Power tool

A power tool and power output technology, applied in the field of power tools, can solve problems such as different adjustment directions and inconvenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

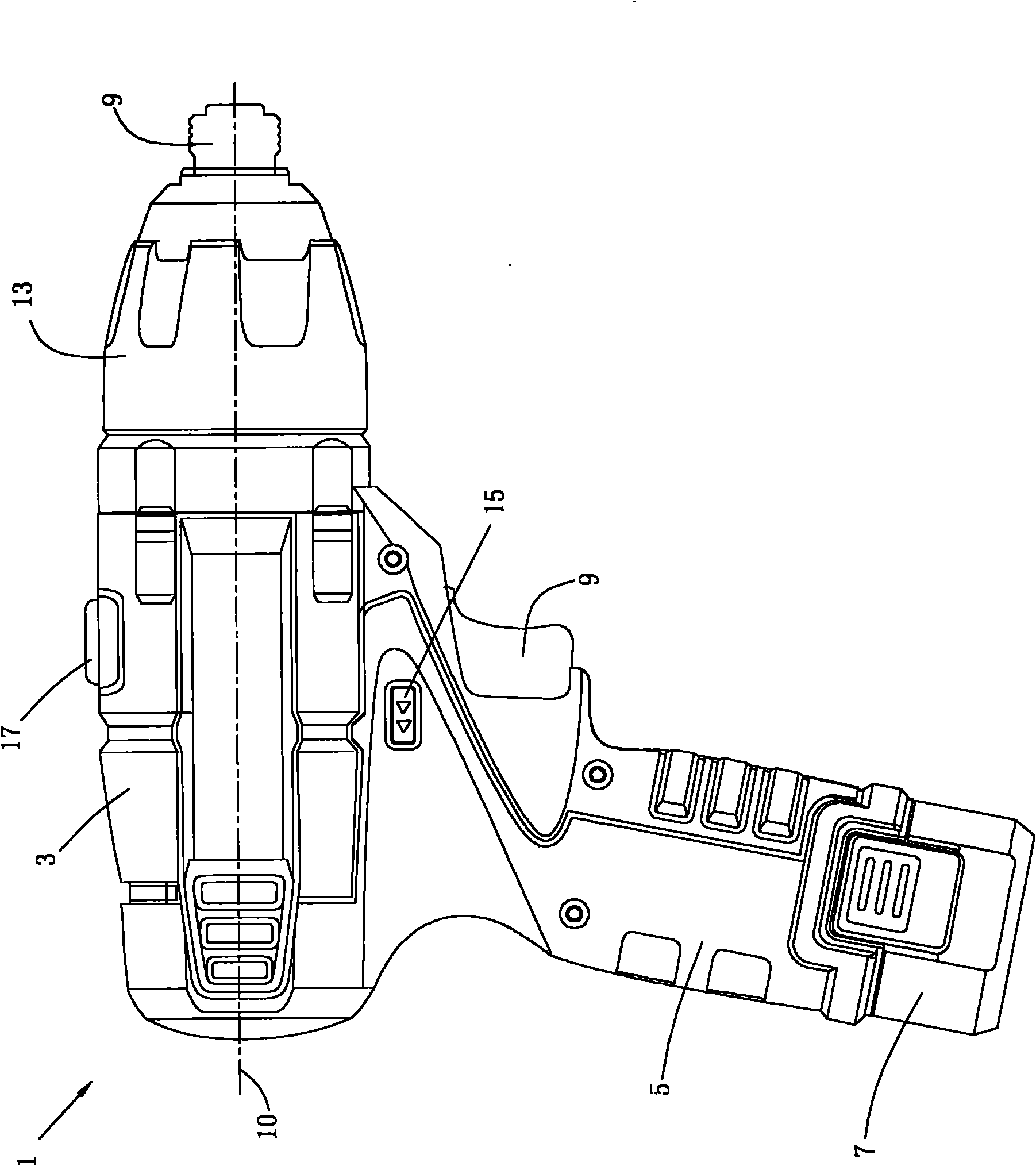

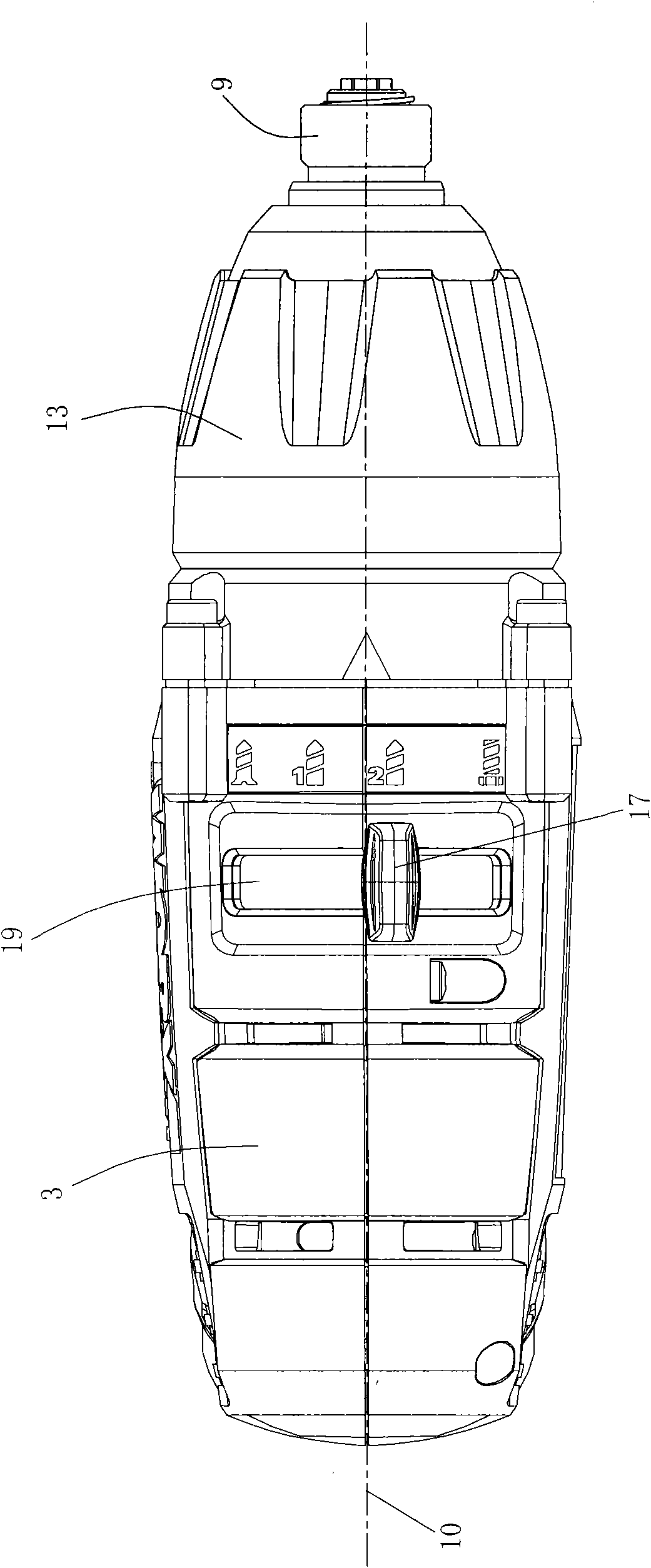

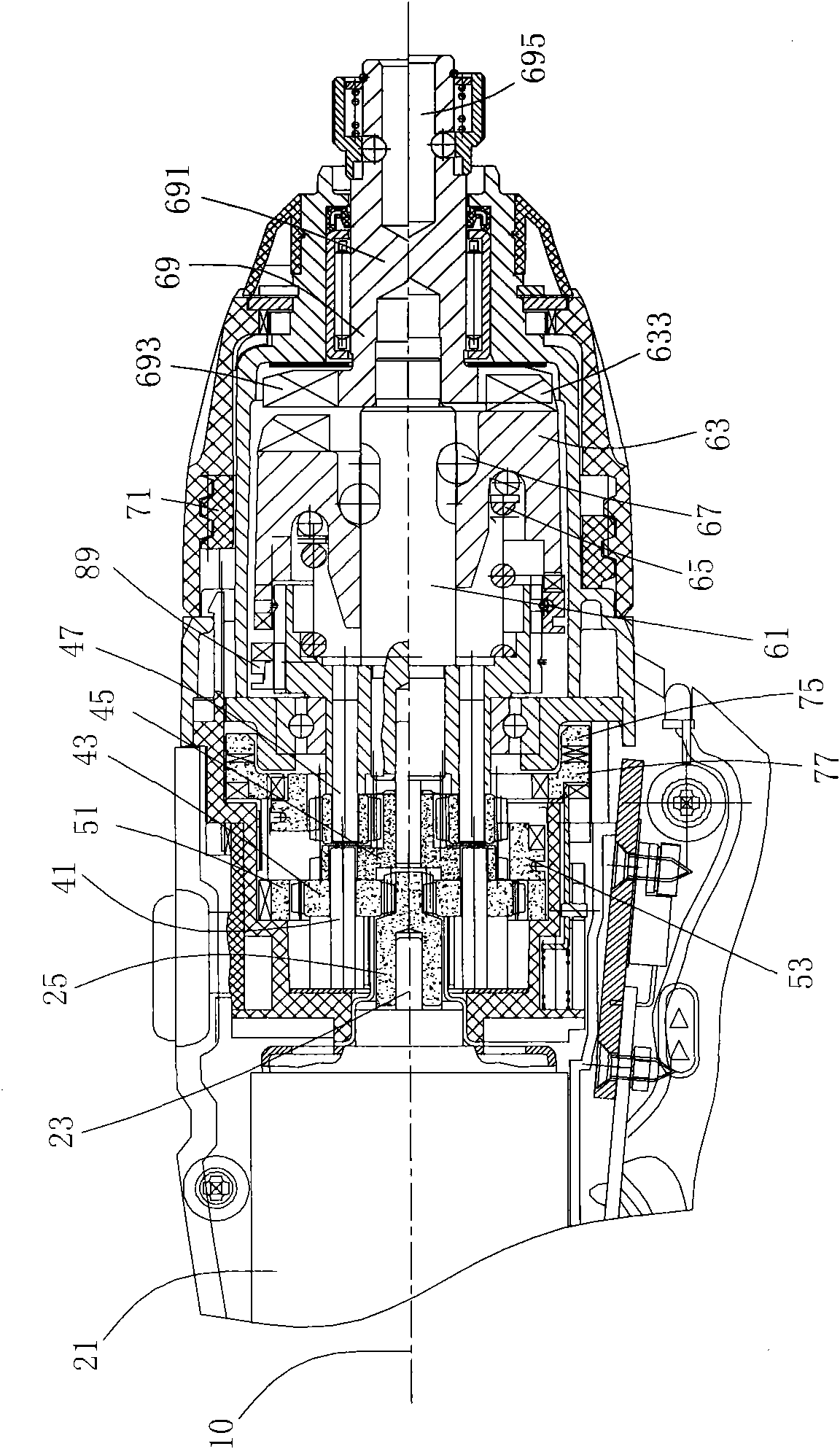

[0096] Figure 1 to Figure 17 What is shown is a specific embodiment of the power tool of the present invention, and the power tool is specifically a multifunctional drill 1 . The multi-function drill 1 has the functions of impact wrench, high-speed drill, low-speed drill, and screwdriver. The high-speed drill and low-speed drill can also be collectively referred to as the drilling function.

[0097] Such as figure 1 As shown, the multifunctional drill 1 is shaped like a pistol, and includes a substantially cylindrical housing 3 , a handle 5 arranged at an angle to the housing 3 , and a detachable battery pack 7 disposed at the bottom of the handle 5 . The housing 3 has a longitudinal axis 10 .

[0098] The front end of the housing 3 is provided with a collet 9 for clamping the working head, which is used to respectively clamp different working heads (not shown) when the multifunctional drill 1 realizes different functions, such as clamping when realizing the impact wrench f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com