Combine

A technology for combine harvesters and engines, which is used in harvesters, cutters, steering mechanisms, etc., can solve the problems of not increasing the speed, simplifying the driving structure, and easily generating shocks, so as to prevent the reduction of the driving speed and reduce the blockage. , the effect of simplification reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

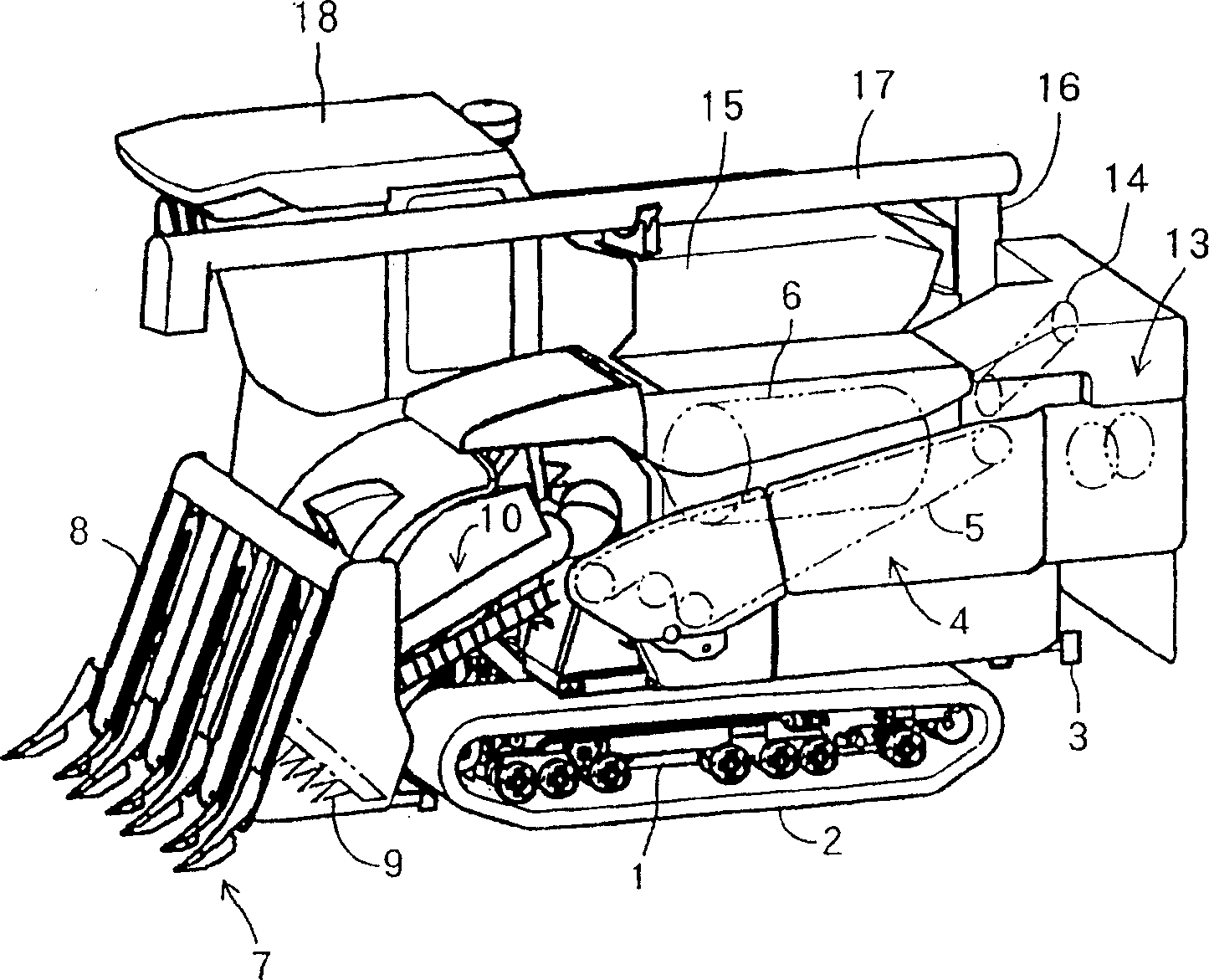

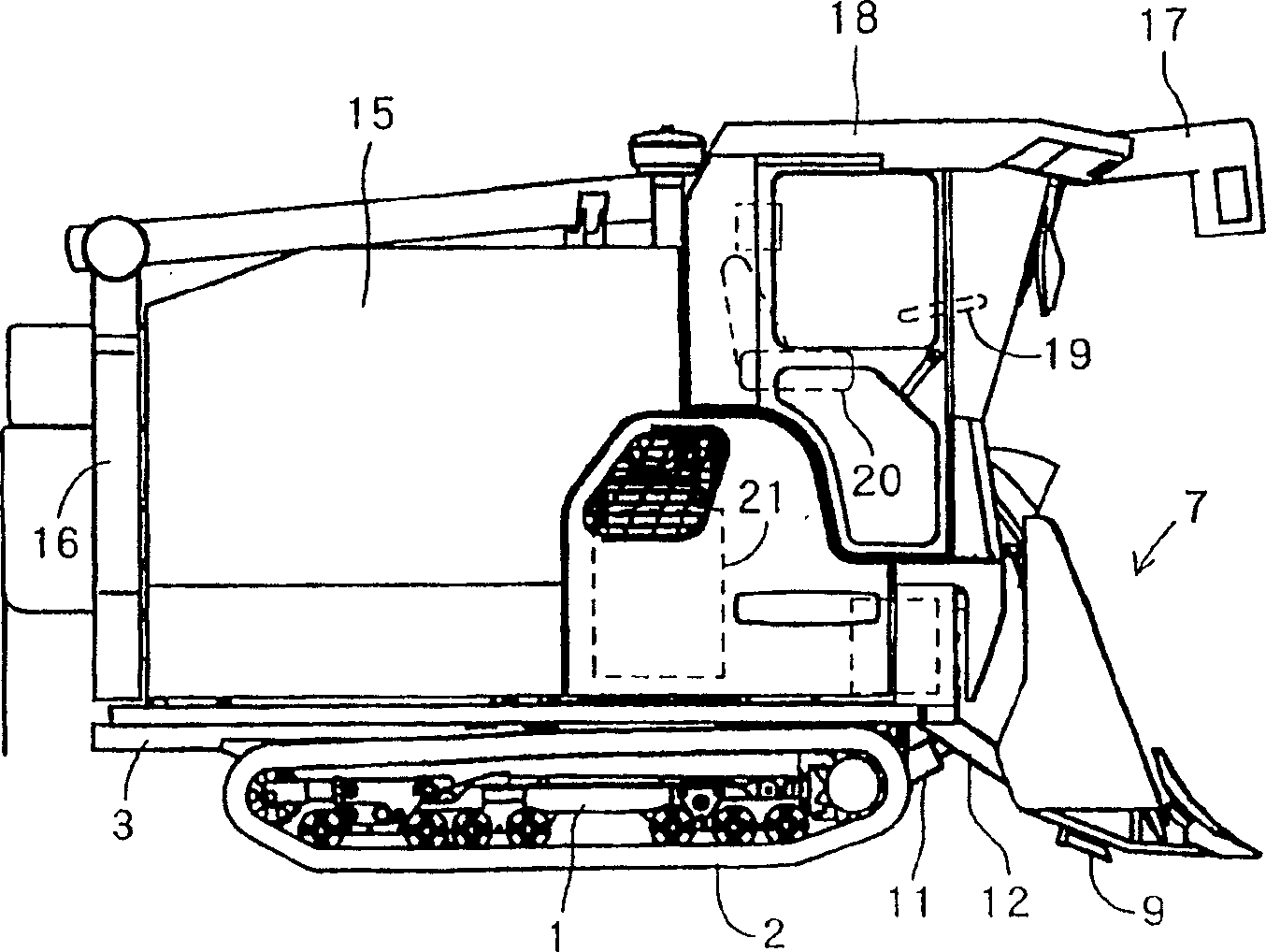

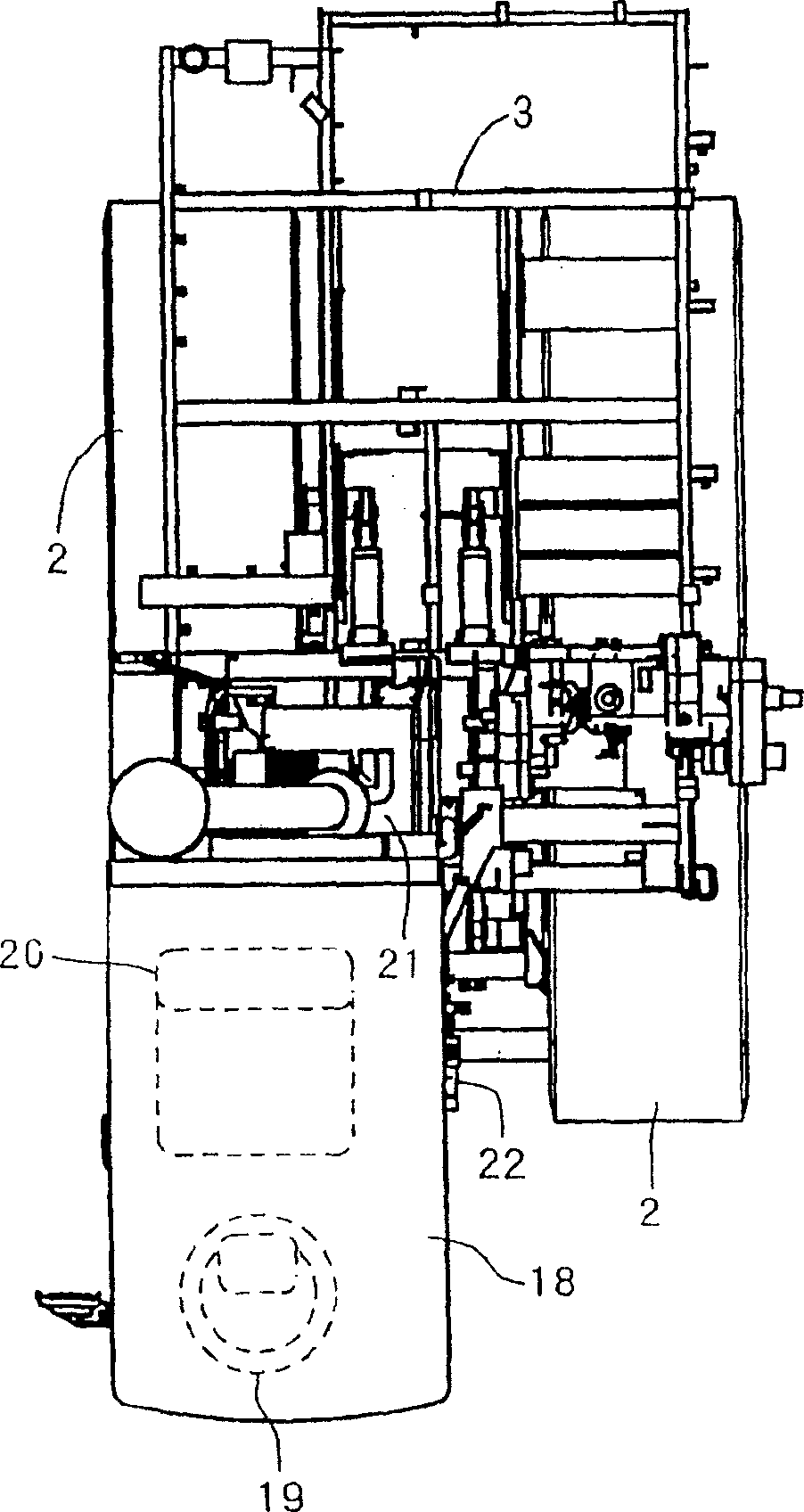

[0047] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings. figure 1 It is a perspective view of the whole combine harvester, figure 2 is the same as the right side view, image 3 It is an explanatory top view, in which 1 is a pair of left and right bogie frames on which a pair of left and right traveling crawler belts 2 are installed, 3 is a machine platform erected on the above-mentioned left and right bogie frames 1, and 4 is a set of feed chains 5 on On the left side, the threshing part of the threshing machine that has built-in operation tube 6 and processing tube, 7 is to have the harvesting part of raising mechanism 8 and harvesting knife 9 and grain stalk conveying mechanism 10 etc., and 11 is to pass through harvesting frame 12, make The hydraulic lifting cylinder of the harvesting section 7 lifting, 13 is the straw discharge processing section facing the 14 terminals of the straw discharge chain, the 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com