Completely-biodegradable polylactic acid-based blow molding thin film and preparation method thereof

A polylactic acid-based, biodegradable technology, applied in the field of PLA biodegradable film and its preparation, can solve problems such as unresearched PLA blown film, achieve great economic and social significance, maintain transparency, and have broad market prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

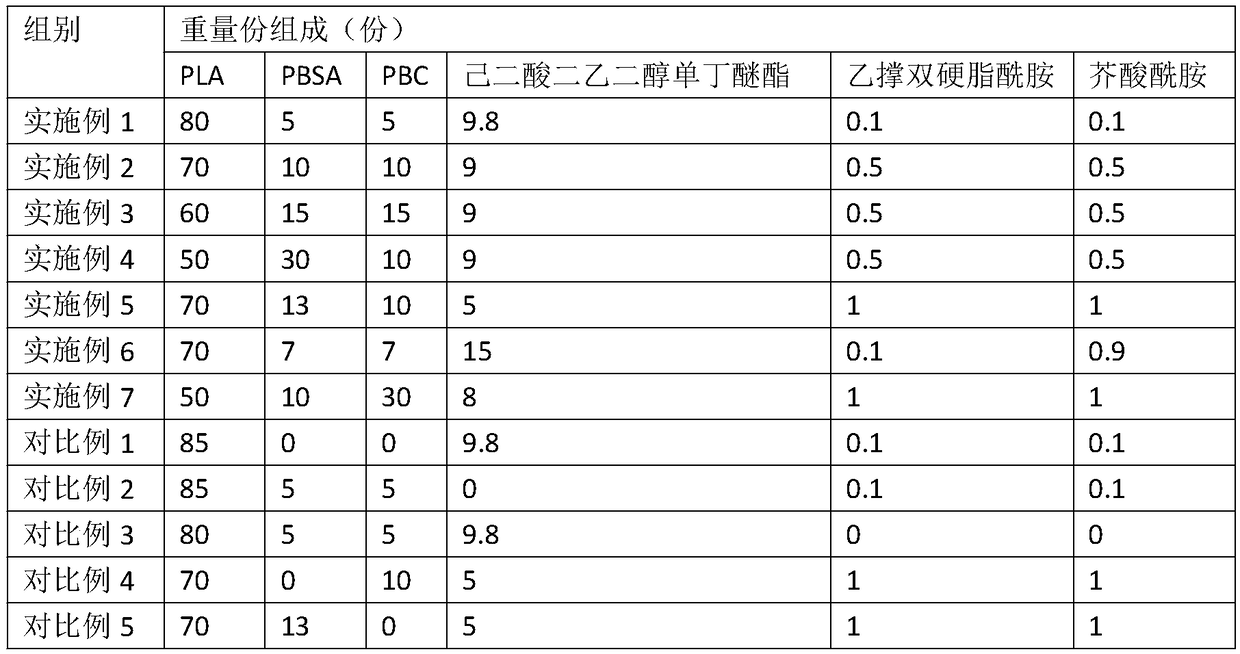

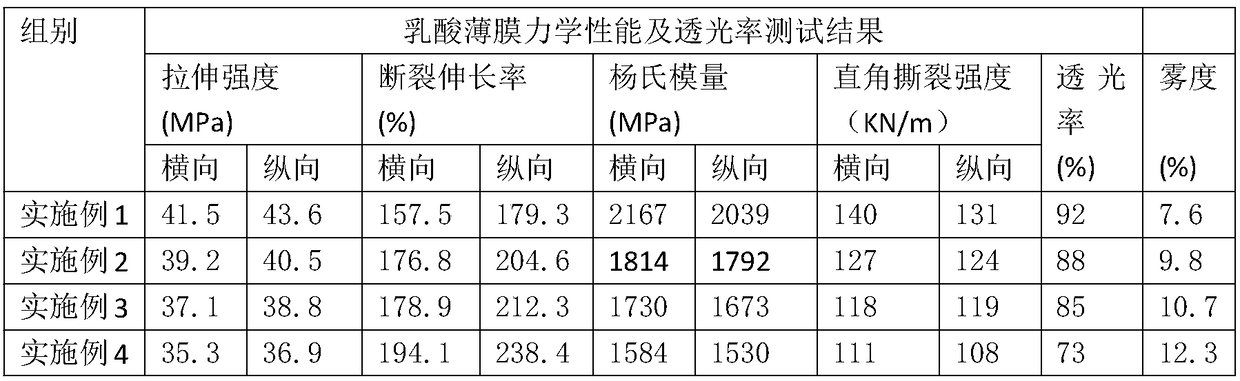

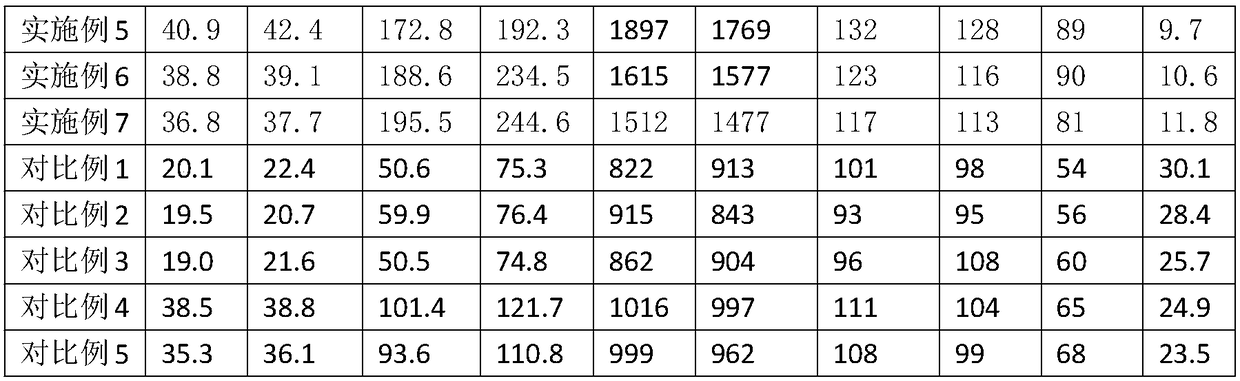

[0042] Examples 1-7 and comparative examples 1-5 complete biodegradable polylactic acid-based blown film weight proportions are shown in Table 1; wherein, comparative example 1 is the same as embodiment 1, only PBSA and PBC are replaced by PLA; comparative example 2 is the same as in Example 1, only diethylene glycol monobutyl ether adipate is removed; Comparative Example 3 is the same as in Example 1, only the lubricant and the opening agent are removed.

[0043] Among them, the weight average molecular weight of PLA is 1.5×10 5 g·mol -1 ; PBSA weight average molecular weight 2.5 × 10 5 g·mol -1 ;PBC weight average molecular weight 1.23×10 5 g·mol -1 .

[0044] The preparation method of the completely biodegradable polylactic acid base blown film of embodiment 1-7 and comparative example 1-5 is:

[0045] 1) Weighing PLA, PBSA, PBC, ethylene bisstearamide and erucamide according to the weight ratio, and mechanically blending each component for 5 minutes;

[0046] 2) Add...

Embodiment 8

[0056] Raw material ratio, by weight, PLA 78 parts, PBSA 20 parts, PBC 10 parts, acetyl tributyl citrate 10 parts, ethylene bis stearamide 0.8 parts, oleic acid amide 0.6 parts;

[0057] Preparation method: 1) Weigh PLA, PBSA, PBC, ethylene bisstearic acid amide, and oleic acid amide according to the weight ratio, and mechanically blend the components for 5 minutes;

[0058] 2) Add the mixed raw materials into the twin-screw extruder, add the above-mentioned acetyl tributyl citrate quantitatively with a peristaltic pump to the side line of the extruder during the extrusion process, and the conditions for extrusion and granulation are: The set temperature is: Zone 1: 130°C, Zone 2: 150°C, Zone 3: 160°C, Zone 4: 160°C, Zone 5: 165°C, Zone 6: 170°C, Zone 7: 170°C, Zone 8: 170°C, machine head: 170°C, screw speed: 150rpm, extrude, granulate and dry to obtain polylactic acid blown film resin material;

[0059] 3) The resin material obtained in step 2) is blown into a film by a blow...

Embodiment 9

[0061] Raw material ratio, by weight, 60 parts of PLA, 10 parts of PBSA, 20 parts of PBC, 15 parts of diacetyl epoxy vegetable glycerin oleate, 0.6 part of ethylene bis stearamide, 0.2 part of oleic acid amide;

[0062] Preparation method: 1) Weigh PLA, PBSA, PBC, ethylene bisstearic acid amide, and oleic acid amide according to the weight ratio, and mechanically blend the components for 5 minutes;

[0063] 2) Add the mixed raw materials into a twin-screw extruder, and add the above-mentioned diacetyl epoxy vegetable glycerin oleate quantitatively with a peristaltic pump to the side line of the extruder during the extrusion process. The conditions for extrusion and granulation are: twin-screw extrusion The set temperature of the machine is: zone 1: 140°C, zone 2: 150°C, zone 3: 150°C, zone 4: 160°C, zone 5: 165°C, zone 6: 165°C, zone 7: 165°C, zone 8 Zone: 170°C, machine head: 170°C, screw speed: 250rpm, extrude, granulate and dry to obtain polylactic acid blown film resin mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com