Method for optimizing laser nondestructive characterized Youngs modulus of membrane

A technology of Young's modulus and optimization method, which is applied in the direction of measuring devices, processing detection response signals, and using sound waves/ultrasonic waves/infrasonic waves to analyze solids.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

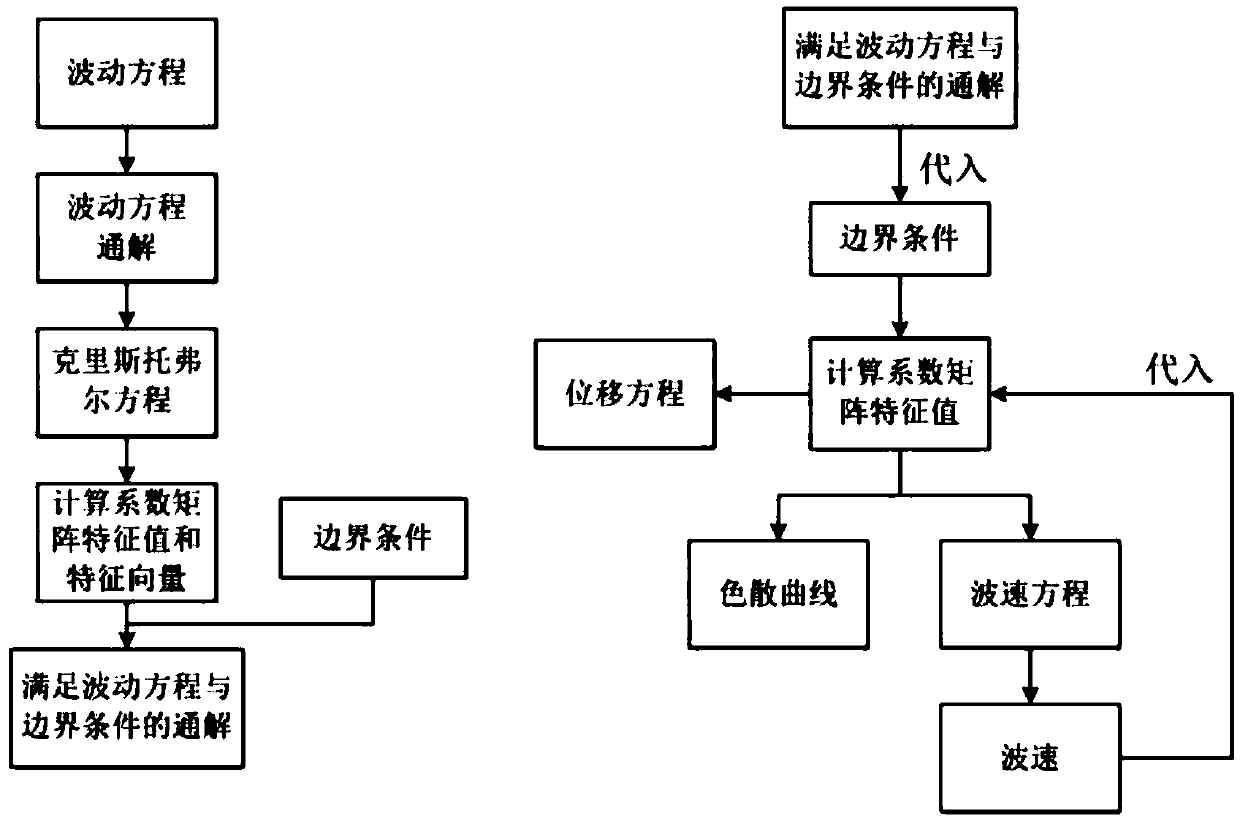

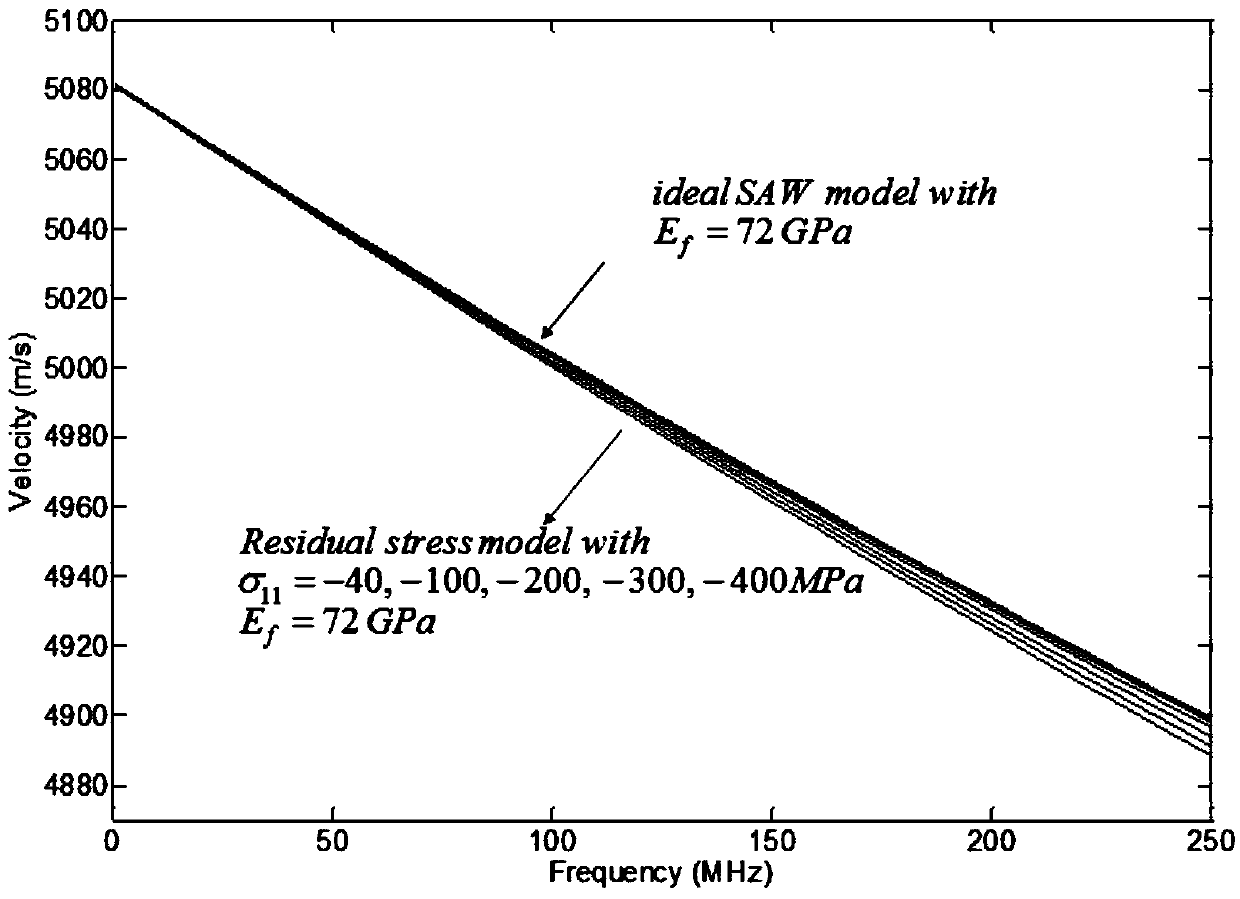

[0019] Based on the theory of acoustic elasticity, the present invention analyzes the ideal model of surface acoustic wave propagation in a film containing residual stress, studies the influence of residual stress on the measurement of Young's modulus of the film, and introduces the error criterion "ΔE / E" to describe the residual stress Influence on Young's modulus measurement. where ΔE is the difference between the Young's modulus represented by the same dispersion curve in the ideal model and in the residual stress model. The invention includes a calculation method for calculating the applicable range of the ideal model, within the range, the impact of residual stress on the measurement of Young's modulus of the film is less than 5%, which can be neglected. SiO 2 / Si structure as an example, the implementation scheme is as follows:

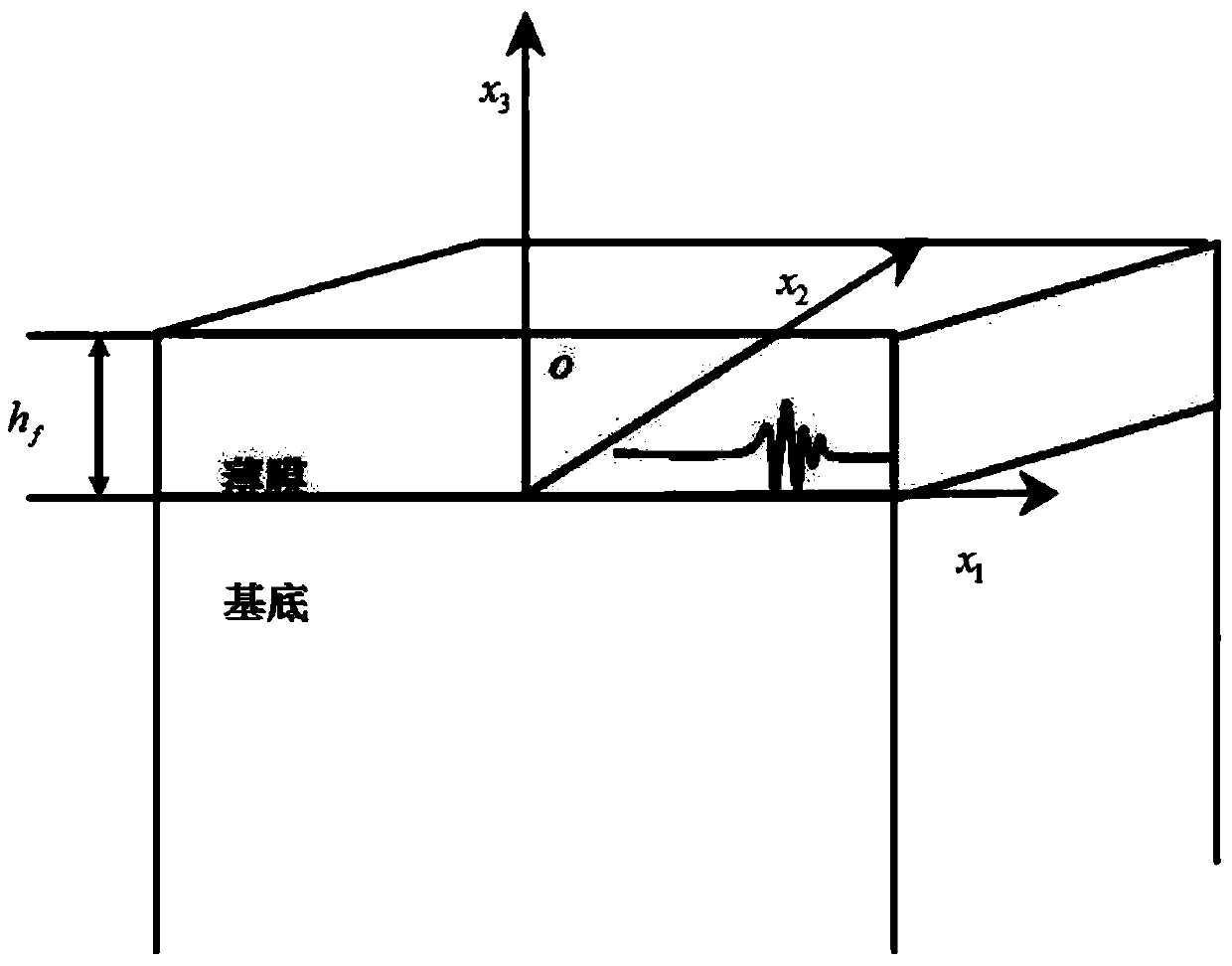

[0020] (1) SAW in SiO 2 / Si structure in the propagation model such as figure 1 , for the initial coordinates, the motion equation of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com