Patents

Literature

165results about How to "Realize speed regulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

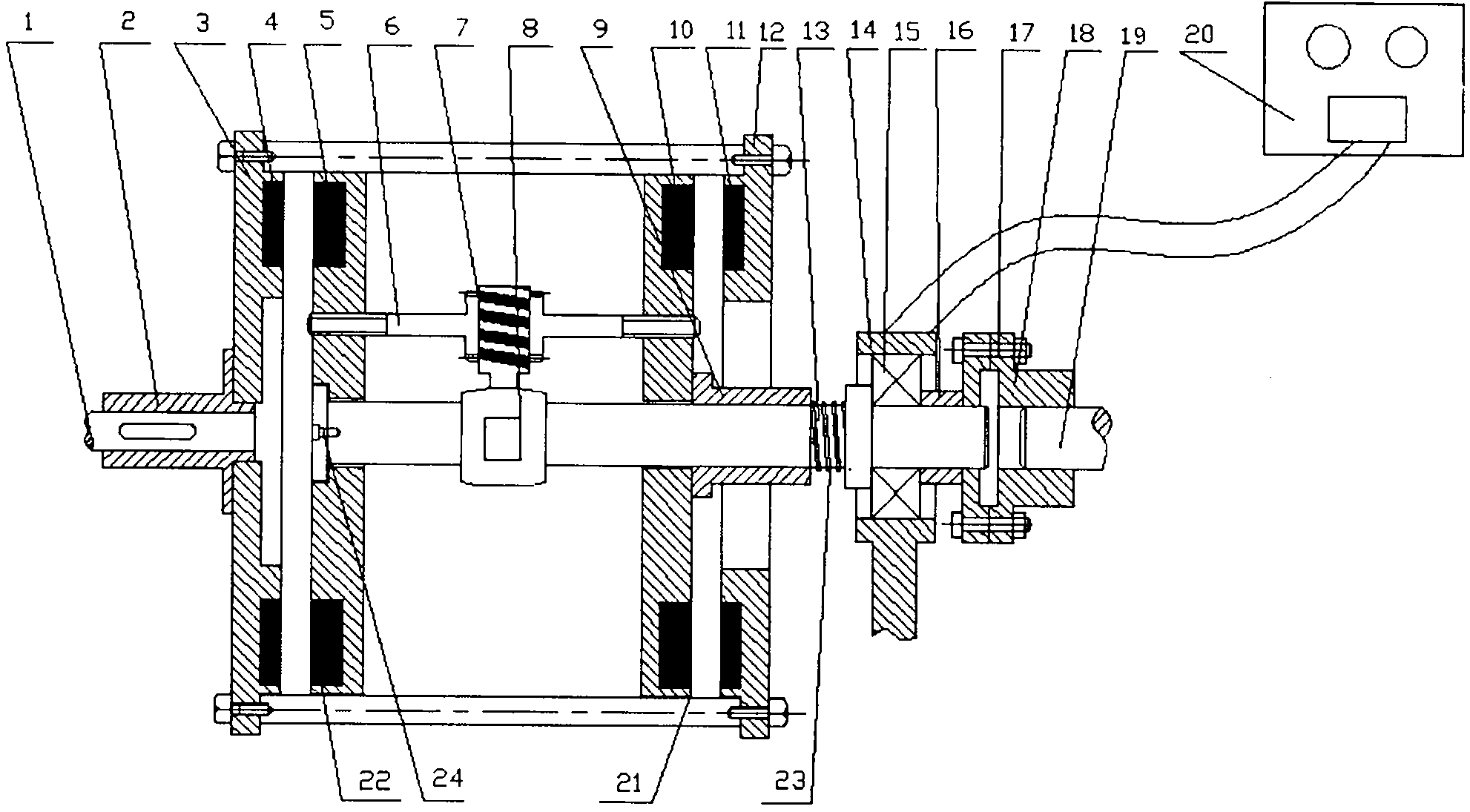

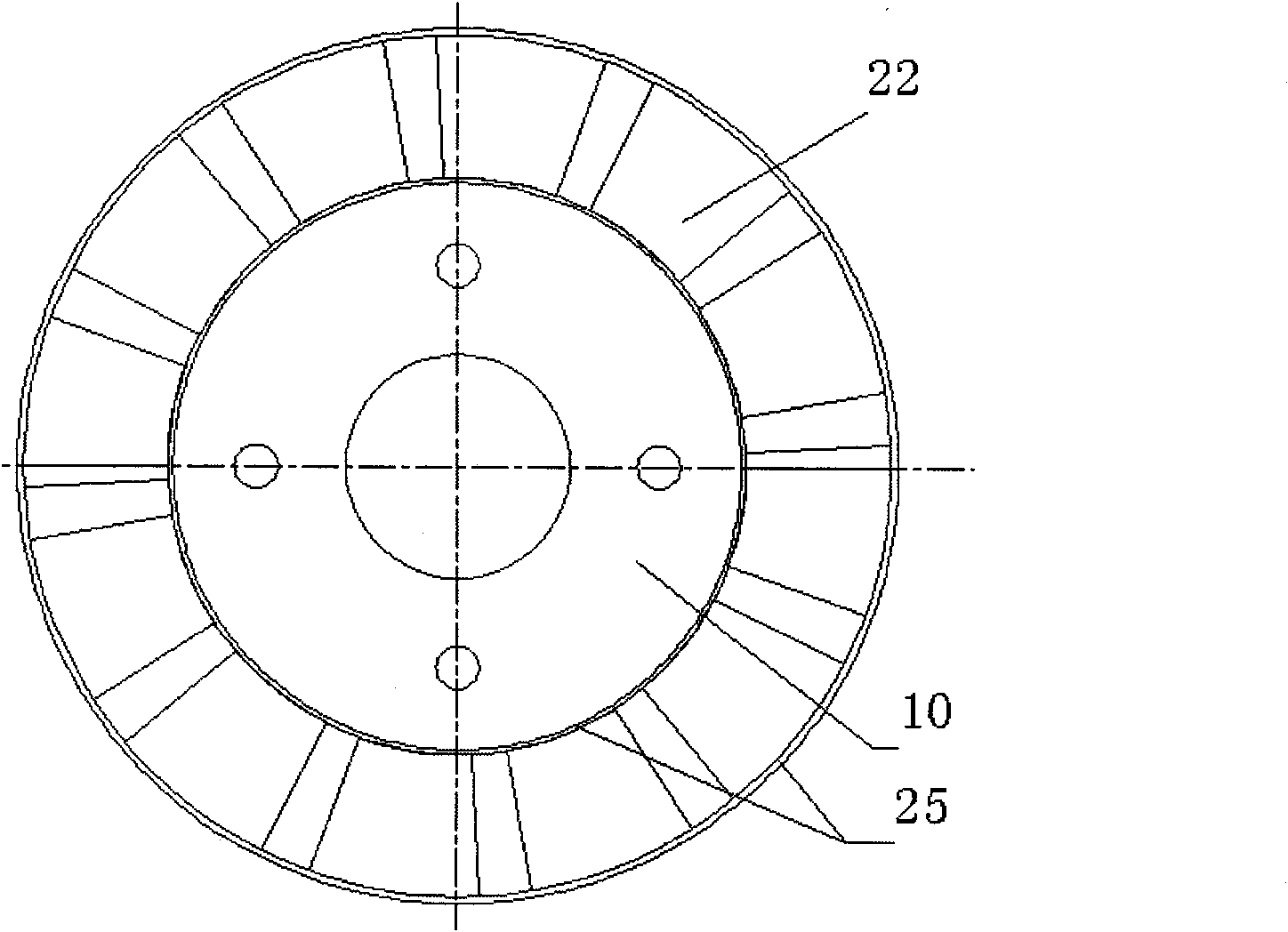

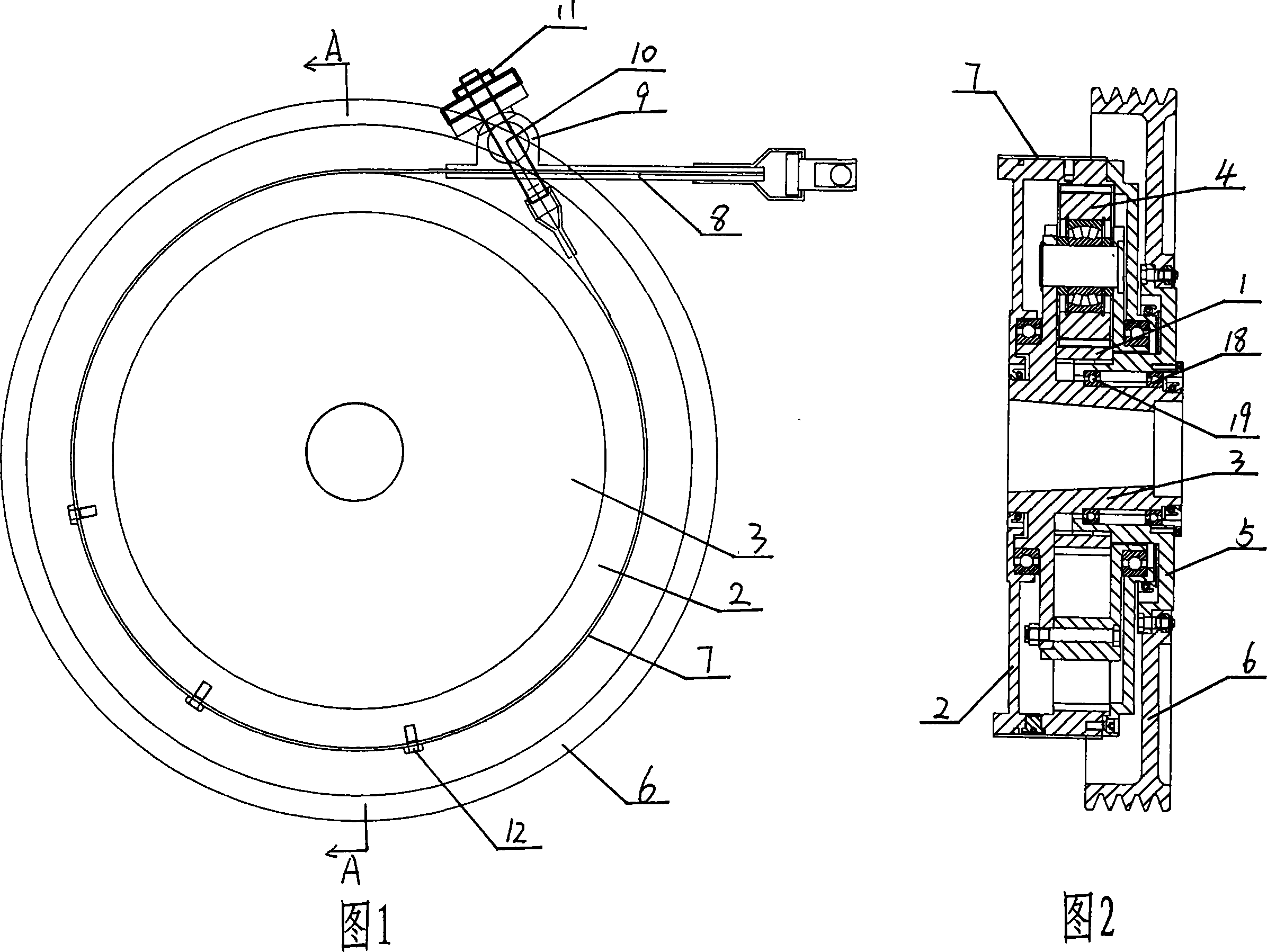

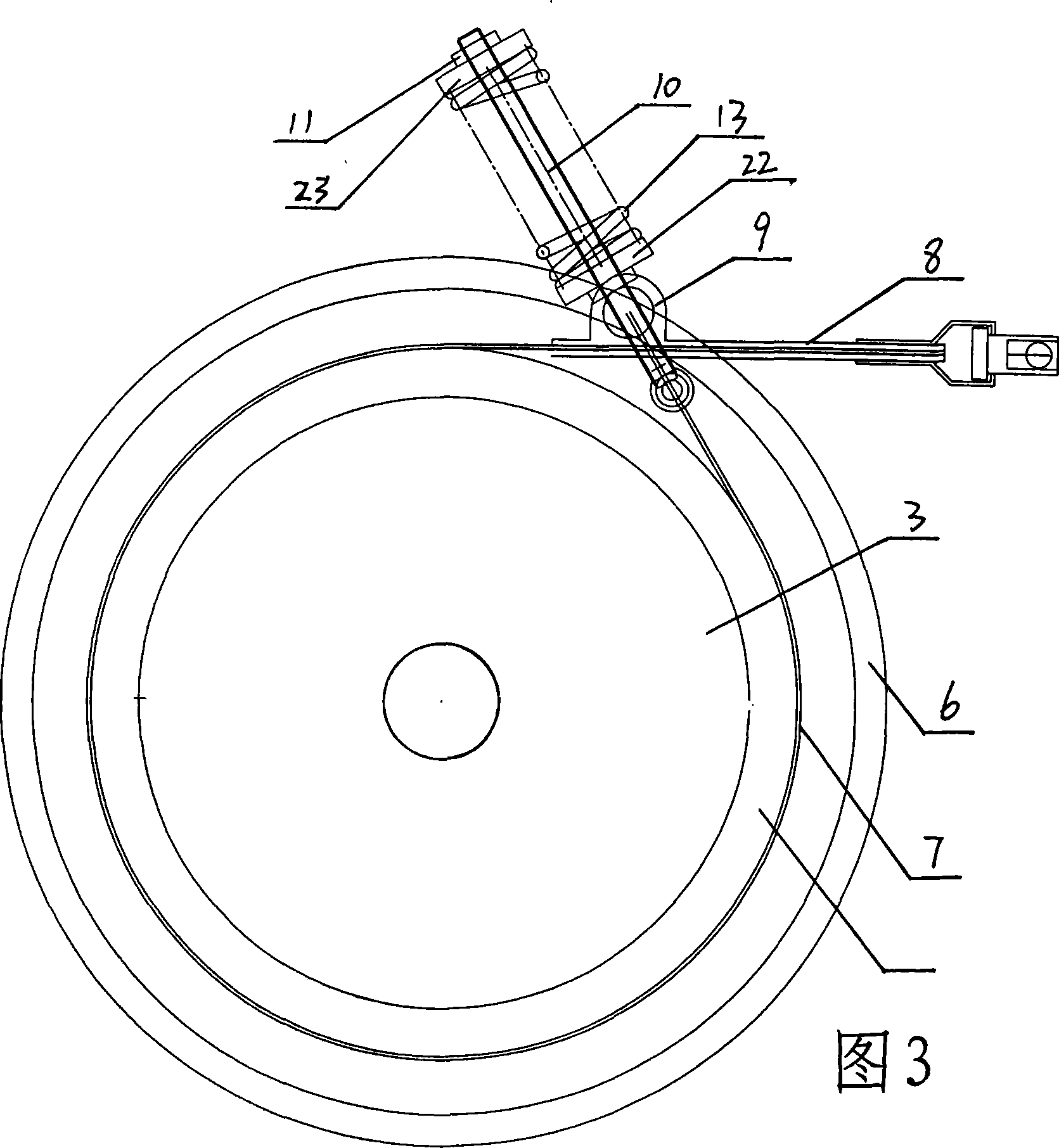

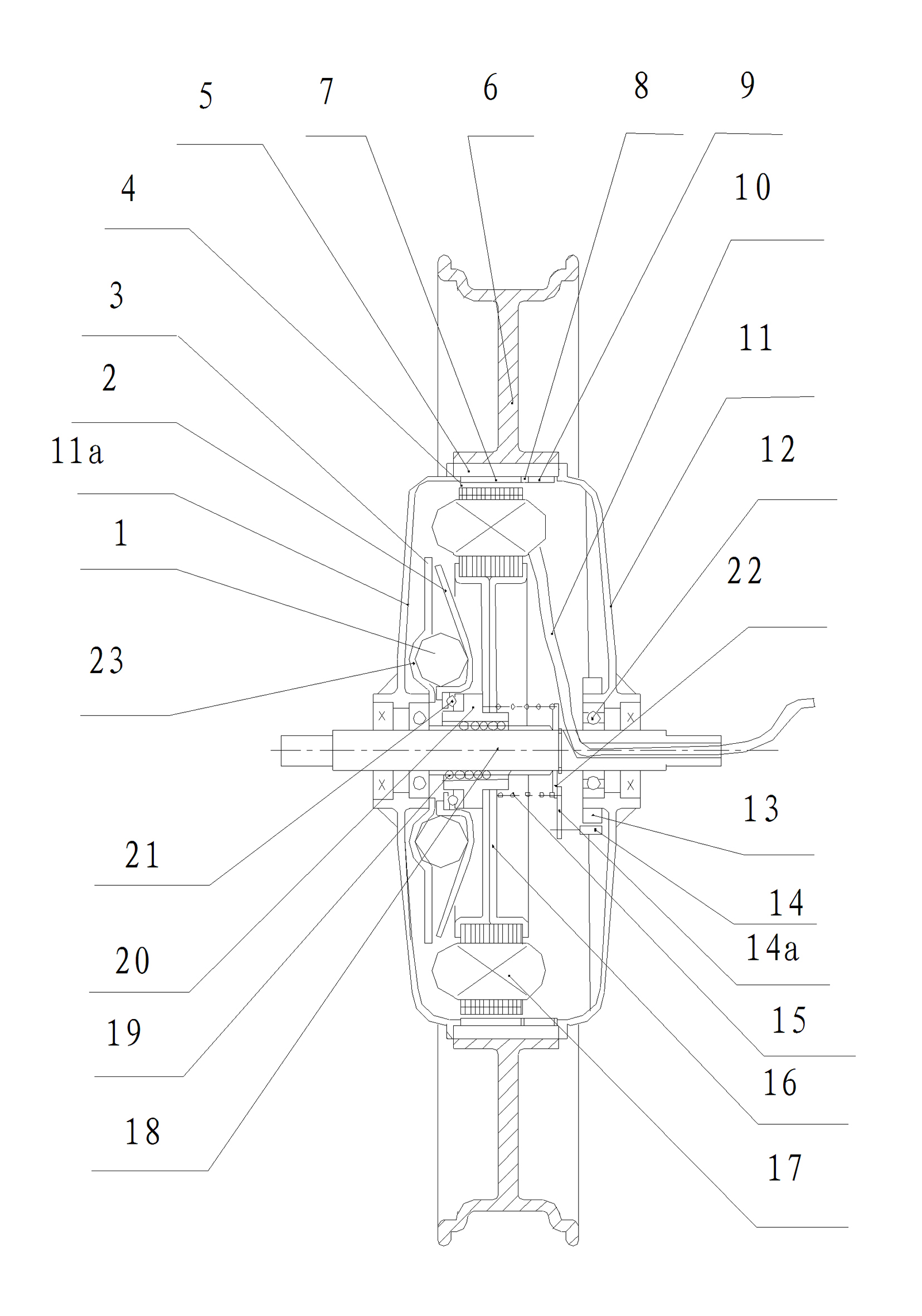

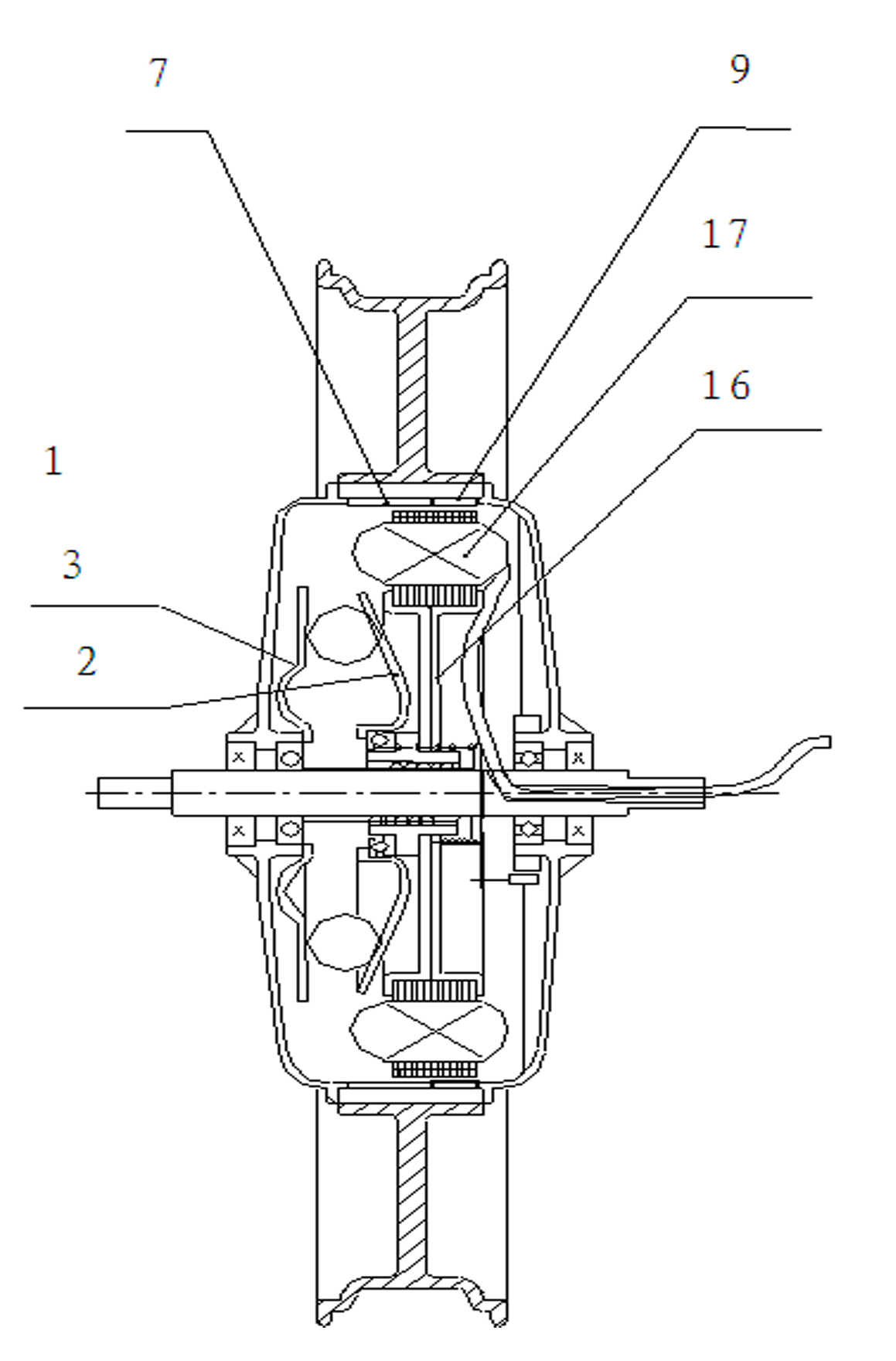

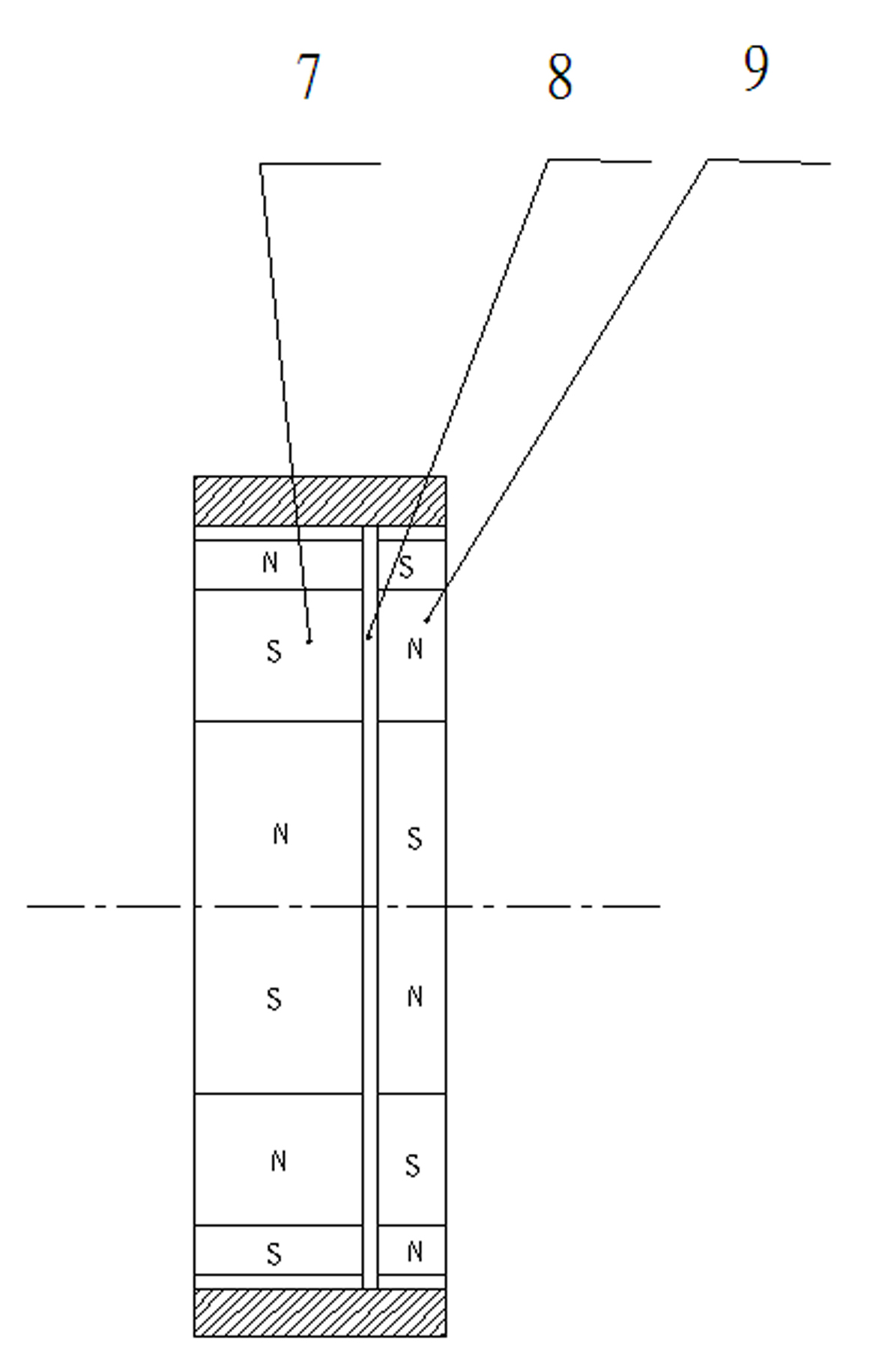

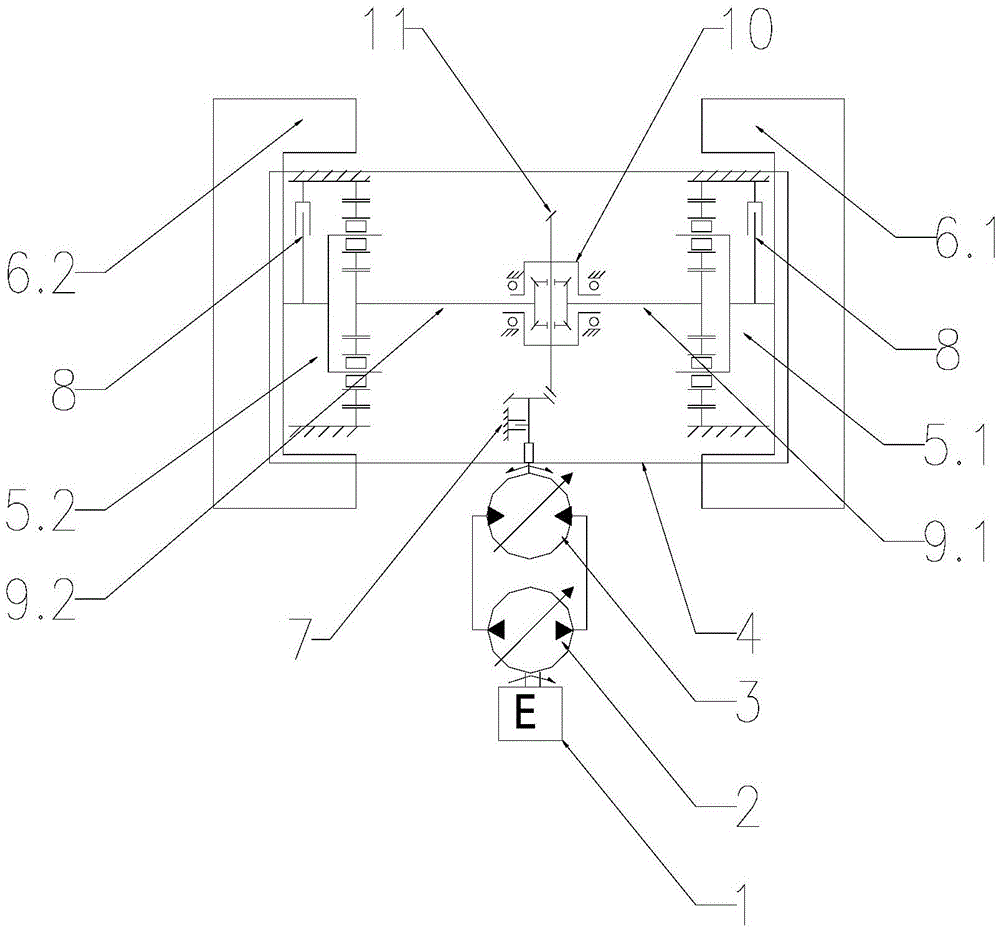

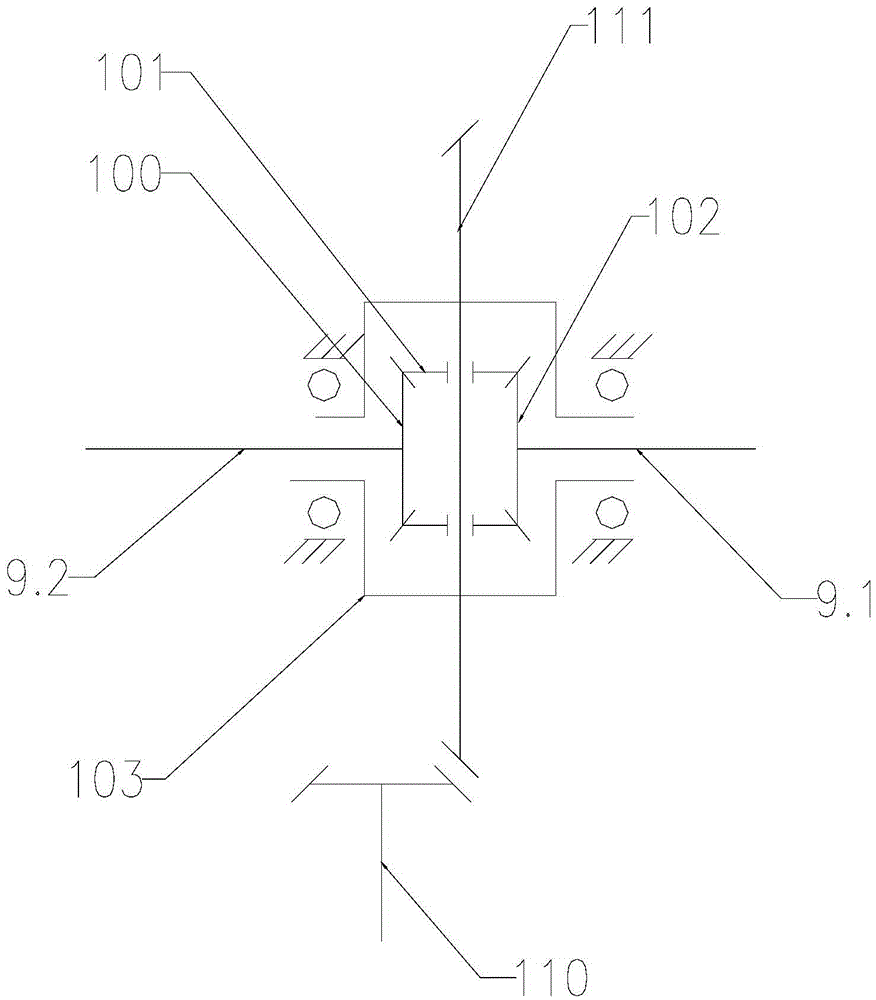

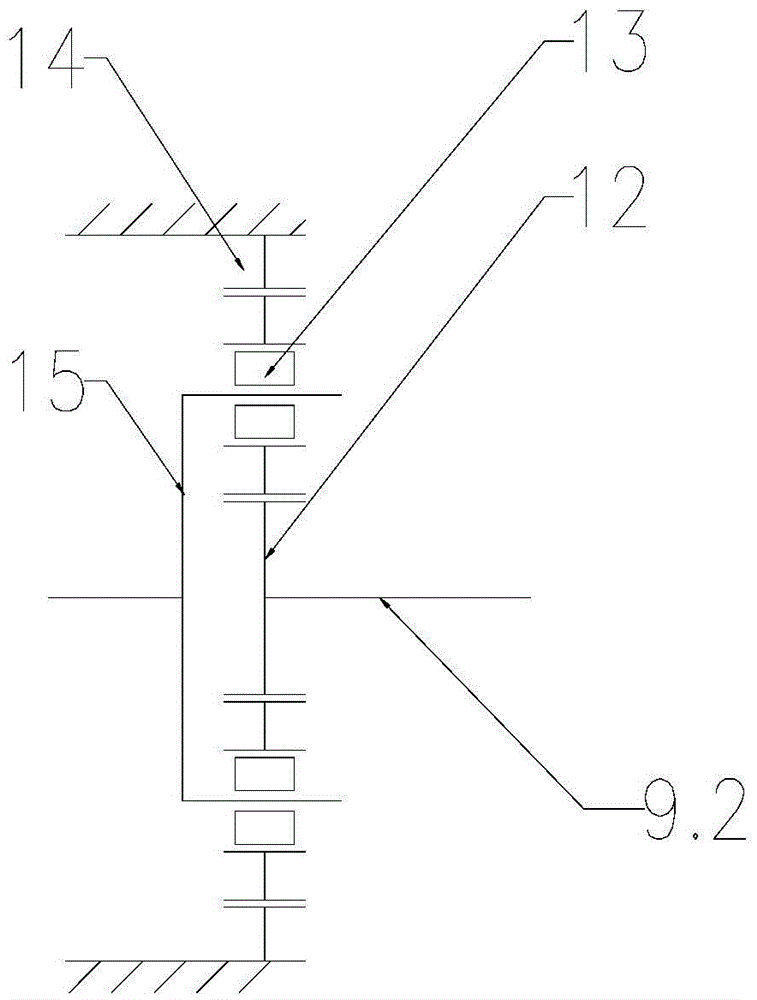

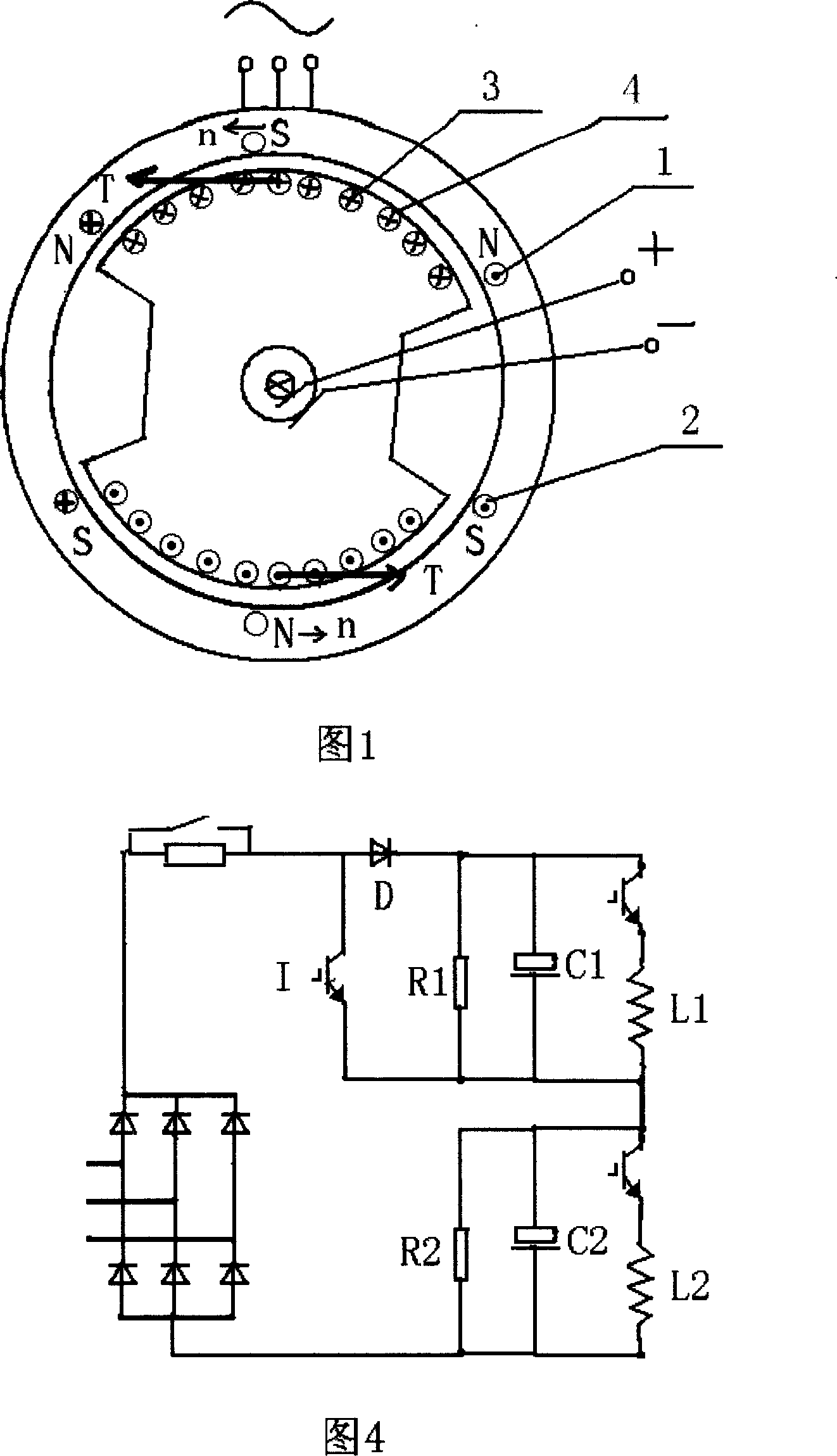

Remote automatic control adjustable-speed disc magnetic coupling

InactiveCN101917112AEliminate side playMeet the requirements of continuous change at any timeDynamo-electric gearsAutomatic controlMicro motor

The invention discloses a remote automatic control adjustable-speed disc magnetic coupling, and relates to the technical field of transmission in mechanical engineering. The magnetic coupling consists of a driving disc assembly, a driven disc assembly and a speed regulation device assembly, and is characterized in that: the speed regulation device consists of a micro motor, a speed reducing mechanism, a double threaded screw rod and a speed controller; the micro motor is arranged on a driven shaft of the driven disc assembly of the magnetic coupling; the speed reducing mechanism is arranged on an output shaft of the micro motor; the speed controller controls the micro motor to rotate and drives the double threaded screw rod to rotate through the speed reducing mechanism; and left and right ends of the double threaded screw rod are in threaded connection with a left driven disc substrate and a right driven disc substrate of the driven disc assembly respectively. The rotating directions of threads at the two ends of the double threaded screw rod are opposite, when the double threaded screw rod rotates around the axis thereof, the left driven disc substrate and the right driven disc substrate of the driven disc assembly move close to or away from each other along the driven shaft of the magnetic coupling, so that air gaps among two groups of driven discs and driving discs are changed at the same time.

Owner:JIANGSU UNIV

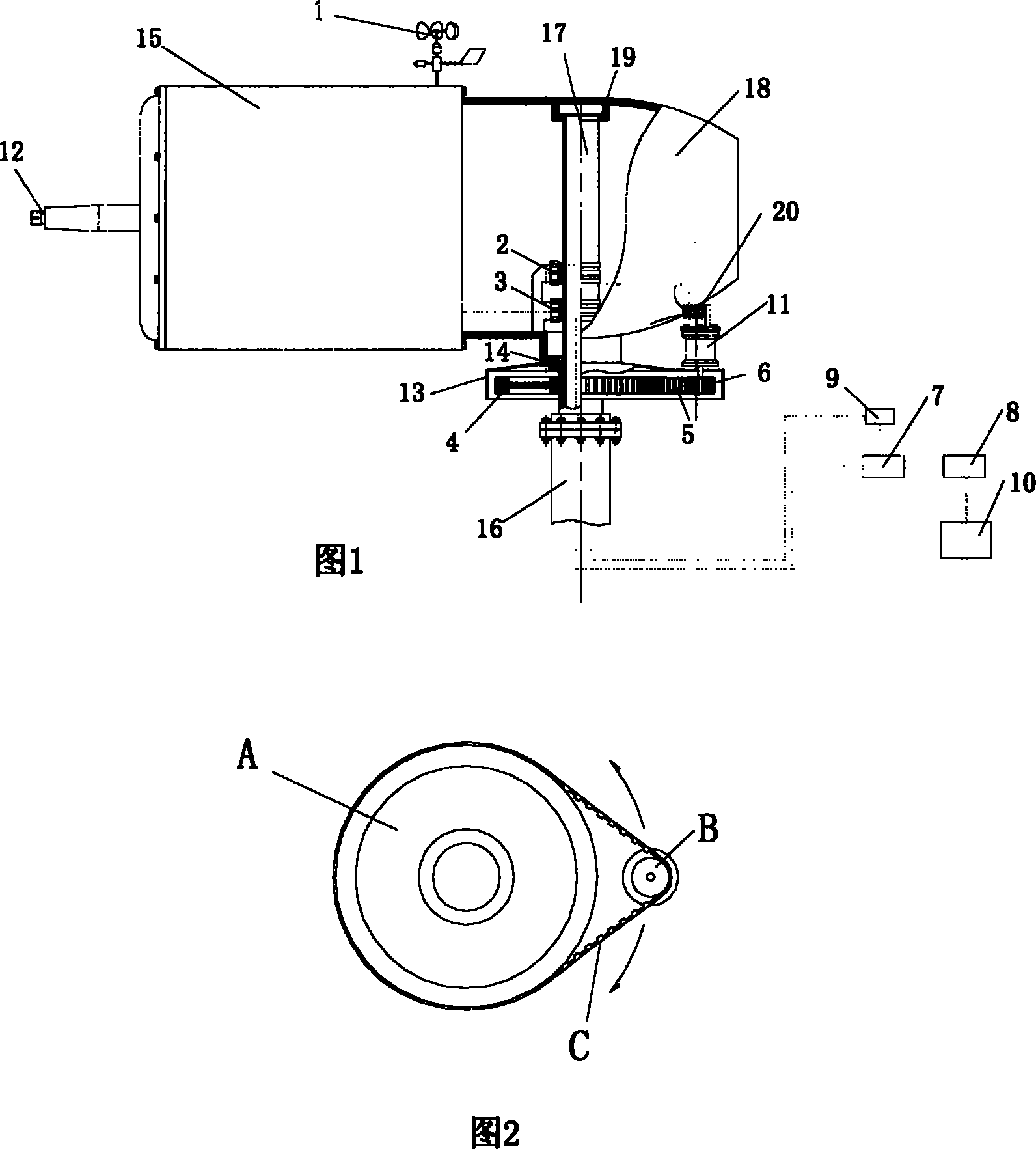

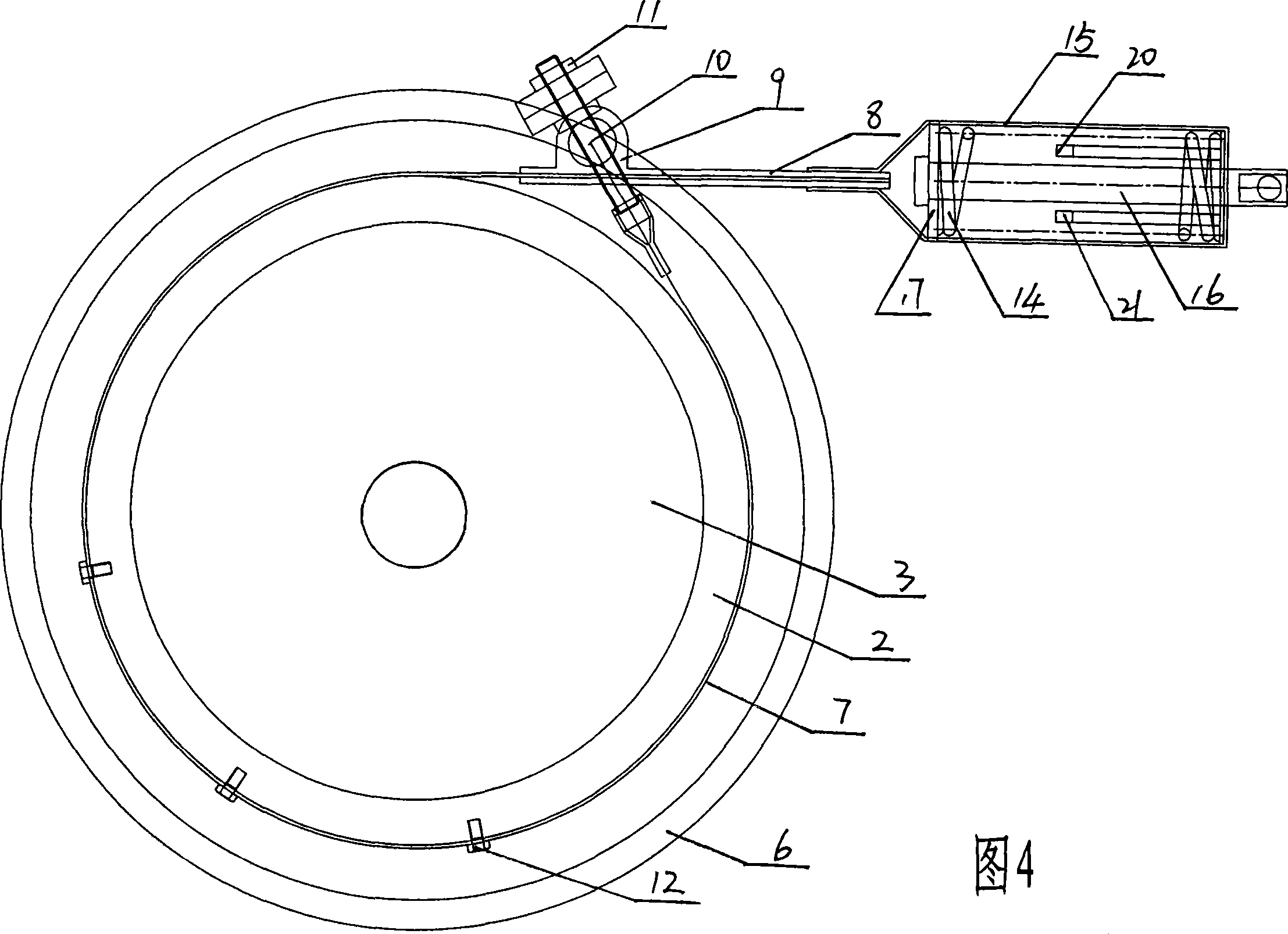

Wind-driven generator synchronous belt transmission automatic wind-aiming drift device

InactiveCN101122279ARealize speed regulationImplement speed limitWind motor controlMachines/enginesWind drivenElectricity

The invention is a timing belt transmission automatic wind opposing deviation device of a wind power generator. A power generator (15) is connected with a revolving body (engine cabin) (18). The revolving body shaft (17) is connected with a pole (16). The shaft (17) is provided with a carbon brush (2), a carbon brush (3) and a large synchronous belt pulley (4). The shaft (17) cooperates with the engine cabin (8) via a cone gear (14) and a deep groove ball bearing (19). The engine cabin (18) is equipped with a timing belt tension spring (20) outside, which is connected with a stepped electric motor (11). The stepped electric motor (11) is connected with a small synchronous belt pulley (6). Thus, the revolving body can drive the small synchronous belt pulley (6) to rotate circumferentially around the large synchronous belt pulley (4) on the revolving body shaft (17) via a timing belt (5). The carbon brush (2) is responsible to input the externally stored electric current into the stepped electric motor (11), while the carbon brush (3) is responsible to output the power generated by the generator (15). The advantage of the wind deviation device is that when the wind power generator is working, the device can oppose the wind automatically and deviates from the wind in the case of a strong wind, so as to reach the purpose of automatic speed controlling and limiting and achieve the self-protection function of the wind power generator. The device avoids large tail fins of a wind power generator in the past. With the device, a wind power generator can be controlled and operated intelligently, is more reliable in the work, and is free of maintenance for a long time.

Owner:ZHEJIANG BIHUALI ELECTRIC TECH

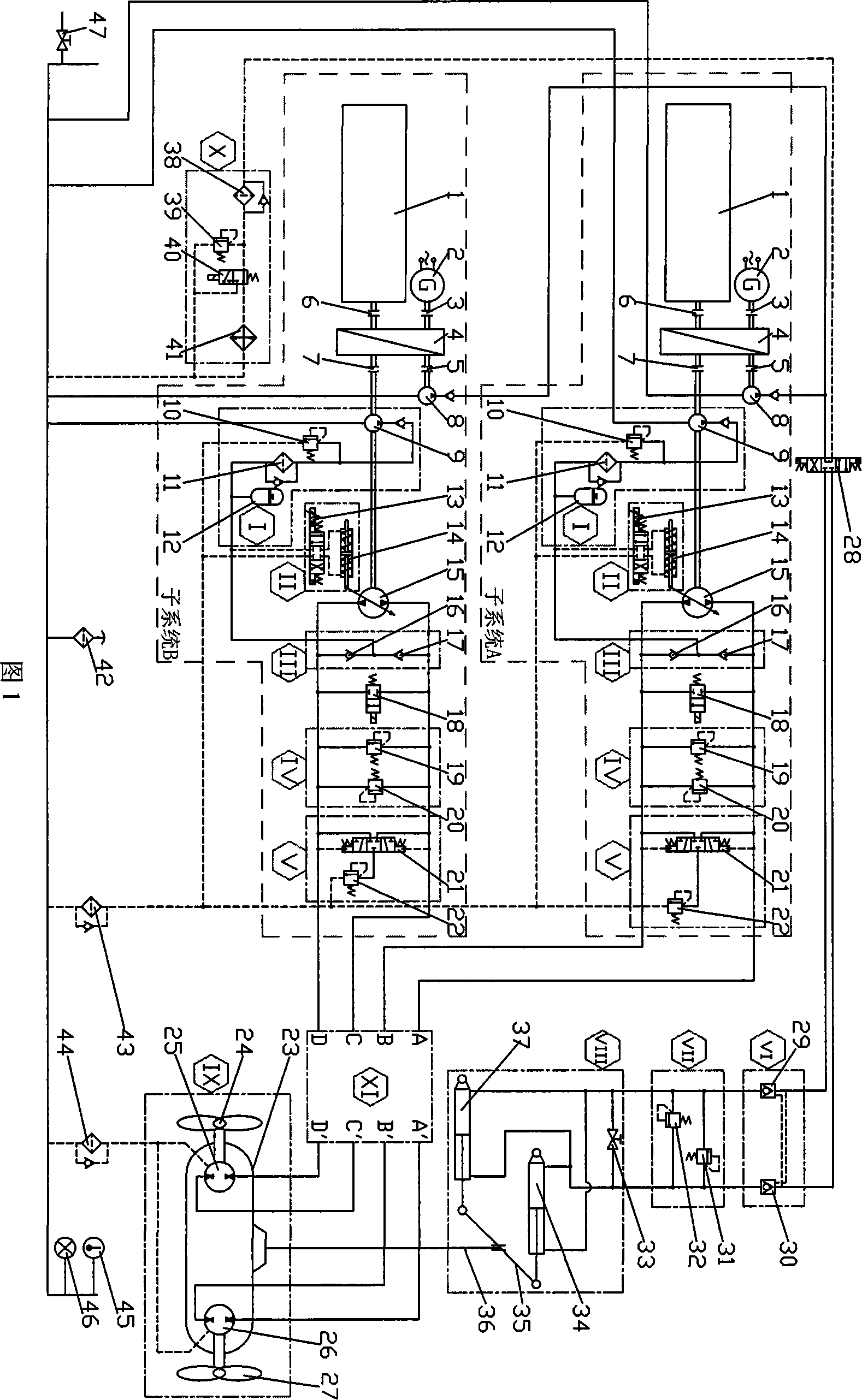

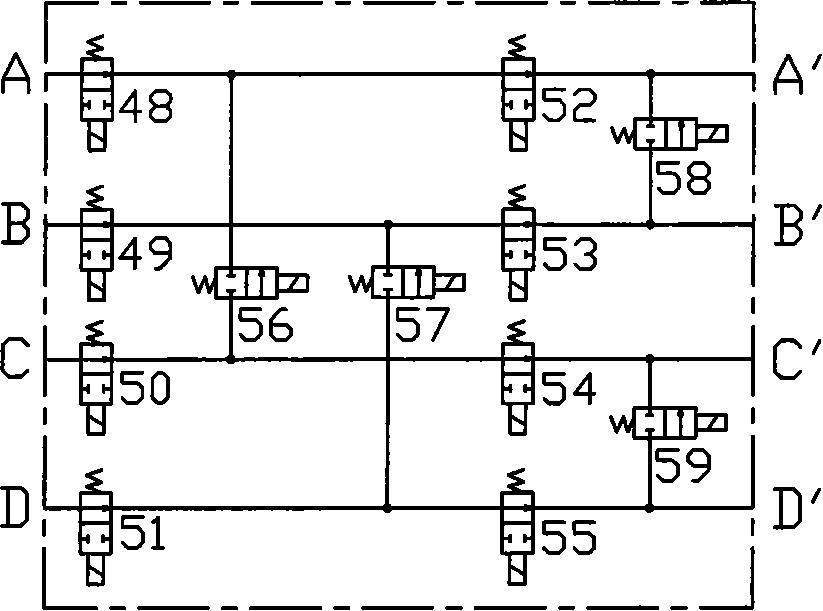

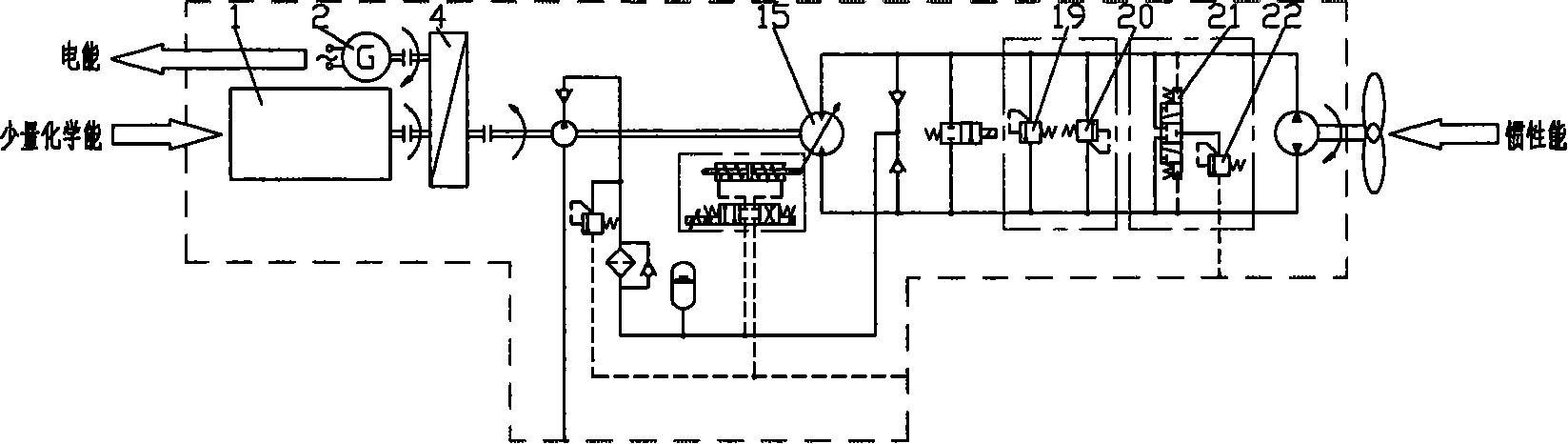

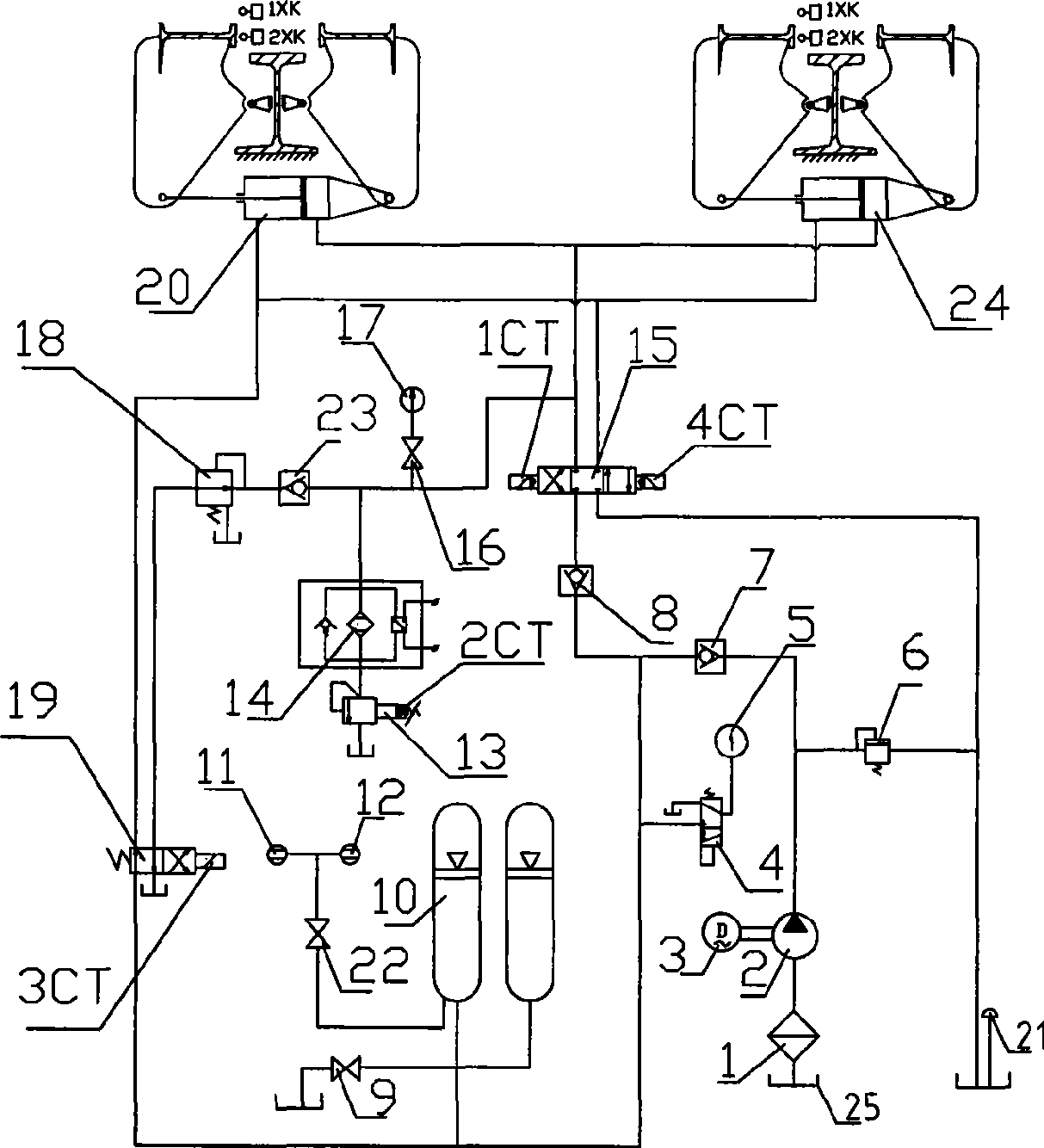

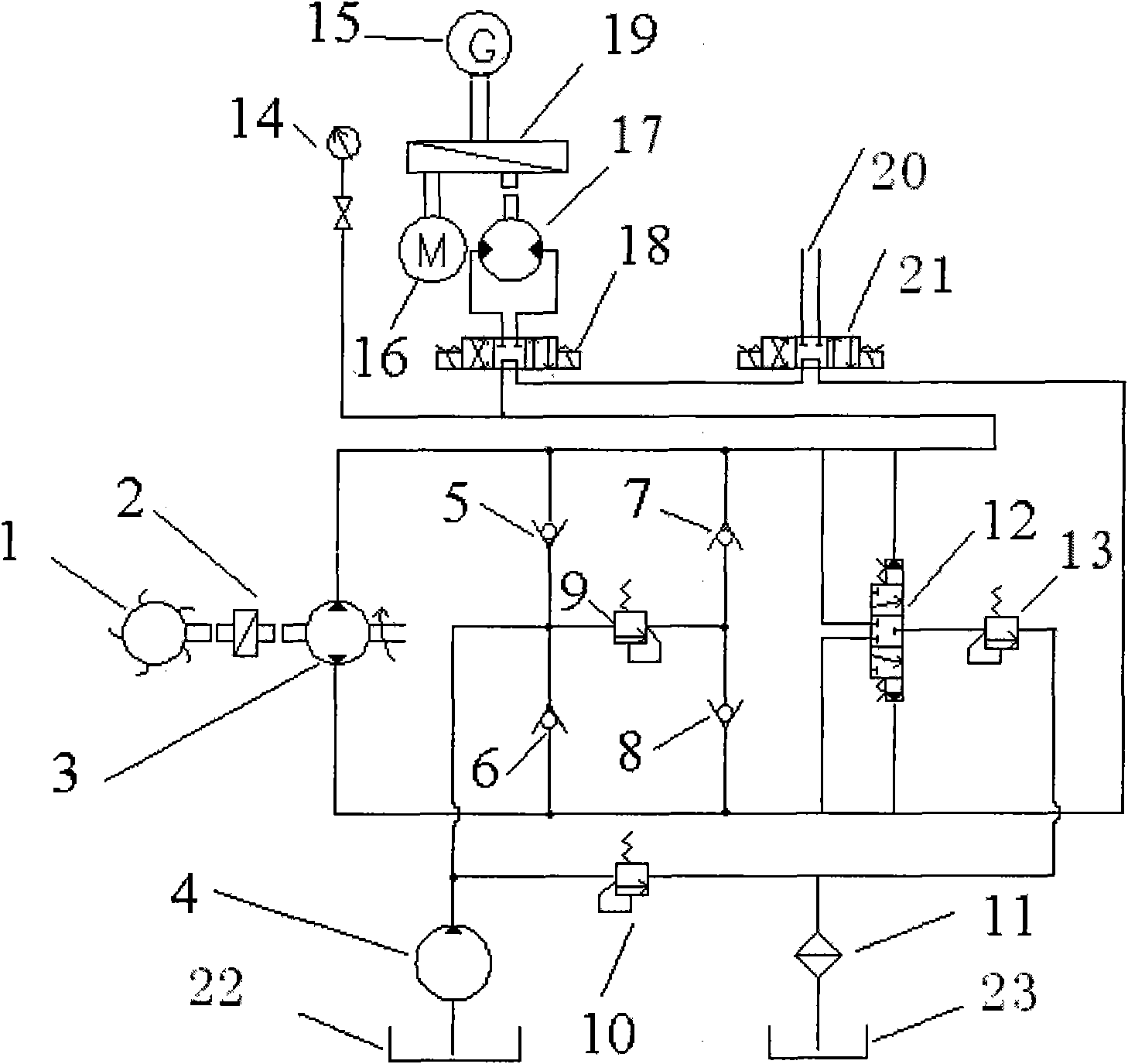

Ship craft integrated hydraulic propulsion method and device

InactiveCN101249884ARealize speed regulationRealize commutationTransmission with non-mechanical gearingPropellerMechanical energy

Disclosed are a propelling method and a device for vessels and other navigating machinery in water. The method based on the hydraulic transmission principle includes transforming mechanical energy output by a plurality of main engines (more than two) into pressure energy of hydraulic oil, after power integration and distribution, respectively driving a propeller screw, a steering engine (which can be canceled after employing a pod revolving device), a lateral-thrust unit and other auxiliary devices, using a shaft generator to replace a ship auxiliary engine, adjusting revolution rate and steering of the propeller screw by controlling a pump and the main engines, realizing coordinated working of other auxiliary devices of the propeller screw, the steering engine, the lateral-thrust unit and the like and various working modes of the main propelling system, simultaneously recycling inertia energy produced by the propeller screw and vessel in the brake process and the like. The propelling method has the advantages of flexible engine room arrangement, large power-to-weight ratio of devices, high safety and reliability, high maneuverability, good work condition engaging characteristic, strong overload protection capacity, inertia energy recycle and the like.

Owner:纪玉龙

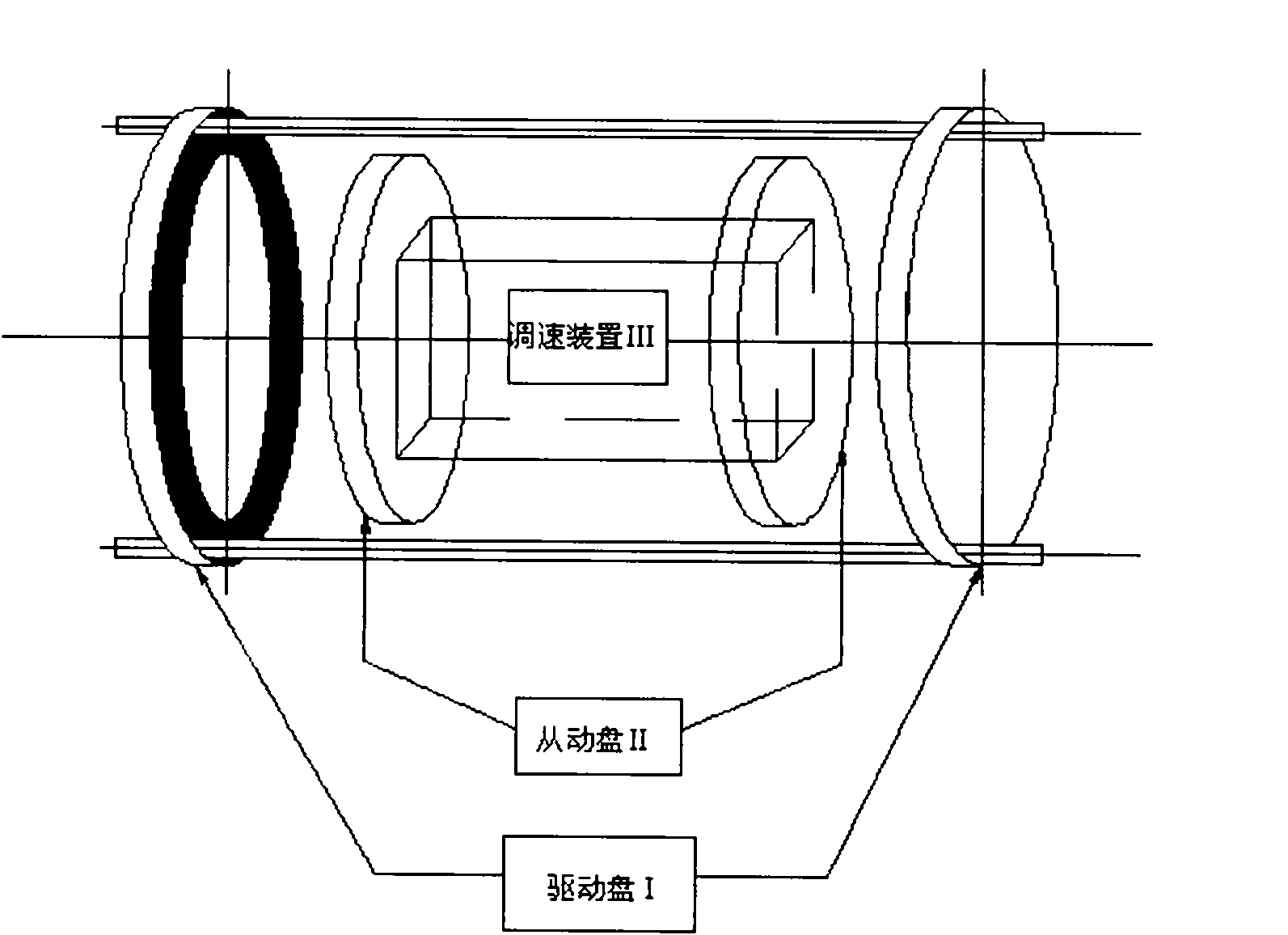

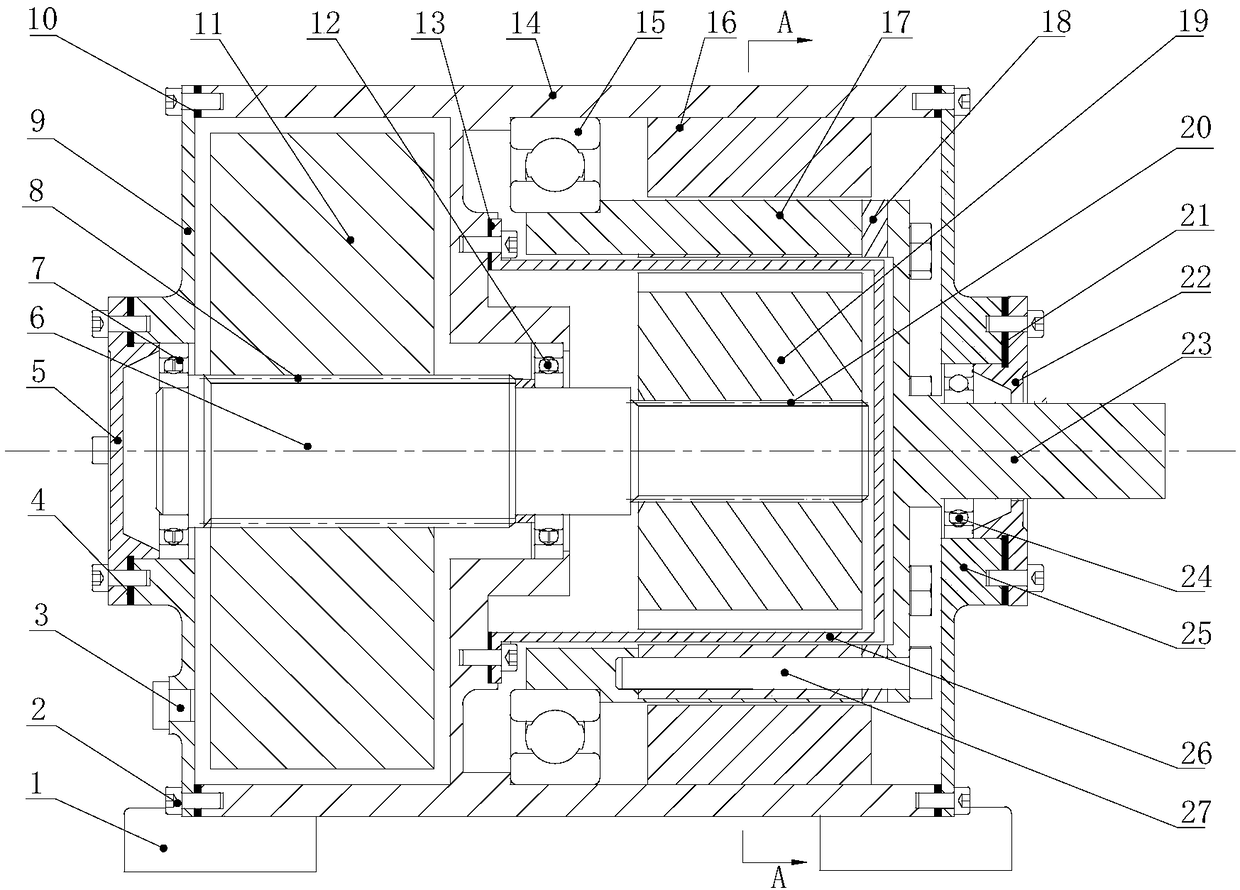

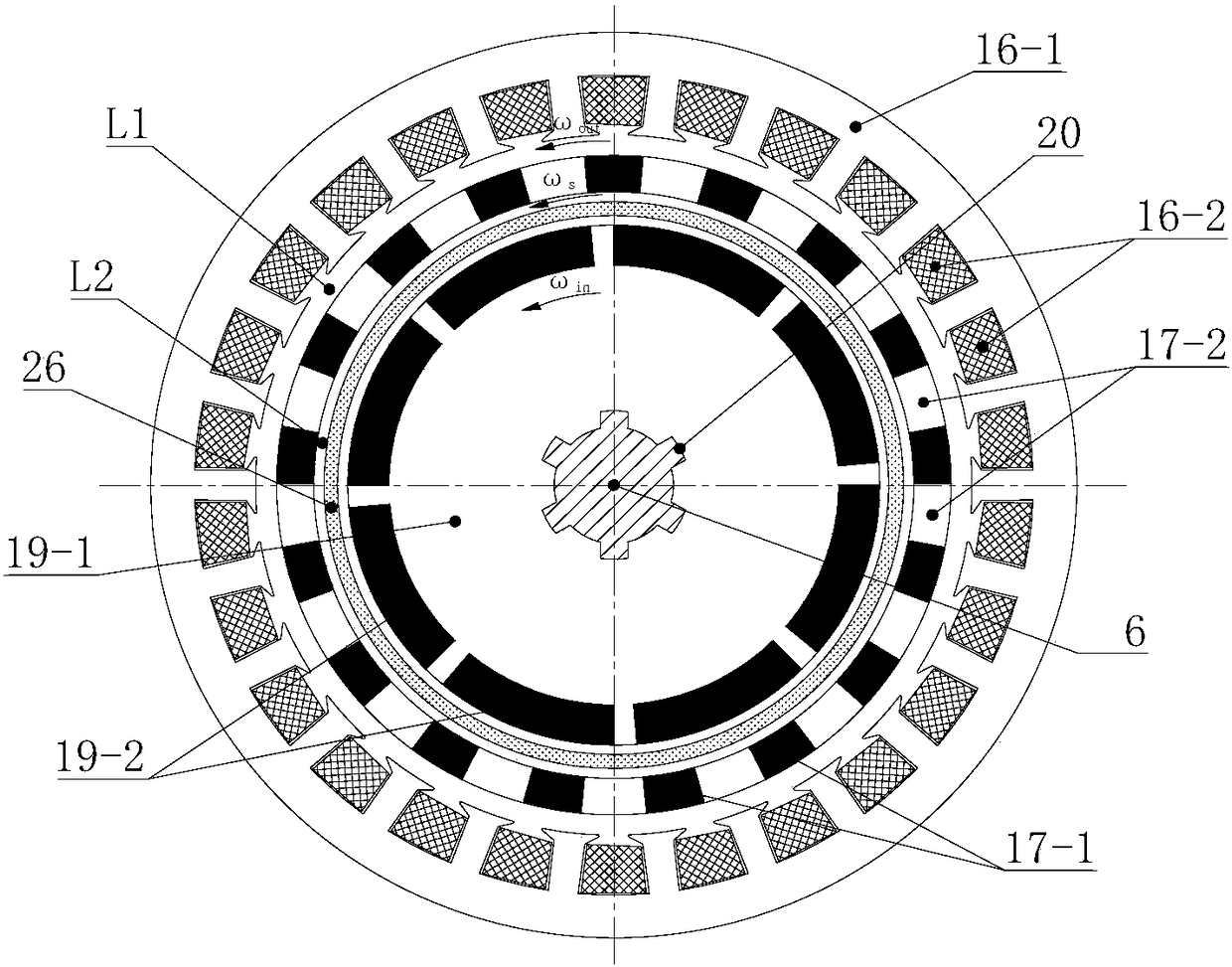

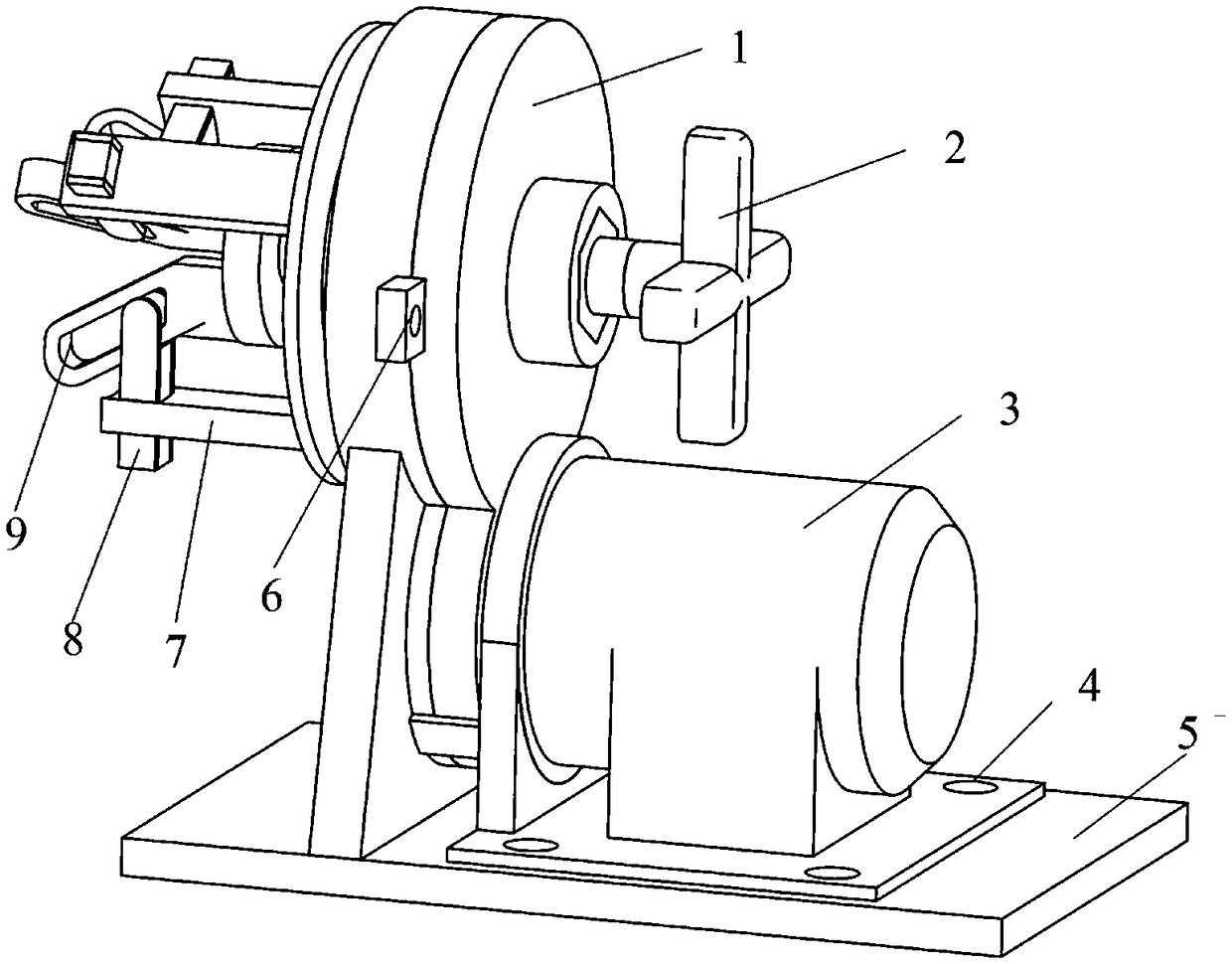

Flywheel energy storage magnetic coupling transmission device

PendingCN108321978ANo friction lossReduce vibrationPermanent-magnet clutches/brakesMechanical energy handlingElectric driveFlywheel energy storage system

The invention discloses a flywheel energy storage magnetic coupling transmission device which mainly comprises a housing, an inner case body, a flywheel rotor, a spindle and a magnetic coupling transmission mechanism, wherein a stator, a permanent magnet rotor and an adjustable magnet ring rotor of the magnetic coupling transmission mechanism are cylindrical; the adjustable magnet ring rotor is located between the stator and the permanent magnet rotor; a radial air gap exists between the adjustable magnet ring rotor and the stator; a radial air gap exists between the adjustable magnet ring rotor and the permanent magnet rotor; one end of an adjustable magnet ring rotor shaft is connected with the adjustable magnet ring rotor; and the other end of the adjustable magnet ring rotor shaft extends out of the housing. The device can recover braking energy of a vehicle; and compared with the traditional electric driven and mechanical flywheel energy storage systems, the device has the advantages of compact structure, small size, static sealing, small temperature rise in the case body, magnetic transmission, stepless speed change and the like.

Owner:SOUTH CHINA UNIV OF TECH

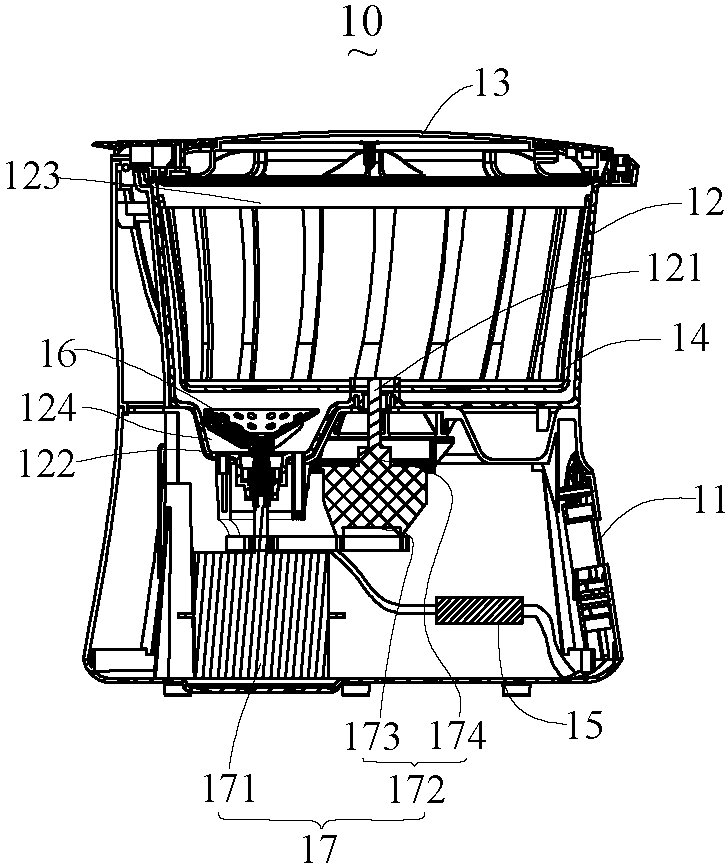

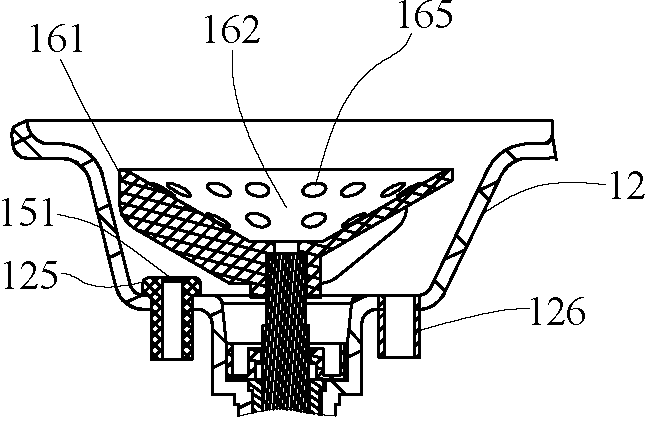

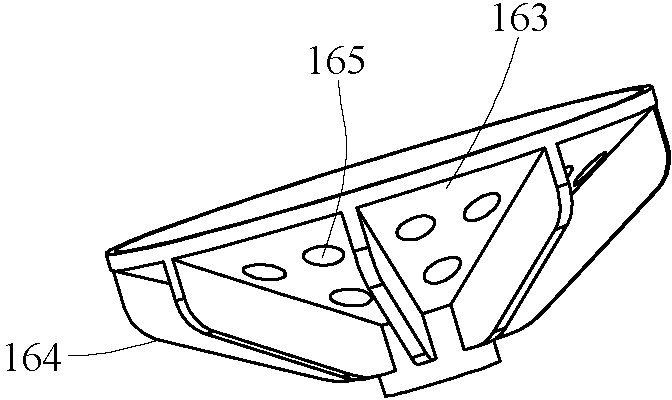

Fruit and vegetable cleaning machine

ActiveCN102934955AGuarantee the effect of purification (sterilization and disinfection)Improve the effect of purification (sterilization and disinfection)Kitchen equipmentBiologyMechanical engineering

The invention relates to a fruit and vegetable cleaning machine. The fruit and vegetable cleaning machine comprises a machine body, a washing barrel for containing water, an upper cover and a washing basket for containing fruits and vegetables, wherein a washing rotating shaft is arranged in the washing barrel; the washing basket is arranged on the washing rotating shaft; the fruit and vegetable cleaning machine also comprises an ozone generator, an aerating apparatus and an aerating rotating shaft, and the aerating apparatus and the aerating rotating shaft are arranged on the washing barrel; the aerating apparatus is arranged on the aerating rotating shaft; an air inlet hole communicated with the ozone generator is formed on the washing barrel; a driving device for driving the washing rotating shaft and the aerating rotating shaft to rotate is arranged in the machine body; the aerating apparatus comprises a suction port and an aerating piece; ozone generated by the ozone generator enters the washing barrel through the air inlet hole to form ozone bubbles; and the ozone bubbles are aerated by the aerating apparatus to be broken up, micro-fined down and rapidly dissolved in water. Therefore, the drawback of the traditional aeration stone is avoided, the concentration of the ozone dissolved in and entering water is ensured to the maximum extent, the purification effect of fruits and vegetables is ensured, the utilization rate of the ozone is increased while the dissolving efficiency of the ozone is increased through repeated aeration, and energy sources are saved.

Owner:JOYOUNG CO LTD

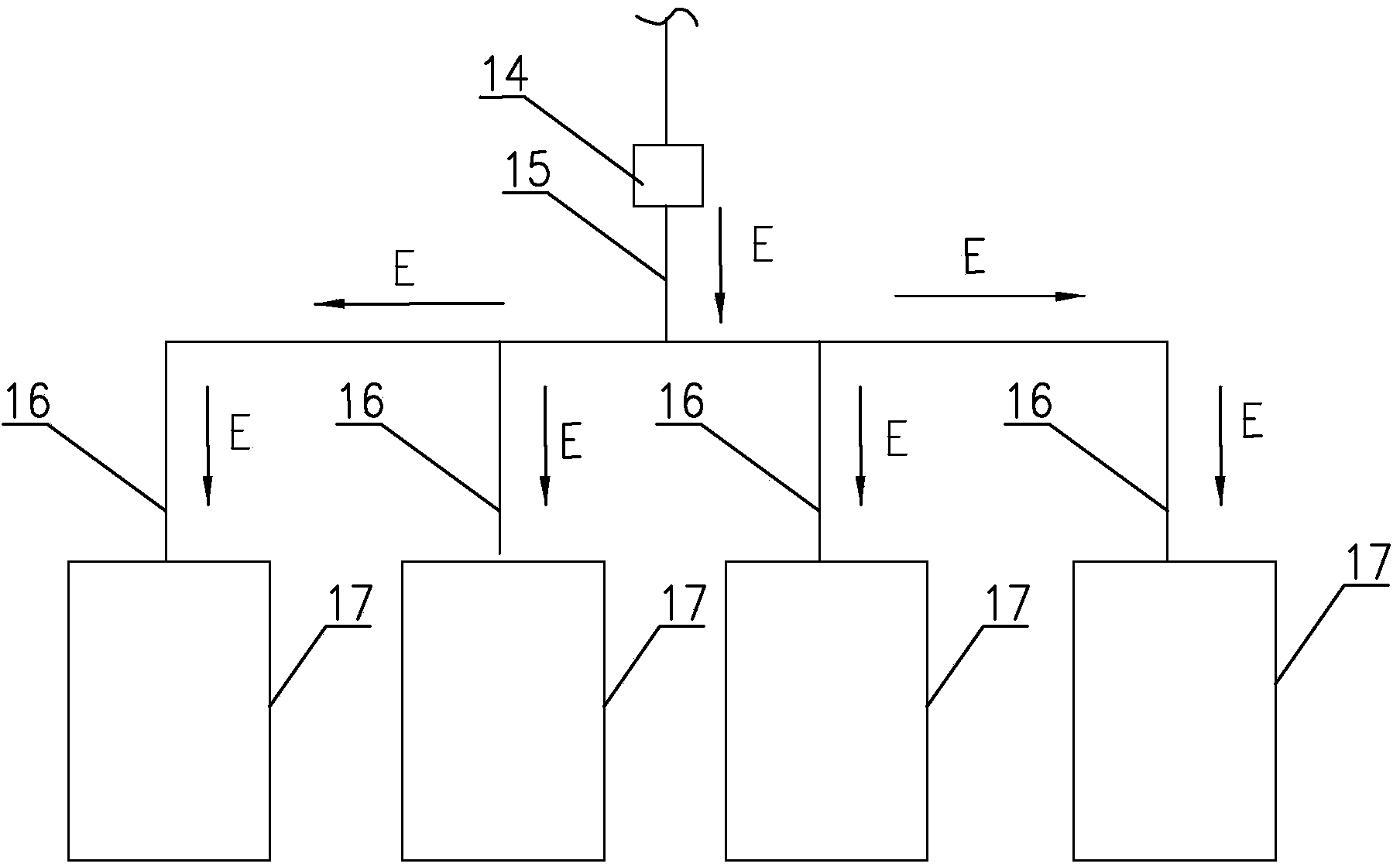

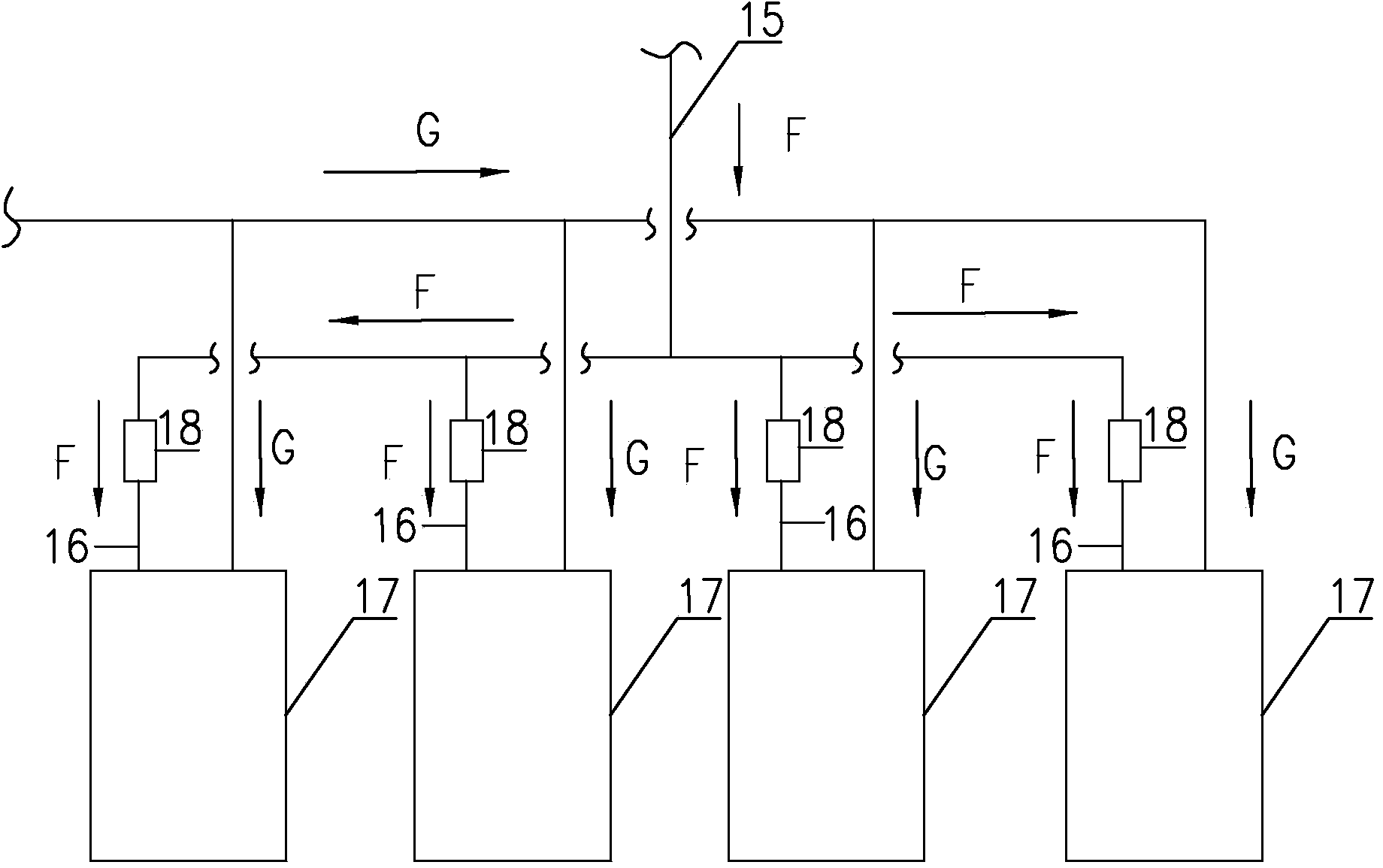

Control method for automatic object distribution and recycling device

ActiveCN106241246ALow costRealize speed regulationControl devices for conveyorsMechanical conveyorsDrive wheelLower grade

Owner:山东大树达孚特膳食品有限公司

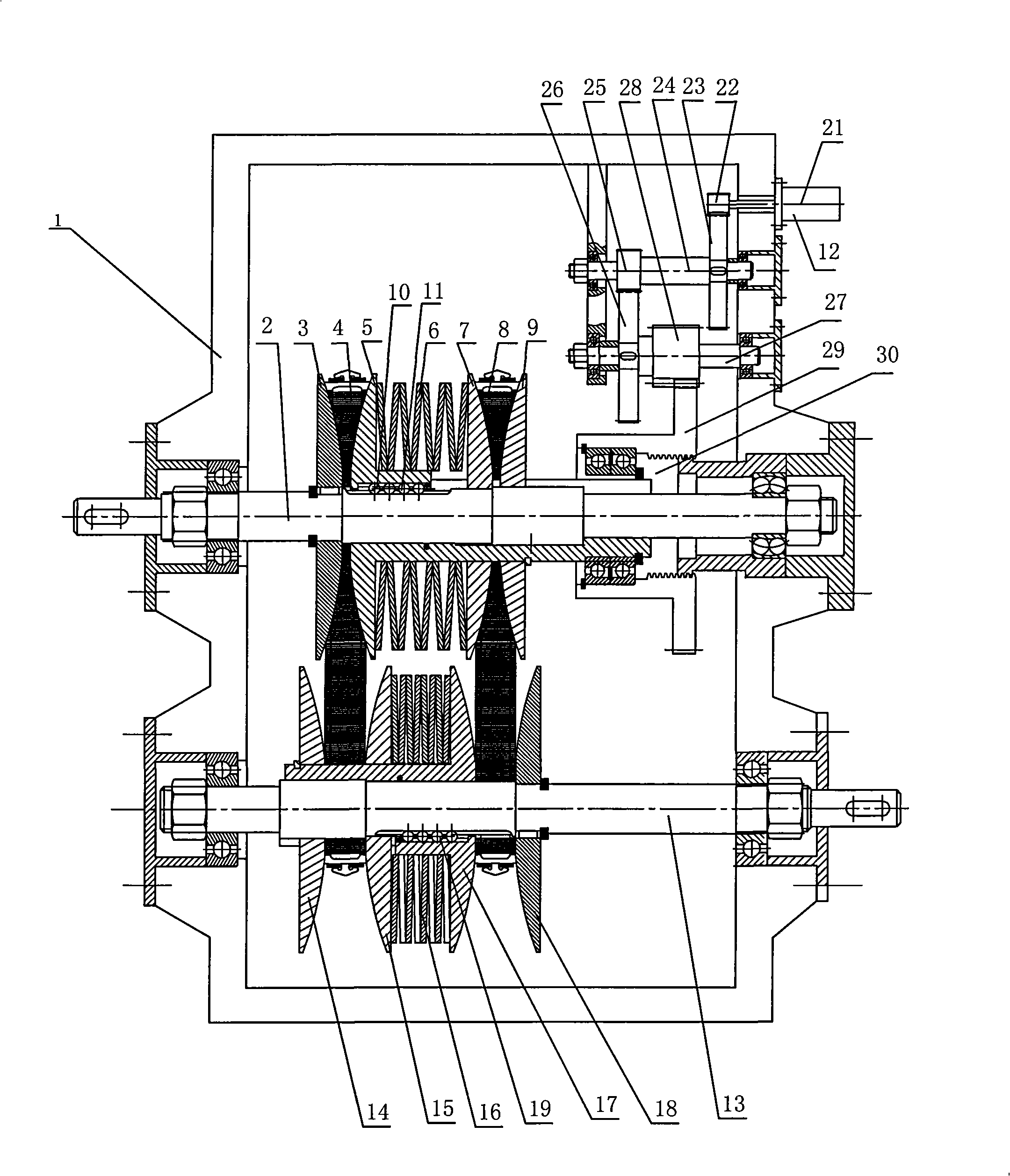

Bimetallic strip stepless variable drive

InactiveCN101328961ASimple structureRealize speed regulationGearingGearing controlAxial pressureDrive shaft

The invention discloses a double metal strap stepless speed change device, comprising a drive shaft and a driven shaft, wherein, a drive shaft is provided with a left drive fixed conical disk, a left drive movable conical disk, a right drive fixed conical disk, a right drive movable disk and a right metal strap; a driven shaft is movably provided with a left driven movable conical disk, a left driven fixed conical disk, a right driven movable conical disk and a right driven fixed conical disk. The invention is characterized in that: a counter balance spring is arranged between the left drive movable conical disk and the right drive fixed conical disk; the left drive movable conical disk is connected with a first sleeve which is connected with the right drive movable conical disk through the right drive fixed conical disk; a pressure spring is arranged between the left driven fixed conical disk and the right driven movable conical disk; and the left driven movable conical disk is connected with a second sleeve which is connected with the right driven movable conical disk through the left driven fixed conical disk. A structure can be greatly simplified by adopting the sleeves to be connected with two movable conical disks which are coaxial; a compression speed regulating system adopts mechanical pressurization and designs an axial pressure-balanced device with compact and efficient structure, thereby speed regulation by a miniature motor can be realized. The device has the advantages of simple structure, small volume, large speed change range and simple control.

Owner:重庆工学院

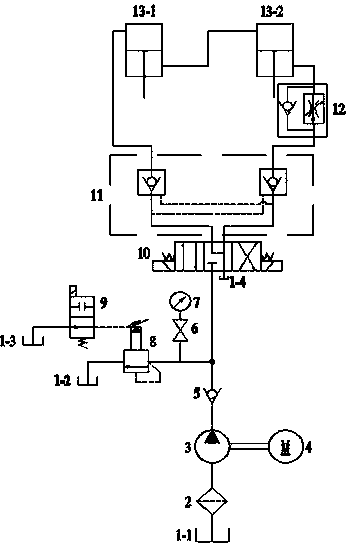

Pressure maintaining and speed stabilizing hydraulic system of hydraulic machine

InactiveCN104006015ARealize speed regulationFast and stable return tripServomotor componentsServomotorsHydraulic pumpEngineering

The invention provides a pressure maintaining and speed stabilizing hydraulic system of a hydraulic machine. The pressure maintaining and speed stabilizing hydraulic system comprises an oil tank, a filter, a hydraulic pump, a motor, a one-way valve, a pilot operated compound relief valve, a two-position two-way electromagnetic directional valve, a three-position four-way electromagnetic directional valve, a double-hydraulic-control one-way valve and a one-way speed regulating valve. When the hydraulic machine works in the feeding working station, the left position of the three-position four-way electromagnetic directional valve is connected; oil liquid enters a first hydraulic cylinder rodless cavity through the one-way valve, the three-position four-way electromagnetic directional valve and the left one-way valve in the double-hydraulic-control one-way valve under the effect of the hydraulic pump; oil liquid in a rod cavity enters a second hydraulic cylinder rodless cavity through a pipe and returns to the oil tank through a speed regulating valve body in the one-way speed regulating valve, and a valve opening of the speed regulating valve body is set to be capable of achieving the stability of the motion speed of the hydraulic machine during feeding. The hydraulic system of the hydraulic machine has the advantages of being remarkable in pressure maintaining effect in the feeding working condition, stable in running speed, rapid in returning and high in efficiency.

Owner:南通东海机床制造集团有限公司 +1

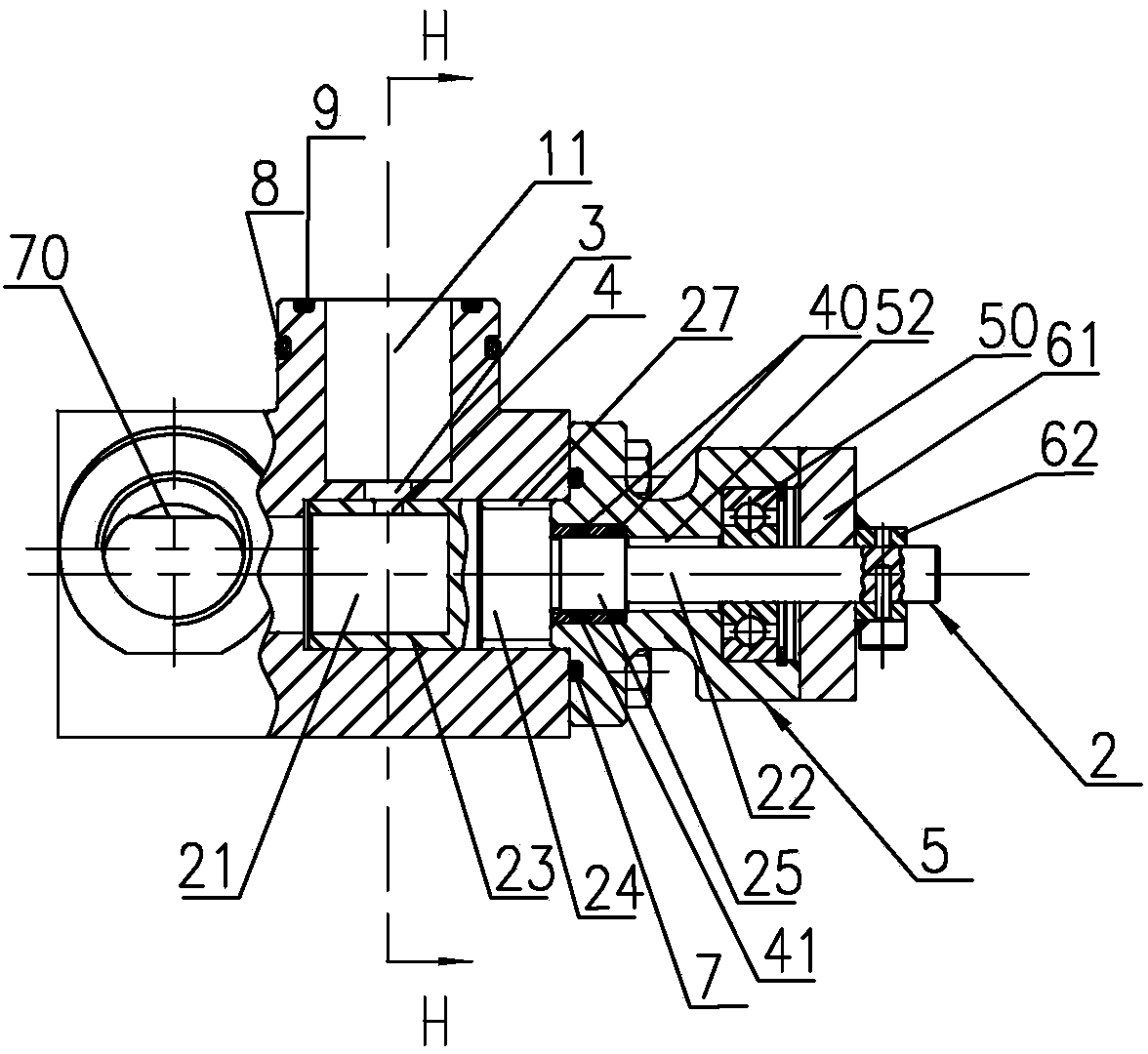

Quantitative control valve of fuel gas entering cylinder on gas engine

ActiveCN103453167AImprove securityControl gas supplyOperating means/releasing devices for valvesInternal combustion piston enginesInlet channelEngineering

The invention discloses a quantitative control valve of fuel gas entering a cylinder on a gas engine. The quantitative control valve comprises a valve body and a valve rod arranged in the valve body, wherein the valve body is internally provided with a gas inlet channel and a gas outlet channel, and the central lines of the gas inlet channel and the gas outlet channel are mutually crossed or vertical; one end of the gas inlet channel is the gas inlet end, and the other end of the gas inlet channel is arranged on one end surface of the valve body and is an adjusting end; the gas outlet channel is positioned on a valve body wall close to the adjusting end of the gas inlet channel; an inner port of the gas outlet channel is communicated with the gas inlet channel to form an adjusting outer hole; the front end part of the valve rod is barrel-shaped, is inserted into the gas inlet channel from the adjusting end of the gas inlet channel and can rotate in the gas inlet channel; the rear end part of the valve rod extends out of the valve body to be connected with a load controller; a gas chamber communicated with the gas inlet port is formed at the front end part of the valve rod; the peripheral wall of the gas chamber of the valve rod is provided with a through hole as an adjusting inner hole; the adjusting inner hole and the adjusting outer hole correspond in the axial position of the valve rod; the adjusting inner hole can change between states of complete coincidence with the adjusting outer hole and complete staggering with the adjusting outer hole along with rotation of the valve rod to adjust the entering amount of the fuel gas.

Owner:GUANGZHOU DIESEL ENGINE FACTORY

Intelligent belt pulley

InactiveCN101205969ARealize the deceleration functionRealize overload skidding protection functionGearingPortable liftingGear wheelReduction drive

The invention relates to a belt pulley in a belt driving mechanism, in particular to an intelligent belt pulley for walking beam type pumping unit in oil fields. The invention solves the problems that: the prior speed reducer and belt driving mechanism for walking beam type pumping unit can not meet the requirements of long-stroke low-frequency pumping units and the energy-saving requirements of a matched low power motor. The intelligent belt pulley comprises a planet gear mechanism consisting of a sun wheel, an annular gear, a planet carrier and a planet gear, and a belt pulley consisting of a belt pulley core and a belt pulley, wherein the belt pulley core is axially fixed on a planet carrier shaft through a bearing, the sun wheel is in floating connection with the belt pulley core, the annular gear is surrounded by an external friction tape, one end of the friction tape is fixed on a connecting plate on the body of the speed reducer, the other end of the friction end is fixed on a screw which passes through the connecting plate and is fixed through a nut. The invention which has reasonable and simple structure, high mechanical efficiency and lower power consumption can meet the requirements of long-stroke low-frequency pumping units in various types of oil fields and is also applicable to other universal machines.

Owner:樊世耀 +1

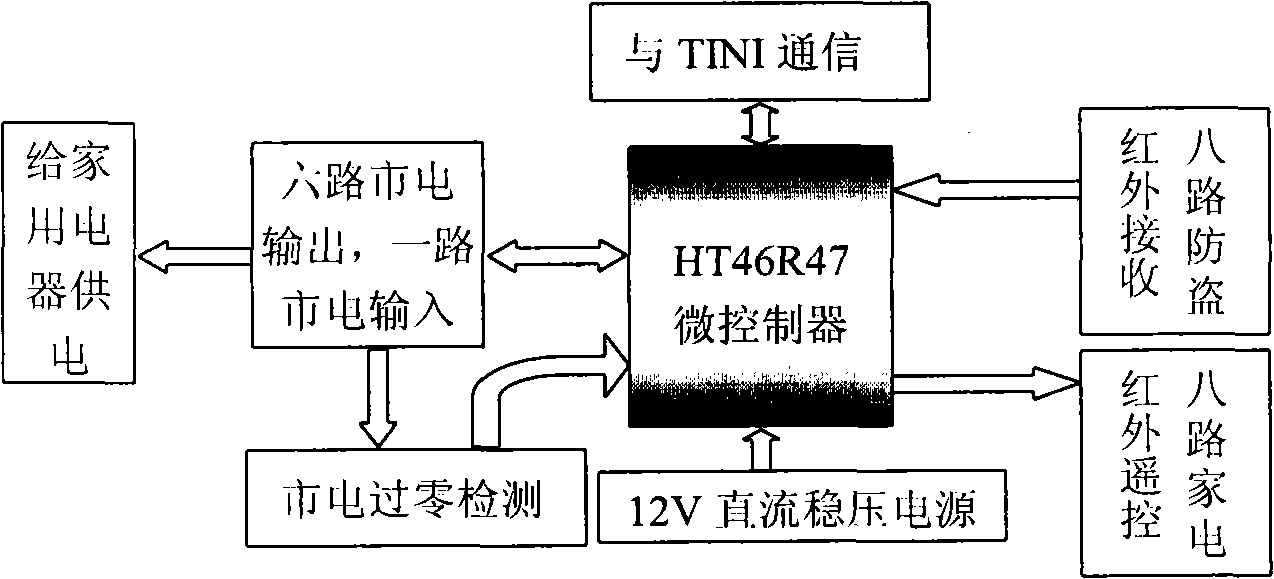

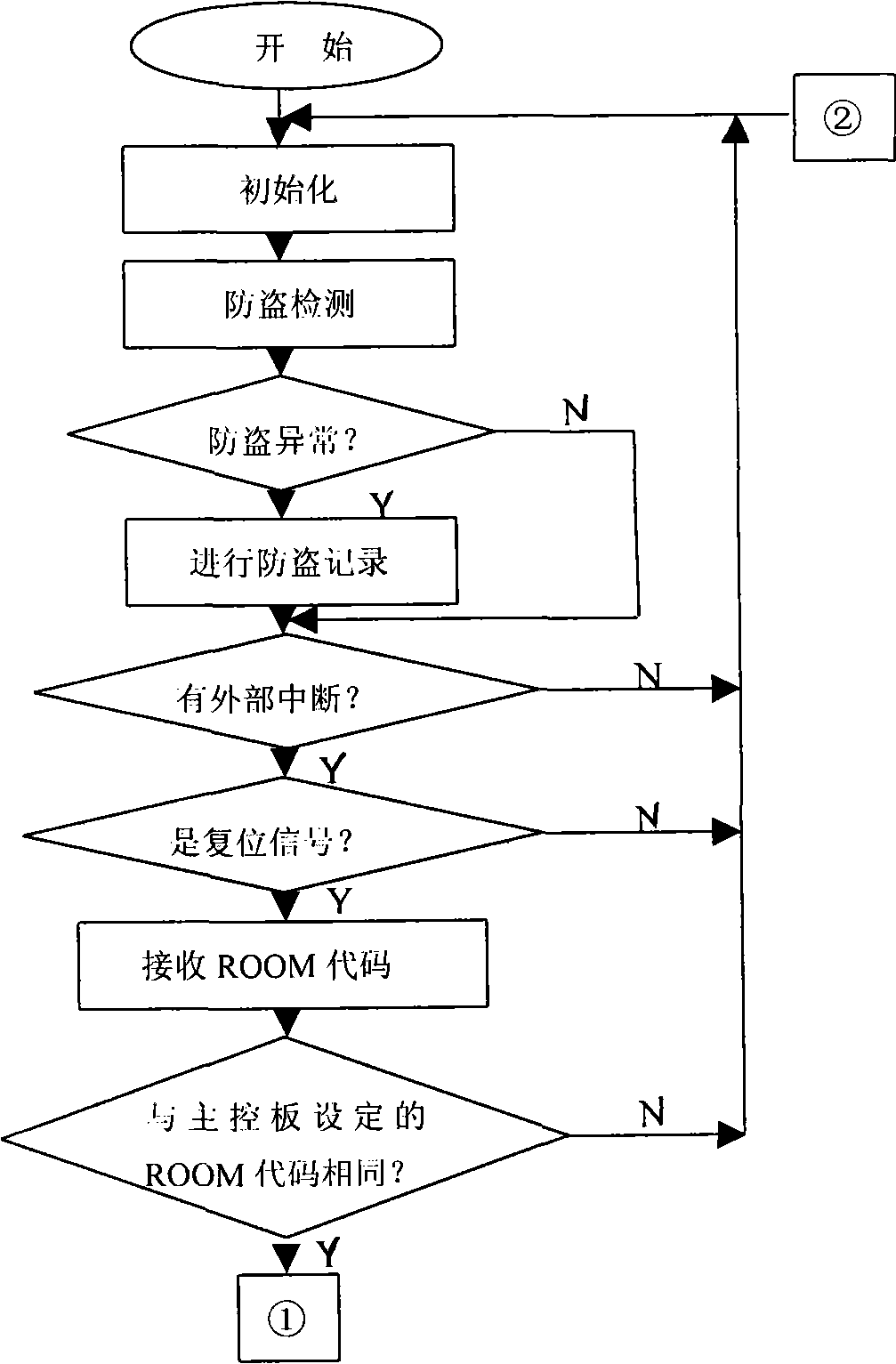

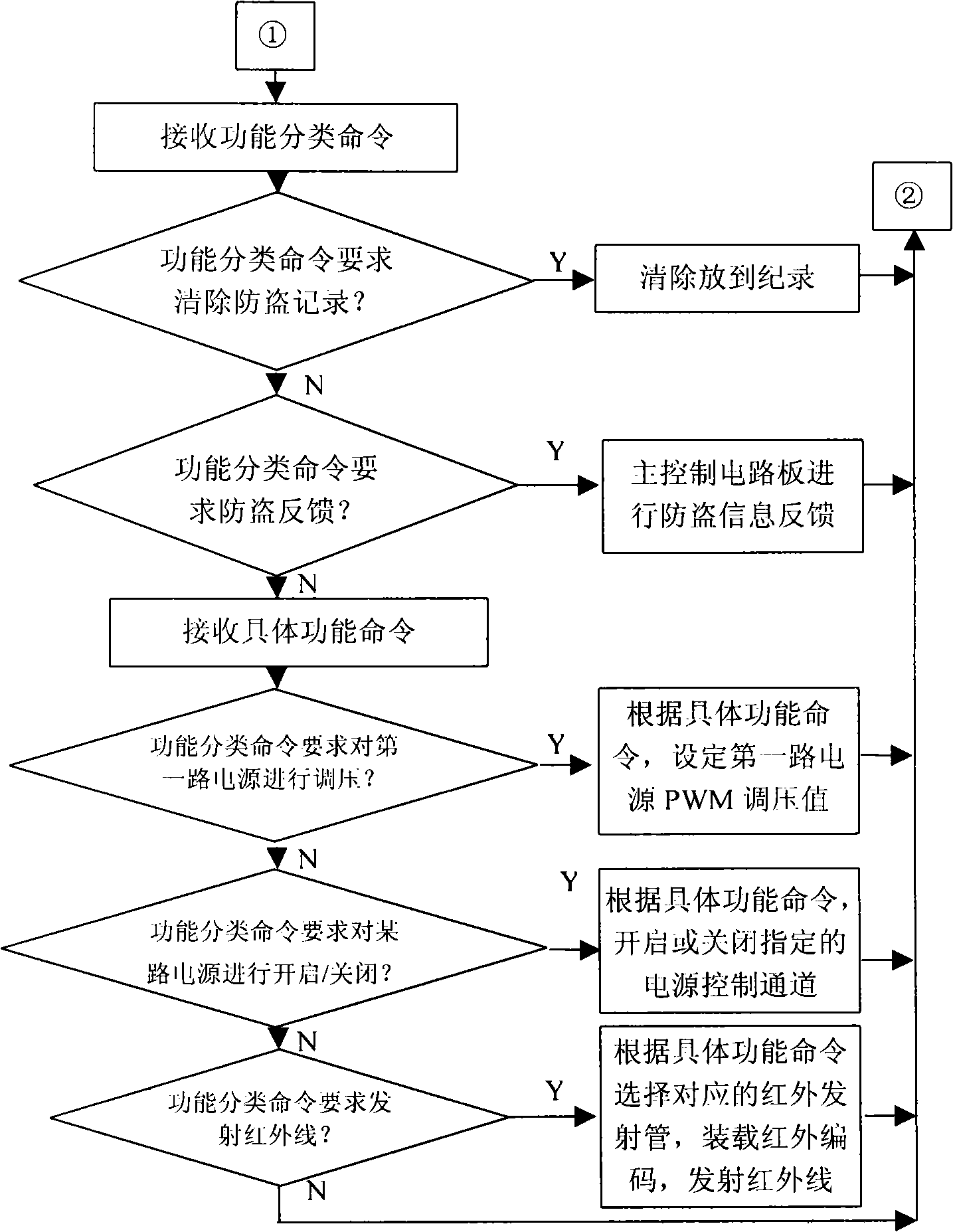

Household network intelligent measuring and control machine

InactiveCN101282271ASimple structureLow costTelemetry/telecontrol selection arrangementsData switching by path configurationEmbedded systemAutomatic meter reading

The invention discloses a household network intelligent test and control machine, which is composed by a household network access embedded type apparatus TINI, a power source module, a six-path 50Hz high power alternating current power supply output module, a commercial power over 0 detection module, an infrared ray transmission module and an infrared ray reception module. A user is connected with the Internet via an Ethernet interface of the TINI, Java language is applied on the TINI system to establish a Web server circumstance so that the user can remotely monitor the household apparatuses via the Internet. The invention is simple in structure, low in cost and convenient for bus expansion and maintenance, the user terminal can conveniently realize remote operations via the Internet, such as automatic meter reading (water meter, ammeter and gas meter), and secure prevention of leakage of fuel gas and illegal invasion and control of appliances.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

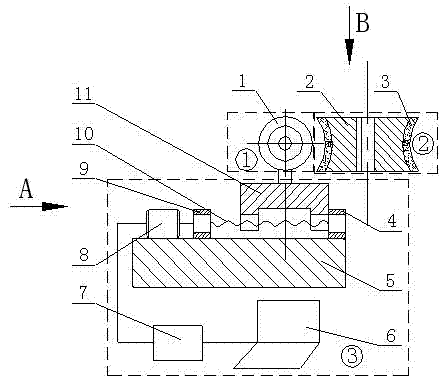

Centering and clamping device for multi-diameter pipe

PendingCN109382776ARealize clamping and centeringRealize speed regulationWork holdersPositioning apparatusBall bearingEngineering

The invention provides a centering and clamping device for a multi-diameter pipe. The device comprises a rack end cover, a rocker, a motor, a motor base, a rack, a connecting block, a sliding block vertical column, a movable sliding block, a screwing-in sliding frame, a transmission gear, a rotating shaft frame, a motor gear, a motor shaft, a threaded rod, a fixing nut, a ball bearing and a shaftsleeve, wherein the rack end cover is arranged on the right side of the upper part of the rack through bolts; the rocker is clamped at the right end of the threaded rod, and the motor is welded to theupper part of the motor base. The motor drives the motor gear to rotate, the rotating shaft frame is rotated through gear transmission, the movable sliding block and the screwing-in sliding frame aredriven to rotate synchronously, and the pipe rotates along with the movable sliding block and the screwing-in sliding frame; the simple structure is used, so that clamping and centering of pipes withdifferent diameters are achieved in the actual operation process, the rotating speed during pipe machining is adjusted, the tool cost is reduced, and the quality and machining efficiency of the outersurface of the pipe are improved.

Owner:SHAANXI SCI TECH UNIV

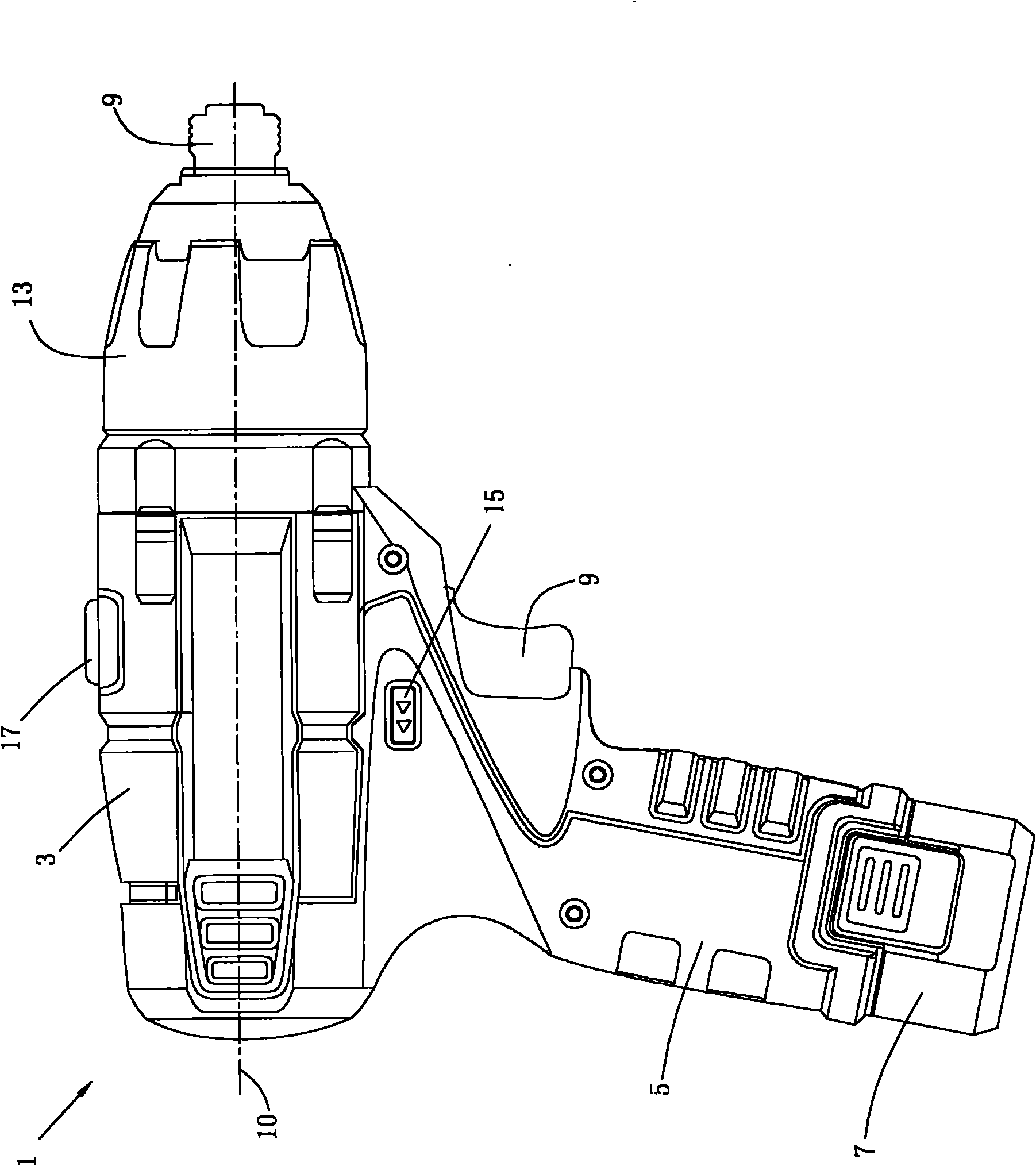

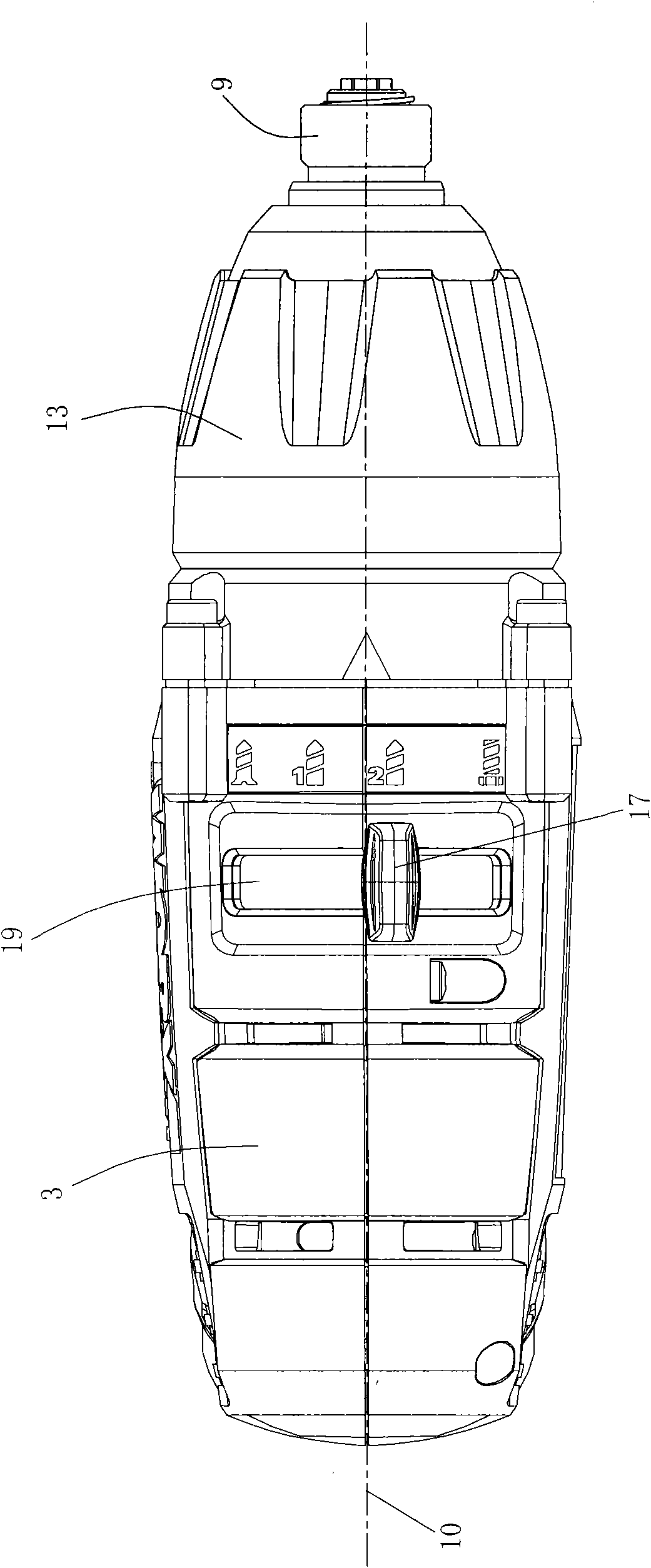

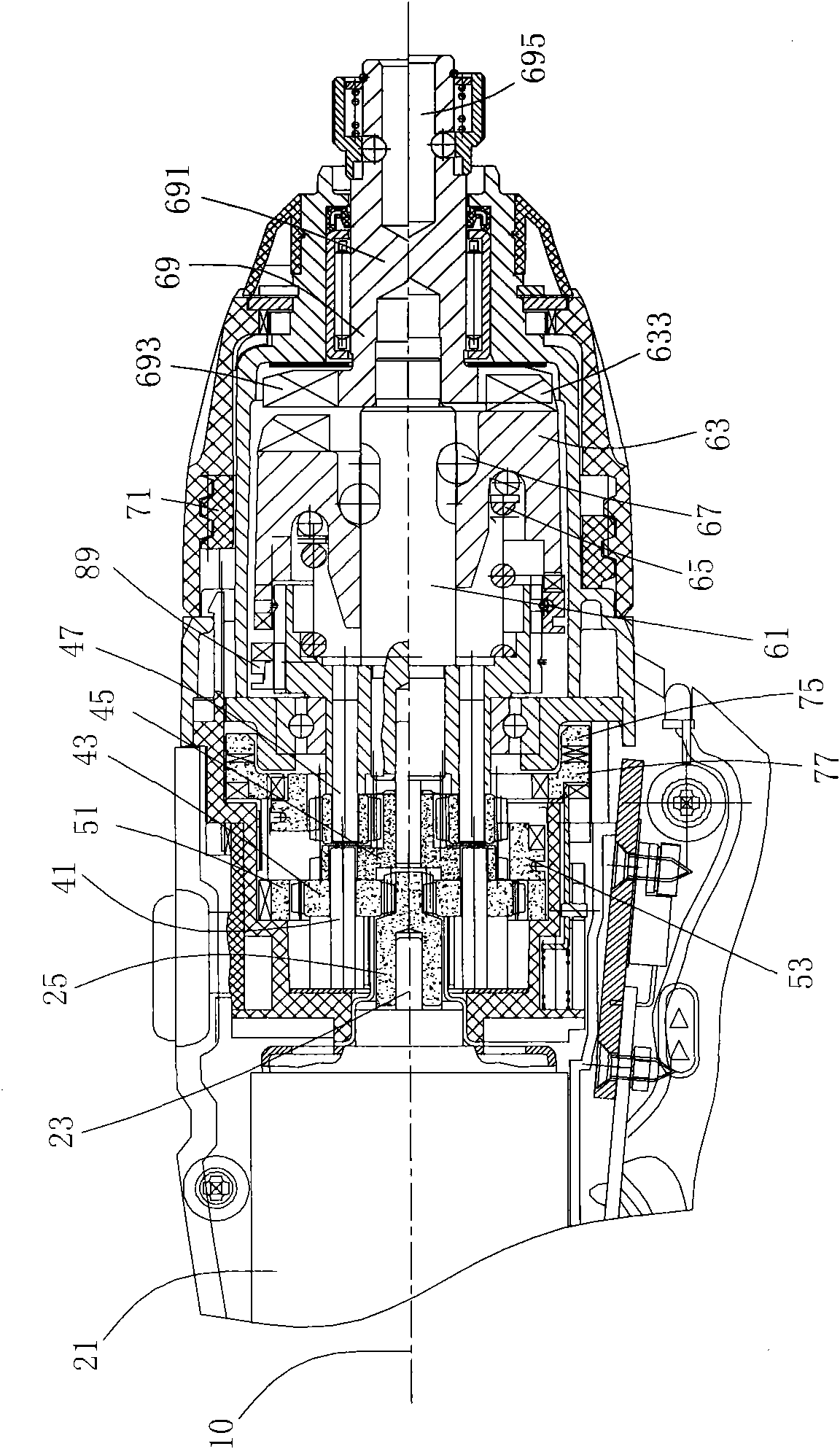

Power tool

ActiveCN102335904ARealize switchingImprove simplicityPortable power-driven toolsLow speedEngineering

The invention relates to a power tool. The power tool comprises a shell, a motor, a planetary gear deceleration system, a power output system, a switching window, and a function switching button; the motor is positioned in the shell and is provided with an output shaft which provides rotary output; the planetary gear deceleration system decelerates the rotary output of the output shaft and then performs rotary output; the power output system transfers the rotary output of the planetary gear deceleration system to a work head; the switching window is positioned on the shell; and at least one part of the function switching button is accommodated in the switching window, and the function switching button moves in the switching window to select an impact wrench function, a high-speed drilling function, a low-speed drilling function and a screwdriver function for the power tool. The function switching button can slide on the shell to realize speed regulation, and the impact wrench function can be switched, so that operation convenience is improved.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

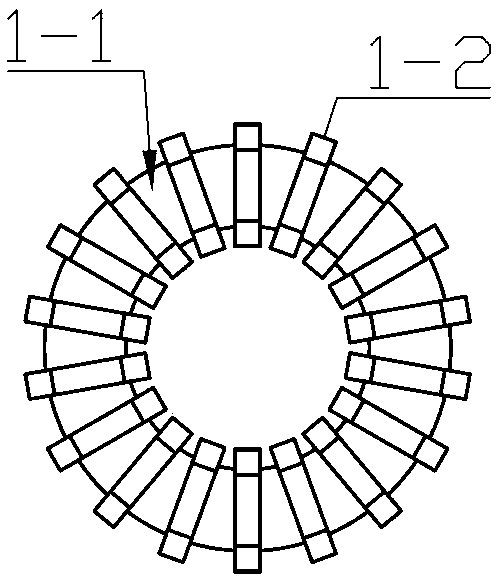

Permanent-magnet variable-speed hub motor with complementing excitation rotor

InactiveCN102064657AReduce frictionEnsure continuous changeMagnetic circuit rotating partsMagnetic sourceElectric machine

The invention relates to a permanent-magnet variable-speed hub motor with a complementing excitation rotor. Two groups of excitation magnetic sources of which the polarities complement are arranged at the inner rotor surface of a hub, a main magnetic flux source excitation body and an auxiliary magnetic flux source excitation body are respectively configured with alternate polarities by a plurality of permanent magnets in a rotor yoke to form an annular shape which takes a stator shaft as the center, a polar distance is staggered between the peripheral polarity distributions of the auxiliary magnetic flux source excitation body and the main magnetic flux source excitation body, a stator and the stator shaft are matched via a spline to form a stator which can move axially, and a plurality of rollers which push the stator shaft to move axially through an eccentric exercise are arranged between a track plate arranged in a left end cover of the hub and a push disc arranged on the stator, so that the magnetic flux is reduced due to the axial motion of the stator to change the torque-rotating speed properties of the motor and realize speed changing. According to the invention, Not only can the mechanical properties of the permanent-magnet variable-speed hub motor per se be improved, but also the full power speed regulating ranges of the permanent-magnet variable-speed hub motor can be increased, meanwhile, the motor size is not increased, and the production cost is saved.

Owner:杨荷

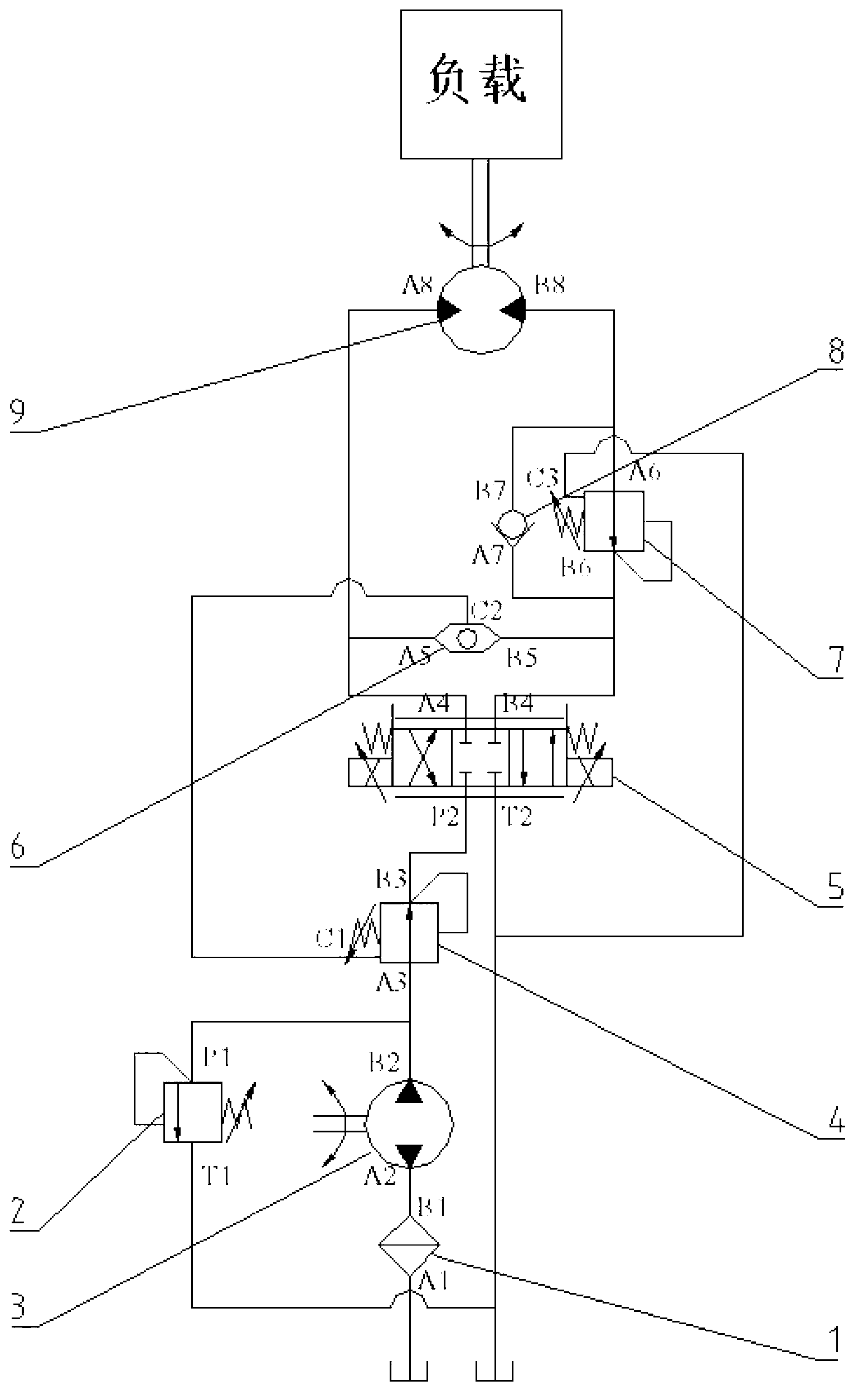

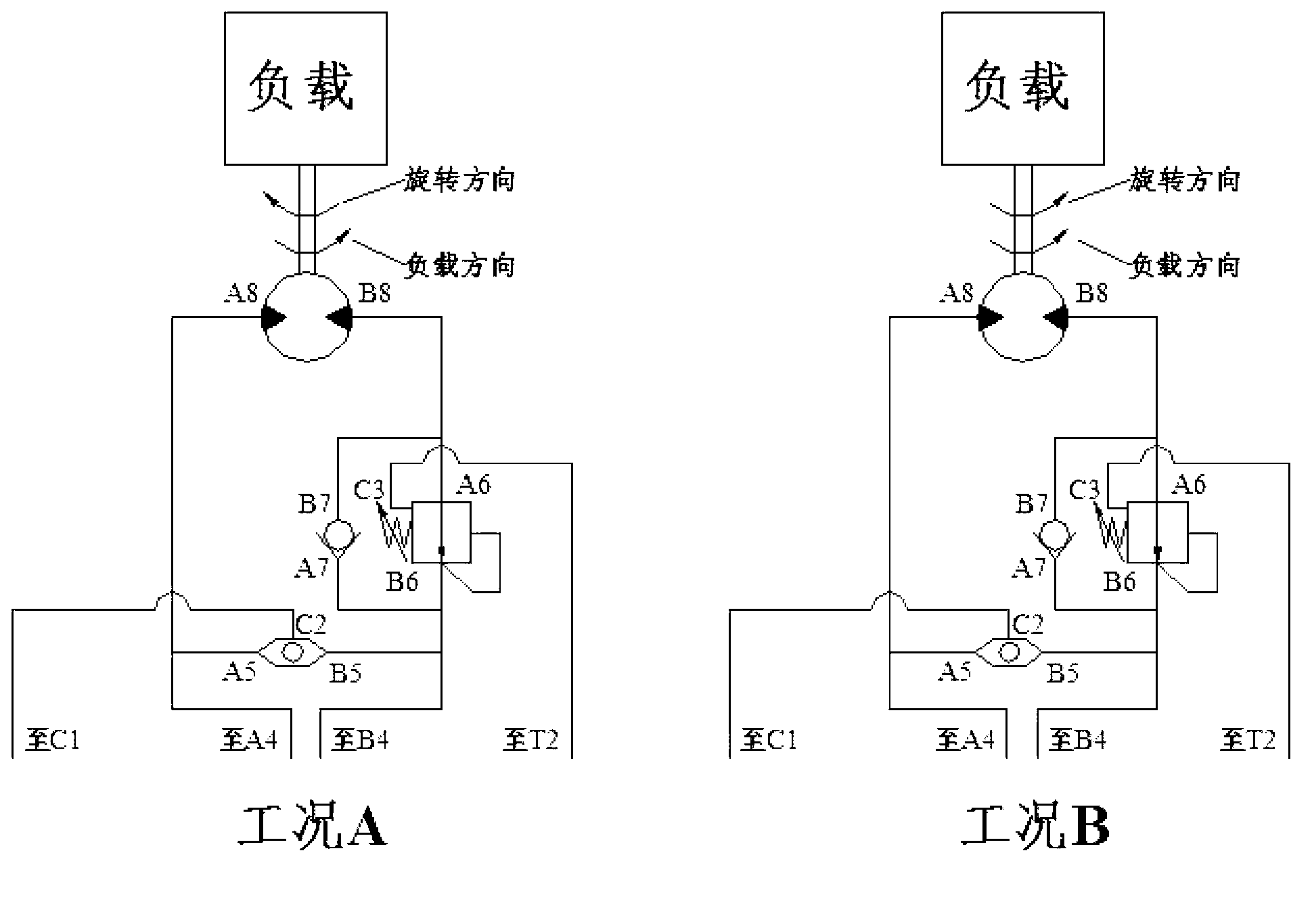

Hydraulic system capable of independently adjusting speed by adopting two pressure compensators

The invention discloses a hydraulic system capable of independently adjusting speed by adopting two pressure compensators. The hydraulic system comprises an oil filter (1), an overflow valve (2), a quantification pump (3), a pressure compensator I (4), a pressure compensator II (7), a proportion reversing valve (5), a shuttle valve (6), a unidirectional valve (8) and a bidirectional motor (9), wherein the pressure compensator I (4) is arranged in front of an oil inlet P2 of the proportion reversing valve (5); the pressure compensator II (7) is arranged behind an oil outlet B4 of the proportion reversing valve (5); an oil outlet B3 of the pressure compensator I (4) is communicated with the oil inlet P2 of the proportion reversing valve (5); an oil outlet A4 of the proportion reversing valve (5) is communicated with an oil inlet A5 of the shuttle valve (6) and an oil inlet A8 of the bidirectional motor (9) respectively; and an oil outlet B4 of the proportion reversing valve (5) is communicated with an oil inlet B5 of the shuttle valve (6), an oil inlet A7 of the unidirectional valve (7) and an oil outlet B6 of the pressure compensator II (7).

Owner:ZHEJIANG UNIV

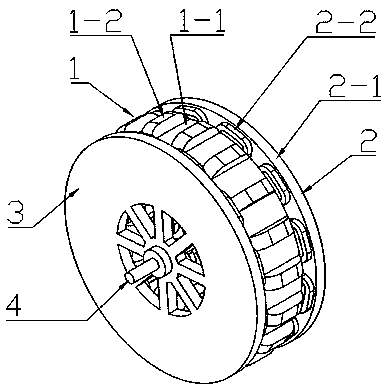

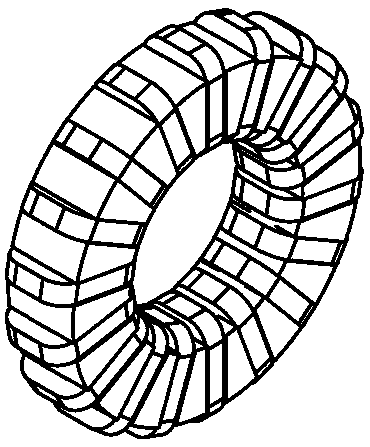

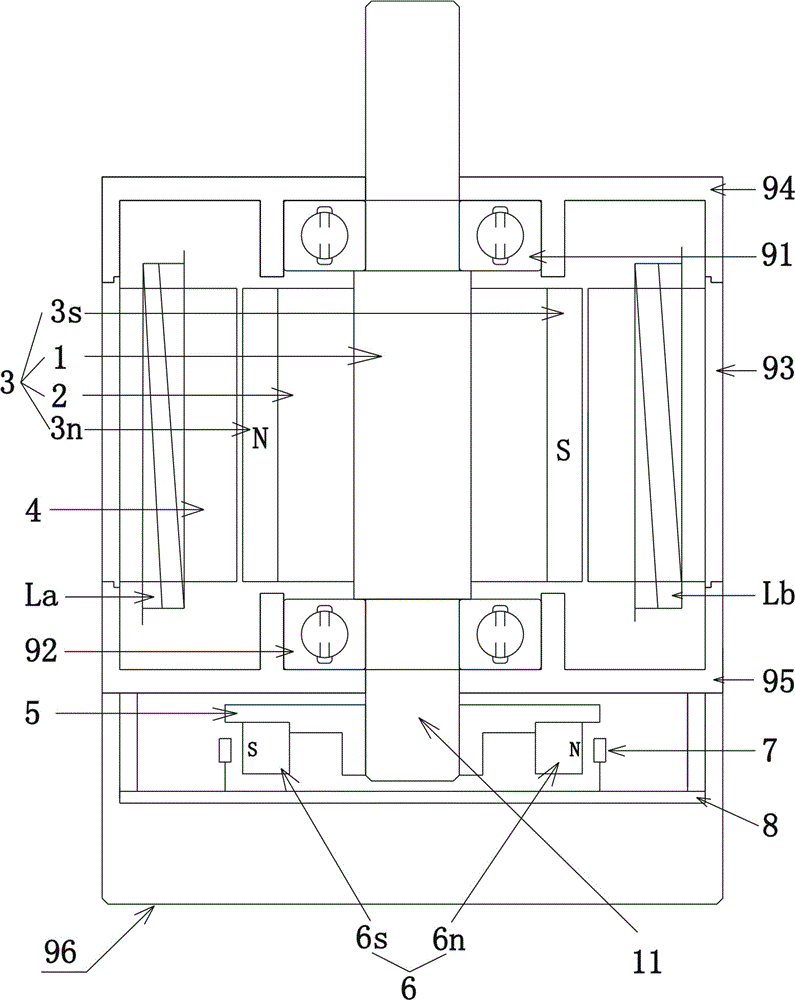

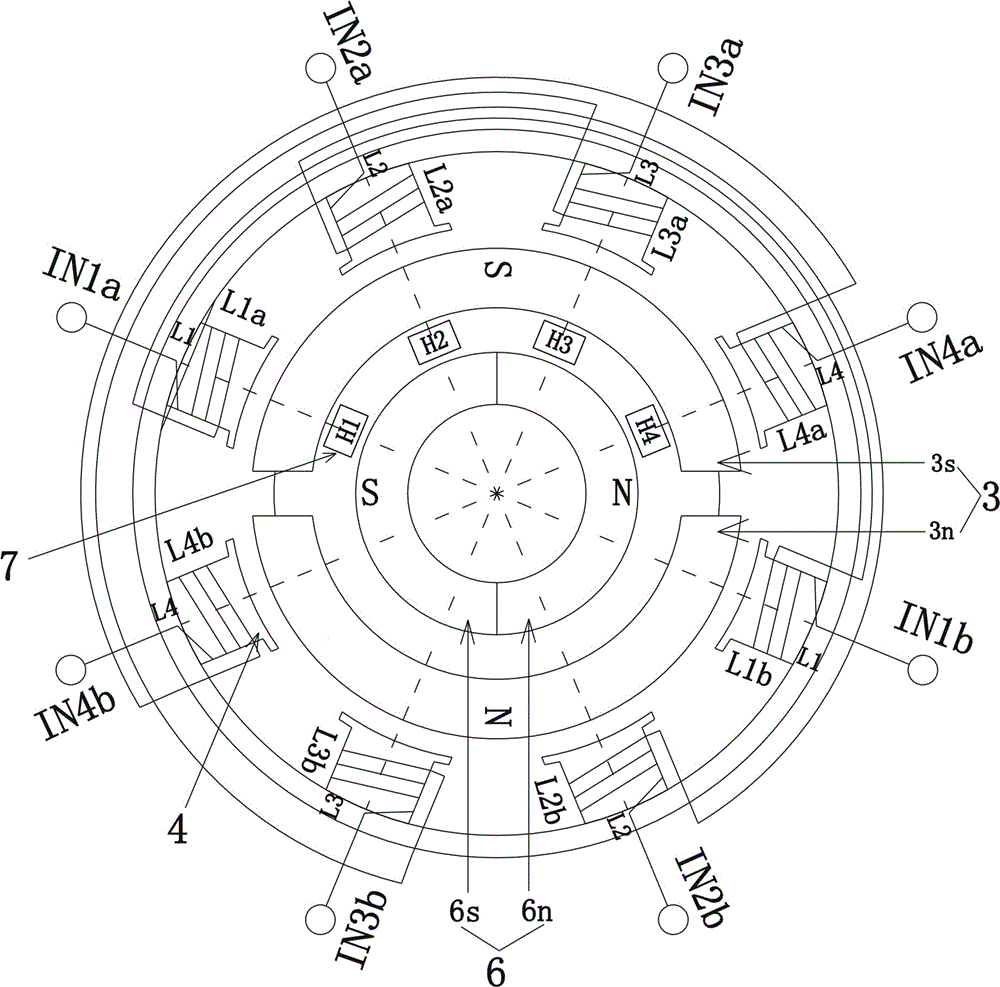

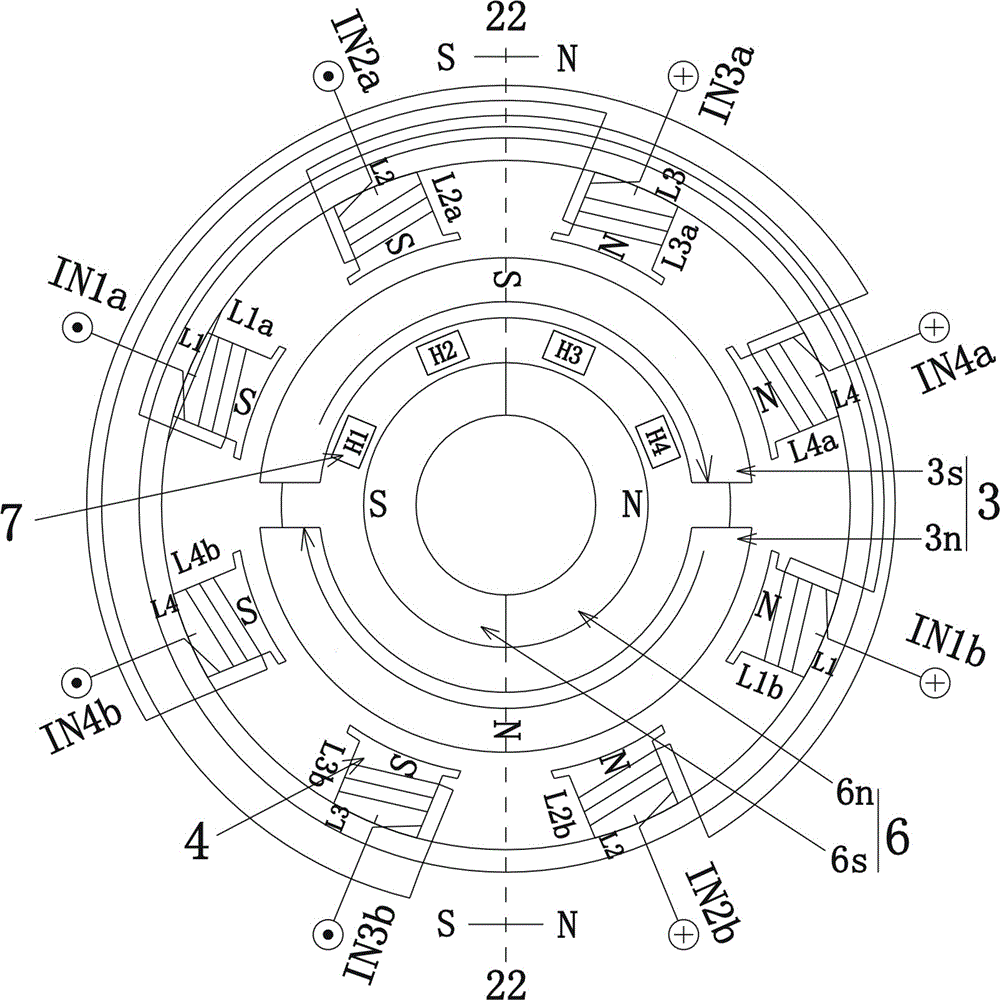

Variable-pole variable-phase dual-rotor axial magnetic flux annular winding synchronous motor

PendingCN109660098AGood heat dissipationImprove insulation performanceAssociation with control/drive circuitsPhysicsSynchronous motor

The invention belongs to the technical field of motors and discloses a variable-pole variable-phase dual-rotor axial magnetic flux annular winding synchronous motor comprising a stator and rotors, wherein the rotors comprise a right rotor, a left rotor and a rotor shaft; the right rotor and the left rotor are coaxially connected to the rotor shaft; the stator is disposed between the right rotor and the left rotor; independent air gaps are arranged between the right rotor and the stator and between the left rotor and the stator; the stator comprises a stator core and a stator annular winding; the stator core is a disc-shaped annular core; the stator annular winding is connected with an inverter; the left and right rotors each comprise a rotor core and an exciting winding; the stator annularwinding corresponds to the exciting winding; and the exciting winding is connected to a controllable DC power supply. The variable pole and the variable phase of the motor are achieved by changing the direction and the magnitude of the exciting current and the magnitude and the phase of the armature current. The phase number and the pole number of the motor can be changed in a non-stop manner, and the speed of the motor can be regulated within a wide range.

Owner:ZHENGZHOU UNIV +2

Land leveler transmission system and land leveler

ActiveCN105569108ASolve the phenomenon of unilateral slippageIncrease speedMechanical machines/dredgersDifferential gearingsHydraulic motorLeft half

The invention discloses a land leveler transmission system and a land leveler. The land leveler transmission system comprises a power source, a hydraulic pump, a hydraulic motor, an axle, a left wheel and a right wheel. The left wheel is mounted on the left side of the axle, and the right wheel is mounted on the right side of the axle. The power source is connected with the hydraulic pump. The hydraulic pump is connected with the hydraulic motor through a hydraulic oil way. The hydraulic motor is connected with the axle. The axle comprises a left half axle and a right half axle. The left half axle is connected with a left planetary reducer. The right half axle is connected with a right planetary reducer. The left wheel is mounted on the left planetary reducer. The right wheel is mounted on the right planetary reducer. The power transmission path of the land leveler transmission system is short, a gearbox and a balance box are omitted, structural arrangement is compact, and manufacturing cost is low.

Owner:HUNAN SANY ROAD MACHINERY

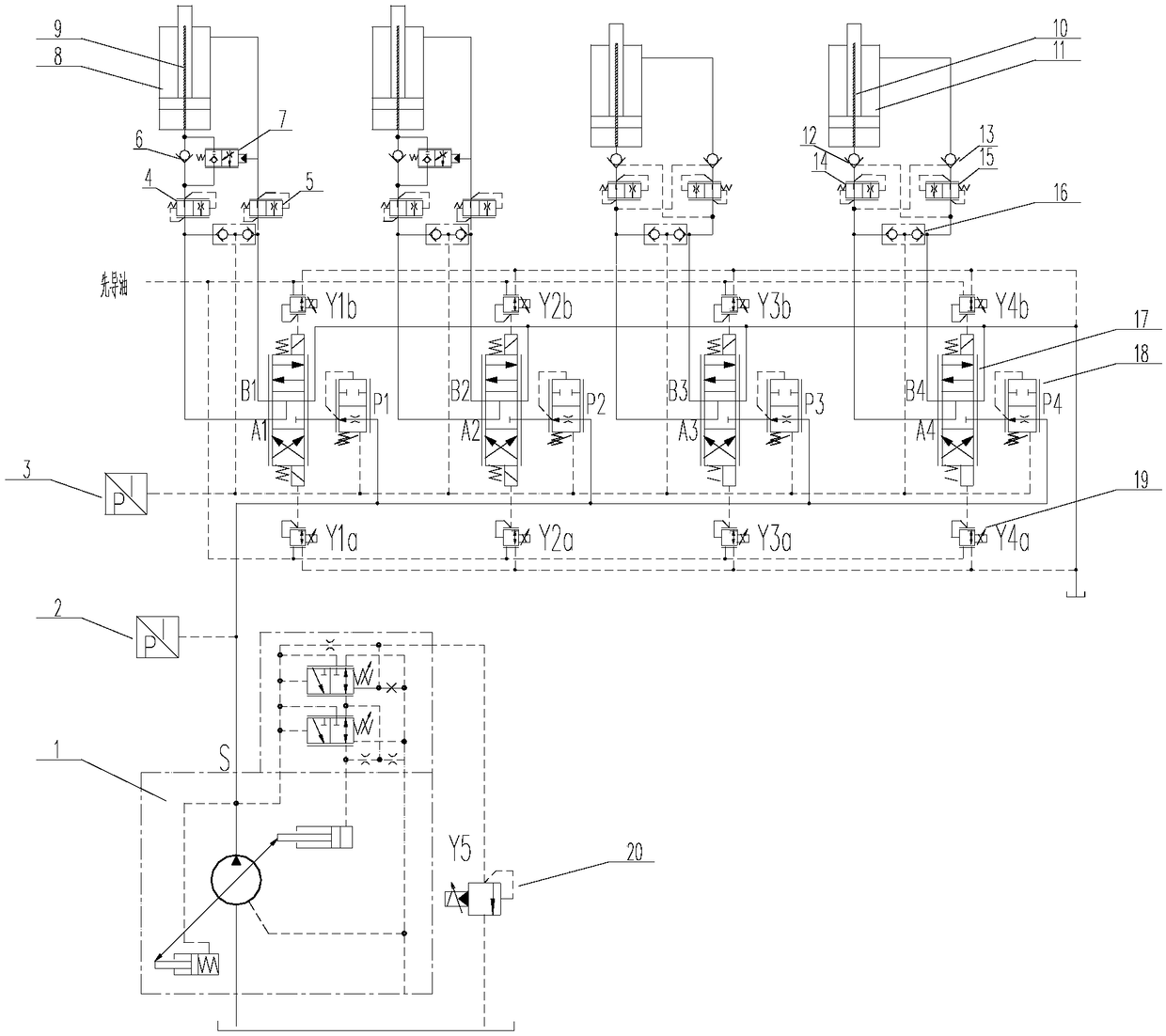

Hydraulic control system for stepless brake retarder

ActiveCN101391613AIncreased speed of mitigationImprove compilation efficiencyTrack brakesEngineeringFuel tank

The invention relates to a hydraulic control system of a stepless brake speed reducer, which comprises an oil tank, an oil cylinder, an oil pump which is driven by a motor and an energy accumulator, and is characterized in that: the hydraulic control system of the stepless brake speed reducer further comprises a first reversing valve, a second reversing valve, a pressure reducing valve, a first one-way valve, a second one-way valve, a third one-way valve and a proportional valve; the oil pump is accessed to the energy accumulator through the first one-way valve, the energy accumulator is communicated with a relief cavity of the oil cylinder through the second one-way valve and the first reversing valve sequentially; one end of the second reversing valve is accessed to the oil tank, the other end is accessed to a brake cavity of the oil cylinder through the pressure reducing valve and the third one-way valve sequentially; the oil tank is accessed to the oil pump, the energy accumulator is accessed to the oil tank; the brake cavity of the oil cylinder is accessed to the oil tank through the first reversing valve; and the relief cavity of the oil cylinder is accessed to the oil tank through the proportional valve. The hydraulic control system of the stepless brake speed reducer realizes the stepless speed regulation, has rapid repeated brake response, strong adaptability and no impact on a vehicle and is conductive to prolonging the service life of the vehicle and the device.

Owner:西安优势铁路新技术有限责任公司

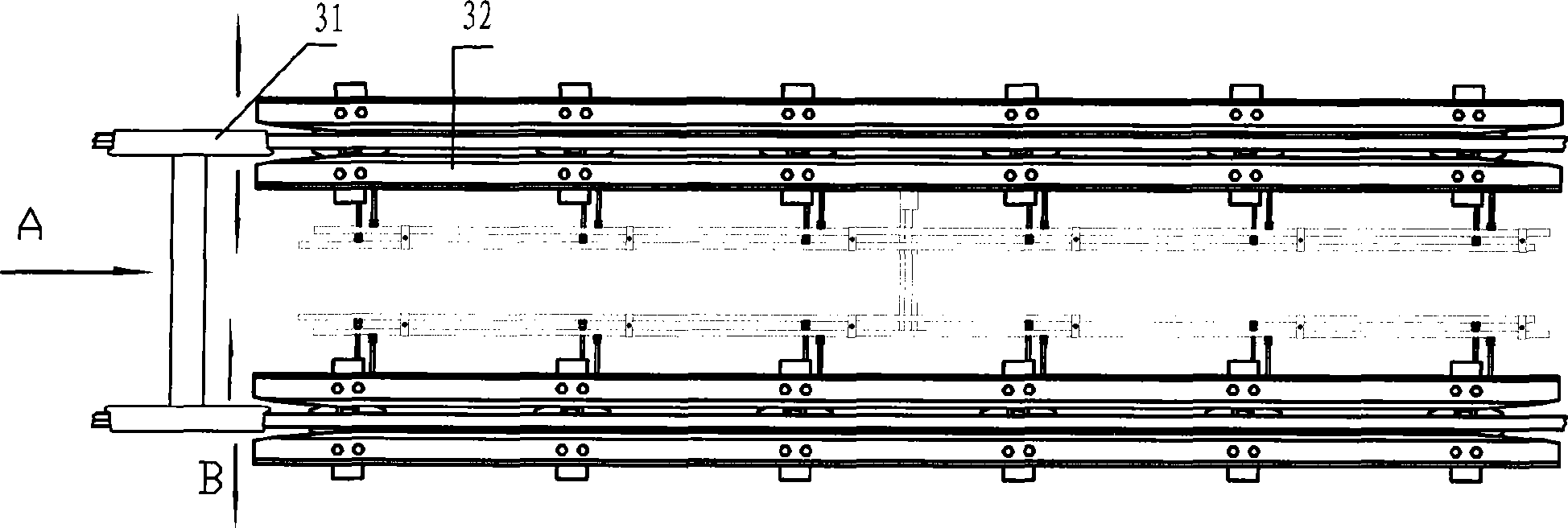

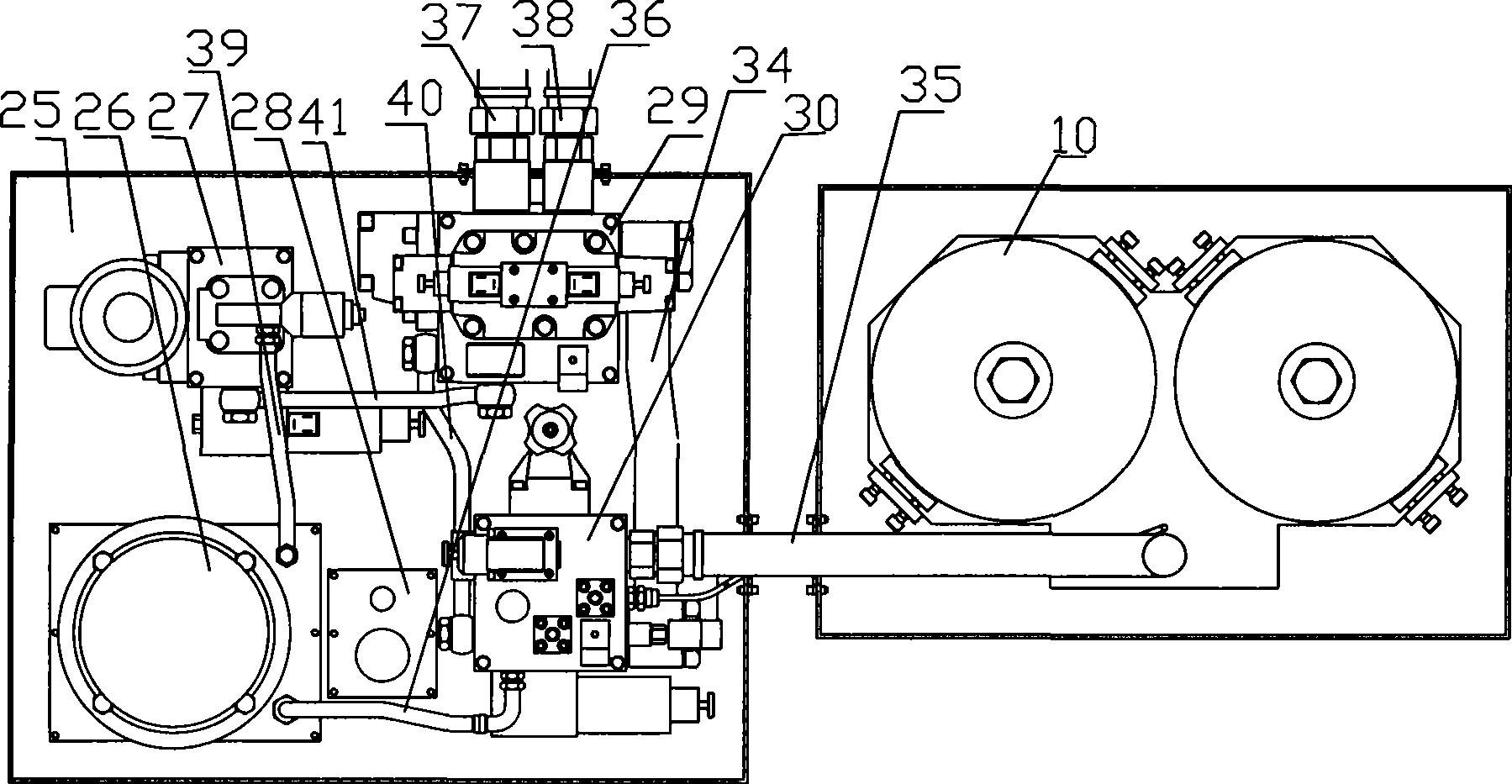

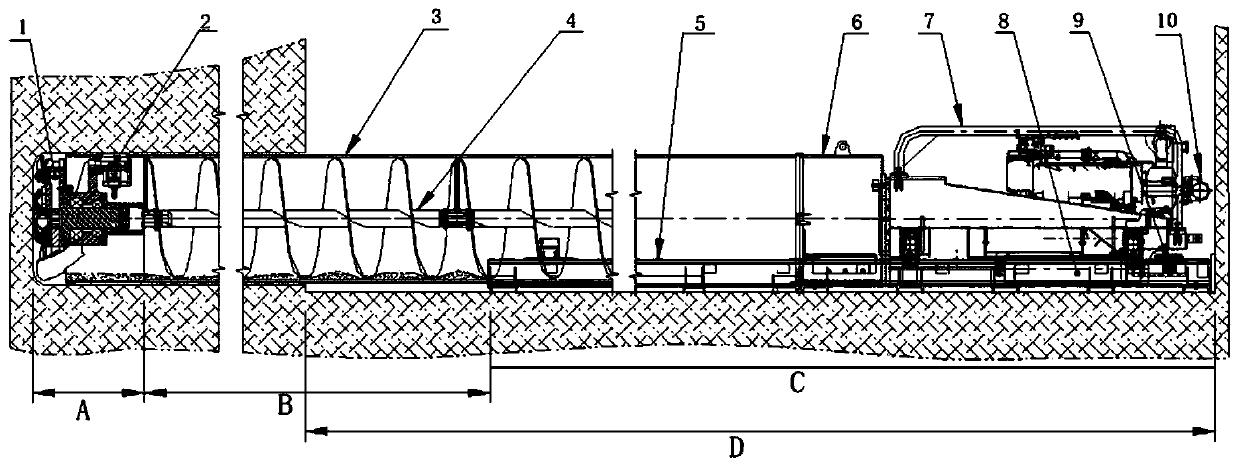

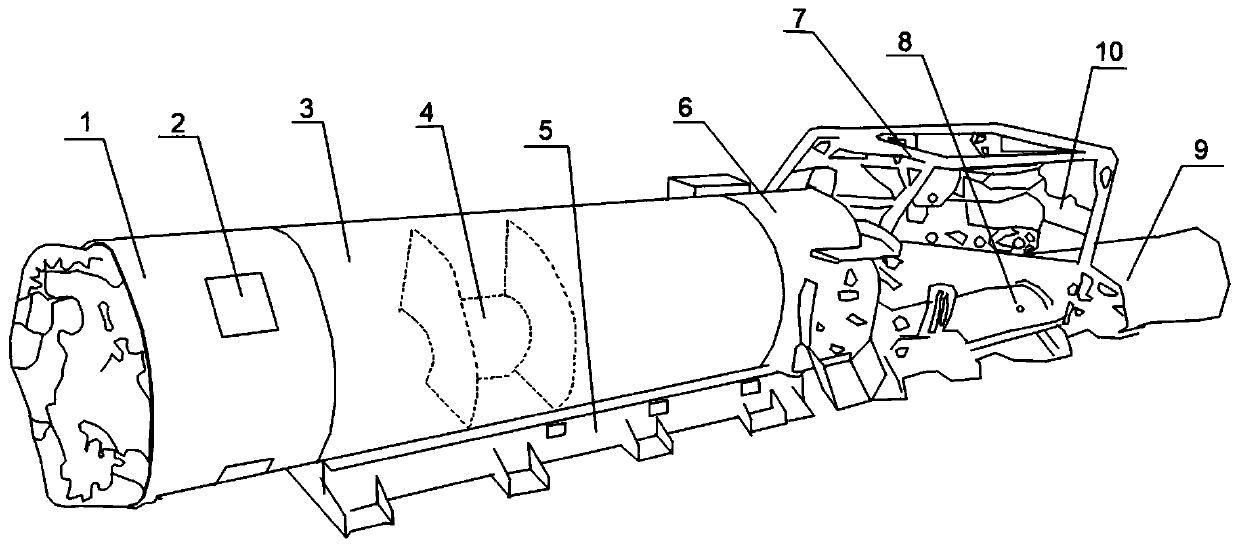

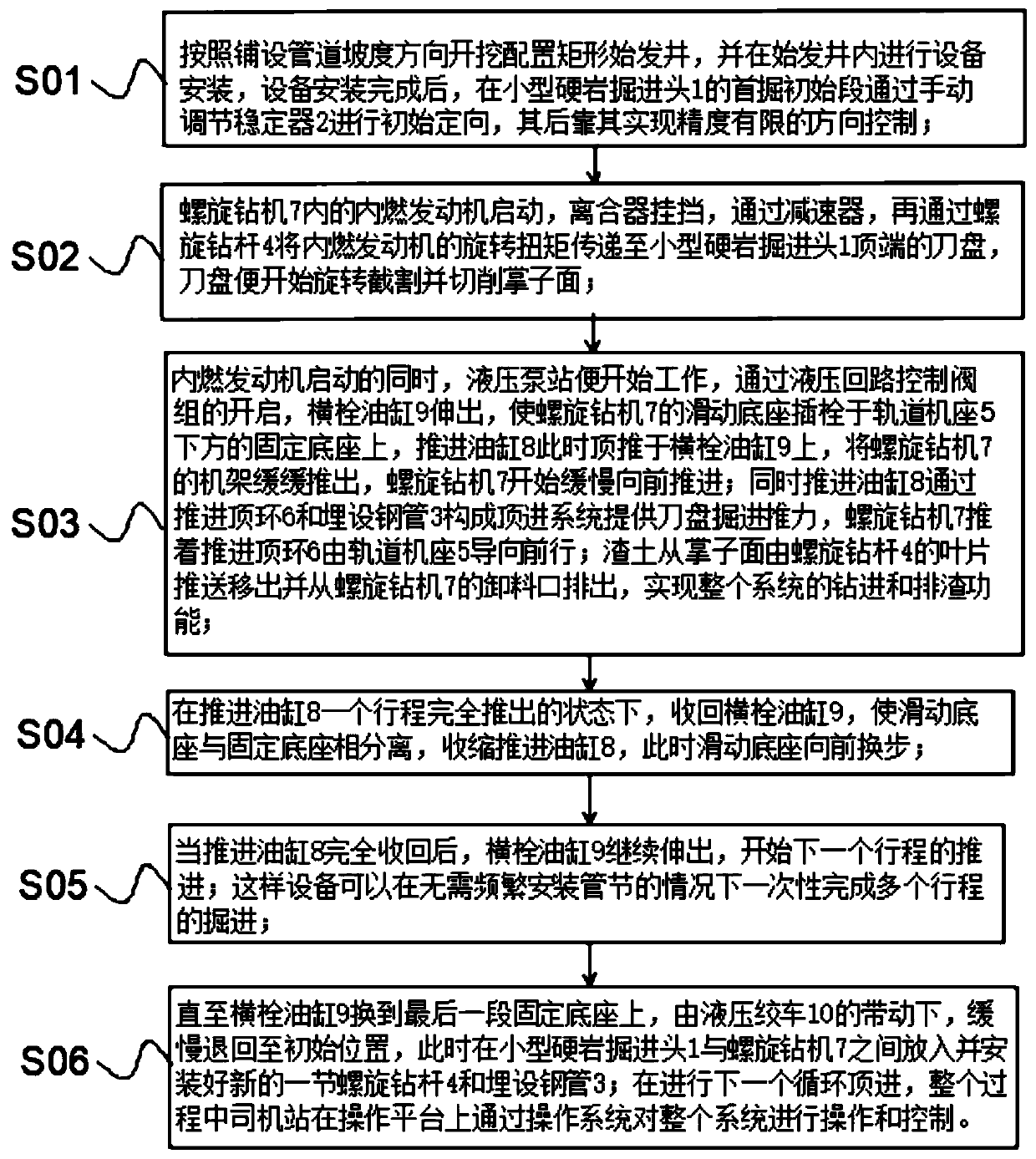

Integrated micro heading machine pushing system with screw drive and working method of integrated micro heading machine pushing system

The invention discloses an integrated micro heading machine pushing system with screw drive and a working method of the integrated micro heading machine pushing system, and relates to the field of heading machine. The integrated micro heading machine pushing system with the screw drive comprises a track machine seat, a thrust oil cylinder, a buried pipeline, a micro hard rock heading head, a screwdrilling machine, a screw drill pipe, a thrust ejecting ring, a horizontal pin oil cylinder and a hydraulic winch; a sliding base in sliding fit with the track machine seat is arranged at the bottomof a machine frame of the screw drilling machine; a stabilizer is arranged on the outer side part of the micro hard rock heading head; and the buried pipe sleeves the screw drill pipe in a connectingmode. According to the integrated micro heading machine pushing system with the screw drive, the pushing system is integrated into mechanical equipment, an engine is used as a power source to simultaneously meet power of rotation of a cutter and power of the whole machine thrust, a screw rod device is used for discharging excavated muck, and a slurry system is eliminated for the whole traditionalmicro heading machine system; and the construction cost is reduced, the construction process is simplified, the heading speed of the micro heading machine is improved, and the construction work periodis shortened.

Owner:江苏马超地下工程设备有限公司

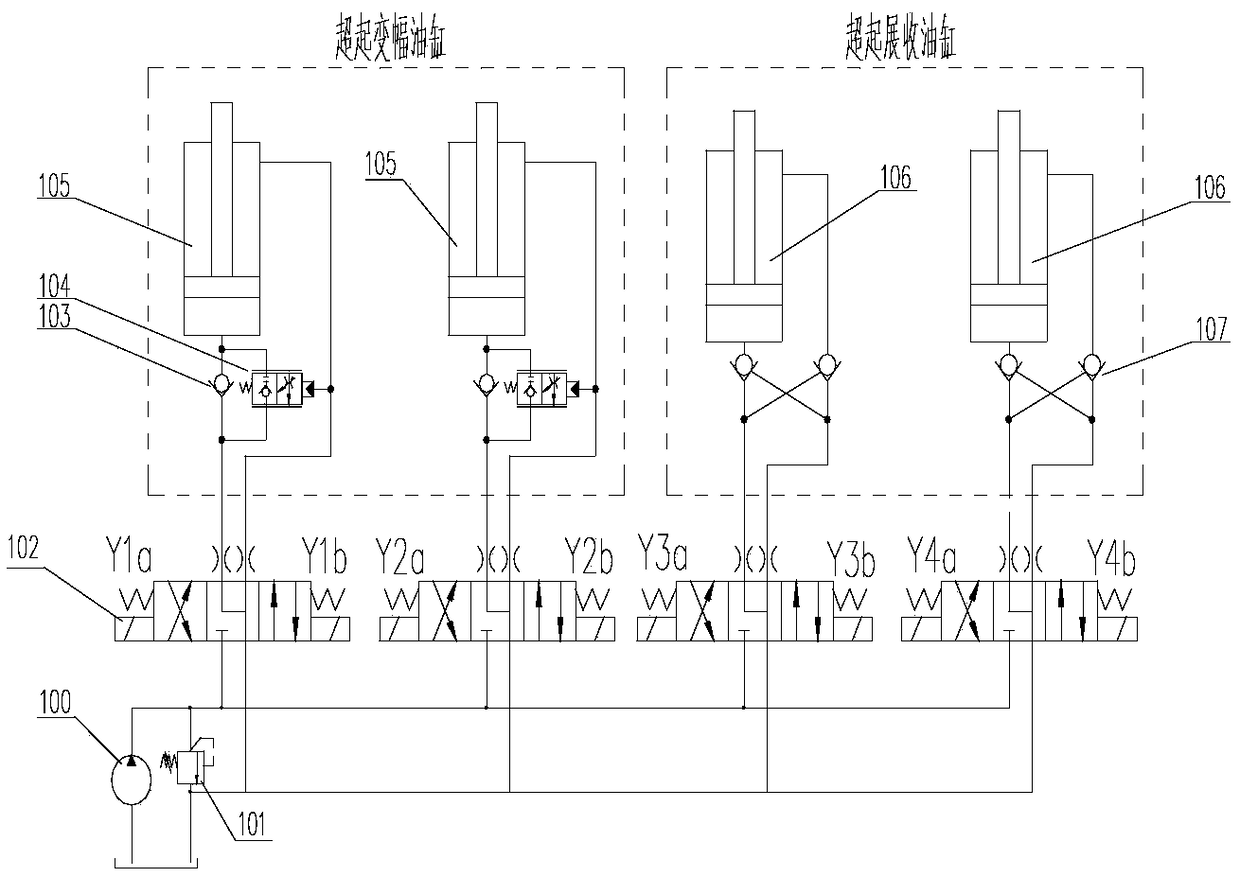

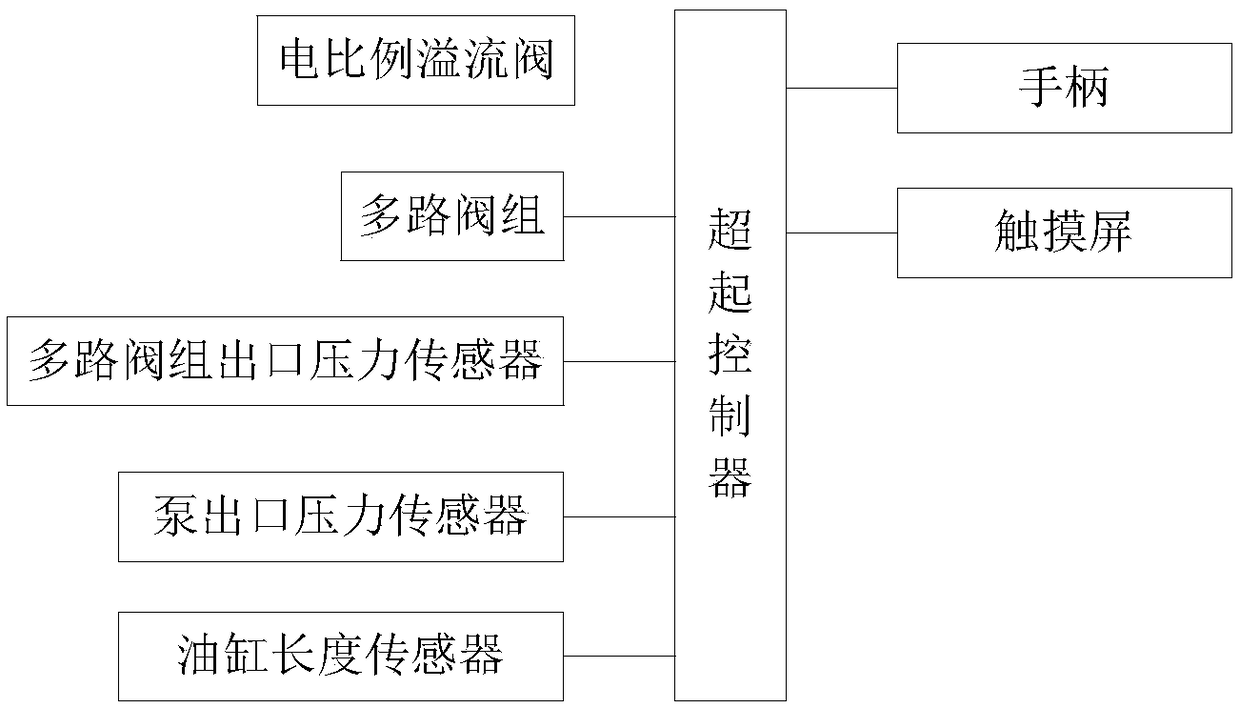

Super-tonnage lifting extension and retraction system and control method for all-ground crane

PendingCN109368500ARealize speed regulationImprove synchronicityServomotor componentsServomotorsEnergy lossElectricity

The invention discloses a super-tonnage lifting extension and retraction system and control method for an all-ground crane. The outlet pressure of a multi-path valve bank is compared with the outlet pressure of a pump through a super-tonnage lifting controller, a current value used for controlling an electric proportional overflow valve in a hydraulic source is output, and a pressure cut-off valveof a constant-pressure variable pump is changed, so that the outlet pressure of the constant-pressure variable pump and the outlet pressure of the multi-path valve blank are maintained at a constantpressure difference value. In this way, the super-tonnage lifting amplitude can be changed through the system and method, and an oil cylinder has good synchronicity and speed regulation performance when extending and retracing; prompting or automatic tensioning is achieved in use when the oil cylinder retracts, the speed can be automatically decreased when the oil cylinder approaches an upper deadpoint and a lower dead point, system impact is reduced, and the safety and stability of the system are improved; and the output flow is matched with the flow required by a load, the response speed ofthe system is ensured while the energy loss of the system is reduced, and the controllability of the system is improved.

Owner:臧其亮

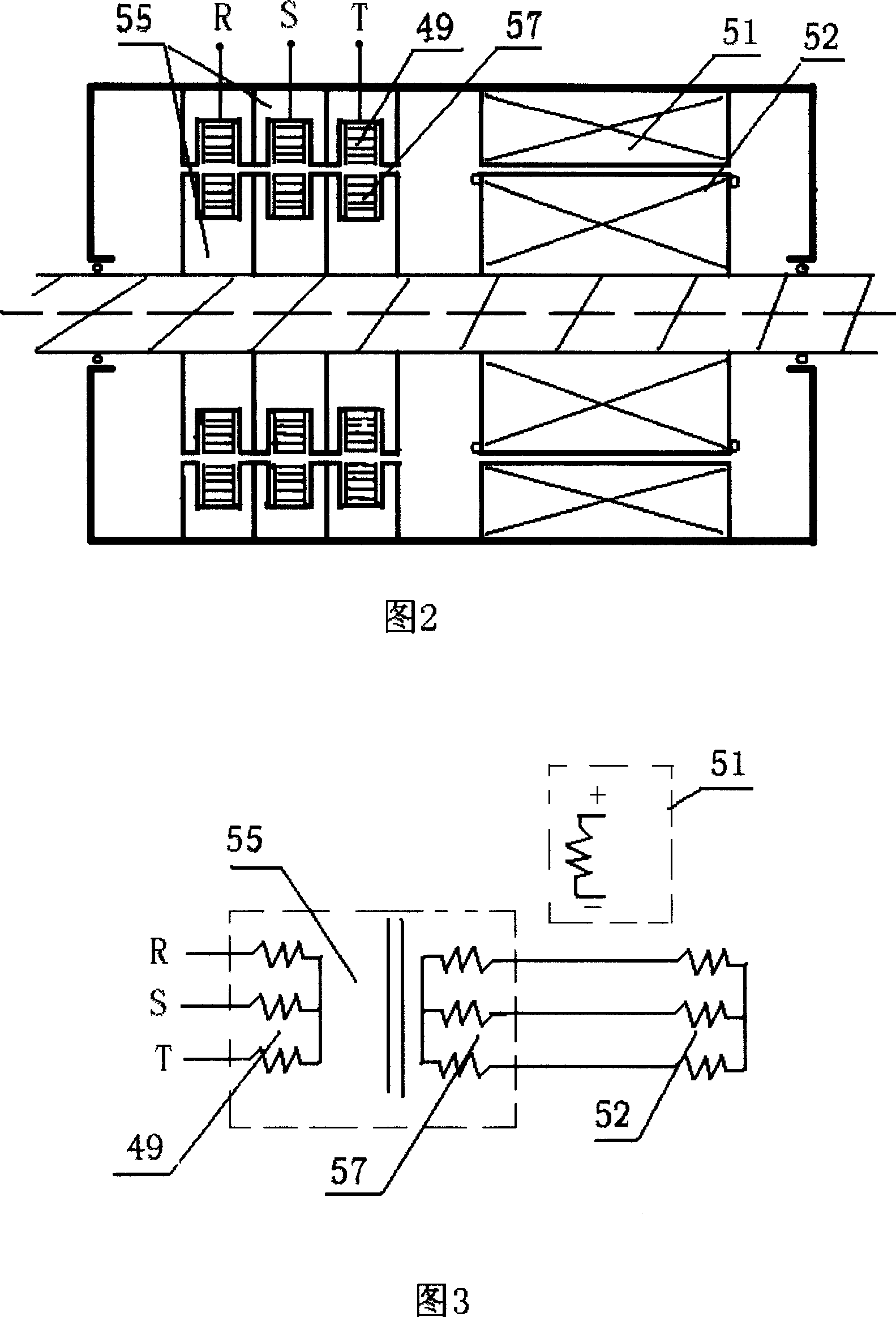

Synchronization motor and its speed adjustment of DC armature three-phase AC excitation

InactiveCN101102067ARealize speed regulationAC motor controlSynchronous motorsEngineeringThree-phase

The invention is concerned with the three phase direct armature altermating current exciting synchronous machine and its timing, belongs to the electric machine manufacturing and the power electronic technology technique field. The three phase altermating current group 1 is designed as the excitation winding with its power taking the smaller part of the machine capacity, which locating in the circle groove of the stator core 2, and the current winding 3 is designed as the armature winding with its power taking large part of the machine capacity, which locating within the rotor core ex-circle groove 4 in distributed winding state. The invention uses the simply large power current variable voltage control device instead of the more expensive or complicated one, especially, the high current transducer to achieve the timing of the synchronous machine.

Owner:丁振荣

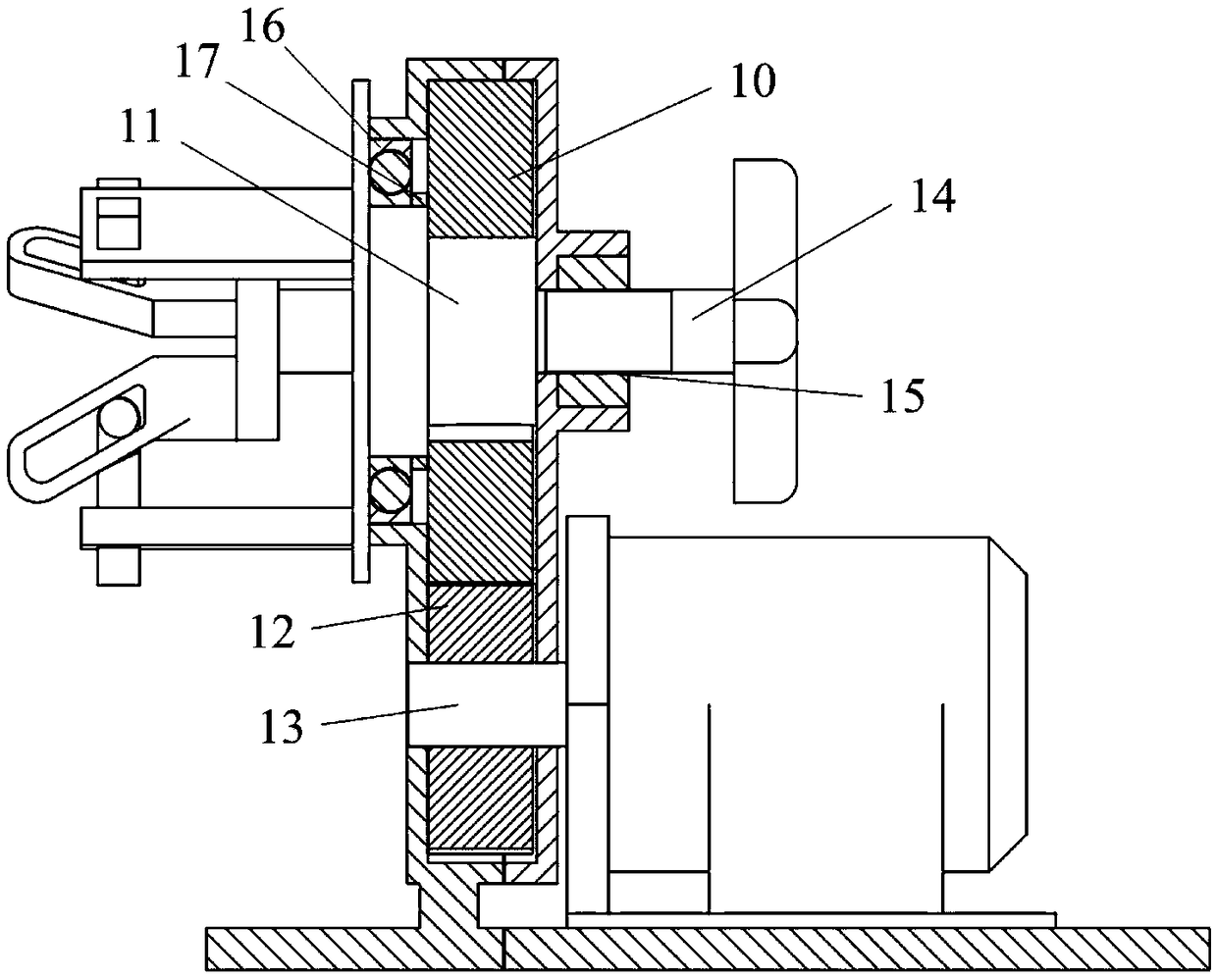

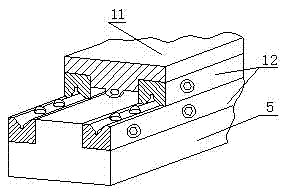

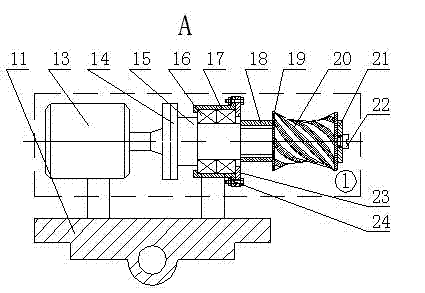

Speed-adjustable permanent magnet inductive worm and wormwheel transmission device

ActiveCN103036392AImprove exercise efficiencyReduce feverDynamo-electric gearsDrive motorMagnetic flux

The invention relates to the technical field of mechanical transmission, in particular to a speed-adjustable permanent magnet inductive worm and wormwheel transmission device which comprises a drive assembly, a driven assembly and a speed adjusting device assembly. The drive assembly is fixed arranged on the speed adjusting device assembly, a worm of the drive assembly and a wormwheel of the driven assembly form an included angle of 90 degrees, and uniform air gaps are formed between the worm and the wormwheel. When the worm is driven by a drive motor to rotate, the whole drive assembly can be driven by the speed adjusting device assembly to conduct side-to-side motion, so that the worm can be driven to move away from the wormwheel or move close to the wormwheel, and at the same time, sizes of the air gaps of conductive bodies or conductive body layers on the worm and of the permanent magnet on the wormwheel are changed and magnetic flux of an air-gap magnetic field can be quickly adjusted. Output rotating speed and torque can be better and more quickly controlled and the aim of achieving infinitely variable speed and transmitting motion and power between two mutually perpendicular shafts is achieved.

Owner:JIANGSU UNIV

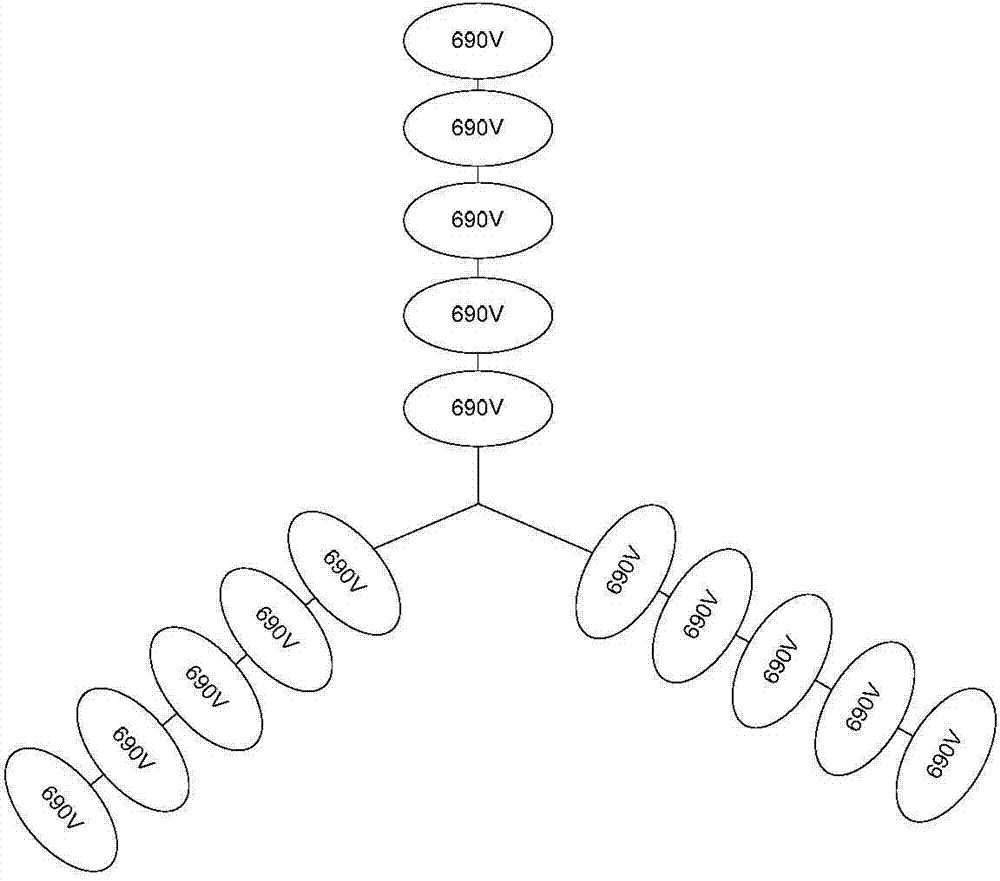

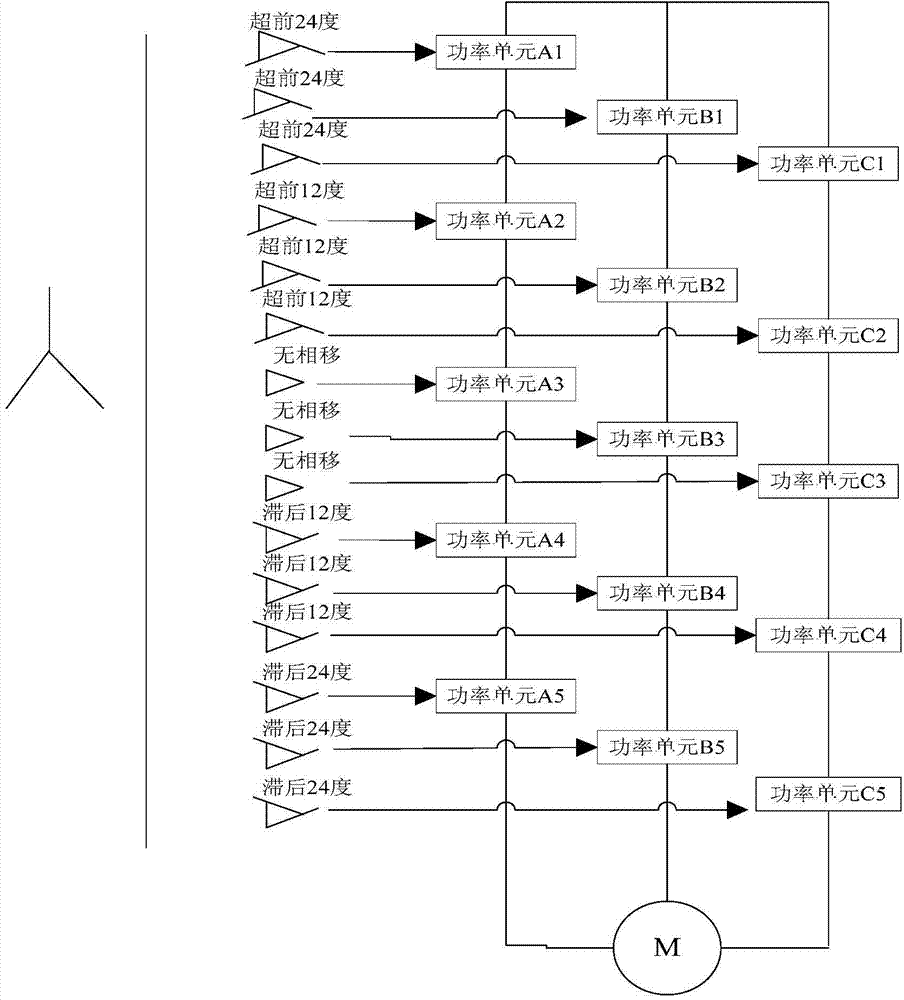

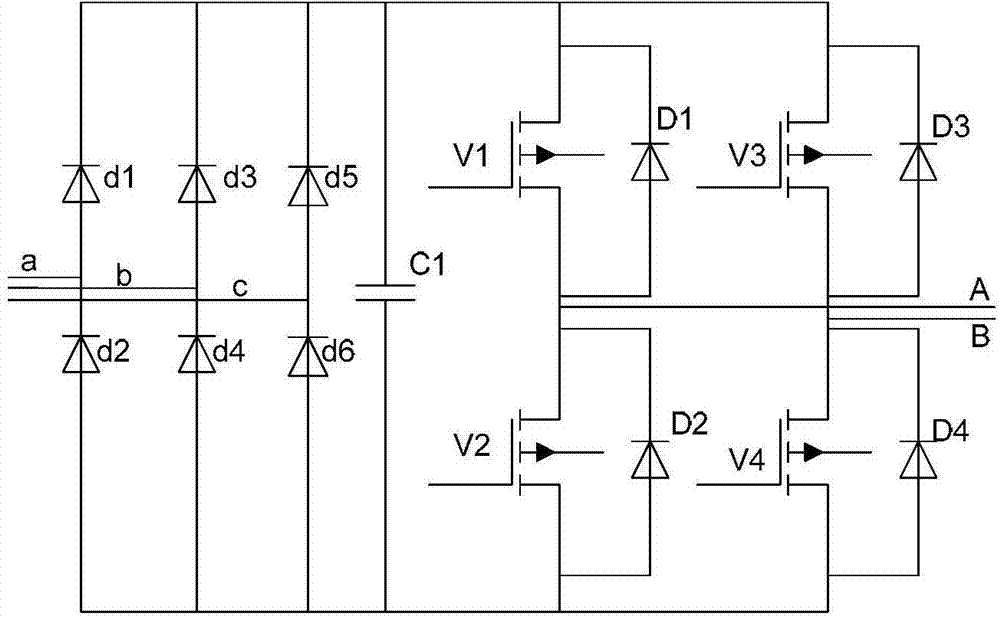

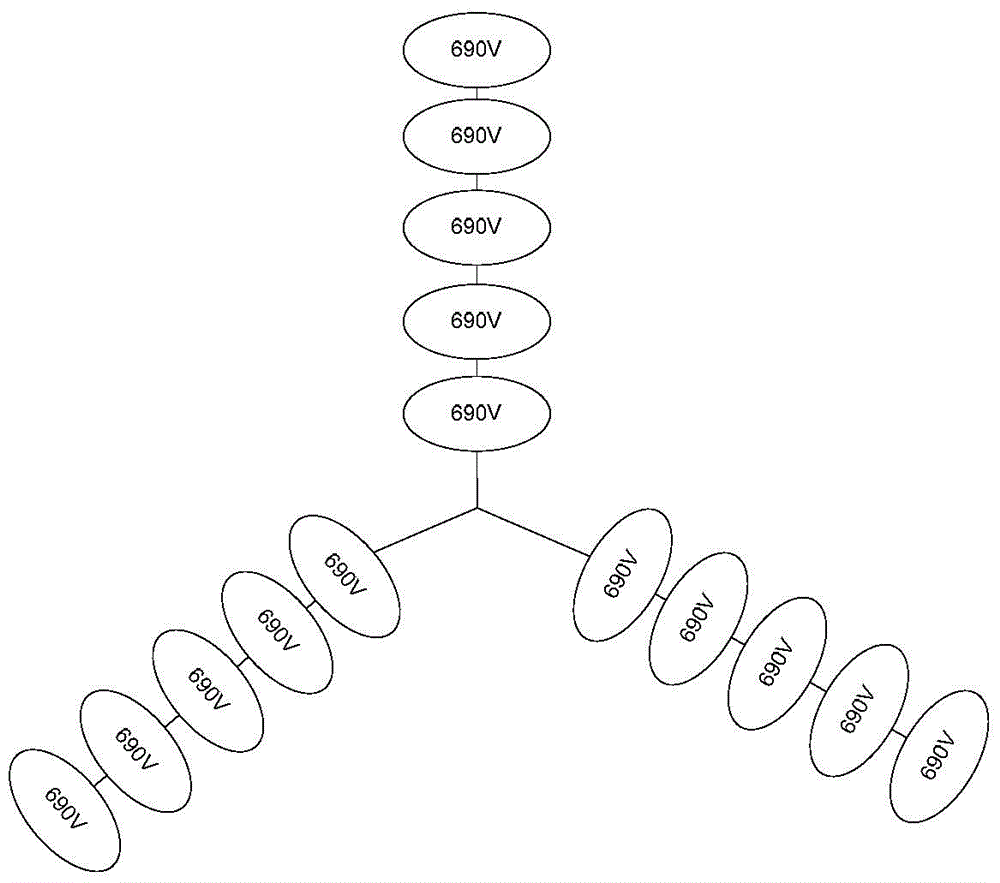

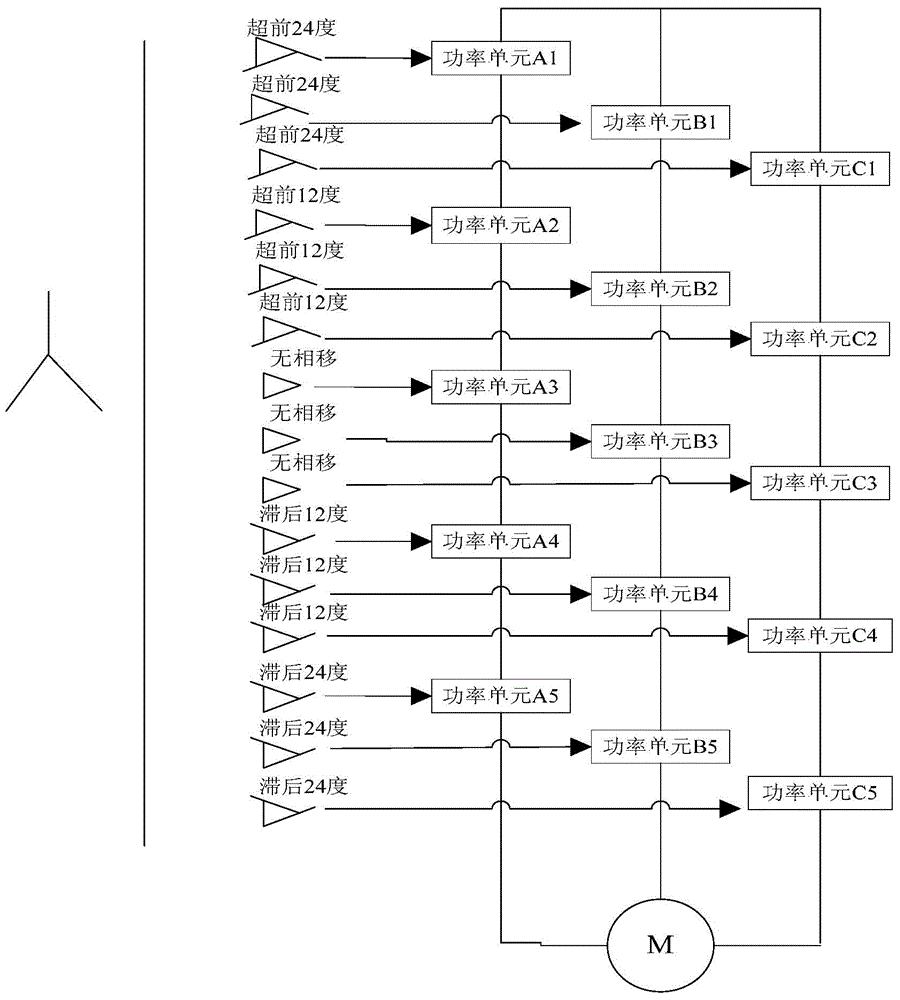

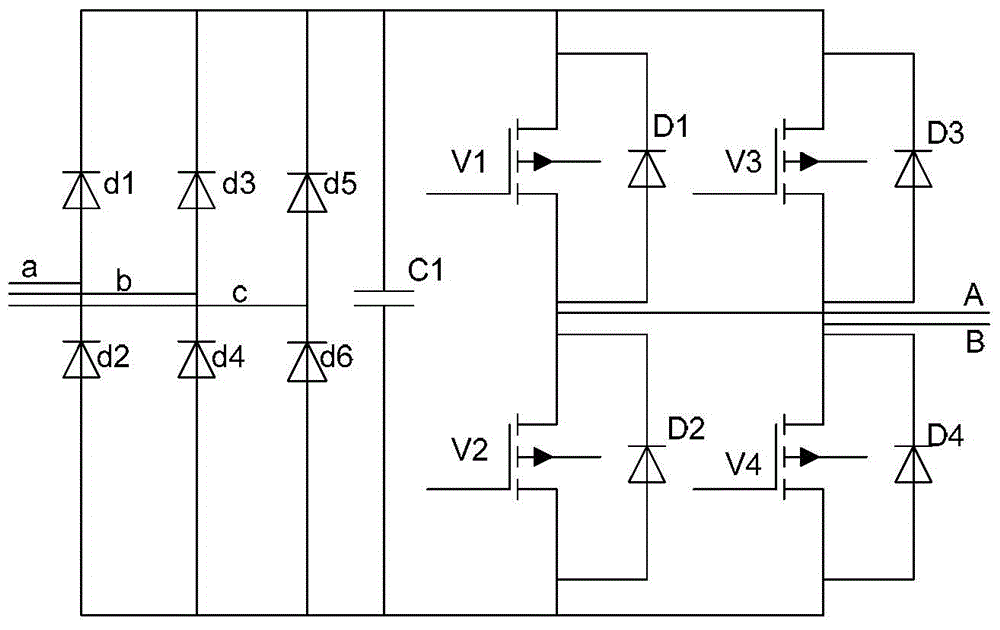

Unit cascaded type frequency converter based on DSP (digital signal processor) and FPGA (field programmable gate array)

InactiveCN104506112ASave resourcesLow costAC motor controlDynamo-electric converter controlDigital signal processingFrequency changer

The invention discloses a unit cascaded type frequency converter based on a DSP (digital signal processor) and an FPGA (field programmable gate array). The unit cascaded type frequency converter based on the DSP and the FPGA comprises a main circuit, the DSP and the FPGA, wherein the DSP is used to receive input frequency from a keyboard and calculate a modulation degree, and furthermore sends modulated wave frequency and a voltage modulation degree to the FPGA through a special SPI (serial peripheral interface), the FPGA is used to generate an SPWM (sinusoidal pulse width modulation) signal according to the modulated wave frequency and the voltage modulation degree, which are input, so as to control connection and disconnection of a power pipe in the main circuit, the main circuit comprises a phase shifting transformer and n power modules which are cascaded, and n is an integer, and larger than or equal to 3. The unit cascaded type frequency converter based on the DSP and the FPGA can flexibly adjust carrier frequency, the modulating wave frequency and the modulation degree, is rapid in respond, and can effectively guarantee speed regulation performance of the unit cascaded type frequency converter based on the DSP and the FPGA.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

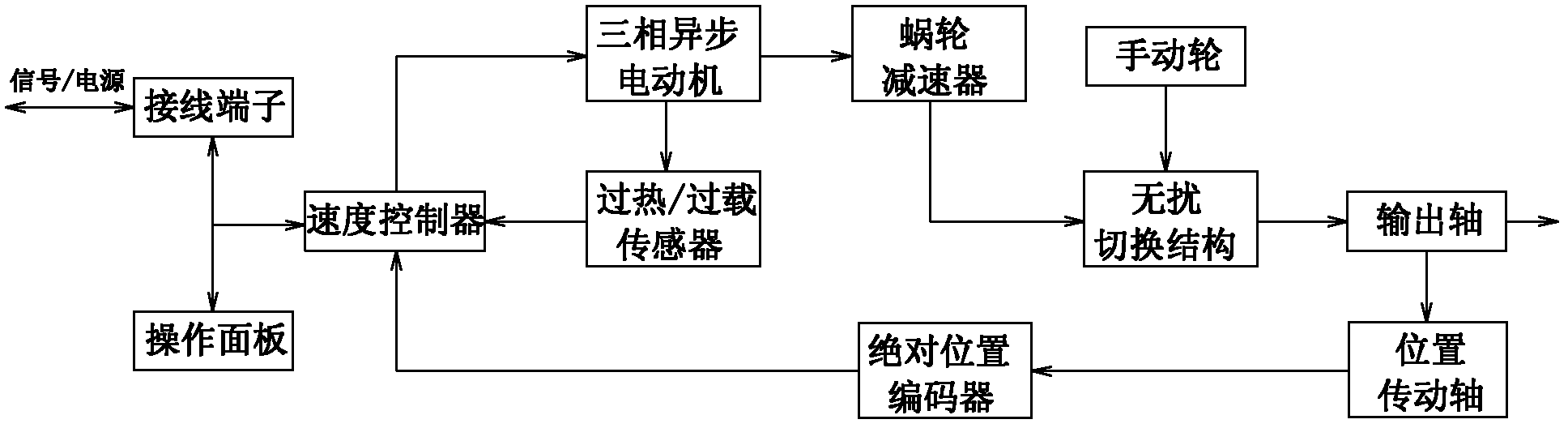

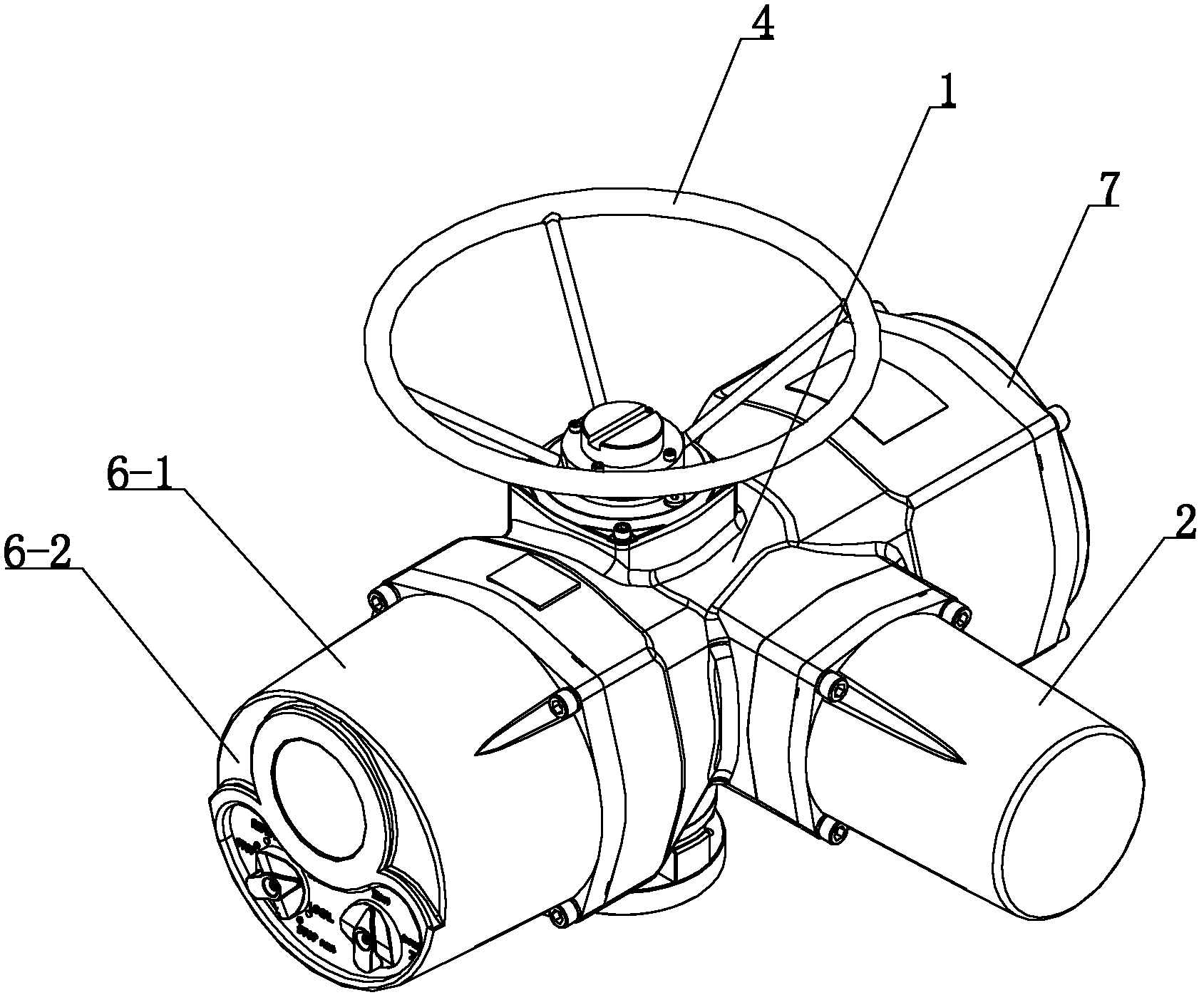

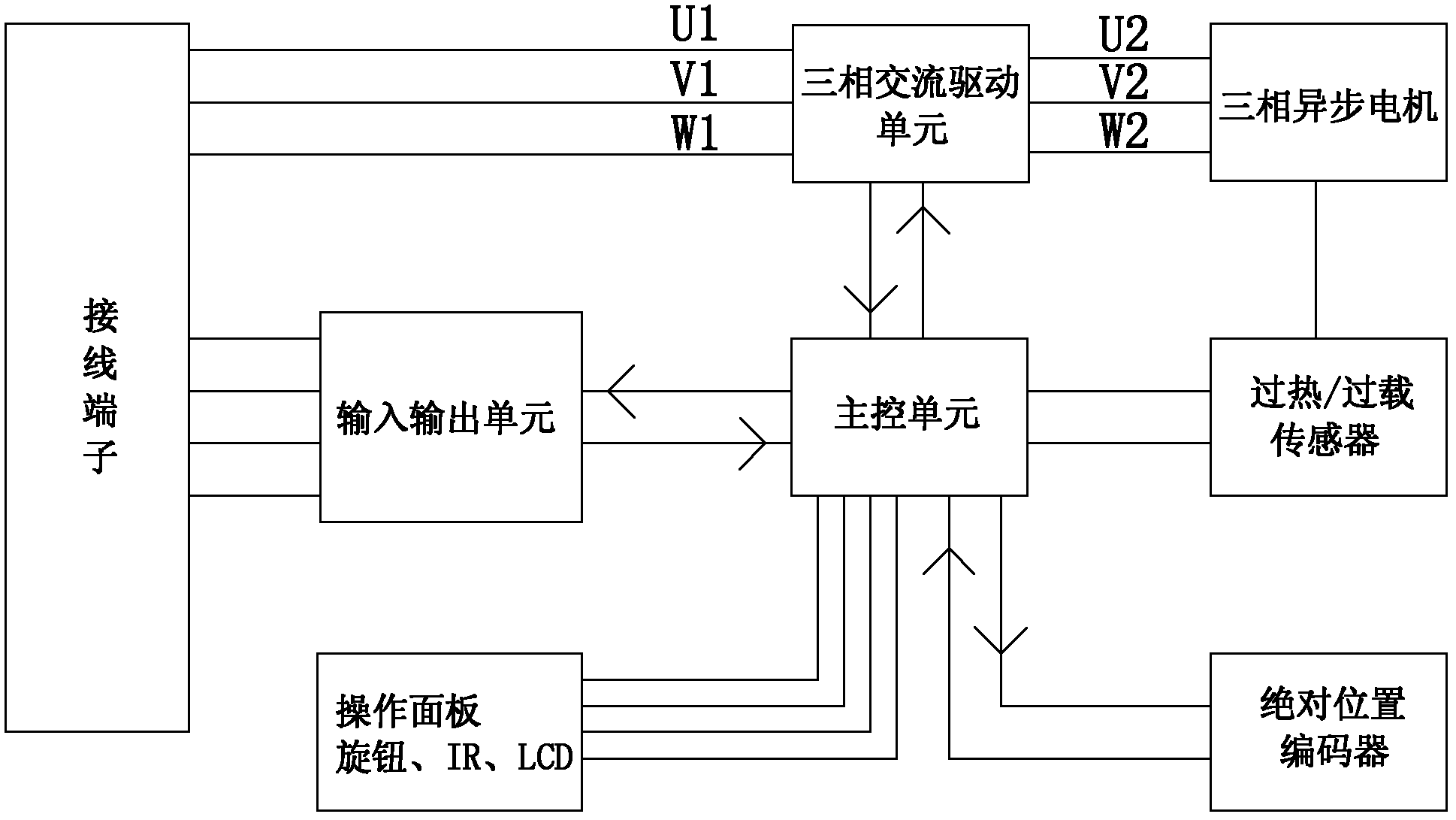

Multi-rotation type versatile electric actuating mechanism

ActiveCN102588653ADoes not affect field wiringCompact structureOperating means/releasing devices for valvesReduction driveDrive shaft

The invention relates to a multi-rotation type versatile electric actuating mechanism, which comprises a casing, a motor, a speed reducer, a hand-operated wheel, an output shaft and an output shaft angular displacement detecting device. The multi-rotation type versatile electric actuating mechanism is characterized in that the casing is in a T-shaped structure, the motor and the hand-operated wheel are mounted at a front port and an upper port of the casing respectively, a speed controller and an operation panel are mounted at a lateral port of the casing, a binding terminal is mounted at theother lateral port of the casing, the lower port of the casing is an output end, a bumpless switching structure is arranged between the speed reducer and the hand-operated wheel, and the output shaftangular displacement detecting device consists of a position driving shaft and an absolute-position encoder. The T-shaped structure of the casing is compact, the output shaft is kept perpendicular orhorizontal, and field wiring, panel display and hand operation cannot be affected by mounting of the valve. The speed of the motor can be adjusted by the speed controller, electric or mechanical impact is effectively avoided, and valve positioning can be driven accurately. Hand operation and electric operation can be switched automatically by the bumpless switching structure, so that labor is saved. Besides, loss of data of valve location after power off is avoided by the aid of the absolute-position encoder.

Owner:TIANJIN XIANGJIA FLUID CONTROL SYST CO LTD

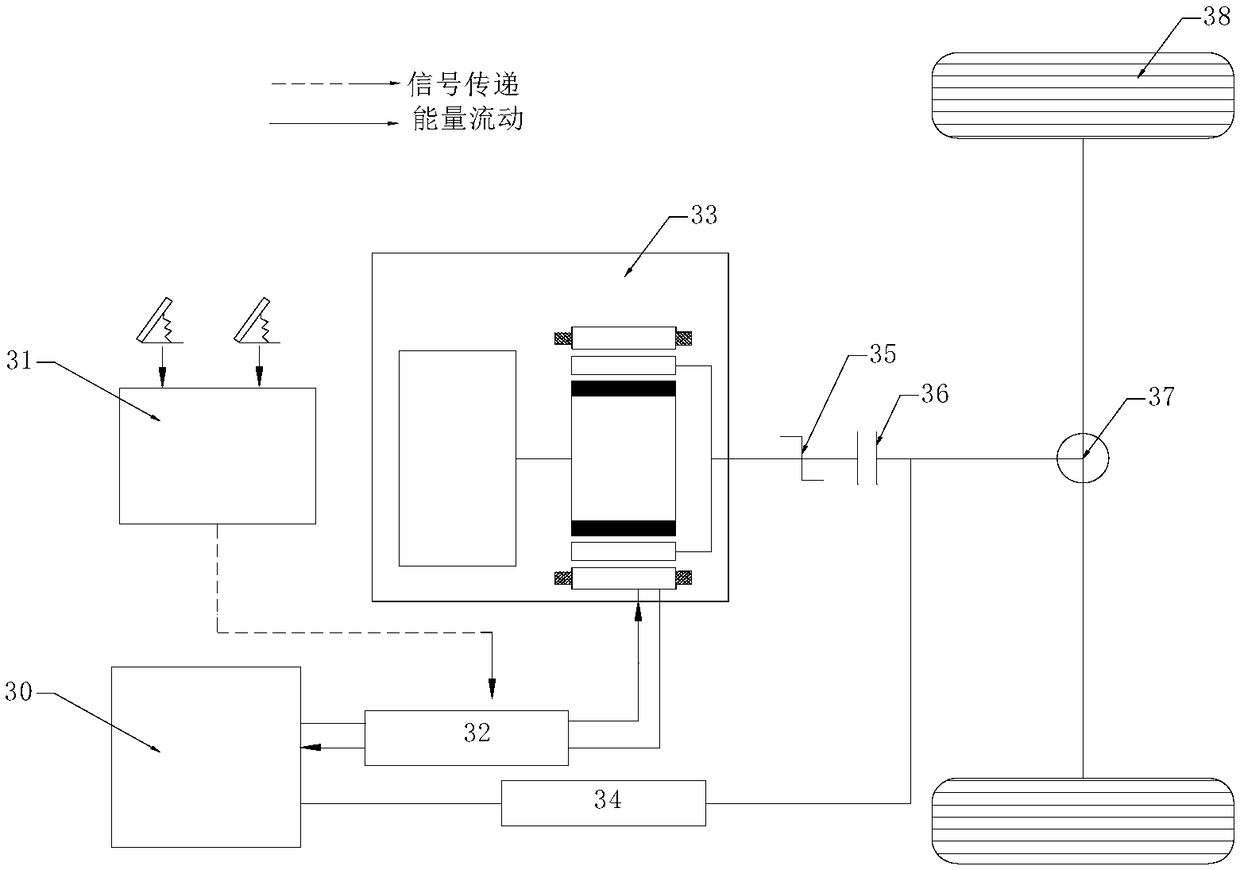

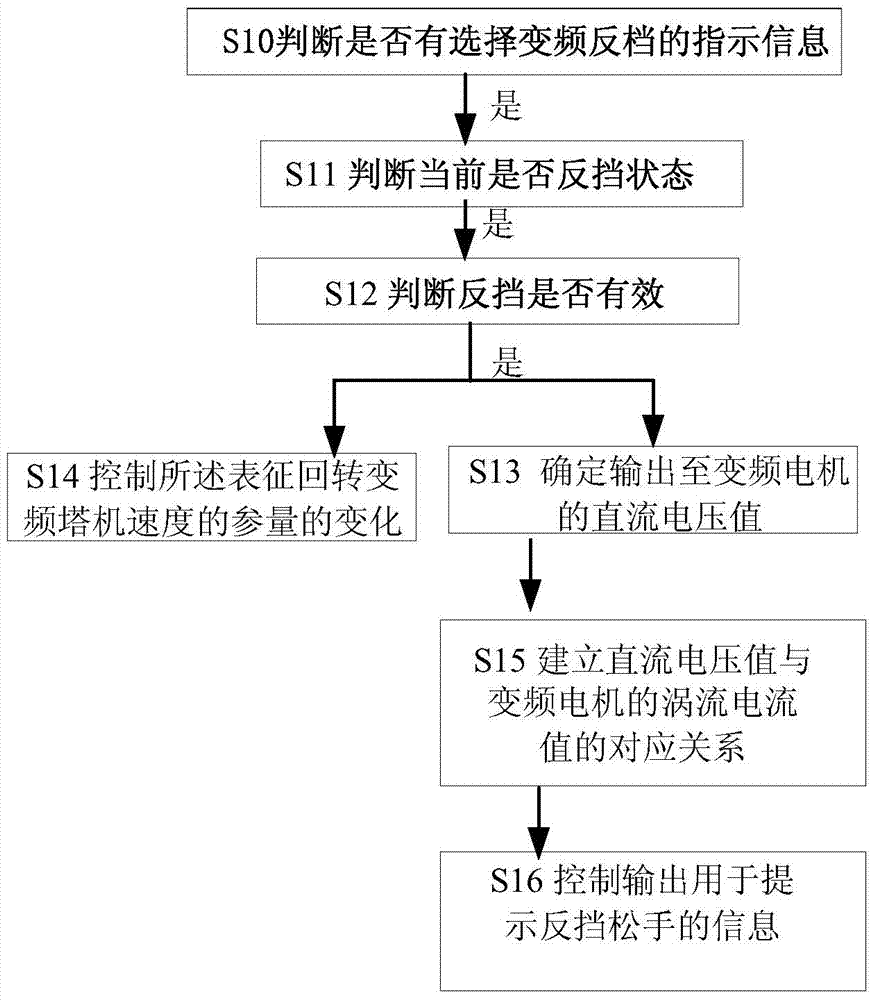

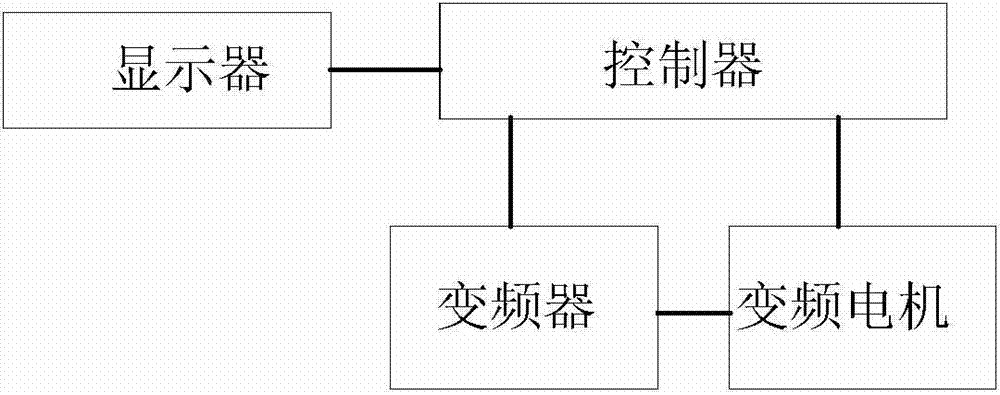

Tower crane speed regulating method, device and system

ActiveCN104261257ARealize speed regulationOvercoming the Inadequacy of Cannot Realize Parking by Playing Reverse GearLoad-engaging elementsEddy currentTower crane

The invention discloses a tower crane speed regulating method, device and system. A parking control method comprises the steps that whether a tower crane is in the reverse gear state or not is judged according to a handle gear detected in real time and parameters for representing the speed of the tower crane; after the phenomenon that the tower crane is in the reverse gear state is determined, a direct-current voltage value output to a variable frequency motor is determined according to the handle gear detected in real time, and therefore the variable frequency motor outputs an eddy current value for braking moment force; changes of the parameters for representing the speed of the tower crane are controlled according to the handle gear detected in real time. According to the tower crane speed regulating method, device and system, reverse-gear parking control over the tower crane can be achieved.

Owner:HUNAN SANY TOWER CRANE CO LTD

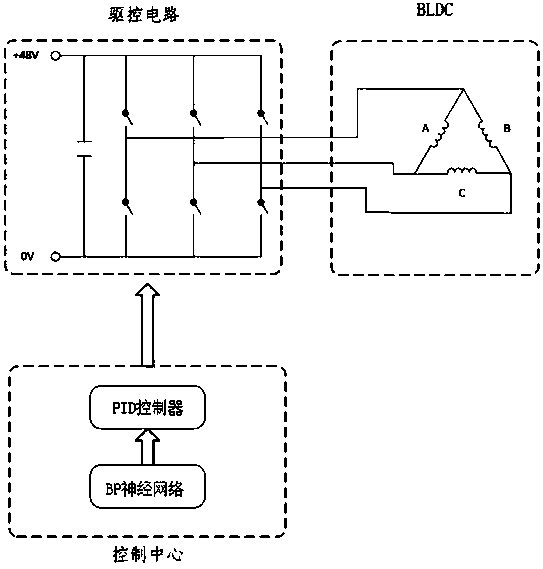

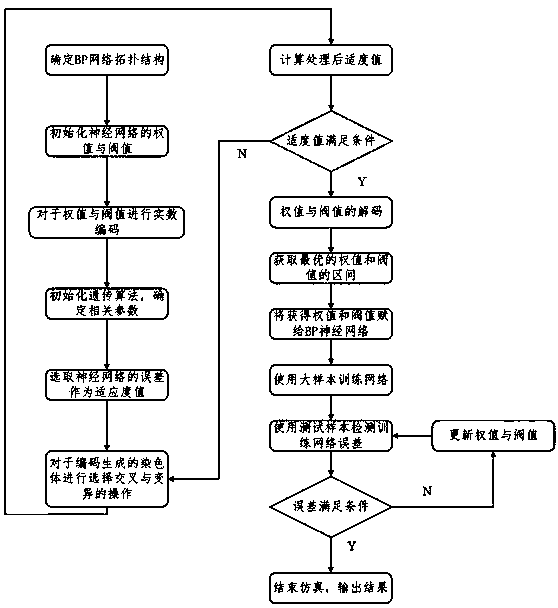

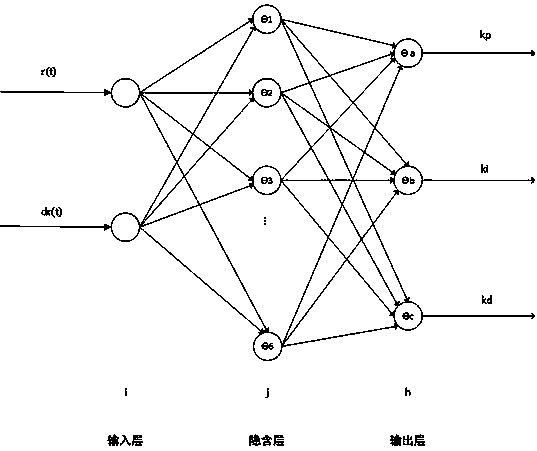

Brushless direct current motor PID speed regulation method based on genetic neural network

InactiveCN111245313AFast convergenceEffective controlAC motor controlModelling/simulations for controlHidden layerNeural network controller

The invention discloses a brushless direct current motor PID speed regulation method based on a genetic neural network. The method comprises a BP neural network, a PID controller and a brushless direct current motor. The input end of the PID controller is connected with the output end of the BP neural network, and the output end of the PID controller is connected with the brushless direct currentmotor. The method is characterized by comprising the step of optimizing the weight and threshold of the BP neural network by using a genetic algorithm, wherein the BP neural network has three layers including an input layer, a hidden layer and an output layer; the number of nodes of the input layer is 2, the number of nodes of the hidden layer is 6, and the number of nodes of the output layer is 3; the threshold value of the hidden layer is shown in the specification, the threshold value of the output layer is shown in the specification, the weight from the input layer to the hidden layer is shown in the specification, and the weight from the hidden layer to the output layer is shown in the specification; and {0 < = < = 2, 0 < = < = 6, 0 < = < = 3; , epsilon}. According to the method, thecontrol state of the PID controller can be more stable, and the method can effectively adapt to the nonlinear condition of a controlled object.

Owner:爱科赛智能科技(浙江)有限公司

Forming and driving method for triggering type permanent magnet brushless direct-current motor

ActiveCN104377931ARealize speed regulationEnables brushless operationMagnetic circuit rotating partsSingle motor speed/torque controlPhase currentsMagnetic poles

The invention discloses a forming and driving method for a triggering type permanent magnet brushless direct-current motor. The forming and driving method includes the steps that a rotor and a triggering magnetic ring are arranged, wherein the triggering magnetic ring rotates along with the rotor and is the same as the rotor in pole number, and the same poles of the triggering magnetic ring and the rotor are staggered; coils are wound around stator pole shanks, and the coils on the stator pole shanks are connected in series to form phase windings; basic control units with the phase as the unit are composed of sensors, H bridges and the phase windings, and a driving circuit of the motor is composed of the multiple basic control units; the sensors of the basic control units are triggered by the triggering magnetic ring to output position signals of the rotor magnetic poles to control the output states of the H bridges, currents of the phase windings are connected, the directions of the currents in all phases are controlled, a stator magnetic field which is the same as the triggering magnetic ring in pole number and space distribution is triggered by the currents in the phases, and the rotor is driven to rotate. Compared with the prior art, by means of the method, the defects of a traditional direct-current motor are overcome, the advantages of the traditional direct-current motor are kept, and the forming and driving method has the advantages that the speed can be adjusted, position-negative rotation control is convenient, and the driving circuit is simple.

Owner:朱福善

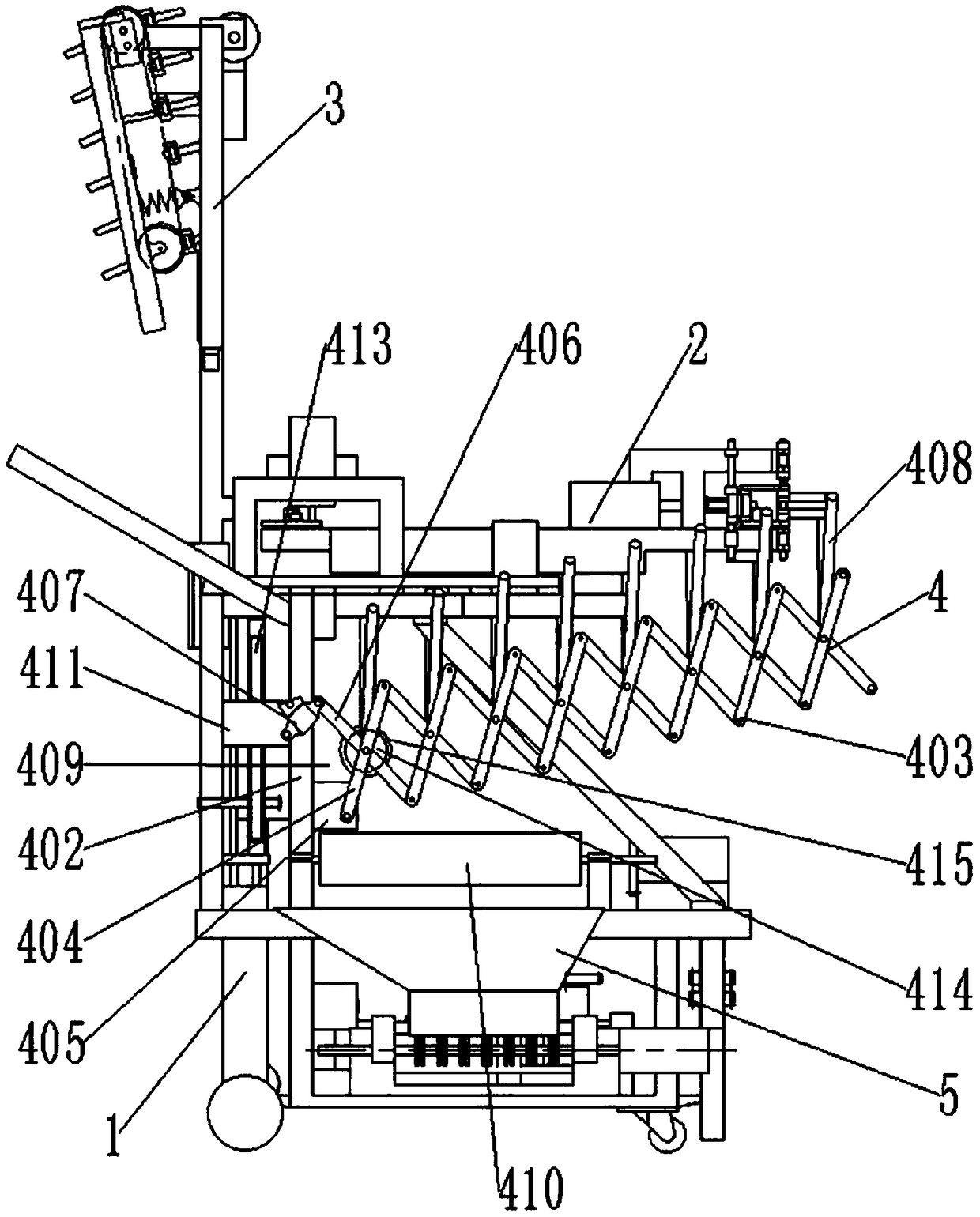

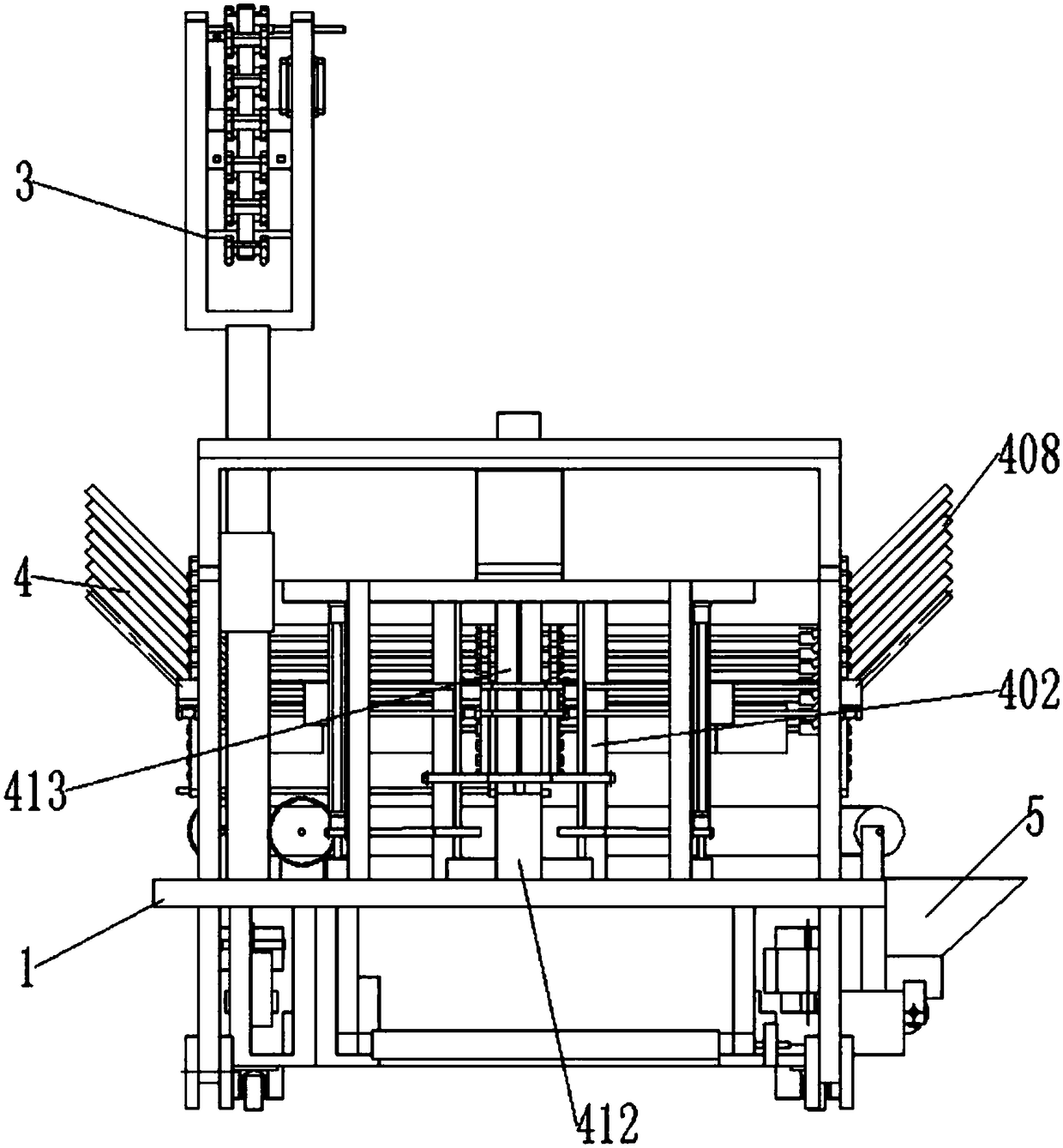

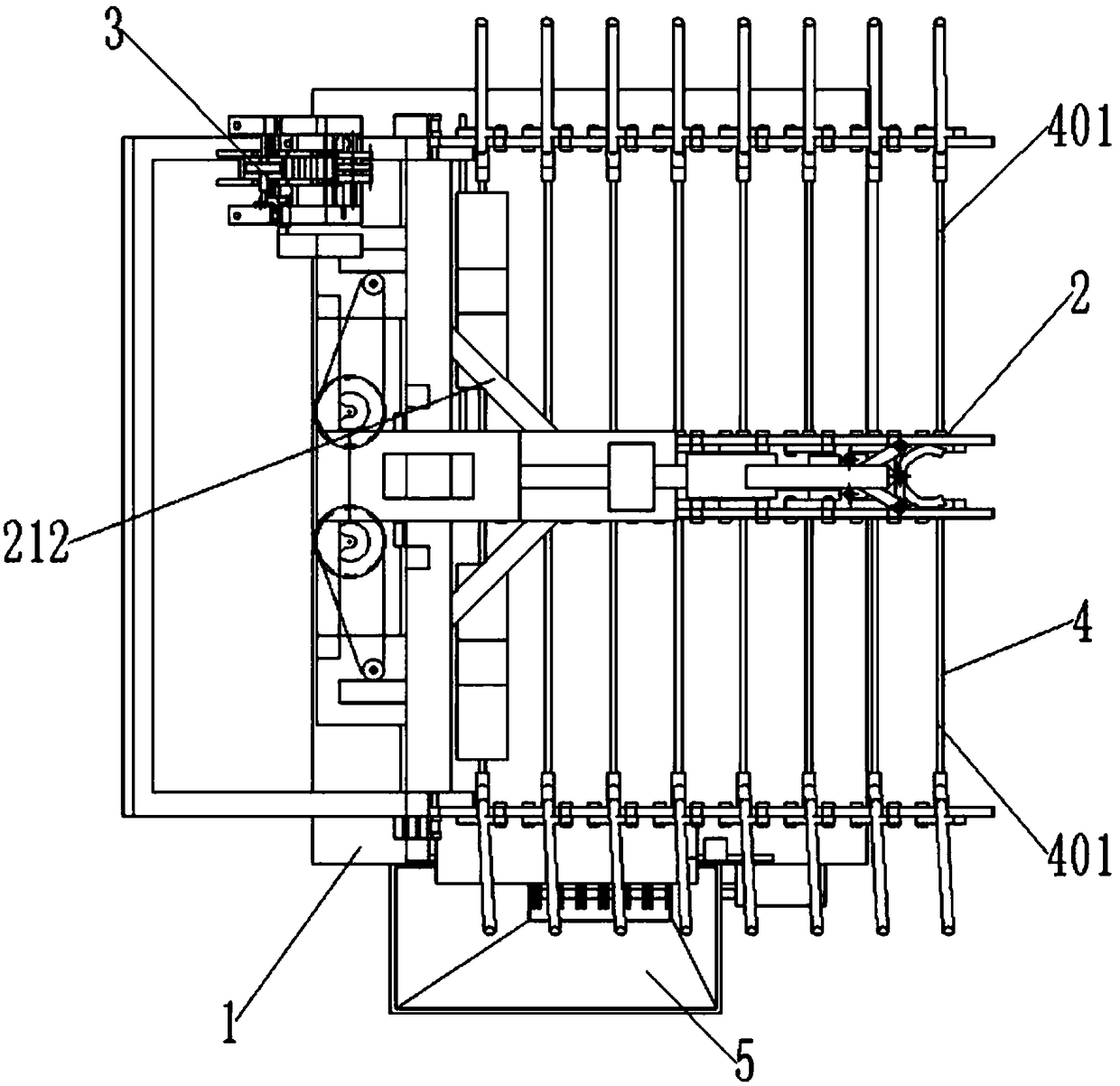

Jujube picking, collecting and grading machine

PendingCN108575315APicking clean and thoroughBenefit maximizationPicking devicesGradingEngineeringZiziphus jujuba

The invention belongs to the technical field of fruit picking equipment and particularly relates to an apparatus of jujube picking, grading and collecting integration, namely a jujube picking, collecting and grading machine, comprising a frame, and a vibrating-shaking picking device, a handheld rolling device, a collecting device and a grading device mounted on the frame; in white mature stage ofjujube, the handheld rolling device is used to perform picking; in crisp mature stage of jujube, the vibrating-shaking picking device and the handheld rolling device are used together to perform picking; in full mature stage of jujube, the vibrating-shaking picking device is used for performing picking, the picked fruits are collected by the collecting device, and the fruits collected by the collecting device are conveyed to the grading device for grading; therefore, picking, collecting and grading are integrated, complete functions are provided, labor steps are decreased, labor is freed, andlabor intensity is reduced for workers, and the apparatus is efficient and quick.

Owner:TAIYUAN INST OF TECH

Control method of cascaded type frequency converter based on DSP and FPGA

The invention discloses a control method of a cascaded type frequency converter based on a DSP and an FPGA. According to the control method, the DSP is adopted to receive an input frequency from a keyboard, a modulation degree is calculated, and the modulating wave frequency and the voltage modulation degree are sent to the FPGA through a unique SPI; the FPGA is adopted and used for generating an SPWM signal according to the input modulating wave frequency and the voltage modulation degree in order to control connection and disconnection of a power tube in a main circuit; the main circuit comprises a phase-shifting transformer and n cascaded power modules, and the n is an integer and is larger than or equal to three. Through the control method of the cascaded type frequency converter based on the DSP and the FPGA, the carrier frequency, the modulating wave frequency and the modulation degree can be flexibly adjusted, response is rapid, and the speed control performance of the frequency converter can be effectively guaranteed.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Hydraulic transmission method and device using boat diesel engine afterheat

InactiveCN101550890AImprove work efficiencySave energyInternal combustion piston enginesEngine componentsMechanical energyHydraulic pump

A hydraulic transmission method and device using boat diesel engine afterheat relates to the technical field of hydraulic transmission, in particular suitable for the utilization of waste gas afterheat for producing the boat diesel engine. Based on the principle of the hydraulic transmission, the waste gas afterheat of the boat diesel engine is used and is extracted from the bypass valve; the turbine is pushed to rotate; the hydraulic pump converts the turbine mechanical energy into the pressure energy of the hydraulic oil which respectively assists the driving dynamo and steering engine by a power distribution loop. The device includes a hydraulic system driving loop, a system oil compensating loop and a system pressure overload safety protection loop in order to fit various running working conditions of boat. The method and device can effectively use the waste gas afterheat of diesel engine in the navigation of the boat and can improve the working efficiency so as to reach the purpose of saving energy.

Owner:SHANGHAI MARITIME UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com