Quantitative characterization method of elastoplasticity performance parameter of gradient modification layer on surface of titanium alloy

A surface gradient, quantitative characterization technology, applied in the direction of strength characteristics, measuring devices, testing material hardness, etc., can solve the problem of lack of quantitative characterization methods for mechanical properties parameters of titanium alloy surface gradient modified layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Taking molybdenum molybdenum Mo on the surface of pure titanium Ti as an example (process parameters are: source negative bias voltage -660~-900V, workpiece negative bias voltage -300~-650V, temperature 900°C, holding time 3h), through the method of the present invention to solve The elastoplastic performance parameter of Mo gradient modification layer specifically comprises the following steps:

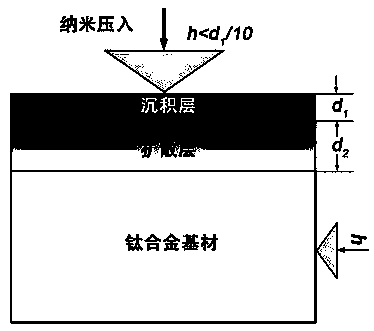

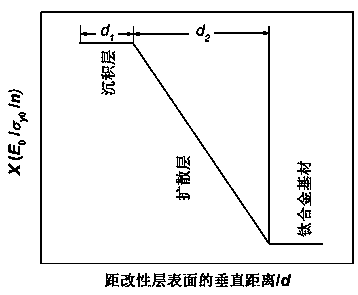

[0032] Step 1: Determine the thickness of the deposition layer and the diffusion layer: Use GDOES-750 glow discharge spectrometer to detect the composition distribution of the gradient modified layer, and determine the thickness d of the deposition layer in combination with the cross-sectional scanning electron microscope photos 1 and the thickness of the diffusion layer d 2 ;

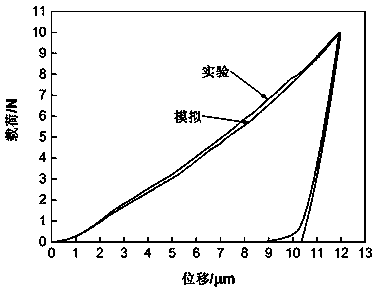

[0033] Step 2: Nanoindentation test: select 10 test points, adopt displacement loading mode, conduct nanoindentation test on the titanium alloy substrate and the surface of the deposited layer respect...

Embodiment 2

[0048]Taking nickel-impregnated Ni on the surface of titanium alloy Ti6Al4V as an example (process parameters are: source negative bias voltage -700~-900V, workpiece negative bias voltage -500~-700V, temperature 930°C, holding time 3h), using the same example 1, the elastic-plastic performance parameters of the Ni gradient modified layer are obtained in Table 2.

[0049] Table 2 Elastoplastic performance parameters of Ni gradient modified layer on Ti6Al4V surface

[0050]

Embodiment 3

[0052] Take zirconium-nitrogen (Zr-N) co-infiltration on the surface of titanium alloy Ti6Al4V as an example (process parameters are: source negative bias voltage -720~-820V, workpiece negative bias voltage -450~-500V, process temperature 930°C, heat preservation Time 3h), adopt the method and steps with embodiment 1, obtain the elastoplastic property parameter of Zr-N gradient modification layer and see Table 3.

[0053] Table 3 Elastoplastic properties parameters of Zr-N gradient modified layer on Ti6Al4V surface

[0054] .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com