Toughened thermosetting resin and its preparation method

A thermosetting and resin technology, applied in the field of rubber toughened thermosetting resin and its preparation, can solve the problems such as the decrease of heat resistance and strength of thermosetting resin, unsatisfactory toughening effect, and high process control requirements, and achieve vitrification. The effect of temperature increase, obvious toughening effect and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

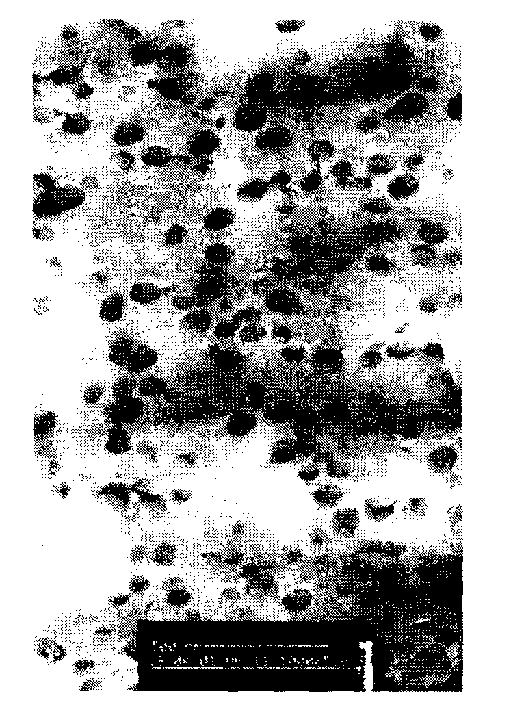

[0019] Weigh 24 grams of epoxy resin (produced by Wuxi Resin Factory, trade name: E-44), premix (NMRT-1) (self-made) of epoxy resin prepolymer and rubber particles, 43.2 grams, 45 grams of methyl tetra Hydrophthalic anhydride (Zhejiang Jiaxing Dongfang Chemical Plant) was put into a three-necked flask, heated in a constant temperature water bath at 90°C, stirred and mixed for 30 minutes, added 0.9 g of triethanolamine (Jiamusi Petrochemical Plant), stirred and evacuated for 5 minutes, and then The mixture was poured into a polytetrafluoroethylene mold preheated to 130°C, pre-cured at 130°C for 1 hour, cooled and demolded, and post-cured at 110°C for 16 hours to obtain a product, and various properties were tested. The test results are shown in Table 1. The transmission electron microscope photograph of the sample is attached figure 1 , the shaded part in the figure is the rubber particles dispersed in the thermosetting resin matrix, with an average particle size of about 90nm...

Embodiment 2

[0022] Change the consumption of epoxy resin and NMRT-1 into 48 grams and 14.4 grams respectively, all the other conditions are with embodiment 1, test result is shown in Table 1.

Embodiment 3

[0024] Change the consumption of epoxy resin and NMRT-1 into 36 grams and 28.8 grams respectively, all the other conditions are the same as Example 1, and the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com