Grooved wheel compensation device

A compensating device and sheave technology, applied in the direction of overhead lines, etc., can solve the problems of complex installation on the construction site, high manufacturing process requirements, and insufficient braking effect, so as to improve the installation speed and installation quality, and the braking effect is good. Effect of short braking distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

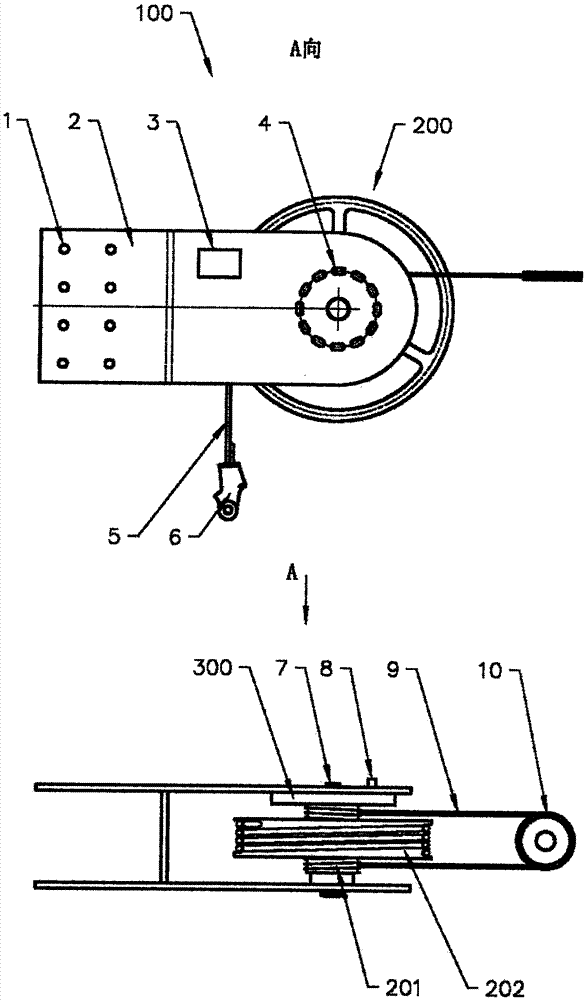

[0036] In Embodiment 1, a built-in brake 300 is installed on one side of the connecting frame 2, which at least includes a connecting hole 1, a connecting frame 2, a nameplate 3, a locking hole 4, a steel wire rope 5, double ear wedge clamps 6, a main shaft 7, a locking pin 8, and a steel wire rope 9 , balance wheel 10, wheel body 200 and brake 300 are formed.

[0037] In Embodiment 1, the wire rope 5 is wound and fixed in the wire groove of the large circle 201 of the wheel body 200; one end of the wire rope 9 is fixed and wound in the wire groove of the small circle 202 of the wheel body 4, and the other end of the wire rope 9 is connected to the balance wheel 10 Then wind in the other side wire groove of the small circle 202 of the wheel body 200 in turn. Catenary conductors (carrying cables and catenary wires) produce thermal expansion and contraction under the influence of ambient temperature, through the synchronous operation of the small circle 201 of the upper wheel bo...

Embodiment 2

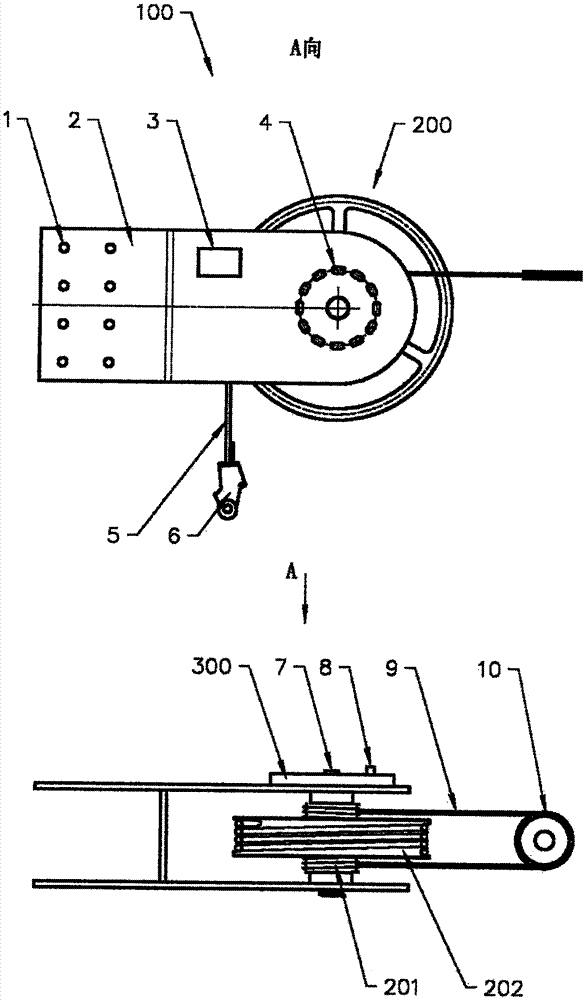

[0051] In Embodiment 2, an external brake 300 is installed on one side of the connecting frame 2 , which is the second way of installing the brake 300 on the sheave compensation device 100 . The difference from Embodiment 1 is that the brake 300 is arranged outside the connecting frame 2 .

Embodiment 3

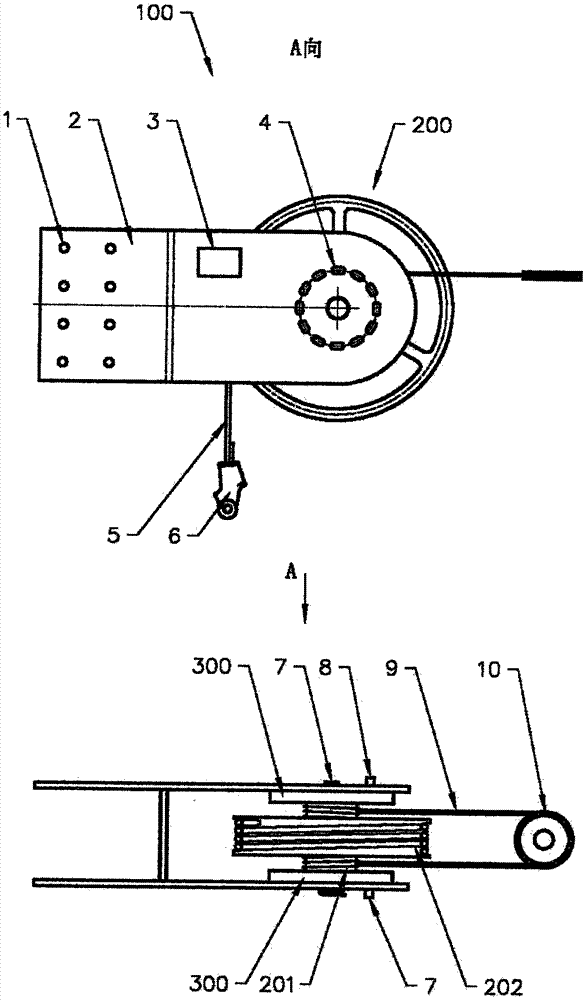

[0052] In Embodiment 3, built-in brakes 300 on both sides of the connecting frame 2 are the third way of installing the brakes 300 in the sheave compensation device 100 . The difference from Embodiment 1 is that two brakes 300 are installed inside the connecting frame 2 at the same time. This Embodiment 3 is suitable for a sheave compensation device 100 with a rated tension greater than 30-60 kN.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com