Hub motor driving automobile integrative design and cooperative control test platform and implementation method

A hub motor and test platform technology, which is applied in vehicle testing, machine/structural component testing, measuring devices, etc., can solve problems related to hub motor drive vehicle performance and collaborative control that need to be developed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

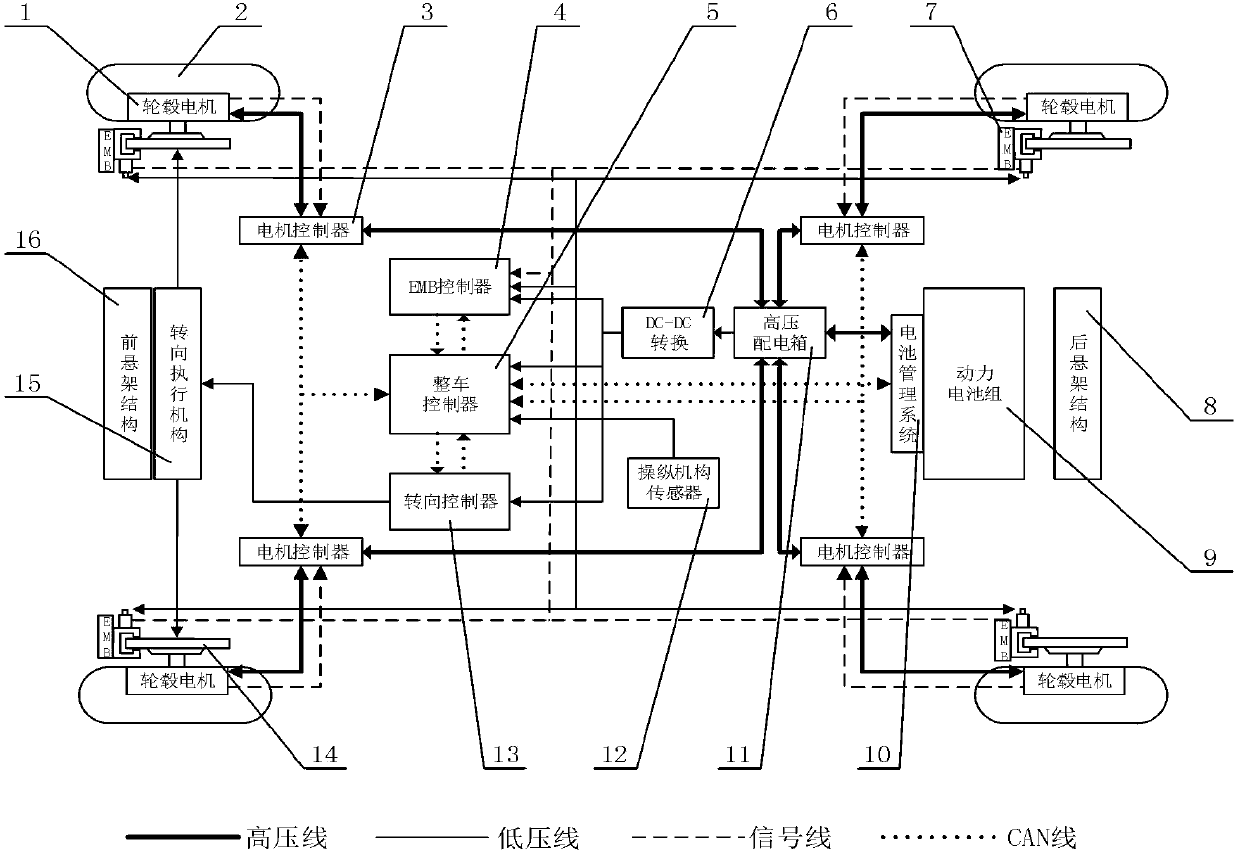

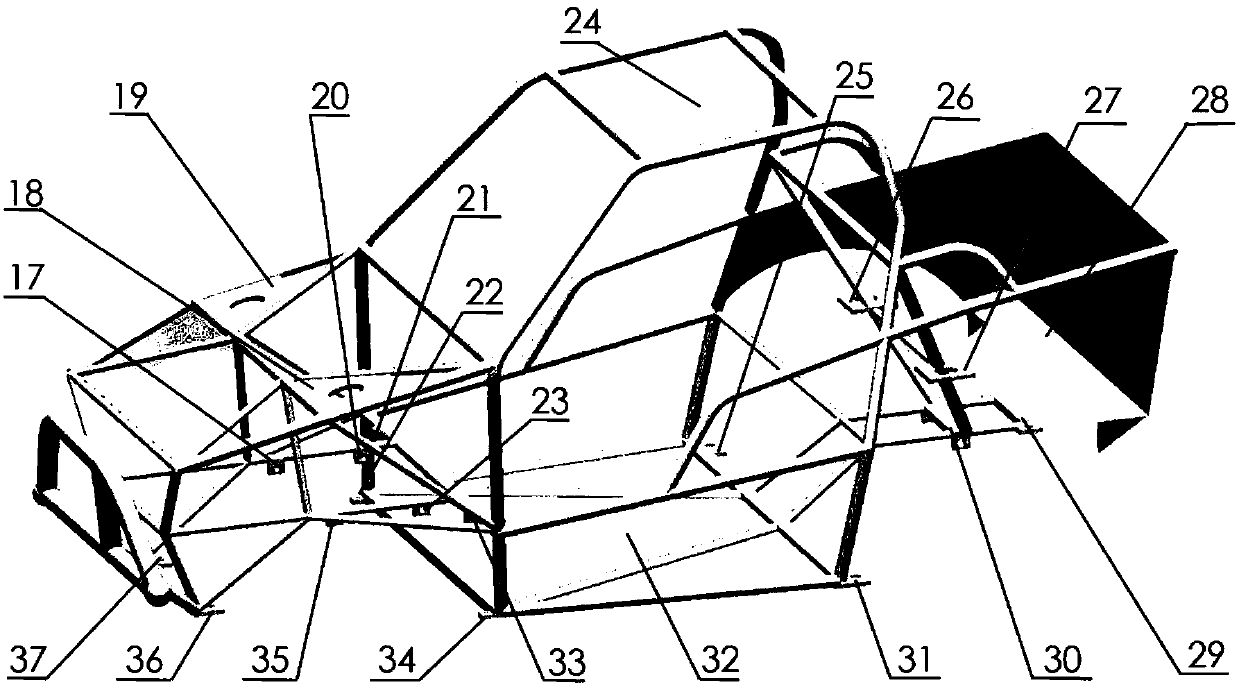

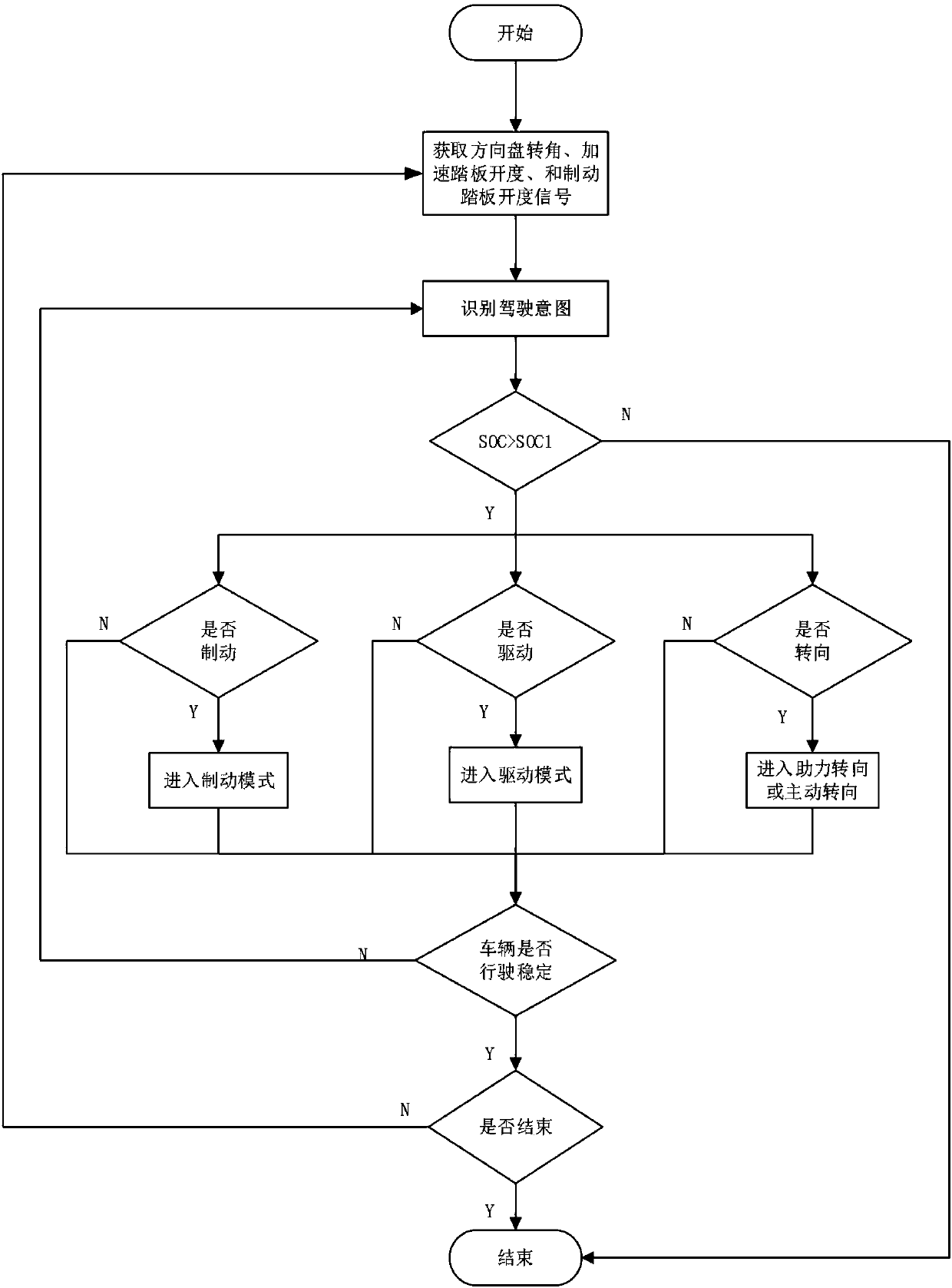

[0048] Such as figure 1 As shown, the integrated design and collaborative control test platform of the hub motor drive vehicle of the present invention includes a vehicle control system, an active distributed drive system, an EMB electromechanical braking system, an active steering system, a power battery pack and a battery management system, Complete vehicle frame structure and suspension modules.

[0049] Specific as figure 1Shown is a schematic diagram of the overall structure of an in-wheel motor-driven vehicle integrated design and collaborative control test platform of the present invention, wherein: in-wheel motor 1, wheel 2, four motor controllers 3, EMB controller 4, vehicle controller 5, DC-DC conversion device 6, four EMB brakes 7, rear suspension mechanism 8, power battery pack 9, battery management system 10, high-voltage distribution box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com