Producing method for three-dimensional craft of final product assembly

An assembly process, three-dimensional technology, applied in the direction of image data processing, special data processing applications, instruments, etc., can solve the problem of relying on the technical level and assembly experience of craftsmen, affecting product quality, product assembly production efficiency, and inability to intuitively reflect product assembly relationship To achieve the effect of shortening the process preparation cycle, improving the efficiency of the final assembly process, improving the assembly quality and assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be described in further detail below in conjunction with the accompanying drawings.

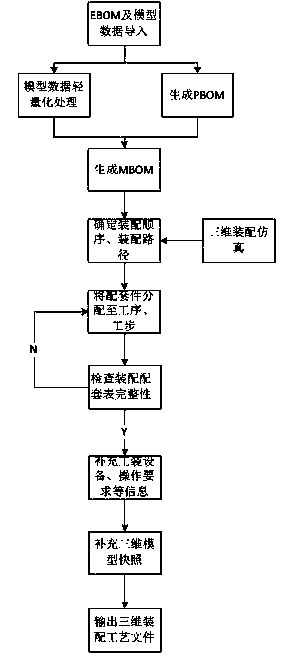

[0008] The implementation process of the 3D assembly process design method is as follows: figure 1 shown. The specific implementation method is as follows:

[0009] 1. Import the product assembly EBOM and 3D model data into the 3D assembly process design software Teamcenter, add the sample information on the basis of EBOM and convert it into PBOM, and convert the 3D model into .jt lightweight format. In the 3D assembly process design environment, the part name, code name, quantity, material and other information corresponding to the 3D design model are extracted and associated with the lightweight model.

[0010] 2. According to the three main assembly links of section assembly, docking assembly, and test line reassembly, according to the process flow, process division, and station conditions, rearrange and divide the assembly parts on the basis of PBOM to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com