Projectile or warhead

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

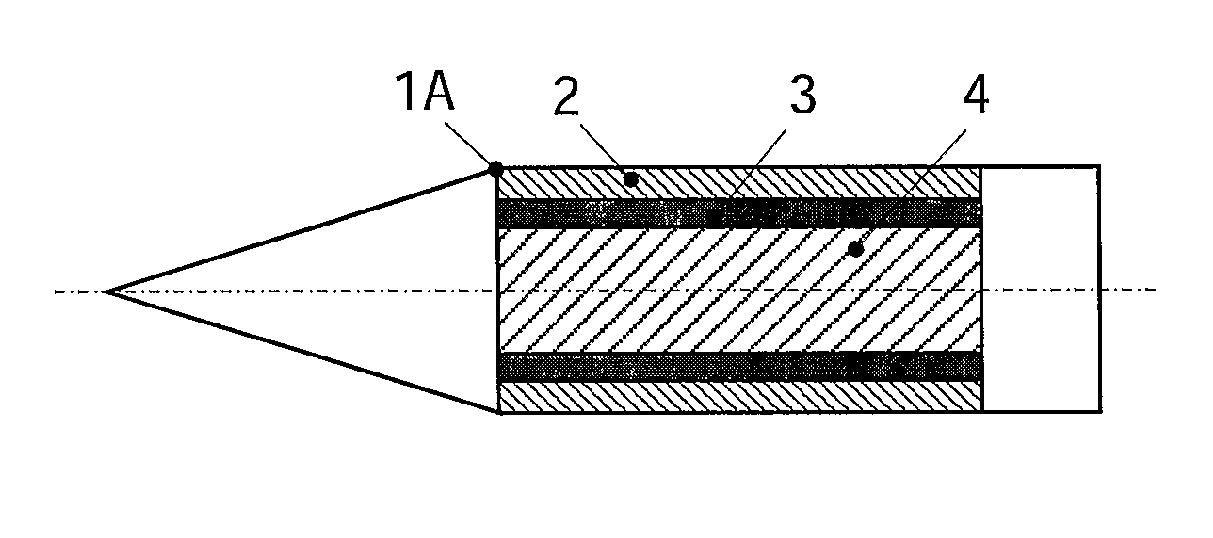

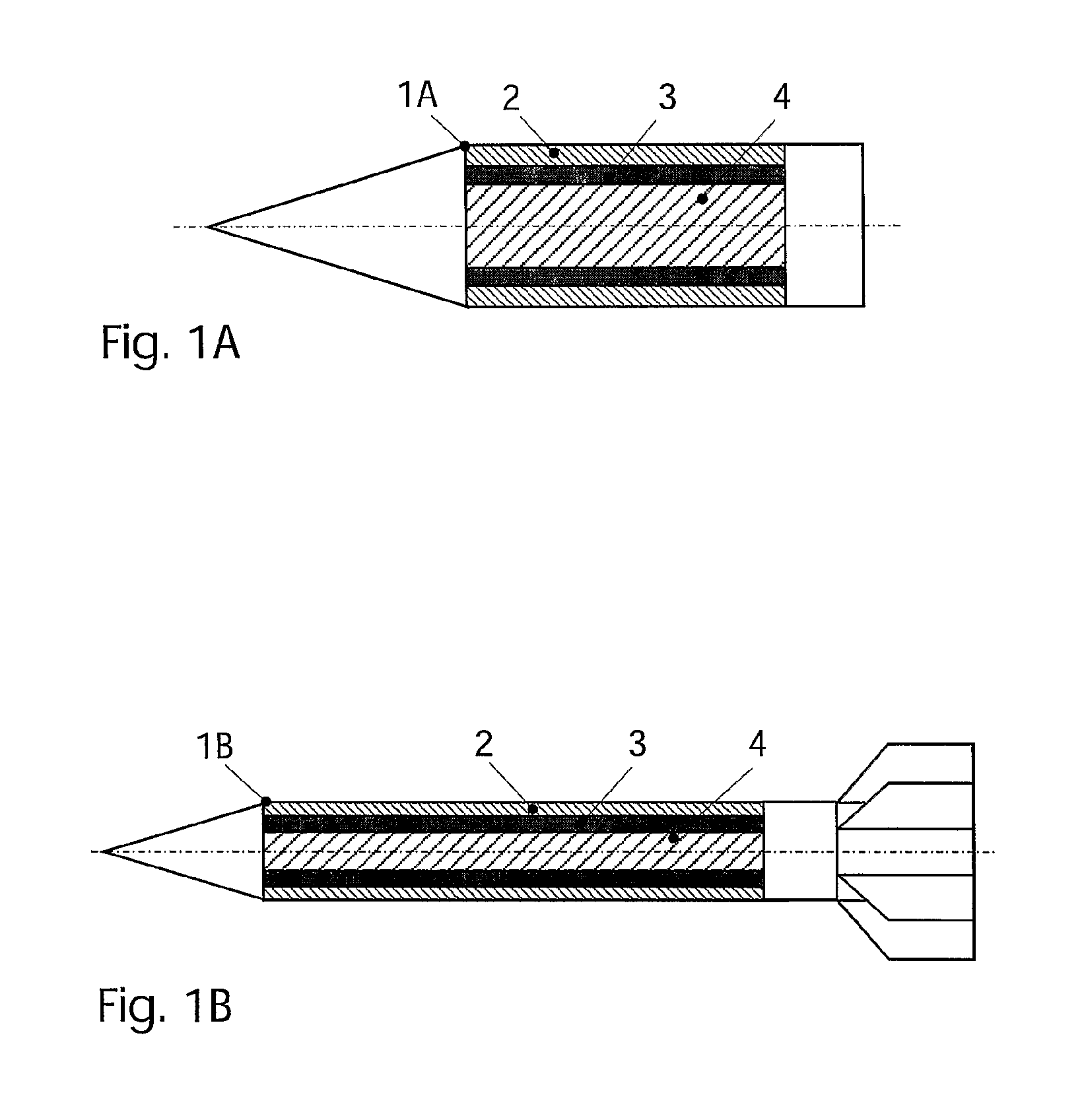

[0071]FIG. 1A shows the basic structure of a spin-stabilised explosive layer-fragment projectile 1A with a fragment casing / fragment jacket / fragmentation projectile jacket 2, an explosive layer / explosive covering / explosive surface / pyrotechnic layer 3 disposed under the casing, and a damming or stemming internal body 4. Integrated detonation firing elements with actuating means or electronic firing means for the explosive layer are indicated. Actuation and triggering of the explosive layer is to be adapted to the respective state of the art. The effectiveness of the arrangement remains substantially unaffected thereby.

[0072]The operating principle according to the invention equally allows application to aerodynamic stabilised projectiles as diagrammatically shown in FIG. 1B. This Figure also shows the basic structure of the explosive layer-fragment projectile 1B with fragment casing 2, explosive layer 3 and damming internal body 4, as well as firing elements or other projectile or war...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com