Patents

Literature

40 results about "Contact radius" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Variable ratio transmission elements for motor drive shafts

ActiveUS7075213B2Piezoelectric/electrostriction/magnetostriction machinesSemiconductor/solid-state device manufacturingMotor driveVariable ratio

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

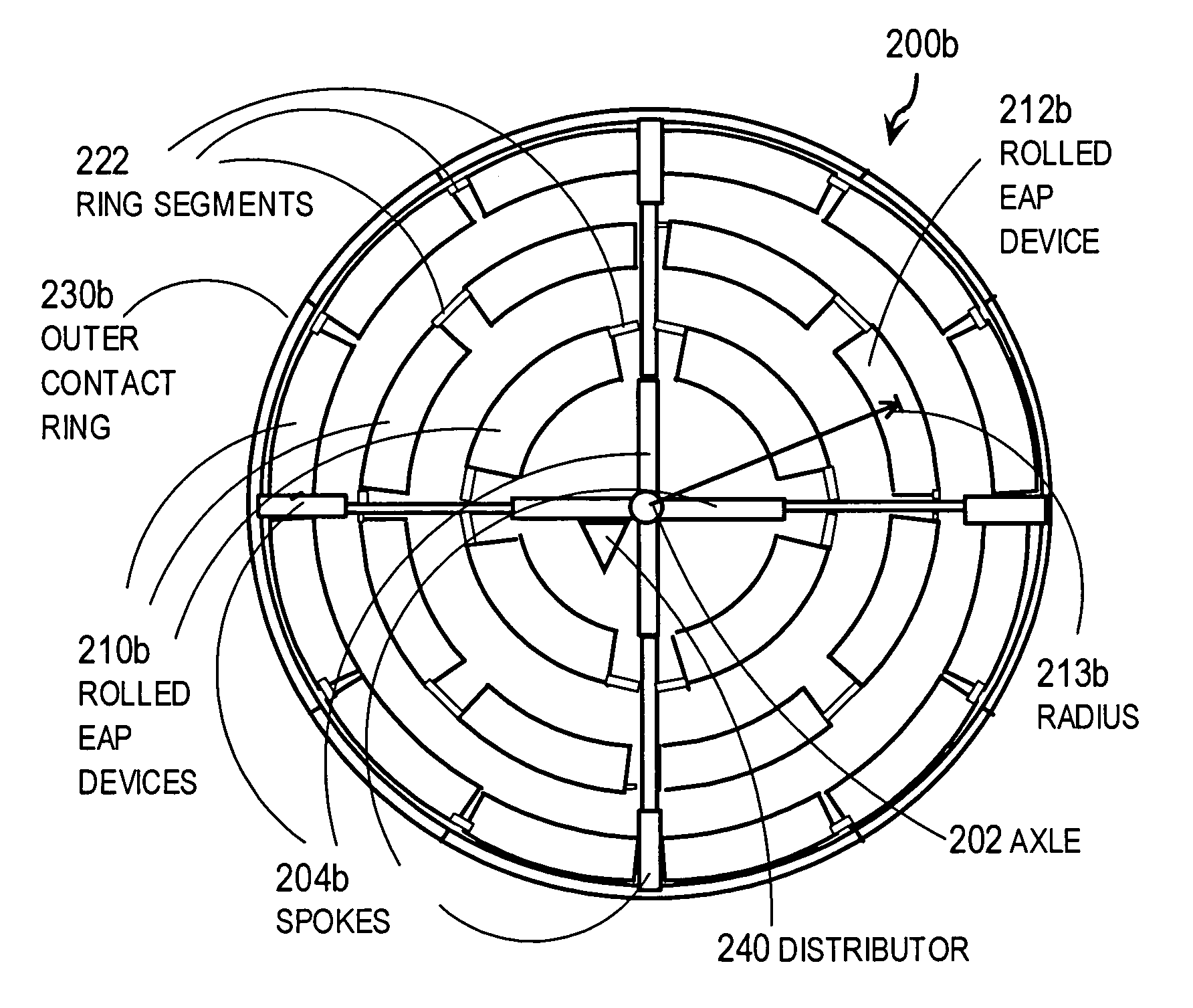

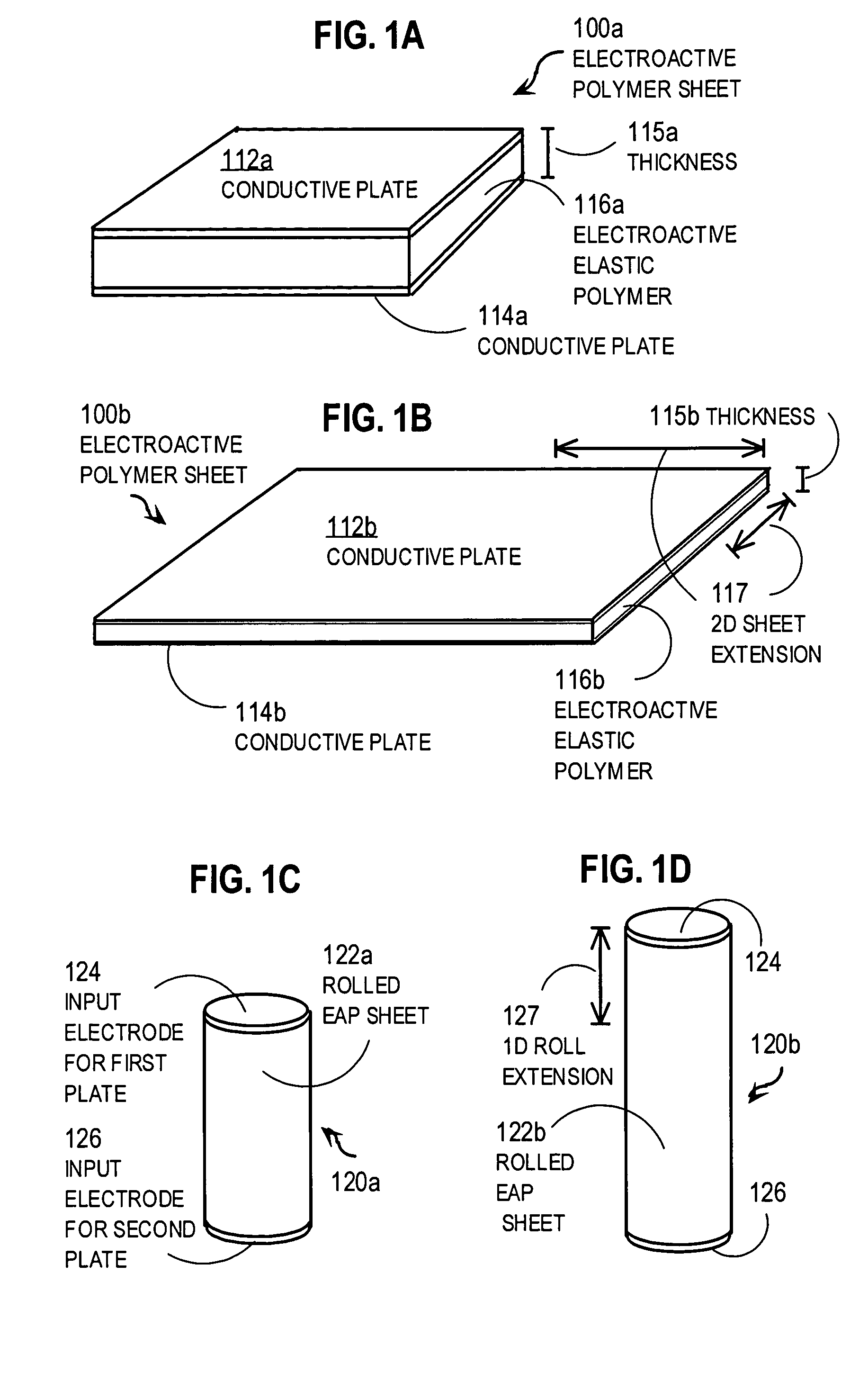

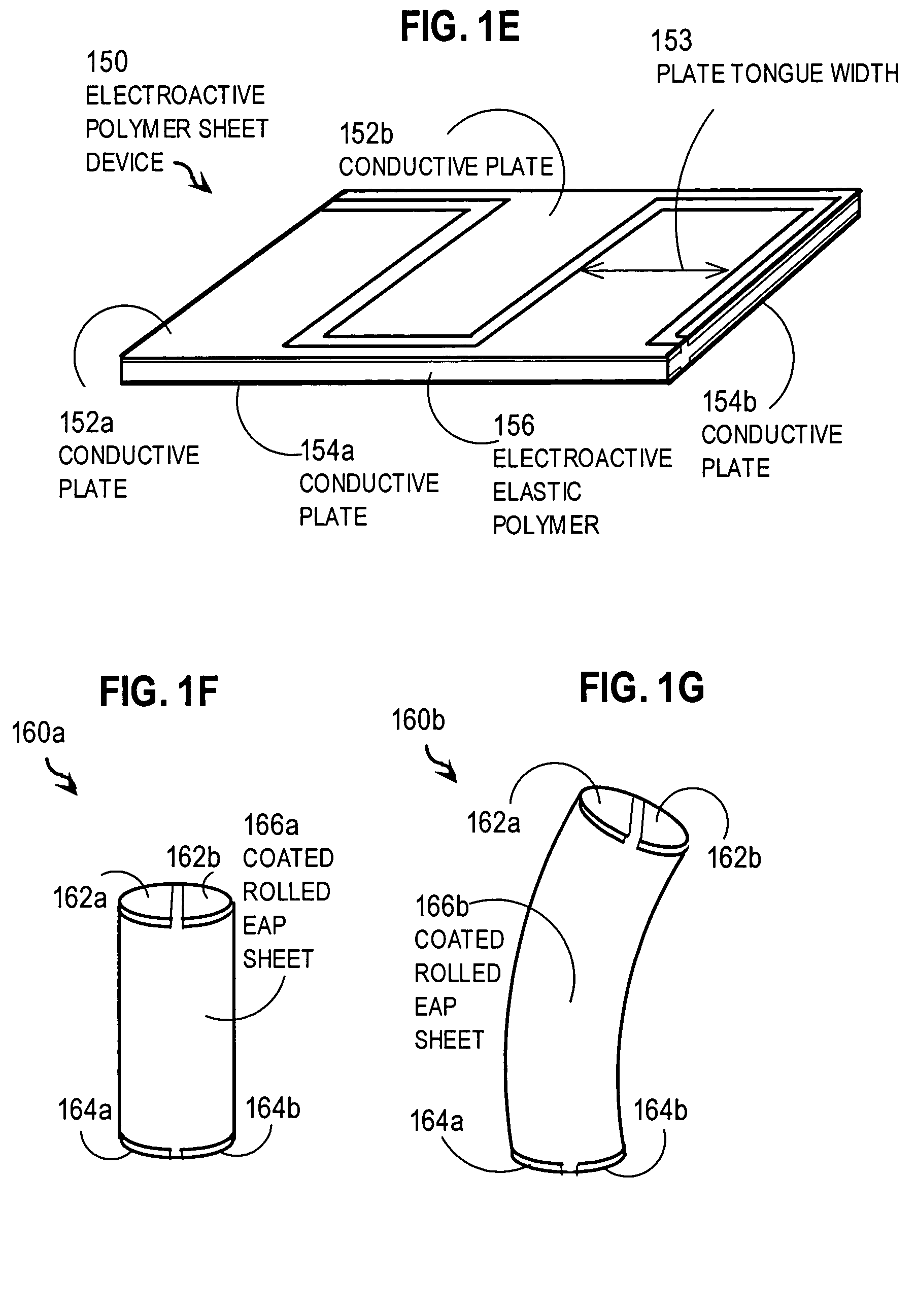

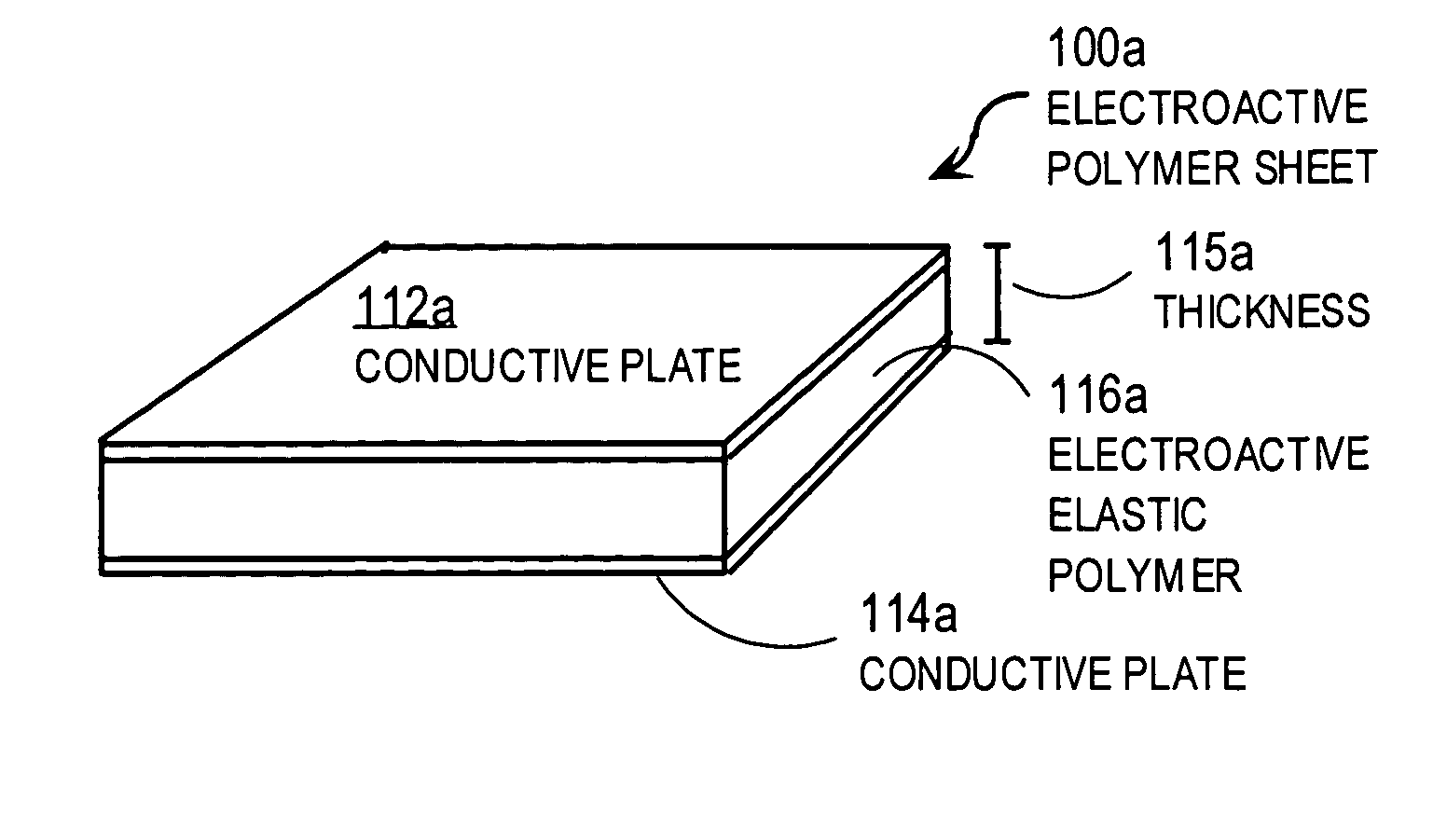

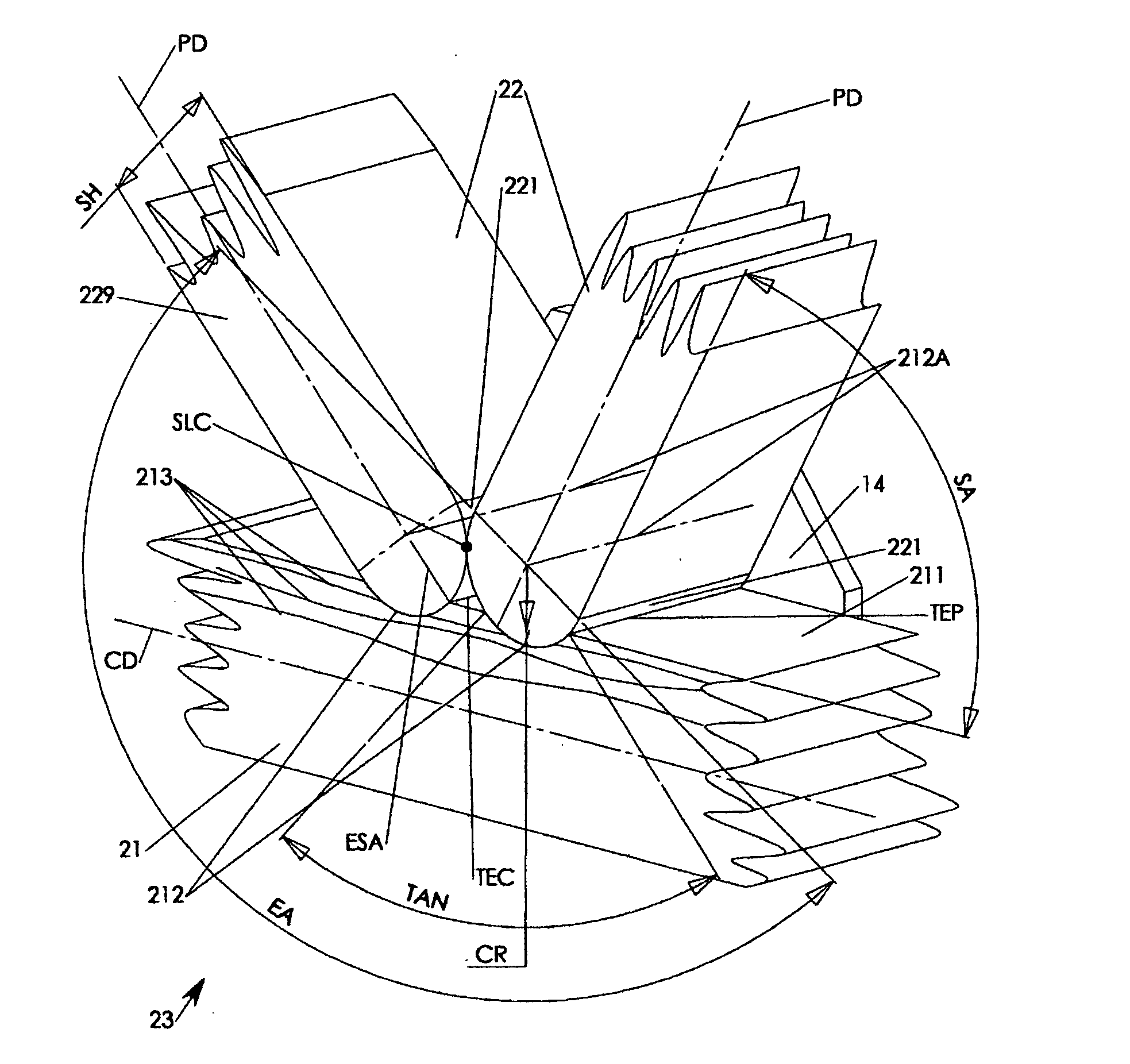

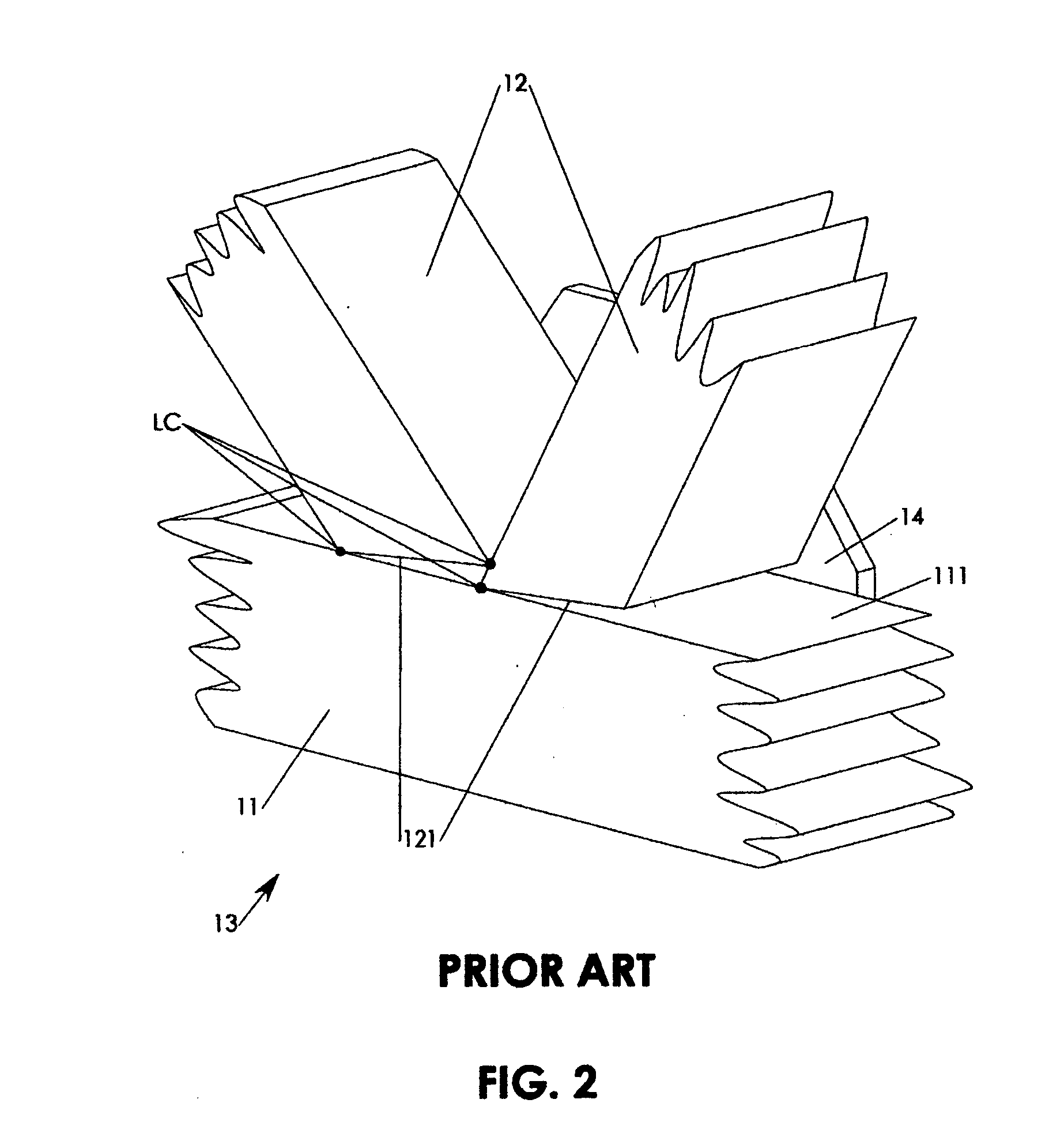

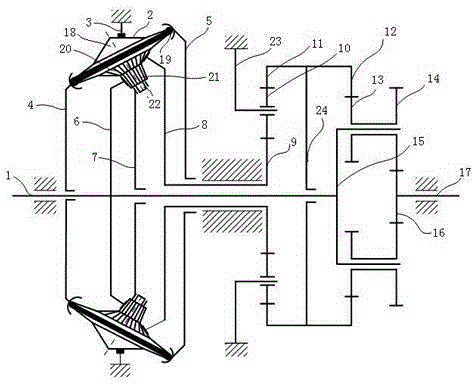

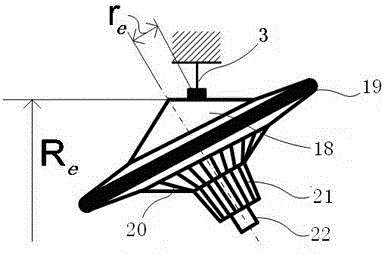

Variable ratio transmission elements for motor drive shafts

ActiveUS20050162049A1Increase radiusImprove the circumferencePiezoelectric/electrostriction/magnetostriction machinesSemiconductor/solid-state device manufacturingMotor driveEngineering

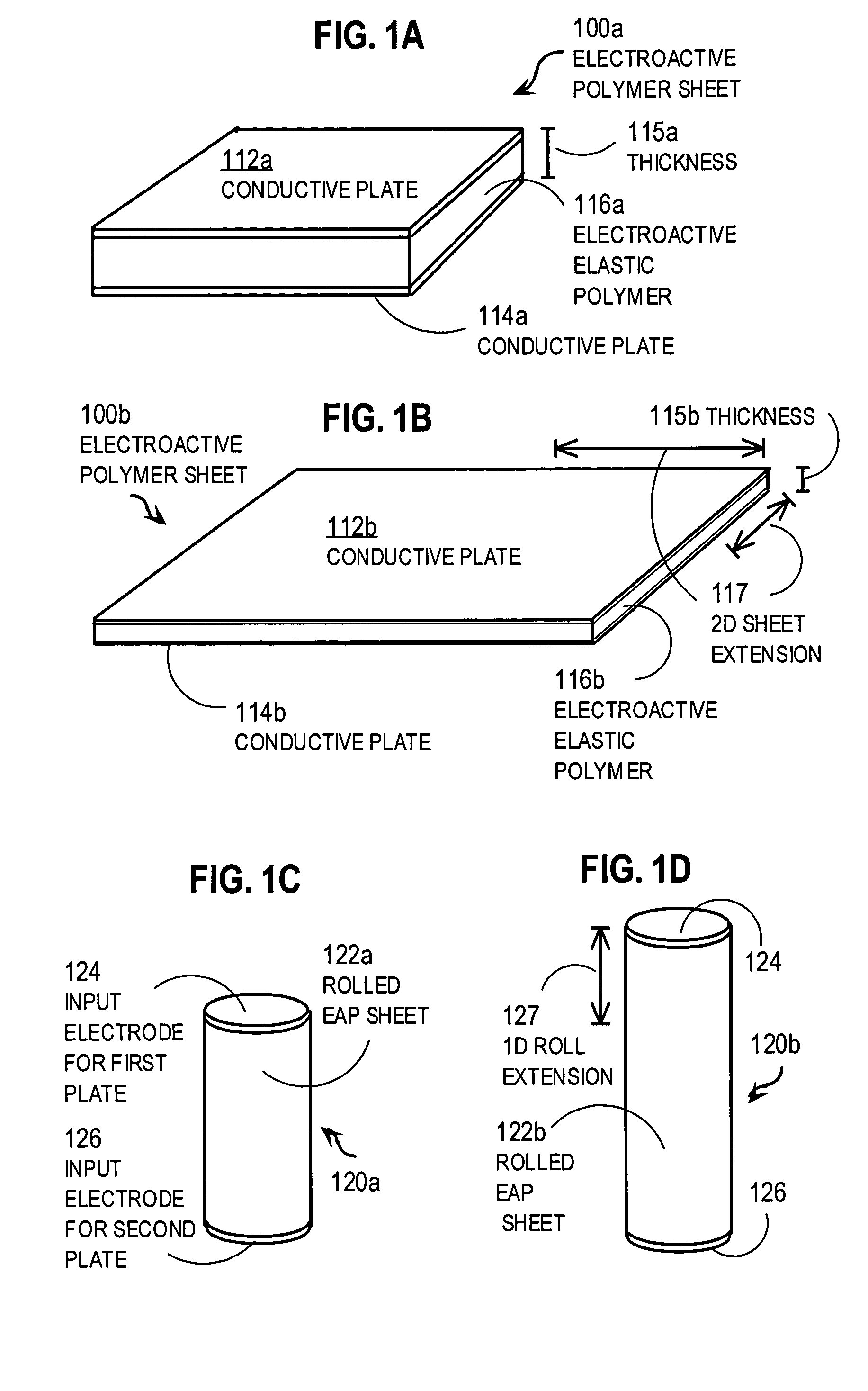

A motor transmission element includes an axle, an expandable circumferential component and multiple rolled electroactive polymer (EAP) devices. The circumferential component is located at a contact radius from the axle for connection to a different rotating body and is mechanically connected to the axle. The rolled EAP devices are mechanically connected to the circumferential component and the axle. Each rolled EAP device has a pair of input electrodes and is configured to deform substantively parallel to a roll longitudinal axis upon application of a voltage difference. Deformation of a rolled EAP device causes a change in the contact radius. A voltage difference that expands the rolled EAP device increases the contact radius, and thereby the circumference of the transmission element. By varying the voltage, a continuously variable ratio can be achieved between a rate of rotation of the transmission element and a rate of rotation of the second body.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

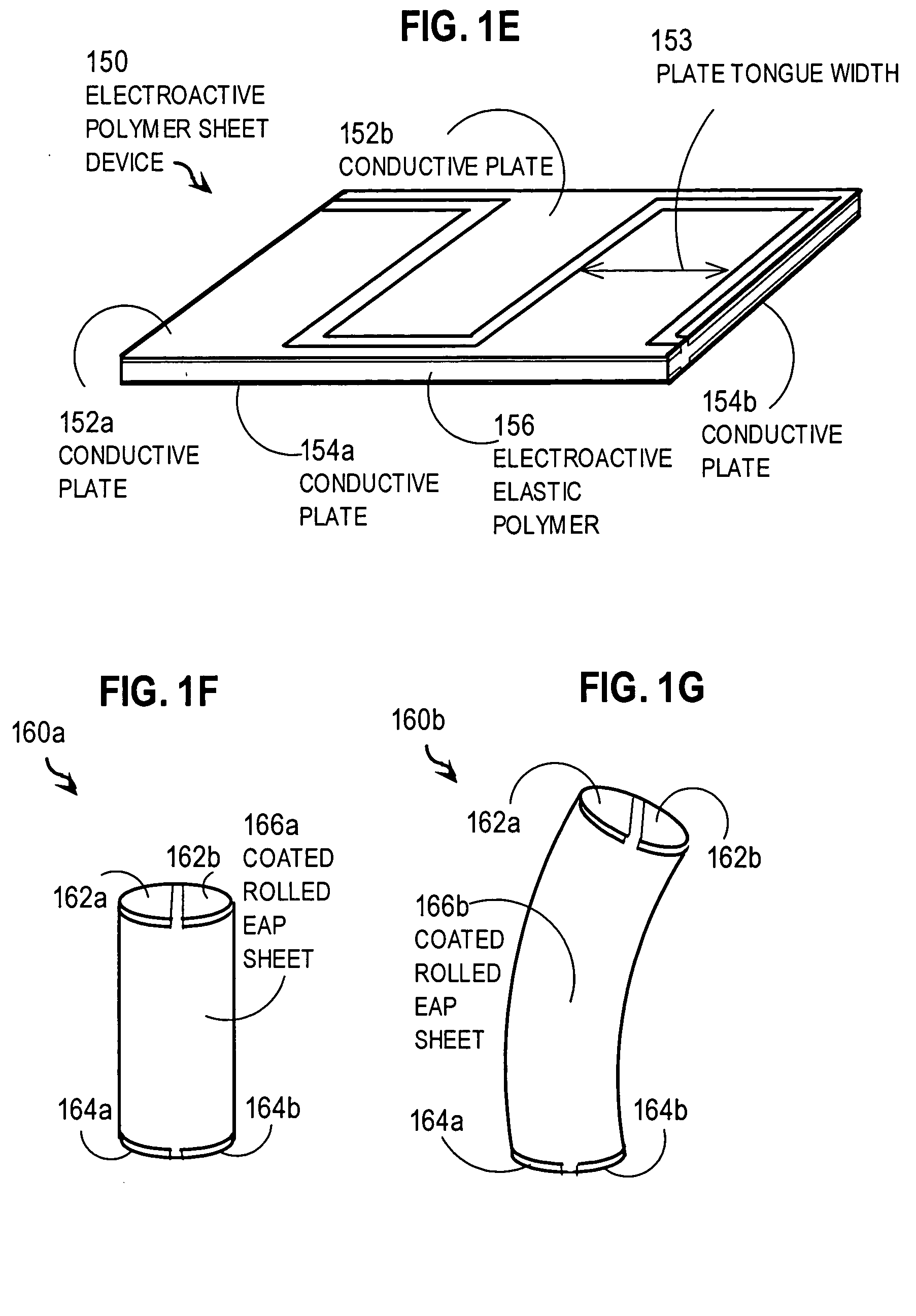

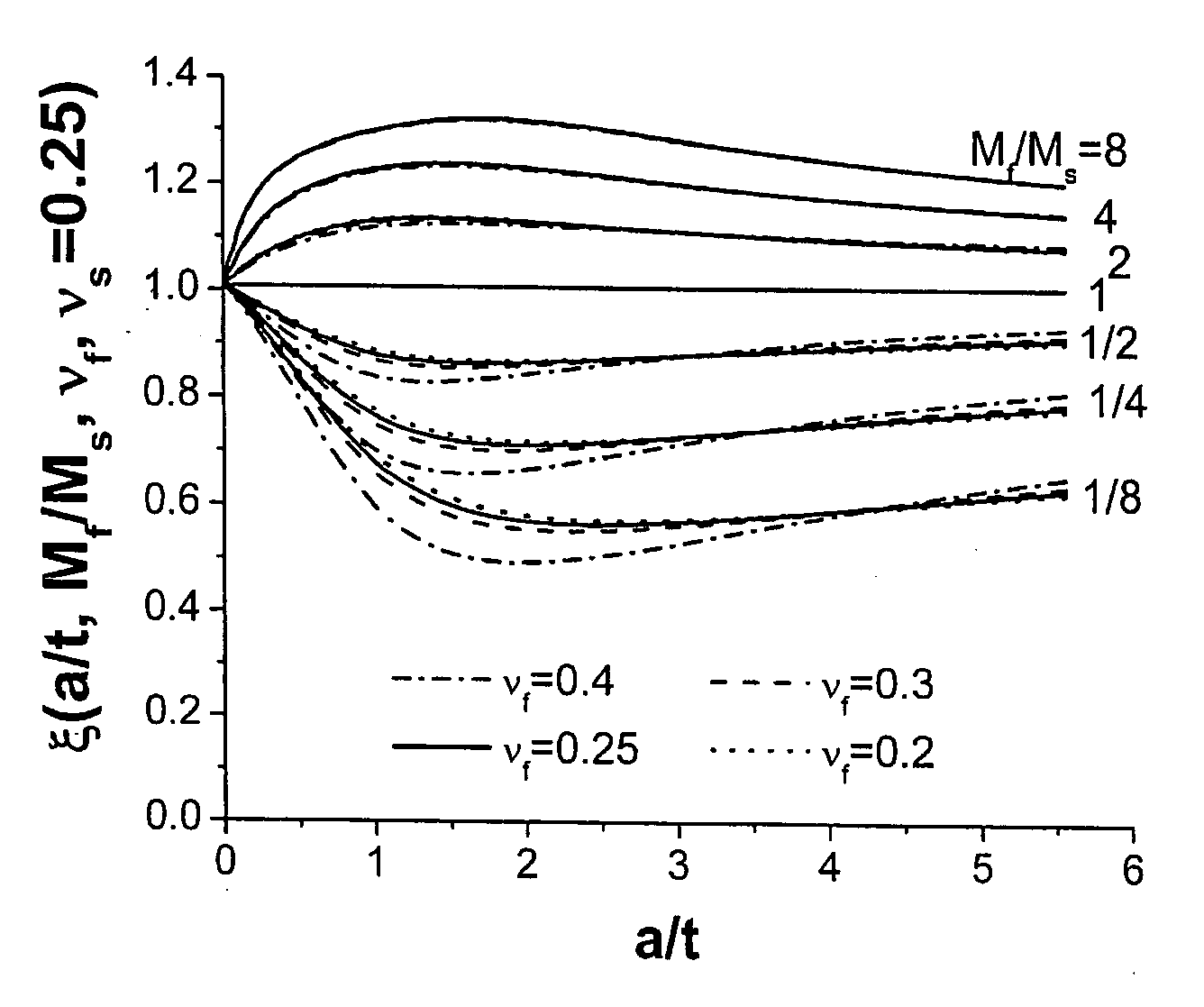

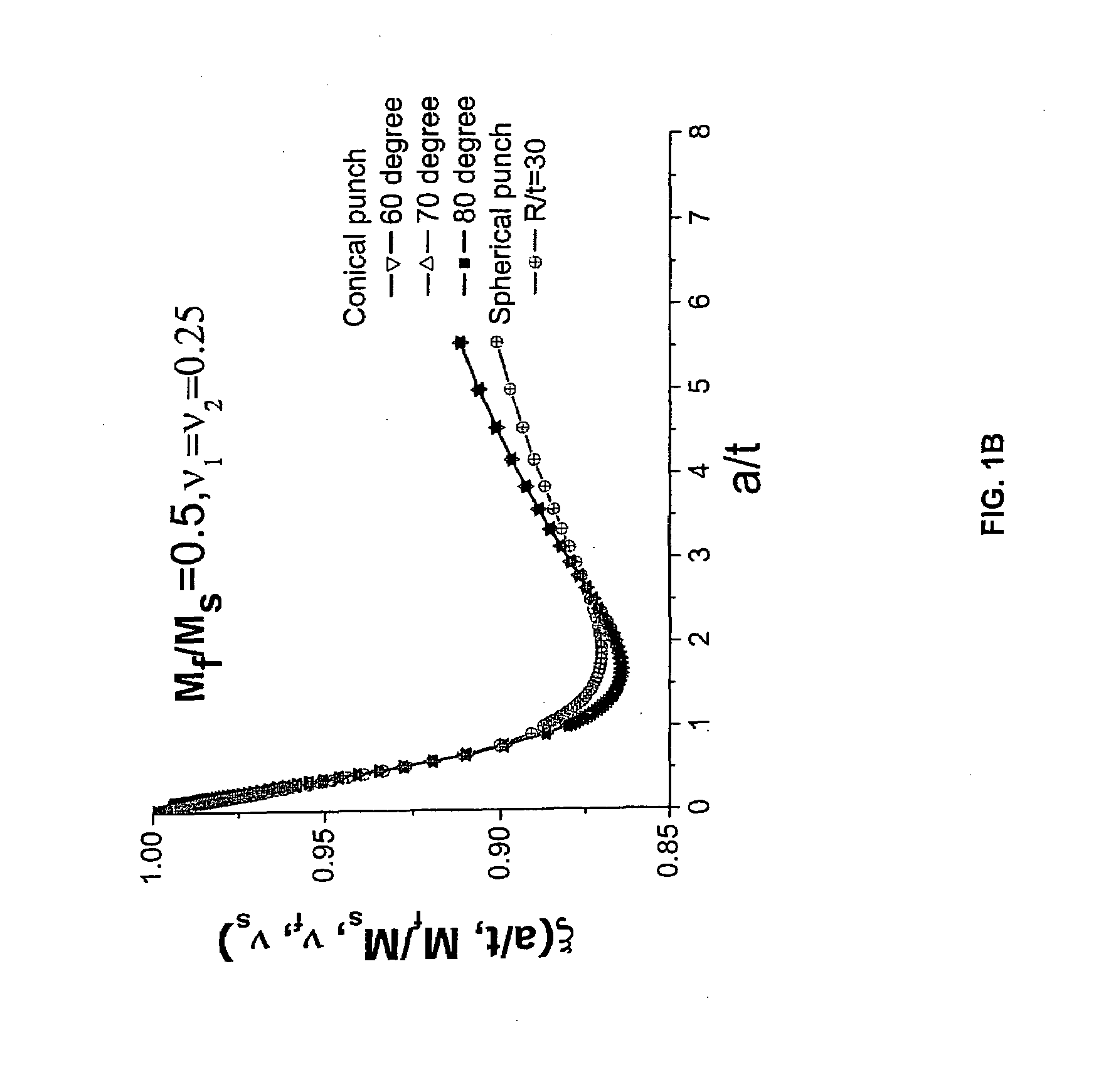

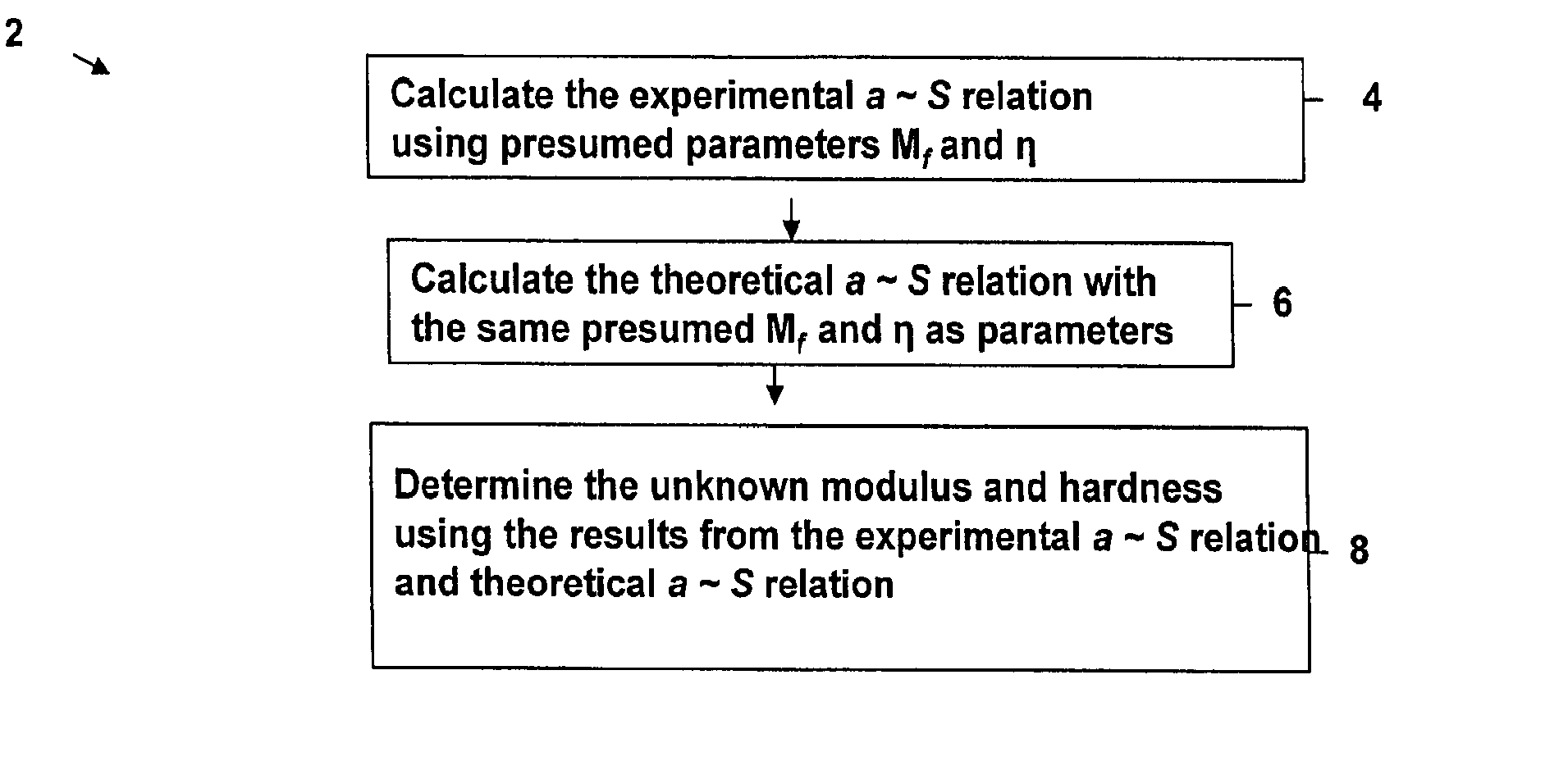

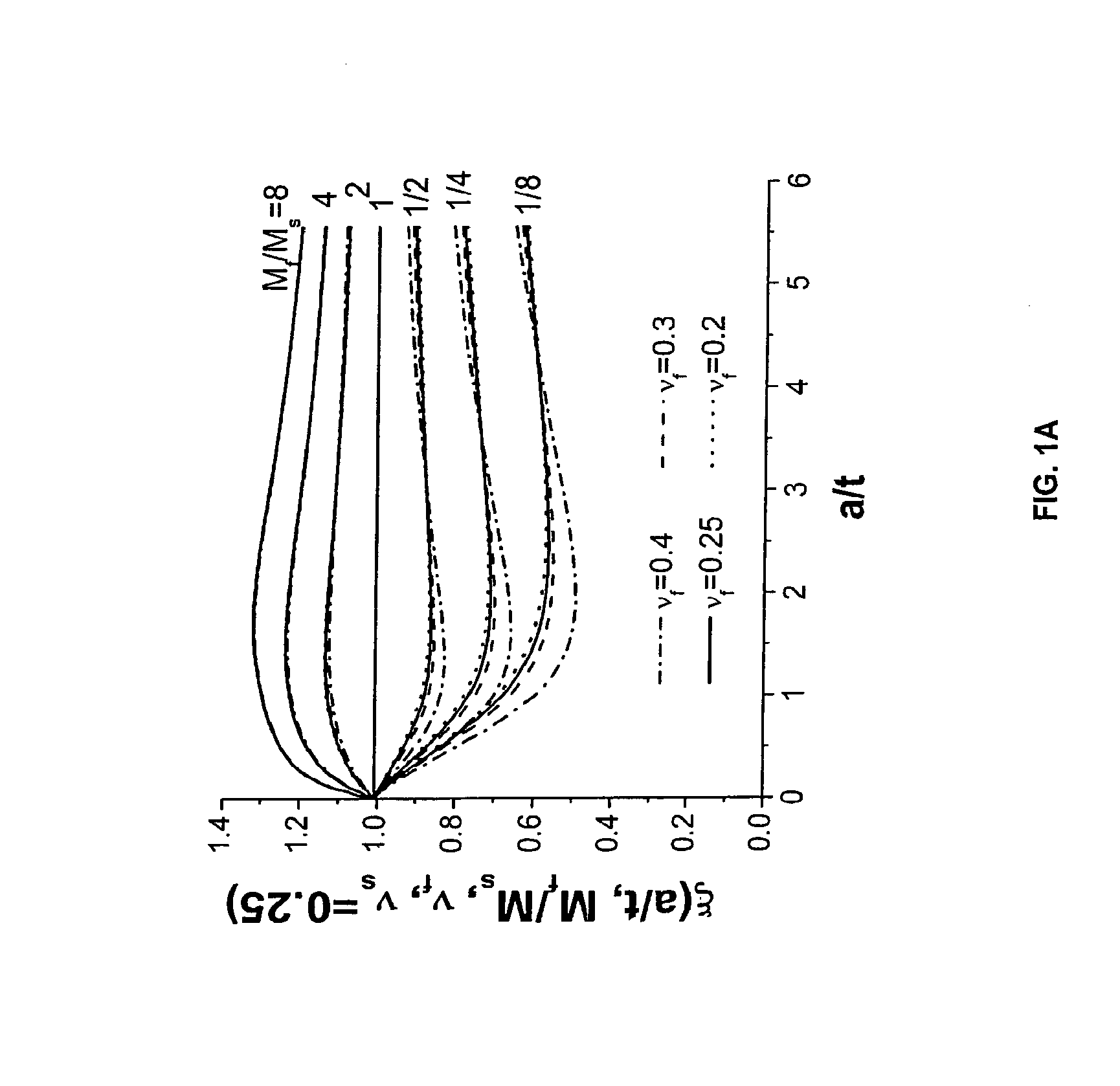

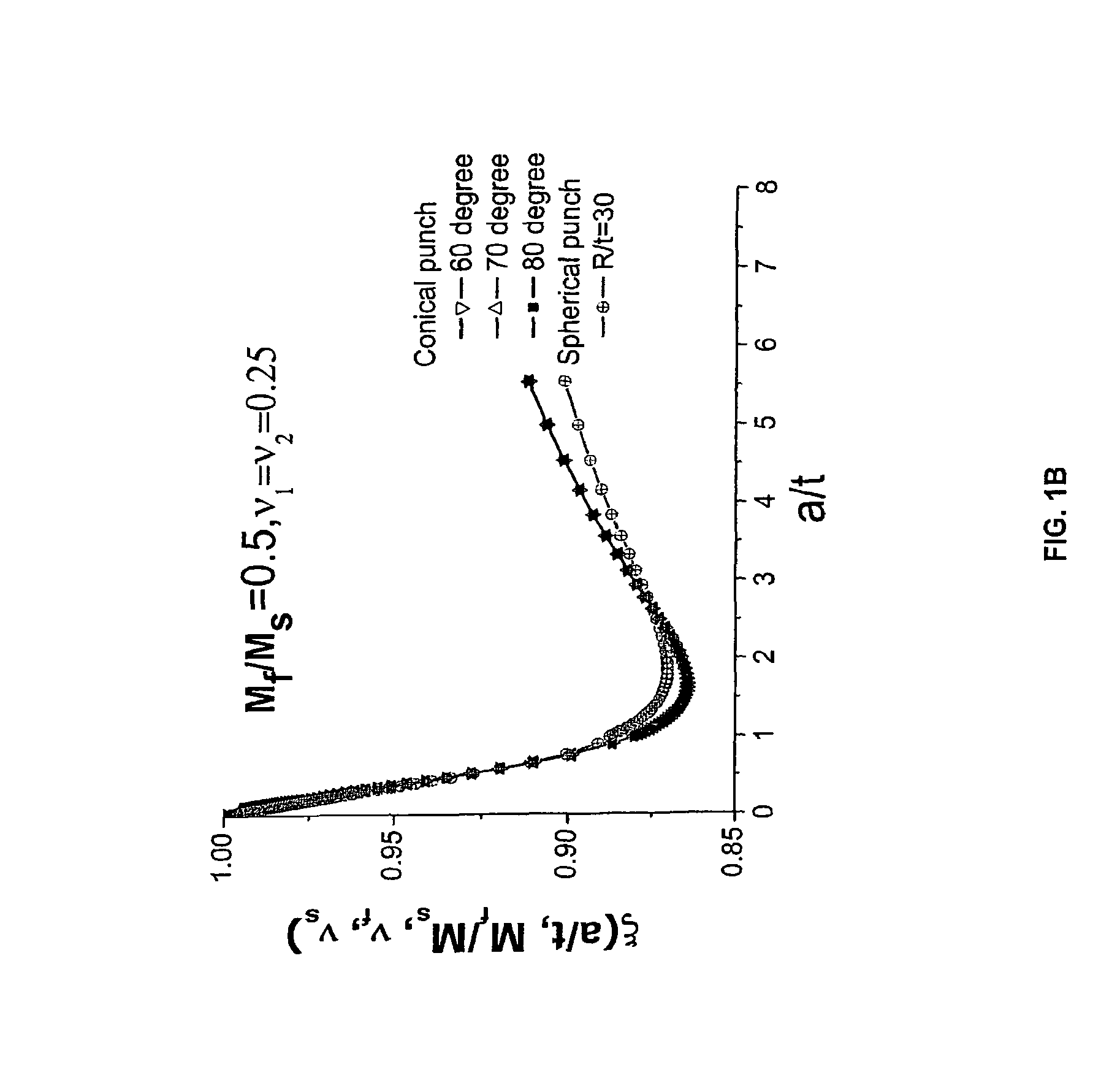

Method to measure the elastic modulus and hardness of thin film on substrate by nanoindentation

A method of measuring the elastic modulus and hardness of a thin film on substrate using nanoindentation technique is provided. The method includes calculating a series of experimental corrected stiffness and contact radius pairs associated with one or more presumed parameters and information obtained from a loading curve associated with the thin film and substrate. Also, the method includes calculating a series of theoretical corrected stiffness and contact radius pairs associated with the same one or more presumed parameters and information obtained from the loading curve associated with the thin film and substrate. Furthermore, the method includes using results obtained from the experimental and theoretical corrected stiffness and contact radius pairs to compute the elastic modulus and hardness of the film material.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

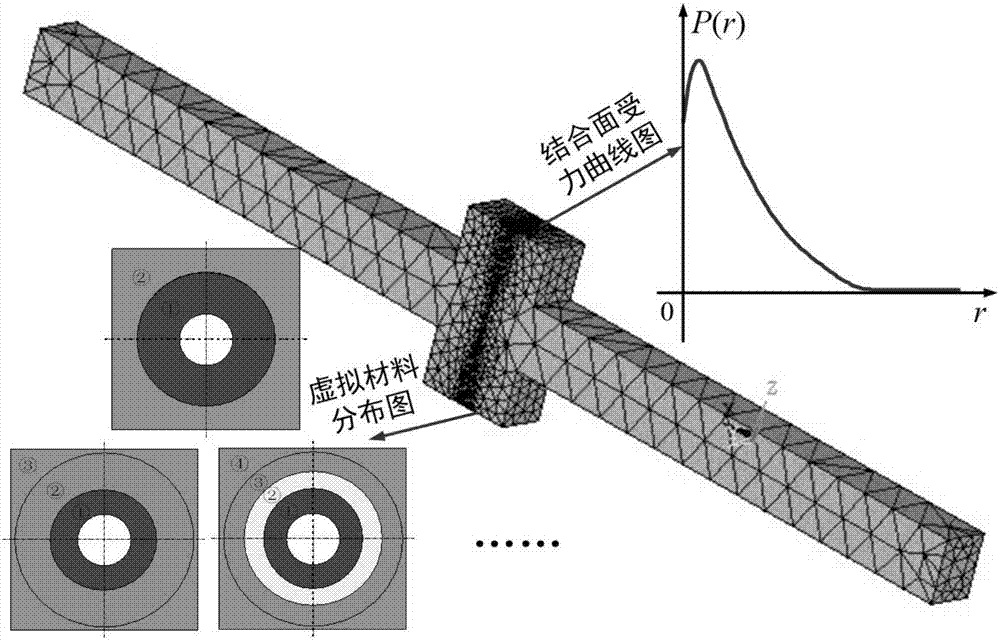

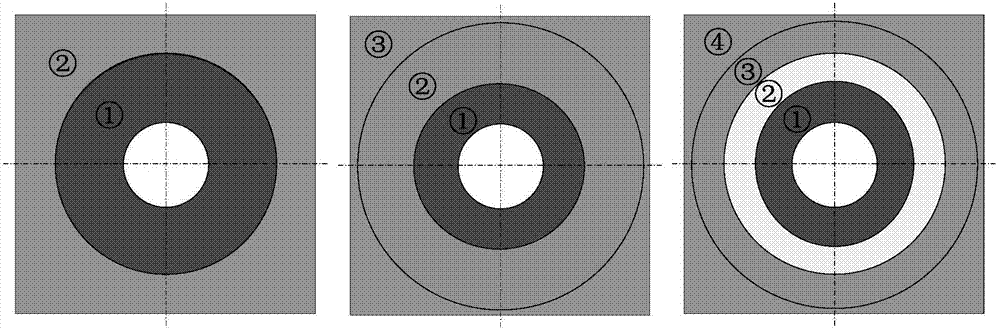

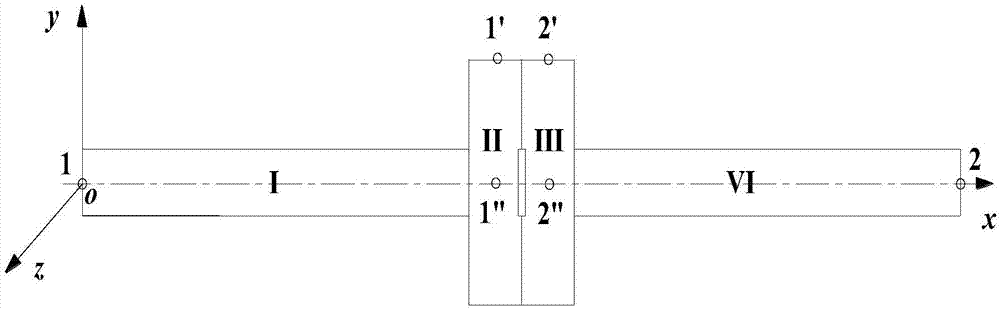

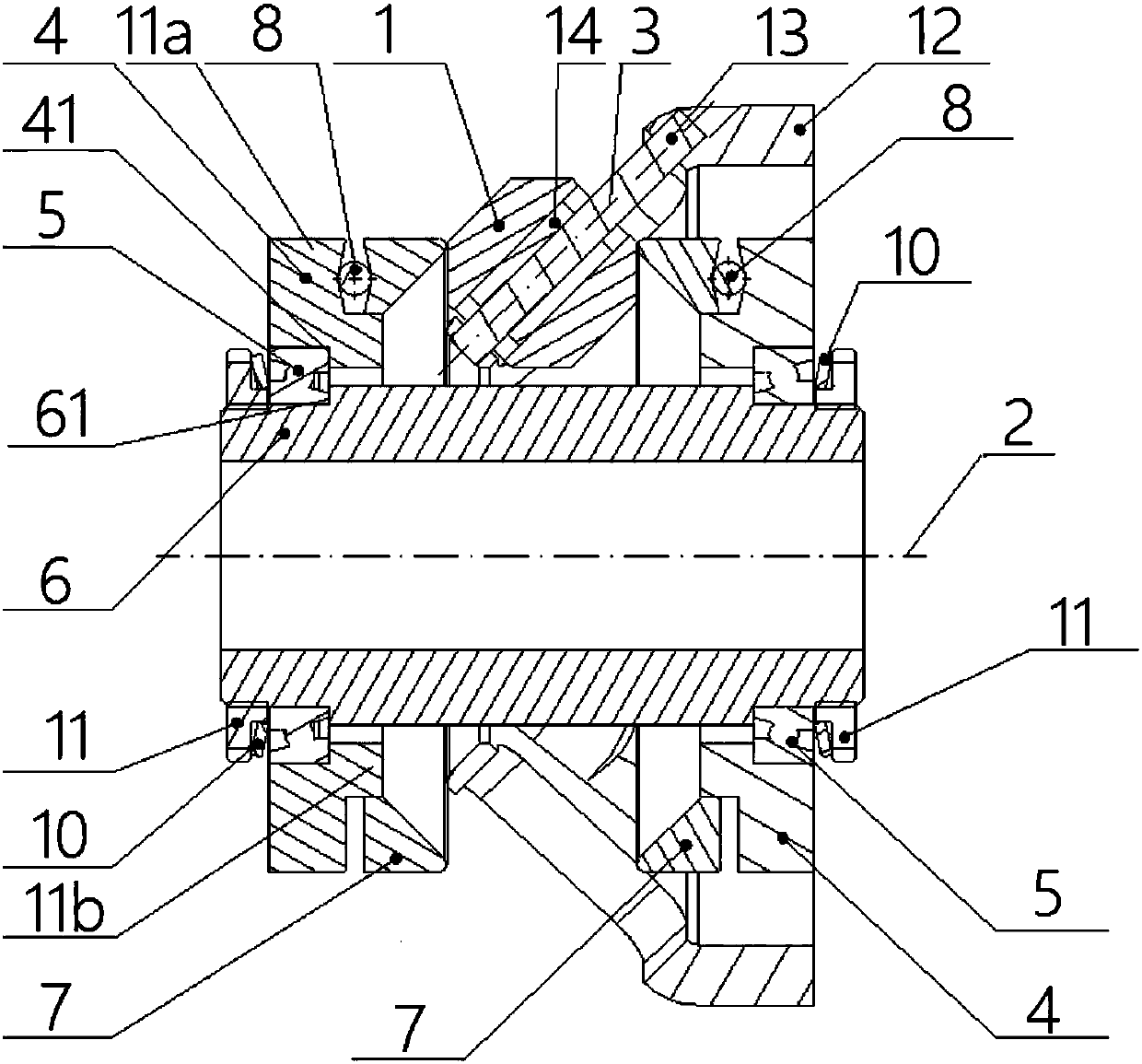

Method for utilizing virtual material to perform equivalence of dynamic characteristic of bolting joint part

ActiveCN107491624AHigh precisionVerify correctnessGeometric CADDesign optimisation/simulationContact pressureElement model

The invention discloses a method for utilizing a virtual material to perform equivalence of dynamic characteristic of a bolting joint part. The bolting joint part is regarded as a plurality of virtual material layers, a finite element method is utilized to simulate stress conditions of different of bolting joint part at the contact areas under different bolt pretightening forces, and the contact pressure distribution of the bolting joint part is equivalent to be a fourth-order polynomial function with respect to the contact radius; an equivalent virtual material model of the bolting joint part is established by utilizing material mechanics knowledge, to determine a function relationship between the contact radius in an effective contact area and virtual material properties (elastic modulus, shear modulus, Poisson's ratio, density and virtual layer thickness); by the finite element method, two-layer, three-layer or more-layer virtual materials coupled with each substructure to establish a finite element model of the whole structure, and dynamic response analysis is performed, an obtained frequency response function is compared with modal test data to verify the correctness of the model, and the novel idea and method are provided for studying the dynamic characteristics of the bolting joint part.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

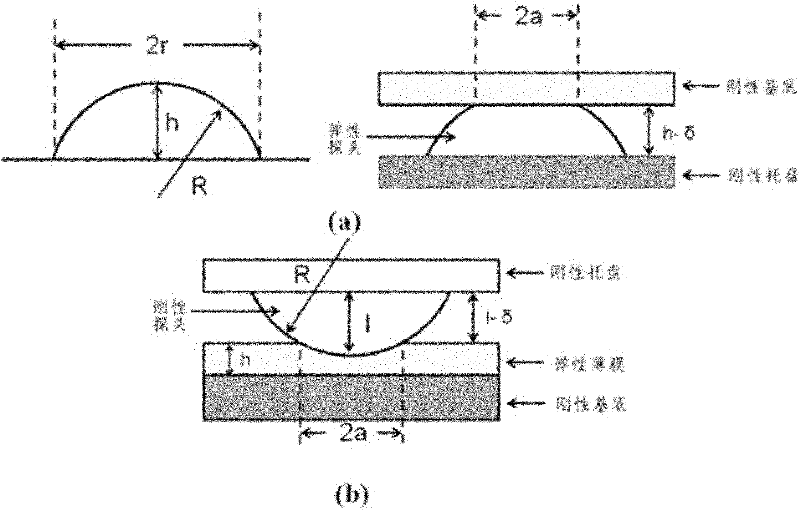

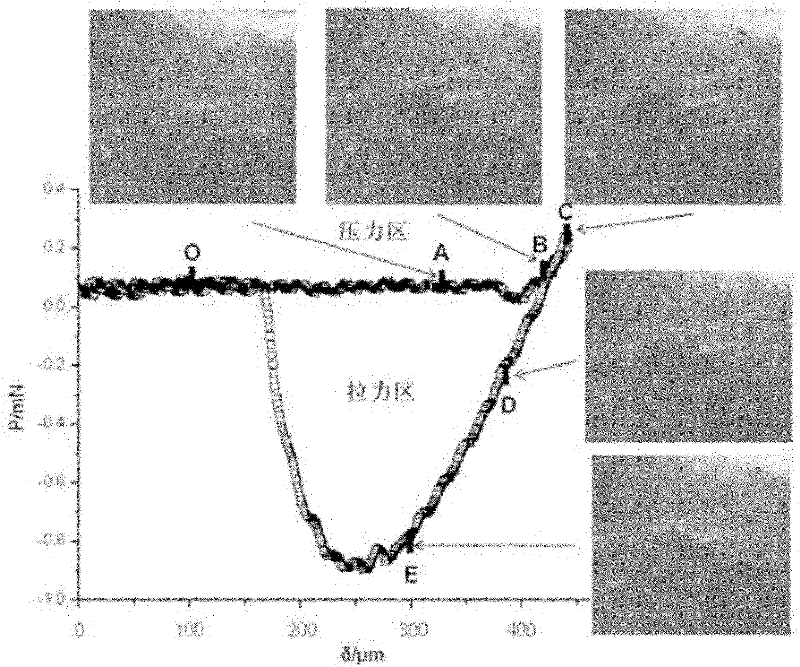

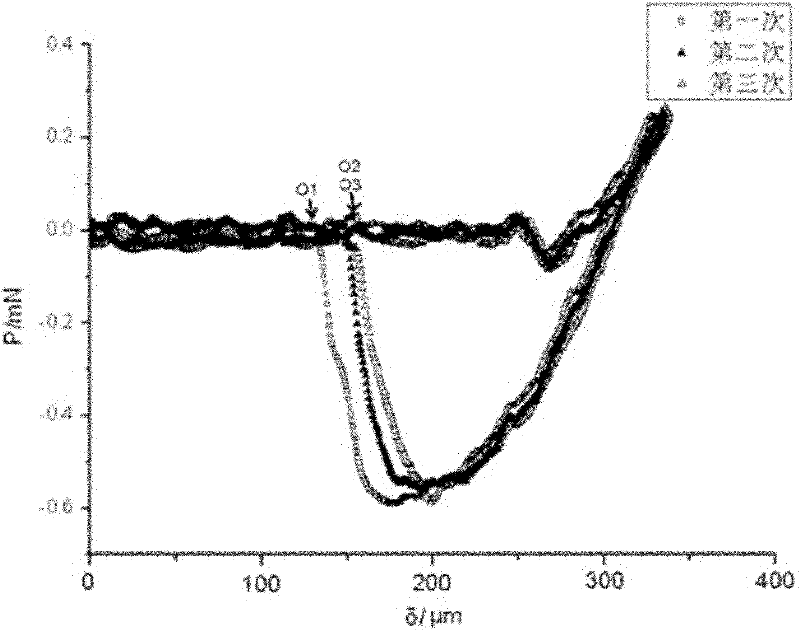

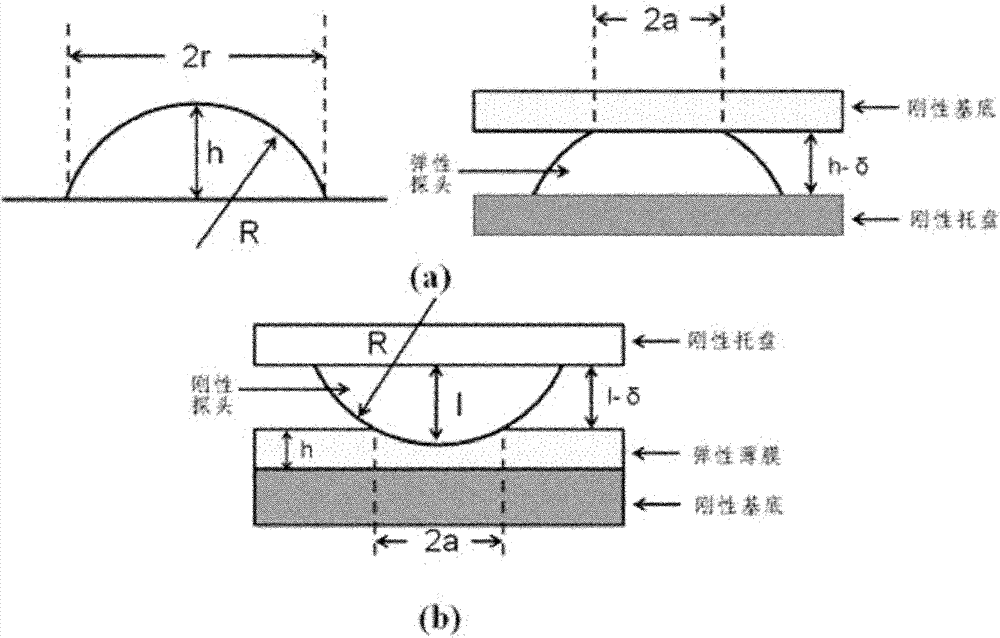

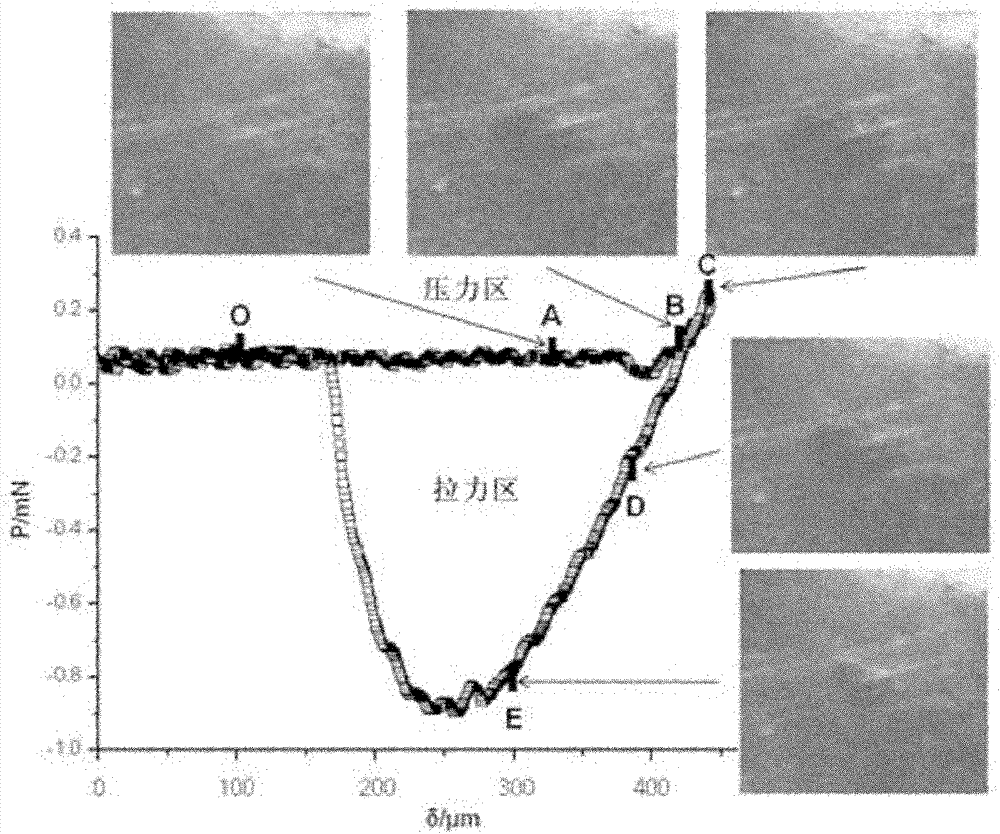

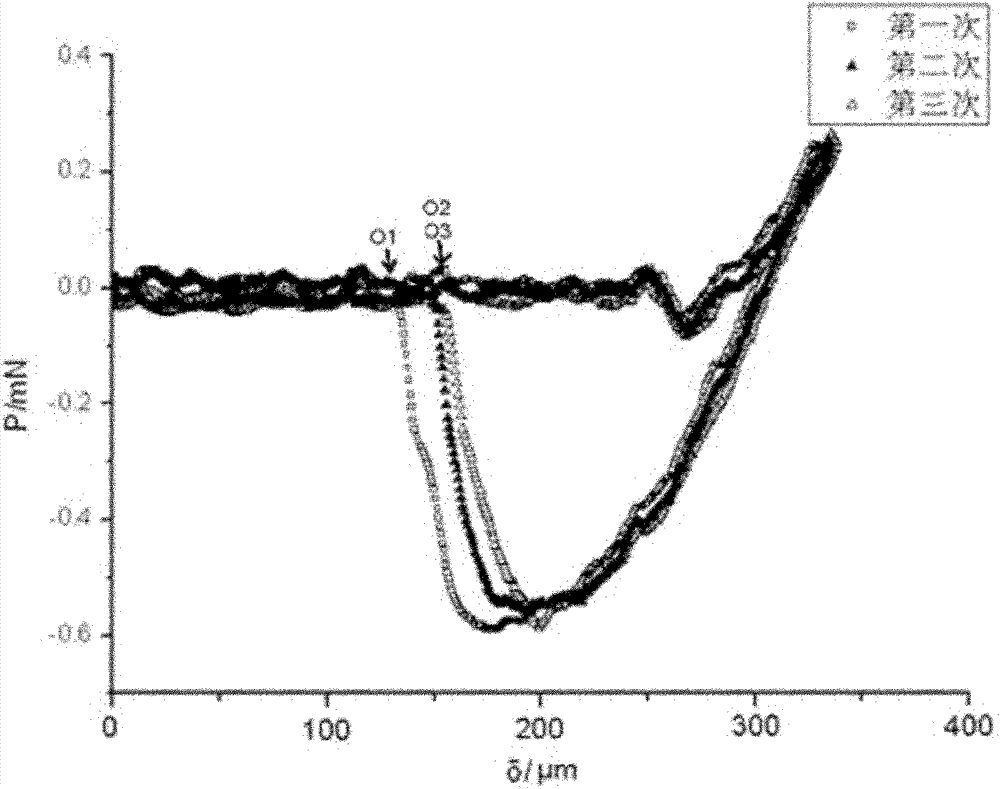

Method for measuring surface adhesive capacity and elastic modulus of soft material

InactiveCN102183441AReduce volumeWide range of test materialsSurface/boundary effectStrength propertiesElastomerSpherical probe

The invention discloses a method for measuring the surface adhesive capacity and an elastic modulus of a soft material, the method comprises the following specific steps of: (1) preparing a sample and selecting a probe according the physical property and the chemical property of a tested sample; (2) controlling a horizontal substrate and the spherical probe to move oppositely to be contacted and separated at a constant speed; (3) measuring an interaction force P, a relative displacement delta and a contact radius a respectively by using a pressure sensor, a displacement sensor and an optical microscope in the whole process of the step (2) when the substrate and the probe are contacted with each other; (4) frequently repeating the steps (2) and (3) under the control of software; and (5) quantitatively analyzing the adhesive capacity and the elastic performance of the tested material by using data obtained in the step (3) according to a jabatan kerja raya (JKR) theory. The measurement method has giant application potential in the aspects of scientific research on soft materials such as high-molecule elastic body, biogel and the like, product quality control in industrial manufacturing processes and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

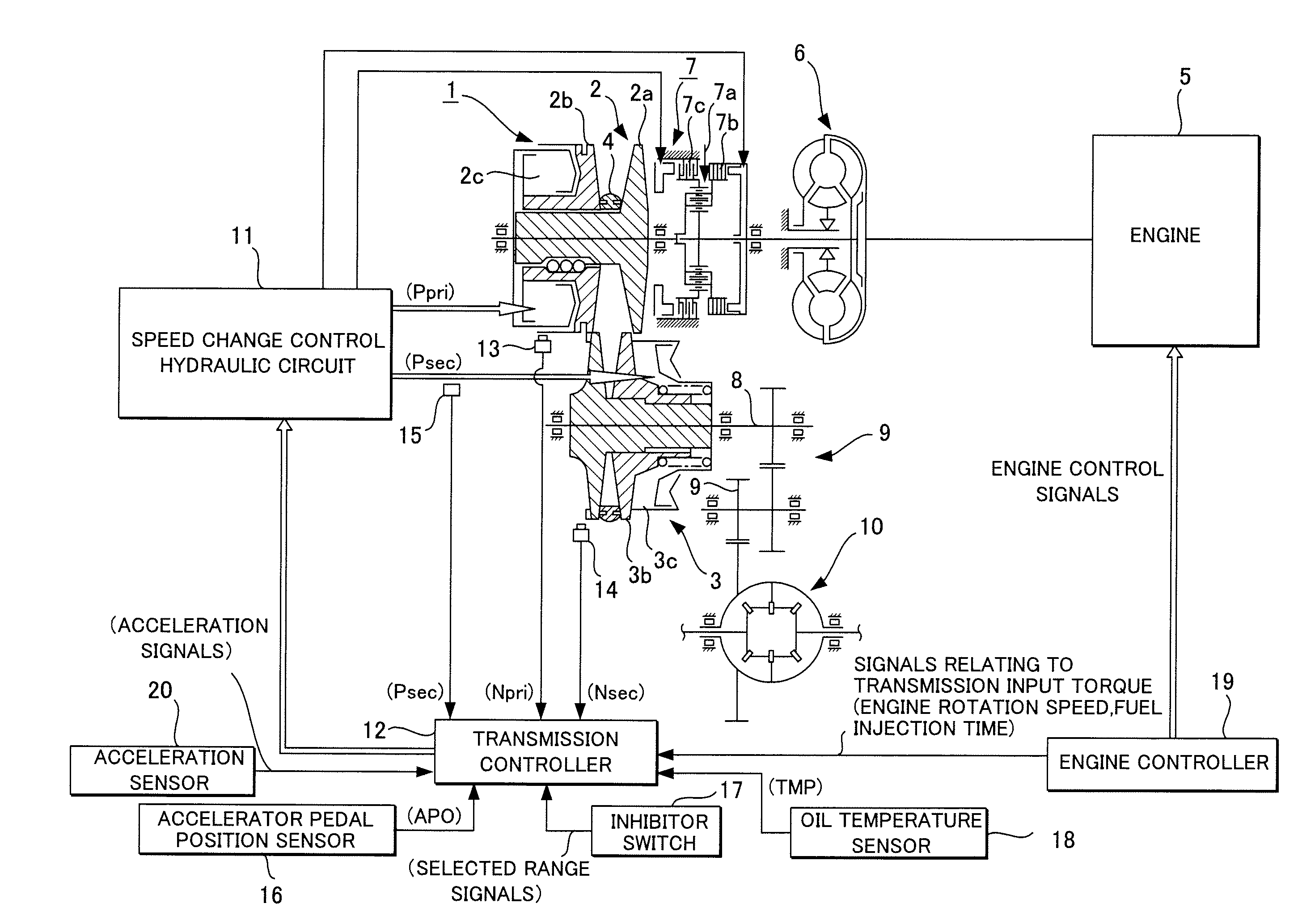

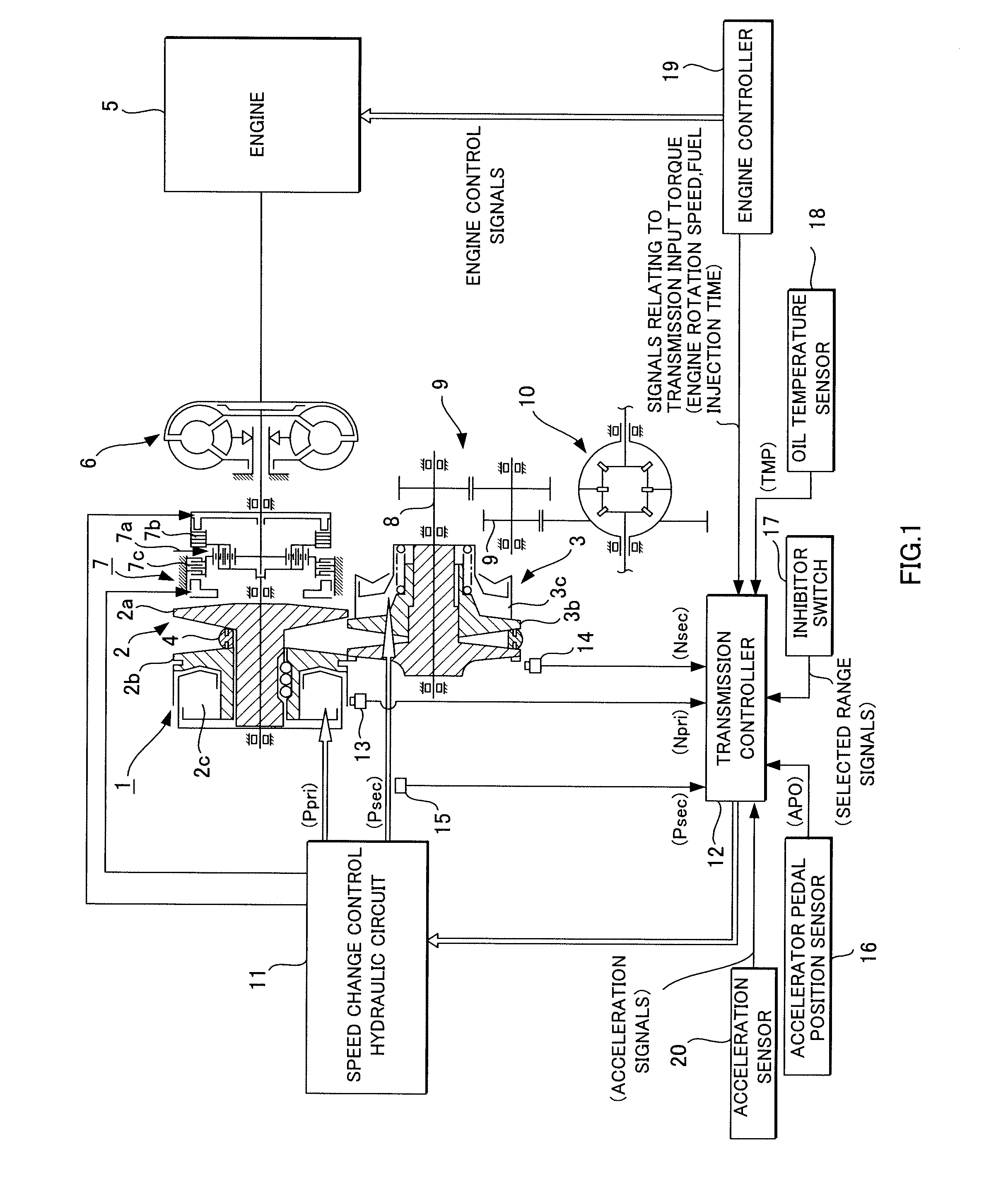

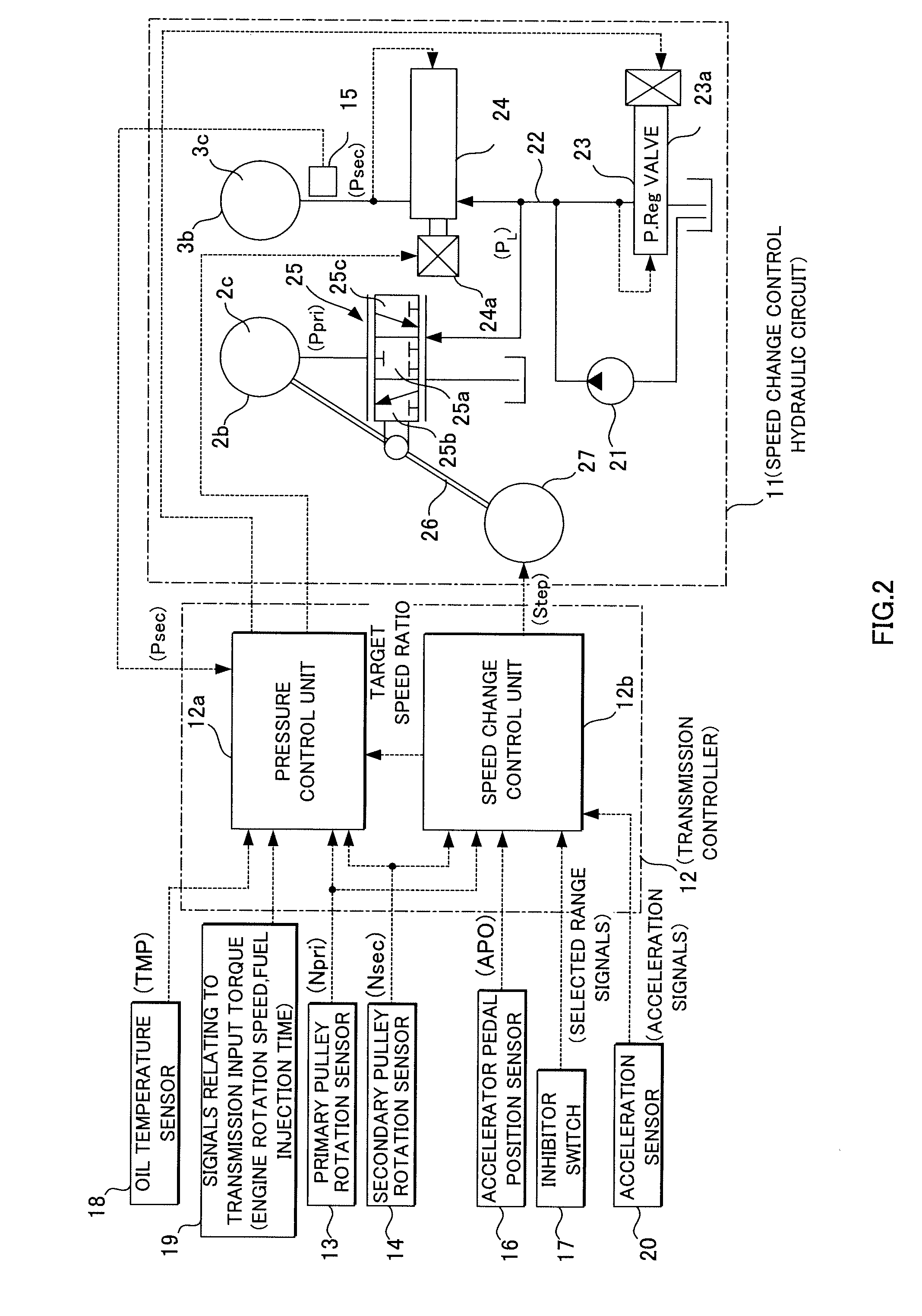

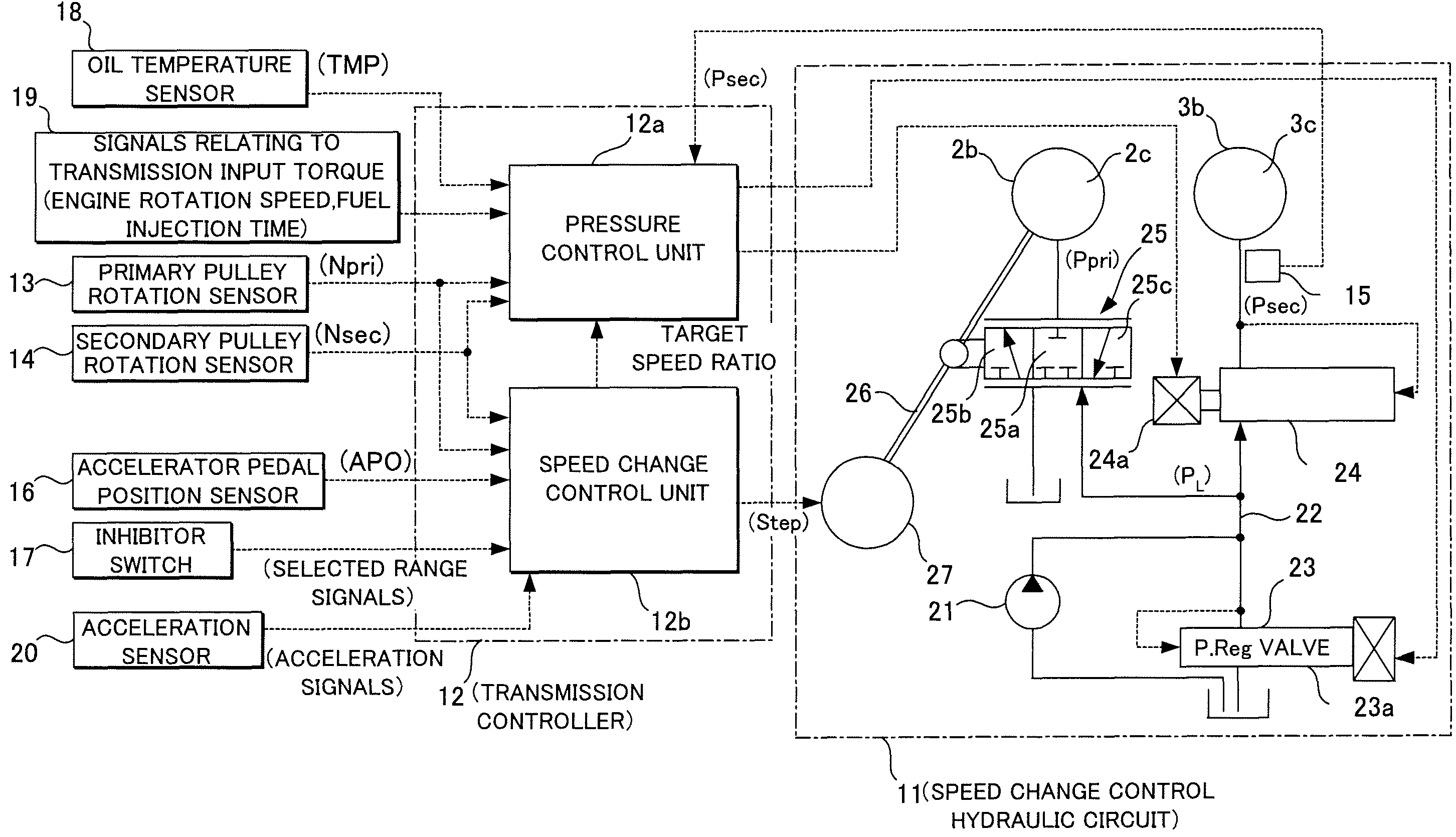

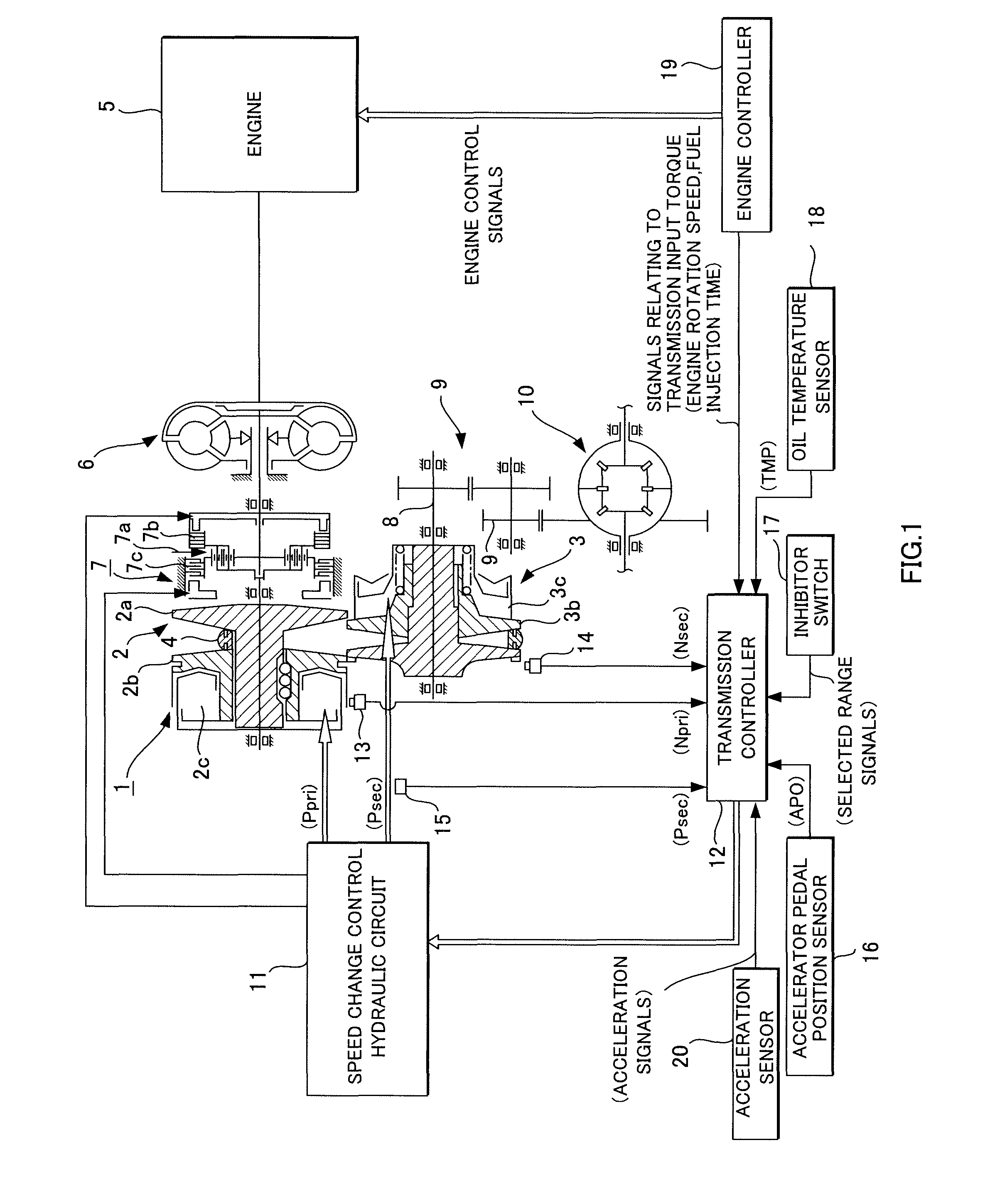

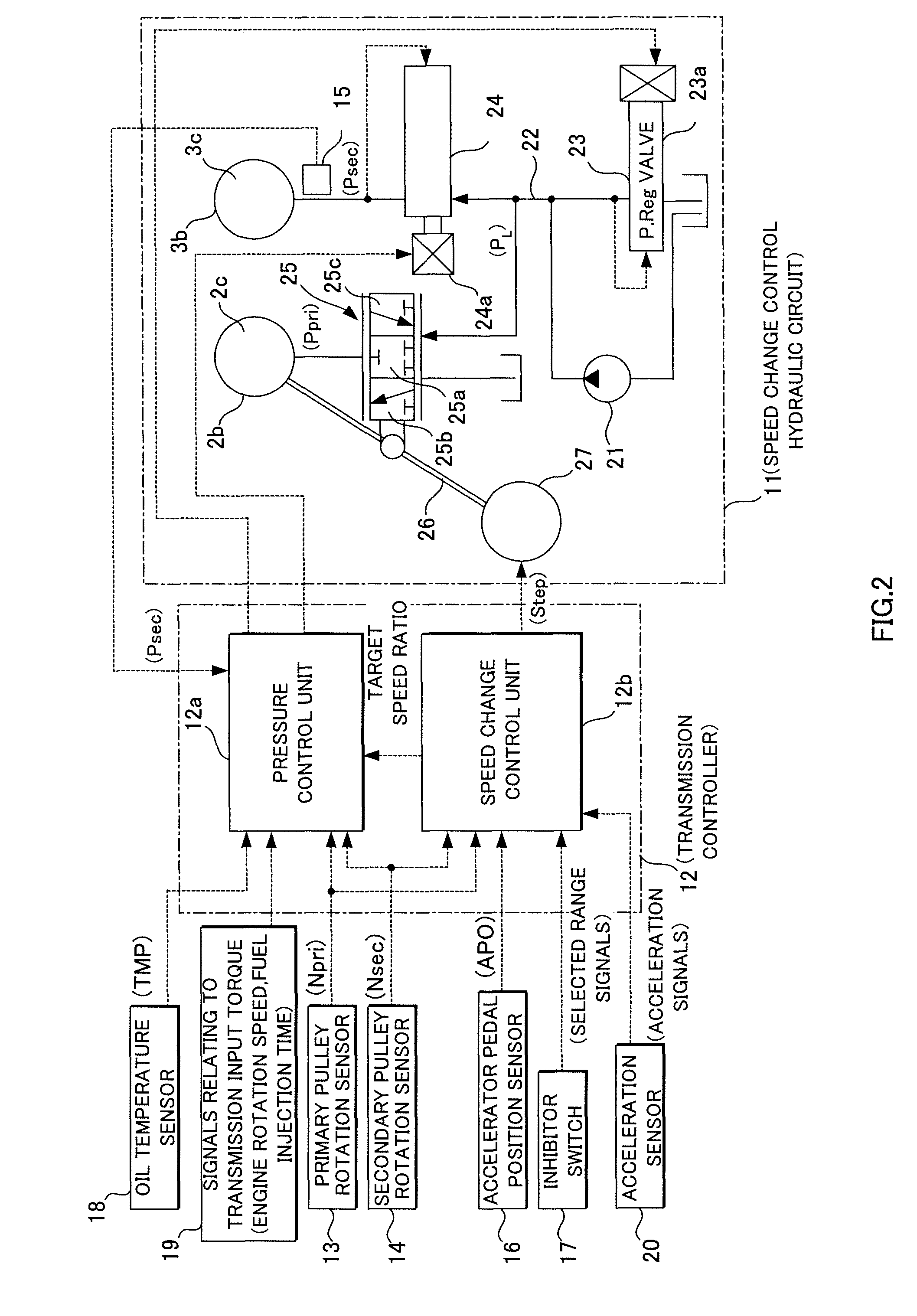

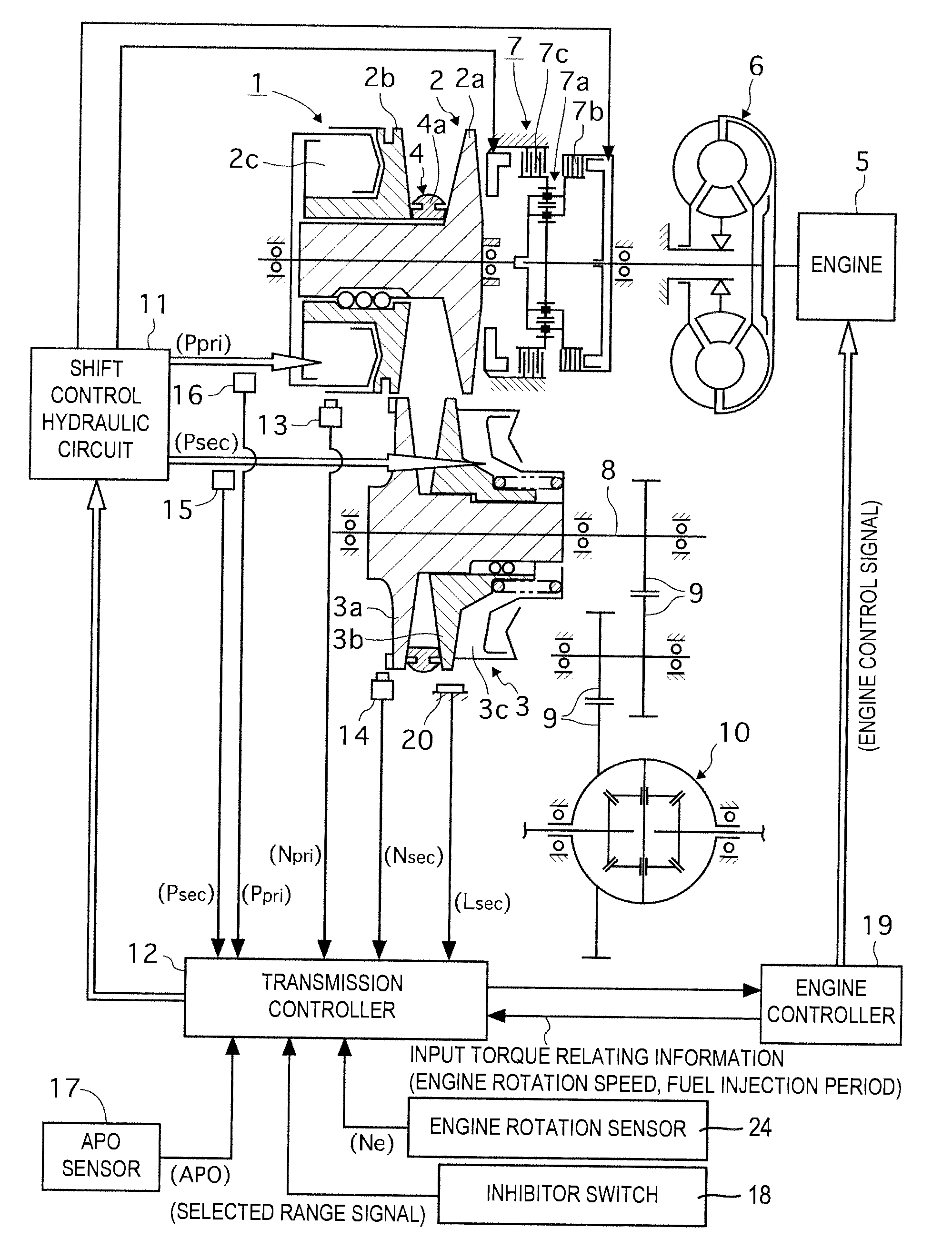

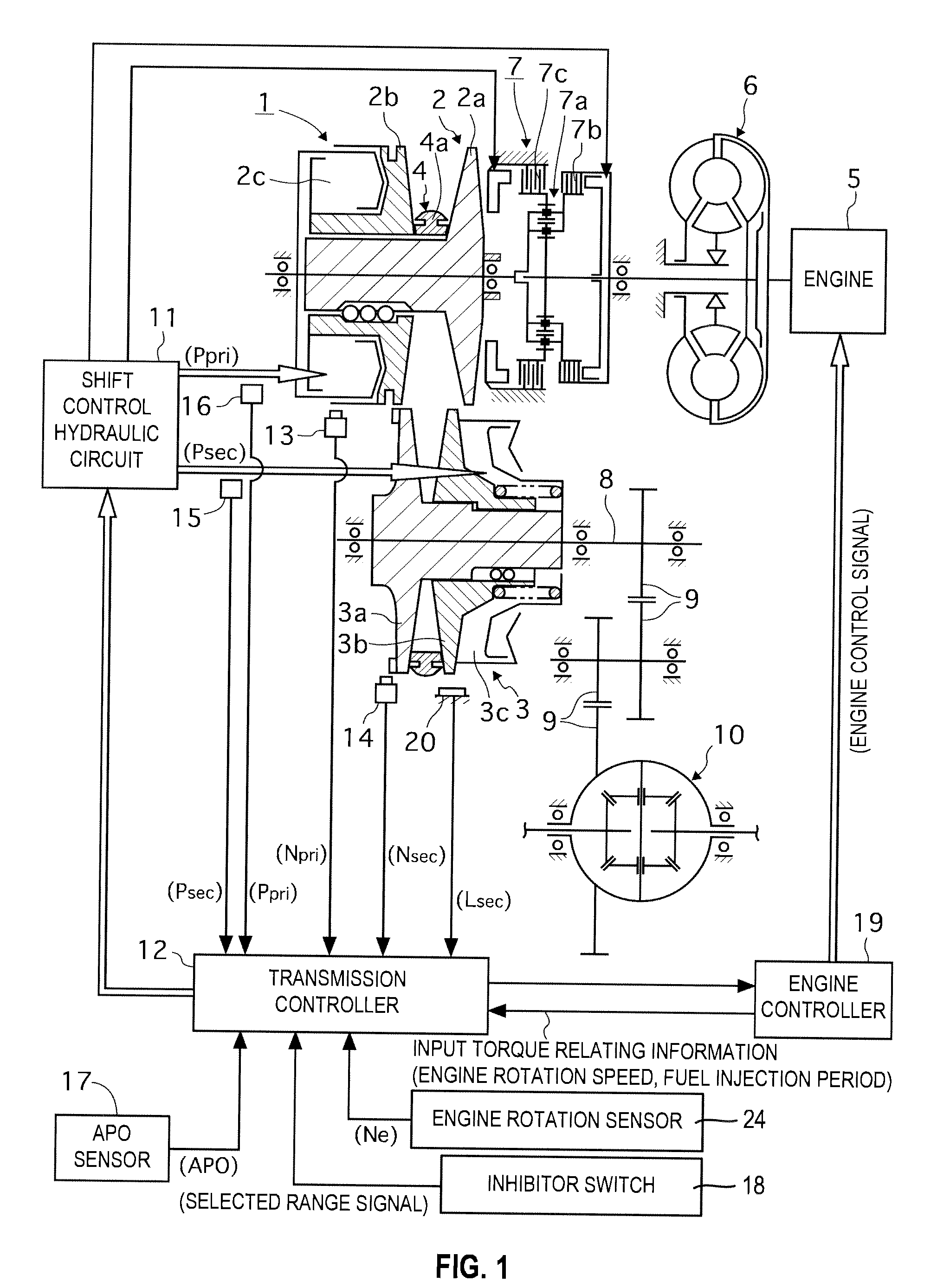

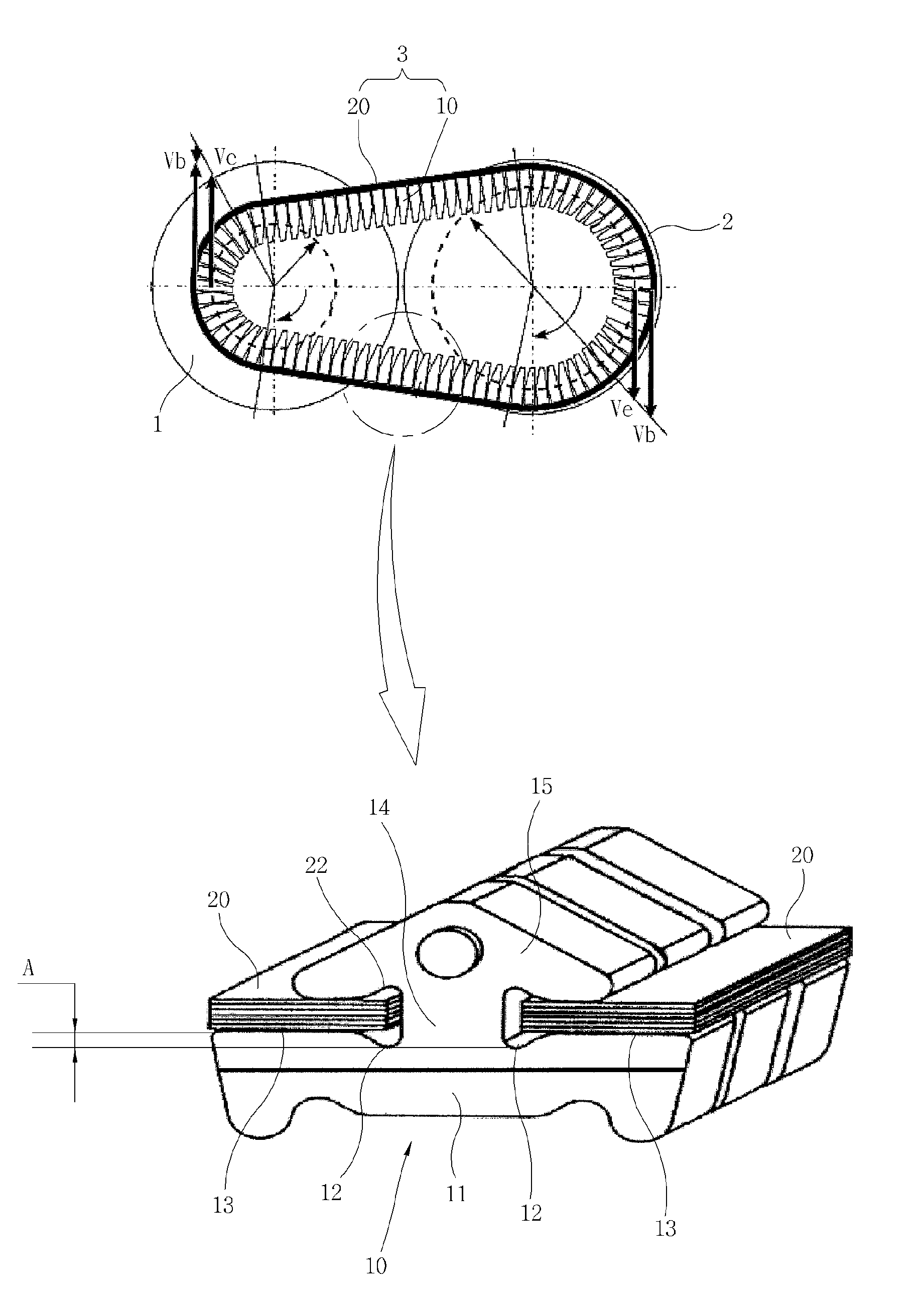

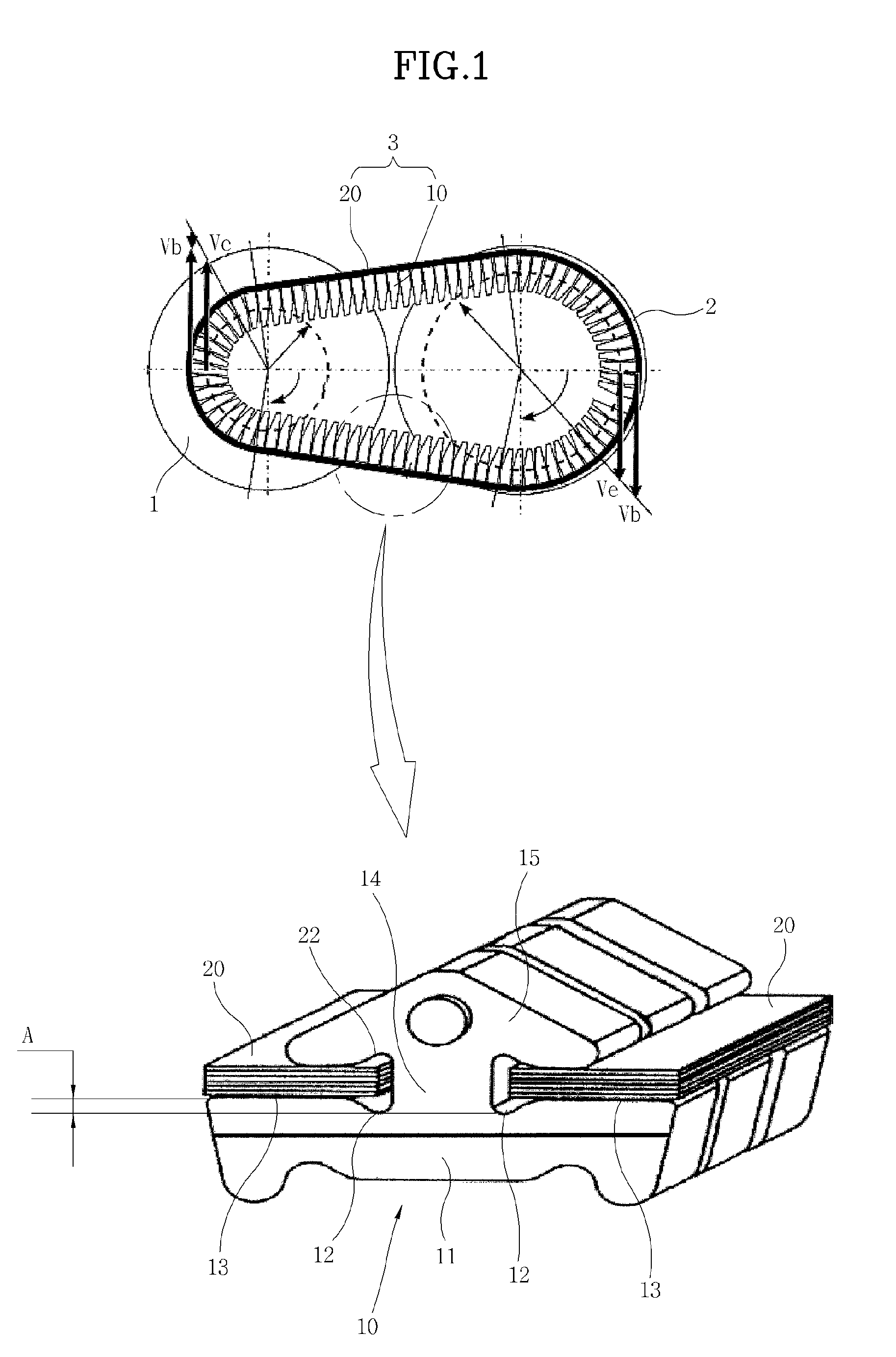

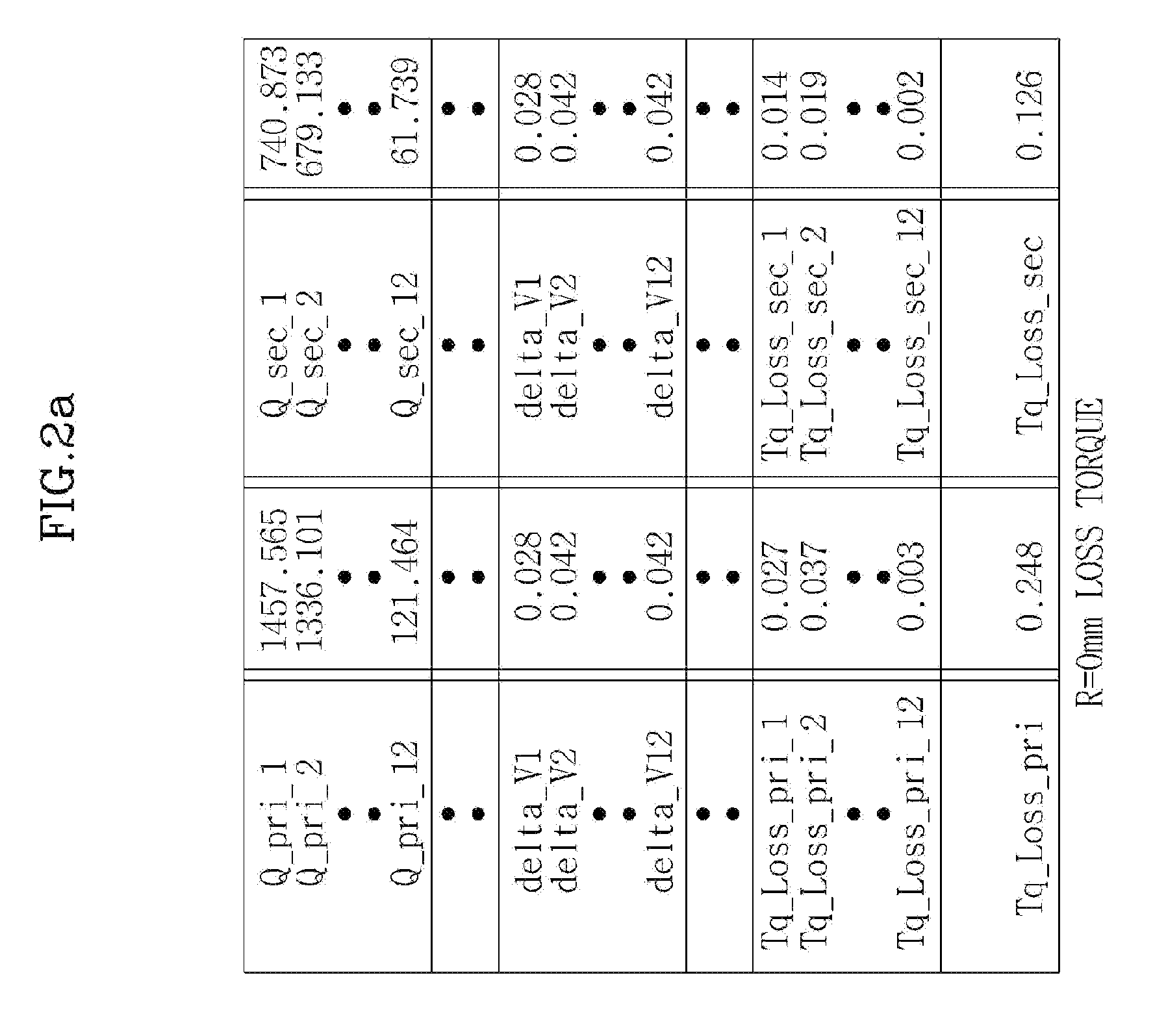

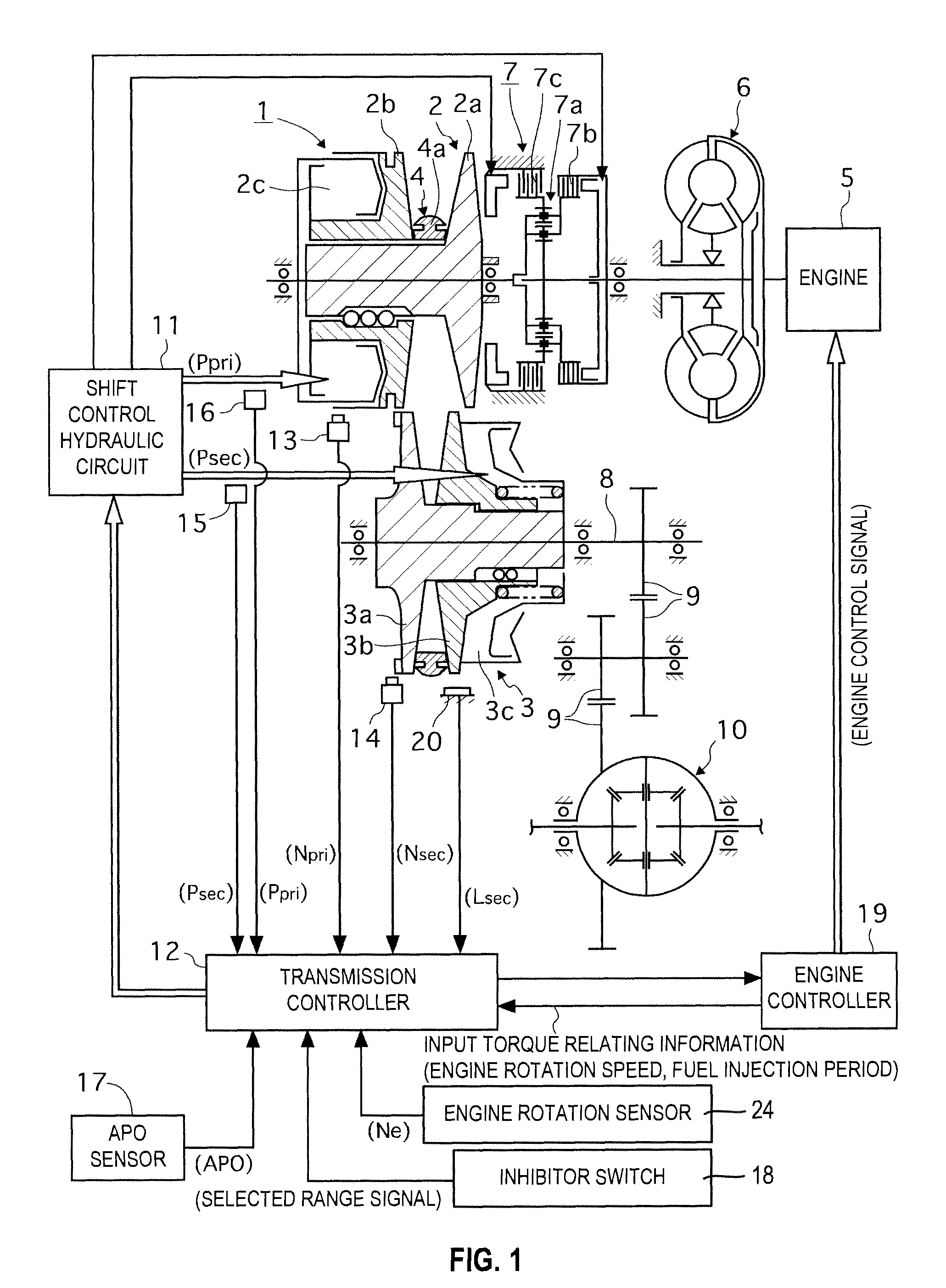

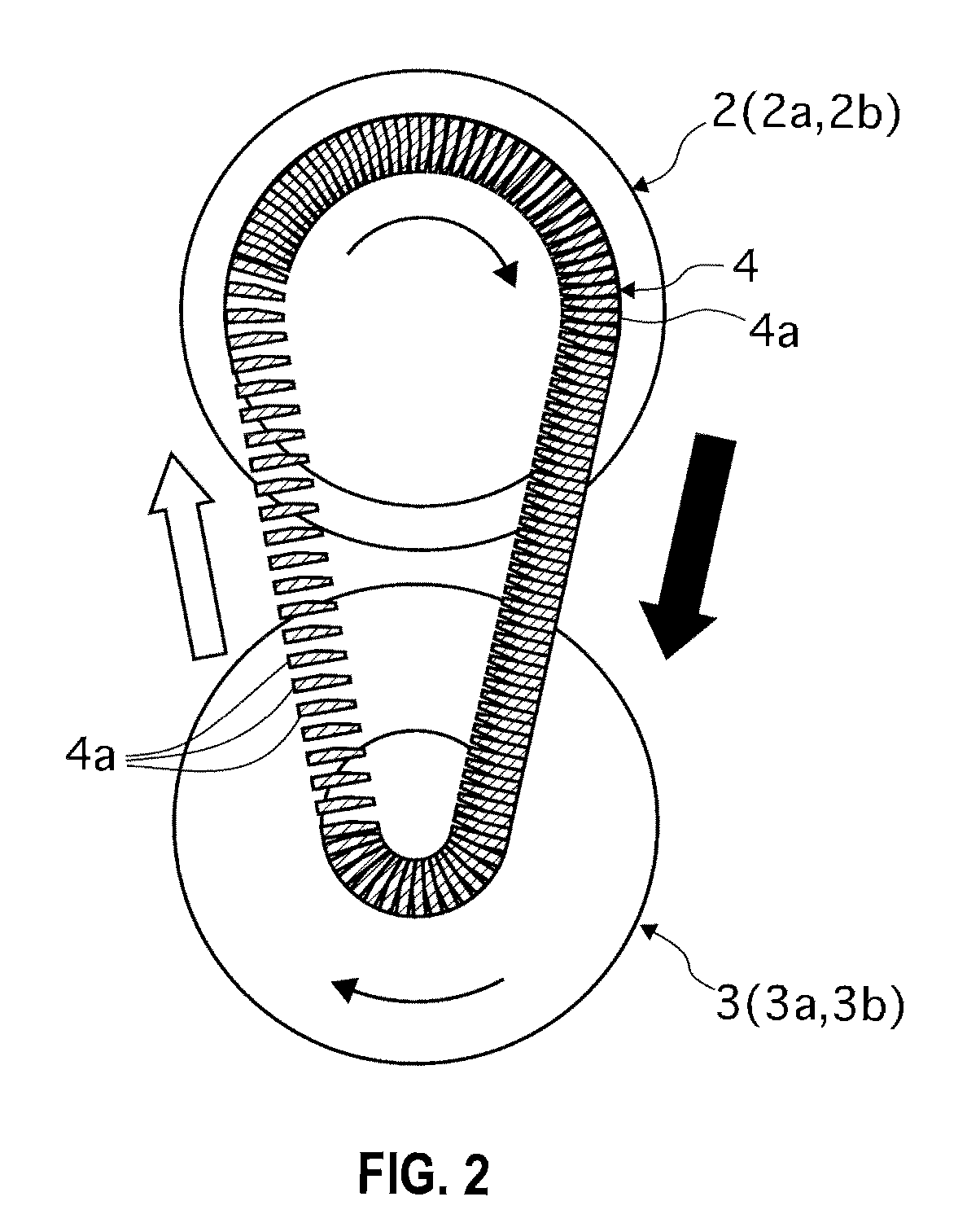

Control device and control method for continuously variable transmission

ActiveUS20080139350A1Ensure performanceAccurate estimateDigital data processing detailsPortable liftingLow speedControl theory

During Low return control, in which a speed ratio determined by a contact radius of a V-belt (4) with a non-rotating primary pulley (2) and a non-rotating secondary pulley (3) is shifted toward lowest speed ratio while the vehicle is stationary, an estimated speed ratio (ic) is calculated on the basis of a secondary pulley pressure (Psec). When a start request is issued to the vehicle while Low return control is underway, a primary pulley pressure (Ppri) and the secondary pulley pressure (Psec) are controlled on the basis of the estimated speed ratio (ic).

Owner:JATCO LTD +1

Control device and control method for continuously variable transmission

ActiveUS7789780B2Accurate estimatePrevent belt slippageDigital data processing detailsPortable liftingLow speedEngineering

During Low return control, in which a speed ratio determined by a contact radius of a V-belt (4) with a non-rotating primary pulley (2) and a non-rotating secondary pulley (3) is shifted toward lowest speed ratio while the vehicle is stationary, an estimated speed ratio (ic) is calculated on the basis of a secondary pulley pressure (Psec). When a start request is issued to the vehicle while Low return control is underway, a primary pulley pressure (Ppri) and the secondary pulley pressure (Psec) are controlled on the basis of the estimated speed ratio (ic).

Owner:JATCO LTD +1

Method for measuring mobility of graphene microcell with semiconductor as substrate

ActiveCN107037284AAccurate evaluationElectrical testingConductive atomic force microscopyWork function

The invention provides a method for measuring the mobility of a graphene microcell with a semiconductor as a substrate. The method comprises steps of coating the surface of the semiconductor substrate with graphene to form a graphene microcell and disposing a conductive probe in contact with the graphene microcell; connecting the conductive probe with a scanning Kelvin probe force microscope to measure the actual work function of the graphene microcell to obtain a barrier height [Phi]Bn0 between the graphene microcell and the semiconductor substrate; connecting the conductive probe with a conductive atomic force microscope to collect a current-voltage curve of the graphene microcell; analyzing and fitting the current-voltage curve according to the barrier height [Phi]Bn0 between the graphene microcell and the semiconductor substrate and a hot electron emission model to obtain the effective contact radius of the conductive probe and the graphene microcell; and calculating the value of the graphene microcell mobility [mu] based on the effective contact radius of the conductive probe and the graphene microcell and the actual contact radius. The method can measure the mobility of the graphene microcell with any semiconductor as the substrate.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

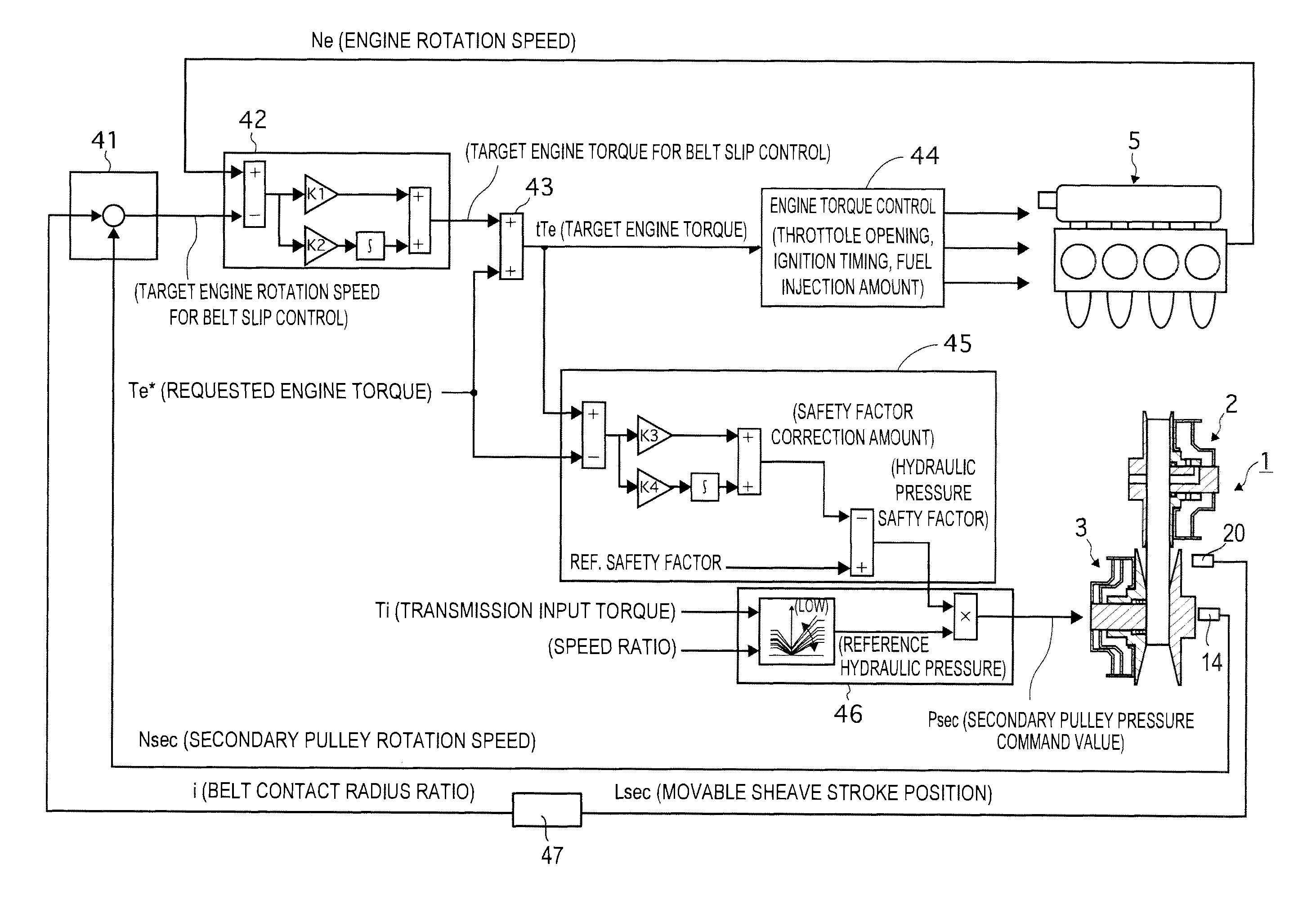

Control apparatus of driving force in case of belt slipping for vehicle equipped with v-belt continuously variable transmission and control method thereof

InactiveUS20100318270A1Reduce deteriorationReduce transmissionDigital data processing detailsGearing controlEngineeringControl theory

A control apparatus of a driving force in case of belt slipping includes a belt slip control detecting unit adapted to detect that the belt slip control is in execution, a belt contact radius ratio calculating unit adapted to calculate a belt contact radius ratio of the V-belt to the pulleys, and a power source output torque determining unit adapted to determine a target power output torque according to the belt contact radius ratio in execution of the belt slip control in response to signals from the belt slip control detecting unit and the belt contact radius ratio calculating unit.

Owner:NISSAN MOTOR CO LTD +1

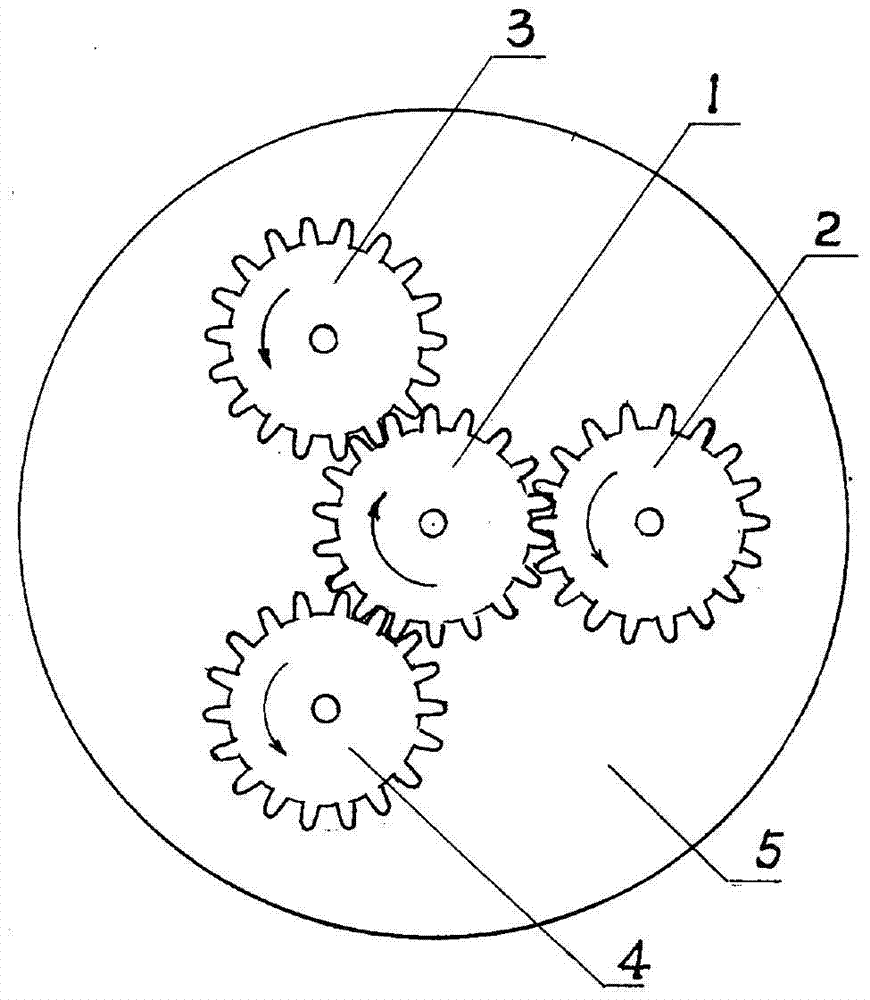

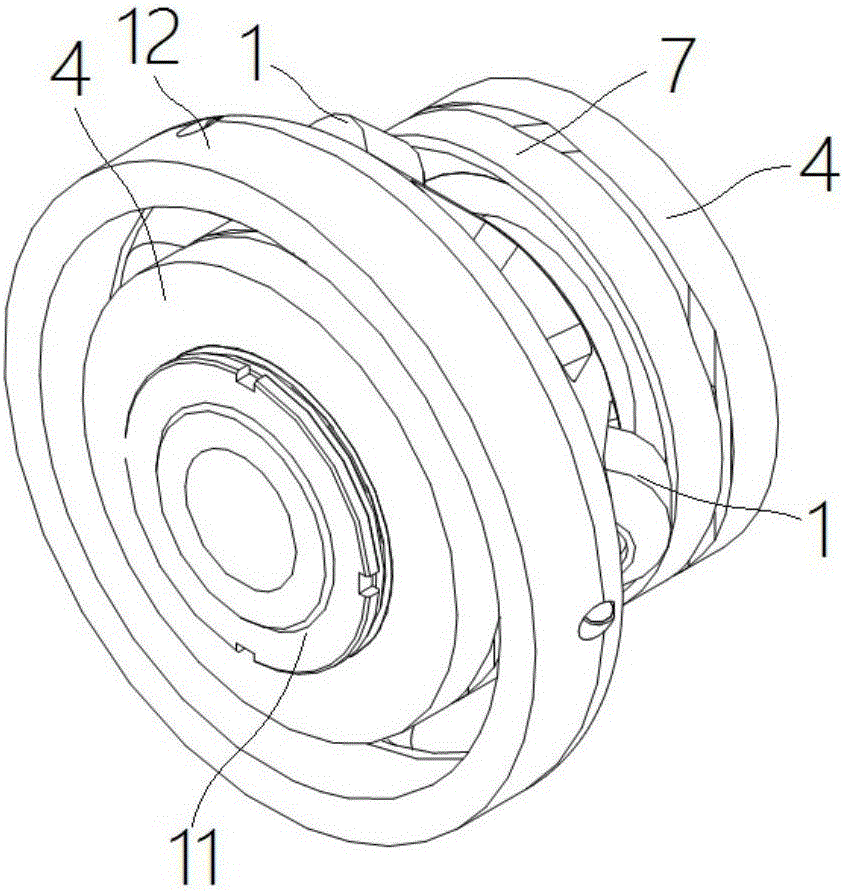

Automobile stepless speed change device

InactiveCN103791055ASimple structureSimple and fast operationGearingGearing controlCircular discMotor drive

The invention provides an automobile stepless speed change device. A friction drive mechanism of the automobile stepless speed change device is composed of a driving gear, three driven gears, three branch friction discs, a main friction disc and a compression spring. The driving gear is coaxially connected with a main shaft of an engine. The driven gears are meshed with the driving gear. The branch friction discs are arranged on a driven gear shaft and drive the main friction disc and the compression spring through idler wheels. A rotating shaft of the main friction disc is connected with a rear axle of an automobile. A speed regulation mechanism is composed of an idler wheel defining disc and an idler wheel synchronous stirring disc which are located between the branch friction discs and the main friction disc. A speed regulation motor drives the idler wheel synchronous stirring disc to rotate through a speed regulation gear. The idler wheel synchronous stirring disc drives the three idler wheels to synchronously move in the radial direction through spiral sliding grooves, idler wheel pull rods and idler wheel sliding blocks, and therefore the contact radius between the idler wheels and the branch friction discs and between the idler wheels and the main friction disc are continuously changed, and stepless speed change is achieved. The automobile stepless speed change device is simple in structure, low in cost, balanced in stress, high in power delivery efficiency, large in gear ratio range, small in occupied space and capable of being integrated with a clutch.

Owner:SHENYANG JIANZHU UNIVERSITY

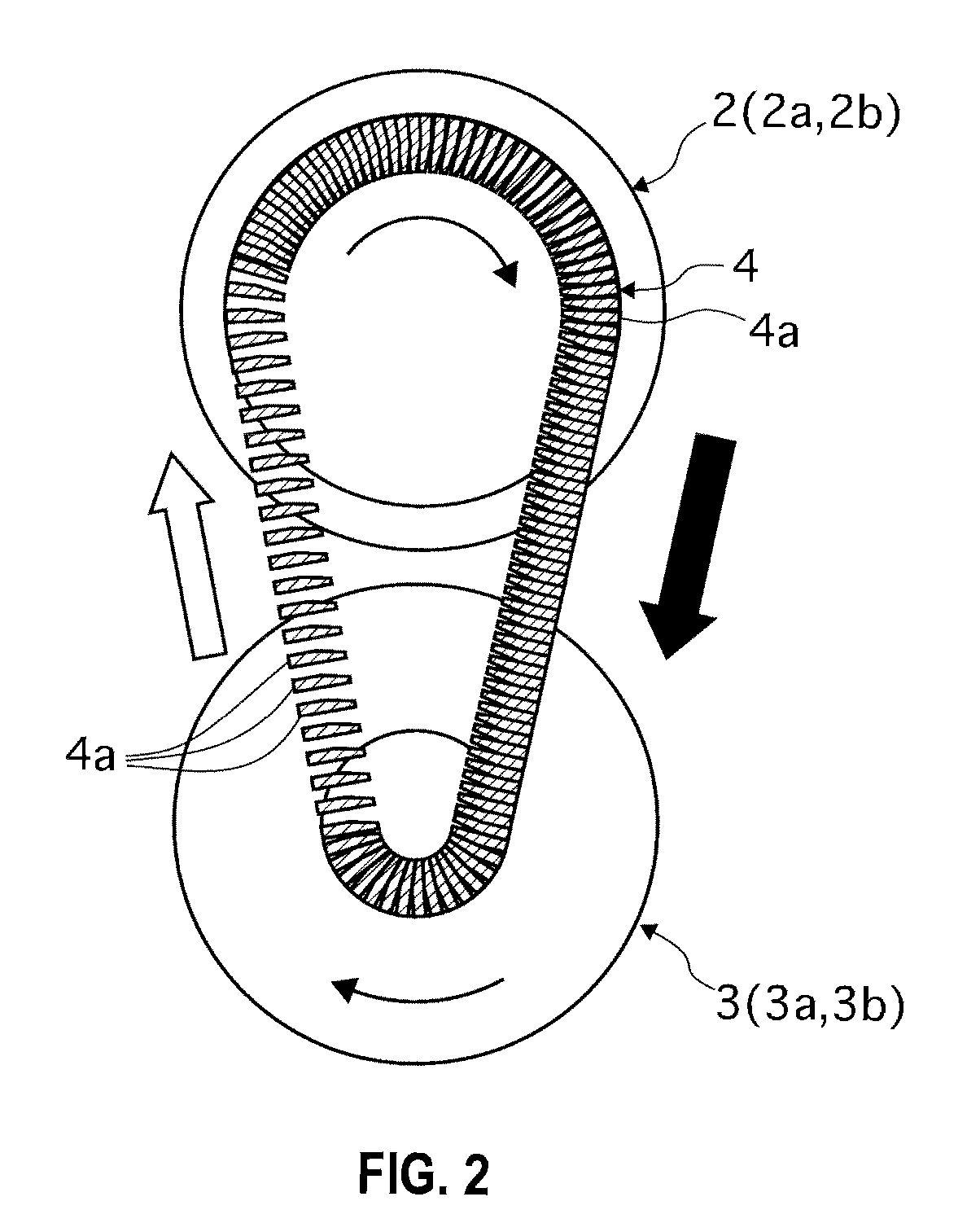

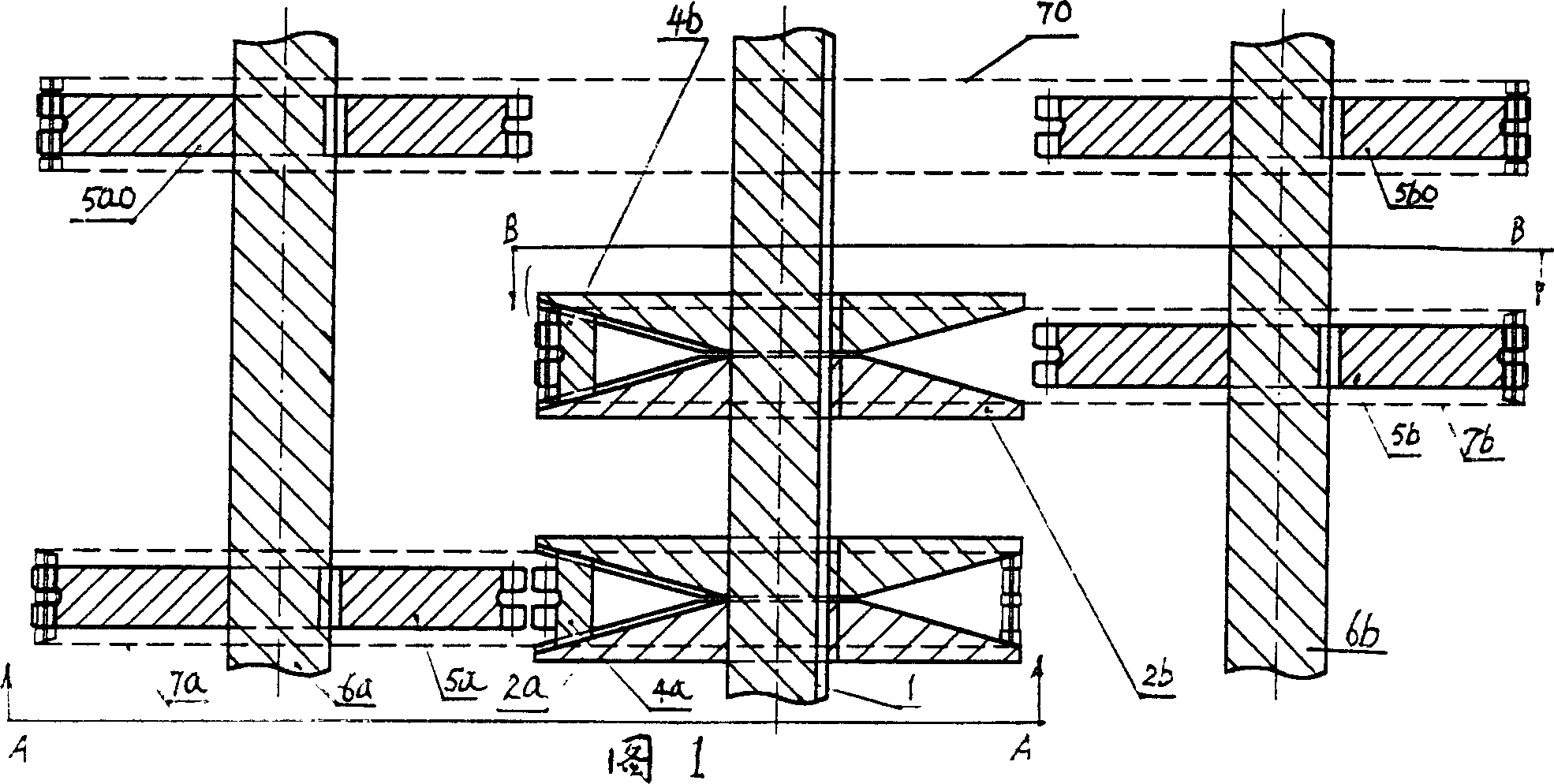

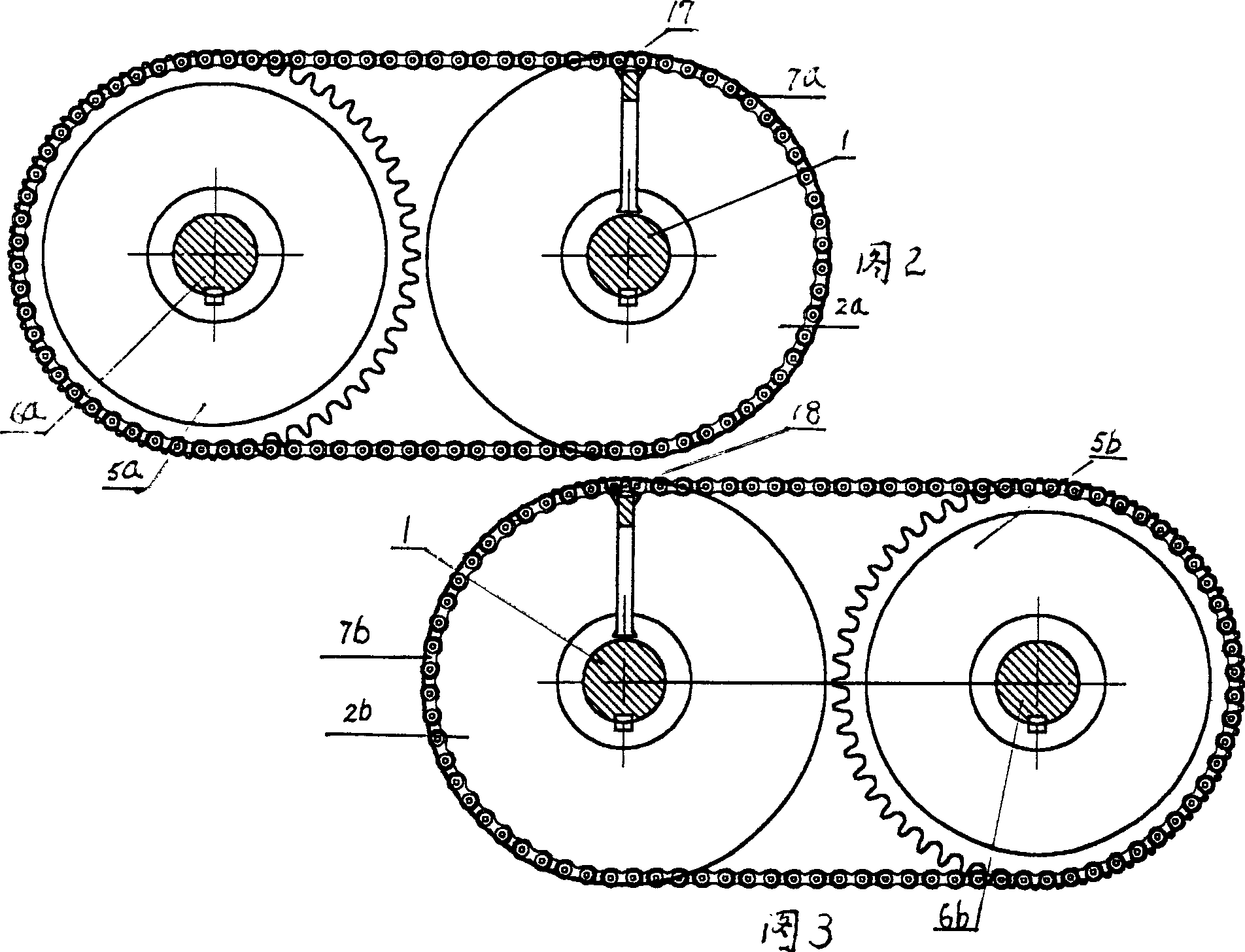

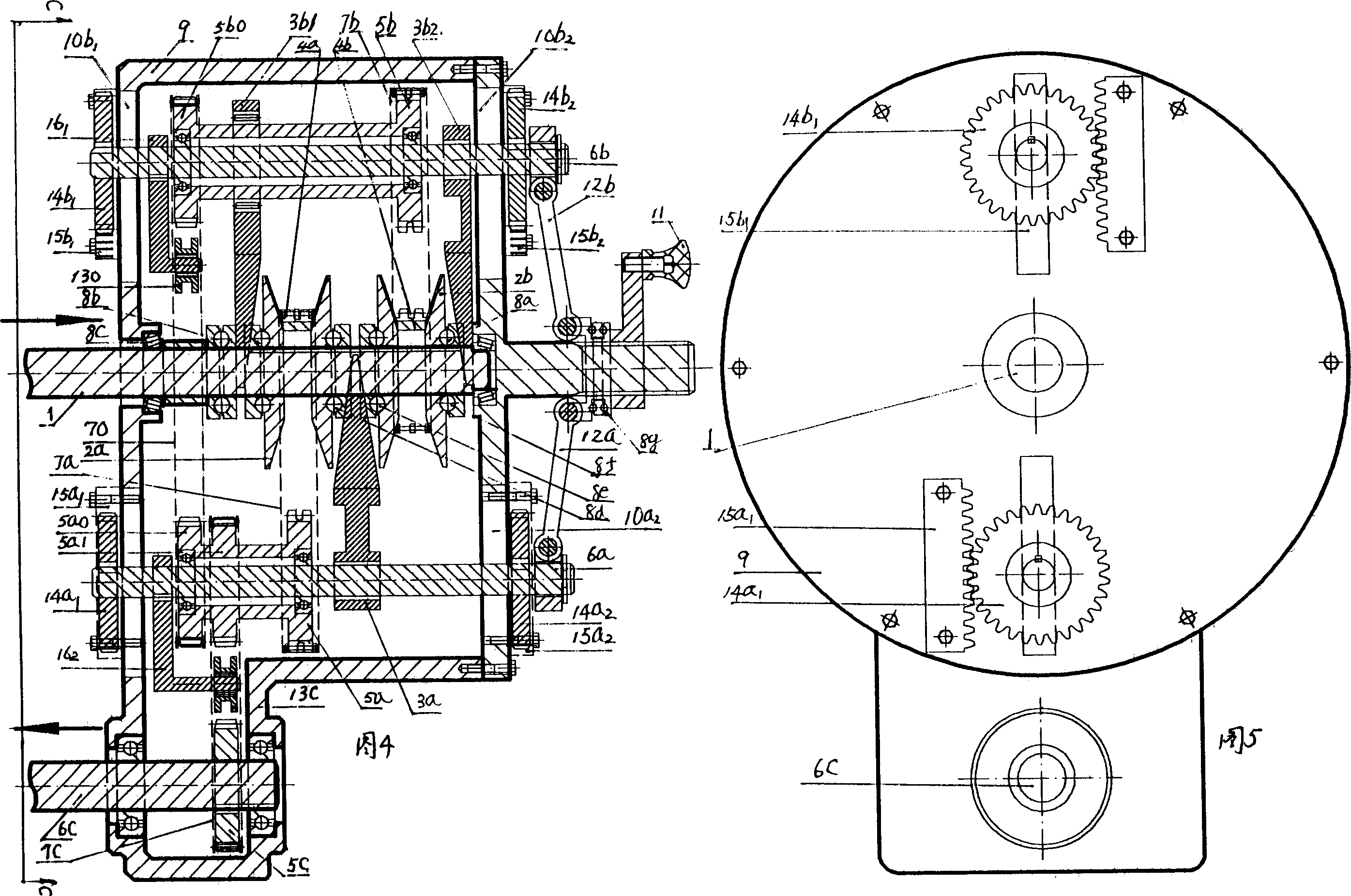

Transmission radius variable cone disc-sprocket wheel transmission piece and engagement driving stepless speed transmission

Cone disc chain wheel tumbler and engagement drive stepless gear with variable driving radius characterized by that, the speed transmission is realized by changing the contacting radius of the chain on the chain wheel with variable driving radius, and using their combined action to realize the stepless speed change together with the fixed chain wheel. The invention also discloses a variable intermeshing stepless speed change gear using the parallel axes central distance, and also an engagement drive stepless gear of the planet-sprocket structure.

Owner:沈勇

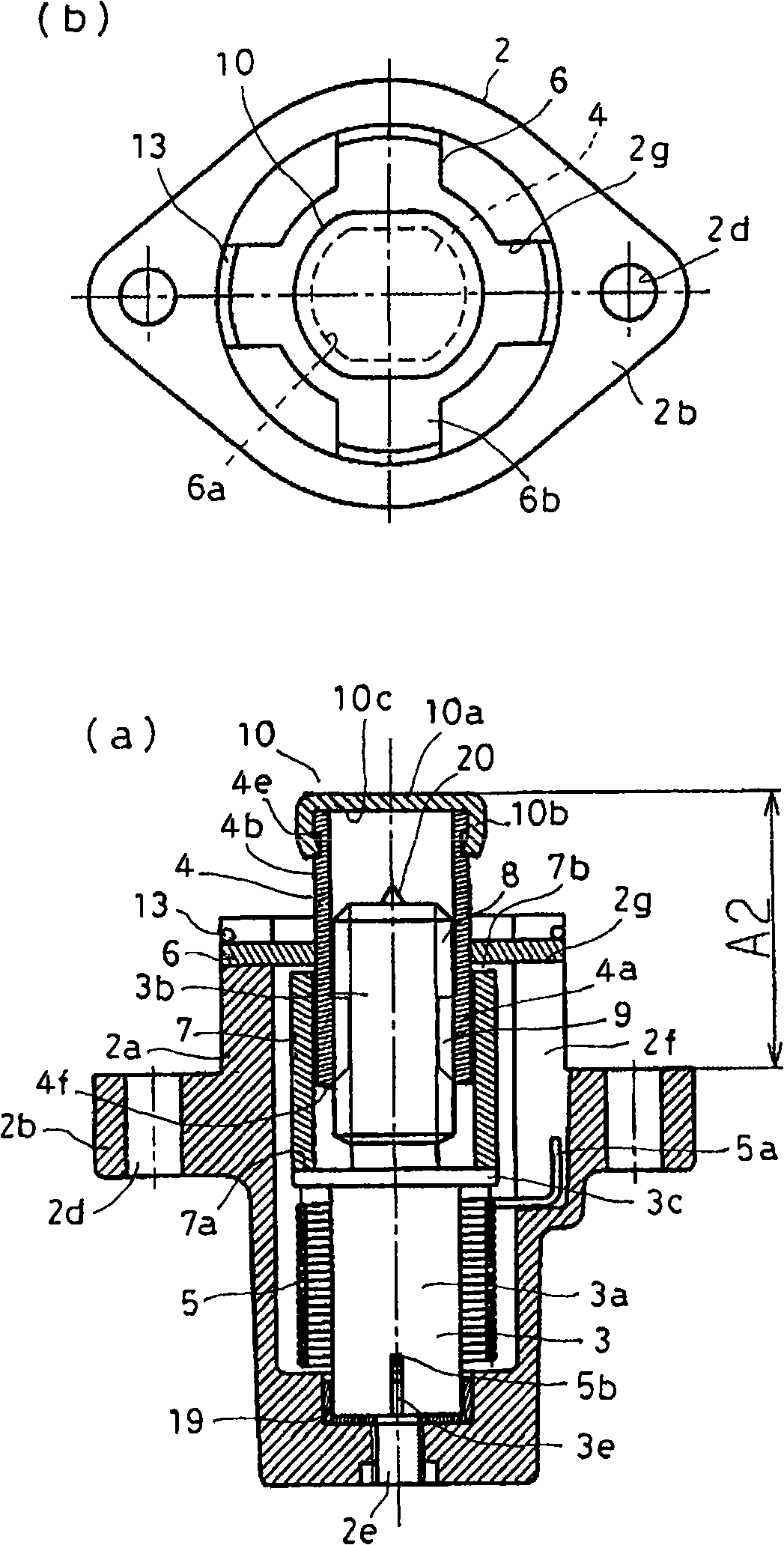

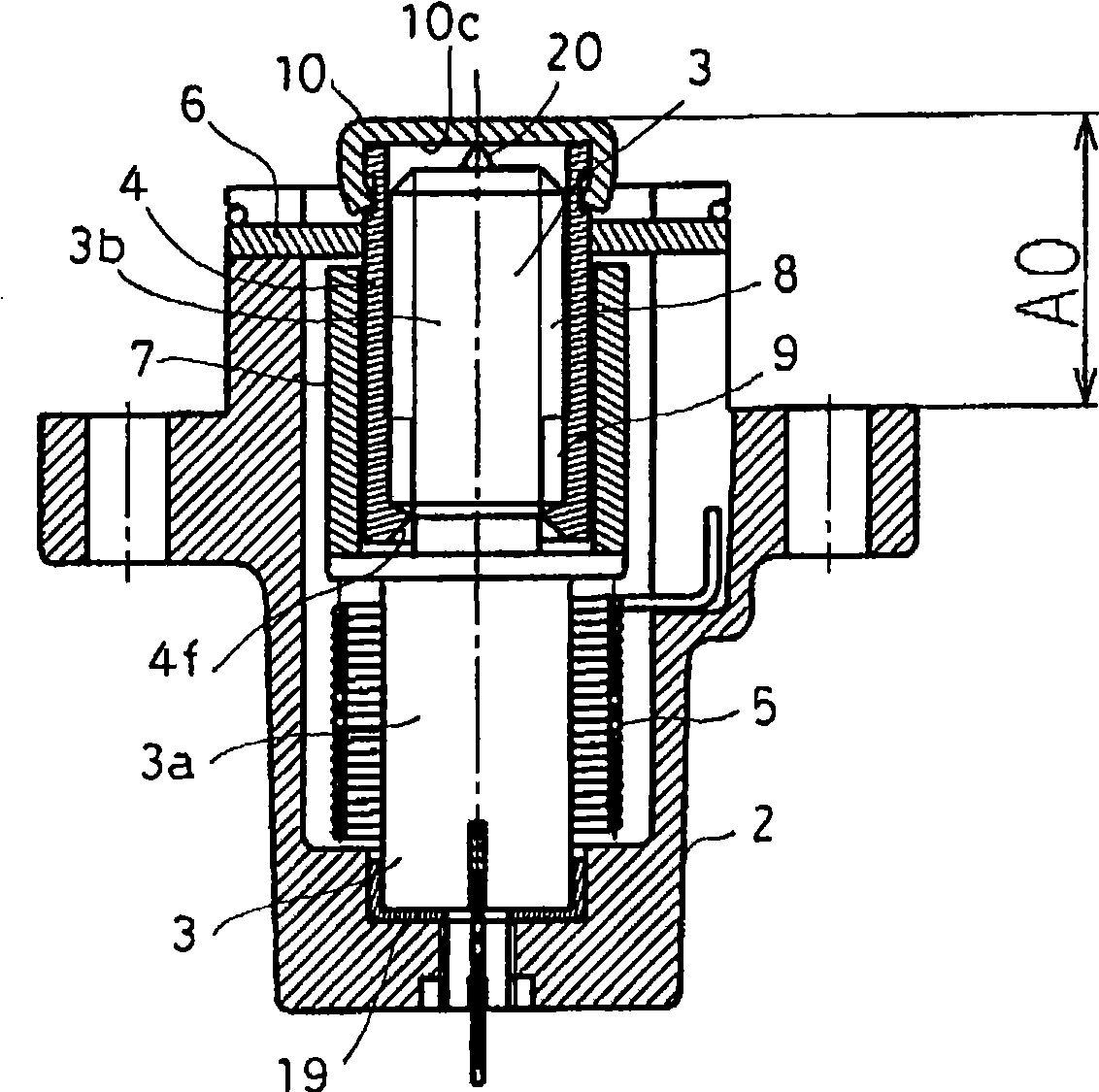

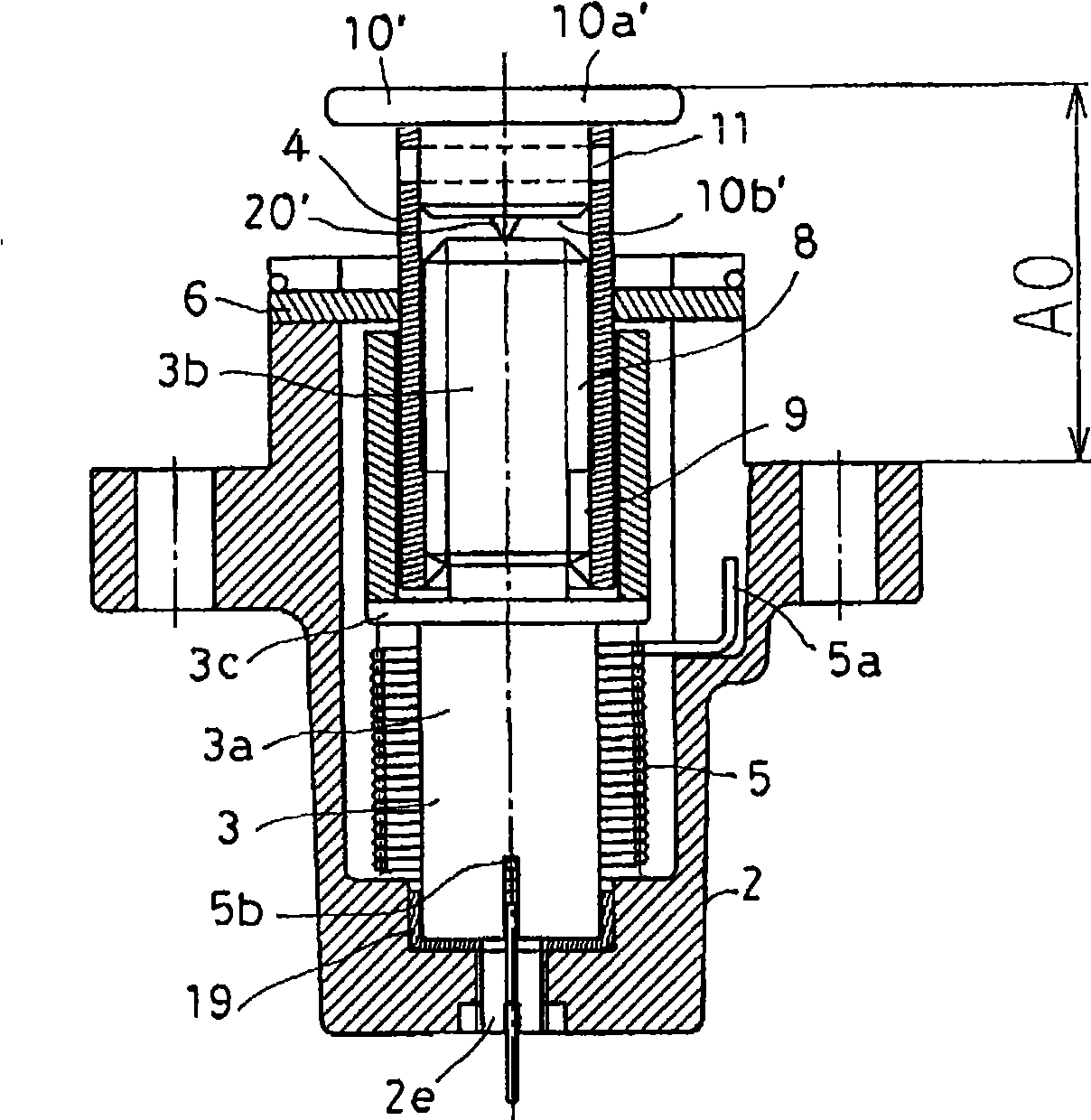

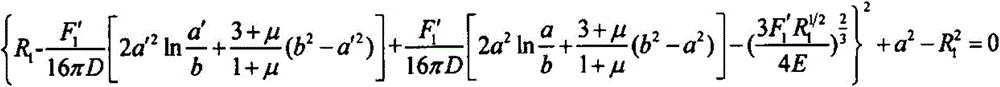

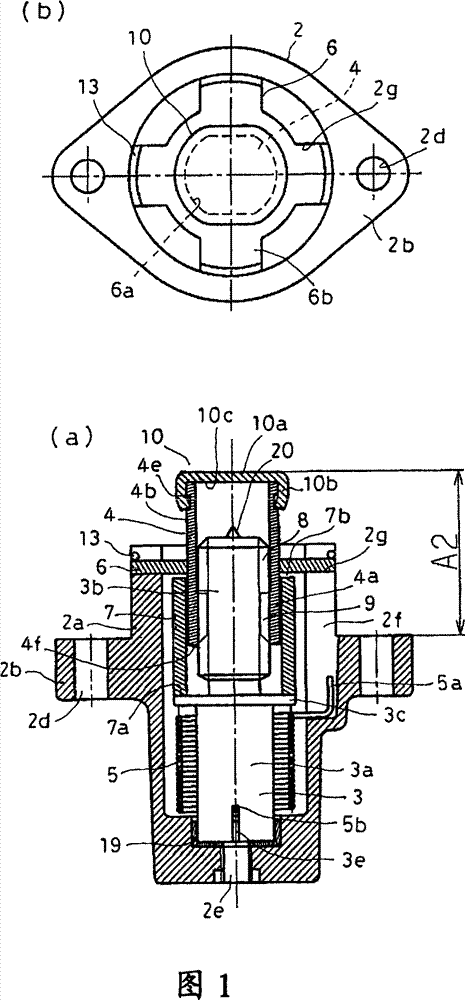

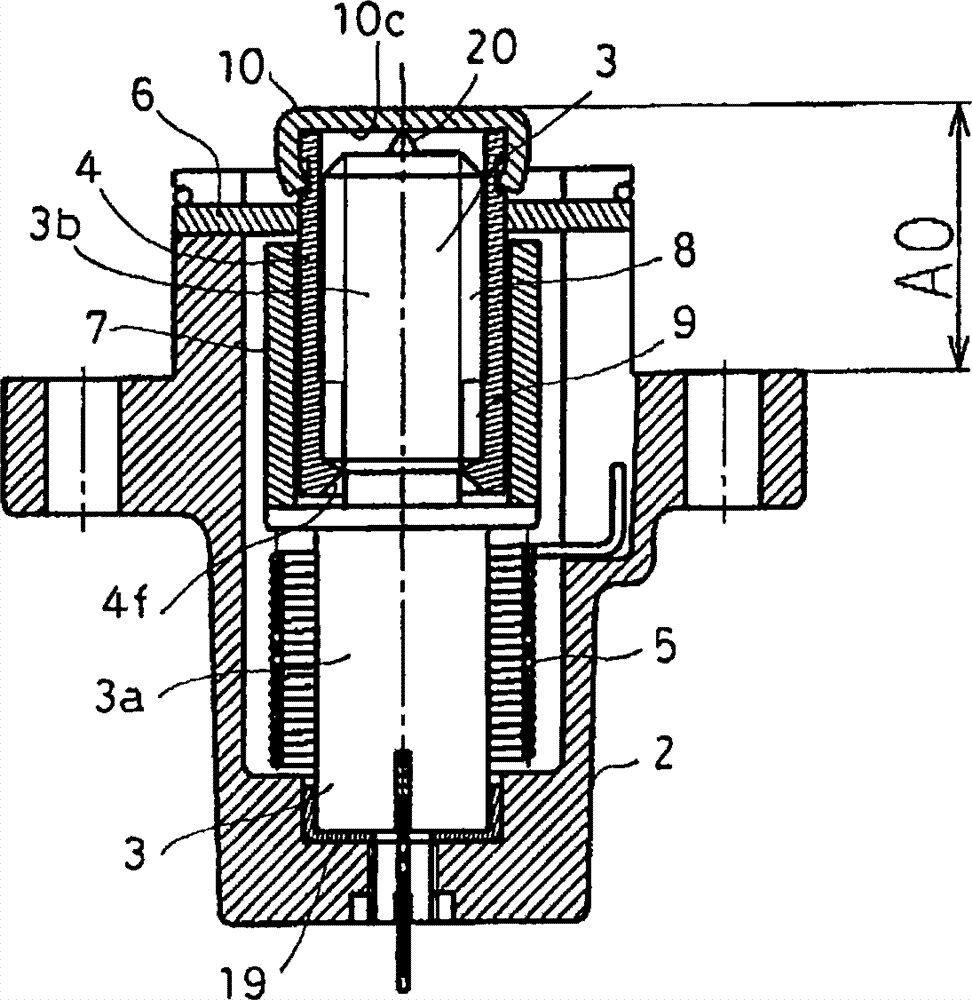

Tensioner

A tensioner in which sticking between a rotation member and a drive member when the tensioner is in a fully retracted state is prevented by using a simple mechanism, thereby ensuring reduced man-hour for control in assembling the tensioner and enabling the tensioner to function when it is abnormally operated. A pair of shaft members (3, 4) is threaded to each other by thread sections (8, 9), and one (3) of the shaft members (3, 4) is rotatingly urged by a spring (5) and driven by rotational force transmitted from the one shaft member (3) with the other shaft member (4) restrained from rotating. A contact section (20) is formed at that portion of the shaft members (3,4) which is other than that of the thread sections (8, 9), and the contact section (20) come into contact with the other shaft member (4) when it is moved in the direction opposite the drive direction. The contact section (20) is set to satisfy the expression of R1 / R2 < -tan([mu]2 - alpha) / [mu]1, where R1 is a contact radius caused by contact, R2 is the effective diameter of the thread sections (8, 9), [mu]1 is the coefficient of friction of the contact section (20), [mu]2 is the coefficient of friction of the thread sections (8, 9), and alpha is the lead angle of the thread faces of the thread sections (8,9).

Owner:NHK SPRING CO LTD

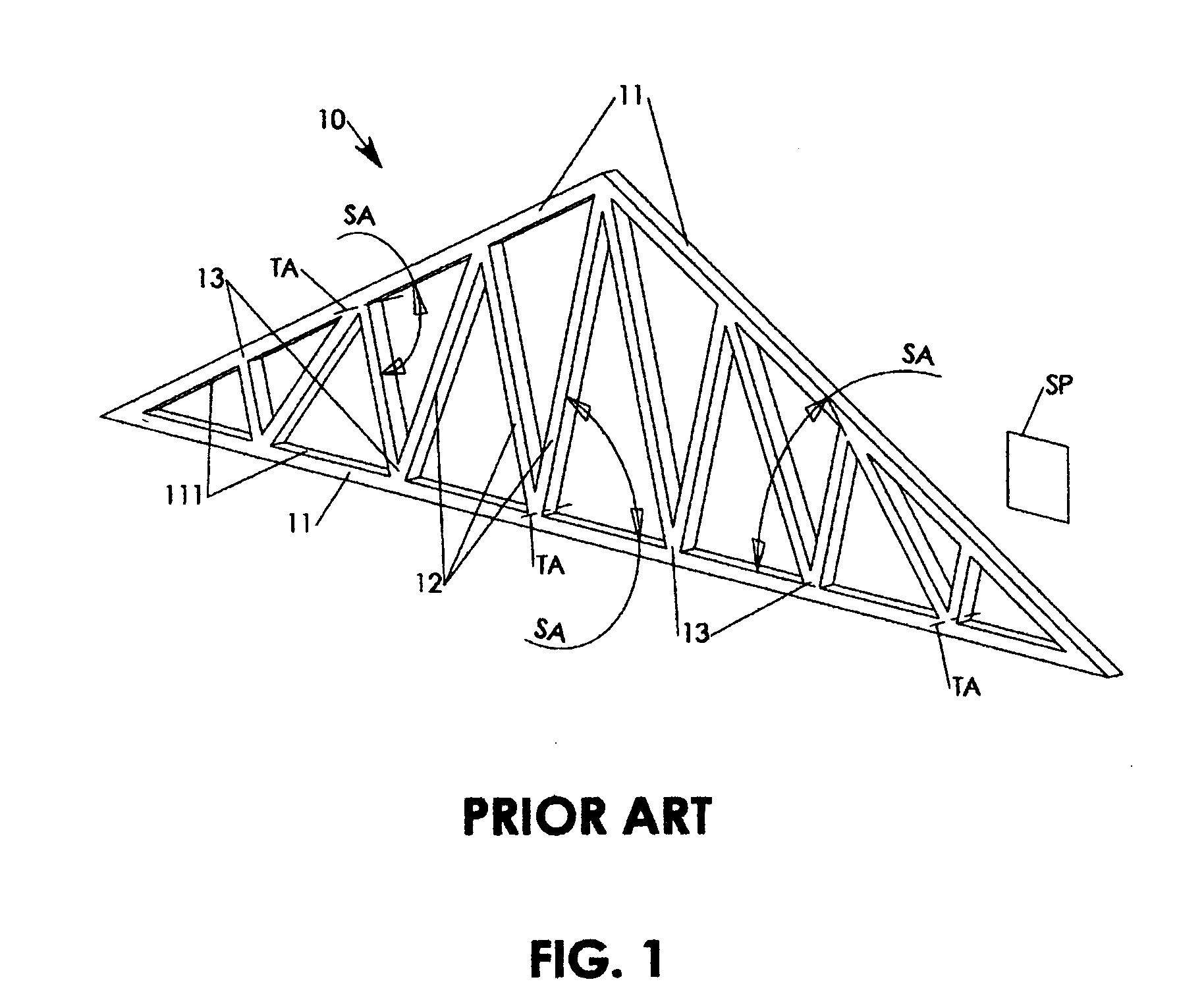

Area contact truss strut joint

InactiveUS20060201097A1Increase contact areaIncrease loadFloorsGirdersBiomedical engineeringJoint angle

A strut joint of a truss features a contact trough on an inner chord face being in an area contact with a rotationally symmetric strut end surface having a contact radius of at least half a strut height. The rotation axis of the strut end surface and the trough is substantially perpendicular to the struts protrusion direction and the chord's protrusion direction. The area contact provides for snug contact irrespective deviations from a predetermined strut joint angle between strut end and chord. An optional interposing structure may extend the area contact in between two opposite strut end surfaces of a single strut joint.

Owner:DAVIS JOHN D

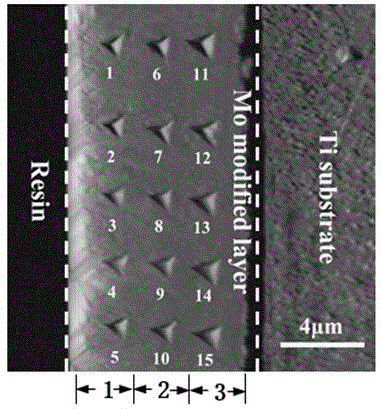

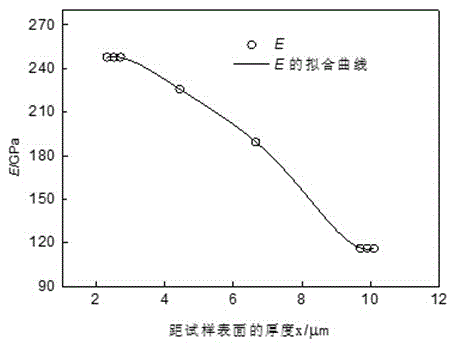

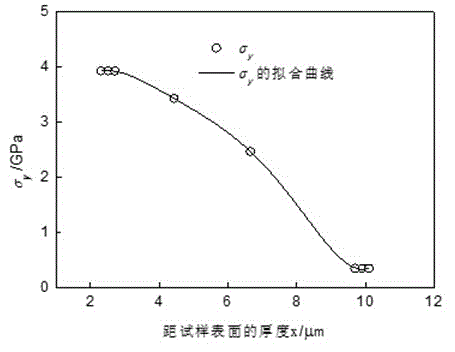

Characterization method of mechanical properties of elastic-plastic graded modification layer on metal surface

InactiveCN104792617ARapid Quantitative CharacterizationEffective quantitative characterizationMaterial strength using tensile/compressive forcesElastic plasticFinite element software

The invention discloses a characterization method of mechanical properties of an elastic-plastic graded modification layer on a metal surface and belongs to the field of characterization of properties of modification layers on metal surfaces. According to the method, a plasma surface alloying method is adopted for a polished metal base material, infiltration elements are selected reasonably, and the elastic-plastic graded modification layer is formed on the surface of the polished metal base material. Butt bonding, sample inlaying and polishing treatment are performed on cut and prepared sample cross sections. The modification layer is divided into multiple sub-layers according to the thickness of the modification layer and the indentation contact radius for a nano-indentation test. Inverse analysis calculation is performed on a load-displacement curve obtained through test of each sub-layer with ANSYS v10.0 finite element software, and the elastic-plastic property parameter of each sub-layer is obtained. Mechanical property parameters of all the sub-layers are numerically fitted, so that mechanical property parameters of all points in the thickness direction of the elastic-plastic graded modification layer on the metal surface are obtained quantitatively. The method is easy to operate, besides, the matrix effect is eliminated, and the result is accurate and reliable.

Owner:TAIYUAN UNIV OF TECH

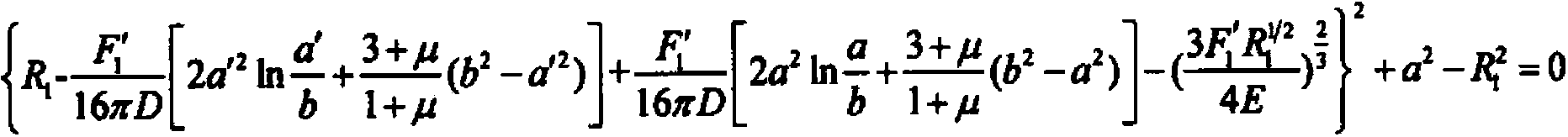

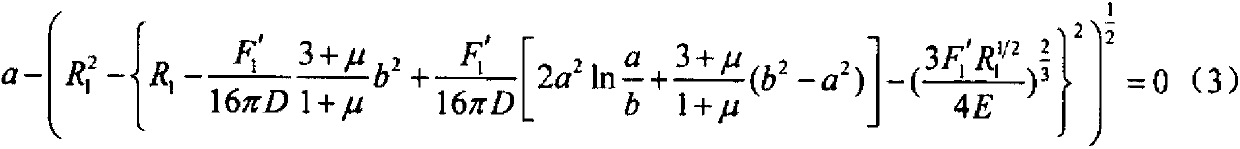

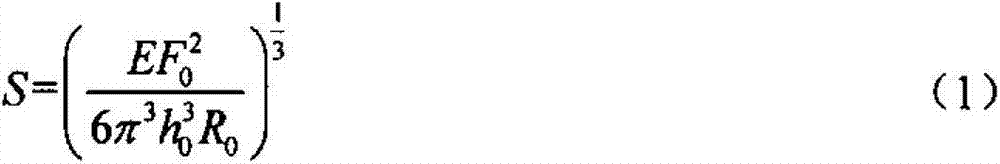

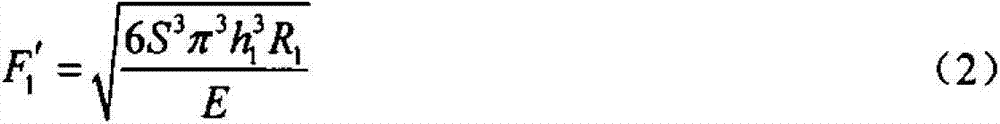

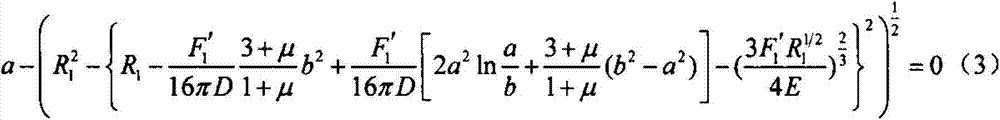

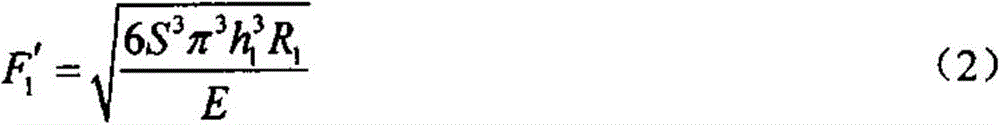

Predication method for layered threshold value load under transverse impact of laminated board

InactiveCN103884609AImprove forecast accuracyMaterial strength using single impulsive forcePredictive methodsEngineering

The invention relates to a predication method for a layered threshold value load under the transverse impact of a laminated board. The predication method comprises the following steps: (1) carrying out an impact test on the composite material laminated board which can have the infinite thickness as a standard test piece to obtain the layered threshold value load; and (2) calculating the layered threshold value load of the predicated laminated board of a same material system by using the layered threshold value load. Compared with the prior art, for the method disclosed by the invention, in the data processing, the influences on the contact radius by the deflection are considered, and the predication method has the advantages of high predication precision and the like.

Owner:SHANGHAI JIAO TONG UNIV

Belt unit for continuously variable transmission

A belt unit for a continuously variable transmission that transmits power from a primary pulley to a secondary pulley, may include at least a band overlapped each other, and a segment including a body base and a locking end portion which are connected by a neck therebetween, wherein an upper surface of the at least a band is coupled to the locking end portion and a lower surface of the at least a band is coupled to a segment shoulder of the body base, and wherein lower grooves are formed at lower portions of the neck between the neck and the segment shoulder of the body base at both sides of the neck such that an upper surface of the respective body base is higher than the corresponding lower groove to form a contact radius difference between the lower groove and the upper surface of the body base.

Owner:HYUNDAI MOTOR CO LTD

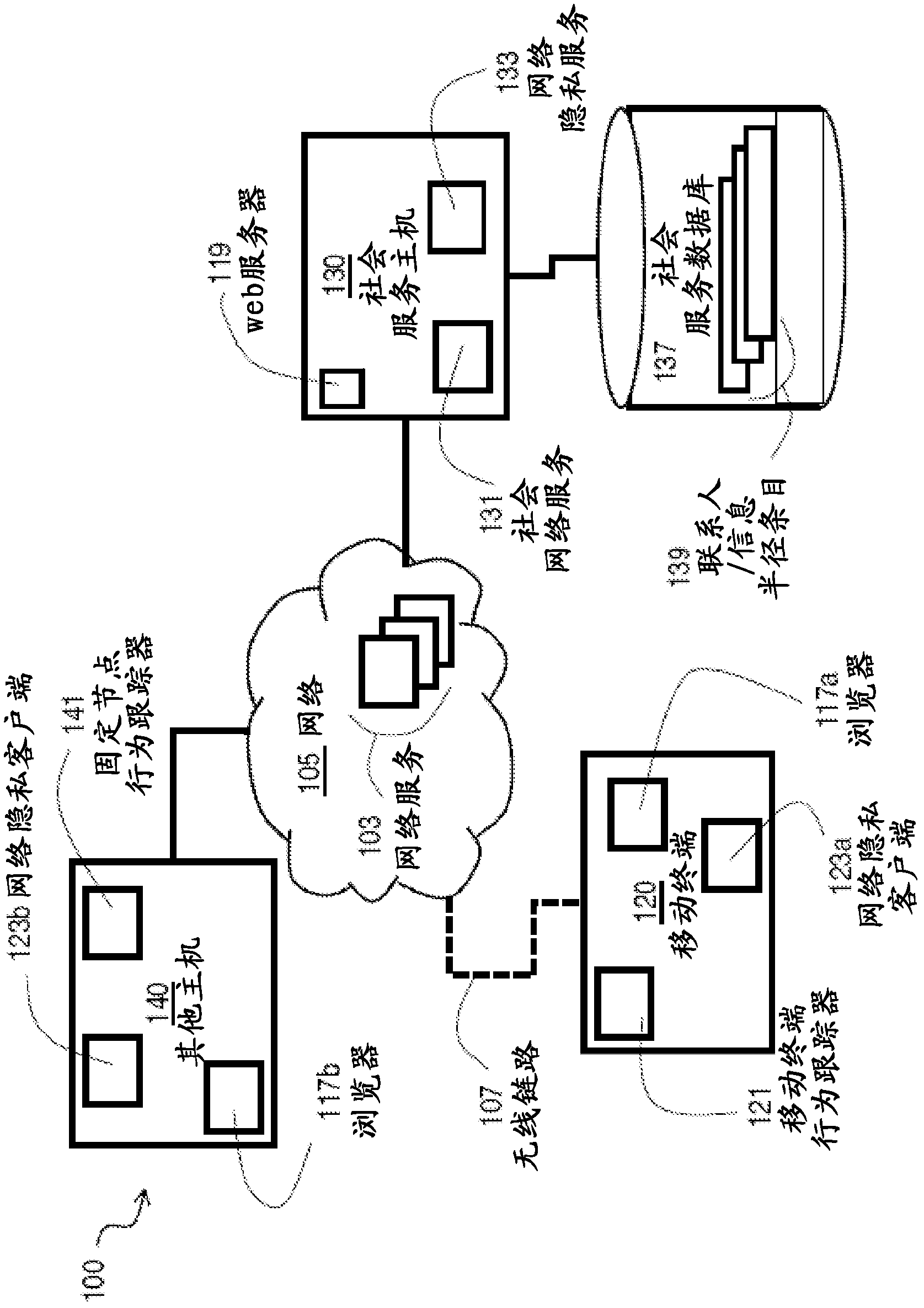

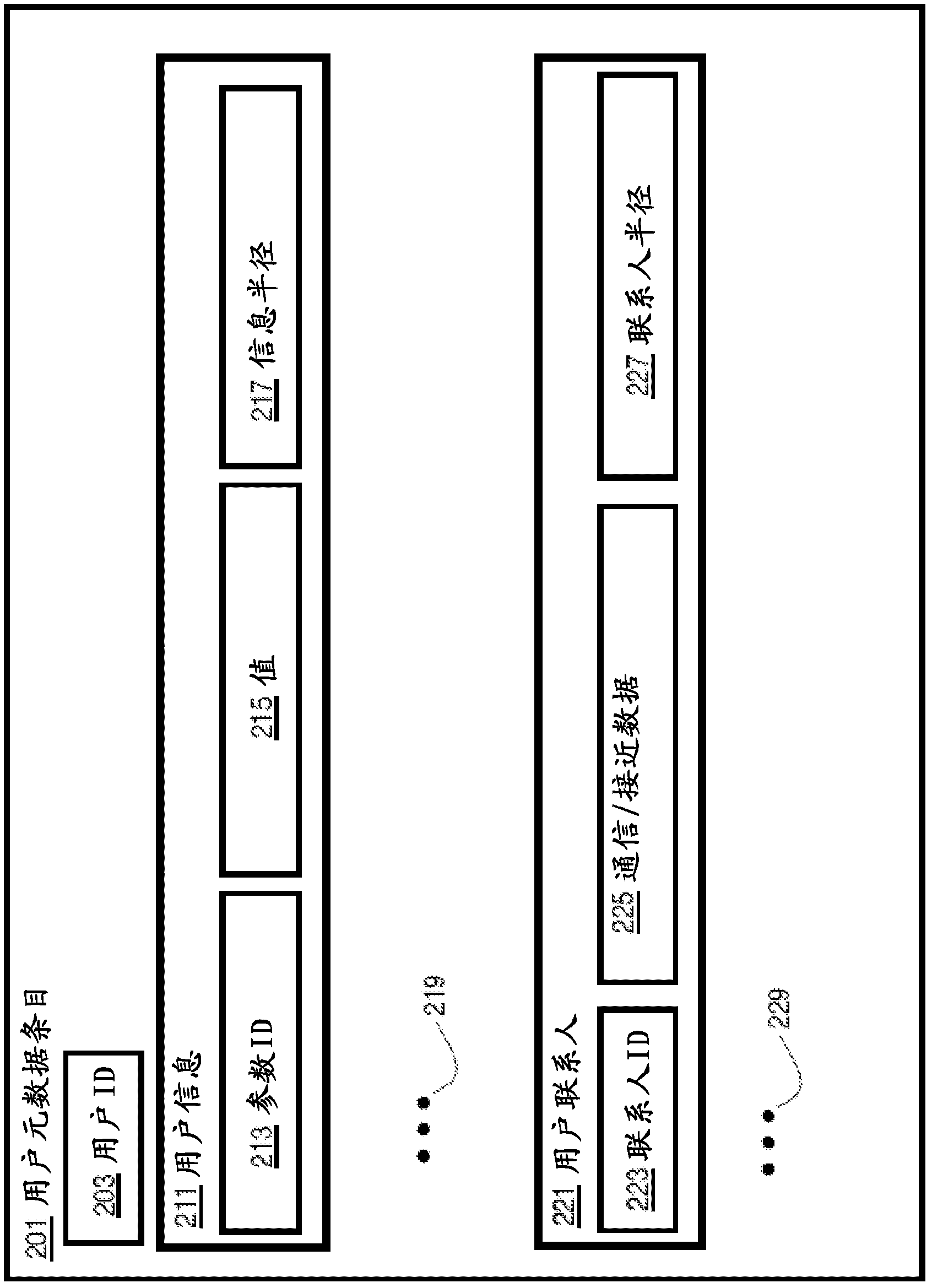

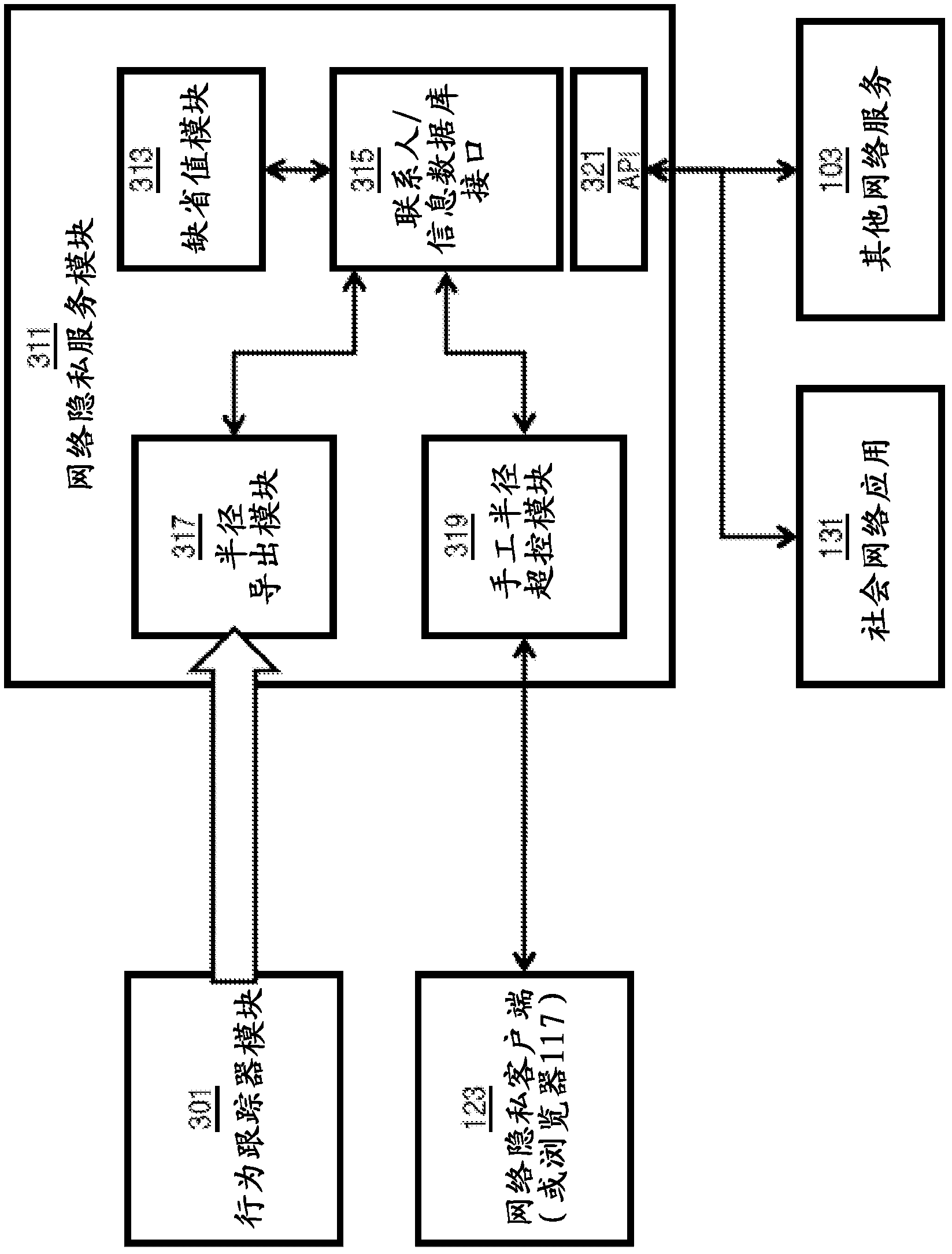

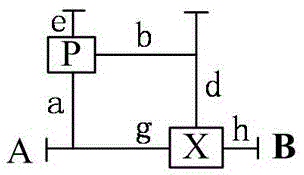

Method and apparatus for intuitive management of privacy settings

An approach is provided for intuitive management of privacy settings, which includes receiving data that indicates a contact radius and an information radius. The contact radius is related to how socially close a contact is to a user who is registered with a network service. The information radius is related to how private the information about the user is. In response to a request from the contact for information about the user, information about the user is provided, which has an information radius value in a range that is based on a value of the contact radius associated with the contact.

Owner:NOKIA TECHNOLOGLES OY

Control apparatus of driving force in case of belt slipping for vehicle equipped with V-belt continuously variable transmission and control method thereof

InactiveUS8527167B2Reduce transmissionReduce deteriorationDigital data processing detailsGearing controlControl theoryControl equipment

A control apparatus of a driving force in case of belt slipping includes a belt slip control detecting unit adapted to detect that the belt slip control is in execution, a belt contact radius ratio calculating unit adapted to calculate a belt contact radius ratio of the V-belt to the pulleys, and a power source output torque determining unit adapted to determine a target power output torque according to the belt contact radius ratio in execution of the belt slip control in response to signals from the belt slip control detecting unit and the belt contact radius ratio calculating unit.

Owner:NISSAN MOTOR CO LTD +1

Method to measure the elastic modulus and hardness of thin film on substrate by nanoindentation

A method of measuring the elastic modulus and hardness of a thin film on substrate using nanoindentation technique is provided. The method includes calculating a series of experimental corrected stiffness and contact radius pairs associated with one or more presumed parameters and information obtained from a loading curve associated with the thin film and substrate. Also, the method includes calculating a series of theoretical corrected stiffness and contact radius pairs associated with the same one or more presumed parameters and information obtained from the loading curve associated with the thin film and substrate. Furthermore, the method includes using results obtained from the experimental and theoretical corrected stiffness and contact radius pairs to compute the elastic modulus and hardness of the film material.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

Method for measuring surface adhesive capacity and elastic modulus of soft material

InactiveCN102183441BReduce volumeWide range of test materialsSurface/boundary effectStrength propertiesElastomerSpherical probe

The invention discloses a method for measuring the surface adhesive capacity and an elastic modulus of a soft material, the method comprises the following specific steps of: (1) preparing a sample and selecting a probe according the physical property and the chemical property of a tested sample; (2) controlling a horizontal substrate and the spherical probe to move oppositely to be contacted and separated at a constant speed; (3) measuring an interaction force P, a relative displacement delta and a contact radius a respectively by using a pressure sensor, a displacement sensor and an optical microscope in the whole process of the step (2) when the substrate and the probe are contacted with each other; (4) frequently repeating the steps (2) and (3) under the control of software; and (5) quantitatively analyzing the adhesive capacity and the elastic performance of the tested material by using data obtained in the step (3) according to a jabatan kerja raya (JKR) theory. The measurement method has giant application potential in the aspects of scientific research on soft materials such as high-molecule elastic body, biogel and the like, product quality control in industrial manufacturing processes and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

Data processing method for prediction of multilevel threshold force caused by composite impact

InactiveCN103344512AHigh precisionMaterial strength using single impulsive forceComposite laminatesEngineering

Owner:JINGDEZHEN CHANGHE AVIATION EQUIPMEMT TECH CO LTD

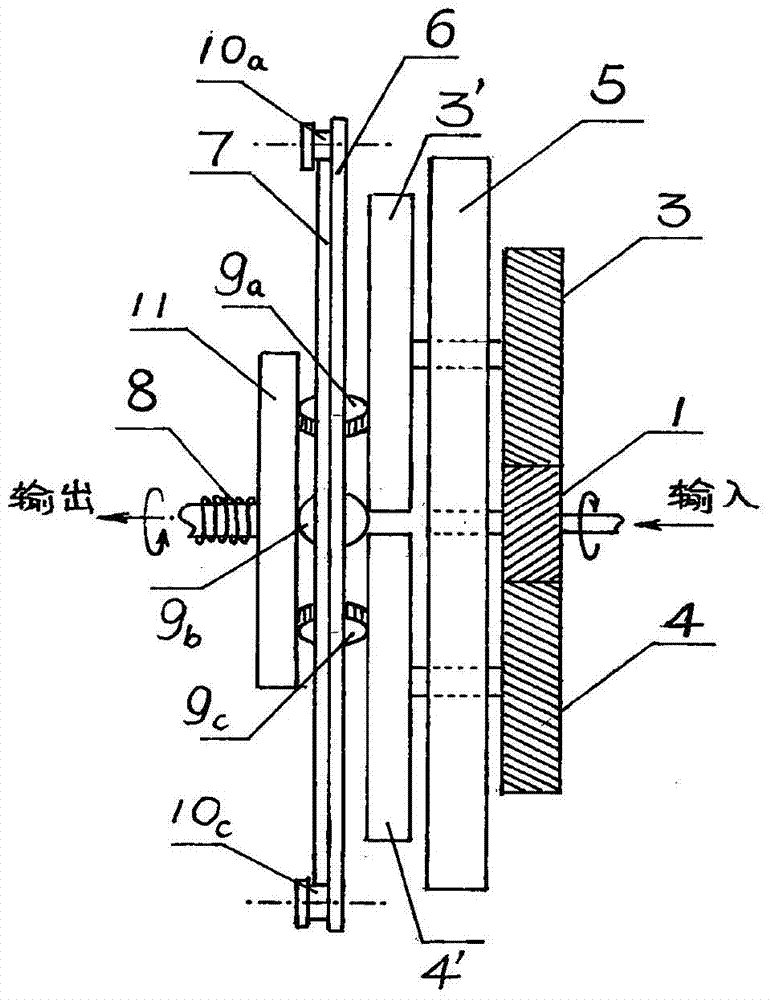

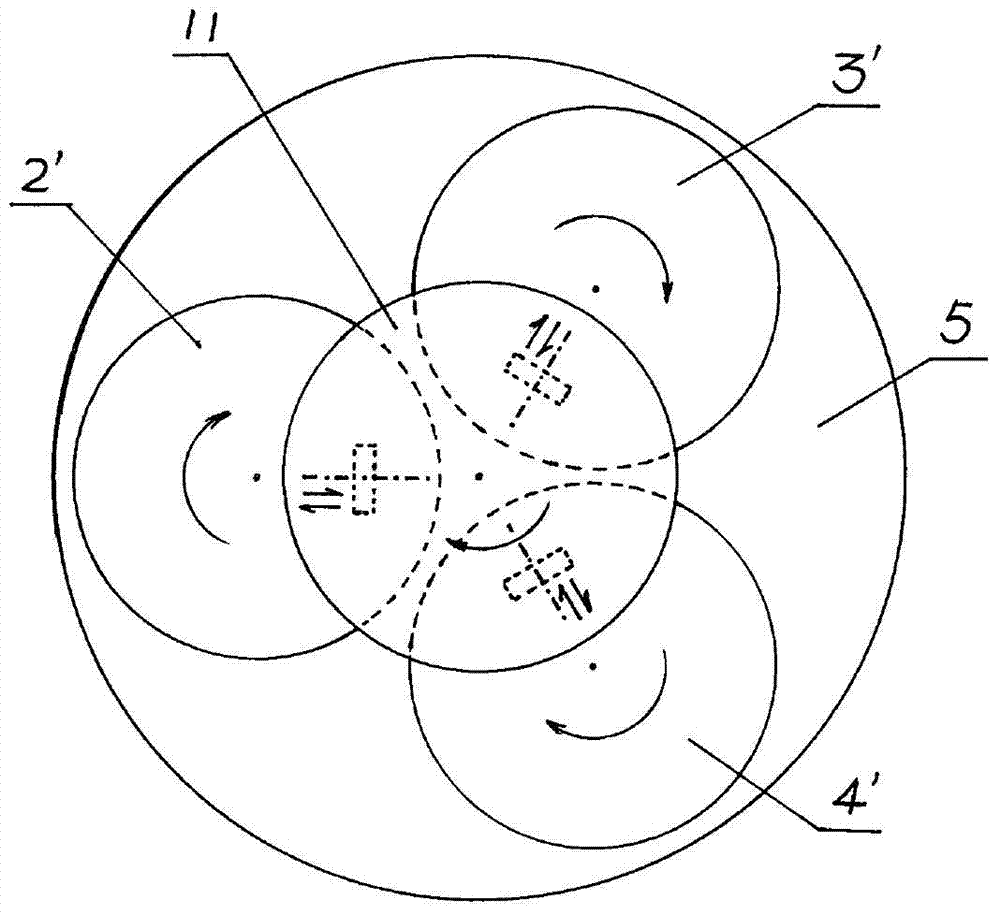

Power split planetary ring bevel gear type continuously variable transmission

InactiveCN103591231BSmooth transmissionEasy to startToothed gearingsGearing detailsPower splitEngineering

The invention provides a power splitting planetary ring bevel gear type stepless speed changer. A planetary ring bevel gear type stepless speed changer and a differential gear train are combined. A small part of power is transmitted through rotation and revolution of planetary ring bevel gears and the differential gear train, most of power is transmitted through a power input shaft and a planetary carrier, and the two parts of power are synthesized on synchronous planetary gears and then transmitted to an output shaft, so that power splitting is finished. Stepless speed changing drive is achieved through changing the contact radius of the speed regulation rings and the planetary ring bevel gears. The power splitting planetary ring bevel gear type stepless speed changer has the advantages of being stable in drive, good in starting performance, capable of being stably started from zero under full loads and adapted to work of variable working conditions, long in service life and wide in speed changing range. In comparison with an existing planetary type stepless speed changer, the power splitting can be achieved, meanwhile, power reflowing is avoided, high power transmission is achieved, geometrical slipping is reduced to the minimum, and transmission efficiency is higher.

Owner:ZHONGBEI UNIV

Data processing method for prediction of multilevel threshold force caused by composite impact

InactiveCN103344512BHigh precisionMaterial strength using single impulsive forceComposite laminatesEngineering

The invention relates to a data processing method for the prediction of a multilevel threshold force caused by composite impact, which comprises the following steps: 1) carrying out an impact experiment on the composite laminated board serving as a reference experiment component so as to obtain a multilevel threshold force of the composite laminated board, wherein the thickness of the composite laminated board is regarded as an infinite thickness; and 2) calculating multilevel threshold forces of laminated boards which are different in thickness and belongs to a same material system under the action of impact heads with different radiuses by using the obtained multilevel threshold force. Compared with the prior art, according to the invention, the influence of the deflection of plate on the contact radius is considered in data processing, and therefore, the method has an advantage of high prediction precision.

Owner:JINGDEZHEN CHANGHE AVIATION EQUIPMEMT TECH CO LTD

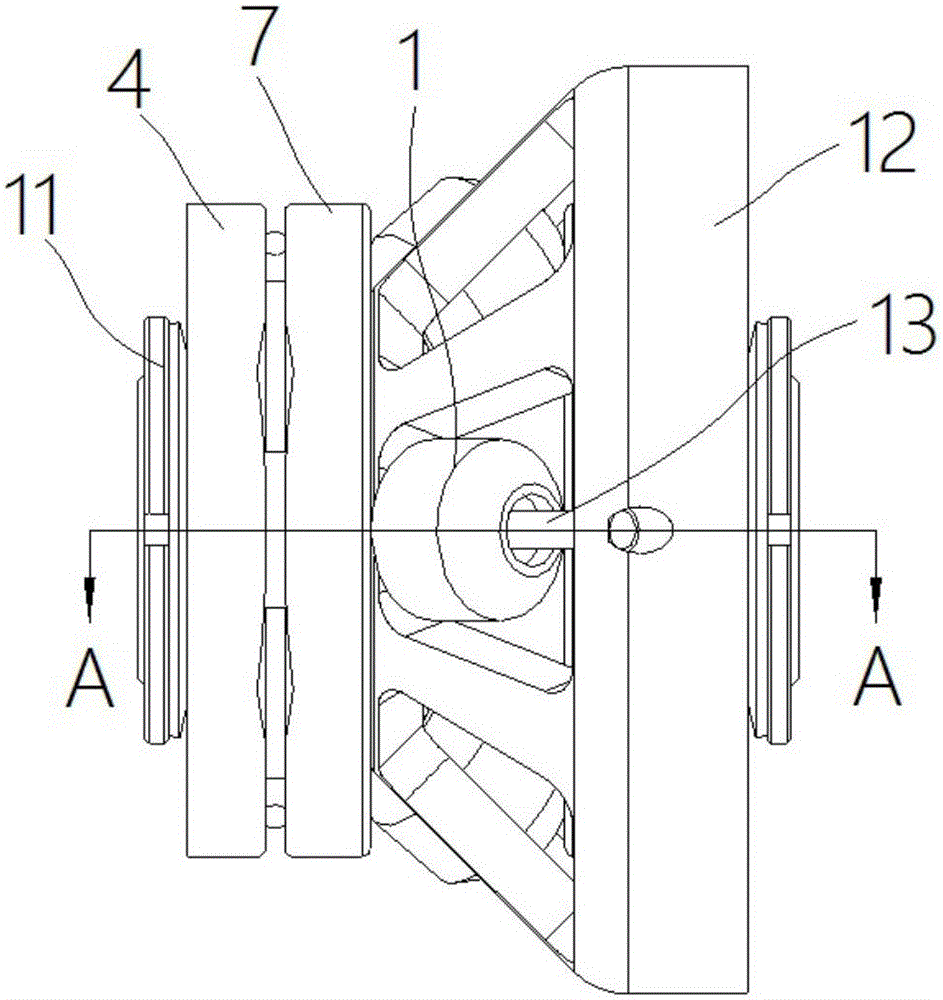

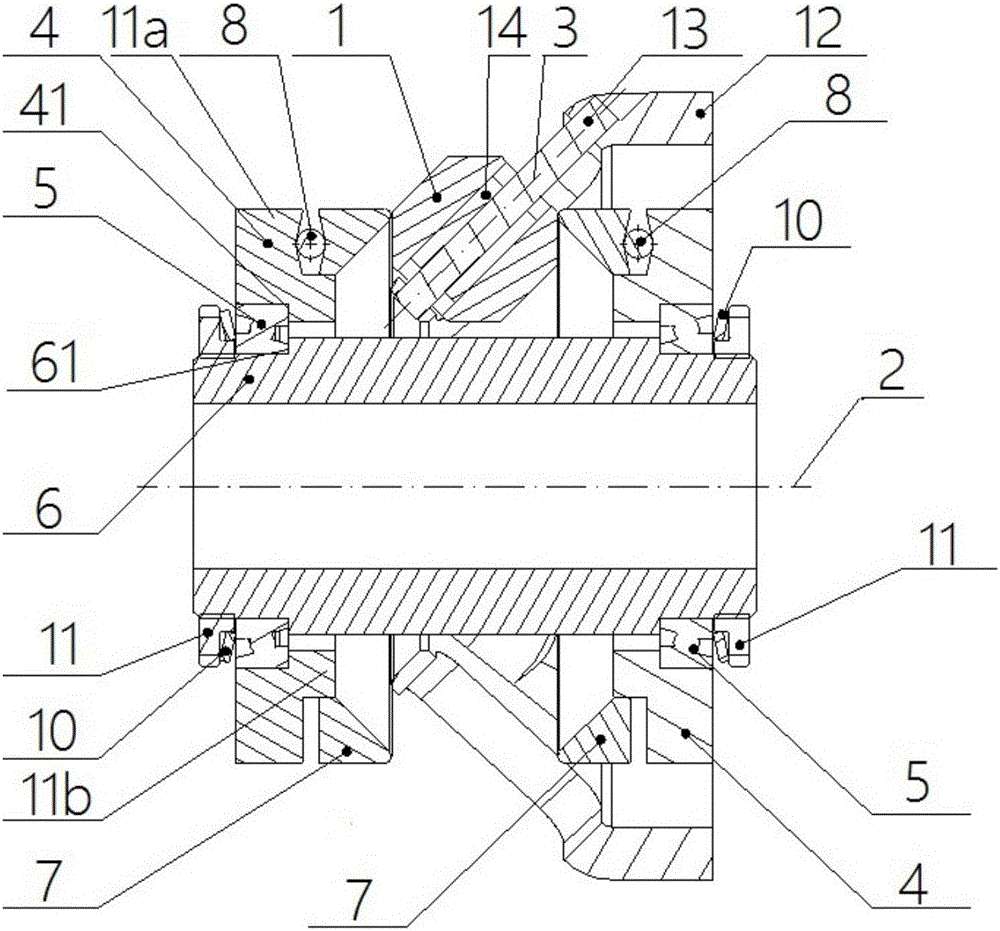

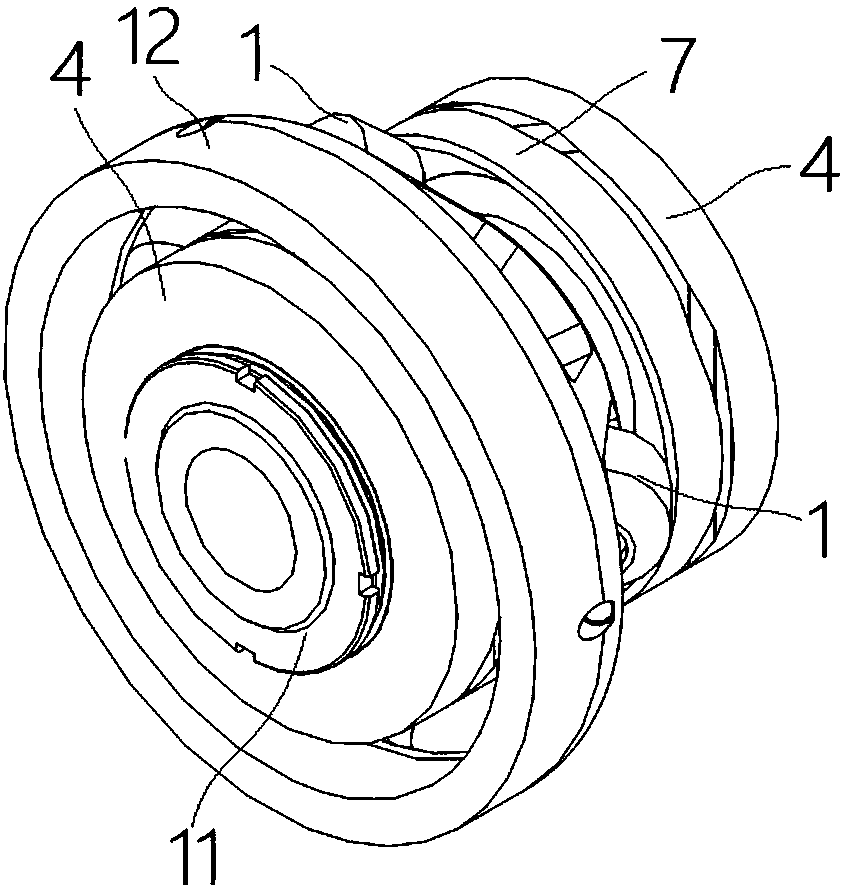

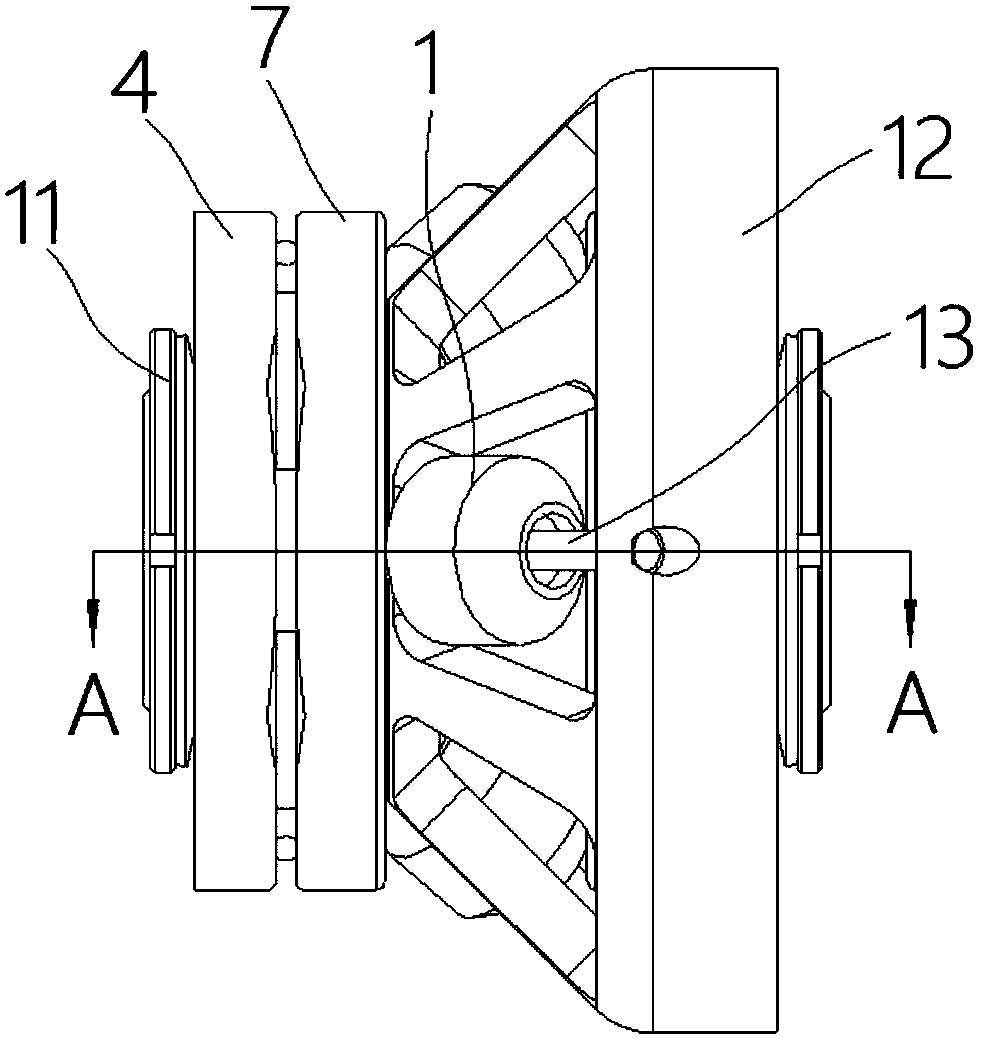

Stepless transmission

InactiveCN105757197AControl the contact radius to change continuouslySimple structureFriction gearingsRolling resistanceEngineering

The invention discloses a stepless transmission. The stepless transmission comprises an input component, an output component and columnar cones. A rotation axis of the input component and a rotation axis of the output component are collinear; the columnar cones are arranged at intervals around the rotation axes peripherally and clamped between the input component and the output component; each columnar cone comprises a middle cylindrical section, an input conical section and an output conical section, wherein the input conical section and the output conical section are arranged at two ends of the middle cylindrical section, and conical generatrix of each of the input conical section and the output conical section is perpendicular to the rotation axes. The input component is abutted against and tightly pressed on the conical surface of each input conical section and transfers the torque by means of rolling friction, the output component is abutted against and tightly pressed on the conical surface of each output conical section and transfers the torque by means of rolling friction, and the columnar cones are enabled to move axially to realize stepless gear ratio variation between the input component and the output component. The stepless transmission has the advantage that continuous variation of a contact radius between the columnar cones and each of the input component and the output component can be controlled to realize stepless transmission.

Owner:吉安市瑞鹏飞精密科技有限公司

A stepless transmission

InactiveCN105757197BControl the contact radius to change continuouslySimple structureFriction gearingsRolling resistanceEngineering

The invention discloses a stepless transmission. The stepless transmission comprises an input component, an output component and columnar cones. A rotation axis of the input component and a rotation axis of the output component are collinear; the columnar cones are arranged at intervals around the rotation axes peripherally and clamped between the input component and the output component; each columnar cone comprises a middle cylindrical section, an input conical section and an output conical section, wherein the input conical section and the output conical section are arranged at two ends of the middle cylindrical section, and conical generatrix of each of the input conical section and the output conical section is perpendicular to the rotation axes. The input component is abutted against and tightly pressed on the conical surface of each input conical section and transfers the torque by means of rolling friction, the output component is abutted against and tightly pressed on the conical surface of each output conical section and transfers the torque by means of rolling friction, and the columnar cones are enabled to move axially to realize stepless gear ratio variation between the input component and the output component. The stepless transmission has the advantage that continuous variation of a contact radius between the columnar cones and each of the input component and the output component can be controlled to realize stepless transmission.

Owner:吉安市瑞鹏飞精密科技有限公司

A Prediction Method of Delamination Threshold Load Under Lateral Impact of Laminates

InactiveCN103884609BImprove forecast accuracyMaterial strength using single impulsive forceEngineeringMaterial system

The invention relates to a predication method for a layered threshold value load under the transverse impact of a laminated board. The predication method comprises the following steps: (1) carrying out an impact test on the composite material laminated board which can have the infinite thickness as a standard test piece to obtain the layered threshold value load; and (2) calculating the layered threshold value load of the predicated laminated board of a same material system by using the layered threshold value load. Compared with the prior art, for the method disclosed by the invention, in the data processing, the influences on the contact radius by the deflection are considered, and the predication method has the advantages of high predication precision and the like.

Owner:SHANGHAI JIAO TONG UNIV

Tensioner

A tensioner in which sticking between a rotation member and a drive member when the tensioner is in a fully retracted state is prevented by using a simple mechanism, thereby ensuring reduced man-hour for control in assembling the tensioner and enabling the tensioner to function when it is abnormally operated. A pair of shaft members (3, 4) is threaded to each other by thread sections (8, 9), and one (3) of the shaft members (3, 4) is rotatingly urged by a spring (5) and driven by rotational force transmitted from the one shaft member (3) with the other shaft member (4) restrained from rotating. A contact section (20) is formed at that portion of the shaft members (3,4) which is other than that of the thread sections (8, 9), and the contact section (20) come into contact with the other shaft member (4) when it is moved in the direction opposite the drive direction. The contact section (20) is set to satisfy the expression of R1 / R2 < -tan(µ2 - a) / µ1, where R1 is a contact radius caused by contact, R2 the effective diameter of the thread sections (8, 9), µ1 the coefficient of friction of the contact section (20), µ2 the coefficient of friction of the thread sections (8, 9), and a the lead angle of the thread faces of the thread sections (8,9).

Owner:NHK SPRING CO LTD

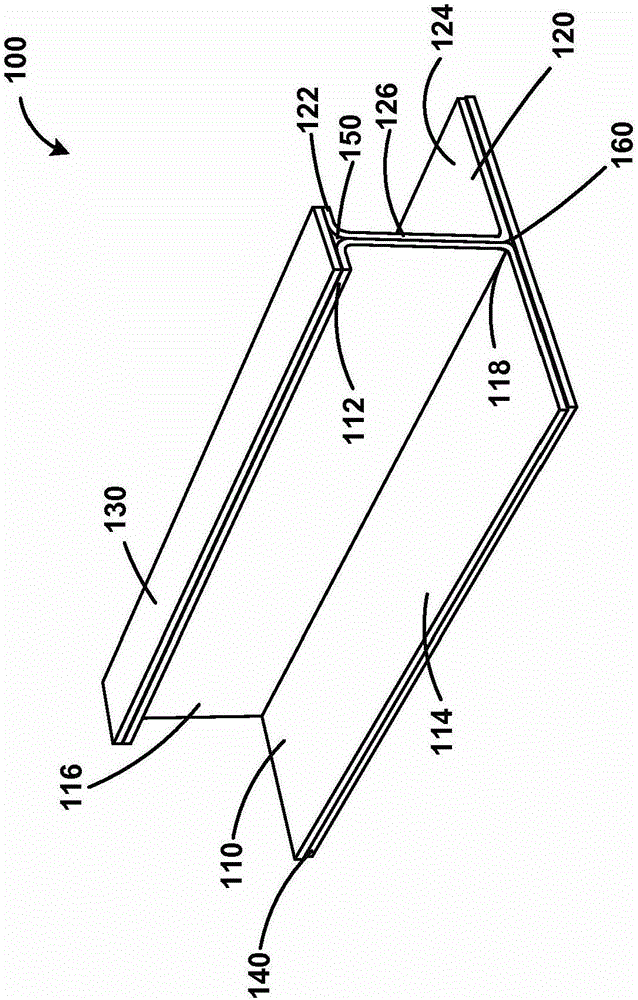

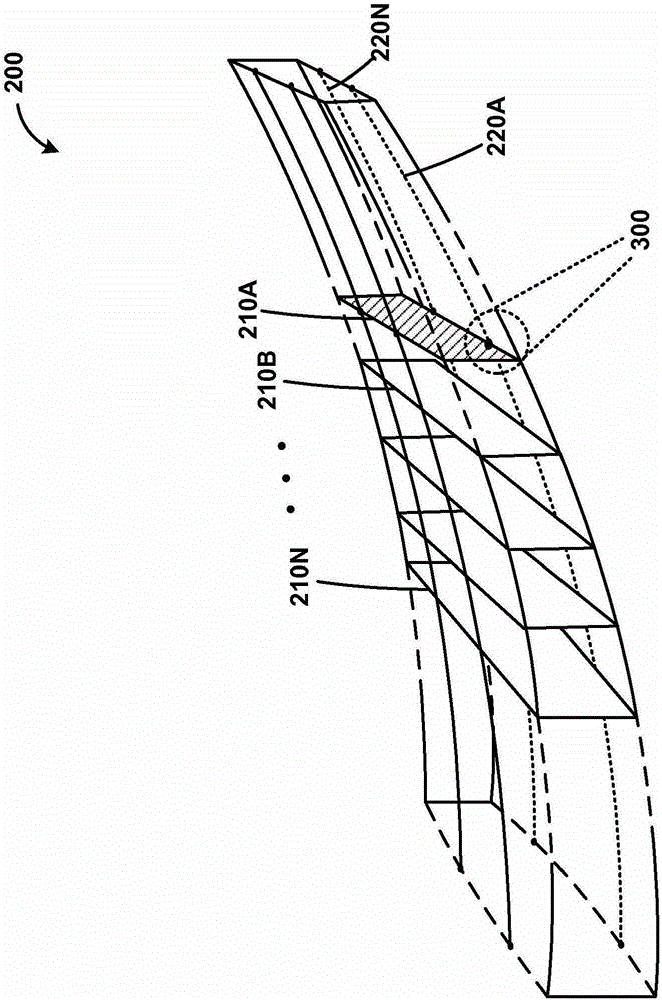

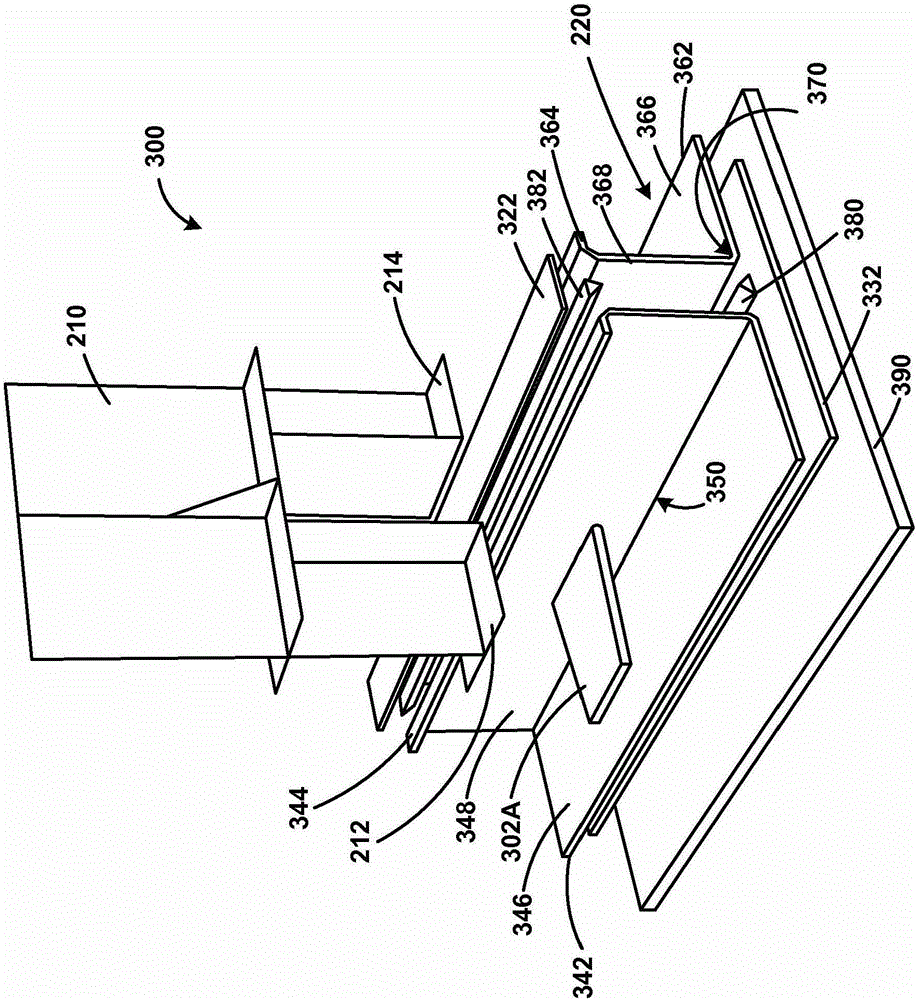

Sloped corner radius fillers to reduce the risk of delamination in laminated stringer assemblies

This article describes the techniques used to enhance joint capability and reduce the risk of stringer delamination using slope angle radius fillers. Beveled corner radius fillers (302A, 302B) for enhanced bondability include top (303A, 303B) and bottom (305A, 305B) surfaces separated by thickness. The radius filler also includes a radius contact side (304A, 304B) having a cutting edge radius (307A, 307B) sized to match the radius of the web joint of the stringer. The radius filler also includes a pair of opposing non-parallel sides (306A, 308A, 306B, 308B) extending at an acute angle from the radius contact side and a rear side (310A, 310B) shorter than the radius contact side.

Owner:THE BOEING CO

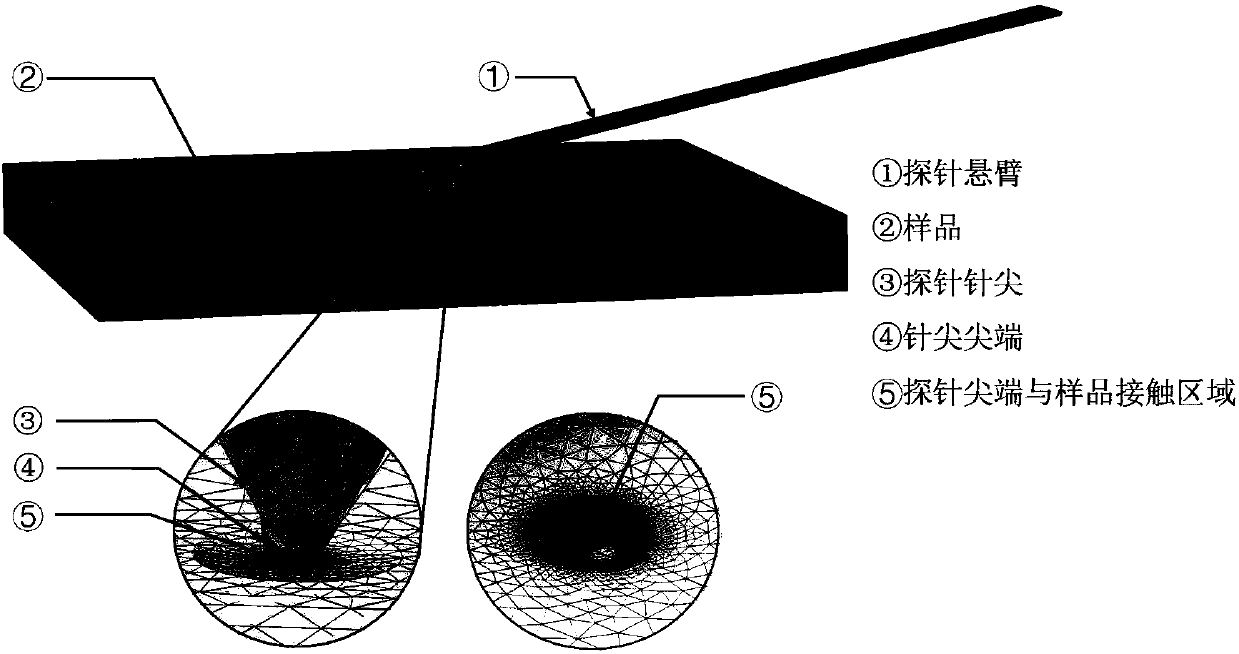

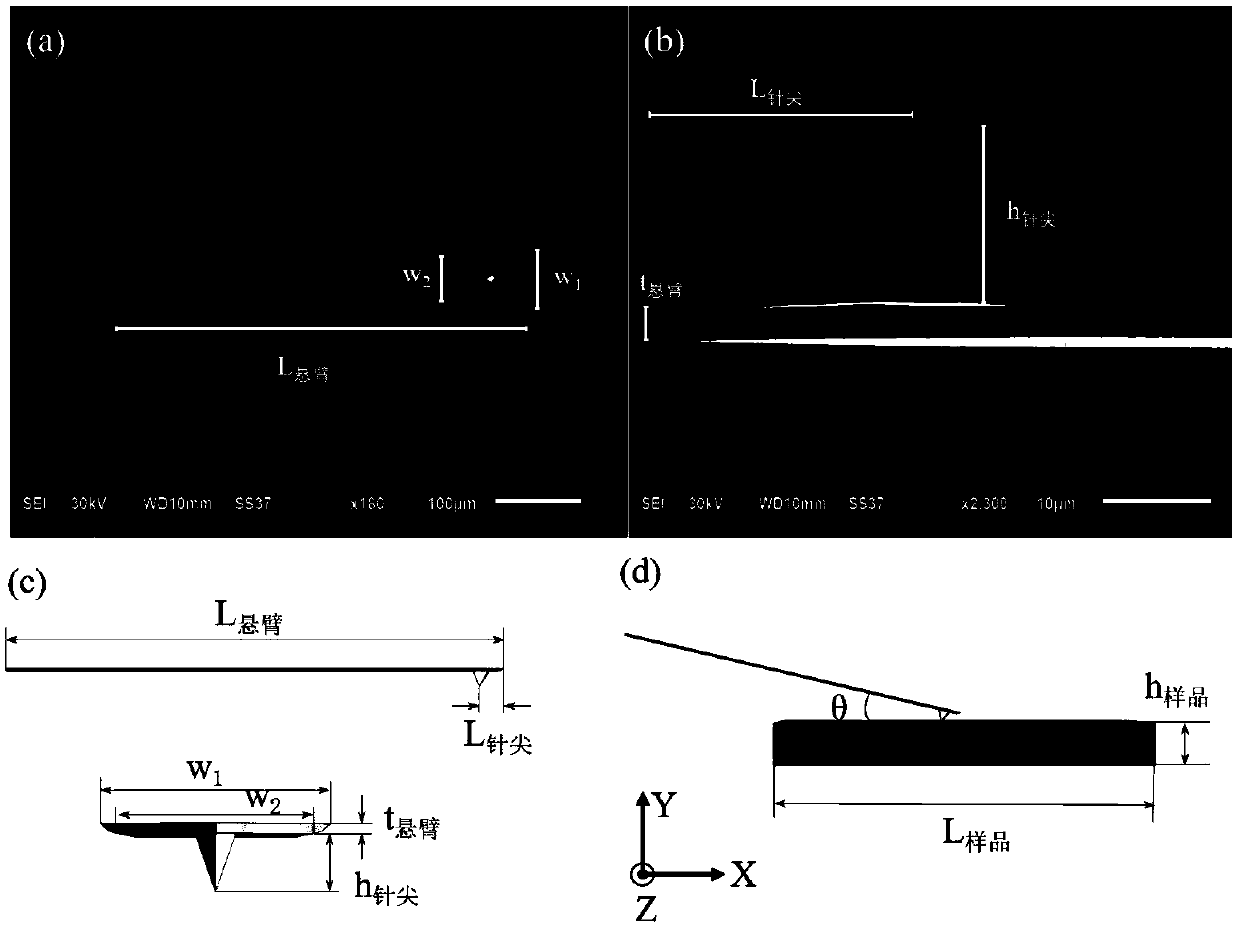

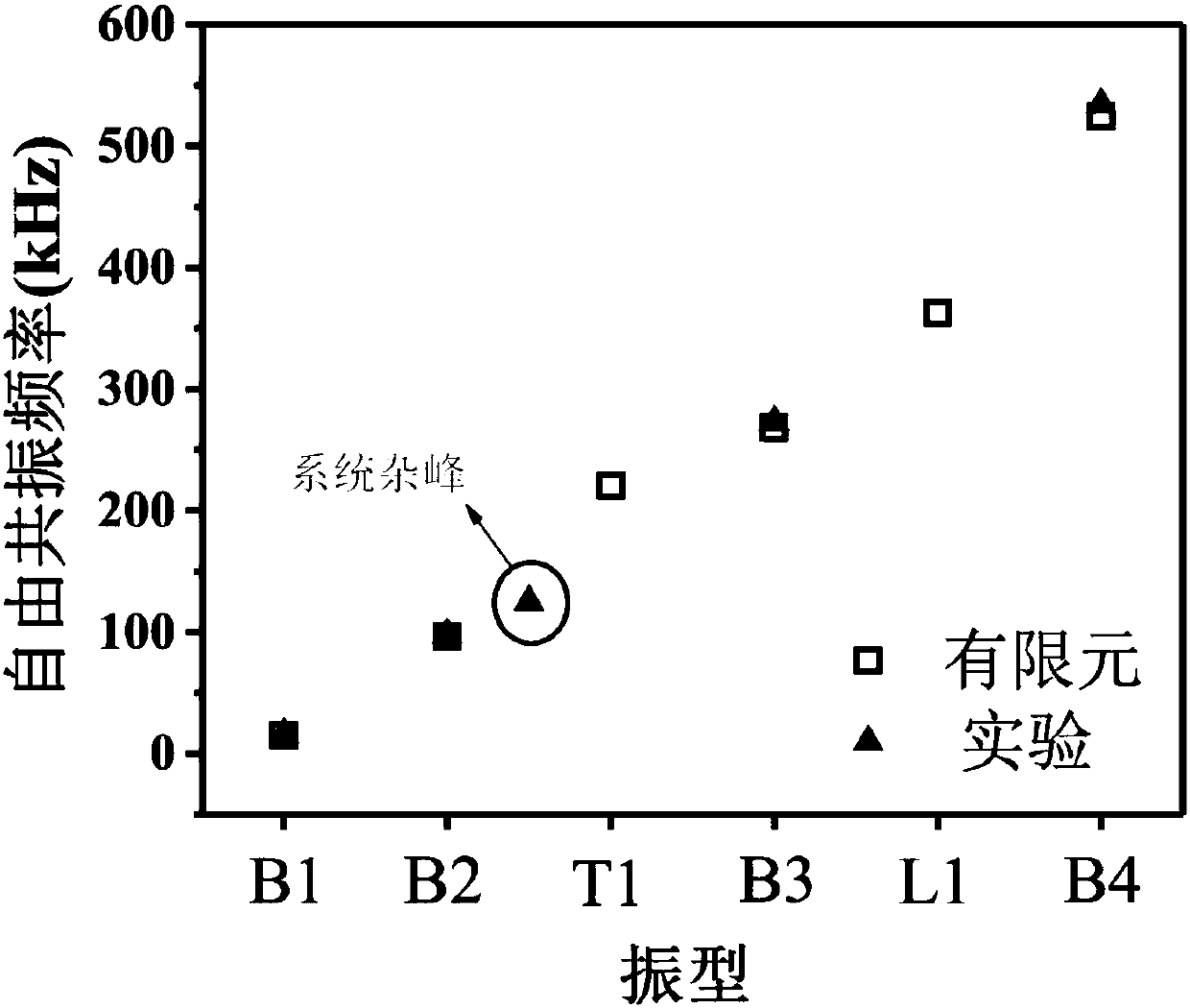

Frequency scanning signal analysis method based on atomic force microscopy technology and application thereof

ActiveCN110046362AOptimize geometryImprove applicabilityDesign optimisation/simulationSpecial data processing applicationsAtomic force microscopyElement model

The invention relates to contact resonance frequency signal analysis of an atomic force microscope, in particular to a finite element simulation method for probe-sample contact resonance. The finite element simulation method for probe-sample contact resonance comprises the following steps: establishing a probe free resonance finite element model, and using an experiment free resonance result to fit and optimize the geometric dimension of a probe; establishing probe-sample contact resonance finite element model, determining the inclination angle of the probe, the contact radius and the sample material attribute. According to the contact resonance finite element modeling method, contact resonance frequency signals of different samples and different types of probes are output by taking an atomic force microscope experiment principle as a requirement, high-order contact resonance frequency is calibrated, vibration modes of different-order resonance are judged, and the influence of different material attributes on resonance frequency drift is quantified; powerful discrimination is provided for interference signals, false signals and noise coverage in an AFM experiment; and meanwhile, guidance of probe design is provided for designers.

Owner:XIANGTAN UNIV

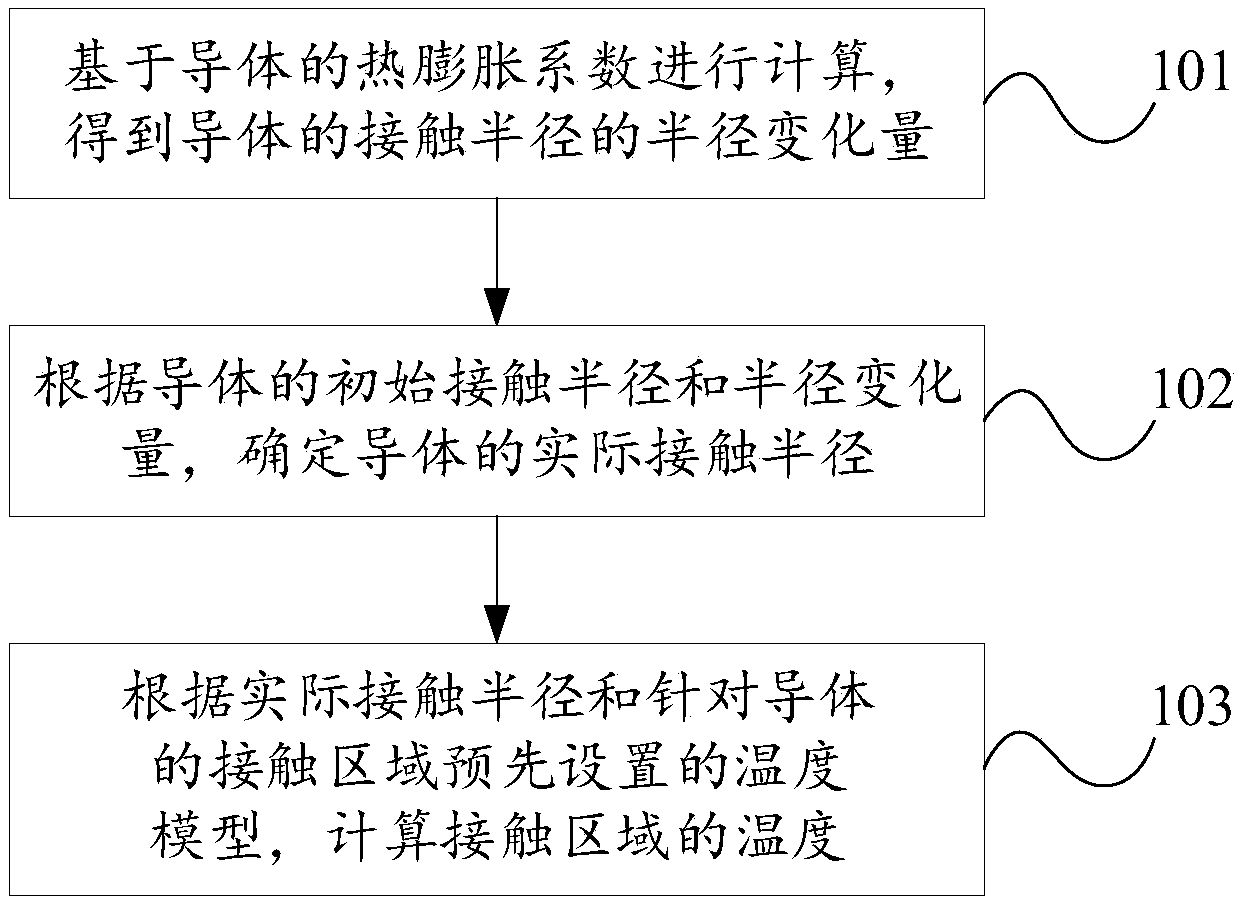

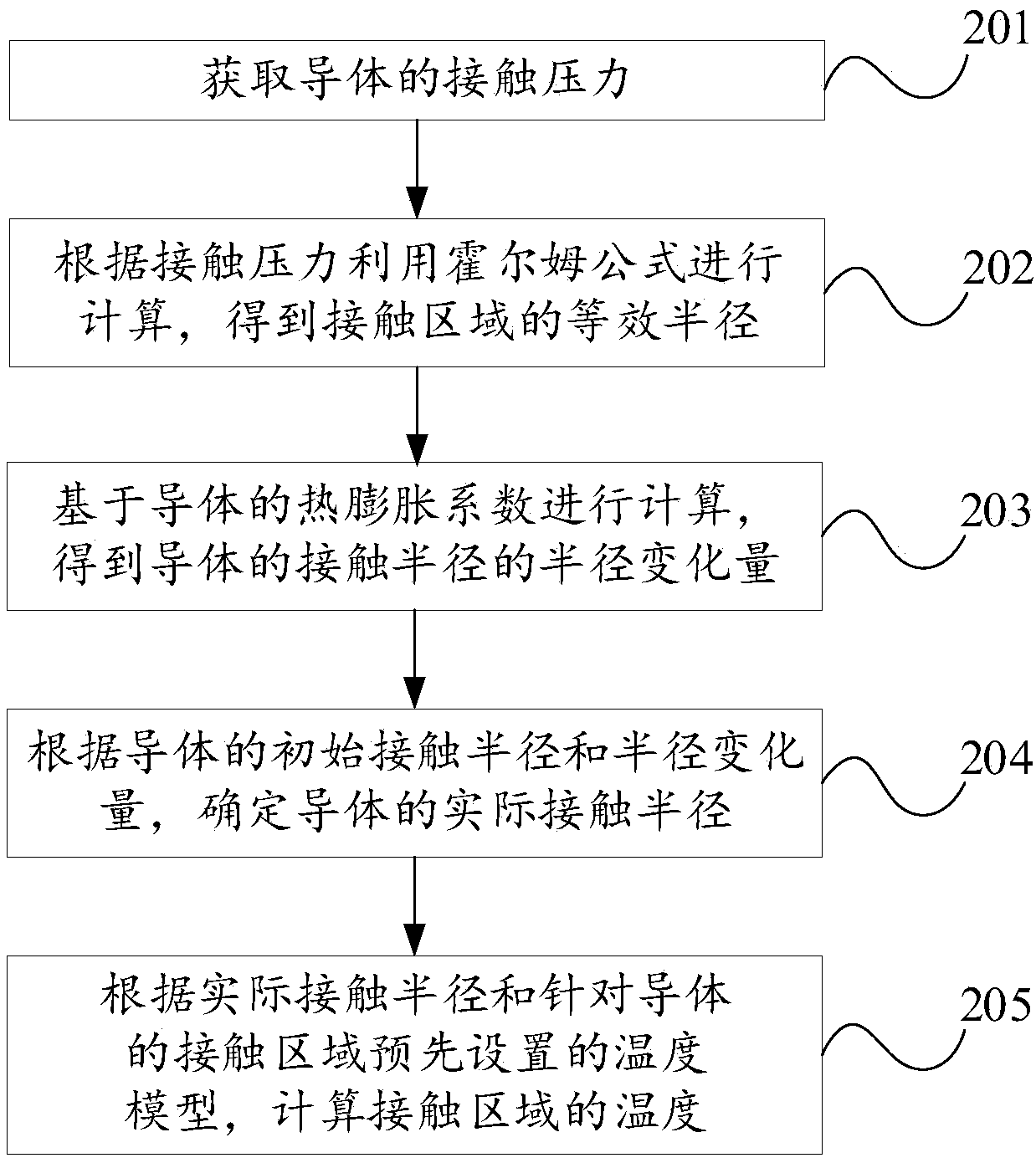

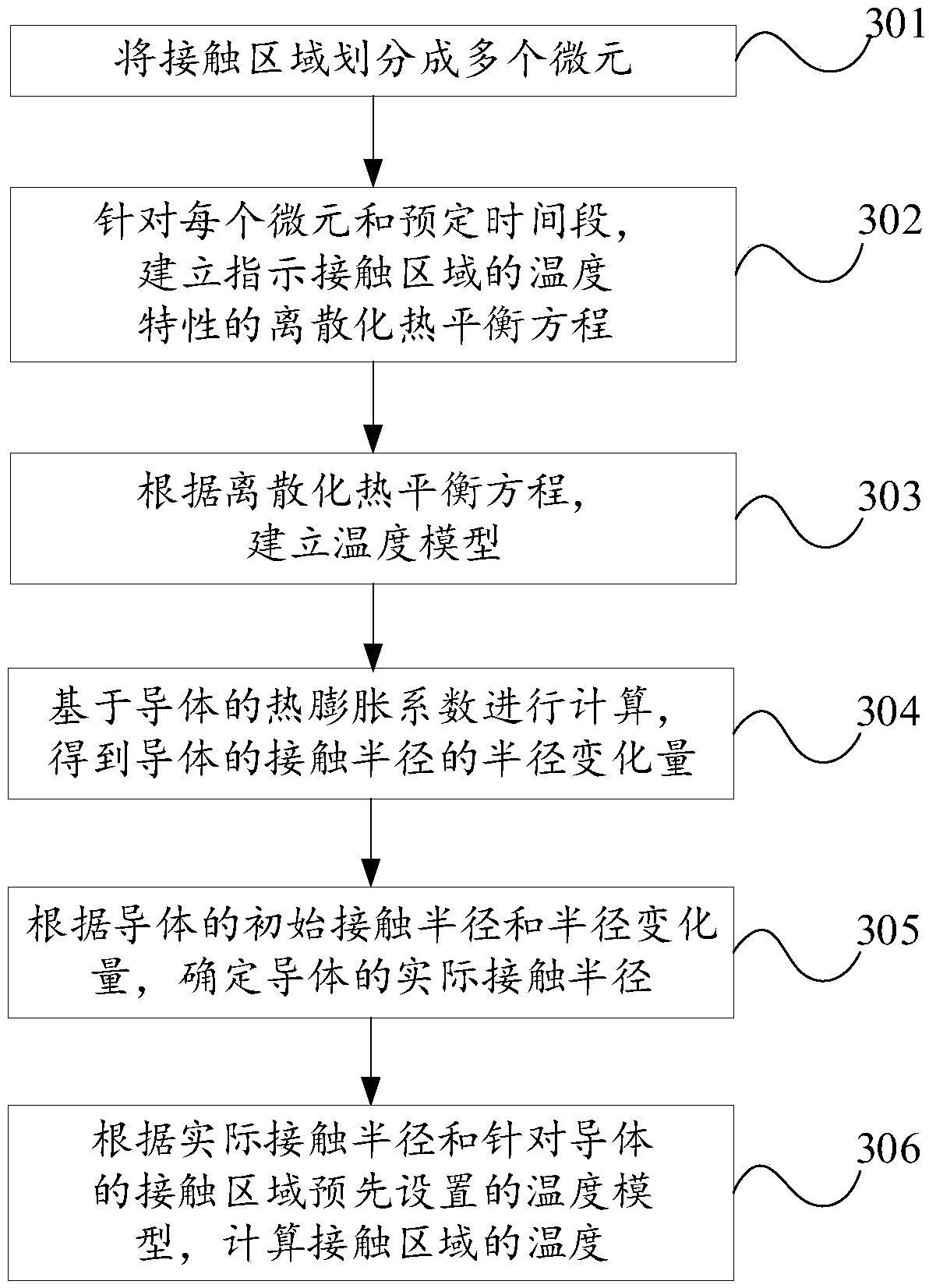

Temperature calculation method and device

ActiveCN109446712AAccurate calculationImprove accuracyDesign optimisation/simulationSpecial data processing applicationsElectrical conductorEngineering

The invention provides a temperature calculation method and device, and relates to the technical field of electric power, and the method comprises the steps of carrying out the calculation based on the thermal expansion coefficient of a conductor, and obtaining the radius variation of the contact radius of the conductor; determining the actual contact radius of the conductor according to the initial contact radius and the radius variation of the conductor; and calculating the temperature of the contact area according to the actual contact radius and a temperature model preset for the contact area, the temperature model being used for indicating the temperature characteristic of the contact area; calculating the radius variation of the contact radius of the conductor based on the thermal expansion coefficient of the conductor; and using the radius variation for the temperature calculation of the contact area of the conductor, so that the influence of the thermal expansion factor of thecontact area is introduced into the temperature calculation result, the temperature of the contact area can be calculated more accurately under the condition that the temperature of the contact area is changed, and the accuracy of determining the temperature of the contact area is improved.

Owner:GUANGDONG POWER GRID CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com