Layered fertilizer applying device

A technology of layered fertilization and height detection device, applied in fertilization devices, fertilizer distributors, planting methods, etc., can solve the problems of affecting growth and development, seeds cannot absorb enough nutrients, and uneven distribution of nutrients, so as to ensure the depth of fertilization, improve the Fertilization effect, effect of enhancing absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better understand the purpose, function and specific design of the present invention, the layered fertilization device of the present invention will be further described in detail below.

[0024] The layered fertilization device of the present invention is mainly used in sowing machinery and equipment, and its main function is to cooperate with the sowing process to fertilize the sown land to ensure that the seeds of crops can absorb sufficient nutrients during germination and seedling growth.

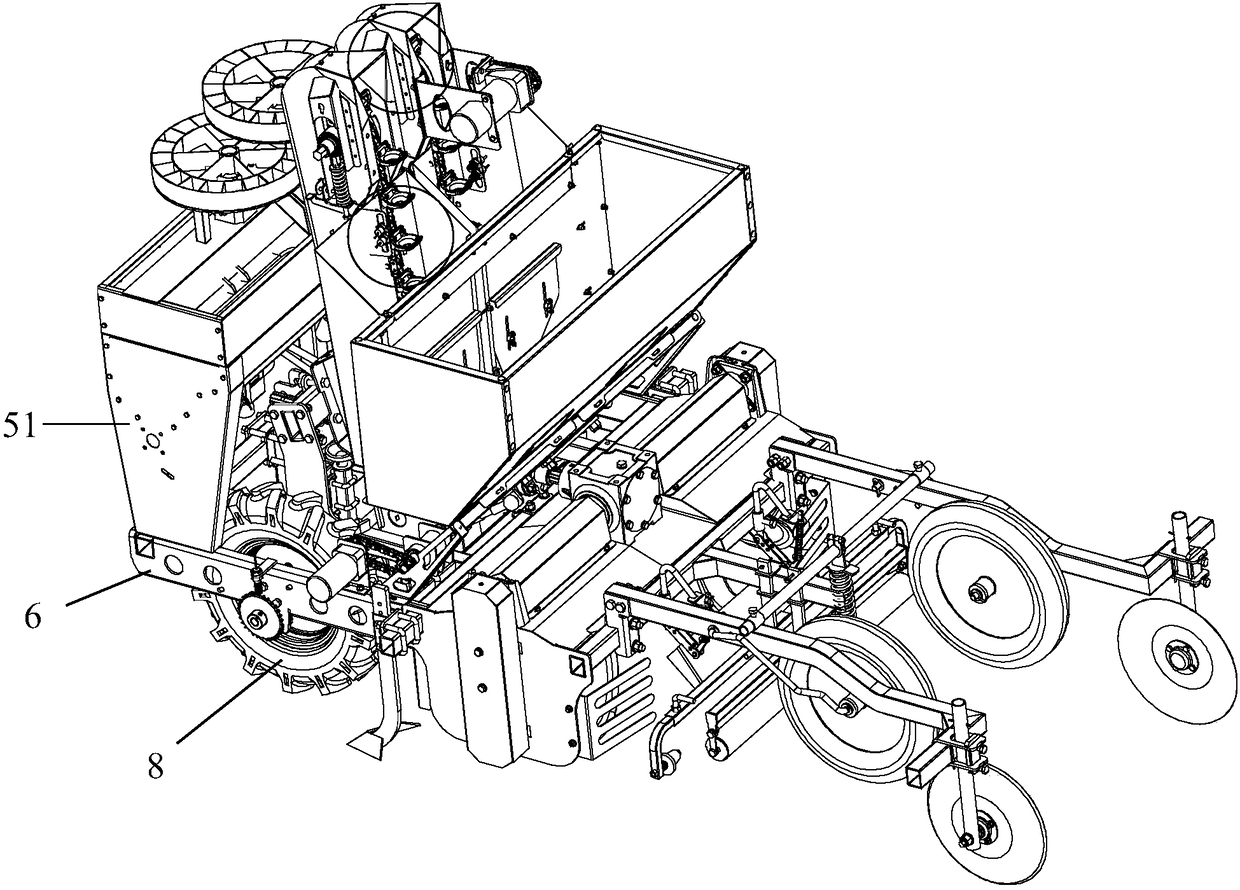

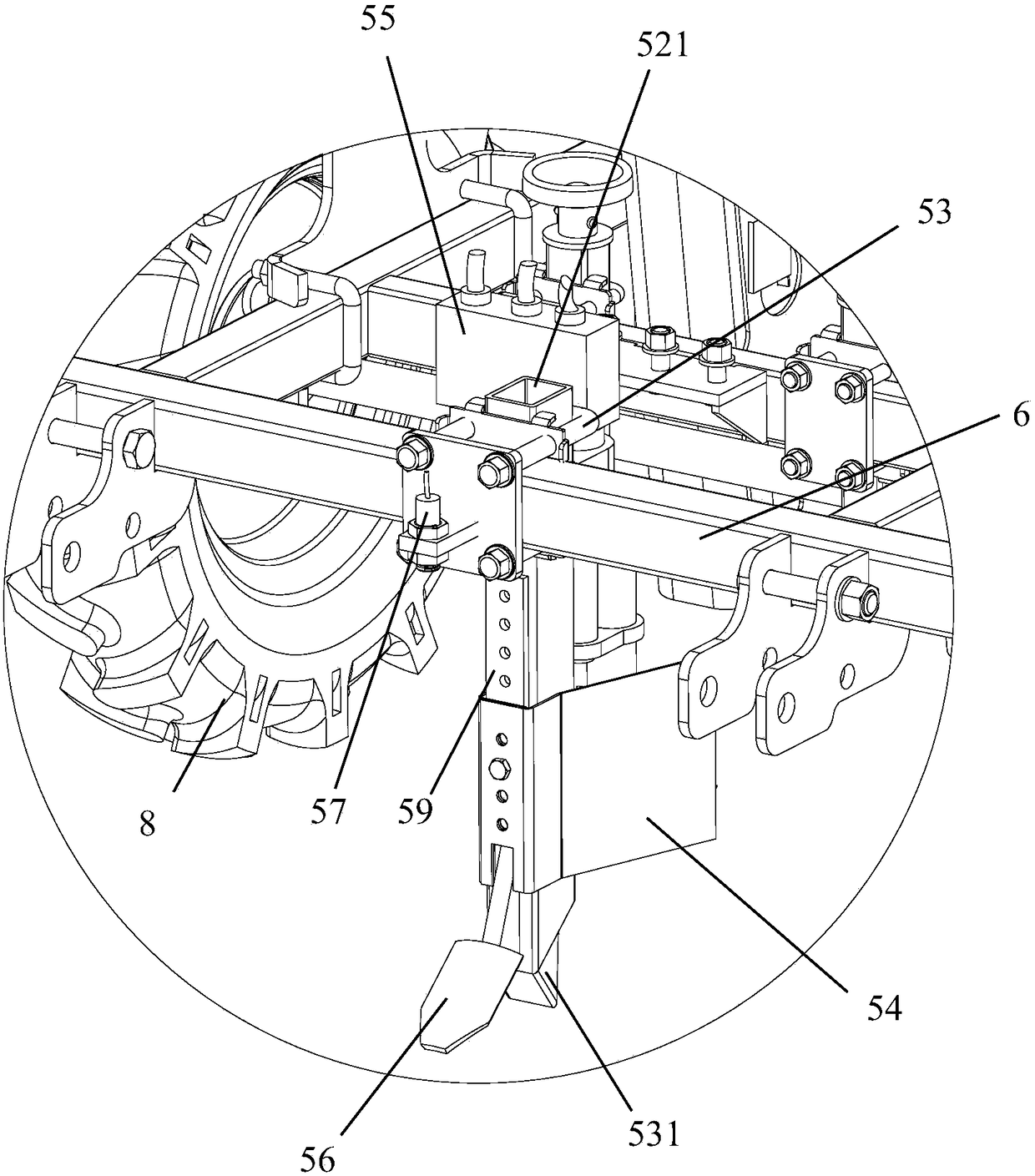

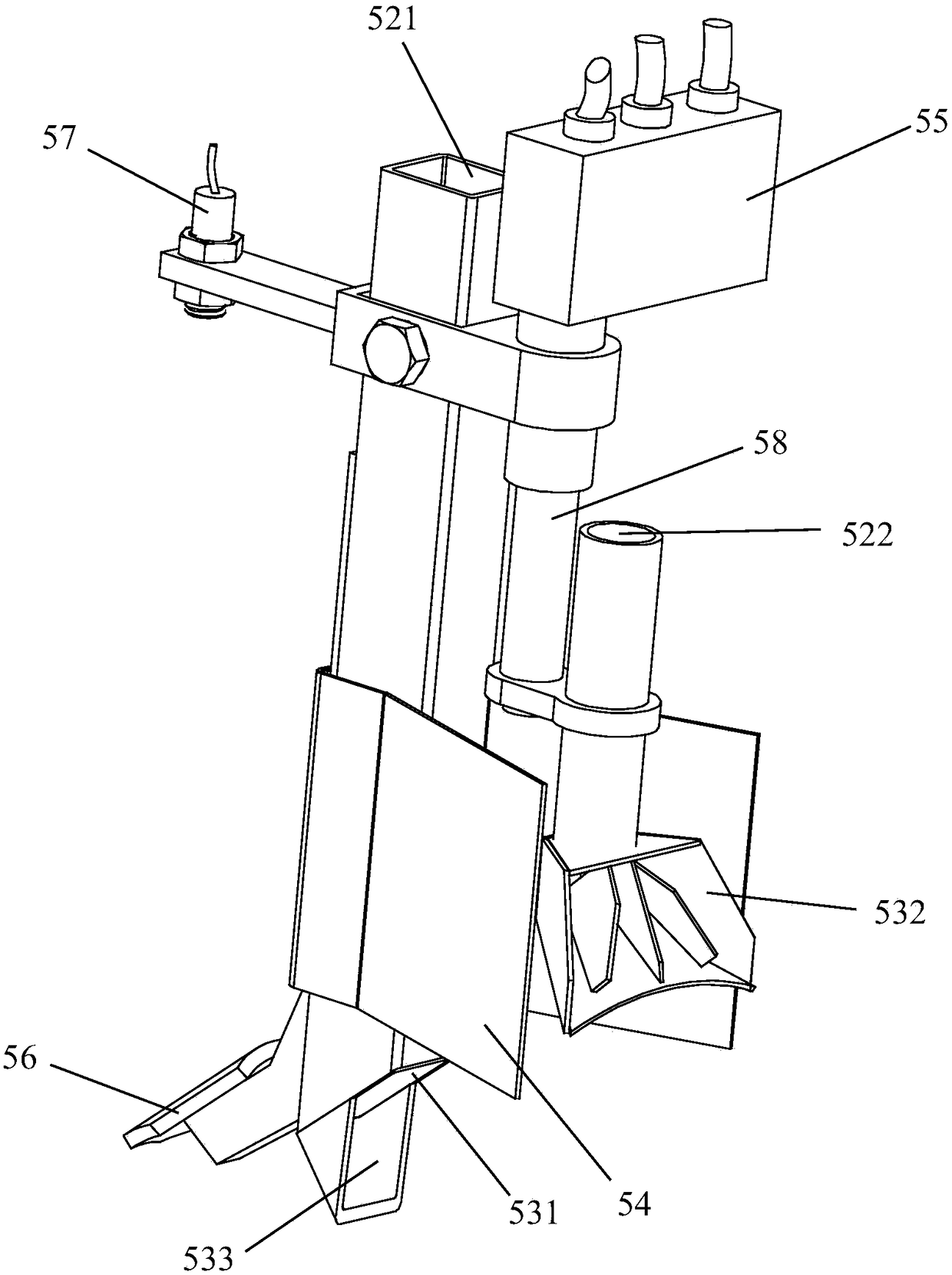

[0025] Such as figure 1 As shown, taking a potato planter as an example, the potato planter includes a frame beam 6 suspended on a tractor or traction equipment, and ground wheels 8 are symmetrically arranged on both sides of the frame beam 6 . The tractor or traction device moves the potato planter forward by dragging the frame beam 6 . The fertilizer box 51 is arranged on the frame beam 6 , and the layered fertilization device is arranged under the fertilizer box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com