Preparation method of PP/PET microfiber reinforced blend

A technology of blends and microfibers, which is applied in the field of reaction processing of polymer materials and can solve problems such as low tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

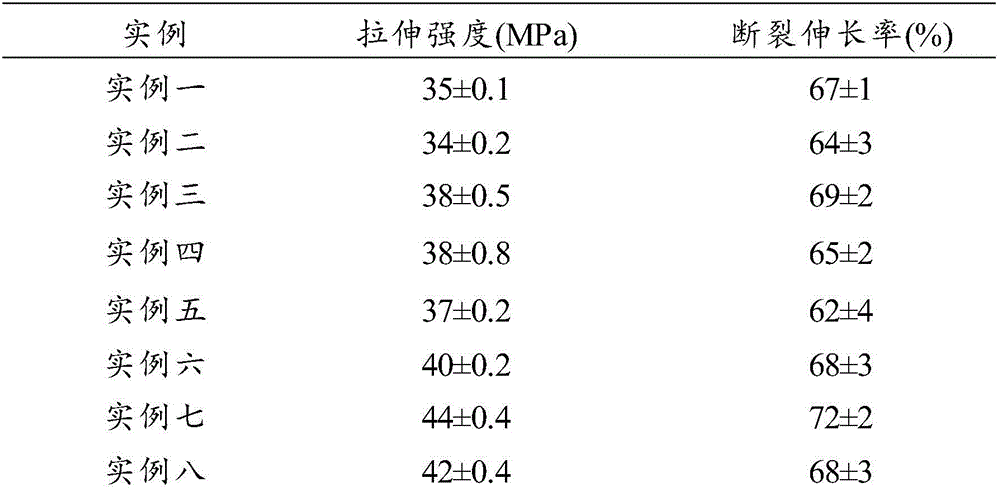

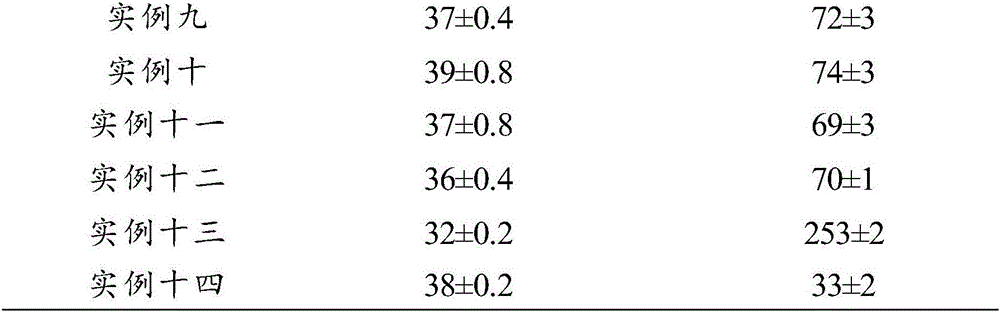

Examples

Embodiment 1

[0033] (1) Preparation of PP-g-(DAP-co-GMA) graft

[0034] On the extruder whose rotating speed is 120rpm, utilize the metering pump to inject the mixed material in the melting section (the total mass of GMA and DAP is 10% of the PP quality, the monomer molar ratio of DAP and GMA is 0.4, and the amount of initiator DCP is GMA and 0.5% of the total mass of DAP, the amount of free radical scavenger antioxidant 1010 is 0.1% of the PP mass), and the speed of adding the mixed material is controlled to prepare PP-g-(DAP-co-GMA) high grafting rate grafts . The temperature from the hopper to the die of the extruder is: the first temperature section is 165°C, the second temperature section is 170°C, the third temperature section is 180°C, the fourth temperature section is 185°C, and the fifth temperature section is 190°C , Die temperature is 185 ℃; screw speed is 60 ~ 100 rpm;

[0035] (2) Preparation of special materials for compatibilization

[0036] Dry PP, PP-g-(DAP-co-GMA) graf...

example 2

[0046] The monomer molar ratio of DAP and GMA in the example one step (1) becomes 0.2, and others are the same as example one.

example 3

[0048] The monomer molar ratio of DAP and GMA in the example one step (1) becomes 0.8, and others are the same as example one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com