Patents

Literature

369 results about "Technical design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Technical Design. Technical Design is a communication skill using graphics and computers to communicate technical information and data. Technical Design students learn to use hand drawing and sketching, Computer Aided Drafting (CAD), computer modeling, and 3D printing to test and communicate designs. Technical Designers are an essential component in...

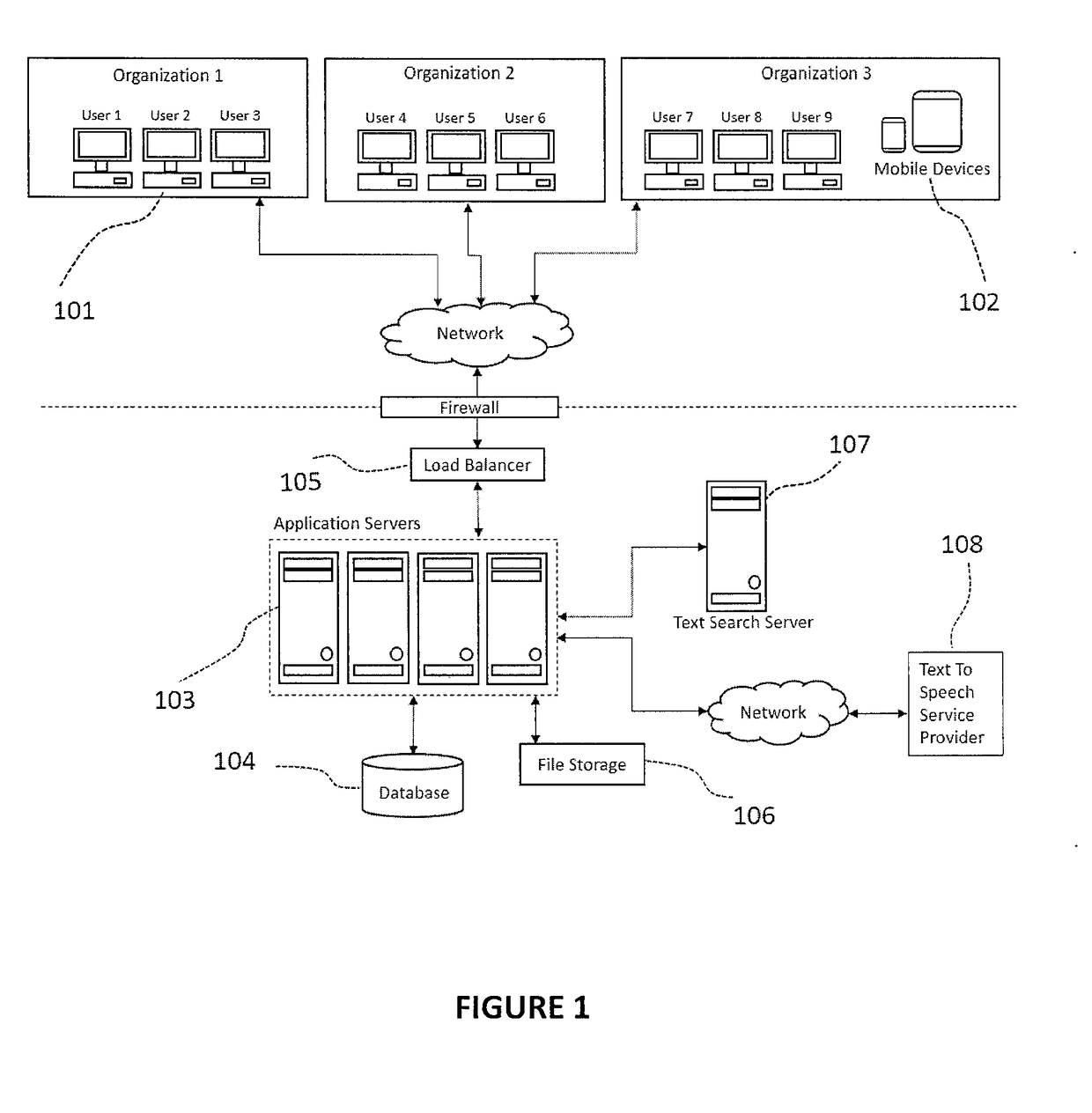

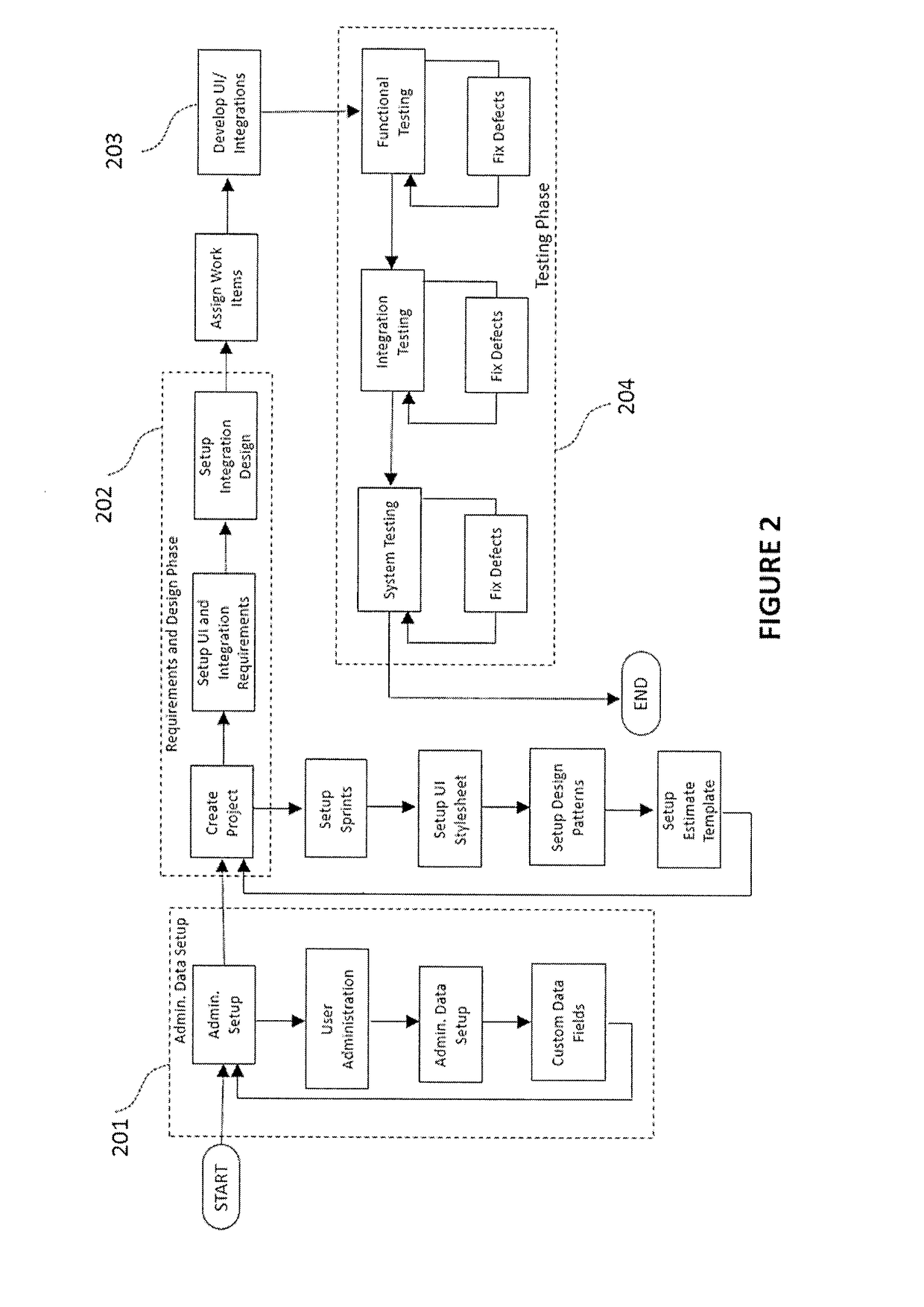

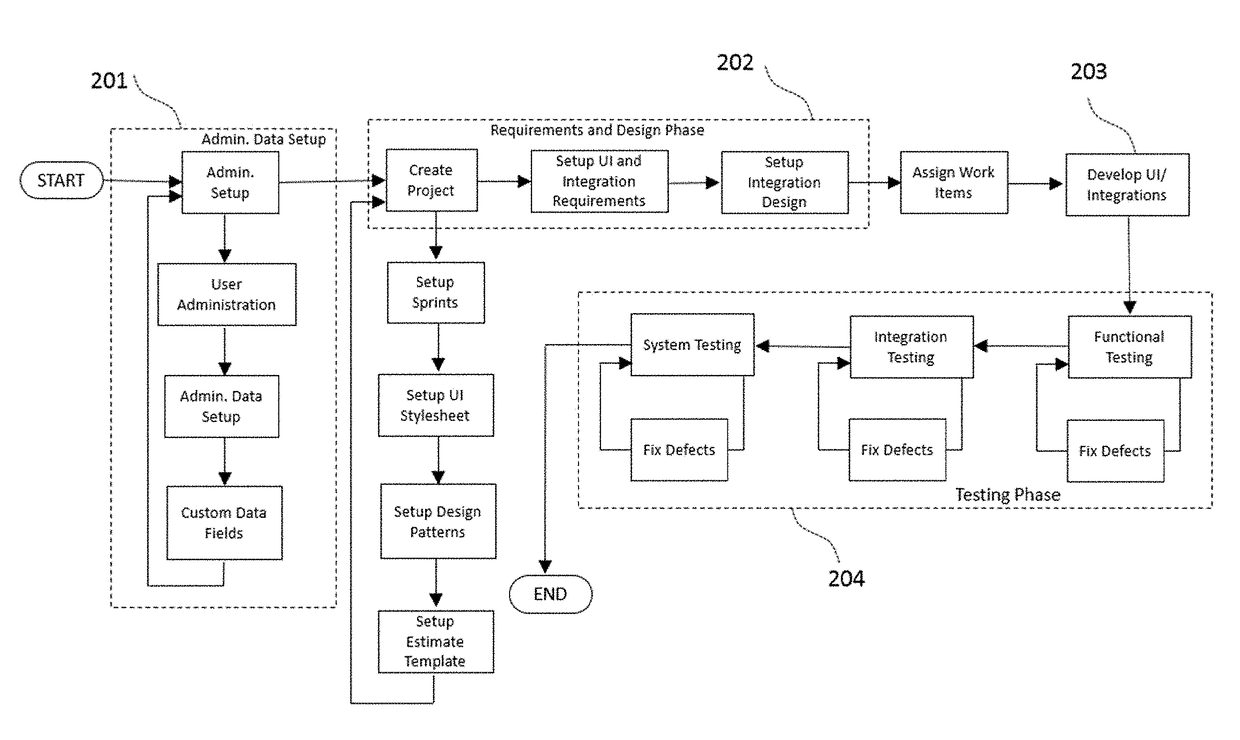

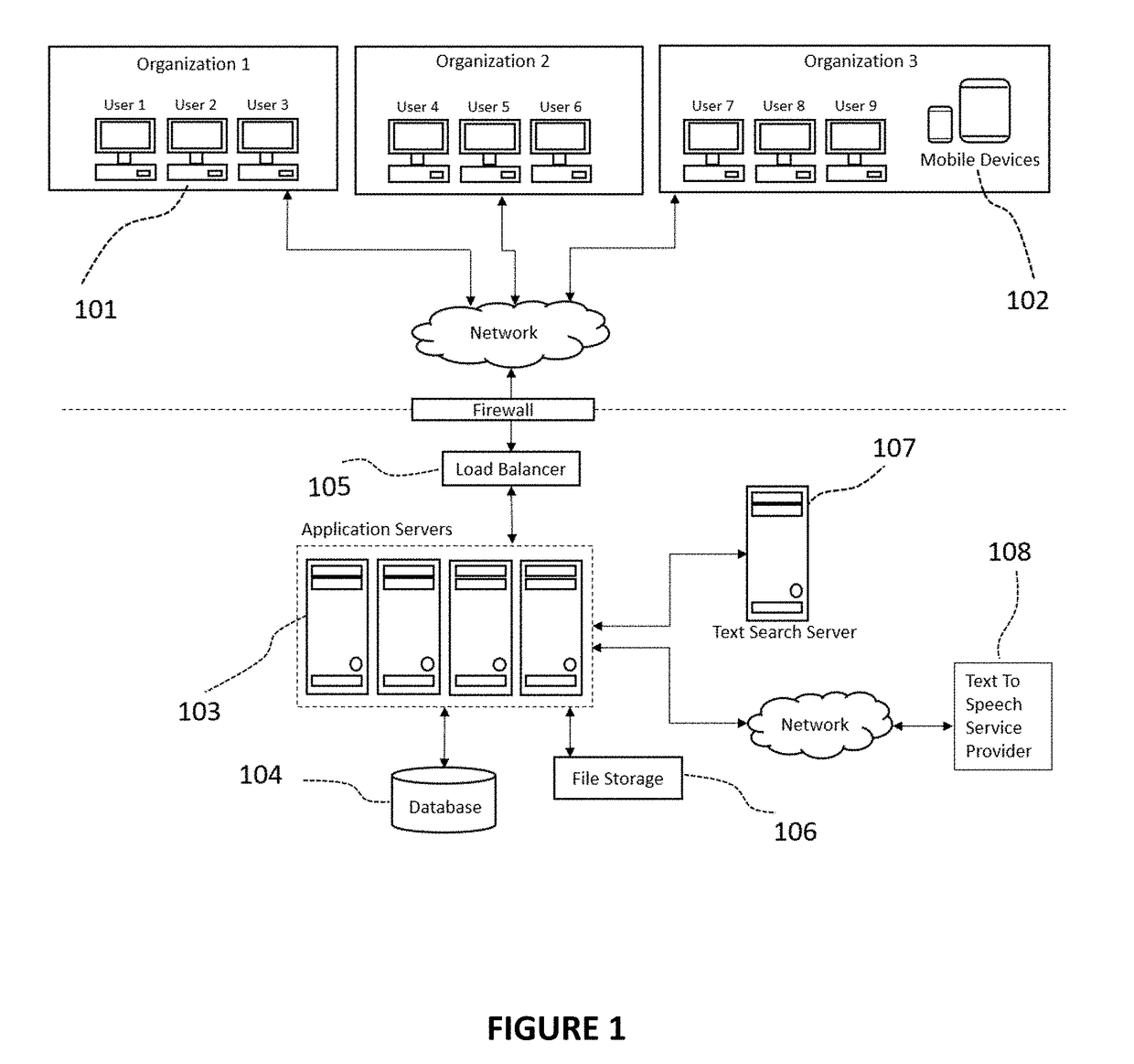

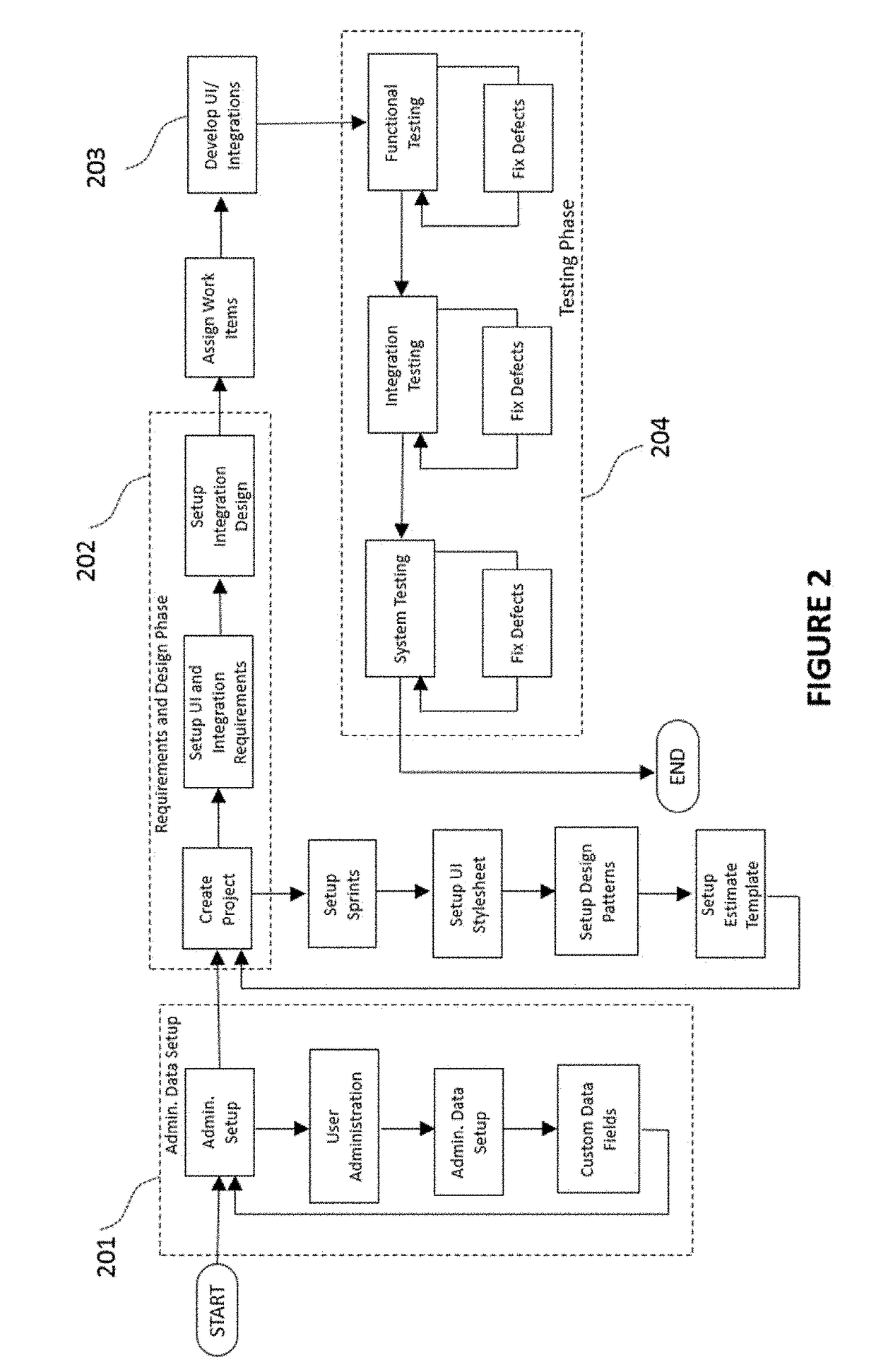

Integrated system for software application development

InactiveUS10001975B2Equally distributedProgram initiation/switchingVersion controlIntegrated softwareProject management

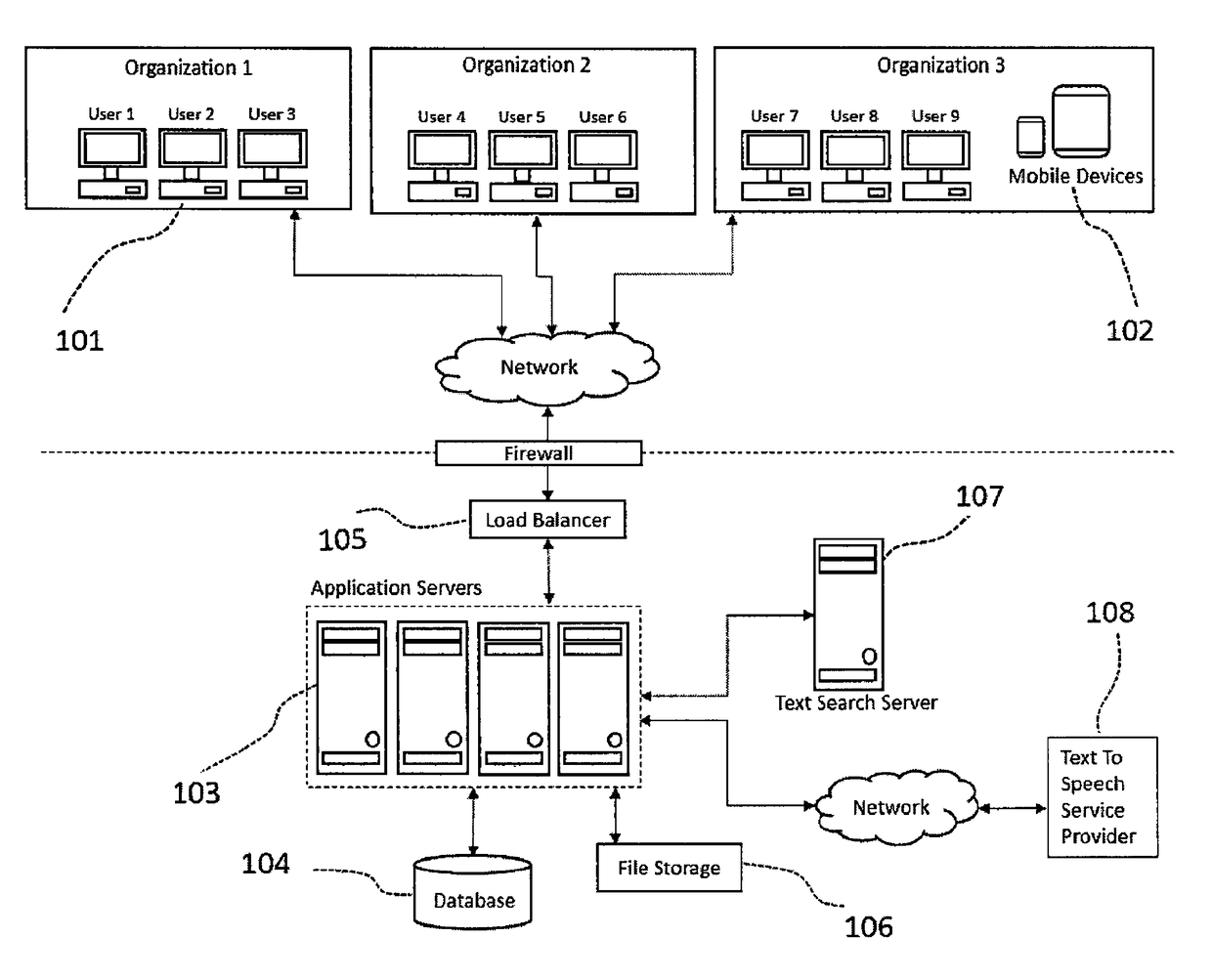

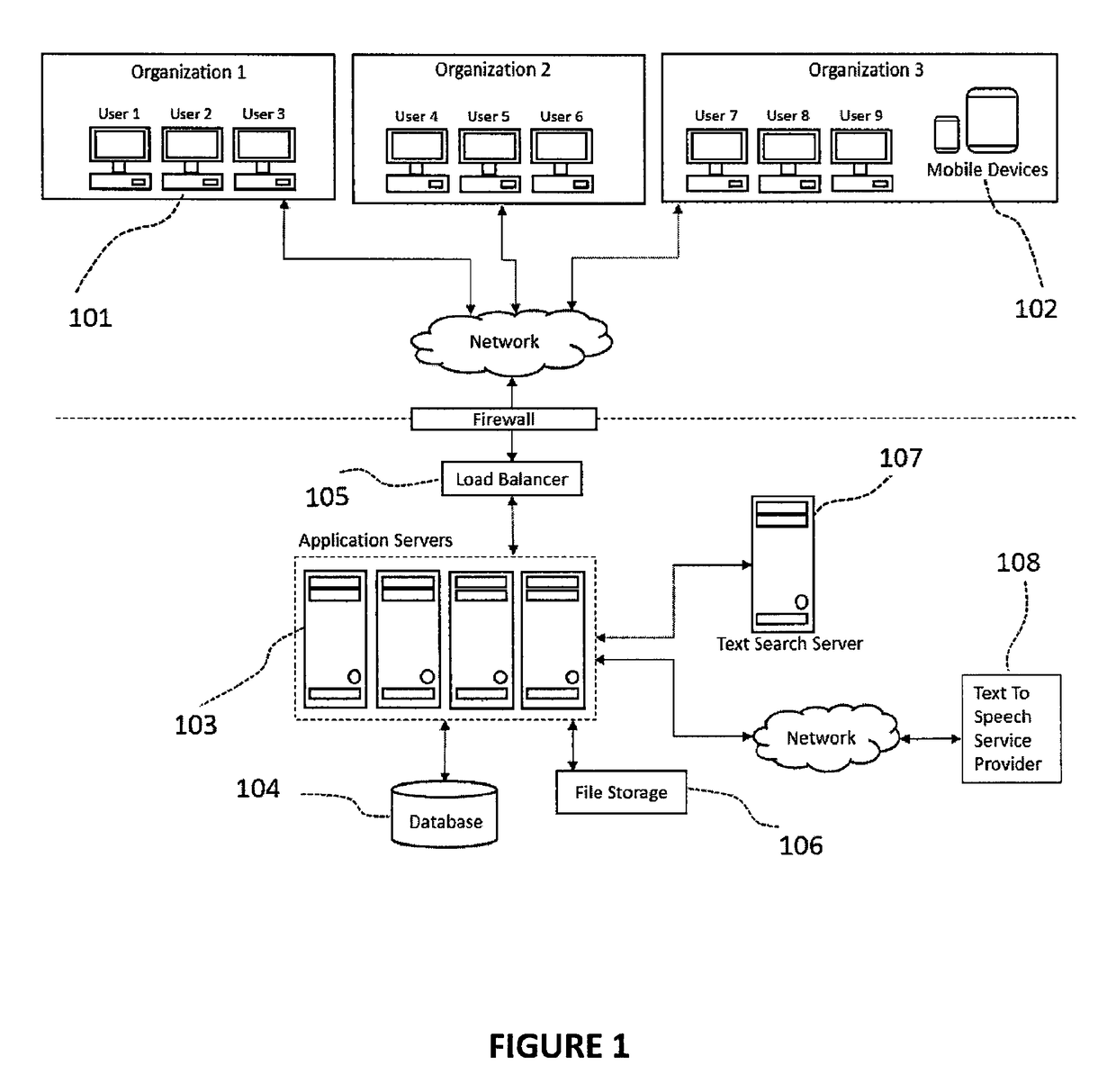

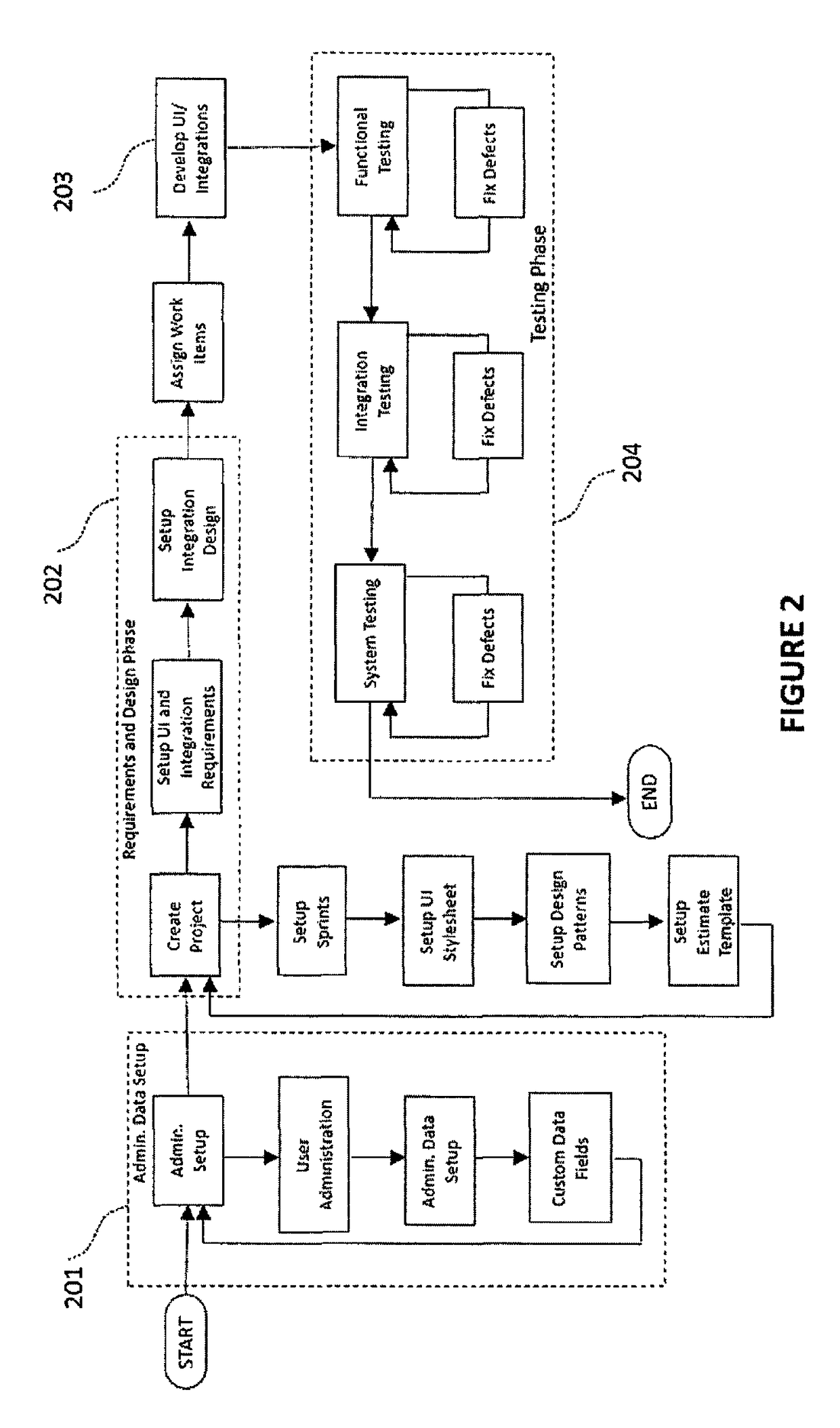

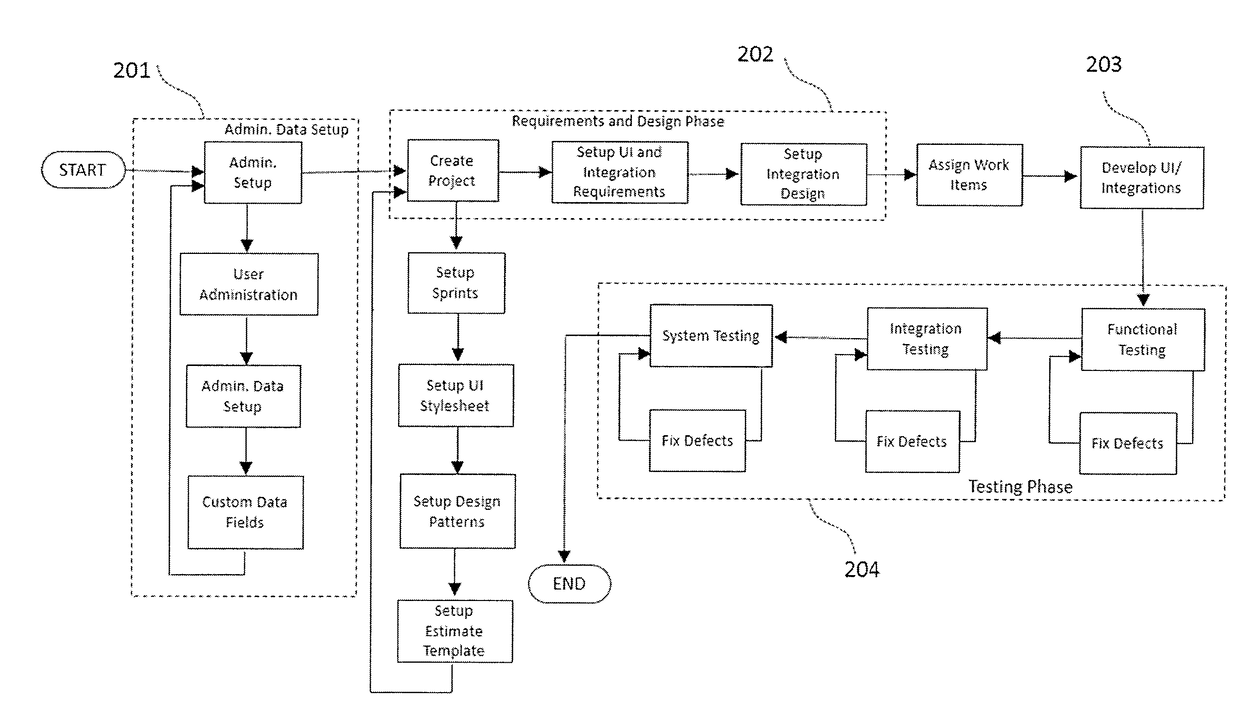

Methods and systems are disclosed for developing a software application through requirements specification, design, effort estimation, assigning and tracking work items, development, testing, collaboration and project management. The system is structured as an integrated software development system allowing for structured, systematic and user friendly set up of requirements specification (including workflow, user interface, business rules and integrations), technical design for UI features and integrations using design patterns, automated effort estimation, automated story card and task creation. The system also provides a novel, audio-video playback capability for workflow visualization. Further, the system provides visual depiction of defects and changed items side-by-side with requirements, as well as predictive modeling of defects that allows for forecasting of defect completion rate. In the preferred embodiment, the system is delivered as a multi-tenant Software as a Service.

Owner:BHARTHULWAR SHRIDHAR V

Integrated System for Software Application Development

InactiveUS20170083290A1Equally distributedDigital data information retrievalVersion controlSoftware development processPredictive modelling

Methods and systems are disclosed for developing a software application through requirements specification, design, effort estimation, assigning and tracking work items, development, testing, collaboration and project management. The system is structured as an integrated software development system allowing for structured, systematic and user friendly set up of requirements specification (including workflow, user interface, business rules and integrations), technical design for UI features and integrations using design patterns, automated effort estimation, automated story card and task creation. The system also provides a novel, audio-video playback capability for workflow visualization. Further, the system provides visual depiction of defects and changed items side-by-side with requirements, as well as predictive modeling of defects that allows for forecasting of defect completion rate. In the preferred embodiment, the system is delivered as a multi-tenant Software as a Service.

Owner:BHARTHULWAR SHRIDHAR V

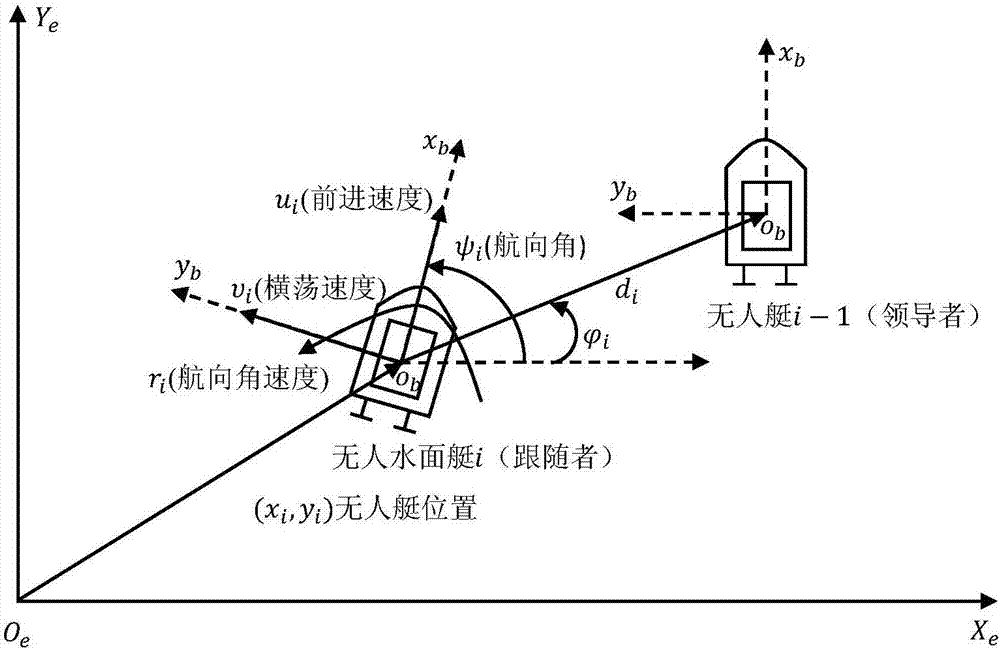

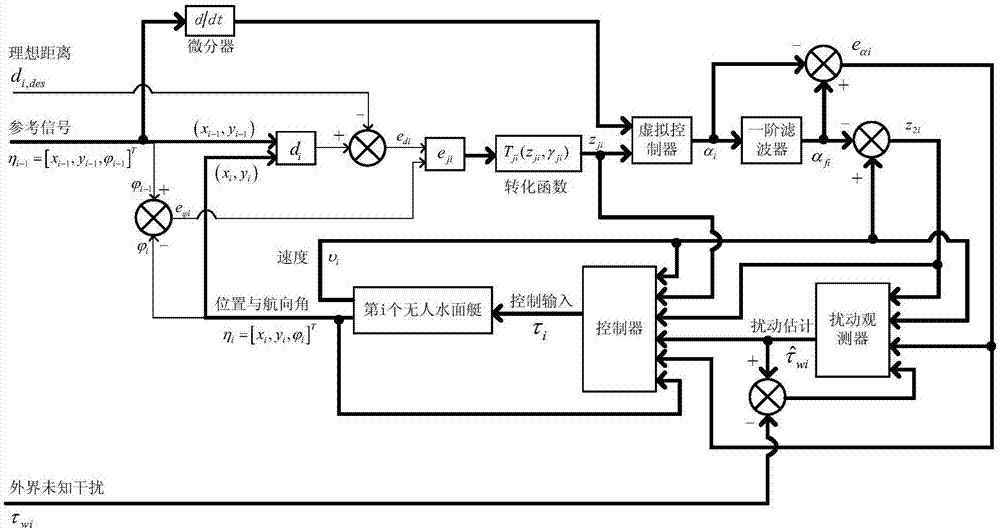

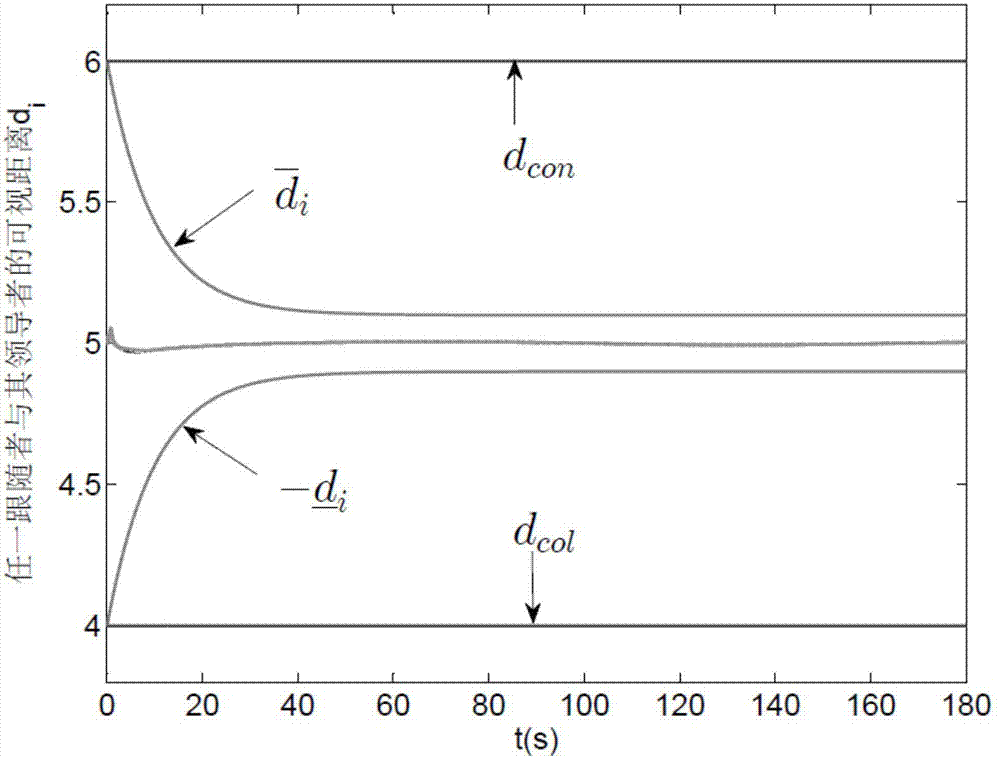

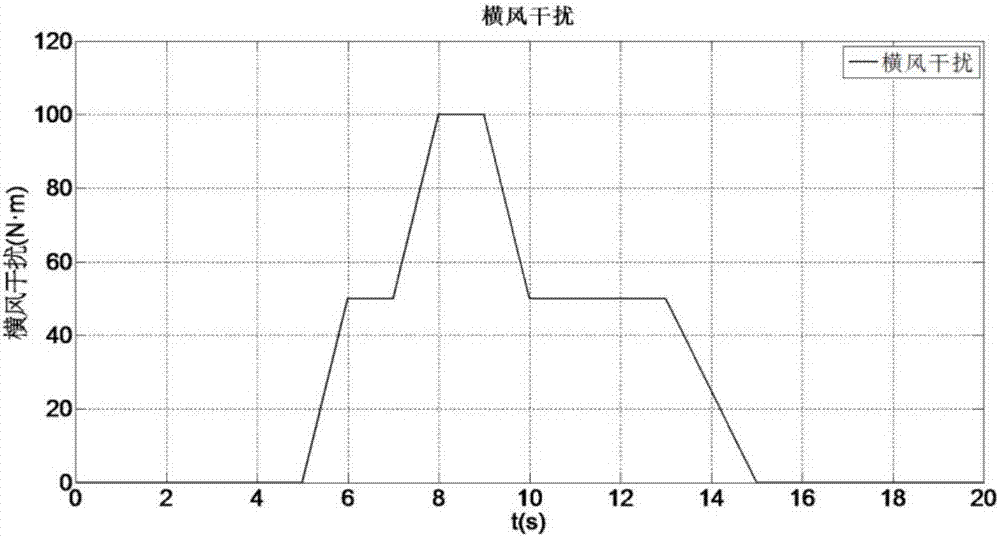

Unmanned surface vessel formation control method based on leader follow-up structure

ActiveCN107085427AImprove robustnessImprove practicalityPosition/course control in two dimensionsWind waveDynamic models

The invention discloses an unmanned surface vessel formation control method based on a leader follow-up structure. The method is used for multiple fully-driven unmanned surface vessel systems, and a formation control method based on a leader-follower is provided to prevent any follower from colliding and being kept in connection with a leader thereof. The method comprises following steps of establishing a dynamic model of an unmanned surface vessel; setting a position output tracking error constraint condition of a follower; designing a tracking error conversion function; applying the dynamic surface control technology and designing a virtual controller; designing a disturbance observer for compensating external unknown interference like wind wave flows; and constructively designing a tracking formation controller. According to the invention, it is ensured that any follower is always kept away from the leader thereof for a certain safe distance, and is in a communication connection range of the leader thereof; and by use of the dynamic surface control technology, accelerated speed of the leader is prevented from being used and practicability of a design scheme is improved.

Owner:SOUTH CHINA UNIV OF TECH

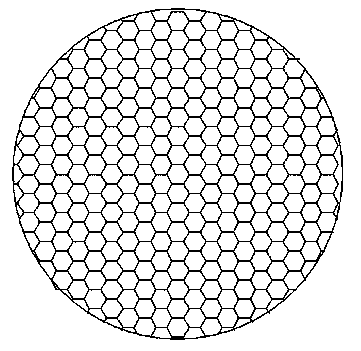

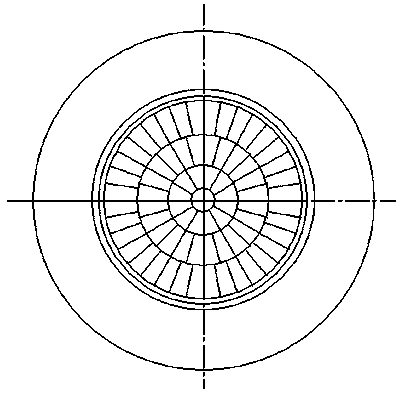

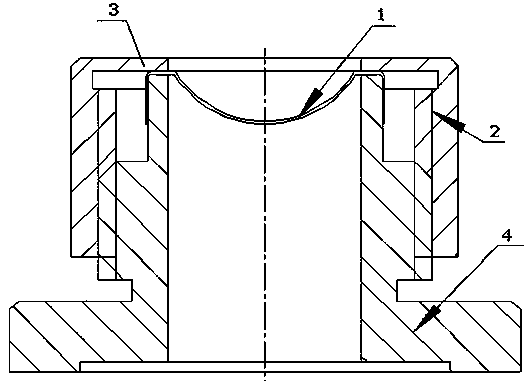

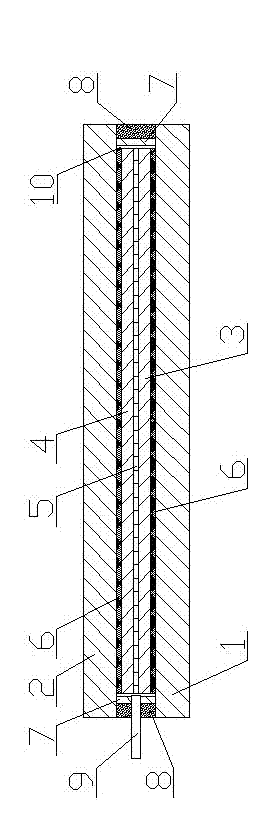

Picosecond pulse laser cutting preparation method for grid-control traveling wave tube grid mesh

ActiveCN103531414AHigh dimensional accuracyImprove consistencyNon-emitting electrodes manufacturePicosecond laserPicosecond pulsed laser

The invention discloses a picosecond pulse laser cutting preparation method for a grid-control traveling wave tube grid mesh. The method comprises the following steps of performing cleaning, hydrogen burning and annealing on a grid mesh material, then pressing the grid mesh material through a die on a punching machine to form a spherical grid mesh blank with high curvature radius precision, performing destressing hydrogen burning on the blank to eliminate stress during processing to guarantee the stability of the curvature radius of a spherical cap of a grid mesh, and finally cutting the grid mesh by adopting picosecond pulse laser of an optimized technology to prepare the grid-control traveling wave tube grid mesh with high size precision and high consistency. According to the preparation method for the grid mesh of a grid-control traveling wave tube, specific technical parameters of picosecond laser cutting are screened through a large number of experiments, the operability is high, the technical design is reasonable, and the application range is large; the prepared grid mesh is high in size precision, high in consistency, high in yield and high in reliability and has an important application value; the shortcoming of an existing electric spark grid mesh processing technology can be effectively overcome.

Owner:NANJING SANLE GROUP

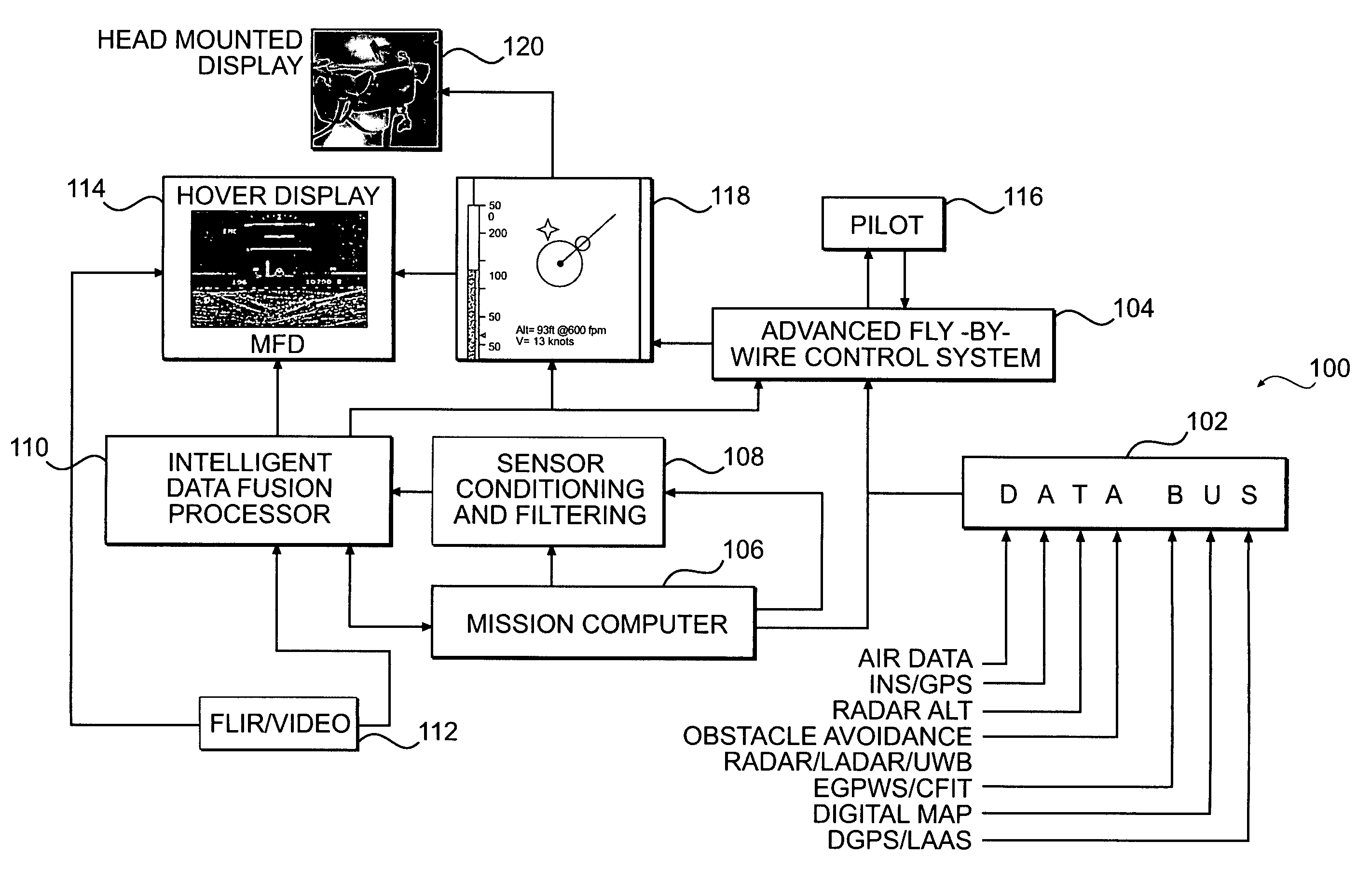

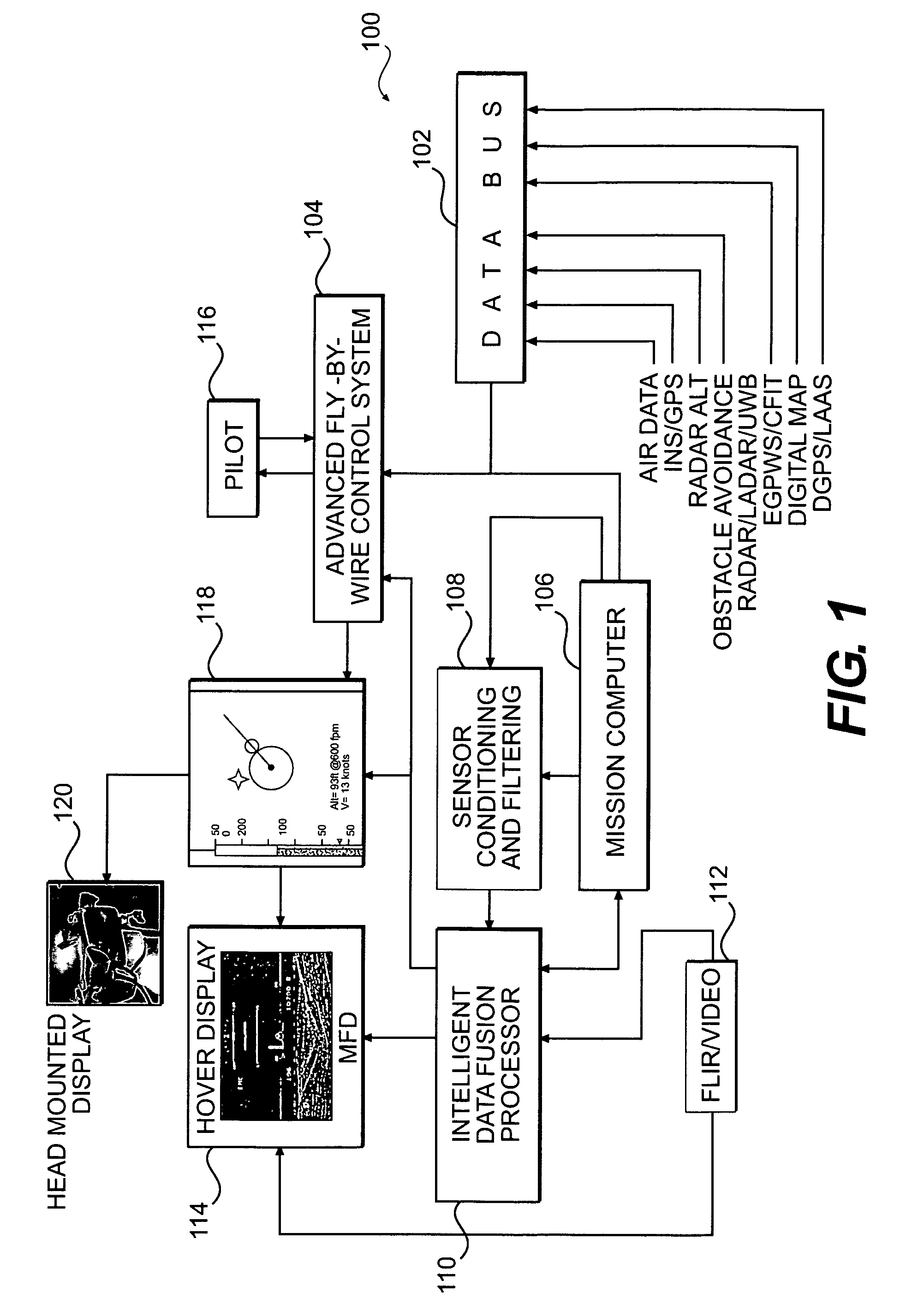

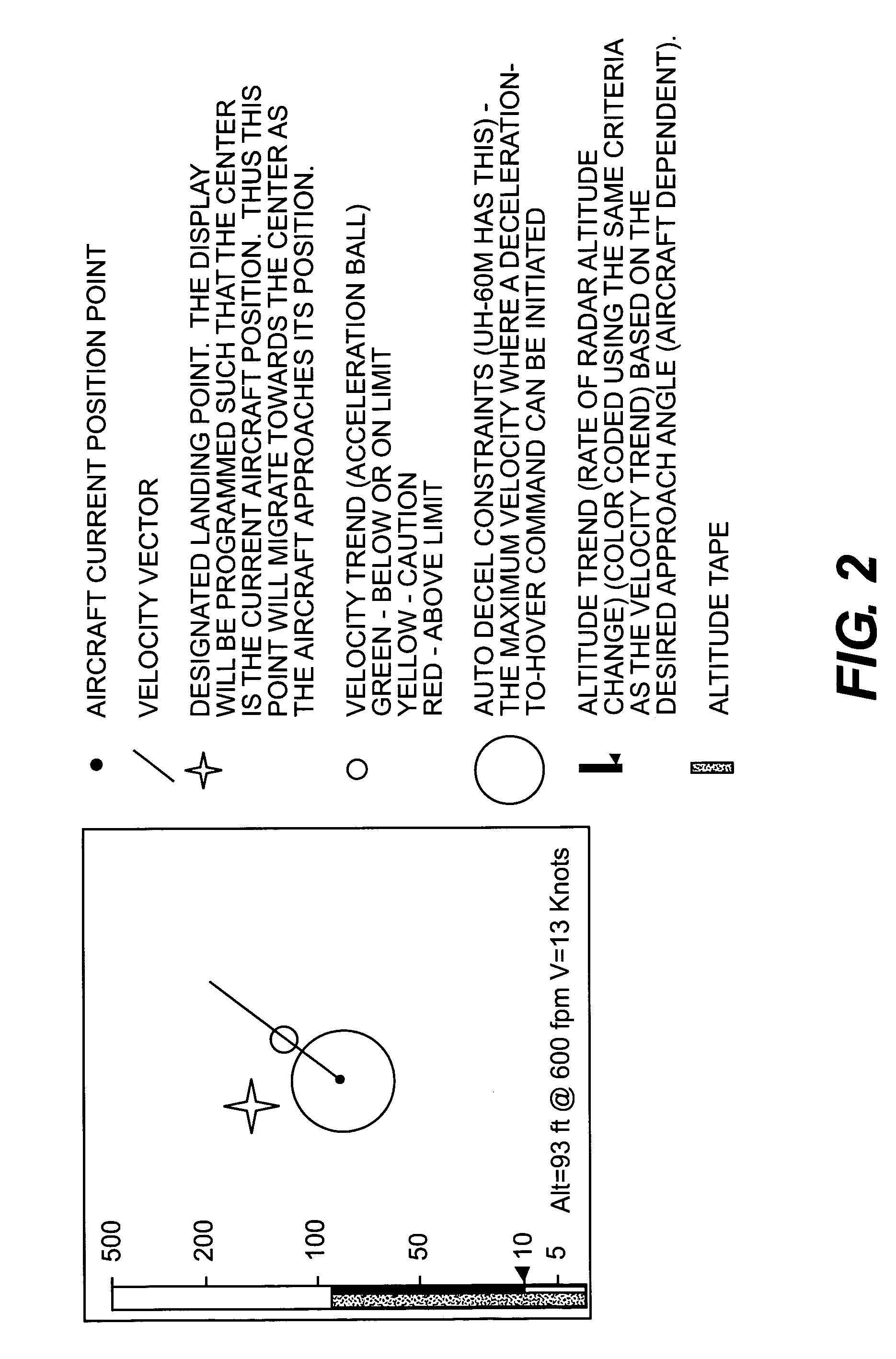

Technical design concepts to improve helicopter obstacle avoidance and operations in "brownout" conditions

ActiveUS7106217B2Accurate predictionLess customizationAnalogue computers for trafficNavigation instrumentsHead-up displayFly-by-wire

A method for flying in a degraded visual environment comprising the steps of collecting environmental data, processing the data and fusing the data together into a combined input output. The output is fed into a head down display, head mounted or heads up display and, preferably to a fly-by-wire vertical take-off and landing capable vehicle wherein the fly-by-wire system makes automatic adjustments to the helicopter.

Owner:SIKORSKY AIRCRAFT CORP

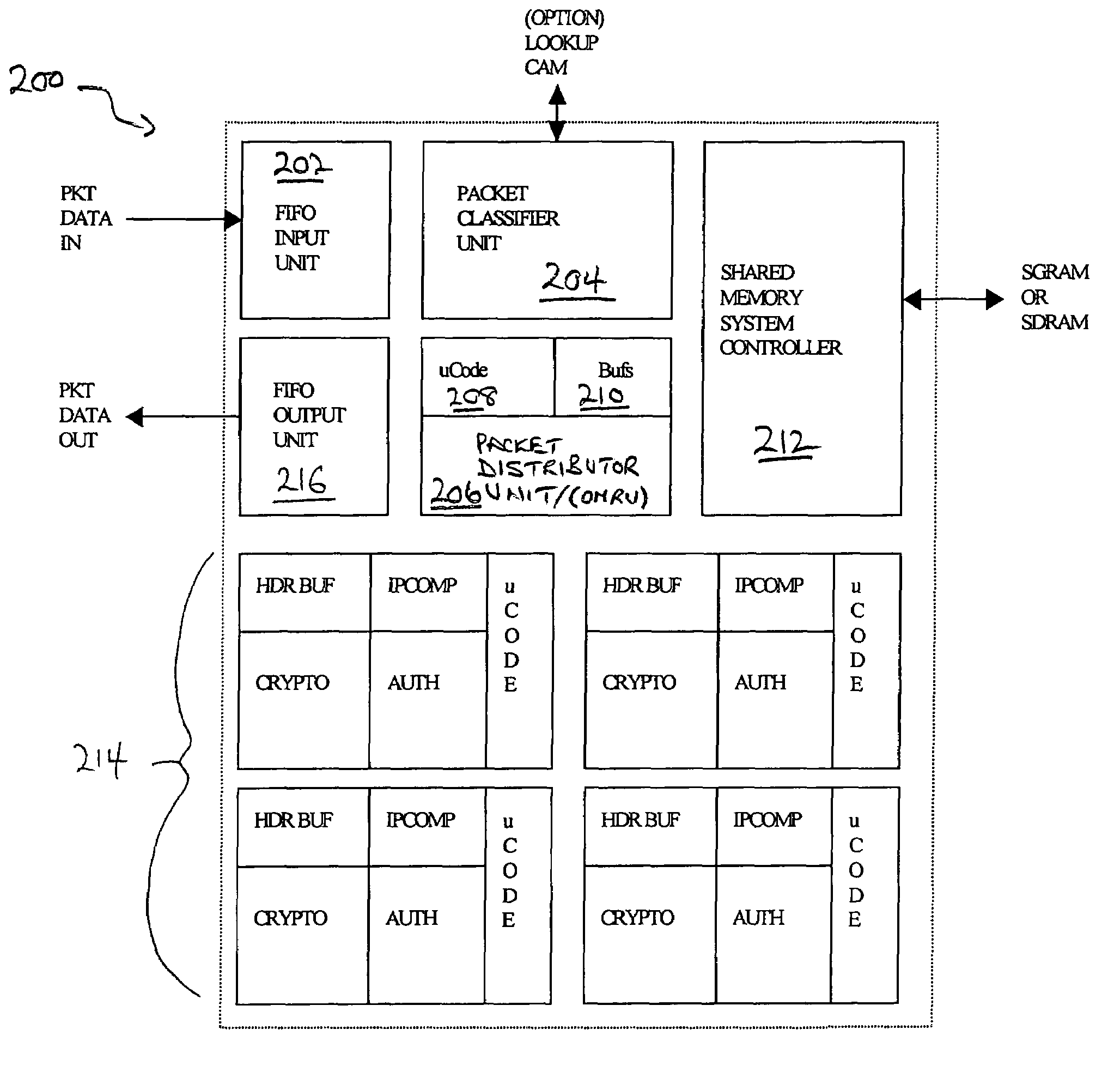

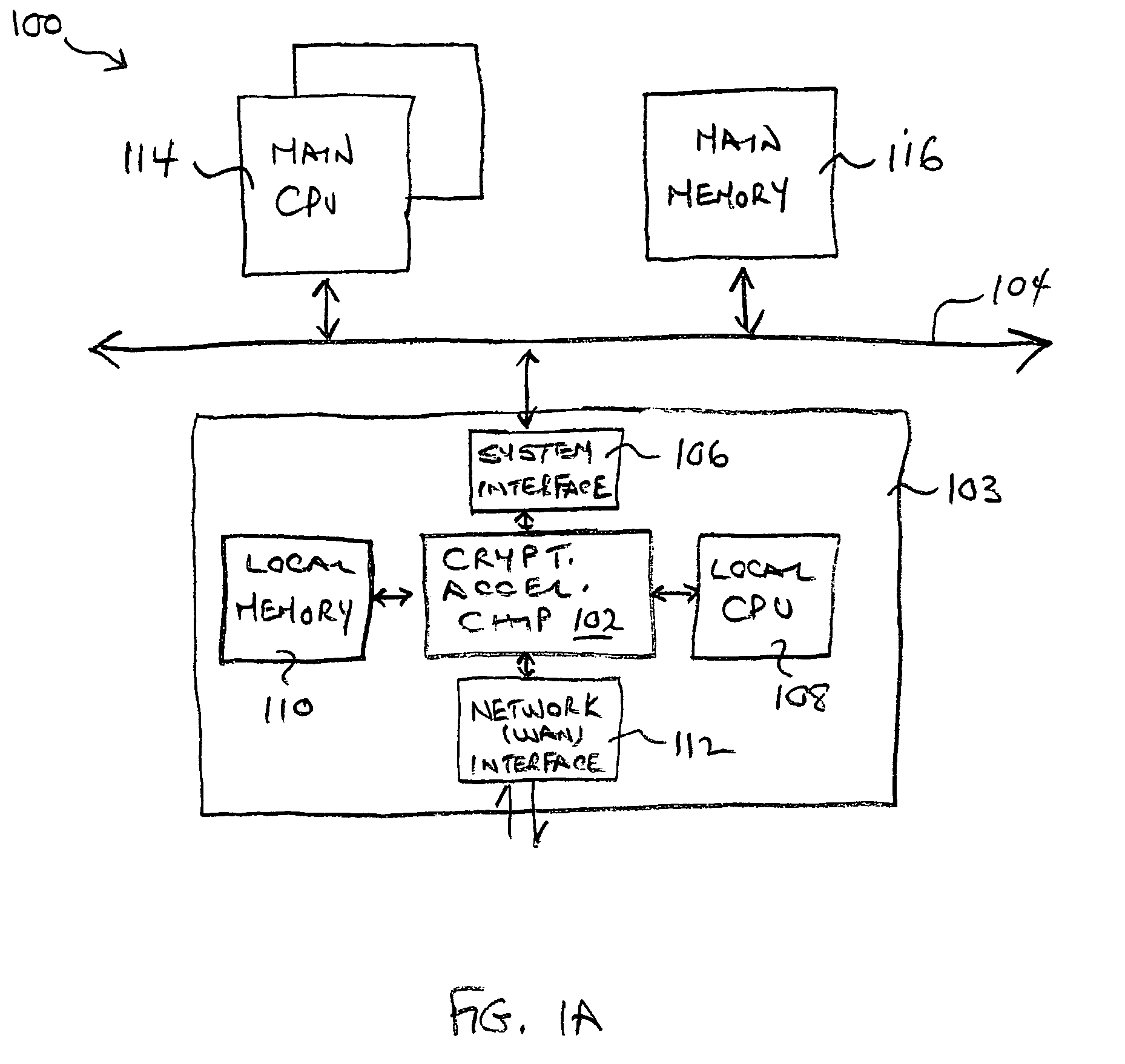

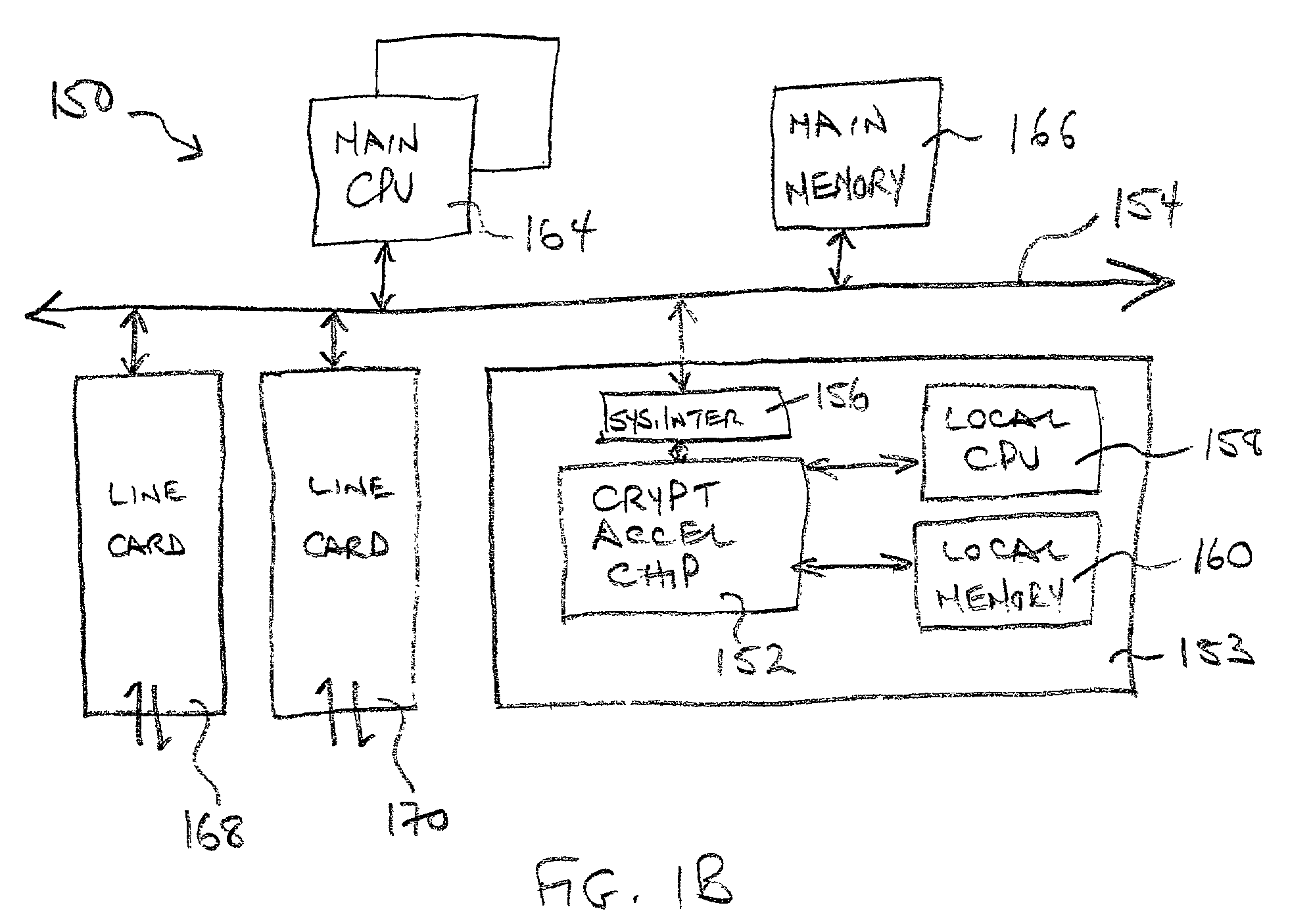

Distributed processing in a cryptography acceleration chip

InactiveUS7600131B1Efficient processingImprove performanceDigital data processing detailsUnauthorized memory use protectionCryptographic acceleratorNetwork service

Provided is an architecture for a cryptography accelerator chip that allows significant performance improvements over previous prior art designs. In various embodiments, the architecture enables parallel processing of packets through a plurality of cryptography engines and includes a classification engine configured to efficiently process encryption / decryption of data packets. Cryptography acceleration chips in accordance may be incorporated on network line cards or service modules and used in applications as diverse as connecting a single computer to a WAN, to large corporate networks, to networks servicing wide geographic areas (e.g., cities). The present invention provides improved performance over the prior art designs, with much reduced local memory requirements, in some cases requiring no additional external memory. In some embodiments, the present invention enables sustained full duplex Gigabit rate security processing of IPSec protocol data packets.

Owner:AVAGO TECH INT SALES PTE LTD

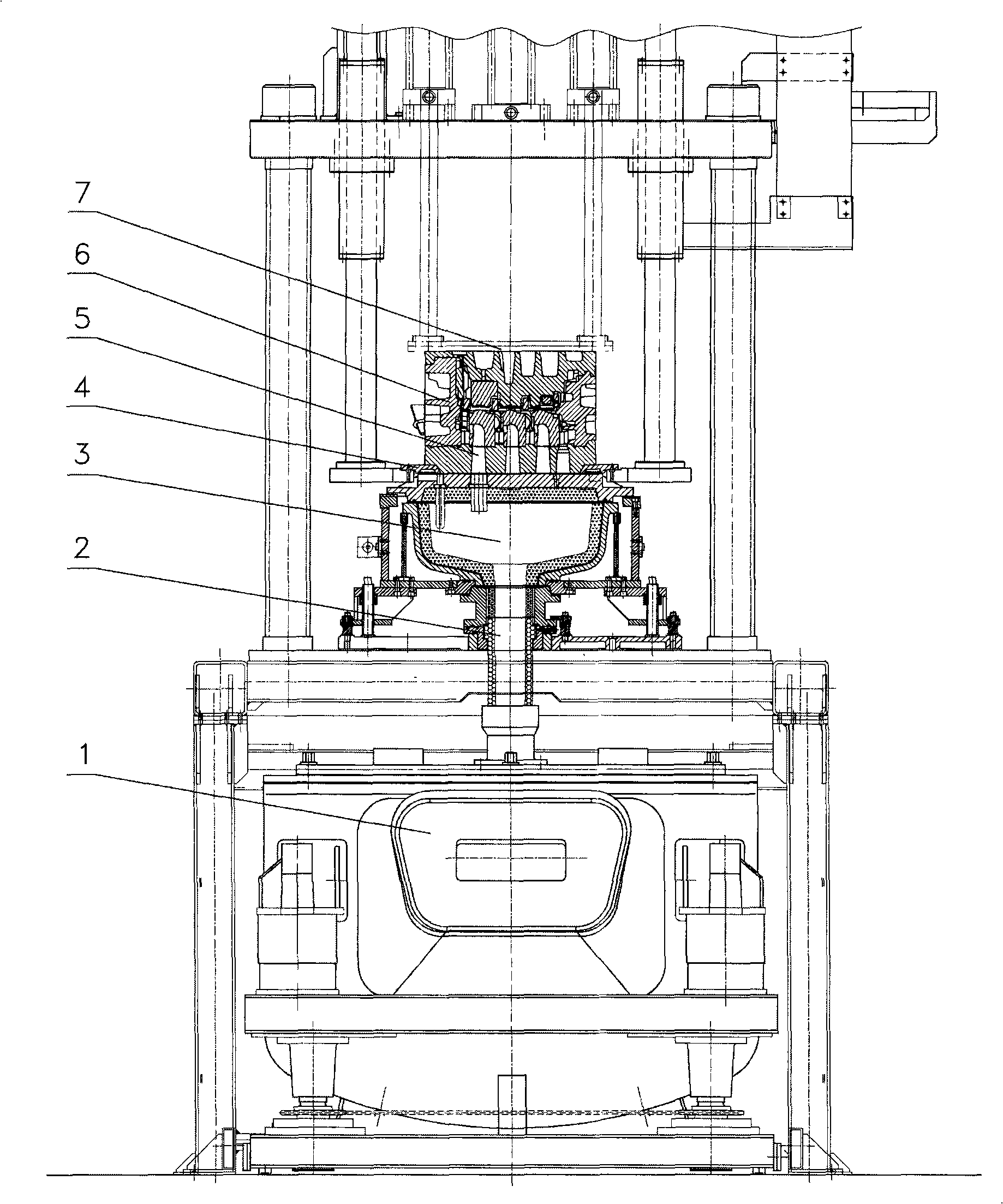

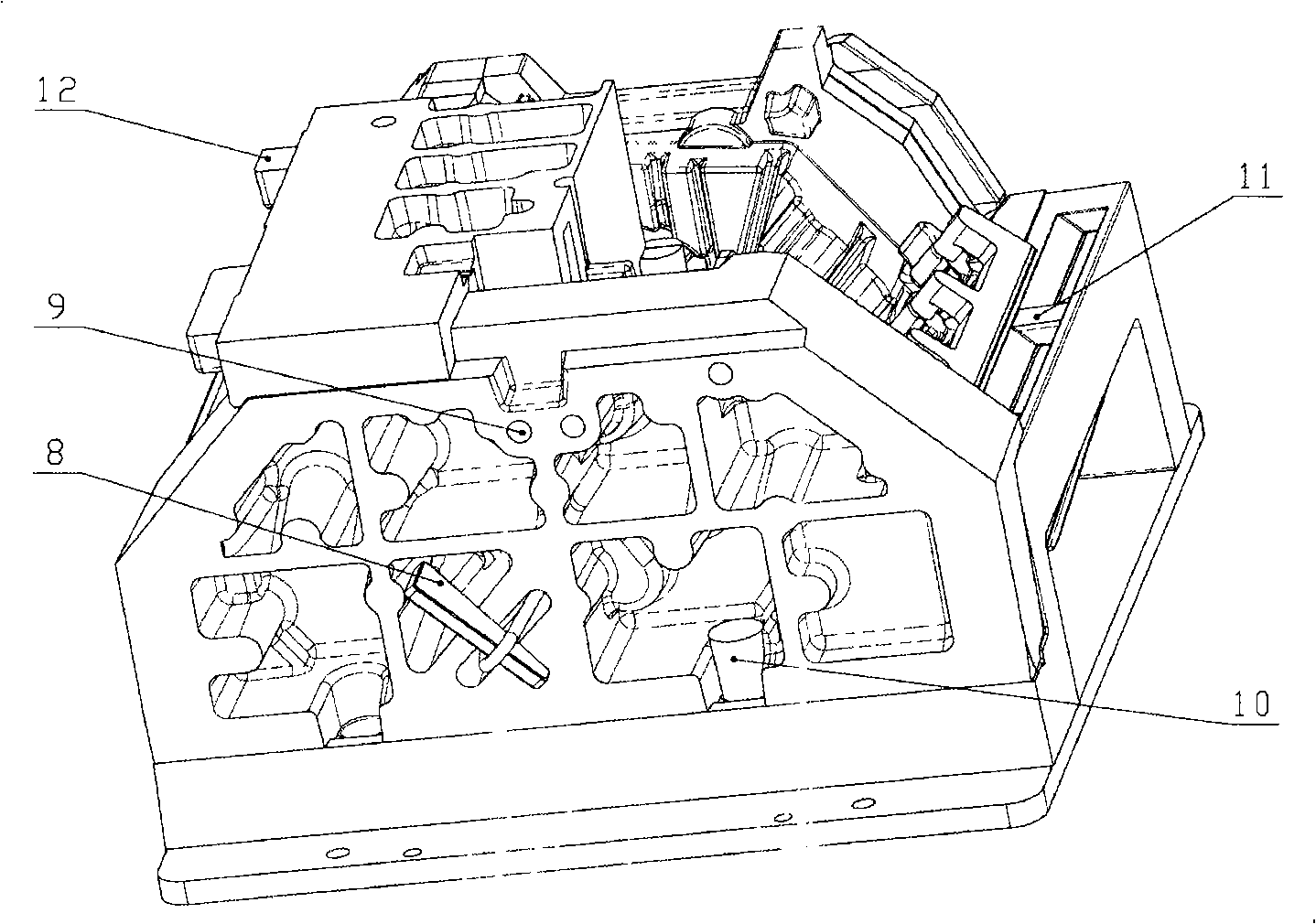

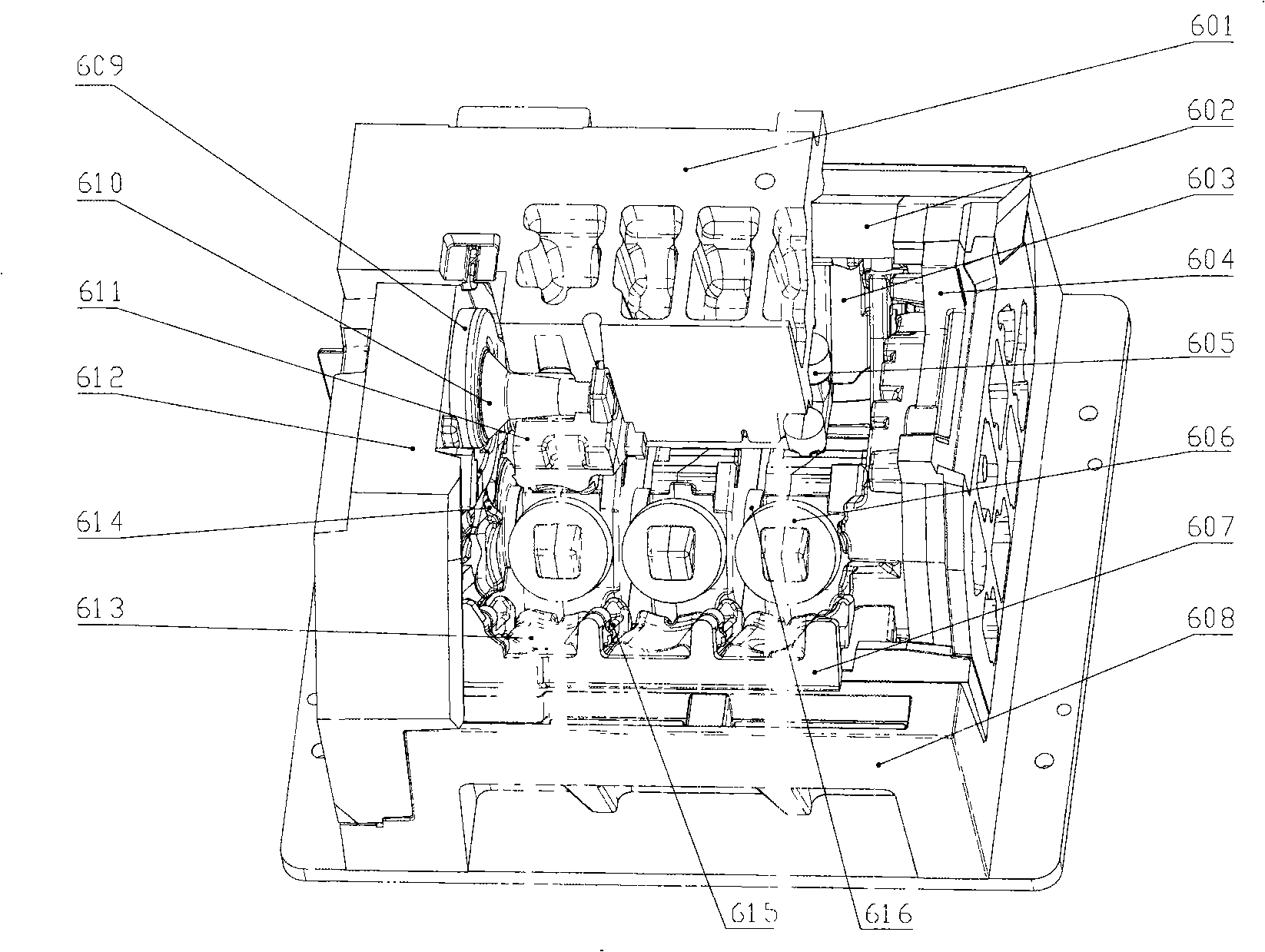

Low pressure multiple-core casting technique of engine V6 aluminum cylinder

InactiveCN101298091AImprove qualityLow costFoundry mouldsFoundry coresProduction lineHigh volume manufacturing

The invention discloses a low-pressure core assembly casting technique for V6 aluminum cylinder-block of engines, which is used for casting V6 aluminum cylinder-block of automobile engines. The casting technique adopted combines a low-pressure casting method and a core assembly method; the three-dimensional modeling of products is firstly carried out; according to the shape of the cast product, a crankcase is determined to be downwards and the aluminum liquid is let in from the baffle of the crankcase during casting course; the position of the sprue is selected and the size of the sprue is determined; a casting simulation software is adopted to carry out a simulation casting, the defects that are possible to occur are analyzed and a technical design scheme is made according to the analytic result, which essentially comprises the steps of : 1) making cores; 2) combining sand cores into a sand core group (6); 3) casting under low pressure. The casting technique of the invention can adopt flexible core assembly modes according to different shapes of engine blocks to produce aluminum cylinder-block cast products which are complex and of fine quality and has thin wall, meanwhile, the casting technique is applicable to the mass production with automatic production lines, thus having the advantages of low cost, high efficiency and high qualification rate.

Owner:NINGBO HELI TECH CO LTD

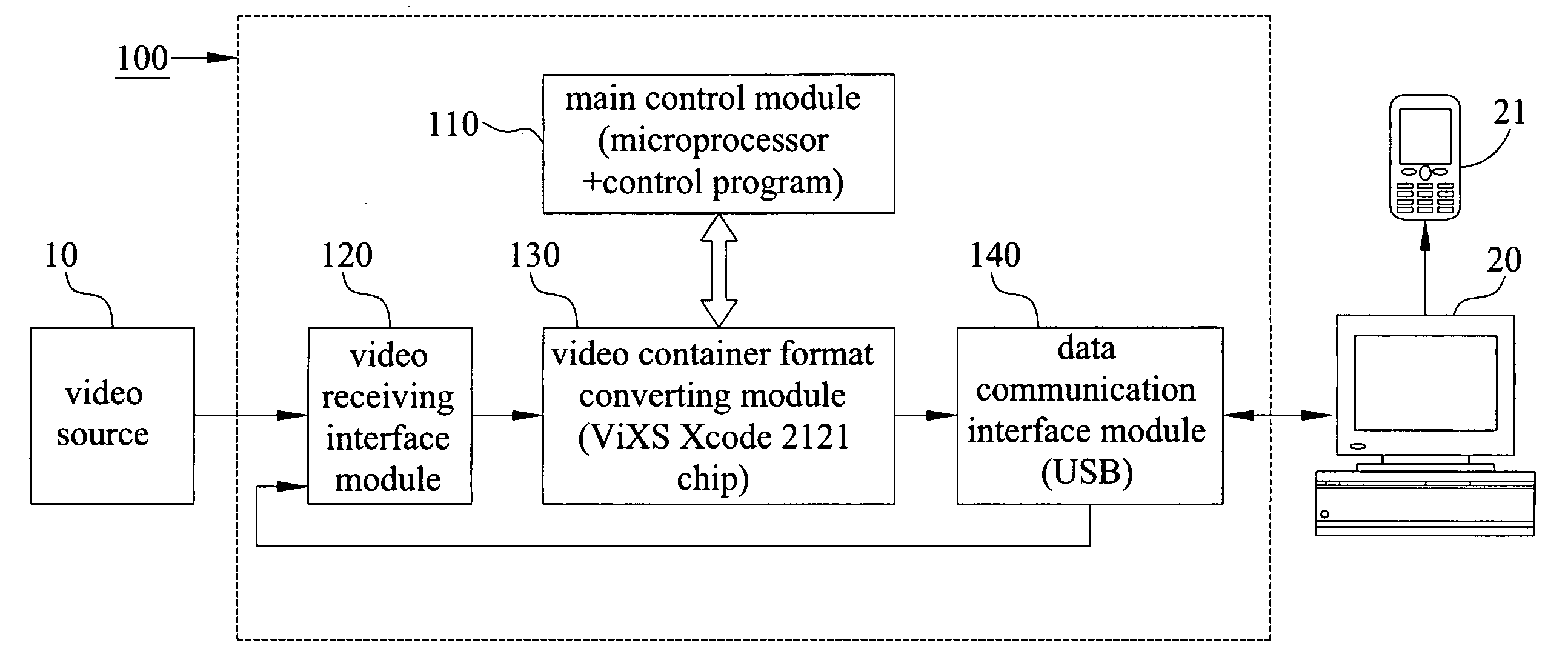

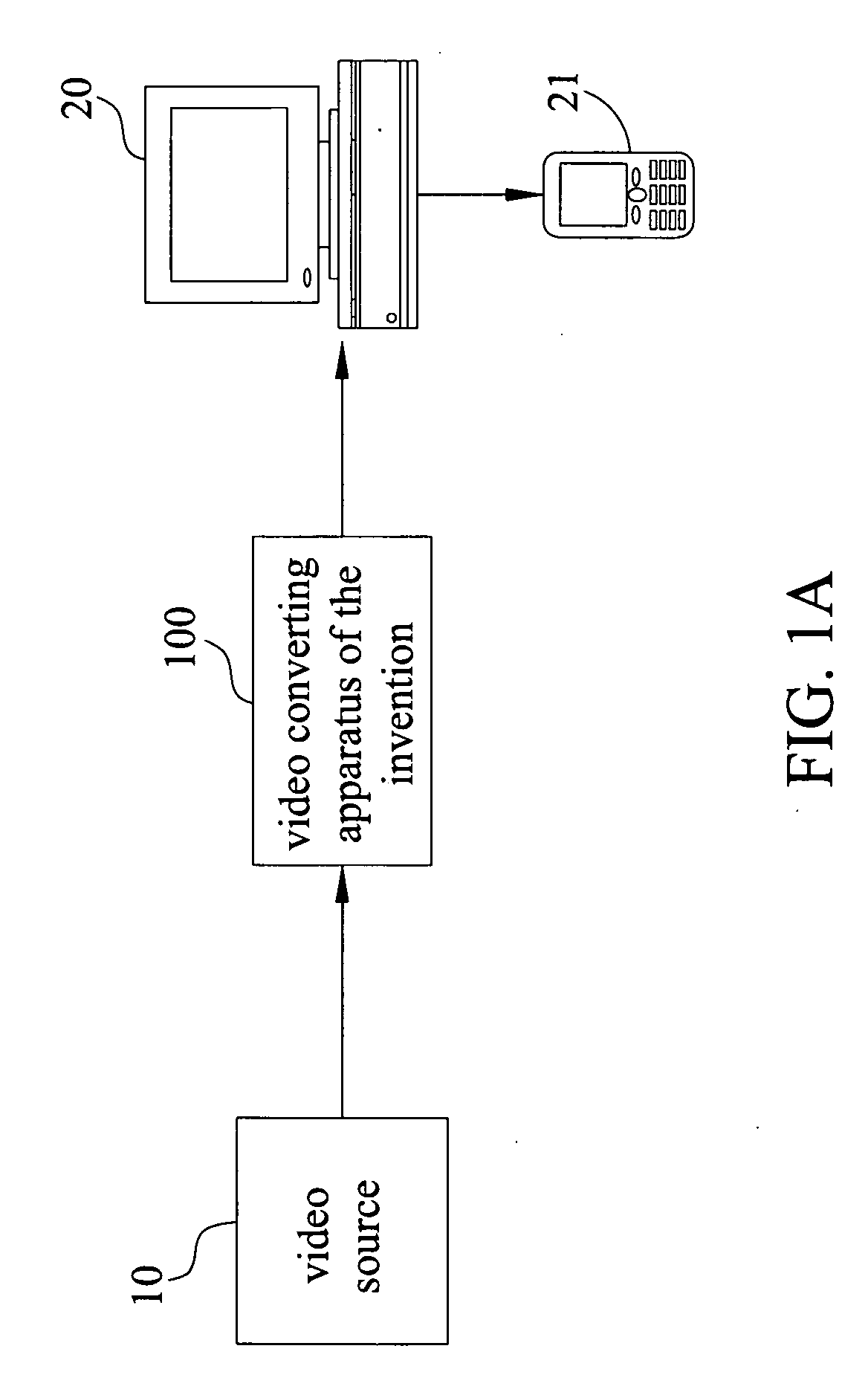

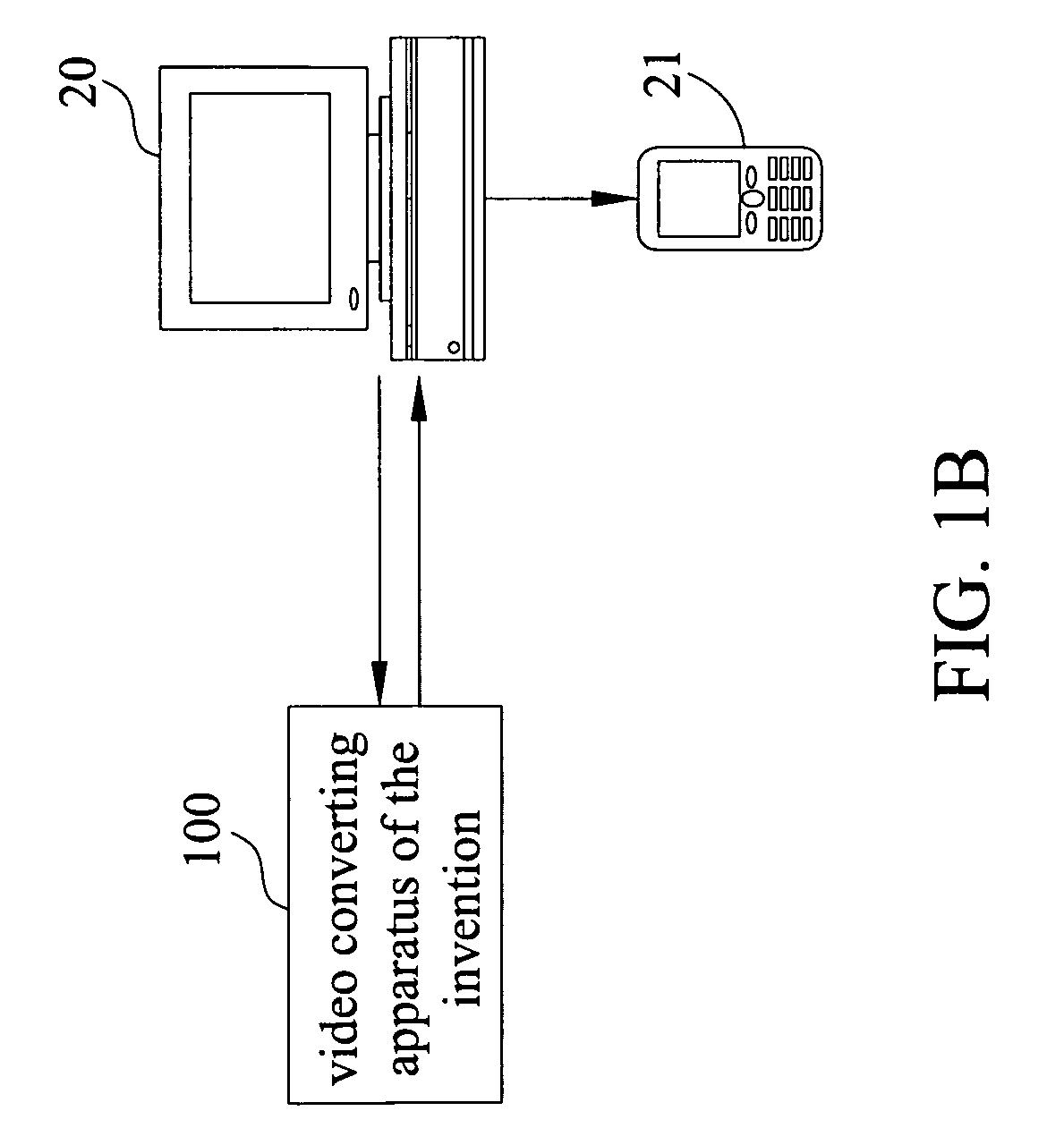

Schedulable multiple-formal video converting apparatus

InactiveUS20080284905A1Easy to processIncrease speedTelevision system detailsPicture reproducers using cathode ray tubesDigital videoVideo transmission

A programmable scheduling video converting apparatus applicable for converting the stream of video transmission signals in both analog and digital formats that are generated from various types of video data sources—such as cable TVs, digital TVs, digital video data of American and Japanese specification, satellite set-top boxes, CD / DVD disc players, digital cameras and surveillance cameras, or various kinds of digital video files stored in computers—to a storage file format specified by the user. The present invention is characterized in that it has a programmable scheduling converting function and, unlike prior art designs that use computer software programs, it employs a hardware-based converting chip to carry out format conversion, thereby improving the speed of format conversion over prior techniques.

Owner:INVENTEC MULTIMEDIA & TELECOM

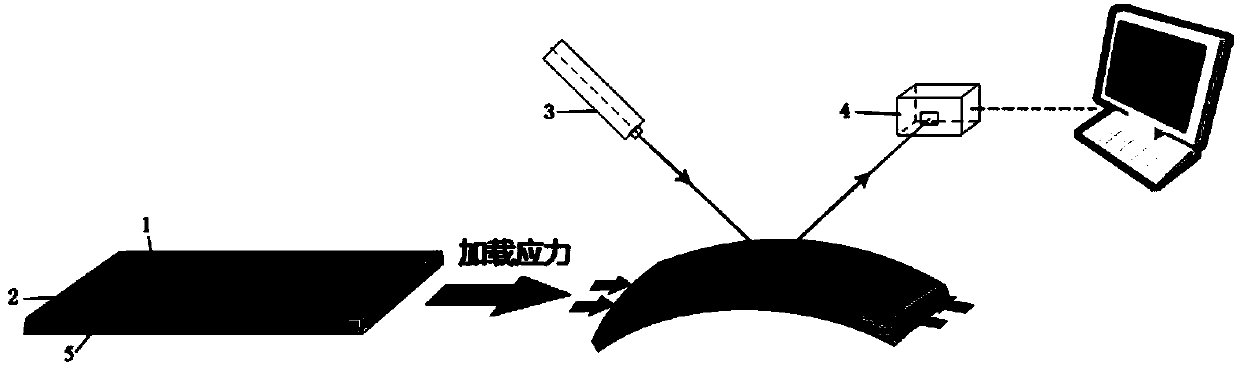

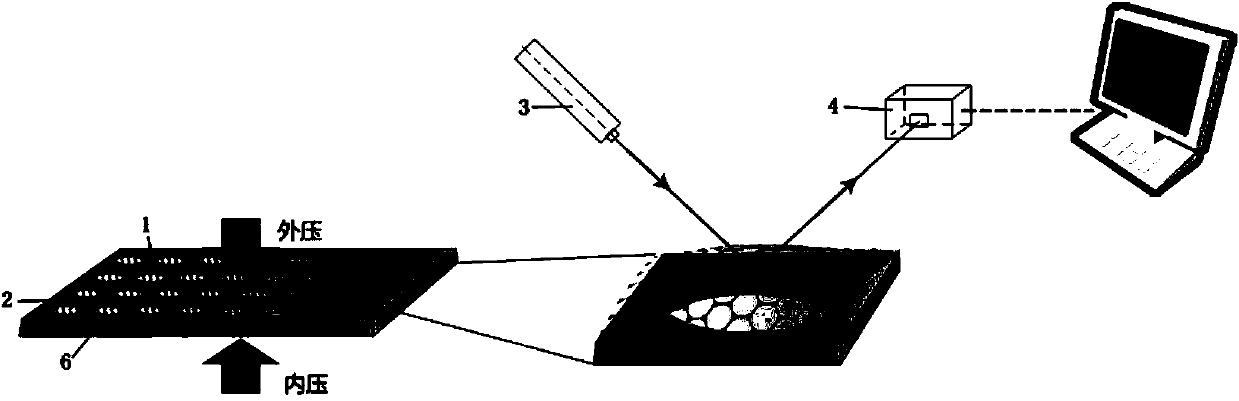

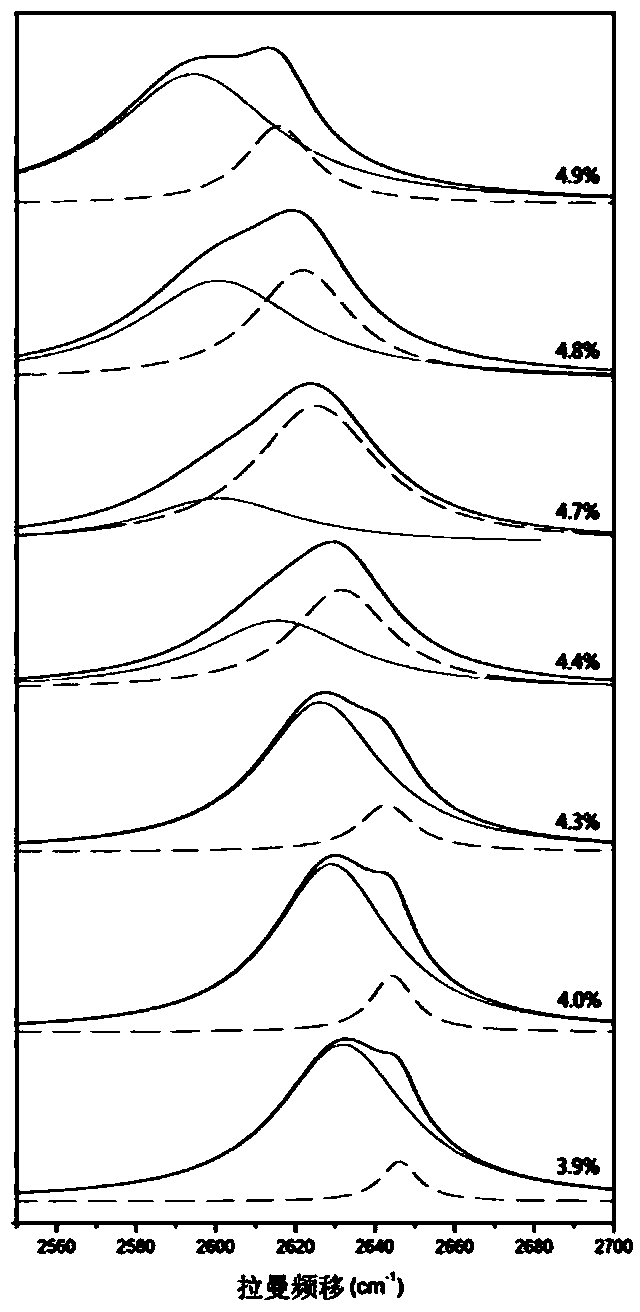

Device for measuring object stress by utilizing graphene membrane, and preparation method and testing method of device

ActiveCN103630272ASimple structureEasy to operateUsing optical meansChemical vapor deposition coatingStress measurementTechnical design

The invention discloses a device for measuring object stress by utilizing a graphene membrane, and a preparation method and a testing method of the device. The testing method is characterized in that graphene is arranged on a flexible stretchable substrate by utilizing a growth and transfer technology of the graphene and is tightly adhered to the surface of a to-be-measured object or a single crystal silicon substrate which is provided with a through hole, a characteristic peak of a Raman spectrum of the graphene can be subjected to shifting and splitting when the to-be-measured object is subjected to deformation or gas pressure difference exists between the internal part and the external part of the through hole, and sensing on strain or gas pressure can be realized basing on shifting and splitting amount of the characteristic peak. According to the device, the preparation method and the testing method, disclosed by the invention, the technical design is simple, the performance is stable, non-contact with the to-be-measured object is realized, and the complexity of an electrical measurement method which is in need of arranging leading wires can be avoided; the strain loading range is large, and the stress measurement accuracy degree is high.

Owner:西安超宇微晶新材料技术有限公司

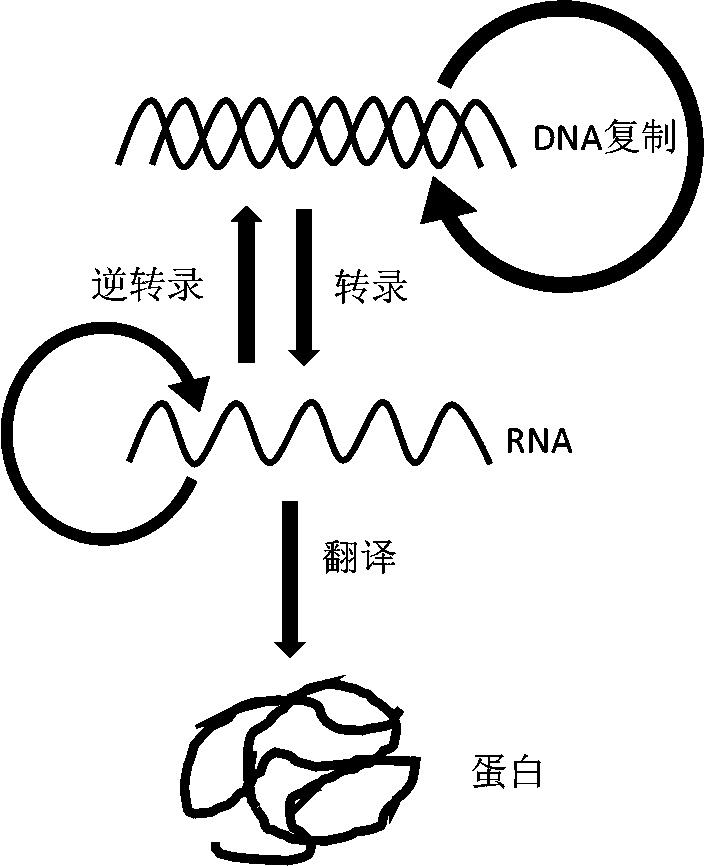

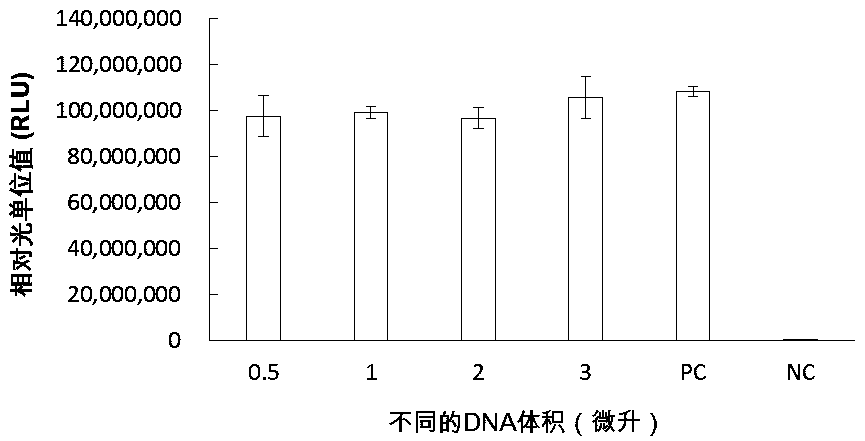

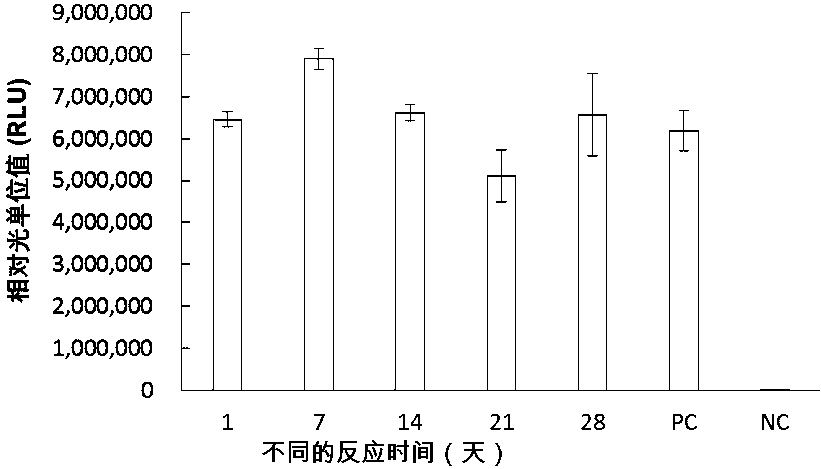

Synthesis system, preparation, kit and preparation method of in-vitro DNA-to-Protein (D2P)

The invention provides a theoretical design and technical design of cell-free protein synthesis for DNA replication, transcription and translation coupling, a preparation, a kit and a preparation method. Specifically, with the application of the in-vitro cell-free synthesis system provided by the invention, complex protein can be synthesized, and moreover, DNA and mRNA can be synthesized; and effective, high-throughput and quite convenient protein synthesis can be completed with the use of a DNA template by a minute quantity (nanogram-microgram).

Owner:KANGMA SHANGHAI BIOTECH LTD

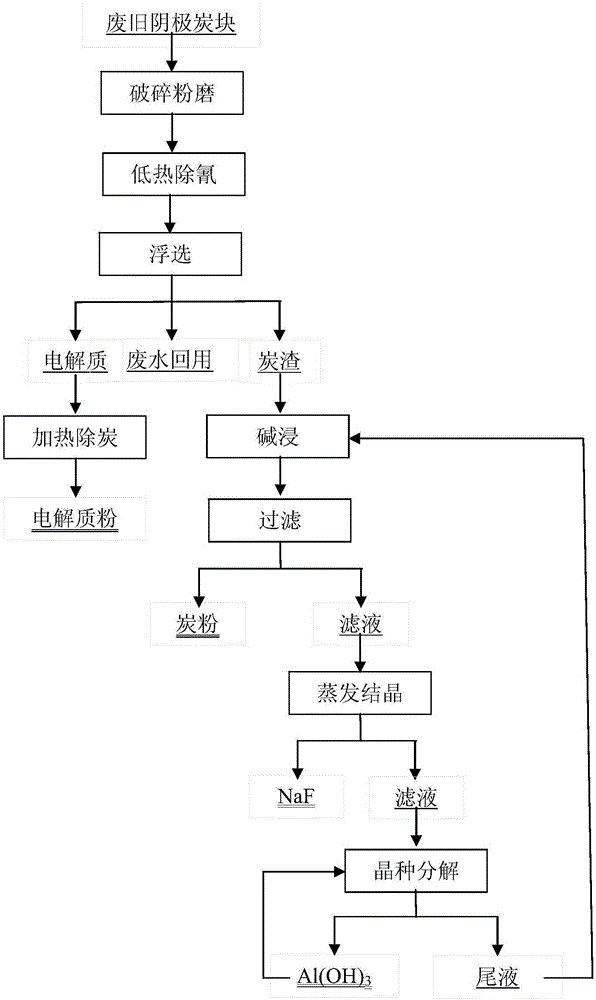

Comprehensive resource recycling method for waste cathode carbon blocks of aluminum cells

The invention relates to a comprehensive resource recycling method for waste cathode carbon blocks of aluminum cells and belongs to the technical field of comprehensive utilization of waste solid resources. The method includes the steps that the waste cathode carbon blocks of the aluminum cells are broken, so that spare particles are obtained; the particles are heated to the temperature of 200-400 DEG C, and flotation is carried out after the temperature is preserved, so that carbon slag and electrolyte slag are obtained; the electrolyte slag is heated to the temperature of 550-800 DEG C, the temperature is preserved, and then electrolyte powder is obtained; the carbon slag is added into alkali liquor for leaching, filtering is carried out after leaching, and filter residues and filtrate are obtained; the obtained filtrate is heated to the temperature of 60-90 DEG C and then subjected to evaporative crystallization, a solid A is separated out, filtering is carried out, and the solid A and residual fluid are obtained; and aluminum hydroxide seeds are added into the residual fluid, the mixture is heated to the temperature of 25-60 DEG C, the temperature is preserved, filtering is obtained, and a solid B and tail fluid are obtained. The method is reasonable in technical design, high in processing efficiency, high in matter recovery rate and recycling utilization ratio, free of secondary pollution and suitable for large-scale industrial application.

Owner:CENT SOUTH UNIV

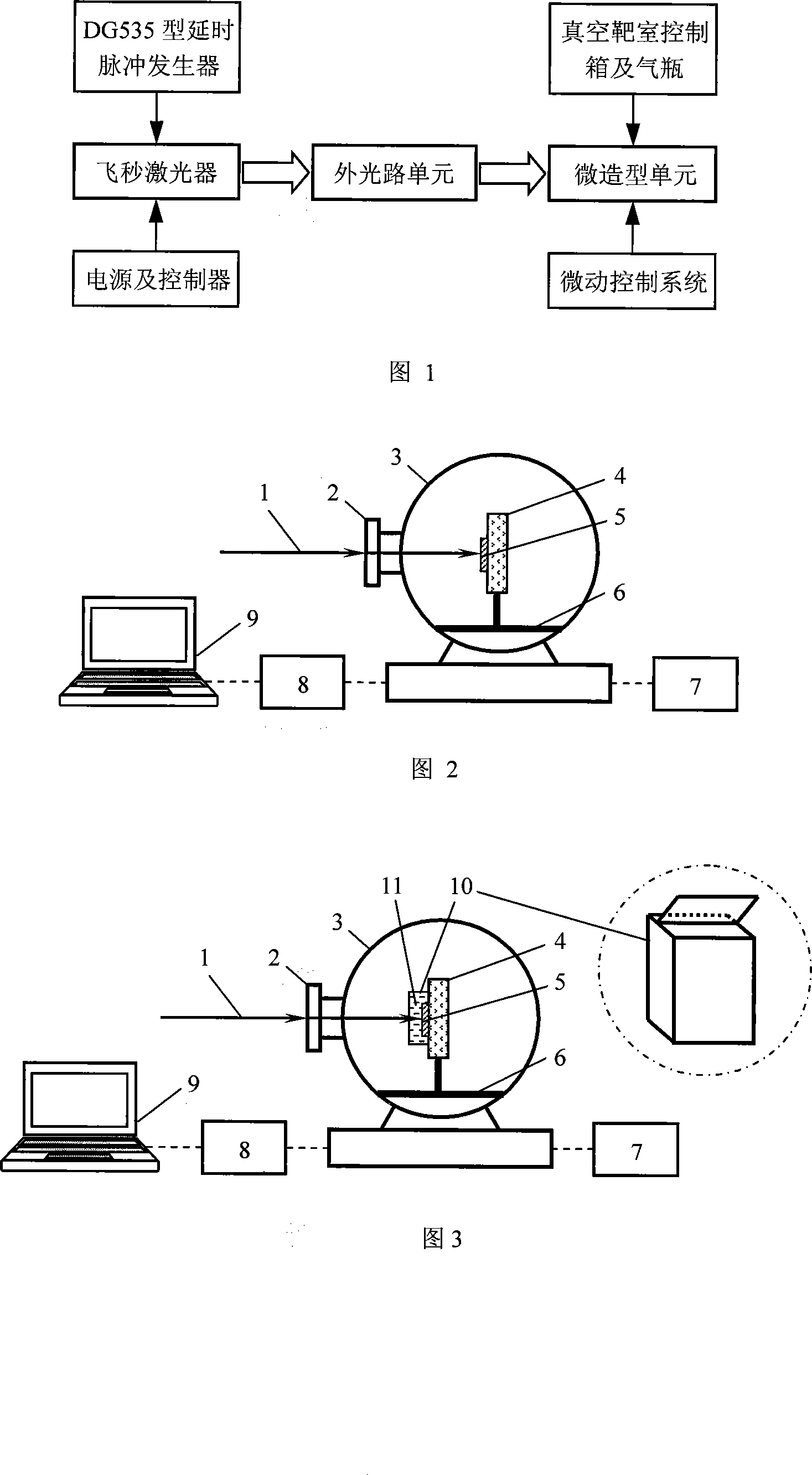

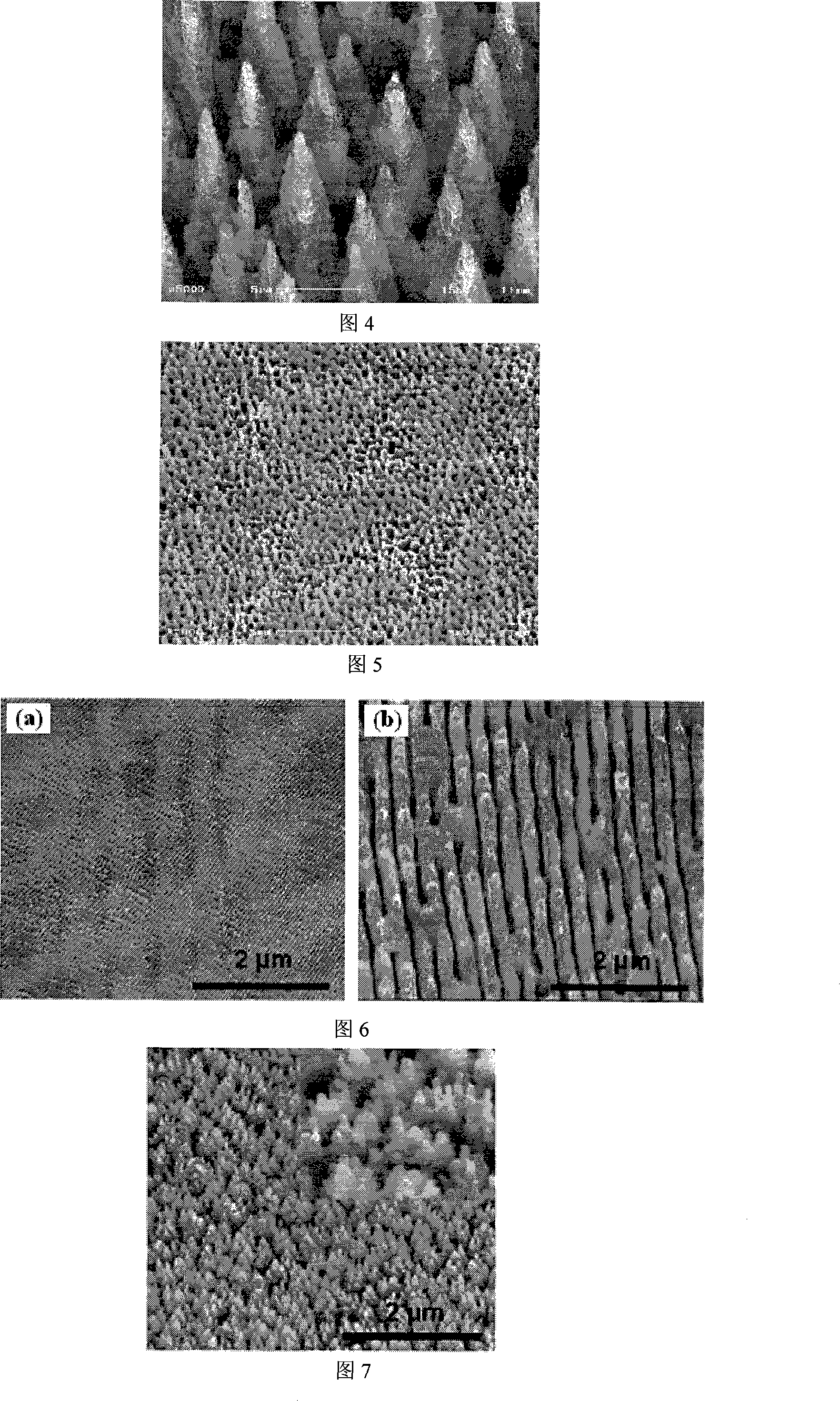

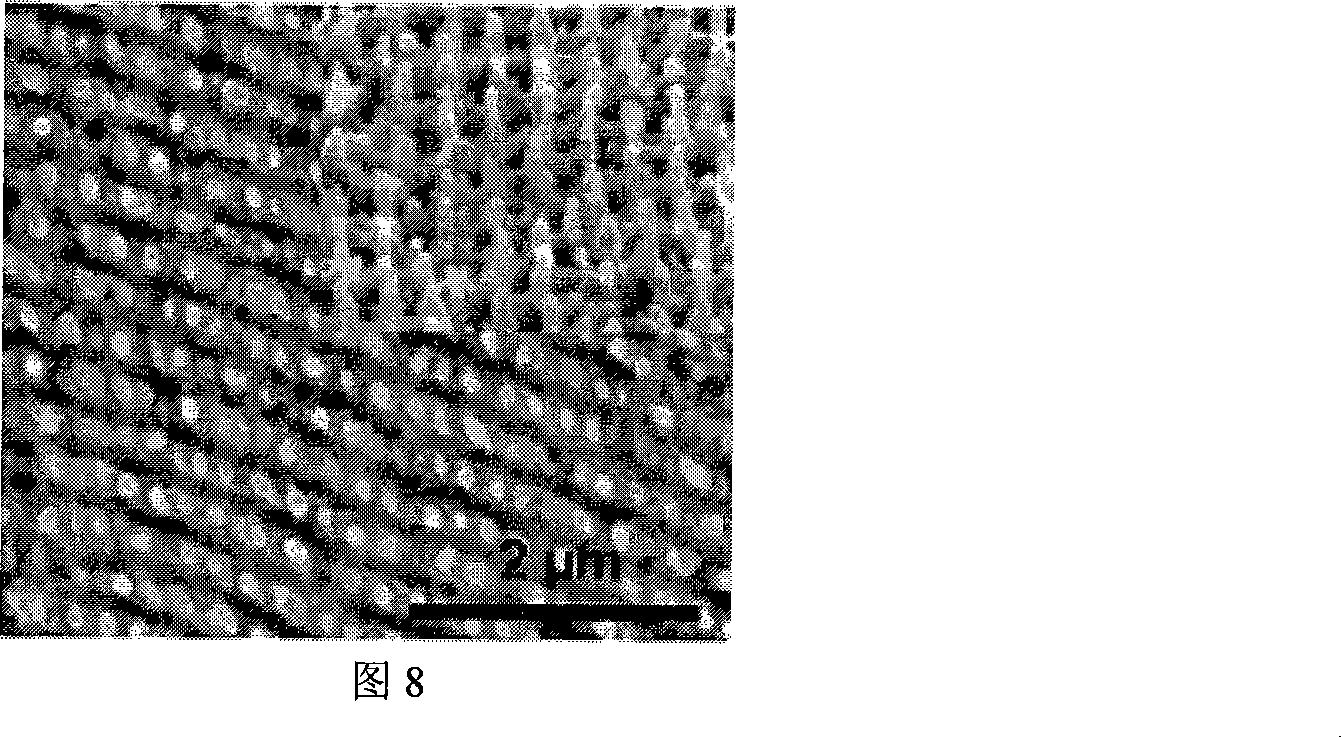

Laser modeling method for semiconductor material micro-nano multi-scale function surface

InactiveCN101219770AEasy to operateLow costNanostructure manufactureDecorative surface effectsMicro nanoMaterials preparation

The invention relates to a laser shaping method of a multi-scale functional surface of micronano for semiconductor material, relating to micronano material preparation and laser micromachining technical field; the invention aims at providing a method and a device for preparing femtosecond laser of super-hydrophobic functionalization for microstructural surface based on the semiconductor material and through the systematically technical design of multi-scale surface micro-shaping and microstructural surface processing, and realizing optional and controllable preparation of semiconductor material surface having multi-scale microstructure such as micron, submicron and nano. The invention solves the technical problems such as high cost, low efficiency and difficult operation in traditional preparation methods of microstructural surface with super-hydrophobic function.

Owner:JIANGSU UNIV

Preparation method of titanium-steel single-sided composite board

ActiveCN102773254AReasonable process designLow requirements for welding conditionsMetal rolling arrangementsLayer removalTechnical design

The invention discloses a preparation method of a titanium-steel single-sided composite board, comprising the following processing steps of: (1) respectively selecting two titanium plates with same size and two steel plates with same size and carrying out rust and oxide layer removal treatment on the surfaces of the plates; (2) assembling to form multiple layers of symmetrical combined blank sequentially including a steel plate, a transition layer, a titanium plate, a parting agent, a titanium plate, a transition layer and a steel plate, wherein a gap exists between the periphery of the titanium plate and a barrier strip in the combined blank; (3) compressing the combined blank and respectively welding the barrier strip with a first steel plate and a second steel plate to form a closed cavity among the first steel plate, the second steel plate and the barrier strip, drilling holes in the barrier strip and welding a steel tube in the holes, and communicating the steel tube and the closed cavity; (4) conveying the combined blank into a heating furnace to heat and vacuumizing; (5) sealing the outer end of the steel tube and then conveying the combined blank into a rolling mill; and (6) cutting the combined blank after rolling to obtain the titanium-steel single-sided composite board. The preparation method disclosed by the invention is rational in technical design and low in production cost.

Owner:河南盛荣金属复合新材料有限公司

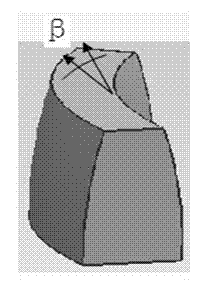

Fine forging forming method of spiral bevel gears

InactiveCN102240774AReduce radial flowAvoid destructionForging/hammering/pressing machinesWheelsSand blastingTechnical design

The invention discloses a fine forging forming method of spiral bevel gears, comprising the steps of: preparing for a material bar satisfying technical design requirements; heating the material bar to 1150-1180 DEG C; upsetting and punching as well as ring-enlarging the material bar on a press; pre-forging and forming in a pre-forging die on a multistage hot die forging press to obtain a pre-forging blank with pre-forging teeth, wherein the curved tooth spiral angle beta of the pre-forging die is 8-12 degrees smaller than that of a finish forging die; arranging the pre-forging blank on the multistage hot die forging press, and finish-forging and forming in the finish forging die; after a spheroidizing annealing treatment, cleaning the surface by sand-blasting, and phosphating and saponifying the surface; and finishing tooth profiles at normal temperature in a hydraulic machine. The method provided by the invention adopts a gradually forming manner consisting of pre-forging first and finish forging at last, therefore, the radial flow of the blank is greatly reduced, the side pressure of the blank to the tooth profile die cavity is reduced, the tooth profiles of the curved teeth of the forging die are prevented from being damaged, the service life of the forging die is prolonged, the production efficiency is improved, and the production cost can be efficiently reduced.

Owner:CHONGQING CHUANGJING WARM FORGING FORMING

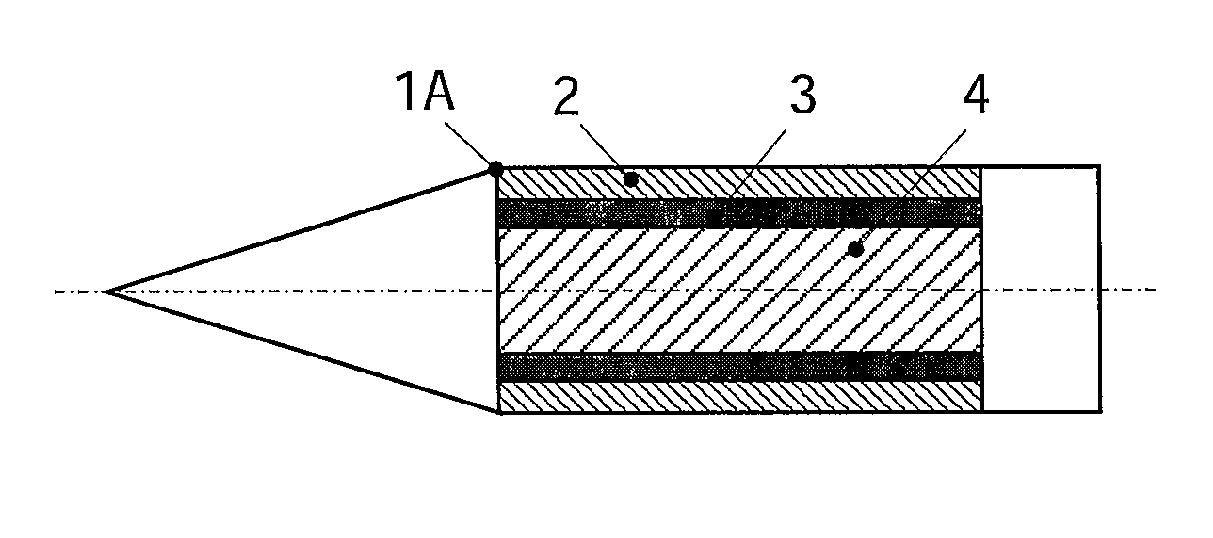

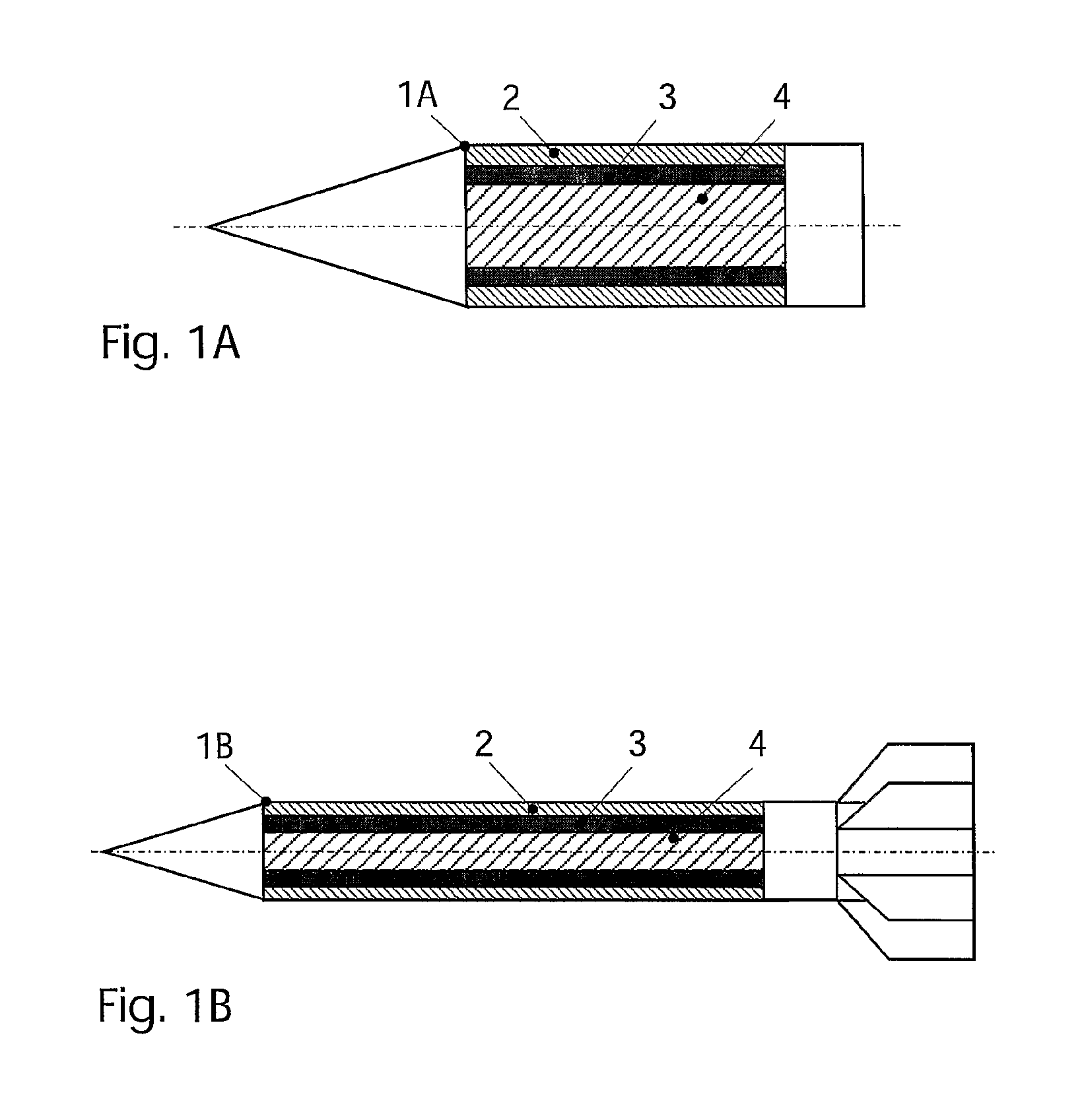

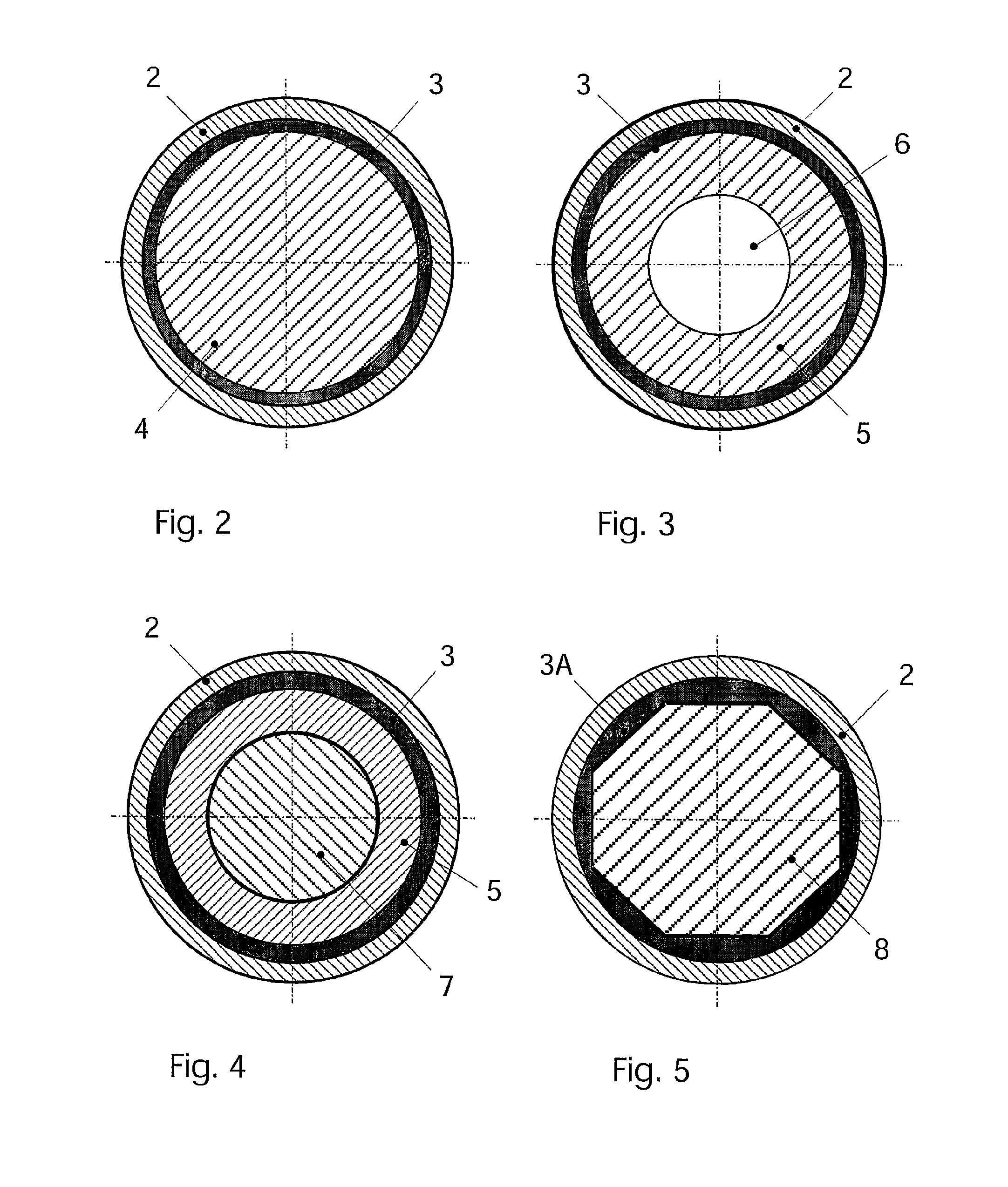

Projectile or warhead

InactiveUS20100199875A1Improve efficiencyHigh degreeAmmunition projectilesProjectilesEngineeringExplosive material

The aim of the invention is to obtain great final ballistic effectiveness of fragmentation bullets and warheads regardless of the impact speed while using as little explosive material as possible. Said aim is achieved by combining explosive shell (3) with a damming inner member (4) in connection with an accelerated outer jacket (2). This arrangement results in the best possible conversion of the explosive energy while offering great creative flexibility regarding the design. A wide range of additional possible effects is created by blast-compacting the inner damming member (4). Furthermore, the shape of the inner damming member allows the fragments to obtain a directionally controlled effect. Depending on the caliber and technical design, the amount of explosive material used can be reduced by 50 to 80 percent compared to conventional explosive bullets at comparable fragment speeds or sub-bullet speeds. The explosive material economized is available as additional effective mass. The accelerated jacket (2) can also be entirely or partly composed of preformed fragments or sub-bullets.

Owner:GEKE TECH

Integrated System for Software Application Development

InactiveUS20180210709A1Many stepsEqually distributedProgram documentationIntelligent editorsSoftware development processPredictive modelling

Methods and systems are disclosed for developing a software application through requirements specification, design, effort estimation, assigning and tracking work items, development, testing, collaboration and project management. The system is structured as an integrated software development system allowing for structured, systematic and user friendly set up of requirements specification (including workflow, user interface, business rules and integrations), technical design for UI features and integrations using design patterns, automated effort estimation, automated story card and task creation. The system also provides a novel, audio-video playback capability for workflow visualization. Further, the system provides visual depiction of defects and changed items side-by-side with requirements, as well as predictive modeling of defects that allows for forecasting of defect completion rate. In the preferred embodiment, the system is delivered as a multi-tenant Software as a Service.

Owner:BHARTHULWAR SHRIDHAR V

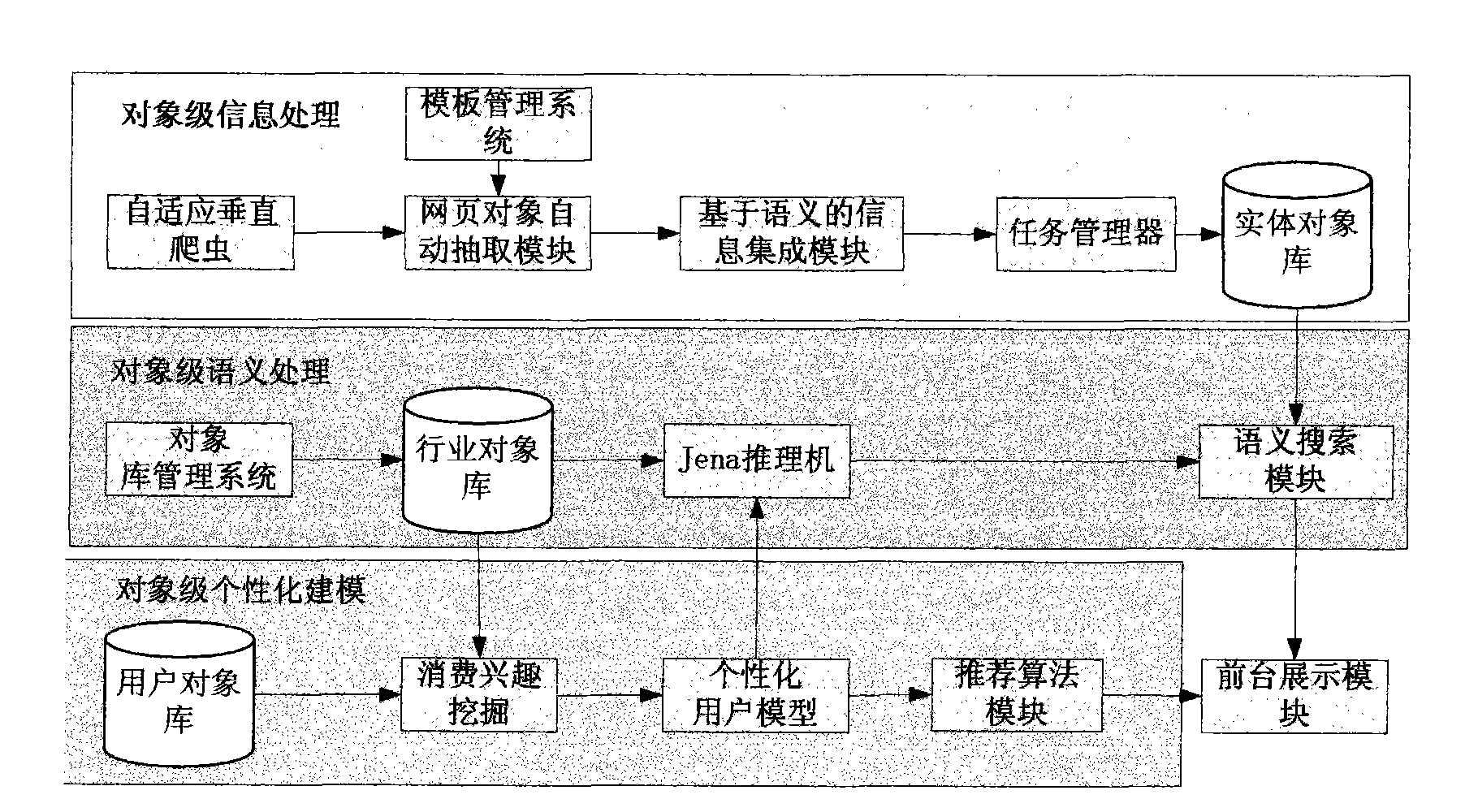

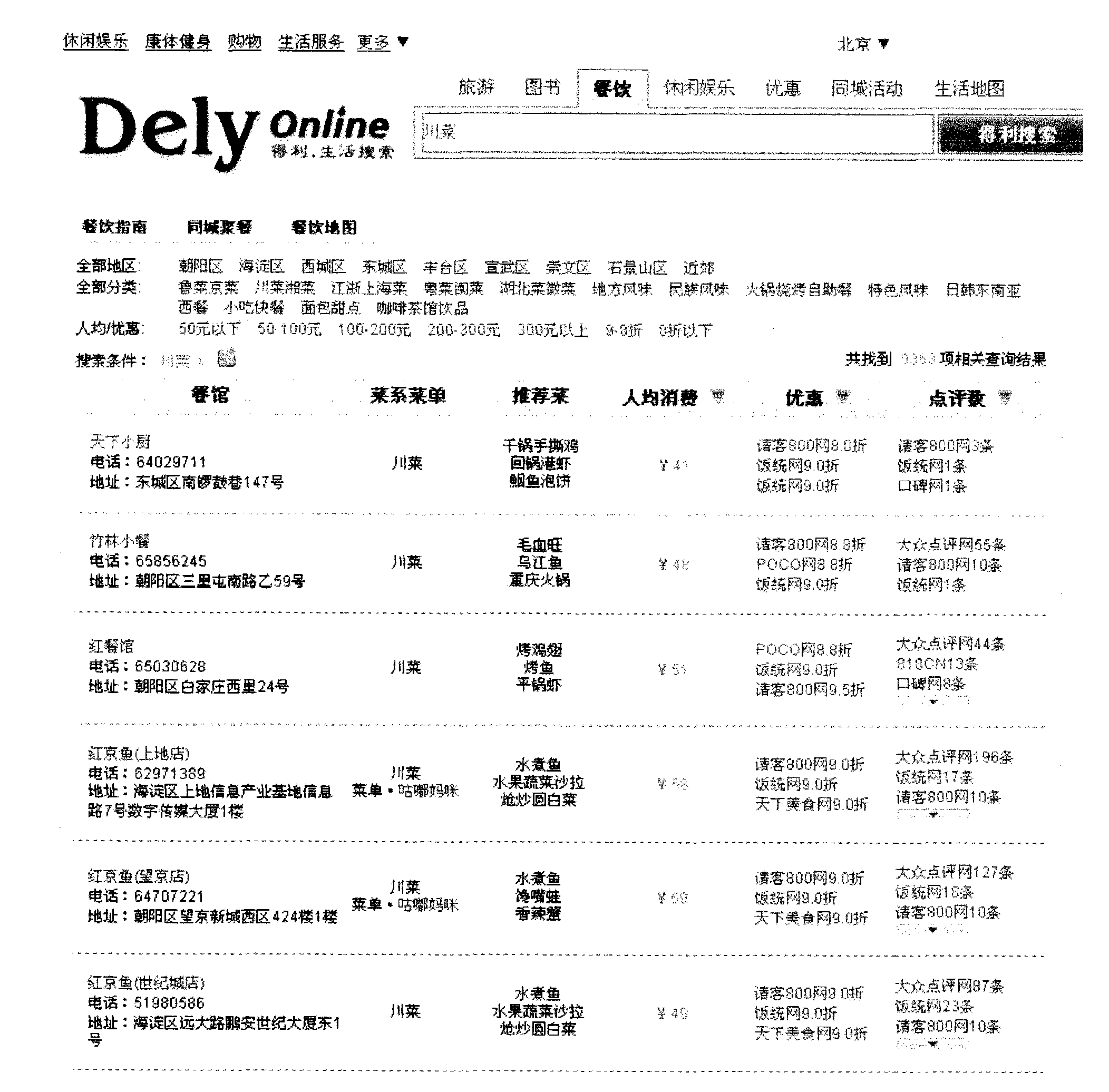

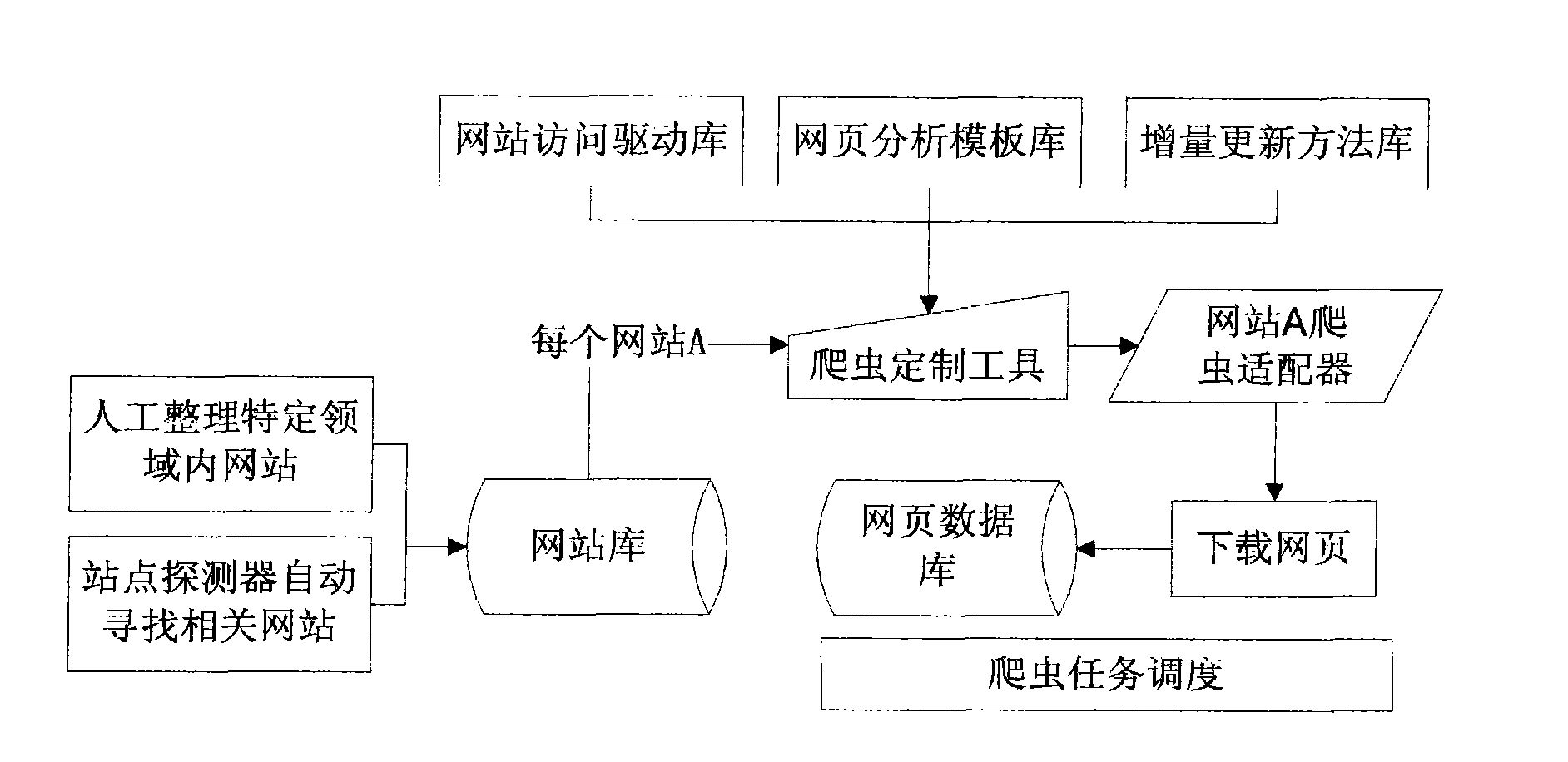

Design technology for object-level personalized vertical search engine

InactiveCN102402539AImplement auto-discoveryAchieve crawlingSpecial data processing applicationsPersonalized searchThe Internet

The invention discloses a design technology for an object-level personalized vertical search engine. The basic idea of an algorithm is that: related web pages on the Internet are acquired by an adaptive vertical crawler technology, data is subjected to a series of objectification processing such as semantic analysis, extraction, integration and the like, objectified information on the Internet is acquired, and a personalized object ordering result is returned to each user in a search engine mode. The original page data is highly purified and organized by the search engine designed by the technology through a data mining technology, so that the quality of the data is ensured, and the inclusion of illegal information is controlled to the greatest extent. In addition, by a personalized search recommendation technology, the consumption preference of each user can be accurately determined, and the query intention of each user is understood. The object-level personalized vertical semantic search engine is subjected to integrated innovation on the basis of fully learning and absorbing the advantages of semantic search, object-level search and personalized search technologies, and completely accords with the development direction of a next-generation search engine.

Owner:倪毅

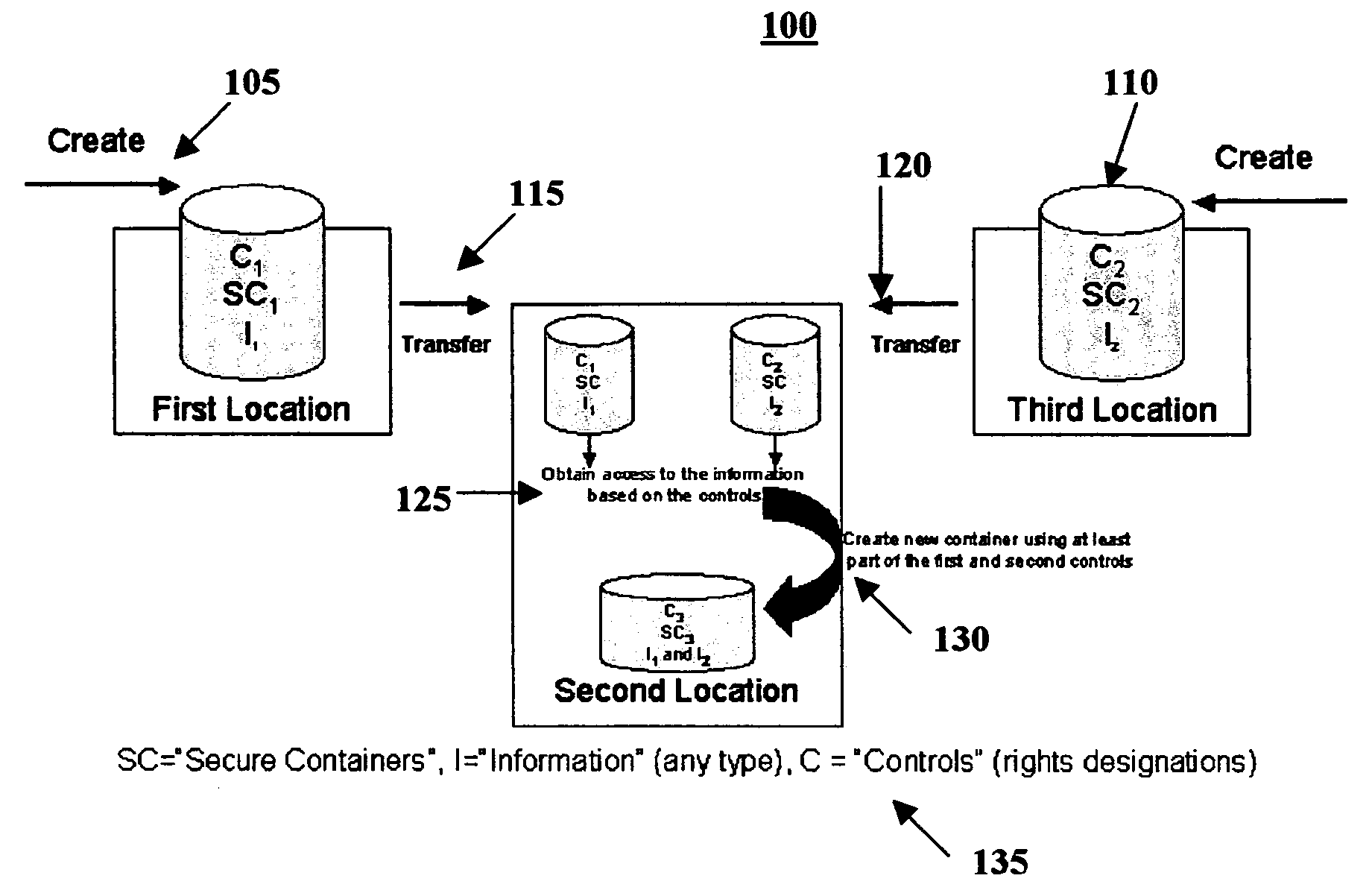

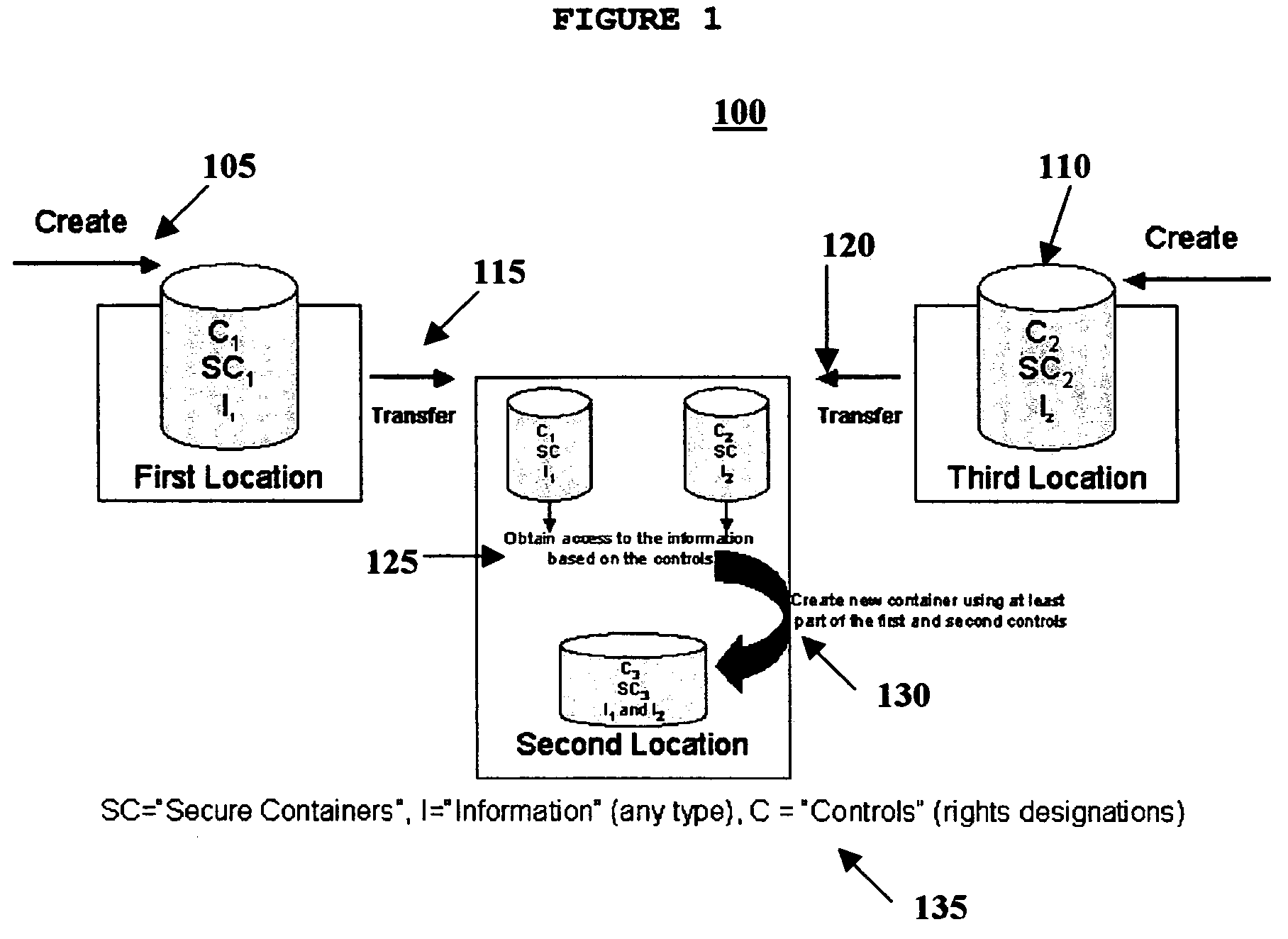

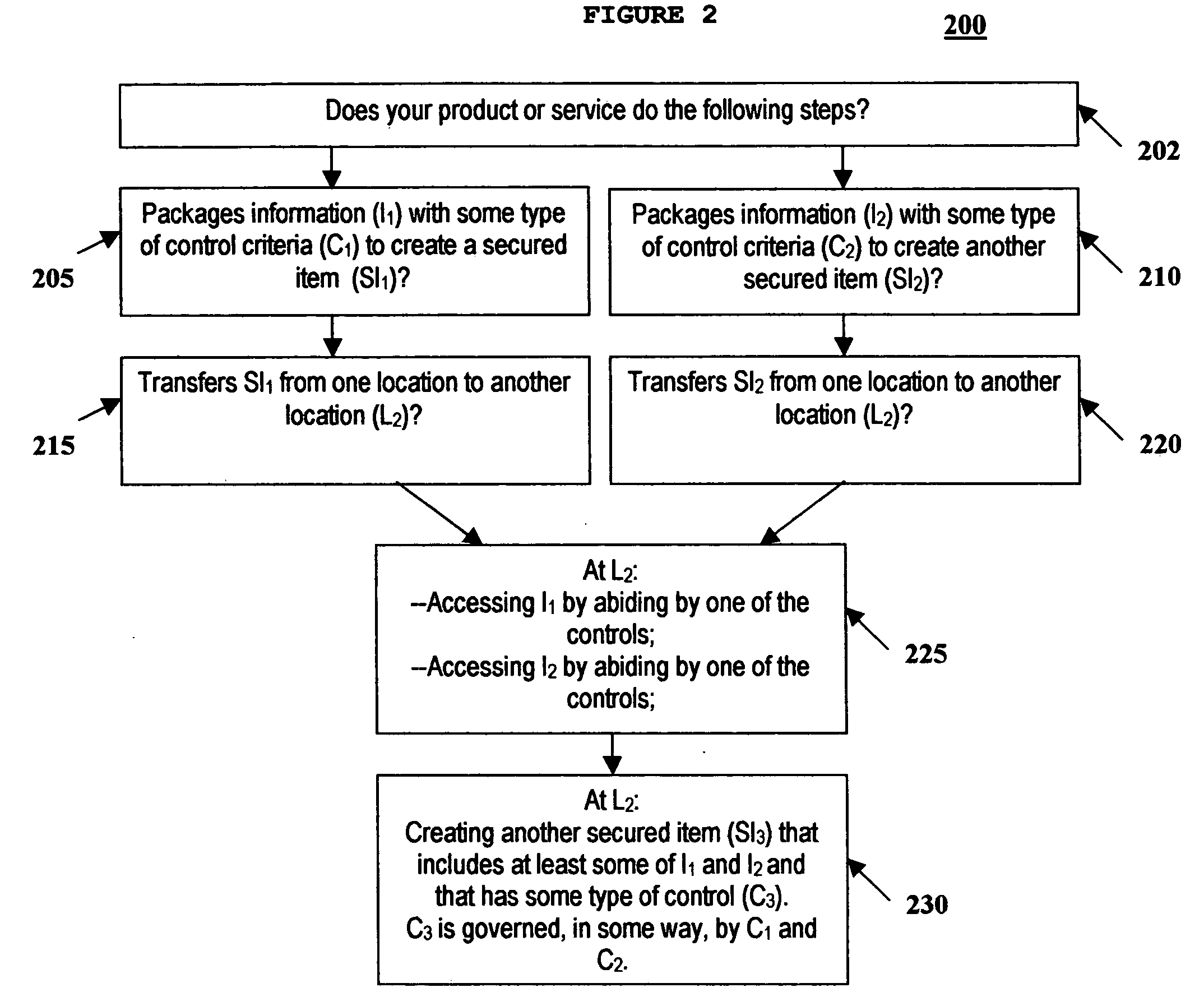

Systems and methods for evaluating information to identify, and act upon, intellectual property issues

InactiveUS20050114169A1Office automationSpecial data processing applicationsIntellectual propertyCombined technique

The systems and methods of the present invention enable users to identify whether a composition of matter, technical design, product, service, component, technology, feature, business model or any other item may have intellectual property issues associated therewith. The present invention includes a set of screens, filters, comparison sheets, and / or questionnaires (referred to generically as screens) which are derived from patent claims and used to evaluate whether a composition of matter, technical design, product, service, component, technology, feature, business model or any other item may have intellectual property issues associated therewith. The present invention further comprises systems and methods designed to help groups of people, in a collaborative environment, manage the use of screens.

Owner:ANSARI HAZIM

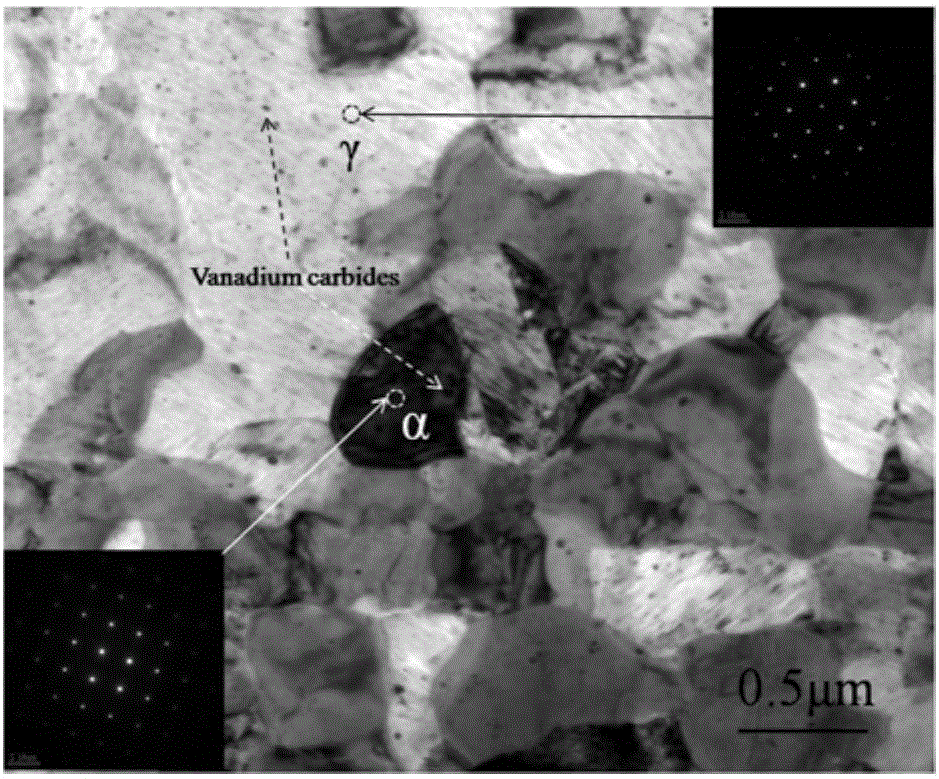

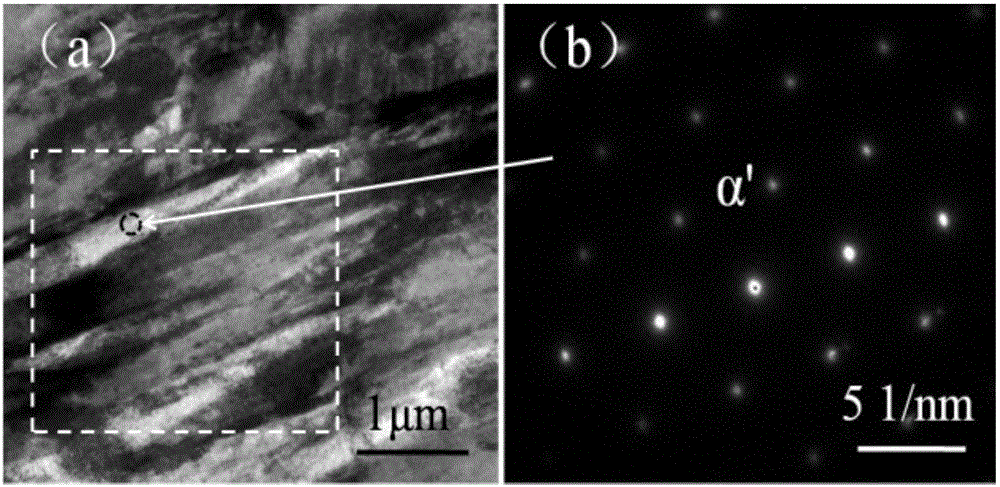

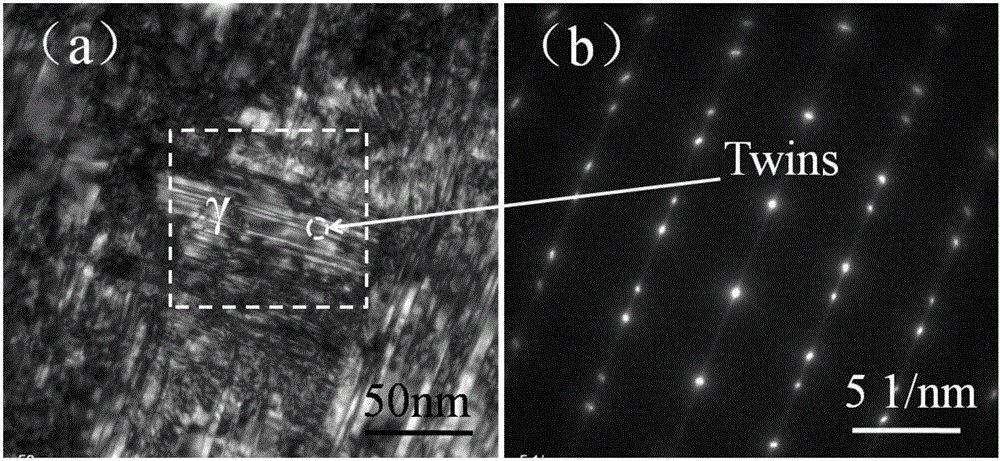

Super-high-strength medium-Mn automobile steel plate with excellent plasticity and preparing method thereof

The invention provides a super-high-strength medium-Mn automobile steel plate with excellent plasticity and a preparing method thereof and belongs to the technical field of production of third-generation steel plate rolls for automobiles. The super-high-strength medium-Mn automobile steel plate comprises the following chemical components in a percent: 0.3-0.5wt% of C, 8-12wt% of Mn, 1.8-3.5wt% of Al, 0.25-0.7wt% of V, smaller than or equal to 0.008wt% of P, smaller than or equal to 0.08wt% of S and the balance of Fe and unavoidable impurities. Through reasonable chemical components and technical design, a comprehensive application strengthened by various mechanisms, such as precipitation strengthening, deformation induced phase change strengthening and twinning strengthening, is realized, thereby obtaining super-high strength. Through hot rolling, acid pickling, warm rolling and cover annealing technologies, the steel plate with more than 1500MPa tensile strength and 20-40GPa.% static toughness can be obtained; and otherwise, the cold-rolled steel plate with more than 1200MPa tensile strength and 35-65GPa.% static toughness can be obtained through hot rolling, hot rolling annealing, acid pickling, cold rolling and continuous annealing technologies.

Owner:CENT IRON & STEEL RES INST

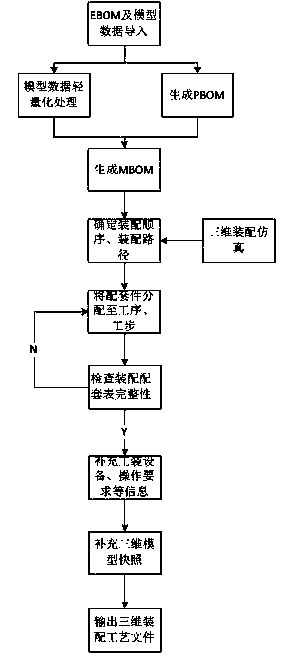

Producing method for three-dimensional craft of final product assembly

InactiveCN104252554ASolve the problem that the assembly relationship cannot be reflected intuitivelyImprove accuracyImage data processingSpecial data processing applicationsButt jointDimensional modeling

The invention discloses a producing method for a three-dimensional craft of a final product assembly. The method comprises the following steps: introducing product EBOM and three-dimensional model (containing MDB information) into a three-dimensional assembling technical design environment; performing light weight treatment on the three-dimensional model in the technical design environment; reconstructing on the PBOM according to the links of subassembly, butt-joint and test line and the assembling level, sequence and division in each link; adding an assembling virtual part according to the requirement and lastly generating MBOM; confirming an assembling sequence and an assembling path on the MBOM; establishing processes and steps and distributing the parts in the MBOM into each process and step; establishing a three-dimensional model snapshoot and labeling for the mounting content of each assembling component; adding the information, such as, assembly equipment, technical accessory, operation demand, and finishing the editing for a technical file.

Owner:NANJING CHENGUANG GRP

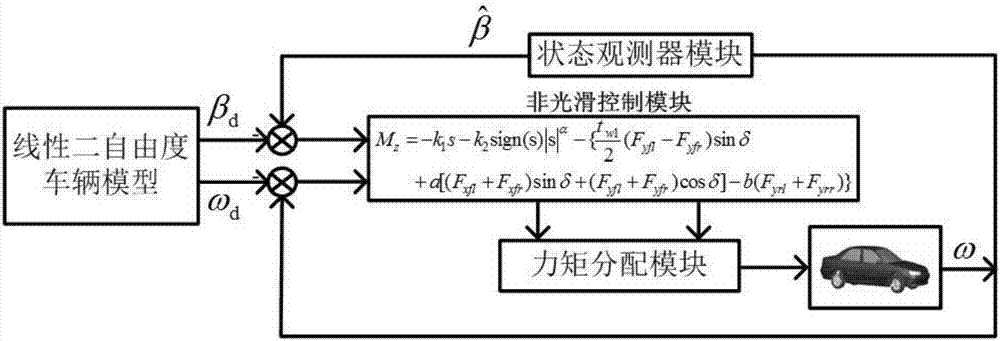

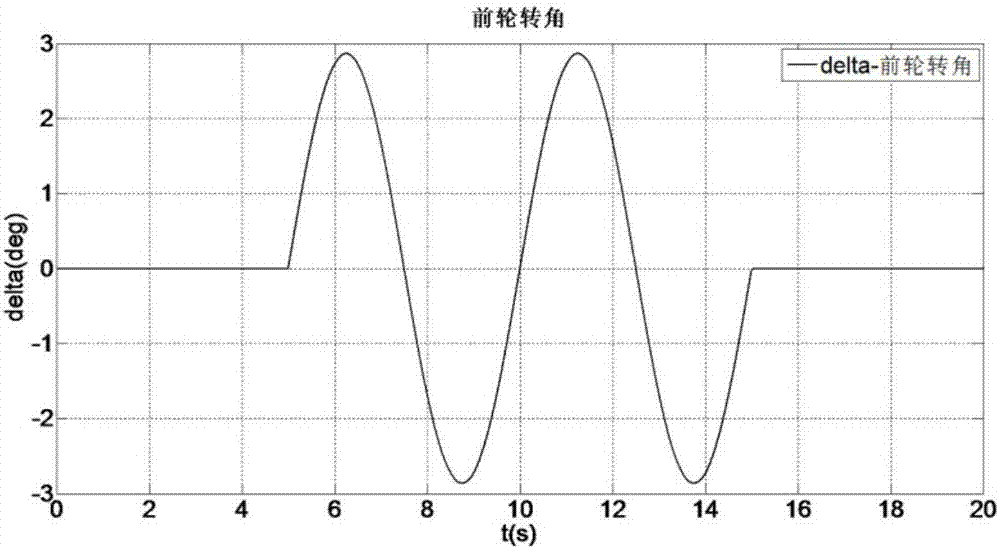

Non-smooth technique-based direct yaw moment control method of electric vehicles

InactiveCN107139775ALow costFast convergenceGeometric CADSpeed controllerVehicle dynamicsState observer

The invention discloses a non-smooth technique-based direct yaw moment control method of electric vehicles. By means of the method, the vehicle stability under extreme driving circumstances can be increased under the conditions of external disturbances and system uncertainty. The method comprises the following main steps: (1) building a linear two-degree-of-freedom vehicle dynamic model and a seven-degree-of-freedom whole vehicle dynamic model; 2, calculating the ideal yaw velocity and ideal side slip angle of the vehicles through the linear two-degree-of-freedom model, and constructing a state observer to observe the actual side slip angle of the vehicles; 3, designing a non-smooth control module controlled by yaw moment on the basis of non-smooth control technique; and 4, distributing the yaw moment by using a moment distributing module, thereby realizing the stable control of the vehicles. The method disclosed by the invention has the advantages that (1) the system has fast convergence performance and better disturbance-resistant performance; and (2) a chattering phenomenon is effectively avoided while good robust performance is obtained at the same time.

Owner:JIANGSU UNIV

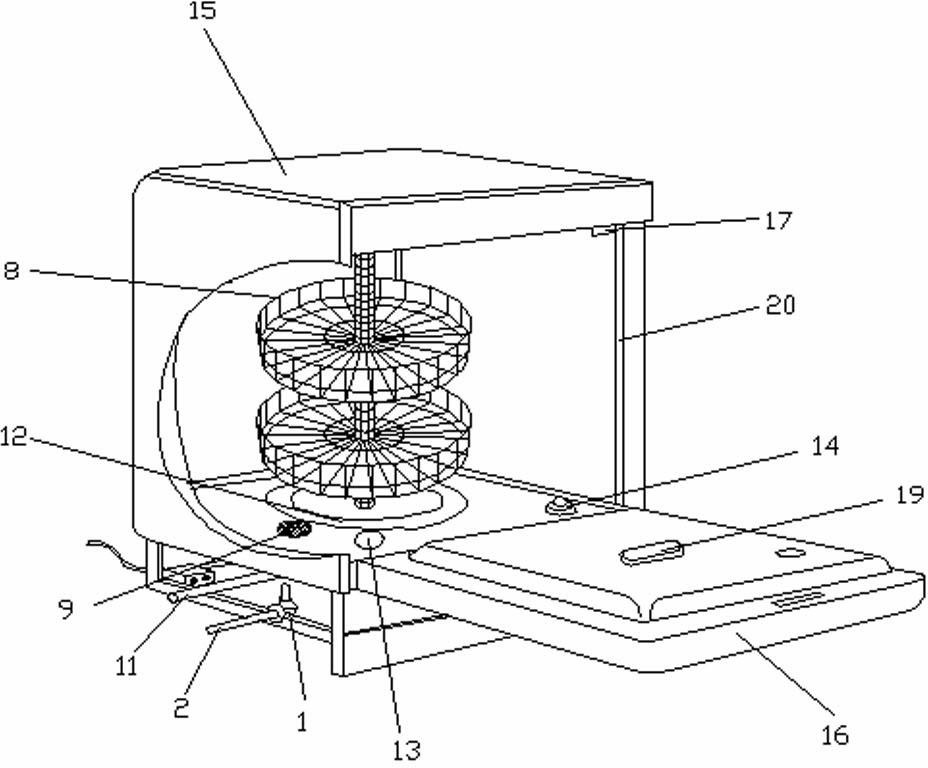

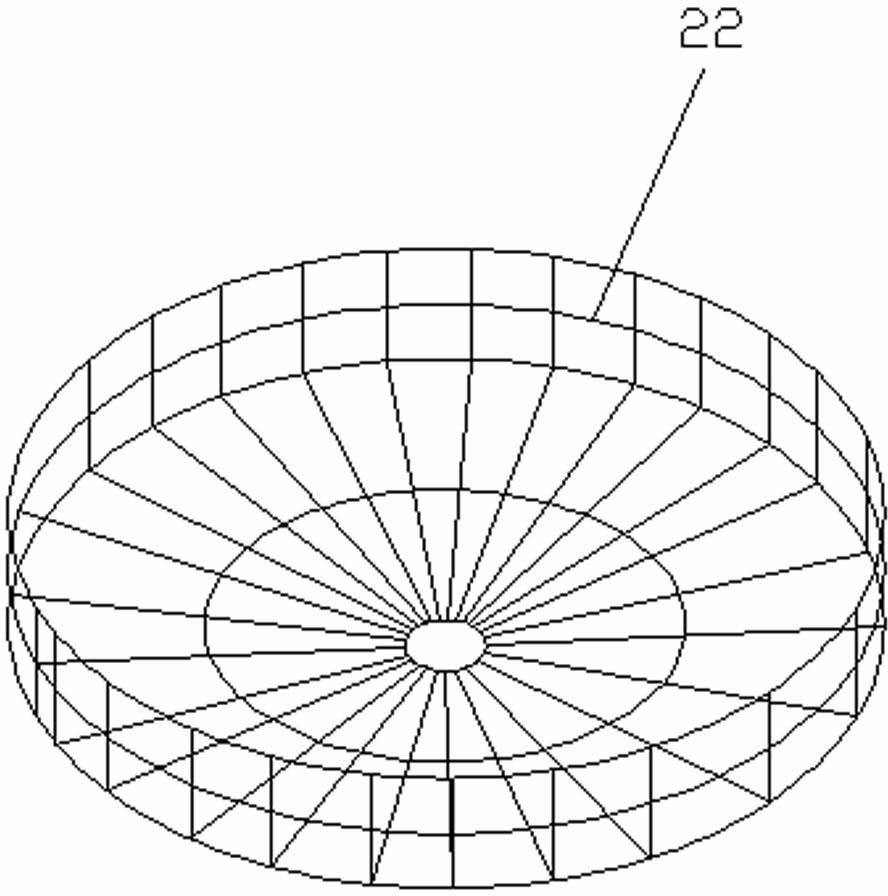

Dishwasher with rotary cage

InactiveCN102113872AFast cleaningShort timeTableware washing/rinsing machine detailsElectricityWater flow

The invention relates to a dishwasher with a rotary cage, which comprises a case body and a rotary cage mounted inside a cleaning chamber of the case body, wherein the rotary cage is mounted on a central shaft that is rotated under the action of a jet water flow or under the drive of a motor, a dish holder is arranged on the rotary cage and used for holding bowls and dishes, and the rotary cage is made by weaving and welding stainless steel wires. With the technical design of the rotary cage, the dishwasher is suitable for both domestic and commercial use. The dishwasher can perform complete cleaning without needing to rotate the water jet pipe. The dishwasher achieves the effect of multi-angle all-direction washing of tableware, is very suitable for cleaning bowls, pots, cups and other deep-edge tableware and utensils in Chinese cuisines, and is more suitable for cleaning western tableware. The dishwasher increases the cleaning speed, reduces the cleaning time and saves water and electricity. The water jet pipe of the dishwasher can supply water to wash the tableware in different angles and all directions, so as to well clean the tableware within a short time, reduce the cleaning time and save water and electricity.

Owner:袁哲

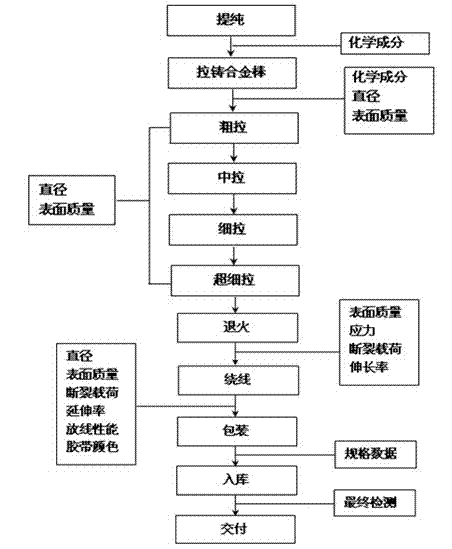

Preparation method of bonded gold-silver alloy wire

ActiveCN102776405AImprove conductivityStable chemical propertiesSemiconductor/solid-state device detailsSolid-state devicesCeriumTechnical design

The invention relates to a preparation method of a bonded gold-silver alloy wire, and belongs to the technical field of bonded wire processing processes. The bonded gold-silver alloy wire comprises the following metal materials by weight: 20-30% of silver, 5-1000 ppm of palladium, 5-1000 ppm of calcium, 5-1000 ppm of beryllium, 5-1000 ppm of cerium and the balance of gold; the preparation method comprises the following steps: 1), preparing materials; 2) smelting an alloy ingot; 3) pulling and casting an alloy rod; 4) wire-drawing; 5) annealing; 6) coiling; and 7) packaging. The preparation method of the bonded gold-silver alloy wire, provided by the invention, has the advantages of reasonable and standard technical design, and simple operation, the produced bonded gold-silver alloy wire has the advantages of strong conductivity, stable chemical performance, good oxidation resistance, flowability and plasticity, higher breaking force and better elongation, and moderate cost, and requirements of semiconductor package industry and LED (Light Emitting Diode) illumination technology on the performances of the bonded gold-silver alloy wire can be completely satisfied.

Owner:烟台招金励福贵金属股份有限公司

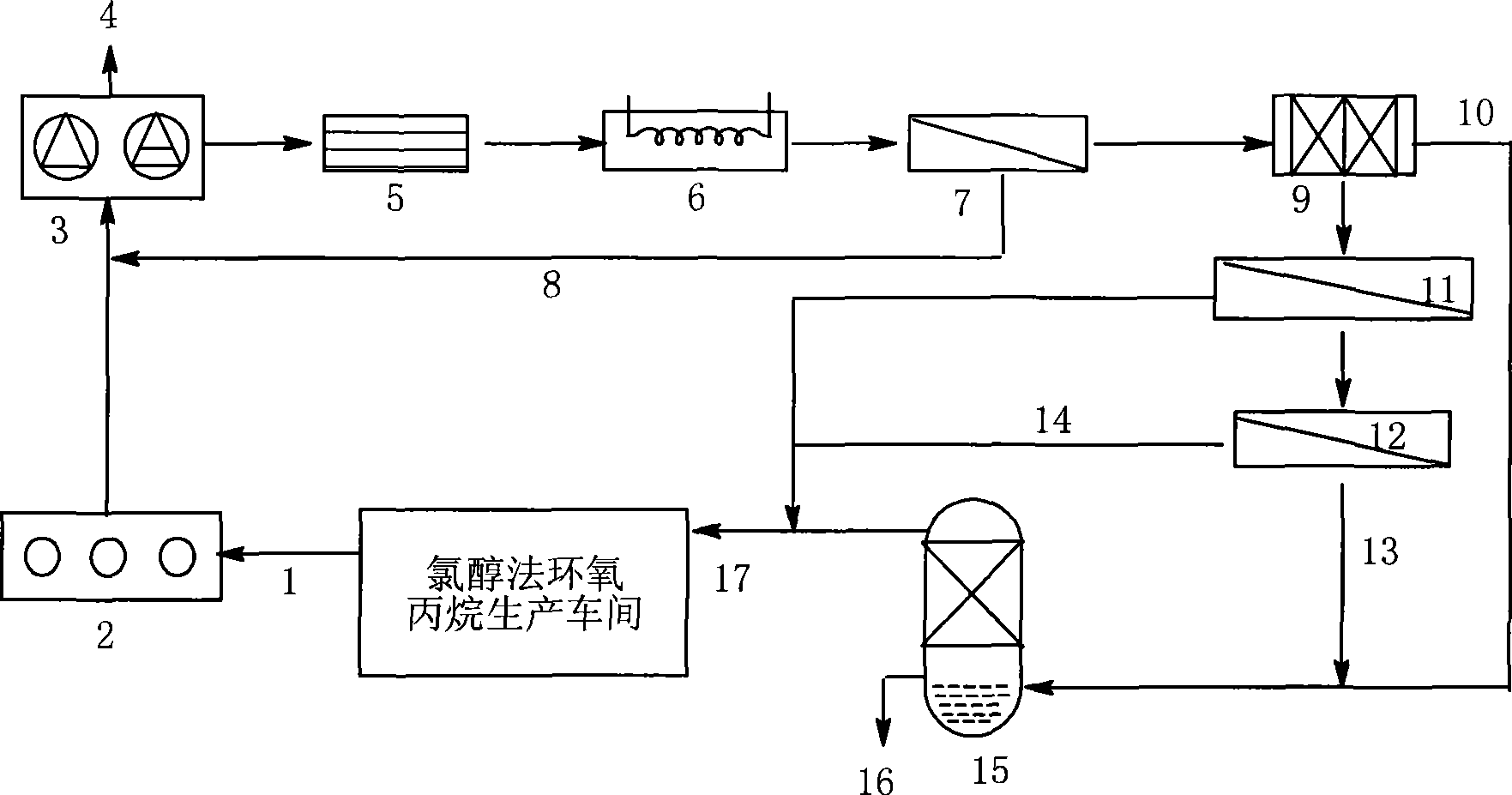

Process for treating saponification wastewater by chlorohydrination

ActiveCN101481190ASmooth cycle processingTroubleshoot placement issuesCalcium/strontium/barium chloridesDispersed particle separationChemical treatmentSocial benefits

The invention discloses a chemical processing method, and in particular discloses a method for recovering and reusing saponified waste water generated by a chlorohydrination method. The invention uses the novel film method and the salt and water recovering and reusing method to process the saponified waste water generated by a chlorohydrination method, and the technical designs, such as gas flotation, crystallizing prevention, ceramic film filtration, heat exchange, electrodialysis concentration, vaporizing recovery and the like are applied in the method. The invention has the advantages that the zero discharge of the waste water is basically realized, the salt and the water can be recovered, the small land area is occupied, the running expense is low, and the economic and social benefits are high. The invention can be widely used in the factories using the chlorohydrination method for producing propylene oxide.

Owner:HANGZHOU WATER TREATMENT TECH DEV CENT

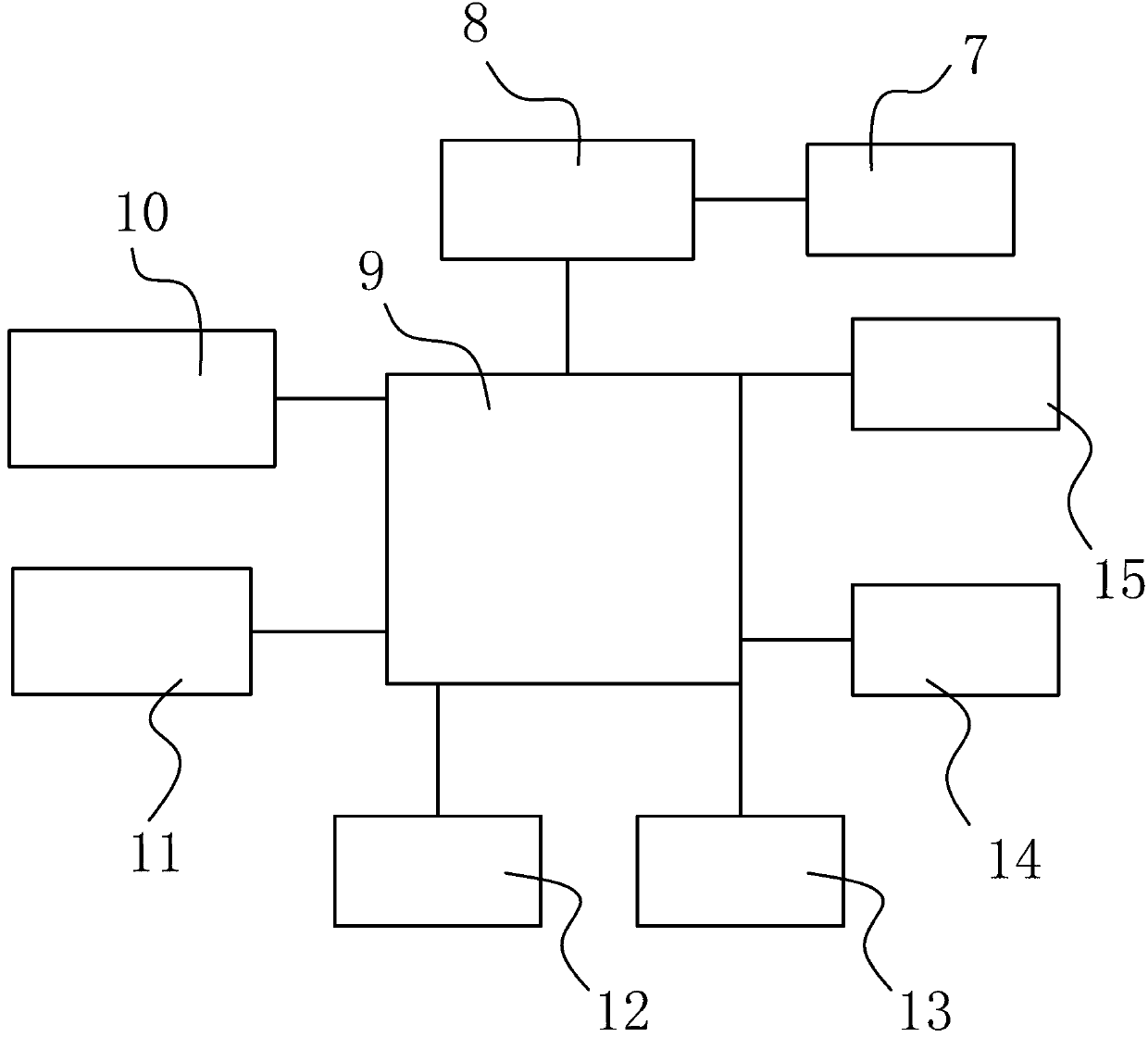

Intelligent analysis and retrieval method for video surveillance and system thereof

InactiveCN103106250AQuality improvementShorten the timeClosed circuit television systemsSpecial data processing applicationsVideo retrievalVideo monitoring

The invention belongs to the field of security technologies and relates to an intelligent analysis and retrieval method for video surveillance and a system thereof. The intelligent analysis and retrieval method for video surveillance and the system thereof resolve the technical problems that an existing technology design is not reasonable enough and the like. The intelligent analysis and retrieval method for video surveillance comprises the following steps: (1) video enhancement and (2) video retrieval, wherein the step of the video retrieval comprises dynamic analysis, coding recombination, result marking and behavior analysis. A dynamic analysis module is connected with a coding recombination module. A result marking module and a behavior analysis module are both connected with the coding recombination module. A video enhancement module is connected with the dynamic analysis module or the coding recombination module. The intelligent analysis and retrieval method for video surveillance and the system thereof have the advantages of combining image enhancement, retrieval compression, intelligent analysis and abstract statistics into one, embodying five characteristics of being advanced, high-efficiency, reliable, convenient and practical in use, achieving the enhancement of video images, the retrieval and compression of video documents, the intelligent analysis of behaviors of people and automobiles, and the like, thus obtaining the needed information rapidly and accurately and being capable of providing strong and effective criminal investigation supports for public security officers to scout and solve a case.

Owner:ZHEJIANG UHOPE COMM TECH

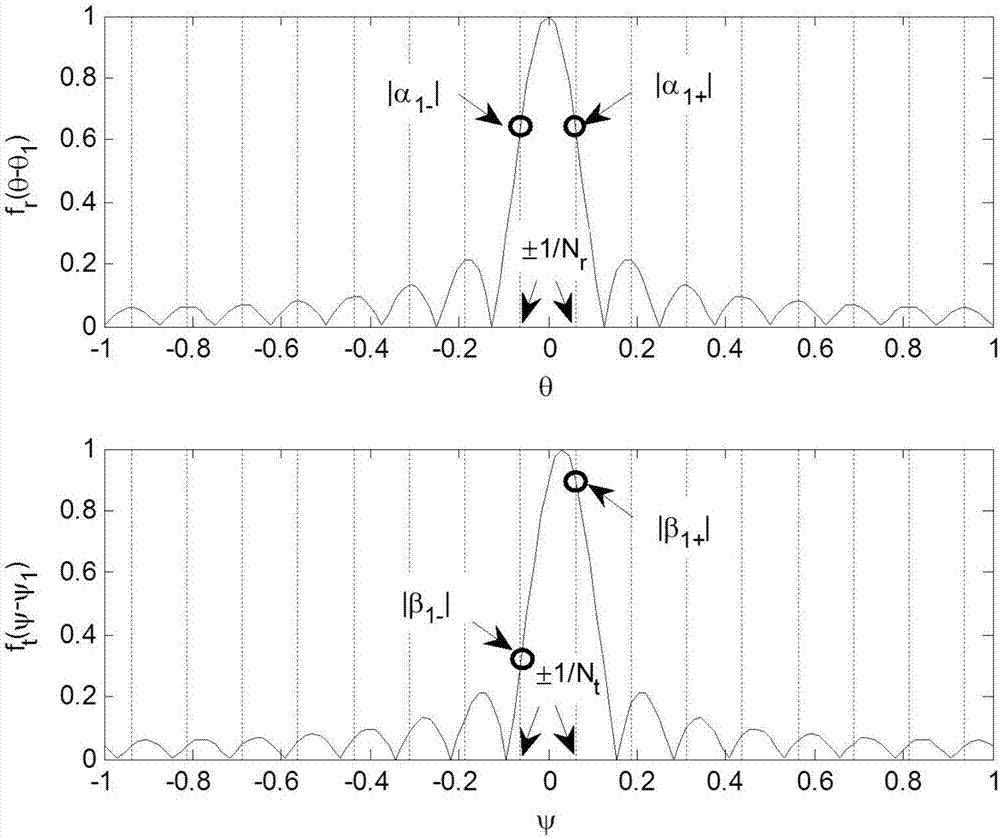

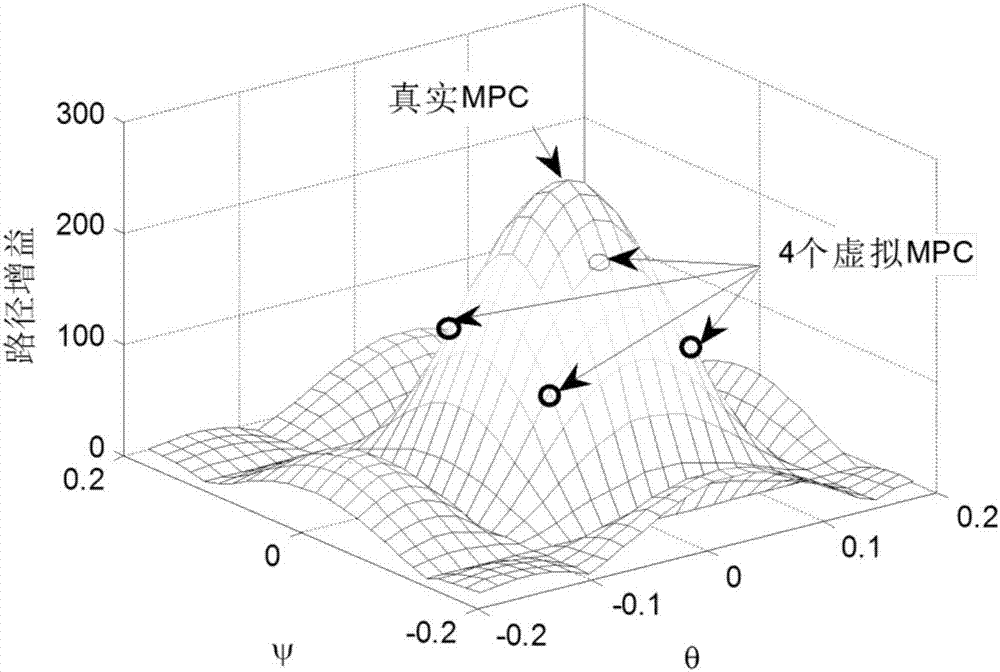

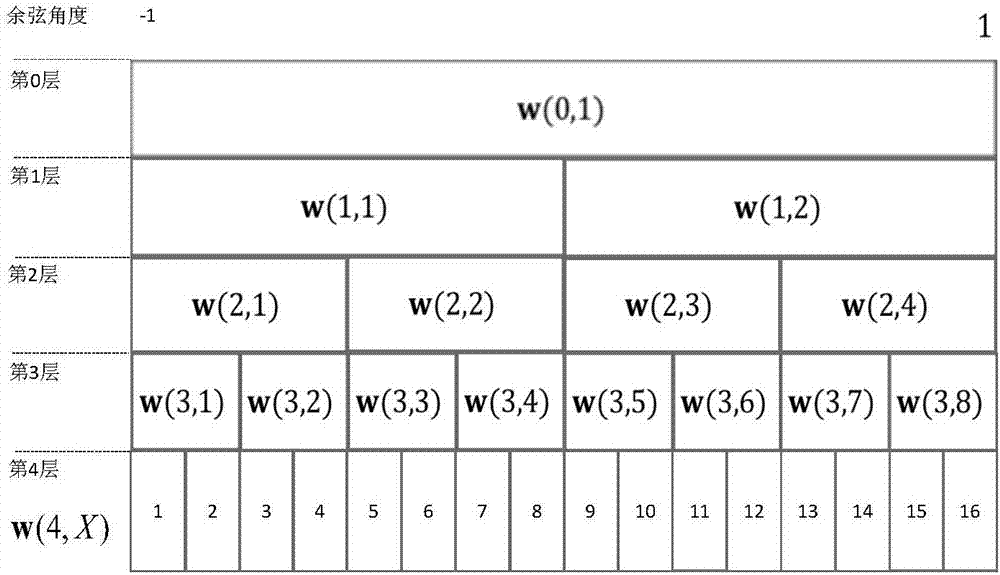

Channel estimation method in millimeter wave communication

ActiveCN107040296AReduce training overheadReduce time complexityRadio transmissionChannel estimationPrecodingComputation complexity

The invention discloses a channel estimation method in millimeter wave communication. The method is realized based on virtual multipath acquisition and sparse reconstruction. According to the method, when the virtual multipath acquisition is carried out, real multipath components are not searched, virtual multipath components of the real multipath components are deduced, and the virtual multipath components are obtained on a codebook with conventional resolution through hierarchical search; and when the sparse reconstruction is carried out, the real multipath components are reconstructed by the obtained virtual multipath components. According to the method, a hierarchical codebook for the hierarchical search is designed and obtained through utilization of a subarray enhancement technology, and the codebook can be applied to two structures of analog beam shaping / combination and hybrid analog / digital precoding / combination. Through application of the method, training expenses for the channel estimation can be greatly reduced; the search time complexity is reduced; and the sparse reconstruction is carried out through adoption of the virtual multipath components, so a relatively small dictionary matrix is obtained and the computing complexity is greatly reduced.

Owner:BEIHANG UNIV

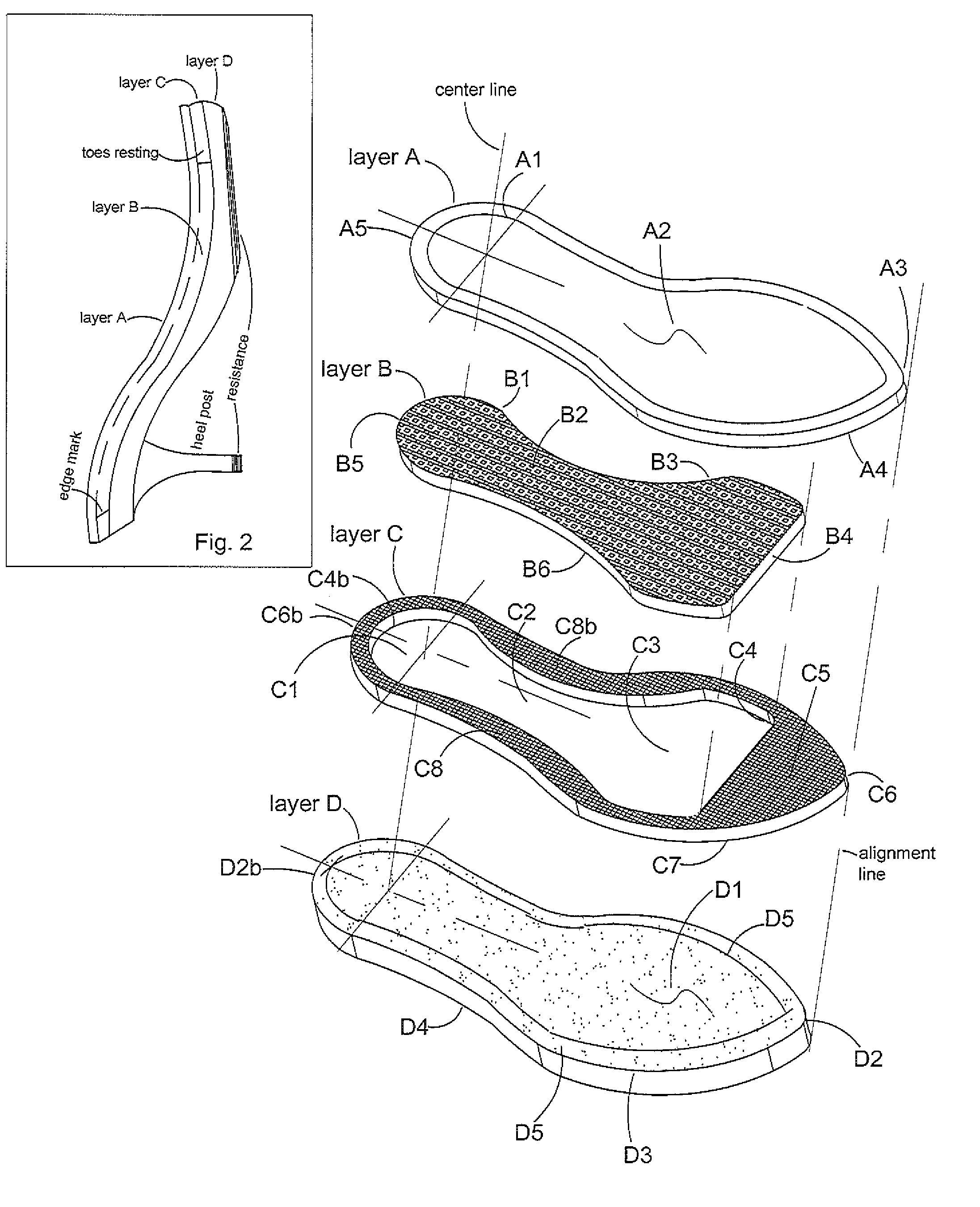

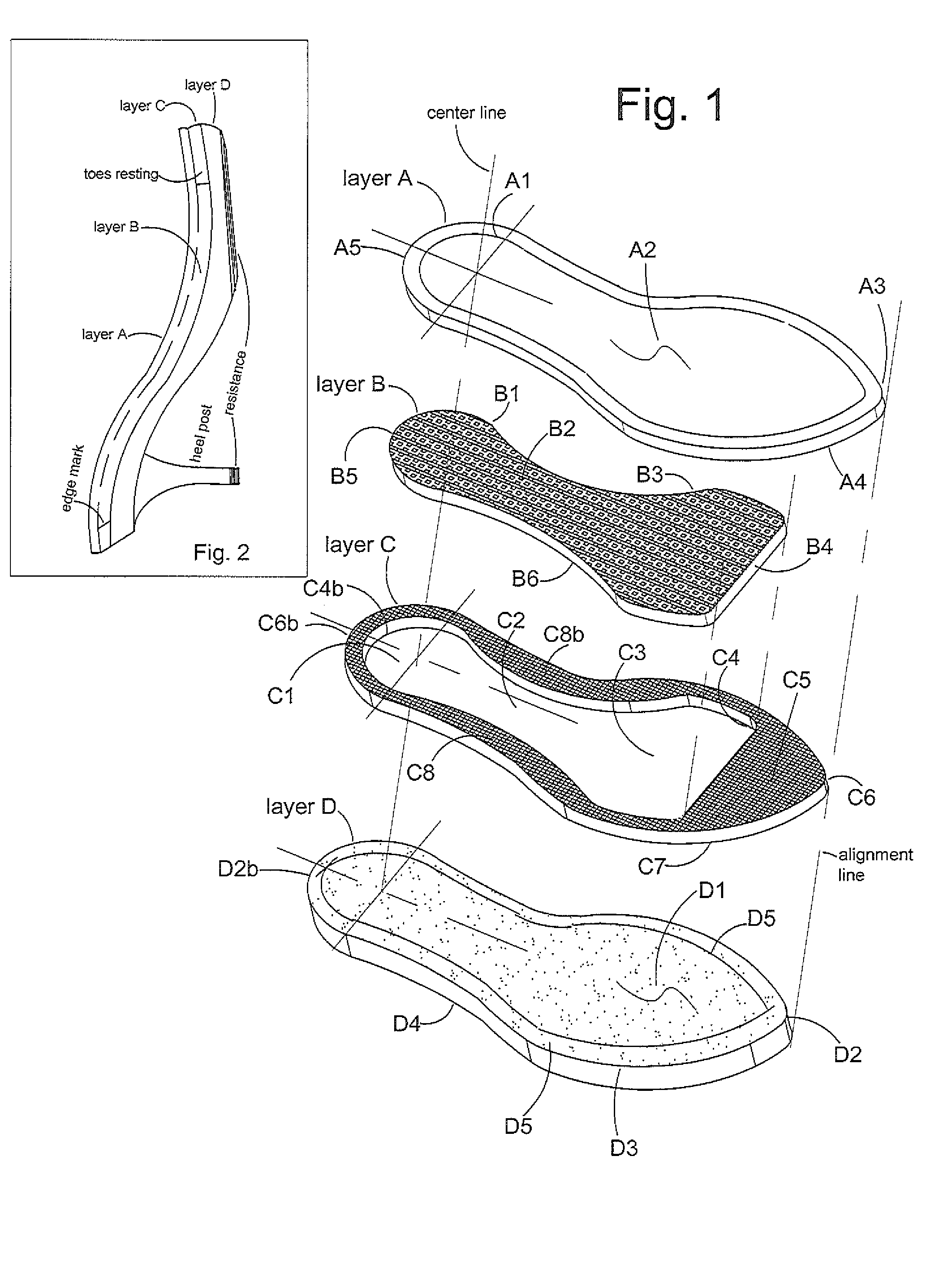

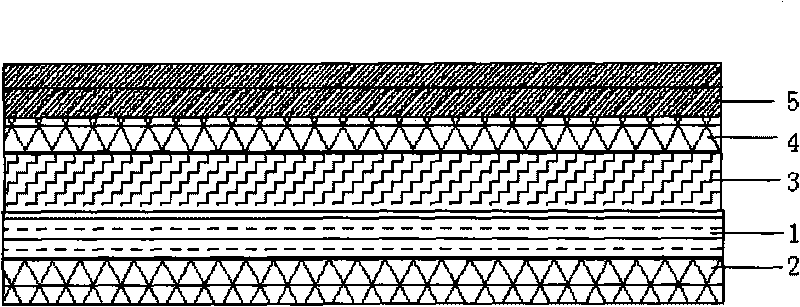

Footwear Pressure Elimination & Dipersibility Systematic

Pain caused by plantar fasciitis is usually accompanied by heel pain and arch pain or forefoot regions are possibly most painful when you first attempt to stand or walk. There are also many other painful conditions of the feet that could be cause from the foot discomfort in footwear composition or technical designed. The present invention is footwear consisting composition method to disperse an exertion of force such as pressures recess of the foot relating above painful conditions. Said it mean of relieving foot strain in the advantage of composition interior cushiony sole that it insert to inside of an outer element composed in corresponding cushiony sole of others in advantage of pain reliever or shocks absorption. FIG. 2 preferred an embodiment to accomplish of present invention. Top layer A preferred to top fine adhered above Pref. C layer cast wherein cauterized in midsection pref. B inside sole series attachment construct outer layer pref. D consisting resistance outer impact.

Owner:TANG HUNG V

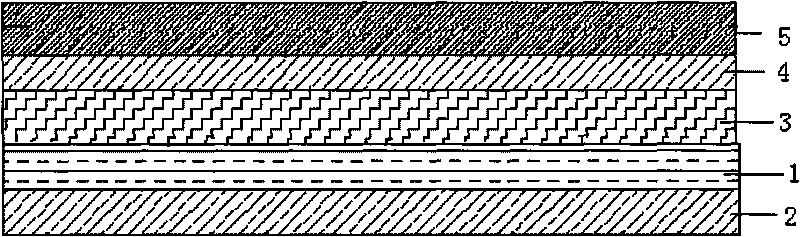

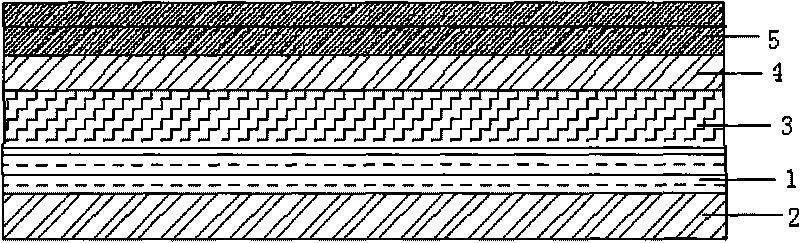

High-brightness release paper, and preparation method and applications thereof

ActiveCN101709559AImprove flatnessGood residual adhesionSpecial paperFilm/foil adhesivesAdhesion forceBiochemical engineering

The invention discloses a high-brightness release paper, and a preparation method and applications thereof. The high-brightness release paper is composed of base-material-layer base paper (1), a film layer (2), an adhesive layer (3), a film layer (4) and a release layer (5), wherein the film layer (2) is sprayed on one side of the base paper (1), the adhesive layer (3) is coated on the other side of the base paper (1), the film layer (4) is attached to the adhesive layer (3), and the release layer (5) is coated on the film layer (4). The high-brightness release paper of the invention has favorable surface smoothness and residual adhesion force. The adhesive sticker prepared from the release paper of the invention has favorable adhesive surface smoothness, and thus, the invention can solve the technical problem of inadequate adhesive surface smoothness (blushing) of the adhesive stickers. The preparation method of the release paper has the advantages of reasonable technical design, high operability, high production efficiency and high finished-product pass rate, and can realize industrial mass production.

Owner:SUZHOU SIDIKE NEW MATERIALS SCI & TECH

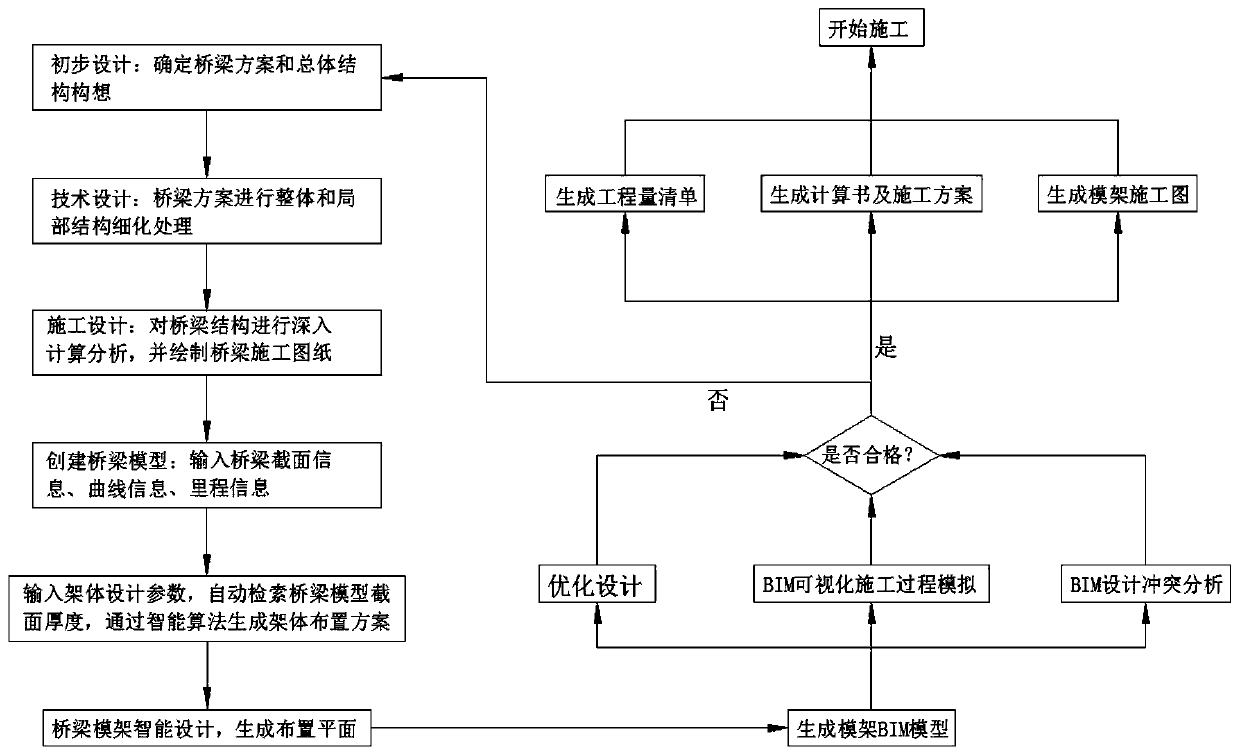

Bridge formwork intelligent design method based on BIM

ActiveCN109753753AImprove design efficiencyImprove accuracySpecial data processing applicationsIntelligent designShop drawing

The invention discloses a bridge formwork intelligent design method based on BIM, and belongs to the field of BIM bridges, and comprises the following steps: 1) preliminary design: determining a bridge scheme and overall structure concepts, such as arrangement of a bridge plane, a vertical surface and a cross section, by professionals; and 2) technical design: carrying out integral and local structure refinement processing on the bridge scheme determined in the preliminary design. The bridge formwork intelligent design method provided by the invention has a powerful rapid modeling function. Abridge three-dimensional model can be quickly created according to a CAD construction drawing. The problem that traditional two-dimensional design expression is not perfect, visual and clear is solved, through design conflict analysis, possible problems in the bridge construction process are found in advance and solved in advance, the traditional management thought is changed, namely, passive management of a waiting problem is converted into active management of an active discovery problem, and the working efficiency is improved.

Owner:广东星层建筑科技股份有限公司

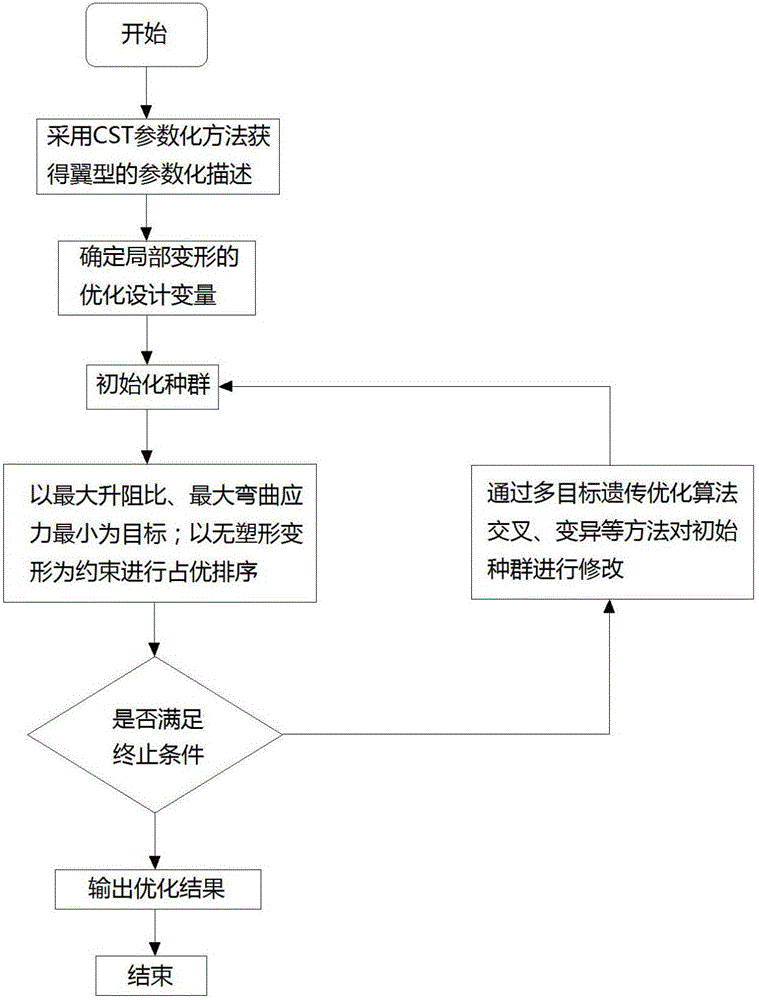

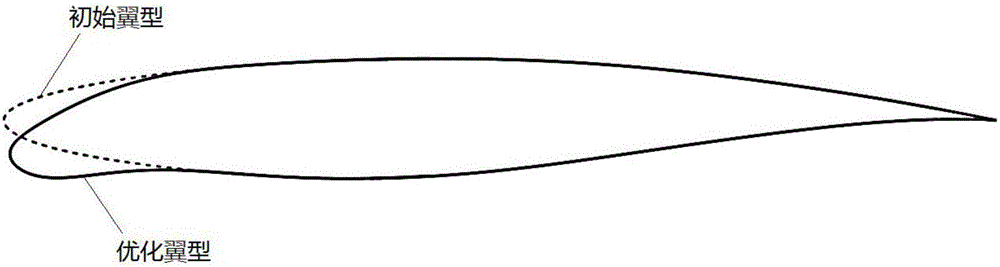

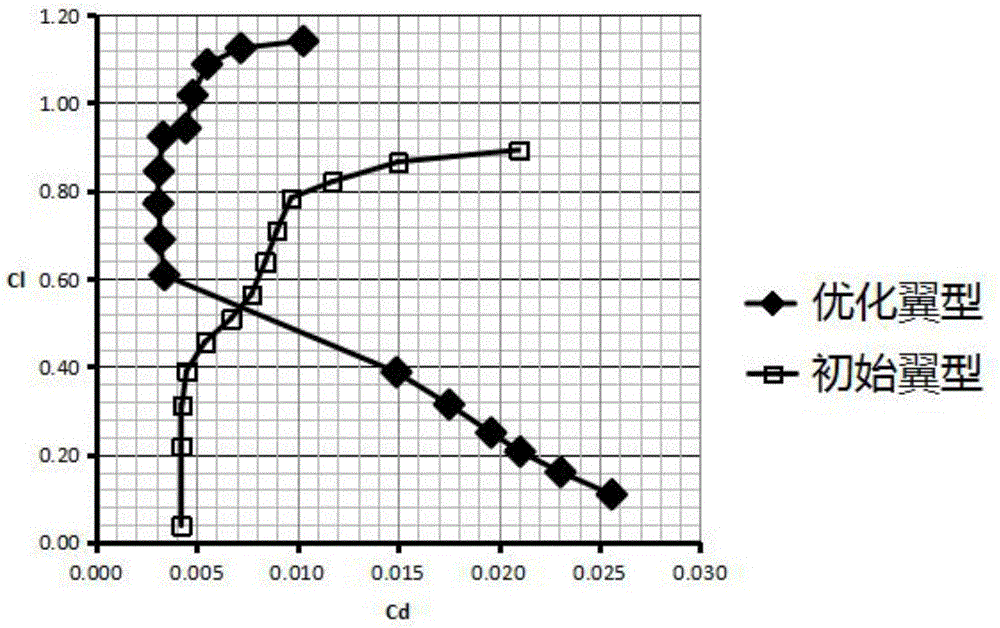

Design method of self-adaptive wing profile

ActiveCN106845019AImprove engineering realizabilityImprove performanceGeometric CADSustainable transportationLeading edgeSelf adaptive

The invention discloses a design method of a self-adaptive wing profile. Firstly, parameterized description of a selected initial wing profile is obtained with a CST parameterization method, an optimal design variable of local deformation is determined, populations are initialized with a selected optimization algorithm, domination sequencing is performed on the populations under the conditions that the lift-to-drag ratio reaching the maximum when the lift coefficient CL is equal to 0.9 and the maximum bending stress reaching the minimum after change of leading edge camber are taken as optimization objects and non-plastic deformation is taken as a constraint, and finally, an optimized wing profile meeting the terminal conditions is selected. With pneumatic characteristics expected by the wing profile as the design objects, a constraint relation between the self-adaptive wing profile and an original wing profile is established, a reasonable target wing profile can be provided for design of a deformation driving technology, the engineering implementability is improved, and the design optimization efficiency is further improved.

Owner:LOW SPEED AERODYNAMIC INST OF CHINESE AERODYNAMIC RES & DEV CENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com