Composite modified polyphenylene sulfide material for water supply pipe insert and preparation method thereof

A technology of composite modification and polyphenylene sulfide, which is applied in the field of composite modified plastics, can solve the problems of high processing cost, low yield, and non-environmental protection, and achieve the effect of high quality and comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

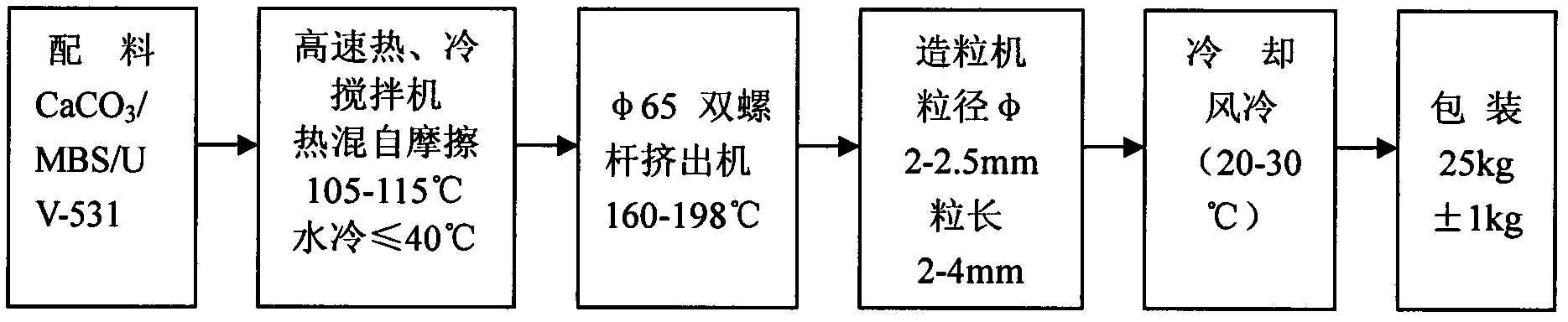

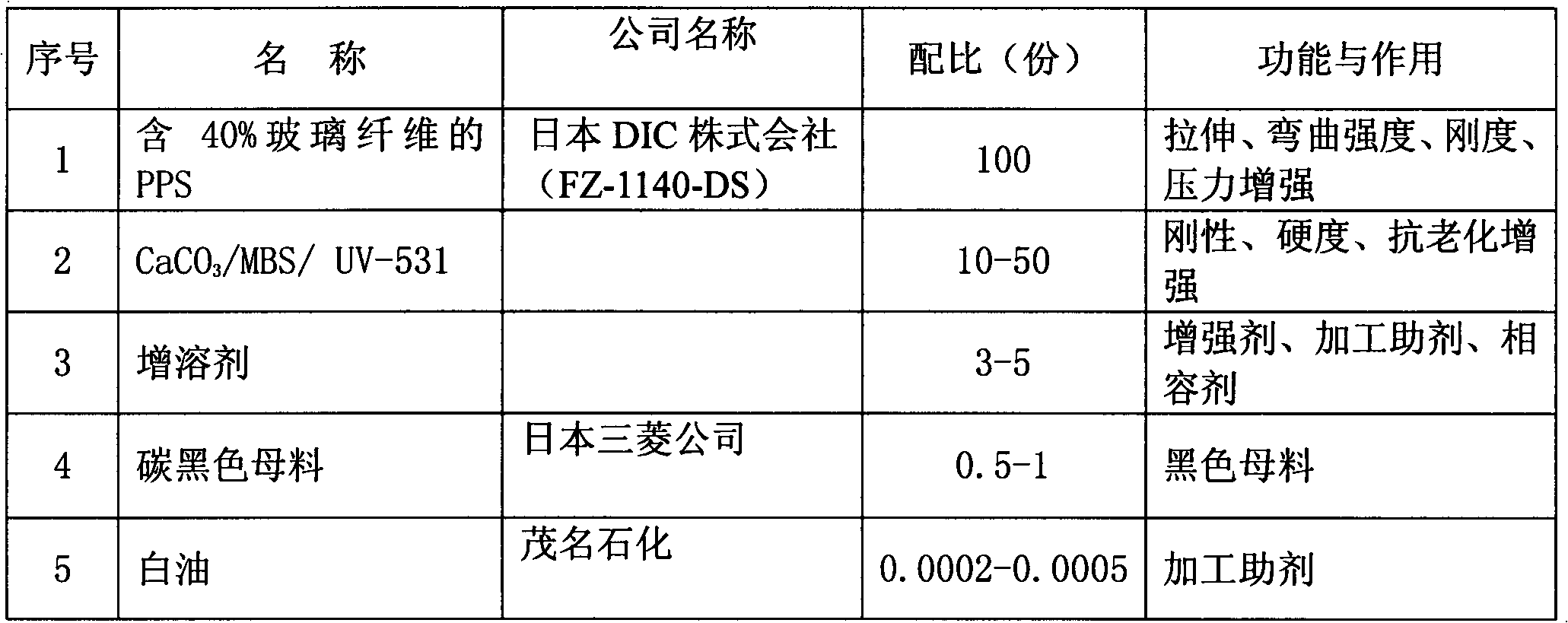

[0031] Embodiment 1: A composite modified polyphenylene sulfide material used for water supply pipe inserts, said composite modified polyphenylene sulfide material used for water supply pipe inserts consists of the following raw materials in parts by weight: 100 parts of PPS containing 40% glass fiber, CaCO 3 / MBS / UV-531 copolymer blend 10 parts, solubilizer 3 parts, carbon black masterbatch 0.5 parts and white oil 0.0002 parts. Among them, CaCO 3 / MBS / UV-531 copolymer blend is composed of the following raw materials in parts by weight: 1000 mesh light CaCO 3 100 parts, 1 part of bis(dioctylphosphoryloxy)ethylene titanate, 2 parts of paraffin, 10 parts of methyl methacrylate-butadiene-styrene copolymer, 0.5 parts of anti-aging agent, processing lubricant 1 part of agent and 1 part of barium stearate.

Embodiment 2

[0032] Embodiment 2: A composite modified polyphenylene sulfide material used for water supply pipe fitting inserts, said composite modified polyphenylene sulfide material used for water supply pipe fitting inserts consists of the following raw materials in parts by weight: 100 parts of PPS containing 40% glass fiber, CaCO 3 / MBS / UV-531 copolymer blend 50 parts, solubilizer 5 parts, carbon black masterbatch 1 part and white oil 0.0005 parts. Among them, CaCO 3 / MBS / UV-531 copolymer blend is composed of the following raw materials in parts by weight: 1000 mesh light CaCO 3 100 parts, 3 parts of coupling agent, 4 parts of dispersant, 30 parts of anti-impact agent, 1 part of anti-aging agent, 2 parts of processing lubricant and 4 parts of barium stearate. In this embodiment, the coupling agent is bis(dioctylphosphoryloxy)ethylene titanate, the dispersant is paraffin, and the anti-impact agent is methyl methacrylate-butadiene-styrene copolymer.

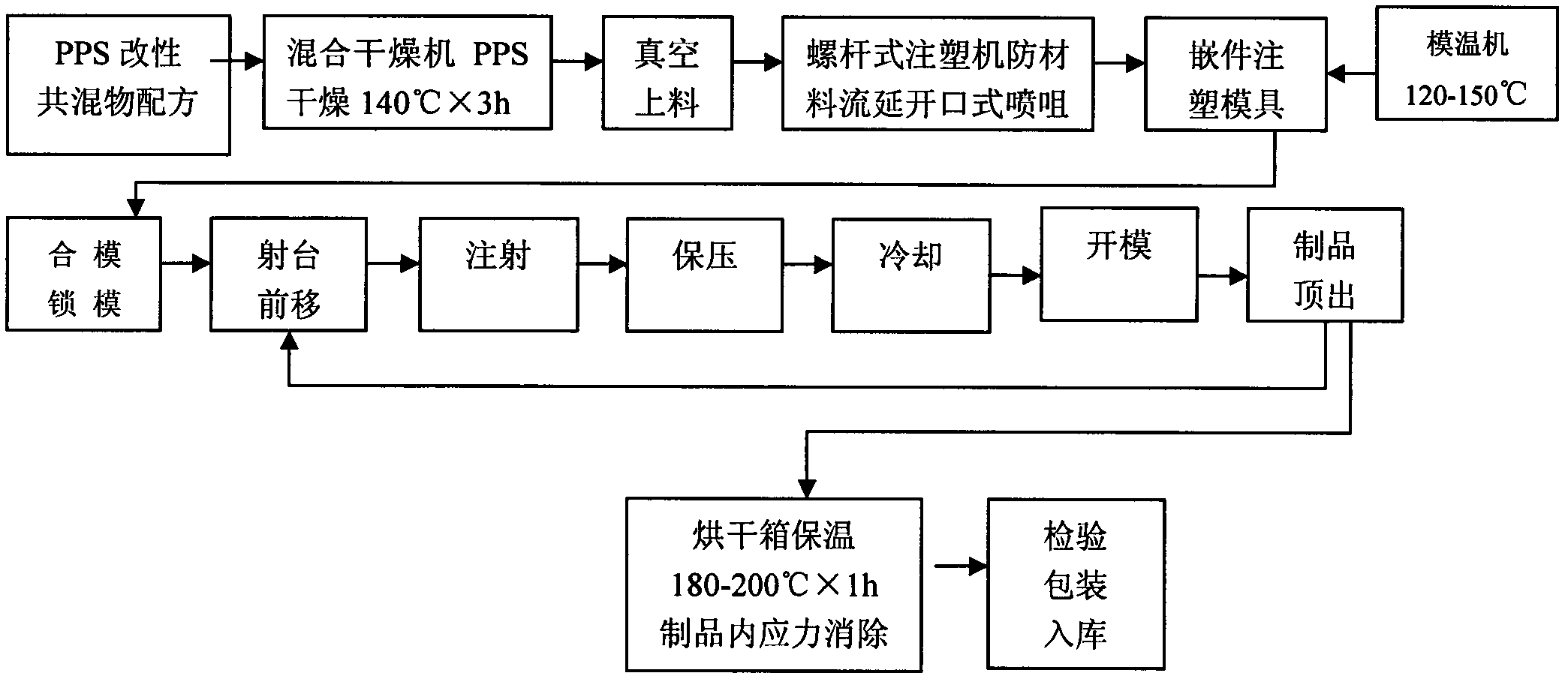

[0033] Such as figure 1 As sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com