film to 13.5-14.5MPa generally, improves the tensile breaking elongation rate of the film to about 1400 percent, and obviously reduces the fish eye number of the film.

Owner:山西天一纳米科技股份有限公司

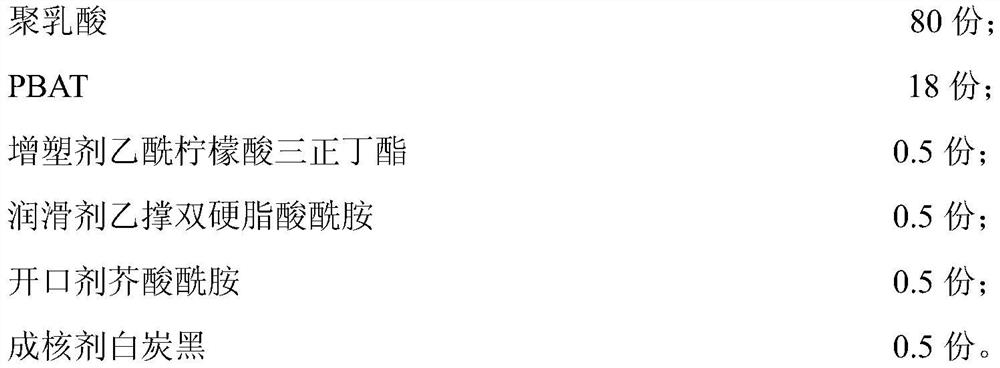

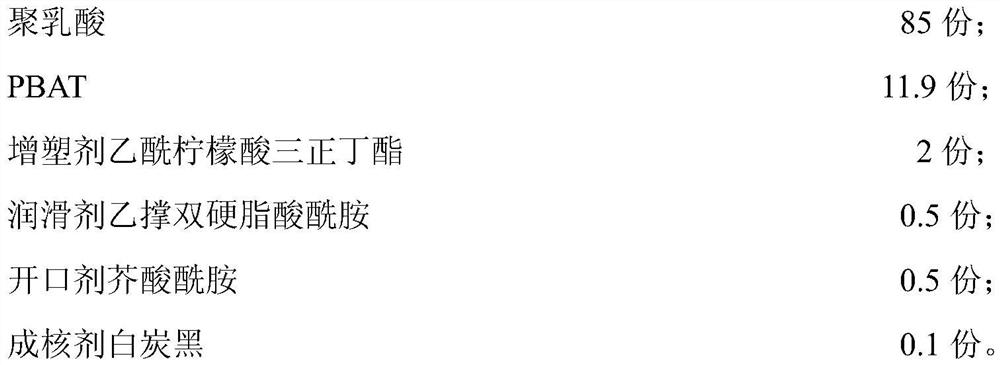

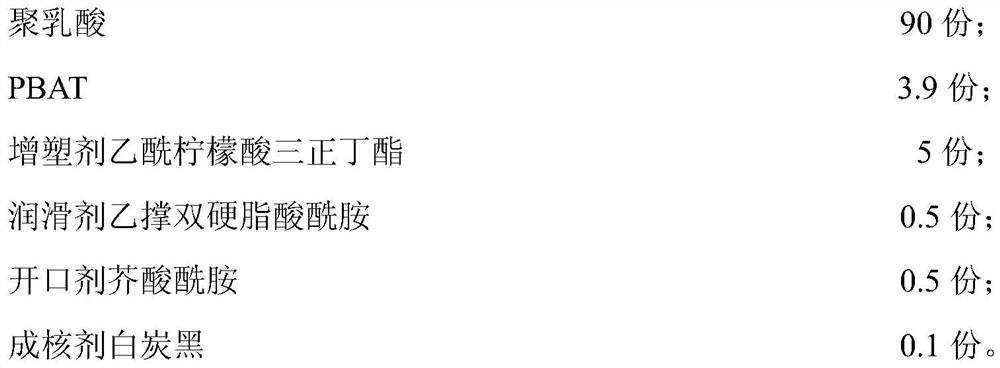

Preparation method of high-transparency easy-to-tear polylactic acid blown film

PendingCN111944287AIncreased tensile elongation at breakSolve serious brittle defectsTensile fractureCarbon black

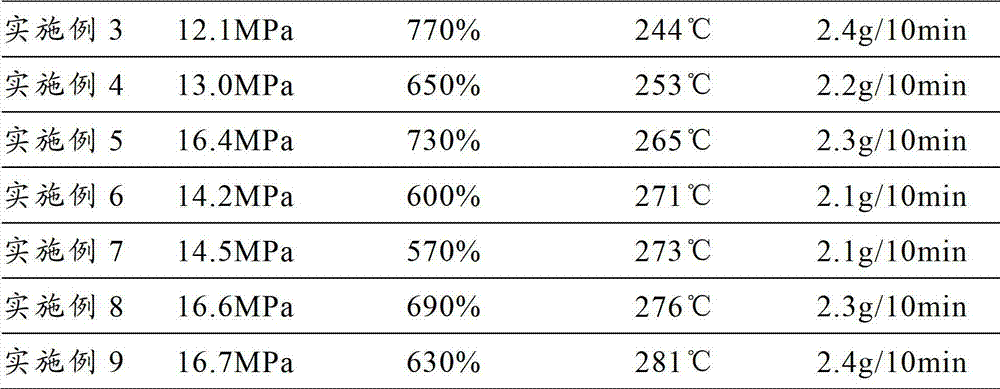

The invention provides a preparation method of a high-transparency easy-to-tear polylactic acid blow-molded film. The high-transparency easy-to-tear polylactic acid blow-molded film is composed of a mixture of polylactic acid (PLA), polyterephthalic acid-adipic acid-butanediol ester (PBAT), a plasticizer acetyl tributyl citrate, a lubricant ethylene bisstearamide, an opening agent erucyl amide anda nucleating agent white carbon black. The preparation method comprises the following steps: weighing PLA, PBAT, a plasticizer, a lubricant, an opening agent and a nucleating agent in proportion, adding into a mixer, uniformly mixing, adding from a feeding hole of a double-screw extruder, carrying out melt extrusion, water cooling, pelletizing and drying to obtain special modified polylactic acidfilm-blowing resin, and carrying out water cooling blow molding film formation by a film blowing machine through a down-blowing method to obtain the high-transparency easily-torn polylactic acid blow-molded film. According to the invention, the PBAT, the plasticizer, the lubricant, the opening agent and the nucleating agent have a synergistic effect, so that the tensile elongation at break of thepolylactic acid film can be effectively improved, the polylactic acid film has high transparency, the flat wrinkle-free easy-to-tear high-transparency complete biodegradable film is obtained, the tensile strength is as high as 54.6 MPa, and when the thickness of the film is 0.025 mm, the light transmittance reaches 94% or above and the haze reaches 5.3%; and the film has good mechanical properties and excellent transparency, and can replace PE, PP, PVC and other films.

Owner:江苏碧升生物新材料有限公司

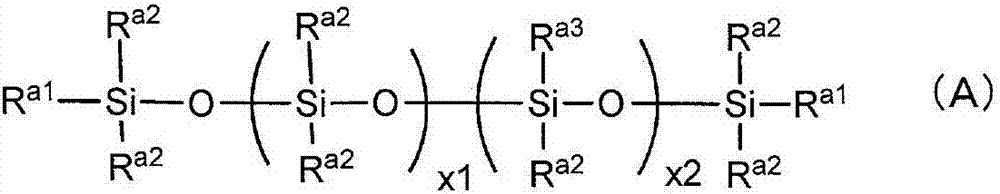

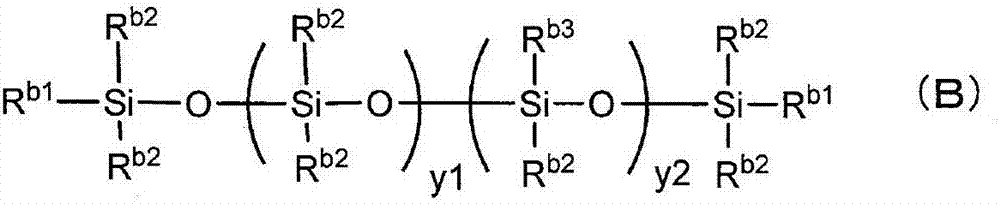

Soluble terminally modified imide oligomer using 2-phenyl-4,4'-diaminodiphenyl ether, varnish, cured product thereof, imide prepreg thereof, and fiber-reinforced laminate having excellent heat resistance

InactiveCN102143989AHigh strengthIncreased tensile elongation at breakOrganic chemistryWoven fabricsImidePolymer science

Disclosed is a novel terminally modified imide oligomer having excellent solubility in organic solvents, excellent solution storage stability, and excellent molding properties such as low melt viscosity. Also disclosed are a varnish obtained by dissolving the terminally modified imide oligomer in an organic solvent; a cure product obtained by using the terminally modified imide oligomer and having excellent thermal and mechanical characteristics such as heat resistance, elastic modulus, tensile strength at break and tensile elongation at break; a prepreg; and a fiber-reinforced laminate. The soluble terminally modified imide oligomer is represented by general formula (1). In the formula, R1 and R2 each represents a divalent aromatic diamine residue; R3 and R4 each represents a tetravalentaromatic tetracarboxylic acid residue; R5 and R6 each represents a hydrogen atom or a phenyl group, with R5 or R6 being a phenyl group; m and n satisfy the following relations: m >= 1, n >= 0, 1 <= m+ n <= 20 and 0.05 <= m / (m + n) <= 1; and the repeating units may be arranged in blocks or randomly.

Owner:KANEKA CORP +1

Processing method for supra-macromolecule polyethylene composite pipe

ActiveCN103587121AImprove wear resistanceGood self-lubricating performanceAntioxidantAging resistance

The invention discloses a processing method for a supra-macromolecule polyethylene composite pipe. The processing method comprises the following steps of (1) uniformly mixing supra-macromolecule polyethylene resin, graphite, polyethylene wax and an antioxidant which serve as raw materials, adding the uniformly mixed raw materials into a material barrel of a screw extruder, and manufacturing a pipe with the same shape as that of a neck mold with a certain shape through the neck mold on the screw extruder under the rotary extrusion action of a screw, wherein the pipe passes through a sizing device and a cooling device and is cooled to be hardened and sized by a water-oil cooling mode; continuously and uniformly leading out a product during cooling after a product plastic piece is extruded from the neck mold, cutting the cooled and sized product through a cutting device, and inspecting the cut product, wherein the qualified product is a supra-macromolecule polyethylene pipe; (2) cutting and posttreating the supra-macromolecule polyethylene pipe, and putting the post-treated supra-macromolecule polyethylene pipe into a steel pipe to obtain the supra-macromolecule polyethylene composite pipe. According to the processing method, the technology is simple; the supra-macromolecule polyethylene composite pipe is easy to produce and manufacture; the manufactured pipe is high in abrasion resistance, self-lubrication property and intensity, stable in chemical property and high in aging resistance.

Owner:YANGZHOU JUYE WEAR-RESISTANT COMPOSITE MATERIAL CO LTD

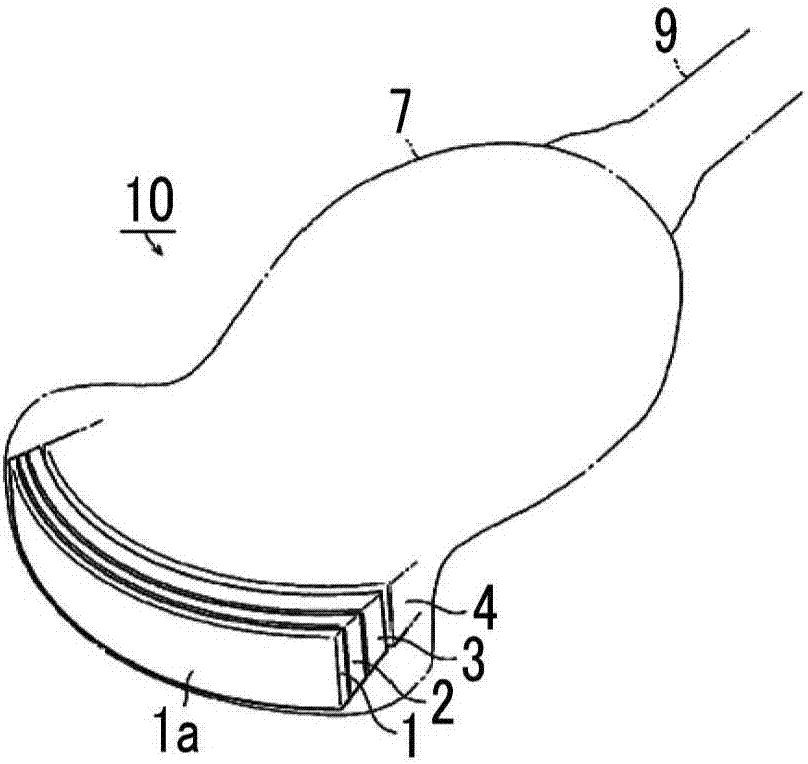

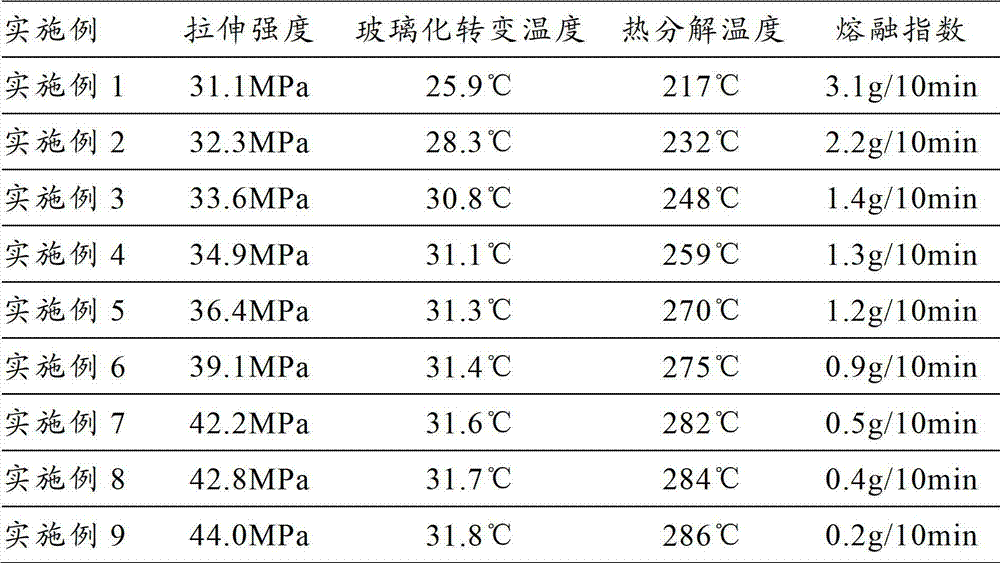

Composition for acoustic wave probe, silicone resin for acoustic wave probe using same, acoustic wave probe, ultrasonic probe, acoustic wave measurement device, ultrasonic diagnostic device, photoacoustic wave measurement device, and ultrasonic endoscope

ActiveCN107005770AHigh hardnessHigh mechanical strengthUltrasonic/sonic/infrasonic diagnosticsSurgeryYTTERBIUM OXIDEMeasurement device

Provided is a composition for an acoustic wave probe, a silicone resin for acoustic wave probe using same, an acoustic wave probe, an ultrasonic probe, an acoustic wave measurement device, an ultrasonic diagnostic device, a photoacoustic wave measurement device, and an ultrasonic endoscope, said composition containing a polysiloxane mixture comprising: a polysiloxane having a vinyl group; a polysiloxane having at least two Si-H groups in the molecular chain thereof; and at least one type of inorganic compound particles. The inorganic compound particles have an average primary particle size of less than 25 nm, and are selected from the group consisting of magnesium oxide, titanium oxide, iron oxide, zinc oxide, zirconium oxide, barium oxide, tin oxide and ytterbium oxide. With this composition for an acoustic wave probe, the silicone resin for acoustic wave probe using same, the acoustic wave probe, the acoustic wave measurement device and the ultrasonic diagnostic device, it is possible to greatly enhance the hardness and mechanical strength (tensile fracture strength, tensile fracture elongation, tear strength and wear resistance) of silicone resins while keeping acoustic wave attenuation low. Moreover, the present invention is capable of enhancing the sensitivity of ultrasonic probes, photoacoustic wave measurement devices and ultrasonic endoscopes using a cMUT as a transducer for ultrasonic diagnosis.

Owner:FUJIFILM CORP

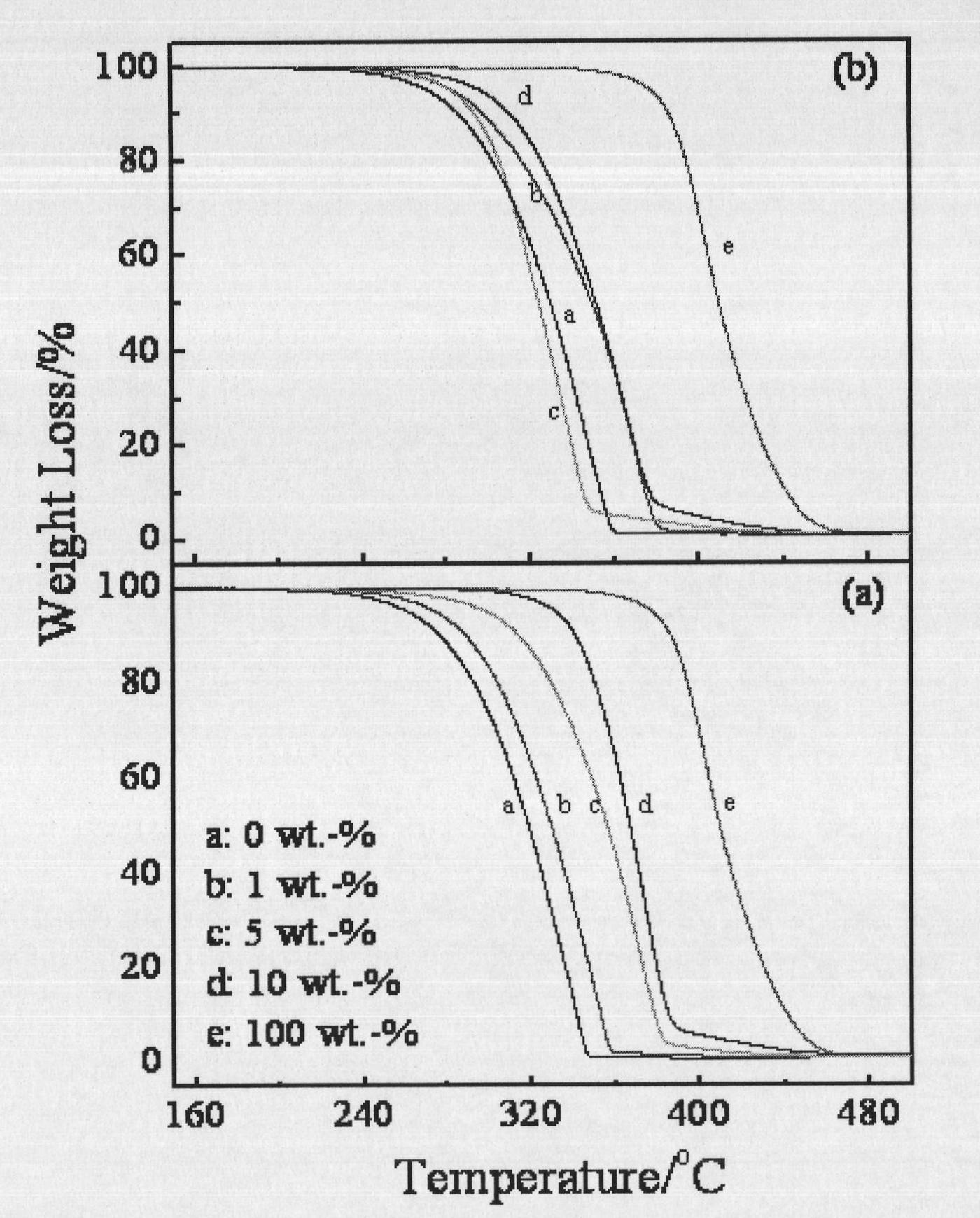

Modified poly (propylene carbonate) and preparation method thereof

The invention provides modified poly (propylene carbonate), which comprises a cross-linked poly (propylene carbonate) with polyphenyl polymethylene polyisocyanates as a cross-linking agent, as well as a polymer of hexanedioic acid and 1,2-propylene glycol ester, wherein the mass ratio of poly (propylene carbonate) to the polyphenyl polymethylene polyisocyanates is 100:(0.1-2), and the mass ratio of the cross-linked poly (propylene carbonate) to the polymer of hexanedioic acid and 1,2-propylene glycol ester is 100:(5-20). A preparation method of the modified poly (propylene carbonate) comprises the following steps: blending and extruding the poly (propylene carbonate) and the polyphenyl polymethylene polyisocyanates to obtain the cross-linked poly (propylene carbonate); and blending and extruding the cross-linked poly (propylene carbonate) and the polymer of hexanedioic acid and 1,2-propylene glycol ester to obtain the modified poly (propylene carbonate). The modified poly (propylene carbonate) provided by the invention is good in thermal stability, high in tensile elongation at break, good in transparency and capable of being biodegraded completely.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Production process of nanometer modified superhigh-molecular-weight polyethylene wear-resisting pipe

The invention discloses a production process of a nanometer modified superhigh-molecular-weight polyethylene wear-resisting pipe, comprising the steps of (1) preparing raw materials in mass percentage, uniformly mixing 74-90% of superhigh-molecular-weight polyethylene resin, 3-5% of nanometer laminated silicate, 2-8% of Si3N4, 3-10% of polyethylene wax and 2-3% of graphite; (2) adding material, performing reacting, extruding and molding; (3) cooling, shaping and drawing; (4) cutting; (5) post treating. The flowing property of the superhigh-molecular-weight polyethylene is improved due to the adding of nanometer laminated silicate and Si3N4, so that the mechanical property of the product is improved and the wear resistance of the product can be improved by more than 40%.

Owner:YANGZHOU JUYE WEAR-RESISTANT COMPOSITE MATERIAL CO LTD

Method for producing unsaturated polyester resin by using polycarboxylic anhydride by-product

The invention discloses a method for producing an unsaturated polyester resin by using a polycarboxylic anhydride by-product, comprising the following steps: preparing raw materials including 5-20 parts of a polycarboxylic anhydride by-product, 0-10 parts of phthalic anhydride, 16-22 parts of maleic anhydride or fumaric acid and 30-38 parts of dihydric alcohol; preparing unsaturated polyester fromthe raw materials by an esterification polycondensation method; diluting unsaturated polyester and styrene to obtain liquid-state unsaturated polyester resin. The unsaturated polyester resin producedby the method keeps relevant properties equivalent to the existing similar products, and the mechanical properties are at least equivalent after curing of the resin, and especially the tensile elongation at break, the heat distortion temperature of the load and Barcol hardness are all promoted. By reusing waste polycarboxylic anhydride by-product to partly or completely replace phthalic anhydride, resource utilization is improved, and cost of raw material, operating cost of manufacturing enterprises and other cost are reduced. Production efficiency is high, and energy consumption is also reduced to some extent.

Owner:ZHENJIANG UNION CHEM IND

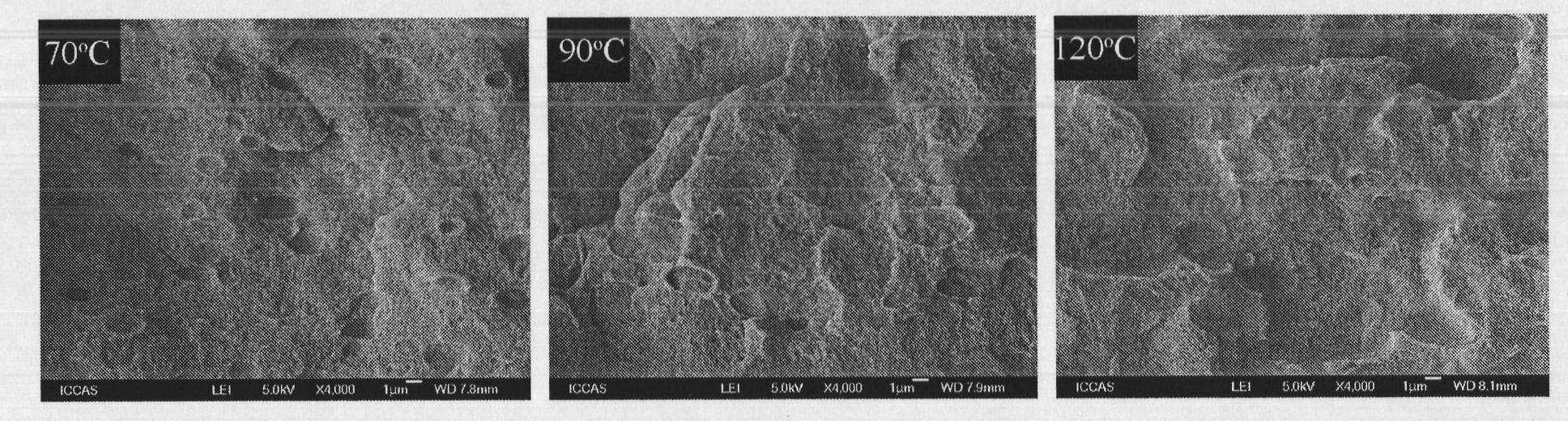

Modified polylactic acid, preparation method and application thereof

InactiveCN102250451AGood compatibilityWide variety of sourcesSurgeryProsthesisElastomerPolymer science

The invention discloses a modified polylactic acid (PLA), its preparation method and application. The preparation method of the modified polylactic acid comprises the steps of: reacting polylactic acid with epoxidized natural rubber (ENR) by a solution co-blending method or a melt extrusion method so as to obtain blends, annealing the blends, thus obtaining the modified polylactic acid. In the method, biodegradable polylactic acid is taken as the raw material, and the natural elastomer NR (natural rubber) or ENR is added through the solution co-blending method or melt extrusion method. By controlling the NR / ENR content and epoxidation degree, the melt extrusion temperature, the annealing temperature and annealing time, etc., the method adjusts the crystallinity, crosslinking degree and phase separation of PLA, so that the weakness of poor toughness of PLA is made up substantially, and the thermostability of PLA is improved. Thus, the processibility of PLA is improved. Characterized by simple process, easy operation and probable enforcement in production, the method provided in the invention provides a new choice for adjusting the properties of PLA.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Method for preparing silicon-containing micron-fiber-toughened PHBV composite material

The invention discloses a method for preparing a silicon-containing micron-fiber-toughened PHBV composite material and belongs to the field of natural polymer material-toughened biodegradable plastics. The method comprises the following steps of dispersing a silicon-containing raw material in an aqueous sodium of sodium hydroxide with mass fraction of 10-35%, holding the temperature in a temperature range of 20-40 DEG C for 4-8 hours, diluting, filtering, adding 1-5% of a dispersant, carrying out low-pressure crushing by a homogenizing apparatus at a homogenizing pressure of 100-200bar, cycling for 6-15 times, separating and carrying out vacuum drying treatment to obtain silicon-containing micron-fiber; carrying out melt blending on silicon-containing micron-fiber, poly(beta-hydroxybutyrate-beta-hydroxyvalerate) (PHBV) at a mass ratio of (1:10)-(1:25), carrying out extrusion molding and granulating to prepare the silicon-containing micron-fiber-toughened PHBV composite material. By the method, when PHBV is toughened by virtue of the plant fiber in the prior art, the problems that the plant fiber needs to be prepared into nanoscale, a large amount of chemicals and power are consumed and the process is complex can be solved. According to the method for preparing the composite material, the agricultural residues can be utilized and thus the environment friendliness is achieved.

Owner:NANJING FORESTRY UNIV

Polyethylene/ polypropylene/ polypropylene three-layer co-extrusion upward bowing film and preparation method thereof

InactiveCN105150648AIncreased tensile elongation at breakHigh tear strengthSynthetic resin layered productsLaminationPolypropyleneBinding force

The invention provides a polyethylene / polypropylene / polypropylene three-layer co-extrusion upward bowing film and a preparation method thereof and belongs to the technical field of high molecular materials. The polyethylene / polypropylene / polypropylene three-layer co-extrusion upward bowing film and the preparation method solve the problems that existing PP melt is low in intensity, and it is difficult to keep transparency after blending and toughening are conducted. The inner layer and the outer layer of the upward blowing film are ethylene blender, and the middle layer is propylene random copolymer. The invention further provides the preparation method of the polyethylene / polypropylene / polypropylene three-layer co-extrusion upward bowing film. The propylene random copolymer is selected to serve as the middle layer of the upward blowing film, the tensile elongation yield and the tearing strength of the PP film can be effectively improved, proper models of PE and PP are blended to serve as the inner layer and the outer layer, the compatibility of the middle layer of the PP film and the PE of the inner layer and the outer layer can be increased, the binding force among layers is improved, the stripping phenomenon among layers is avoided, the transparency of PP can be kept, and the hot-shrinkage rate of multiple layers of films is raised.

Owner:公主岭华美塑料制品有限公司

Method for producing polyurethane toughness-reinforcing cast form nylon composite material

InactiveCN100526383CHigh mechanical strengthIncreased tensile elongation at breakNylon materialToughness

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Polyester-polyamide copolymer and synthetic preparation method thereof

The invention relates to a polyester-polyamide copolymer and a synthetic preparation method thereof. The polyester-polyamide copolymer is composed of polyester and nylon 6 with relative viscosity of 1.5-2.2, intrinsic viscosity thereof is 0.80-0.90dL / g, tensile strength thereof is 40-80MPa, elongation at break thereof is 10-80%, content of a terminal carboxyl group thereof is less than 18mol / t and diglycol content thereof is less than 1.0%. In the invention, the nylon 6 with the relative viscosity of 1.5-2.2 is added during the polyester polymerization process, so that a polyester prepolymer performs copolymerization with the nylon 6 to obtain a polyester copolymer with an acid dyeable amide group which has affinity to acid dyes, thus further processing and preparing polyester chips and fibers, which can be subject to acid dyeing; and the method thoroughly solves the problem of poor compatibility between the nylon and the polyester, and overcomes the problems of low spinning strength,poor dyeing uniformity and easy occurrence of color difference of the copolymer obtained in the prior art.

Owner:CHINESE TEXTILE ACAD

Polylactic-acid block copolymer and preparation method thereof

ActiveCN100535033CLow costAvoids a host of problems associated with ring-opening polymerization processesPolymer scienceDiol

A polylactic acid block copolymer disclosed in the present invention is characterized in that the copolymer is composed of hydroxyl-terminated polylactic acid with an intrinsic viscosity of 0.05 to 0.5 dL / g and aliphatic polylactic acid with an intrinsic viscosity of 0.1 to 1.0 dL / g. Ester diol is prepared by melt reaction in the presence of chain extender diisocyanate. The intrinsic viscosity of the copolymer is 0.7-2.5dL / g, the tensile strength is 10-40MPa, and the elongation at break is 100-800 %. The invention also discloses a preparation method of the copolymer. Since the hydroxyl-terminated polylactic acid prepolymer used in the preparation of the copolymer of the present invention is prepared by melt polymerization, a series of problems caused by the ring-opening polymerization process are avoided, and the product is not only low in cost, but also has It has the advantages of good toughness, high tensile strength, high tensile elongation at break, and good processing performance, and it has laid the foundation for its use as a general-purpose polymer material. The method of the invention is simple, and the reaction is easy to control, so large-scale and continuous industrial production can be realized.

Owner:SICHUAN UNIV

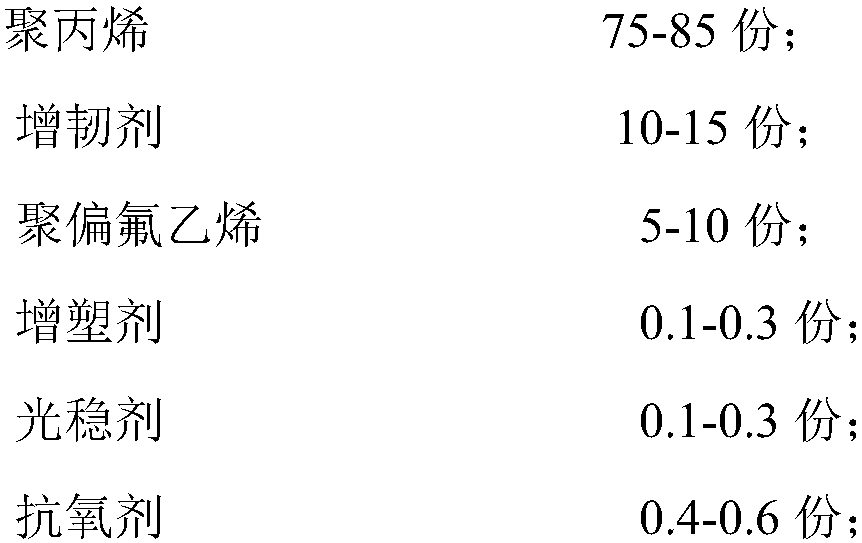

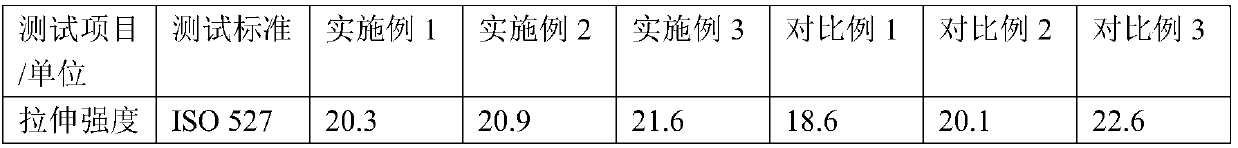

Scratch-resistant impact-resistant polypropylene material and preparation method thereof

ActiveCN110655710AIncreased tensile elongation at breakHigh tensile strengthPolymer scienceAntioxidant

The invention discloses a scratch-resistant impact-resistant polypropylene material and a preparation method thereof. The scratch-resistant impact-resistant polypropylene material is prepared from thefollowing components: polypropylene, a toughening agent, polyvinylidene fluoride, a plasticizer, a light stabilizer and an antioxidant; the polypropylene is polypropylene random copolymer, the content of polyethylene in the polypropylene random copolymer is greater than or equal to 7%, and the tensile elongation at break is greater than or equal to 350%. According to the scratch-resistant impact-resistant polypropylene material prepared by the preparation method disclosed by the invention, the polypropylene random copolymer material with high ductility and low crystallinity is used, so that the material has excellent shearing-rebounding effect, and a certain amount of the compounded toughening agent is added, so that the toughness of the material is further improved, and the scratch depthof the material when the material is scratched is reduced; meanwhile, the polyvinylidene fluoride component is added into the material, so that the surface smoothness of the material is improved, thefrictional resistance is reduced, and the scratch resistance of the material is improved.

Owner:HEFEI GENIUS NEW MATERIALS

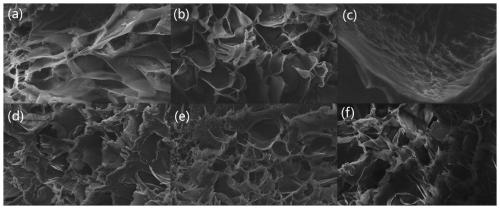

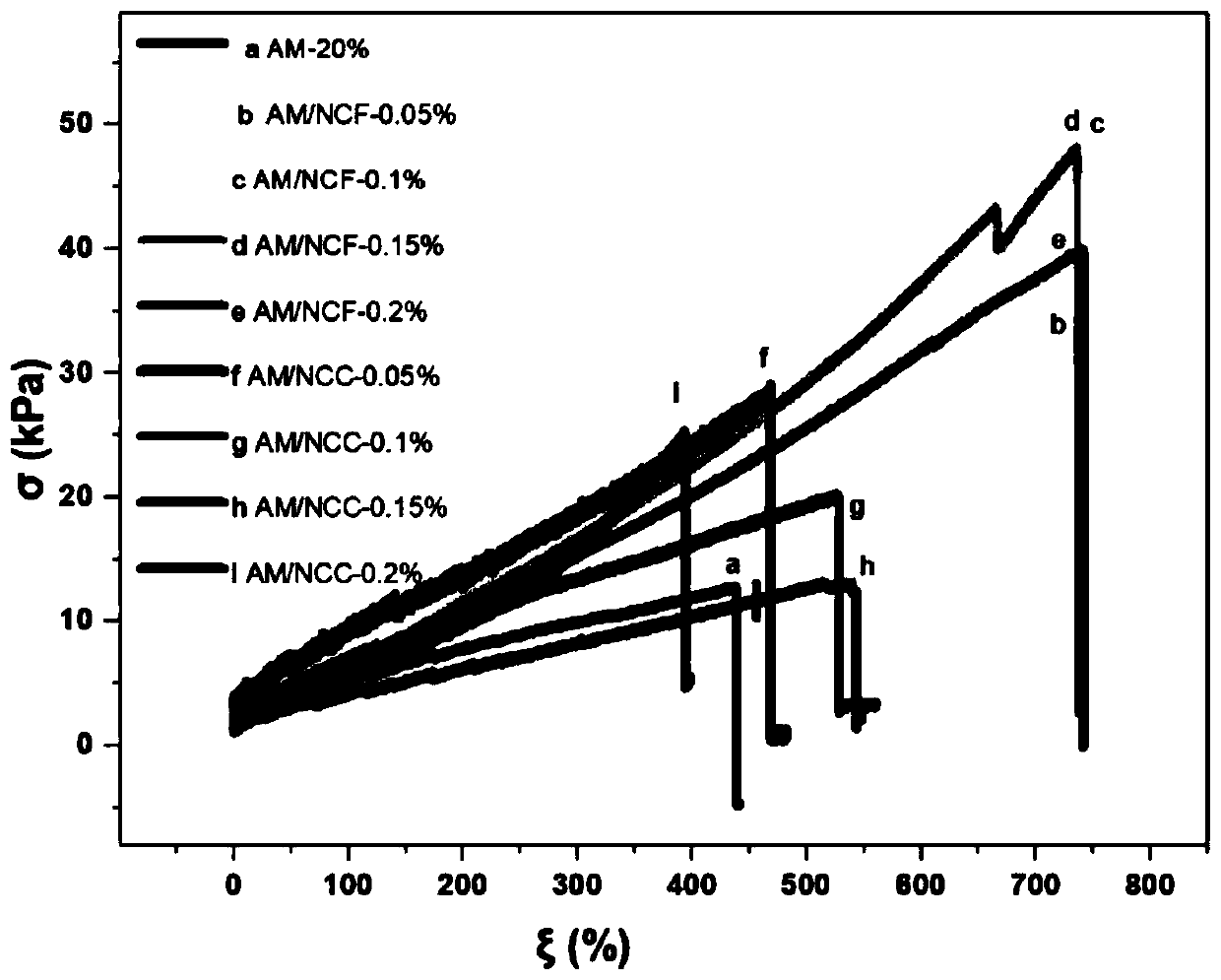

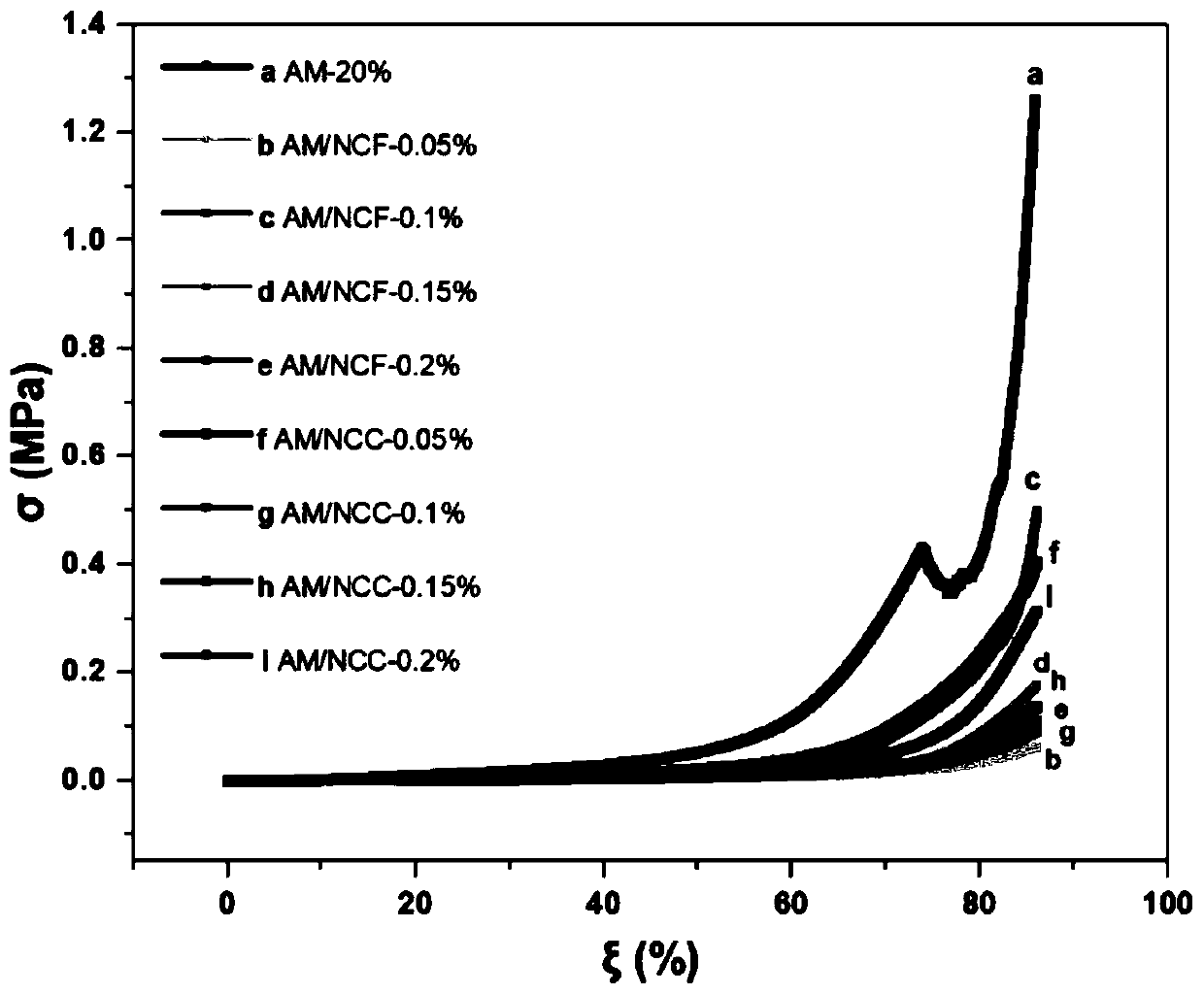

High-elasticity and high-toughness gel micro-nano particle and preparation method thereof

ActiveCN111116827AImprove network structure strengthPoor inhibitory stabilityPolymer chemistryMonomer

The invention provides a high-elasticity and high-toughness gel micro-nano particle and a preparation method thereof. The high-elasticity and high-toughness gel micro-nano-particle is prepared from, by weight, 5 to 20 parts of a monomer, 0.05 to 0.2 part of nano-cellulose, 0.015 to 0.6 part of a cross-linking agent, 0.04 to 0.2 part of an initiator and 79 to 95 parts of deionized water. The invention further provides the preparation method of the high-elasticity and high-toughness gel micro-nano particle. The nano-cellulose is introduced into a gel network structure as a rigid unit of the gel,so the toughness of the gel is improved, and the contradiction between the elasticity and the viscosity of the gel is regulated; and the preparation process is simple and easy to operate, the cost islow, and the problems of low mechanical strength, poor stability, poor crack regulation and control capability and the like of a gel system are effectively solved.

Owner:SOUTHWEST PETROLEUM UNIV

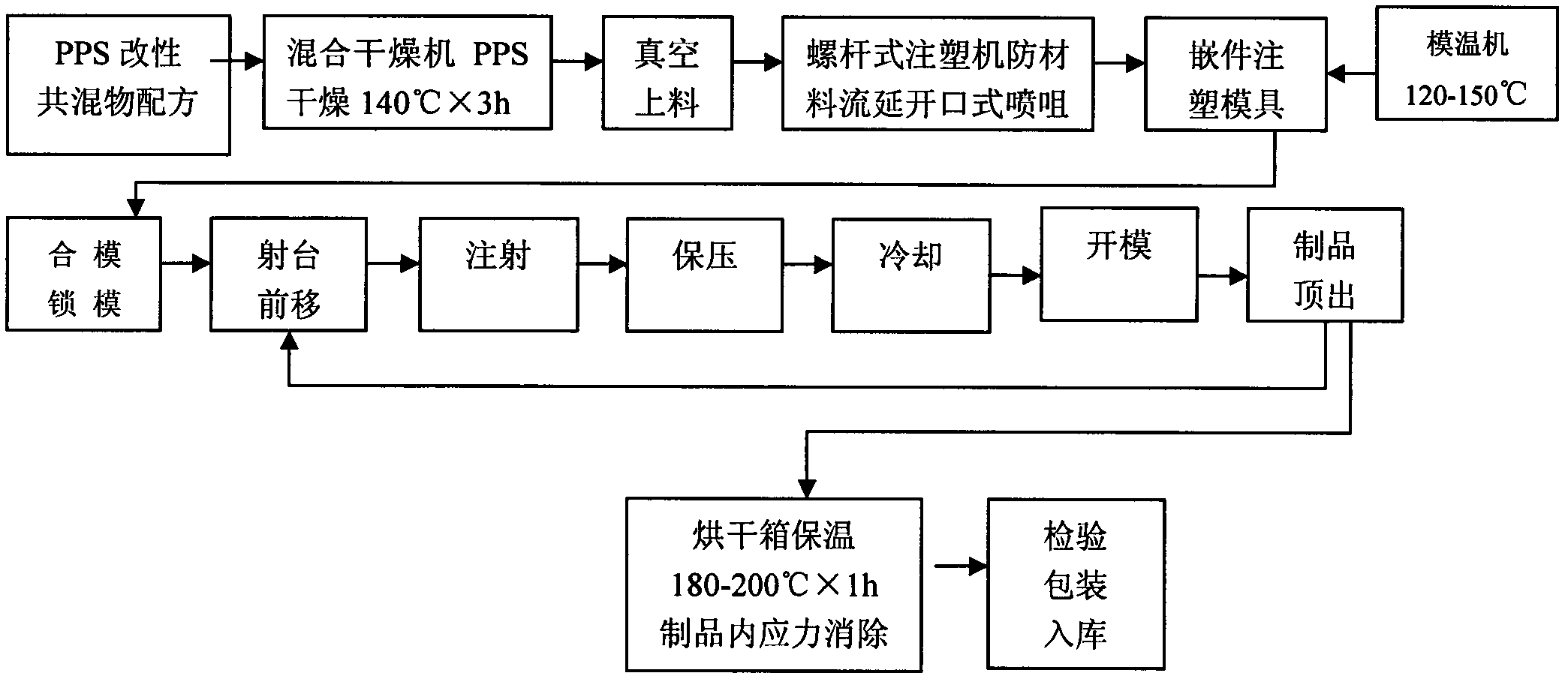

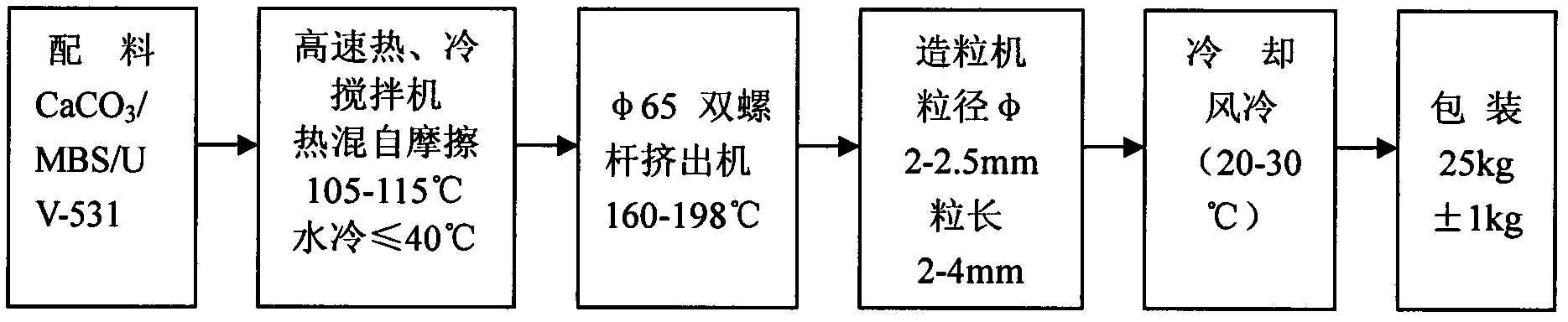

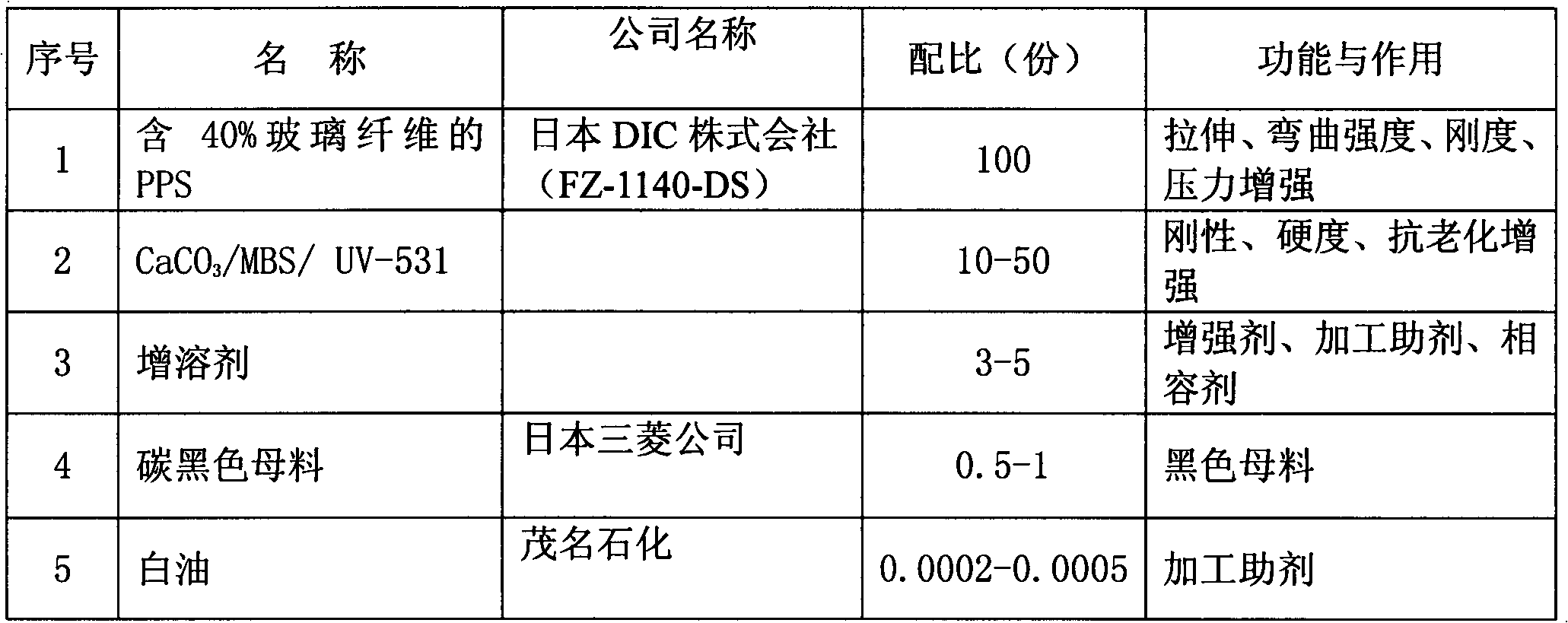

Composite modified polyphenylene sulfide material for water supply pipe insert and preparation method thereof

The invention discloses a composite modified polyphenylene sulfide material for a water supply pipe insert and a preparation method thereof. The material comprises the following ingredients: 100 weight parts of PPS containing 40% of glass fiber, 10-50 weight parts of CaCO3 / MBS / UV-531copolymer mixture, 3-5 weight parts of solubiliser, 0.5-1 weight parts of carbon black color masterbatch, and 0.0002-0.0005 weight parts of white oil. The preparation method comprises the following steps: drying a blend of PPS containing 40% of glass fiber, CaCO3 / MBS / UV-531copolymer mixture, carbon black color masterbatch, and white oil in a mixing drier, then putting the dried blend into an injection machine for injection molding to prepare the composite modified polyphenylene sulfide material for the water supply pipe insert. The prepared material of the invention has comprehensive performance and excellent quality, and can be applied in wide range of areas.

Owner:HUBEI FOR LONG PIPE TECH CO LTD

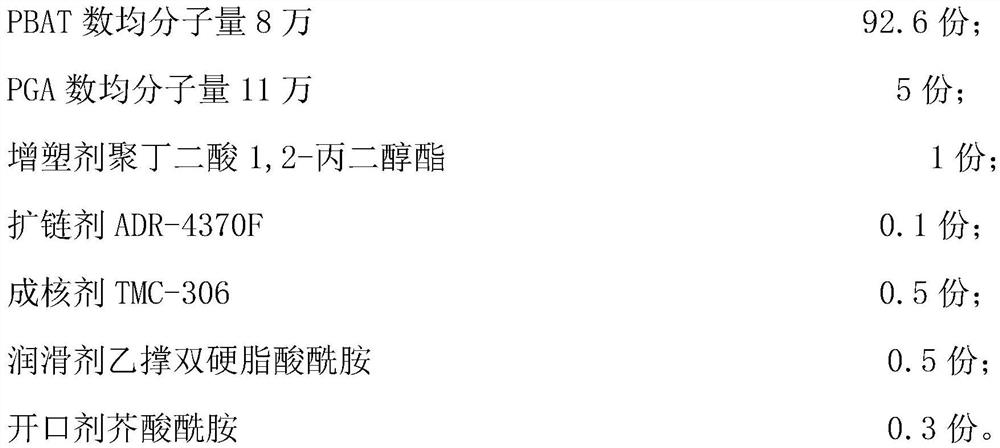

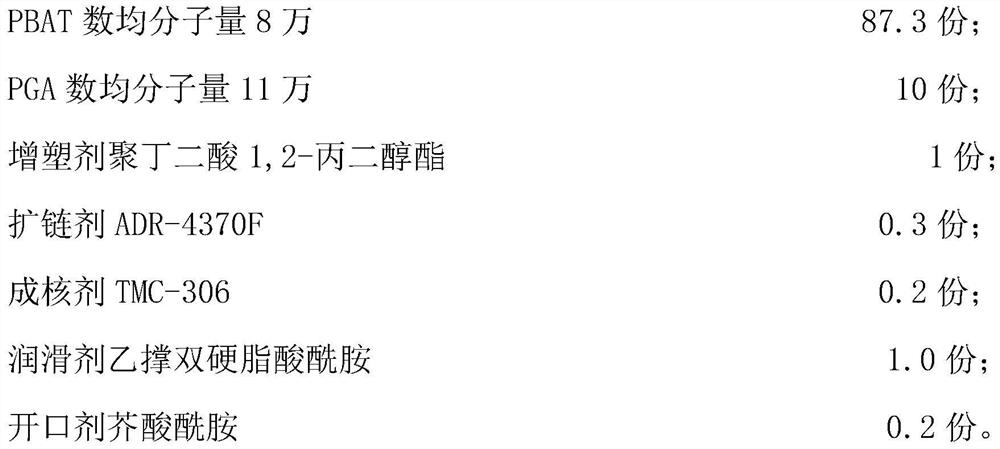

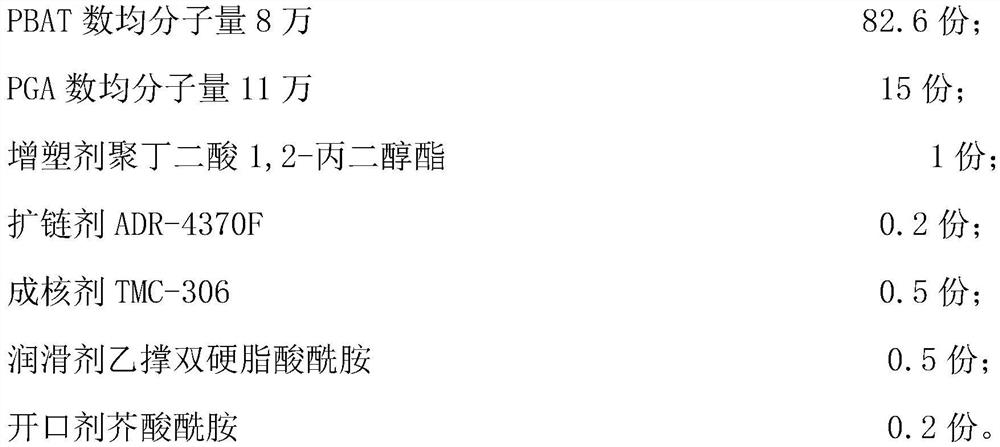

Completely biodegradable film and preparation method thereof

PendingCN113956630AImprove biodegradabilityIncreased tensile elongation at break and tear strengthPlasticizerStearic acid

The invention discloses a completely biodegradable film and a preparation method thereof. The completely biodegradable film is prepared from poly(butylene adipate-co-terephthalate), polyglycolic acid, a chain extender styrene-acrylic acid-glycidyl methacrylate copolymer, a plasticizer poly(succinic acid-1, 2, 4-trimethyl-1, 3-pentanedionate), a plasticizer poly (butylene adipate-co-butylene terephthalate), a plasticizer polysuccinic acid-1, 2-propylene glycol ester, a nucleating agent, a lubricant ethylene bisstearamide and an anti-blocking agent erucyl amide. The preparation method comprises the following steps: weighing the components according to the formula, mechanically mixing to form a premix, metering and adding the plasticizer polysuccinic acid-1, 2-propylene glycol ester from a liquid feeding port of a twin-screw extruder, carrying out melt extrusion, water cooling, pelletizing and drying to obtain special resin for film blowing, and carrying out blow molding film forming through a film blowing machine to obtain the completely biodegradable film. The chain extender, the nucleating agent and the plasticizer can effectively improve the tensile elongation at break and tear strength of the film and obviously improve the rheological behavior of the material, and the film has good mechanical properties and excellent biodegradability and can replace PE, PP, PVC and the like to prepare films and sheets.

Owner:江苏碧升生物新材料有限公司 +1

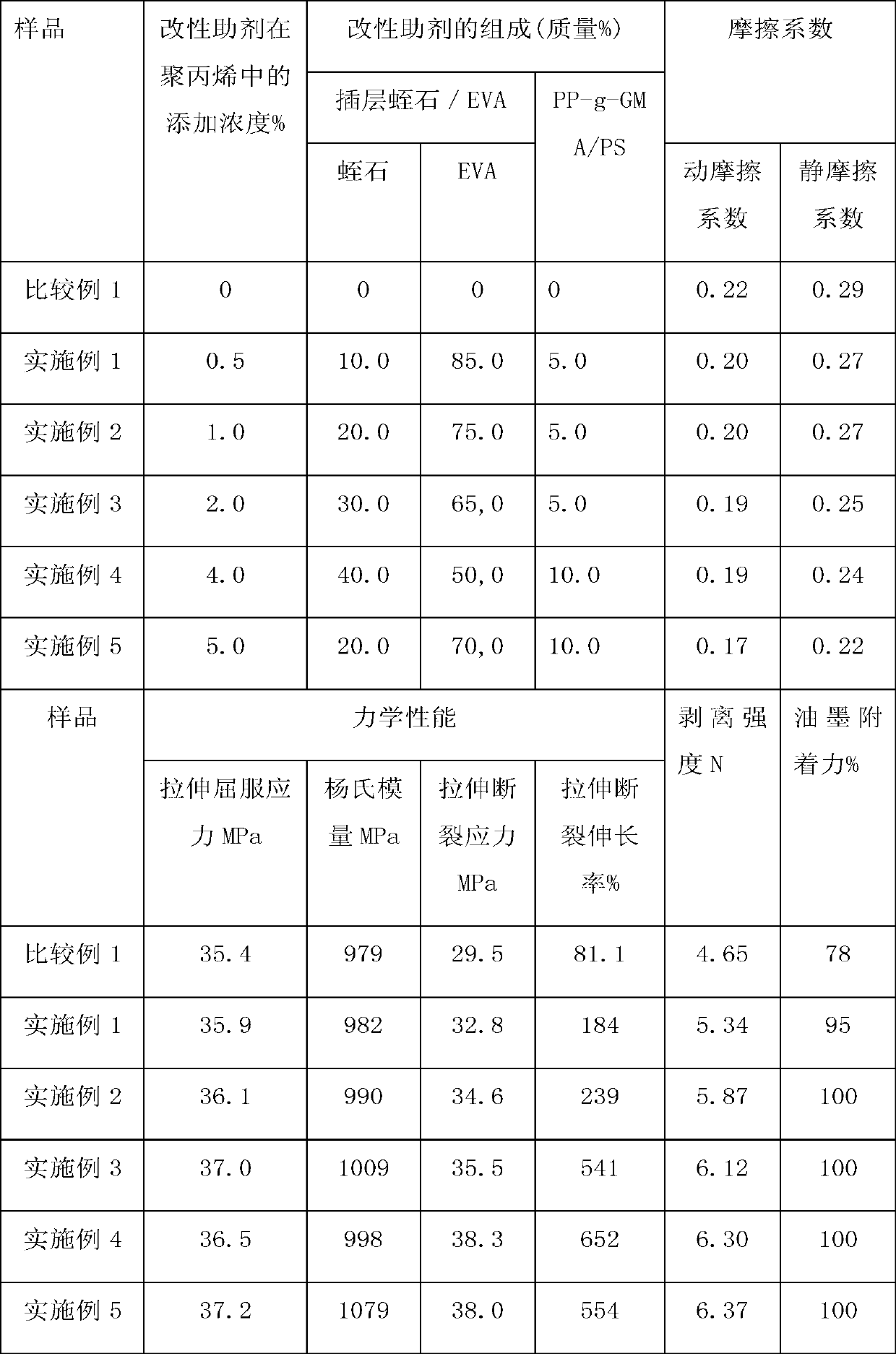

Modified auxiliary capable of improving printing compound performance of polypropylene film, preparation method and application

InactiveCN102964684AIncreased tensile yield stressHigh Young's modulusGlycidyl methacrylatePolymer science

The invention discloses a modified auxiliary capable of improving the printing compound performance of a polypropylene film, a preparation method and an application, belonging to the technical field of processing auxiliaries for polypropylene for food packaging. The auxiliary comprises the following components by weight percent: 10-40 wt% of flake-shaped vermiculite, 55-85 wt% of EVA (ethylene-vinyl acetate copolymer) and 5-15 wt% of polypropylene-grafted glycidyl methacrylate+styrene modified (PP-g-GMA / PS). The preparation method comprises the following steps of: dissolving the EVA resin by a solvent, and then intercalating while crushing the vermiculite and the EVA solution in a ball mill; and then adding the PP-g-GMA / PS, drying to obtain the auxiliary. The polypropylene film modified by the auxiliary disclosed by the invention is greatly improved in mechanical property, slightly increased in tensile yield stress and Young modulus, and greatly increased in tensile elongation at break; and moreover, the film is greatly enhanced in compound strength and ink adhesive force, and greatly reduced in frictional coefficient.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com