Patents

Literature

1166results about How to "High heat distortion temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Optical articles comprising isosorbide polyesters and method for making same

InactiveUS6126992AHigh light transmittanceEasy to copySynthetic resin layered productsPretreated surfacesPolyesterPolymer science

An optical article made of a transparent polymer which includes terephthaloyl moieties, optionally, other aromatic diacid moieties; ethylene glycol moieties; isosorbide moieties; and, optionally, one or more other diol moieties, wherein the polymer has an inherent viscosity of at least about 0.35 dL / g as measured on a 1% solution (weight / volume) in o-chlorophenol at 25 DEG C.

Owner:EI DU PONT DE NEMOURS & CO

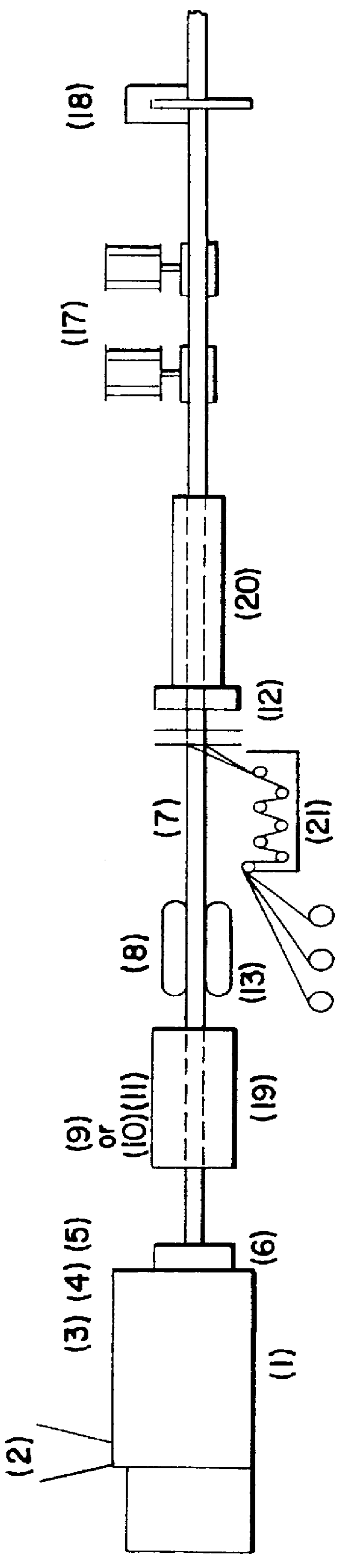

Fiber thermoset reinforced thermoplastic structural member

InactiveUS6106944AHigh strengthImprove mechanical propertiesLayered productsSpecial ornamental structuresYoung's modulusEngineering

In the manufacture of a structural member comprising a thermoplastic composite core with an exterior reinforcing layer, the core member is initially extruded in the shape of a profile. The profile is then contacted with reinforcing fiber and resin to form the exterior reinforcing layer. The exterior thermosetting layer is cured to form a reinforcing layer. The structural member is preferably manufactured using a pultrusion method in which a tractor device is used to provide linear movement of the profile from the extrusion head to the exterior coating operation. The fiber-reinforced thermoset is coated on the entirety of the exterior of the profile or is applied only on a portion of the profile requiring reinforcement in a defined load-bearing direction. A preferred thermoplastic core comprises a polymer-fiber composite material. A structural member of the invention has significantly improved Young's modulus providing strength for applications such as telephone poles, electric poles, electric lighting poles, boat mast or keel applications, lumber replacements, structural members used in window and door manufacture, etc.

Owner:ANDERSEN CORPORATION

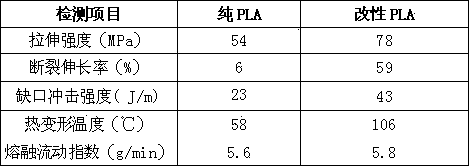

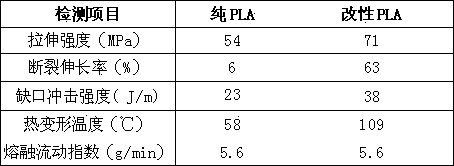

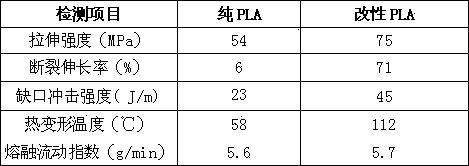

3D printing modified polylactic acid material and preparation method thereof

InactiveCN103467950AIncrease profitSelf-performance has not declinedMonocomponent polyesters artificial filamentArtifical filament manufactureHeat deflection temperaturePolymer science

A 3D printing modified polylactic acid material comprises, by weight, 70-85 parts of polylactic acid, 1-5 parts of chain extenders, 1-5 parts of cross-linking agents, 0.5-1 part of nucleating agents, 5-10 parts of polymers with low molecular weights, 5-10 parts of flexibilizers, 1-5 parts of fortifiers and 0.3-0.8 part of antioxidants. According to the 3D printing modified polylactic acid material, a low-temperature smashing hybrid reaction technology is utilized, modified processing is carried out on polylactic acid, toughness, impact strength and the heat distortion temperature for the polylactic acid are improved to a large extent, and the polylactic acid can have wider application prospects in 3D printing materials.

Owner:佛山市斯太克科技有限公司

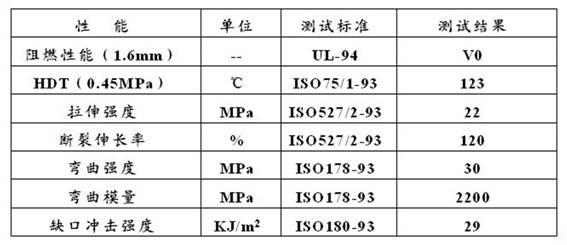

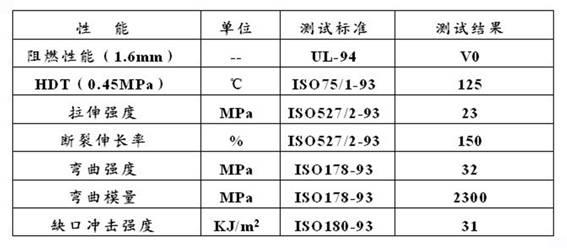

Non-halogen flame-retardant polypropylene composite material and preparation thereof

InactiveCN101412830AImprove flame retardant performanceImprove mechanical propertiesFlexural modulusAcrylonitrile

The invention provides a halogen-free flame-retardant polypropylene composite material, which is characterized by consisting of the following raw materials in weight portion: 82.5 to 12 portions of polypropylene, 0.3 to 2 portions of heat stabilizer, 0.2 to 1 portion of processing aid, 1 to 10 portions of toughening agent, 10 to 40 portions of flame retardant, 1 to 5 portions of glass fiber compatibilizer and 5 to 30 portions of glass fiber. The invention also provides a method for preparing the material. The material has the flame retardancy up to 1.6mm V0, the tensile strength higher than or equal to 50 MPa, the flexural modulus higher than or equal to 3,000 MPa, the notched impact strength more than or equal to 8KJ / m<2>, the shrinkage between 4 and 6 per thousand, the heat distortion temperature higher than or equal to 140 DEG C, as well as the other technical indexes up to or exceeding the standard of flame-retardant acrylonitrile-butadiene-styrene copolymer materials. As the material uses the phosphorus-nitrogen flame retardant containing no halogen, the flame-retardant effect of the material completely reaches UL94-V0 grade.

Owner:SHANGHAI KINGFA SCI & TECH +1

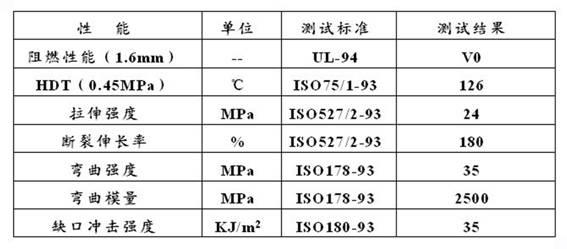

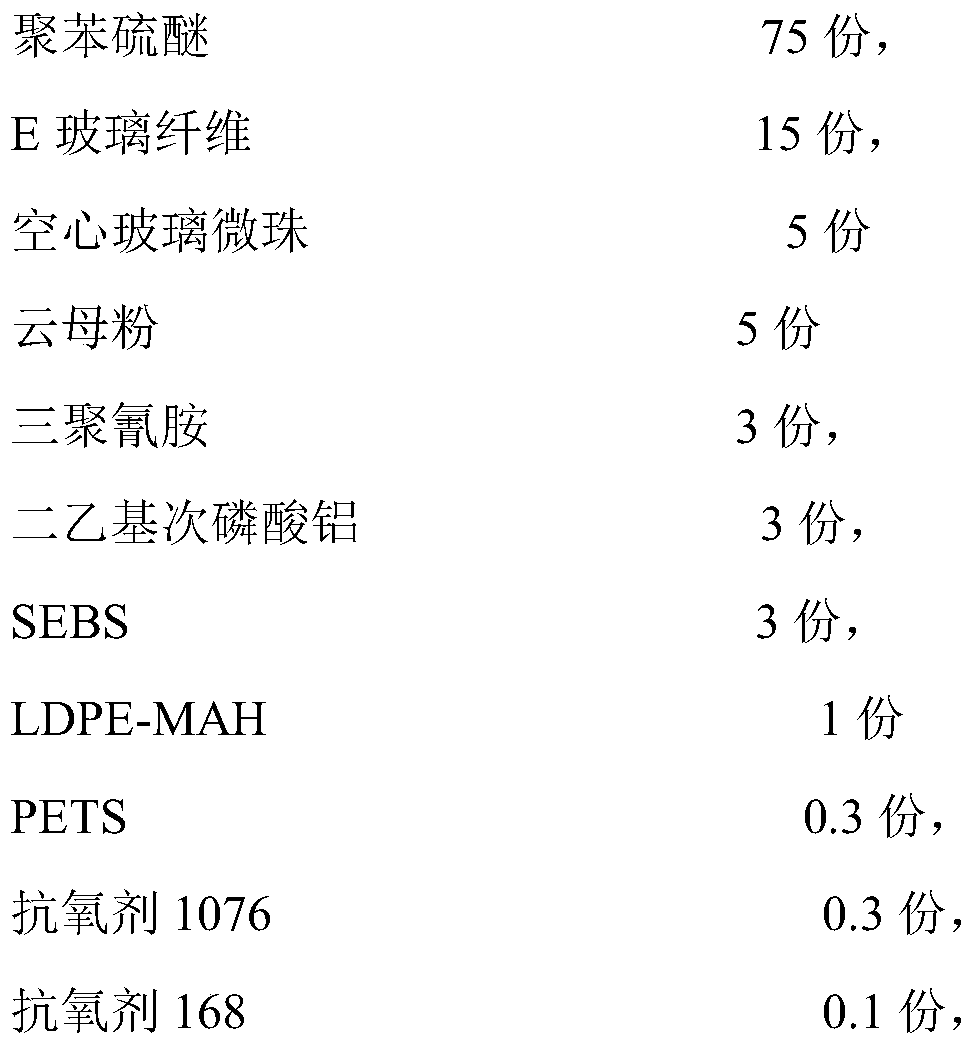

Natural fiber reinforcement halogen-free flame retardant polypropylene composite material and preparation method thereof

InactiveCN101418099AImprove flame retardant performanceImprove mechanical propertiesGlass fiberHeat deflection temperature

The invention provides a natural fiber reinforced halogen-free flame-retardant polypropylene composite material, which is characterized by consisting of the following raw materials in weight portion: 82.5 to 12 portions of polypropylene, 0.3 to 2 portions of heat stabilizer, 0.2 to 1 portion of processing assistant, 1 to 10 portions of toughening agent, 10 to 40 portions of flame retardant, 1 to 5 portions of compatilizer, and 5 to 30 portions of natural fiber. The invention also provides a method for preparing the material. The composite material has the advantages that the composite material has excellent flame-retardant effect and excellent comprehensive mechanical property; the flame-retardant property of the composite material can reach 1.6mm V0; the tensile strength is more than or equal to 60MPa; the bending modulus is more than or equal to 4,000MPa; the gap impact strength is more than or equal to 10KJ / m<2>; the shrinkage ratio is between 4 and 6 per thousand; the heat distortion temperature is more than or equal to 140 DEG C; and the composite material is a novel environment-friendly material, and has no safety and health problems of glass fibers.

Owner:SHANGHAI KINGFA SCI & TECH +1

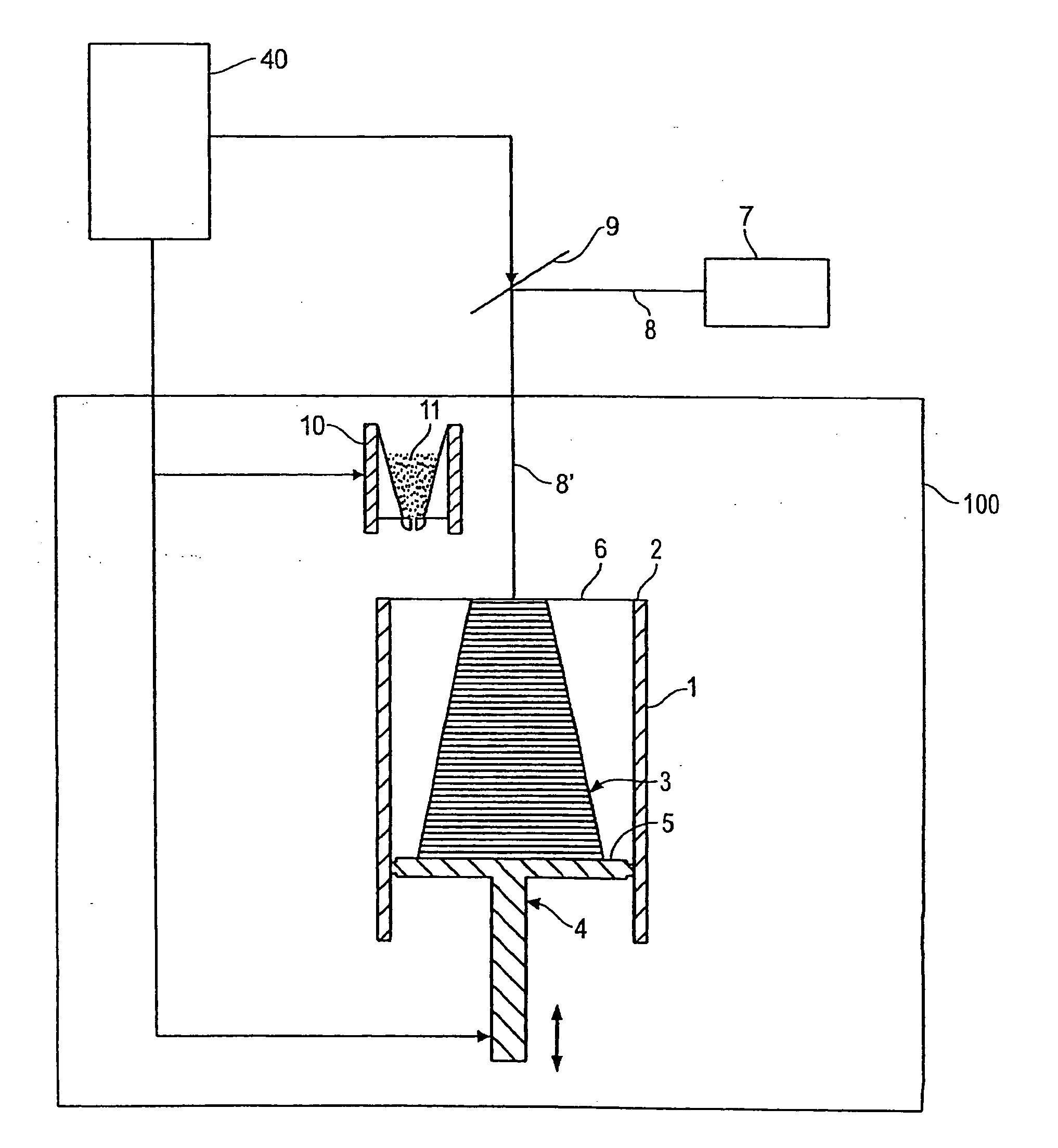

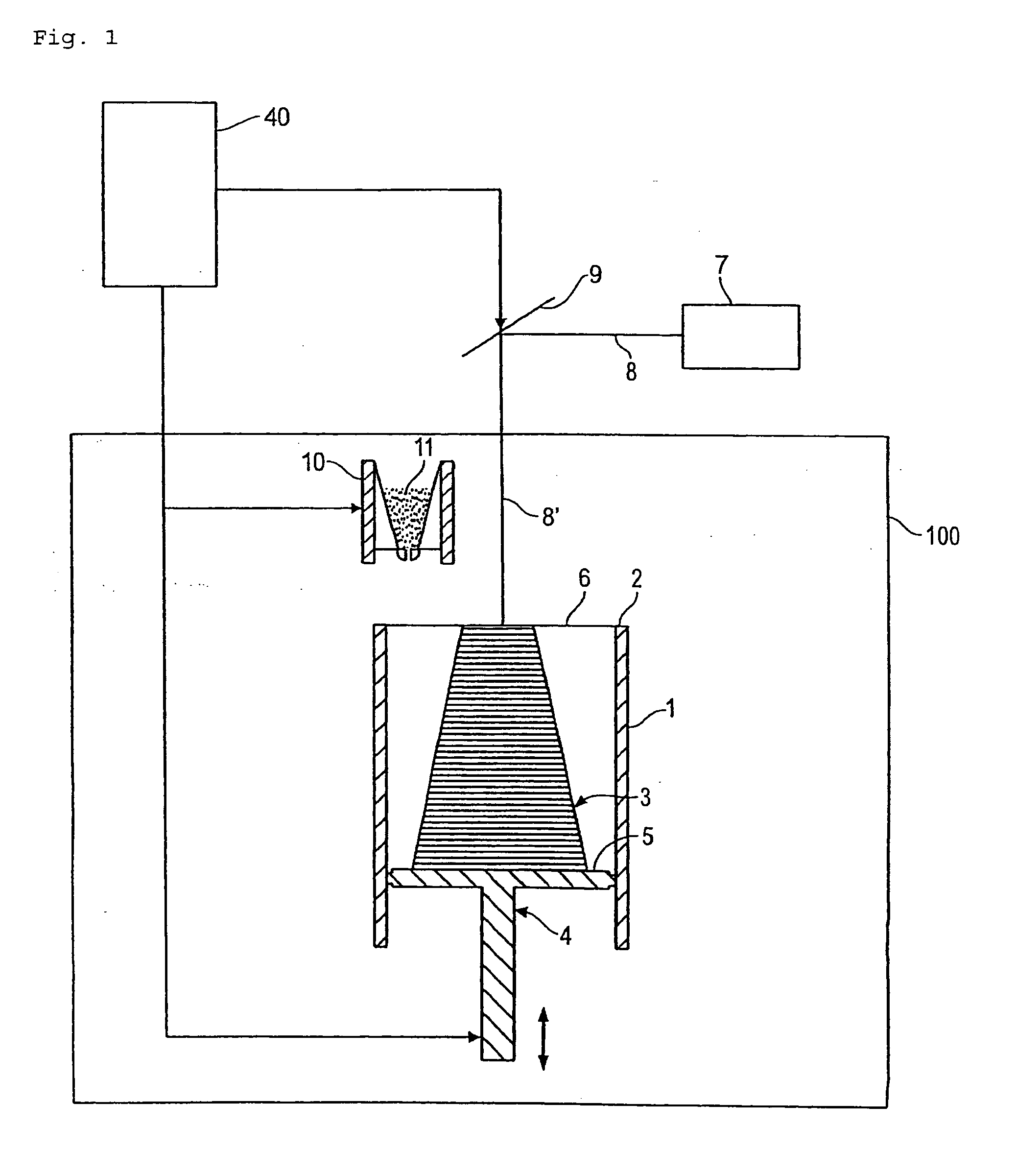

Selective sintering of structurally modified polymers

ActiveUS20090295042A1Improve mechanical propertiesSpeed up the processAdditive manufacturing apparatusLiquid surface applicatorsSelective laser sinteringPolymer science

A three-dimensional object is manufactured by selective sintering by means of electromagnetic radiation, wherein the powder comprises a polymer or copolymer having at least one of the following structural characteristics:(i) at least one branching group in the backbone chain of the polymer or copolymer, provided that in case of the use of polyaryletherketones (PAEK) the branching group is an aromatic structural unit in the backbone chain of the polymer or copolymer;(ii) modification of at least one end group of the backbone chain of the polymer or copolymer;(iii) at least one bulky group within the backbone chain of the polymer of copolymer, provided that in case of the use of polyaryletherketones (PAEK) the bulky group is not selected from the group consisting of phenylene, biphenylene, naphthalene and CH2— or isopropylidene-linked aromatics;(iv) at least one aromatic group non-linearly linking the backbone chain.

Owner:EOS ELECTRO OPTICAL SYST

Sulfonated aliphatic-aromatic copolyesters and shaped articles produced therefrom

ActiveUS7220815B2High crystallinityHigh heat distortion temperatureLayered productsCeramic shaping apparatus1,4-ButanediolPolymer science

Sulfonated aliphatic-aromatic copolyesters and articles made therefrom, and processes for producing the sulfonated aliphatic-aromatic copolyesters and articles are provided. Articles that can be made from the sulfonated aliphatic-aromatic copolyesters include films, coatings and laminates. Some of the compositions and articles are biocompostable. The films can further be used to form shaped articles such as sheets, food packaging such as sandwich wraps, thermoformed containers, and coatings for, for example, films and other substrates. The sulfonated aliphatic-aromatic copolyesters are derived from copolyesters produced from aliphatic-aromatic copolyesters formed from an aromatic dicarboxylic acid component, an aliphatic dicarboxylic acid component, a first glycol component consisting of 1,4-butanediol, a second glycol component, and optionally, a polyfunctional branching agent.

Owner:DUPONT POLYMERS INC

Inorganic nano particle modified high performance recovery plastic and its preparing process

InactiveCN1858101AHigh tensile strengthImprove bending strengthPlastic recyclingGlass fiberAlkali free

The inorganic nanometer particle modified high performance regenerated plastic consists of recovered plastic 5-98 wt%, new plastic in the same type 0-93 wt%, inorganic nanometer particle 1-30 wt%, flexibilizer and compatilizer 1-30 wt%, and alkali free glass fiber 0-45 wt%, and the surface of the alkali free glass fiber is treated with silane coupler in the amount of 0.2- 5% of the added alkali free glass fiber. The said components are mixed homogeneously through stirring, melted and extruded to form.

Owner:NANJING JULONG SCI&TECH CO LTD

Metal-like engineering plastic composite material and preparation method thereof

The invention discloses a metal-like engineering plastic composite material and a preparation method thereof, and relates to a polymer composite material. The invention provides the metal-like engineering plastic composite material which combines plastic with metal and simultaneously keeps the advantages of the two and the preparation method thereof. The composite material comprises thermoplastic engineering plastic, high-density packing, mineral powder, glass fiber, toughener, coupling agent, lubricant and antioxidant. The metal-like engineering plastic composite material has high density, high mechanical properties, excellent thermal deformation temperature and good injection molding property. The preparation method adopts the method of being combined with the coupling agent and the optimized granulation conditions, the process is simple and easy to operate, extrusion and granulation can be carried out by adopting an ordinary twin-screw granulator, and injection molding can be carried out by adopting an ordinary injection machine.

Owner:XIAMEN RUNNER IND CORP

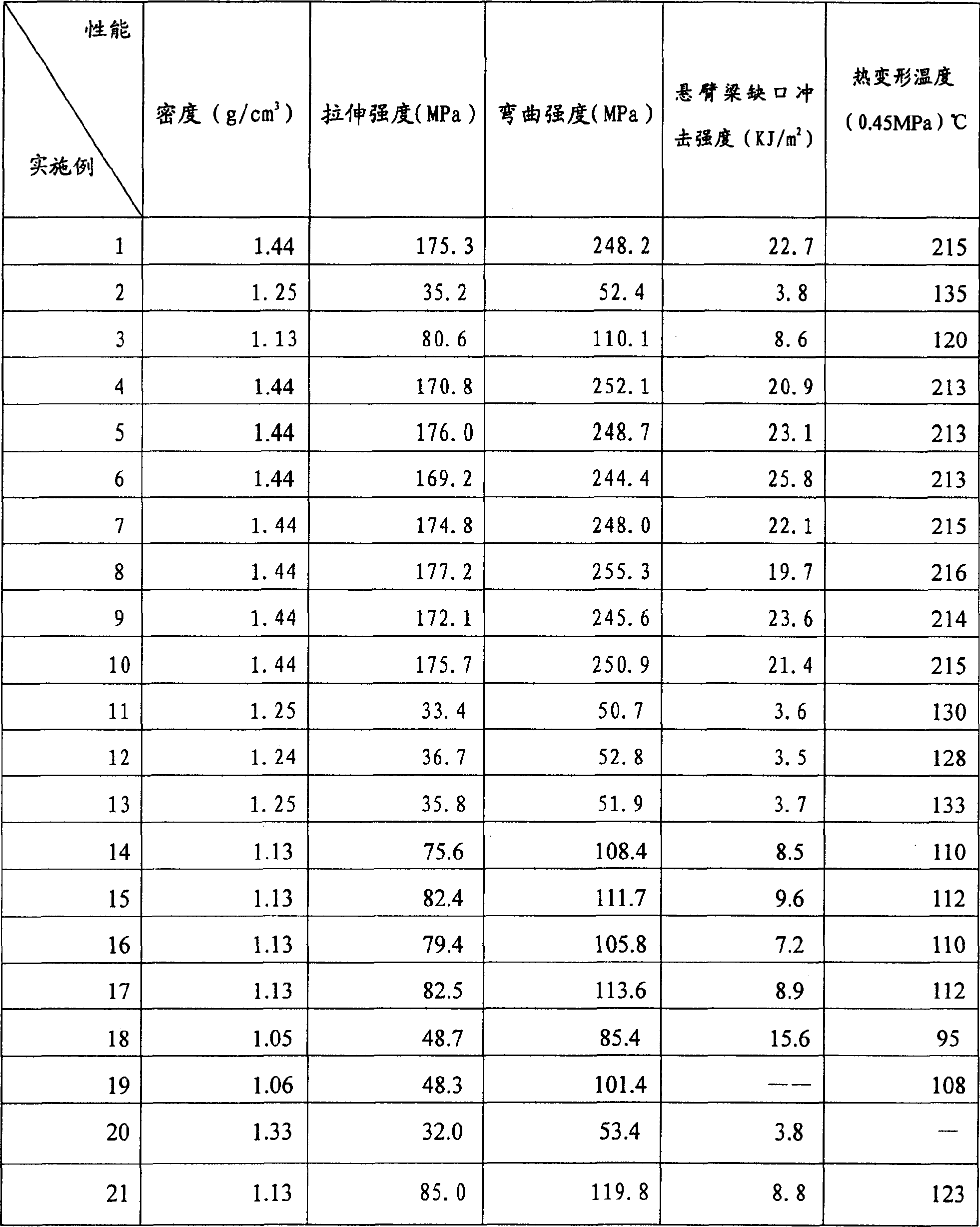

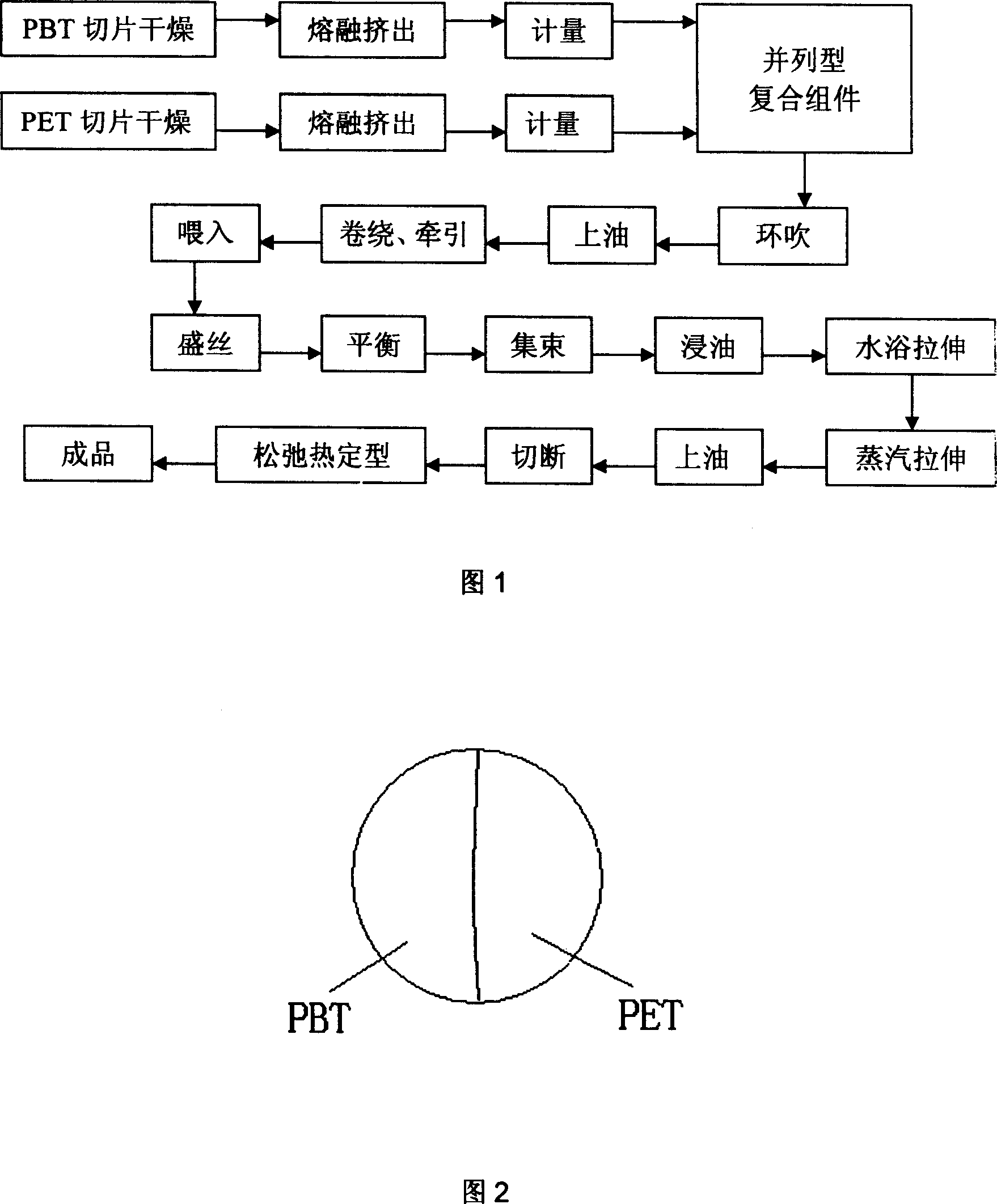

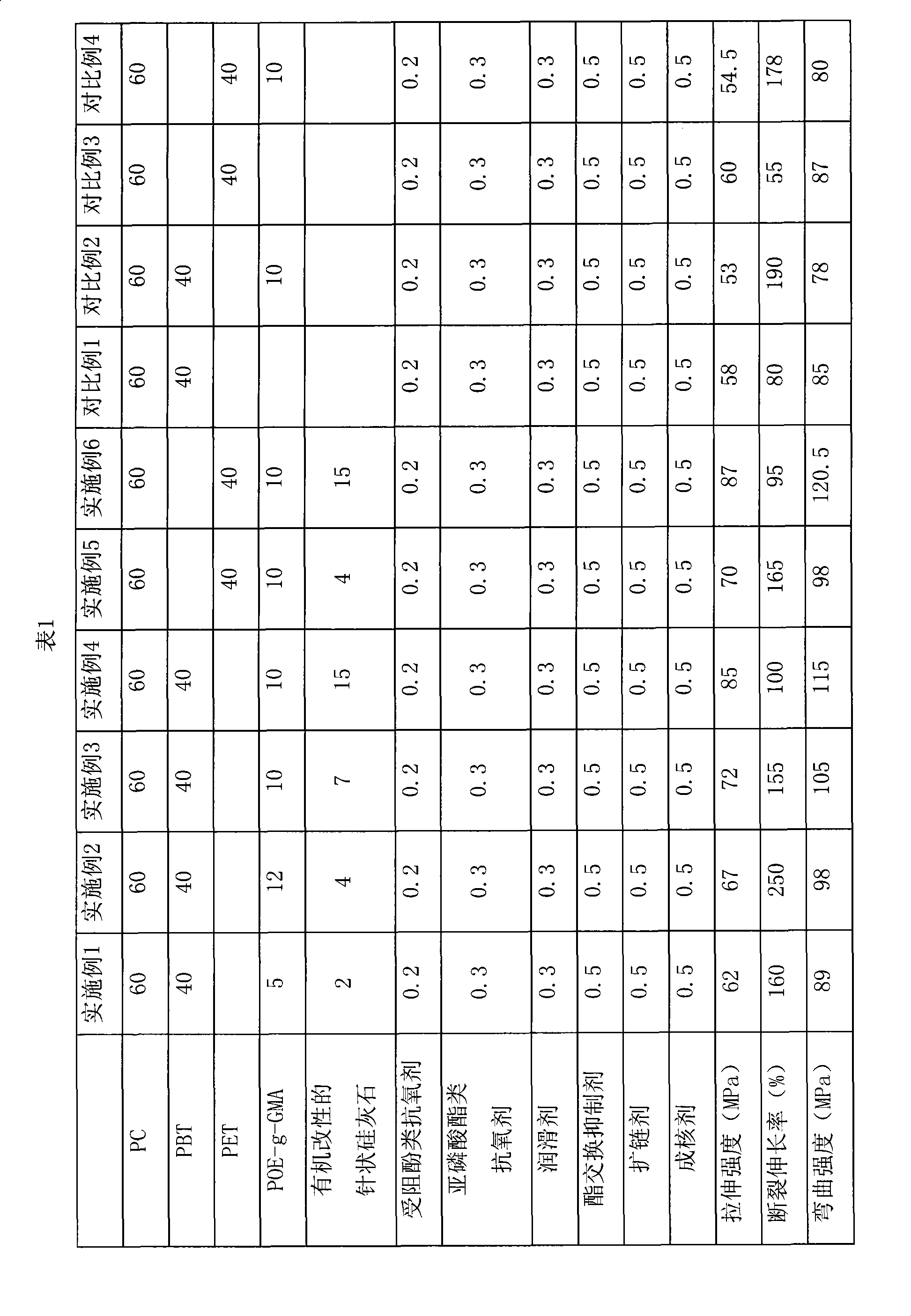

Method for preparing PBT/PET 3-D crimped fiber and use thereof

InactiveCN1962968AIncrease elasticityHigh modulusFilament/thread formingConjugated synthetic polymer artificial filamentsFiberHeat resistance

The invention involves a product method of PBT / PET 3D crimp fiber fabrication which includes steps: (1) PBT biopsies are composed with the PET on the after drying; (2) PET slices are after drying, through high-temperature melting e composite; (3) After blowing Central, greasing winding drive, feed, Sheng be parallel wire composite fiber winding wire; After balancing, cluster, the Baptist tensile oil bath, steam tensile, greasing cut off heat and relaxation to be stereotyped PBT / PET 3D curly fibers. The fibers produced through the method are system of the fiber's flexibility, dyeability and heat resistance and used in flexible woven and knitted fabrics such as high-end sportswear, stretch jeans and strait jacket, Nonwovens and filler widely.

Owner:DONGHUA UNIV

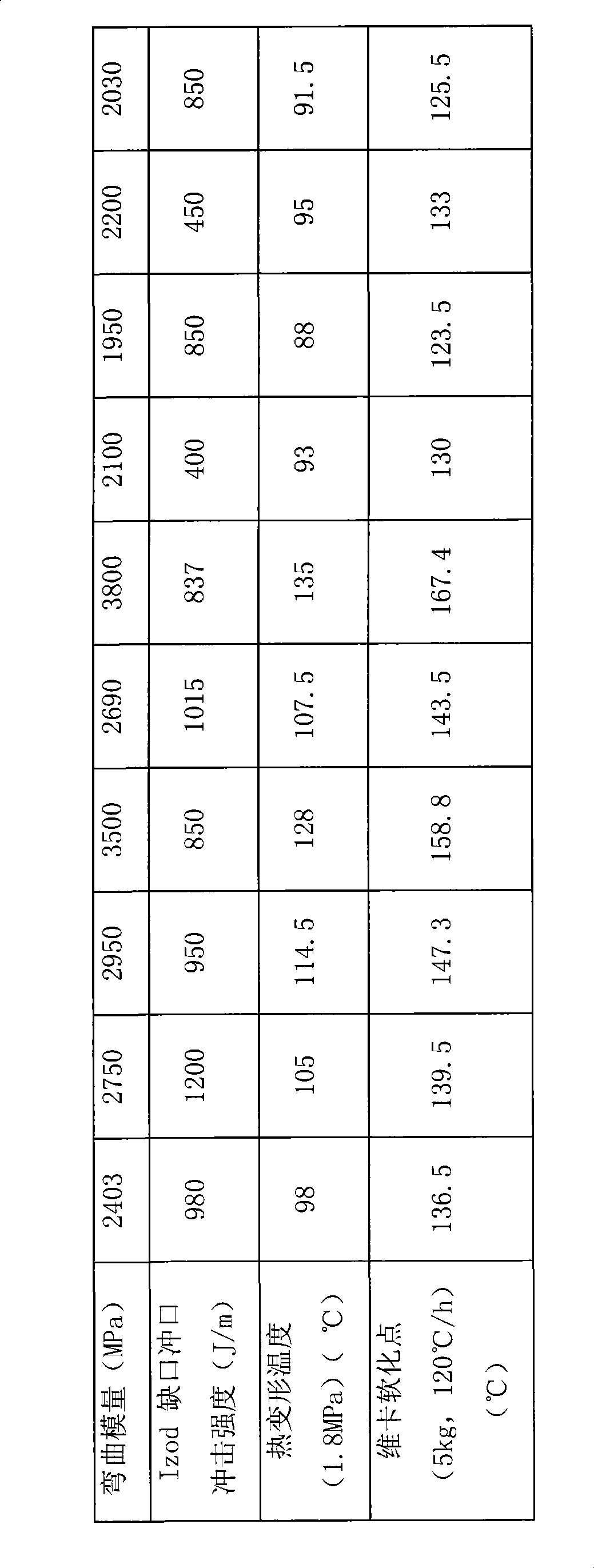

Method of manufacturing polycarbonate/polyester alloy

The invention discloses a preparation method of polycarbonate / polyester alloy. Glycidyl methacrylate grafted ethylene-octylene multipolymer / organic modified needle-shaped aedelforsite composite toughener, i.e. a technology of simultaneously using organic / inorganic rigid particle toughener is adopted; the glycidyl methacrylate grafted ethylene-octylene multipolymer, organic modified needle-shaped aedelforsite, polycarbonate and polyester are melted and mixed in a double-screw extruder, to obtain high-performance alloy material. The prepared polycarbonate / polyester alloy has excellent integrated mechanical properties and size stability, the notched impact strength reaches 1200J / m, the tensile strength reaches 67MPa, the elongation at break reaches 250 percent, the flexural strength is up to 98MPa, the flexural modulus reaches 2750MPa, and the thermal deformation temperature in high load (1.82MPa) is up to 105 DEG C. Therefore, the prepared polycarbonate / polyester alloy can be applied in cars, and to outer decorations, household electrical appliances, IT and the like industrial products.

Owner:SHANGHAI JIAO TONG UNIV +1

Thin and thermal insulation inner wall paint, preparation method and construction method thereof

ActiveCN101085892AImprove the decorative effectLow costFireproof paintsEmulsion paintsPolymer scienceMicrosphere

The invention discloses a kind of thin thermal insulating inner wall paint. The comprised components and their weight proportion are as follows: styrene-acrylic emulsion 28- 35%, titanium dioxide 8- 13%, fillings 10- 18%, borosilicate hollow microsphere 6- 12%, water- brone nanometer anti- pollution agent 0.5- 2%, defoaming agent 0.3- 0.5%. Said hollow microsphere is hollow white spherical powder with thin wall, the main component is silicon dioxide and diboron trioxide, the real density is small and heat conductive coefficient is 0.04- 0.08 w / m.k. The invention aslo discloses the preparation and construction method for said paint. It employs high pressure airless painting process for construction, the aperture of employed gunjet nozzle is 0.6- 0.8 mm, atomization pressure is 15- 18 Mpa, and when the coating layer is 0.3- 1.0 mm, the coating layer is homogeneous and tight, and the thermal insulating effect is good. The paint is especially suitable for building inner wall and ceiling painting.

Owner:上海秀珀化工有限公司

High-temperature resistant flame-retardant epoxy glue and preparation method thereof

ActiveCN104726045AReduce usageHigh heat distortion temperatureNon-macromolecular adhesive additivesCarboxyl rubber adhesivesEpoxyFire retardant

The invention relates to high-temperature resistant flame-retardant epoxy glue and a preparation method of the high-temperature resistant flame-retardant epoxy glue. The epoxy glue is a double-component epoxy glue; when the epoxy glue is used, a first component and a second component are mixed in a weight ratio of 4:(2-3); the first component is prepared from the following raw materials in parts by weight: 30-50 parts of polyfunctional epoxy resin, 5-15 parts of low-viscosity epoxy resin, 3-10 parts of an active toughening agent, 10-30 parts of temperature-resistant reinforcing fillers, 10-15 parts of flame retardant and 0.3-3 parts of antioxidant; the second component is prepared from the following raw materials in parts by weight: 70-95 parts of a temperature-resistant curing agent, 10-30 parts of temperature-resistant reinforcing fillers and 0.3-1 part of a coupling agent. Compared with the prior art, the high-temperature resistant flame-retardant epoxy glue has the advantages of high high-temperature toughness, high adhesion strength, high flame retardant performance and the like.

Owner:上海海鹰粘接科技有限公司

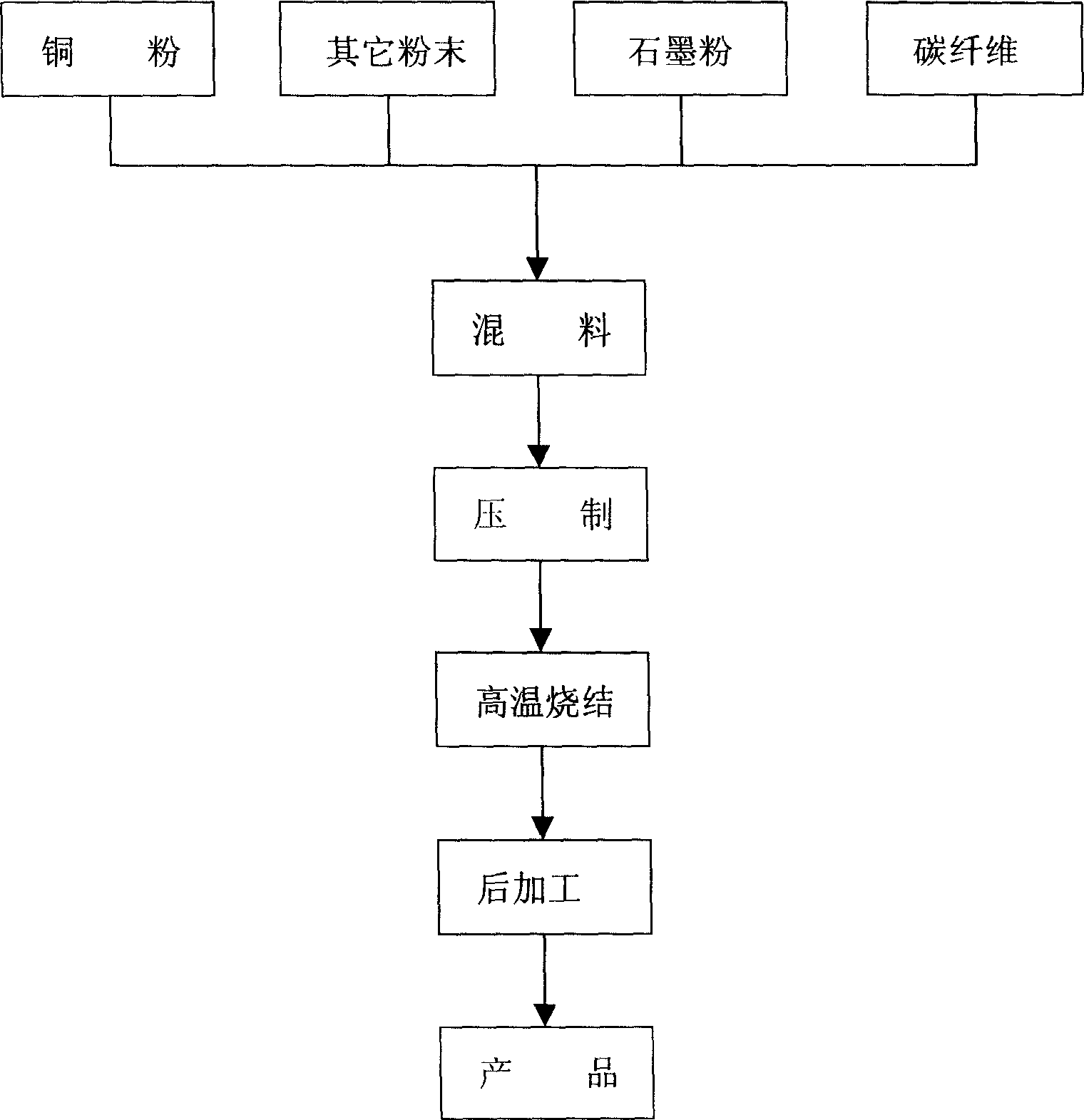

Leadless copper base high temperature self lubricating composite material

InactiveCN1718795AImprove toughnessImprove heat resistanceChemical vapor deposition coatingChemical compositionGraphite

A high-temp self-lubricating non-Pb Cu-base composition has a chemical formula: Ni+C+Sn+Zn+MX+Fe+Cu, where MX is chosen from BN, Si3N4, SiC, Al2O3, TiN, TiC and Cr3 C2 and C is graphite and carbon fibres. It has anti-oxidizing, anti-corrosion and high-temp anti-wear characteristics.

Owner:合肥波林新材料股份有限公司

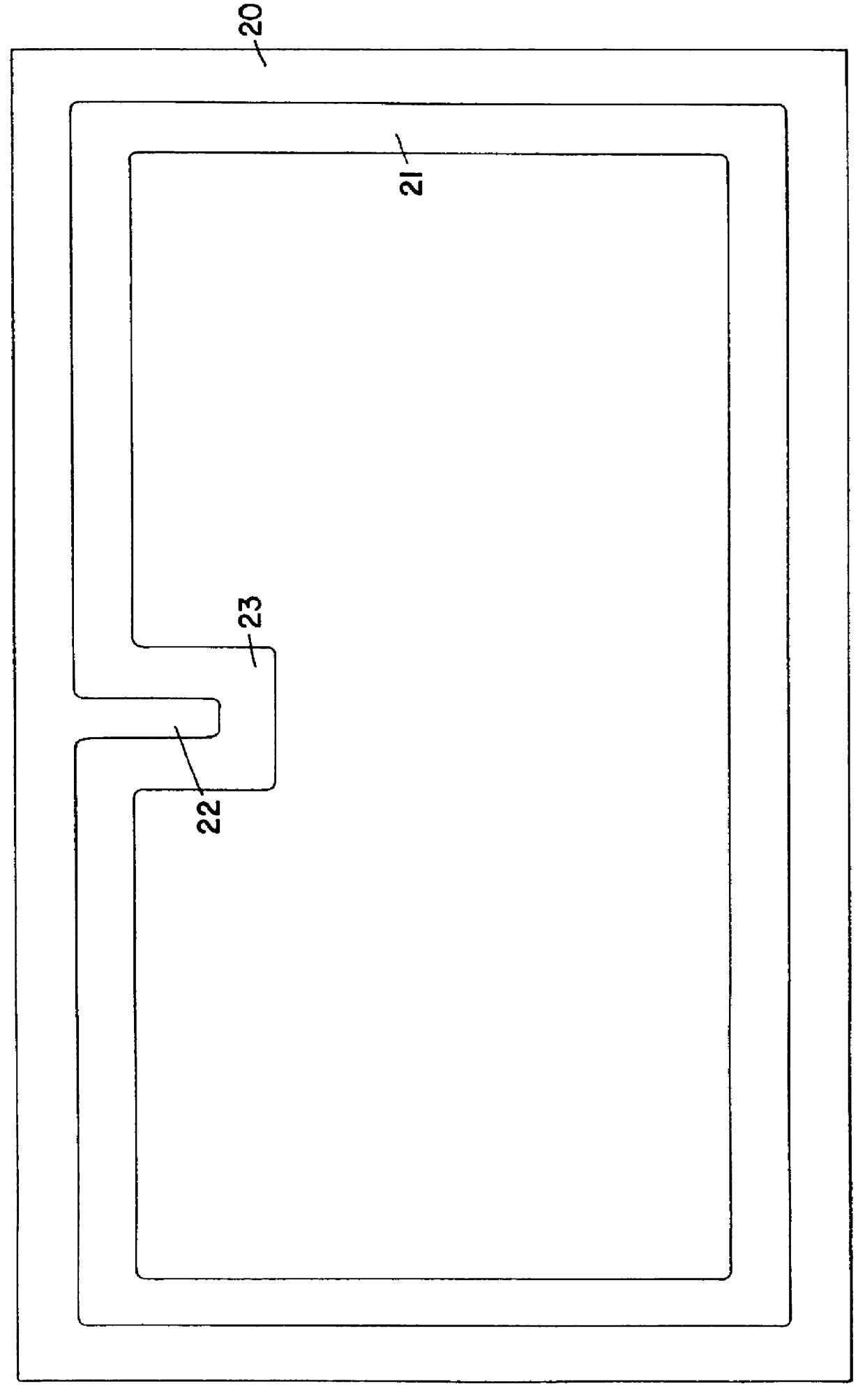

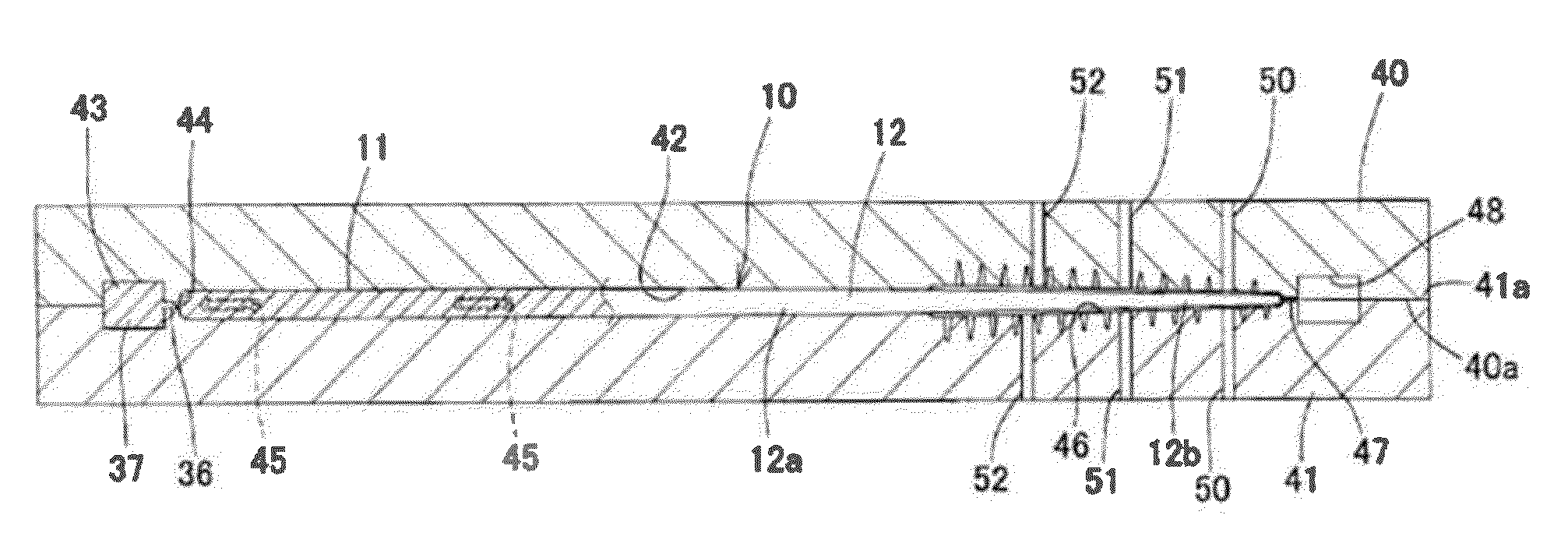

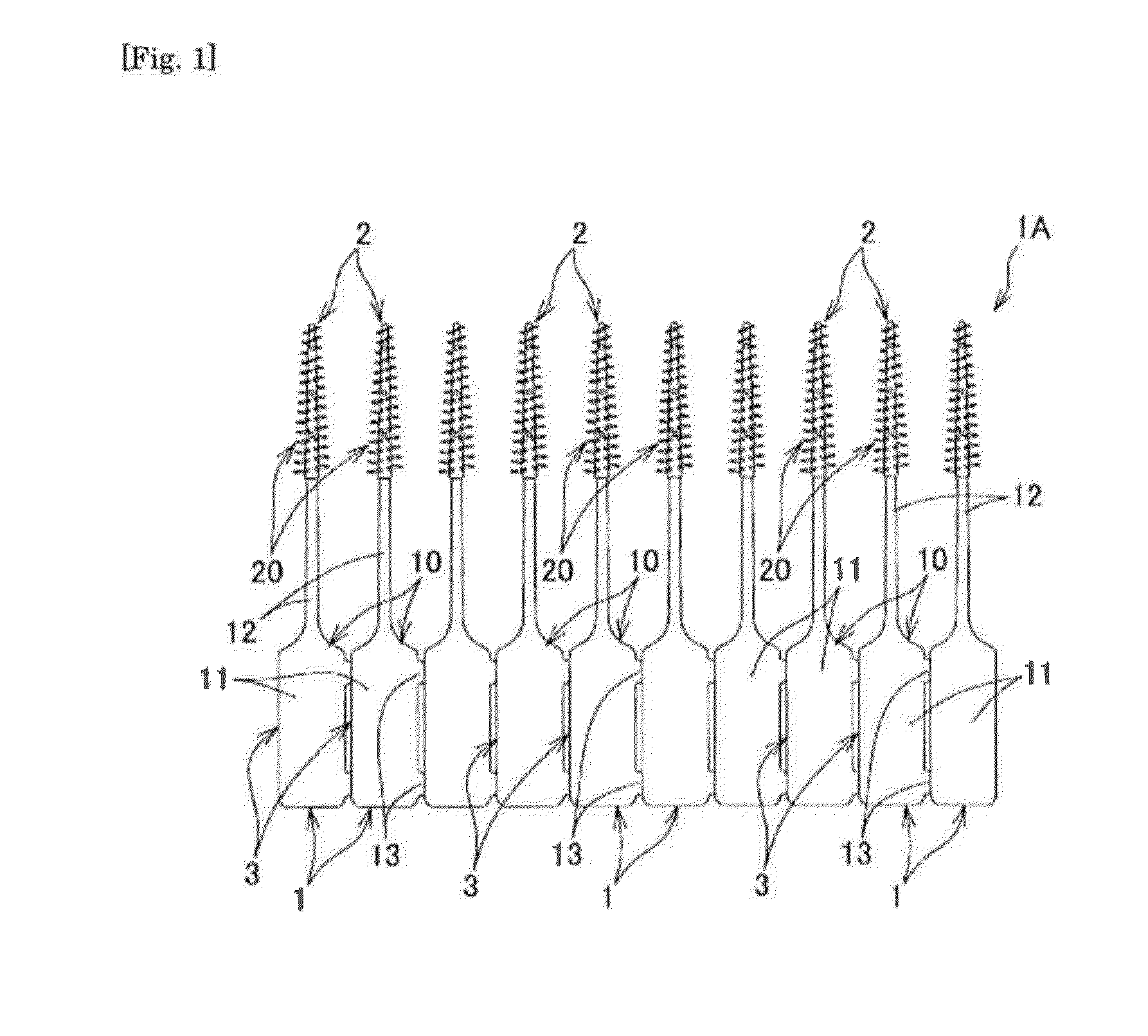

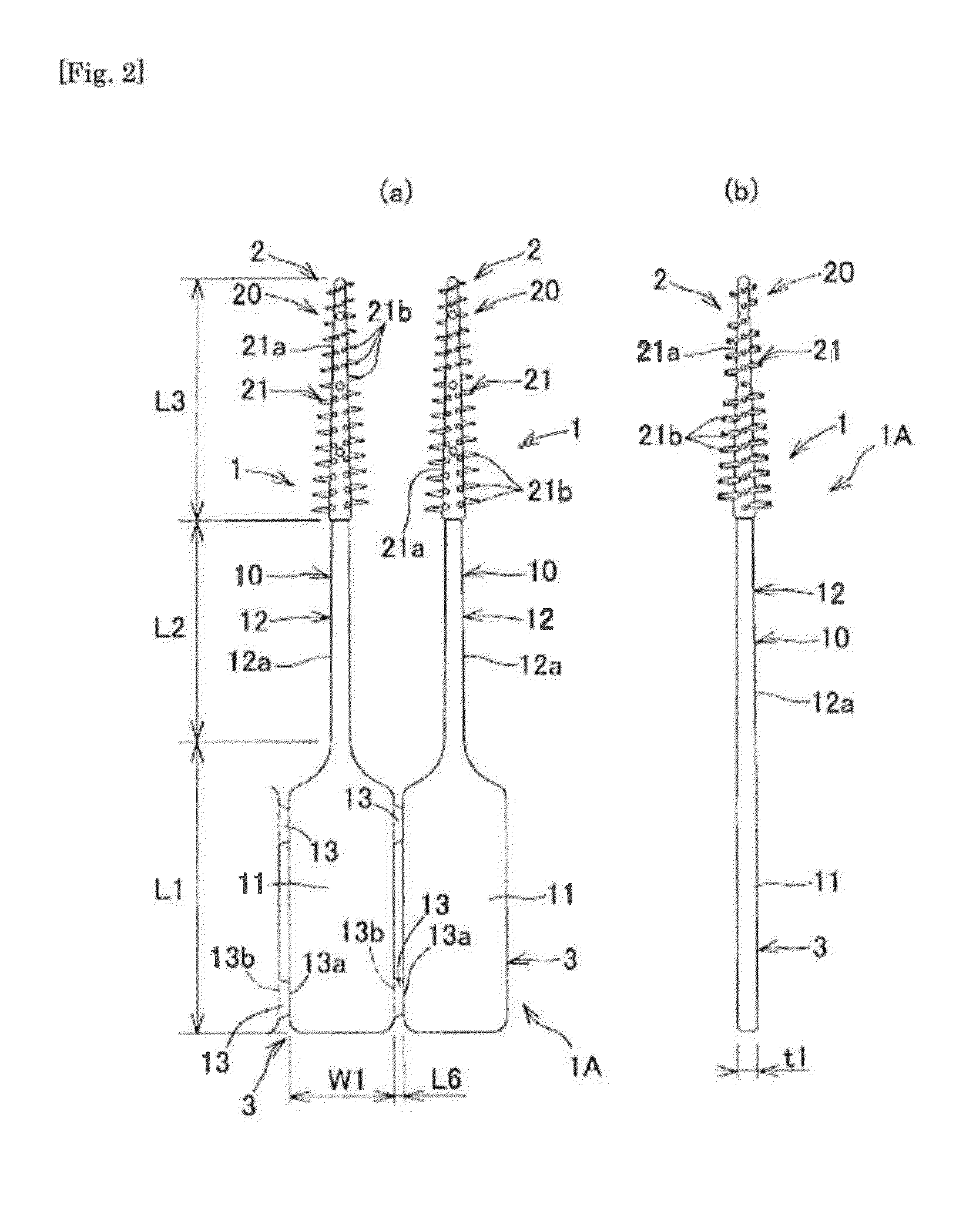

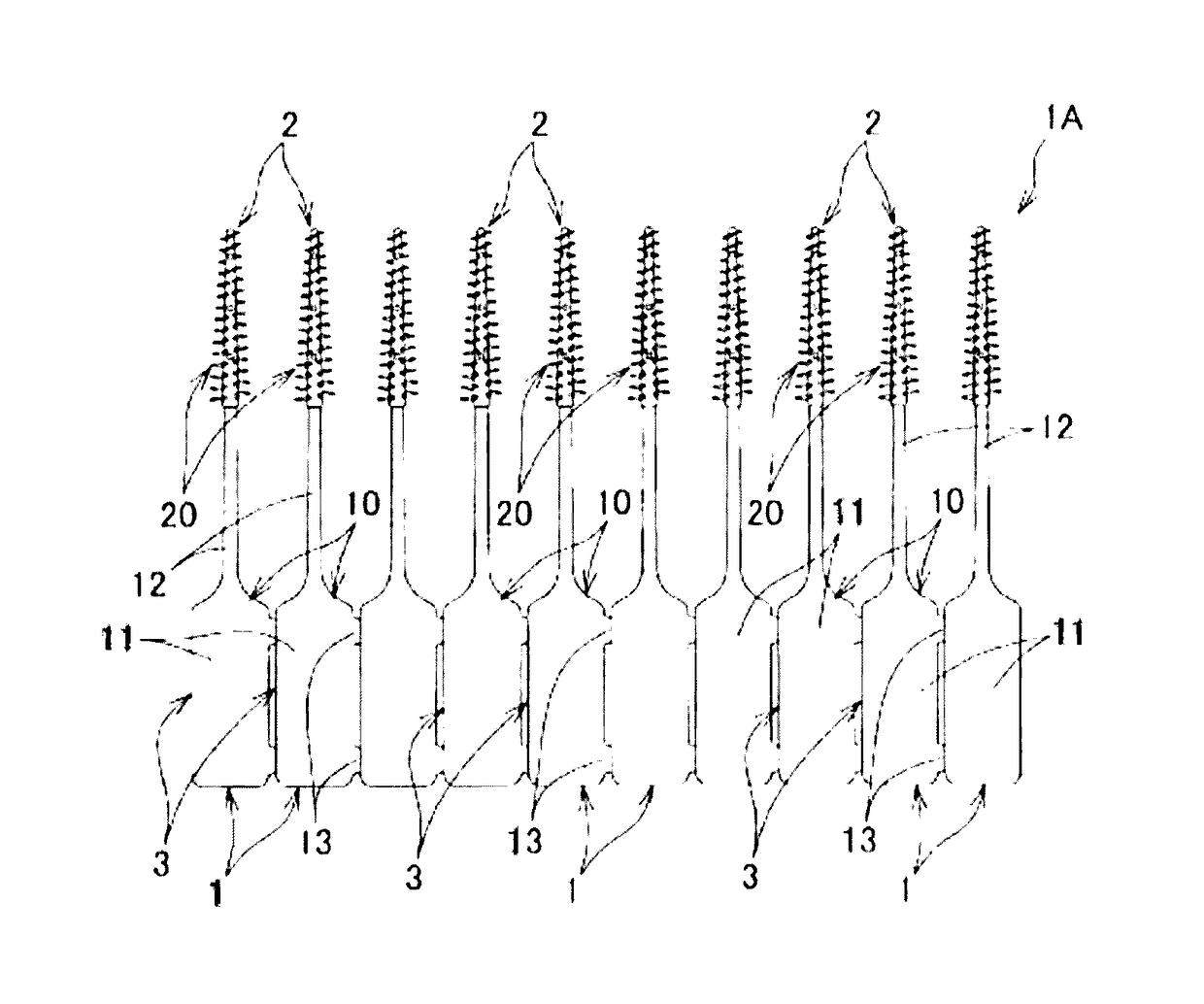

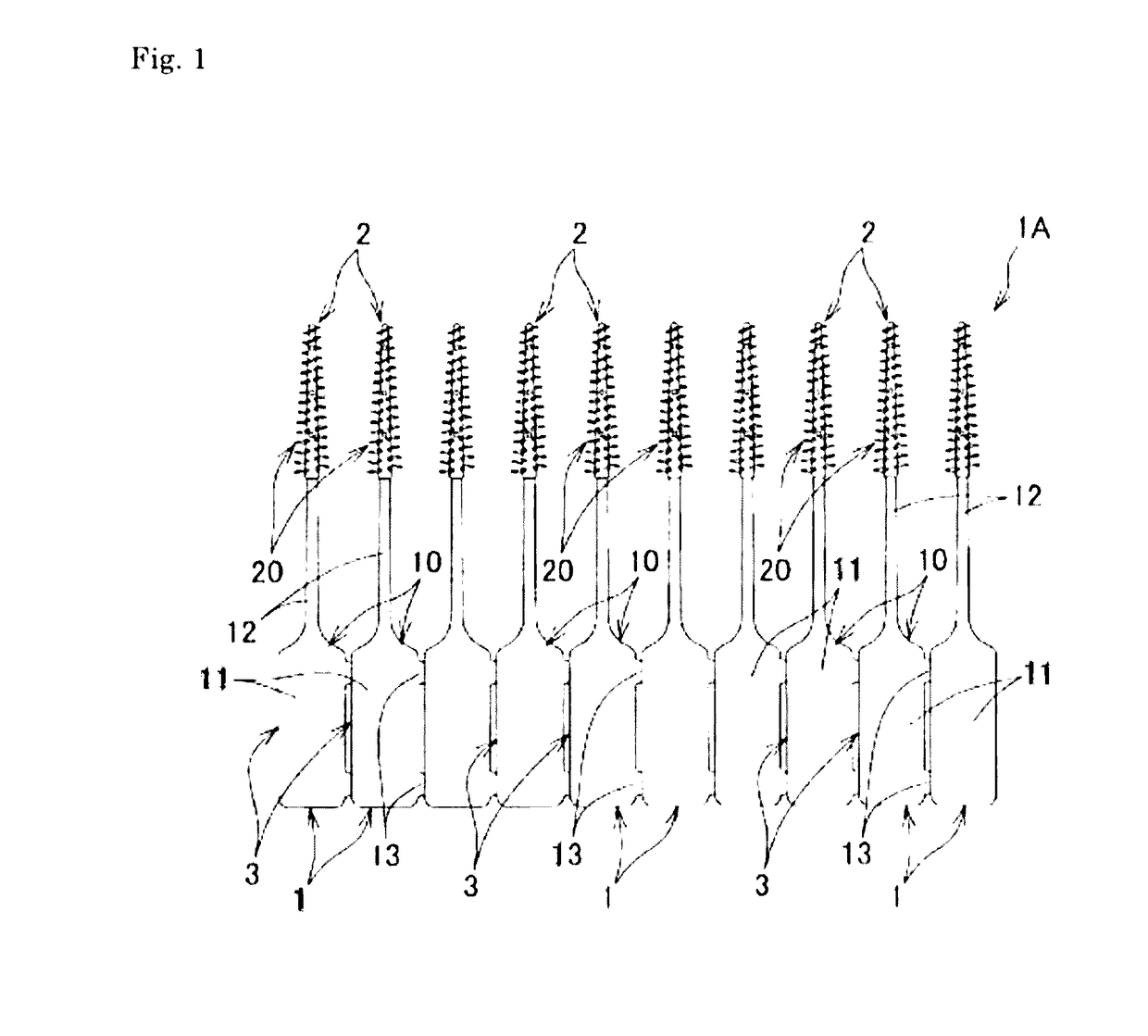

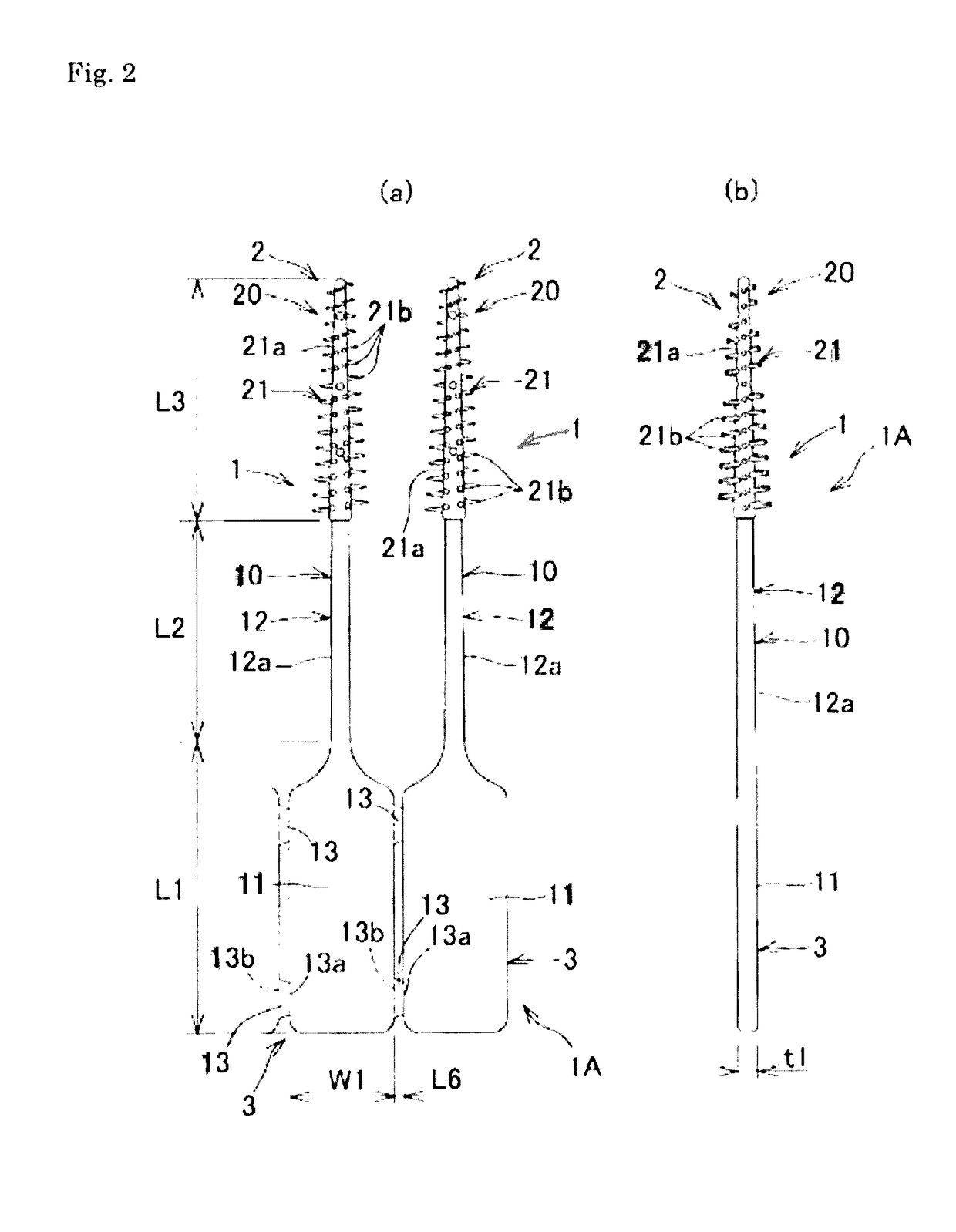

Method for manufacturing an interdental cleaning tool and the interdental cleaning tool

To provide a method for manufacturing an interdental cleaning tool that can prevent deformation of a core base at molding of a cleaning flexible part using an elastomer material, thereby effectively preventing occurrence of molding failure of the cleaning flexible part.The method in the present invention includes: a base part molding step of providing first metal molds 30 and 31 for molding base parts with a plurality of first molding spaces 32 aligned in parallel and including core base molding sections 32a and handle base molding sections 32b, providing the first metal molds 30 and 31 with connection part molding sections 35 to communicate with the adjacent handle base molding sections 32b, and supplying a synthetic resin material with a fiber material at a time to the plurality of first molding spaces 32 from gates 34 to form a plurality of base parts at a time; and a flexible part molding step of setting the core bases of the base parts into second metal molds, holding the core bases at two or more longitudinal portions by a plurality of pairs of hold pins in the second metal molds, each pair including two pins, and charging an elastomer material into the cleaning flexible part molding spaces.

Owner:SUNSTAR SUISSE SA

Toughened thermosetting resin and its preparation method

The toughened thermosetting resin contains thermosetting resin and rubber granules whose mean grain size is 20-500 nm. Said resin is obtained by mixing the fully-vulcanized powder rubber whose mean grain size is 20-500 nm and thermosetting resin prepolymer and making their mixture undergo the process of solidification treatment. Said resin possesses obvious toughened effect, excellent impact resistance and high strength, modulus and heat resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of polypropylene nano composite material

ActiveCN102086280AGood modification effectImprove interface strengthHeat deflection temperatureMasterbatch

The application of the invention discloses a preparation method of a polypropylene nano composite material, which comprises the following steps of: (1) proportionally fusing and blending inorganic nano particles and maleic anhydride grafted polypropylene on an internal mixer, an open mill or a screw extruder to obtain a reinforcing agent master batch; (2) proportionally fusing and blending a beta crystal type nucleating agent and the maleic anhydride grafted polypropylene on the internal mixer, the open mill or the screw extruder to obtain a flexibilizer master batch; and (3) proportionally diluting and dispersing the reinforcing agent master batch and the flexibilizer master batch in a polypropylene high-polymer substrate, and carrying out injection molding to obtain the polypropylene nano composite material. With the preparation method, the technical problem that the nano particles and the nucleating agent agglomerate in the polypropylene substrate is well solved; when the flexibility of the modified polypropylene material is greatly improved, strength, rigidity, heat deflection temperature and other parameters are also improved to a certain extent, and simultaneously the density of the material is hardly increased so that a series of high-strength, high-flexibility and high-heat resistance modified polypropylene materials can be prepared.

Owner:CHINA PETROLEUM & CHEM CORP +1

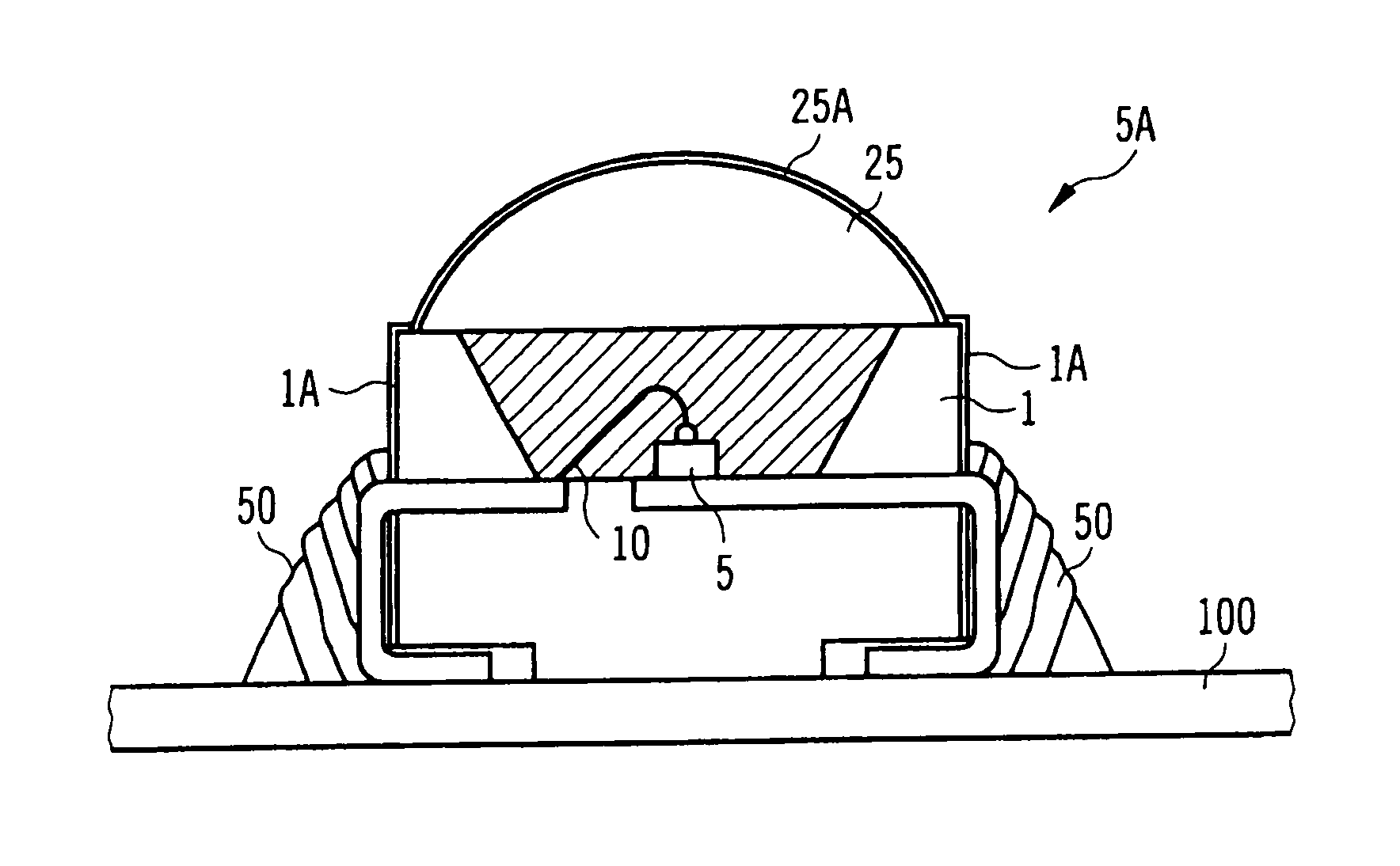

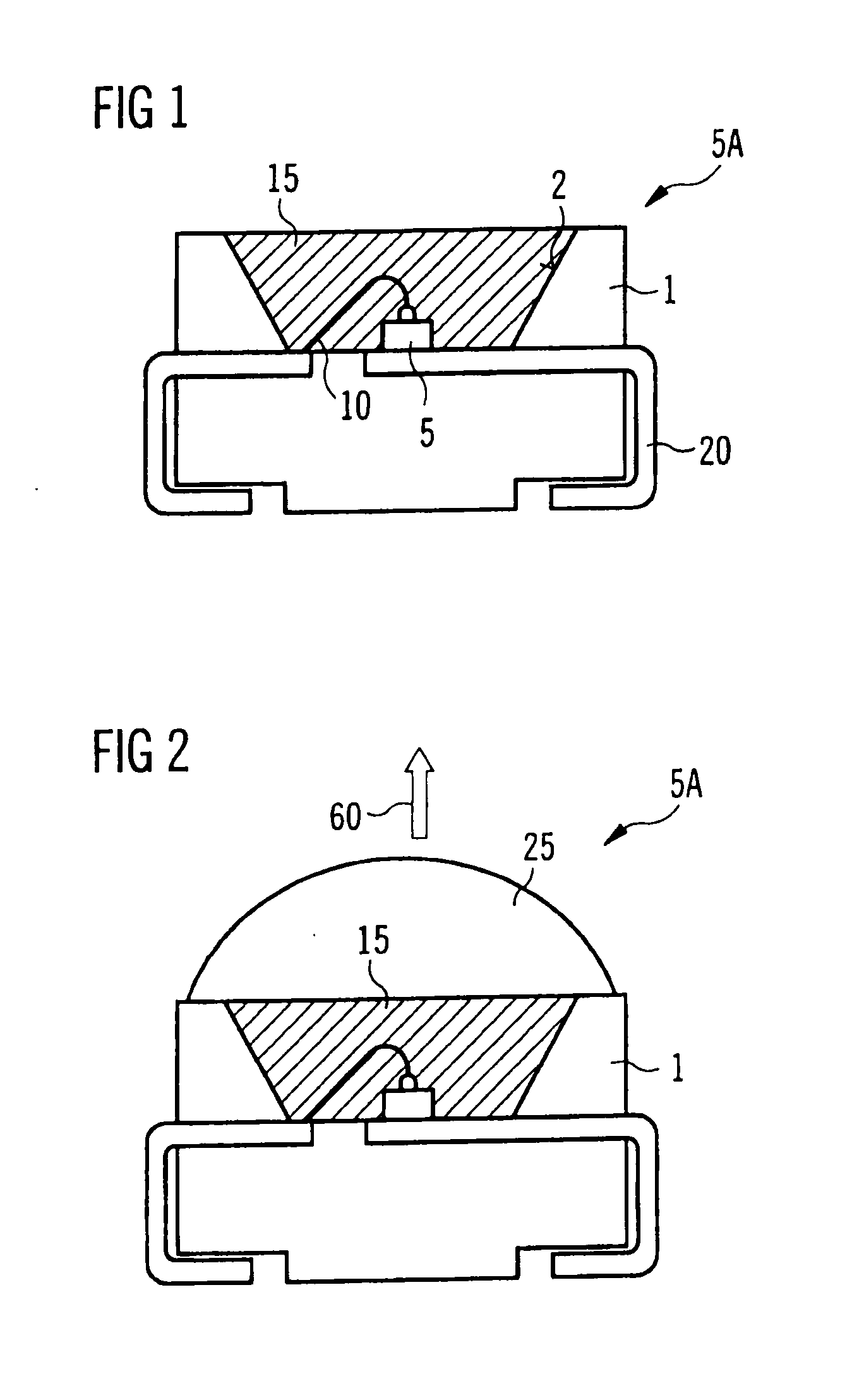

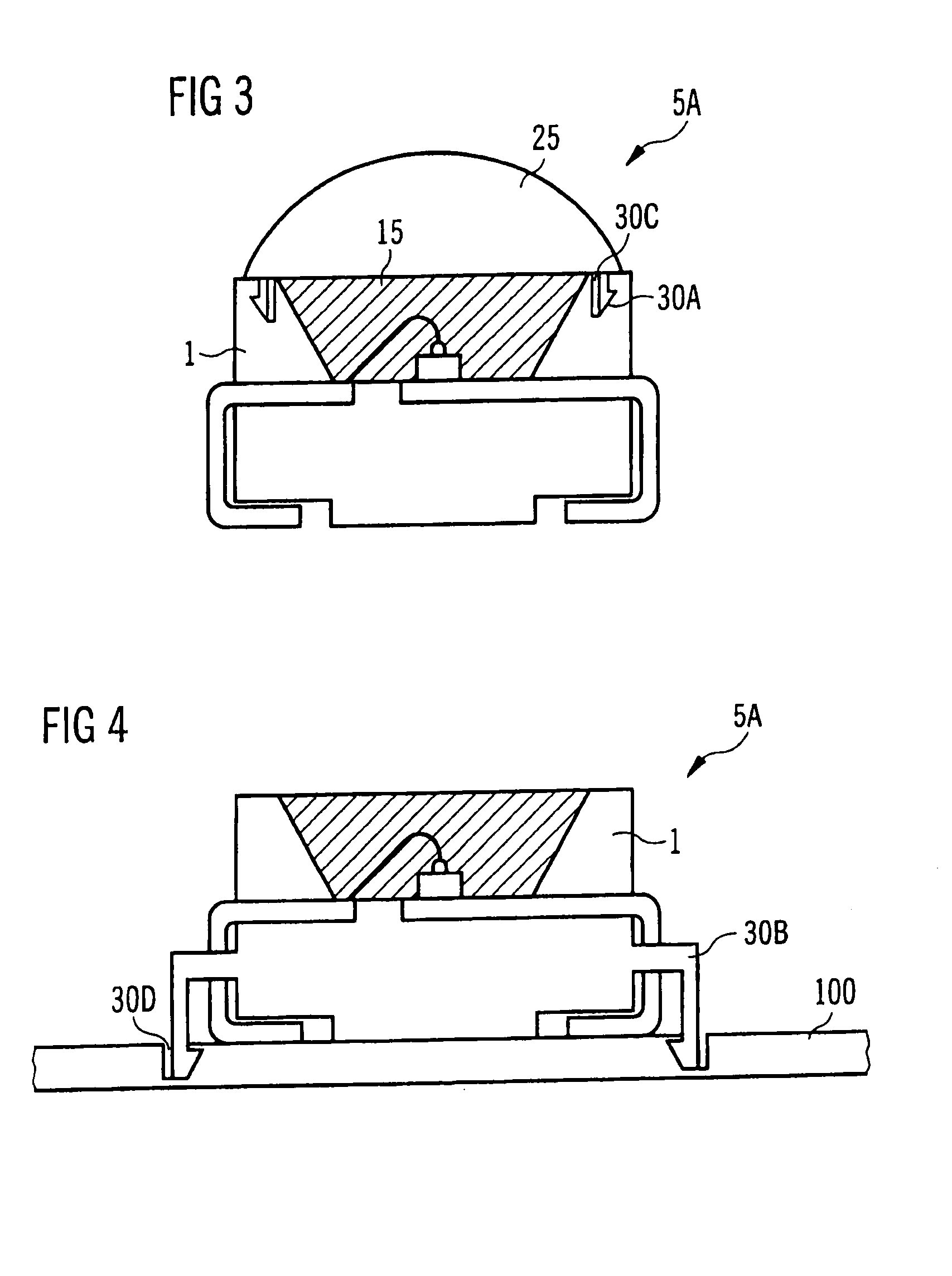

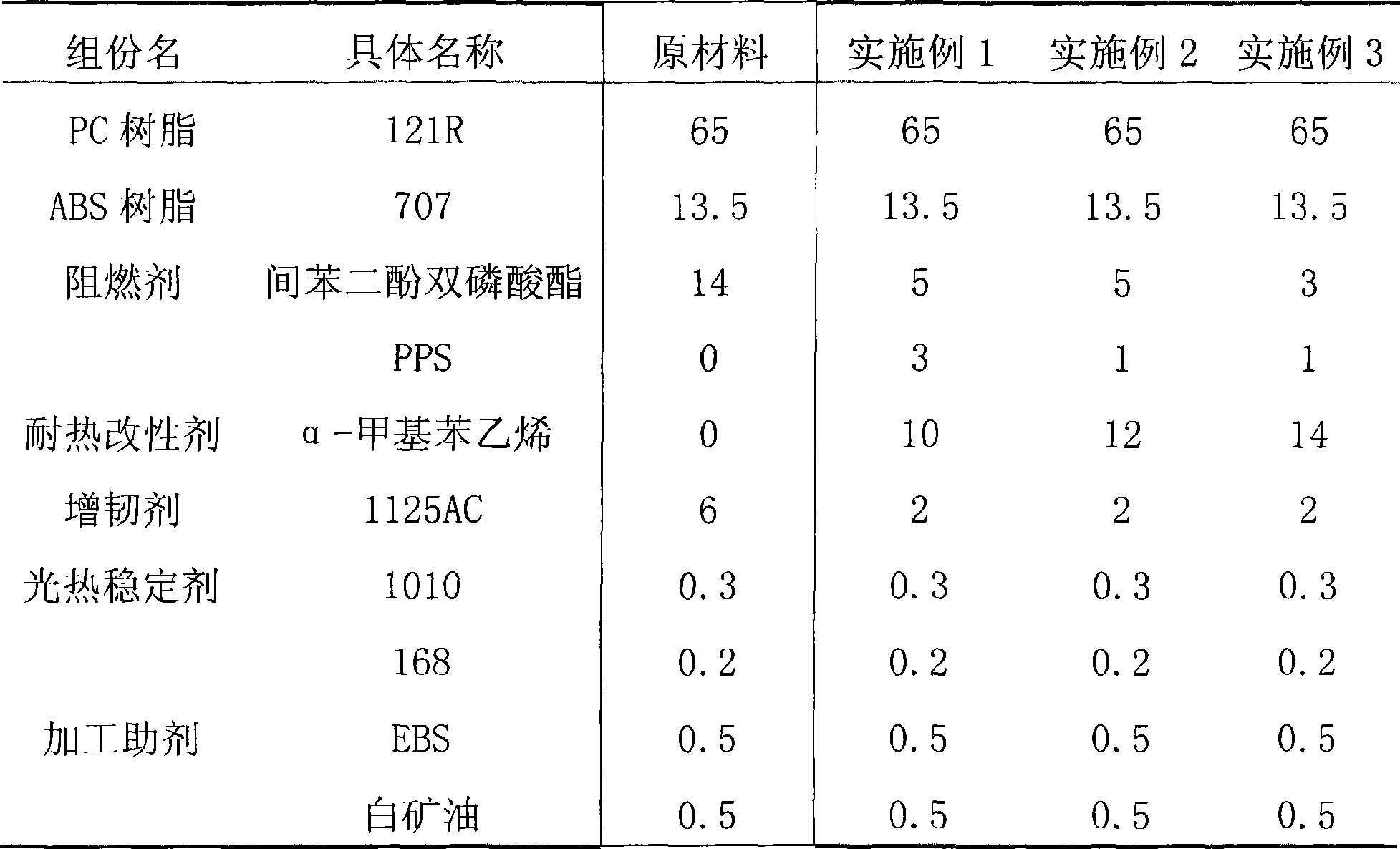

Optical Element, Optoelectronic Component Comprising Said Element, and the Production Thereof

InactiveUS20080224159A1Reduction factorStable against solderingElectric discharge tubesSolid-state devicesHeat deflection temperatureCross-link

The invention relates to an optical element (1, 25) having a defined shape and comprising a thermoplastic material that has been further cross-linked during or following the shaping thereof. Such thermoplastic materials have an increased heat deflection temperature, distortion, but can be easily and economically shaped before the additional cross-linking as a result of the thermoplastic properties thereof.

Owner:OSRAM OPTO SEMICONDUCTORS GMBH & CO OHG

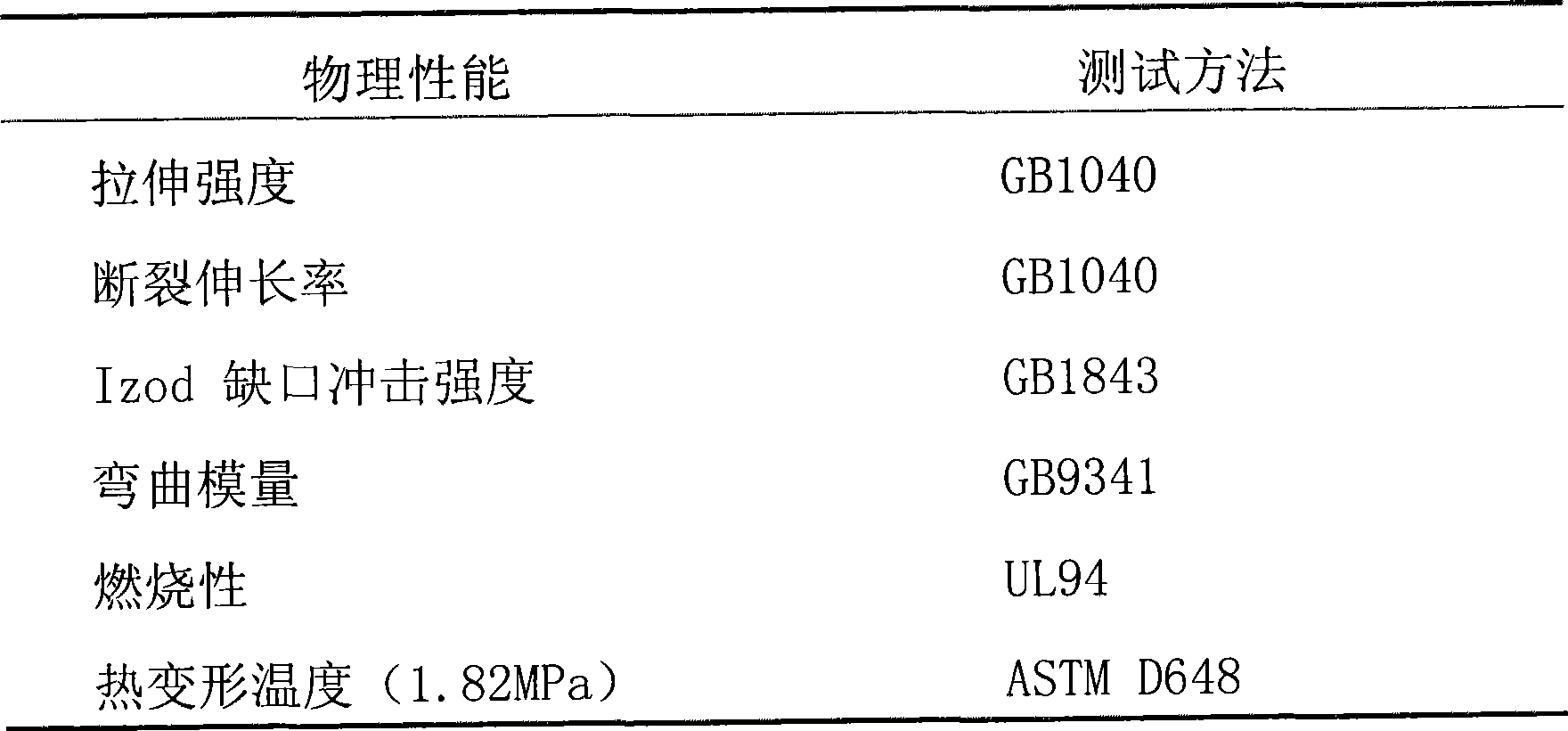

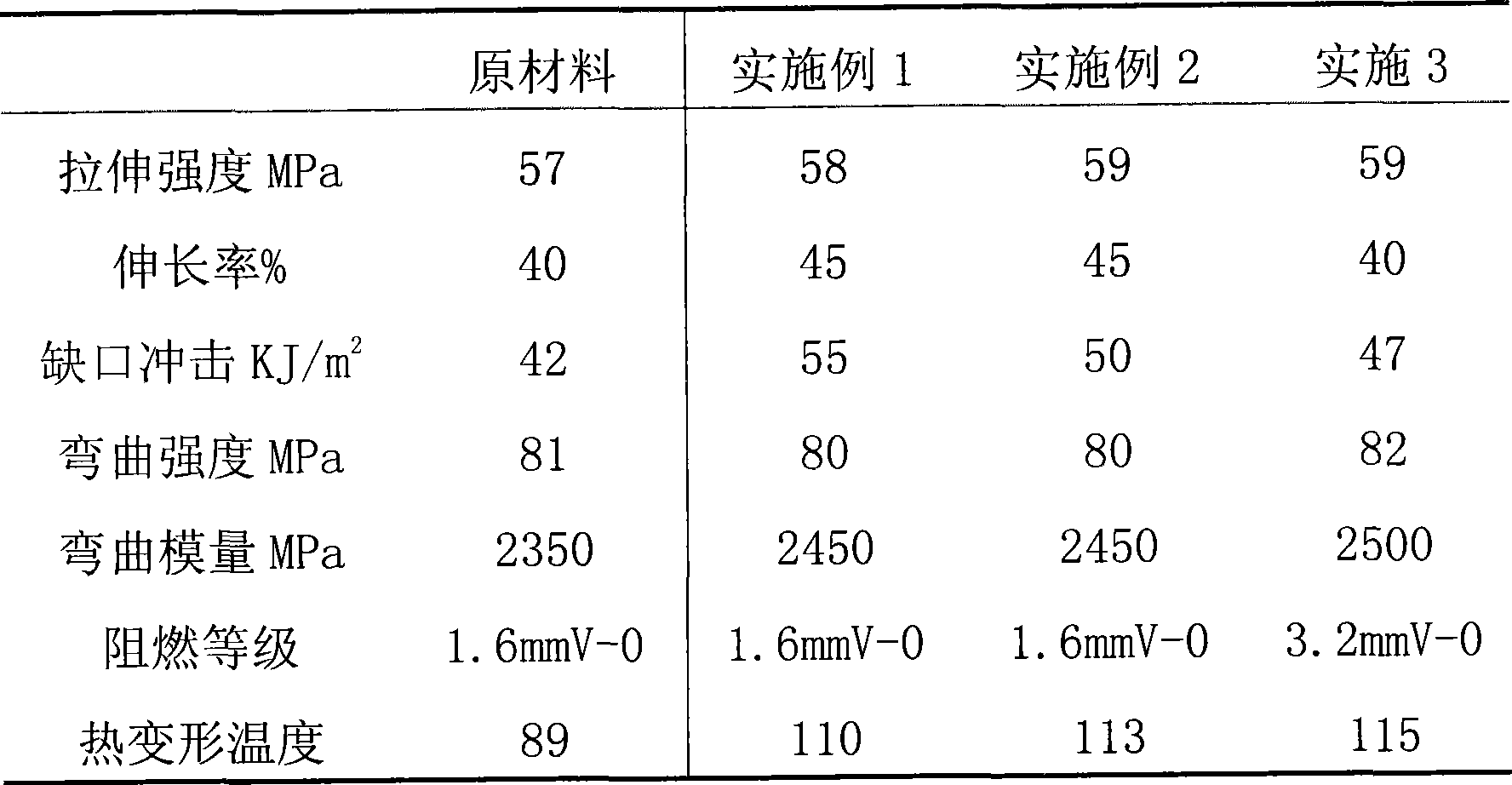

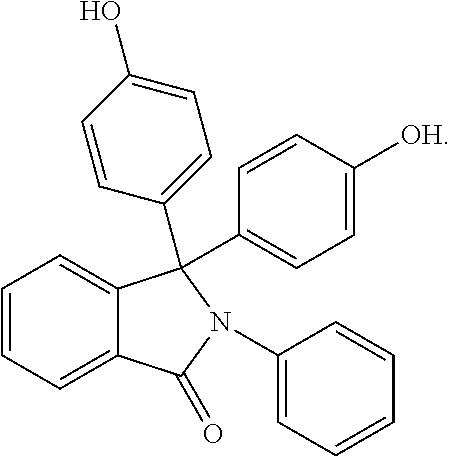

Polycarbonate and acrylic nitrile-butadiene-phenylethylene grafted copolymer heat resisting and flame-retardant alloy

InactiveCN101397396AReduce dosageHigh heat distortion temperatureHeat deflection temperaturePhosphate

The invention relates to an anti-flaming polycarbonate (called PC hereafter) and acrylonitrile-butadiene-styrene graft copolymer (called ABS hereafter) alloy resin, in particular a halogen-free PC and ABS graft copolymer fireproof anti-flaming alloy, and a preparation method thereof. The fireproof anti-flaming alloy comprises the following components as per weight percentage: 53-65 percent of PC, 12-24 percent of ABS resin, 6-18% of flame retardant, 3-12 percent of heat-resistance modifier, 0.6-3 percent of toughener, 0.1-1 percent of optothermal stabilizer and 0.6-3 percent of processing aids, wherein, the flame retardant is the combination of polyphenylene sulfide and organic phosphate flame retardant, and the processing aids include lubricant, coupling agent, antioxidant and processing lubricant aid. The invention uses the mutual matching between the S element contained in the polyphenylene sulfide and the P element contained in the flame retardant to reduce the dosage of the retardant, and improve the heat-resistance and deformation temperature.

Owner:SHANGHAI KINGFA SCI & TECH +1

Ultrahigh-molecular weight polyethylene composite material and preparation method thereof

The invention discloses an ultrahigh-molecular weight polyethylene composite material and a preparation method thereof. The ultrahigh-molecular weight polyethylene composite material comprises the following component in parts by weight: 100 parts of ultrahigh-molecular weight polyethylene, 0.1-10 parts of a lubricating agent, 10-60 parts of a filling material, 5-40 parts of reinforcing fiber and 0.1-10 parts of nanometer inorganic filler. The ultrahigh-molecular weight polyethylene composite material overcomes the difficulty that the ultrahigh-molecular weight polyethylene is very high in melt viscosity and is difficult to prepare; the ultrahigh-molecular weight polyethylene composite material can be prepared into different products through extrusion moulding of an extruder; the modified ultrahigh-molecular weight polyethylene composite material not only has high strength, impact resistance, wear resistance, high rigidity, high surface hardness, chemical corrosion resistance and other performance, but also has good self lubrication and dimensional stability.

Owner:GUANGDONG TAUGHNESS CONVEYOR BELTING

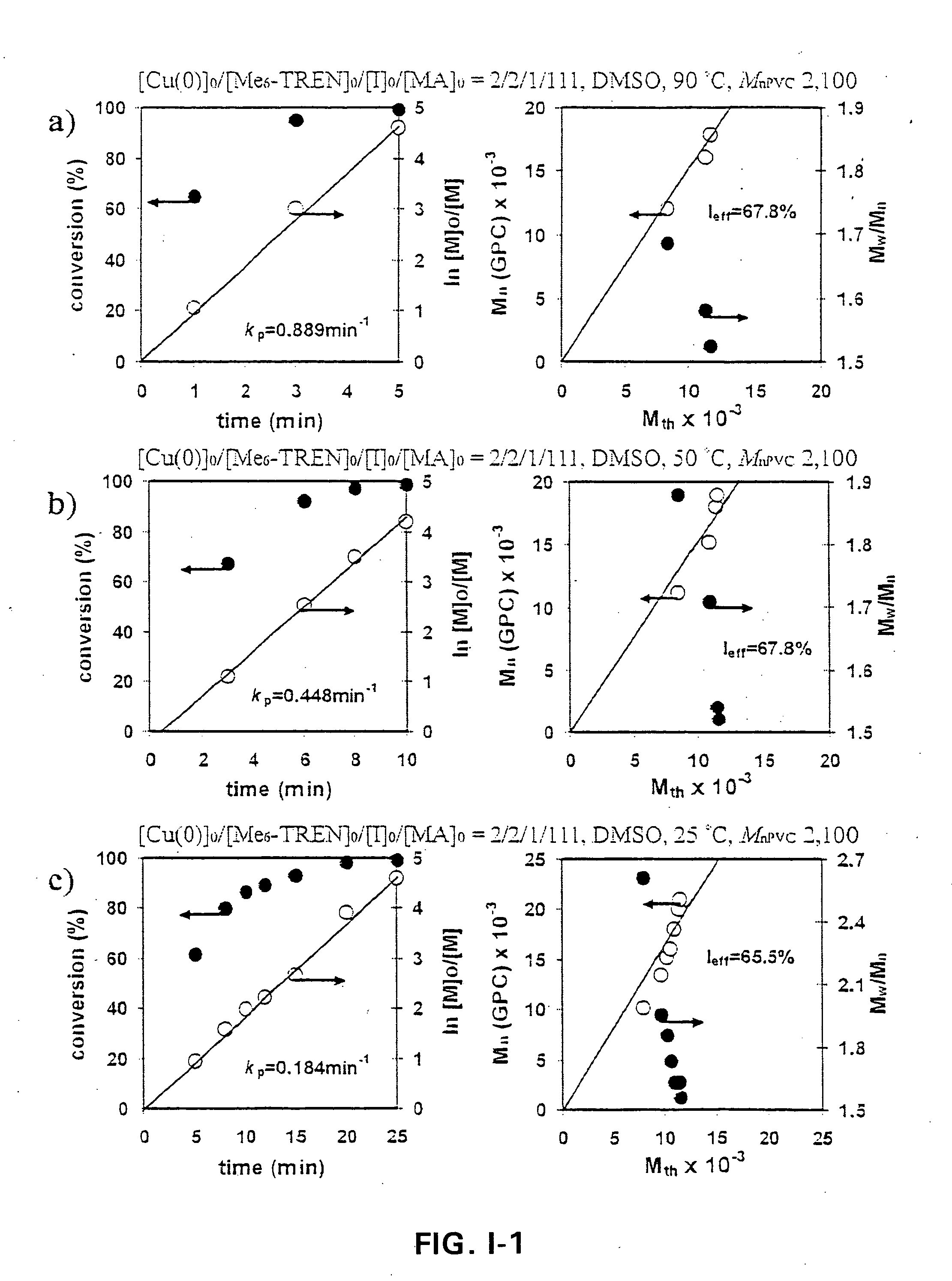

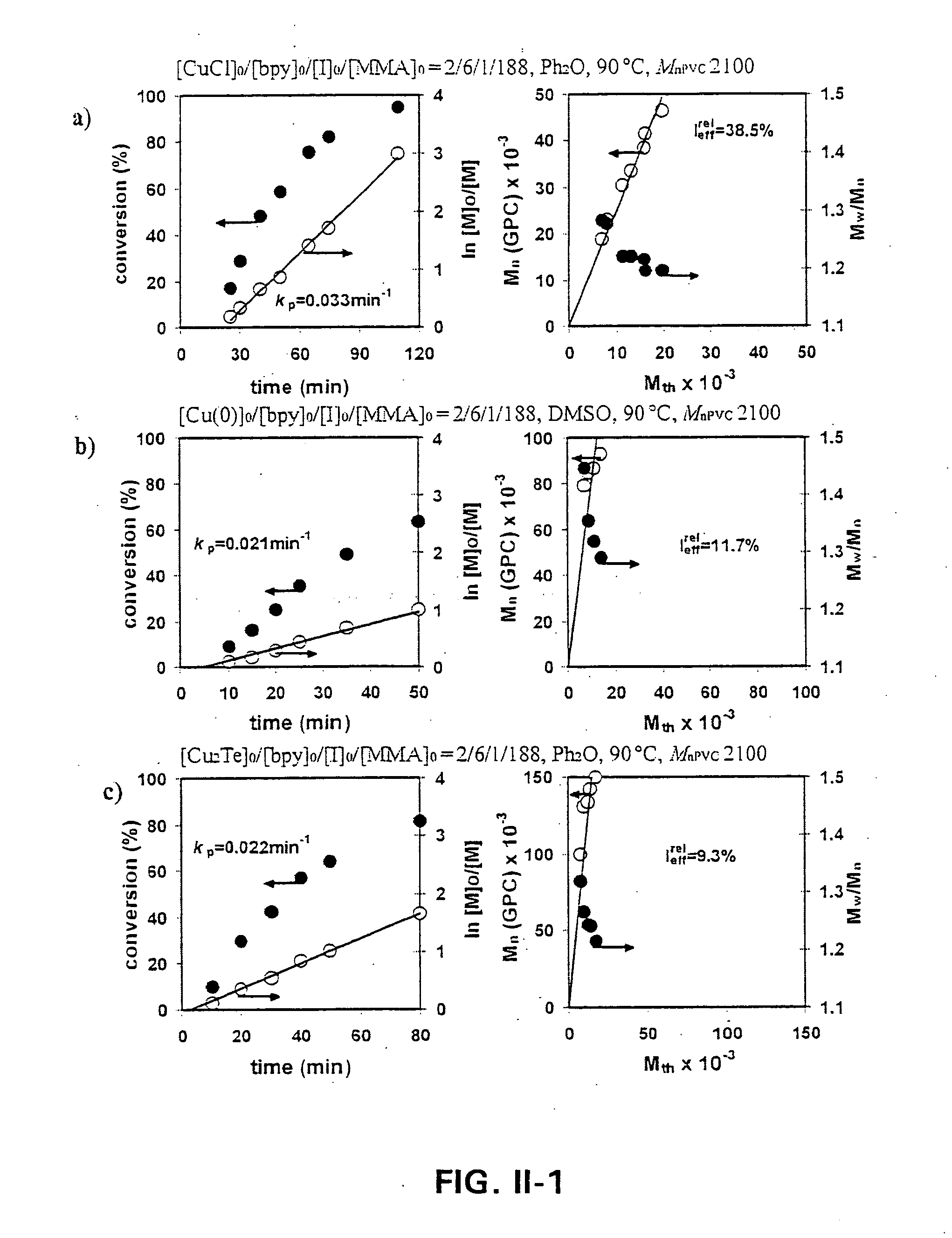

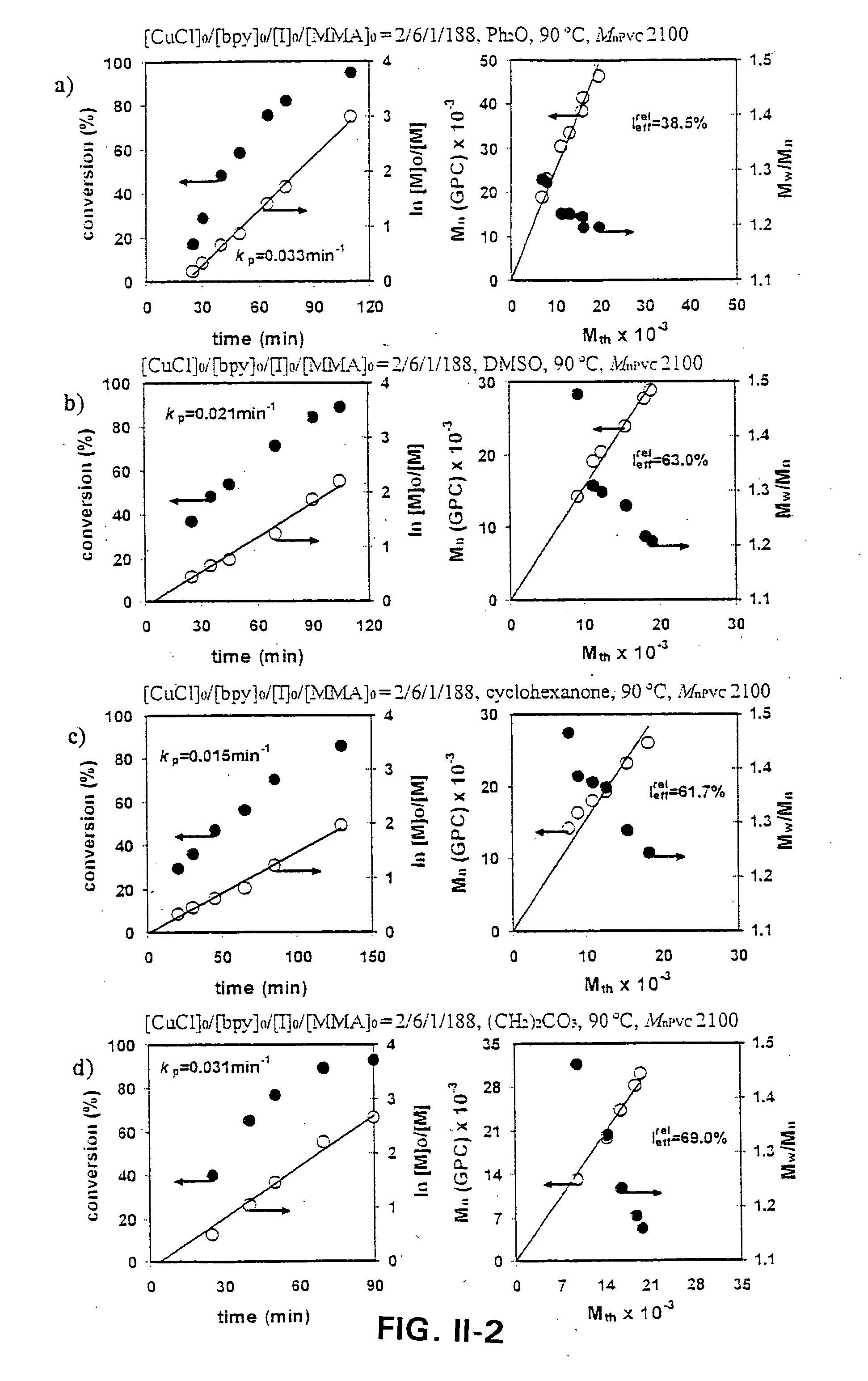

Living radical polymerization of halogen-containing and acrylic monomers and the formation of block copolymers therefrom

InactiveUS20050131186A1High heat distortion temperatureRapid formationCoatingsAdhesivesHalogenVinyl halide

Acrylic polymers are made by the living radical polymerization of acrylic monomers utilizing organo halide initiators with either metal-free or metal catalysts. Moreover, block copolymers of vinyl halide monomers and acrylic monomers are described by generally polymerizing either the vinyl halide monomers or acrylic monomers utilizing an organo halide initiator in the presence of either a metal catalyst or a metal-free catalyst and subsequently polymerizing thereon the remaining type of monomer.

Owner:PENNSYLVANIA UNIV OF

Blow molding grade halogen-free flame-retardant polypropylene material and preparation method thereof

InactiveCN102532727AImprove flame retardant performanceHigh heat distortion temperatureBlow moldingHeat deflection temperature

The invention relates to a blow molding grade halogen-free flame-retardant polypropylene material. A raw material formula of the polypropylene material comprises the following components in percentage by weight: 32-81 percent of polypropylene, 0-1 percent of a thermal stabilizer, 0-1 percent of a lubricant, 2-10 percent of a toughening agent, 10-30 percent of a flame retardant, 2-6 percent of a compatilizer and 5-20 percent of an inorganic filler, wherein the polypropylene is ethylene propylene random copolymerized polypropylene of which the melt flowing rate is 0.01-10 g / 10min and the ethylene mole content is less than or equal to 10 percent; and the flame retardant is a halogen-free phosphorus-nitrogen expandable flame retardant. The polypropylene material disclosed by the invention has excellent flame retardance, high thermal deformation temperature and high comprehensive physical property, and is particularly suitable for blow molding of automobile air channels.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD

Glass fiber reinforced flame retardant polypropylene material for household appliance products and preparation method thereof

The present invention relates to a glass fiber reinforced flame retardant polypropylene material for household appliance products, and belongs to the field of modified polypropylene plastic. The material comprises the following raw materials, by weight: a high-impact-resistance copolymer polypropylene resin, a bromine-based flame retardant agent, antimony trioxide, a flame retardant synergist, alkali-free continuous long glass fibers, a compatibility agent, a toughening agent, a lubricant, a UV absorber and an antioxidant. The present invention provides the glass fiber reinforced flame retardant polypropylene material with higher tensile strength, bending modulus and hardness as well as high impact-resistance, low molding shrinkage, aging resistance and the like. The glass fiber reinforced flame retardant polypropylene material has a high heat deformation temperature, good oxidation resistance at high temperature, and the flame retardant performance up to the level of UL94 V-2, and passes the glow wire test of GWIT: 700 / 3.0. The glass fiber reinforced flame retardant polypropylene material has a low cost and a light weight, and can be used instead of metal or plastic material to produce the household appliance products which need flame retardation and high temperature resistance.

Owner:GUANGDONG JUSHI CHEM CO LTD

Polycarbonate compositions

ActiveUS20140058023A1Improved flame retardance and impact strength and heat resistanceImprove flame retardant performancePhosphorus organic compoundsPolymer sciencePolycarbonate

Disclosed herein are methods and compositions of blended polycarbonate resins with improved flame resistance and impact strength. The resulting compositions can be used in the manufacture of articles while still retaining the advantageous physical properties of blended polycarbonate compositions with improved flame resistance and impact strength. This abstract is intended as a scanning tool for purposes of searching in the particular art and is not intended to be limiting of the present invention.

Owner:SHPP GLOBAL TECH BV

Method for manufacturing an interdental cleaning tool and the interdental cleaning tool

To provide a method for manufacturing an interdental cleaning tool that can prevent deformation of a core base at molding of a cleaning flexible part using an elastomer material, thereby effectively preventing occurrence of molding failure of the cleaning flexible part.The method in the present invention includes: a base part molding step of providing first metal molds 30 and 31 for molding base parts with a plurality of first molding spaces 32 aligned in parallel and including core base molding sections 32a and handle base molding sections 32b, providing the first metal molds 30 and 31 with connection part molding sections 35 to communicate with the adjacent handle base molding sections 32b, and supplying a synthetic resin material with a fiber material at a time to the plurality of first molding spaces 32 from gates 34 to form a plurality of base parts at a time; and a flexible part molding step of setting the core bases of the base parts into second metal molds, holding the core bases at two or more longitudinal portions by a plurality of pairs of hold pins in the second metal molds, each pair including two pins, and charging an elastomer material into the cleaning flexible part molding spaces.

Owner:SUNSTAR SUISSE SA

Polypropylene nucleator and its prepn process

InactiveCN1432594AHigh transparencyRaise the crystallization temperatureOrganic phosphatesLithium compound

The present invention is polypropylene nucleator and its preparation process with alkyl metal phosphate as material. The nucleator is prepared with organic phosphate and its derivative, superfine inorganic oxide, aluminium-lithium compound and high level aliphatic salt as material. The organic phosphate includes alkyl methylene di(2,4-bialkyl phenoxy) phosphate and di[alkyl methylene di(2,4-bialkyl phenoxy)] phosphate. The preparation process includes mixing, grinding and sieving and obtains polypropylene nucleator to 0.5-100 micron diameter.

Owner:YANGZI PETROCHEM

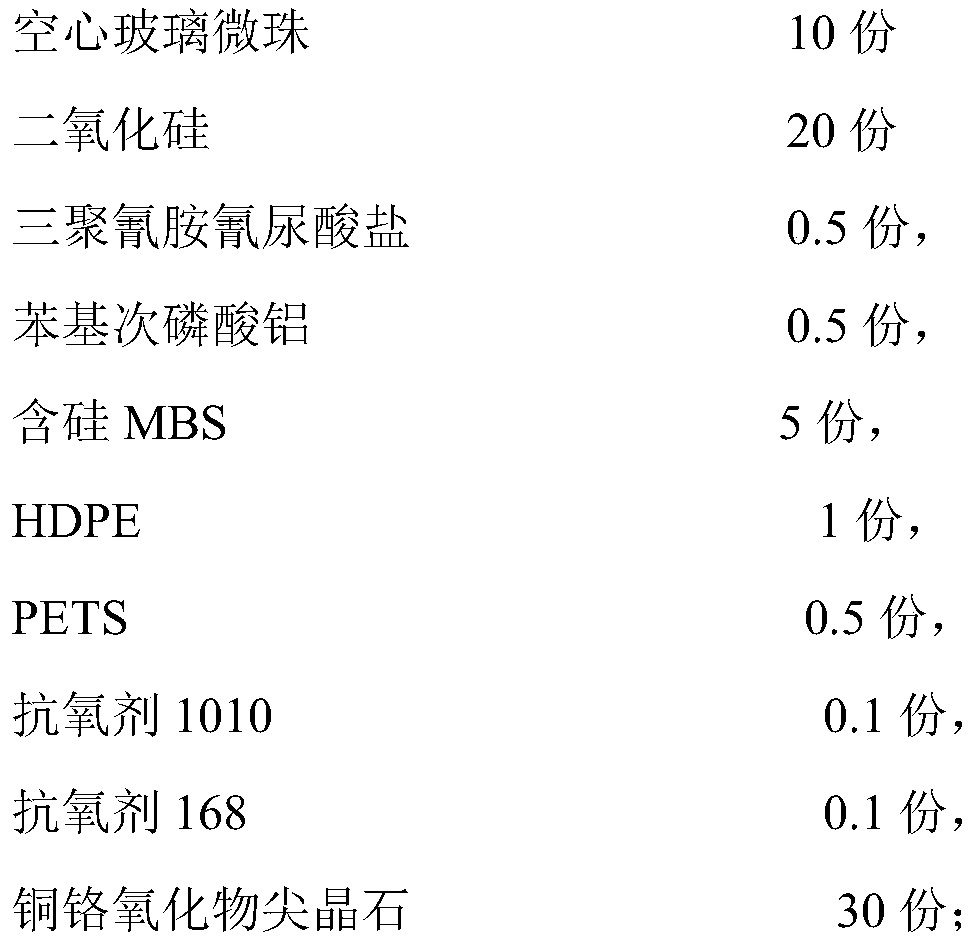

Low-dielectric laser direct structuring composite material suitable for 5G communication and preparation method thereof

ActiveCN110655792ALow dielectric constantHigh heat distortion temperatureChemical platingFire retardant

The invention relates to a low-dielectric laser direct structuring composite material suitable for 5G communication. The composite material is composed of the following components in parts by weight:52 to 86 parts of base resin, 0 to 30 parts of glass fibers, 10 to 30 parts of a filling agent, 1 to 9 parts of a flame retardant, 4 to 15 parts of a toughening agent, 0.1 to 1 part of a lubricating agent, 0.2 to 1 part of an antioxidant and 10 to 30 parts of a laser sensitive additive. A preparation method of the composite material comprises the steps that a twin-screw extruder is used for processing, the melt extrusion temperature is 250-380 DEG C, and the screw rotating speed is 150-300 rpm / min. The composite material has low dielectric property, so that improvement of the transmission speed of 5G communication millimeter wave signals is facilitated, the signal delay is reduced, and the signal loss is reduced; the composite material has the LDS processing capacity, can be rapidly prepared in a small size and a large number, can be subjected to batch laser etching and chemical plating to form a metal connecting circuit, and is an optimal solution of a 5G plastic antenna oscillator material.

Owner:中广核高新核材科技(苏州)有限公司

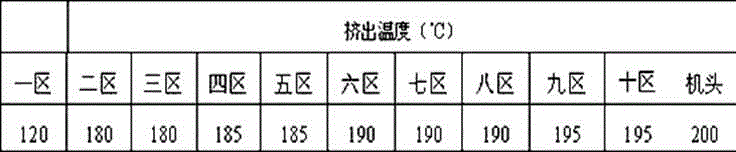

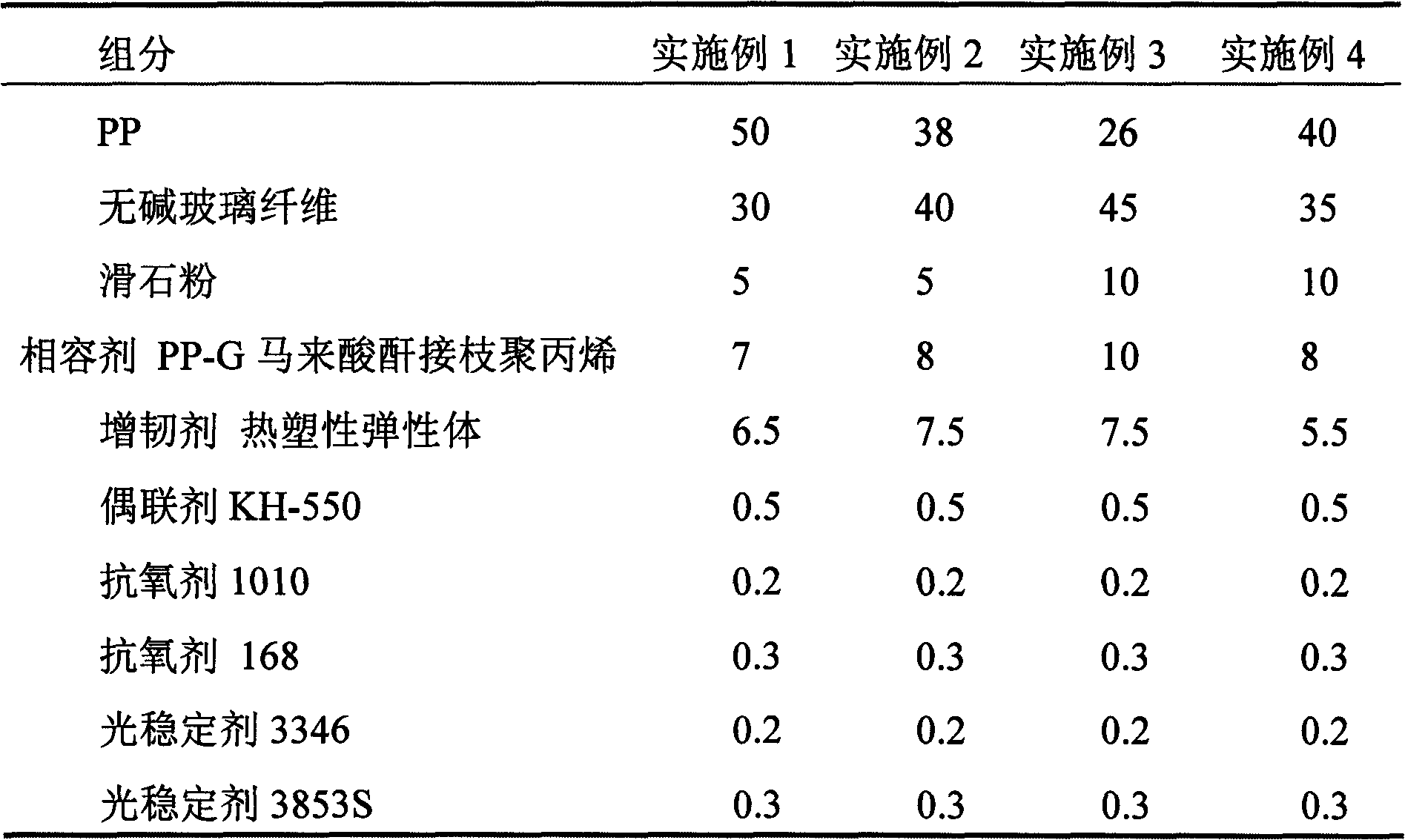

Thermoplastic composite material for hollow building templates and manufacture method thereof and application thereof

InactiveCN103160030AImprove rigidityImprove toughnessForming/stuttering elementsGlass fiberAntioxidant

The invention relates to a thermoplastic composite material for hollow building templates and a manufacture method thereof and application thereof. By weight, 20-55 parts of polypropylene, 30-50 parts of glass fiber, 5-10 parts of inorganic filler, 5-10 parts of flexibilizer, 5-10 parts of compatilizer, 0.1-0.5 part of coupling agents, 0.1-0.3 part of antioxidant and 0.2-0.3 part of light stabilizing agents are mixed for 3-5 minutes in a high-speed mixer, and extruded from a double-screw extruder to form the thermoplastic composite material. The thermoplastic composite material is smelted, extrude-molded, vacuum-cooling-molded, primarily dragged, heated to eliminate stress, secondarily dragged and cut into the hollow building templates meeting requirements. Compared with the prior art, the thermoplastic composite material has the advantages of being high in strength, roughness and size stability, and the like.

Owner:上海铂砾耐材料科技有限公司

Extruded expanded polypropylene beads and preparation method thereof

InactiveCN102295807AControllable foam densityControl the foaming process conditionsPolymer sciencePolypropylene

The invention discloses extrusion expanded polypropylene beads, which comprise 100 weight parts of polypropylene, 0.02 to 0.6 weight part of beta nucleating agent, 0 to 0.6 weight part of antioxygen, 0 to 2 weight parts of lubricating agent, 0 to 3 weight parts of foaming nucleating agent and 0 to 2 weight parts of colorizing agent. The invention also discloses the preparation method of the extrusion expanded polypropylene beads. The method is simple in operation, can be used for continuous production and is suitable for industrial production.

Owner:CGN JUNER NEW MATERIALS +1

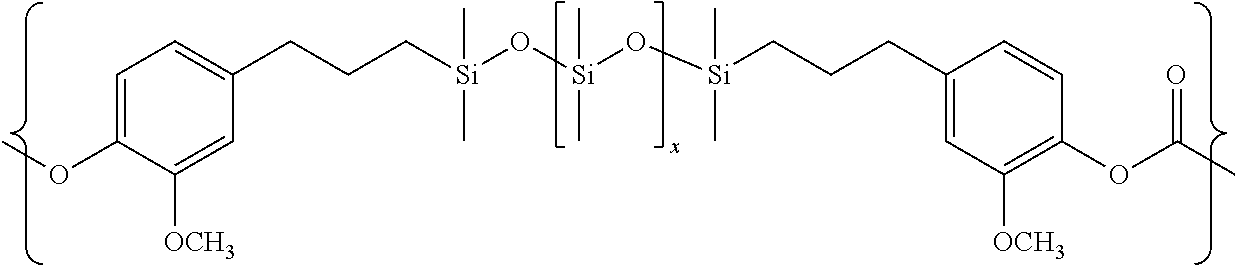

Polyamide composition with high dimensional stability and preparation method thereof

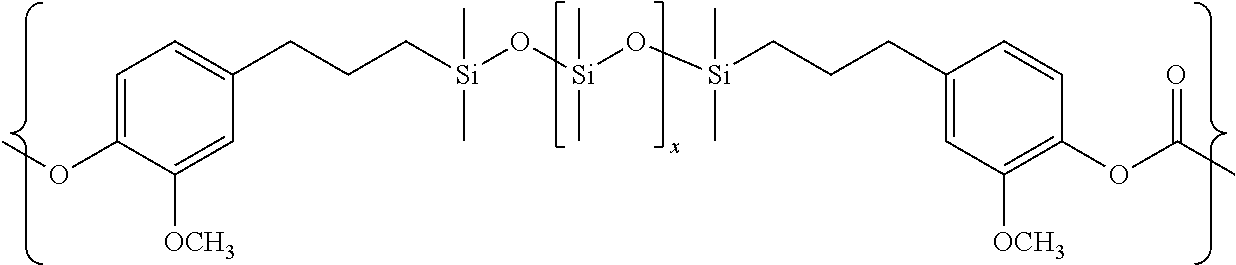

InactiveCN101857723AReduce the degree of orderLow water absorptionHeat deflection temperaturePolyamide

The invention relates to a polyamide composition with high dimensional stability and a preparation method thereof. The polyamide composition comprises the following components in parts by weight: 60 to 90 of fatty polyamide composition, 2 to 10 of compatilizer, 1 to 10 of inorganic metal compound, 0 to 5 of polysiloxane with low molecular weight and 0 to 2 of auxiliary agent. The preparation method comprises the following steps of: premixing the raw materials in a high-speed mixer for 10 to 30min, controlling the temperature to be 40 to 60 DEG C, then adding premix into a double-screw extruder, conveying, melting, shearing, extruding, cooling and granulating so as to prepare a polyamide composition product with high dimensional stability. Compared with the prior art, the invention shows excellent dimensional stability and heat distortion temperature with high retention rate, is suitable for occasions with higher requirement to the dimensional stability, such as the panel of the air conditioner of an automobile, an instrument panel, a camera bracket, a sports apparatus and the like, and can be directly processed by injection molding or other forming methods.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com