Antirust coating for automobile chassis and preparation method thereof

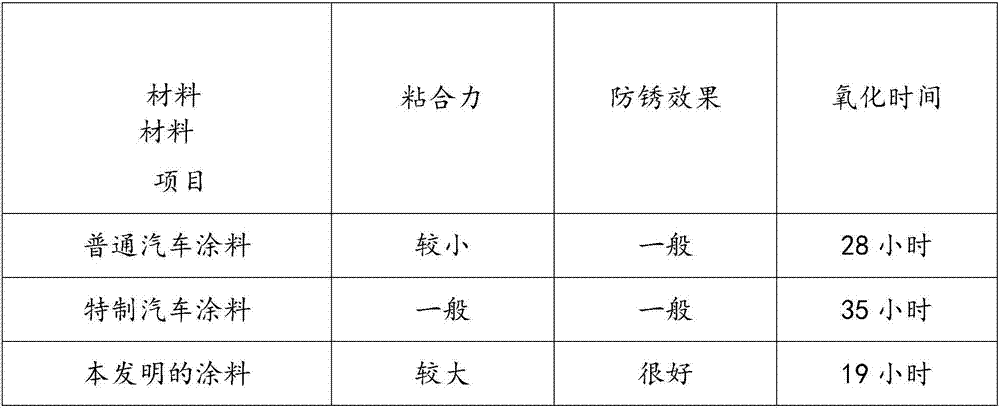

A technology for anti-rust coatings and automobile chassis, applied in the direction of anti-corrosion coatings, coatings, conjugated diene coatings, etc., can solve problems such as weak adhesion, general anti-oxidation effect, and poor wear resistance. Achieve good anti-oxidation effect and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] An antirust coating for an automobile chassis, made of the following materials in parts by weight, including 55 parts of tung oil, 8 parts of castor bean wax, 13 parts of sodium lauryl sulfate, 5 parts of styrene-butadiene rubber emulsion, and 7 parts of isocyanate 17 parts of trichlorofluoromethane, 9 parts of water glass, 13 parts of amino resin, 15 parts of toluenesulfonic acid, 20 parts of polyvinyl acetate, 20 parts of sorbitan monooleate, 6 parts of silica sol, pure acrylic acid 15 parts of emulsion, 8 parts of talc, 13 parts of dipropylene phthalate, 16 parts of cyanoacrylate and 9 parts of graphene.

[0019] A preparation method of an antirust coating for an automobile chassis, comprising the following steps:

[0020] 1) 55 parts of tung oil, 8 parts of castor bean wax, 13 parts of sodium lauryl sulfate, 5 parts of styrene-butadiene rubber emulsion, 7 parts of isocyanate, 17 parts of trichlorofluoromethane, 9 parts of water glass, 13 parts of amino resin, Put 1...

Embodiment 2

[0026] An antirust paint for an automobile chassis, made of the following materials in parts by weight, including 56 parts of tung oil, 9 parts of castor bean wax, 13.5 parts of sodium lauryl sulfate, 7.5 parts of styrene-butadiene rubber emulsion, and 9 parts of isocyanate 18.5 parts of trichlorofluoromethane, 12.5 parts of water glass, 15.5 parts of amino resin, 16.5 parts of toluenesulfonic acid, 22.5 parts of polyvinyl acetate, 22 parts of sorbitan monooleate, 8 parts of silica sol, pure acrylic acid 17.5 parts of emulsion, 9.5 parts of talc, 15 parts of dipropylene phthalate, 18 parts of cyanoacrylate and 11.5 parts of graphene.

[0027] A preparation method of an antirust coating for an automobile chassis, comprising the following steps:

[0028] 1) 56 parts of tung oil, 9 parts of castor bean wax, 13.5 parts of sodium lauryl sulfate, 7.5 parts of styrene-butadiene rubber emulsion, 9 parts of isocyanate, 18.5 parts of trichlorofluoromethane, 12.5 parts of water glass, 15...

Embodiment 3

[0034] An antirust paint for an automobile chassis, made of the following materials in parts by weight, including 57 parts of tung oil, 10 parts of castor bean wax, 14 parts of sodium lauryl sulfate, 10 parts of styrene-butadiene rubber emulsion, and 11 parts of isocyanate Parts, 20 parts of trichlorofluoromethane, 16 parts of water glass, 18 parts of amino resin, 18 parts of toluenesulfonic acid, 25 parts of polyvinyl acetate, 24 parts of sorbitan monooleate, 10 parts of silica sol, pure acrylic acid 20 parts of emulsion, 11 parts of talc, 17 parts of dipropylene phthalate, 20 parts of cyanoacrylate and 14 parts of graphene.

[0035] A preparation method of an antirust coating for an automobile chassis, comprising the following steps:

[0036]1) 57 parts of tung oil, 10 parts of castor bean wax, 14 parts of sodium lauryl sulfate, 10 parts of styrene-butadiene rubber emulsion, 11 parts of isocyanate, 20 parts of trichlorofluoromethane, 16 parts of water glass, 18 parts of amin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com