Differential planetary roller screw

A planetary roller and lead screw technology, which is applied in the direction of transmission devices, belts/chains/gears, mechanical equipment, etc., can solve the problems of unfavorable integration of roller screws and transmission devices, achieve large screw teeth, realize integrated design, The effect of strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

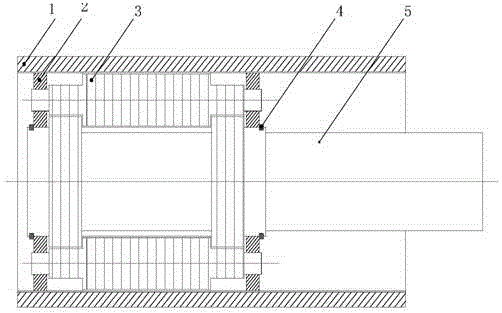

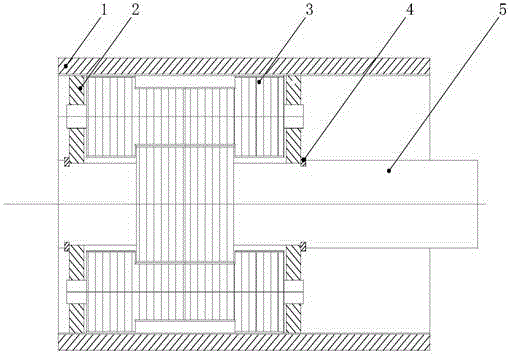

[0025] Please refer to figure 1 , figure 1 It is a schematic cross-sectional schematic diagram A of a typical structure of a reverse differential planetary roller screw. It is also the first embodiment of the present invention.

[0026] The reverse differential planetary roller screw includes a nut 1, two end cages 2, a roller 3, two retaining rings 4, and a screw 5. The nut 1 has an internal thread and a thread lead angle, and is in the form of an integral nut. The number of rollers 3 is 3, 4, 5, 6, 7, 8, 9 or 10, and the structure is in the form of a stepped shaft, and the radial dimensions at both ends of the stepped shaft are smaller than the radial dimension of the middle section , all of which are provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com