Power transmission chain and method of manufacturing the same, and power transmission device

A power transmission device and technology of power transmission, applied in the direction of belt/chain/gear, V-belt, mechanical equipment, etc., can solve the problems of increasing the bending moment of the chain and reducing the power transmission efficiency of the chain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

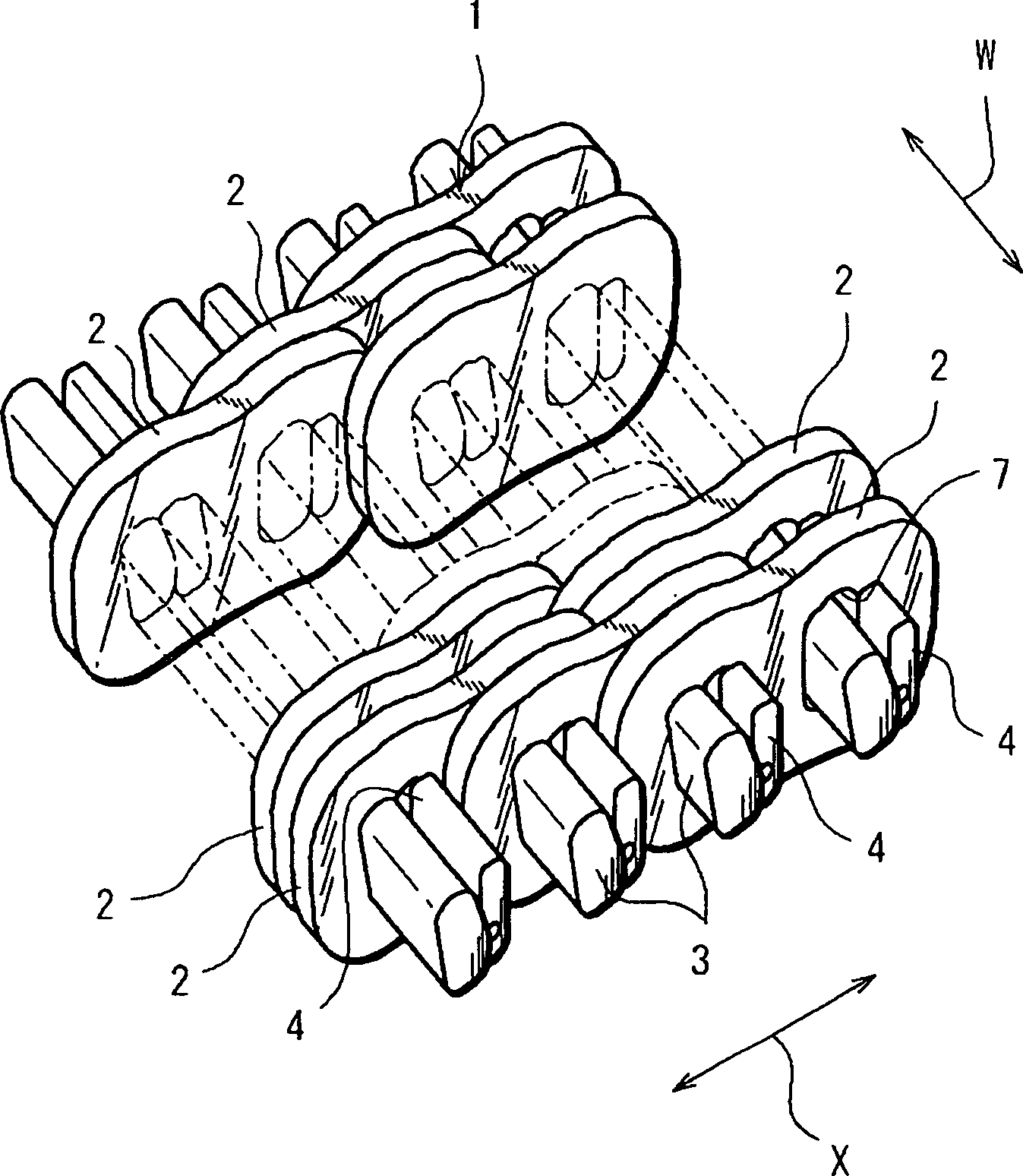

[0035] Preferred embodiments of the present invention will be described with reference to the drawings. figure 1 It is a perspective view typically showing the configuration of a main part of a power transmission chain (hereinafter, simply referred to as a chain) employed in the chain-type continuously variable transmission according to the first embodiment of the present invention. refer to figure 1 , the chain 1 includes: a plurality of link plates 2 arranged in the chain advancing direction X and the width direction W of the chain; a plurality of chain pins 3 for interconnecting these link plates 2; slightly shorter than the chain pins 3 Multiple narrow strips of 4.

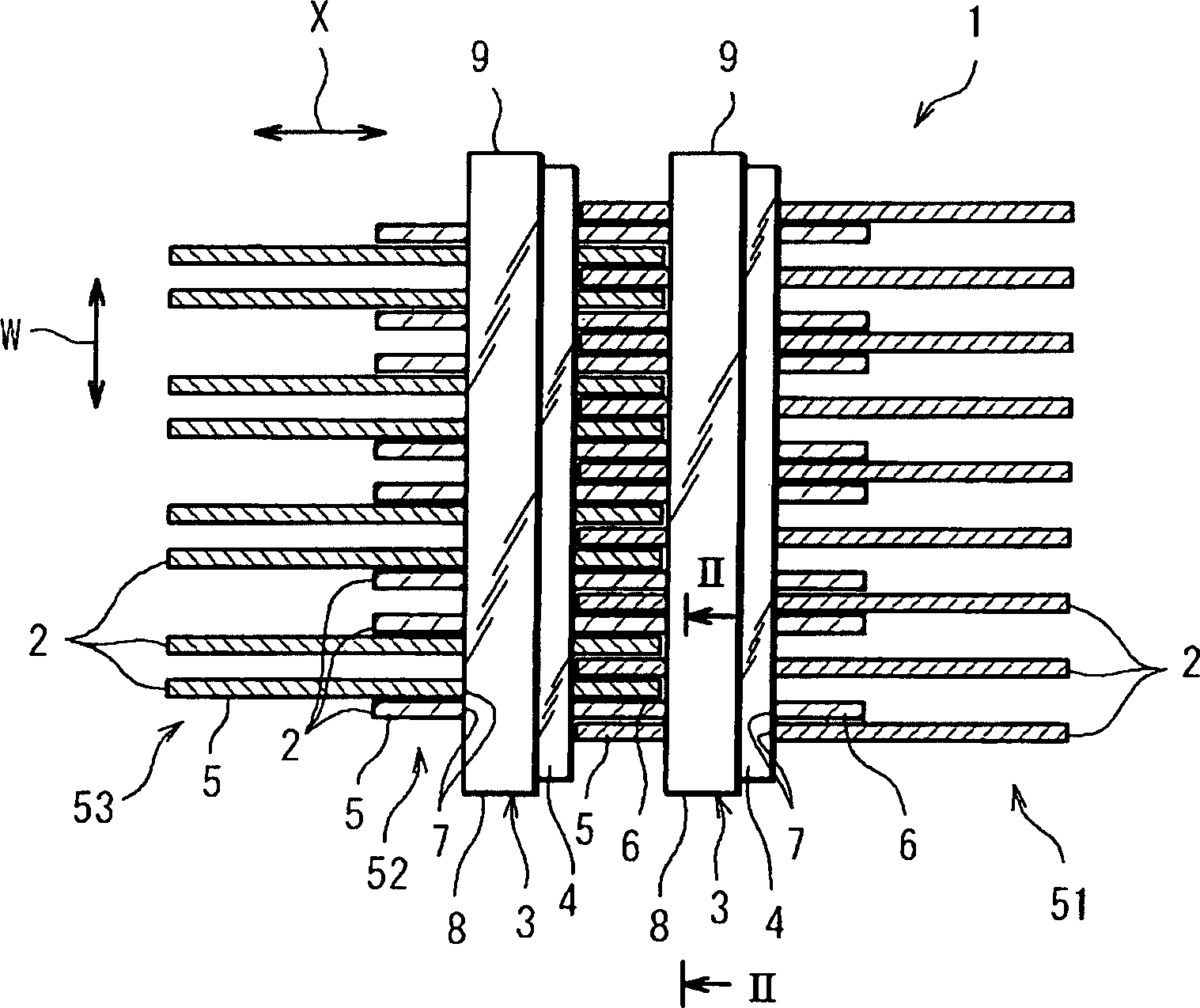

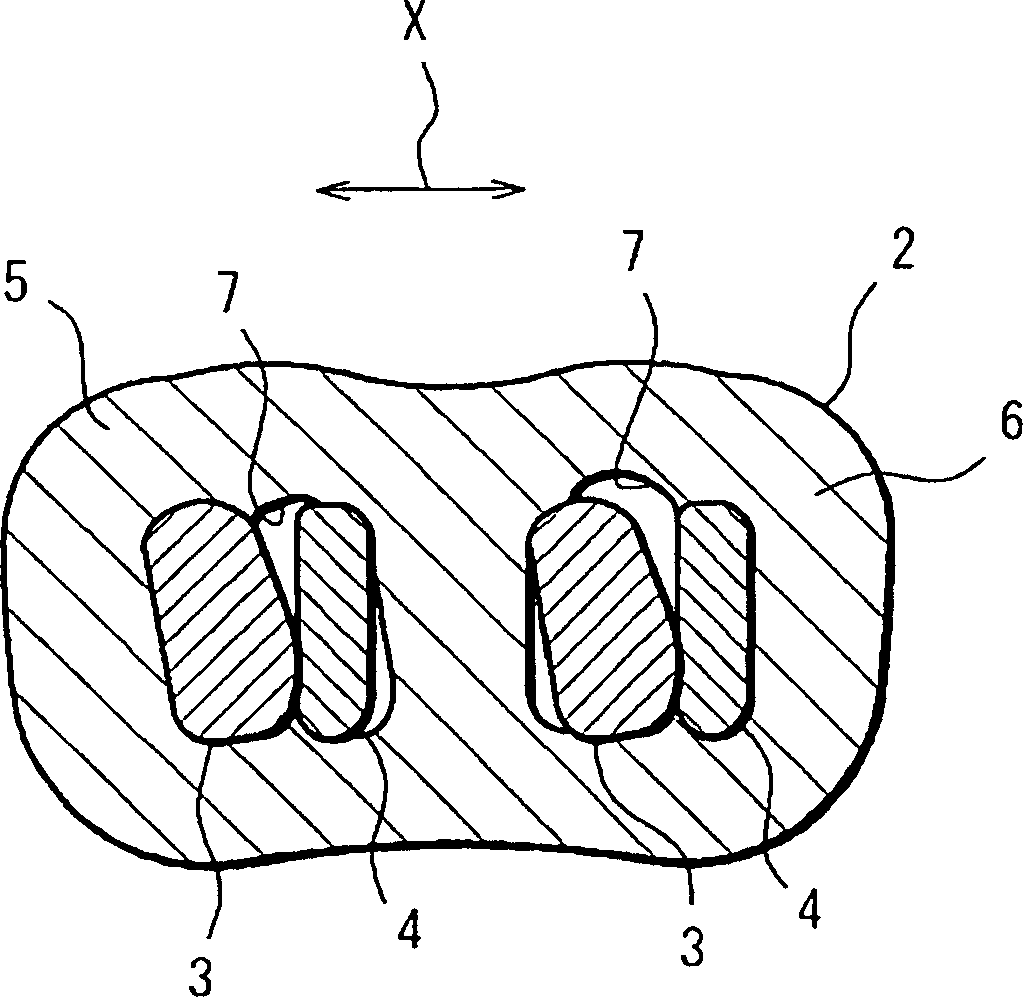

[0036] figure 2 yes means figure 1 The shown cross-sectional view of the main part of the chain 1 shows three sets of link plate groups including a plurality of link plates 2 at the same positions in the chain advancing direction X. As shown in FIG. Specifically, the first link plate group 51 , the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com