Composite calibration method of mold surface optical measurement system

A technology of optical measurement system and calibration method, which is applied in the field of camera calibration, projector calibration and system geometric parameter calibration, and surface optical measurement system comprehensive calibration, which can solve the problem of unfavorable projector and system parameter calibration, affecting the accuracy of basic data acquisition and Efficiency, unsuitability and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

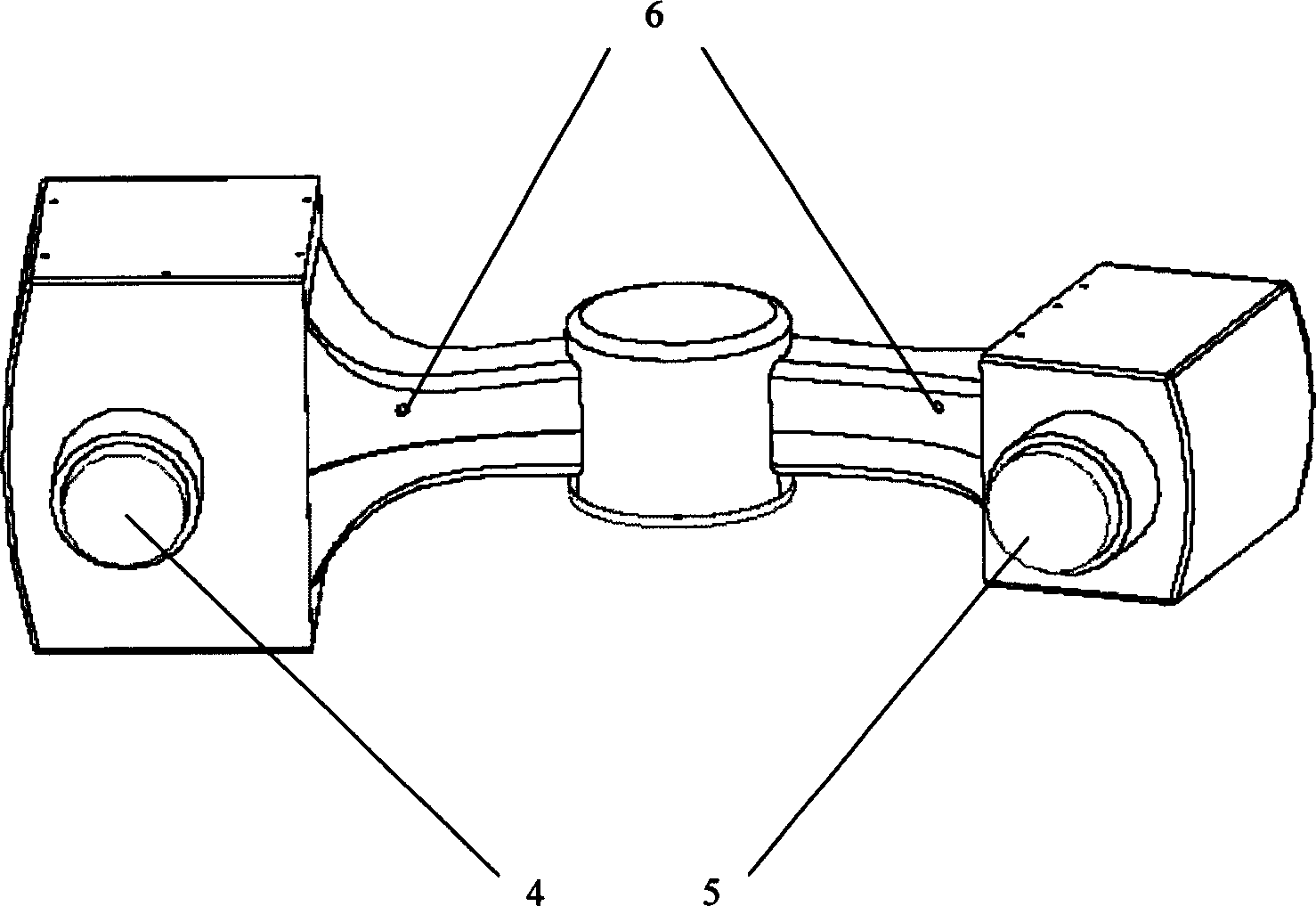

[0016] Such as figure 1 , figure 2 , image 3 As shown, according to the comprehensive calibration method of the profile optical measurement system of the present invention, the specific implementation steps of comprehensive calibration of a structured light projection three-dimensional profile measurement system are as follows:

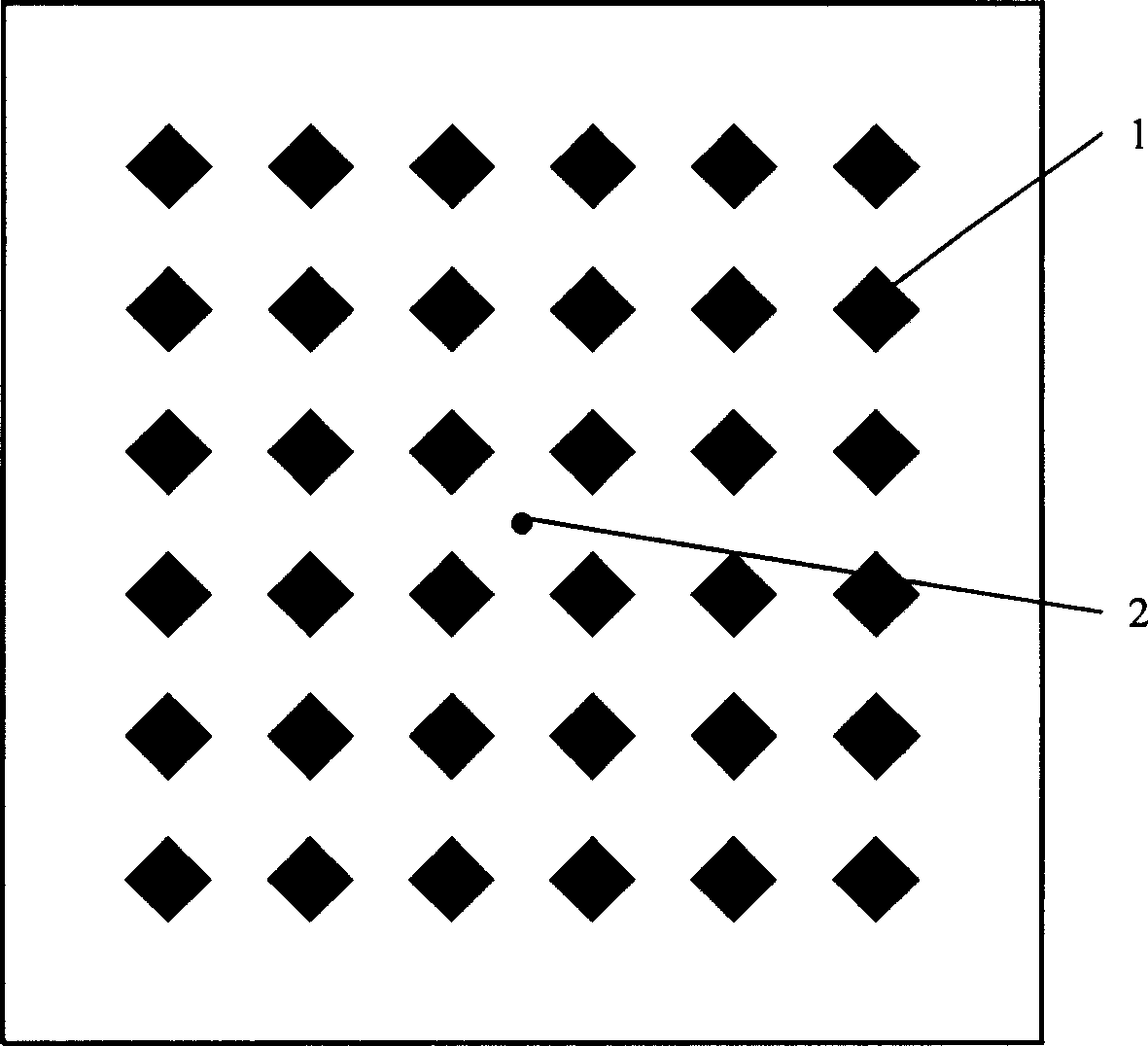

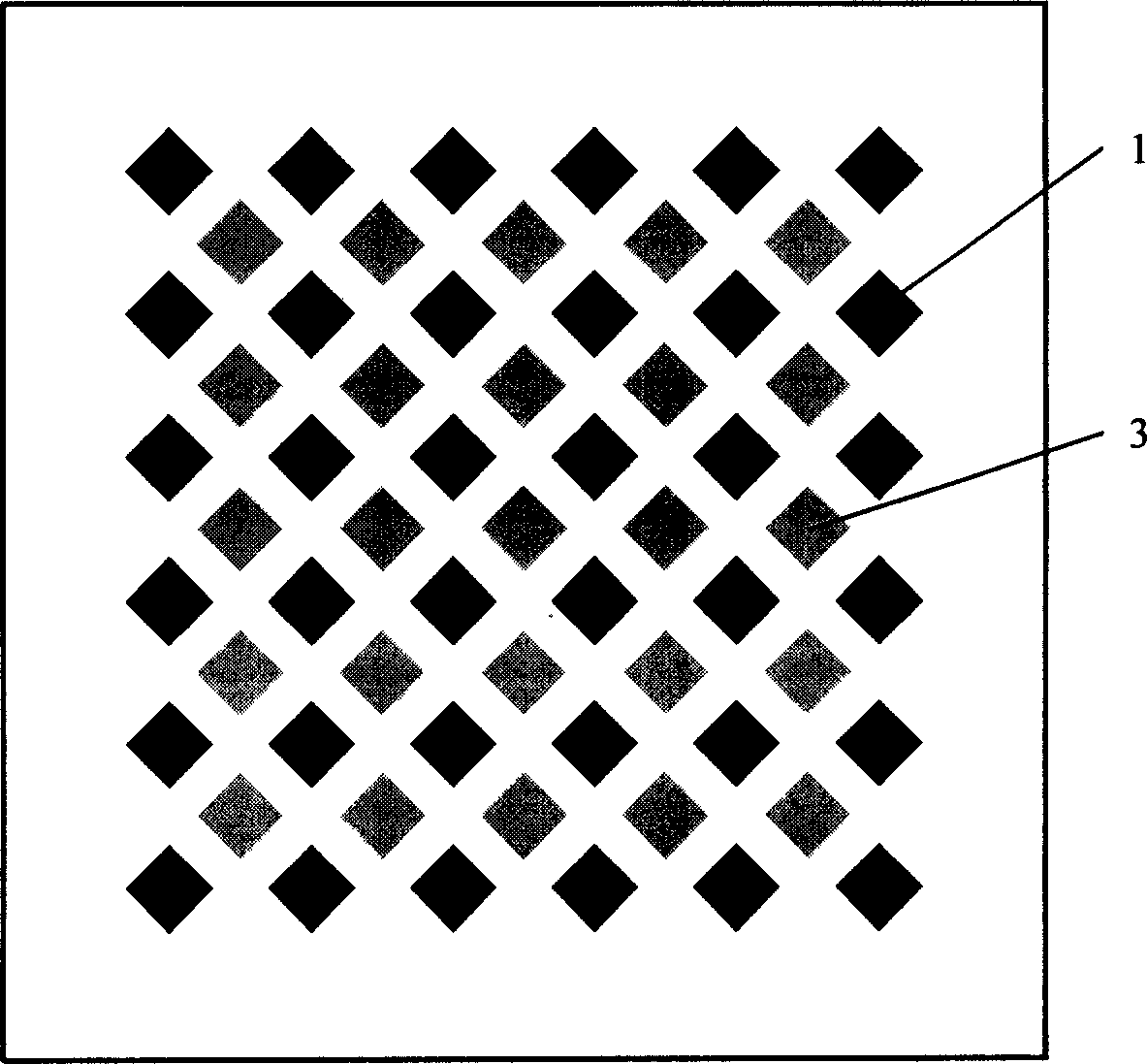

[0017] 1. Make calibration board and projector calibration grating: according to figure 1 According to the characteristics of the measurement system itself, a plane calibration board of corresponding size is made, with white as the background color, and a uniformly distributed black diamond-shaped square grid array 1 on it, and a black positioning point 2 marked in the center of the calibration board. The pattern of the calibration grating of the projector adopts the same diamond-shaped grid array, and its s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com