Pneumatic tire

一种充气轮胎、轮胎的技术,应用在轮胎零部件、轮胎胎面/胎面花纹、运输和包装等方向,能够解决耐磨损性能、操纵稳定性能变差、兼顾困难等问题,达到防止操纵稳定性能、高刚性、提高湿路制动性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

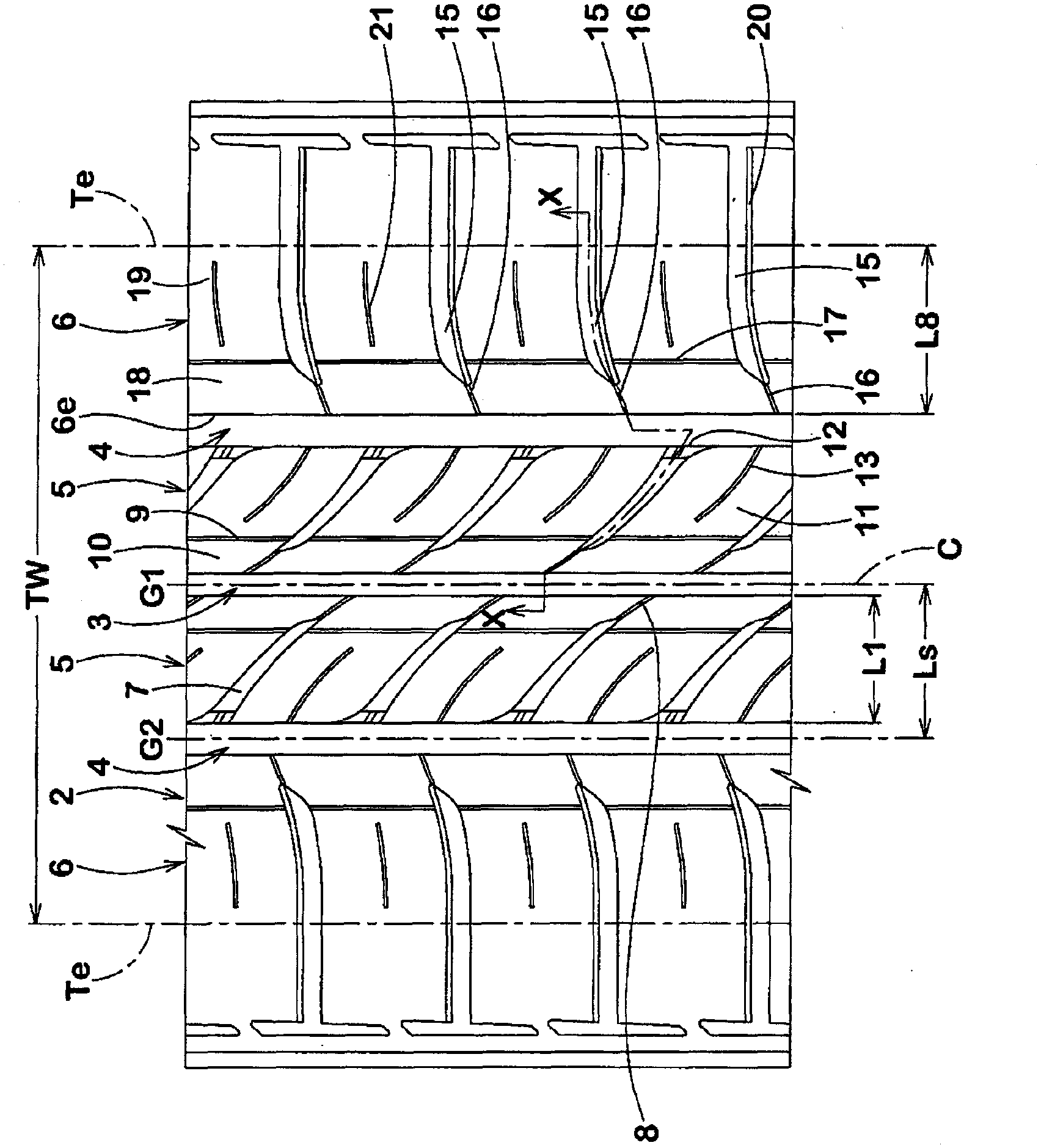

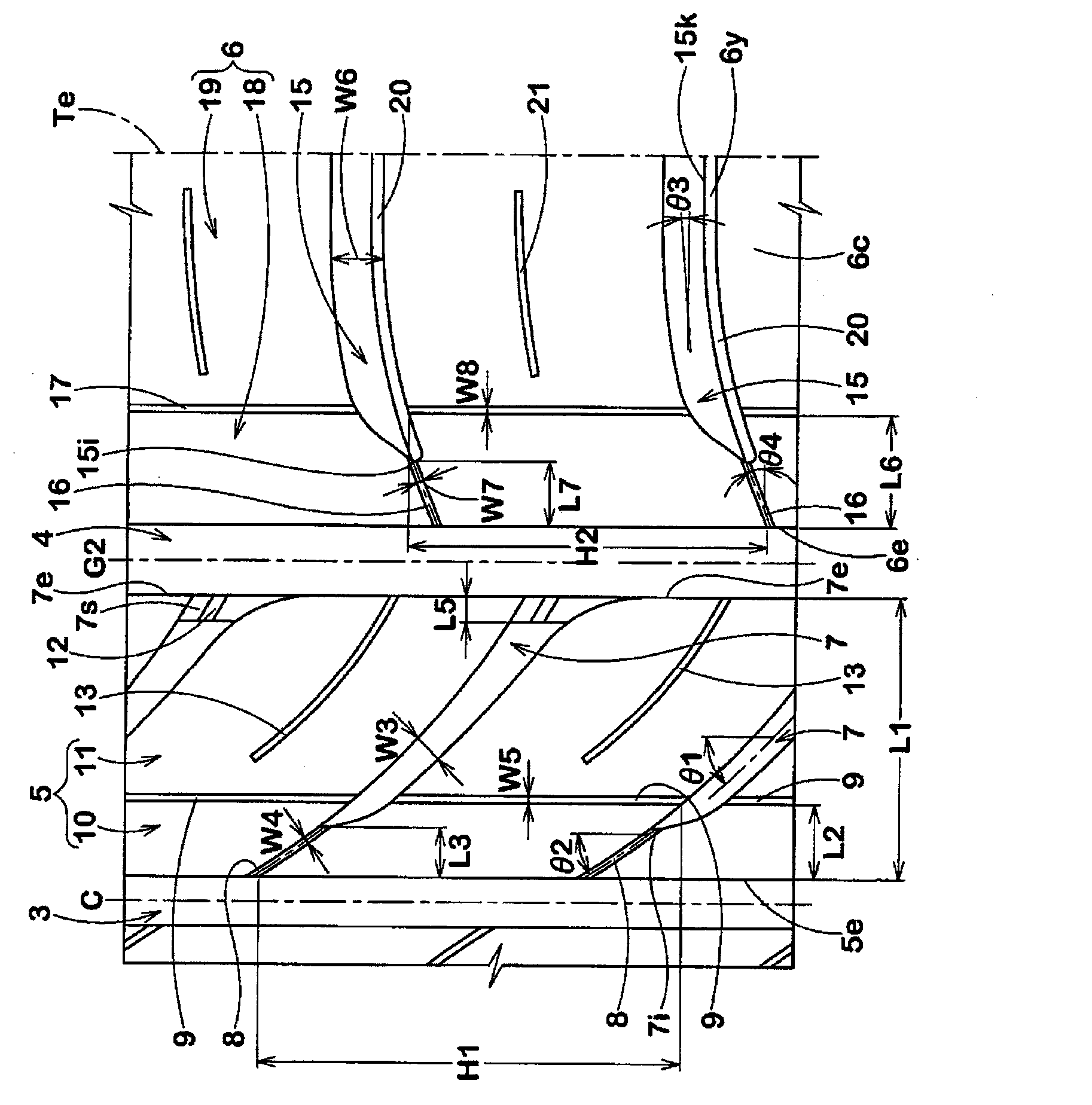

[0055] Manufacturing has figure 1 Pneumatic tires (size: 175 / 65R15) with a pattern based on the specifications in Table 1, and their various properties were tested. In addition, common specifications are as follows.

[0056] Rim size: 15×5J

[0057] Tread contact width TW: 130mm

[0058]

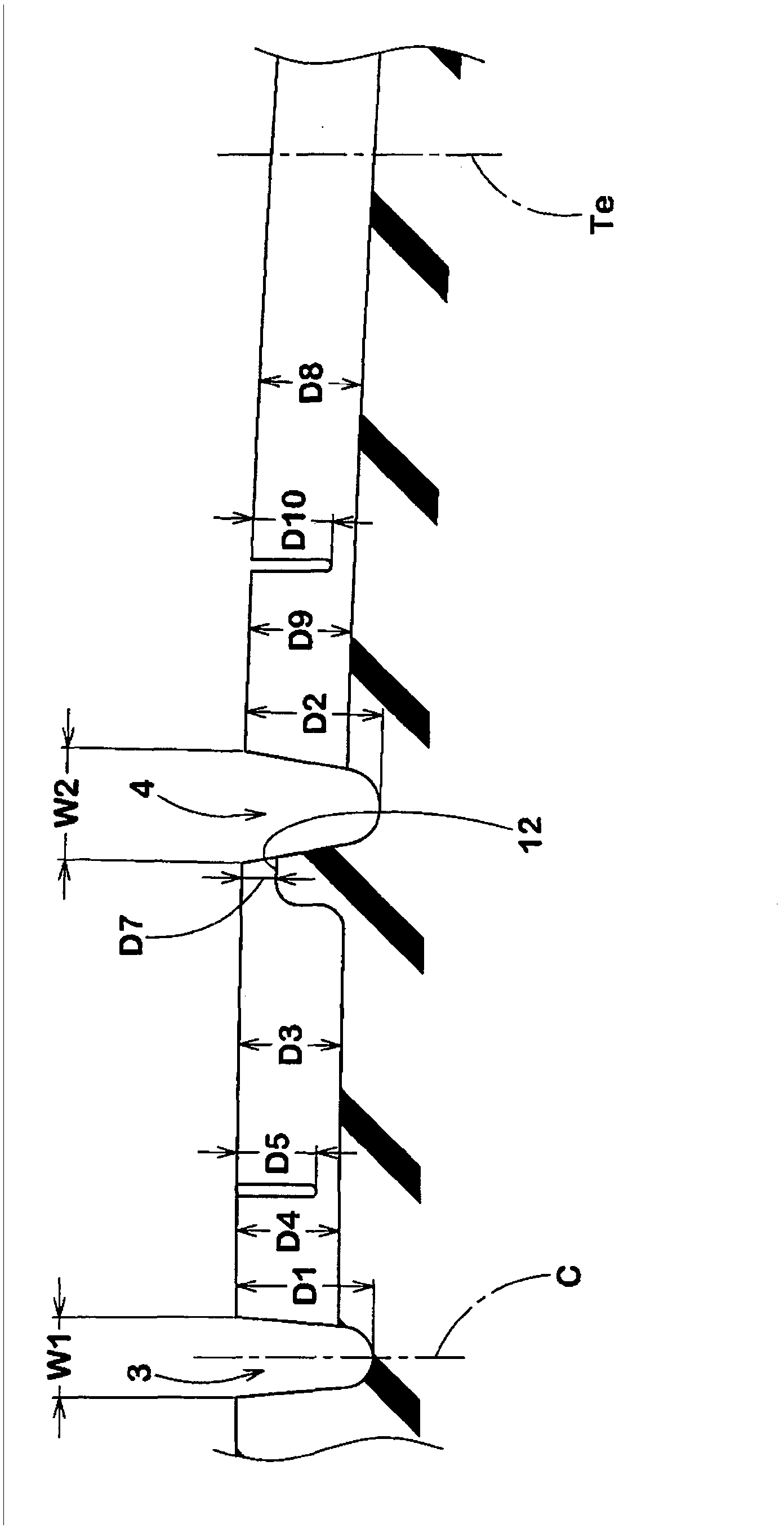

[0059] Groove width W1 / Tread contact width TW: 3.2%

[0060] Groove depth D1: 7.4mm

[0061]

[0062] Groove width W2 / Tread contact width TW: 5.5%

[0063] Groove depth D2: 7.4mm

[0064] Placement Ls / TW: 23%

[0065]

[0066] Groove width W3: 2.0~3.0mm

[0067] Groove depth D3: 5.2mm

[0068] Angle θ1: 40-55 degrees

[0069]

[0070] Sipe width W4: 0.6mm

[0071] Depth D4: 5.0mm

[0072]

[0073] Depth D5: 5.0mm

[0074]

[0075] Groove width W6: 4.0mm

[0076] Groove depth D8: 6.0mm

[0077] Angle θ3: 0~15°

[0078]

[0079] Sipe width W7: 0.6mm

[0080] Depth D9: 5.0mm

[0081] Angle θ4: 15°

[0082]

[0083] Sipe width W8: 0.8mm

[0084] Depth D10: 5.0m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com