High-brightness release paper, and preparation method and applications thereof

A technology of release paper and release layer, which is applied in the field of release paper, can solve the problems of poor surface flatness of release paper, difficulty in uniform surface flatness, poor flatness of rubber surface, etc., and achieve a high qualified rate of finished products , Reasonable process design, good flatness of rubber surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

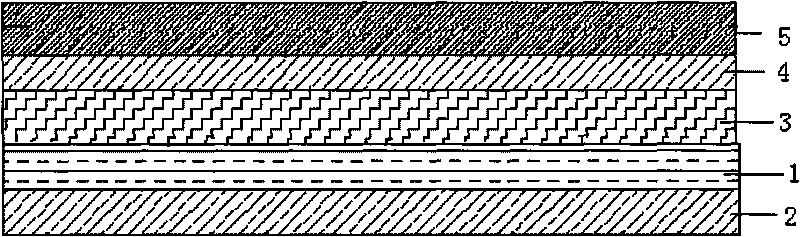

[0028] 1. Such as figure 1 As shown, a high-gloss release paper is composed of a base paper 1, a PET film layer 2 coated on one side of the base paper 1, an adhesive layer 3 coated on the other side of the base paper 1, and a glue The PET film layer 4 on the adhesive layer 3 and the silicone release layer 5 coated on the PET film layer 4 are composed.

[0029] 2. A method for preparing the high-gloss surface release paper described in 1, specifically including the following steps:

[0030] (1) Take the base paper 1 as the base material layer, spread it flat, and compound a PET film layer 2 on one side of the base paper 1 by laminating, and let it stand to cool the PET film layer for use;

[0031] (2) Coat a layer of adhesive layer 3 evenly on the other side of the base paper 1;

[0032] (3) Closely attach another PET film layer 4 on the adhesive layer 3;

[0033] (4) Coat a layer of silicone release layer 5 on the surface of the PET film layer 4 to obtain.

[0034] The step (1) is to fi...

Embodiment 2

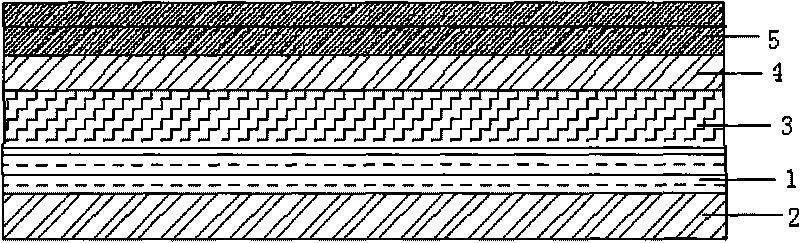

[0036] 1. Such as figure 2 As shown, a high-gloss release paper consists of a base paper 1, a PP film layer 2 coated on one side of the base paper 1, an adhesive layer 3 coated on the other side of the base paper 1, and a glue The PP film layer 4 on the adhesive layer 3 and the silicone release layer 5 coated on the PP film layer 4 are composed.

[0037] 2. A method for preparing the high-gloss surface release paper described in 1, specifically including the following steps:

[0038] (1) Take base paper 1 as the base material layer, spread it flat, and laminate a PP film layer 2 on one side of base paper 1 by laminating, and let it stand to cool the PP film layer for use;

[0039] (2) Coat a layer of adhesive layer 3 evenly on the other side of the base paper 1;

[0040] (3) Closely attach another PP film layer 4 on the adhesive layer 3;

[0041] (4) Coat a layer of silicone release layer 5 on the surface of the PP film layer 4 to obtain.

[0042] The step (1) is to first melt the PP p...

Embodiment 3

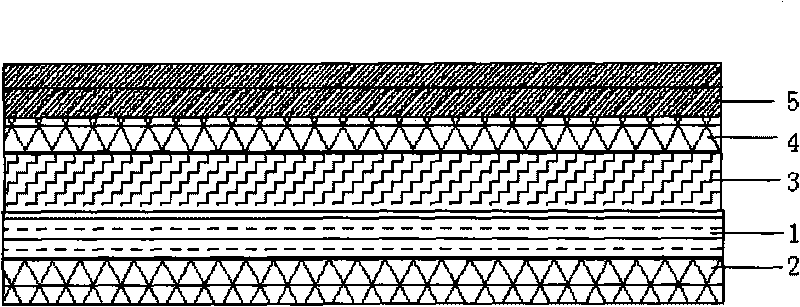

[0044] 1. Such as image 3 As shown, a high-gloss release paper is composed of a base paper 1, a PE film layer 2 coated on one side of the base paper 1, an adhesive layer 3 coated on the other side of the base paper 1, and a glue The PE film layer 4 on the adhesive layer 3 and the silicone release layer 5 coated on the PE film layer 4 are composed.

[0045] 2. A method for preparing the high-gloss surface release paper described in 1, specifically including the following steps:

[0046] (1) Take base paper 1 as the base material layer, spread it flat, and laminate a PE film layer 2 on one side of base paper 1 by laminating, and let it stand to cool the PE film layer for use;

[0047] (2) Coat a layer of adhesive layer 3 evenly on the other side of the base paper 1;

[0048] (3) Closely attach another PE film layer 4 on the adhesive layer 3;

[0049] (4) Coat a layer of silicone oil release layer 5 on the surface of the PE film layer 4 to obtain.

[0050] The step (1) is to first melt th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com