Patents

Literature

100 results about "High speed drilling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

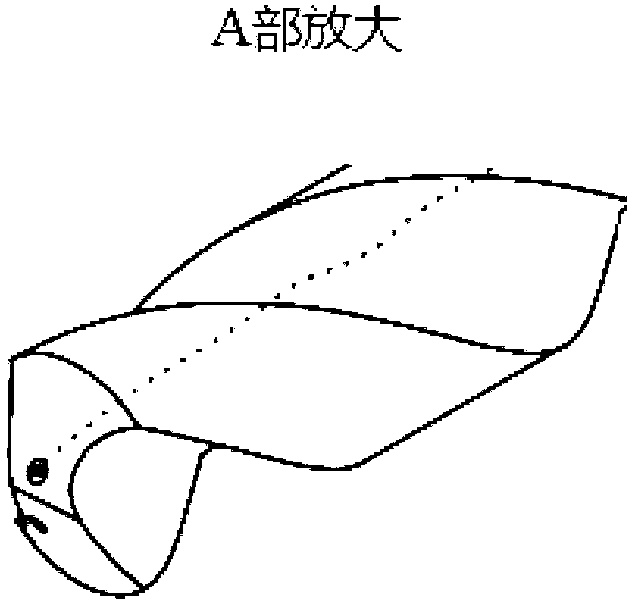

Drill

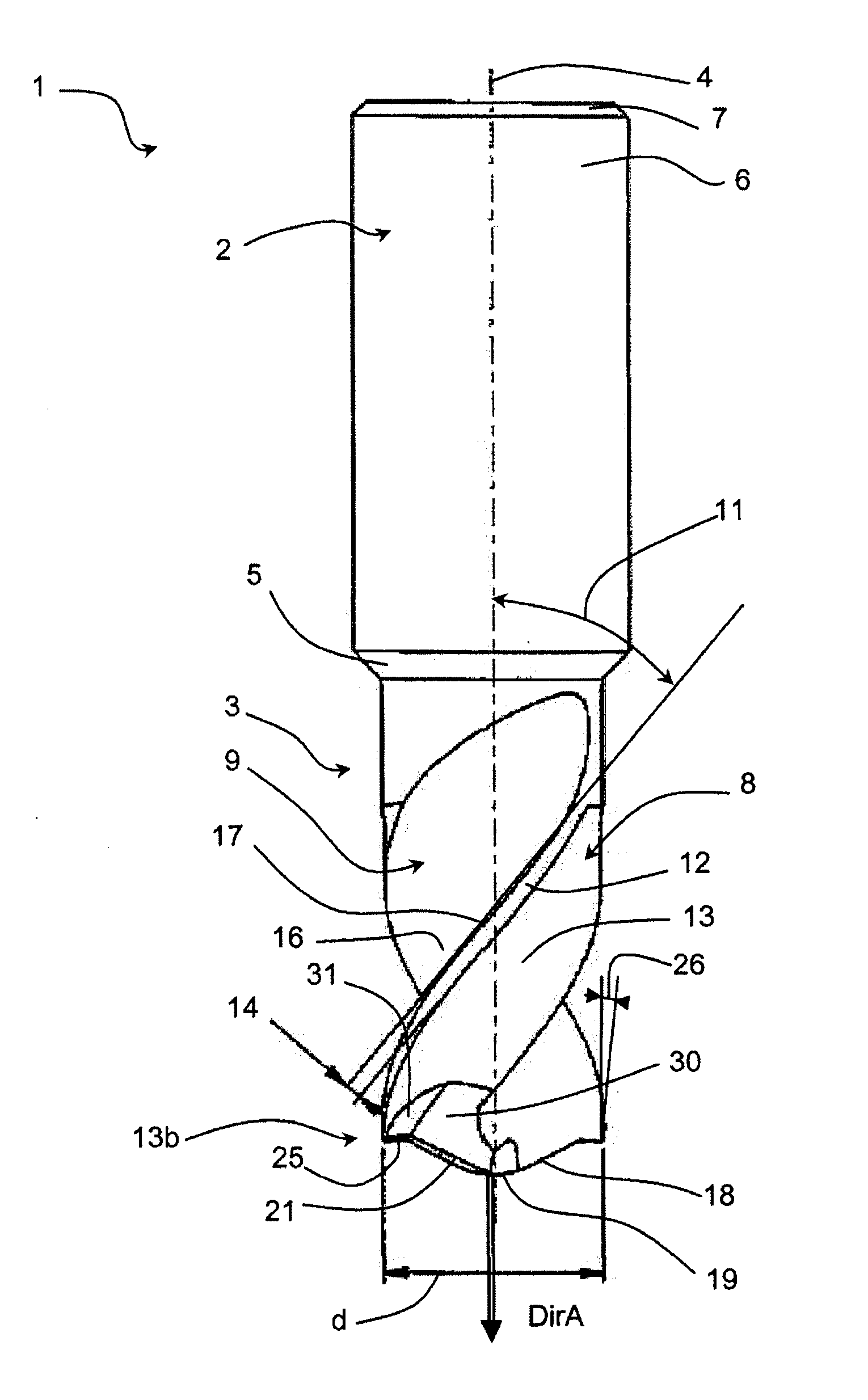

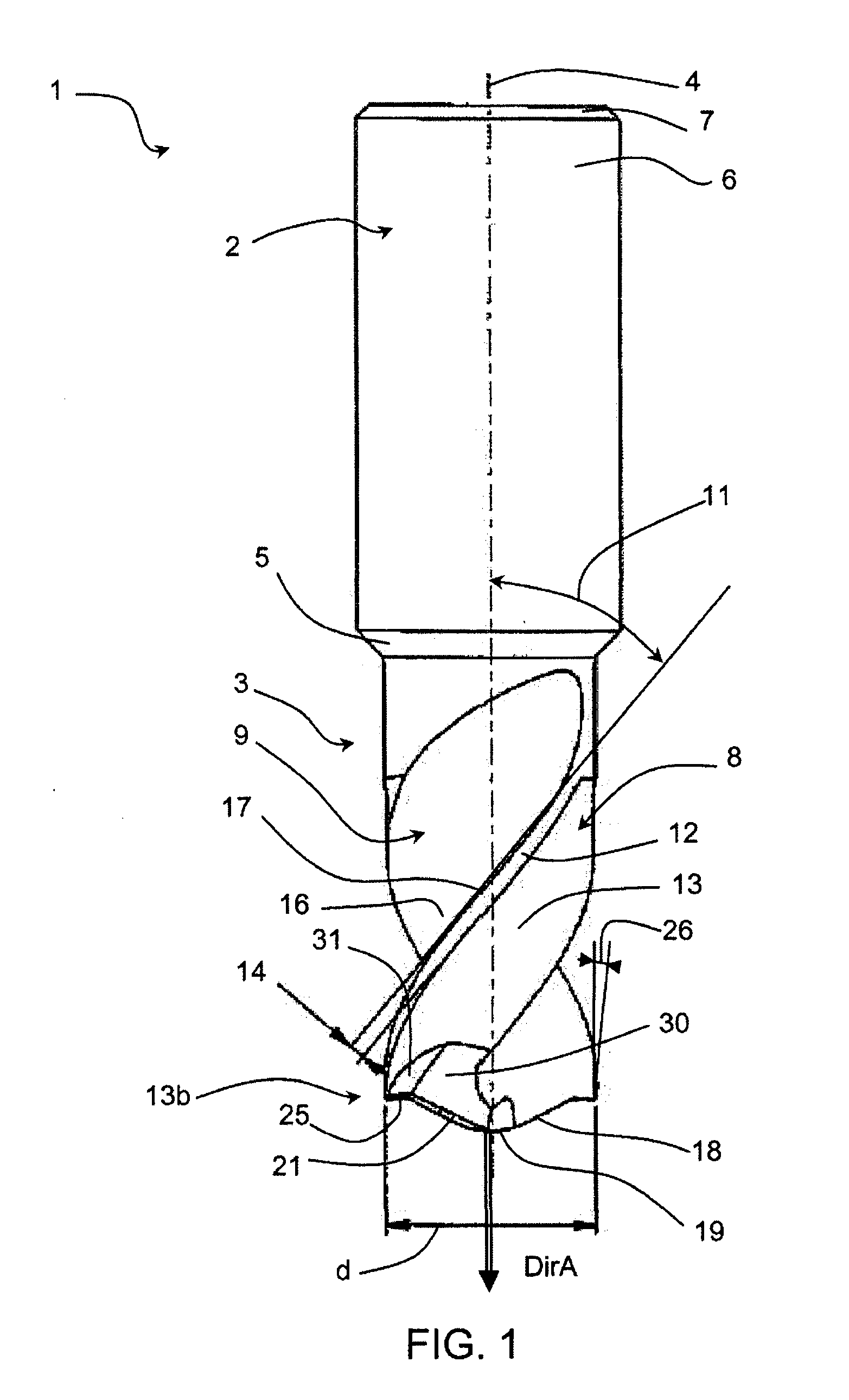

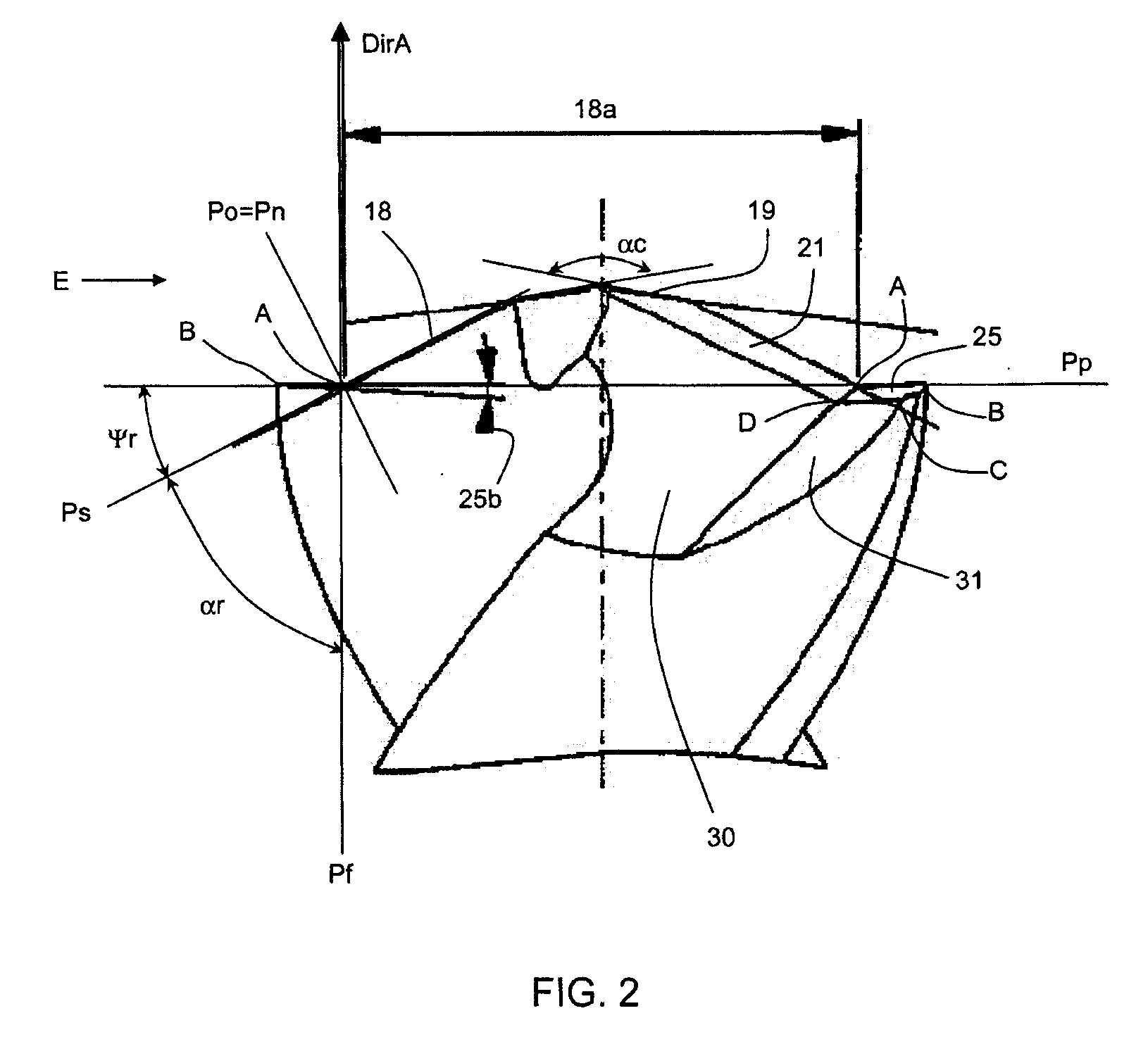

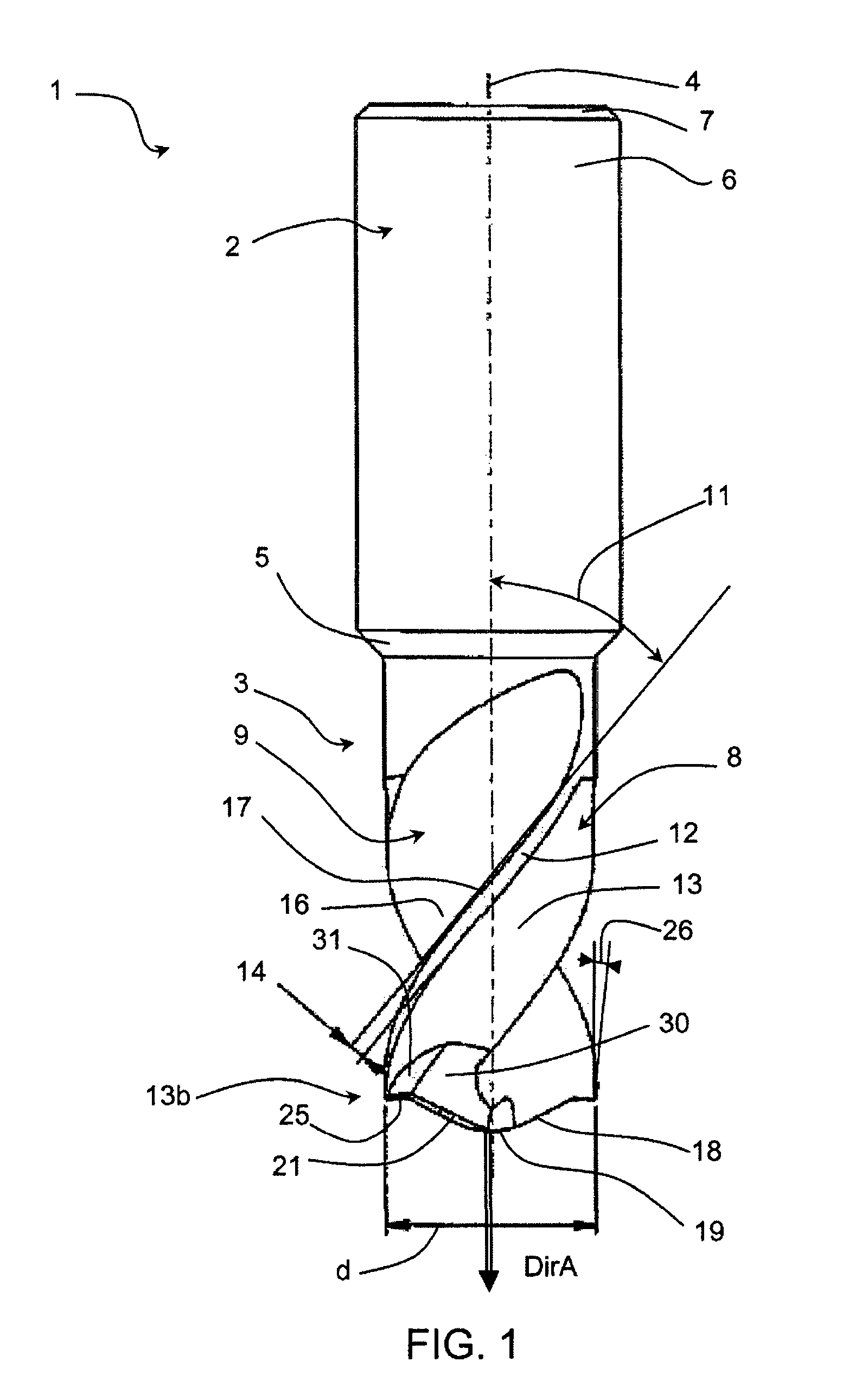

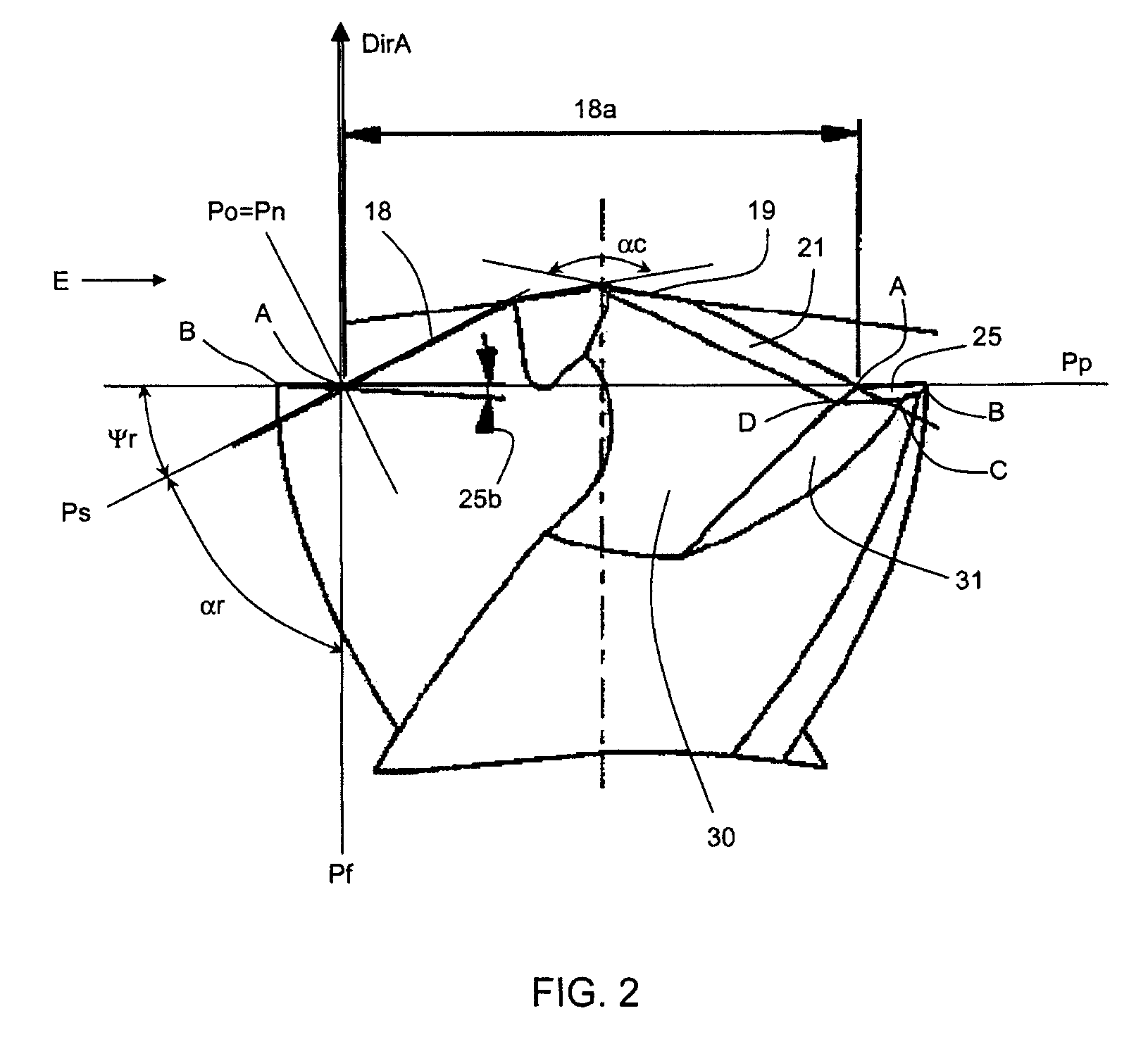

InactiveUS6916139B2Improve wear resistanceDegradation of the cutting ability all along the cutting edge is preventedWood turning toolsTransportation and packagingFluteEngineering

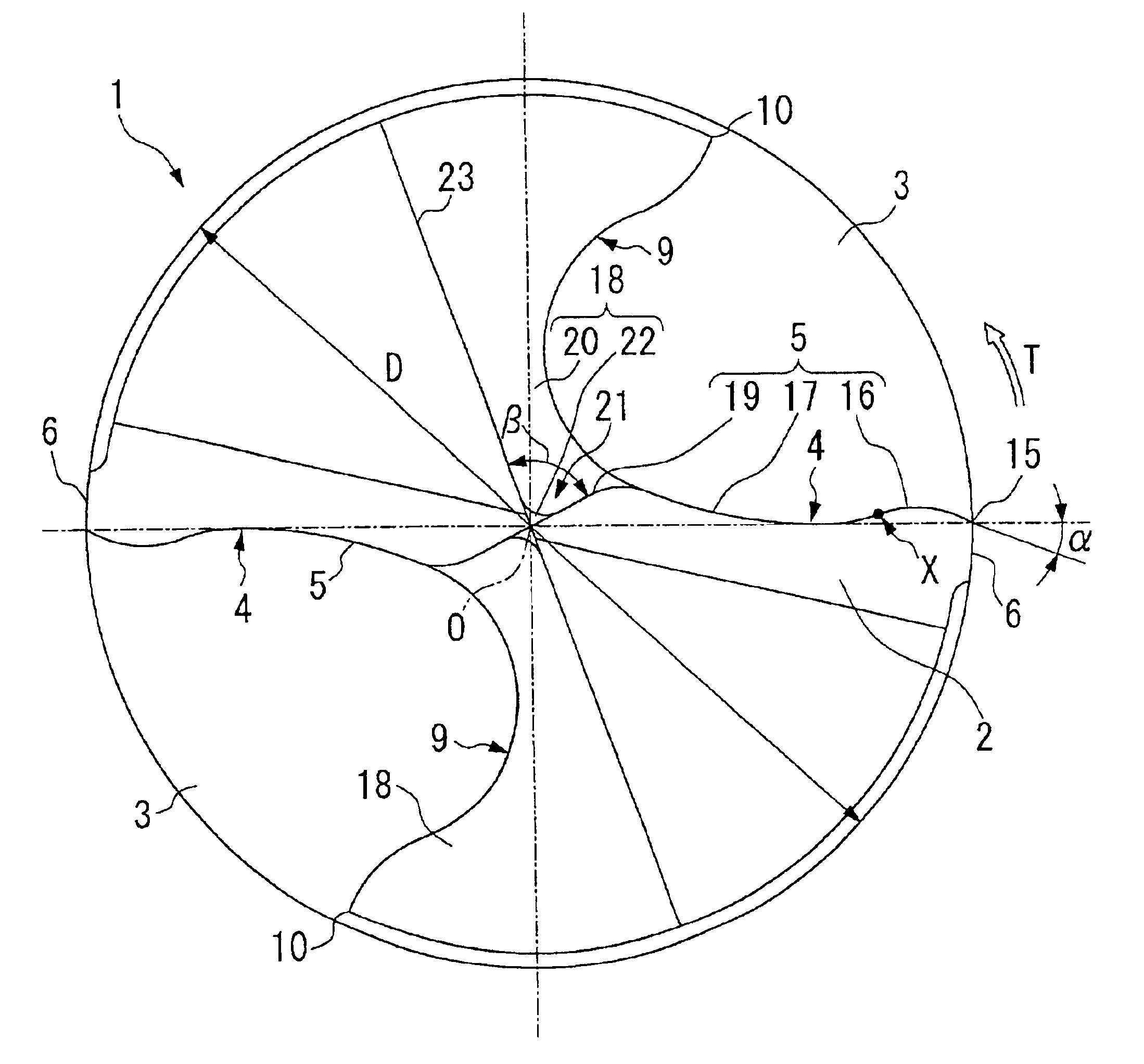

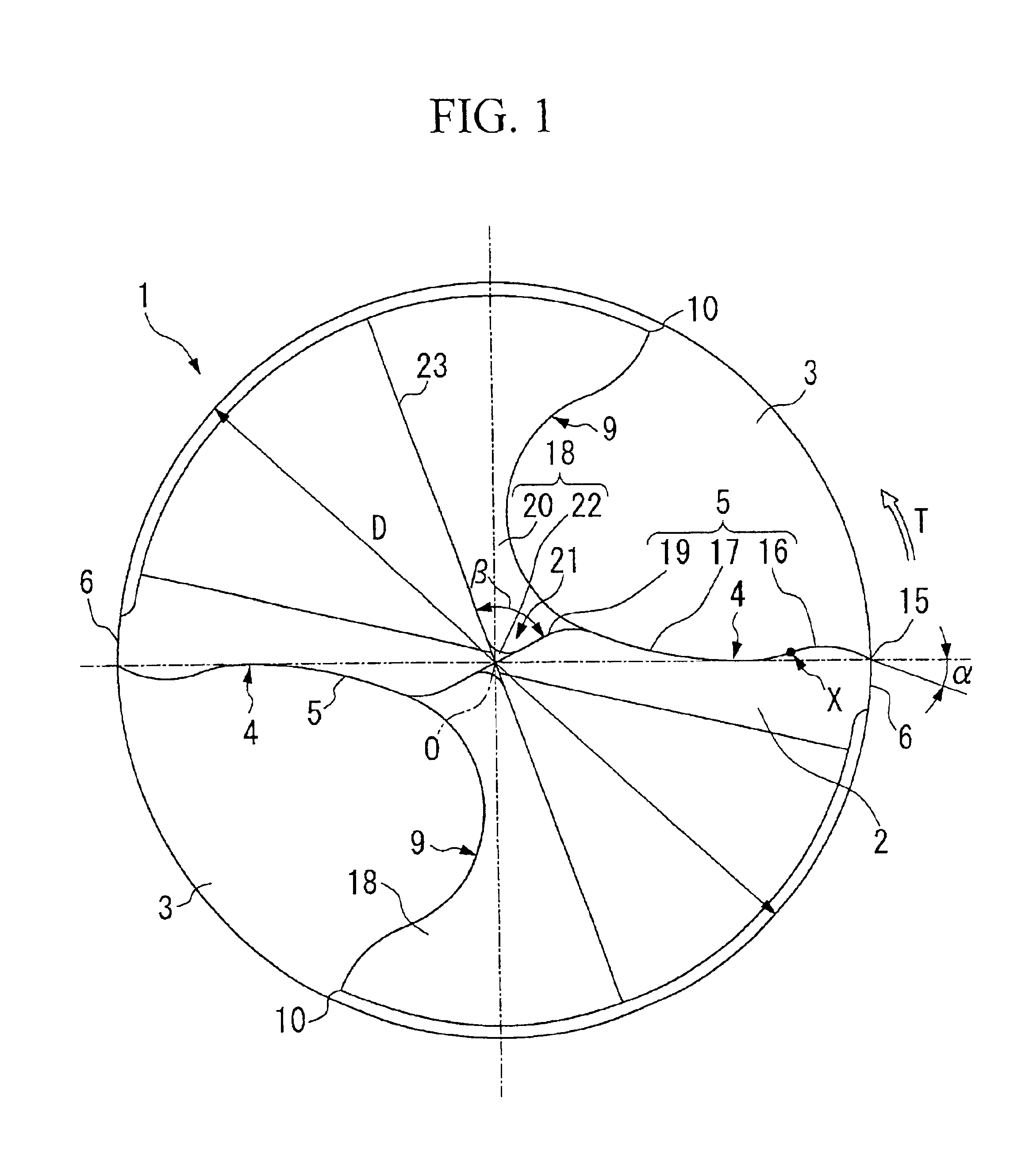

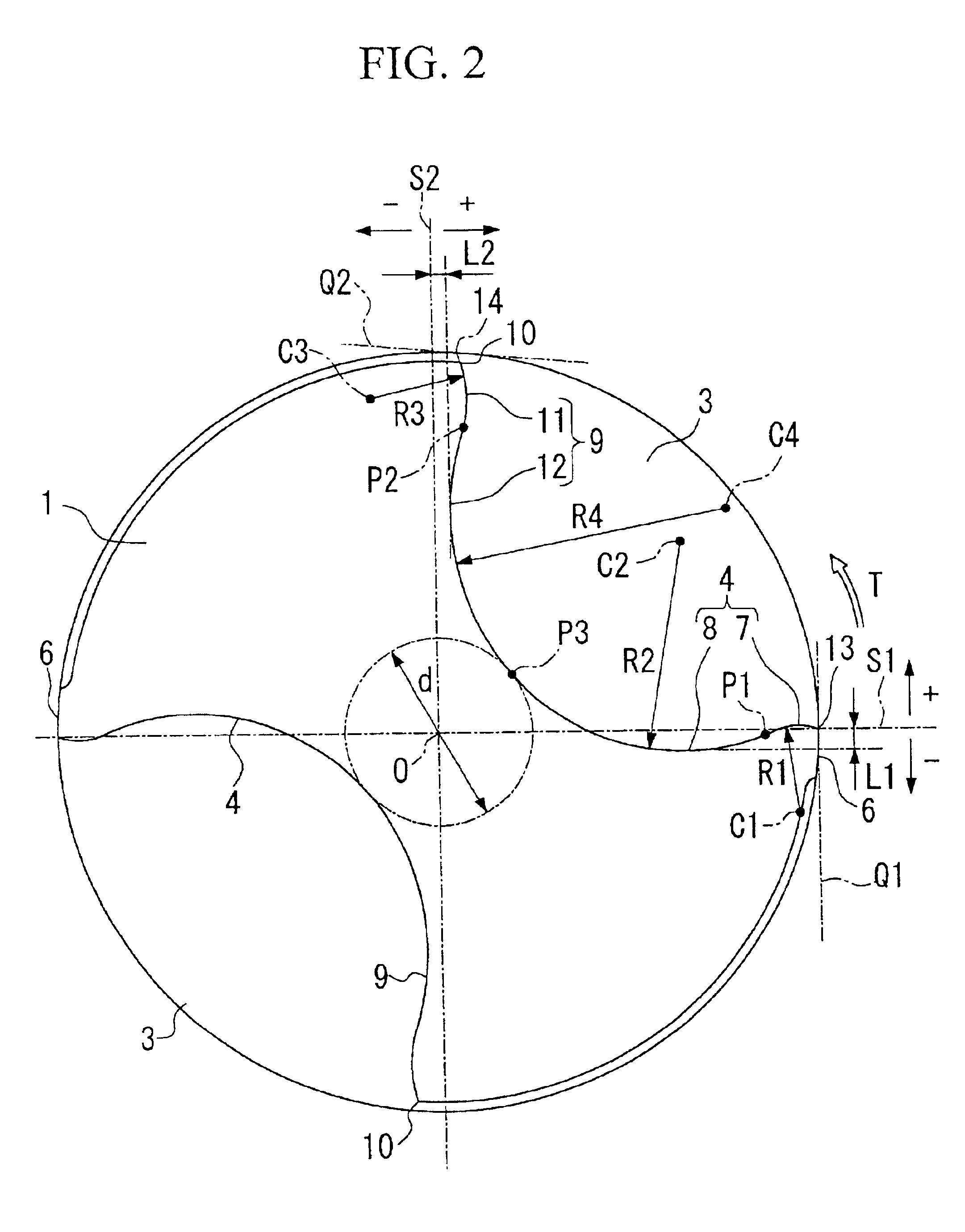

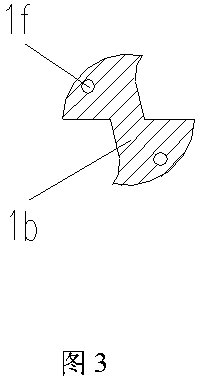

The present invention provides a drill comprising: a drill main body rotatable about an axis of rotation, and having a tip end with a tip flank and a shank; a chip discharge flute formed on a periphery of the drill main body, and extending from the tip end toward the shank of the drill main body; and a cutting edge formed along an intersecting ridge where a wall surface of the chip discharge flute facing in the direction of drill rotation intersects the tip flank of the drill main body, wherein the cutting edge comprises a convex cutting edge toward the periphery and a concave cutting edge smoothly extending from the convex cutting edge. When drilling work is performed with this drill, the chips are generally curled and can be smoothly discharged without being excessively abutted against the wall surface of the chip discharge flute; consequently, the chips can be smoothly discharged, and the drill main body is subjected to less frictional resistance, which leads to less wear on the drill and less driving torque for drilling. Therefore, the drill life can be preferably extended even under severe drilling conditions, such as during high speed drilling, and smooth and stable drilling can be performed.

Owner:MITSUBISHI MATERIALS CORP

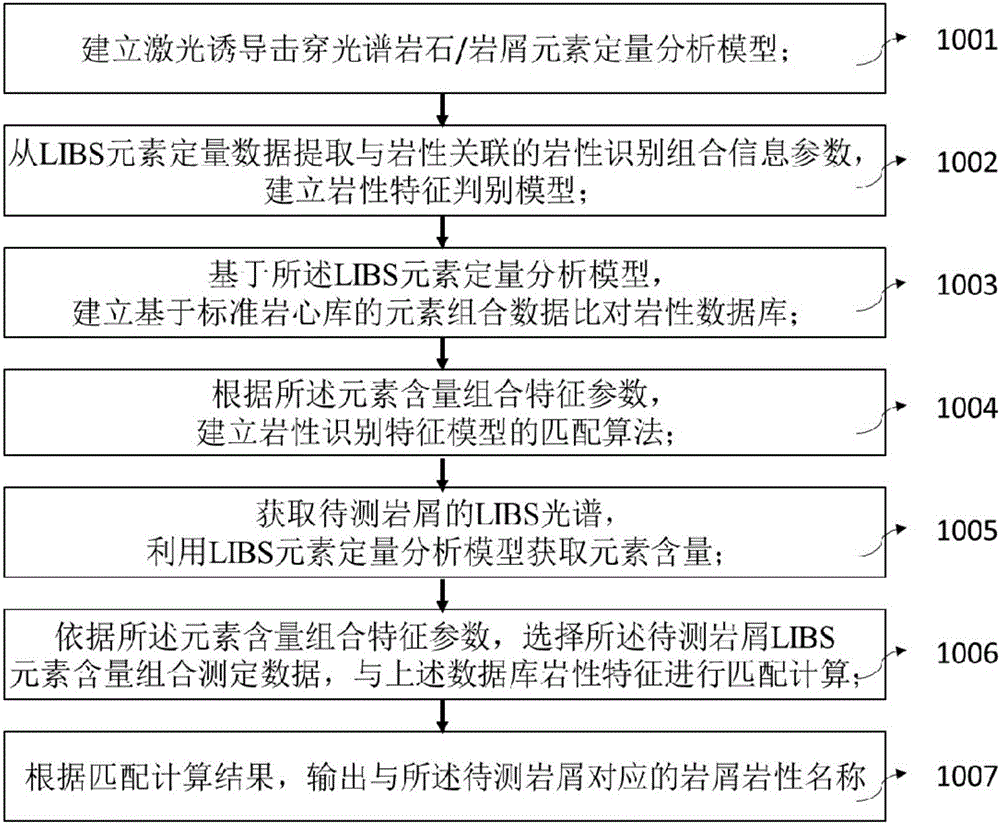

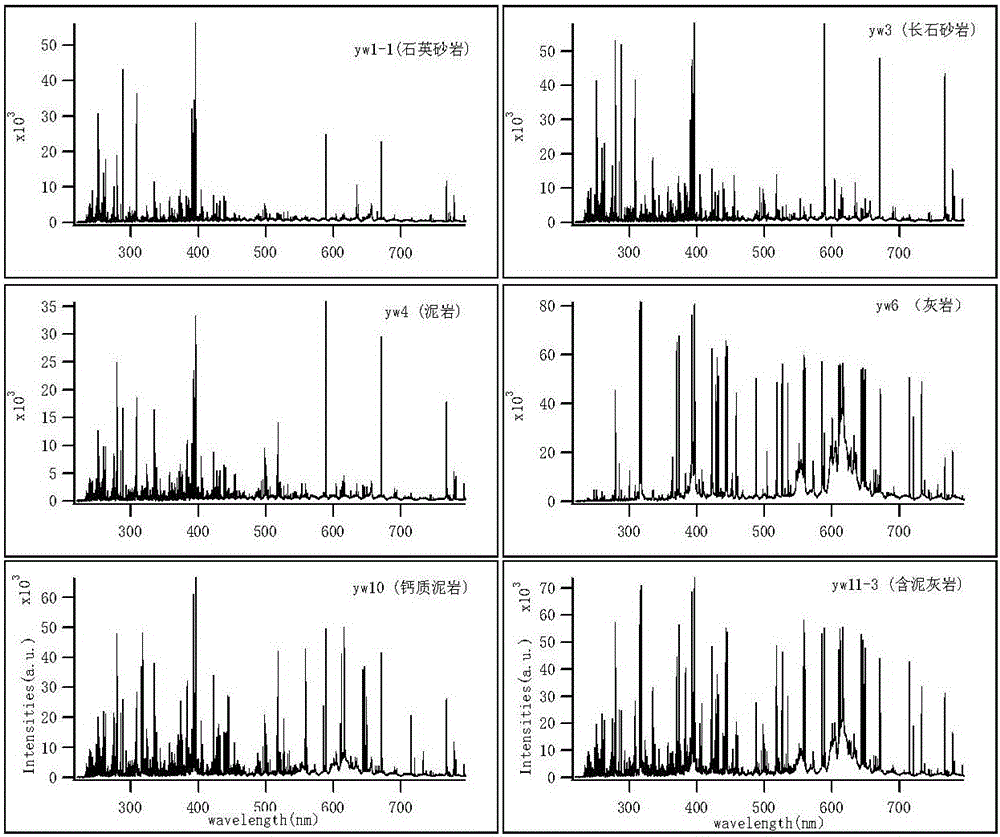

Rock character judging method and system based on laser-induced breakdown spectroscopy

InactiveCN105938099AEfficient lithology identificationReliable lithology identificationAnalysis by thermal excitationLithologyWell drilling

The invention discloses a rock character judging method based on laser-induced breakdown spectroscopy (LIBS). According to the method, a laser-induced breakdown spectroscopy (LIBS) technology is used to establish a rock and / or rock debris element information prediction model based on a least square support vector machine; and the rock characters can be judged according to the element information prediction data of a rock and / or rock debris sample to be detected. The method has the characteristics of directness, rapidness, accuracy, and efficiency. The rock character judgment is accurate and efficient, especially for the logging rock debris powder under a high speed drilling condition, and the rock character judgment results are the same with those of drilling and coring. The invention also provides a system for the method mentioned above at the same time.

Owner:SICHUAN UNIV

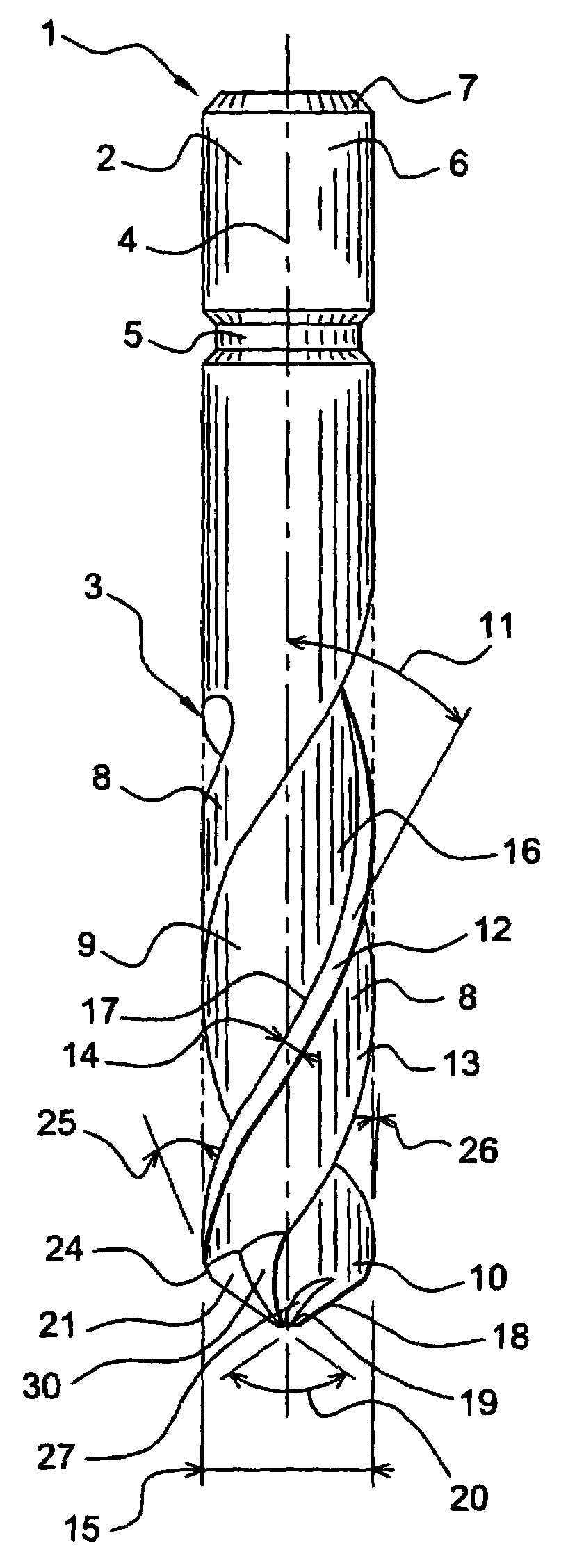

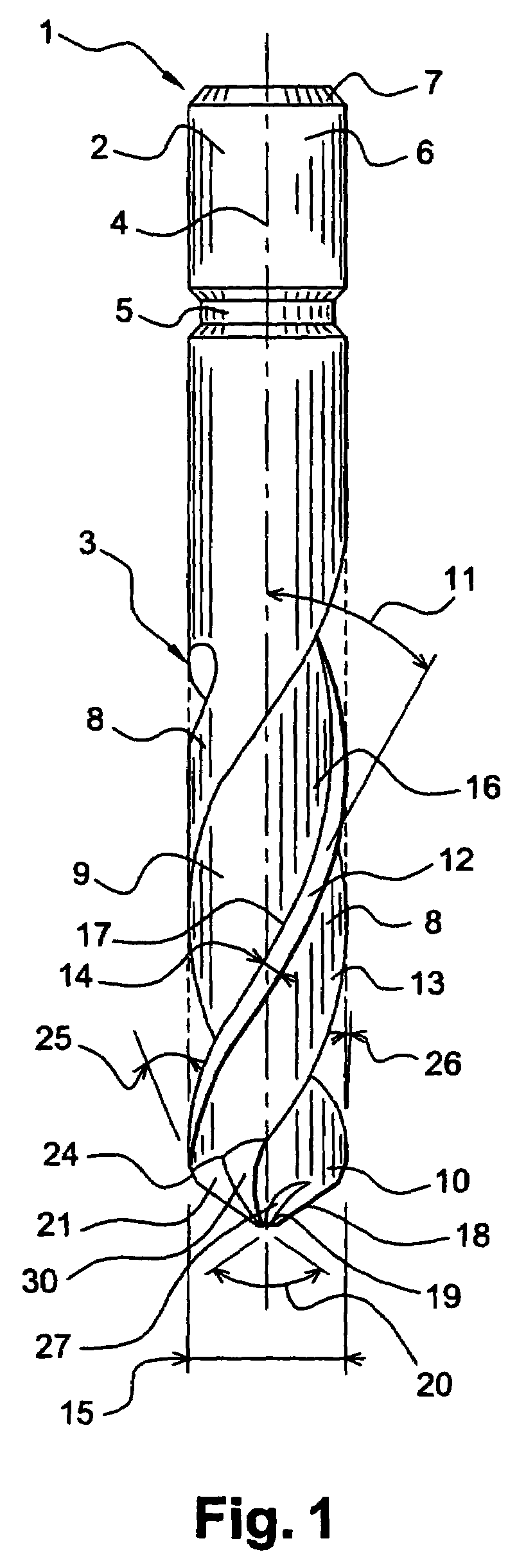

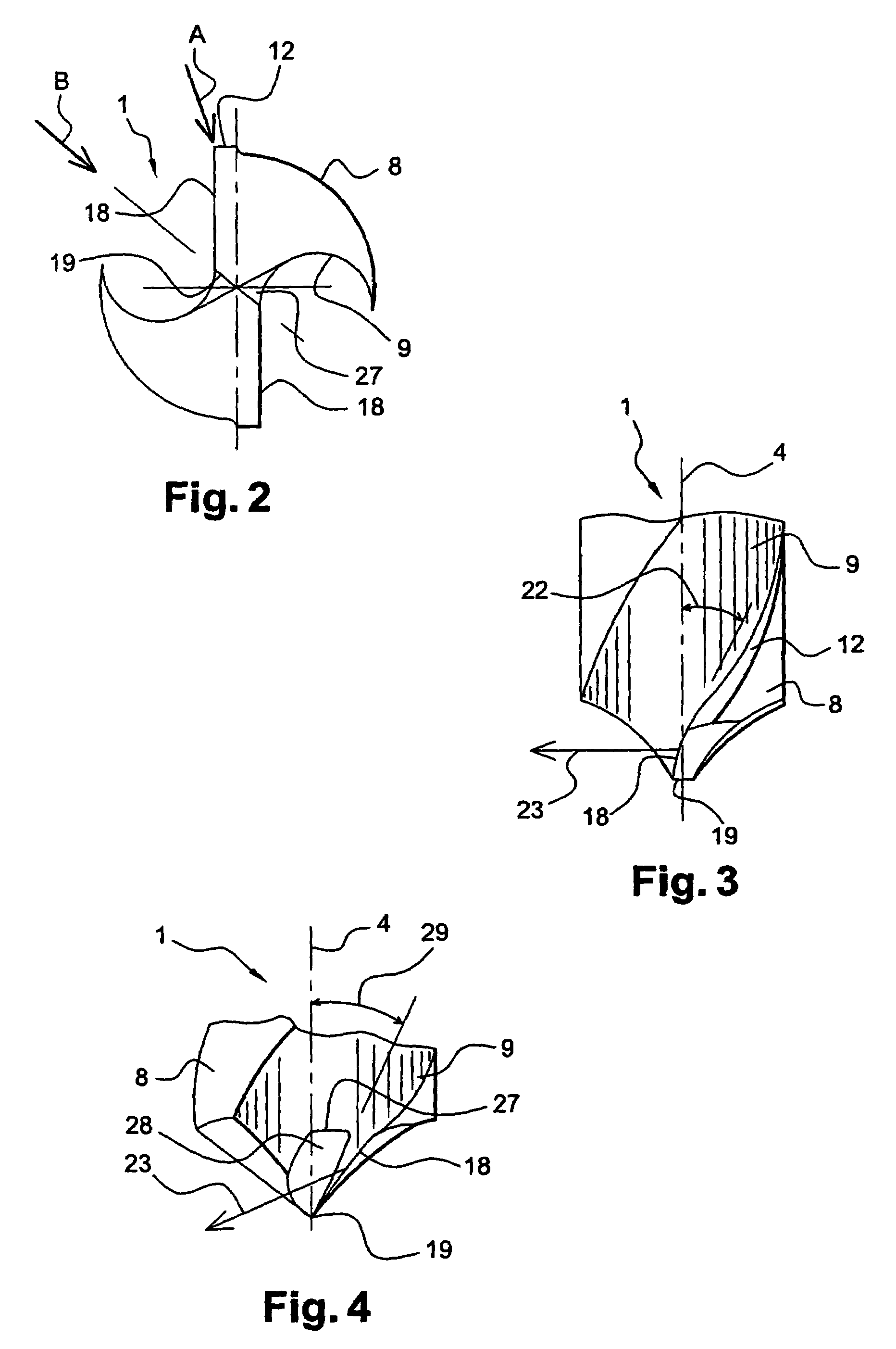

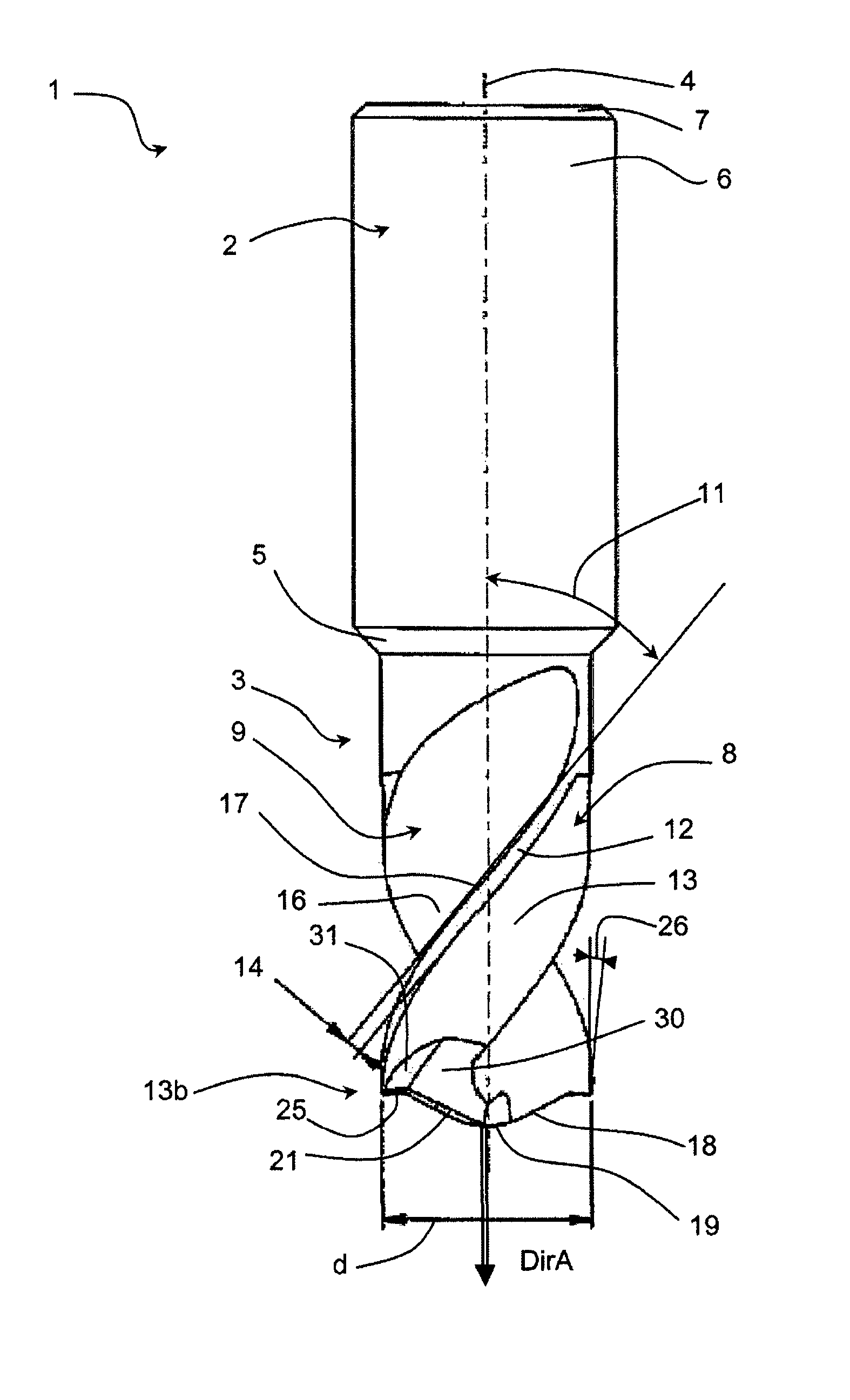

Ceramic bit for high speed drilling

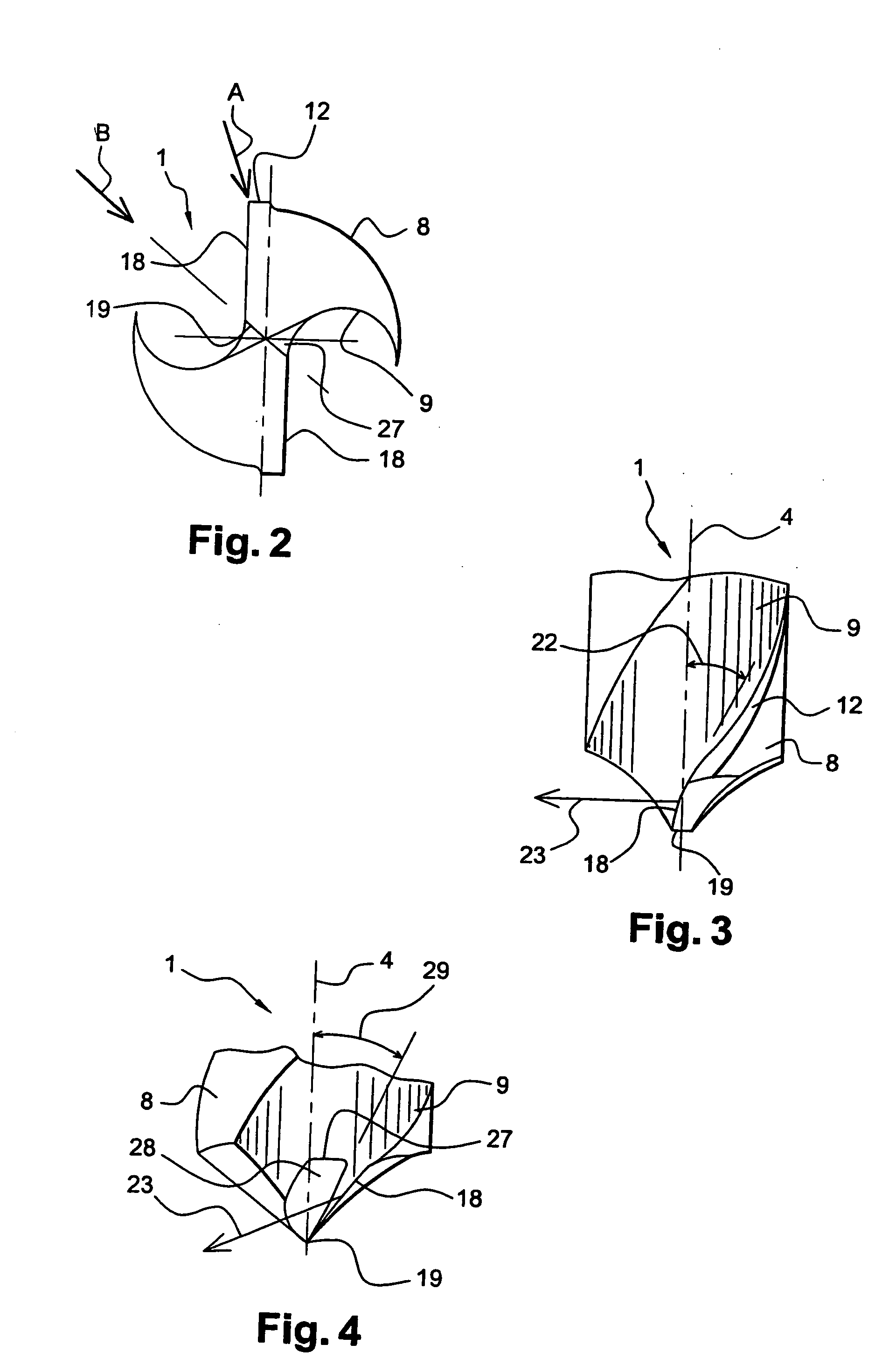

ActiveUS20050135889A1Technically inexpensiveTechnically simpleWood turning toolsTransportation and packagingEngineeringHigh speed drilling

A ceramic drill bit comprising a cylindrical shank and a shaped portion extending axially in line with the shank and having a free end forming the tip of the bit, a relief face extending from each main cutting edge with a relief angle lying in the range 4° to 10° approximately relative to a plane perpendicular to the axis of rotation of the bit, and two notches forming two secondary cutting faces extending from the central edge with positive cutting angles lying in the range 10 to 70 approximately relative to the axis of rotation of the bit.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

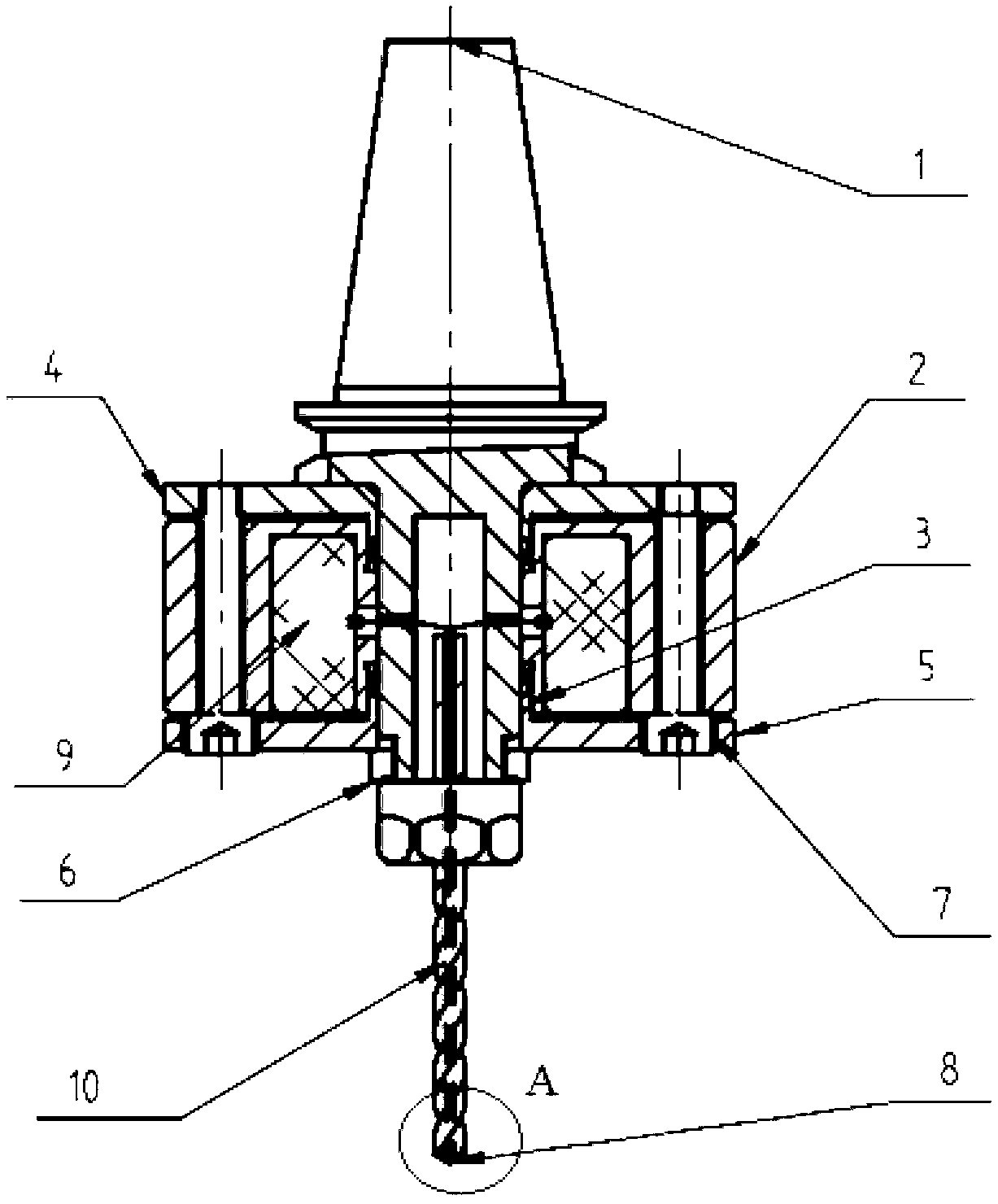

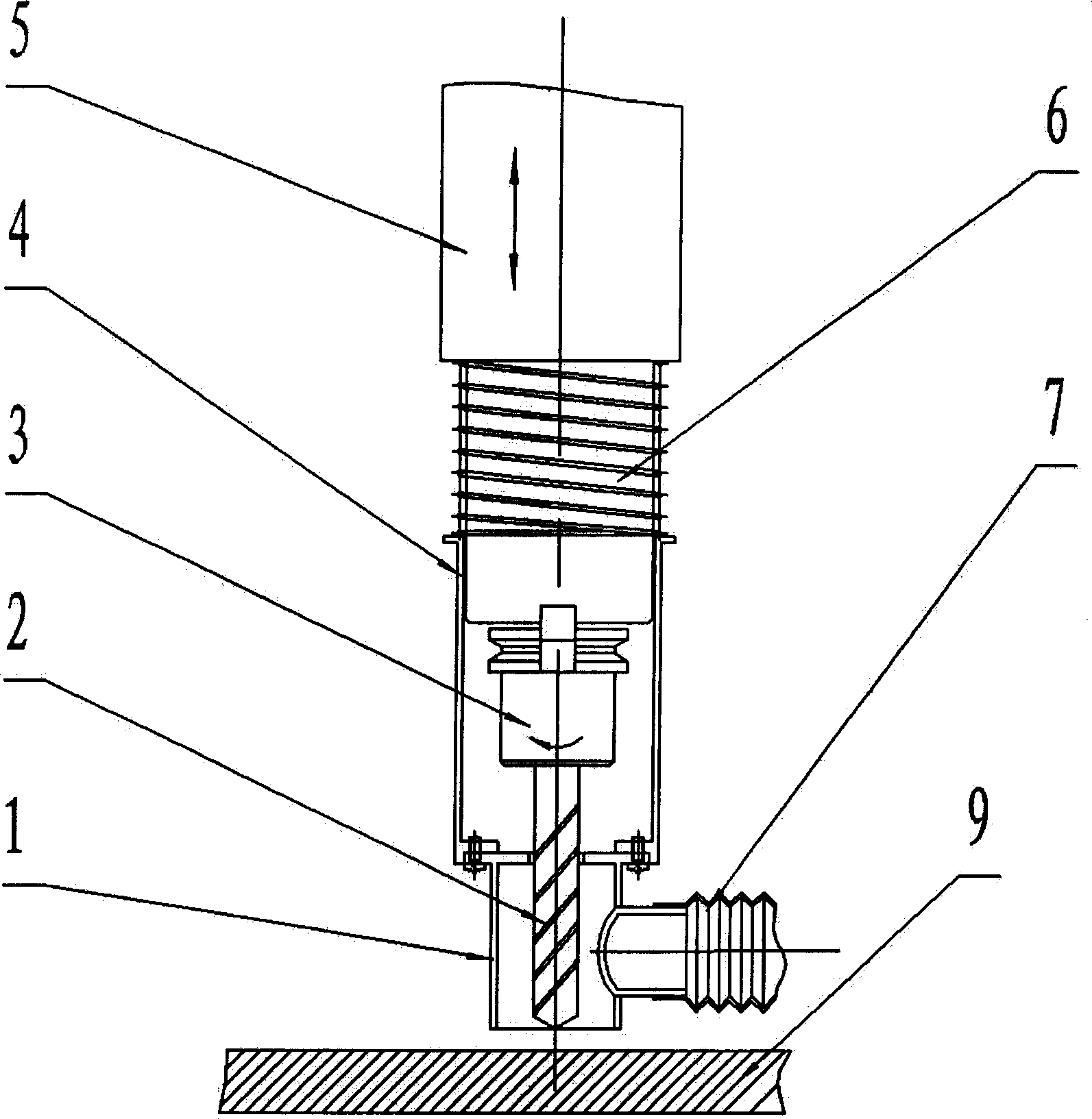

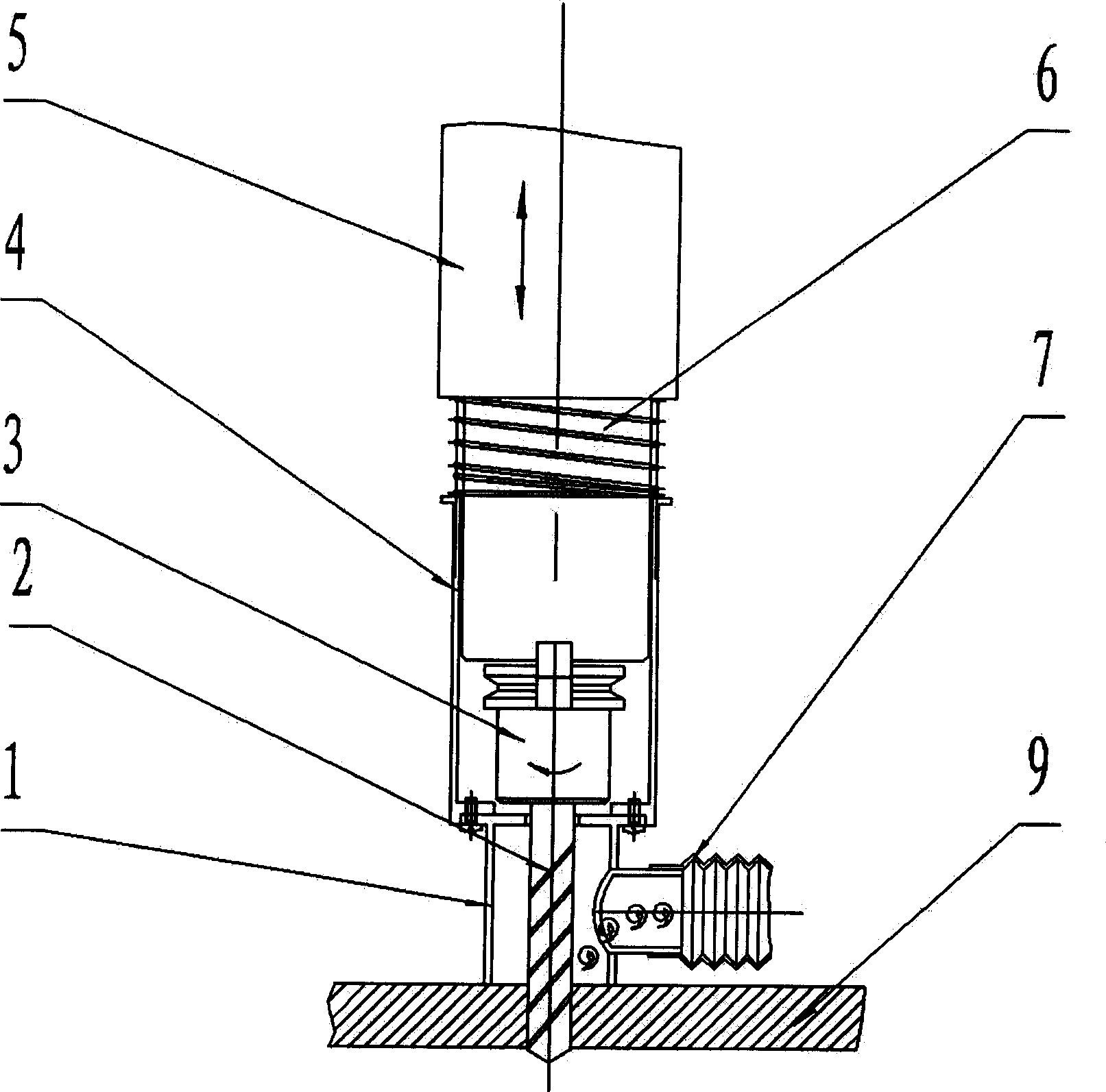

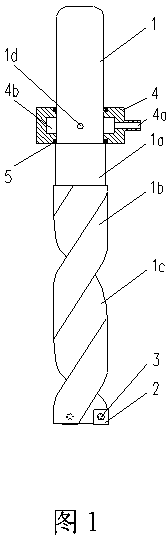

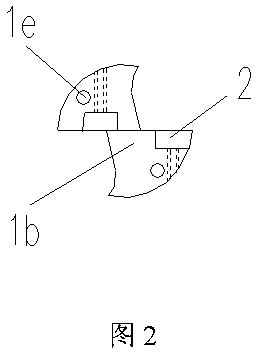

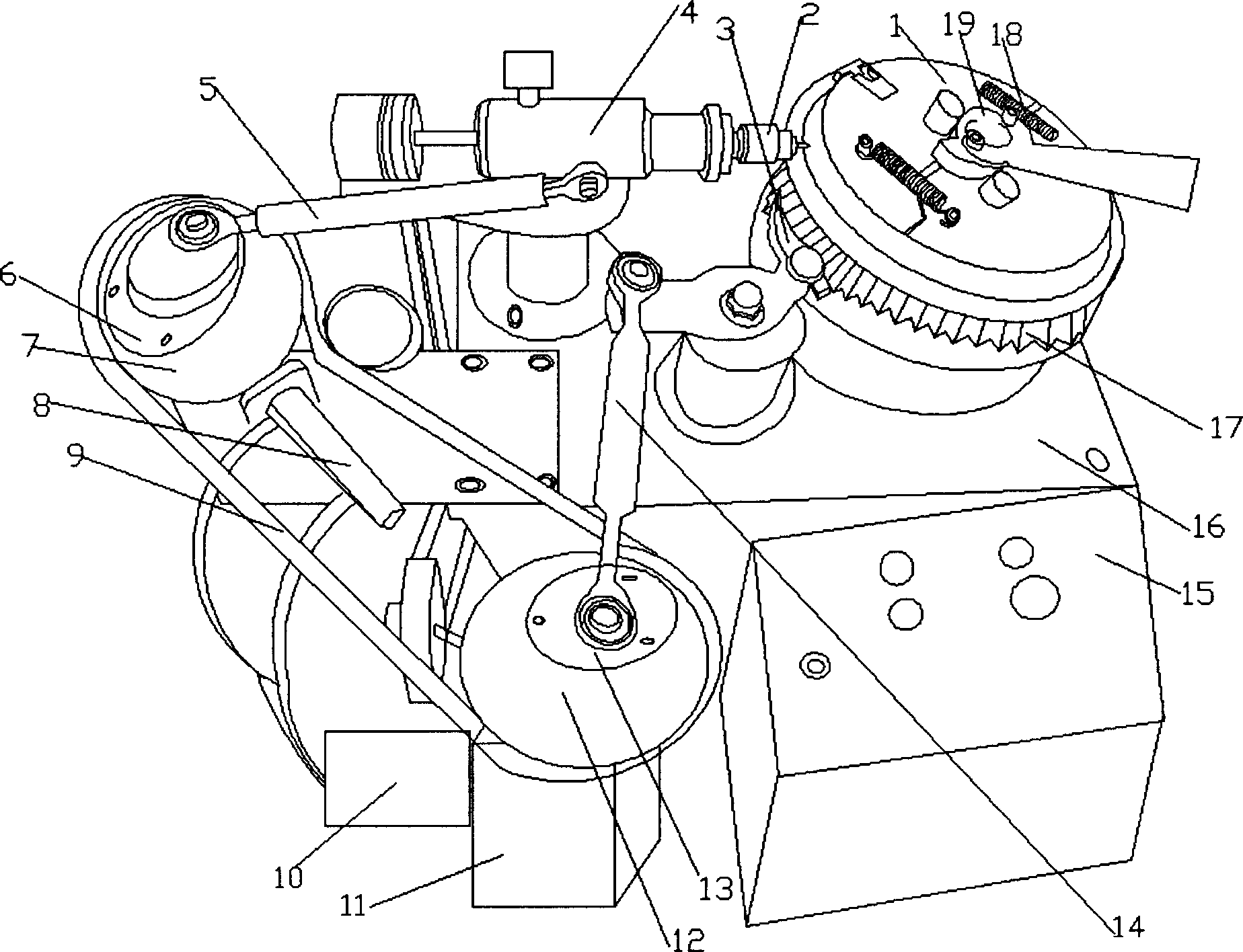

Cutting temperature monitoring device for high-speed drilling process

ActiveCN103128599AMonitor cutting temperatureImprove balanceMeasurement/indication equipmentsMetallic materialsEngineering

The invention discloses a cutting temperature monitoring device for high-speed drilling process. The cutting temperature monitoring device comprises a temperature module housing assembly and a temperature monitoring system. The temperature module housing assembly is arranged on a handle of a cutting tool, and the temperature monitoring system is arranged in the temperature module housing assembly. The temperature monitoring device is capable of continuously monitoring the cutting temperature in the life cycle of the cutting tool for a long time through a one-time experimental setting of the cutting tool. The temperature monitoring device is sound in balancing performance without requiring for the material of workpieces, and is applicable to measuring and recording of the long-time and continuously variable cutting temperature of metal and nonmetallic materials in the high-speed drilling process.

Owner:SHANGHAI JIAO TONG UNIV

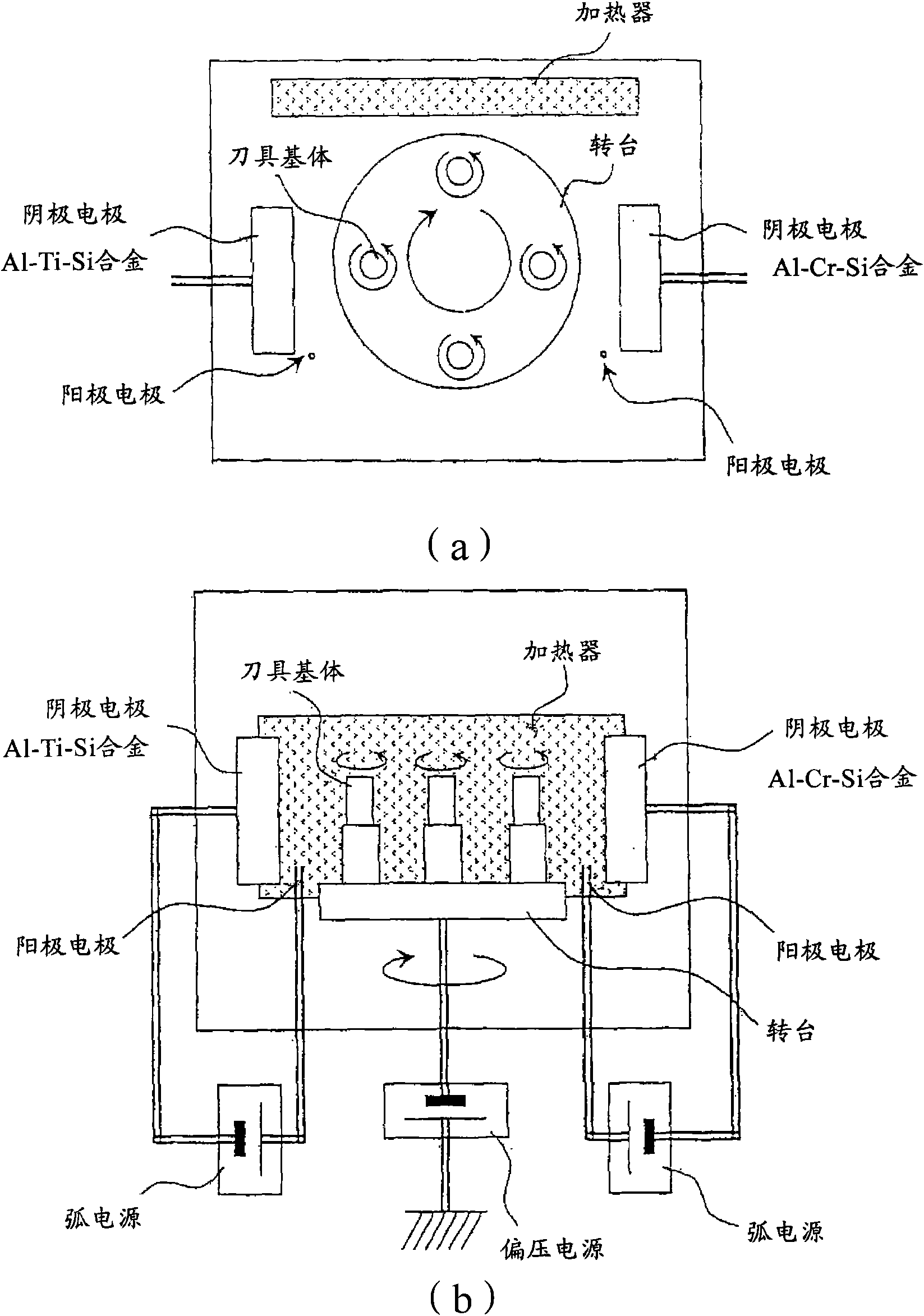

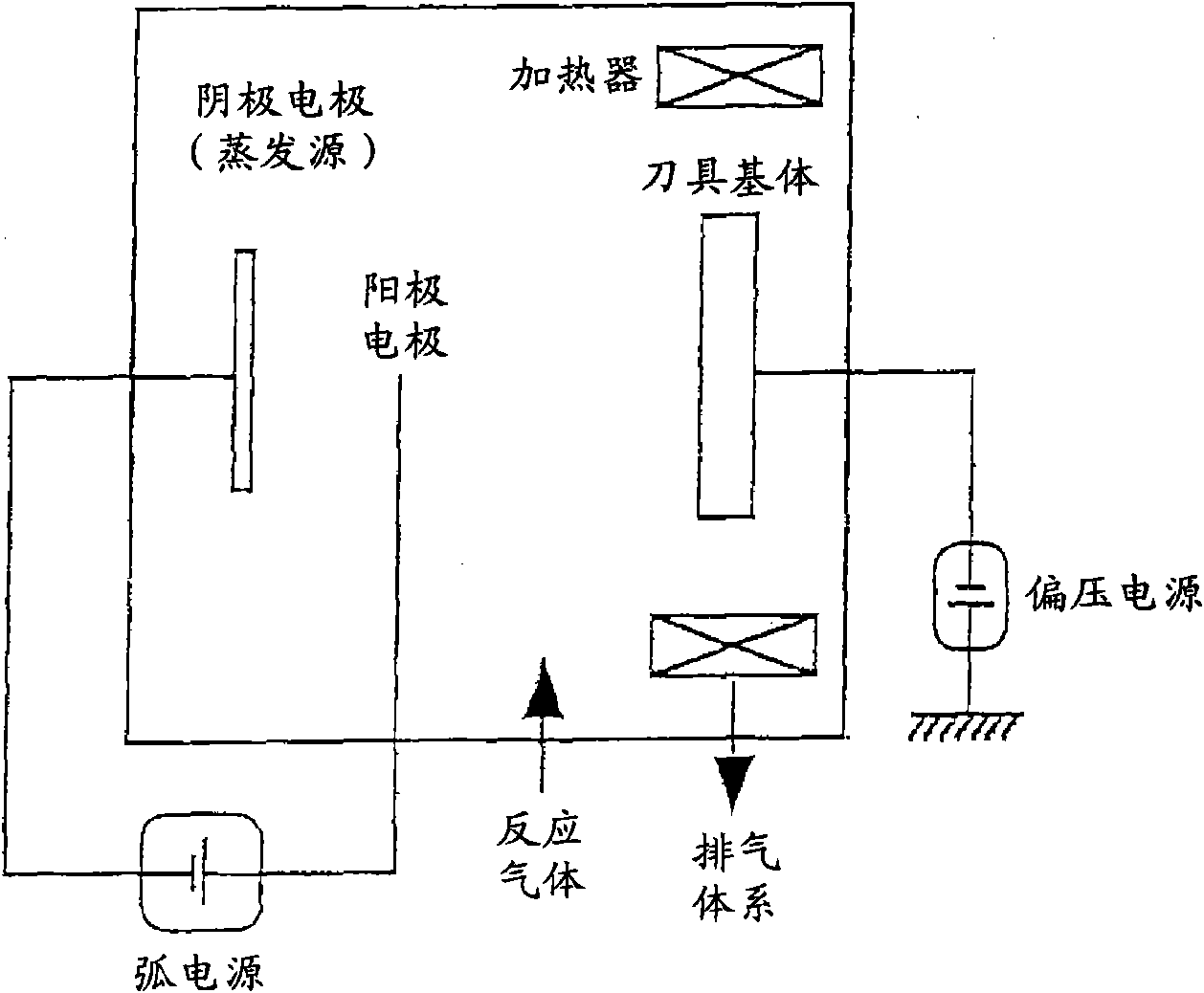

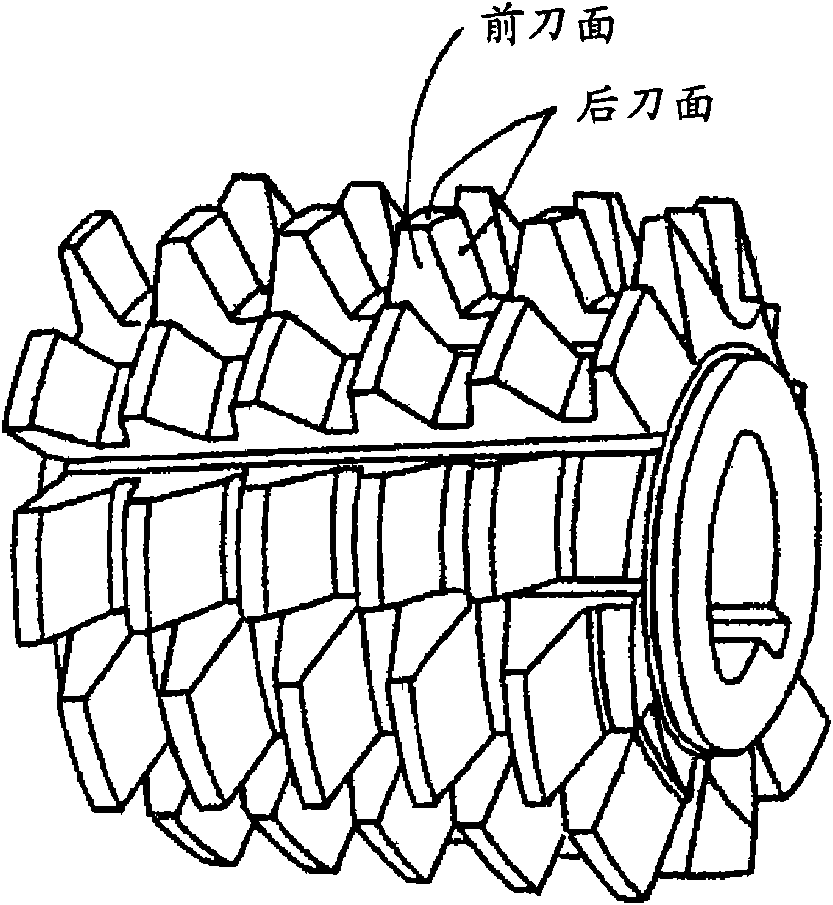

Surface-coated cutting tool

ActiveCN101678467AExcellent high temperature hardnessExcellent high temperature toughnessMilling cuttersVacuum evaporation coatingThin layerCemented carbide

A surface-coated cutting tool which has excellent chipping resistance and wearing resistance in high-speed cutting processing such as high-speed gear cutting processing, high-speed milling processing,and high-speed drilling processing. The surface-coated cutting tool comprises a tool base, e.g., a cemented carbide base, cermet base, or high-speed tool steel base, and at least a hard coating layerformed on a surface of the tool base and having a multilayer structure composed of a thin layer (A) and a thin layer (B) alternating therewith. The thin layer (A) is constituted of an (Al,Cr,Si)N layer satisfying the empirical formula ¢AlXCrYSiZ!N (wherein 0.2 <= X <= 0.45, 0.4 <= Y <= 0.75, 0.01 <=Z <= 0.2, and X+Y+Z=1 in terms of atomic ratio), and the thin layer (B) is constituted of an (Al,Ti,Si)N layer satisfying the empirical formula ¢AlUTiVSiW!N (wherein 0.05 <= U <= 0.75, 0.15 <= V <= 0.94, 0.01 <= W <= 0.1, and U+V+W=1 in terms of atomic ratio).

Owner:MITSUBISHI MATERIALS CORP

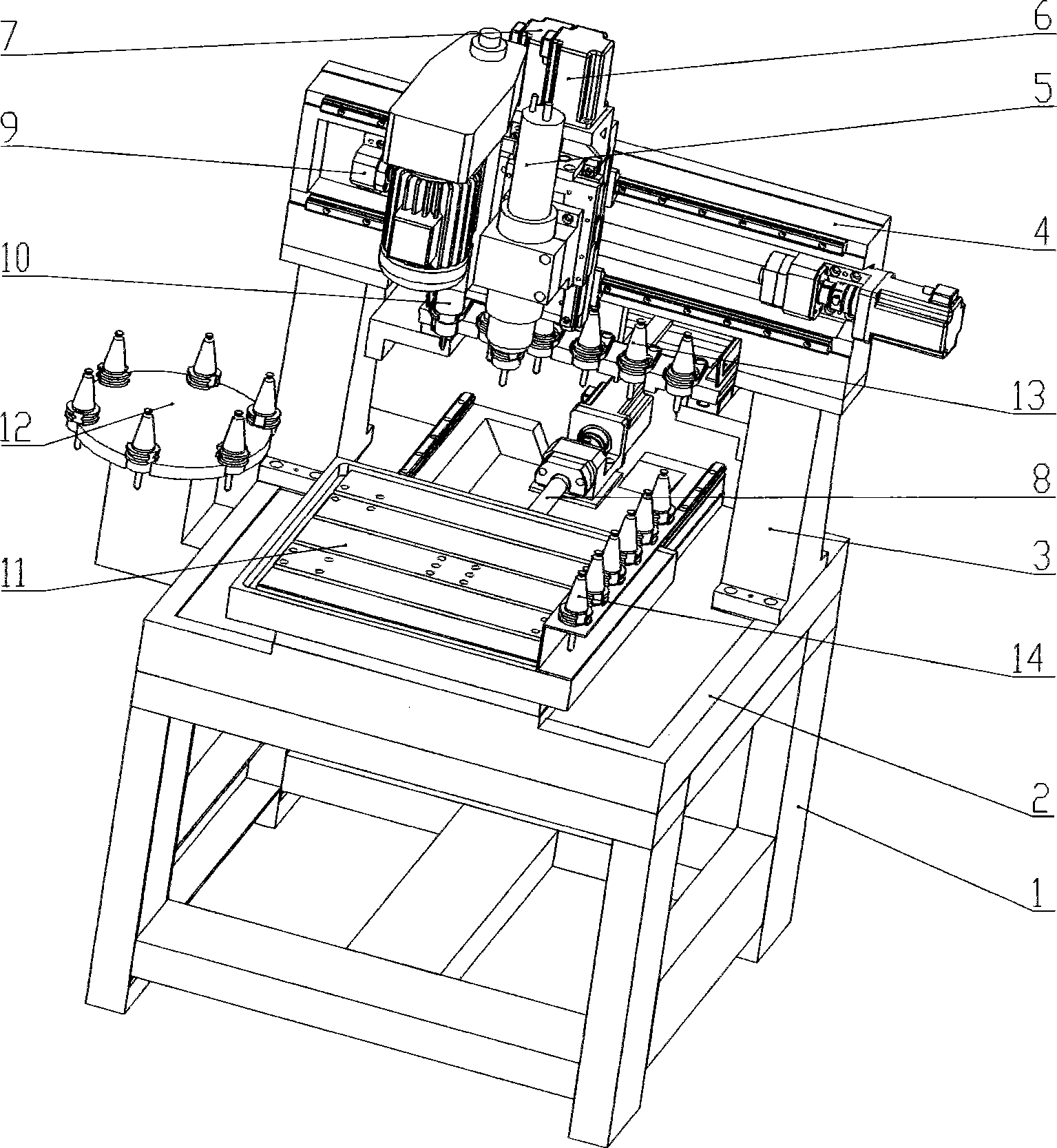

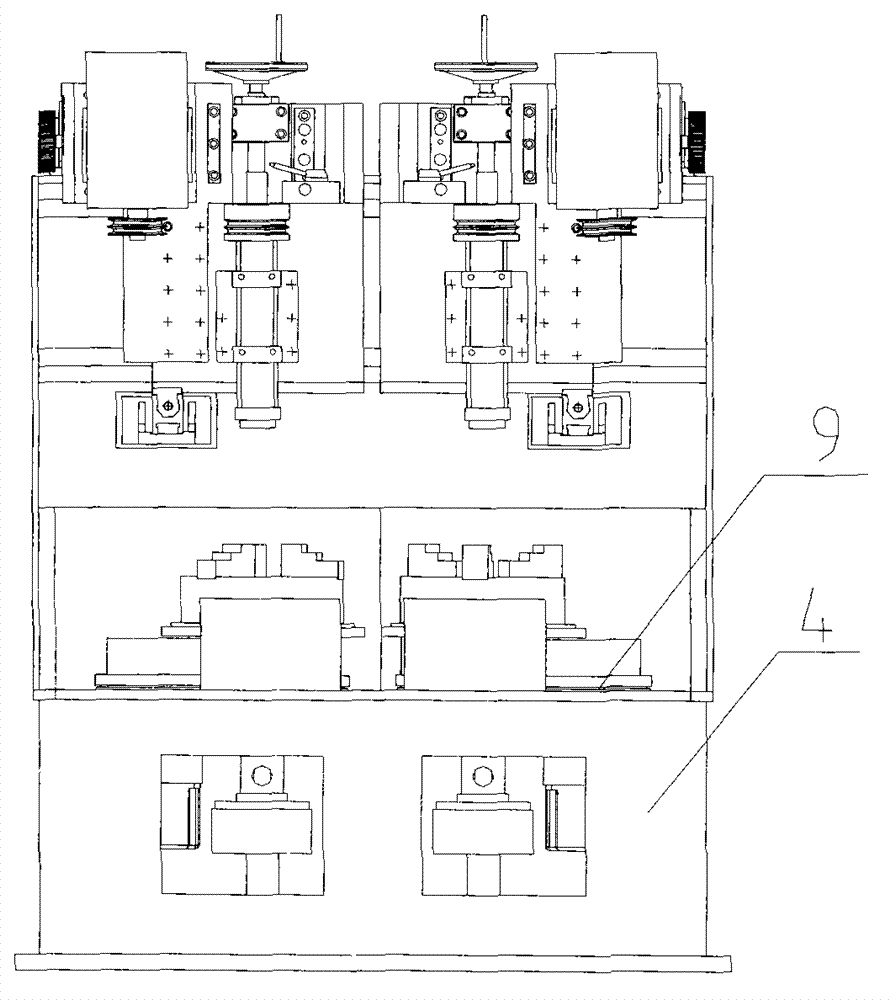

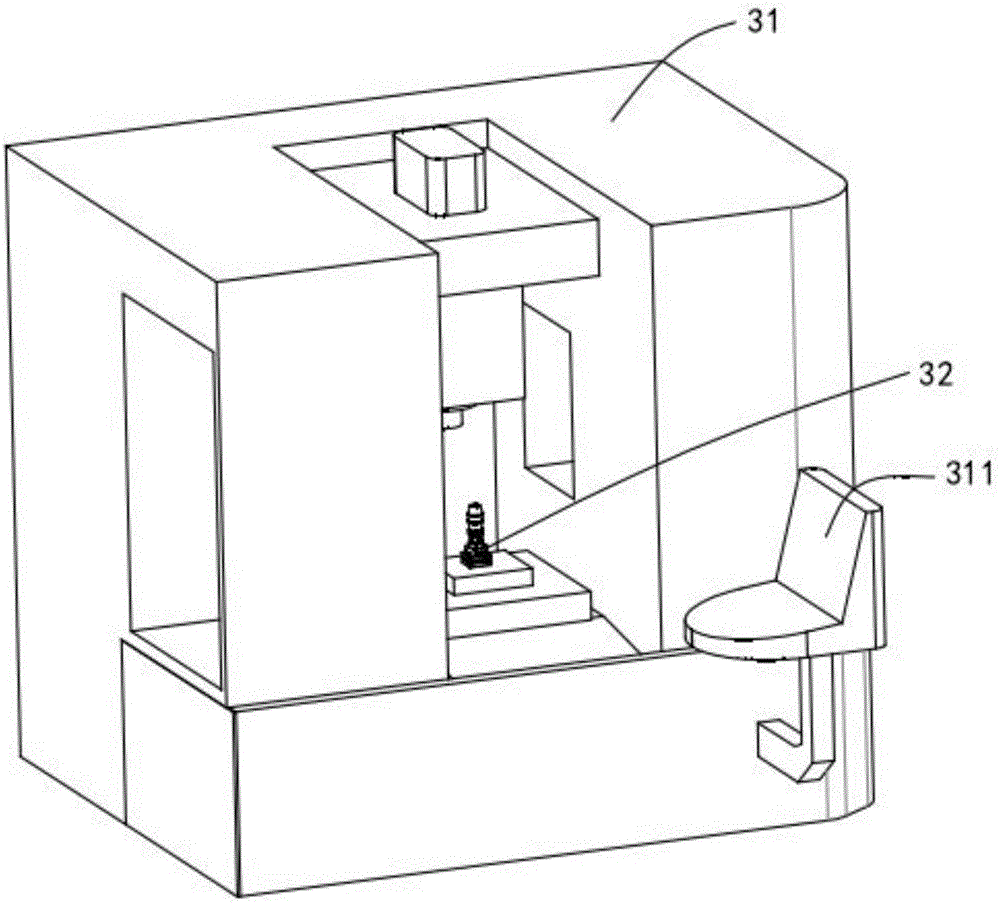

Small-sized gantry double-main shaft numerical control machine for drilling, milling and tapping

InactiveCN101502932AIncrease feed rateHigh positioning accuracyOther manufacturing equipments/toolsPositioning apparatusElectricityNumerical control

The invention relates to a small gantry dual-spindle drilling milling tapping numerical control machine. The small two-axis gantry drilling tapping digital control machine essentially solves the technical problem of providing a drilling milling tapping machine with low cost and high efficiency for the light metal hardware processing of the communication and the consumption electronic industry, and the machine has the advantages of simple structure and stable and reliable operation. The technical proposals for solving this problem is as follows: a frame structure support welded with channel steel, a diamond-shaped rib square structure soleplate and a gantry beam are adopted; a sliding plate of the beam is equipped with dual spindles, and the dual spindles are respectively a high-speed drilling milling head spindle and a high-speed tapping head spindle. The drilling milling head spindle uses a high-speed knife replaceable electric spindle; the tapping head spindle uses a self-invented mechanical tapping spindle able to carry out the screw distance selection automatically. The drilling milling head spindle can install the tool magazine on the rear, left and right positions of the machine; the tool magazine uses row-type tool magazine, inverted bamboo hat style tool magazine or row-type tool magazine and the arbitrary combination methods of inverted bamboo hat tool magazine.

Owner:深圳市康铖机械设备有限公司

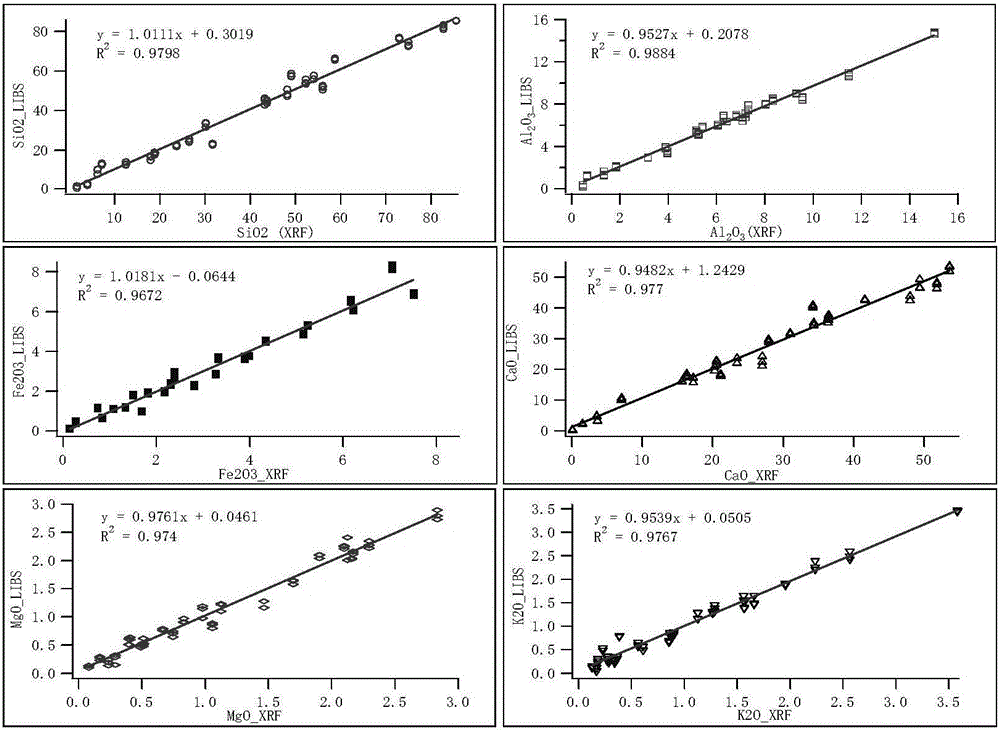

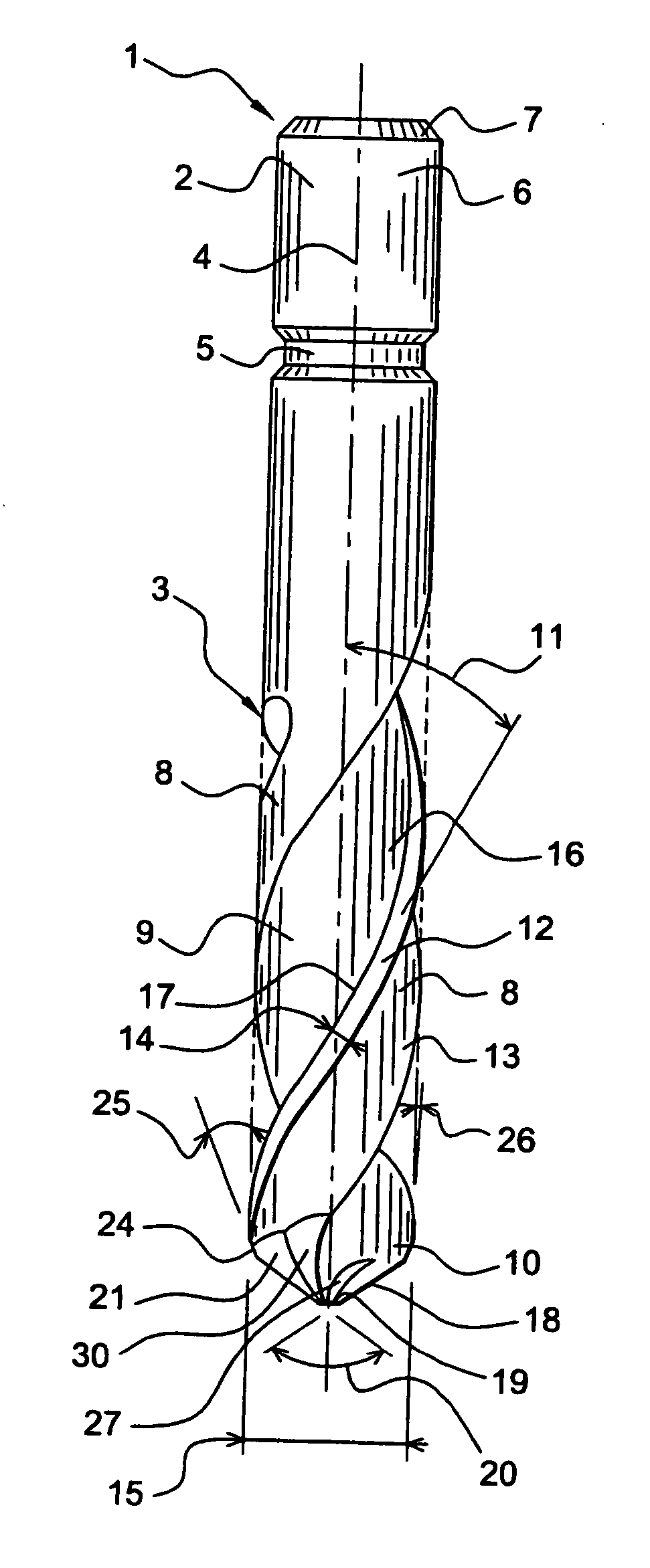

Ceramic bit for high speed drilling

ActiveUS7367758B2Technically inexpensiveTechnically simpleWood turning toolsTransportation and packagingStructural engineeringMechanical engineering

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Ceramic drill bit for high-speed drilling of composites

The ceramic drill bit has a particular geometry and is very advantageously applicable to the very high-speed drilling of parts made of a composite, especially a carbon-fiber composite having an epoxy resin matrix. The invention also relates to a method for the high-speed drilling of composites.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

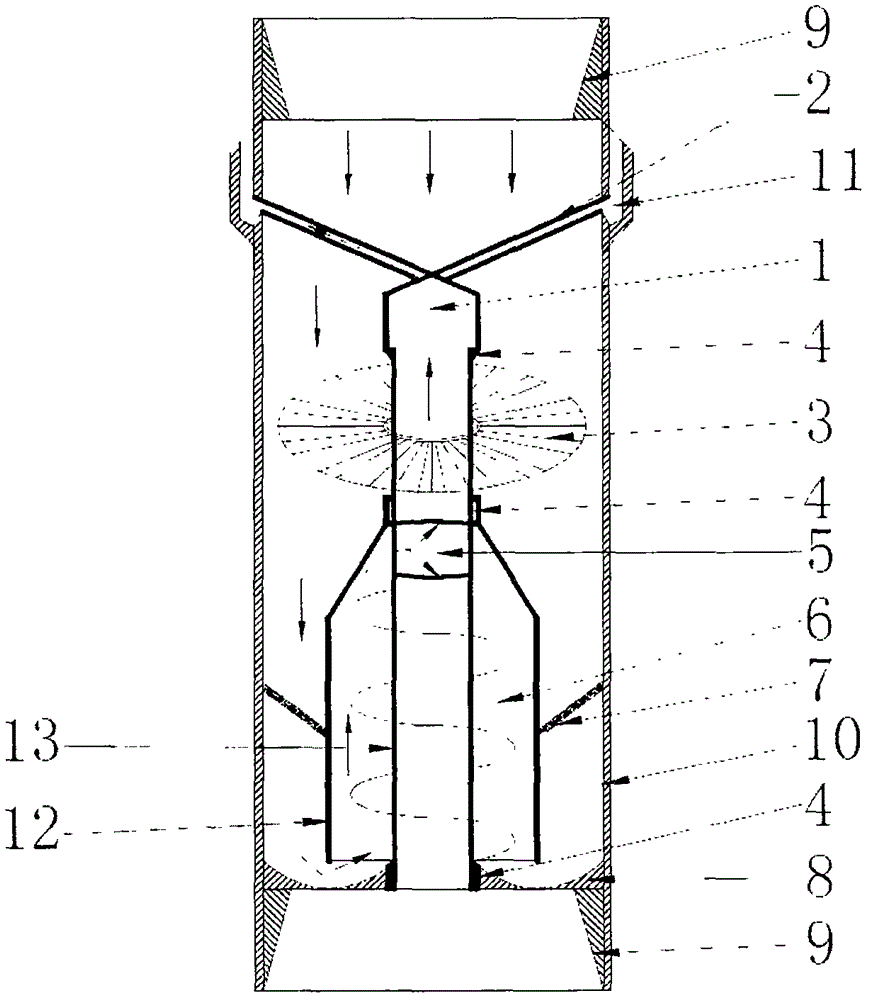

Negative pressure sucking method for recovering waste gas and swarf for high speed drilling

InactiveCN1861302ASolve quality problemsSolve problems that affect subsequent processesDirt cleaningBoring/drilling componentsProduct gasHigh speed drilling

A negative-pressure suction method for recovering waste gas and chips during high-speed drilling is disclosed. A cylindrical sleeve barrel whose internal diameter is 2-2.5 times greater than the diameter of drill bit is attached to front end of drilling axle box. The height of the front end of said sleeve barrel is regulated to same as the cutting edge of drill bit and its back end is connected to a slide sleeve for moving it backward. A flexible suction tube in negative pressure state is connected to the hole on said sleeve barrel to generate airflow at 10-20 m / s for recovering waste gas and chips.

Owner:上海瑞纽机械股份有限公司

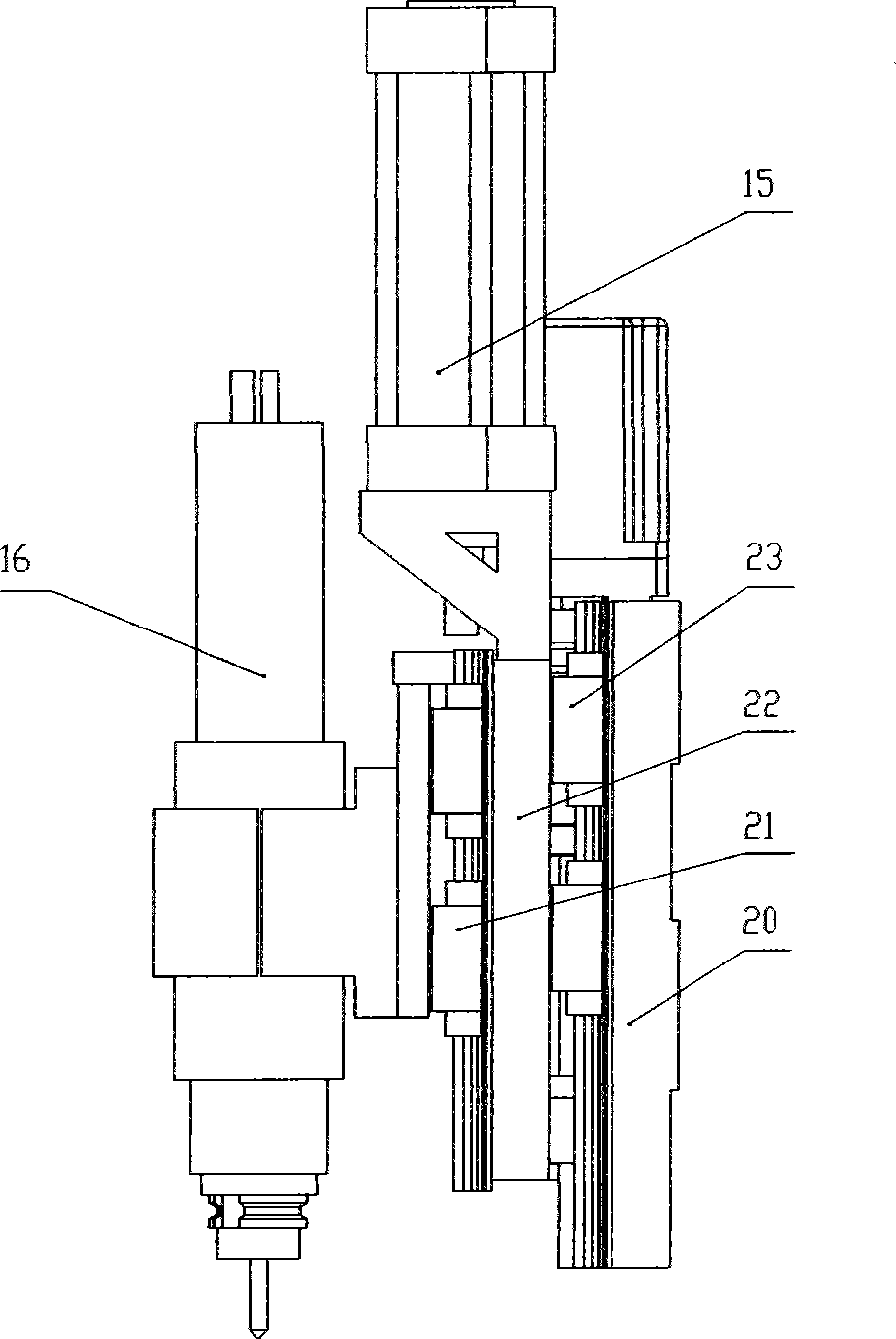

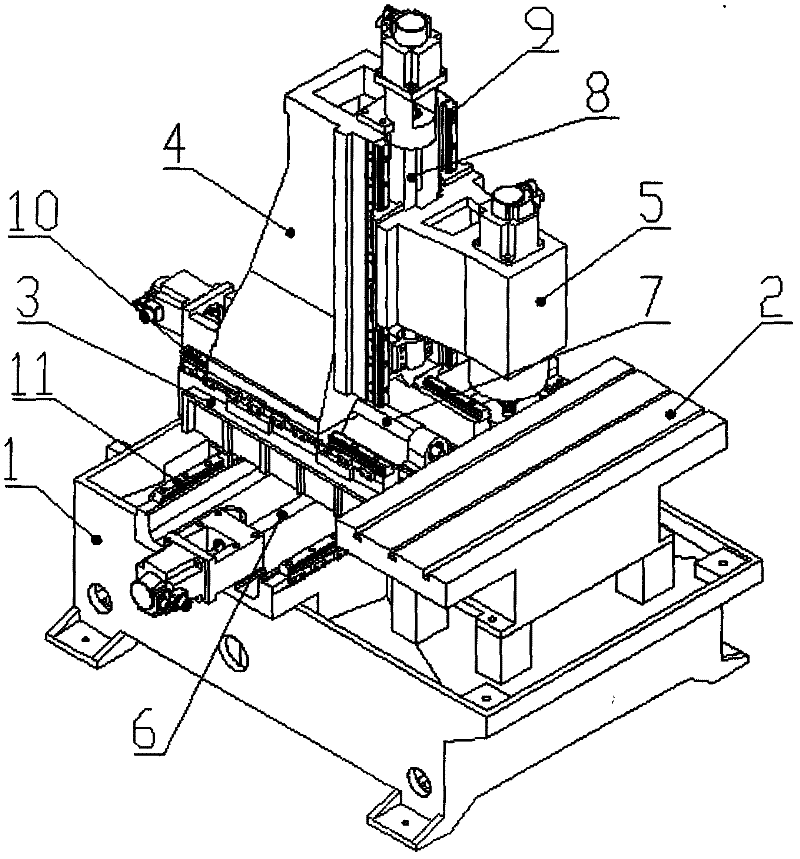

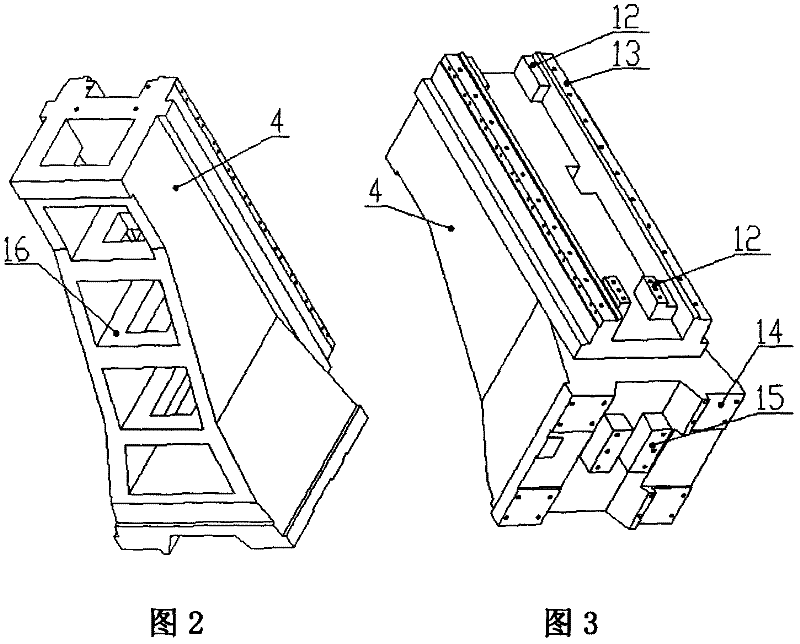

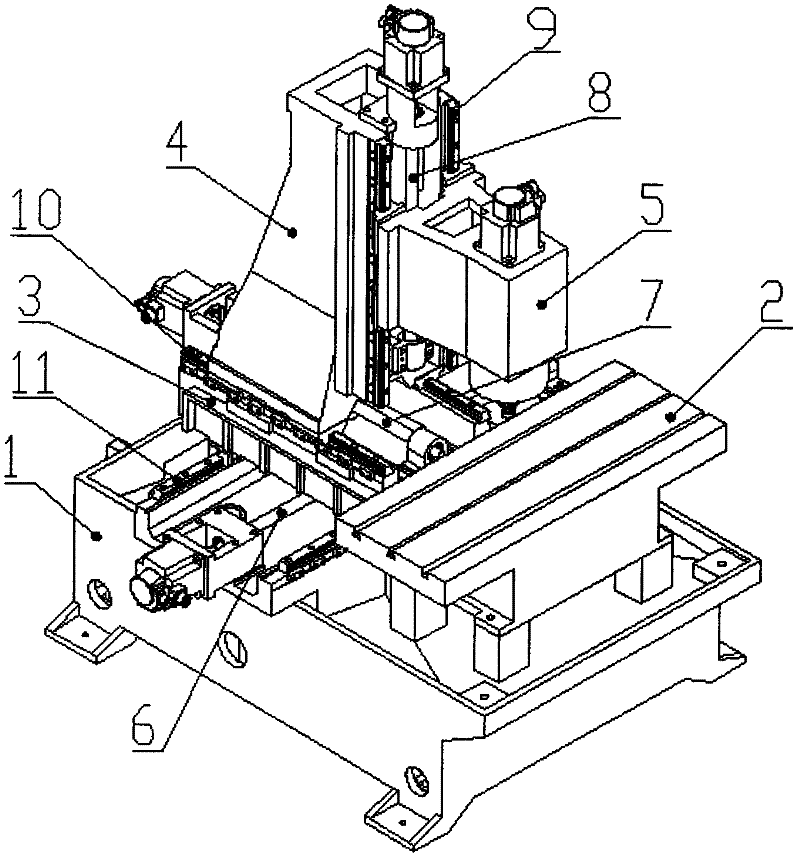

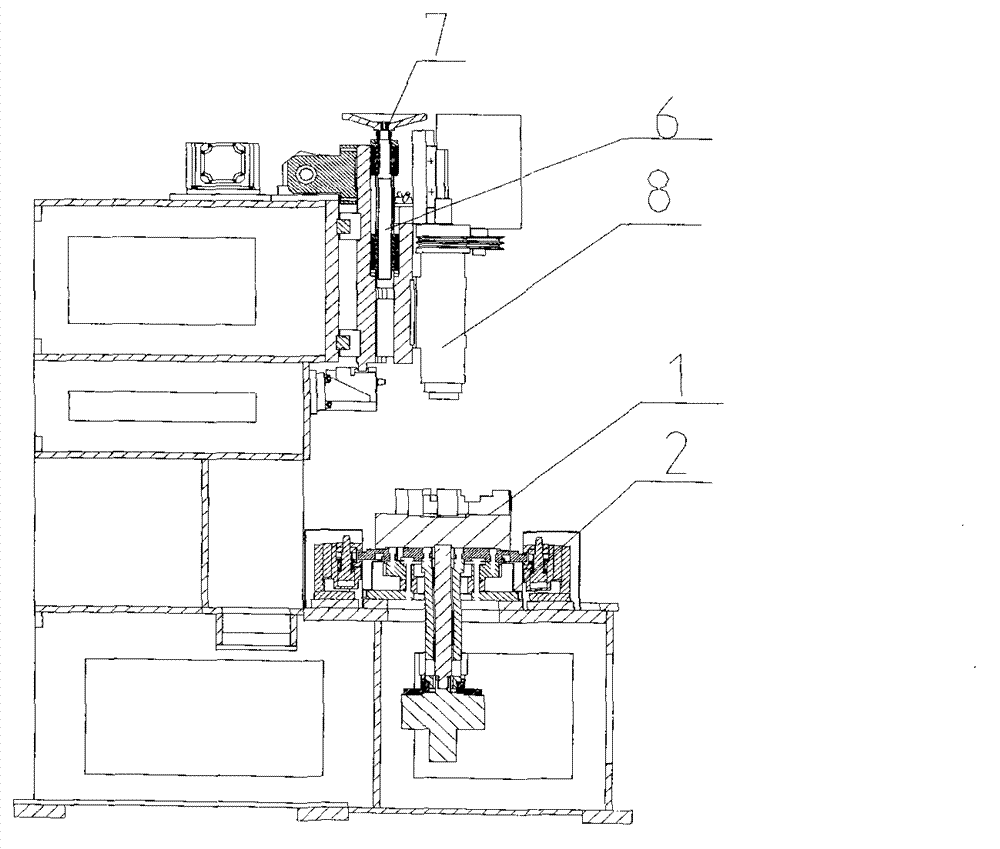

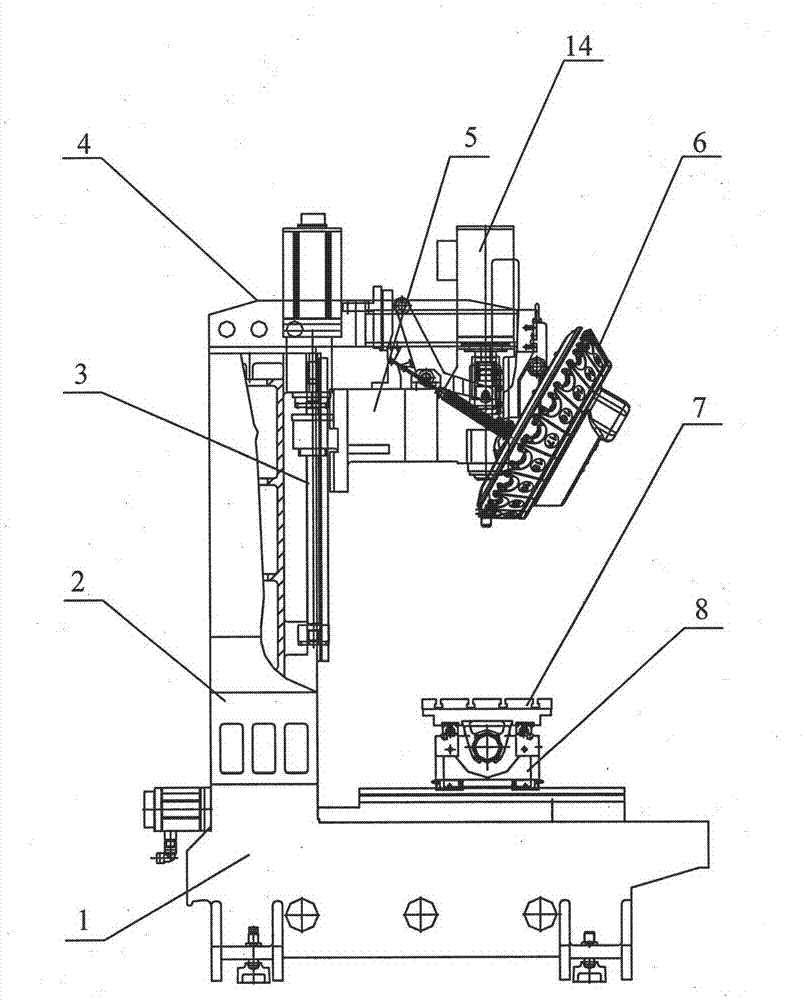

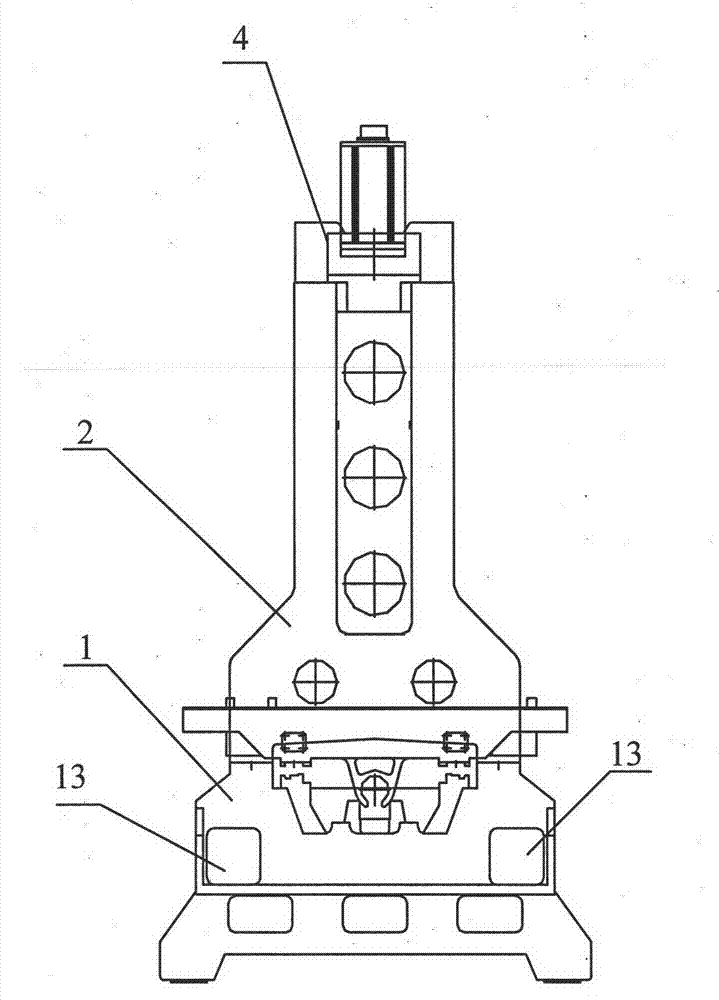

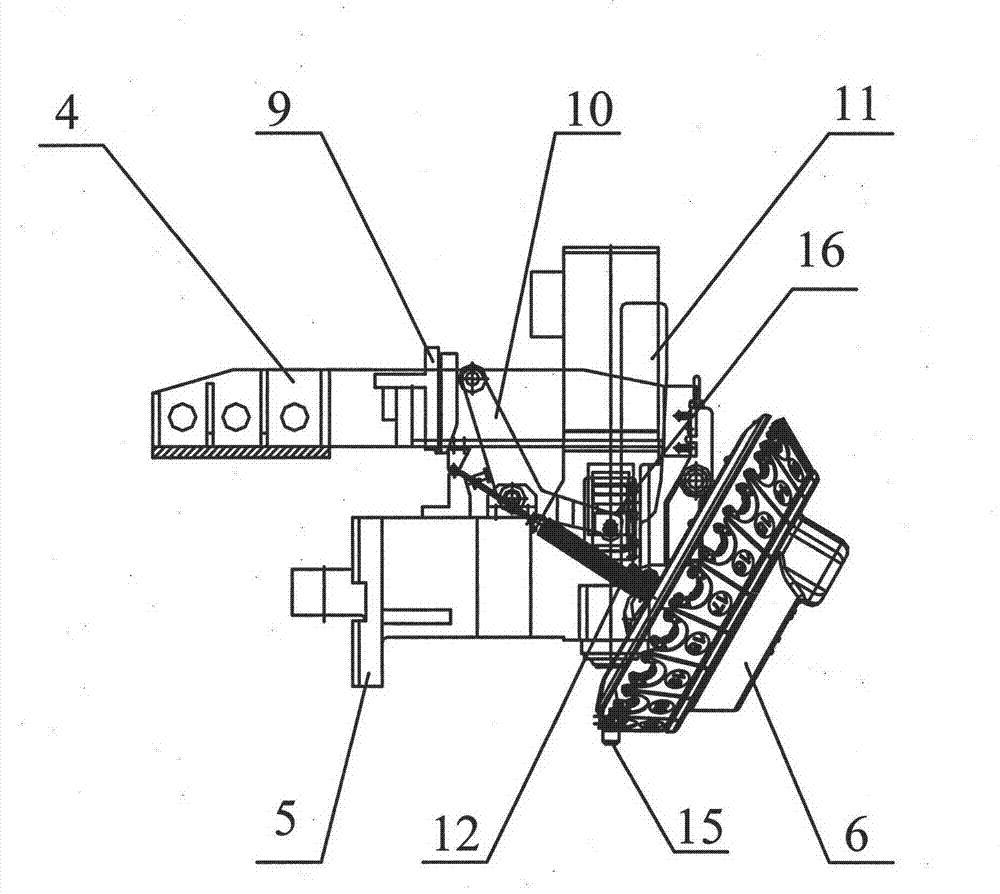

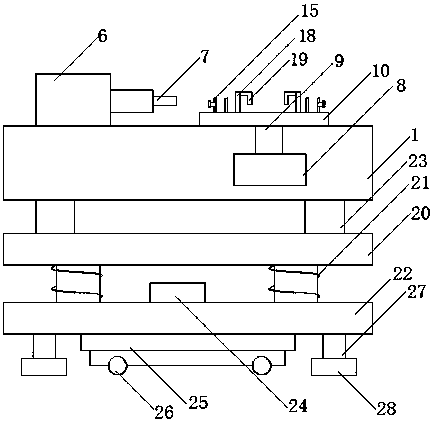

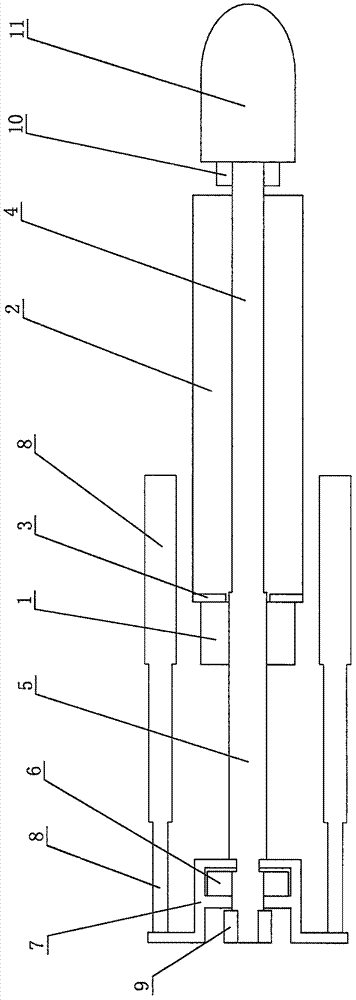

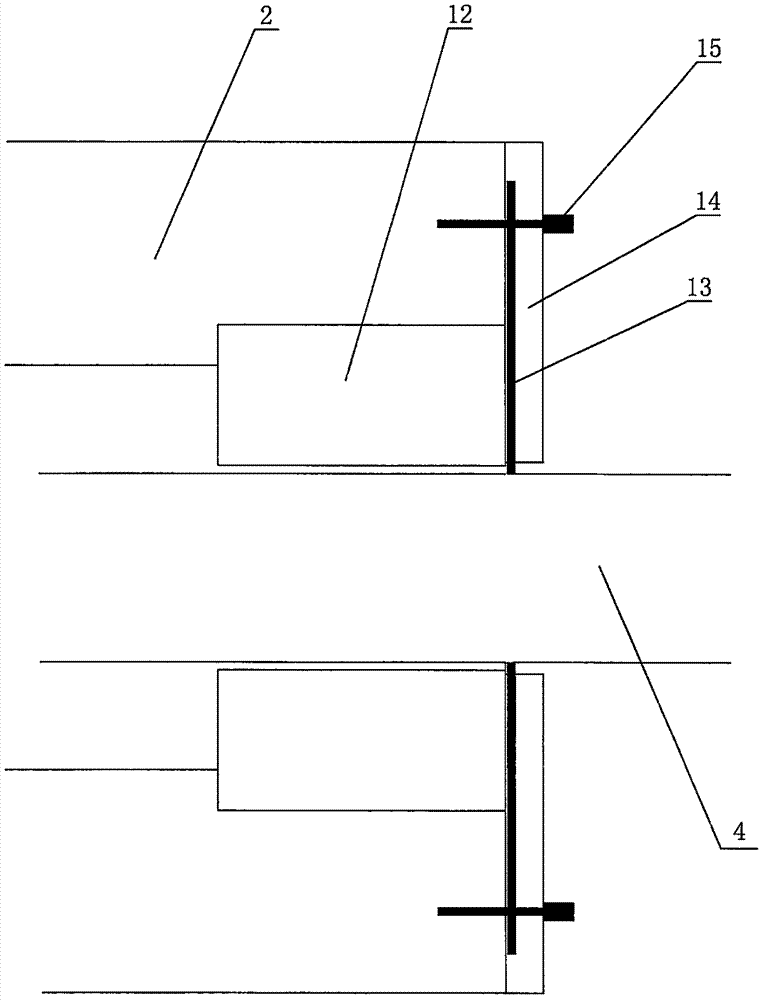

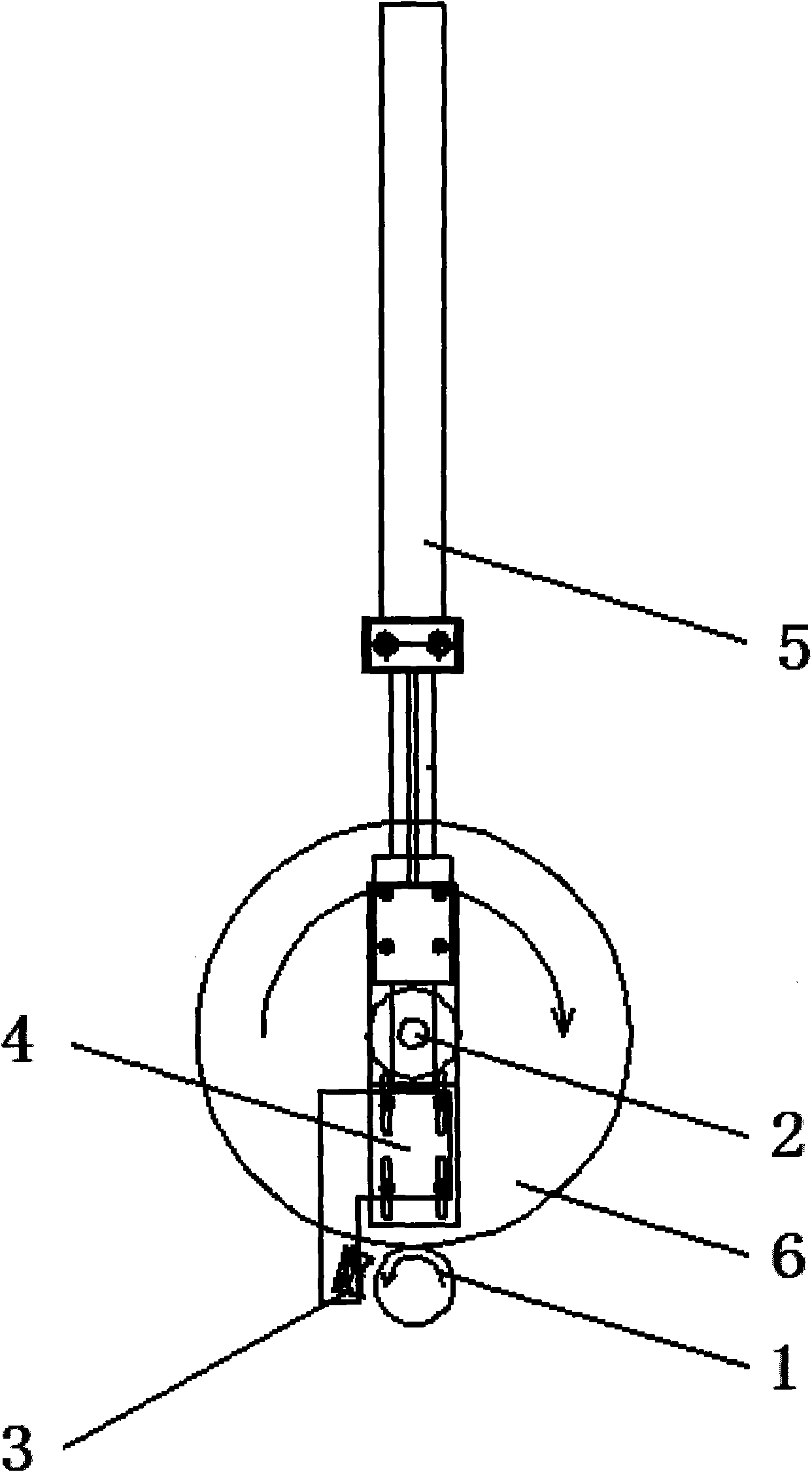

Column mechanism of vertical high speed drilling and milling machining centre for moveable pillar

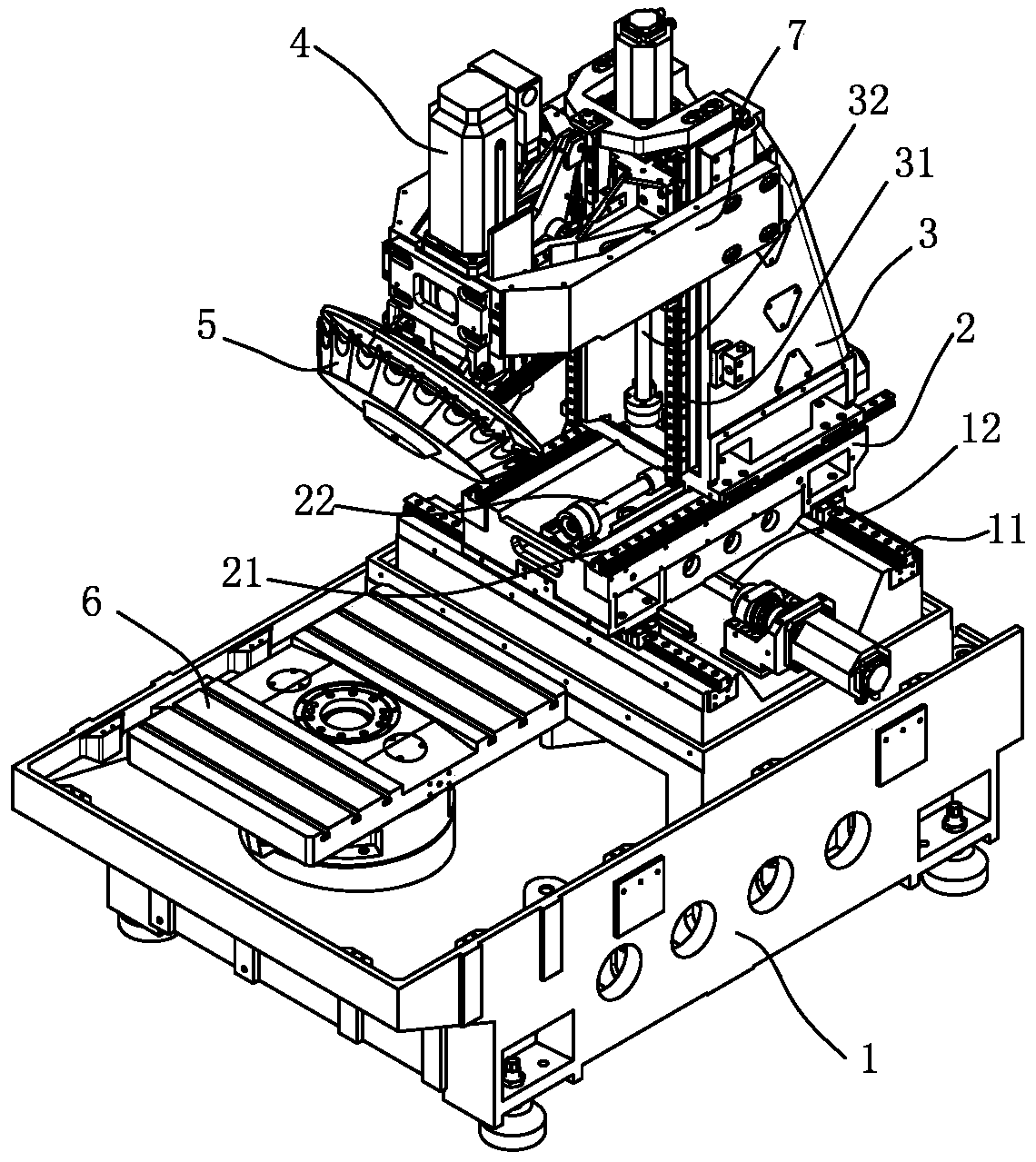

InactiveCN102398159AWeight restrictionExpand the scope of processingLarge fixed membersHigh speed drillingMetallic Lead

The invention discloses a column mechanism of a vertical high speed drilling and milling machining centre for a moveable pillar, comprising a base mechanism (1), a worktable mechanism (2), a sliding saddle mechanism (3), a column mechanism (4) and a main spindle box mechanism (5). The column mechanism (4) is provided with a Z-directional linear guide rail (9) at the front end connected with the main spindle box mechanism (5) and equipped with a servo motor at the same time. The column mechanism (4) is provided with a Y-directional linear guide rail (10) at the bottom end connected with the sliding saddle mechanism (3). The servo motor co-acts with an X-directional lead screw pair (6) and a Y-directional lead screw pair (7) to realize X / Y relative motion between the column mechanism (4) and the sliding saddle mechanism (3) as well as between the sliding saddle mechanism (3) and the base mechanism (1). The invention has the advantages that with design of the moveable pillar, the machining range is expanded, the machining dynamism is guaranteed with fast movement speed reaching 24m / min and machining is not limited by weight of the workpiece.

Owner:SHANDONG PULUTE MACHINE TOOL

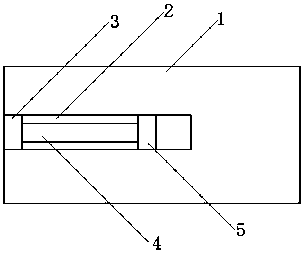

Digital controlled drill

ActiveCN102962488AImprove efficiencyHigh strengthBoring/drilling machinesElectrical controlEngineering

The invention discloses a digital controlled drill, which mainly comprises a host machine, a cooling system, a hydraulic system, an electrical control system and the like. The drill can be used for processing multiple pore diameters, can adapt to a variety of specifications of workpieces, and is double-power head high pressure cooling high speed drilling equipment. The electrical digital control system adopts centralized control; two power heads are not mutually subordinated, are independently separated, and are independent working units in a working process, so that the efficiency is enhanced, and the strength and the stability are increased; an X shaft and a W shaft are digitally controlled, a Z shaft is manually controlled, a workpiece can be accurately located in a central line in a working region, the drilling operation is completed, the feeding speed can be adjusted, when being far away from the workpiece, a drill bit is fed quickly, and when being close to the workpiece, the drill bit is fed slowly; and a lubricating system adopts a dispersion lubricating manner, has a simple structure, and is convenient to use and maintain.

Owner:SHANDONG TARGUS PRECISION MACHINE

Ceramic drill bit for high-speed drilling of composites

The ceramic drill bit has a particular geometry and is very advantageously applicable to the very high-speed drilling of parts made of a composite, especially a carbon-fiber composite having an epoxy resin matrix. The invention also relates to a method for the high-speed drilling of composites.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

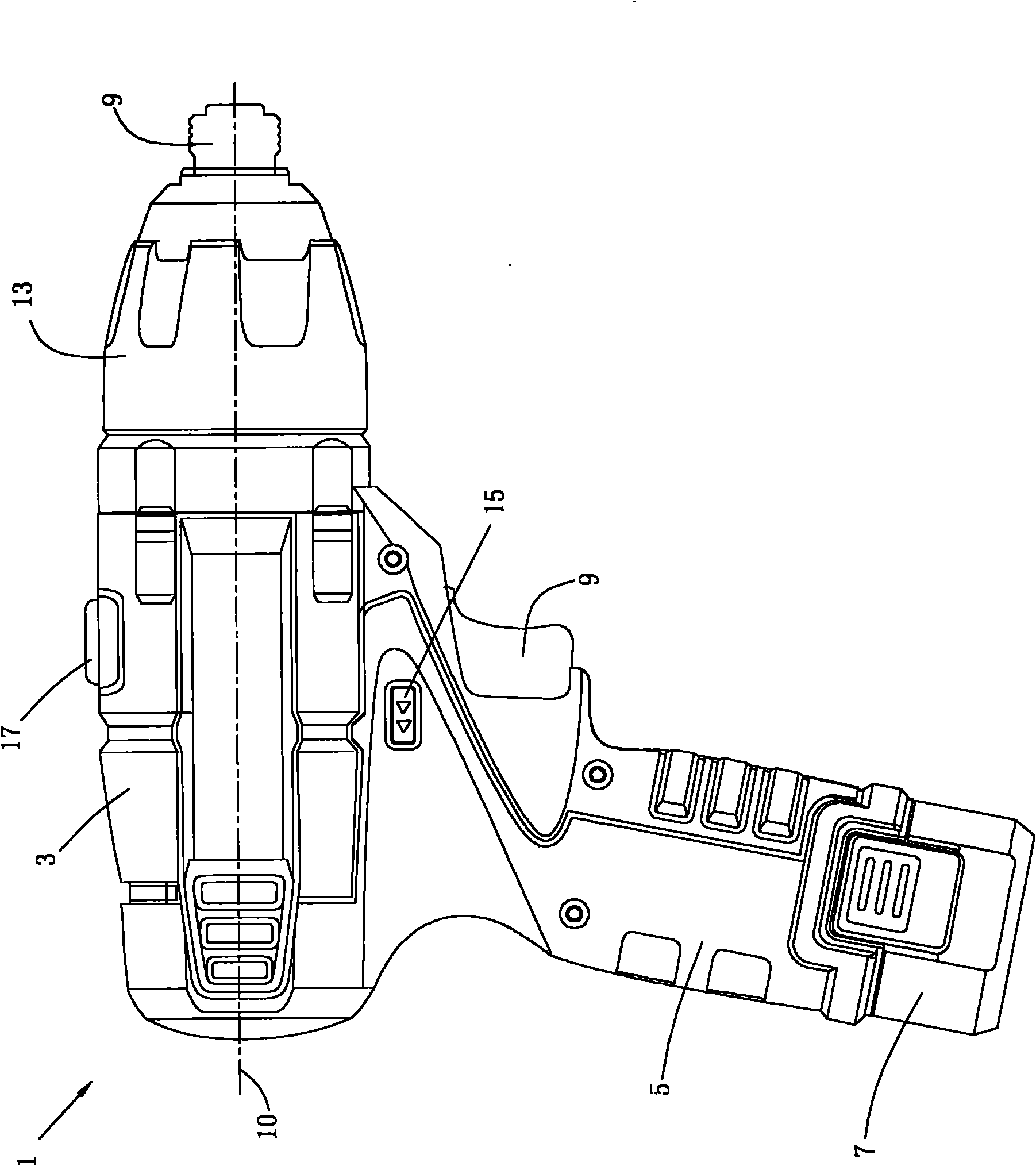

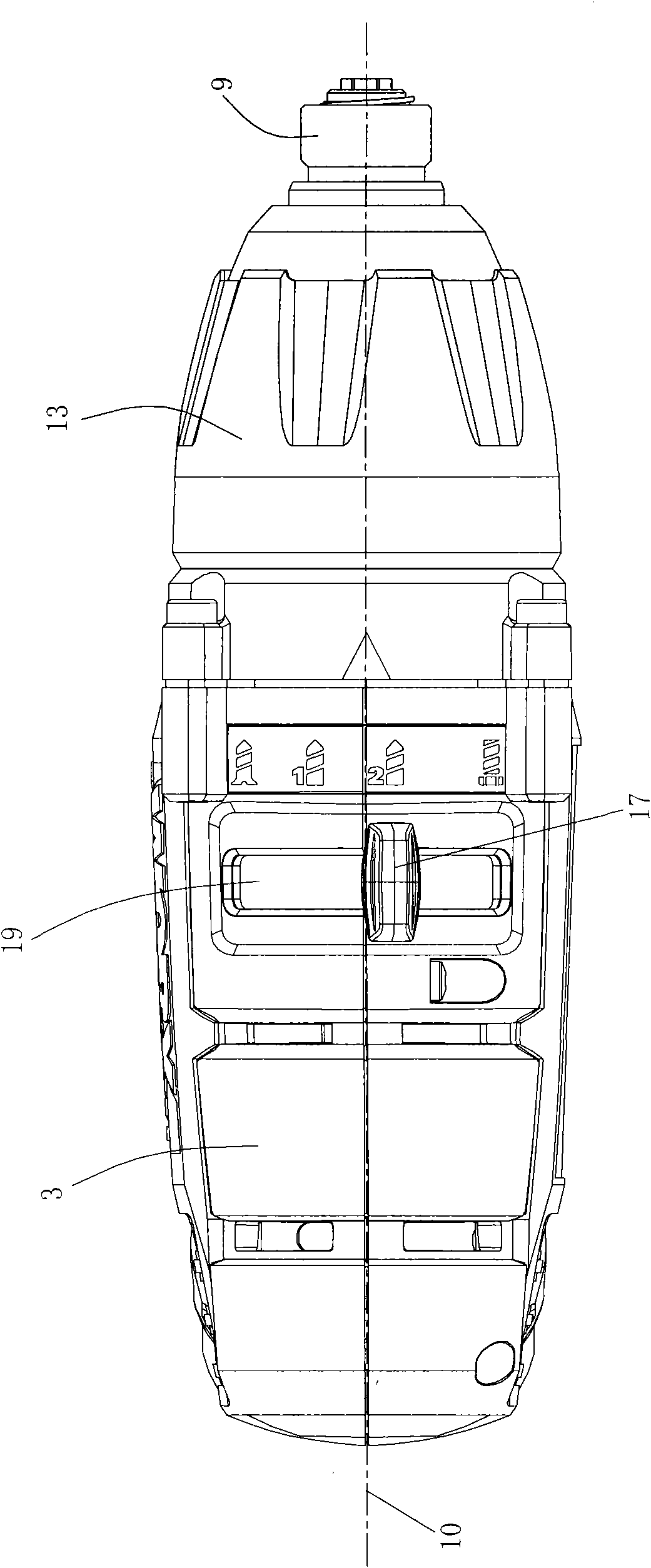

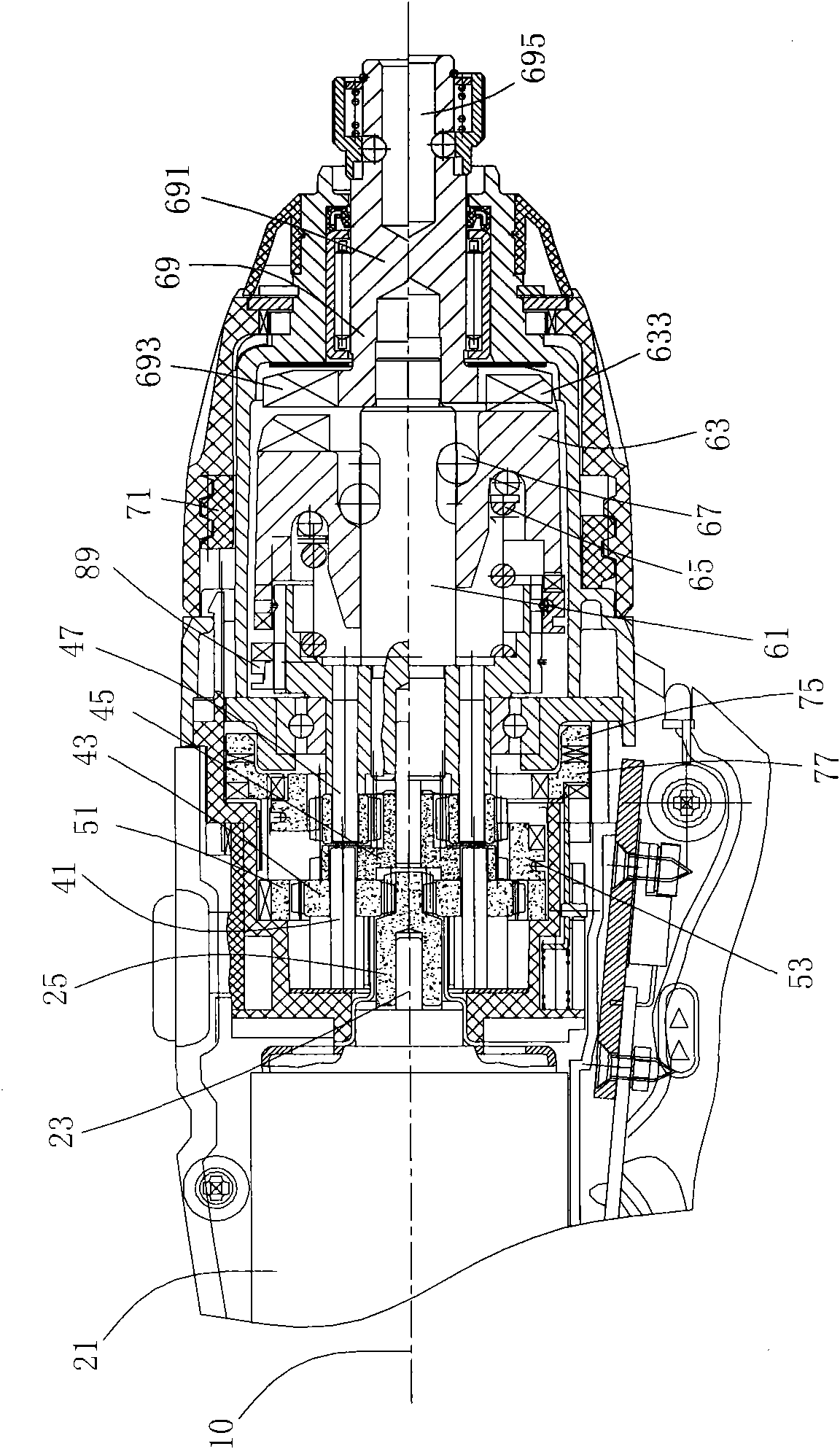

Power tool

ActiveCN102335904ARealize switchingImprove simplicityPortable power-driven toolsLow speedEngineering

The invention relates to a power tool. The power tool comprises a shell, a motor, a planetary gear deceleration system, a power output system, a switching window, and a function switching button; the motor is positioned in the shell and is provided with an output shaft which provides rotary output; the planetary gear deceleration system decelerates the rotary output of the output shaft and then performs rotary output; the power output system transfers the rotary output of the planetary gear deceleration system to a work head; the switching window is positioned on the shell; and at least one part of the function switching button is accommodated in the switching window, and the function switching button moves in the switching window to select an impact wrench function, a high-speed drilling function, a low-speed drilling function and a screwdriver function for the power tool. The function switching button can slide on the shell to realize speed regulation, and the impact wrench function can be switched, so that operation convenience is improved.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

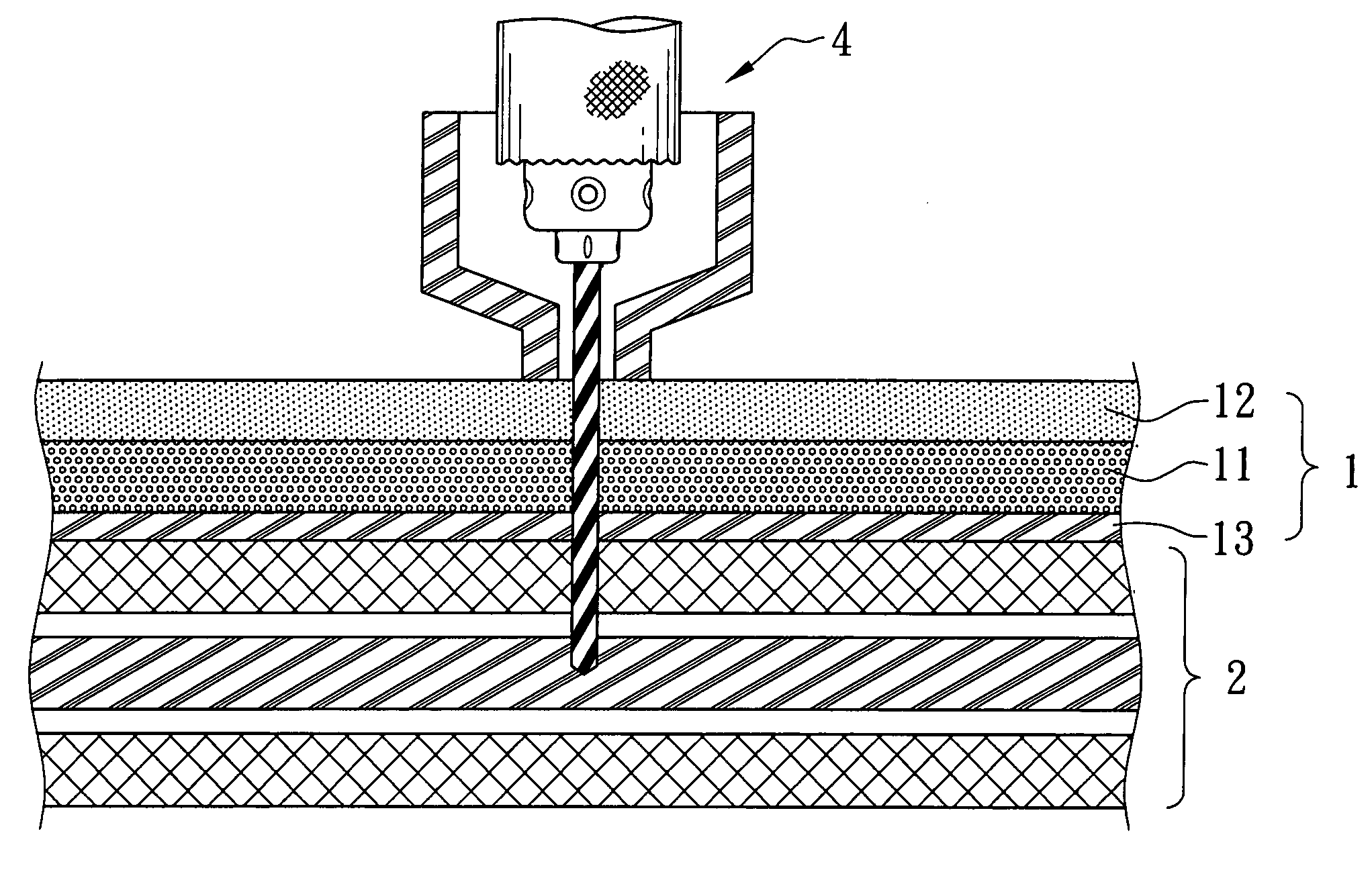

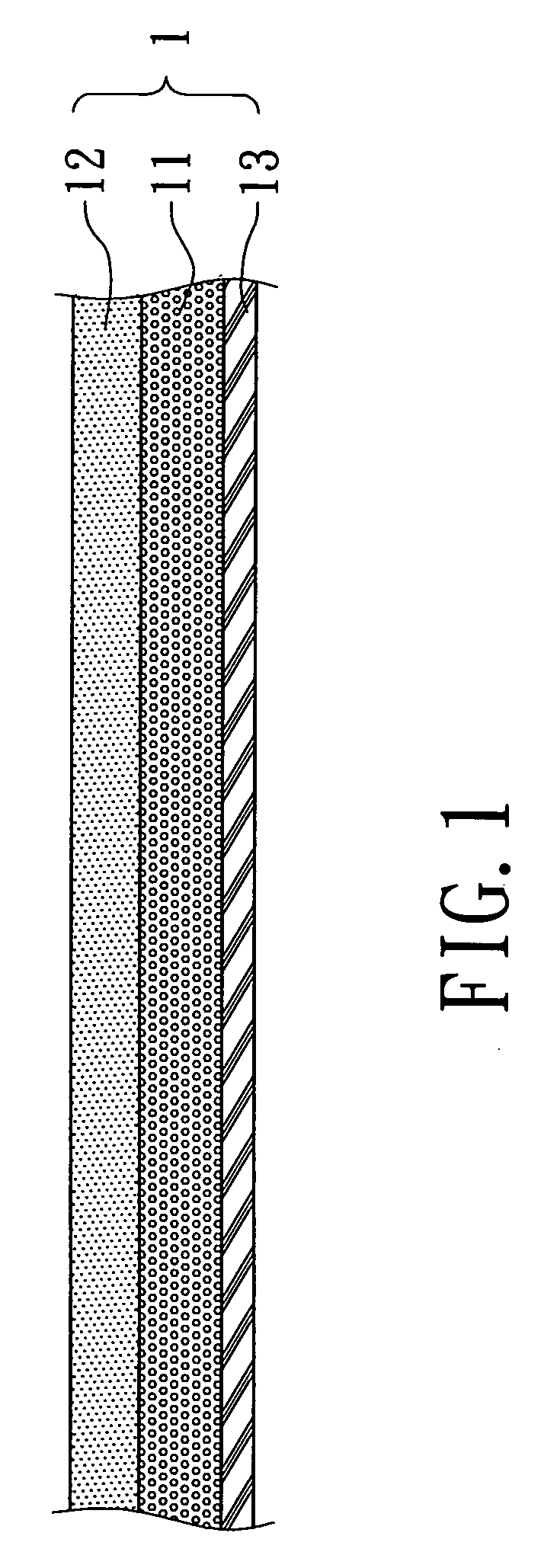

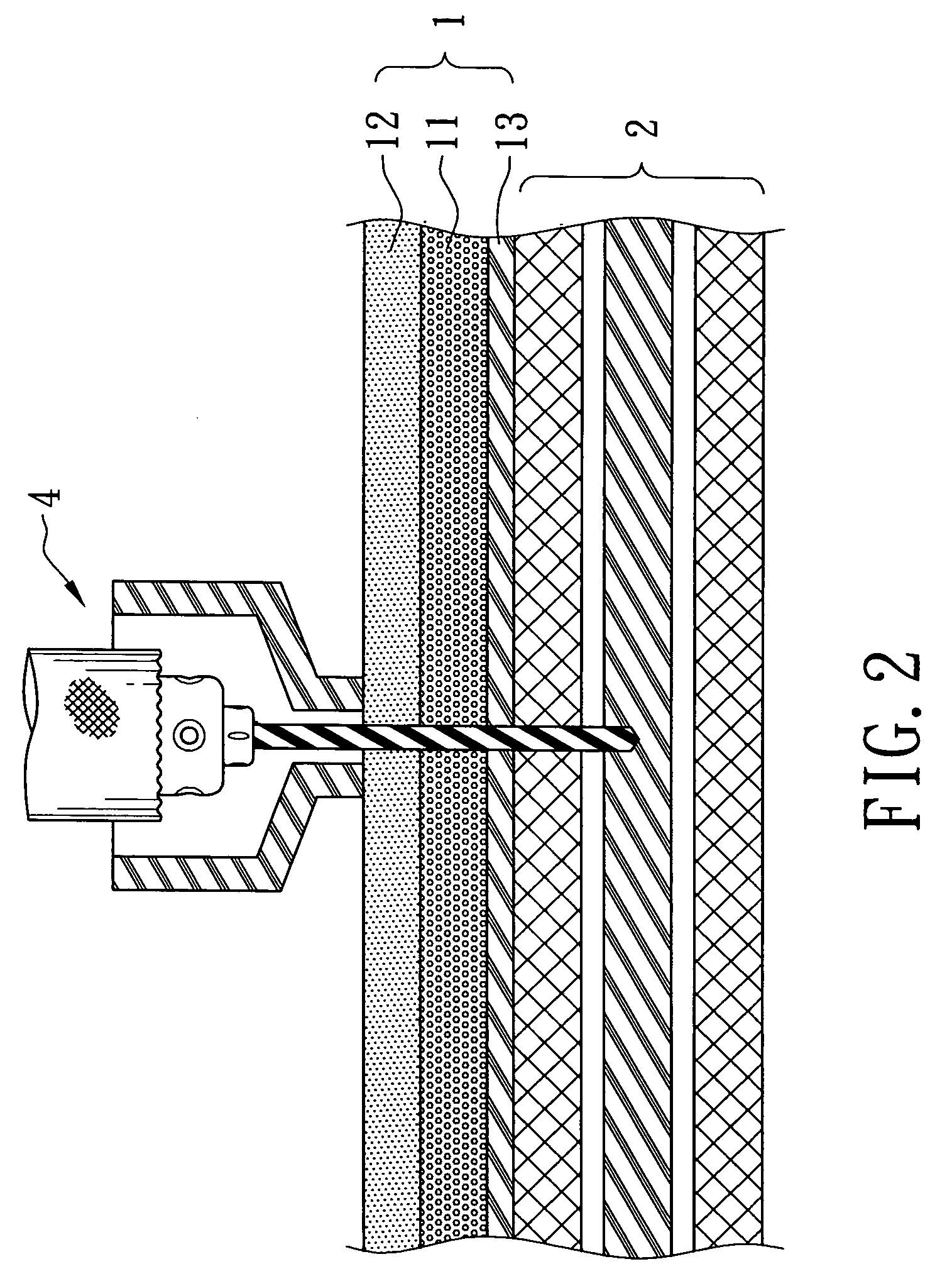

Heat-dissipating accessory plate for high speed drilling

InactiveUS20070231562A1Simple compositionLow costSynthetic resin layered productsPaper coatingNano structuringPrinted circuit board

A heat-dissipating accessory plate for high speed drilling, prepared by adhering a composite material which is a solid state, abrasion-resistant, lubricating coating comprised of nano-structure powder and a high heat-conducting compound, over a supporting material, and then covering a lubricating layer over said composite material, can provide an action of grinding and lubricating a drill bit as well as dissipate heat generated during drilling processing on a printed circuit board.

Owner:UNIPLUS ELECTRONICS

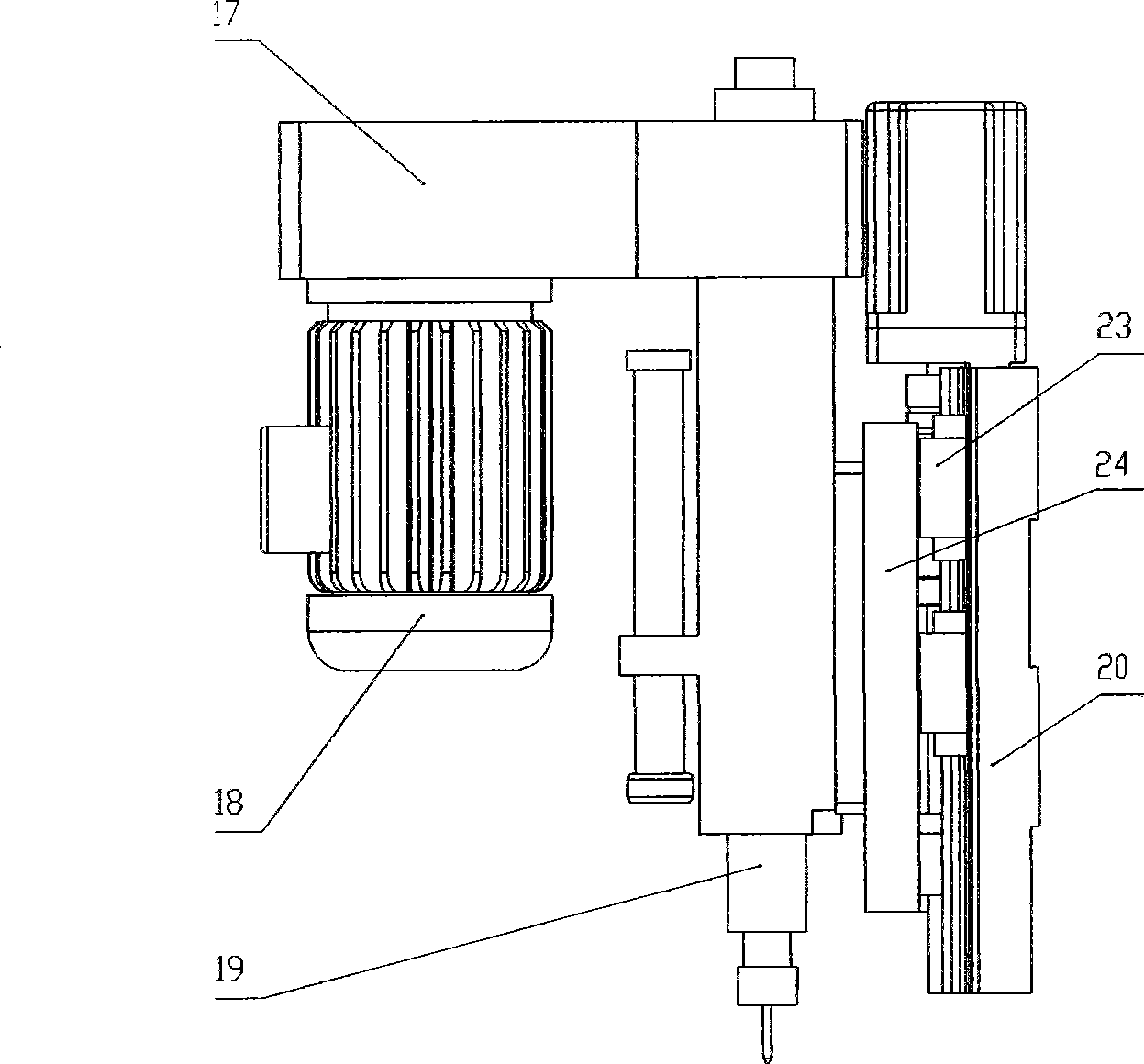

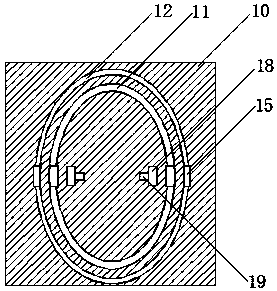

Numerical-controlled high-speed drilling and milling device

InactiveCN103240602AGood workmanshipReduce processing auxiliary timeOther manufacturing equipments/toolsLarge fixed membersNumerical controlBall screw

The invention discloses a numerical-controlled high-speed drilling and milling device comprising a lathe bed, a stand column, a ball screw rod, a tool changer support, a spindle box, a tool changer, a workbench and a carriage. The stand column is fixed on the lathe bed, the ball screw rod is positioned on one side of the stand column, the tool changer support is fixed on the stand column, the spindle box is fixed below the tool changer support, the tool changer is connected with the tool changer support, and the workbench and the carriage are arranged on the lathe bed. The numerical-controlled high-speed drilling and milling device has an optimized structure, production efficiency can be improved and production cost can be greatly reduced.

Owner:上海莱必泰精密机电有限公司

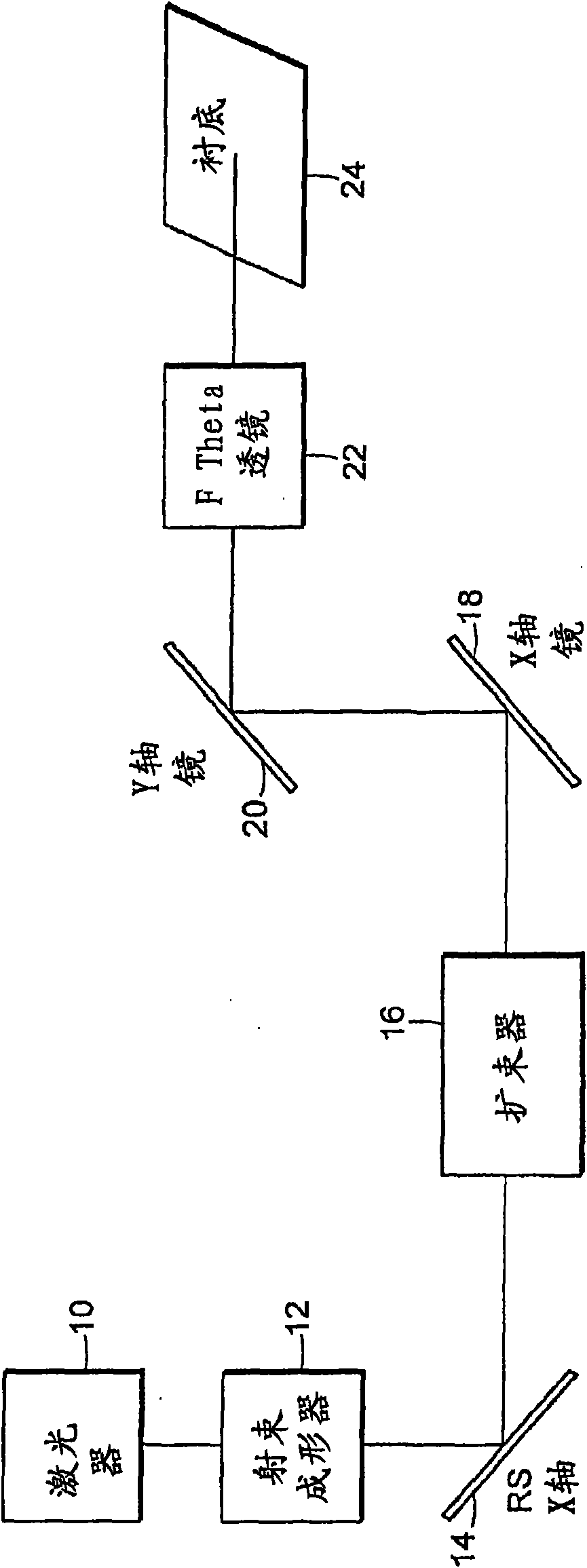

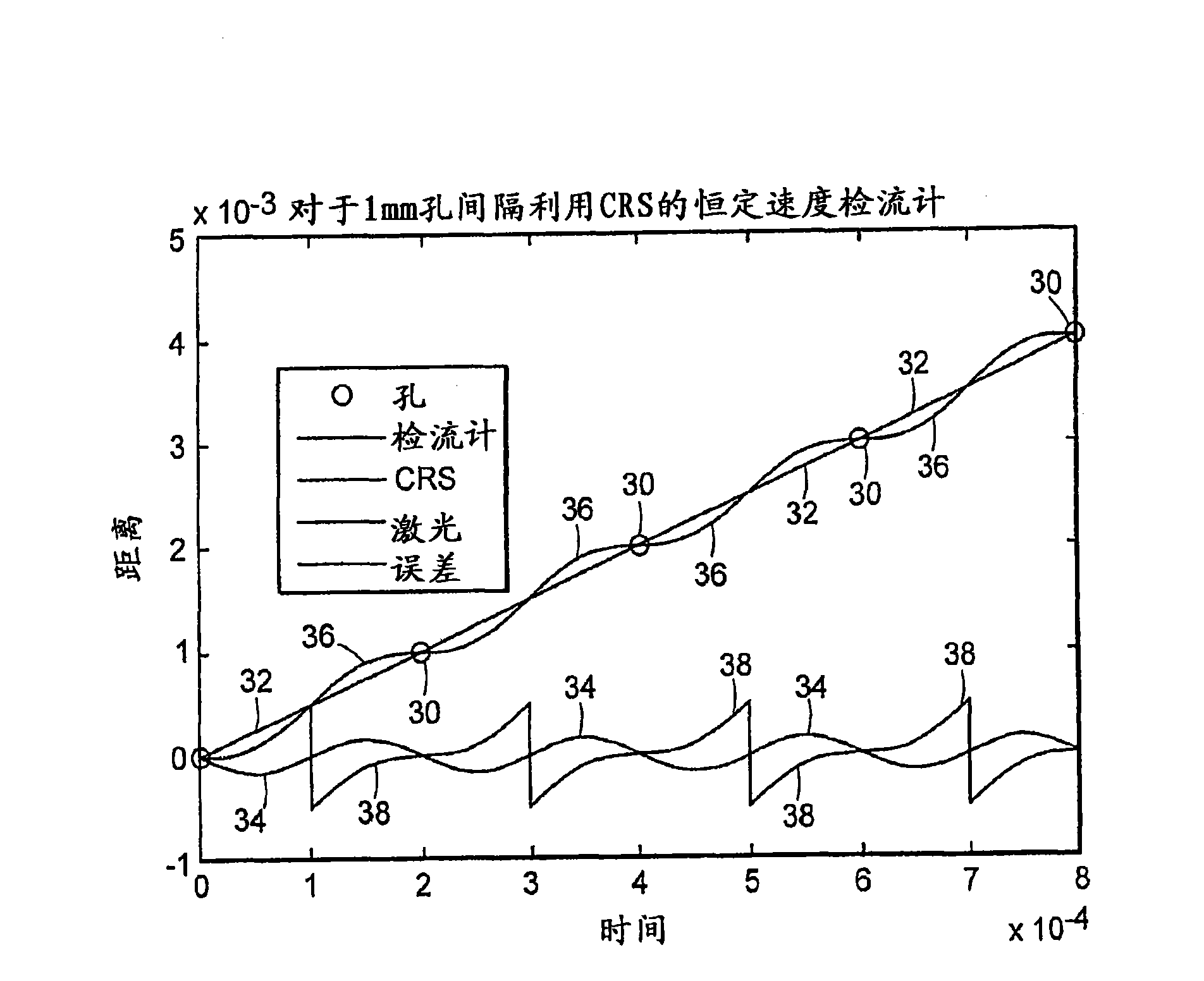

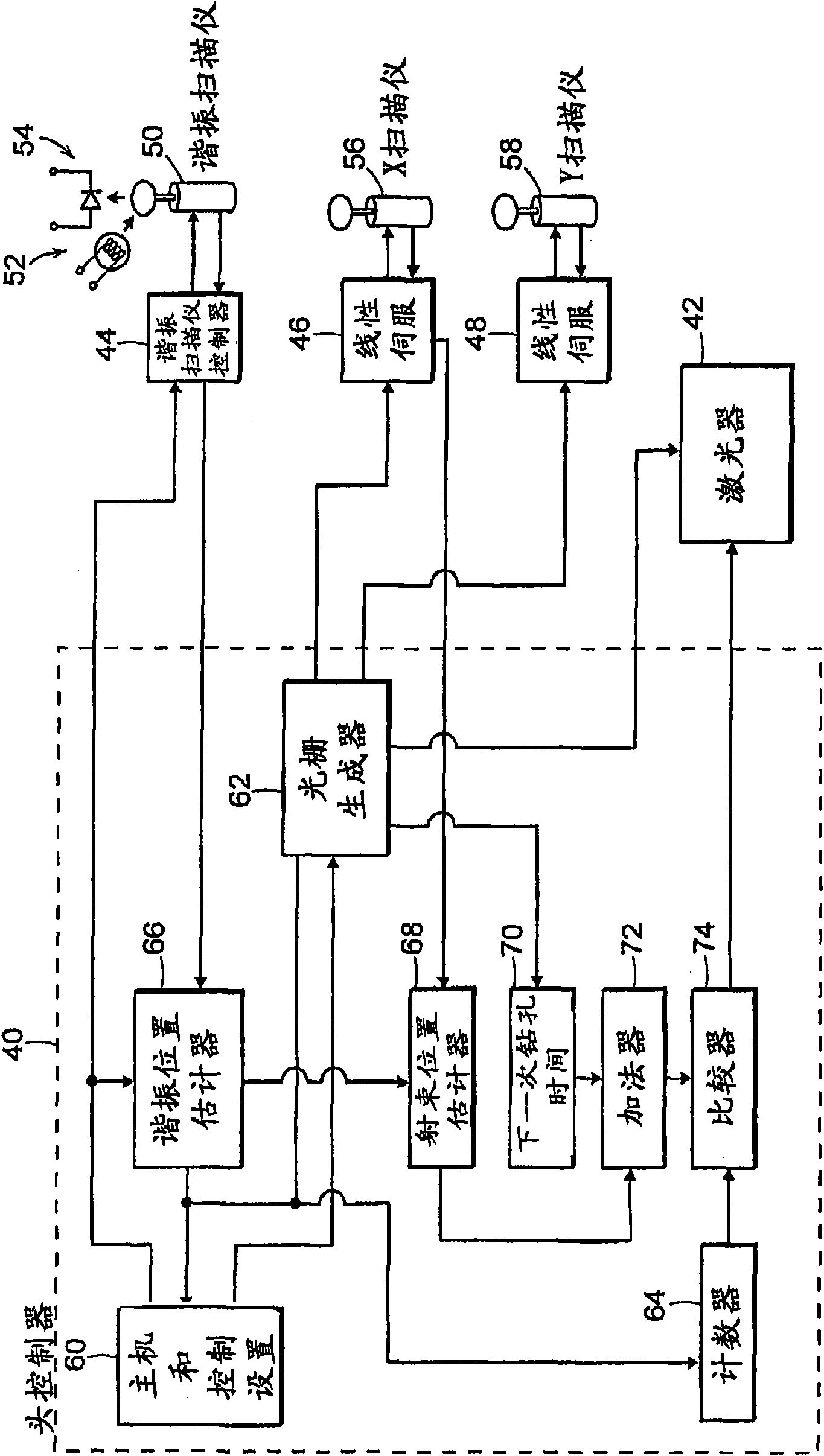

System and method for employing a resonant scanner in an X-Y high speed drilling system

A laser processing system is disclosed for providing a relatively small velocity of a laser beam at target location while at least one scanner scans at a relatively larger velocity. The system includes a laser source, a first scanning unit, a beam expander, a second scanning unit and focusing optics. The laser source is for providing a pulsed laser output having at least one beam with a beam dimension. The first scanning unit is for scanning the laser output in a first direction along a first axis at the target location. The beam expander is for receiving the laser output and for modifying a beam diameter of the laser output and providing a modified laser output. The second scanning unit is for scanning the modified laser output from the beam expander in a second direction along the first axis at the target location. The second direction is substantially opposite to the first direction along the first axis such that a net velocity of the modified laser output along the first axis at the target location may be made to be effectively zero during a laser pulse. The focusing optics is for focusing the modified laser output toward the target location.

Owner:诺万达公司

Indexable bit

InactiveCN103464811ASimple structureImprove cooling effectTransportation and packagingTrepanning drillsCooling effectEngineering

The invention relates to an indexable bit, and belongs to the technical field of mechanical machining tools. A bit body comprises a drill handle and a chip rod; the lower portion of the drill handle is provided with a holding table, a chip groove is formed on the chip rod, and the end of the chip rod is fixed with a indexable blade through a screw; the drill handle is provided with a liquid inlet, the chip rod is provided with a liquid outlet, a liquid channel is formed in the bit body, and the liquid inlet and the liquid outlet are communicated through the liquid channel; an annular sleeve is sleeved on the liquid inlet above the holding table on the upper portion of the drill handle, the annular sleeve is located on the holding table, and a liquid storing groove and a seal groove are formed in the inner hole of the annular sleeve; the liquid storing groove is located in the position of the liquid inlet, a liquid inlet port is formed on the outer edge and is provided with a liquid inlet hole communicated with the liquid storing groove, and a seal ring is mounted in the seal groove. The indexable bit adopts inner-cooling structure, is reasonable in design, simple in structure, good in cooling effect and convenient to use, and adaptable to high-speed drilling.

Owner:DANYANG CITY EAGLE TOOLS

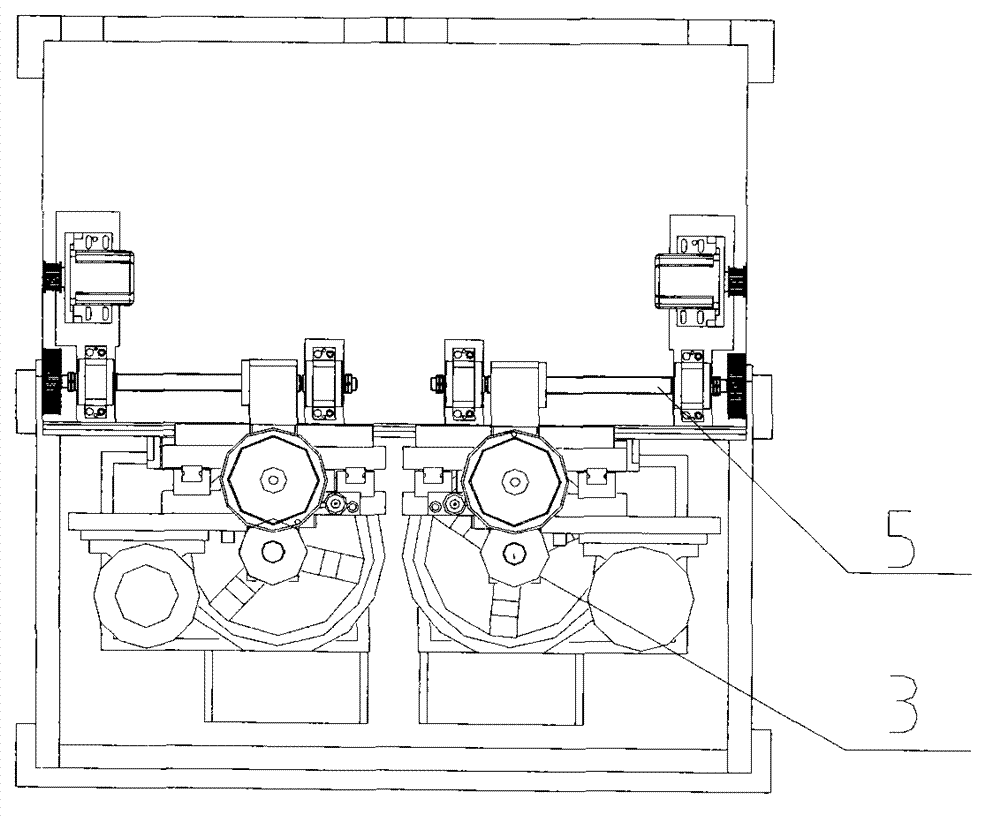

High-speed drilling and milling center

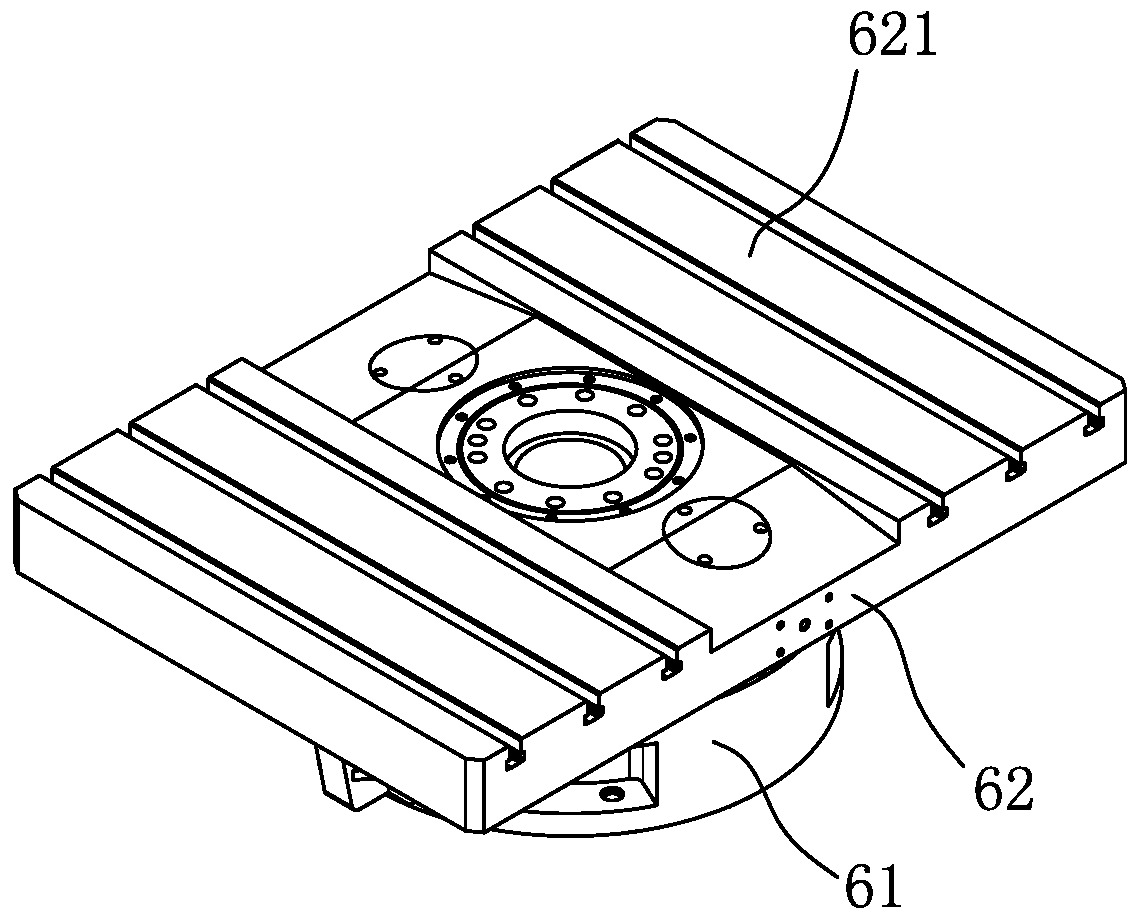

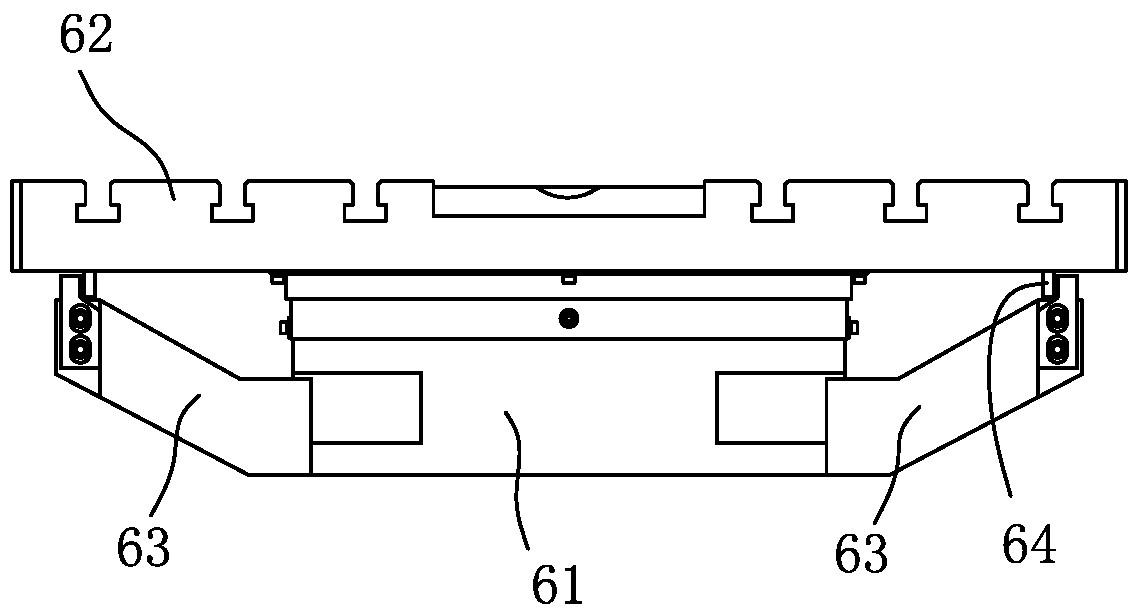

InactiveCN105500038AQuick responseReduce distortionFeeding apparatusLarge fixed membersEngineeringMachine tool

The invention provides a high-speed drilling and milling center which comprises a spindle box, a pallet changer, a base provided with an X-direction guide rail, a carriage provided with a Y-direction guide rail and a stand column provided with a Z-direction guide rail. The pallet changer comprises a worktable base and a worktable arranged on the upper portion of the worktable base in a rotating mode, tabletops are arranged at the front end and the rear end of the worktable, and the tabletop at the rear end of the worktable is arranged below the spindle box. The rotating worktable is adopted, a workpiece can be machined at one end, a workpiece can be clamped at the other end, and thus assisting time is shortened; the worktable is connected with a direct-driving type motor through a connecting disc, the speed is high accordingly, the assisting time of a machine tool is shortened, and thus the machining efficiency of the machine tool is greatly improved; a supporting frame on the worktable base can support the stretching-out end of the worktable, deformation of the worktable is relieved, and the weight of the workpiece which can be machined by the worktable is increased.

Owner:嘉泰数控科技股份公司

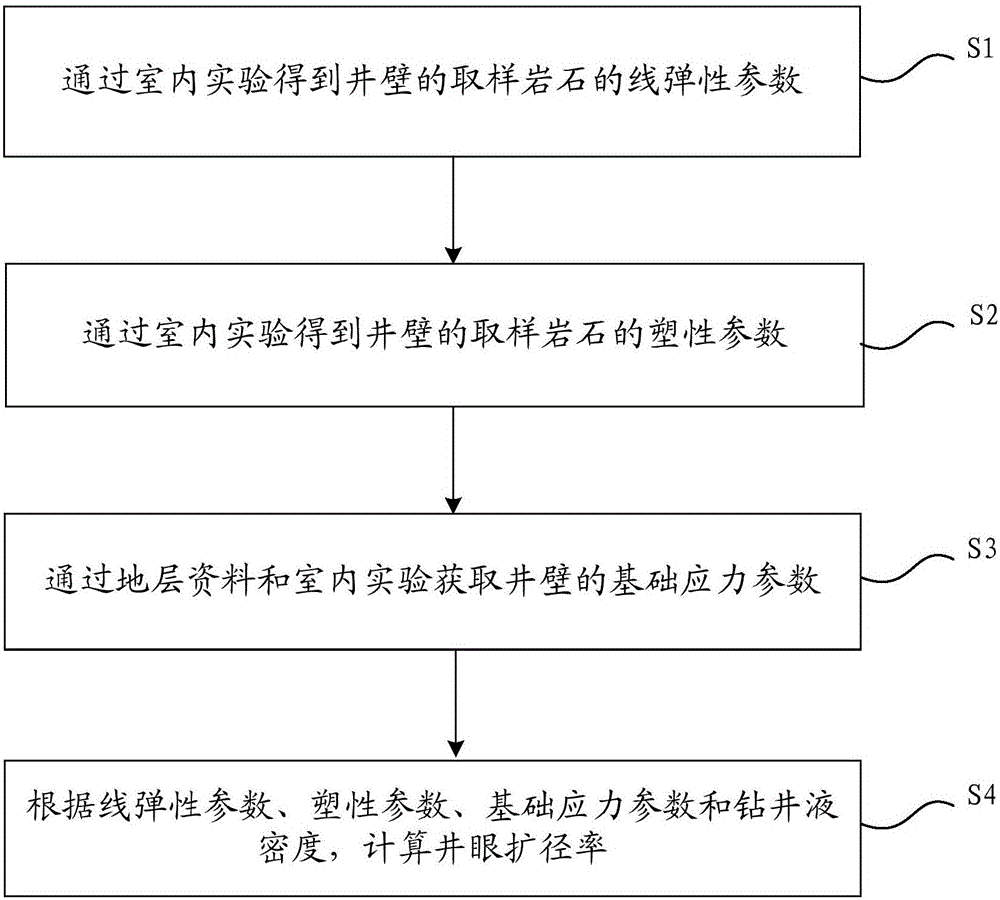

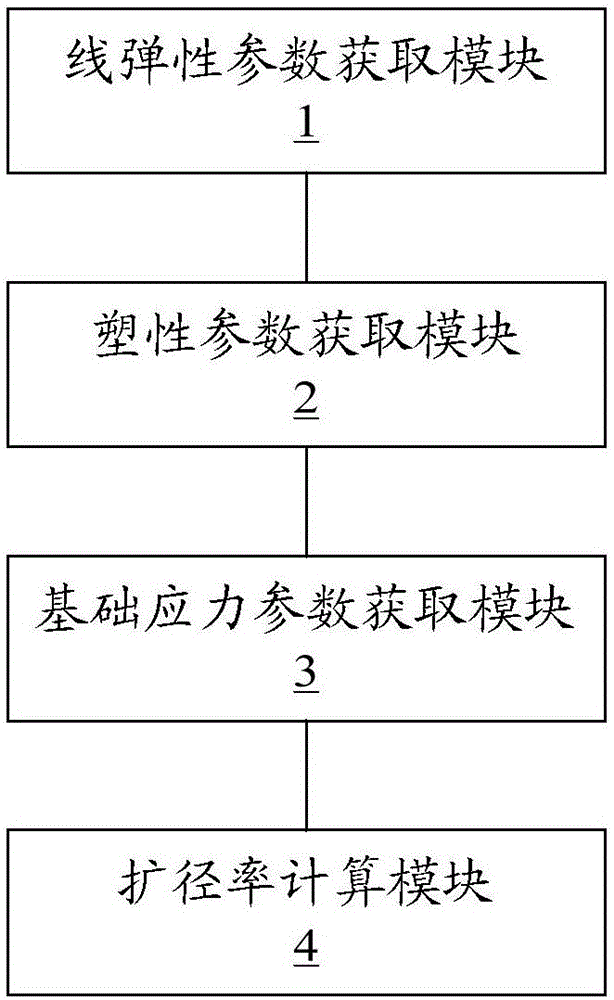

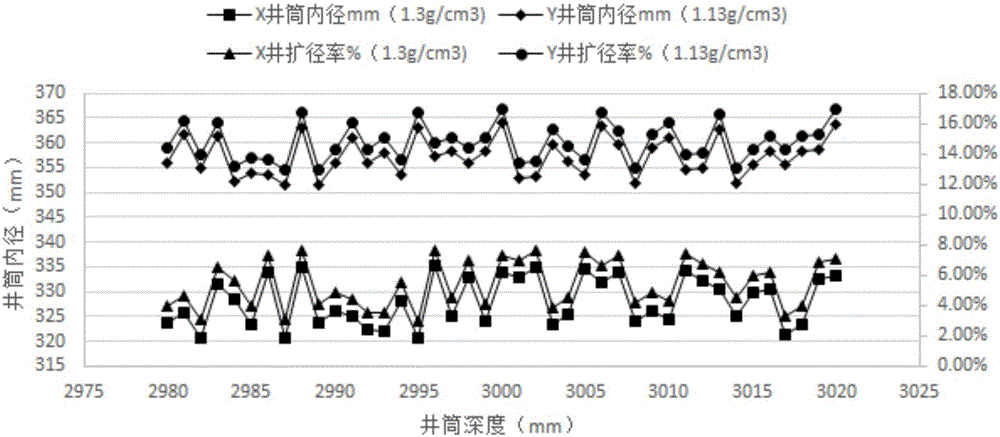

Borehole diameter expanding ratio calculation method and device

ActiveCN106682384ADensity selection and allocationSpecial data processing applicationsInformaticsWell drillingHigh speed drilling

The invention provides a borehole diameter expanding ratio calculation method and device. The method includes the steps: acquiring linear elastic parameters of sampling rocks of a well wall by indoor experiments; acquiring plastic parameters of the sampling rocks of the well wall by the indoor experiments; acquiring basic stress parameters of the well wall by stratum data and the indoor experiments; calculating borehole diameter expanding ratio according to the linear elastic parameters, the plastic parameters, the basic stress parameters and drilling fluid density. The borehole diameter expanding ratio of a bored well can be obtained under the condition of given drilling fluid density, so that reasonable drilling fluid density can be accurately selected and set, and technical support is provided for high-quality and high-speed drilling.

Owner:PETROCHINA CO LTD

Photosensitive coating resin of auxiliary plates for drilling and application thereof

A photosensitive resin composition and auxiliary plates for drilling are introduced. The auxiliary plates are made by coating the photosensitive resin composition on aluminum foil and photocuring the coated resin to make the resin bonded on the aluminum foil. The resin composition comprises a first polymer formed by the reaction of 1,2,4,5-pyromellitic dianhydride and polyetheramine; and a second polymer formed by the reaction of polyetheramine and vinyl chloride, wherein the second polymer is a photosensitive polymer. The novel resin composition provided by the present invention can be coated on drilling auxiliary plates. When the drilling auxiliary plates coated with the resin composition are used in a drilling process, it can avoid the coated resin being cracked due to the heat caused by friction of high speed drilling, so it can further enhance the stability, accuracy, and precision of drilling.

Owner:GTA ELECTRONICS CO LTD

Drilling machine for battledore

ActiveCN103212733AControl workReduced speed movementPrecision positioning equipmentPositioning apparatusProduction rateEngineering

The invention belongs to the field of production equipment for a battledore, and particularly relates to the field of equipment for production and machining of side holes of the battledore. A drilling machine for the battledore comprises a battledore clamping device, a drilling device and a hole spacing controlling device, wherein the battledore clamping device is arranged on a working table, and the drilling device and the hole spacing controlling device are connected with the battledore clamping device. The drilling device comprises a high-speed drilling machine which is provided with a high-speed drilling head facing toward the battledore clamping device. The high-speed drilling machine is provided with a first connecting rod, a clutch cam plate is connected at the end, far away from the high-speed drilling machine, of the first connecting rod, and the clutch cam plate is connected with the hole spacing controlling device. The battledore clamping device comprises a gear plate which is installed on the working table. The gear plate is provided with an interval displacement expansion device. The drilling machine for the battledore can achieve that one-step installation of the battledore can achieve machining of all the side holes of the battledore, and avoid the hole spacing error caused by multiple installation and clamping. Meanwhile, the drilling efficiency is high, and a production rate is improved greatly.

Owner:舒城县周瑜体育用品有限公司

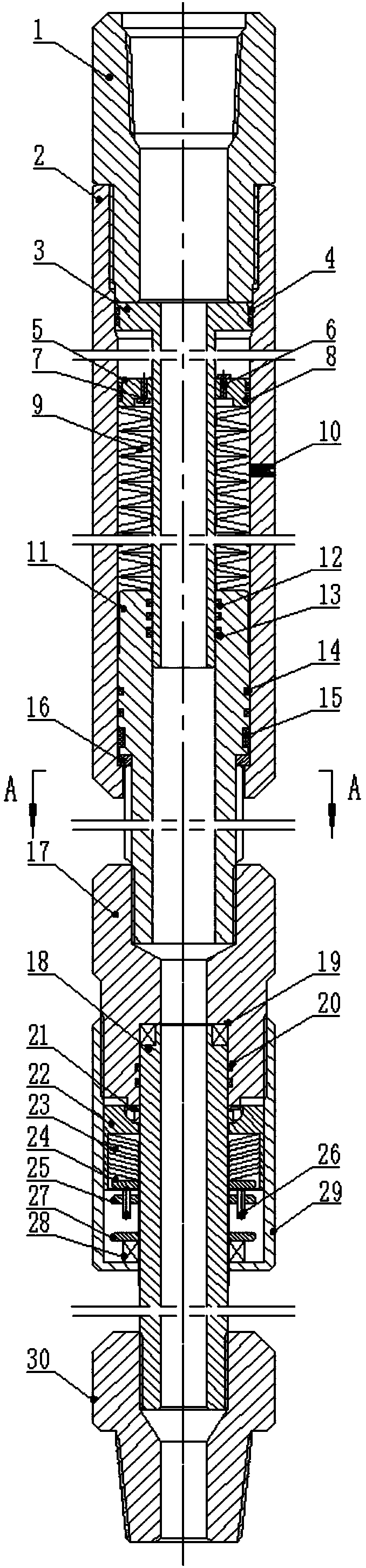

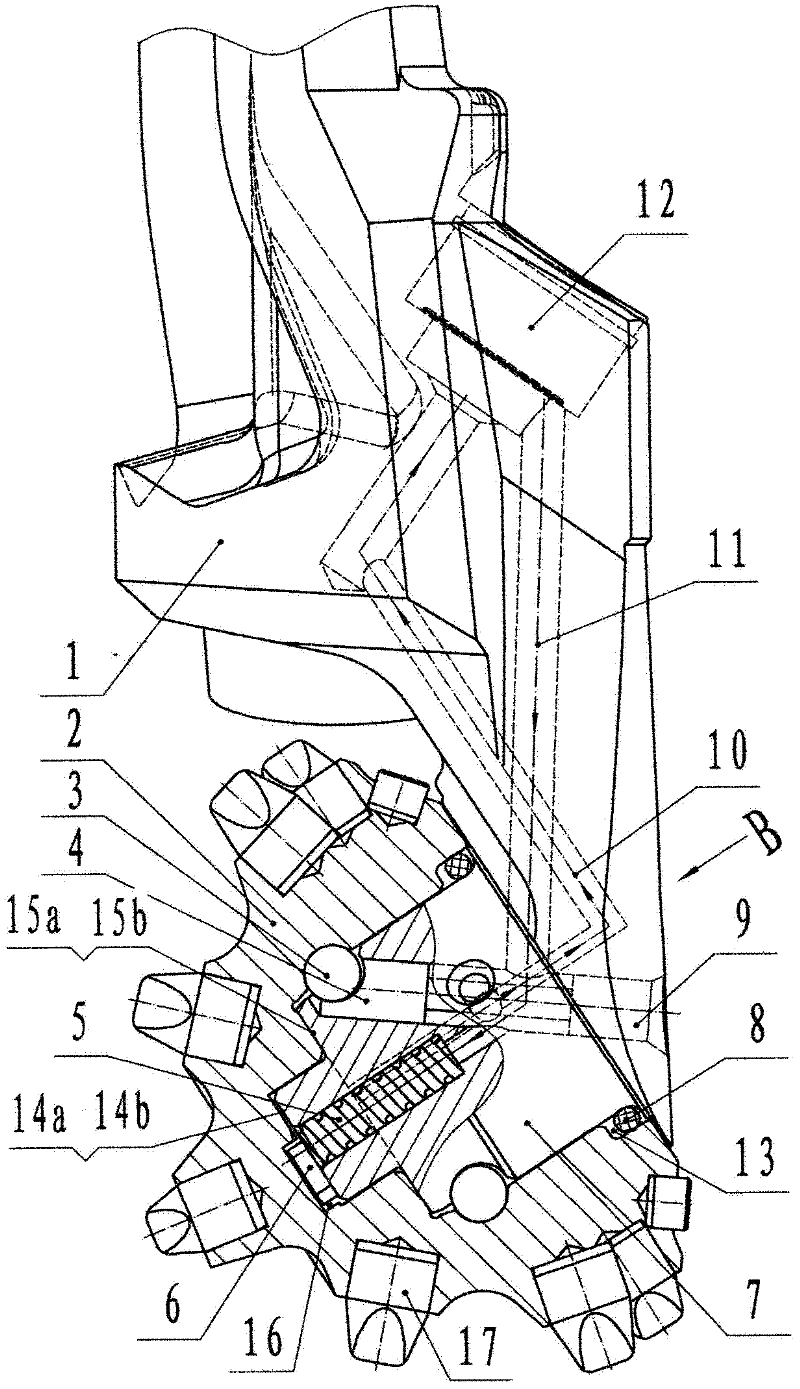

Rock burst drilling device based on pressurizer and rock breaking method

ActiveCN106194029ALower requirementImprove rock breaking efficiencyLiquid/gas jet drillingUpper jointEngineering

The invention relates to drilling engineering technologies, and provides a rock burst drilling device based on a pressurizer. The rock burst drilling device based on the pressurizer comprises a pressurizer shell and an upper joint. The pressurizer shell is provided with a normal pressure pipe and a high pressure pipe. An upper valve plate, a lower valve plate and a driving part are arranged in the pressurizer shell. A first through hole is vertically formed in the upper valve plate, and a second through hole and a third through hole are formed in the lower valve plate. A piston and a piston rod are further arranged inside the pressurizer shell. A first chamber is formed between the piston and the lower valve plate. A second chamber is formed between the piston and the pressurizer shell. A third chamber is formed between the piston rod and the high pressure pipe. A first control valve is arranged inside the high pressure pipe. The third chamber communicates with the outer side of the pressurizer shell through a second control valve. The invention further provides a rock breaking method involving the rock burst drilling device. Water bombs are jet periodically at the position of the high pressure pipe so as to bombard rock, the rock breaking efficiency is improved through a rock burst inducing mode, the purpose of high-speed drilling can be achieved, and the reliability and service life of a drill bit can be guaranteed.

Owner:成都欧维恩博石油科技有限公司

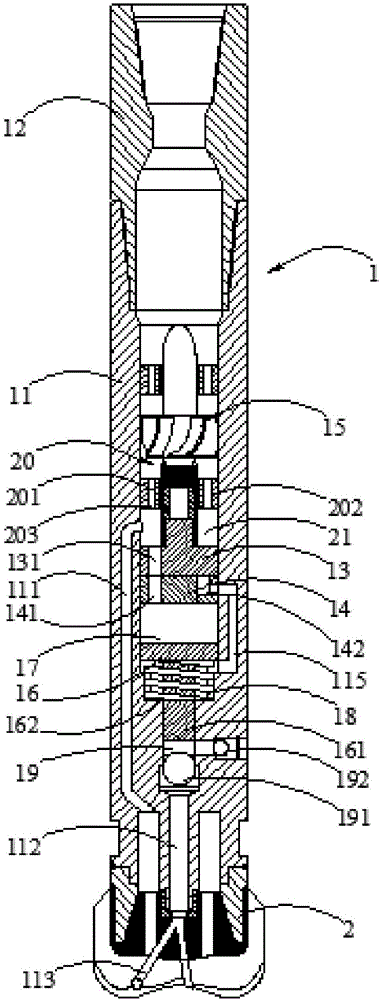

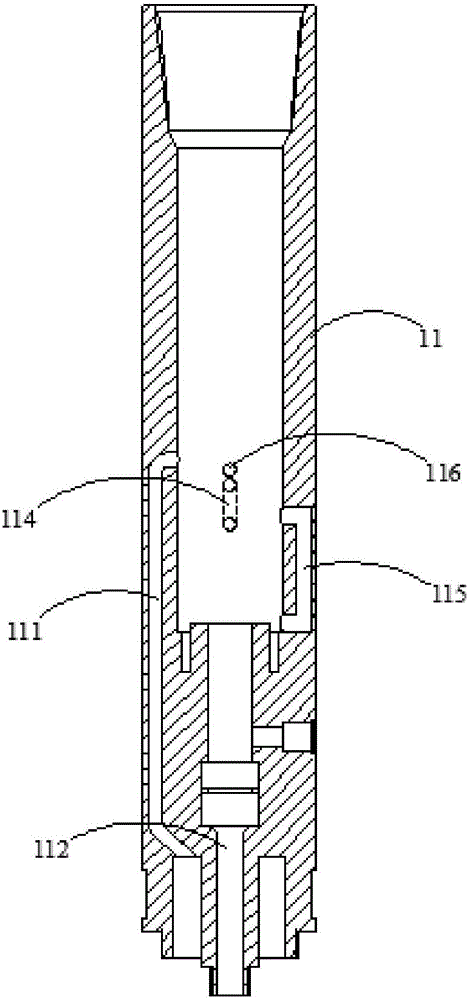

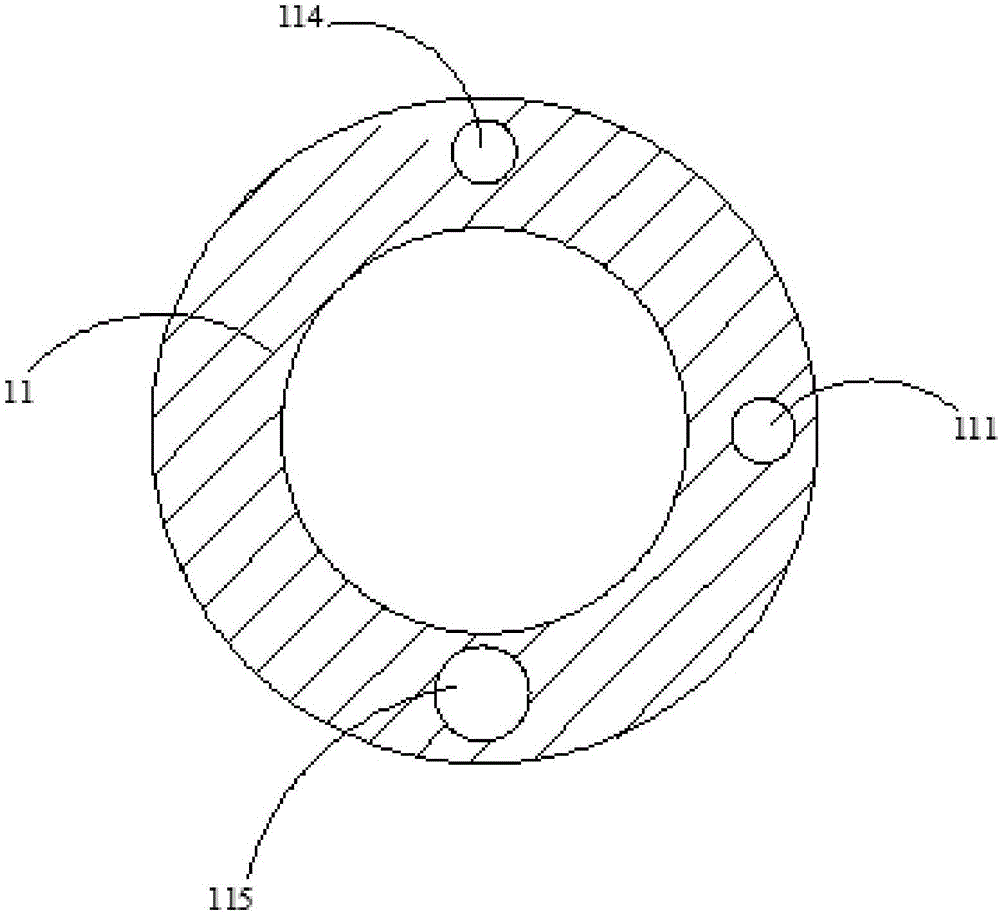

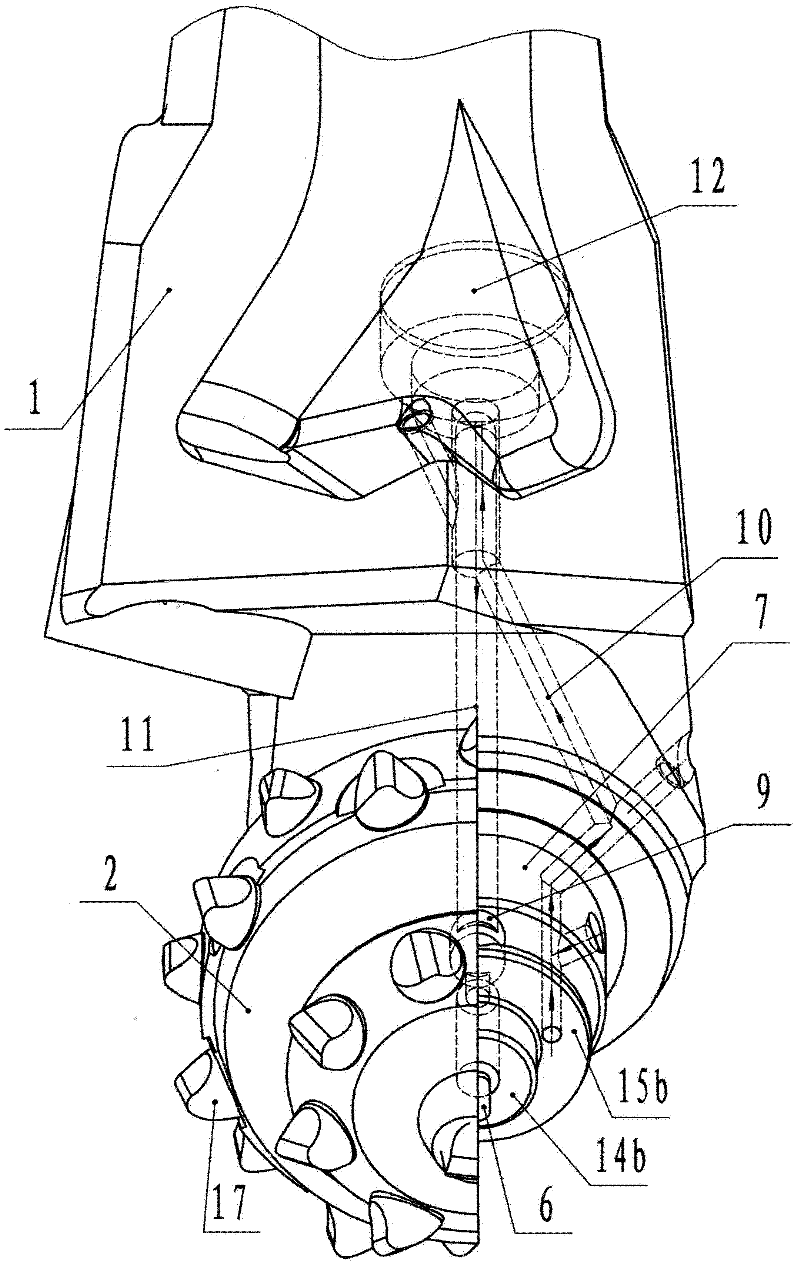

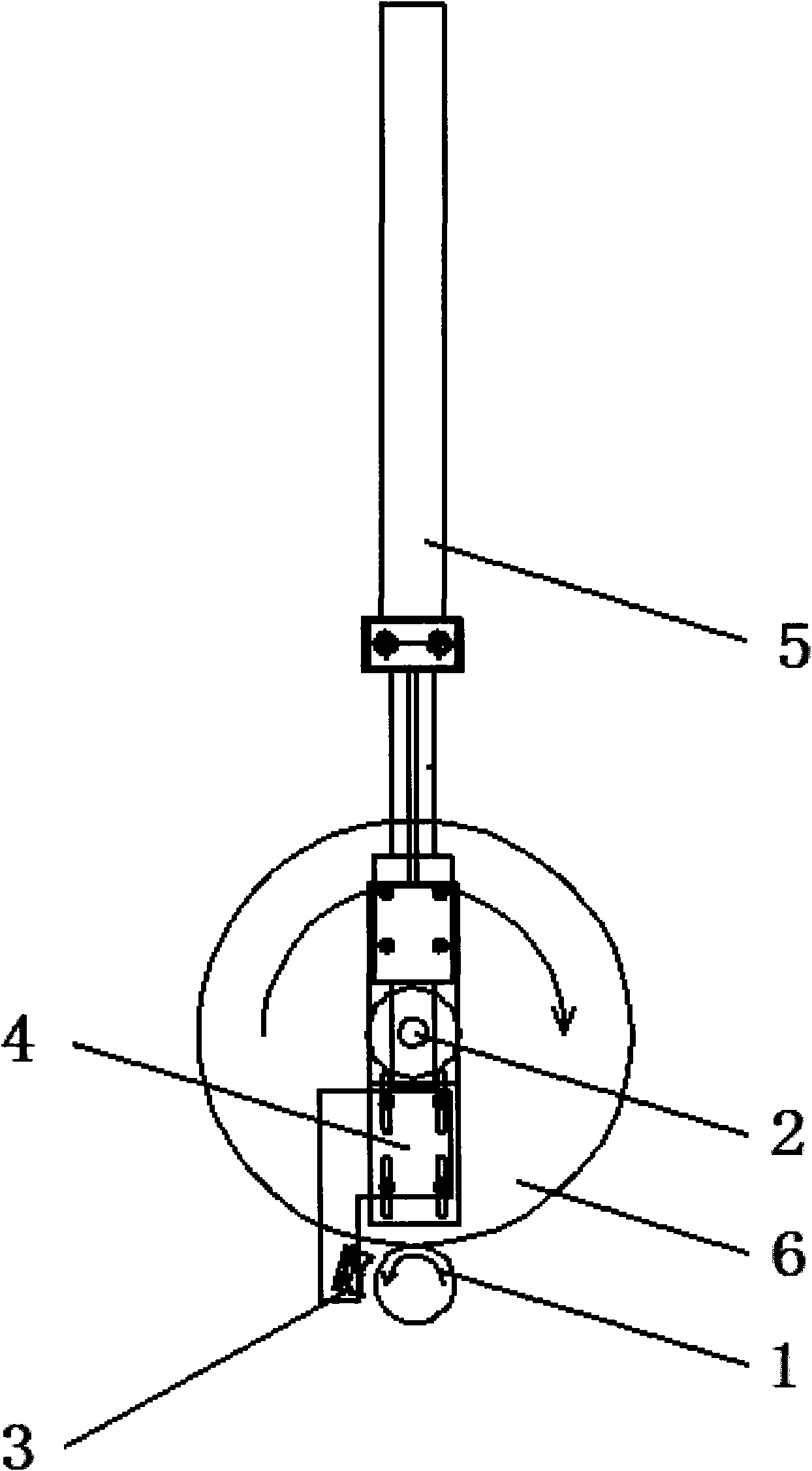

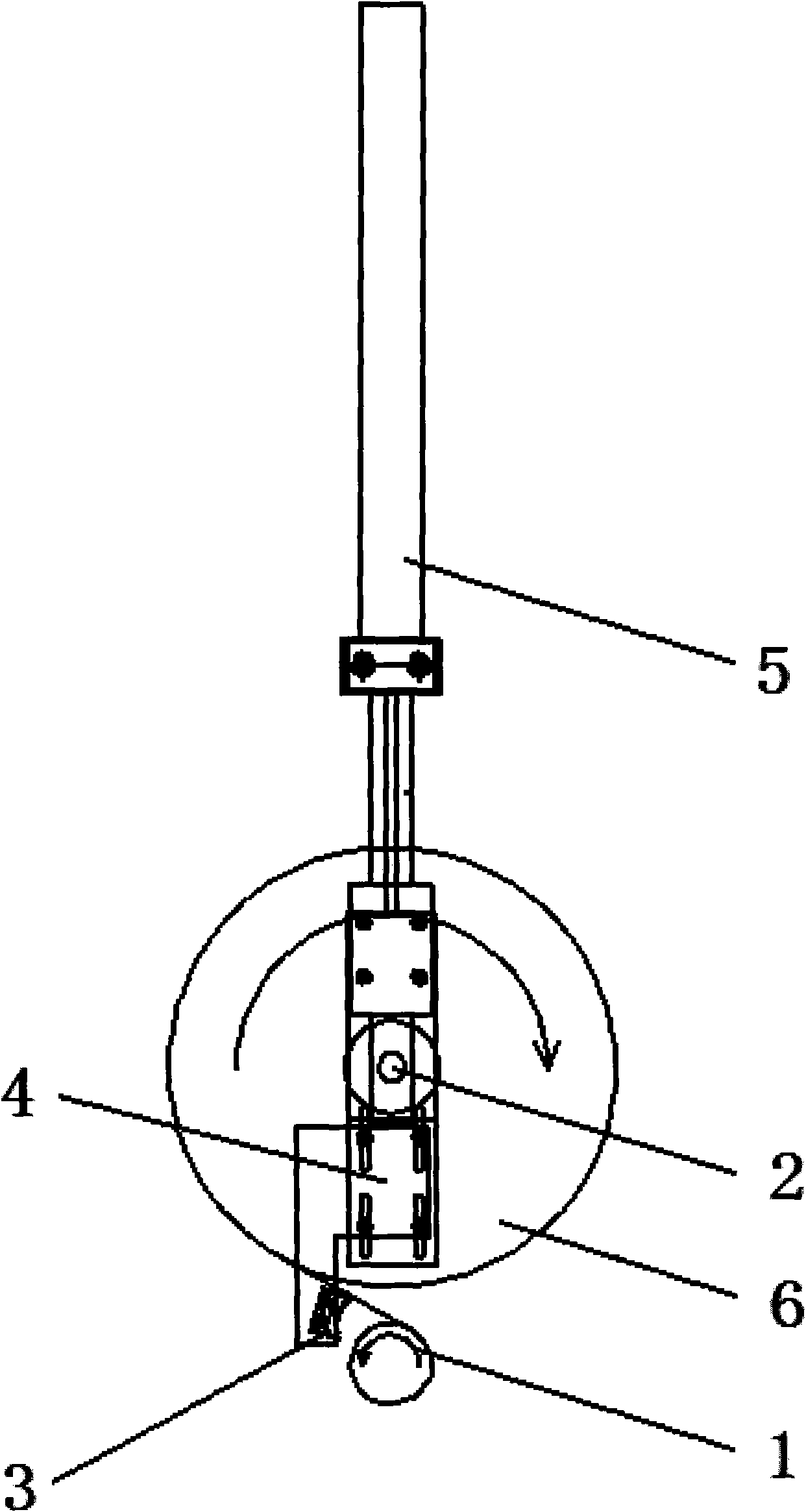

Downhole compression torsion balancing tool

ActiveCN108798532AReal-time automatic adjustment of bit pressureStable WOBEarth drilling toolsAutomatic control for drillingHydraulic cylinderWell drilling

The invention relates to the technical field of petroleum well drilling, in particular to a downhole compression torsion balancing tool. A central pipe I of the downhole compression torsion balancingtool is installed in a hydraulic cylinder sleeve, and a boss is arranged at the upper end of the central pipe I, wherein the boss and the inner wall of the hydraulic cylinder sleeve are sealed; a baffle ring I is connected to the central pipe I, and an upper damping cavity is formed among the central pipe I, the hydraulic cylinder sleeve and the upper end face of the baffle ring I; the upper end of a central pipe II is installed on the outer side of the lower end of the central pipe I in a sleeving mode and can move up and down along the central pipe I, an elastic mechanism I is installed between the upper end face of the central pipe II and the baffle ring I, and the central pipe II is connected to a step on the inner wall of the hydraulic cylinder sleeve in a hung mode. The drill pressure of a drill bit can be automatically adjusted in real time, drilling torque is limited, thus the tool face is stabilized, the build-up rate is ensured, the influence of backing pressure of a drill tool on orientation is reduced, stable and high-speed drilling of the drill bit is guaranteed, the construction risk is reduced, and the downhole compression torsion balancing tool can be widely appliedto well drilling construction of a high-inclination well, a large displacement well and a horizontal well.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

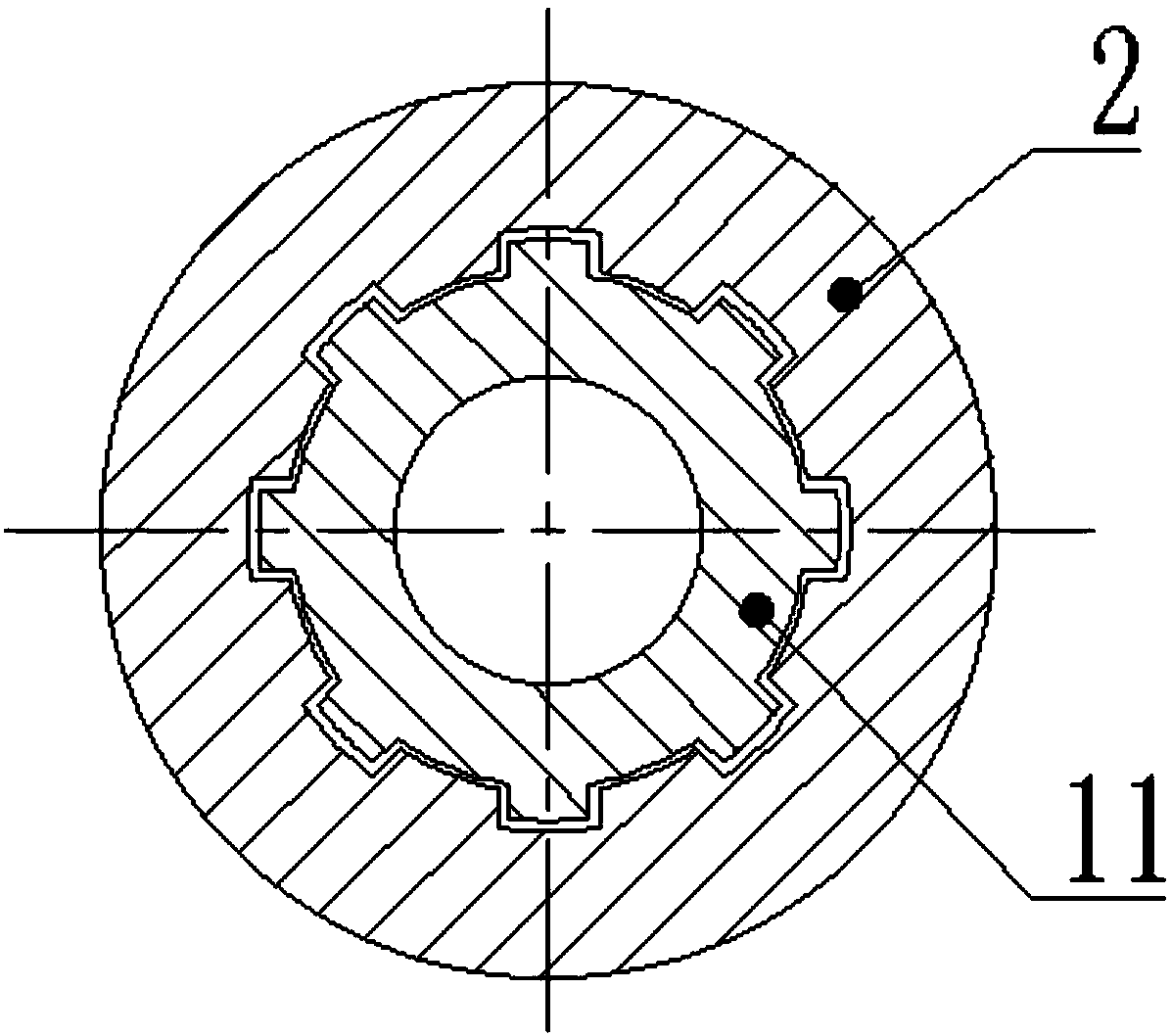

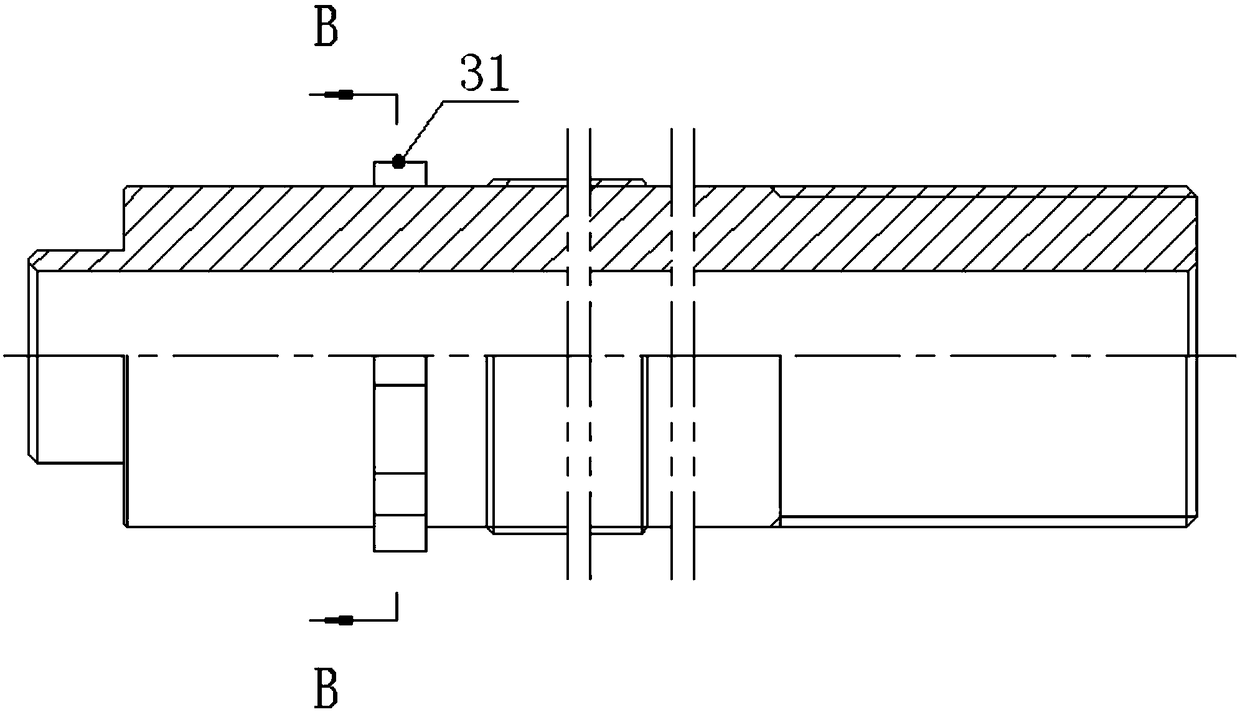

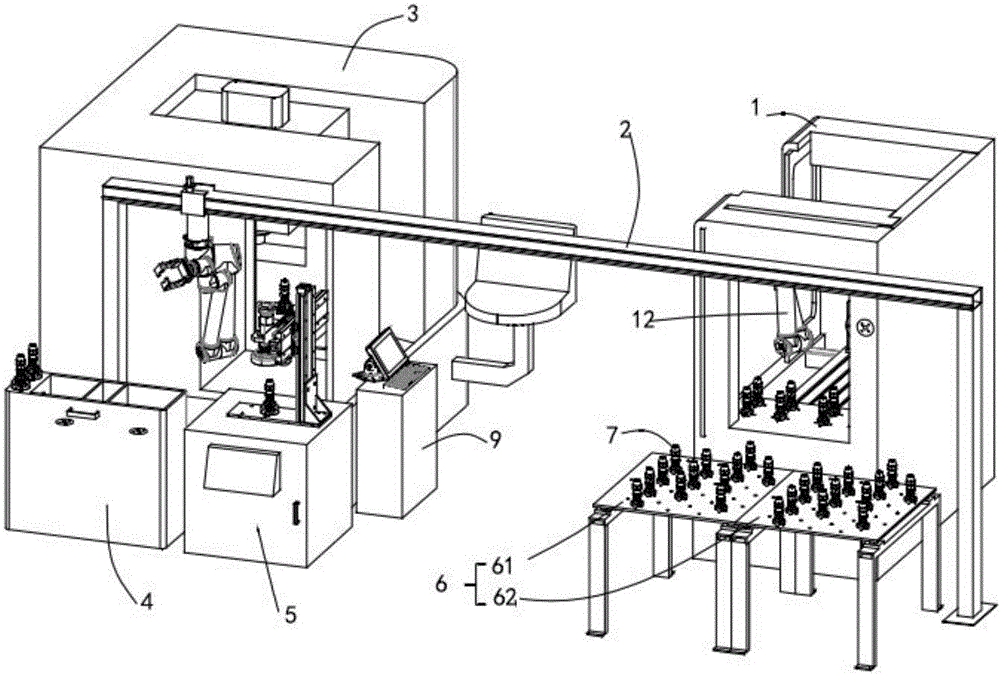

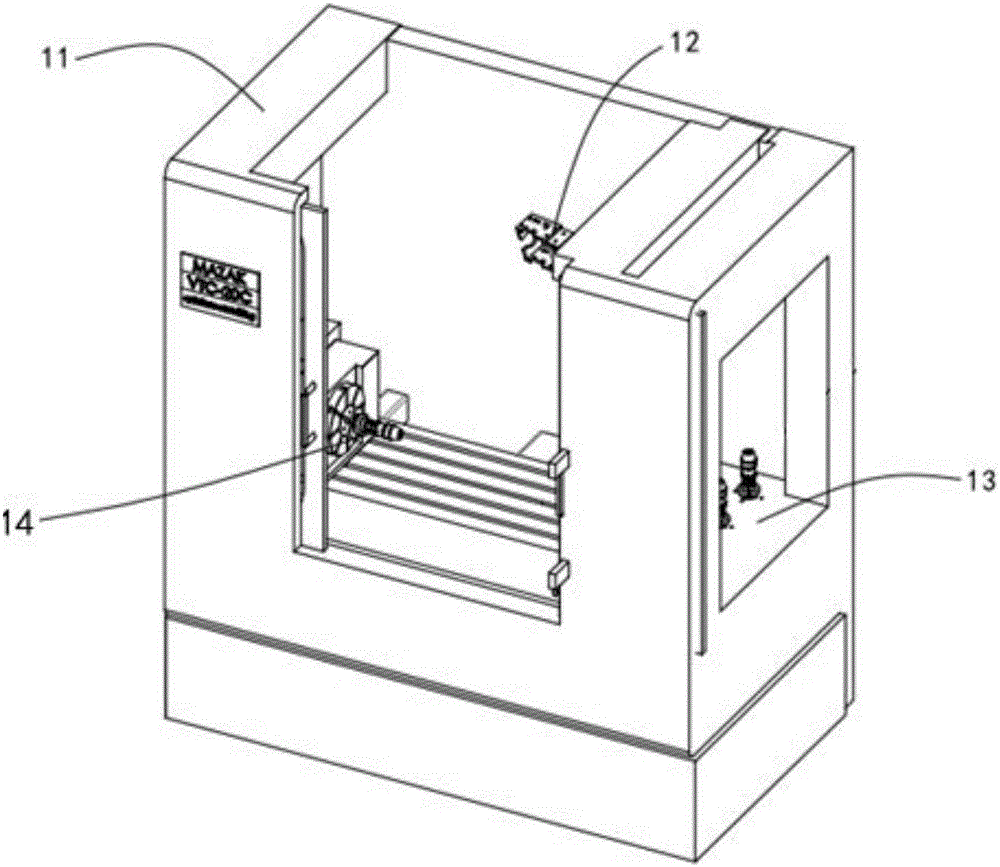

Spinning nozzle machining automatic production system and method

ActiveCN106799595ARealize automated productionImprove production efficiencyMeasurement/indication equipmentsOther manufacturing equipments/toolsEngineeringWorkstation

The invention relates to a spinning nozzle machining automatic production system. A turning machining workstation is used for conducting appearance turning machining on a blank. A high-speed drilling machining workstation is used for conducting drilling on a spinning nozzle workpiece processed through appearance turning machining, and enabling a formed spinning hole and a spinning nozzle to be coaxial. A multifunctional ultrasonic cleaning facility is used for cleaning and drying the spinning nozzle workpiece processed through drilling. A high-precision image measuring facility is used for measuring spinning nozzle key parameters of the spinning nozzle workpiece processed through cleaning. A material conveying facility conveys the workpiece among the turning machining workstation, the high-speed drilling machining workstation, the multifunctional ultrasonic cleaning facility and the high-precision image measuring facility. The invention further relates to a spinning nozzle machining automatic production method. The spinning nozzle machining automatic production system and method achieve high-efficiency and high-quality spinning nozzle automatic production.

Owner:DONGHUA UNIV

Hydraulic power depressurization acceleration tool for deep drilling well bottom

InactiveCN106801578ASolve power problemsImprove solid phase particle efficiencyBorehole drivesFlushingWell drillingHigh pressure

The invention relates to a hydraulic power depressurization acceleration tool for a deep drilling well bottom, which mainly consists of a solid-phase collector, a solid draft tube, a turbine accelerator, a rotational sealer, a power connector, a rotational flow separator, a support rod and a flow guider. The tool mainly aims at solves the problems that at the bottom of a deep well, the drilling fluid density is high, the chiphold down effect is serious, and the mechanical drilling rate is low. The concrete implementation mode of the hydraulic power depressurization acceleration tool for the deep drilling well bottom is as follows: high-pressure high-speed drilling fluid is pumped underground from the ground surface, the drilling fluid lashes the turbine accelerator to supply rotational power for the rotational flow separator, after the drilling fluid is separated by the rotational flow separator, the solid phase in the drilling fluid enters an annular space between the drilling rod and a stratum, and is brought back to the ground surface by the drilling fluid which moves upwards in the annular space, and the drilling fluid after separation flows downwards to enter a drill bit through the interior of a rotational flow rotor. By the hydraulic power depressurization acceleration tool, the power problem of tools can be solved, the separation efficiency of solid-phase particles in the drilling fluid is improved, meanwhile, the chiphold down effect at the bottom of the deep well is effectively reduced, the mechanical drilling rate is improved, the drill bit life is prolonged, and the cost is lowered.

Owner:CNPC DRILLING RES INST +1

Dynamic pressure circulating lubrication roller bit

The invention provides a dynamic pressure circulating lubrication roller bit to overcome defects of the traditional lubrication system roller bit. The technical scheme is that: the end part of a palm is provided with a palm small shaft; the back of the palm is provided with a sealing oil storage hole; the top end of the palm small shaft is provided with a small shaft oil pump; and the palm is provided with an oil inlet channel and an oil outlet channel which are connected with a bearing chamber and the sealing oil storage hole. A lubrication dead zone at a sealing ring is eliminated, so that the end part of a plug is more easily seamlessly fitted with a runway of a locking steel ball, and the safety factor of the bit is improved; the traditional pressureless lubrication is changed into pressure lubrication, the dynamic pressure of fluid can timely repair a broken lubricating grease oil film, a pressure-bearing surface of a journal of the bit is supplemented with bit grease instantly, and a bearing cannot be quickly worn due to lubrication failure; and the service life of the bit is greatly prolonged, the rotating speed of the bit can be not under control, and the bit can better meet the requirement of high-pressure high-speed drilling in modern times and even in the future.

Owner:三原石油钻头厂

Drilling and deburring integrated machine for producing badminton rackets

ActiveCN109079517AIncrease productivityRealize integrated productionOther manufacturing equipments/toolsEngineeringMechanical engineering

The invention discloses a drilling and deburring integrated machine for producing badminton rackets. The drilling and deburring integrated machine comprises a base, wherein a first sliding chute is formed in one side of the upper surface of the base; an electric push rod base is arranged on one side inside the first sliding chute; an electric push rod is arranged on the electric push rod base; a fixed seat is welded on one side of the electric push rod; a high-speed drilling machine is fixedly arranged at the top end of the fixed seat through threads; two arc-shaped sliding chutes, namely a first arc-shaped sliding chute and a second arc-shaped sliding chute, are embedded into the upper surface of the operation platform; a first electric sliding block which can move around the first arc-shaped sliding chute is arranged inside the first arc-shaped sliding chute; a second electric sliding block which can move around the second arc-shaped sliding chute is arranged inside the second arc-shaped sliding chute; fixed frames are respectively welded at the top end of the first electric sliding block and the top end of the second electric sliding block; a locking bolt is arranged at the upper end of one fixed frame; abrasive discs are respectively arranged at the lower ends of adjacent sides of the two fixed frames.

Owner:磐安县天诚科技有限公司

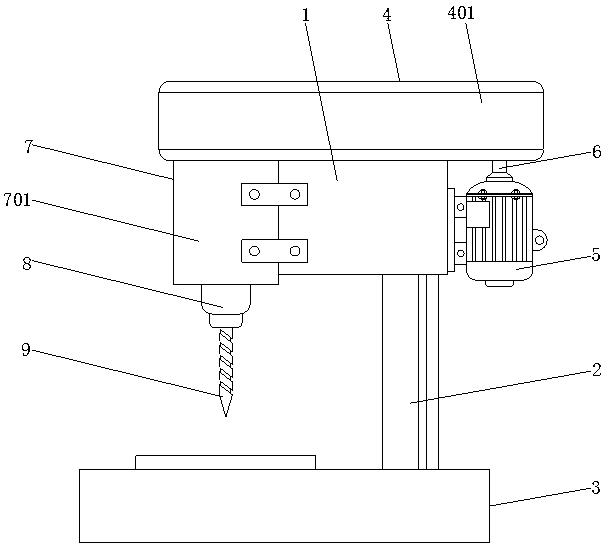

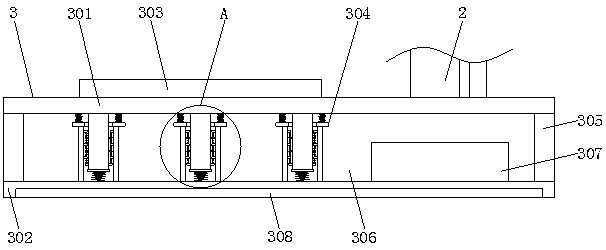

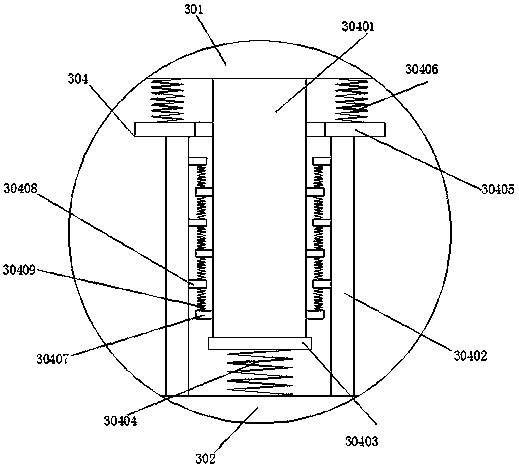

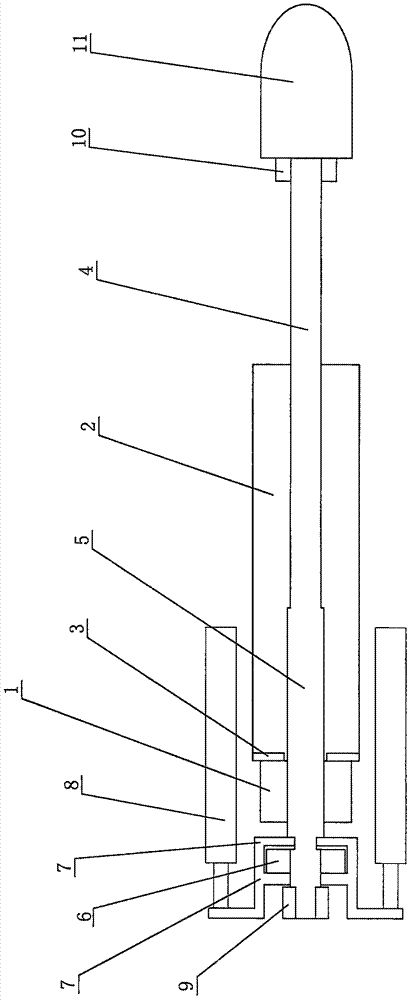

High-speed drilling machine with noise lowering function

PendingCN109226830AAvoid damageProtect healthLarge fixed membersBoring/drilling componentsDrive shaftEngineering

The invention discloses a high-speed drilling machine with a noise lowering function. The high-speed drilling machine comprise a drilling machine body, the right side of the bottom of the drilling machine body is fixedly connected with a stand column, the bottom of the stand column is fixedly connected with a base, and the top of the drilling machine body is fixedly connected with a transmission mechanism. The right side of the drilling machine body is fixedly connected with a driving motor, an output shaft of the driving motor is fixedly connected with a driving rotary shaft, the top end of the driving rotary shaft penetrates through the transmission mechanism and extends into the transmission mechanism, and the left side of the drilling machine body is fixedly connected with a silencer.According to the high-speed drilling machine, by arranging the base and the silencer, the noise lowering function is achieved, sounds caused by drill bit transmission shaft rotation are subjected to noise lowering through the silencer, vibration between a machined workpiece and the drilling machine is subjected to noise lowering through a damping device in the base when the drilling machine is used, it is avoided that hearing of a worker is damaged by noise pollution damage, health of the worker is guaranteed, and the fame and benefits of factories are guaranteed.

Owner:ZHEJIANG HANDA MACHINERY

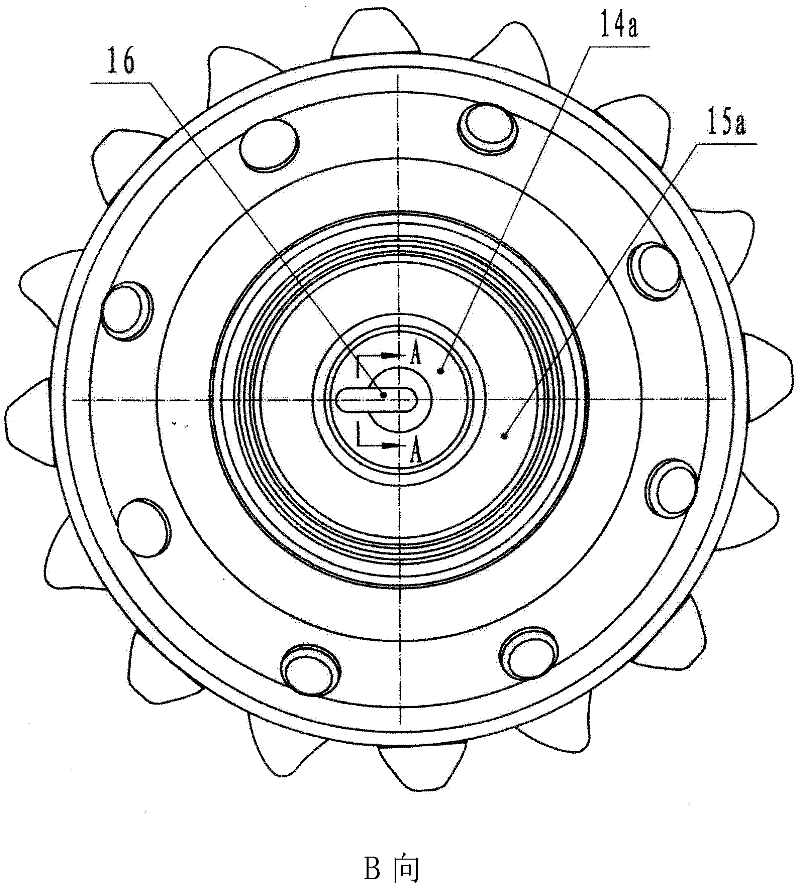

Heading machine cutting head with rake teeth, extensible structure and attached drilling tools

The invention relates to a cutting head of a roadheader with rake teeth, a telescopic structure and an attached drilling tool, belonging to the category of mining equipment. It is restructured from the existing roadheader. Its features are: the original cutting arm can not be stretched or stretched when one part bears pressure, and becomes a stretchable structure that bears pressure at both ends. Hydraulic motor direct drive. The outer spray is changed to the inner water spray structure, so that the pick can be effectively cooled, and the longitudinal thrust is directly pushed and pulled by two hydraulic cylinders. There are 3 additional shallow hole drilling tools on the arm, still using the existing idle power, capable of high-speed drilling, combined with appropriate blasting technology, the whole constitutes a new generation that can really drill soft and hard rocks, including extra hard rocks The new roadheader has low consumption, fast excavation speed, light and flexible body, and can also drill smaller-sized roadways.

Owner:韩自俊

Rolling device of laser drilling machine for thin material

The invention discloses a winding device of a laser drilling machine for a thin material, which comprises a main winding shaft driven by a motor to rotate. The rolling device is characterized by also comprising an auxiliary winding shaft which can driven by a driving device to move away from or toward the main winding shaft, and the auxiliary winding shaft is driven to rotate by the friction force of the main winding shaft when the auxiliary winding shaft abuts against the main winding shaft; meanwhile, the rolling device also comprises an air tap which can be driven by the driving device and can move along with the auxiliary winding shaft, and the air tap is located on one side of the main winding shaft and can blow and paste a double faced adhesive tape to the surface of the main winding shaft; and the air tap is provided with a cut, and the cut intersects with the internal common tangent of the main winding shaft and the auxiliary winding shaft along with the movement track of the air tap. The rolling device provided by the invention can automatically carry out roll change during high speed drilling process and can effectively remove an undrilled thin material during accelerated roll delivering process.

Owner:苏州市博海激光科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com