Manufacture method of power transmission chain

A technology of power transmission and manufacturing method, applied in the field of power transmission chain manufacturing, can solve the problems of reducing the power transmission efficiency of the chain and increasing the bending moment of the chain, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

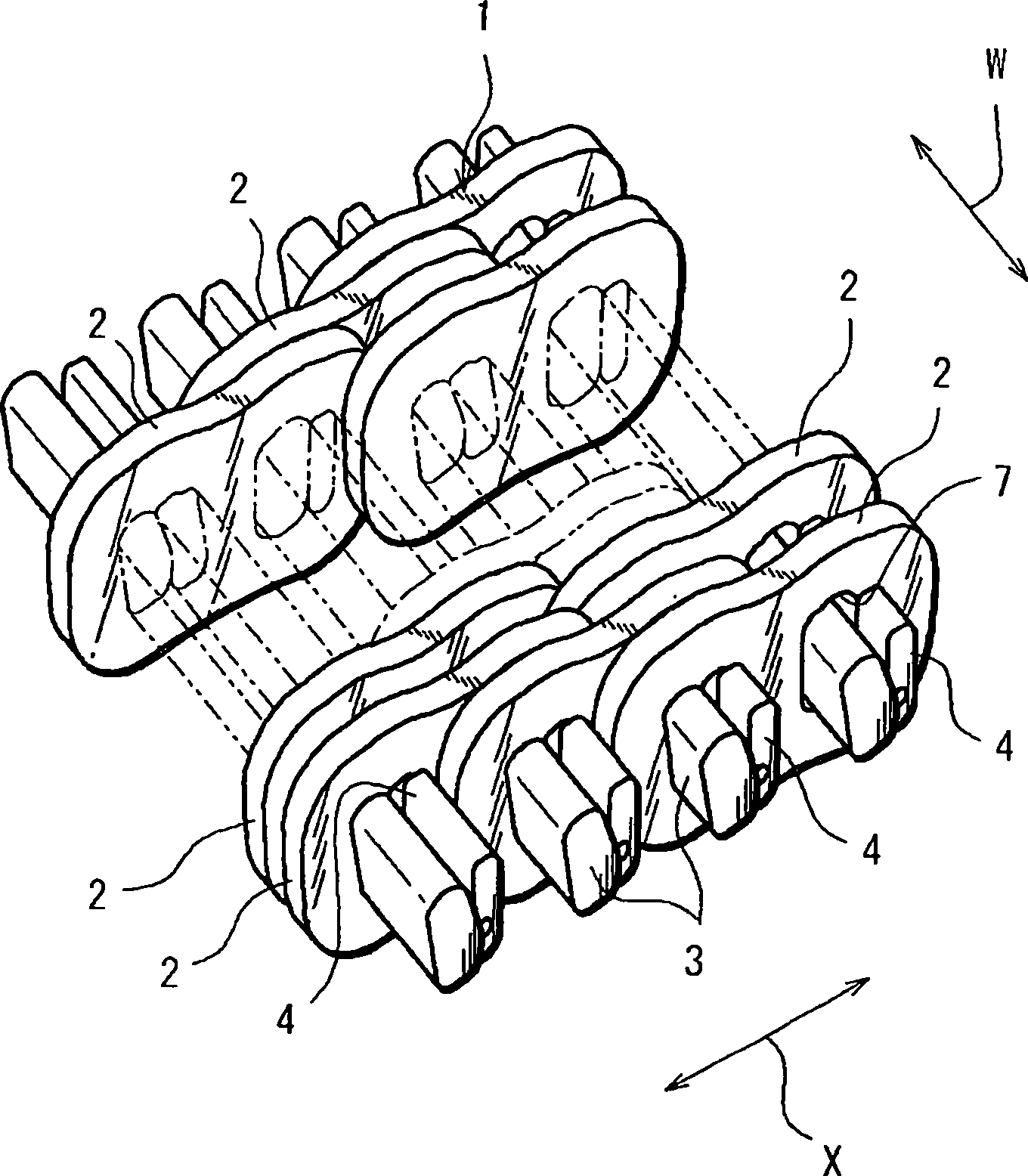

[0035] Preferred embodiments of the present invention will be described with reference to the drawings. figure 1 It is a perspective view typically showing the configuration of a main part of a power transmission chain (hereinafter, simply referred to as a chain) employed in the chain-type continuously variable transmission according to the first embodiment of the present invention. refer to figure 1 , the chain 1 includes: a plurality of link plates 2 arranged in the chain advancing direction X and the width direction W of the chain; a plurality of chain pins 3 for interconnecting these link plates 2; slightly shorter than the chain pins 3 Multiple narrow strips of 4.

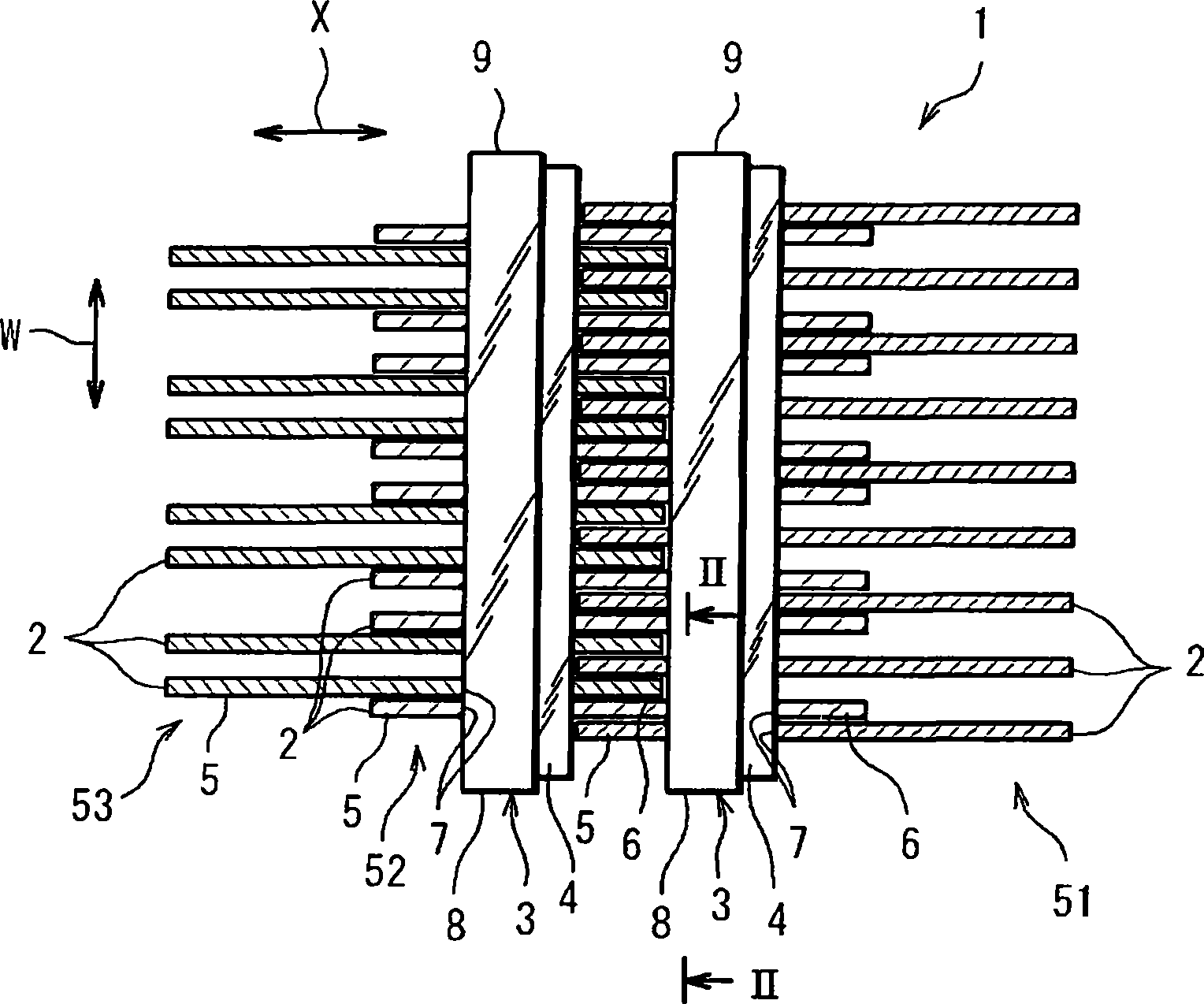

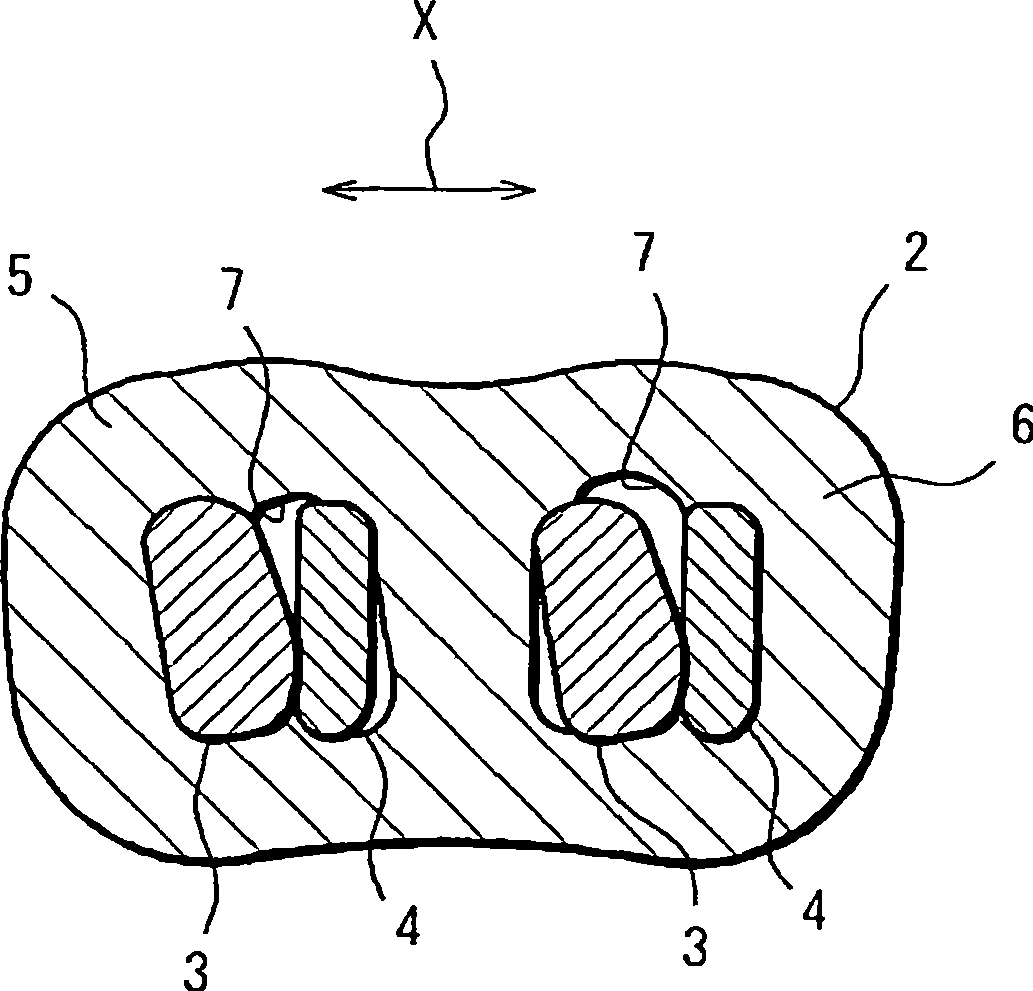

[0036] figure 2 yes means figure 1 The shown cross-sectional view of the main part of the chain 1 shows three sets of link plate groups including a plurality of link plates 2 at the same positions in the chain advancing direction X. As shown in FIG. Specifically, the first link plate group 51 , the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com