Patents

Literature

116results about How to "Large shifting range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

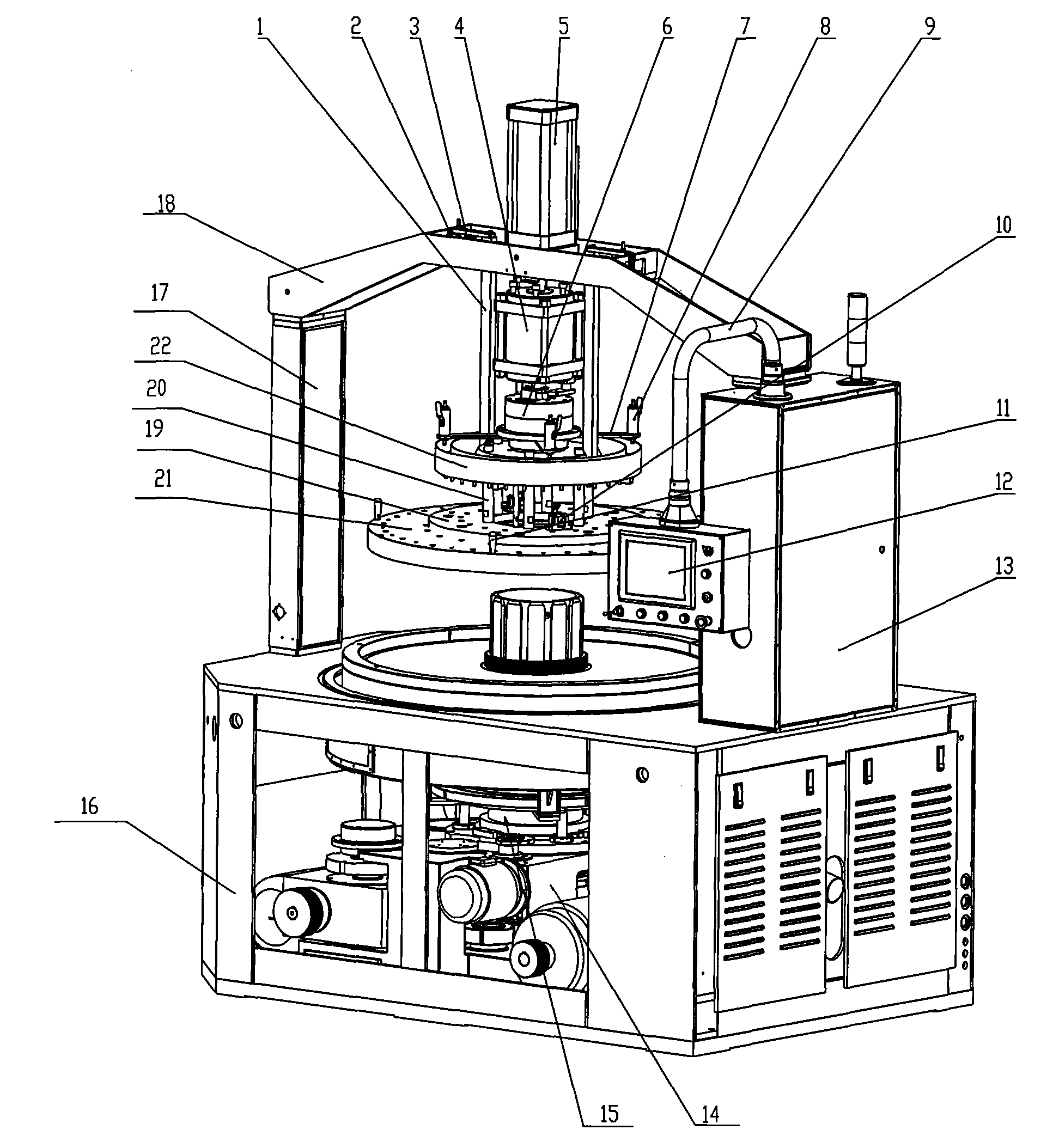

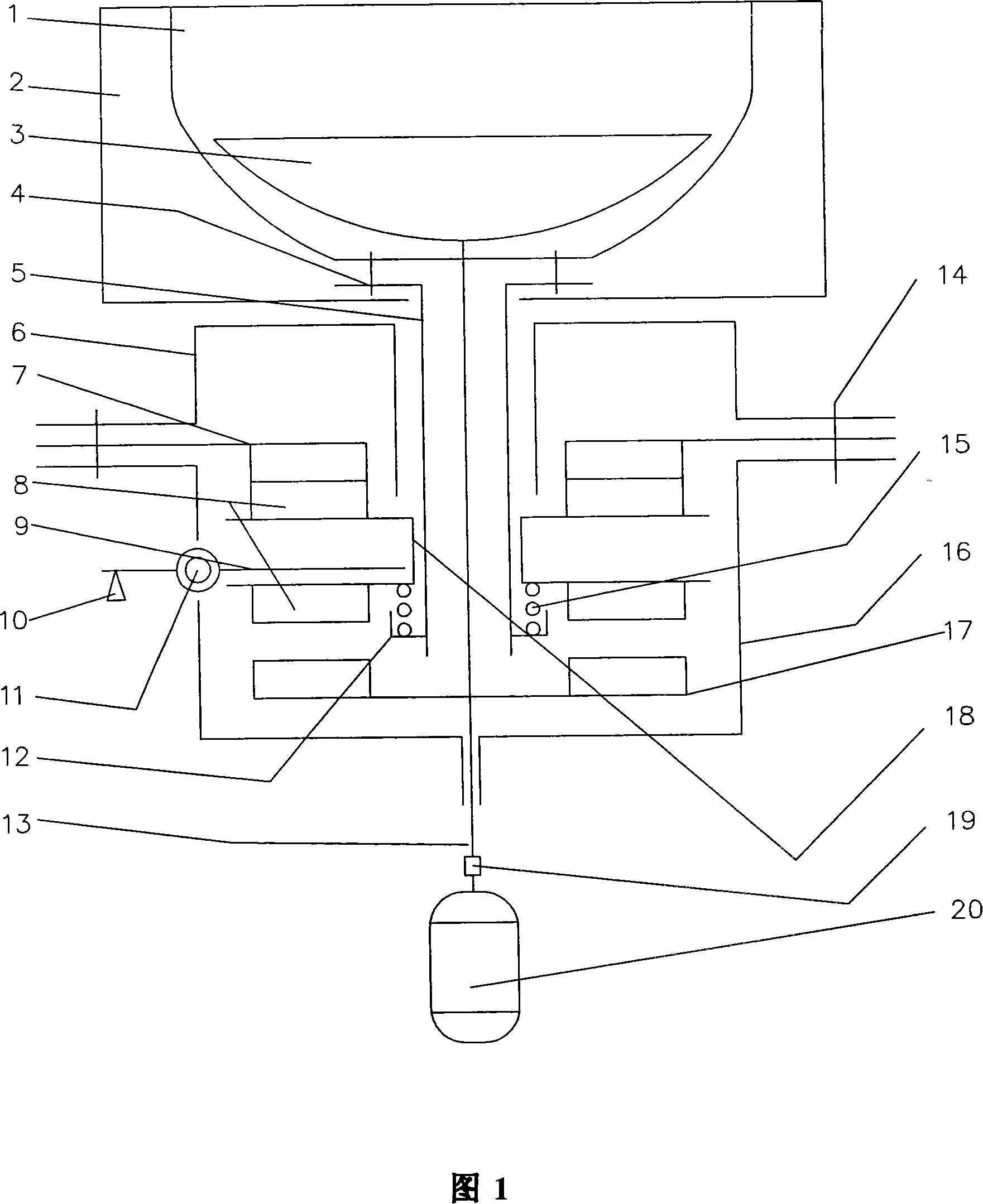

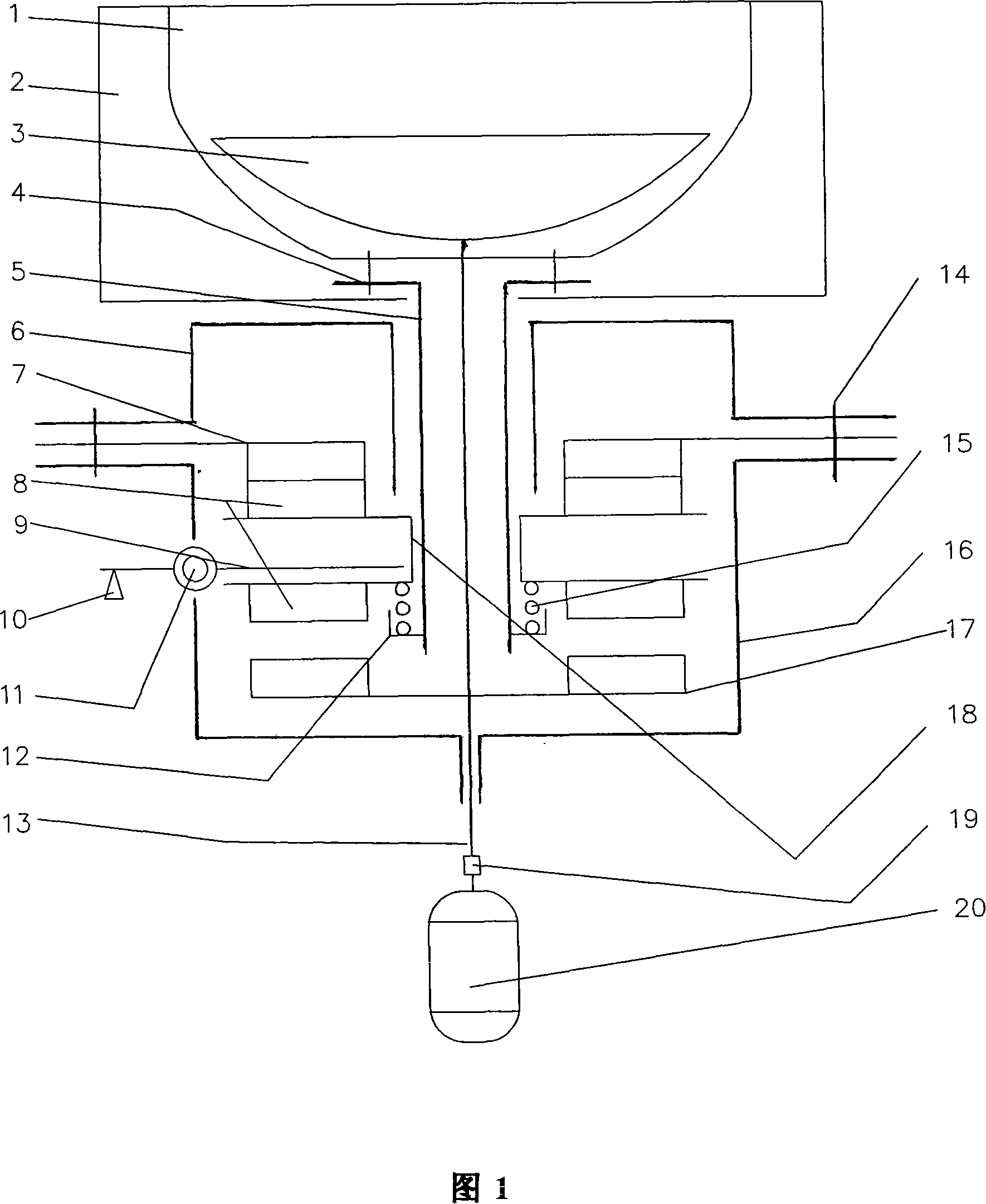

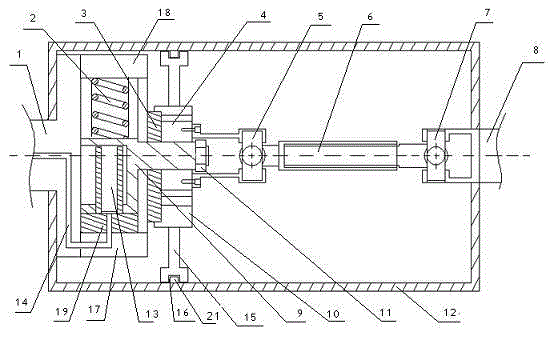

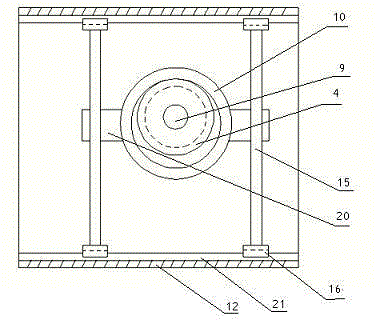

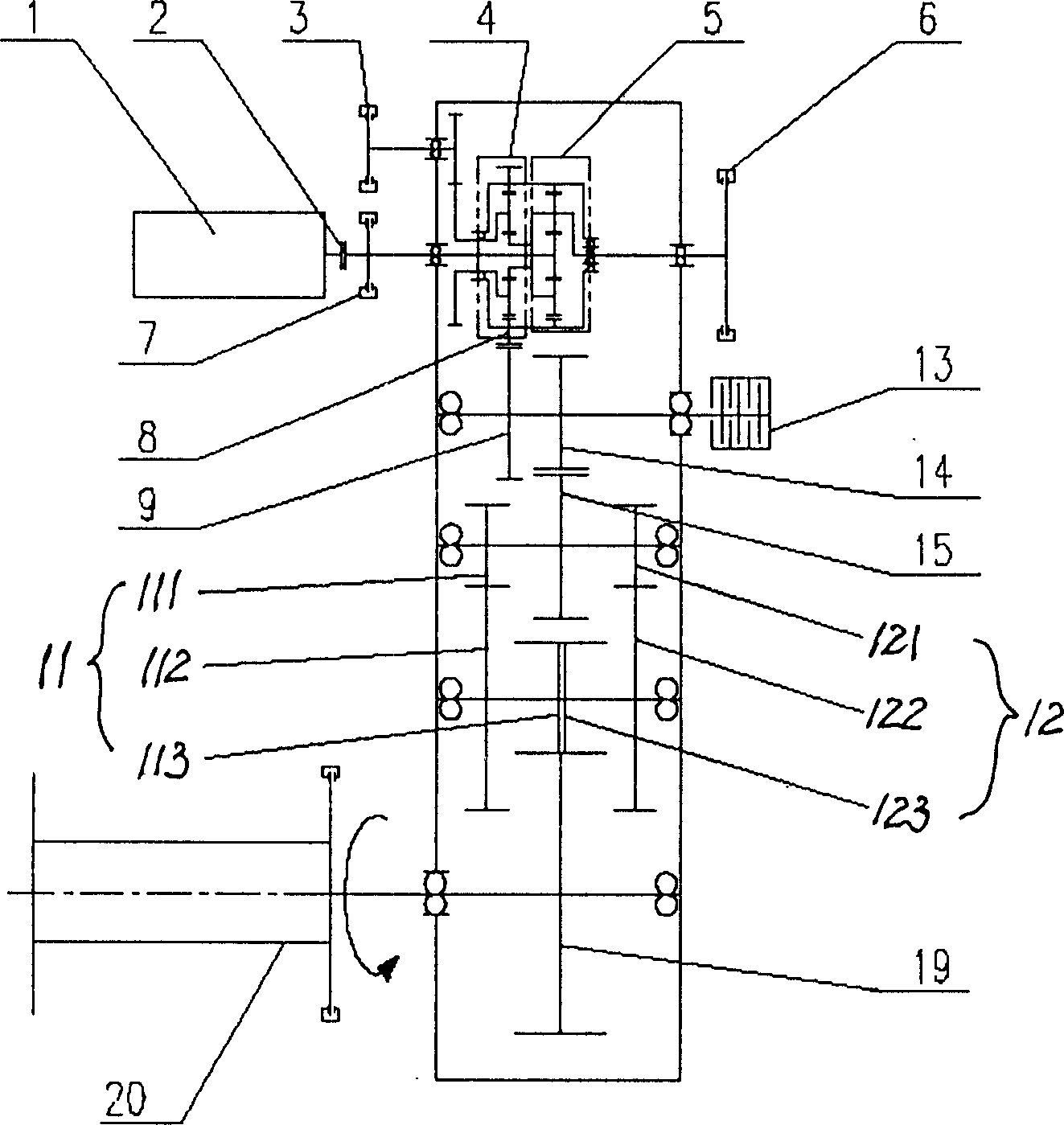

Numerically-controlled precise grinding polisher

InactiveCN101596693AFlexible editingFlexible planning of processing technologyPlane surface grinding machinesMotor driveEngineering

The invention relates to grinding processing equipment mainly used for a silicon wafer, a harddisk substrate, a master disc of a compact disc, a ceramic wafer, a quartz crystal and other hard and brittle materials, in particular to a numerically-controlled precise grinding polisher. The grinding processing equipment comprises a welding box body (16); a main supporting seat (14) of the welding box body is provided with a mainshaft drive system (15); a cylinder rod of a rapid acting cylinder (5) of an upper disc device is downward and fixedly arranged in the center of a crossbeam; the cylinder rod of the rapid acting cylinder (5) is connected with a slow acting cylinder (4); the inside of an operating box (12) is provided with a flat computer of an upper machine for controlling motion; and the inside of an electric appliance cabinet (13) is provided with an industrial controller for controlling motion and a motor drive mechanism. The grinding processing equipment has wide speed regulation range, higher moving precision, rapider response speed and strong antijamming capacity, can be better suitable for the requirements of different grinding materials and grinding processes and realizes soft startup, soft shutdown, stable speed regulation and small impact.

Owner:LANZHOU RAPID INDGRPCO

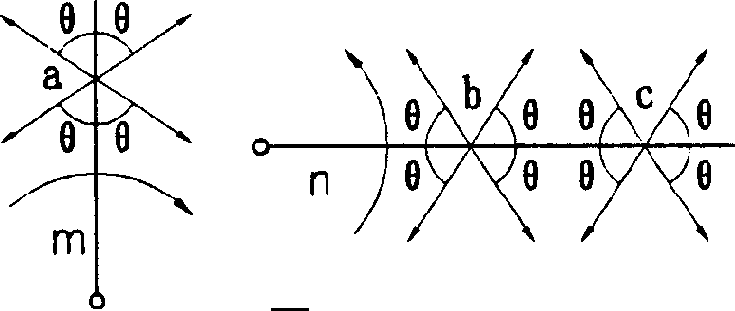

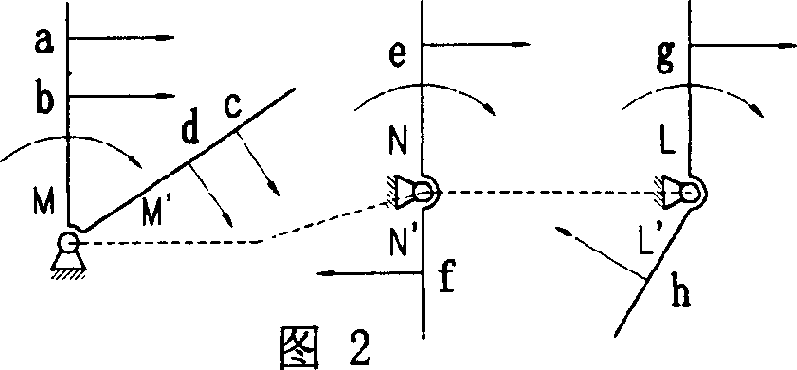

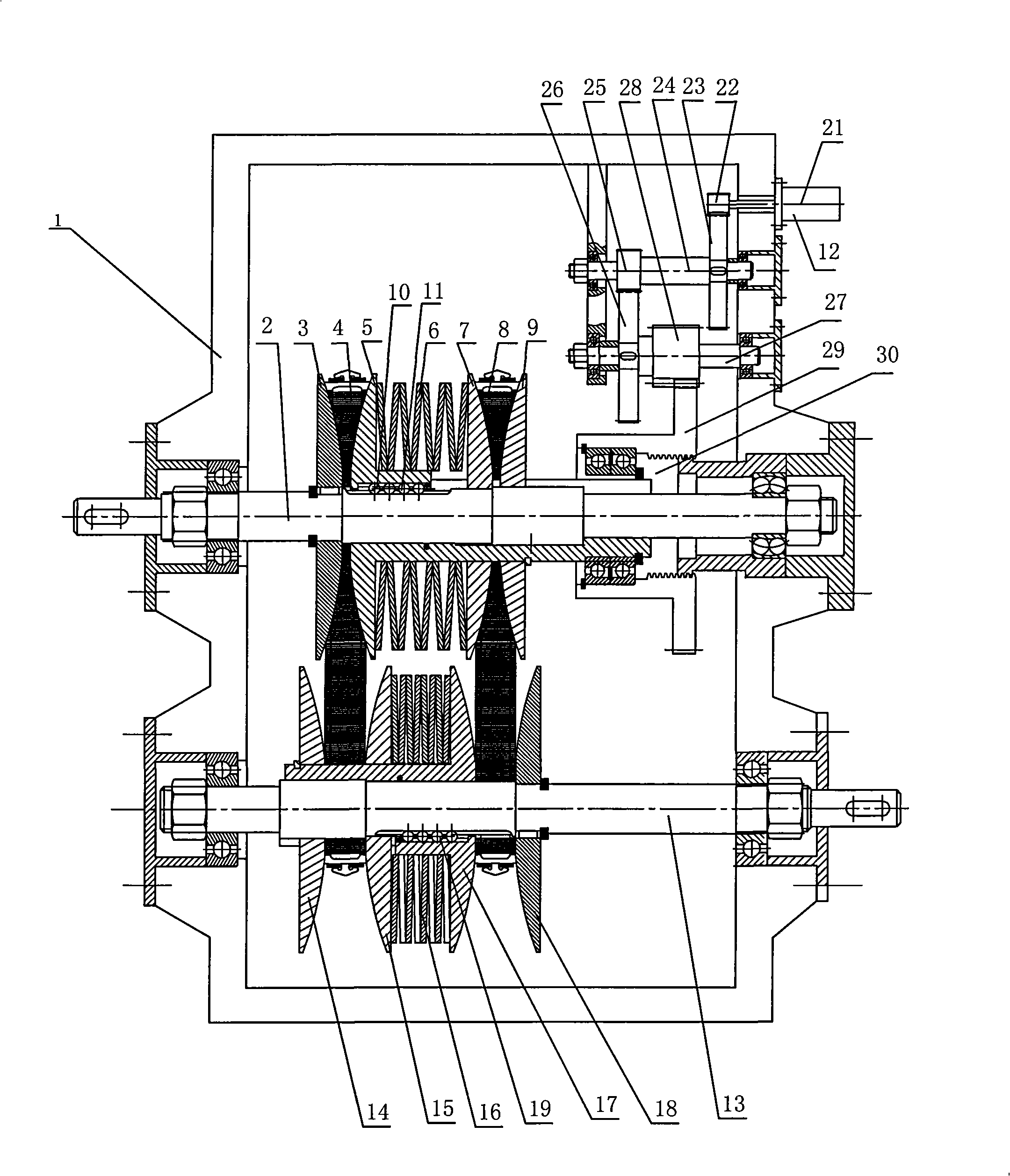

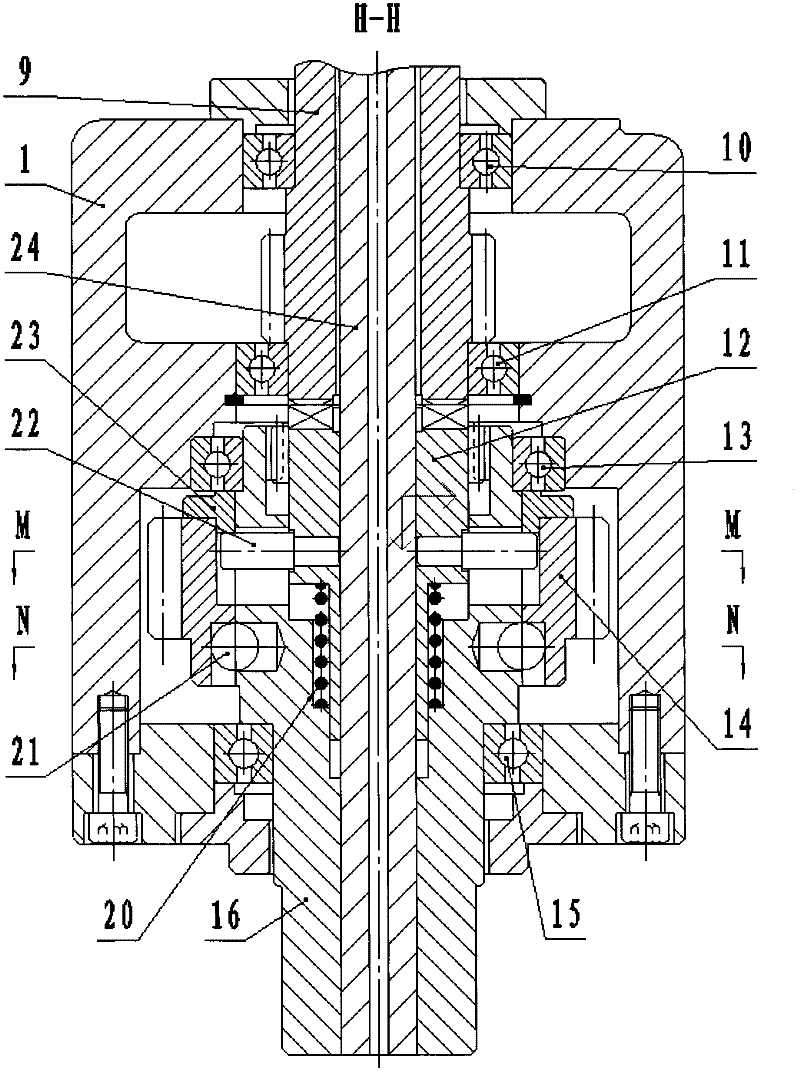

Mechanical stepless speed gear with equal angular speed and shape-position and high gear ratio

A constant angular speed and synchro-positioning mechanical stepless gear with low paired and high gearing ratio is designed as infinitely gear with equally regular characteristics on theories of constant angular speed and synchro-positioning movement and constant angular speed and iso-directional and reversal speed regulation so as to dissolve the vital problem of traditional impulsive stepless gear. No weakness in the whole driving chain has equal bearing capacity and high load and shock resistance. The spatial structural series is flexible and can have driving shaft in all the directions. Its advantages include reasonable structure, easy operation, accurate and stability, and economical efficiency. Its main gearing system works at low-paired transmission, with high loading ability and outputs torque at low speed.

Owner:王国斌

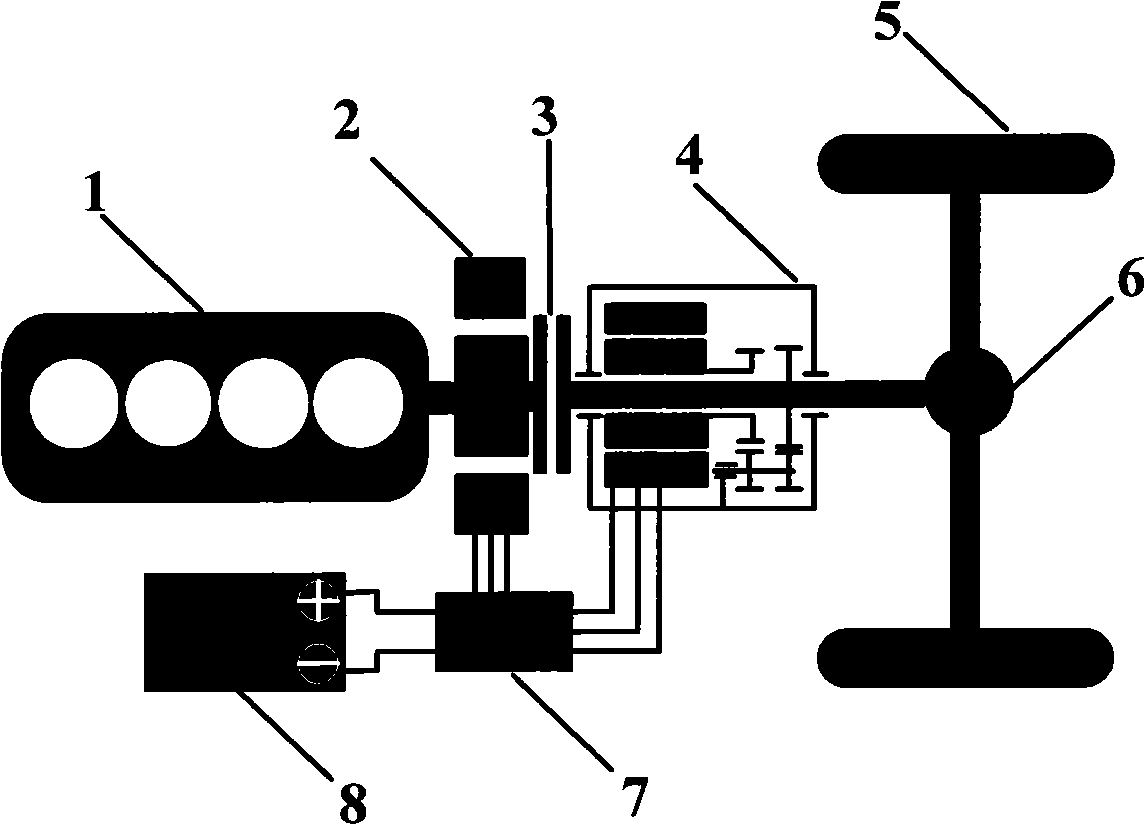

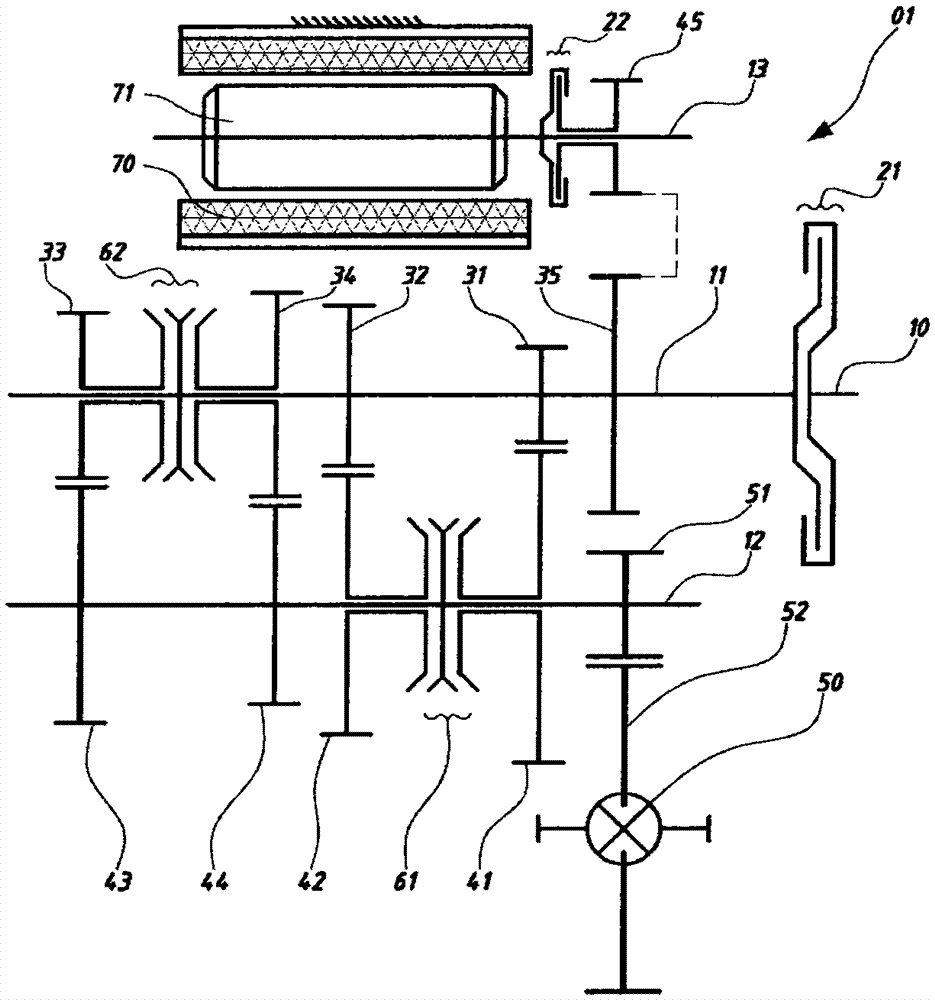

Motor coach hybrid power driving system

InactiveCN101327728ALow powerSeries hybrids haveGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingStarter generatorLow speed

The present invention discloses a hybrid power drive system of motor coach, and belongs to the technological field of vehicle engineering; wherein, an engine is coaxially connected with an integrated starting generator; the integrated starting generator is connected with an automatic clutch driving disc; the automatic clutch is connected with a reducing mechanism through a driving motor; the reducing mechanism is respectively connected with the driving motor and a main reducer-differential; the main reducer-differential is connected with vehicle wheels through a driving bridge; a power battery is connected with a motor controller through a cable; and the motor controller is respectively connected with the integrated starting generator and the driving motor through a cable. The hybrid power drive system maintains the traditional vehicle structure to the greatest extent, and adopts two motors to optimize the working points of the engine, so that the engine can stably operate in the high-efficiency and low-emission regions, in particular in the operating conditions of low-speed city buses.

Owner:SHANGHAI JIAO TONG UNIV

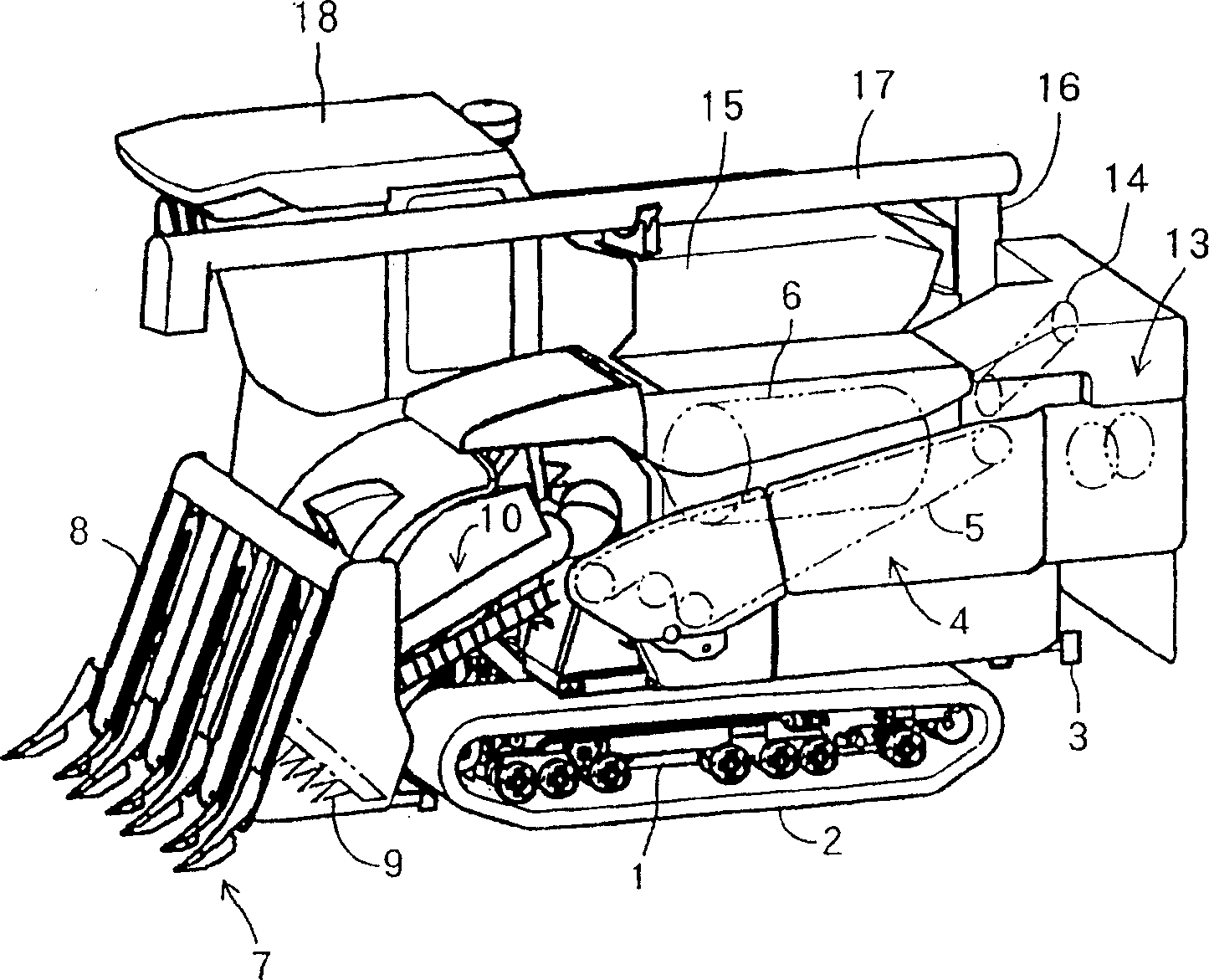

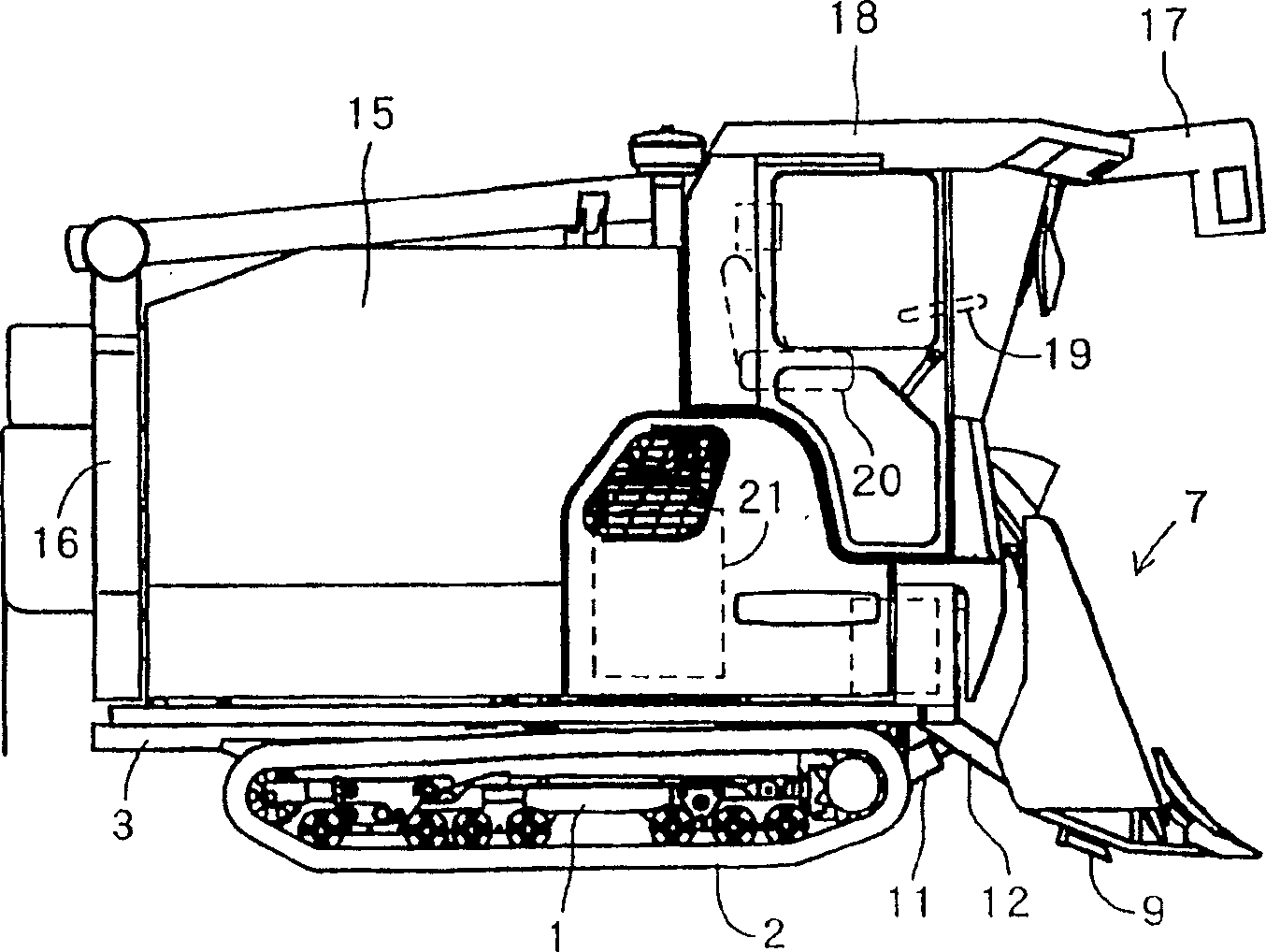

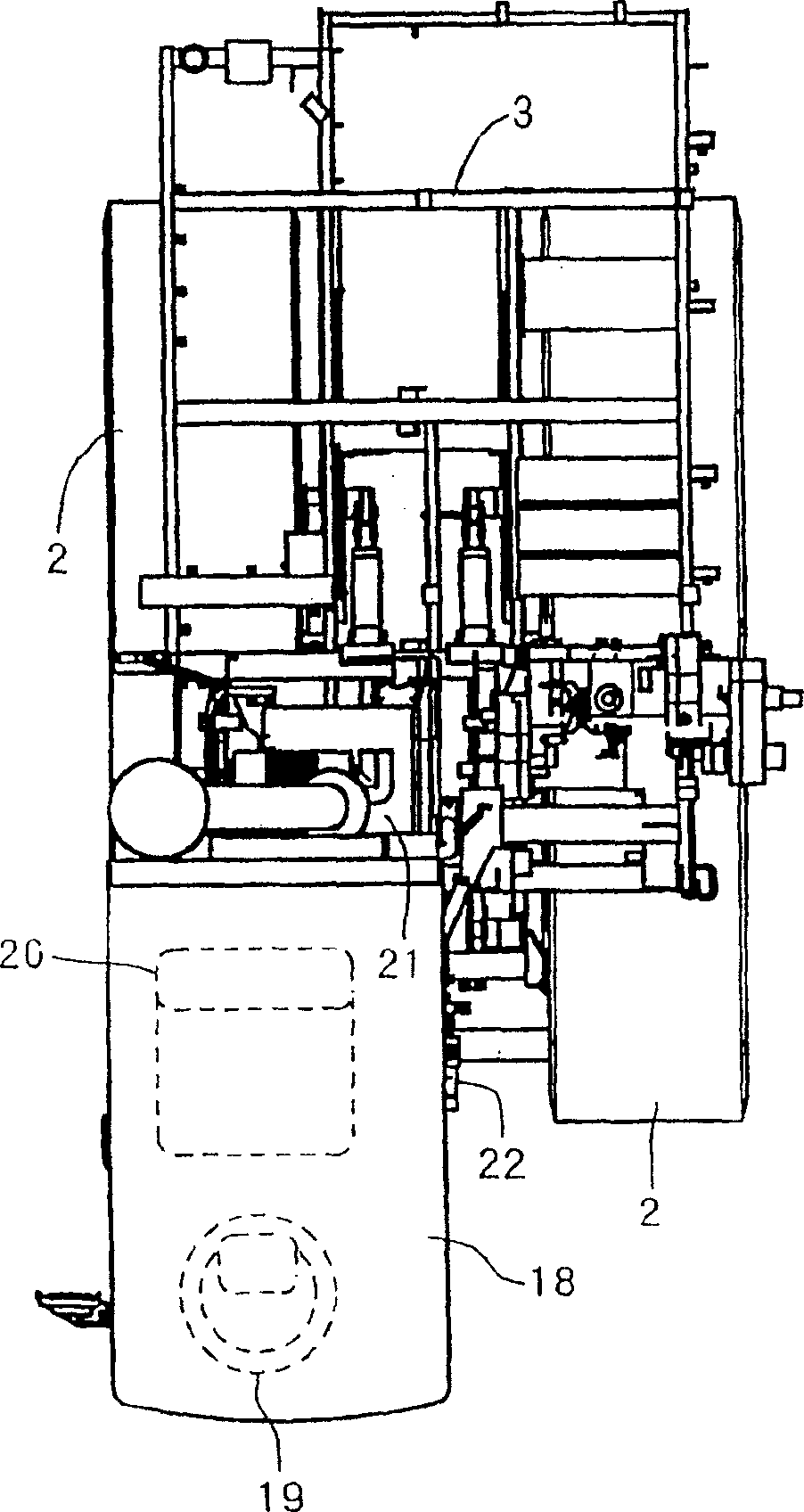

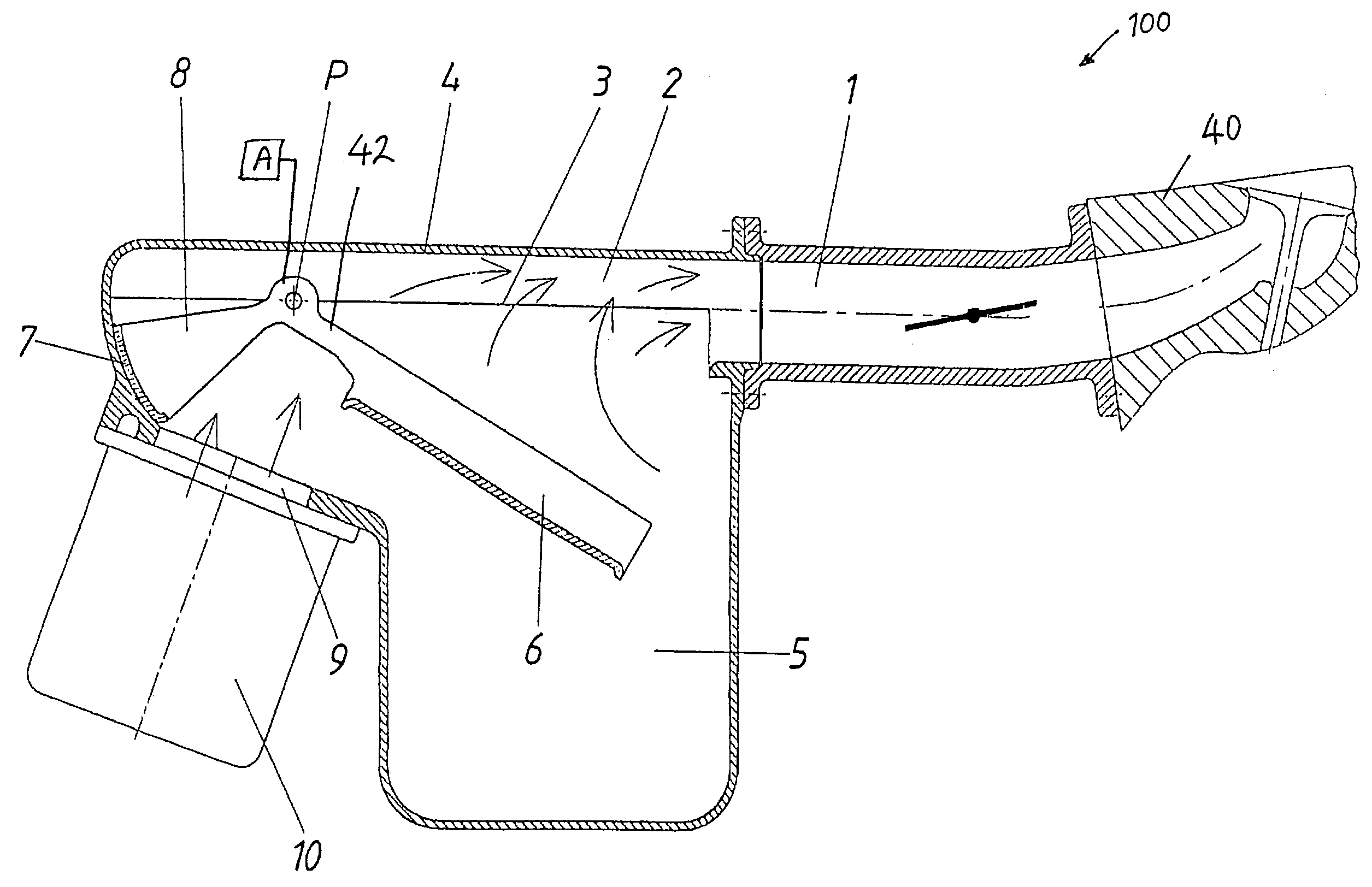

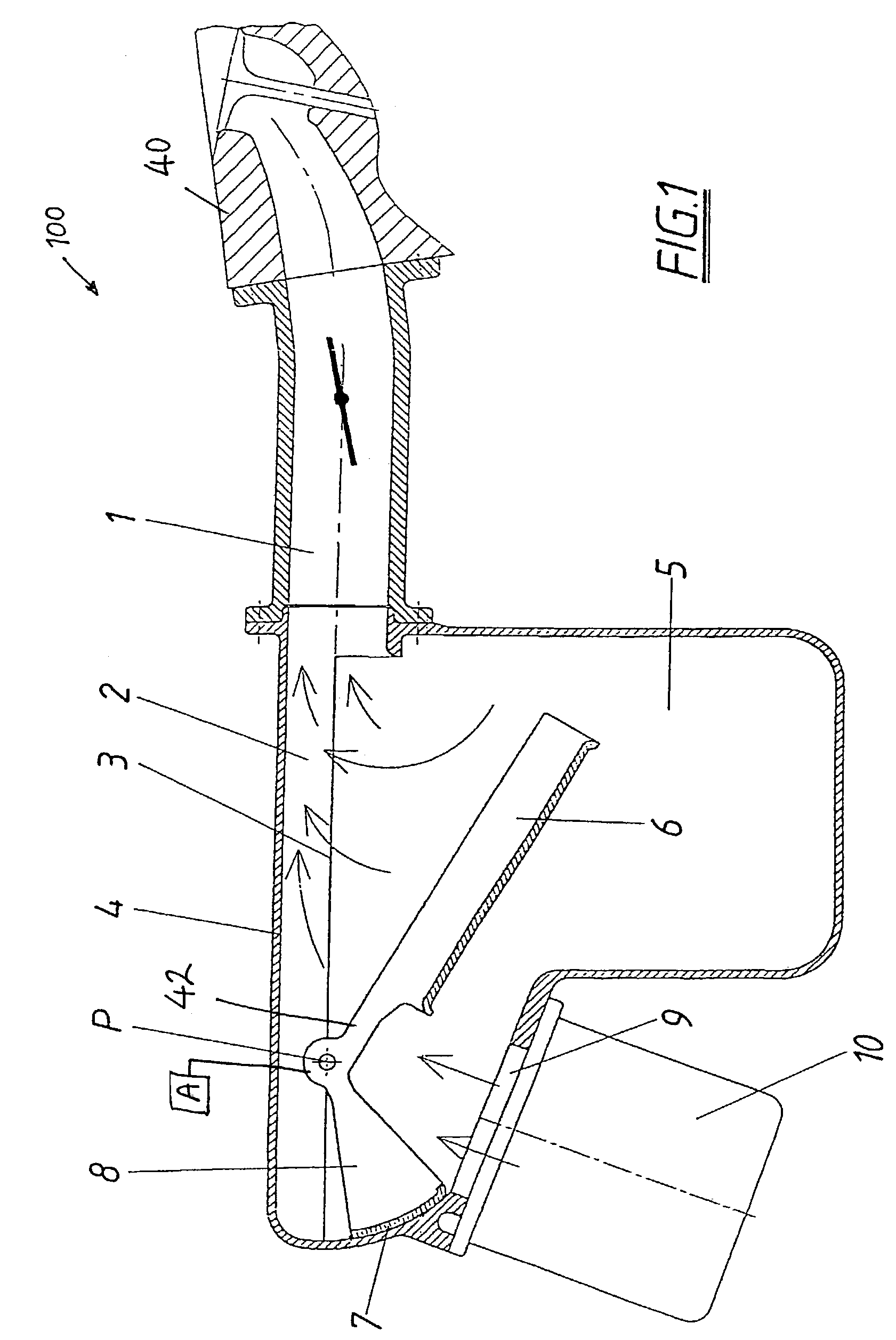

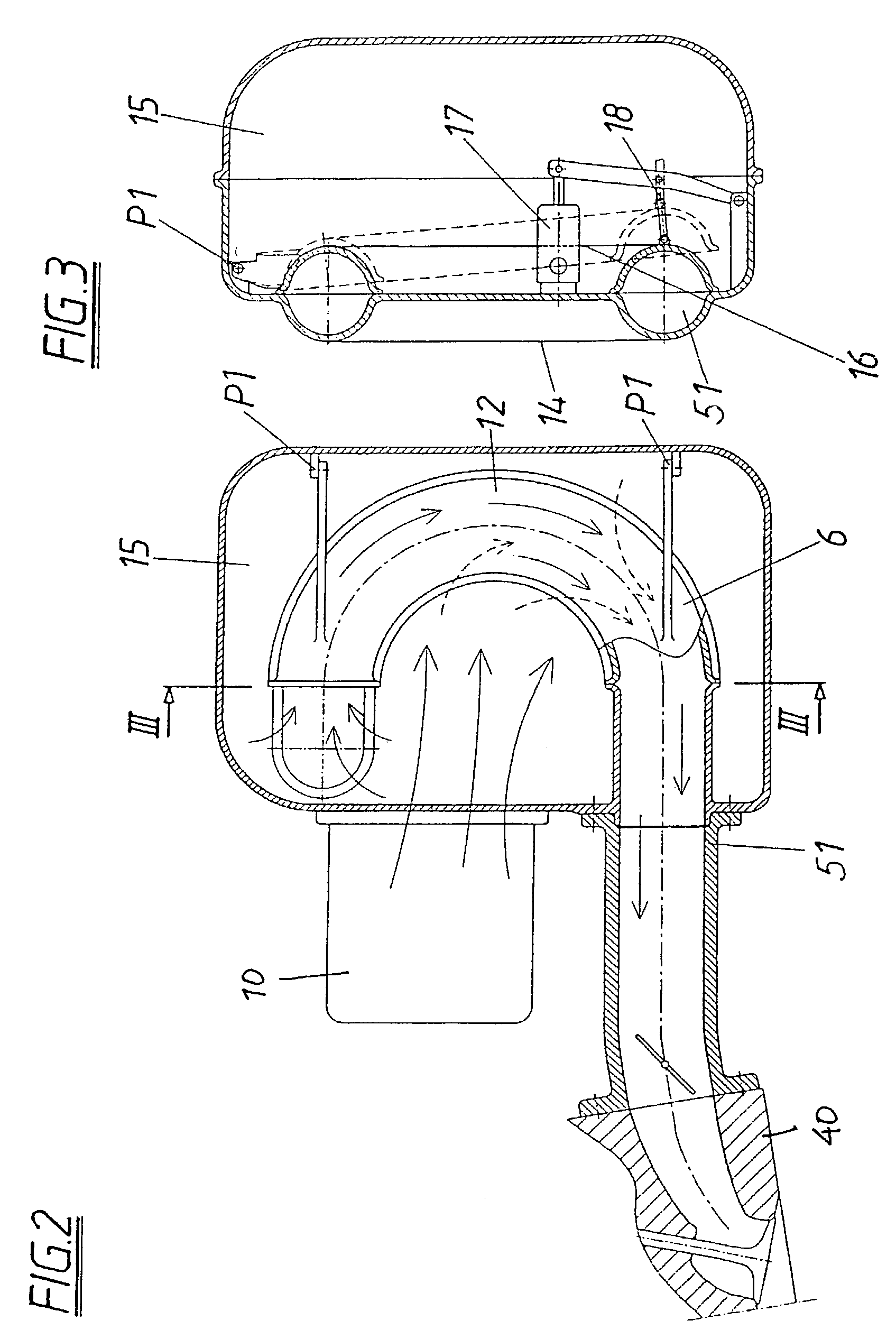

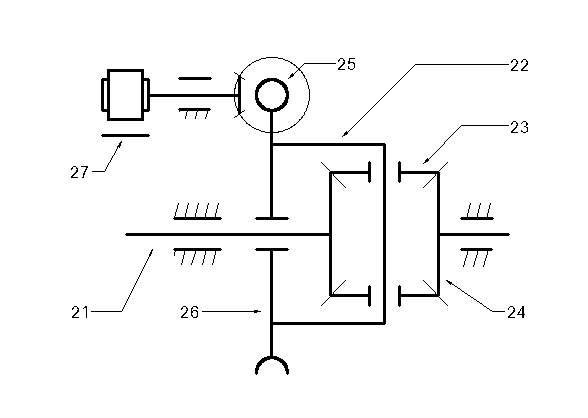

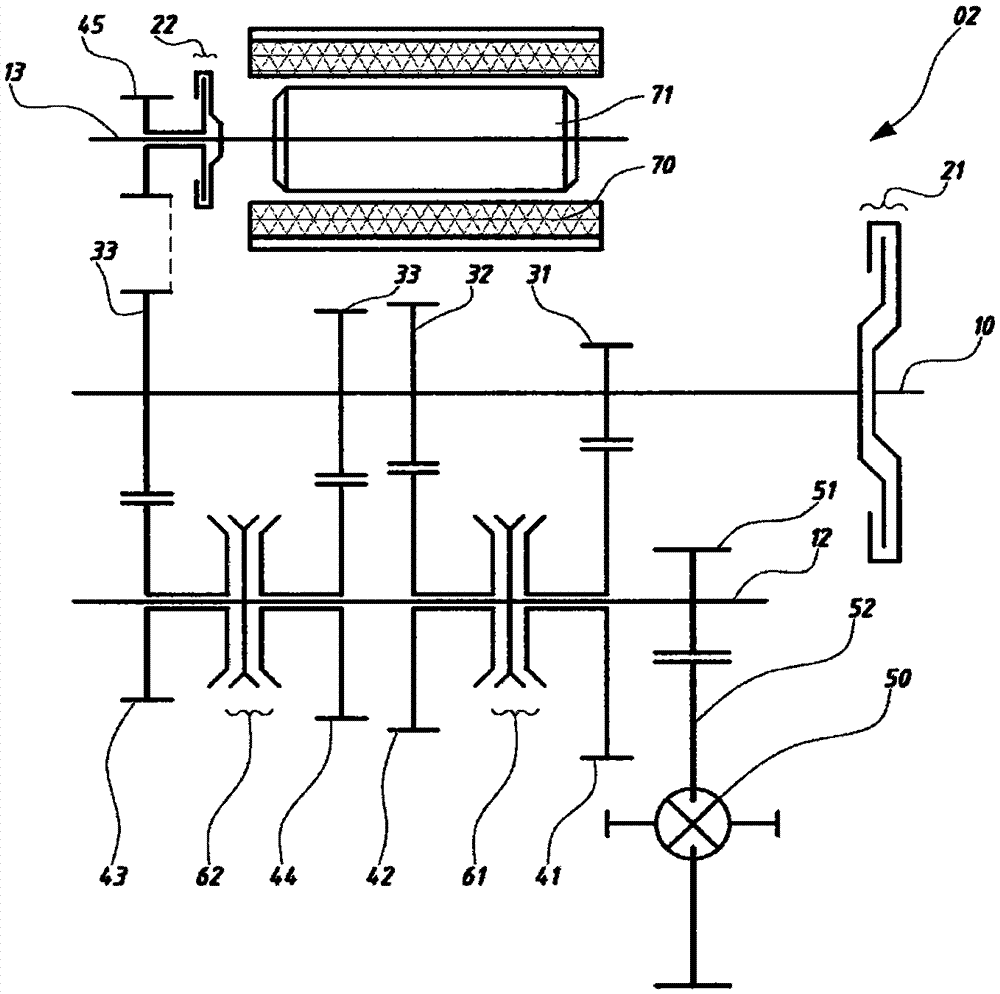

Combine

InactiveCN1668184AReduced power transmission efficiencyReduce drive speedMowersGearing controlEngineeringTransmission loss

A combine for driving a traveling section (2) by transmitting the power of an engine (21) to a transmission case (22) provided with a traveling speed change mechanism (40), characterized in that the power of the engine (21) is transmitted to a counter case (25) in order to drive a threshing section (4) by a substantially constant rotational output and the speed change output from the traveling speed change mechanism (40) is transmitted to the counter case (25) in order to drive a reaping section (7) at a speed synchronous with the vehicle speed, and the counter case (25) is arranged such that the reaping section (7) is driven at a substantially constant speed by a substantially constant rotational output from the counter case (25). The counter case (25) for driving the threshing section (4) at a constant speed can also drive the reaping section (7) at a speed synchronous with the vehicle speed or at a substantially constant speed, and the reaping section (7) can be driven at a constant speed utilizing a part of the driving system of the threshing section (4), resulting in simplification of driving structure of the reaping section (7), or the like and reduction of transmission loss.

Owner:YANMAR CO LTD

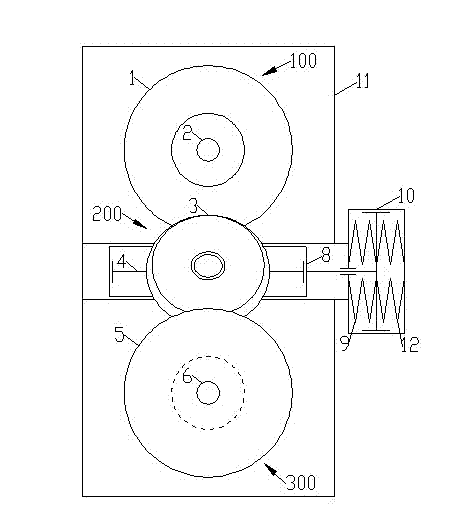

Bimetallic strip stepless variable drive

InactiveCN101328961ASimple structureRealize speed regulationGearingGearing controlAxial pressureDrive shaft

The invention discloses a double metal strap stepless speed change device, comprising a drive shaft and a driven shaft, wherein, a drive shaft is provided with a left drive fixed conical disk, a left drive movable conical disk, a right drive fixed conical disk, a right drive movable disk and a right metal strap; a driven shaft is movably provided with a left driven movable conical disk, a left driven fixed conical disk, a right driven movable conical disk and a right driven fixed conical disk. The invention is characterized in that: a counter balance spring is arranged between the left drive movable conical disk and the right drive fixed conical disk; the left drive movable conical disk is connected with a first sleeve which is connected with the right drive movable conical disk through the right drive fixed conical disk; a pressure spring is arranged between the left driven fixed conical disk and the right driven movable conical disk; and the left driven movable conical disk is connected with a second sleeve which is connected with the right driven movable conical disk through the left driven fixed conical disk. A structure can be greatly simplified by adopting the sleeves to be connected with two movable conical disks which are coaxial; a compression speed regulating system adopts mechanical pressurization and designs an axial pressure-balanced device with compact and efficient structure, thereby speed regulation by a miniature motor can be realized. The device has the advantages of simple structure, small volume, large speed change range and simple control.

Owner:重庆工学院

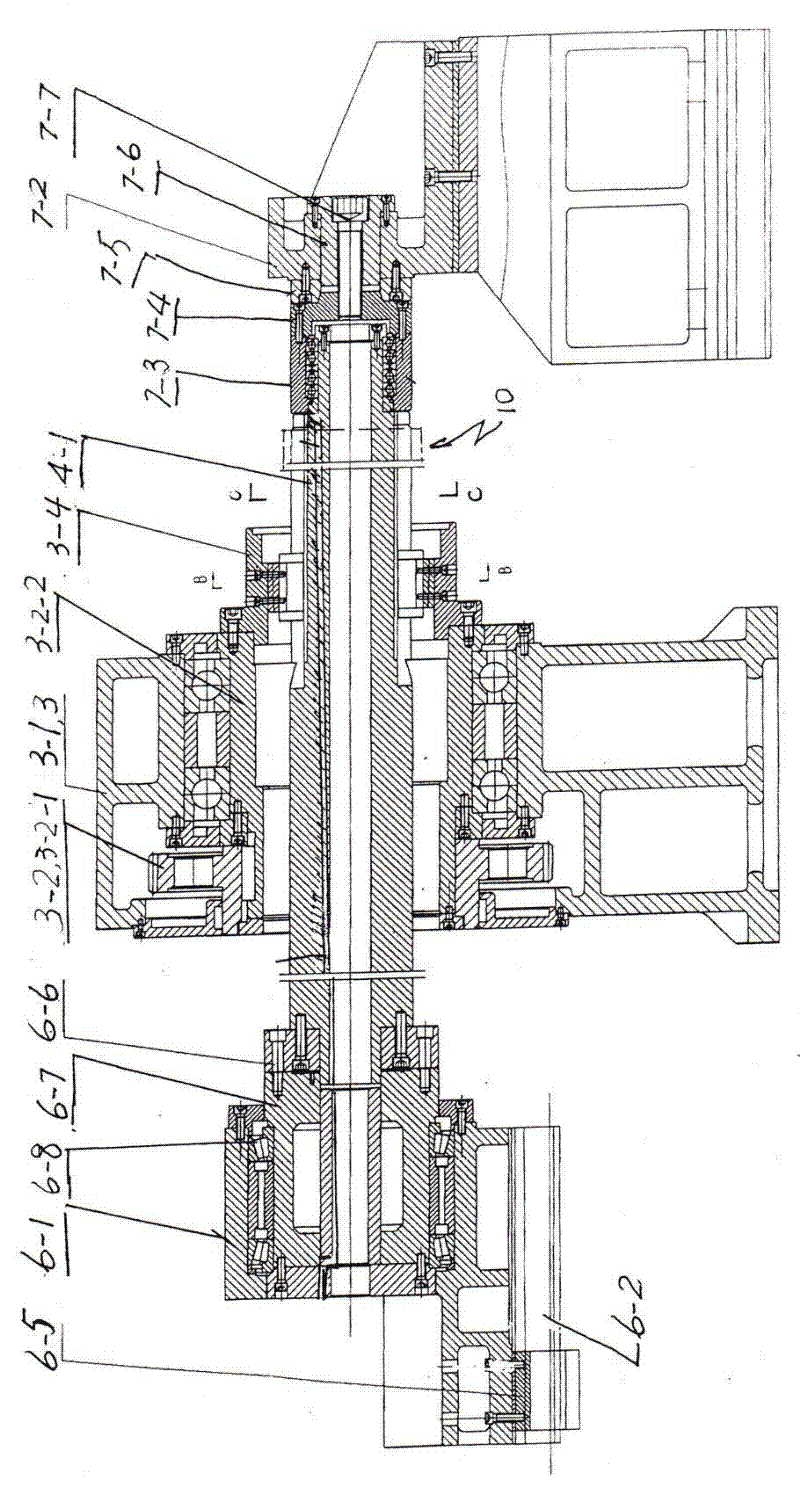

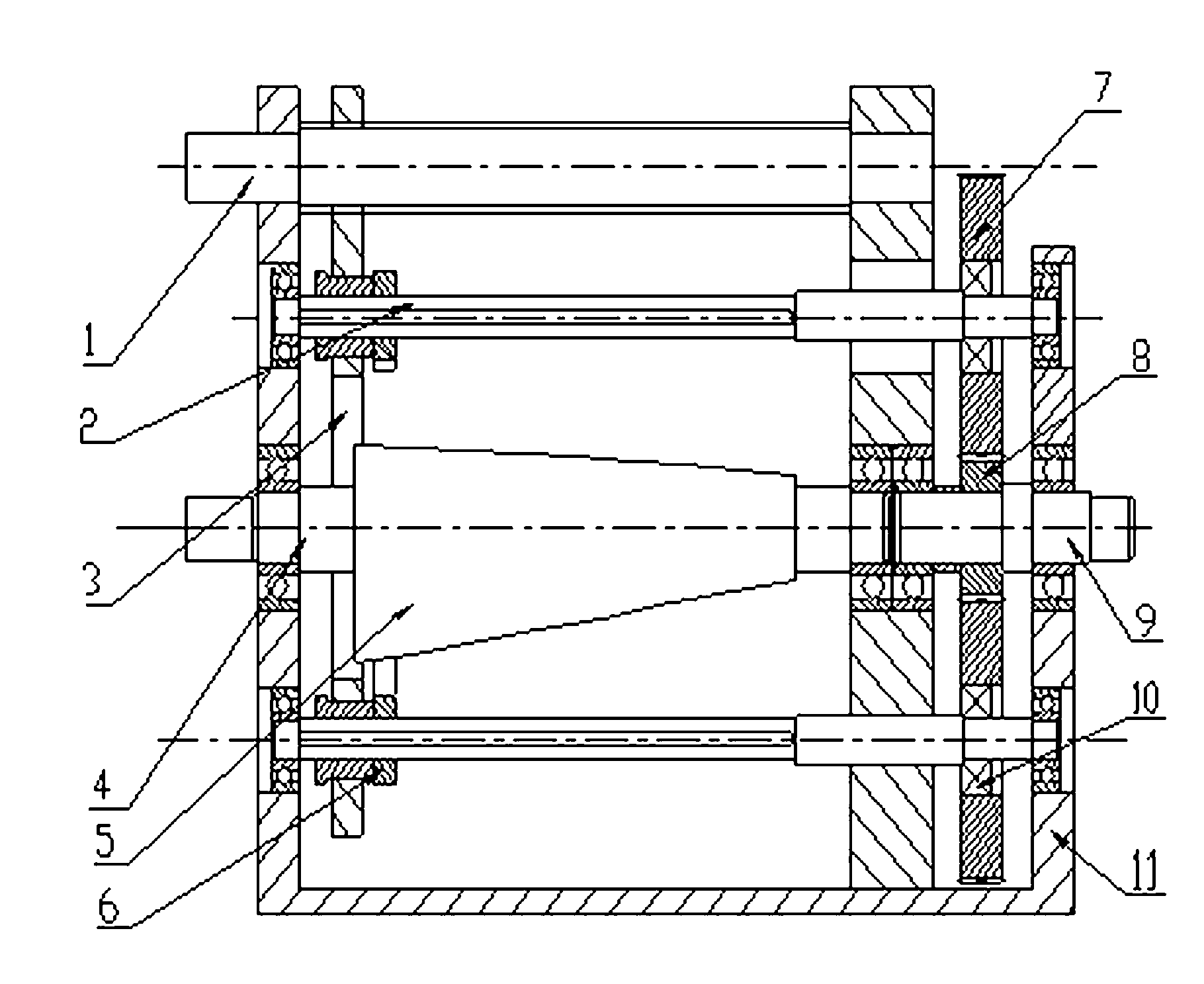

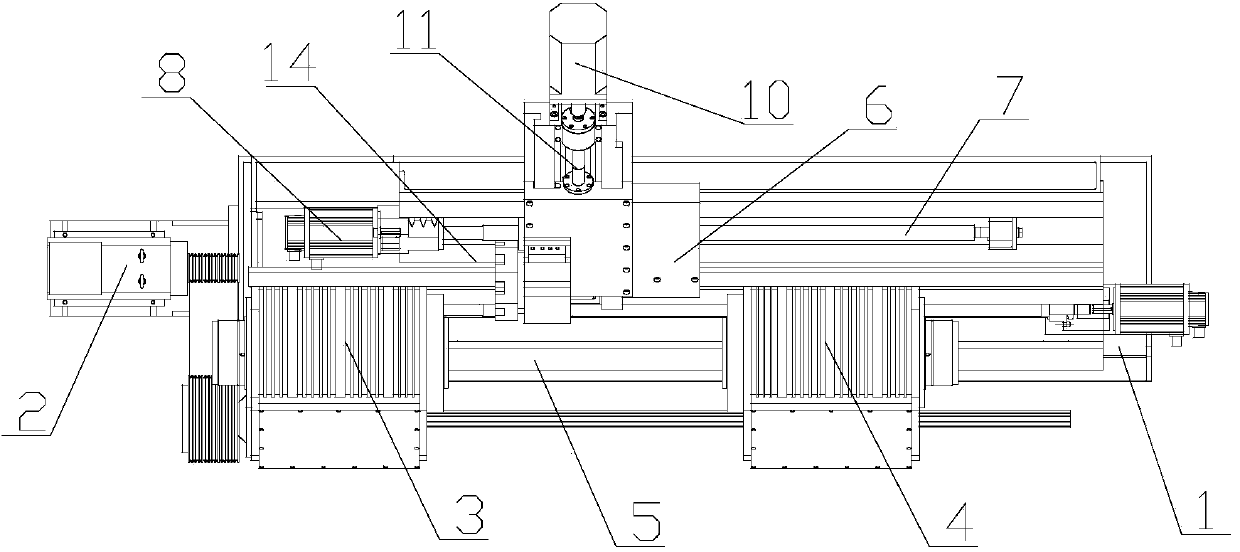

Workpiece inner hole processing equipment

InactiveCN102284719ALarge shifting rangeSolve the machining accuracyBoring barsPositioning apparatusSet screwGear wheel

The invention discloses workpiece inner hole processing equipment. The workpiece inner hole processing equipment is mainly characterized in that: a workpiece supporting component is flexibly clamped and fastened; a main transmission box adopts multi-stage gear pair transmission controlled by a numerical controller and driven by a first speed-changing motor; a boring cutter combined device is thata boring cutter driving disk is matched with a boring bar double key groove pair and a boring cutter fixed block is slidingly matched with a boring cutter sliding block movement guide rail base; the boring cutter sliding block and the boring bar combined device are driven by a second speed-changing motor and a third speed-changing motor which are controlled by the numerical controller; and a boring bar front bracket and a boring bar are connected by one fastening screw axially. The workpiece inner hole processing equipment has the characteristics of advanced structure, simpleness and convenience for operation, high processing precision, high automation degree, high processing efficiency, multiple functions of turning, boring and grinding and the like.

Owner:CHANGZHOU BAOLING HEAVY IND MACHINERY

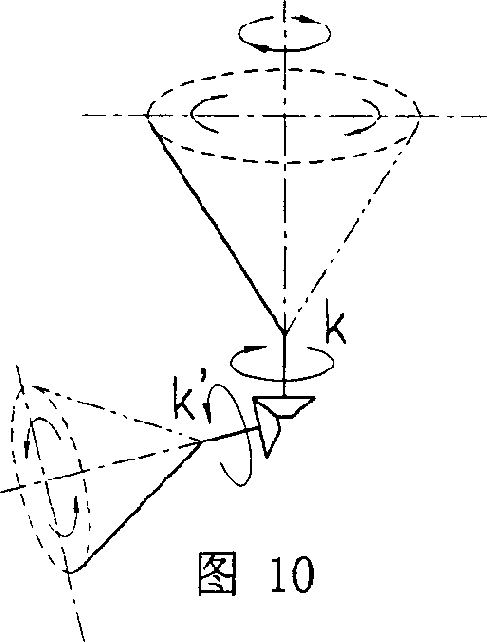

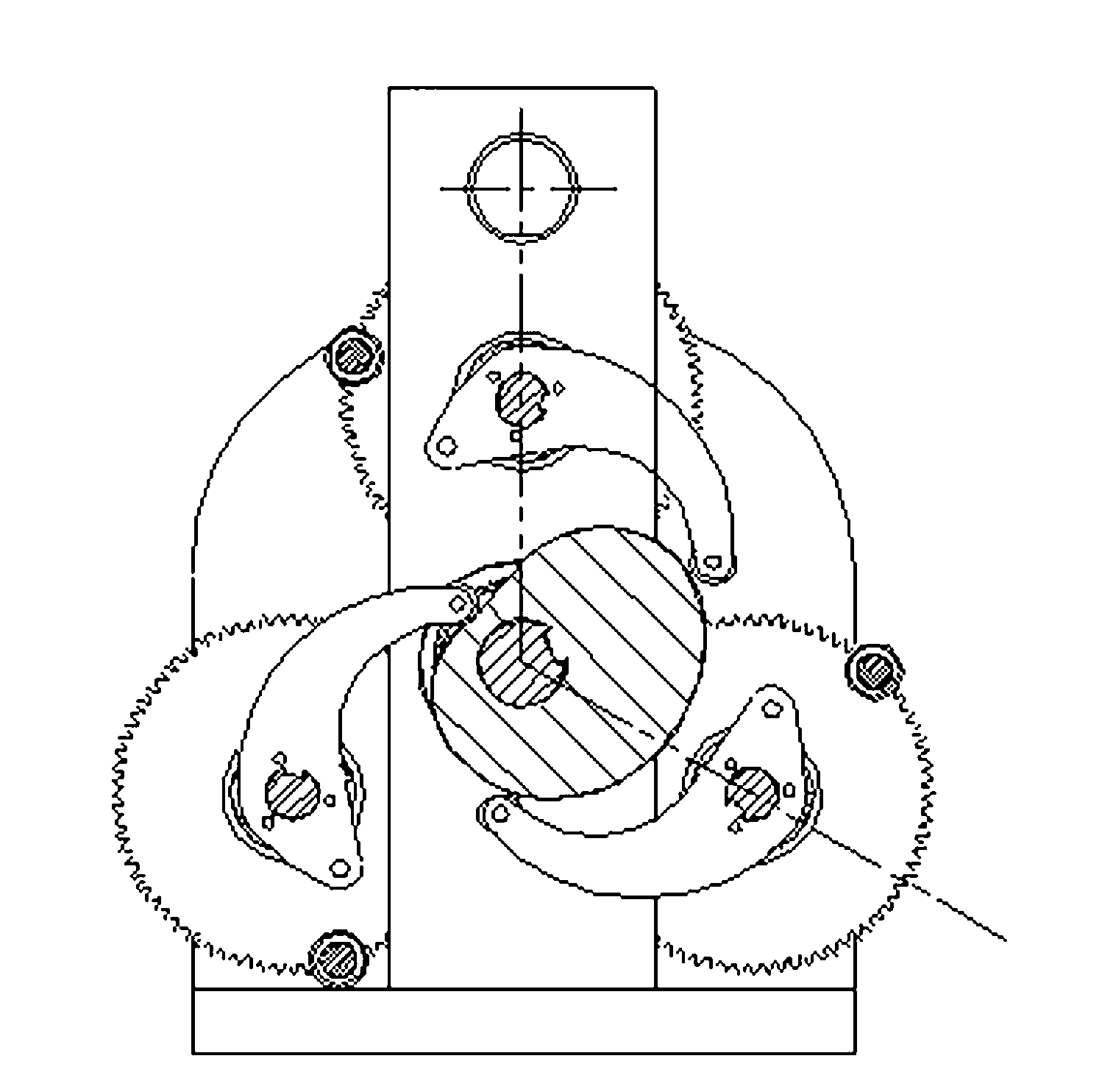

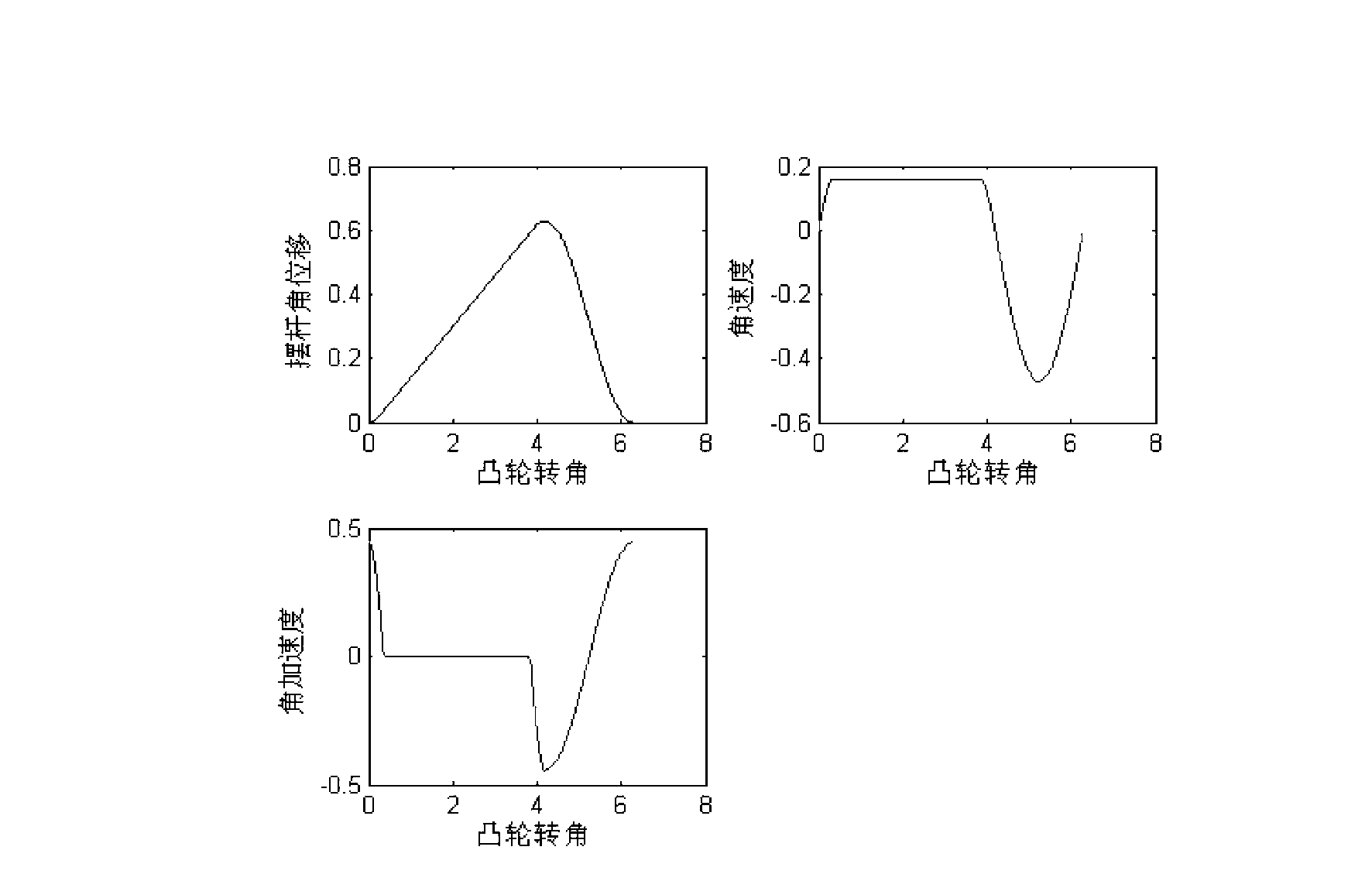

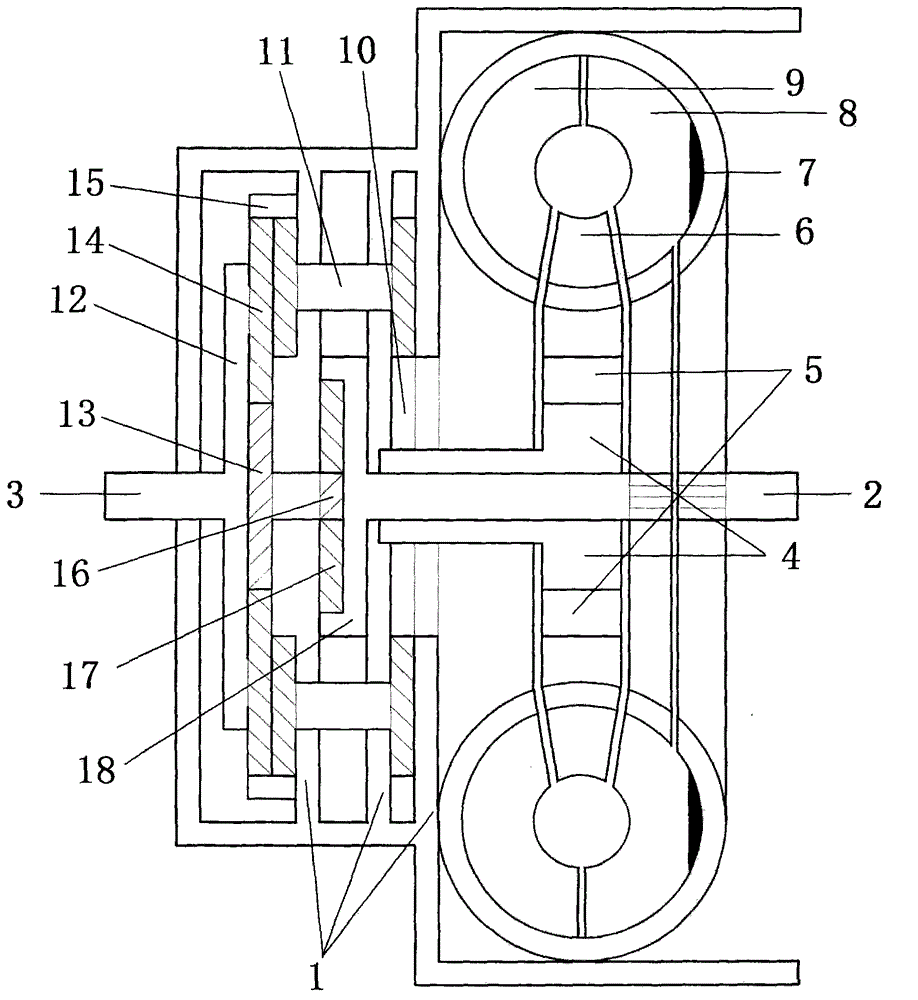

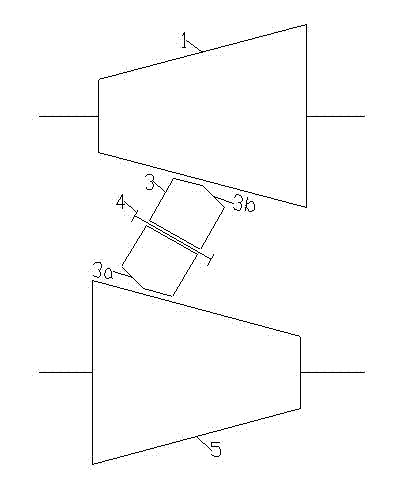

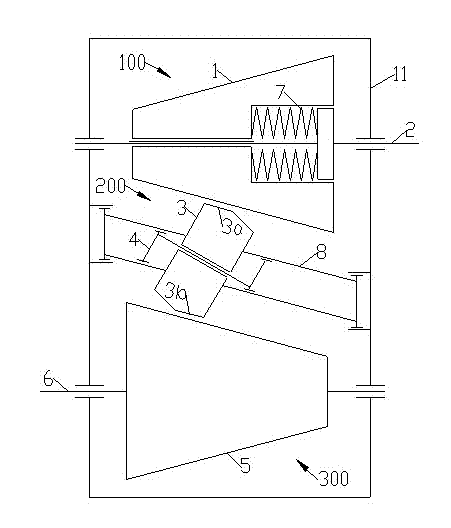

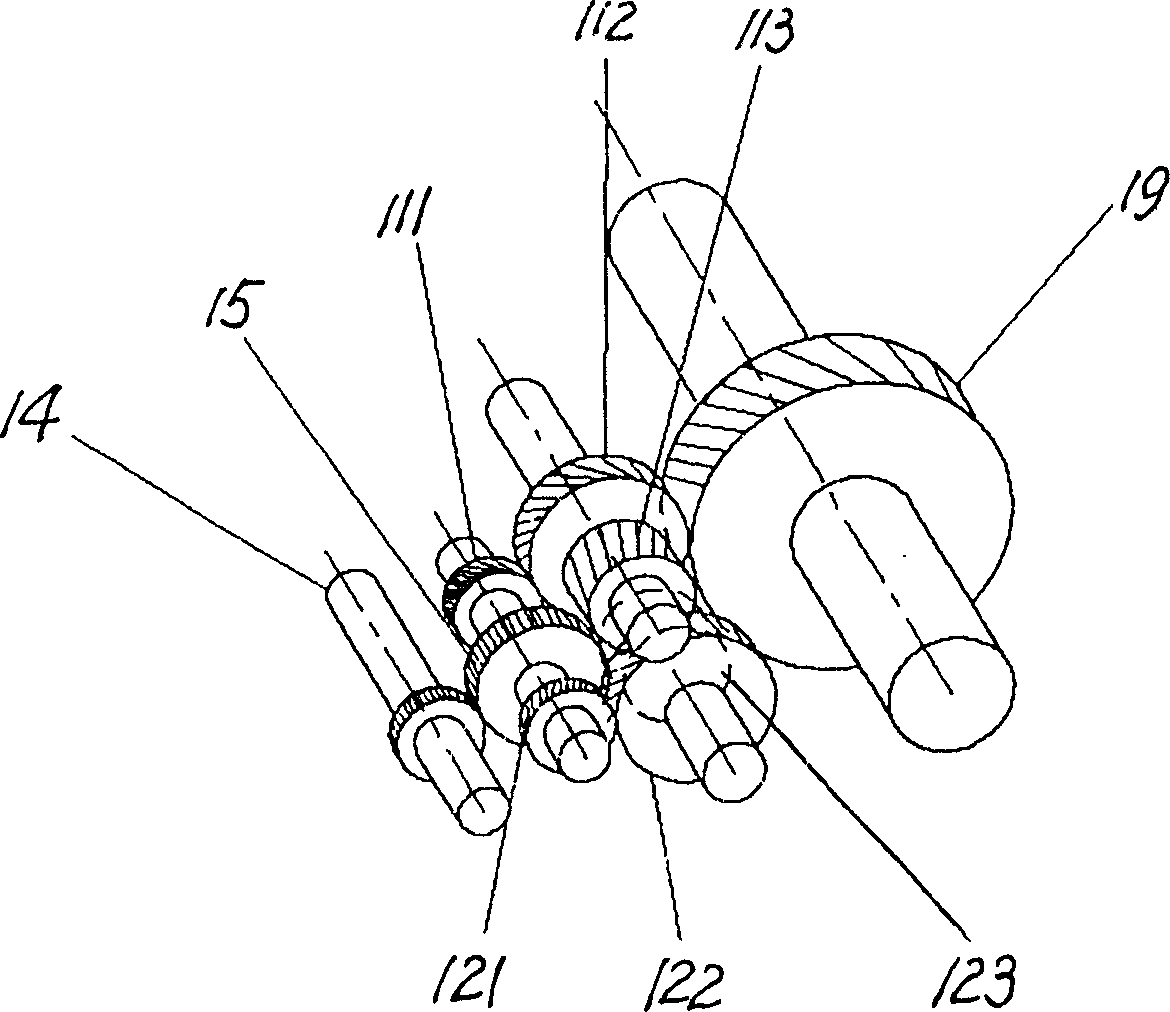

Spatial swing cam type stepless variable drive

The invention provides a spatial swing type stepless pulse transmission, and is characterized in that a main body structure is as follows: an input shaft and an output shaft are coaxially arranged on a frame, a space cam is fixed on the input shaft, the space cam is provided with the same base circle in an axial direction, a swing travel of the space cam is monotonously increased from zero to one side of the frame along an axial direction, and a section outline of the space cam is designed according to a rule that the rise travel movement is uniform movement; the outer edge of the space cam is sheathed with a sliding plate, a plurality of swing rods are uniformly distributed on the outer periphery of the sliding plate, one ends of the swing rods are butted to the space cam for pressing, the other ends of the swing rods are respectively connected with a rotating shaft, wherein the right side of the rotating shaft is connected with an inner ring of an overrunning clutch, an outer ring of the overrunning clutch is respectively connected with a gear, and each gear is engaged with a driven gear on the output shaft; and a speed regulating mechanism and the sliding plate are in transmission connection. According to the invention, the variable-speed drive at zero pulse degree is realized, and the spatial swing cam type stepless variable drive has the advantages of simple and compact structure and wide speed change range.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

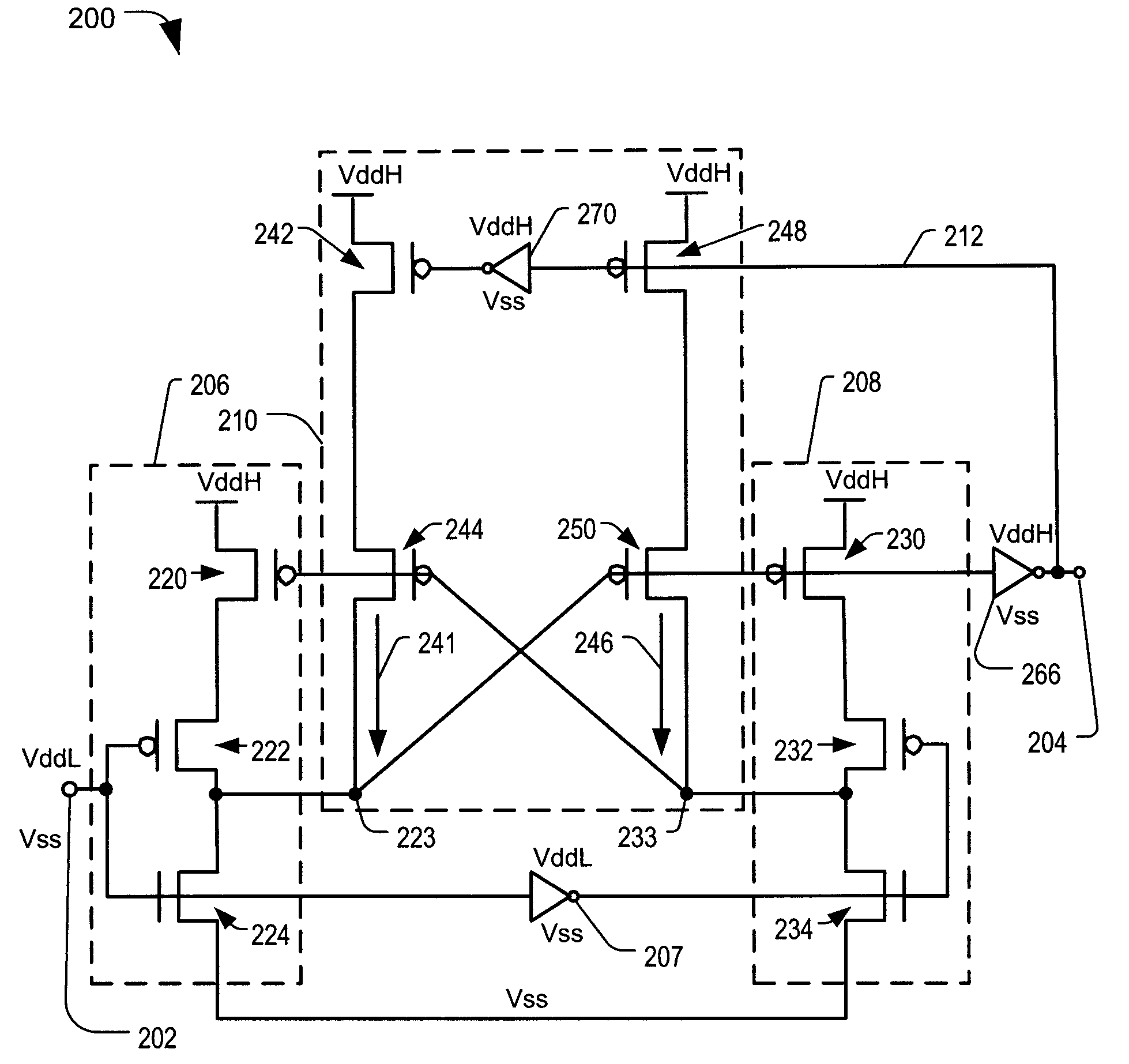

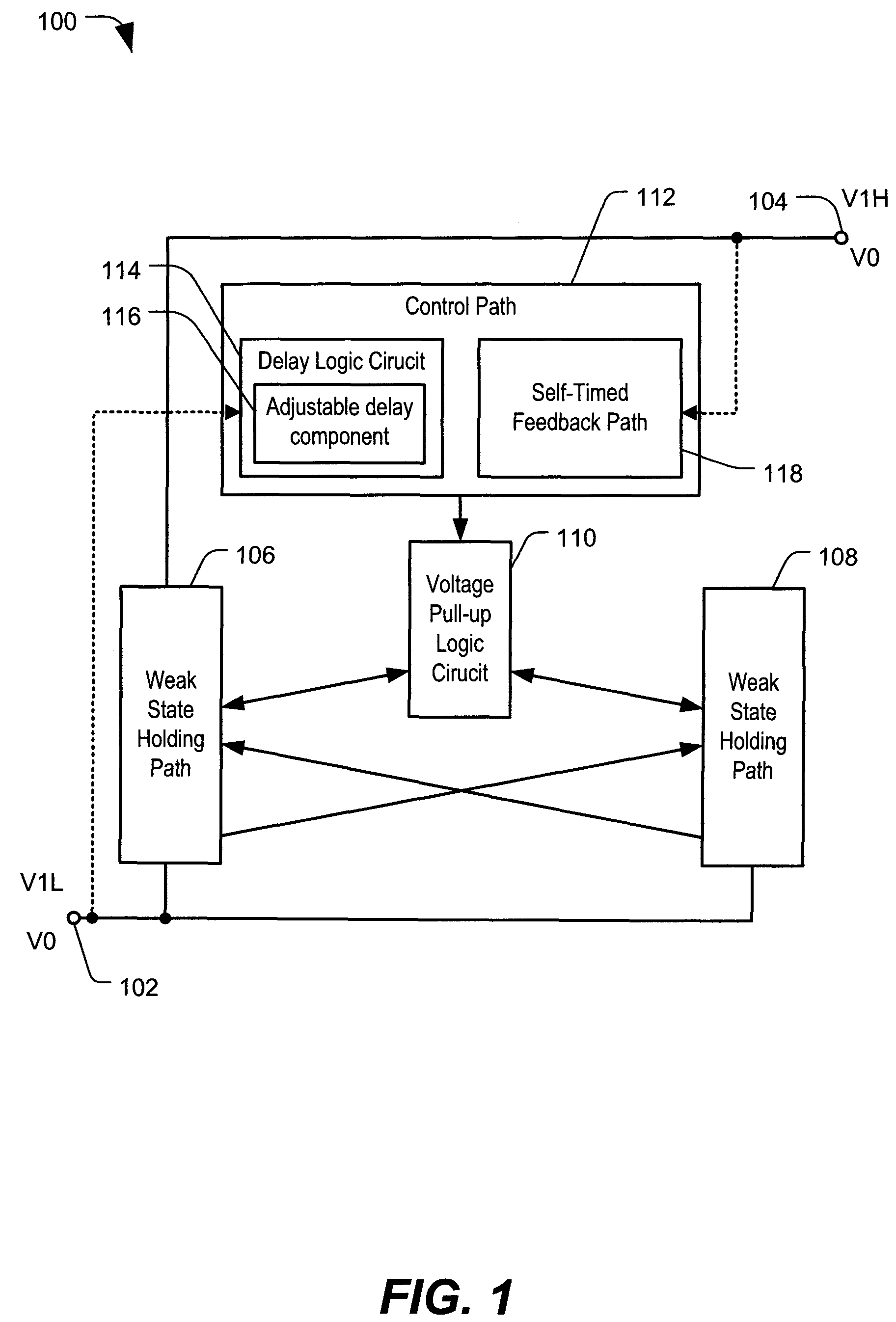

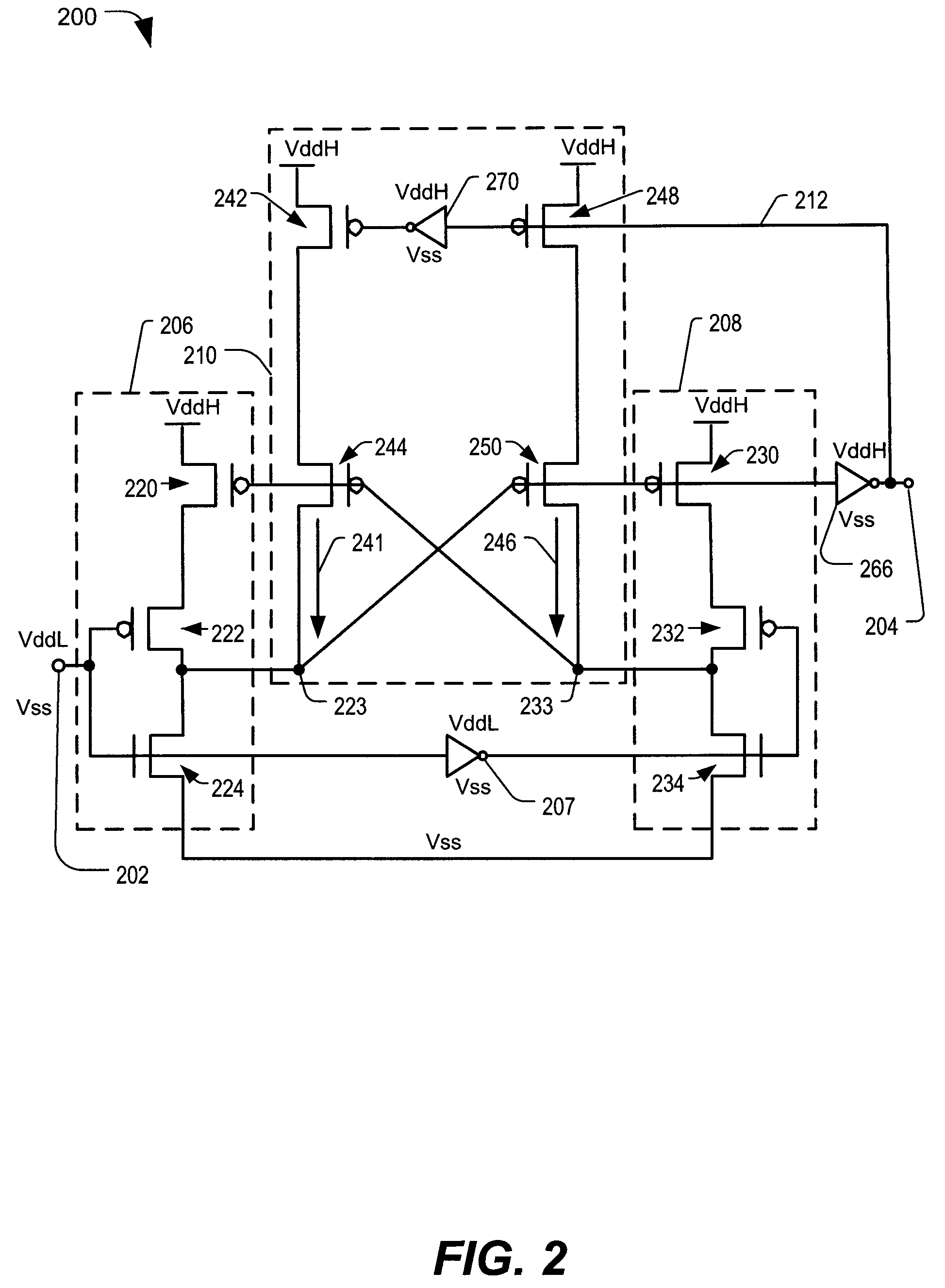

Voltage level shifting circuit and method

ActiveUS7884645B2Large shifting rangeRapid responsePulse automatic controlElectric pulse generatorLevel shiftingLogic circuitry

In a particular embodiment, a method includes receiving an input voltage at an input to a level shifting circuit that includes voltage pull-up logic. The method includes providing an output signal from the level shifting circuit. The method also includes selectively activating the voltage pull-up logic circuit of the level shifting circuit.

Owner:QUALCOMM INC

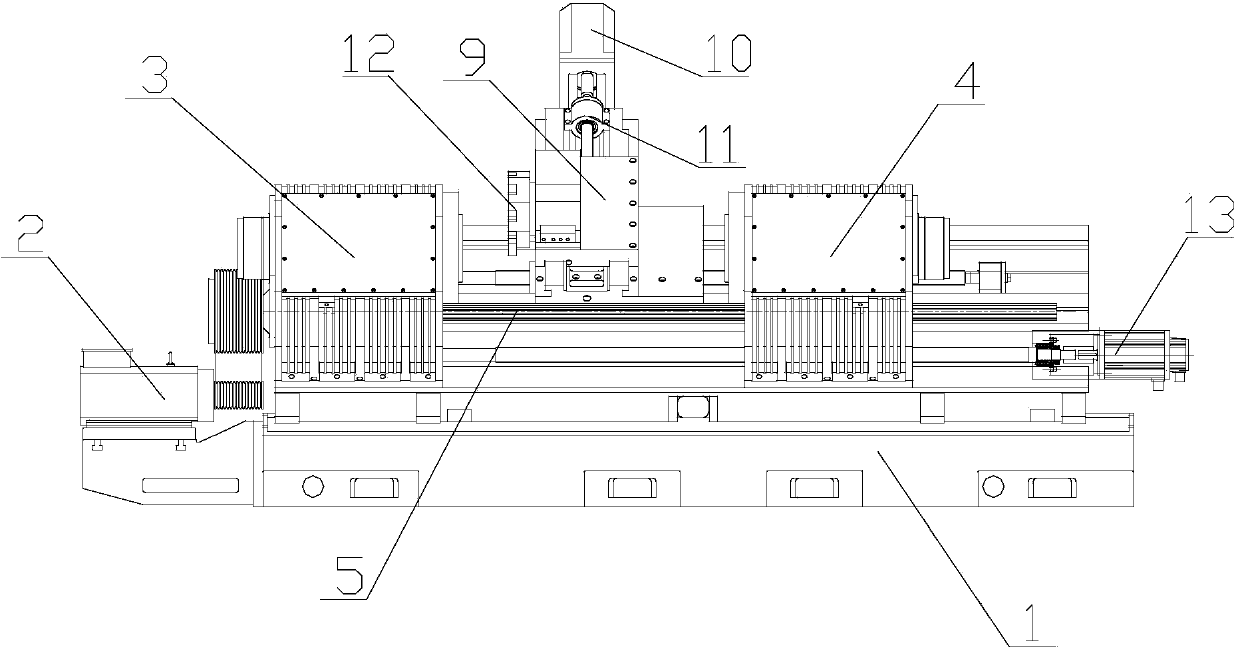

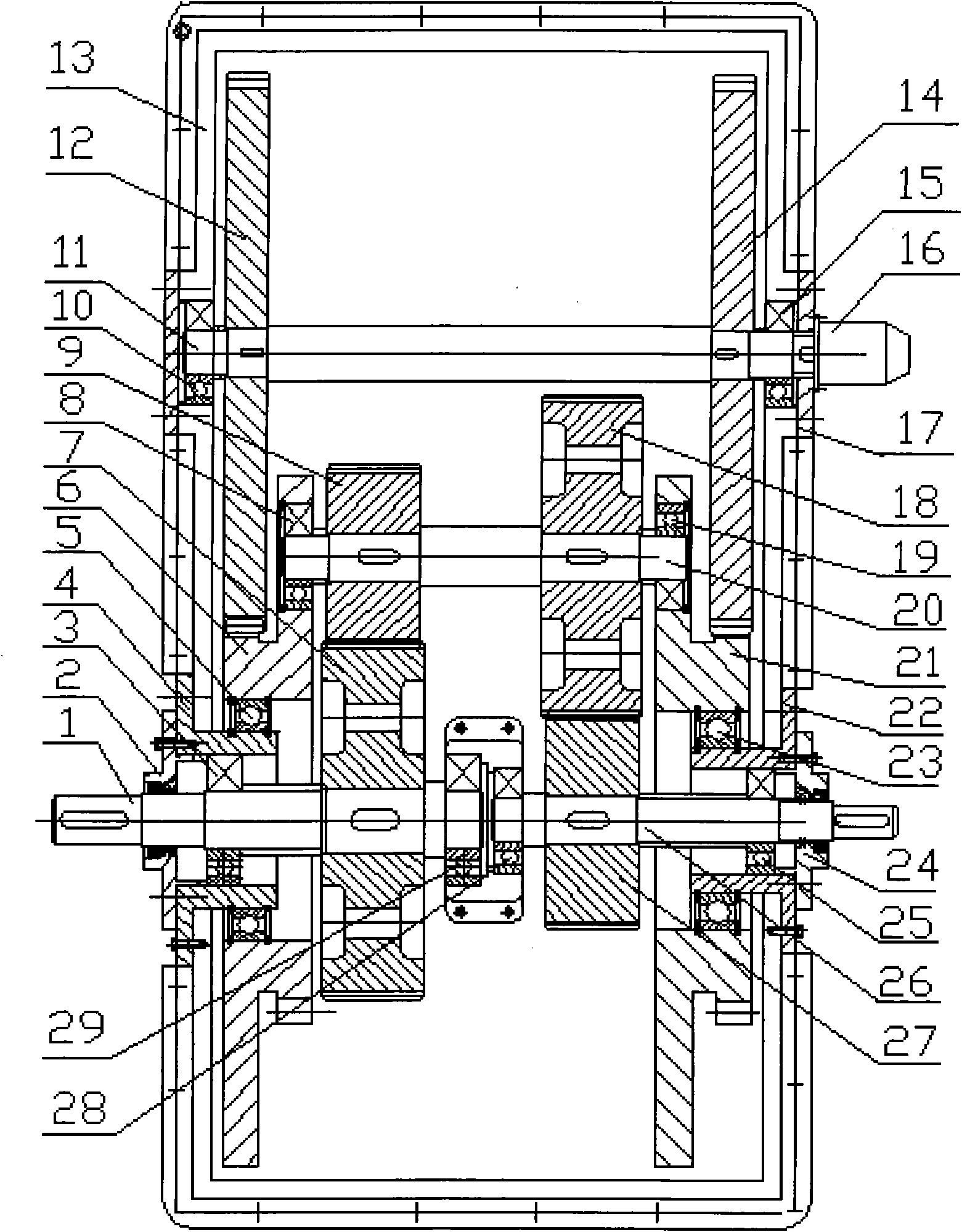

Synchronous double-spindle-box numerically controlled lathe

InactiveCN104190954AReduce coefficient of frictionIncrease coefficient of frictionAutomatic/semiautomatic turning machinesBall screwLong axis

The invention discloses a synchronous double-spindle-box numerically controlled lathe. The synchronous double-spindle-box numerically controlled lathe comprises a lathe body and a main motor arranged on one side of the lathe body, wherein a left spindle box and a right spindle box are arranged at the two ends of the lathe body, a synchronous shaft is arranged between the left spindle box and the right spindle box, the lathe body is provided with a lathe saddle, the lathe saddle is provided with a ball screw a, a servo driving motor a is arranged on one side of the lathe saddle, a middle supporting plate is arranged on the lathe saddle, a servo driving motor b is arranged on one side of the middle supporting plate, a ball screw b is arranged in the middle supporting plate, and an electric tool tower is arranged on the middle supporting plate. When the lathe machines a long-axis-class workpiece, the two ends of the workpiece can be clamped and rotate synchronously, multiple times of machining can be carried out on the workpiece through one time of clamping, and production efficiency is improved. Thus, the dimensional accuracy of the workpiece is guaranteed, the automation degree is high, the productivity efficiency is improved by 6-8 times, and the labor cost is largely reduced.

Owner:LIUAN RUIPU NC MACHINERY

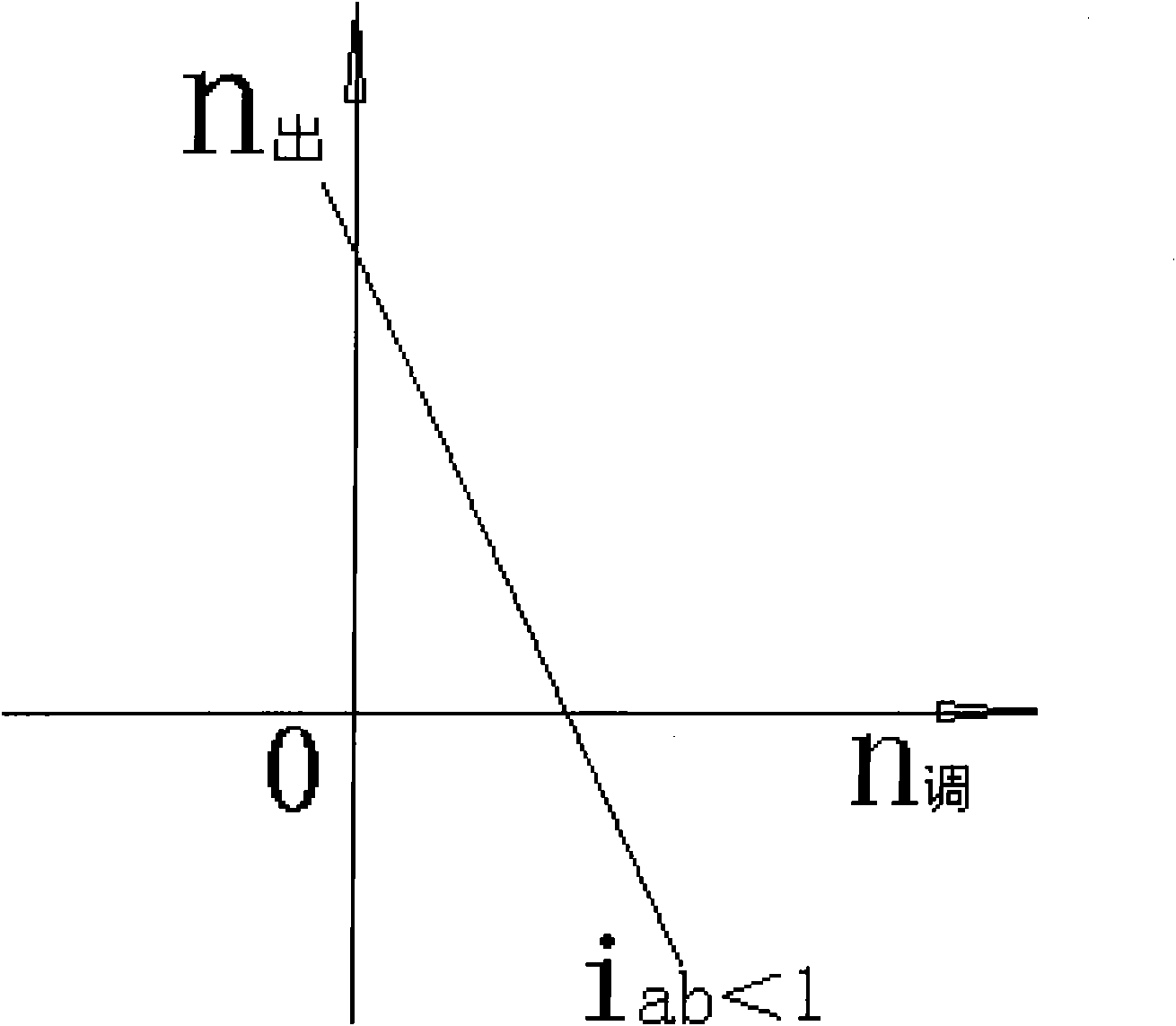

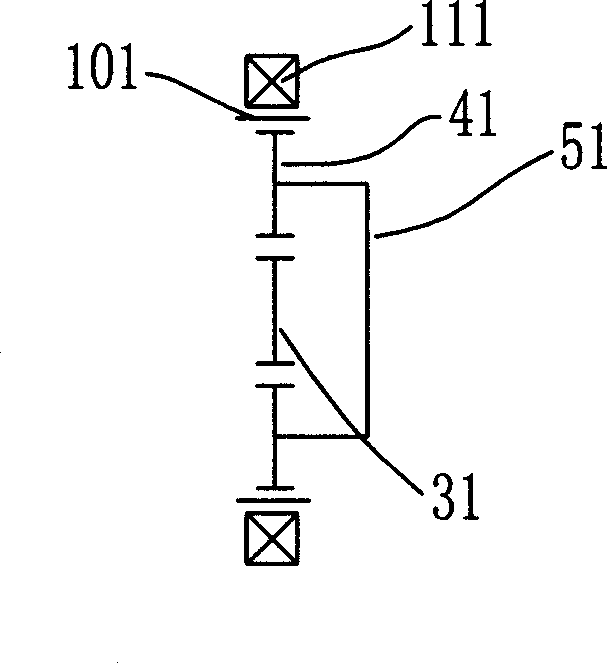

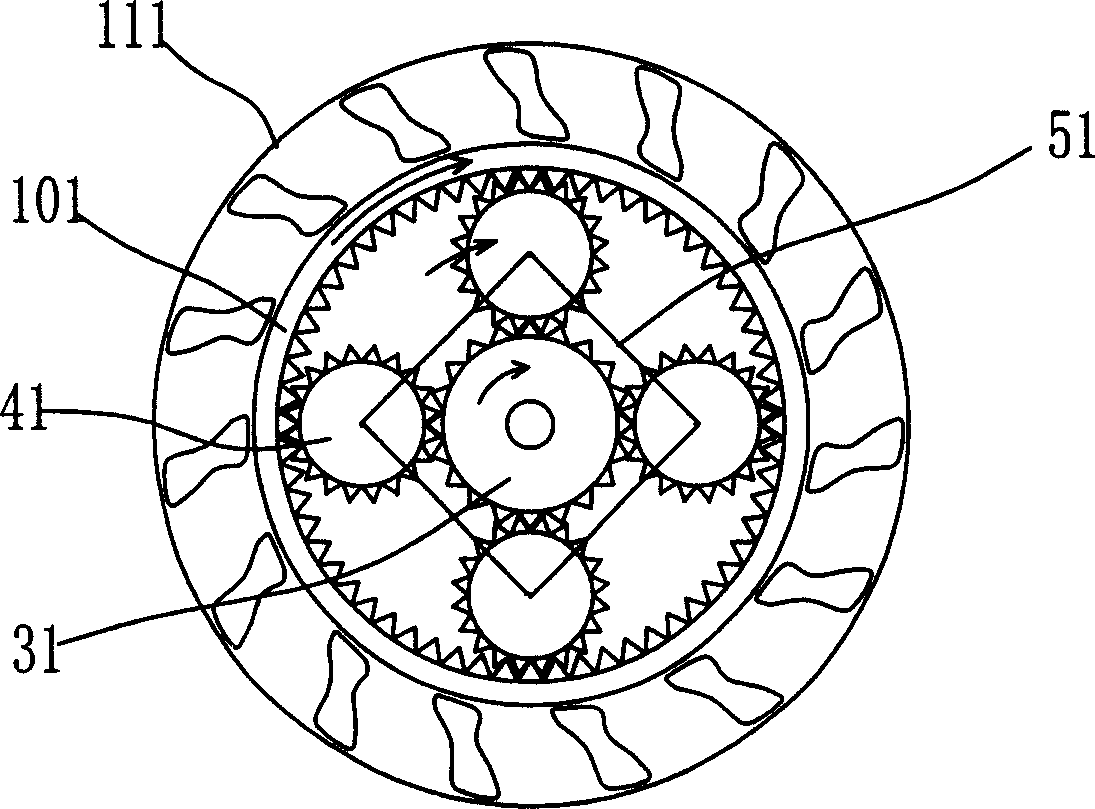

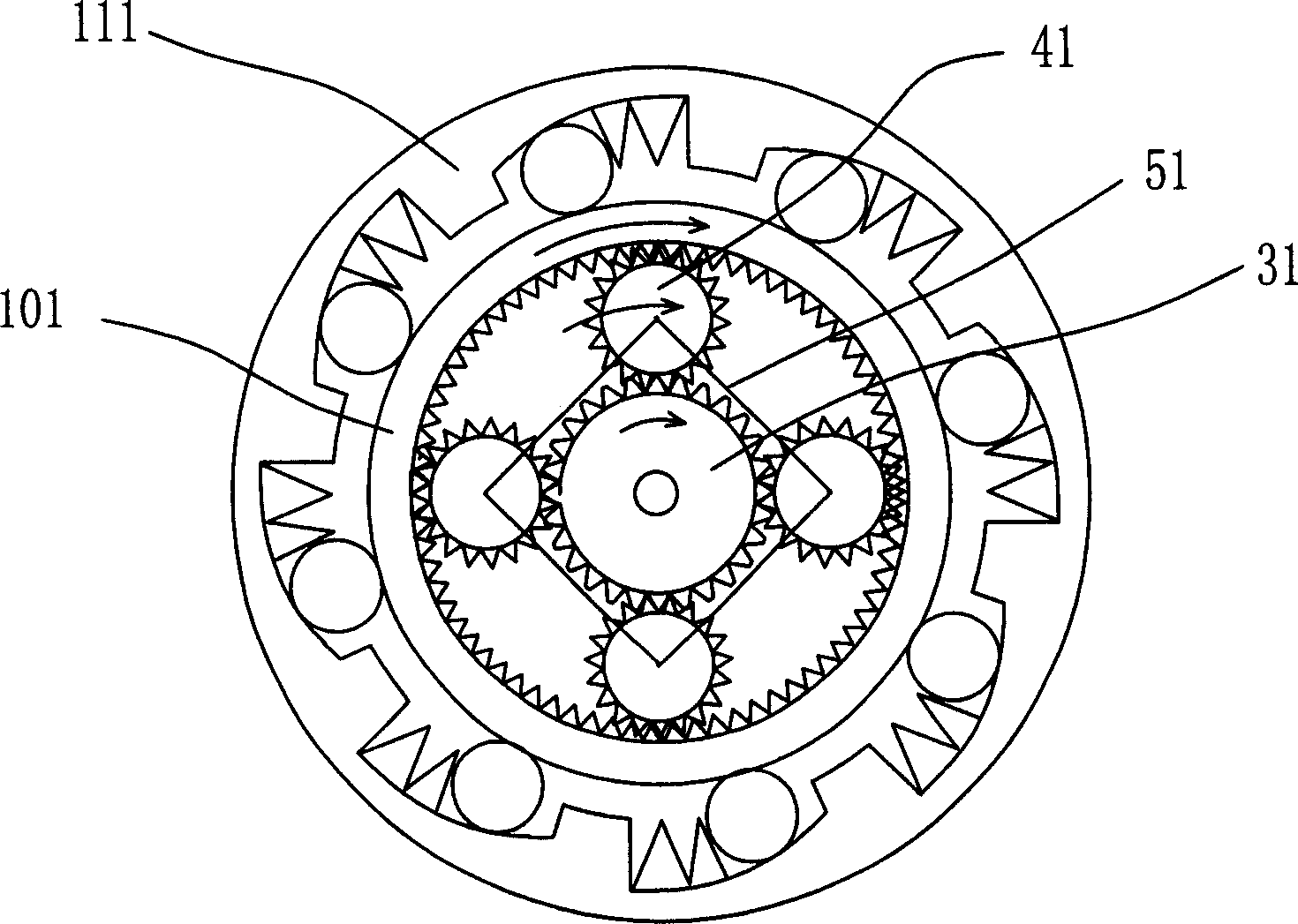

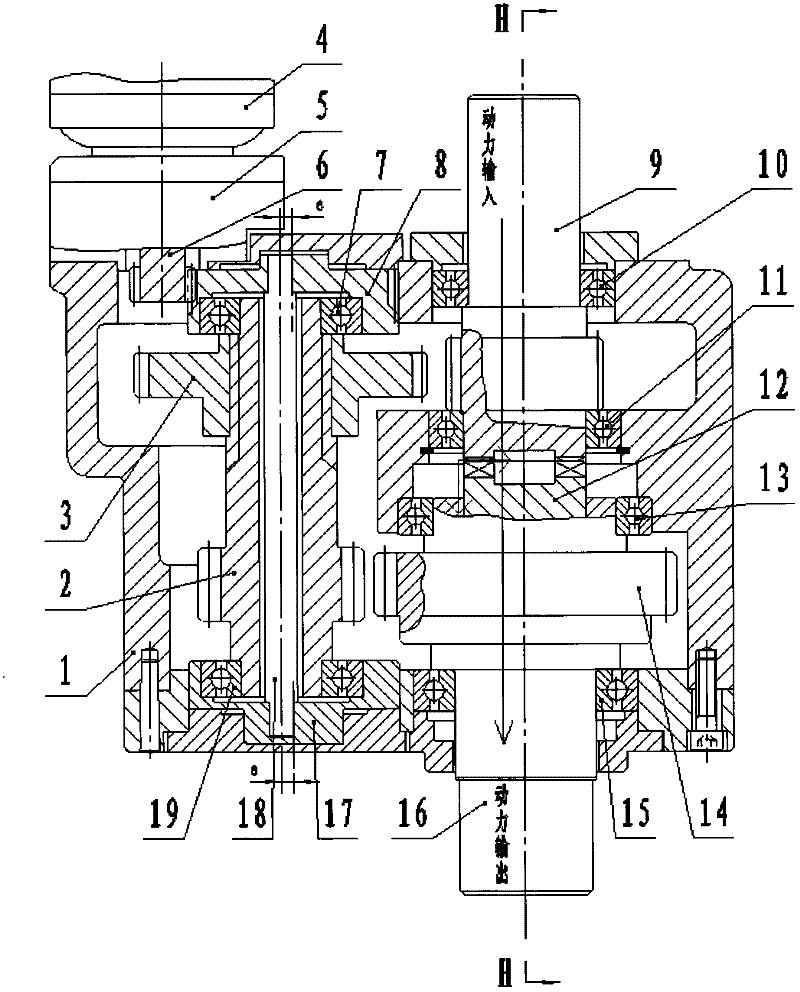

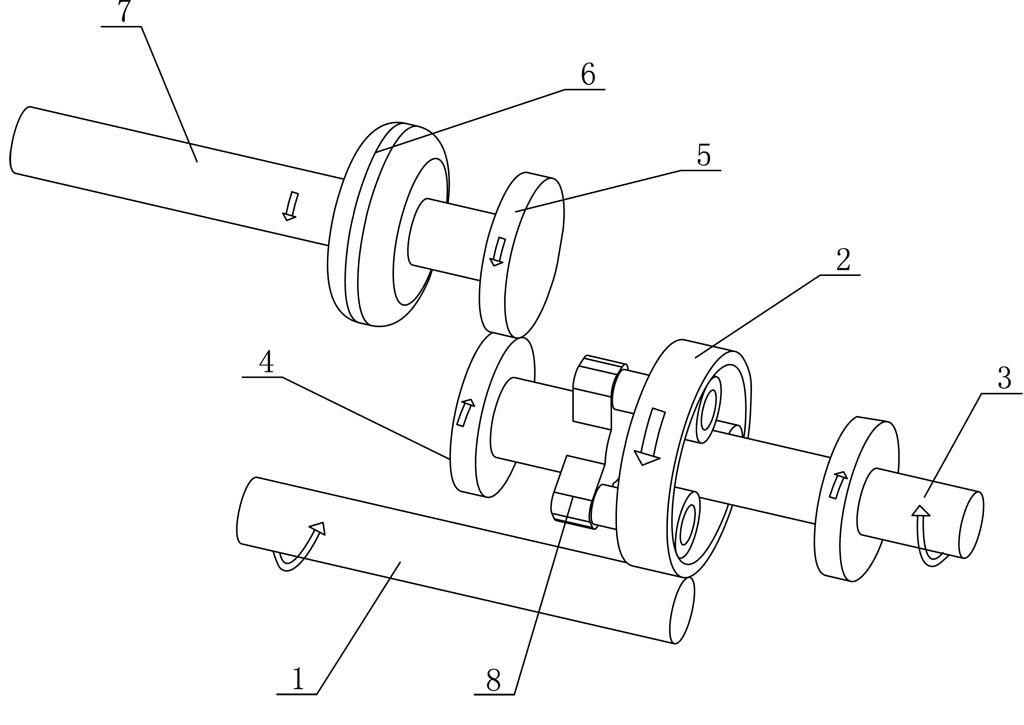

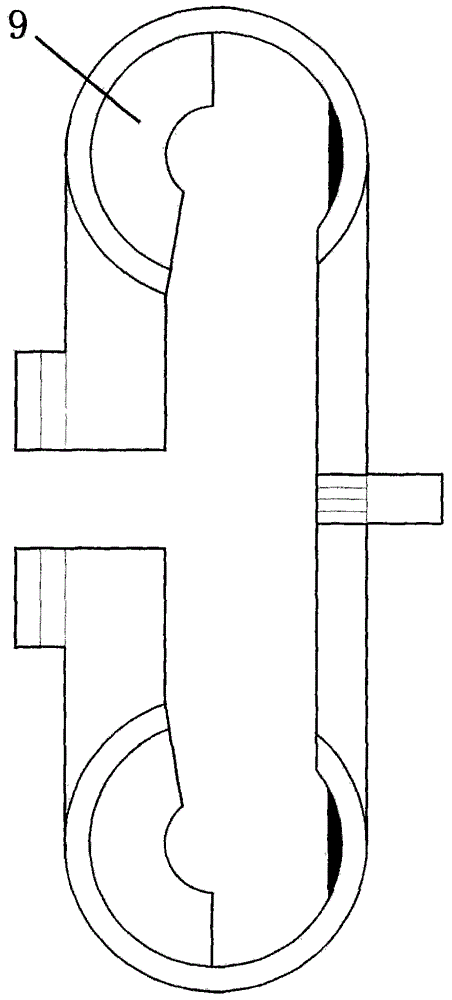

Planetary gear continuously variable transmission

The invention relates to a planetary gear continuously variable transmission, which comprises a box body in which a dual planetary gear train and an ordinary gear train are installed, and is characterized in that the ordinary gear train comprises a speed control gear I, a speed control gear II, a speed control gear shaft and a continuously variable transmission device, and the dual planetary gear train comprises an input shaft, a central gear I, a planetary gear I, a tie bar I, planetary axles, an output shaft, a central gear II, a planetary gear II and a tie bar II; the tie bar I is supported on an input flange, is provided with external cylindrical teeth and is externally meshed with the speed control gear I of the ordinary gear train, and the tie bar II is supported on an output flange, is provided with external cylindrical teeth and is externally meshed with the speed control gear II of the ordinary gear train; the planetary axles are respectively supported in the tie bar I and the tie bar II, and the planetary gear I and the planetary gear II are respectively and externally meshed with the central gear I and the central gear II; and the size parameters of the speed control gears I and II are same, and the size parameters of the external teeth of the tie bar I and the tie bar II are same. The invention solves the problems that the existing single planetary gear chain uses an eccentric output mechanism and has insensitive speed control.

Owner:DALIAN JIAOTONG UNIVERSITY

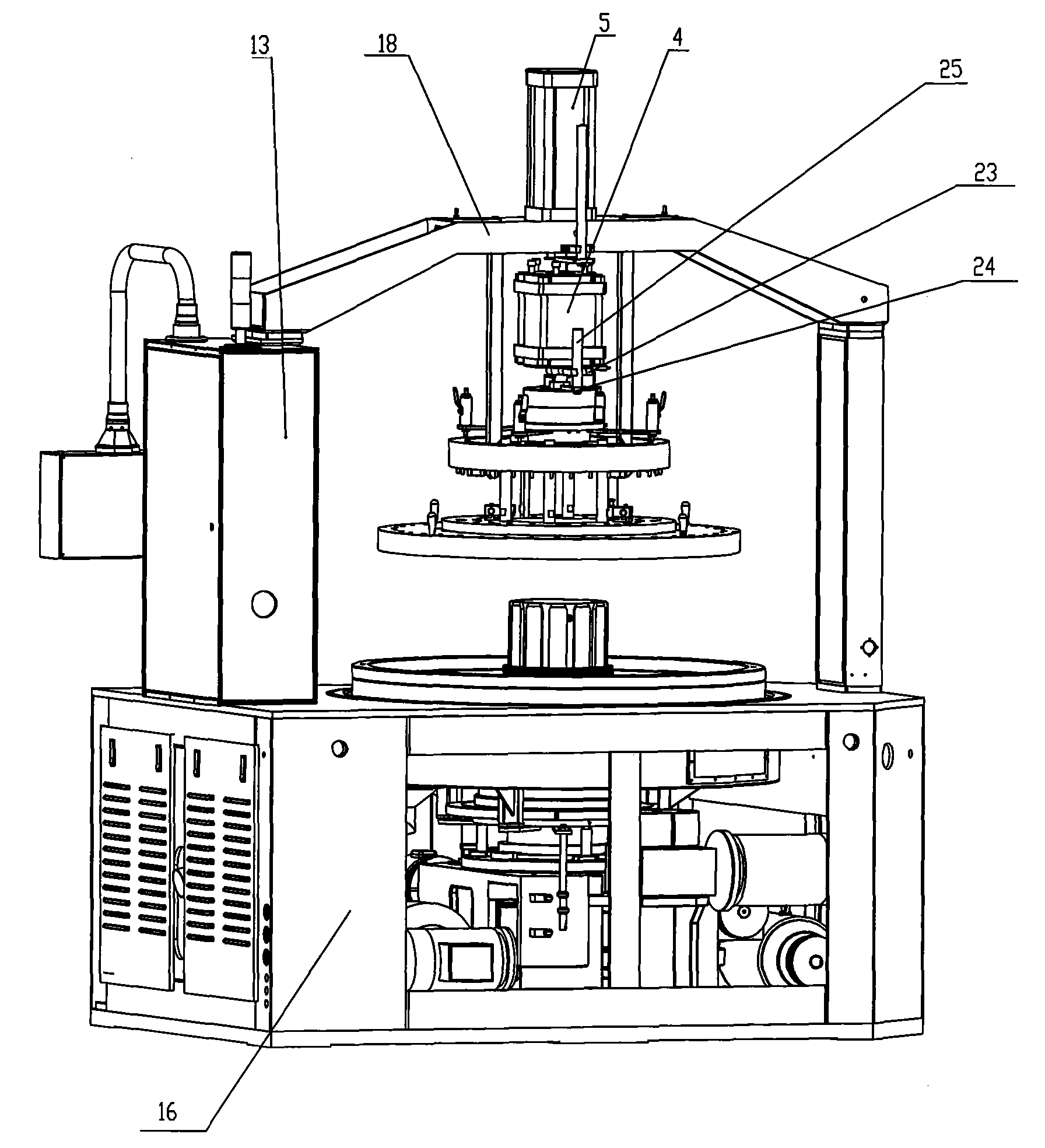

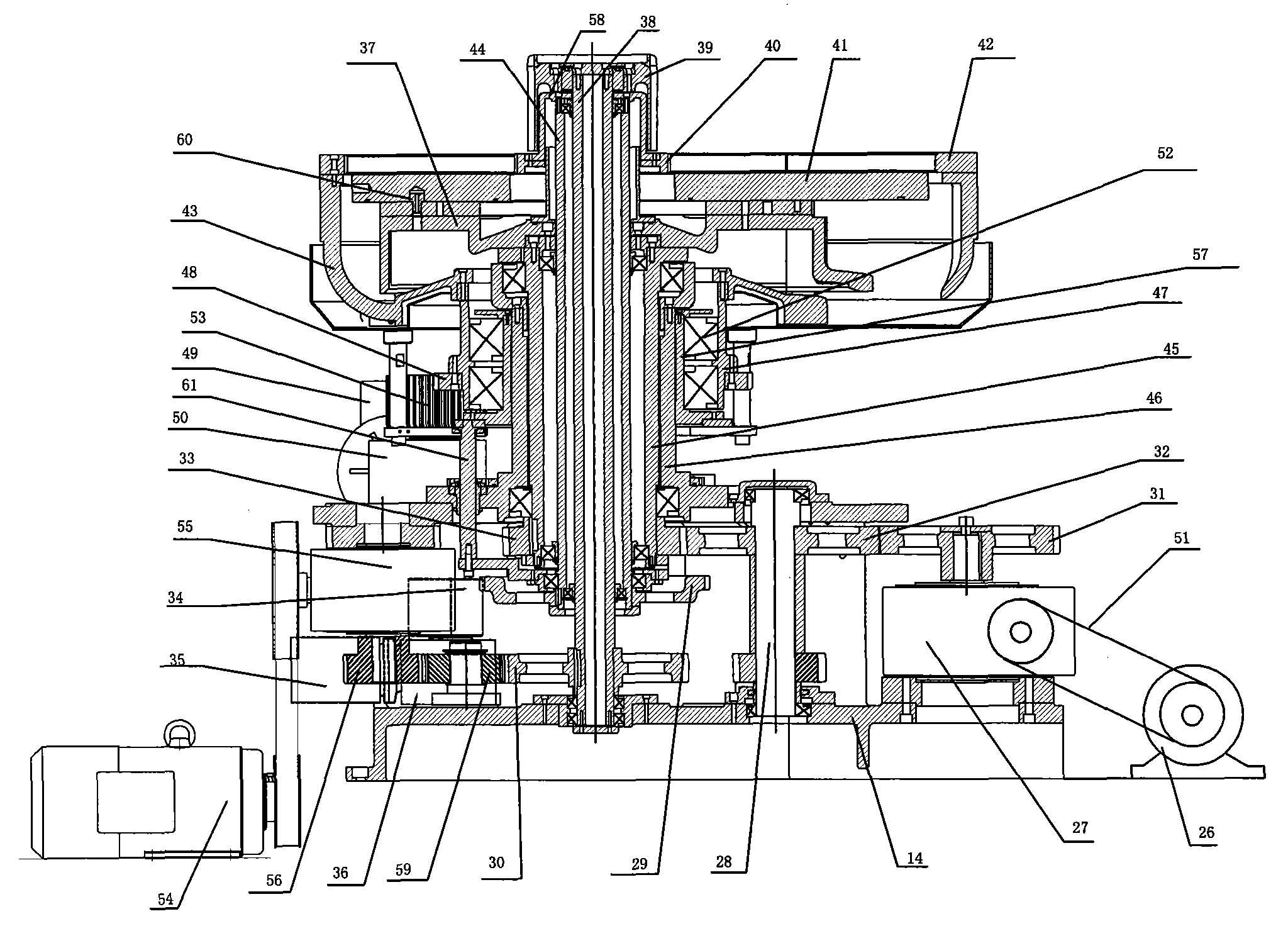

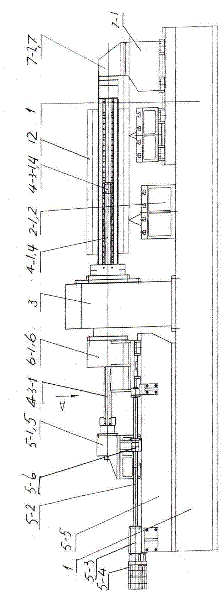

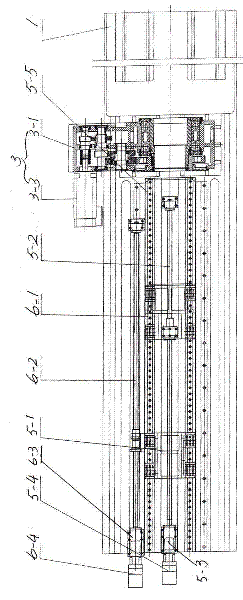

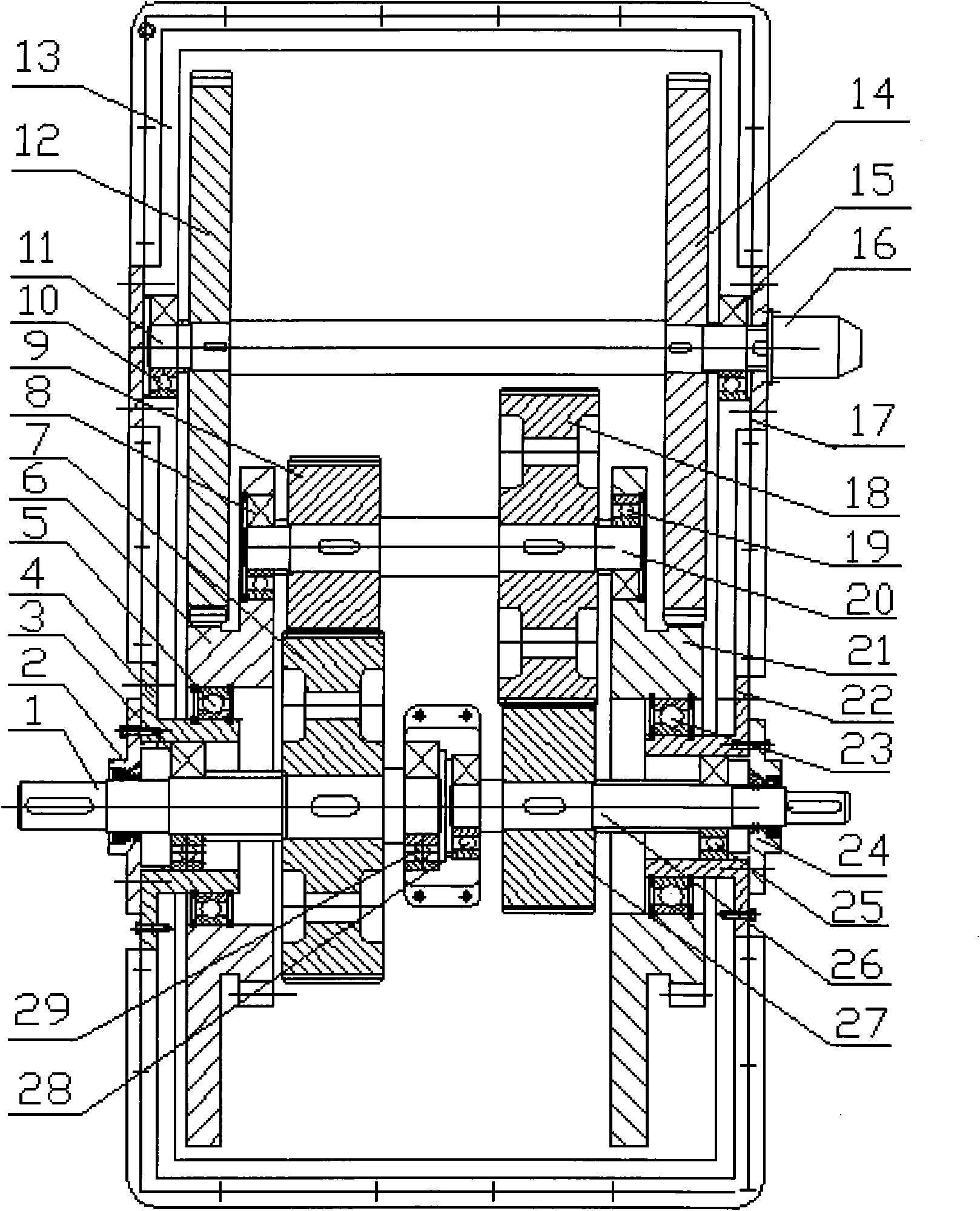

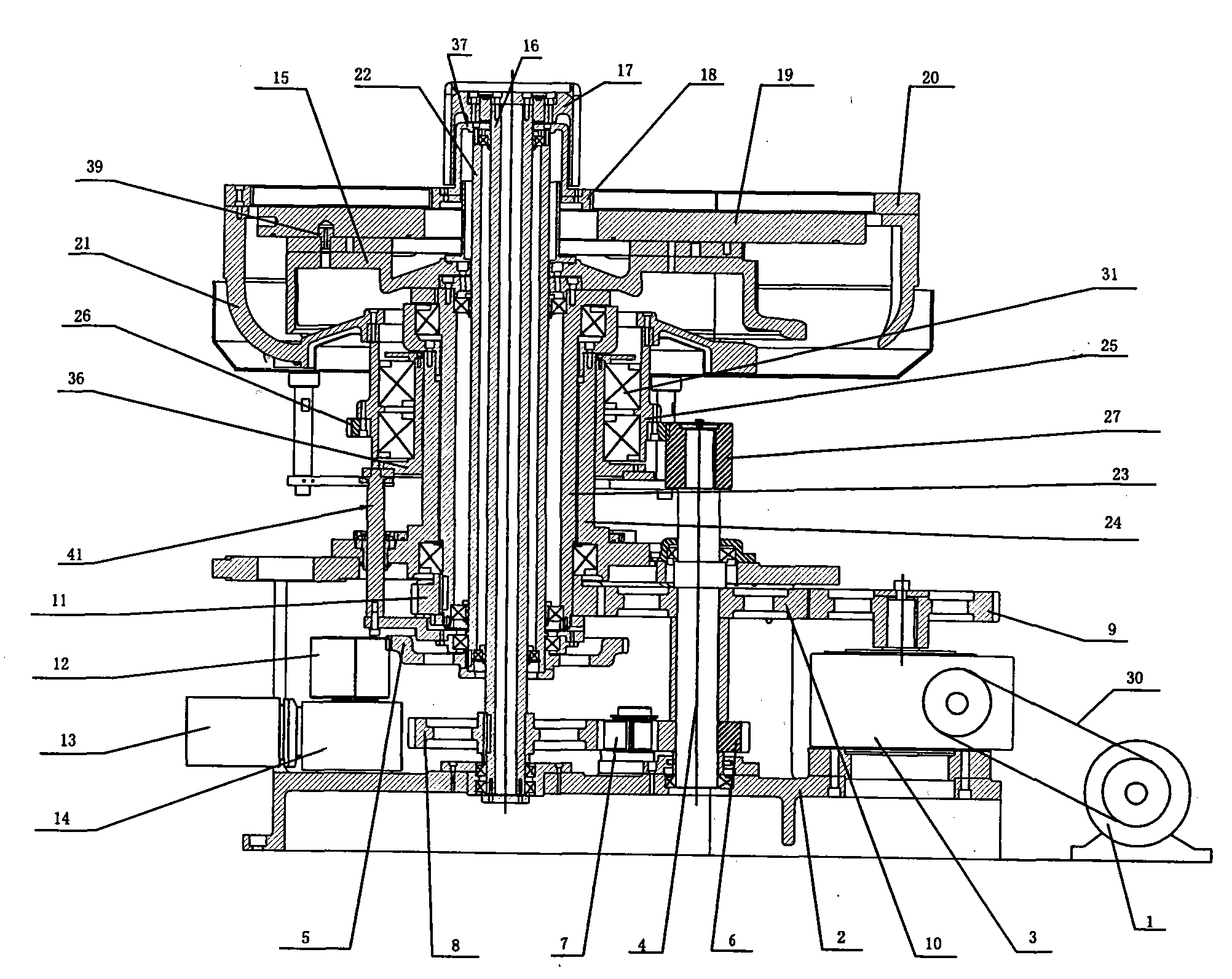

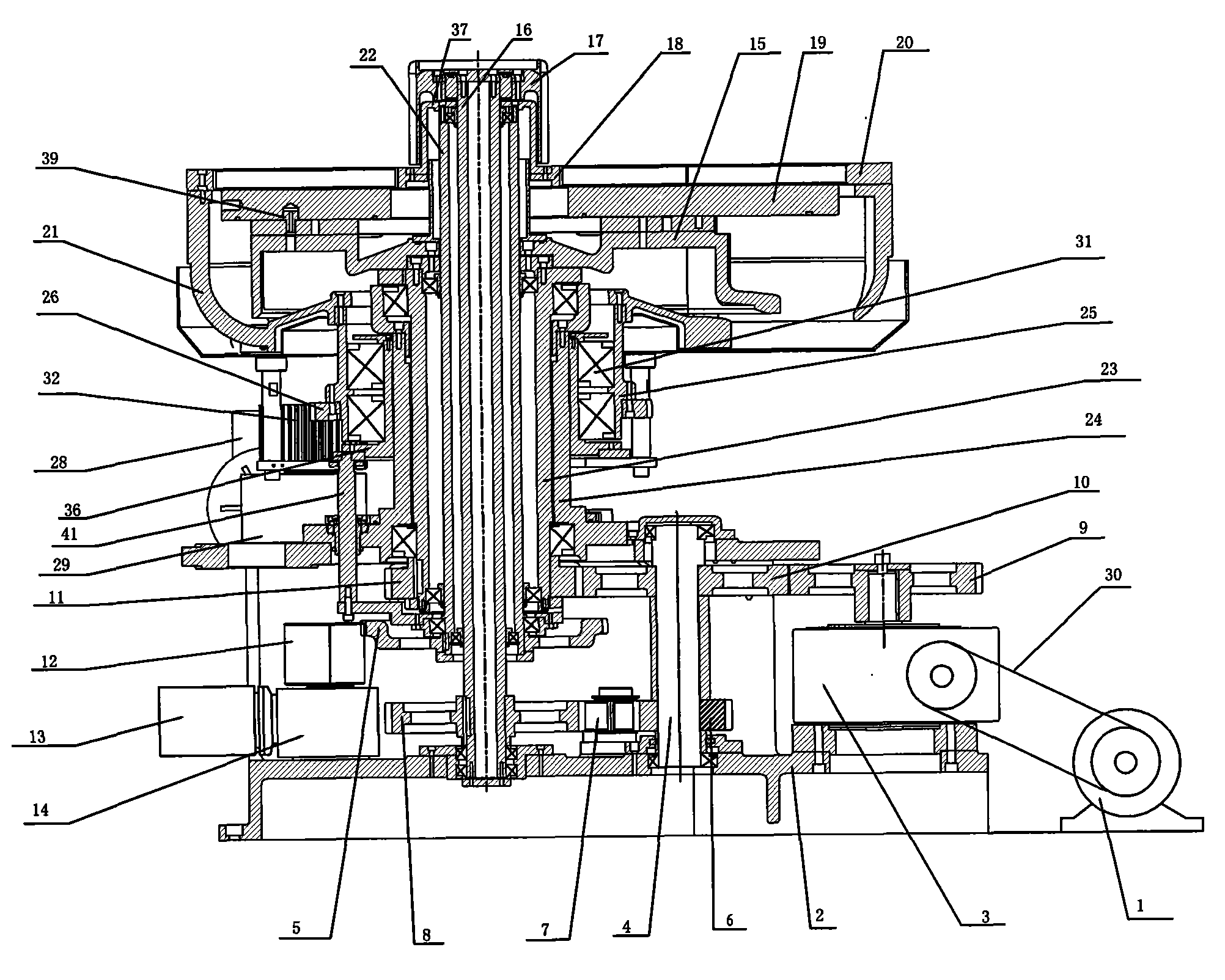

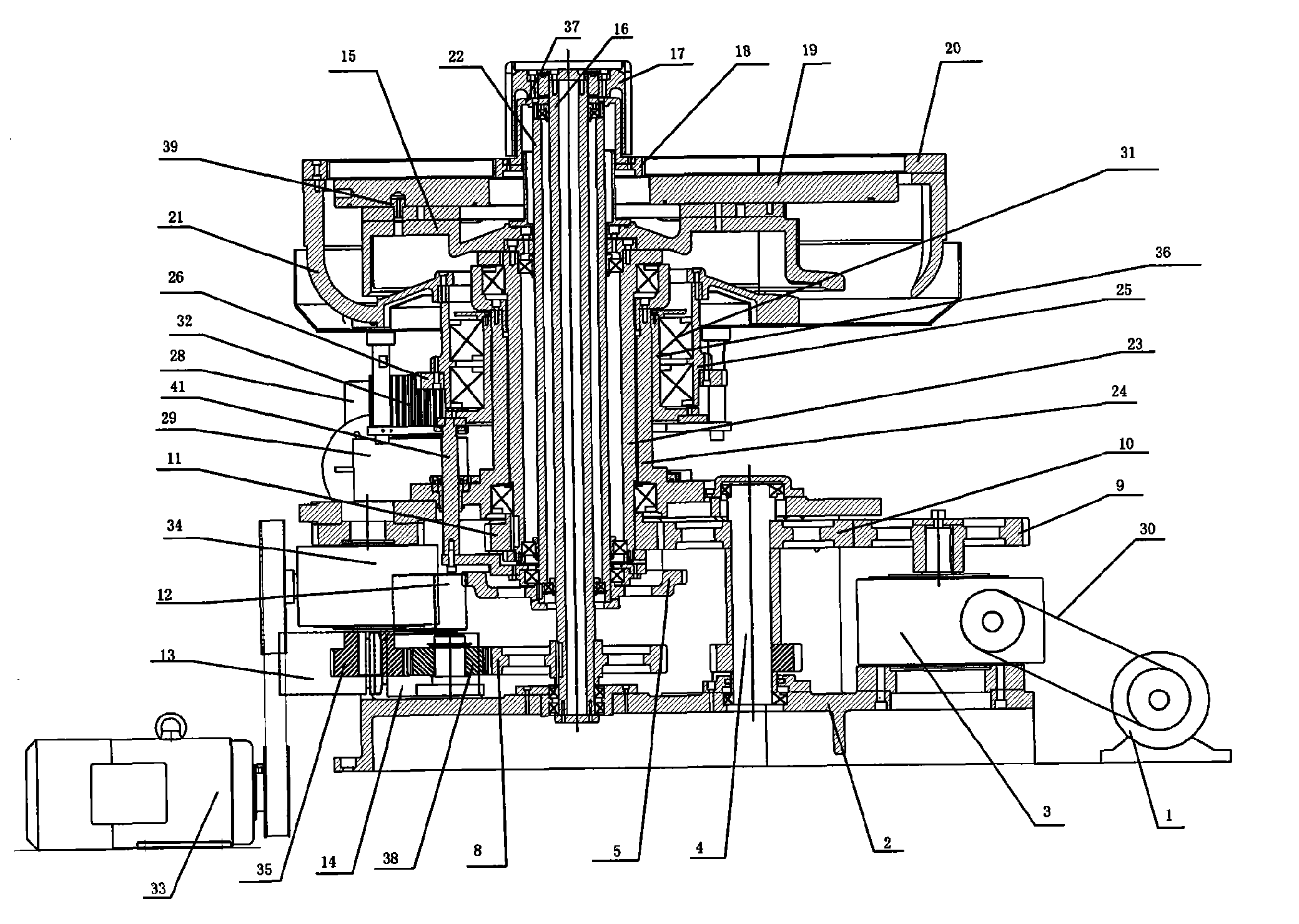

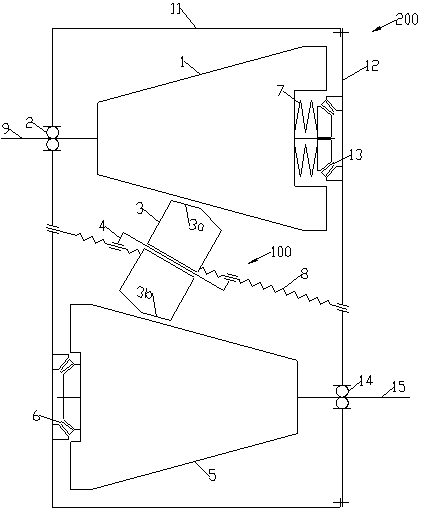

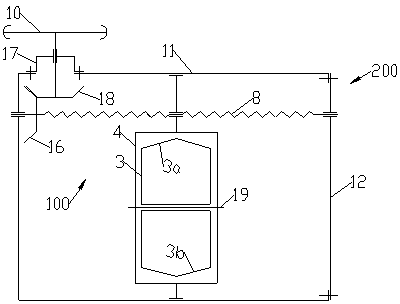

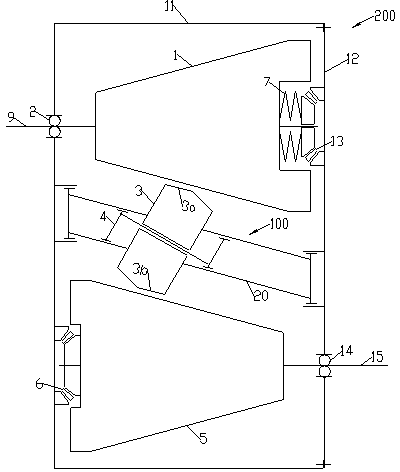

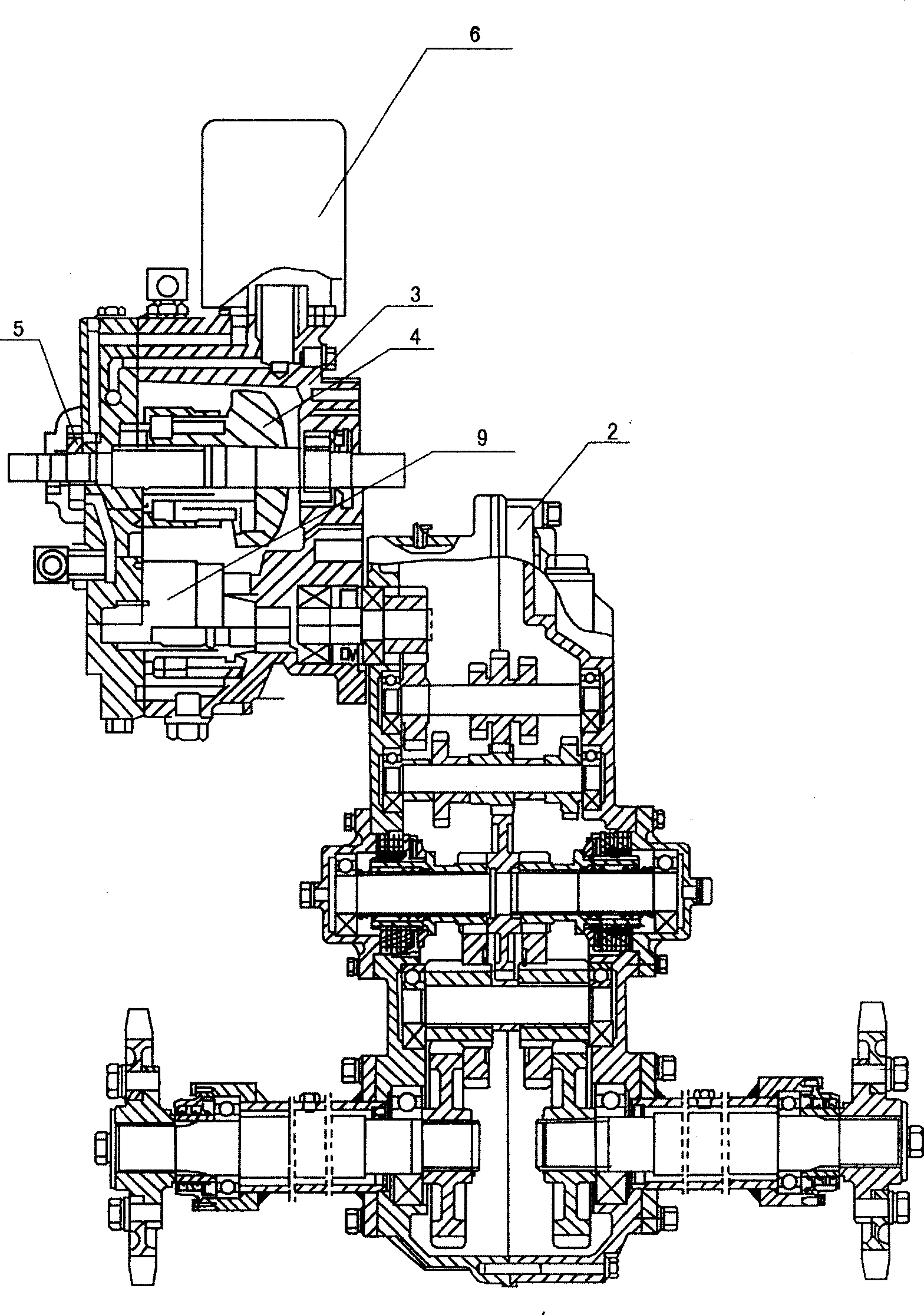

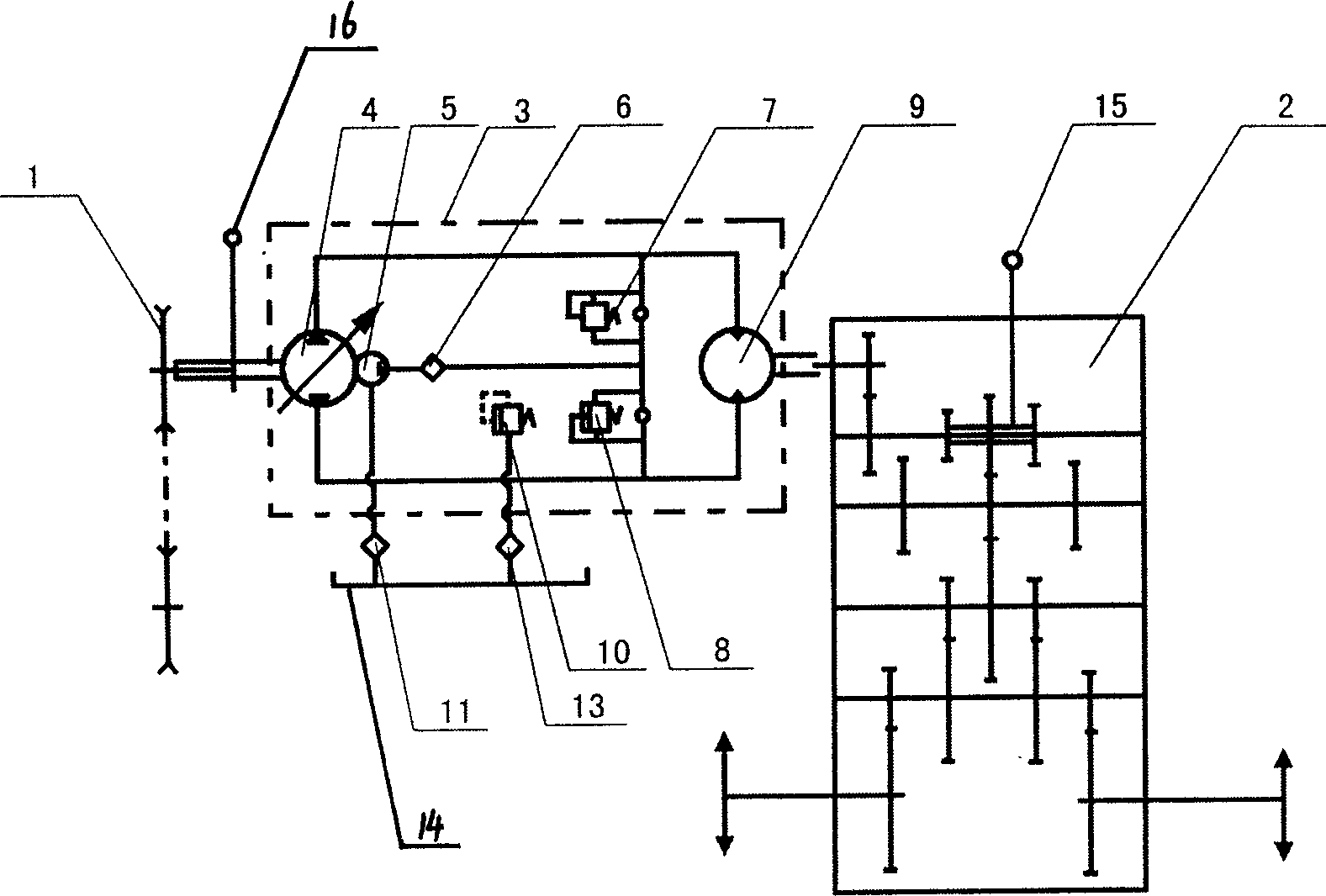

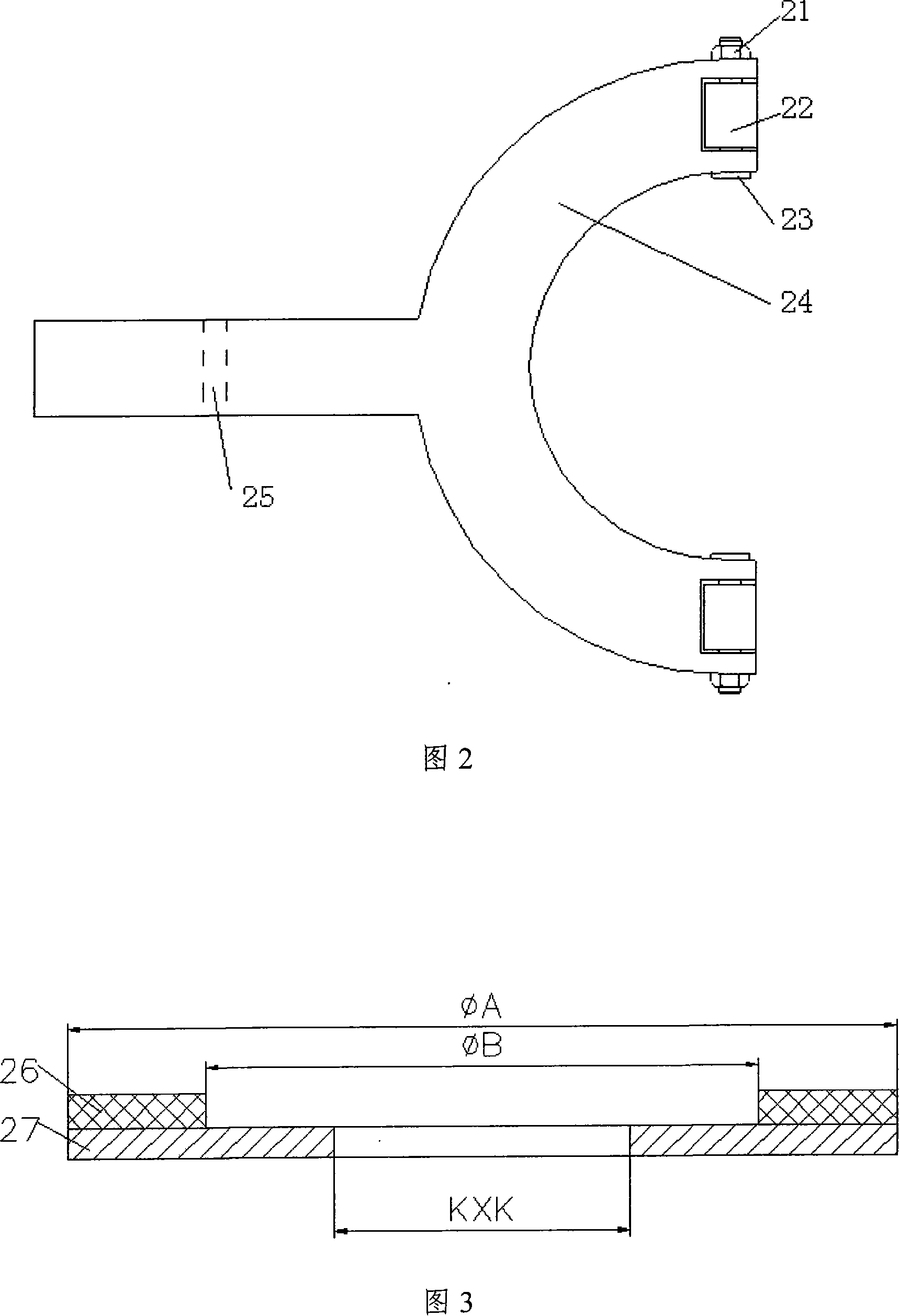

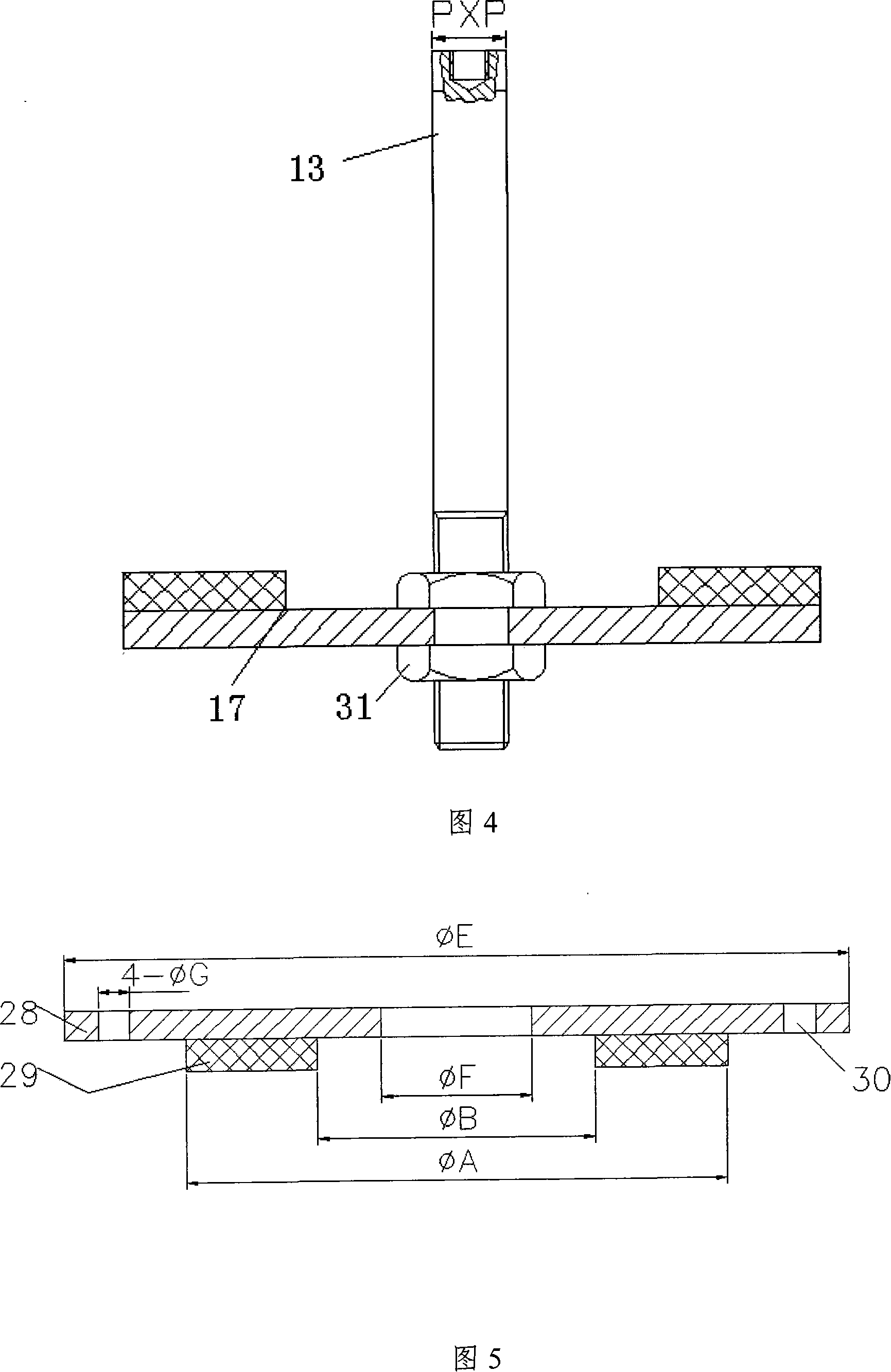

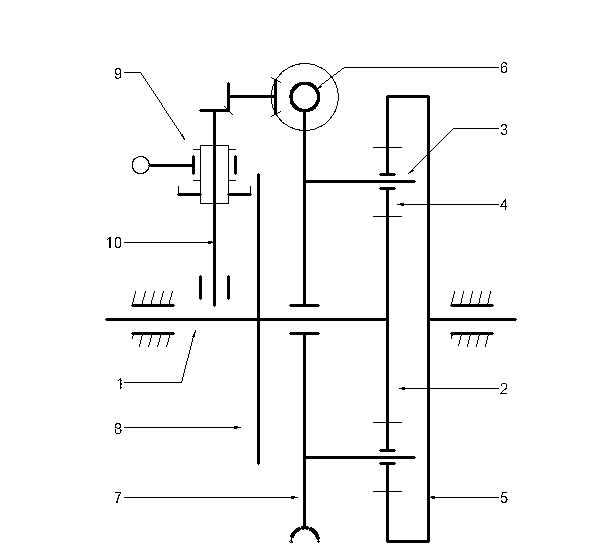

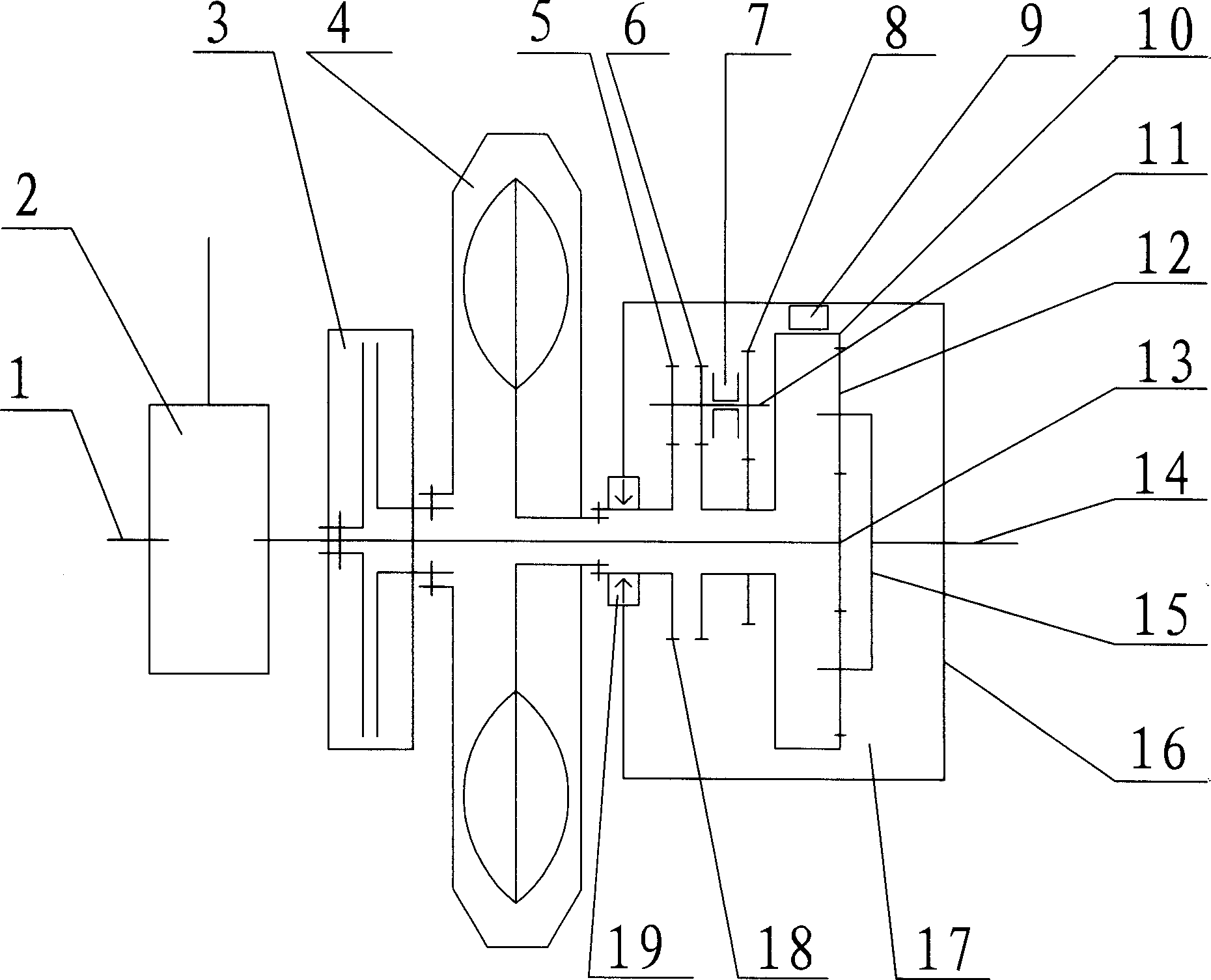

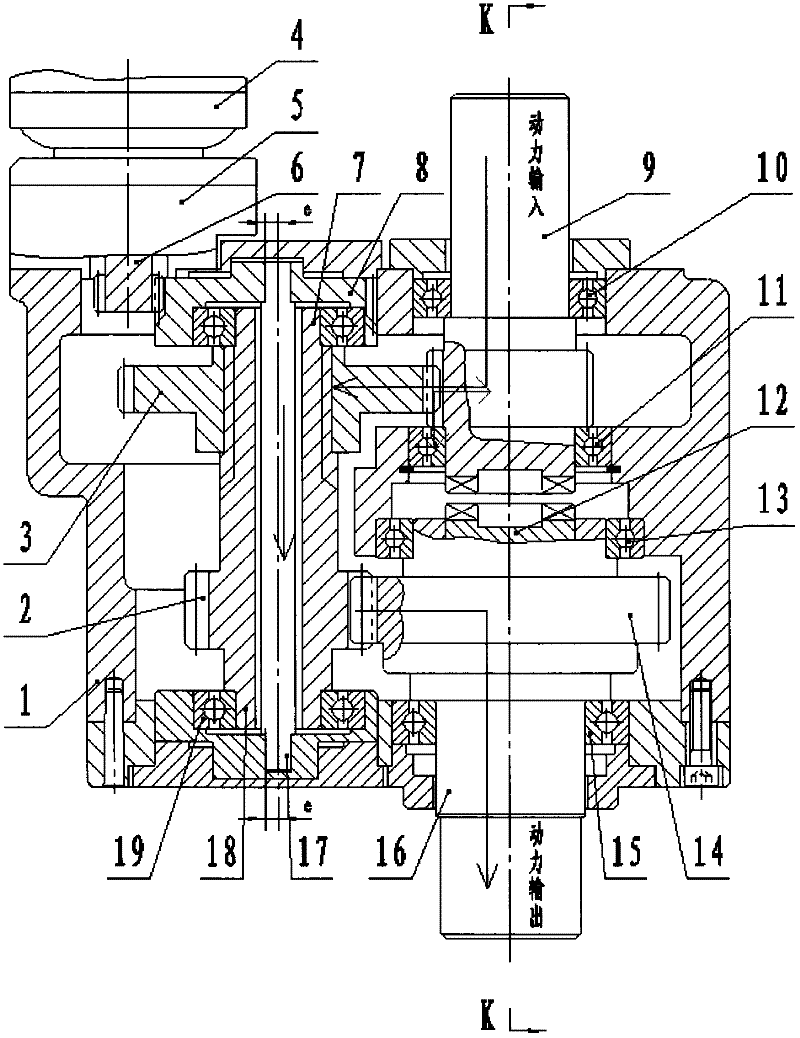

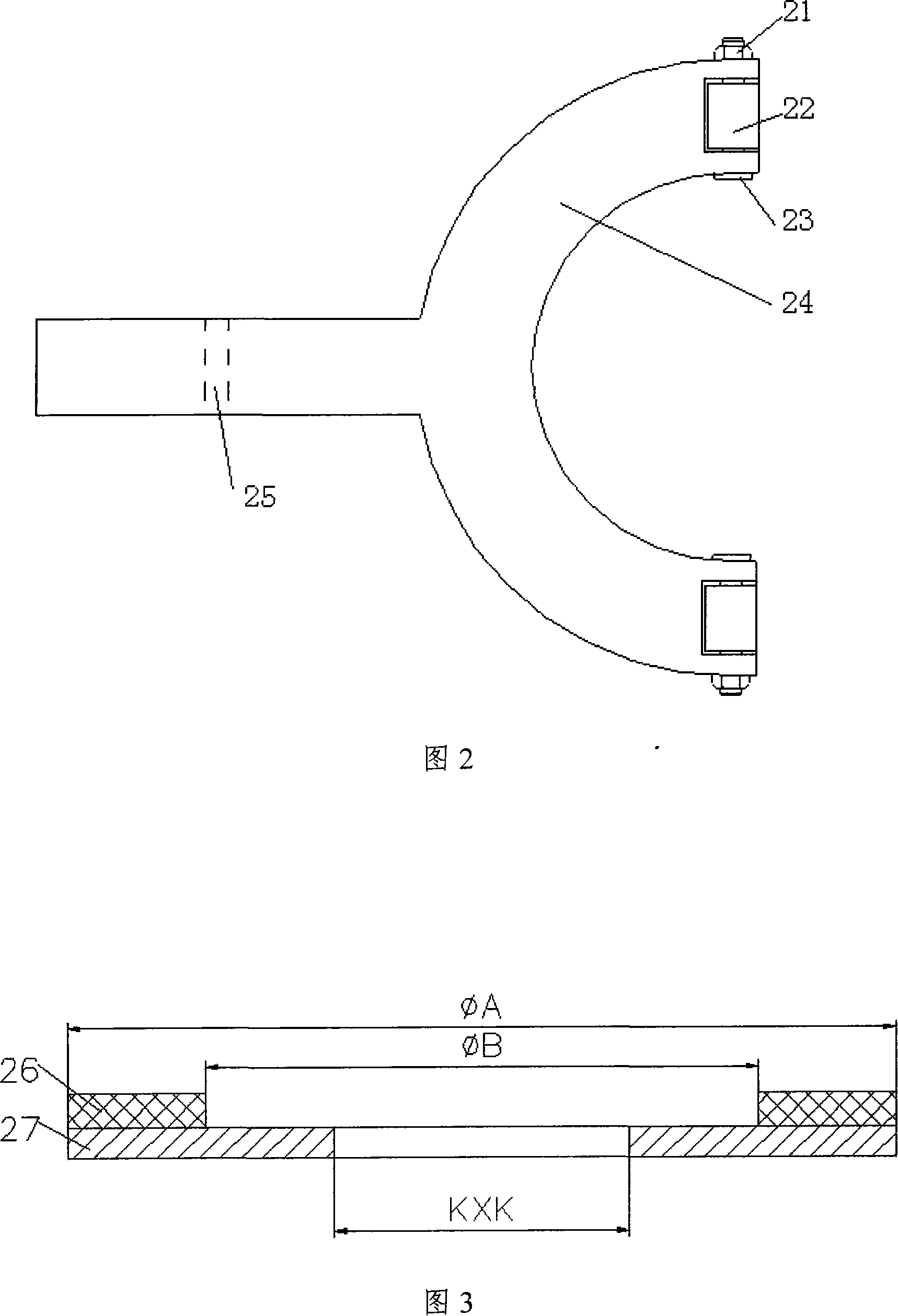

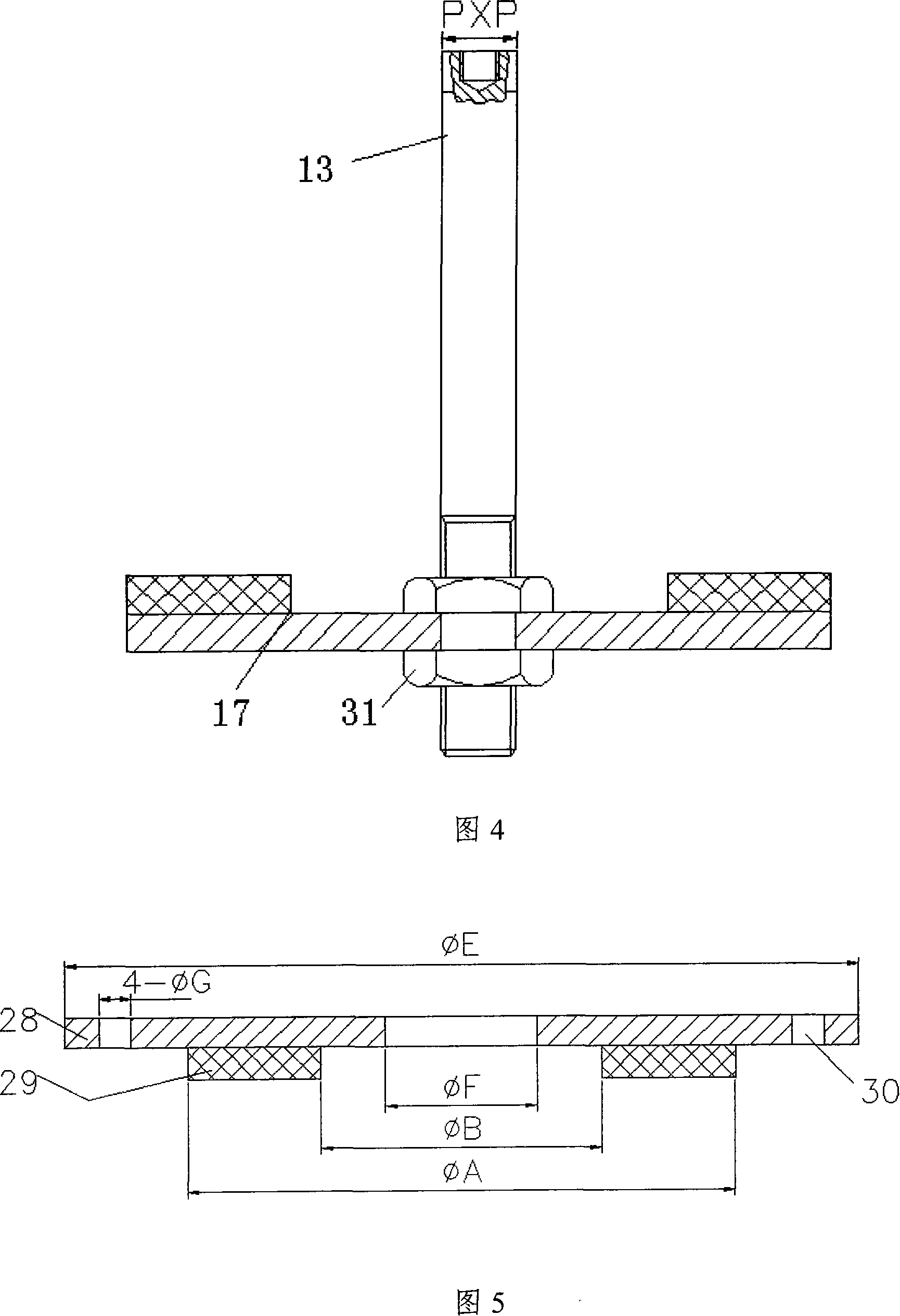

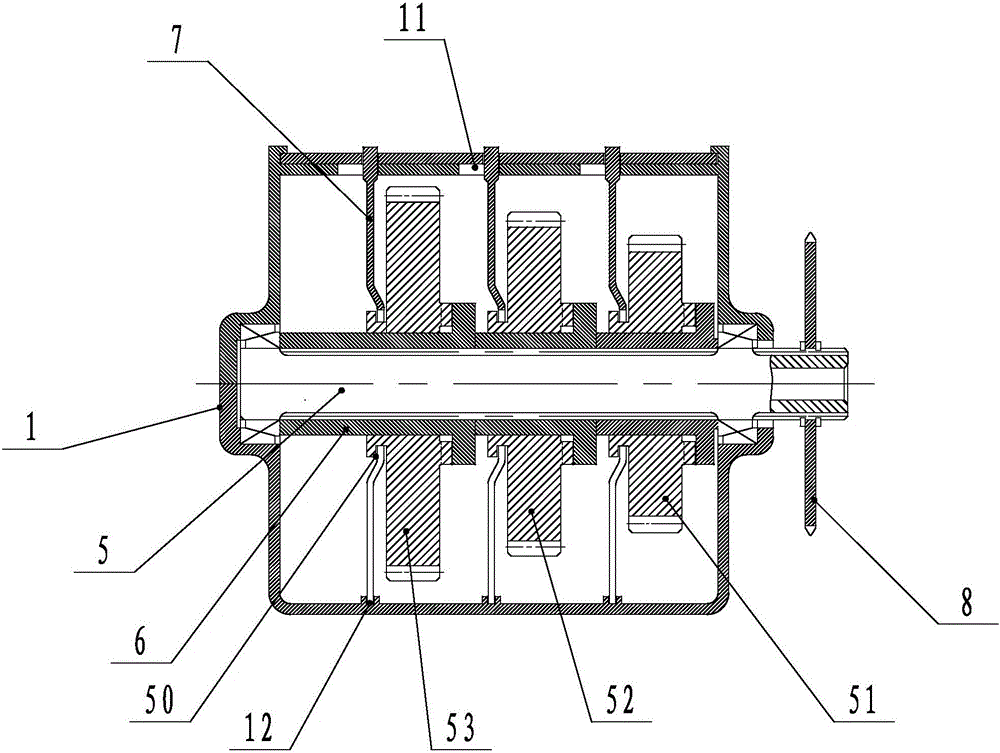

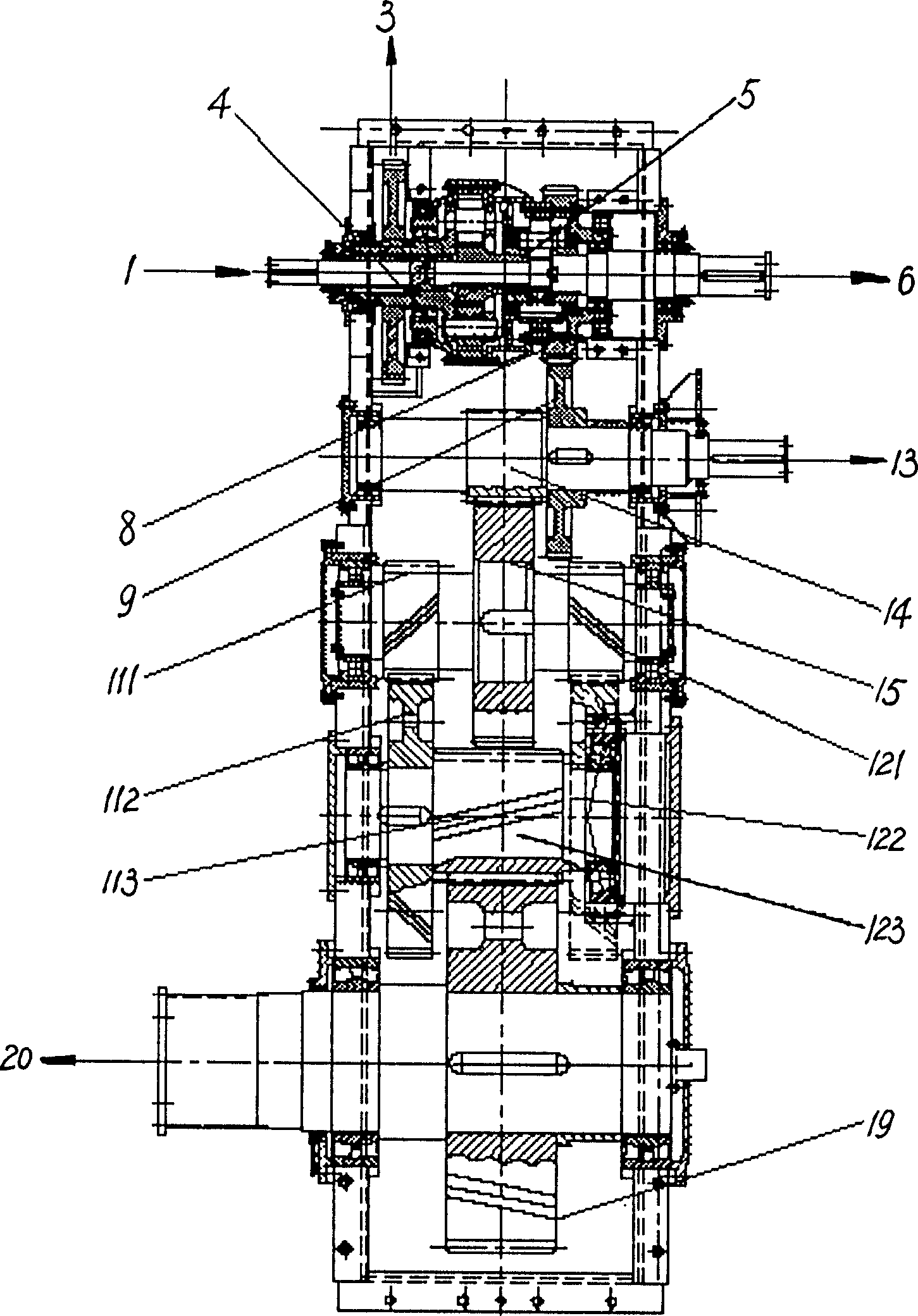

Mainshaft transmission system of numerically-controlled precise grinding polisher

InactiveCN101596697ALarge shifting rangeHigh movement precisionGrinding drivesTransmission systemEngineering

The invention relates to the technical field of numerically-controlled precise grinding polishers and particularly relates to a mainshaft transmission system of the numerically-controlled precise grinding polisher. The mainshaft transmission system comprises a main motor (1) arranged on a stand and a main supporting seat (2); the mainshaft transmission system is characterized in that a supporting sleeve (24) is arranged on the main supporting seat (2); the lower part of a lifting sleeve (36) is provided with a lifting mechanism (41); a gear ring sleeve (25) is arranged on the lifting sleeve (36); the gear ring sleeve (25) is provided with a gear ring driven gear (26); the inside of the supporting sleeve (24) is provided with a lower disc shaft (23) through a bearing; the inside of the lower disc shaft (23) is provided with a solar axle (22) through a bearing; the inside of the solar axle (22) is provided with a central axis (16) through a bearing; the upper part of the central axis (16) is fixedly connected with a dividing wheel (17) for driving an upper disc to rotate; and the lower part of the central axis (16) and the main supporting seat (2) are mounted and positioned through bearings. The mainshaft transmission system can be dragged by one or more servo motors, has wide speed regulation range, higher moving precision, rapider response speed and strong antijamming capacity.

Owner:LANZHOU RAPID INDGRPCO

Gear stepping type stepless speed change device

The invention relates to a gear stepless speed changer, which comprises: planet gear system and one-way bearing as one-way clutch, wherein the gear system comprises an active sun wheel connected to the power input; there are 3-6 output planet wheels meshed with the circumference of active sun wheel; the output planet wheel is mounted on the planet wheel support fixed with the power output; each output planet wheel is meshed with one tooth ring; one-way bearing is arranged on the tooth ring; the output planet wheel and the planet wheel support are the output; the revolution speed of planet wheel support is the output rotation speed; the active sun wheel is the input; the tooth ring is the input used when changing speed; the power of driving tooth ring can be obtained from the input axle; the rotation direction of tooth ring is same as active sun wheel; the one-way bearing sheathes the tooth ring or the element connected to the tooth ring, to rotate the tooth ring at single direction. The invention has simple structure, stepless speed change, and wider speed range.

Owner:秦桂强

Long cone and rolling cone type CVT (continuously variable transmission)

InactiveCN103016660ASmall geometric slip rateReduced geometric slip rateToothed gearingsFriction gearingsThrust bearingPulp and paper industry

The invention discloses a long cone and rolling cone type CVT (continuously variable transmission), which comprises a box body, a first long cone roller wheel, a second long cone roller wheel, at least one pressure device, a first thrust bearing, a second thrust bearing and a middle rolling cone wheel set, wherein the middle rolling cone wheel set comprises a middle rolling cone wheel, a connecting device and an adjusting device; a first conical surface and a second conical surface are arranged on the middle rolling cone wheel; and the first long cone roller wheel and the second long cone roller wheel are connected with the box body through the first thrust bearing and the second thrust bearing respectively. The axial pressing action of the first long cone roller wheel is performed through the pressure device; the contact positions of the middle rolling cone wheel on the two long cone roller wheels are adjusted; and the working radiuses of the two long cone roller wheels can be continuously changed to achieve the effect of CVT. According to the CVT, the geometrical slippage value in the optimal transmission state is 0, the geometrical slippage phenomenon in the cone wheel type long cone and rolling cone type CVT is effectively reduced, the transmission efficiency is improved and the transmission power is increased. The CVT can be used for the fields of various vehicles, ships, mechanical transmission and the like.

Owner:郭克亚

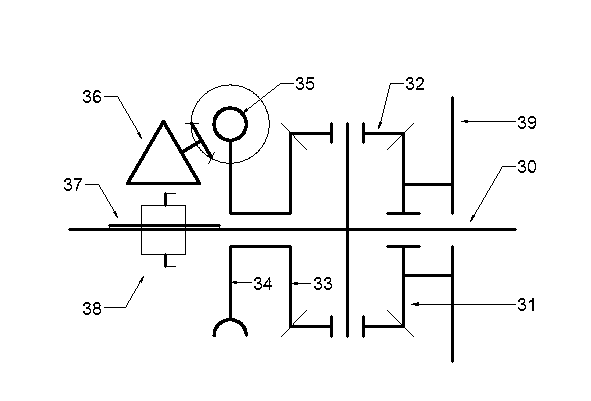

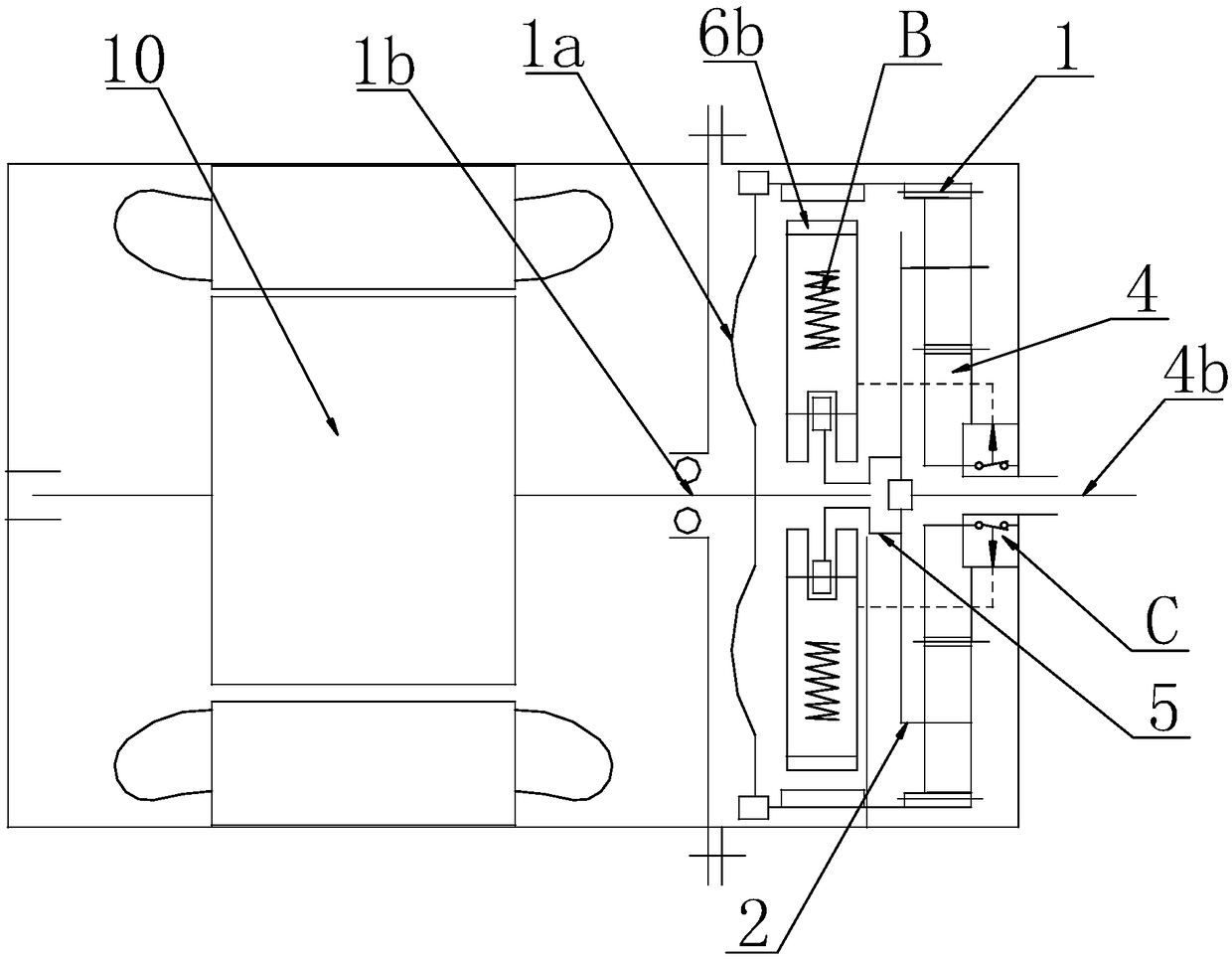

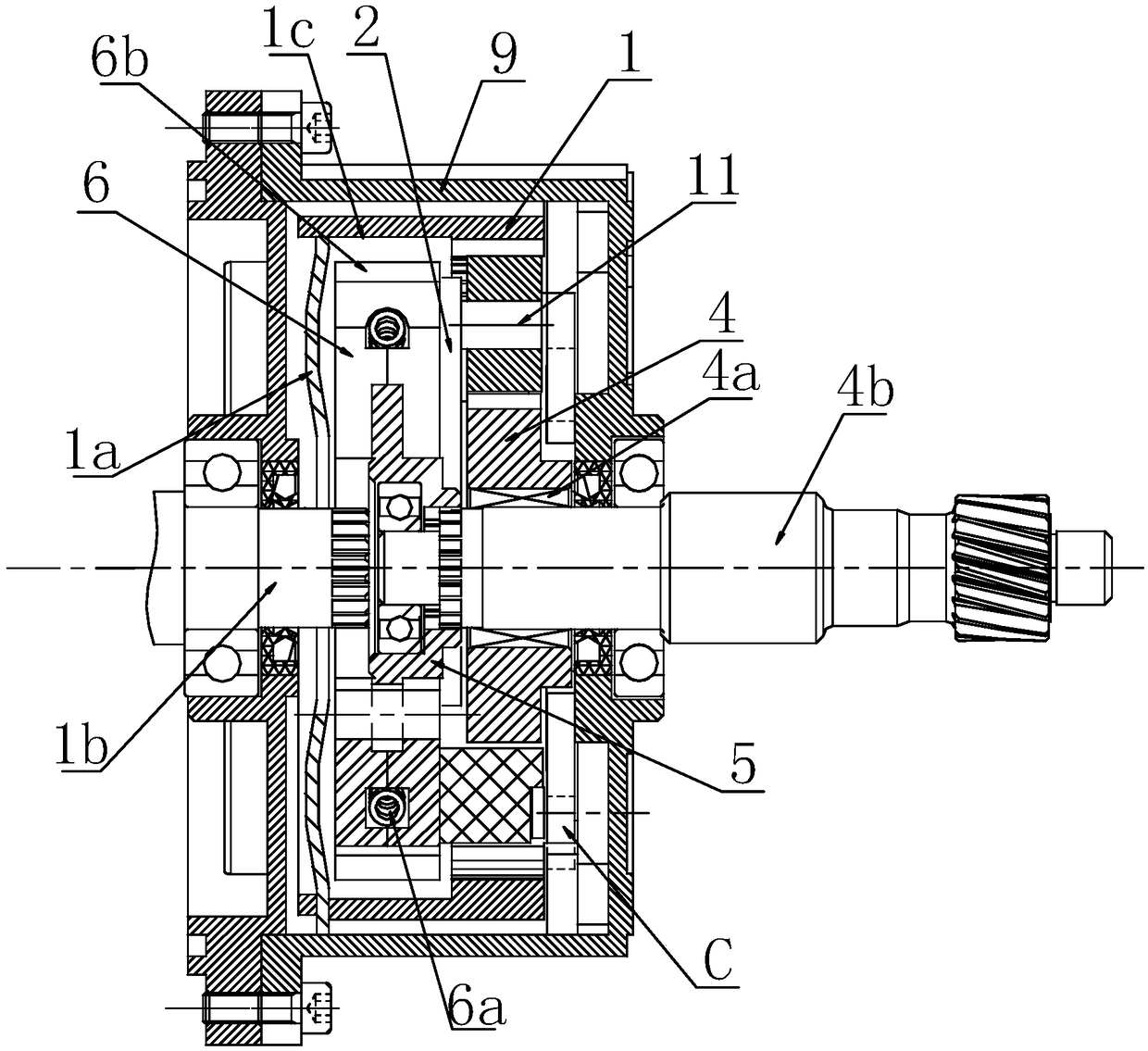

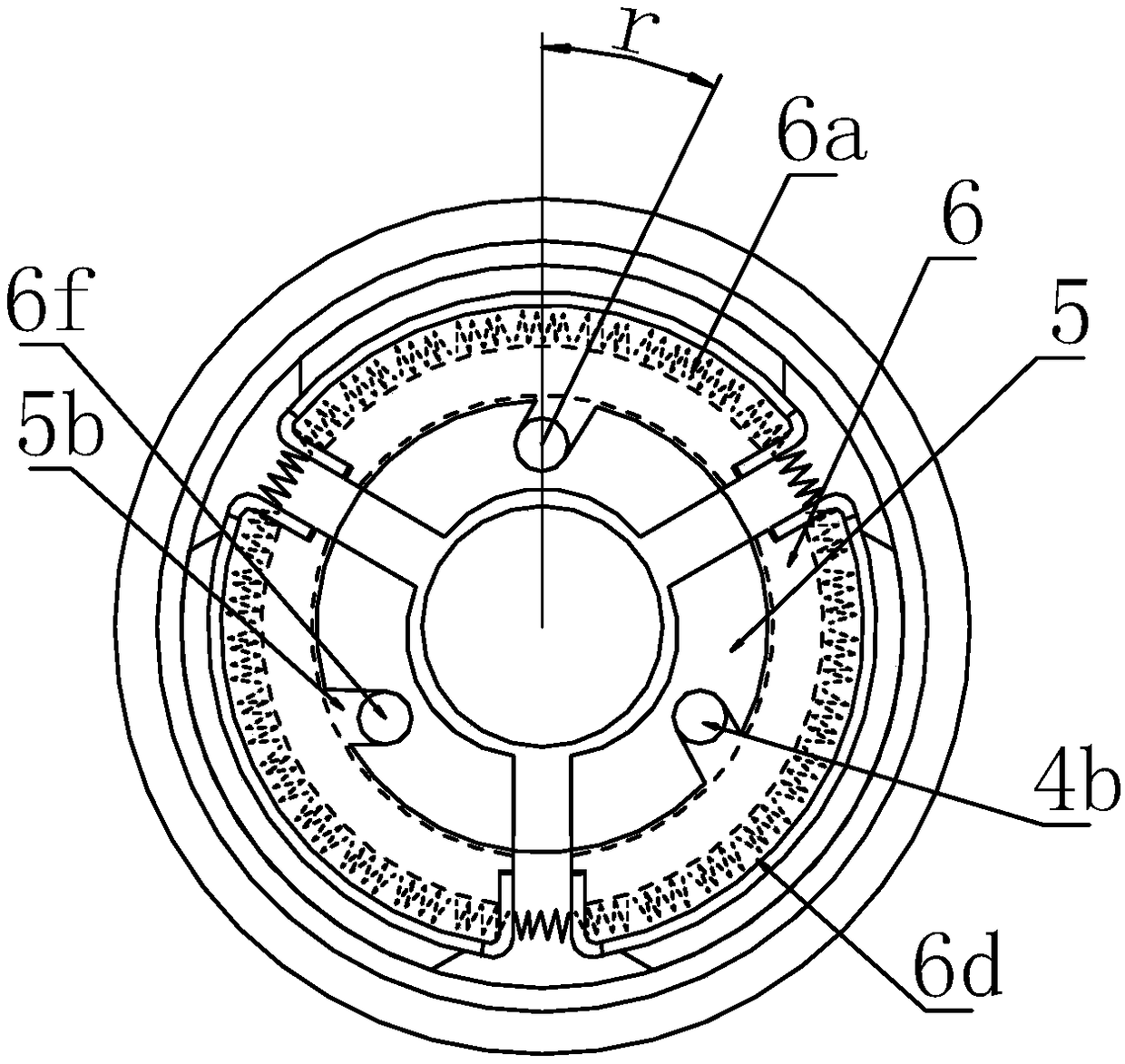

Driving device for full feeding rice and wheat combine power driver

The present invention discloses a kind of power driven transmission device for full feeding rice and wheat combine. The transmission device includes one power driven mechanism, one speed change gear box, and a step-less speed variator in between. There is also a step-less speed variator between the power driven mechanism and the walking gear box for realizing step-less speed variation of the gear box, expanding speed varying range, reducing impact force, raising transmission reliability and prolonging service life. Inside the speed consists of gear box, there are three-speed gear and gear shift mechanism, and this makes it possible for selecting proper operation shift and step-less speed varying mechanism according to harvested crop and field conditions.

Owner:泰州现代锋陵农业装备有限公司

Wave-wheel washing machine adapted for frequency conversion technology

InactiveCN101109141AFull performanceSimplify complex transmission mechanismsOther washing machinesWashing machine with receptaclesFrequency conversionOptimal combination

A wave-wheel washer applicable for frequency conversion technology comprises an inner barrel, an outer barrel and a wave wheel in the inner and outer barrel, a dewatering shaft connected with the inner barrel and a main body of the washer with a clutch having a drainage dragger. The washer is characterized in that the washer comprises additionally a frequency conversion motor, and the clutch is a synchronous clutch, the washing shaft is a cylindrical part whose upper end and lower part are square. In the upper and lower casing of the clutch, from down to up sequentially are a dewatering friction plate assembly fixed on the washing shaft, movable friction plates fixed respectively on the upper and lower part of the slide sleeve of the dewatering shaft, a pressure spring and an adjusting nut looped on the dewatering shaft; the washing friction plate assembly fixed on the joining site of the upper and lower casing is put against the bottom of the slide sleeve together with the roller on the shift fork assembly connected with the drainage dragger. The invention can realize the optimal combination of different washing, rinsing and dewatering, so as to save power, water, wash clean, achieve low wear and high dewatering rate, and the invention has greatly simplified the manufacturing process and reduced the cost.

Owner:QINGDAO TECHN COLLEGE

Variable air intake pipe length

InactiveUS7210444B2Simple wayLarge shifting rangeInternal combustion piston enginesAir intakes for fuelLow speedInternal combustion engine

An air intake system for an internal combustion engine has at least one air box and a short duct for each cylinder. Each duct can be extended to provide higher torque at low speed. At high speed, the shorter duct length can be selectively provided for enhanced engine performance.

Owner:BRP POWERTRAIN

Infinitely variable transmission for planetary gear

InactiveCN102840286AReduce weightLarge shifting rangeToothed gearingsGearing detailsGear wheelClassical mechanics

The invention relates to a mechanical transmission, in particular to an infinitely variable transmission for a planetary gear. The infinitely variable transmission mainly comprises one group of planetary gears, a worm gear, a worm, a friction transmission and the like, wherein a star wheel bracket is fixedly connected with the worm gear; and the transmission is used for controlling the rotating speed of the worm; and a planetary gear set is an execution device for the transmission. The infinitely variable transmission can be realized while high-power driving is carried out and the skidding is avoided. The infinitely variable transmission is wide in variable range and high in overload capacity. The infinitely variable transmission has respective advantages of vehicular CVT (Continuously Variable Transmission) and transmission gear boxes and is simpler and more reliable.

Owner:顾愈宝

Hydraulic planetary automatic stepless gearbox

InactiveCN1734129AThe principle is simpleSimple structureGearing controlFluid gearingsGear driveEngineering

This invention discloses a hydraulic planetary infinitely variable device, which includes the apron changing device, the torque-converter connector and the integrated fluid torque-converter, wherein the input shaft connects with the torque-converter by the apron changing device, and the torque-converter connects with the integrated fluid torque-converter, and the output shaft of the integrated fluid torque-converter connects with the driving gear of the different planetary wheels composed by the gears, and the input shaft connects with the solar wheel by the apron changing device, the output shaft of the integrated fluid torque-converter connects with the driving gear, the driving gear joggles with the driven gear, and the driven gear connects with the synchronous gear coaxially, and the synchronous gear joggles with the external gear loop, the external gear loop and the solar gear drive the planetary gear, the planetary gear drives the planetary frame, and the planetary frame connects with the output shaft.

Owner:刘岩

Driving wheel variable-speed gear

ActiveCN102518760ALarge shifting rangeUnique structureToothed gearingsPortable liftingLow noiseLow speed

The invention discloses a driving wheel variable-speed gear, which is provided with a movable gear train capable of radially moving, and has two sections of rotating speed output when being matched with a variable-speed motor. When the movable gear train moves outward to disengage two gear wheels, the power input through an input shaft is directly output from a clutch and an output shaft, then gear wheel engagement and gear wheel noise are avoided; and when the movable gear train moves inward to engage the two gear wheels, the clutch is disengaged from the input shaft, the power input through the input shaft is transmitted to the output shaft after the speed reduction of the two gear wheels, and is output through the output shaft, as a result, the driving wheel variable-speed gear achieves the purposes of high speed and low noise, low speed torque increasing and speed range widening, has an unique structure, and is widely applicable.

Owner:山东济清科技服务有限公司

Stepless speed change structure for planetary gears

InactiveCN102537238AChange speed ratioRealize infinitely variable speedToothed gearingsGearing detailsControl powerGear wheel

The invention discloses a stepless speed change structure for planetary gears, which has the advantages of high torque bearing capability, no slipping, simple structure, less parts, low manufacture and maintenance costs, superior long service life and wide speed change range, and can be applied to heavy-duty vehicles, large-scale vehicles and mini-type vehicles. Based on the structural characteristics of the planetary gears, the stepless speed change of power input and output speeds is realized when the revolution ratio between a gear ring and a sun gear is changed by changing the rotational speed of a planetary gear rack. The stepless speed change structure comprises the gear ring, the planetary gear rack and the sun gear, wherein the gear ring is connected with the power input shaft of a vehicle engine; the sun gear is connected with the power output shaft; the planetary gears are mounted on the planetary gear rack and are connected with a power adjusting control device capable of changing the speeds of the planetary gears; and the power adjusting control device comprises a control power input shaft and a control gear arranged at one end of the control power input shaft.

Owner:宏万兵

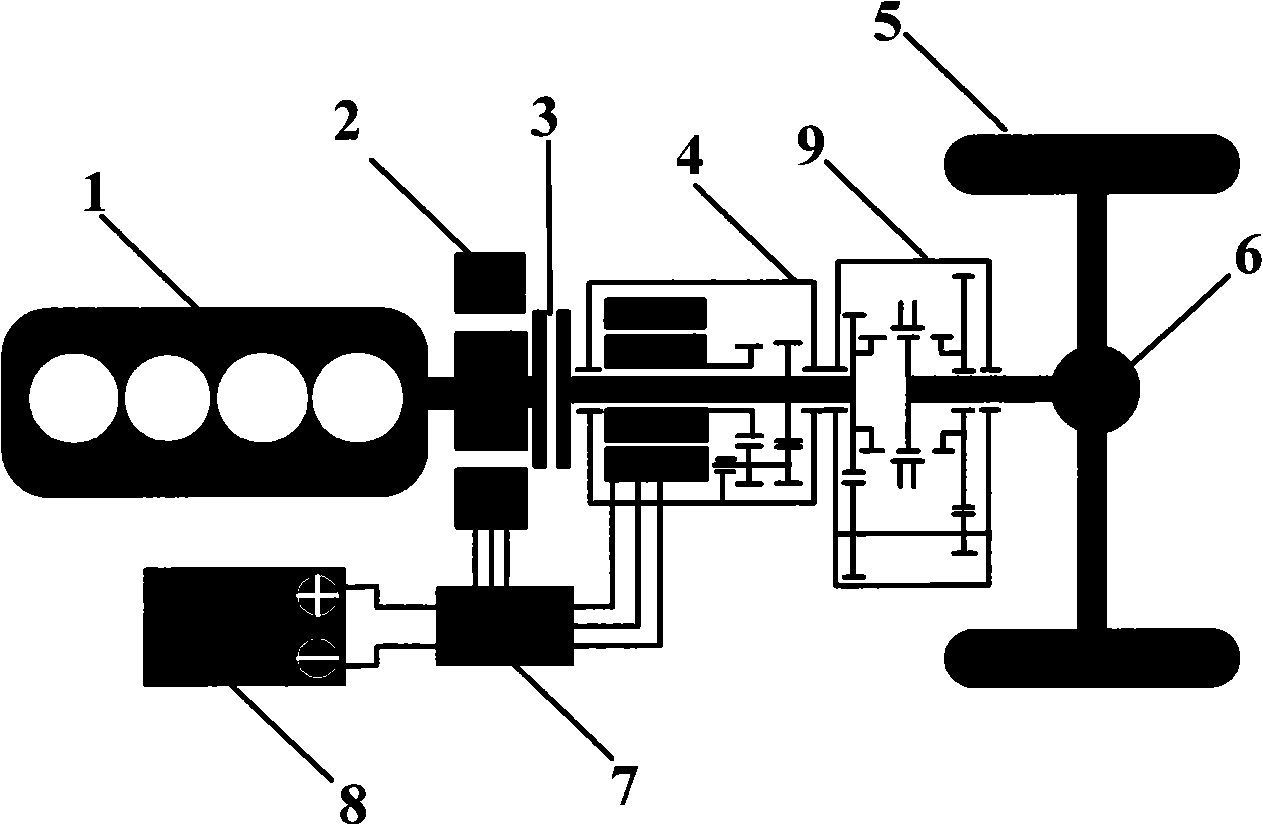

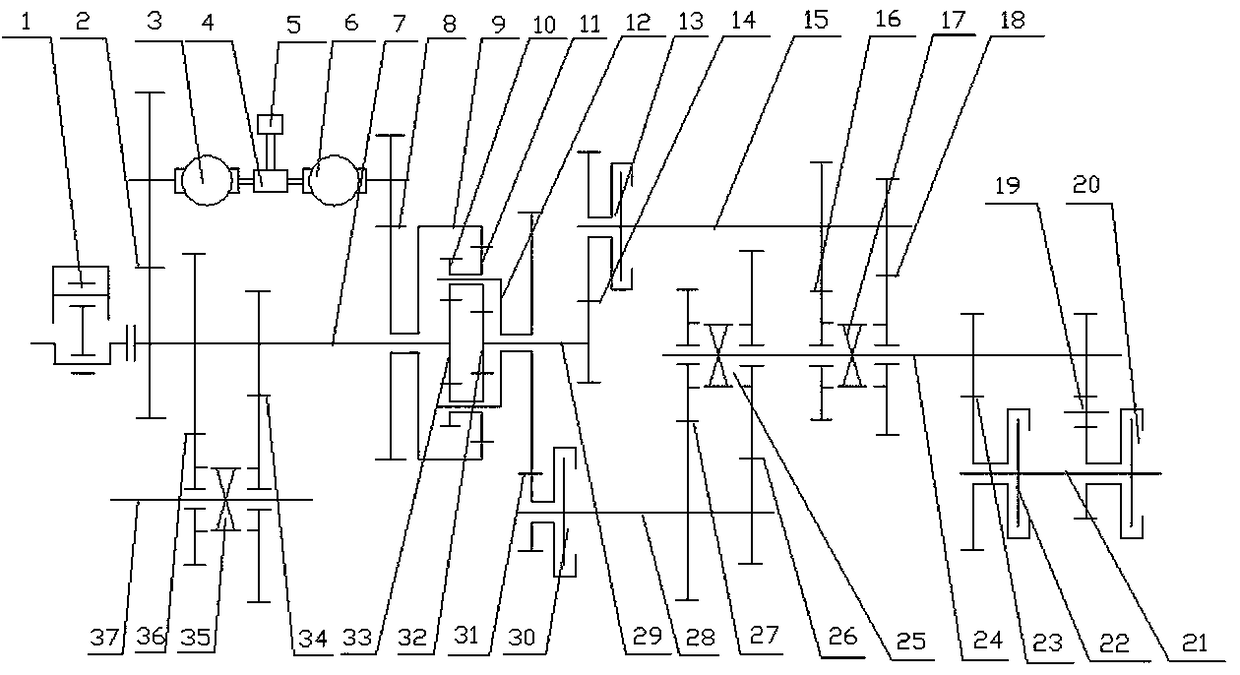

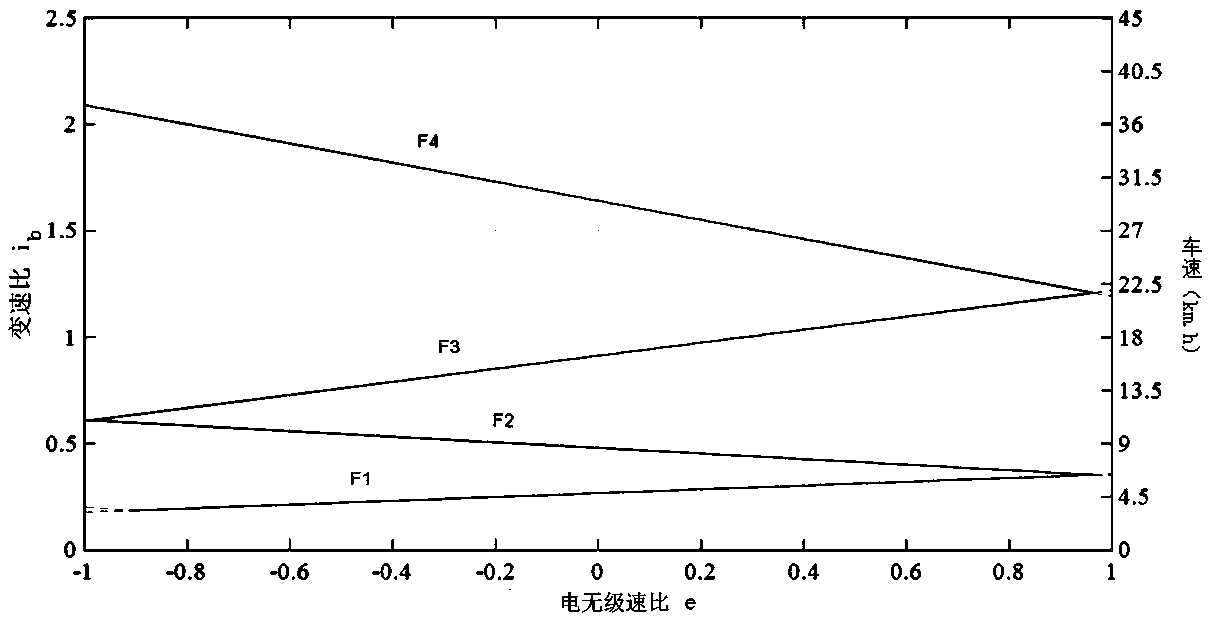

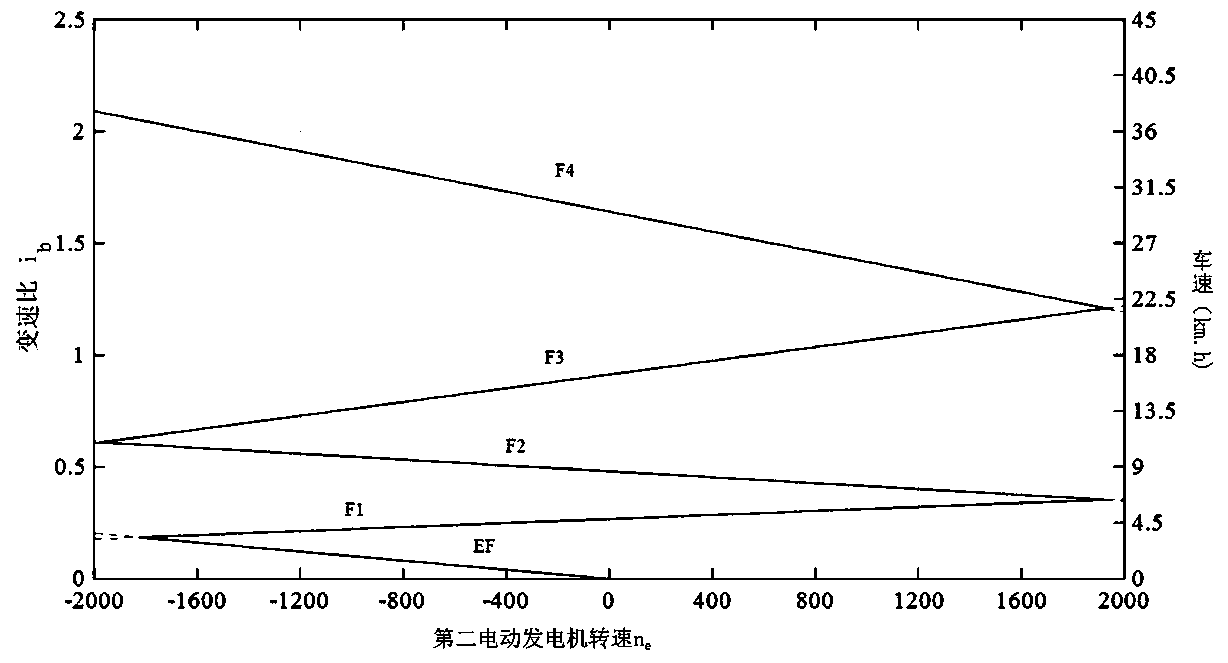

Hybrid tractor continuously variable transmission

PendingCN109353210ALarge shifting rangeHigh transmission efficiencyGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingVariatorEnergy recycling

The invention relates to the field of transmission equipment, in particular to a hybrid tractor continuously variable transmission. The hybrid tractor continuously variable transmission comprises a transmission input shaft, a transmission output shaft, an electric power system and a compound planetary gear mechanism. The hybrid tractor continuously variable transmission has the advantages that while the requirements of traction force, traction power and traction speed of various working conditions of a tractor are met, multi-stage continuous stepless speed change can be achieved, and two different hybrid power modes and special working modes such as loaded parking, brake energy recycling and parking for charging can also be achieved, thereby meeting the requirements of the complex workingconditions of the tractor; the speed range is wide, the transmission efficiency is high, good fuel economy and environmental protection of the tractor can be achieved, energy is saved, the efficiencyis high, the multi-stage continuous stepless speed change can be achieved by using a motor generator with less power, thereby reducing the volume of the motor generator, so that the transmission structure is more compact.

Owner:HENAN UNIV OF SCI & TECH

Automatic transmission for electric vehicles

ActiveCN108644326ACompact structureRealize reverse gearToothed gearingsGearing controlLow speedAutomatic transmission

The invention discloses an automatic transmission for an electric vehicle. The automatic transmission comprises a speed change mechanism arranged between an input shaft and an output shaft, wherein aplanetary transmission mechanism and a clutch device are arranged in the speed change mechanism; the planetary transmission mechanism is composed of a first transmission part, a second transmission part and a third transmission part; when the first transmission part is connected with the input shaft, the second transmission part or the third transmission part is connected with the output shaft; and the clutch device is composed of a driving disc, a first clutch unit and a second clutch unit, wherein the first clutch unit is installed on the first transmission part in a matched mode, and the second clutch unit is installed on the second transmission part or the third transmission part in a matched mode. The automatic transmission has the advantages of compact structure, high and low speed two-gear automatic shifting, stable shifting, wide shifting range and no impact. At the same time, the reverse rotation of a driving motor can further enable a motor vehicle to reverse.

Owner:重庆乾威科技有限公司

Synchro clutch for washing machine

InactiveCN101109143AHumanized functionBig choiceOther washing machinesWashing machine with receptaclesSynchroEngineering

The invention relates to a synchronous clutch for washers. In the up and lower casing that are closing each other, from down to up sequentially the following parts are provided: a dewatering friction plate assembly fixed on the washing shaft and near to the bottom of the casing, movable friction plates fixed respectively on the upper and lower part of the slide sleeve that are connected with the dewatering shaft by a spline; washing friction plates that are fixed on washing friction plate assembly located at the joining site of the upper and lower casing and corresponding with the movable friction plates; a roller that is connected with the drainage dragger and passes into the shift fork assembly located at the perimeter of the lower casing through a pin shaft is put against the bottom of the outer cylindrical face of the spline in the slide sleeve. The invention is of novel, reasonable and simple structure. A wave-wheel washer using the invention as a drive system can realize the optimal combination of different washing, rinsing and dewatering, so as to save power, water, wash clean, achieve low wear and high dewatering rate, and can greatly simplify the complex drive mechanism and high manufacturing cost of wave-wheel washers.

Owner:QINGDAO TECHN COLLEGE

Variable-diameter crankshaft type gear stepless speed change method and speed changer

The invention discloses a variable-diameter crankshaft type gear stepless speed change method and a speed changer. A variable-diameter slider is arranged on the end face of a power input shaft to form an end face friction pair, the variable-diameter slider and a planetary gear of a planetary gear train are coaxial, a crankshaft radius is formed by controlling the axis of the variable-diameter slider and the axis of the power input shaft, and the power input shaft inputs power to drive the variable-diameter slider to rotate and enable the axis of the variable-diameter slider to rotate around the center line of the power input shaft to form crankshaft movement. The planetary gear of the planetary gear train is driven to rotate by means of the crankshaft movement of the center line of the power input shaft, and power of the center line of the variable-diameter slider is transferred to an output shaft by the planetary gear under the limiting action of a gear ring of the planetary gear train to realize a function of continuous stepless speed change. Gear normally meshed shaft transmission is adopted for realizing continuous variable speed change, the speed change range is wide, the speed ratio ranges from zero to a fixed value, using a clutch for starting is not needed, large torque is available while 'skidding' is avoided, the speed change response is quick, and transmission efficiency is free of fluctuation.

Owner:杨建明

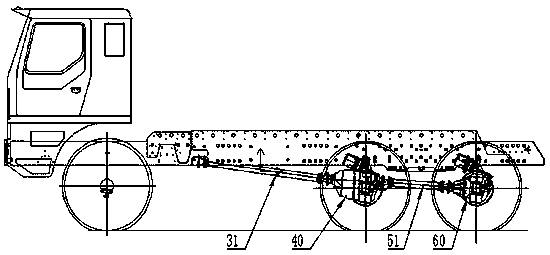

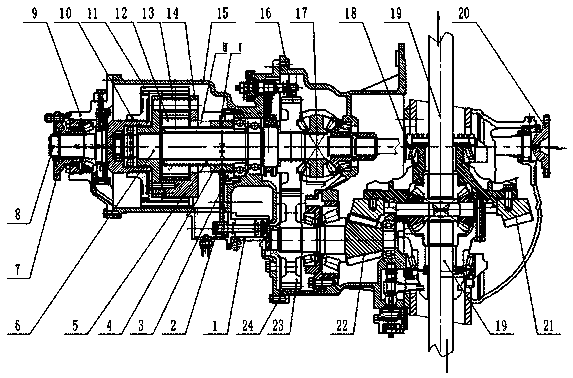

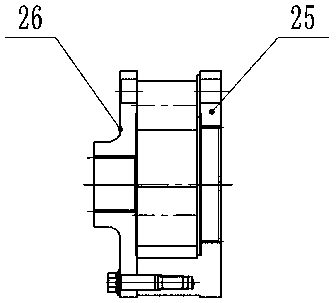

Heavy truck duplex driving axle capable of achieving double speeds

PendingCN109334348AHighlight shifting functionWith variable speed functionAxle unitsControl devicesDrive shaftControl system

The invention discloses a heavy truck duplex driving axle capable of achieving double speeds. The driving axle is composed of a middle axle assembly and a rear axle assembly, and is characterized in that a power transmission system of the middle axle assembly is composed of an input flange, an input shaft, an end cover, a box body, a planetary speed reducing device, a spline sleeve, a sliding meshing sleeve, a fixed support, an output shaft, an inter-axle differential assembly of the duplex driving axle, a driving cylindrical gear, a driven cylindrical gear, a driving bevel gear, a driven bevel gear pair, an inter-wheel differential assembly, a half shaft (19), a through shaft, an inter-axle transmission shaft and the rear axle assembly; a control system of the middle axle assembly is composed of a spline sleeve, a sliding meshing sleeve, a fixed support, a shifting fork and a reversing valve assembly. The driving axle has a speed change function, the use range of a truck is wider, andthe driving axle has the advantages of being simple and compact in structure, having few reversing elements, being high in transmission efficiency and the like.

Owner:SHANDONG PENGXIANG AUTOMOBILE

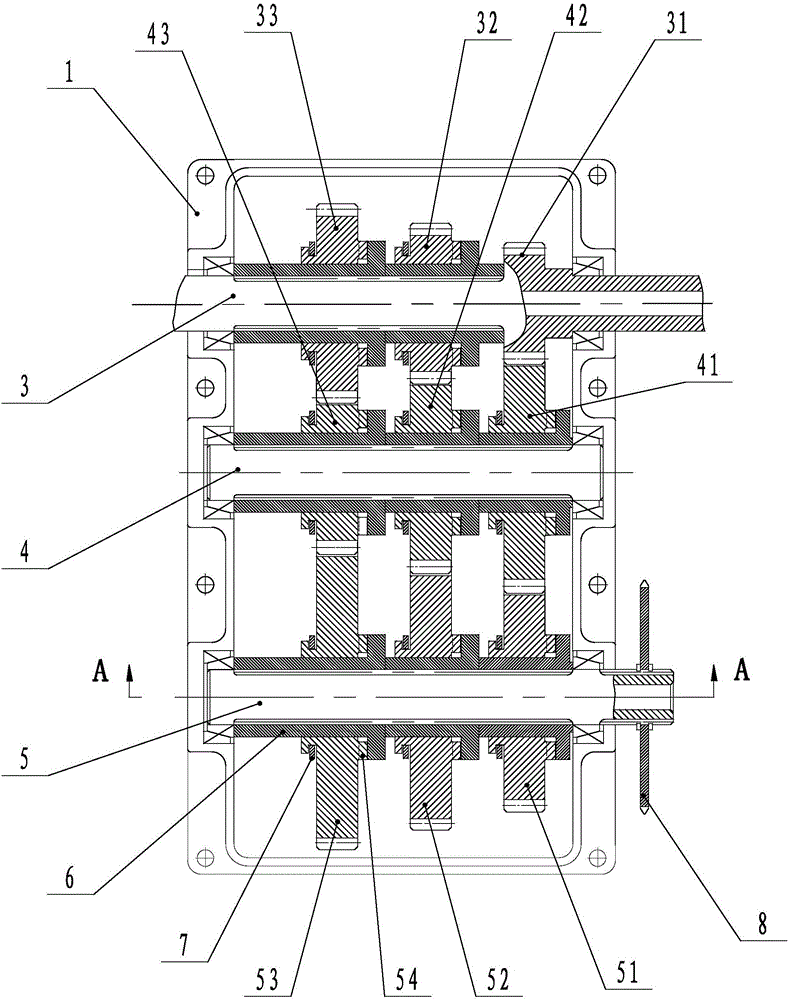

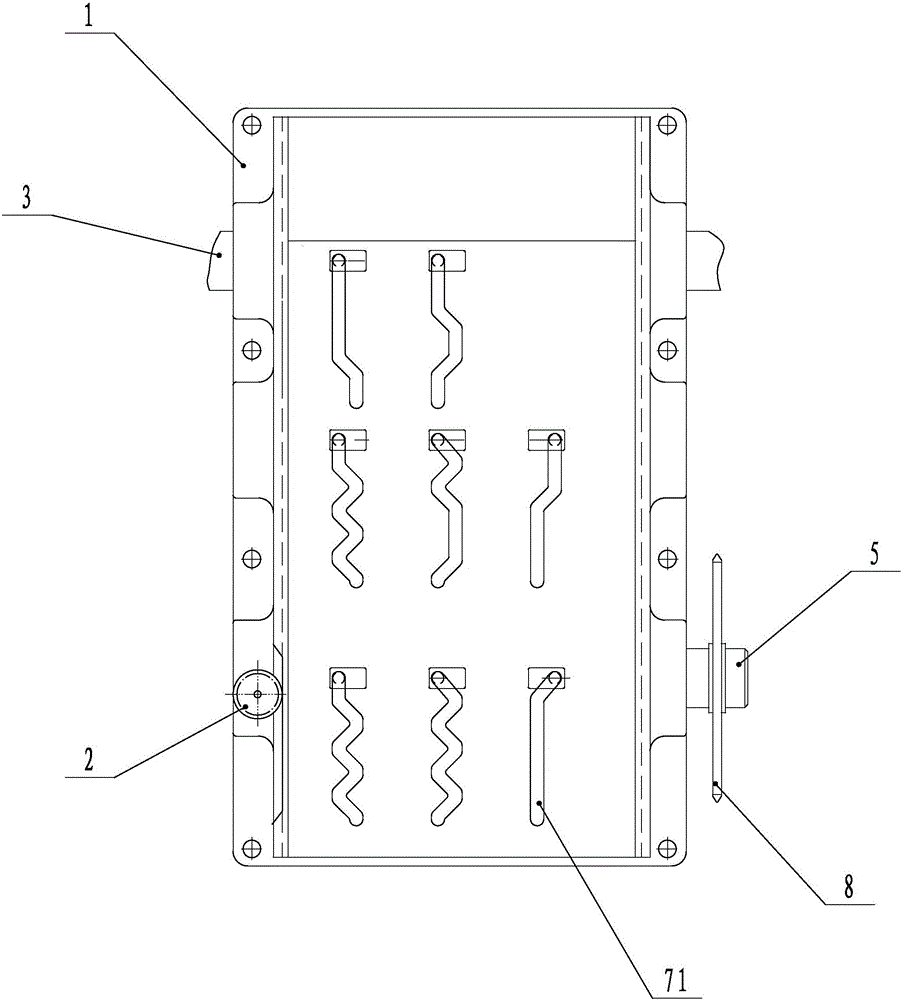

Line control and electricity control double-gear-shifting-mode bicycle center shaft gearbox with multi-gear speed change function

ActiveCN106080949ARealize electronically controlled shiftingAvoid erosionWheel based transmissionCycle actuatorsElectricityGear wheel

The invention discloses a line control and electricity control double-gear-shifting-mode bicycle center shaft gearbox with a multi-gear speed change function. The line control and electricity control double-gear-shifting-mode bicycle axis gearbox comprises a box body and a driving motor, wherein a center shaft, a middle shaft and a driven shaft are arranged in the box body; a corresponding driving gear, a middle gear and the driven gear are respectively arranged on the center shaft, the middle shaft and the driven shaft. The line control and electricity control double-gear-shifting-mode bicycle center shaft gearbox has the advantages that two kinds of gear shifting modes including line control and electric control are realized; in addition, many gears can be set; the speed change range is wide; in addition, through the arrangement of the middle shaft, the appearance of the device is ingenious, the weight is light, and the use influence due to too large size is avoided. The use is simple; the cost is low; the speed change regulation is fast and convenient; in addition, one end of a separation plate is inserted and connected with the lower end of the box body; the other end of the separation plate extends out of the outer part of the upper end of the box body; force required for driving the separation plate is small; the driving motor can easily push the separation plate to realize the precise speed change; in addition, main transmission components are arranged in the box body; the erosion of sundries such as silt and rainwater is avoided; the performance is stable; the fault rate is low; the practicability is high.

Owner:ZHONGSHAN JUNGUO ELECTRICAL APPLIANCES CO LTD

Stepless gearbox

InactiveCN104061307AExtended torqueLarge shifting rangeFluid gearingsGearing detailsGear wheelEngineering

The invention belongs to the field of transmission, and relates to a stepless gearbox. The gearbox solves the problems that the cost is high, a transmission belt is easy to damage, larger load cannot be born, and the like, existing in the existing stepless gearbox. The advantages of the stepless gearbox are achieved, and larger load can also be born. The gearbox has the advantages of simple and reliable structure, compactness and low cost. The gearbox transfers power to a hydraulic torque converter pump impeller 9 and ring gears 15 of a planetary gear set through an input device 2. A planetary carrier 12 of the planetary gear set is connected with an output device 3 to output power; a sun gear 13 of the planetary gear set is connected with a turbine 8 of a hydraulic torque converter, so that the turbine 8 of the hydraulic torque converter rotates reversely. The speed difference between the pump impeller 9 and the turbine 8 of the hydraulic torque converter is increased, so that the bending moment range and the speed change range are expanded. The torque, the rotational speed and the rotation direction of the turbine 8 are changed by the pump impeller, so that the power output of the gearbox is changed.

Owner:夏兴旺

Long-conical and rolling-conical type stepless variable drive mechanism

InactiveCN102927227ASmall geometric slip rateReduced geometric slip rateToothed gearingsFriction gearingsMechanical driveContact position

The invention discloses a long-conical and rolling-conical type stepless variable drive mechanism which comprises a first long-conical roller, a second long-conical roller and an intermediate rolling-conical wheel; a first conical surface and a second conical surface are arranged on the intermediate rolling-conical wheel; the first conical surface is in contact drive with the first long-conical roller; the second conical surface is in contact drive with the second long-conical roller; the contact positions of the intermediate rolling-conical wheel on two long-conical rollers can be adjusted, therefore, the working radiuses of the two long-conical rollers can be continuously changed, and as a result, the stepless variable drive can be achieved. According to the long-conical and rolling-conical type stepless variable drive mechanism, the geometrical slippage is zero under the optimal drive, so that the geometrical slippage of the conical wheel type long-conical and rolling-conical type stepless variable drive mechanism can be effectively reduced, and the drive efficiency and power can be increased. The long-conical and rolling-conical type stepless variable drive mechanism is applicable to various fields such as the vehicle field, the ship field and the mechanical drive field.

Owner:郭克亚

Four-speed transmission for hybrid power vehicle

The invention provides a four-speed transmission for a hybrid power vehicle. The four-speed transmission is mainly applied to the hybrid power vehicle and can provide four forward gear ratios, the torque and rotating speed range of a motor of the hybrid power vehicle is expanded, and the motor driving speed range is expanded. The transmission comprises an input shaft, an output shaft, a motor output shaft, a first gear selecting assembly, a second gear selecting assembly and four sets of variable-speed gear pairs, wherein the motor output shaft and the input shaft transmit motion and torque through gears (or chain wheels), one of the four sets of variable-speed gear pairs is selected through the gear selecting assemblies to transmit motion and torque, four gear ratios can be obtained between an engine crankshaft and a driving gear, and four gear ratios can also be obtained between the motor output shaft and the driving gear.

Owner:重庆红岭动力技术有限公司

Ship-locating working winch with large pulling force

InactiveCN1843886AImprove work efficiencyShort construction periodWinding mechanismsPull forceCoupling

The invention discloses a large drawing-force positioning winch of ship, which comprises the systems as power, shift, cylinder group, row wire, ratchet wheel brake, quick-drawing, constant tension and control. Wherein, the shift system comprises a planet power shift device and a power dual-dividing device; the planet power shift device is mounted with a motor, a coupler, two shift brakes, a high-speed brake and two planet supports, while the first planet support is connected to the second sun wheel; the first gear ring is connected to the second gear ring; the coupler is connected to the high-speed brake; the first shift brake is connected to the second planet support; the second shift brake via the coupler is connected to the first planet support; the output of first planet support is mounted with the second gear ring and the output big gear wheel; the power dual-dividing device is mounted with a gear wheel axle, a transmission gear wheel, two branch gear transmission devices and water-cooling brake that meshed with output big gear wheel; the water-cooling brake is connected to the gear wheel axle and the transmission gear wheel to realize damping brake. The inventive winch can work on marine with high efficiency, high support ability, anti-impact ability and shortened construction time.

Owner:SHANGHAI ZHENHUA HEAVY IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com