Chain

A chain and chain link technology, applied in the field of structural improvement, to achieve the effects of increasing bending resistance, suppressing string vibration, and suppressing back bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Hereinafter, various exemplary embodiments of the present invention will be described based on the accompanying drawings.

[0055] Figure 1 to Figure 10 A silent chain according to an exemplary embodiment of the present invention is shown, and identical or corresponding components have the same reference symbols in the figures.

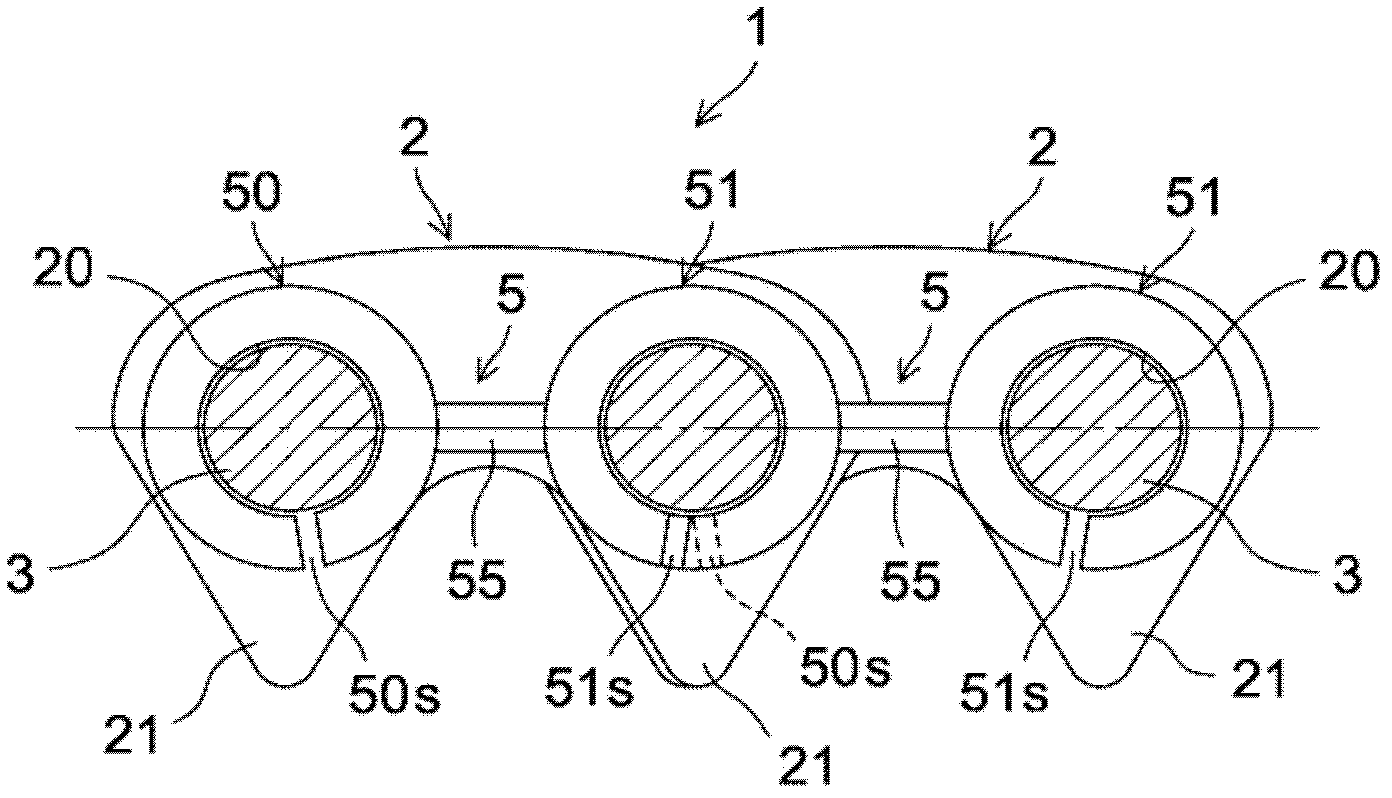

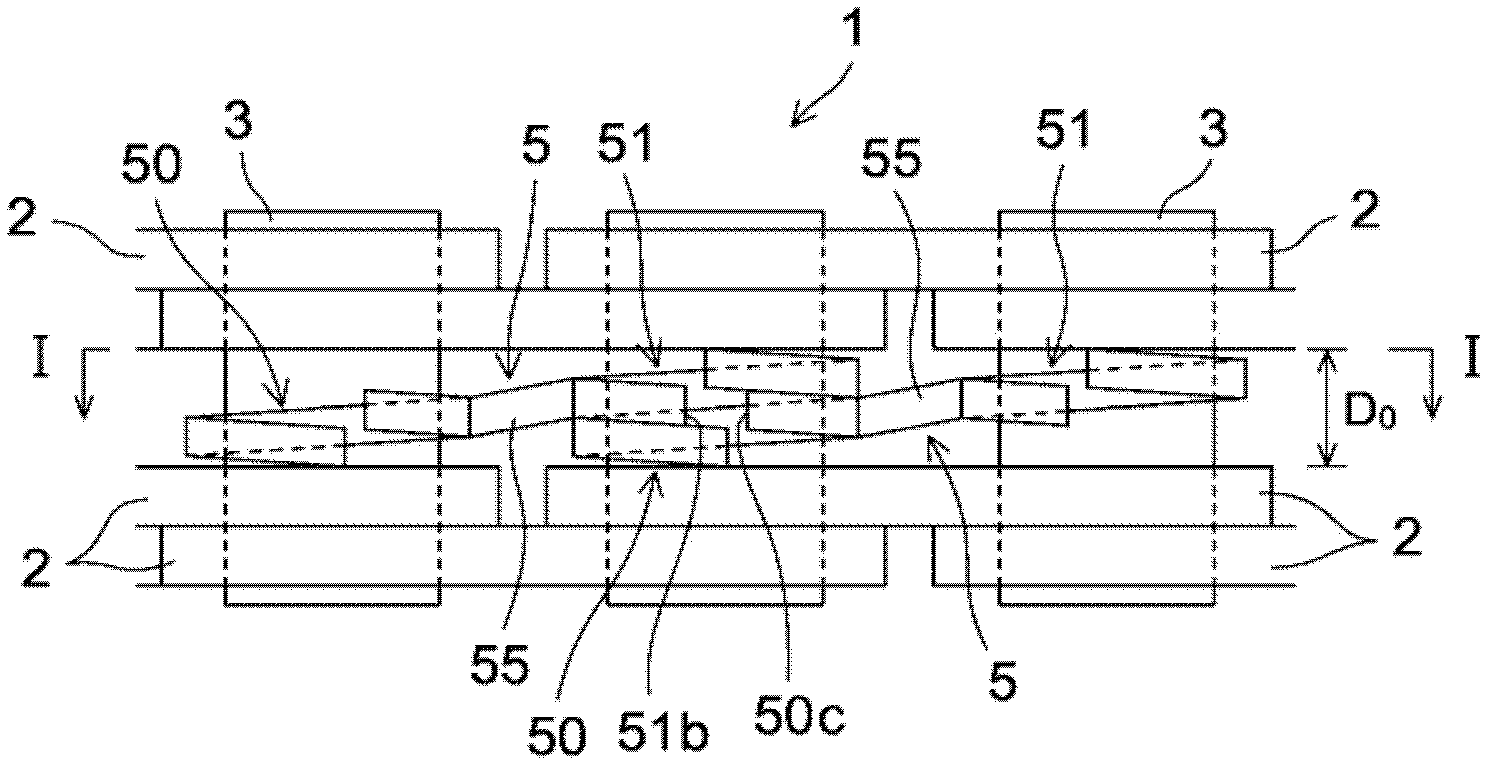

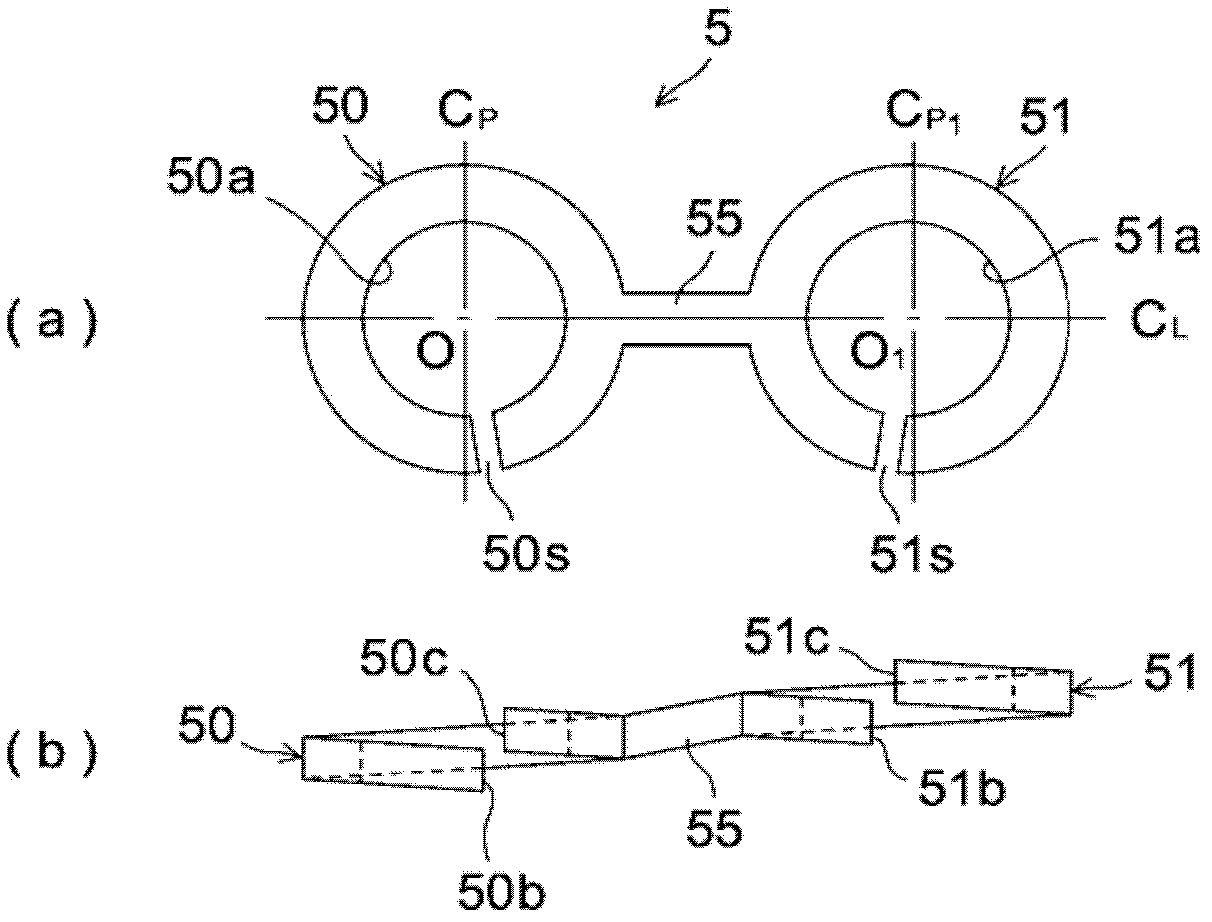

[0056] Such as figure 1 and figure 2 As shown, a silent chain 1 has a structure in which a large number of chain plates 2 with pairs of corresponding pin holes 20 and teeth 21 are stacked in the length direction of the chain ( figure 1 and figure 2 in the left-right direction) and the width direction of the chain ( figure 1 in the direction perpendicular to the page; figure 2 In the vertical direction), and the link plates 2 are connected in a manner capable of being flexed around each other by link pins 3 inserted into the pin holes 20 .

[0057] A plurality of spring washer structures 5 serving as a mechanism for preventing backbend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com