Rolling device of laser drilling machine for thin material

A technology of laser drilling machine and winding device, which is applied in the direction of thin material processing, winding strip, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

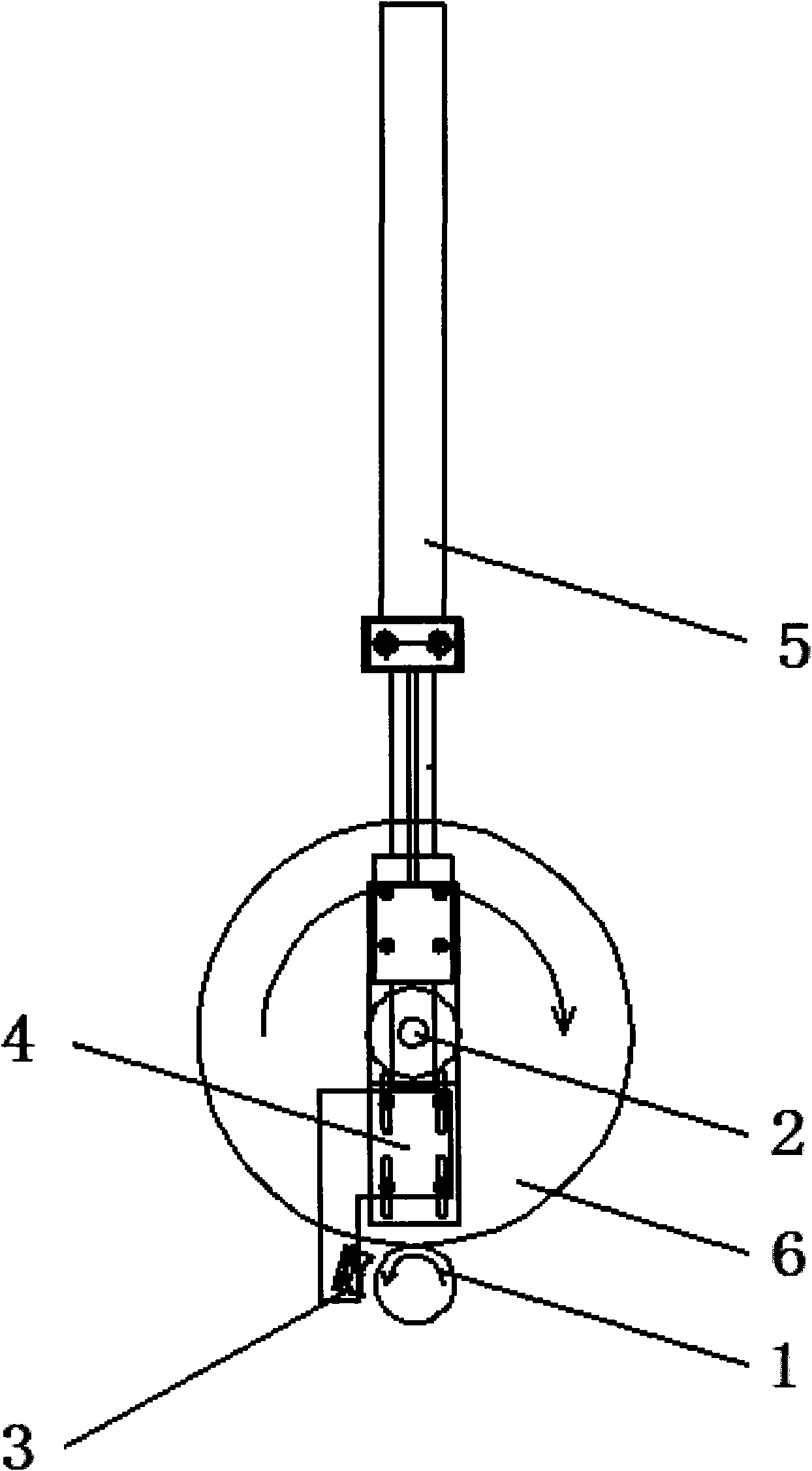

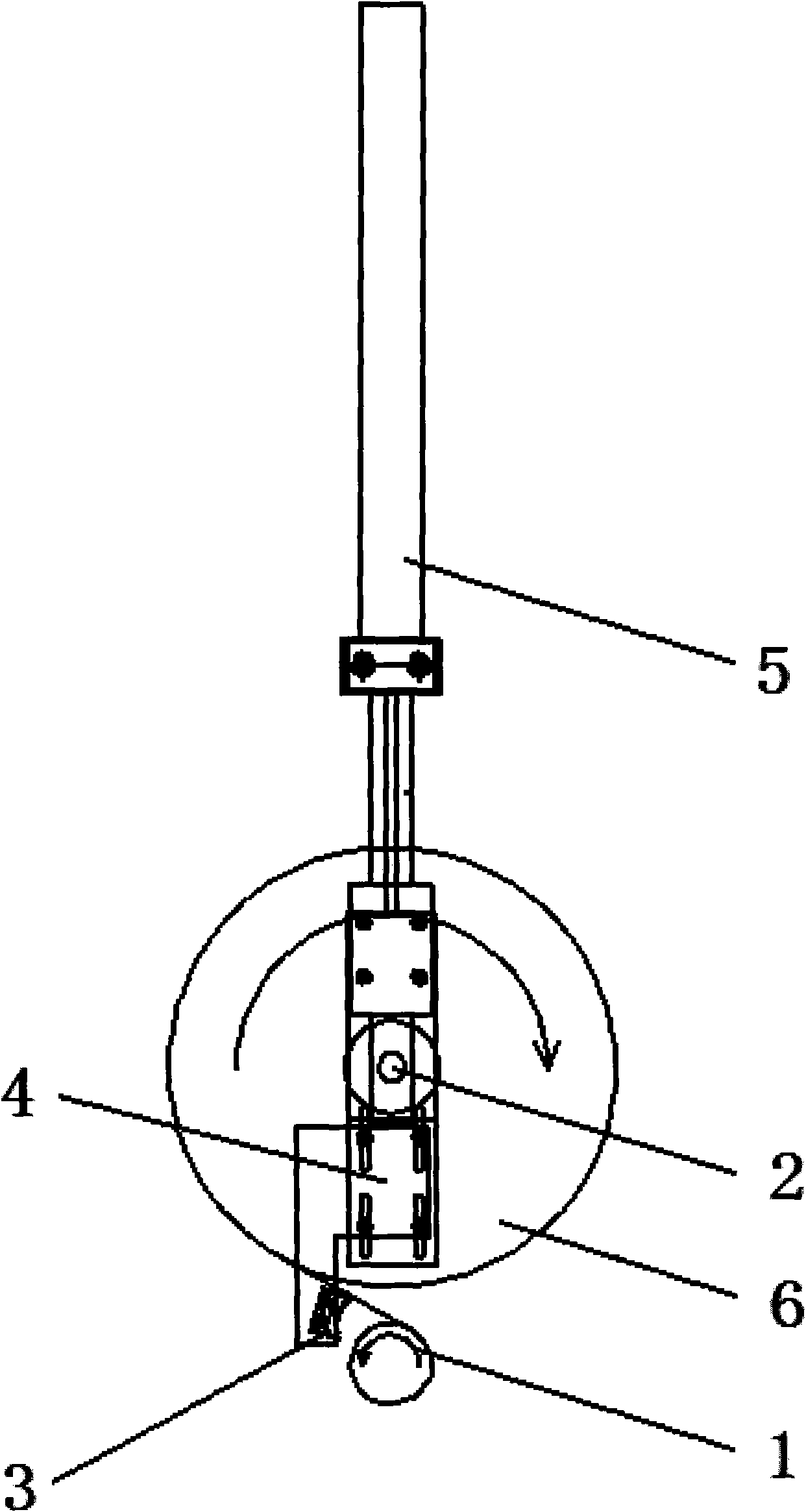

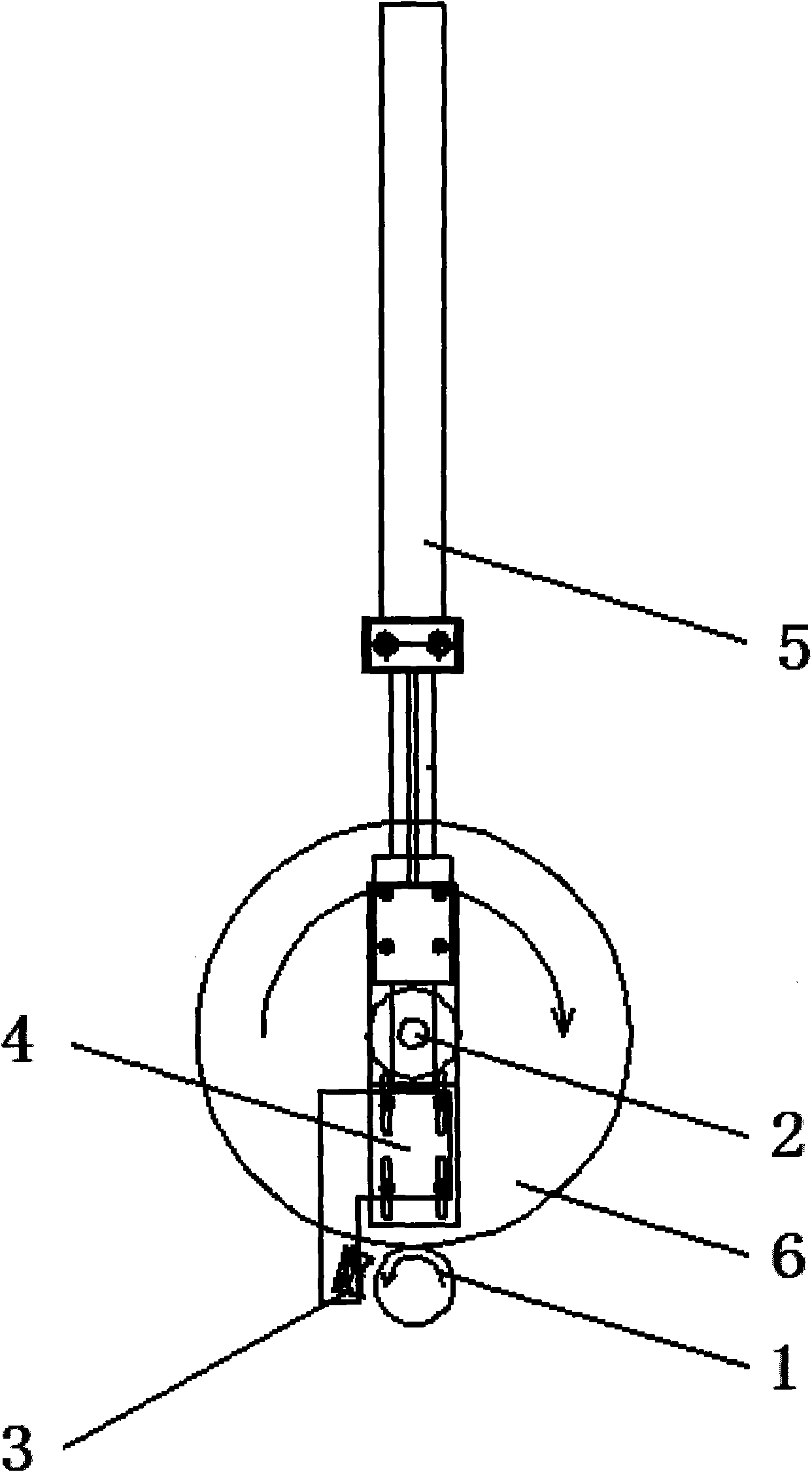

[0021] Example: Combined figure 1 , figure 2 As shown, the thin material punching machine rewinding device provided in this embodiment is specifically used for laser punching of tipping paper, and needs to be used in conjunction with the tipping paper laser punching machine. It mainly includes a main reel 1, an auxiliary reel Reel 2, gas nozzle 3, base 4, cylinder 5 and support (not shown in the figure). The main winding shaft 1 is driven to rotate by a motor (not shown in the figure), the secondary winding shaft 2 is fixed on the base 4 and is located above the main winding shaft 1, and the air nozzle 3 is extended to the main winding shaft through a The connecting plate (not shown) on one side of the reel 1 is fixed on the base 4, and the base 4 is fixed on the cylinder push rod. At the same time, the base 4 in this embodiment is slid in the linear track on the bracket through the slide rail provided on it. In this embodiment, the auxiliary rewinding shaft 2 can be drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com