Patents

Literature

212 results about "Diallyl phthalate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A carcinogenesis bioassay of diallyl phthalate (99% pure) was conducted by administering 0 (vehicle control), 150, or 300 mg/kg diallyl phthalate in corn oil by gavage, 5 days per week for 103 weeks, to groups of 50 male and 50 female B6C3F1 mice.

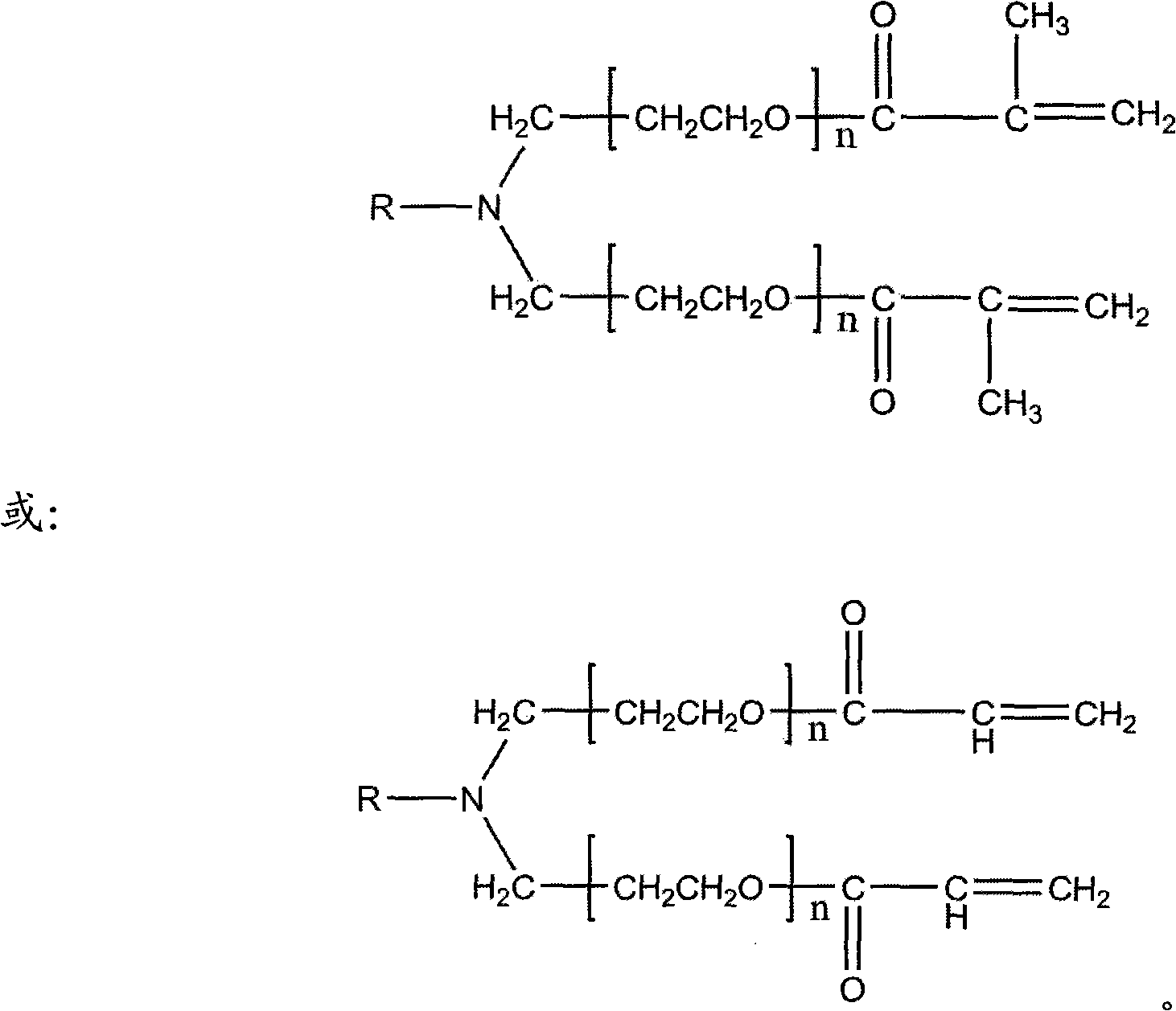

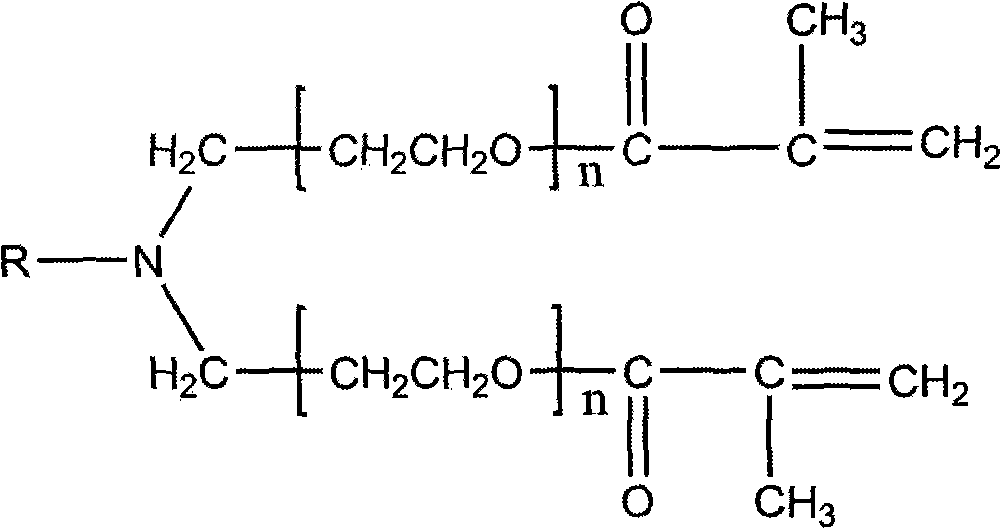

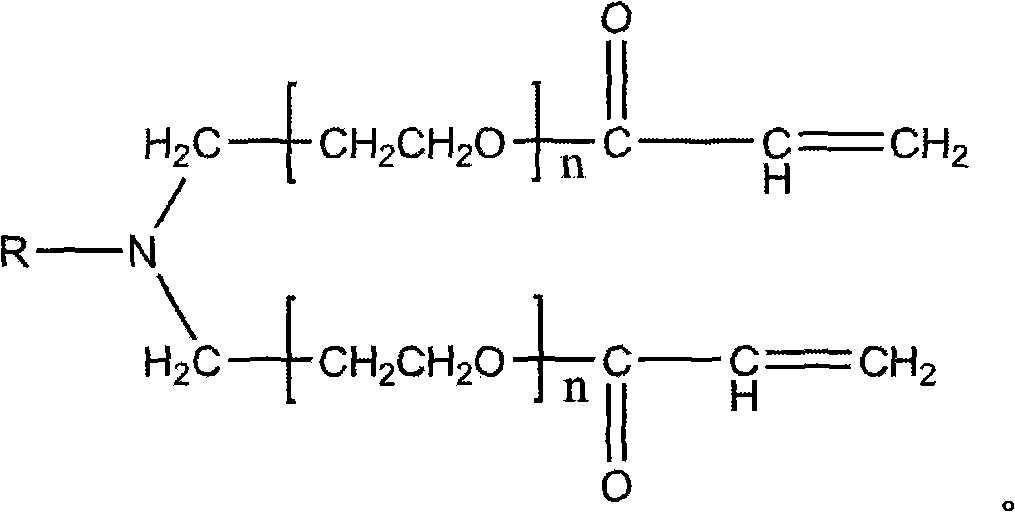

Thickening agent synthesized by acrylic ester and preparation method thereof

InactiveCN101619543AGood thickening effectStrong electrolyte resistanceOrganic compound preparationDyeing processTextile printerSodium methoxide

The invention discloses a preparation method for synthesizing a thickening agent by acrylic ester. The thickening agent synthesized by acrylic ester comprises crylic acid, acrylamide, 25 percent of ammonia water, a functional monomer, EDTA, deionized water, tasteless kerosene, 3<#> white oil, diallyl phthalate, ammonium persulphate, Span 80 and isomeric hexadecanol polyethenoxy ether, wherein the functional monomer is prepared from alicyclic amine polyethenoxy ether, methyl methacrylate, nitroxide free radical pipradrol and sodium methoxide. The preparation method synthesizes a special weak cation type (methyl) acrylic ester functional monomer by adopting an ester exchange method, and the functional monomer and vinyl monomers of the acrylic acid, the acrylamide, and the like are adopted to synthesize a textile printing thickening agent by adopting inverse emulsion polymerization. The thickening agent has the characteristics of high thickening capacity, strong electrolyte resistant capacity and good water-retaining property.

Owner:成都德美精英化工有限公司

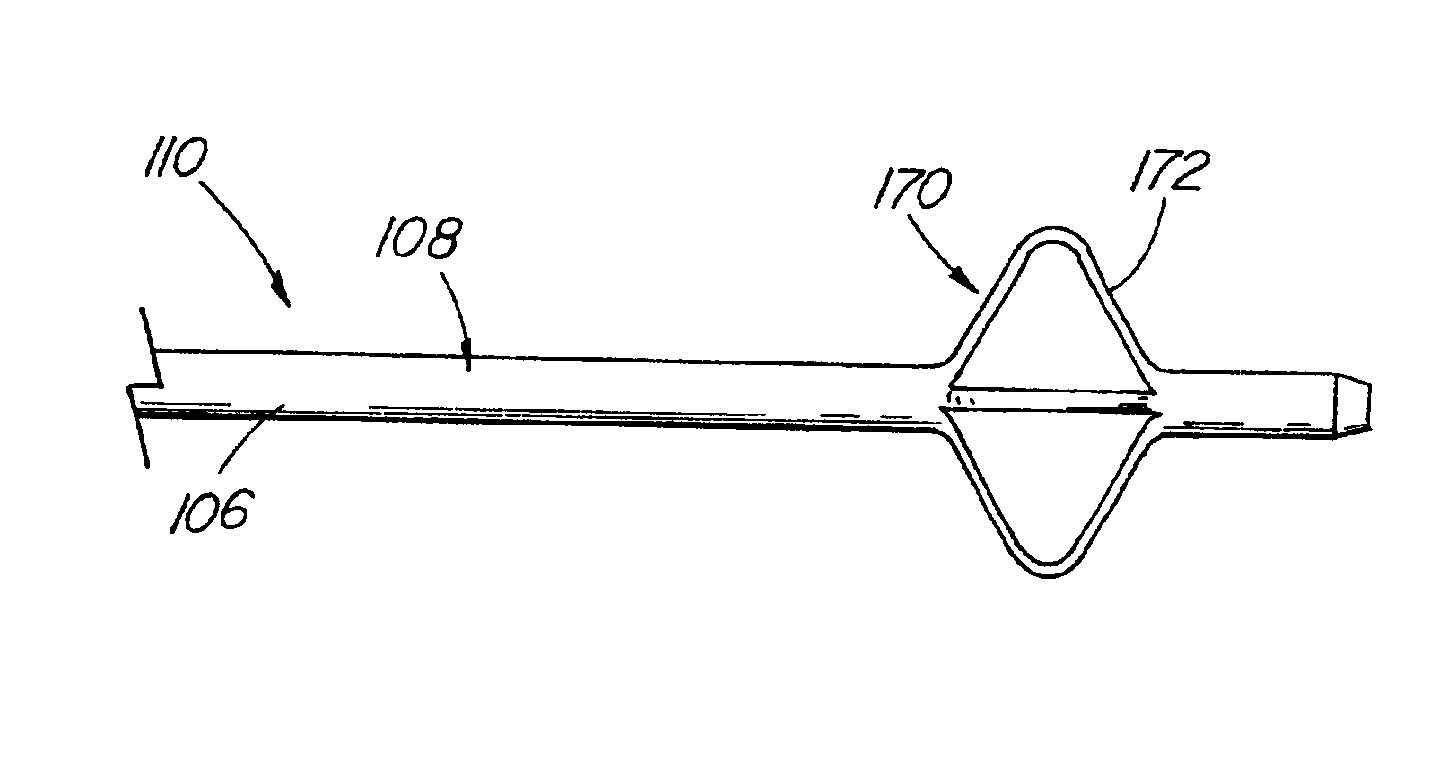

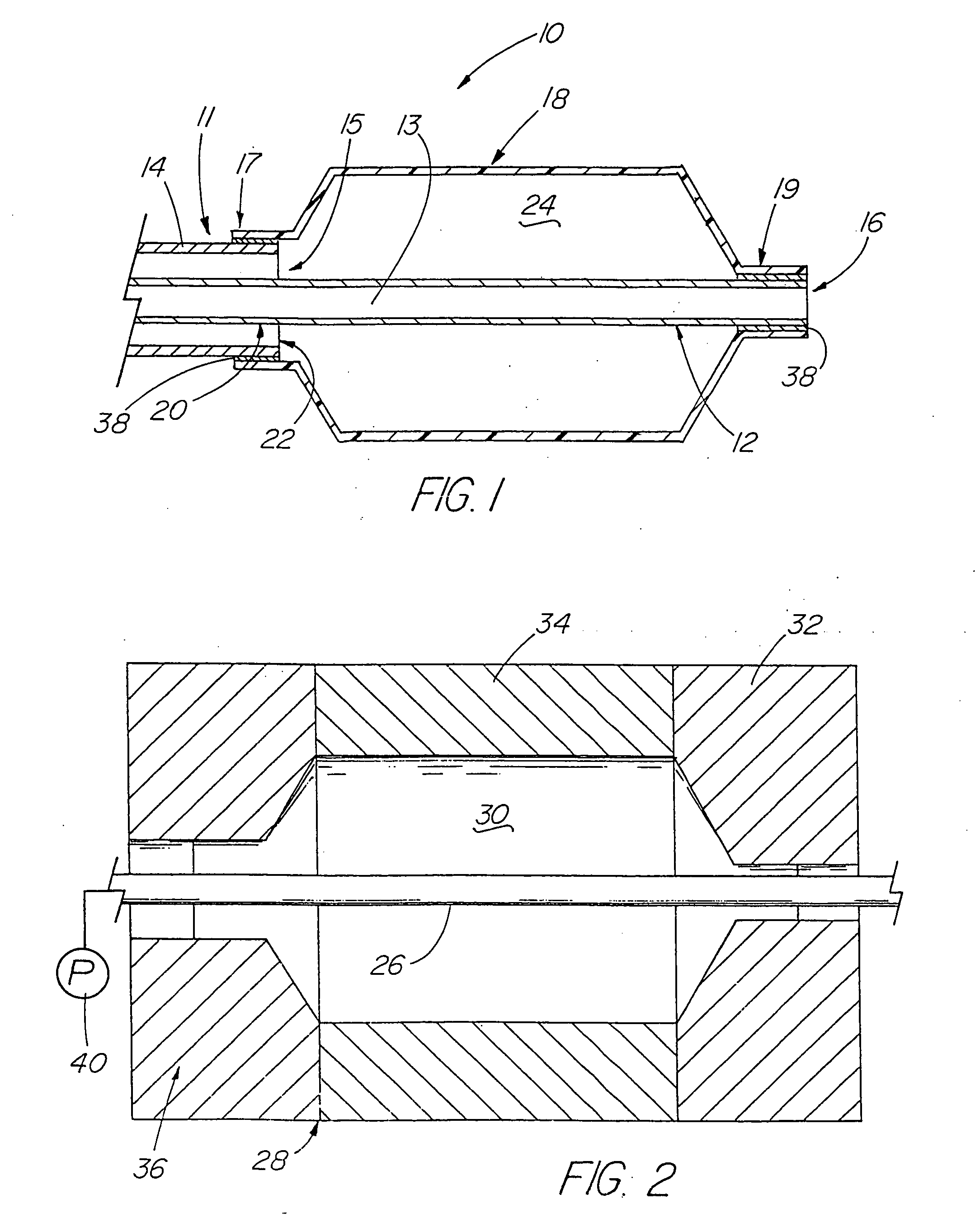

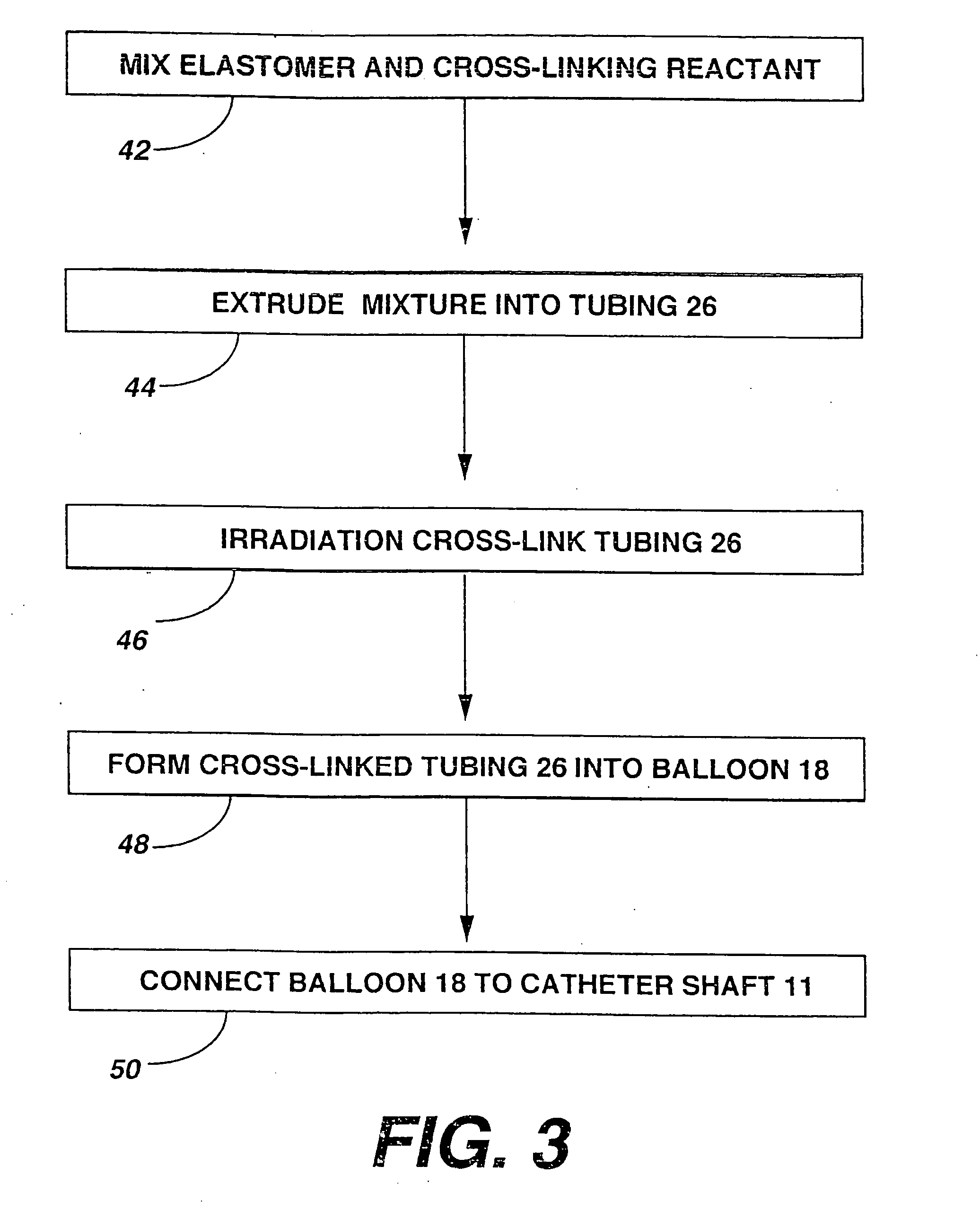

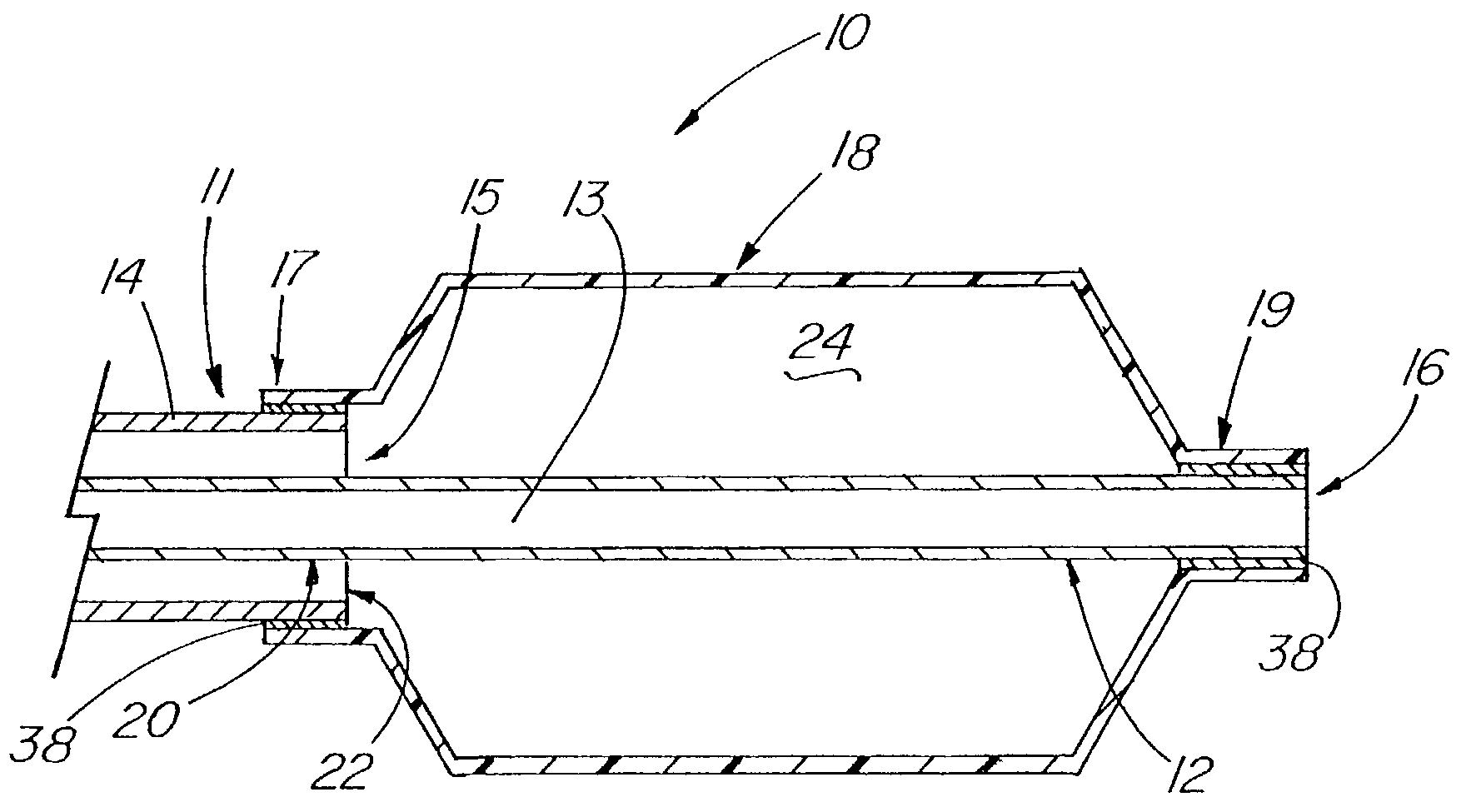

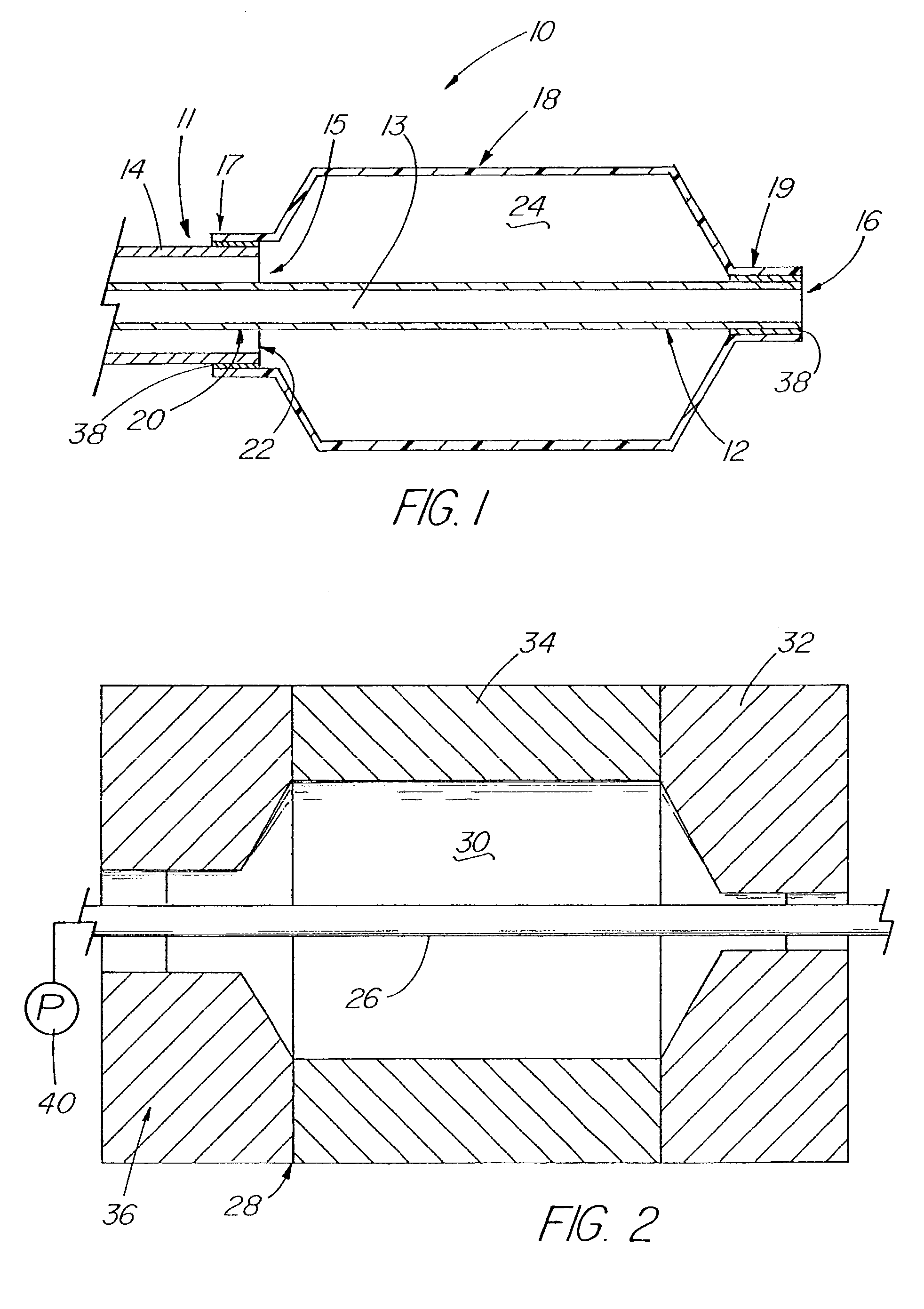

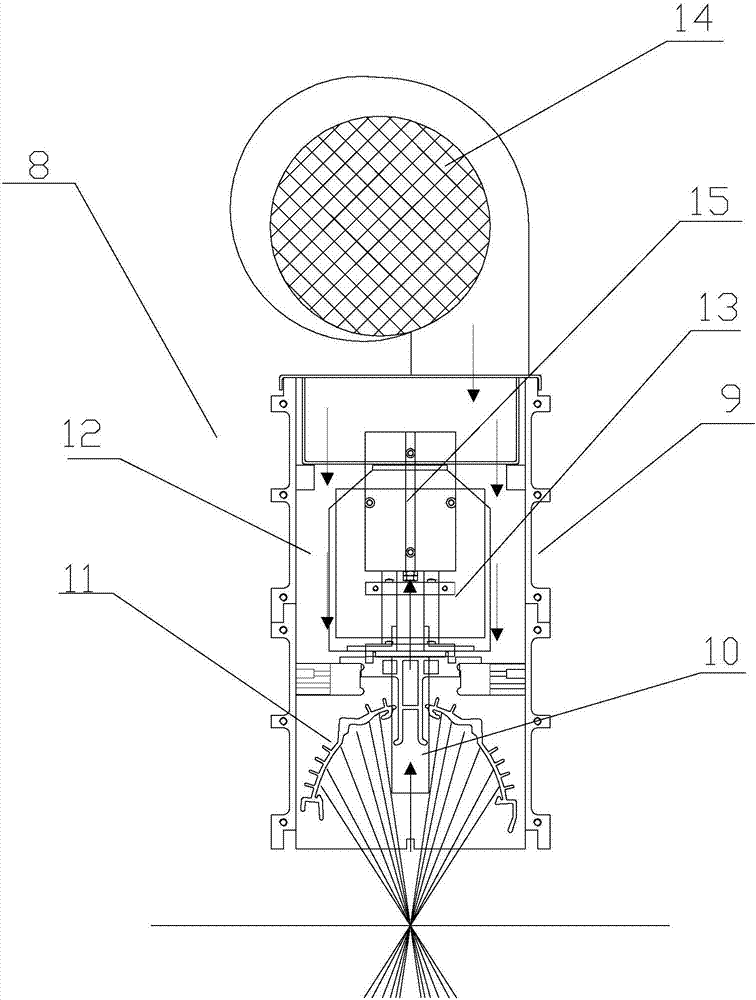

Medical device including unitary, continuous portion of varying durometer

InactiveUS6881209B2Improved combination of strengthPrevent restenosisLaminationLamination apparatusPolyesterCross-link

A medical device (110) including a catheter shaft (111) and a unitarily and continuously formed portion (108) having a varying durometer, and optionally including an expandable balloon (18, 118). One or both of the unitarily and continuously formed portion (108) and the balloon (18, 118) are made from an irradiation cross-linked or cross-linkable mixture of a polyamide elastomer and at least one additional cross-linking reactant. The polyamide elastomer can be a polyester amide, a polyether ester amide or a polyether amide, and is preferably a nylon block copolymer. The aromatic molecule can be 1,3,5 triethyl benzene; 1,2,4 triethyl benzene; and 1,3,5 triisopropyl benzene. The cross-linking reactant can be: (a) a difunctional material, (b) a trifunctional material, (c) a tetrafunctional material, or (d) an aromatic molecule containing at least two ring substituents, each of the ring substituents having labile hydrogens at a benzylic site therein. The cross-linking reactant can also be diallyl phthalate or meta-phenylene dimaleimide.

Owner:COOK MEDICAL TECH LLC

Medical device including unitary, continuous portion of varying durometer

InactiveUS20060016064A1Point becomes highLess reactiveElectric discharge tubesHollow filament manufactureCross-linkPolyester

A medical device (110) including a catheter shaft (111) and a unitarily and continuously formed portion (108) having a varying durometer, and optionally including an expandable balloon (18, 118). One or both of the unitarily and continuously formed portion (108) and the balloon (18, 118) are made from an irradiation cross-linked or cross-linkable mixture of a polyamide elastomer and at least one additional cross-linking reactant. The polyamide elastomer can be a polyester amide, a polyether ester amide or a polyether amide, and is preferably a nylon block copolymer. The aromatic molecule can be 1,3,5 triethyl benzene; 1,2,4 triethyl benzene; and 1,3,5 triisopropyl benzene. The cross-linking reactant can be: (a) a difunctional material, (b) a trifunctional material, (c) a tetrafunctional material, or (d) an aromatic molecule containing at least two ring substituents, each of the ring substituents having labile hydrogens at a benzylic site therein. The cross-linking reactant can also be diallyl phthalate or meta-phenylene dimaleimide.

Owner:COOK MEDICAL TECH LLC

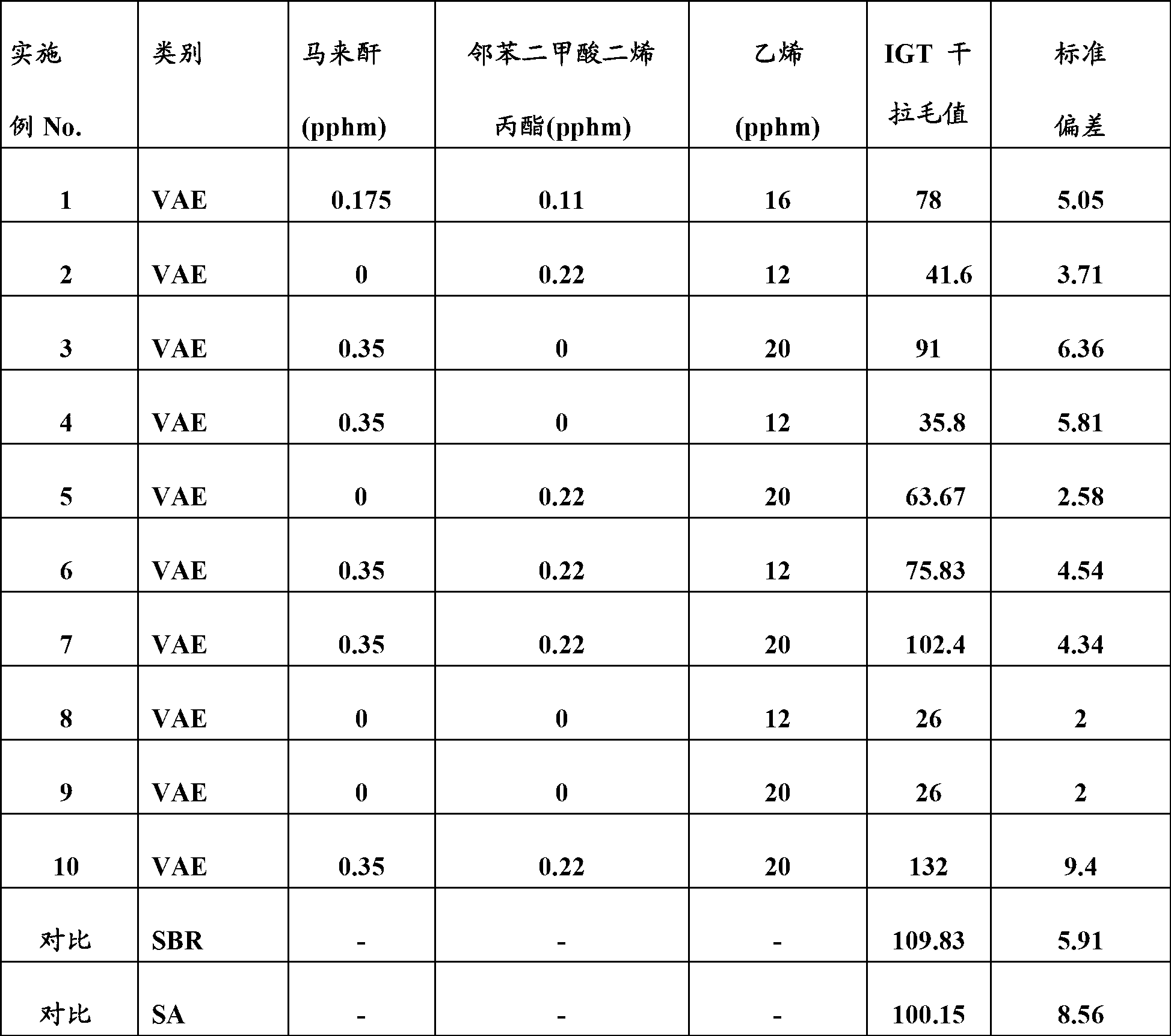

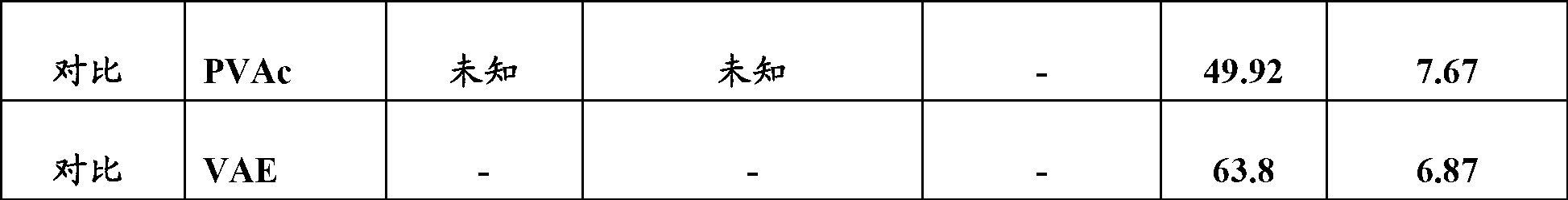

Vinyl ester/ethylene-based binders for paper and paperboard coatings

Disclosed are surfactant-stabilized latex emulsions which can be used as binders in paper coating compositions. Such latex emulsions comprise an interpolymer formed by emulsion polymerizing monomers selected from vinyl esters, e.g., vineyl acetate; ethylene; certain unsaturated mono- and di-carboxylic acid materials such as acrylic acid or maleic anhydride; and certain polyethylenically unsaturated cross-linking co-monomers such as diallyl phthalate. These latex emulsions are stabilized with surfactants which are substantially free of environmentally suspect alkyl phenol ethoxylates (APEs). The paper coating compositions containing latex emulsion binders of this type exhibit especially desirable coating strength as quantified by the Dry Pick Values (as defined herein) which such compositions provide.

Owner:CELANESE INT CORP

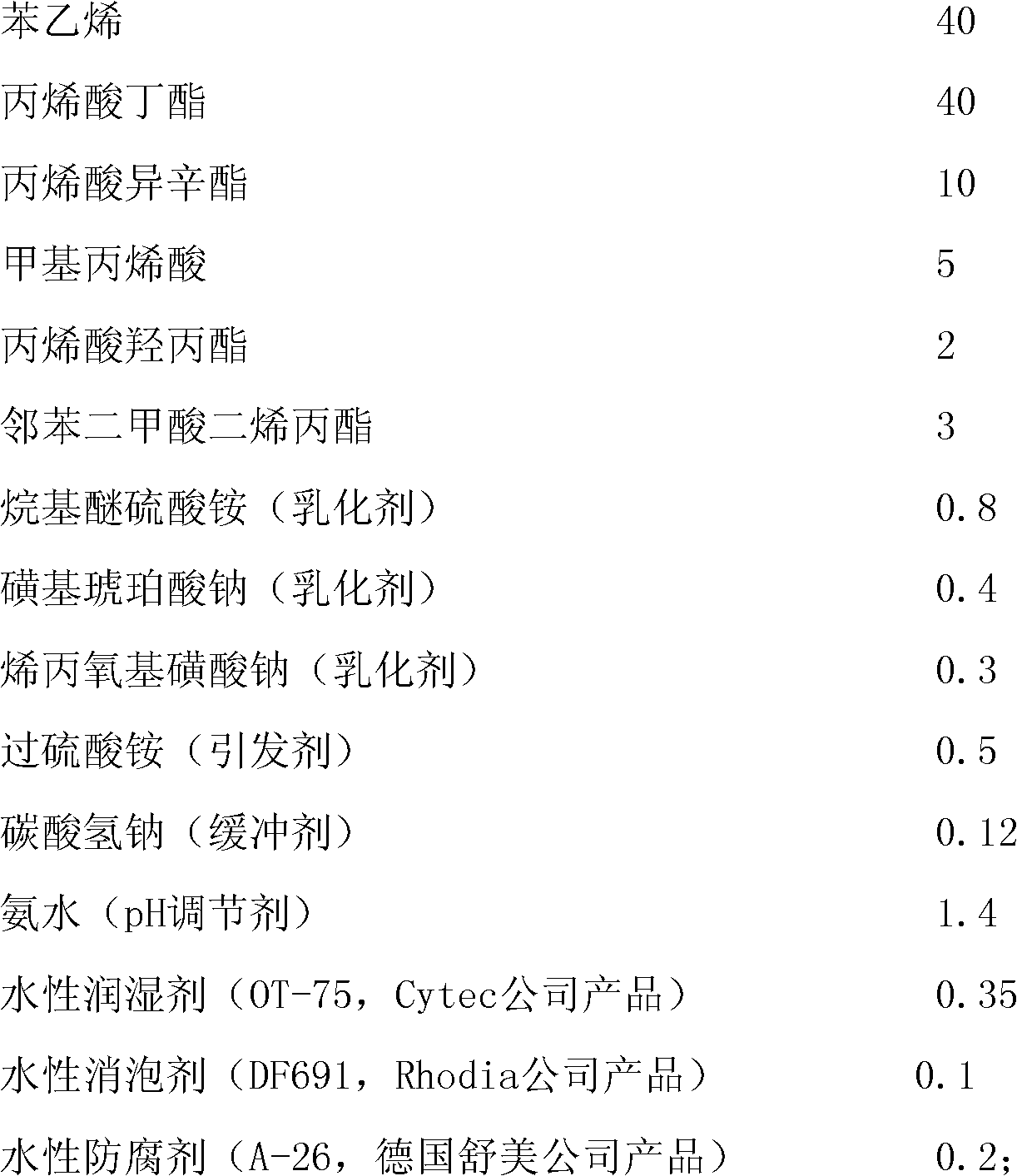

Water-based dry-type complex film adhesive and preparation method thereof

ActiveCN102134463AReduce the amount addedReduce contentHydrocarbon polymer adhesivesIsooctyl acrylateWater based

The invention discloses a water-based dry-type complex film adhesive and a preparation method thereof, belonging to the field of preparation of adhesive. The preparation method of the complex film adhesive comprises the following steps: by using monomers, an emulsifier, an initiator, a buffering agent, deionized water, a pH regulator and water-based assistants as raw materials, emulsifying, carrying out seed reaction and polymerization reaction, and compounding to obtain the complex film adhesive of which the solid content is 45-55%, wherein the monomers comprise a hard monomer, soft monomers and functional monomers; the hard monomer is styrene; the soft monomers comprise butyl acrylate and 2-ethylhexyl acrylate; the functional monomers comprise acrylic acid or methacrylic acid, 2-hydroxyethyl acrylate or 2-hydroxypropyl acrylate, and diallyl phthalate; and the emulsifier comprises ammonium alkyl ether sulfate, sodium sulfosuccinate and sodium allyloxysulfonate in a weight ratio of 2:1:(0.4-0.8). The complex film adhesive has the advantages of high bonding strength, favorable affinity and covering performance for ink, and environment protection since the content of VOCs (volatile organic compounds) is lowered.

Owner:NANTONG GAOMENG NEW MATERIAL

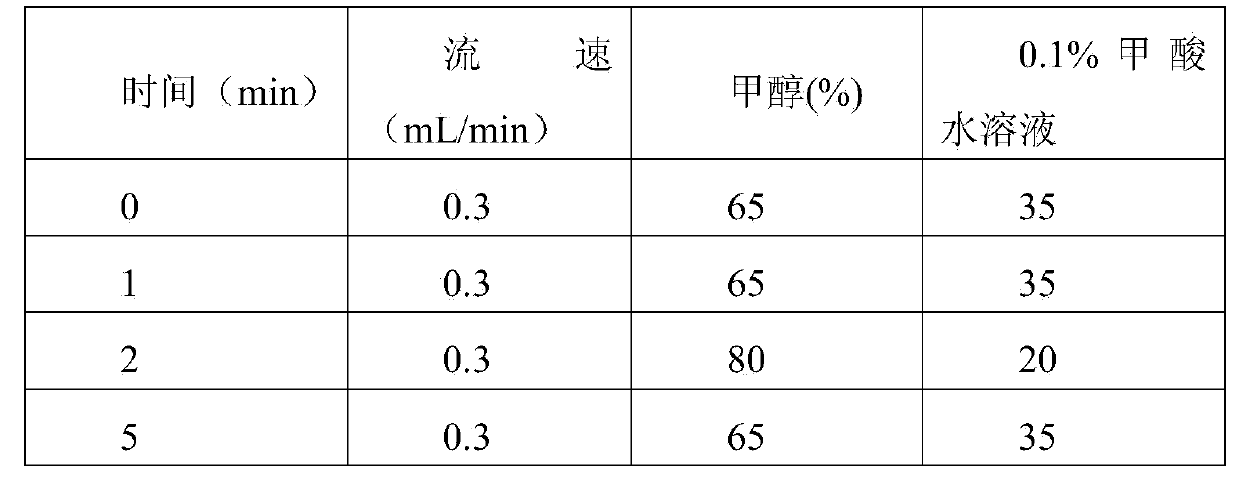

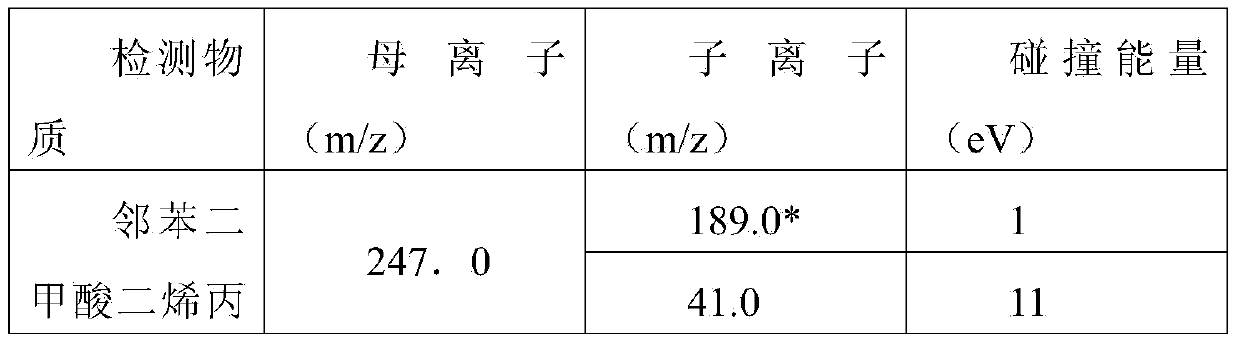

Method for measuring diallyl phthalate migration in food contact materials

ActiveCN103424489AAccurately Measure MigrationQuantitatively accurate and reliableComponent separationFood contact materialsPhysical chemistry

The invention discloses a method for measuring diallyl phthalate migration in food contact materials. The method includes the steps: firstly, preparing a standard working solution, a food stimulant test solution and a blank test solution; secondly, adopting a high performance liquid chromatograph-tandem triple quadrupole mass spectrometer to perform liquid chromatograph-tandem mass spectrum measurement on the three solutions in the first step, drawing a regression curve of the standard working solution by taking concentration x of phthalate in the standard working solution as an abscissa and corresponding measured quantitative ion peak area y as an ordinate, and calculating slope a and intercept b of the regression curve according to a linear equation, of y=ax+b, obtained by the curve; thirdly, according a formula that c=[(y-y)-b] / a, calculating concentration of diallyl phthalate in the food stimulant test solution. By the aid of the method, migration of the diallyl phthalate in the food contact materials can be measured accurately, quantification is accurate and reliable, and reproducibility is good.

Owner:常州进出口工业及消费品安全检测中心

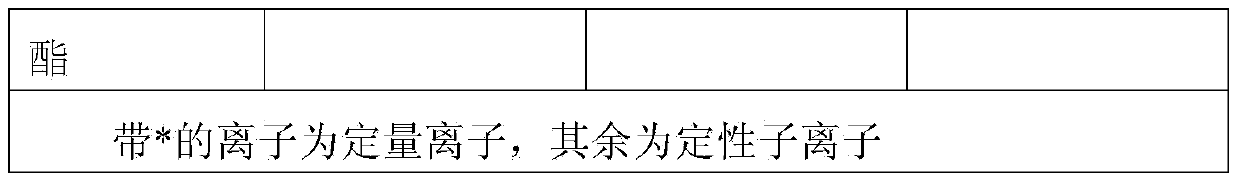

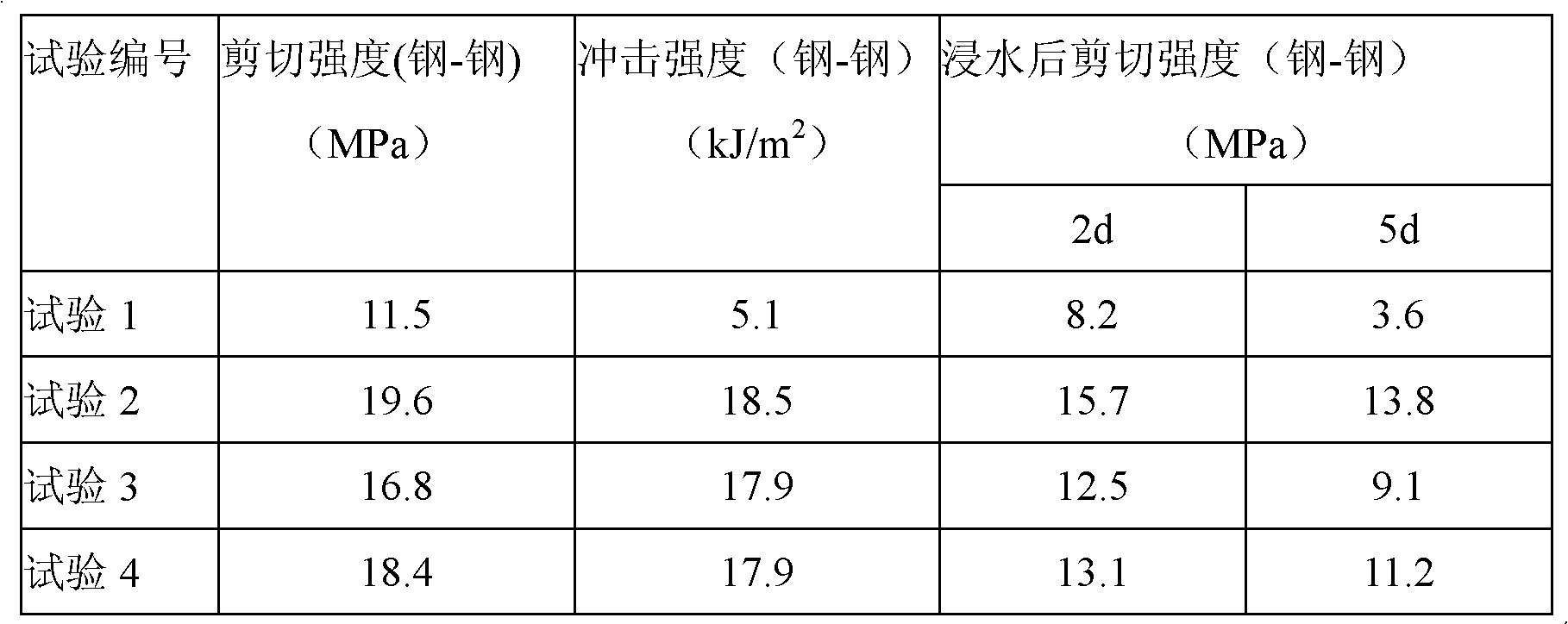

Magnetic material adhesive and preparation method thereof

ActiveCN103205206AHigh strengthImprove impact resistanceNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveAdhesiveUltimate tensile strength

The invention relates to a magnetic material adhesive and a preparation method thereof. The components of the magnetic material adhesive comprise a-cyan ethyl acrylate as a main part, wherein the mass of diallyl phthalate is 6%-18% that of the a-cyan ethyl acrylate; the mass of maleic anhydride is 500-850 ppm that of the a-cyan ethyl acrylate; the mass of a modifier is 250-1,000 ppm of the a-cyan ethyl acrylate; the mass of an anion polymerization inhibitor is 30-1,00 ppm that of the a-cyan ethyl acrylate and the mass of a free radical polymerization inhibitor is 300-750 ppm that of the a-cyan ethyl acrylate. During the preparation, all the components are mixed at a temperature of 40-60 DEG C and stirred to uniform, and thus the magnetic material adhesive with fast adhesive speed, super penetration, high strength, impact resistance and water resistance can be obtained. The preparation process of the invention is simple and easy to operate. The strength, the impact resistance and the water resistance of the adhesive are greatly improved without influencing original fast adhesive speed and long storage life of the adhesive. The magnetic material adhesive has a certain application value.

Owner:浙江久而久化学有限公司

Flexible unsaturated polyester resin and preparation method and application thereof

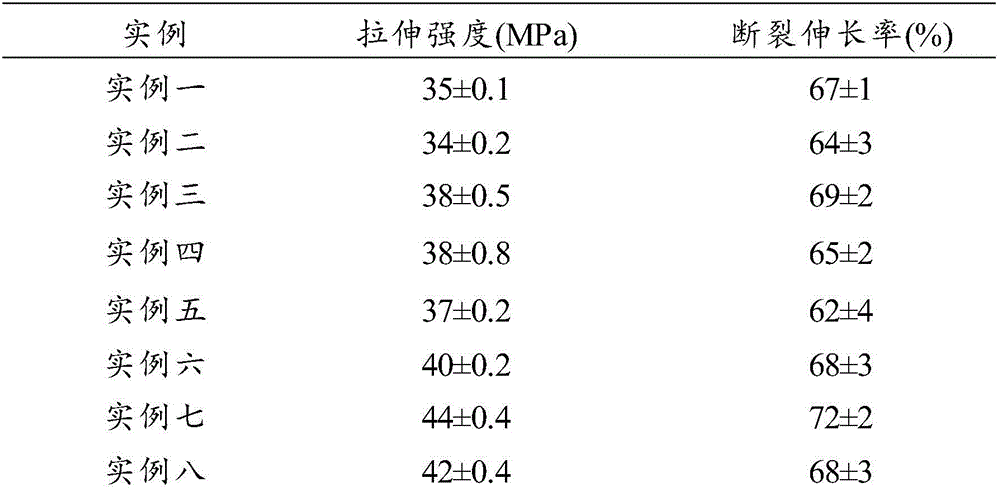

InactiveCN101805429AHigh elongation at breakImprove impact toughnessPhysical propertyUnsaturated polyester

The invention relates to a flexible unsaturated polyester resin and a preparation method and application thereof. The resin is prepared by mixing and reacting a dibasic acid or anhydride, a monobasic acid and dibastic alcohol and diluting the reaction product with a diluent and comprises the following components in percentage by weight: 17 to 24 percent of dibastic alcohol, 3 to 5 percent of monobasic acid, 39 to 53 percent of dibasic acid or anhydride and 26 to 35 percent of diluent, wherein the monobasic acid is oleinic acid; and the diluent is styrene and diallyl phthalate which accounts for 2 to 5 percent of the total weight of the diluent. The preparation method comprises the following steps: performing polycondensation reaction on the dibastic alcohol and the dibasic acid or anhydride for 8 to 12 hours at the temperature of about 200 DEG C, wherein the acid value is 40 to 50mgKOH / g, reducing the temperature, adding the oleinic acid, performing polycondensation reaction for 2 to 3 hours, after the reaction is completed, reducing the pressure and performing vacuum treatment until the acid value is 25 to 35mgKOH / g, adding an additive, cooling, and adding the diluent to obtain the flexible unsaturated polyester resin. The prepared flexible unsaturated polyester resin has high elongation at break and impact toughness and certain strength, and meets the requirements on physical properties of articles.

Owner:上海新天和树脂有限公司 +2

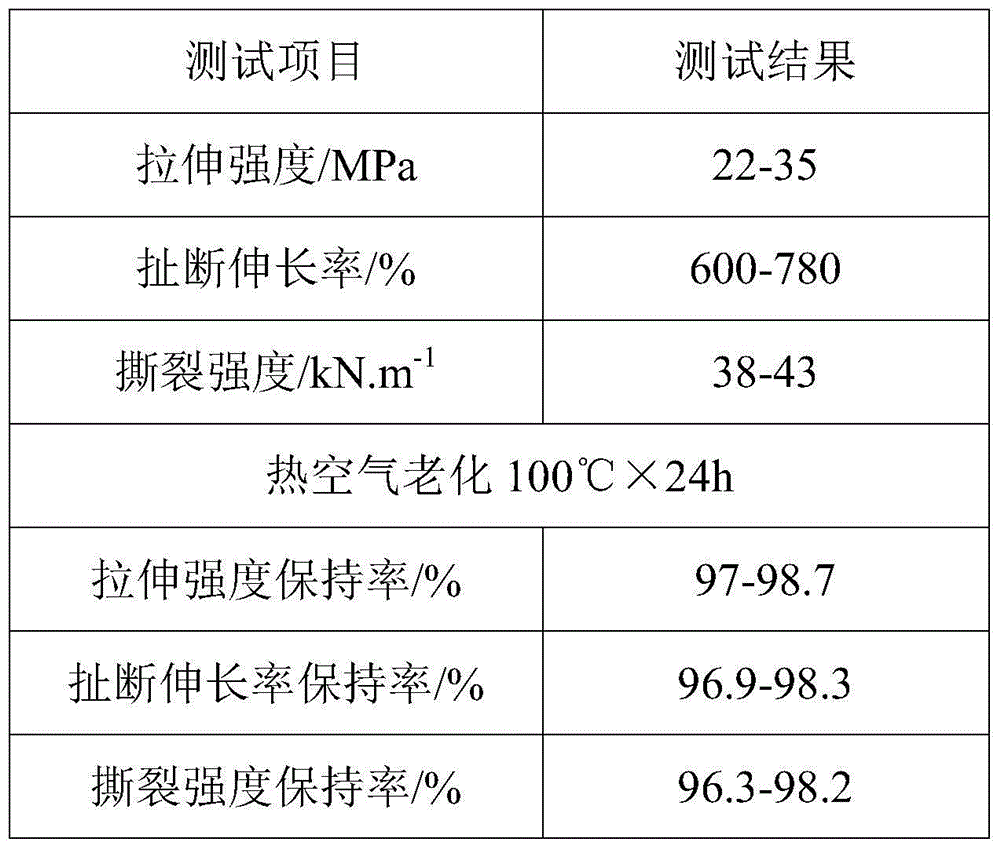

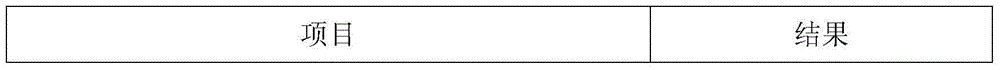

Liquid rubber modified epoxidized natural rubber cable material

InactiveCN104610622AHigh strengthImprove aging resistanceRubber insulatorsPolymer sciencePolystyrene

The invention discloses a liquid rubber modified epoxidized natural rubber cable material. The liquid rubber modified epoxidized natural rubber cable material comprises raw materials in parts by weight as follows: 80-95 parts of epoxidized natural rubber, 5-20 parts of carboxyl-terminated liquid nitrile rubber, 5-15 parts of modified starch, 2-8 parts of ultrafine acrylate rubber powder, 3-8 parts of polystyrene thermoplastic elastomer, 10-25 parts of silica, 8-35 parts of modified diatomite, 15-27 parts of tetrapod-shaped zinc oxide whiskers, 1-2.5 parts of zinc oxide, 0.8-1.3 parts of sorbic acid, 2-4 parts of stearic acid, 1-2.6 parts of sulfur, 2-2.9 parts of dicumul peroxide, 1-3.5 parts of diallyl phthalate, 2-3.5 parts of diethylene glycol dibenzoate, 2-5 parts of calcium stearate, 2-5 parts of an accelerant, 2-5 parts of an anti-aging agent and 3-7 parts of a coupling agent. The liquid rubber modified epoxidized natural rubber cable material has high strength, good anti-aging performance and long service life.

Owner:无为县茂林电缆材料有限公司

Method for preparing high-oil absorption resin

The invention discloses a method for preparing high-oil absorption resin, which is characterized by adding a dispersant of polyvinyl alcohol, a precipitating reagent of cyclohexane, an emulsifying agent of sodium dodecylbenzene sulphonate, a single body of butyl methacrylate and stearyl methylacrylate, an initiator of potassium persulphate into deionized water, introducing nitrogen for deoxygenation, performing suspended emulsion polymerization, after reaction for a certain time, adding a cross-linking agent of diallyl phthalate, continuously reacting for at least two hours, performing cooling, separation, extraction by using an Soxhlet extractor for at least 12 hours and vacuum drying to obtain the products. By the aid of the preparation method of the invention, porous high-oil absorption resin can be obtained, which has oil-absorption capability to toluene reaching up to 24, and can be applied to the field of environmental protection and the like.

Owner:LUDONG UNIVERSITY

Anti-bleeding, anticoagulated colloid for textile decoration printing and preparation thereof

InactiveCN101139801AImprove print outline definitionWith anti-seepage functionDyeing processPhenyl EthersDiallyl phthalate

The invention is a water-tight anticoagulant that mainly comprises the following raw materials: 2-Acrylamido-2-methylpropanesulfonic, Benzenesulfonic acid, 4-ethenyl-, sodium, Methacrylic acid, propenoic acid, aqueous ammonia, Sorbitan MOnooleate, Polyoxyethylene nonyl phenyl ether, Diallyl phthalate and Styrene / alpha-methylstyrene linear body and etc. The water-tight anticoagulant is fabricated through the following three steps of techniques: Neutralization, emulsification and polymerization. The inveintion is a water-tight anticoagulant for textile material printing, and the adding volume should be below 0.5 percent in printing paste or dyeing paste, so that water-tight coagulation prevention function can be fulfilled, and distinct and elegant printing patterns can be gained in dye printing paint printing. Meanwhile, the invention also has advantages of perfect levelling power, dispersion and migration prevention and etc.

Owner:LIAONING FIXED STAR FINE CHEM

Aqueous laminating adhesive and method for making same

InactiveCN101205450AHigh transparencyImprove toughnessEster polymer adhesivesSodium bicarbonateAdhesive

The invention discloses aqueous composite membranes glue which comprises component A: butyl acrylate, styrene, acrylic acid, acrylic acid-2-hydroxypropyl, diallyl phthalate, phenolic ether sulfuric acid and softened water, component B: softened water, emulsifying agent comprising phenolic ether sulfuric acid, alkyl phenol ether and 1-propenyloxy-2-hydroxyl propane sodium sulfonate, sodium bicarbonate and ammonium persulphate, component C: ammonium persulphate and softened water, and component D: 20 percent of ammonia water. The component A is added in a pre-emulsifying tank, and 2 to 5 percent of the component A is taken out as seed liquid after emulsification; the component C is added in an initiator tank to react; the component B which is added in a reaction kettle is stirred to heat up, and then the seed liquid is added and is heated up continuously with the temperature kept between 80 to 90 DEG C; meanwhile, the component C and the residual component A are added drop by drop; after 1.5-hour heat preservation the temperature is cooled down; when the temperature is lower than 40 DEG C, the component D is added finally, the mixture is filtered for discharging. The invention has high safety, aqueous environmental protection and low cost, and is easy for industrialized production; moreover, the invention has high transparence, strong power-covering capability, fast drying speed, good heat endurance and freezeproof property and excellent initial viscidity and hold tack.

Owner:BAODING SUNSHINE CHEM IND RES INST

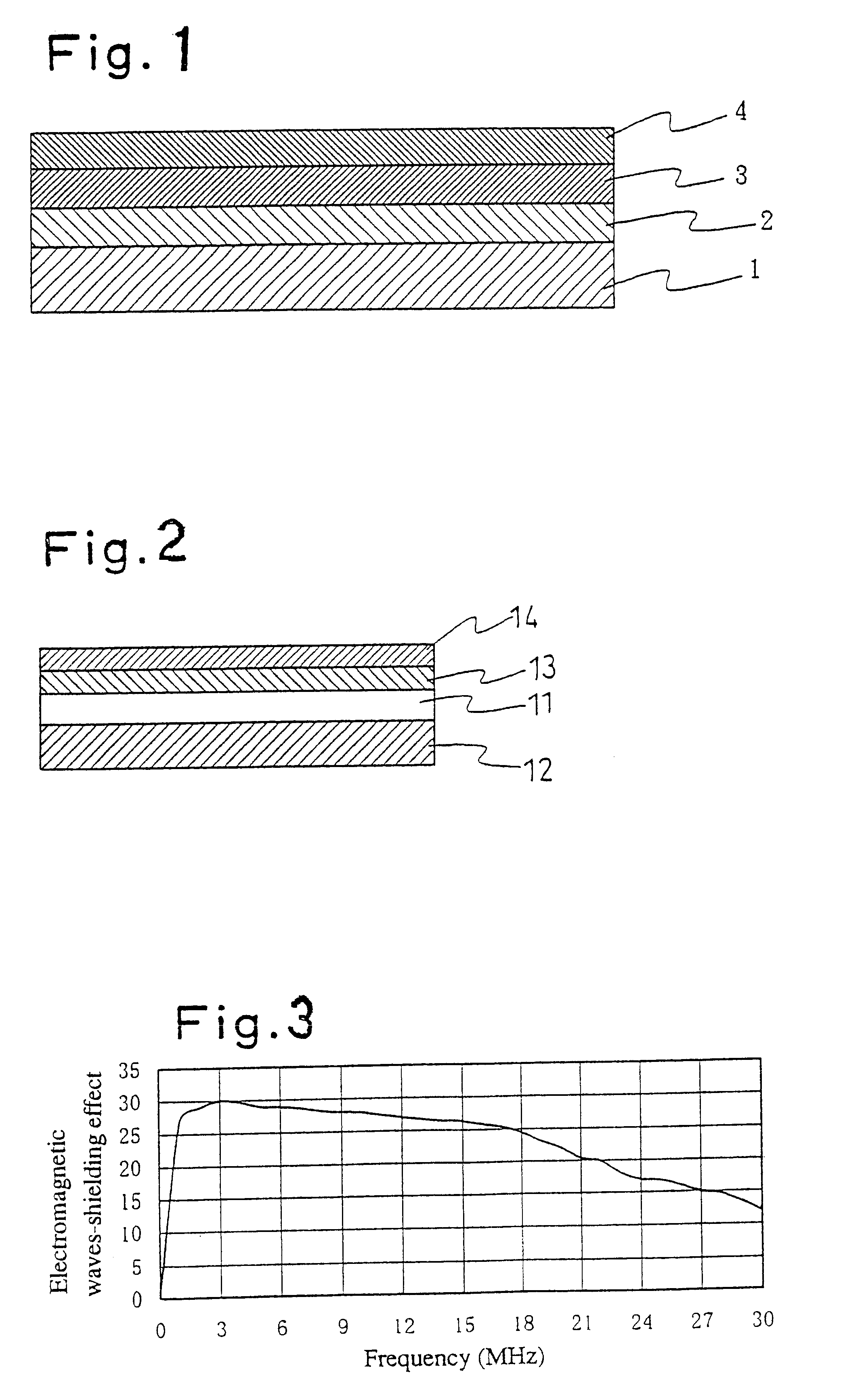

Adhesive transparent resin and a composite including the same

A filter for visual display terminals (VDT), comprising a substrate film having on one surface a deposition layer of indium-tin oxide (ITO) and on the other surface a flexible resin layer comprising a photopolymerized coating derived from a monomeric mixture of at least one of diallyl phthalate, diallyl isophthalate, and diallyl terephthalate, and pentaerythritol tetra(3-mercaptopropionate) in an equivalent ratio of 2:1 to 1:3, and further containing a photopolymerization initiator.

Owner:ASAHI KOGAKU KOGYO KK

Low-smell and high-strength durable PVC artificial leather and production method thereof

ActiveCN103981728AHigh strengthIncreased durabilitySynthetic resin layered productsTextiles and paperFoaming agentAging resistance

The invention relates to the technical field of PVC artificial leather, and especially relates to a low-smell and high-strength durable PVC artificial leather and a production method thereof. The method comprises the following steps: 1, mixing polyvinyl chloride with liquid nitrile butadiene rubber, castor oil and diallyl phthalate to obtain a mixed slurry; 2, directly knife-coating a base material through a knife coating process, and carrying out plasticizing reaction molding; or knife-coating by using a foaming agent-containing mixed slurry, and knife-coating a mixed slurry without the foaming agent; and 3, carrying out a post-treatment process comprising embossing, surface printing and the like to obtain the low-smell and high-strength durable PVC artificial leather. The tension load, ageing resistance and smell tests of the PVC artificial leather with the thickness of 1.4mm obtained in the invention according to QB / T2710, QB / T2779 and QB / T2725 show that the tension load is not lower than 400N, the surface at a low temperature does not crack, and the smell is not greater than 3 grade. The PVC artificial leather satisfies requirements of mechanical properties and smells of artificial leather for yacht seats, artificial leather for household automobile seats and artificial leather for engineering automobile seats.

Owner:SHAANXI UNIV OF SCI & TECH

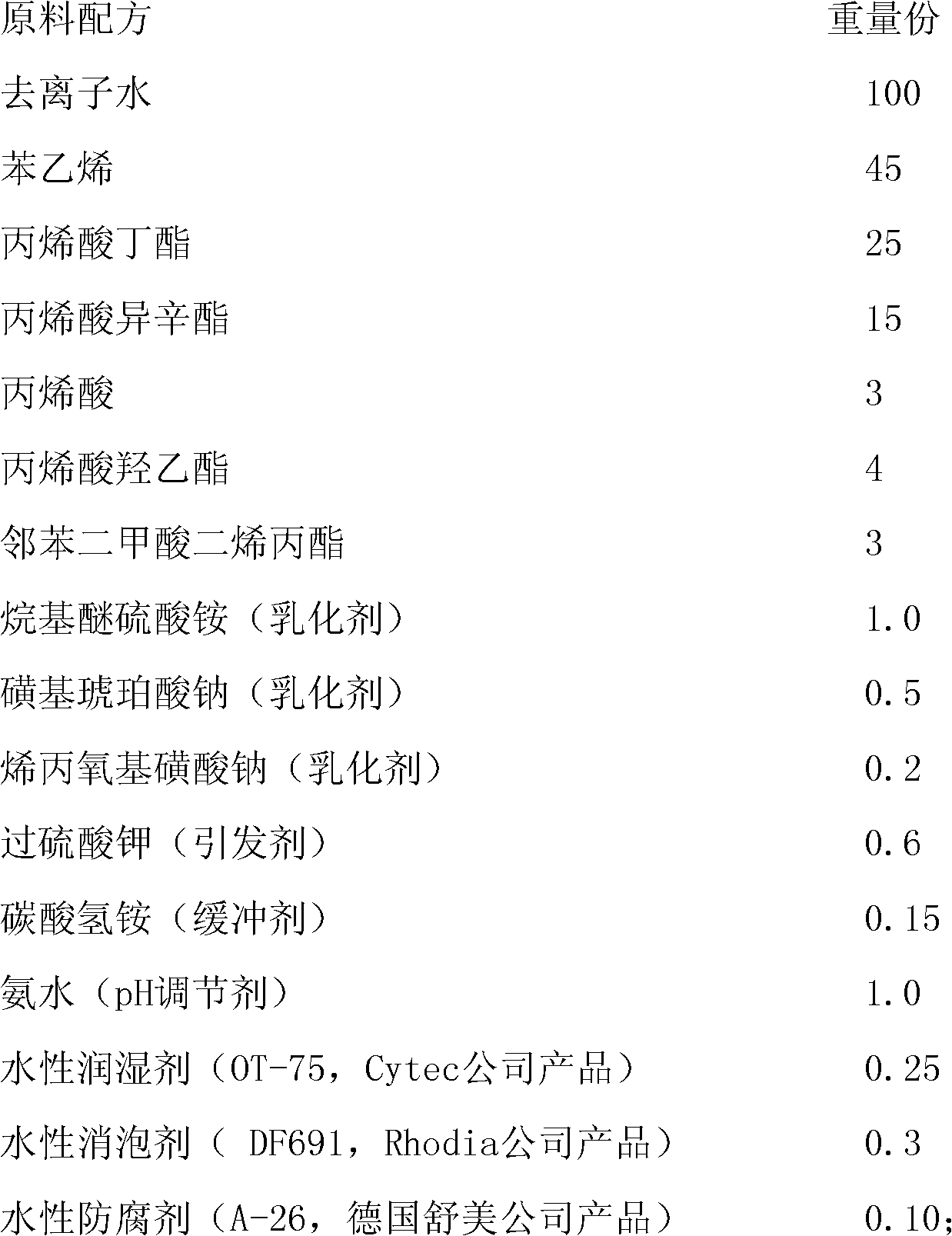

Aqueous dual membrane glue, and fabricating method

ActiveCN1872934AEliminate hazardsReduce hidden dangersEster polymer adhesivesSodium bicarbonateFunctional monomer

This invention discloses a method for preparing a water-borne laminating adhesive. The adhesive is composed of: monomers including acrylic acid and methyl methacrylate, functional monomers including diallyl phthalate, hydroxyethyl acrylate, diallyl maleate and N-hydroxymethylacrylamide, initiator ammonium perdulfate, emulsifiers including sulfosuccinic acid and phenol ether sulfuric acid, buffers including sodium bicarbonate and ammonium bicarbonate, lauryl mercaptan, functional accessory materials including OT-75, mineral oil and water-soluble acrylic resin, pH regulator ammonia solution, and soft water. The adhesive has such advantages as no pollution, no toxicity, high safety and high cohesive force.

Owner:上海奇想青晨新材料科技股份有限公司

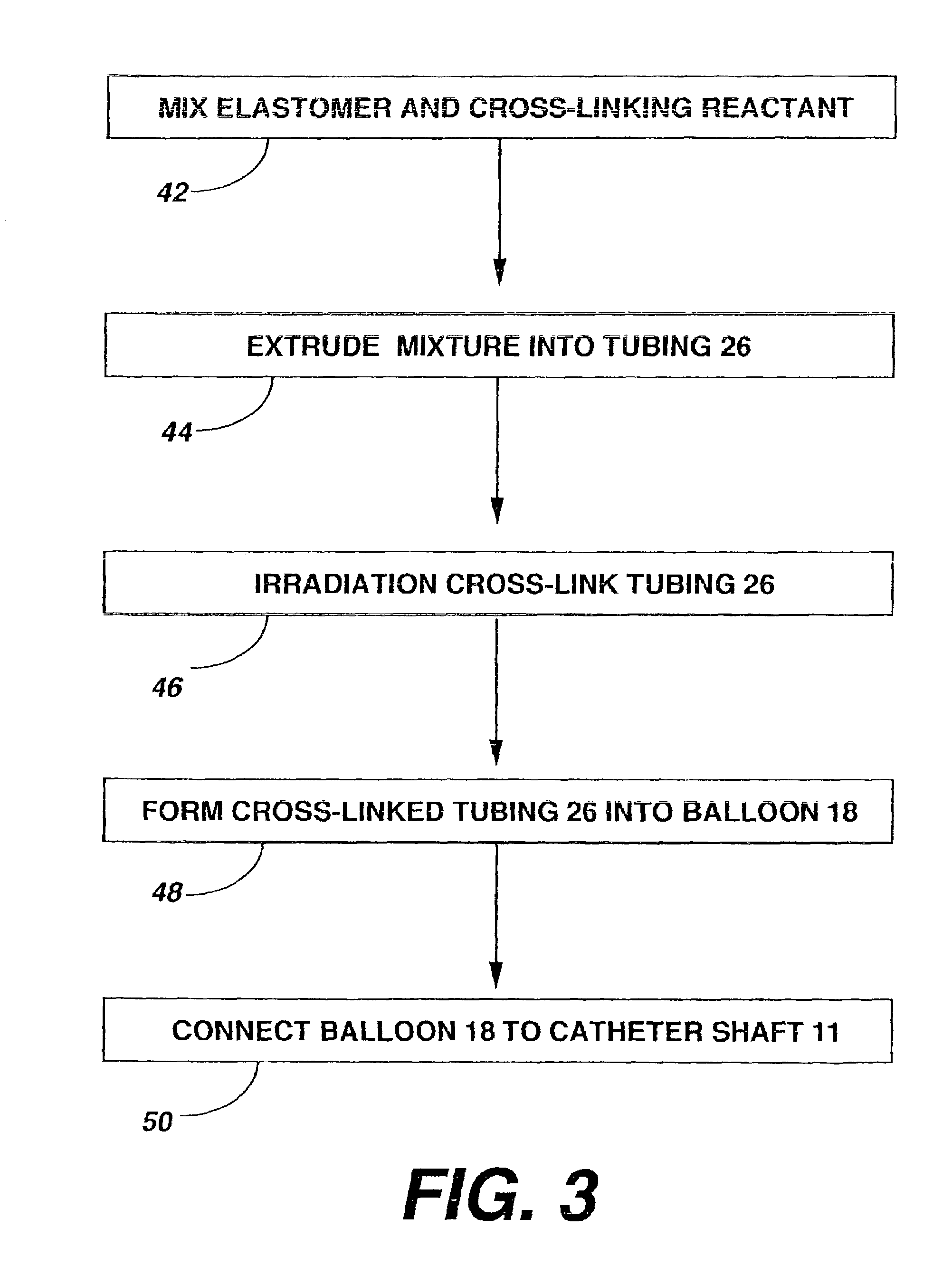

Low pressure power steering tube rubber composition with chlorinated polyethylene rubber as main component

InactiveCN102417666AImprove mechanical propertiesImprove heat resistanceFlexible pipesEpoxyPolymer science

The invention relates to a rubber composition for low pressure power steering tubes. The rubber composition comprises the following components by mass: chlorinated polyethylene rubber 100 parts, fast extruding carbon black 40 to 60 parts, medium thermal carbon black 0 to 20 parts, calcium hydrate 10 parts, dioctyl ester 20 to 30 parts, magnesium oxide 7 to 15 parts, epoxy resin 3 to 5 parts, the antioxidant NBC 1 part, diallyl phthalate 6 to 10 parts, and 1,4-bis(tert-butylperoxyisopropyl)benzene 6 to 8 parts. According to the invention, chlorinated polyethylene is utilized to substitute chlorosulfonated polyethylene in the low pressure power steering tubes, which guarantees heat resistance and oil resistance of the low pressure power steering tubes and enables a low price to be obtained;a production process for the rubber composition is simple, and the product of the rubber composition has widely available sources and better practical application.

Owner:TIANJIN PENGYI GRP CO LTD

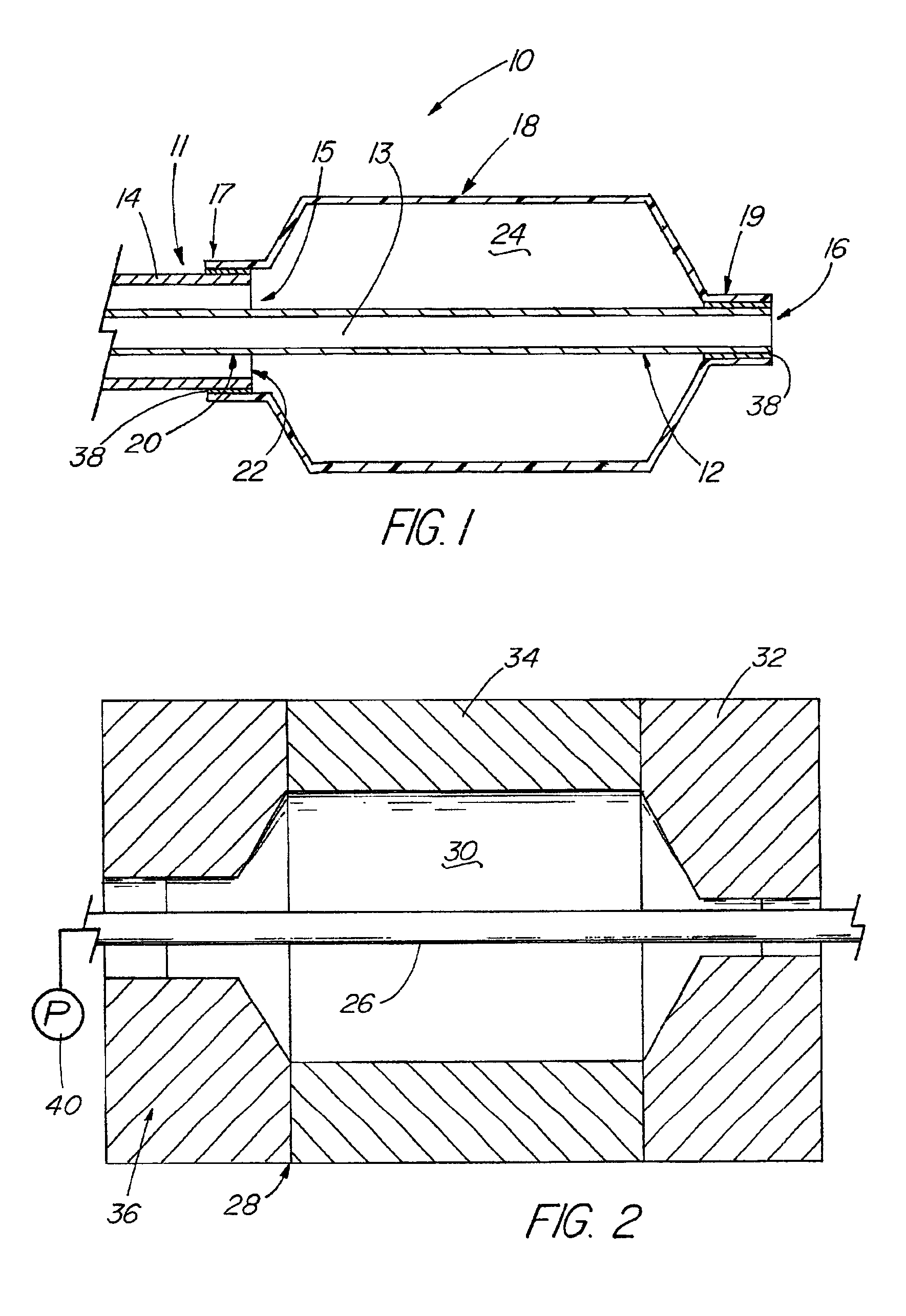

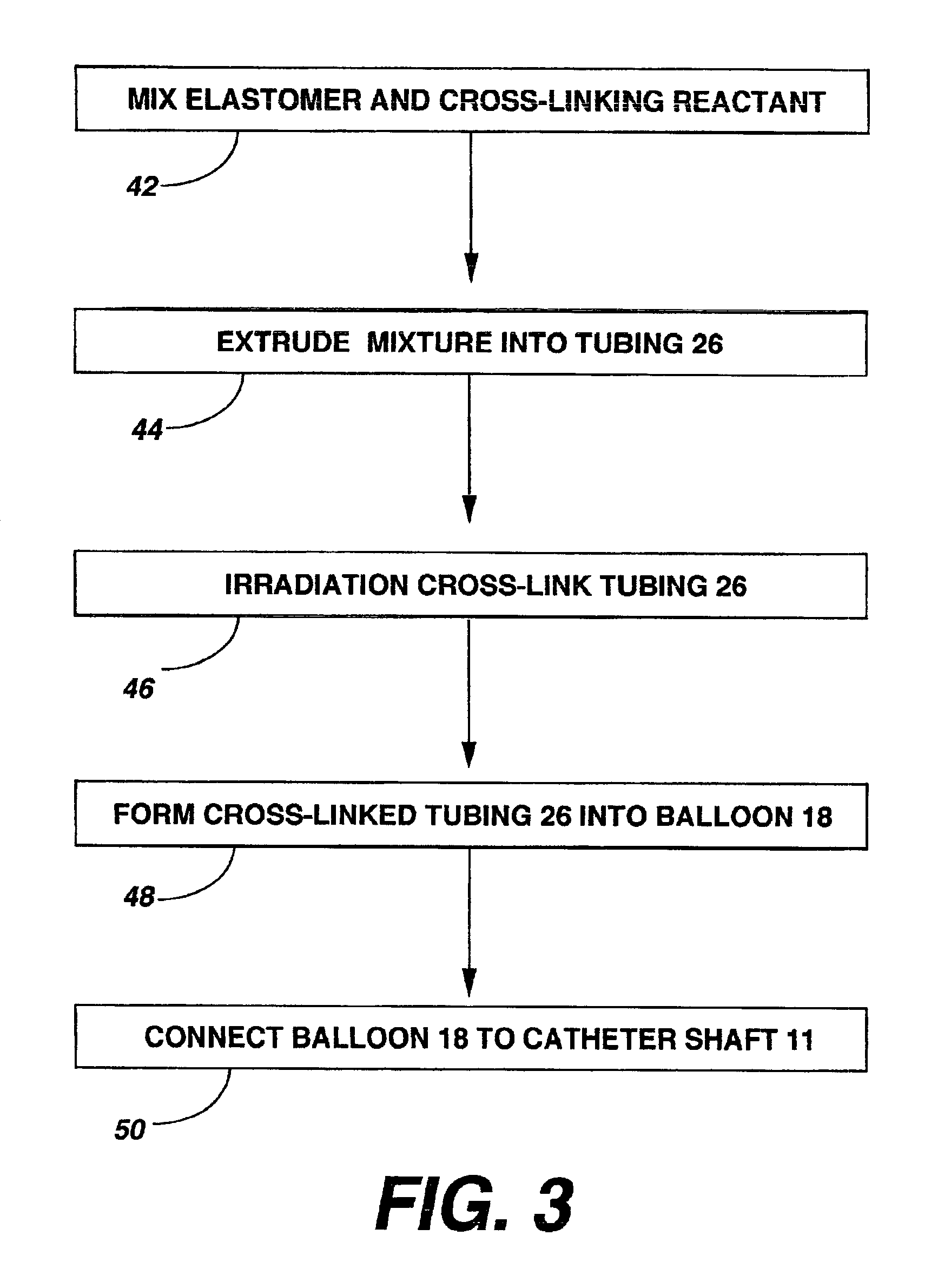

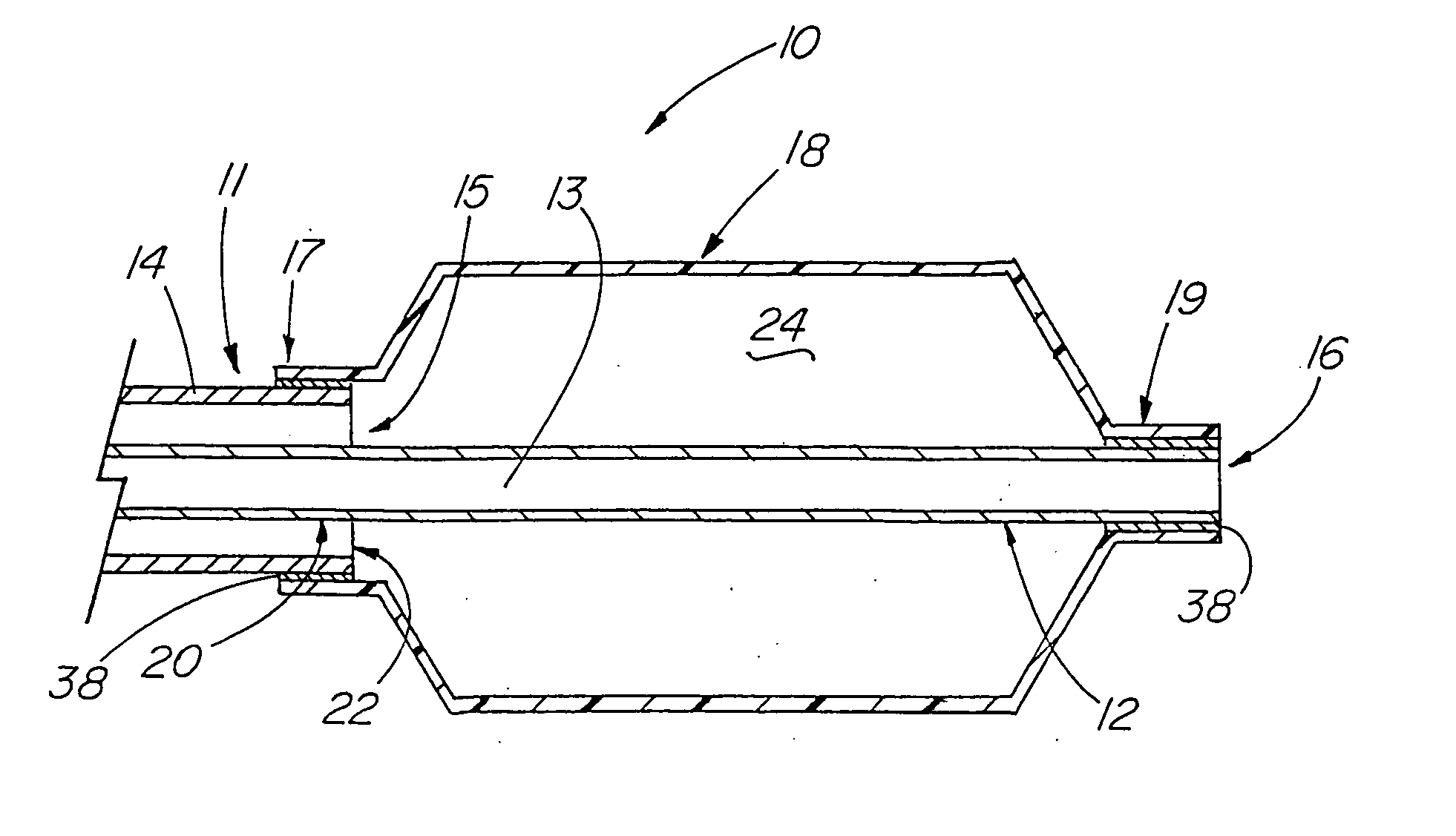

Medical device including improved expandable balloon

InactiveUS7485250B2Point becomes highLess reactiveElectric discharge tubesSynthetic resin layered productsElastomerPolyester

A medical device (10) includes a catheter shaft (11) including inner and outer catheter shafts (12 and 14), and an expandable balloon (18) carried by the catheter shaft (11). The balloon (18) is made from an irradiation cross-linked mixture of a polyamide elastomer and at least one additional cross-linking reactant. The polyamide elastomer can be a polyester amide, a polyether ester amide or a polyether amide, and is preferably a nylon block copolymer. The cross-linking reactant can be: (a) a difunctional material, (b) a trifunctional material, (c) a tetrafunctional material, or (d) an aromatic molecule containing at least two ring substituents, each of the ring substituents having labile hydrogens at a benzylic site therein. The cross-linking reactant can also be diallyl phthalate or meta-phenylene dimaleimide. Irradiation is carried out by exposure to an electron beam or to ultraviolet, X- or gamma radiation, preferably at a total fluence of about 0.5 to about 20 megarads. The amount of the cross-linking reactant is selected to avoid the formation of gelling during the process by which the balloon (18) is made, and the amount of the cross-linking agent and the irradiation fluence are selected to give the balloon a strength generally about equal to that which would be obtained by mere irradiation.

Owner:COOK MEDICAL TECH LLC

Pollution-free textile pulp

InactiveCN104928922AImprove anti-agingImprove stabilityFibre treatmentCyclohexanonePhosphoric Acid Esters

Disclosed is a pollution-free textile pulp. The raw materials of the textile pulp include, by weights: 3 to 6 parts of potato oxidized starch, 5 to 10 parts of polyoxyethylene alkylphenol, 4 to 7 parts of diallyl phthalate, 3 to 5 parts of ethanol, 4 to 6 parts of cyclohexanone, 10 to 16 parts of albumen size, 2 to 3 parts of sodium sulphamidate, 3 to 5 parts of modified silicone defoamer, 8 to 15 parts of polyacrylic acid, 3 to 4 parts of a-amylase plant starch, 2 to 6 parts of polyvinyl alcohol, 3 to 5 parts of polyacrylate, 4 to 7 parts of protein amino acid, 12 to 24 parts of modified starch, 7 to 13 parts of tapioca starch and 6 to 12 parts of phosphate ester starch. The textile pulp has the advantages that the anti-ageing performance is fine, stability is high, the fine affinity, film-forming property, tensile force resistance and folding resistance are achieved, and pollution and energy consumption can be reduced.

Owner:QINGDAO MAIKE 3D HI TECH CO LTD

Heat resistant and oil resistant ethylene propylene diene monomer rubber/acrylate rubber cable material

The invention discloses a heat resistant and oil resistant ethylene propylene diene monomer rubber / acrylate rubber material. The raw material comprises the following components: ethylene propylene diene monomer rubber, acrylate rubber, EPDM rubber grafted with maleic anhydride, ethylene acrylate rubber, carbon black, organically modified montmorillonite, zinc oxide, stearate, magnesia, zinc methacrylate, dicumyl peroxide, trimerization thiocyanate, diallyl phthalate ester, accelerator M, accelerant DZ, an accelerator CZ, an antioxidant, diethylene glycol dibenzoate, epoxy soybean oil, N-cyclohexylthio phthalimide and a silane coupling agent. The heat resistant and oil resistant ethylene propylene diene monomer rubber / acrylate rubber material disclosed by the invention is high in mechanical strength,excellent in oil resistance, heat resistance and resistance to aging, and the cable made from the material is long in service life, so that the cost can be reduced.

Owner:繁昌县菲德通讯材料设计有限公司

Preparation method of PP/PET microfiber reinforced blend

InactiveCN106366452AIncrease capacity synergyPlay a capacity-increasing roleGlycidyl methacrylateDiallyl phthalate

The invention provides a preparation method of a PP / PET microfiber reinforced blend. The PP / PET capacity-increase blend is preapred with PP as the continuous phase, PET as the dispersing phase and diallyl phthalate and glycidyl methacrylate cograft PP graft PP-g-(DAP-co-GMA) as the novel compatibilizer; the dispersing, orienting and fiber forming of PET in the blend are achieved through a proper processing method, the structure is much stored in subsequent products, and therefore the aim of reinforcing PP through PET microfiber in situ is achieved. By means of the method, the mechanical performance of PP can be remarkably improved, and the method has great important significance in expanding the application field of PP.

Owner:CHANGZHOU UNIV HUAIDE COLLEGE

Elastic emulsion with high adhesive force and preparing method thereof

The invention discloses an elastic emulsion with high adhesive force and a preparing method thereof. The elastic emulsion is composed of, by weight, nuclear monomers: 1-10 parts of methyl methacrylate, 4-12 parts of styrene, 0.1-5 parts of diallyl phthalate and 3-25 parts of butyl acrylate; shell monomers: 1-8 parts of methyl methacrylate, 3-10 parts of styrene, 5-12 parts of butyl acrylate, 1-2 parts of methacrylic acid, 0.1-5 parts of glycidyl methacrylate, 0.1-3 parts of organosilicone monomer, 0.1-7 parts of diacetone amide, 0.2-8 parts of adipic dihydrazide, 0.5-2 parts of emulgator, 1-3 parts of initiator and 48-52 parts of water. An outer wall elastic coating prepared from the elastic emulsion has excellent base material adhesive force, the defect that an outer wall elastic coating foams in the presence of water is overcome, and water resistance and stain resistance are realized.

Owner:江苏紫石化工科技有限公司

Metal printing UV varnish and coating method thereof

InactiveCN107227100AImprove protectionHigh glossPretreated surfacesPolyurea/polyurethane coatingsTripropylene glycolPolymer science

The invention relates to the field of printing, and discloses a metal printing UV varnish and a coating method thereof. The UV varnish comprises the following components in percentage by mass: 30-60% of photocuring resin prepolymer, 30-60% of active monomer, 5-15% of photoinitiator and 0-15% of additive. The photocuring resin prepolymer is composed of at least one of a modified epoxy acrylic resin, a modified polyurethane acrylic resin and diallyl phthalate. The active monomer is composed of at least one of ethoxy acrylate, hexanediol diacrylate, acryloylmorpholine, trihydroxy acrylate, hydroxyethyl methacrylate and tripropylene glycol diacrylate. The UV varnish has the advantages of favorable leveling property, favorable gloss, favorable adhesive force and high photocuring efficiency. When being matched with the specific coating method disclosed by the invention, the UV varnish can not easily produce blisters, cratering, particles or other apparent defects.

Owner:HANGZHOU CPMC

Nano-material-modified natural rubber cable material

InactiveCN104629103AImprove aging resistanceImprove mechanical propertiesRubber insulatorsPolymer scienceAlloy

The invention discloses a nano-material-modified natural rubber cable material which is prepared from natural rubber, liquid isoprene rubber, modified superfine lana powder, superfine acrylate rubber powder, stearic acid, zinc oxide, nano calcium carbonate, carbon black, nano alloy, sulfur, 1,4-bis-tert-butyl-peroxycumene, diallyl phthalate, castor oil, bis octadecanol ester, bis(P,P-bis-ethylhexyl diphosphato)ethanediolato titanate, an anti-aging agent and an accelerator. The nano-material-modified natural rubber cable material has the advantages of excellent mechanical properties and favorable aging resistance; and the cable prepared from the material has the advantages of favorable comprehensive properties and long service life.

Owner:无为县茂林电缆材料有限公司

Vinyl ester/ethylene-based binders for paper and paperboard coatings

Owner:CELANESE INT CORP

Improved starch textile sizing agent

The invention provides an improved starch textile sizing agent. The improved starch textile sizing agent is prepared from the following raw materials in parts by weight: 8-17 parts of ethylhexyl-2-acrylate, 9-13 parts of dibutyl diacrylate, 10-15 parts of diallyl phthalate, 5-8 parts of hydroxypropyl methylcellulose, 4-7 parts of nano-silicon nitride, 6-8 parts of hydroxypropyl distarch phosphate, 4-9 parts of lauryl alcohol polyoxyethylene, 7-10 parts of polyacrylate, 15-26 parts of modified starch, 18-27 parts of polyvinyl alcohol, 20-26 parts of nano-silicon dioxide modified starch, 8-14 parts of protein size, 3-5 parts of kaolin, 6-15 parts of wheat starch and 2-3 parts of polyacrylate. The improved starch textile sizing agent has the beneficial effects that the sizing yarn quality is improved, the sizing agent high in strength and low in tension is easy to desize, the adhesiveness of the sizing agent is improved, and the sizing yarn quality is improved; besides, the improved starch textile sizing agent is quick to biodegrade and small in environmental pollution.

Owner:QINGDAO JINGSHITONG PRECISION MACHINERY MFG

Heatproof corrosion-resistant cable material for urban rail transport and preparation method thereof

InactiveCN105175959AImprove heat resistanceImprove corrosion resistancePlastic/resin/waxes insulatorsMicrocrystalline waxMicrosphere

The invention discloses a heatproof corrosion-resistant cable material for urban rail transport and a preparation method thereof. The heatproof corrosion-resistant cable material is prepared from the following raw materials, by weight, 38-46 parts of teflon, 24-33 parts of a liquid crystal polymer, 16-22 parts of polyarylsulfone, 10-15 parts of a nano-zeolite molecular sieve, 6-12 parts of hexaphenoxy cyclotriphosphazene, 5-10 parts of diethylene glycol dibenzoate, 3-6 parts of microcrystalline wax, 8-16 parts of hollow glass microspheres, 14-18 parts of a composite flame retardant, 4-9 parts of melamine cyanurate, 2-3 parts of tri(mercaptoacetic acid n-butyl ester)antimony, 2-3 parts of 2-octyldodecanol, 10-15 parts of diallyl phthalate, 2-3 parts of Stearoylbenzoylmethane and 1-2 parts of 6-ethoxy-2,2,4-trimethyl-1,2-dihydro-quinoline. The cable material has good heat resistance, and the heat resistance grade reaches 160 DEG C. In addition, the cable material has excellent corrosion resistance, is especially resistant to corrosive mediums such as acid, alkali, salt, oil and the like, has good wear resistance, weather ageing resistance, flame resistance and the like, and can completely meet requirements of performance when used under conditions of high-temperature corrosive mediums.

Owner:ANHUI CHUNHUI INSTR CABLE GROUP

High-strength and anti-aging computer cable

InactiveCN105754236AImprove flexibilityGood weather resistancePlastic/resin/waxes insulatorsInsulated cablesPolymer scienceSilanes

The invention discloses a high-strength and anti-aging computer cable. The high-strength and anti-aging computer cable comprises a cable core and a sheath wrapping the cable core, wherein the sheath is made from a chlorinated polyethylene composite; raw materials of the chlorinated polyethylene composite comprise chlorinated polyethylene, polyvinyl chloride, zinc oxide, magnesium oxide, stearic acid, carbon black N234, white carbon black, gamma-mercaptopropyltrimethoxysilane, a silane coupling agent Si-69, zinc stearate, calcium stearate, epoxidized soybean oil, nano-silica, activated carbon, organically modified montmorillonite, a plasticizer DOP, an anti-aging agent, a scorch retarder CTP, sulfur, 1,3,5-trimercapto-2,4,6-triazine, diallyl phthalate and an accelerator. The high-strength and anti-aging computer cable has high strength and excellent ageing resistance and can meet the use requirements of computer cables.

Owner:王社兵

Preparation method of high-molecular graphene modified epoxy resin

The invention discloses a preparation method of high-molecular graphene modified epoxy resin, and belongs to the technical field of epoxy resin. The high-molecular graphene modified epoxy resin is prepared from the following components in parts by weight: 5-10 parts of graphene, 60-80 parts of epoxy resin, 15-20 parts of n-butyl polyacrylate, 5-9 parts of phthalic anhydride, 3-6 parts of azodiisobutyronitrile, 2-4 parts of diallyl phthalate, 5-15 parts of polyglycidyl methacrylate, 28-43 parts of diglycidyl resorcinol ether, 17-29 parts of urea-formaldehyde melamine resin, 10-15 parts of EDTA,13-15 parts of CTBN, 6-13 parts of an organosilicone coupler, 5-8 parts of aminomethyl propanol, 60-90 parts of water, 4-12 parts of carbon powder, 13-15 parts of aluminum silicate powder, and 10-15parts of antimonous oxide. Through combination of the graphene and the epoxy resin, the advantages of the graphene and the epoxy resin are considered, the heat conducting, toughening and abrasion resisting performance of a compound is improved, and the purpose of improving the weather resistance of the compound is achieved.

Owner:苏州博瑞达高分子材料有限公司

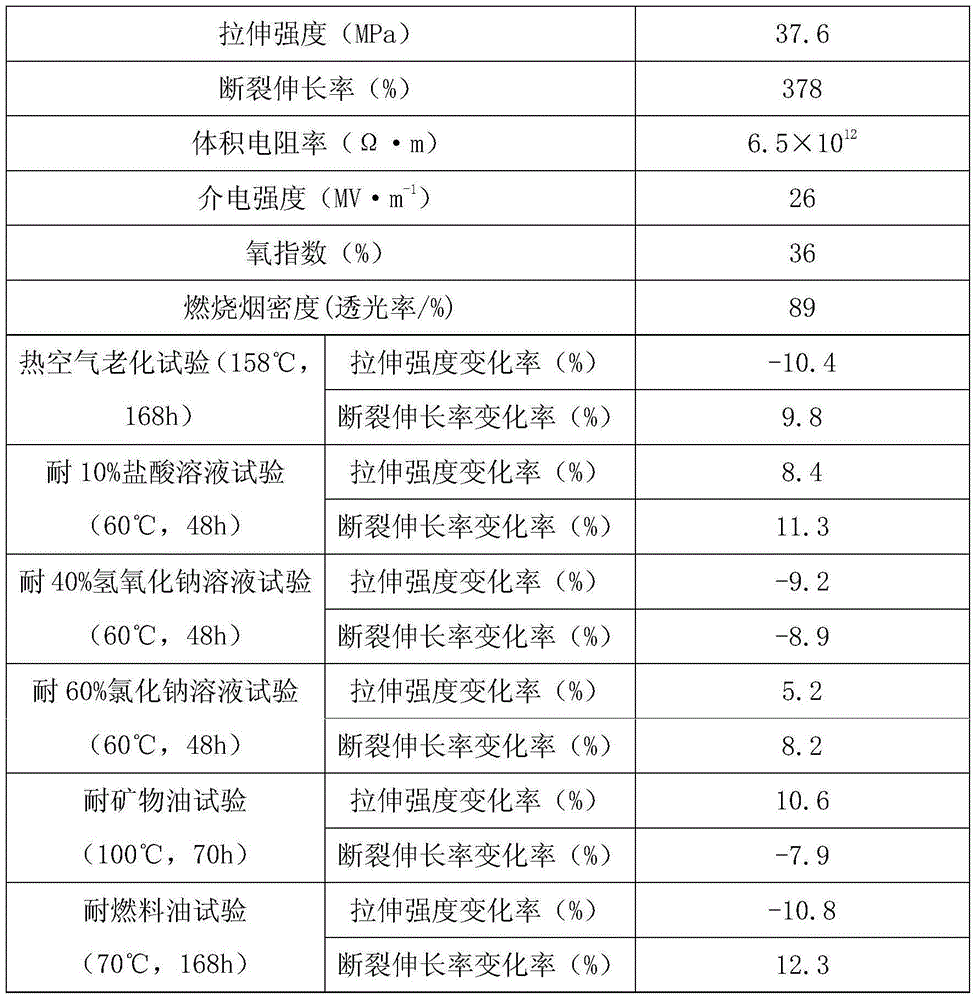

Antirust coating for automobile chassis and preparation method thereof

InactiveCN107057572AImprove adhesionGood adhesionConjugated diene hydrocarbon coatingsAnti-corrosive paintsWear resistantCastor beans

The invention discloses an antirust coating for an automobile chassis. The coating is prepared from the following materials in parts by weight: 55-57 parts of tung oil, 8-10 parts of castor bean wax, 13-14 parts of lauryl sodium sulfate, 5-10 parts of butadiene styrene rubber emulsion, 7-11 parts of isocyanate, 17-20 parts of trichlorofluoromethane, 9-16 parts of water glass, 13-18 parts of amino resin, 15-18 parts of toluenesulfonic acid, 20-25 parts of polyvinyl acetate, 20-24 parts of sorbitan monooleate, 6-10 parts of silica sol, 15-20 parts of pure acrylic emulsion, 8-11 parts of talc powder, 13-17 parts of diallyl phthalate, 16-20 parts of cyanoacrylate and 9-14 parts of graphene. The antirust coating for the automobile chassis, disclosed by the invention, is good in antioxidant effect and strong in bonding force, has an antirust effect, and is good in wear resistant effect.

Owner:芜湖天鸿汽车零部件有限公司

Composite heat-preservation material with kieselguhr and preparation method of composite heat-preservation material

The invention discloses a composite heat-preservation material with kieselguhr and a preparation method of the composite heat-preservation material. The composite heat-preservation material is prepared from the following main components, namely perlite, polystyrene foam granules, hydrogenated butadiene-acrylonitrile rubber and kieselguhr, and semi-hydrated gypsum, methyl vinyl silicone rubber, diallyl phthalate, sucrose acetate isobutyrate, ethylparaben, cetyl trimethyl ammonium bromide, o-hydroxymethylbenzoic acid lactone, polypropylene fiber, polyimide fiber, an adhesive, a surfactant and distilled water through processes such as ball milling, vacuum stirring, heating stirring and pressing molding, and thus the prepared composite heat-preservation material is high in adhesive strength, sufficient in toughness and good in heat-preservation effect, is capable of meeting industrial requirements, and has relatively good application prospects.

Owner:SUZHOU DINGYU ENERGY EFFICIENT EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com