Power split planetary ring bevel gear type continuously variable transmission

A continuously variable transmission, planetary ring cone technology, applied in the direction of gear transmission, belt/chain/gear, transmission parts, etc., can solve the problems of unstable operation, large slip rate, low bearing capacity, etc., to avoid power backflow , good startability and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

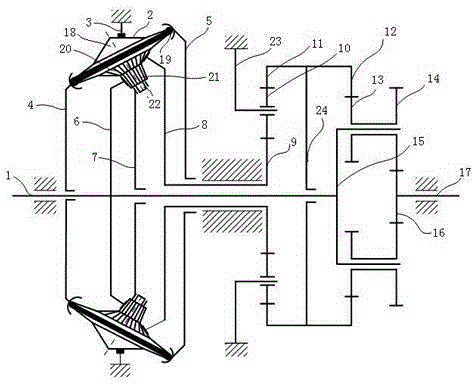

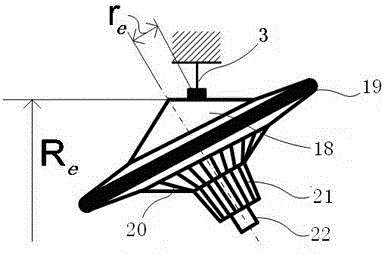

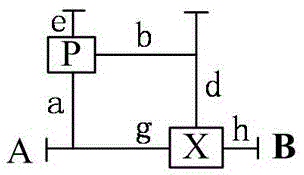

[0016] Power split ring bevel gear type continuously variable transmission, the transmission principle is the combination of planetary ring bevel gear type continuously variable transmission and differential gear train, the transmission structure is as follows figure 1 As shown, it includes power input shaft 1, planetary ring bevel gear 2, speed regulating ring 3, small support ring 4, large support ring 5, driving central bevel gear 6, planetary bevel gear cage 7, driven central bevel gear 8 , synchronous cylindrical gear 9, fixed axis gear 10, central internal meshing gear 11, synchronous internal meshing gear 12, planetary gear 13, synchronous planetary gear 14, planet carrier 15, output sun wheel 16, output shaft 17; small support ring 4, Planetary ring bevel gear cage 7 and driven central bevel gear 8 are vacantly sleeved on power input shaft 1, large support ring 5 is vacantly sleeved on driven central bevel gear 8, and active central bevel gear 6 and planet carrier 15 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com