A kind of preparation method of high-performance lldpe/pet microfiber reinforced blend

A blend, high-performance technology, applied in the field of reaction processing of polymer materials, can solve the problem of low tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

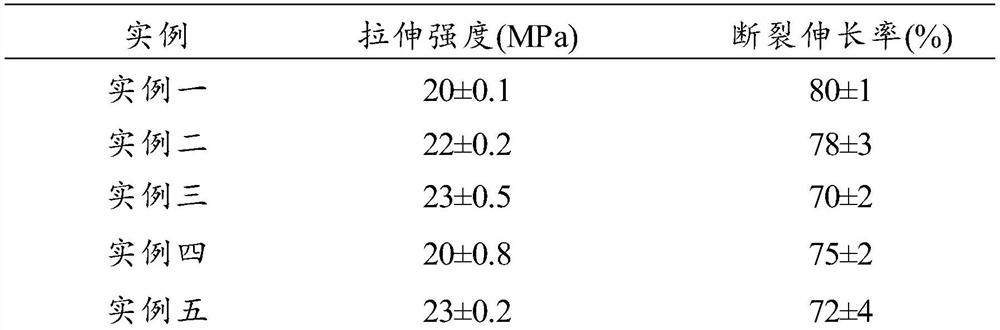

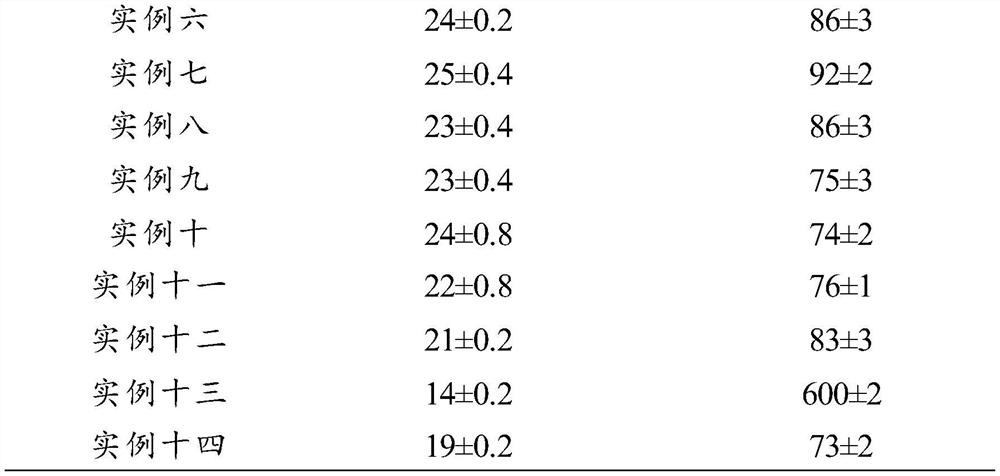

Examples

example 1

[0031] (1) Preparation of LLDPE-g-(DAP-co-GMA) graft

[0032] On the extruder that rotating speed is 120rpm, utilize metering pump to inject mixed material (the total mass of GMA and DAP is 10% of LLDPE quality, the monomer molar ratio of DAP and GMA is 0.4, and initiator DCP consumption is GMA and 0.5% of the total mass of DAP), and the speed of adding the mixed materials is controlled to prepare LLDPE-g-(DAP-co-GMA) grafts with high grafting rate. The temperature from the hopper to the die of the extruder is: 100°C, 170°C, 180°C, 185°C, 190°C, 185°C, and the screw speed of the extruder is 60-100 rpm.

[0033] (2) Preparation of special materials for compatibilization

[0034] Dry LLDPE, LLDPE-g-(DAP-co-GMA) grafts and PET. The dried material is mixed with the antioxidant according to the following mass percentage, and finally extruded and granulated in an extruder. The temperature of the extruder from the hopper to the die is: 100°C, 250°C, 280°C, 280°C, 280°C, 260°C, and...

example 2

[0044] The monomer molar ratio of DAP and GMA in the example one step (1) becomes 0.2, and others are the same as example one.

example 3

[0046] The monomer molar ratio of DAP and GMA in the example one step (1) becomes 0.8, and others are the same as example one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com