Characterization method of mechanical properties of elastic-plastic graded modification layer on metal surface

A metal surface, elastic-plastic technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of many mathematical simplifications, cumbersome derivation, and the inapplicability of elastic-plastic gradient modified layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

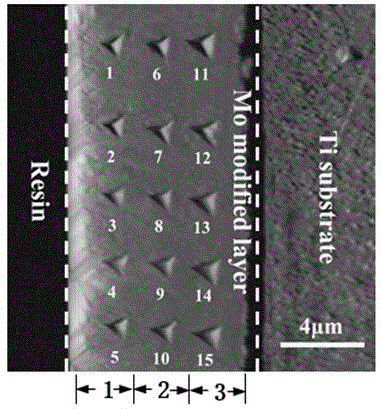

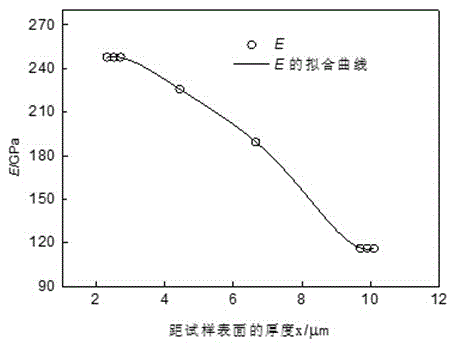

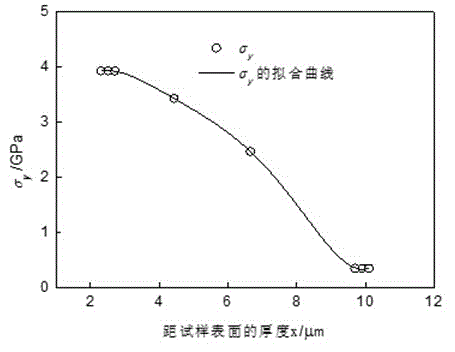

[0030] Now take the elastic-plastic gradient modified layer formed by infiltration on the surface of pure Ti as an example to implement the present invention, as Figure 1 to Figure 5 Can show:

[0031] (1) First, the Ti substrate (Ф18mm×5mm) is polished step by step with 320, 600, 800, 1000, 1500, 2000, 2500 and 3000 mesh SiC emery papers, followed by 0.5μm emery polishing spray Polish until the surface roughness Ra<0.1μm. After polishing, use pure water and acetone to clean ultrasonically in turn and then set aside;

[0032] (2) With the help of the plasma surface alloying method, an elastic-plastic gradient modified layer with high hardness, wear resistance and corrosion resistance is formed on the surface of pure Ti by Mo infiltration. The optimized process parameters are: electrode spacing, that is, the distance between the target and the sample surface, is set to 18mm, the working pressure is 40Pa, the source negative bias is -660~-900V, and the workpiece negative bias...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com