Patents

Literature

547results about How to "Realize industrialized mass production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Powder coating with super-weathering resistance, preparation method and application thereof

InactiveCN101671518AWith super weather resistanceThe ratio is scientific and reasonablePowdery paintsPolyester coatingsPliabilityUltraviolet

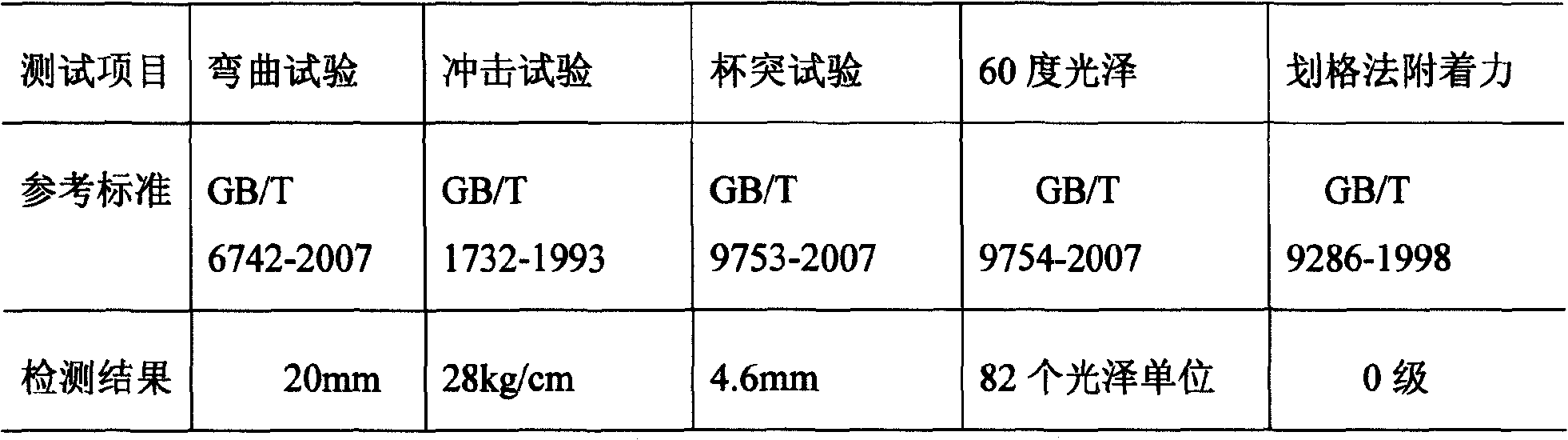

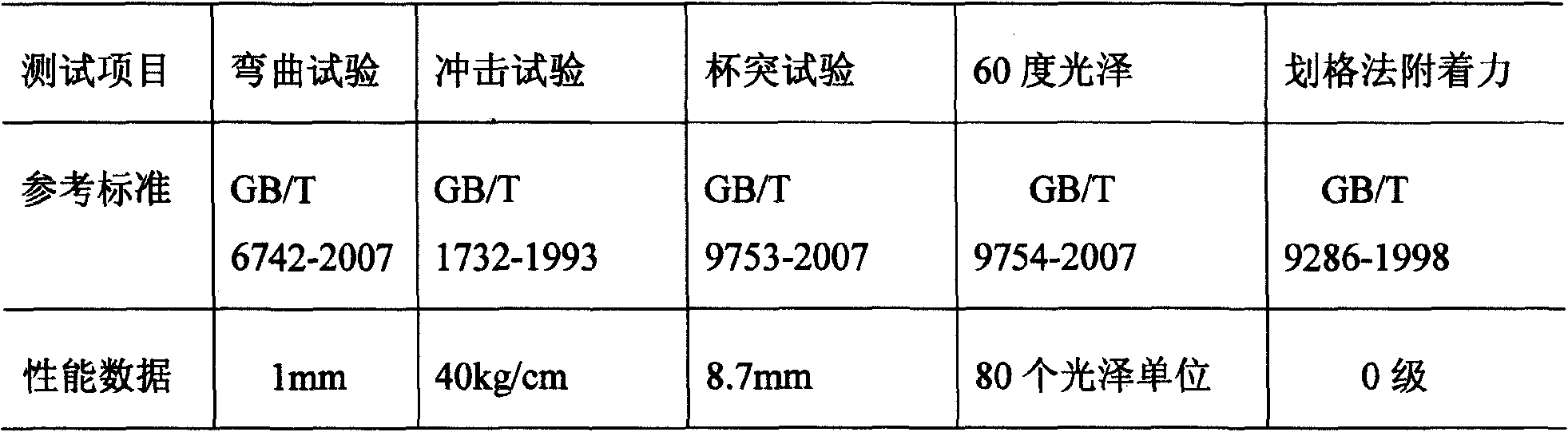

The invention discloses powder coating with super-weathering resistance, a preparation method and an application thereof. The powder coating comprises the following raw materials in parts by weight: 40-90 parts of weather-resistant polyester resin, 3-30 parts of thermosetting fluorocarbon resin, 4-50 parts of curing agent, 0.1-1.5 parts of flatting agent, 0.2-0.8 part of degasifying agent, 0-4.5 parts of defoaming agent and 4-45 parts of pigment and filler. The powder coating with super-weathering resistance provided by the invention has scientific and reasonable proportioning in the aspects of raw material composition and raw materials, fine comprehensive properties such as flexibility, hardness, adhesive force and the like, stable chemical property, easy storage, performances of acid rain, ozone, ultraviolet ray and chemical medicine resistance and the like in long-term outdoor use, environment protection and wide application range. The preparation method provided by the invention has reasonable processes, strong operability, high qualified rate of finished products and capability of realizing industrialized production.

Owner:TIGER DRYLAC TAICANG

Powder coating with antibacterial function and preparation method and application thereof

InactiveCN101665652AHas antibacterial functionThe ratio is scientific and reasonableAntifouling/underwater paintsPaints with biocidesThermal stabilityInhibitory effect

The invention discloses a powder coating with an antibacterial function and a preparation method and an application thereof. The powder coating comprises the following raw materials in the parts by weight: 60-90 parts of resin, 2-40 parts of curing agent, 1.5-10 parts of antibacterial agent color concentrate, 0.5-2 parts of flatting agent, 0-4.5 parts of defoaming agent, 4-30 parts of pigments andfillers and 0-15 parts of other auxiliary agents. The powder coating provided by the invention has the functions of bacterium resistance and broad spectrum and has strong functions of sterilizing andinhibiting various bacteria and mould fungi; the heat resistant temperature of the inorganic antibacterial agent can reach 500 DEG C, and the inorganic antibacterial agent has good heat stability; and the inorganic antibacterial agent is a silver ion antibacterial agent using glass as a carrier, has good transparency and can be made into a transparent antibacterial powder coating which has the advantages of safety and wide application range. The preparation method provided by the invention has reasonable processes, strong operability and high qualified rate of the prepared finished products and can realize industrial production in a large batch.

Owner:TIGER DRYLAC TAICANG

Momordica grosvenori extractive with at least 40 percent grosvenor momordica glycoside and preparation method thereof

InactiveCN101200753AReduce the amount of feedShorten the production cycleFermentationFood preparationSocial benefitsEnzymatic hydrolysis

The invention provides a milk white fructus momordicae extract, fructus momordicae glycoside V and fructus momordicae glycoside of which are respectively larger than or equal to 40 percent and 98 percent. The invention also discloses a preparation method of the extract. Using fresh fructus momordicae as the raw material, the invention is obtained through the water extraction, the concentration, the enzymatic hydrolysis, the macroporous adsorption resin refining, the ion exchange resin decoloration, the concentration and the spray drying. The invention is characterized in that the process parameters of the steps which are suitable for the industrial production are found, the yield and the quality of the fructus momordicae extraction are all obviously improved, and obvious economic benefits and social benefits are obtained.

Owner:GUILIN HUITONG BIOTECH

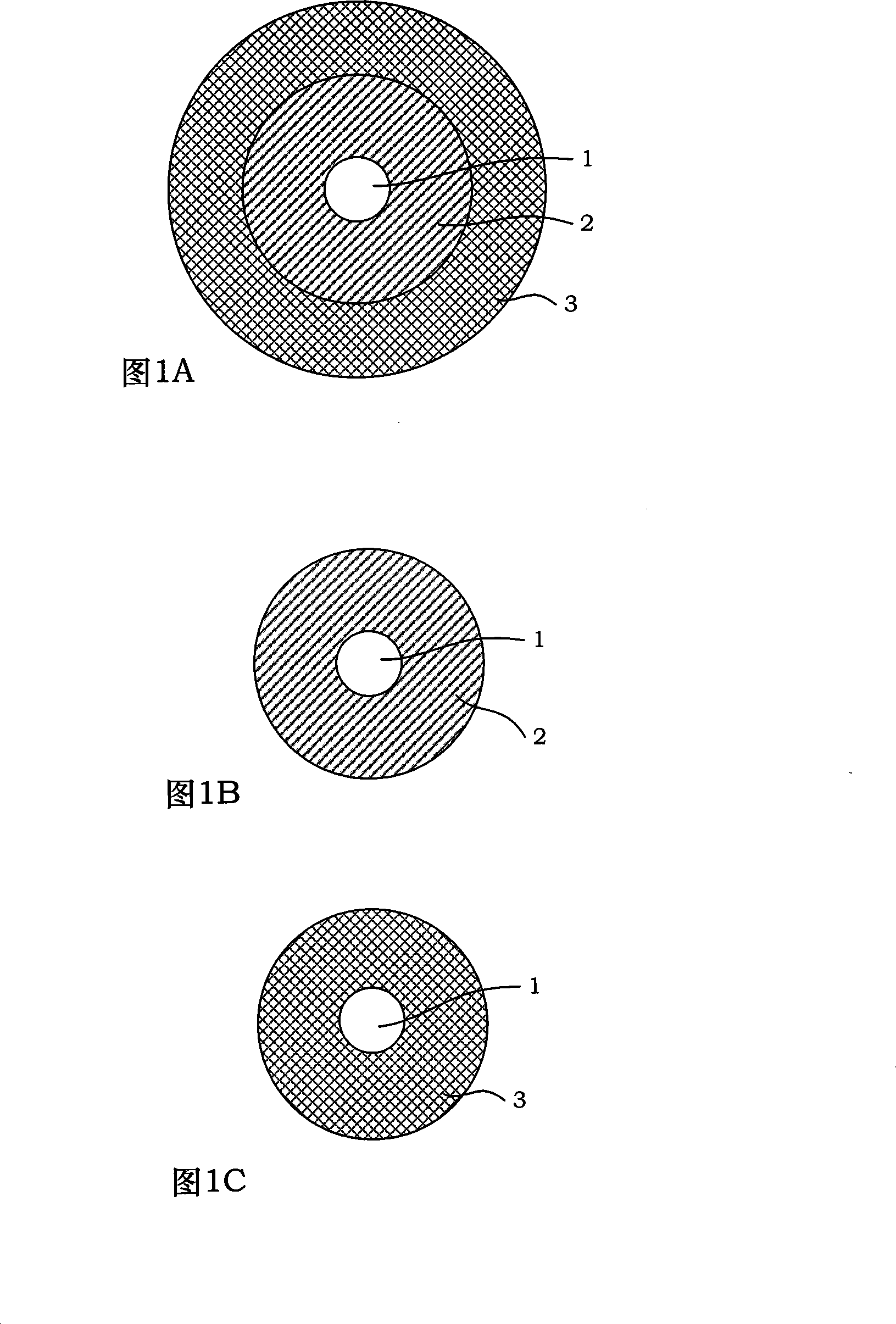

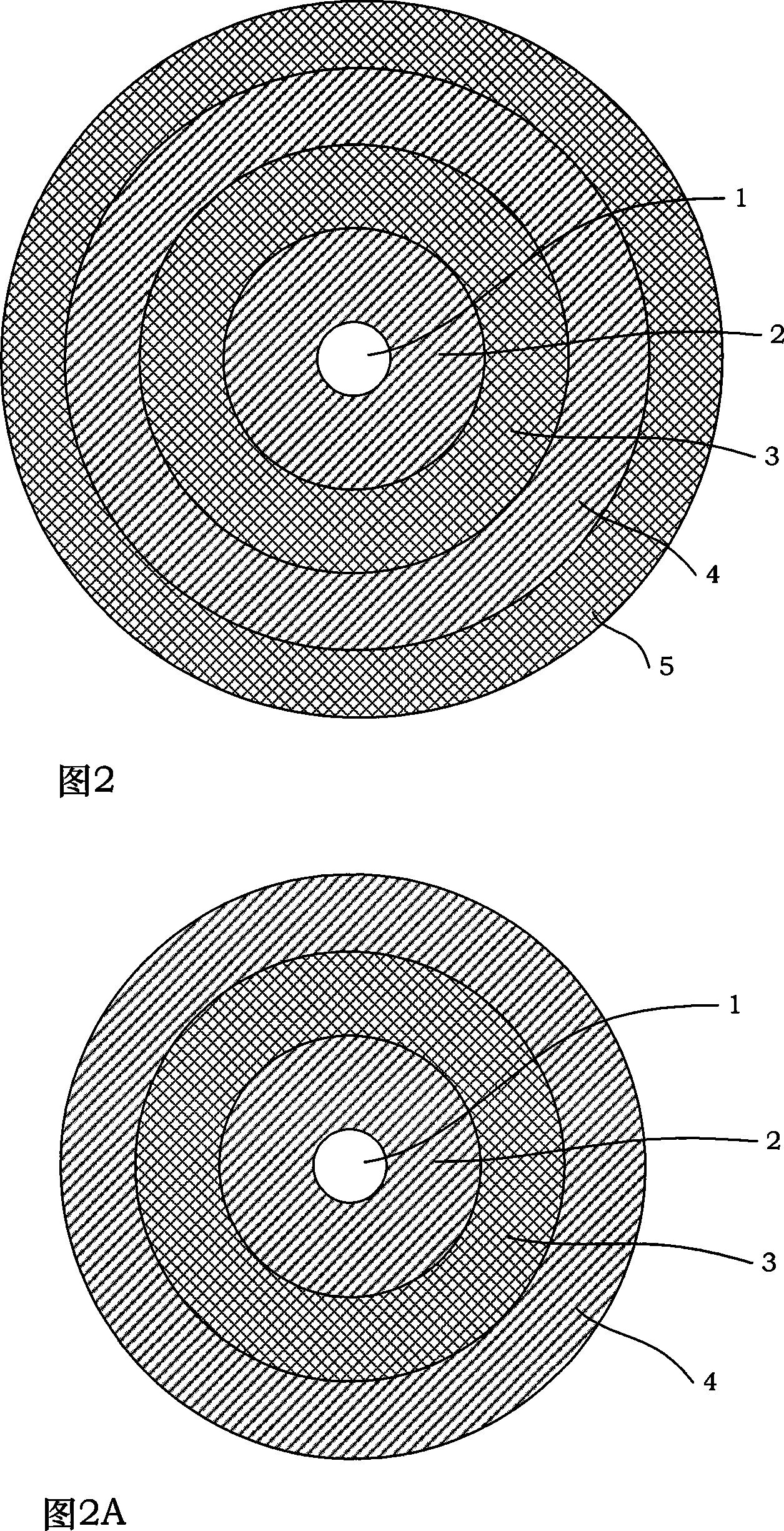

Micro-capsule essence with two-layer capsule wall and preparation method and application thereof

ActiveCN101649254AWell mixedHigh mechanical strengthFibre treatmentEssential-oils/perfumesEngineeringTwo layer

The invention discloses a micro-capsule essence with two-layer capsule walls and a preparation method and an application thereof. The essence comprises inner oil essence, a first micro-capsule wall inthe middle and an outer capsule wall located on outermost layer. The micro-capsule essence with two-layer capsule wall of the invention has two-layer capsule wall structure , good mechanical strengthand flexibitity; in addition, when used in cloth the micro-capsule essence has the advantage of strong washing resistance, long fragrance holding time and easy storage. The preparation method of themicro-capsule essence with two-layer capsule walls adopts complex coacervation phase separation method to prepare the essence, the technological design is seasonable, the maneuverability is strong, micro-capsule essence with different fragrances can be designed according to different demands; in the preparation process, the mechanical strength of the micro-capsule essence can be effectively controlled so as to control the duration time and degree of the frangrance of the micro-capsule essence; in addition, the finished product of the micro-capsule essence with two-layer capsule walls preparedin the invention has high qualification rate and the micro-capsule essence with two-layer capsule can realize industrialized production.

Owner:澳华达香精(广州)有限公司

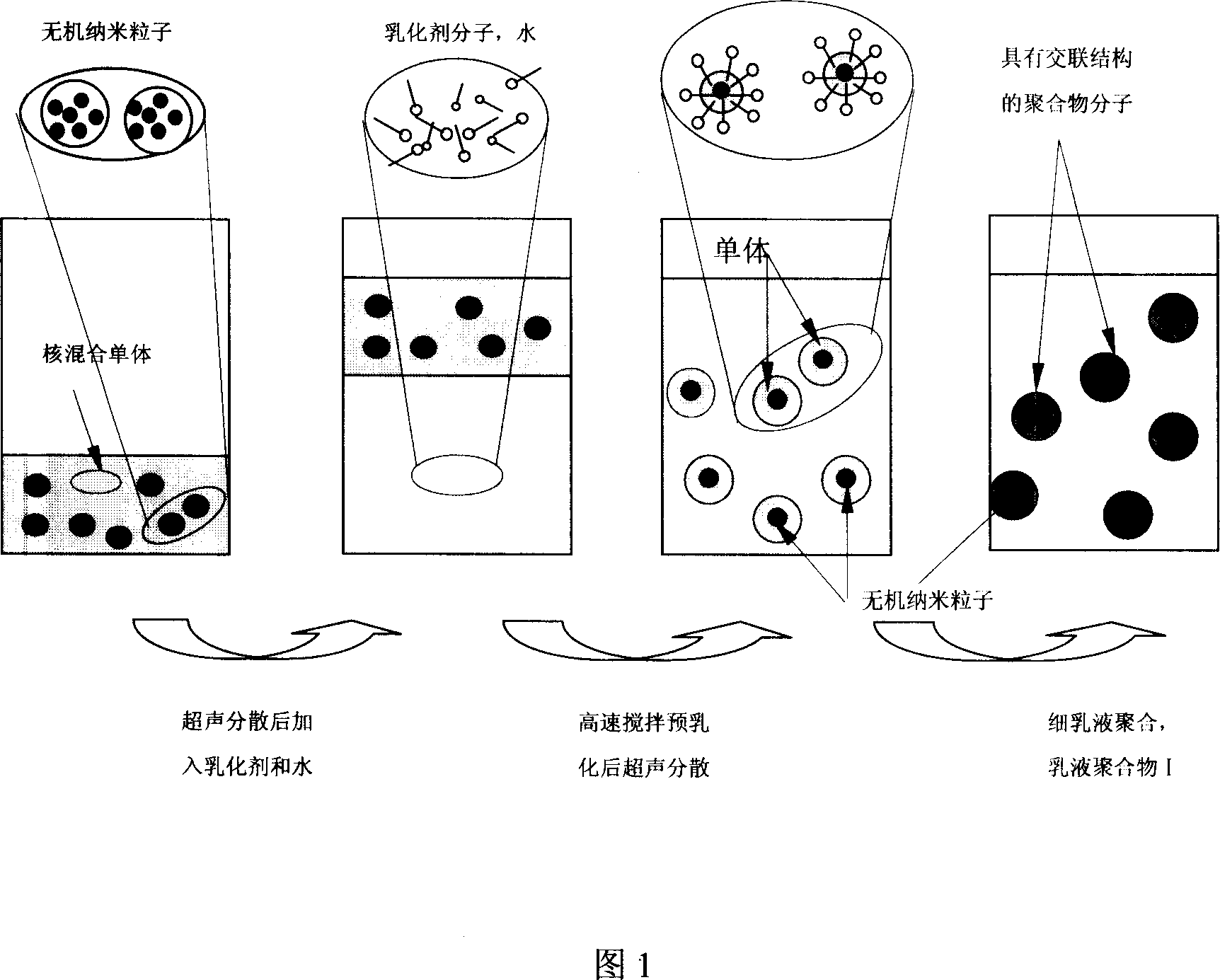

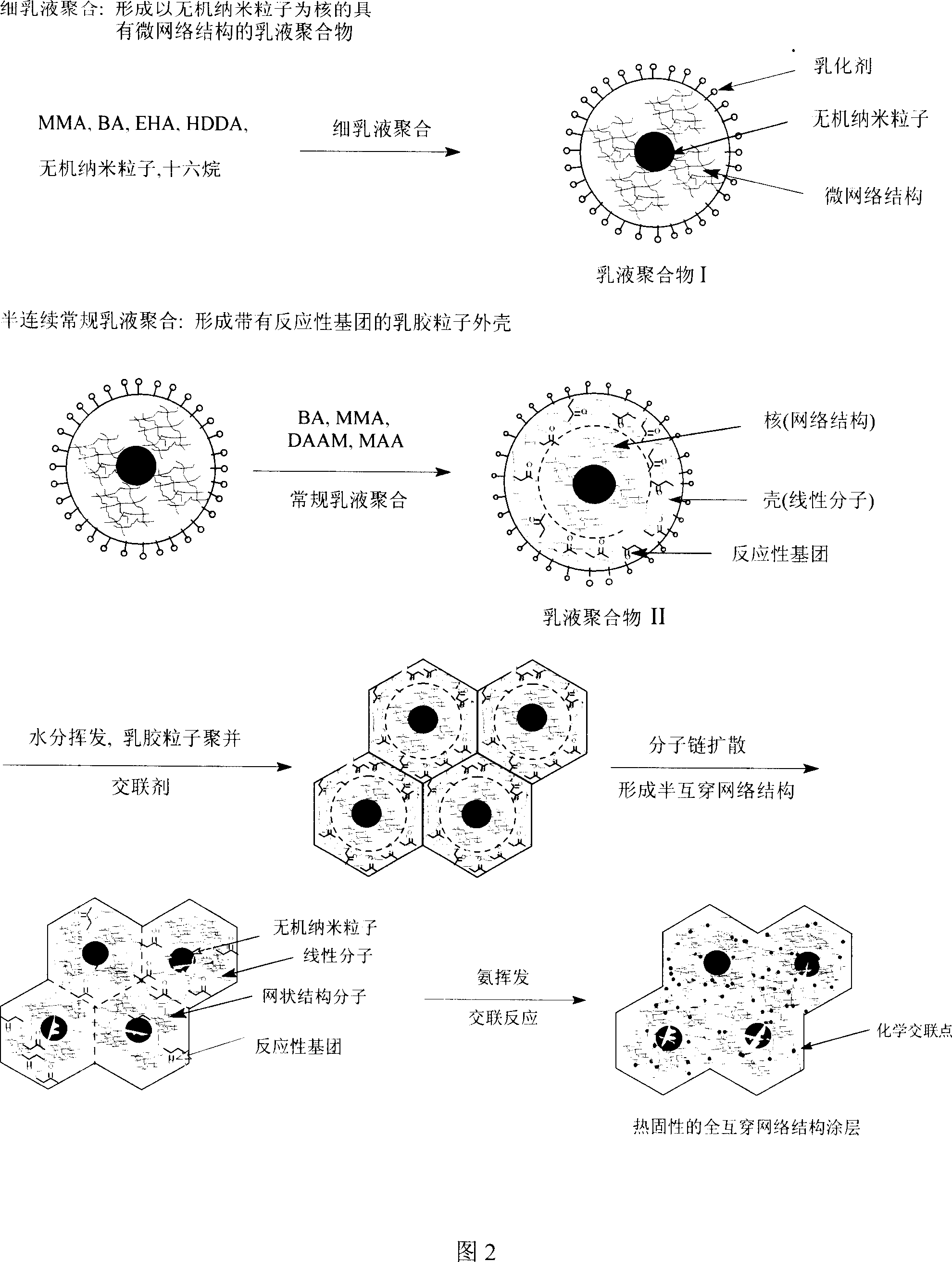

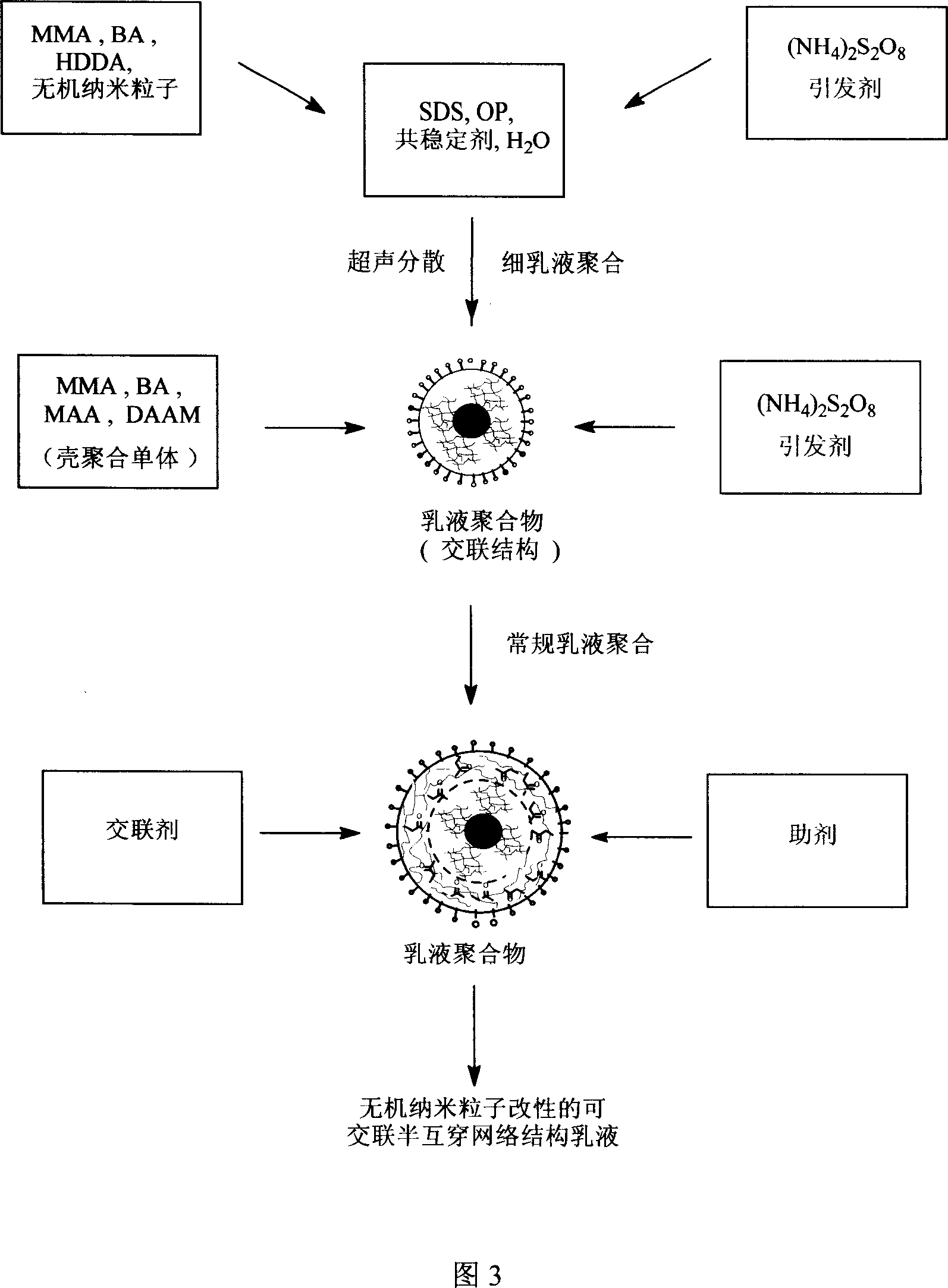

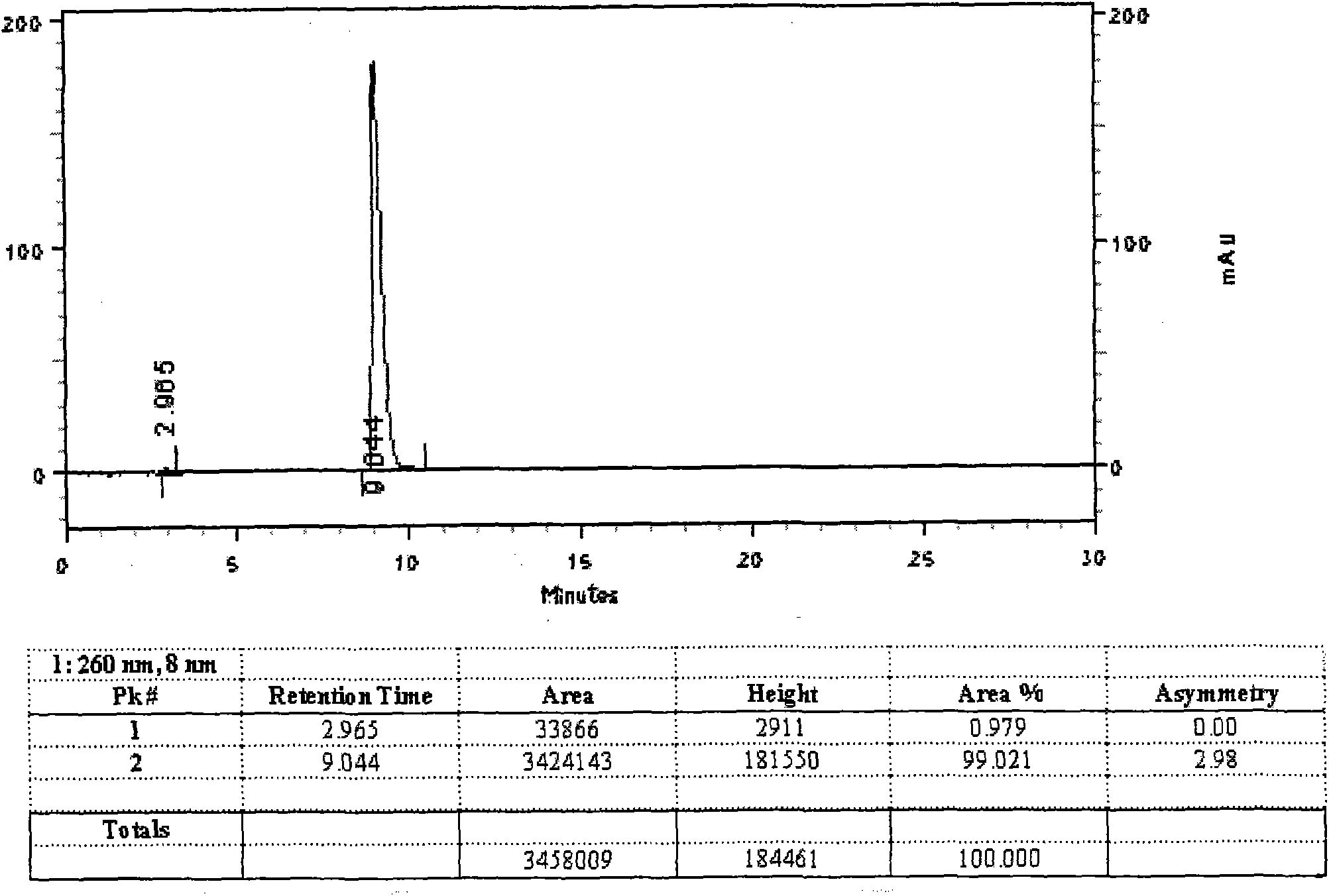

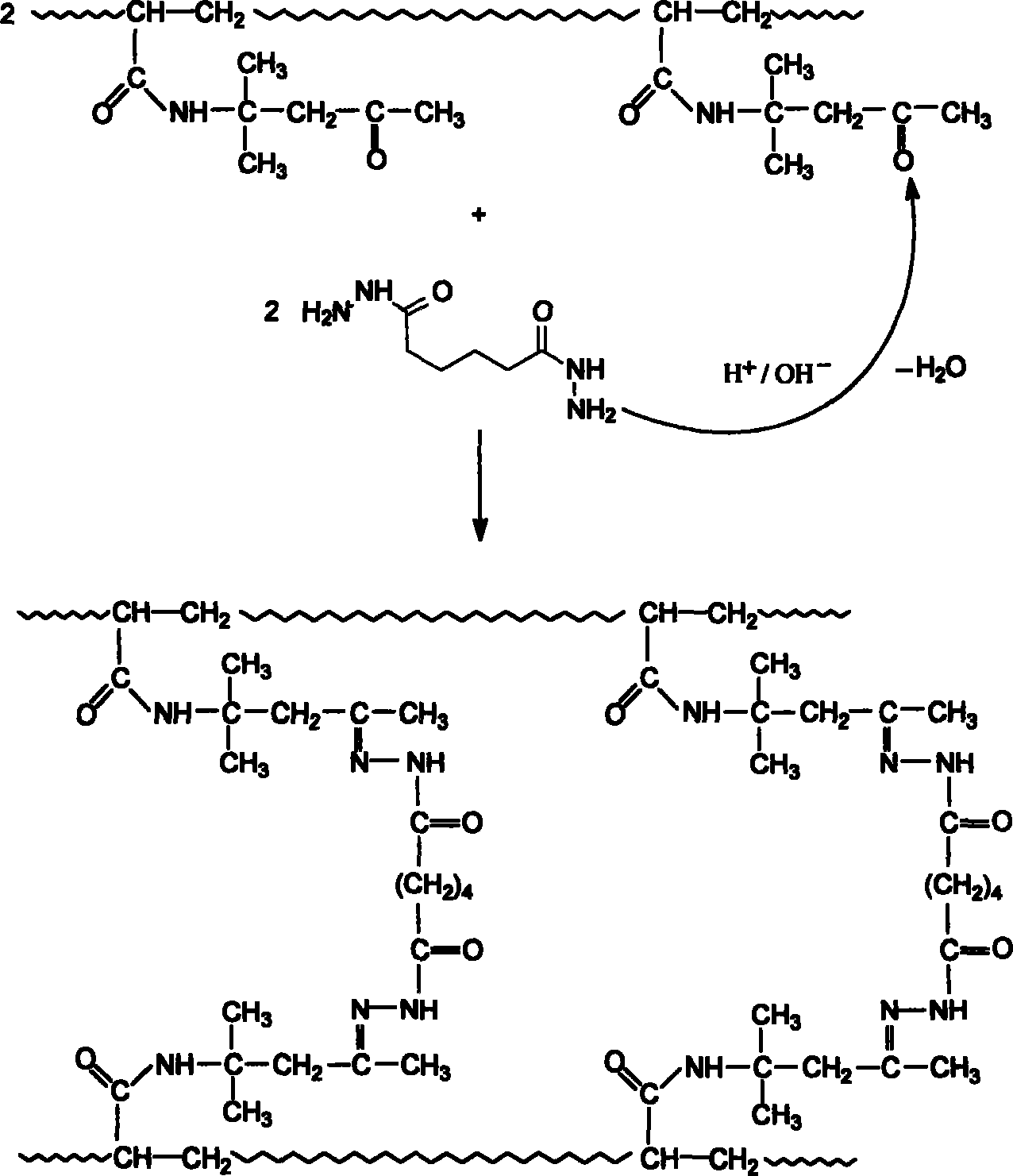

Method of preparing organic/inorganic hybridization reactivity semi-interpenetrating network structure emulsion

The invention discloses a new method for manufacturing Interpenetrating Polymer Network of organic or inorganic reaction latex, which belongs to macromolecule manufacturing polymer synthesis. The emulsion has excellent storage stability. Its coating with a high pencil hardness, excellent scratch resistance, water-resistance, stain resistance, chemical resistance and aging resistance, can be used for wood, metal and surface decoration and construction exterior paint, The water emulsion polymer can be made through the following steps: (a) At least two unsaturated compounds, allyl monomer and inorganic nano particle are polymerized to the cross-linked structure seed emulsion. (b) The unsaturated compounds with reaction and allyl monomer are polymerized to core / shell structure emulsion on the basis of the seed emulsion. (c) In the core / shell structure emulsion, organic / inorganic hybrid with cross-linked structure semi-IPN emulsion can be got for adding cross-linker.

Owner:HUNAN UNIV OF TECH

Comprehensive resource treatment method of food waste

InactiveCN102744243AEfficient use ofRealize industrialized mass productionSolid waste disposalOil and greaseSocial benefits

The invention discloses a comprehensive resource treatment method of food waste, relating to the technical field of resource recycle treatment. The comprehensive resource treatment method comprises the technical steps of impurity separation, oil-slag separation, organic solid matter treatment, oil-water separation, liquid grease treatment, wastewater treatment, methane utilization, methane slurry and methane residue utilization, and membrane filtration wastewater treatment. Compared with the traditional treatment process, the comprehensive resource treatment method disclosed by the invention has the advantages that the treated food waste realizes real innocent treatment, the food waste is fully recycled, and organic solid matters, methane, methane residue and methane slurry generated in the treatment process are all most efficiently utilized, thus not only is the food waste hard to be treated in the prior art changed to be valuable, but also the treatment cost is low; and the industrial large-scale production can be realized, and simultaneously great economic and social benefits are also generated.

Owner:山东博洋环境资源有限公司

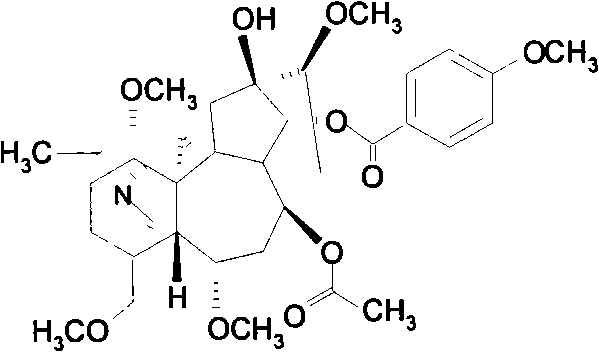

Preparation method of high purity bulleyaconitine A

ActiveCN101555227AHigh purityReduce manufacturing costNervous disorderOrganic chemistrySolvent vaporEthyl acetate

The invention relates to a preparation method of high purity bulleyaconitine A. The preparation method comprises the following steps: root of radix aconiti feri of Yunnan is crushed, and acid alcoholic solvent or alcohol water solution is used for diacolation, and supersound or thermal refluxing extraction. The extracting solution is decompressed and concentrated to be non-alcoholic at the temperature of 80 to 90 DEG C, cooled down to room temperature, to ensure the relative density to be 1.00 to 1.30; standing is performed for 10 to 20 hours; the extracting solution is filtered; the pH is adjusted to 6.0 to 8.0 with basifier; and then the extracting solution is extracted with ethyl acetate or chloroform. The ethyl acetate or chloroform liquid is contracted, column chromatography is performed to the obtained paste, silica gel or neutral alumina are used as fillers, any one of solvent vapor-acetone-diethylamine, ligarine-acetone-diethylamine or cyclohexane-acetone-diethylamine is used for eluation, the bulleyaconitine A in the collected liquid is constantly checked during the thin layer chromatography, the collected liquid containing the bulleyaconitine A is merged, the solvent is concentrated, carbinol or ethanol is dissolved, filtering is performed, crystallization is performed at room temperature, filtering is performed, the crystal is repeatedly rinsed with carbinol or ethanol, and the final product is obtained. The purity of the obtained product is high, the production cost is low, and the toxicity of the used organic solvent is low.

Owner:KPC PHARM INC

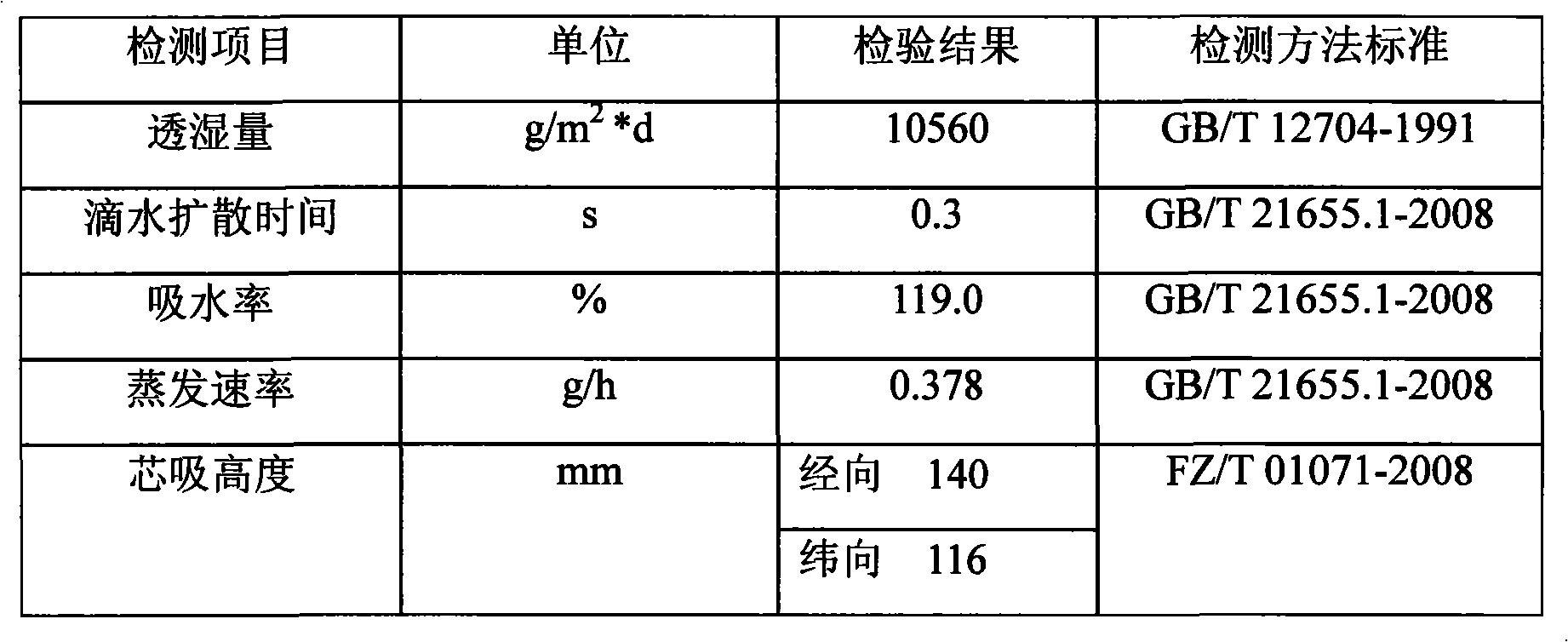

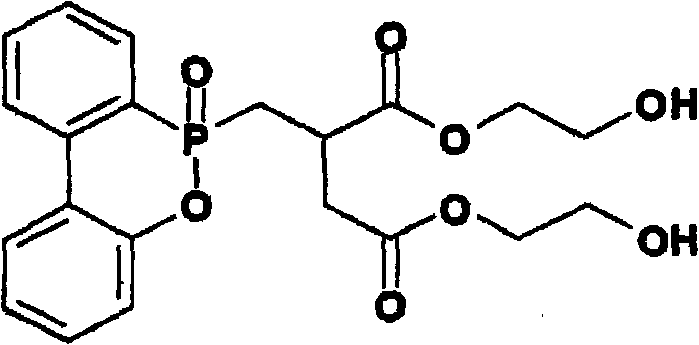

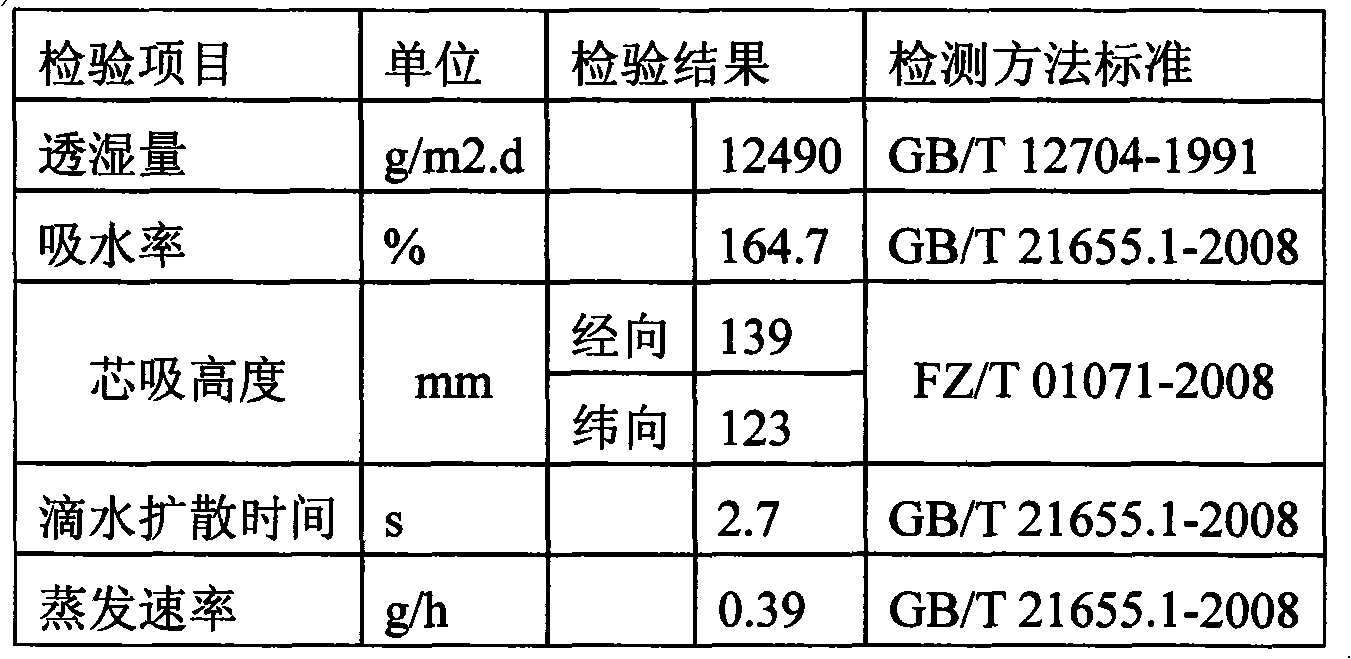

Uvioresistant, antibacterial and moisture conductive terylene fiber, preparation method and application thereof

ActiveCN101629334AImproves UV resistanceLong-lasting antibacterialFilament/thread formingMonocomponent polyesters artificial filamentYarnFiber

The invention discloses an uvioresistant, antibacterial and moisture conductive terylene fiber, a preparation method and an application thereof. The terylene fiber comprises the following raw materials in percentage by weight: 1-5 percent of uvioresistant parent granule, 1-10 percent of silver series antibacterial parent granule and 85-98 percent of terylene fiber forming resin, wherein the cross section of the fiber is a profile cross section. The uvioresistant, antibacterial and moisture conductive terylene fiber, the component proportions of which are scientific and reasonable, is prepared by the following steps: scientifically and organically combining the antibacterial silver series parent granules, the uvioresistant parent granules and the terylene fiber forming resin; preparing a pre-oriented yarn by using a profile hole spinning plate; and then elasticizing and deforming the pre-oriented yarn; thus the terylene fiber has wide range of application. The preparation method of the uvioresistant, antibacterial and moisture conductive terylene fiber has strong operability, reasonable process and high production efficiency and can realize industrial mass production.

Owner:微笑纺织科技(太仓)有限公司

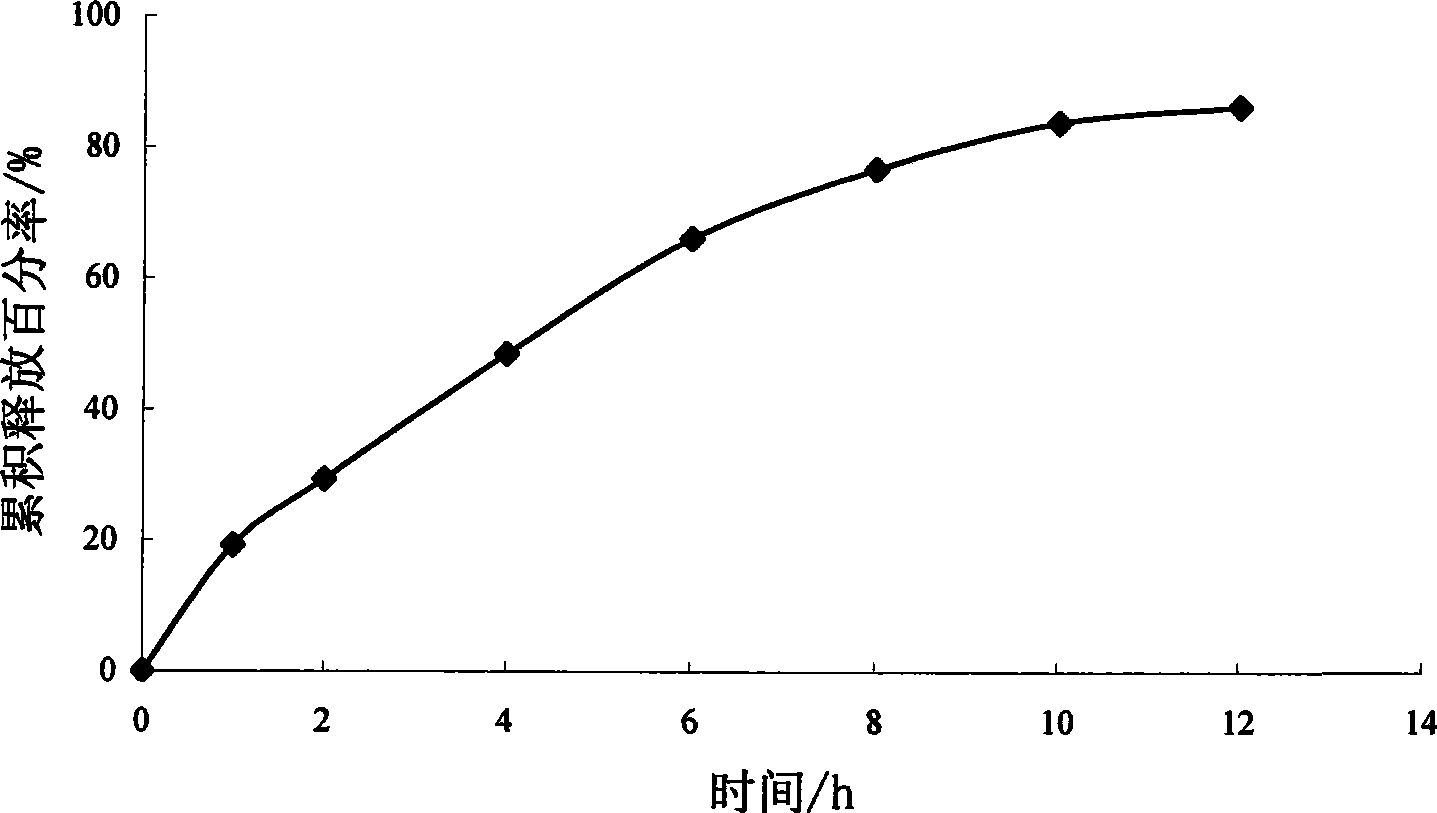

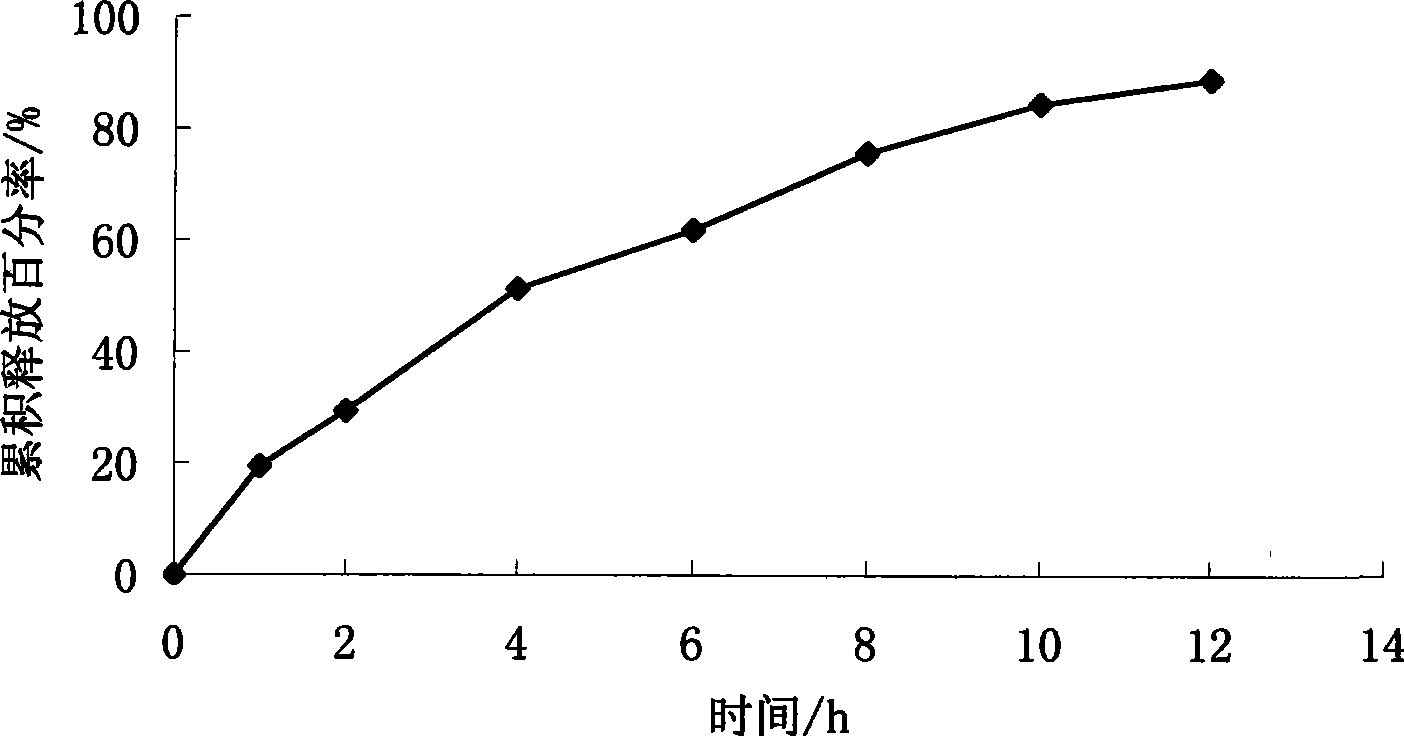

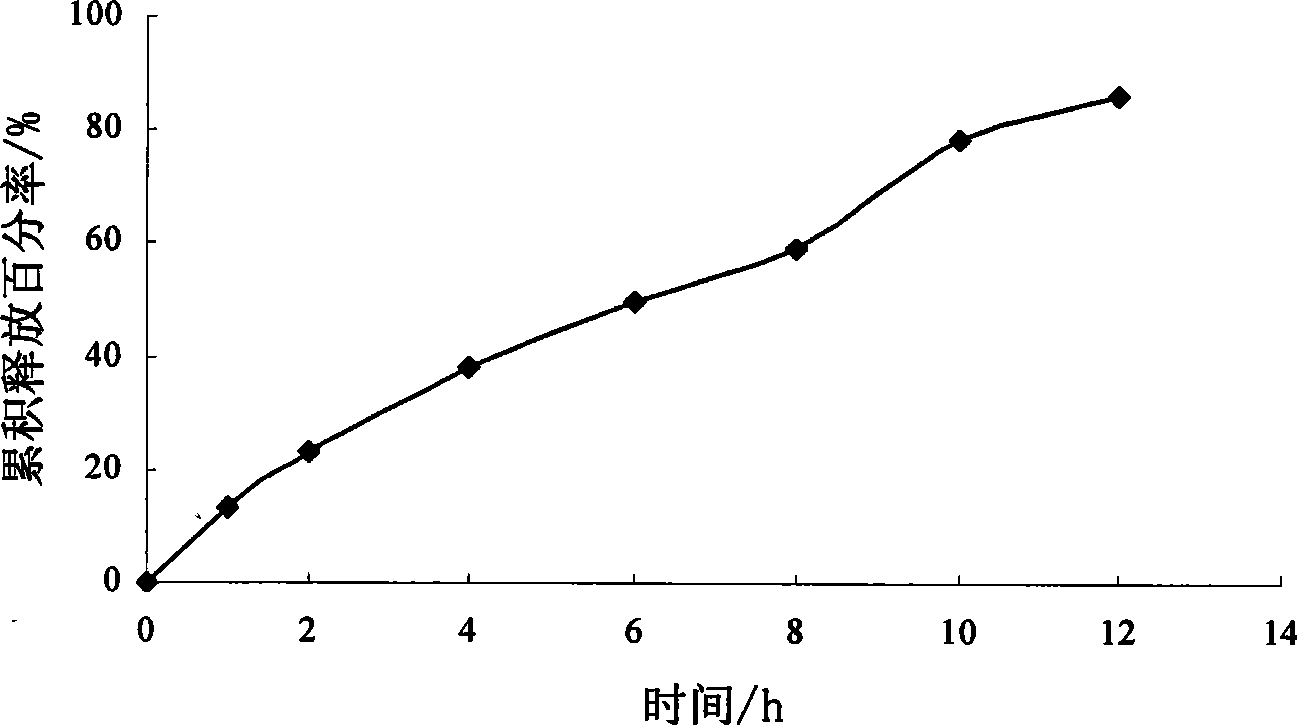

Sirolimos sustained and controlled release preparation and preparation method thereof

InactiveCN101361703AOvercome the problems of poor water solubility and narrow therapeutic windowImprove securityOrganic active ingredientsPharmaceutical delivery mechanismSolubilityCyclodextrin

The invention provides a Sirolimus slow controlled release preparation and a preparation method thereof. By adopting the solubilizing methods including a solid dispersion technology or cyclodextrin inclusion technology or adding one or a plurality of surface active agents after micronizing drugs and the like, the solubility is dramatically improved and further the bioavailability is improved, therefore, a matrix type slow controlled release preparation is made by adding one or a plurality of framework materials and other accessories, or a diaphragm-controlled or osmotic pump type slow controlled release preparation is made by adopting slow controlled release materials for coating. The Sirolimus slow controlled release preparation has better solubility and dissolution rate, high bioavailability as well as slow controlled release effect, thus being capable of maintaining steady blood concentration, bringing down the concentration of peak, reducing the occurrence of adverse reaction and improving the safety of clinical medicines, in addition, the raw materials can be acquired easily, the preparation process is simple and feasible with high yield rate and low cost, and the large-scale industrial production can be realized and the economic benefit is marked.

Owner:宋洪涛

Method for dissolving cellulose

The invention discloses a method for dissolving cellulose, characterized by: using at least one from the group consisting of wood pulp, cotton pulp, hemp pulp, bamboo pulp, bagasse pulp, grass fibered pulp, cellulose non-woven fabric or steam exploded cellulose pulp as cellulose raw material, uniformly stirring the cellulose raw material, NaOH and water at a temperature of -15-50 DEG C to obtain a cellulose solution. The prepared cellulose concentrated solution has good spinnability and film forming property. The method breaks through a dissolution method of traditional gluing technology, does not relate to carbon disulfide and other substance causing serious environmental pollution, and is green and environmentally friendly. According to the invention, the cellulose raw material can be directly rapidly dissolved at room temperature, without heating or precooling a solvent. The method has the advantages of saving energy, and reducing energy consumption. By using raw materials having low cost, the method has the advantages of simple operation, small investment, high productivity, and is easy to realize large-scale industrial production.

Owner:NANHUA UNIV +1

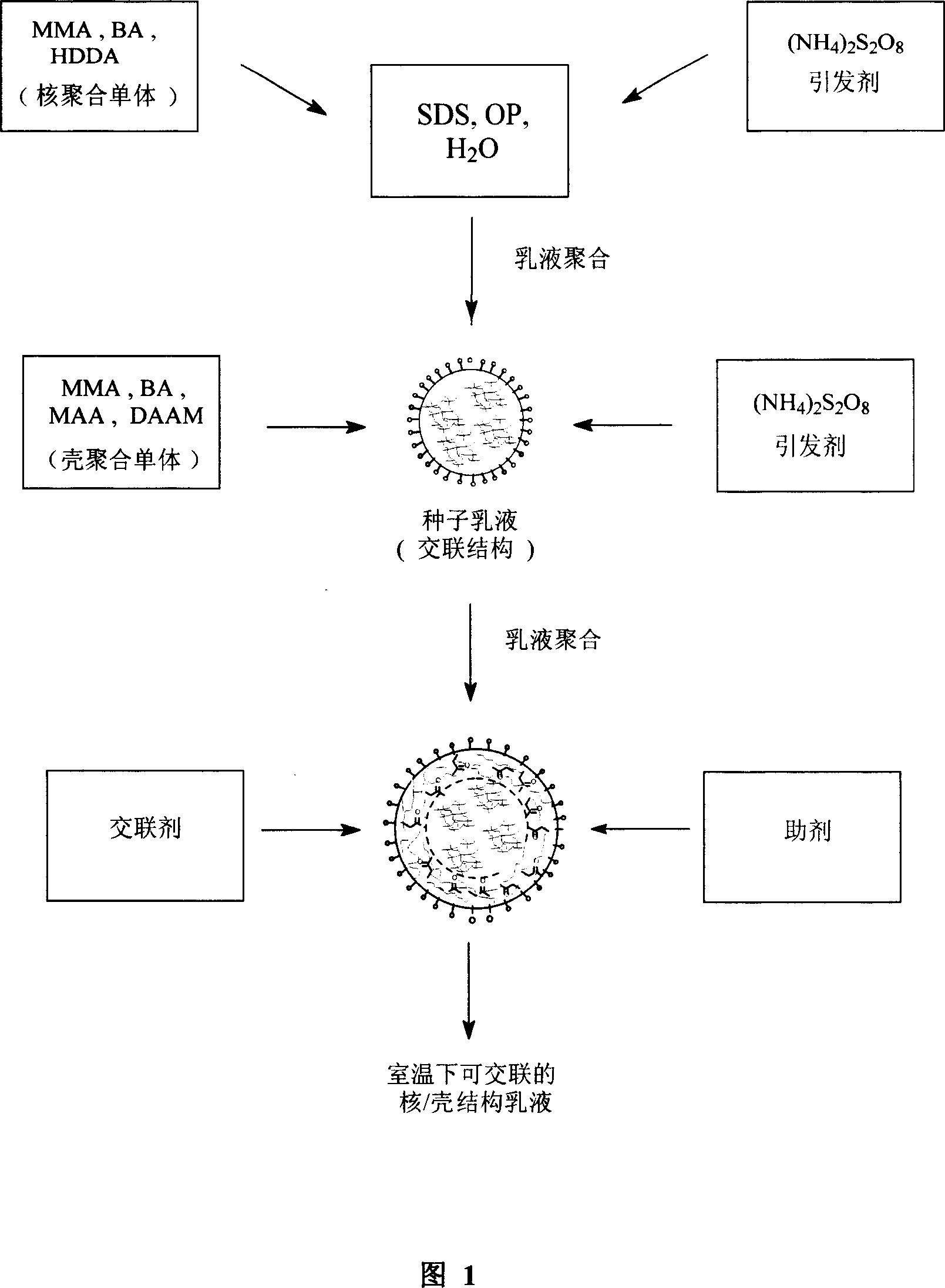

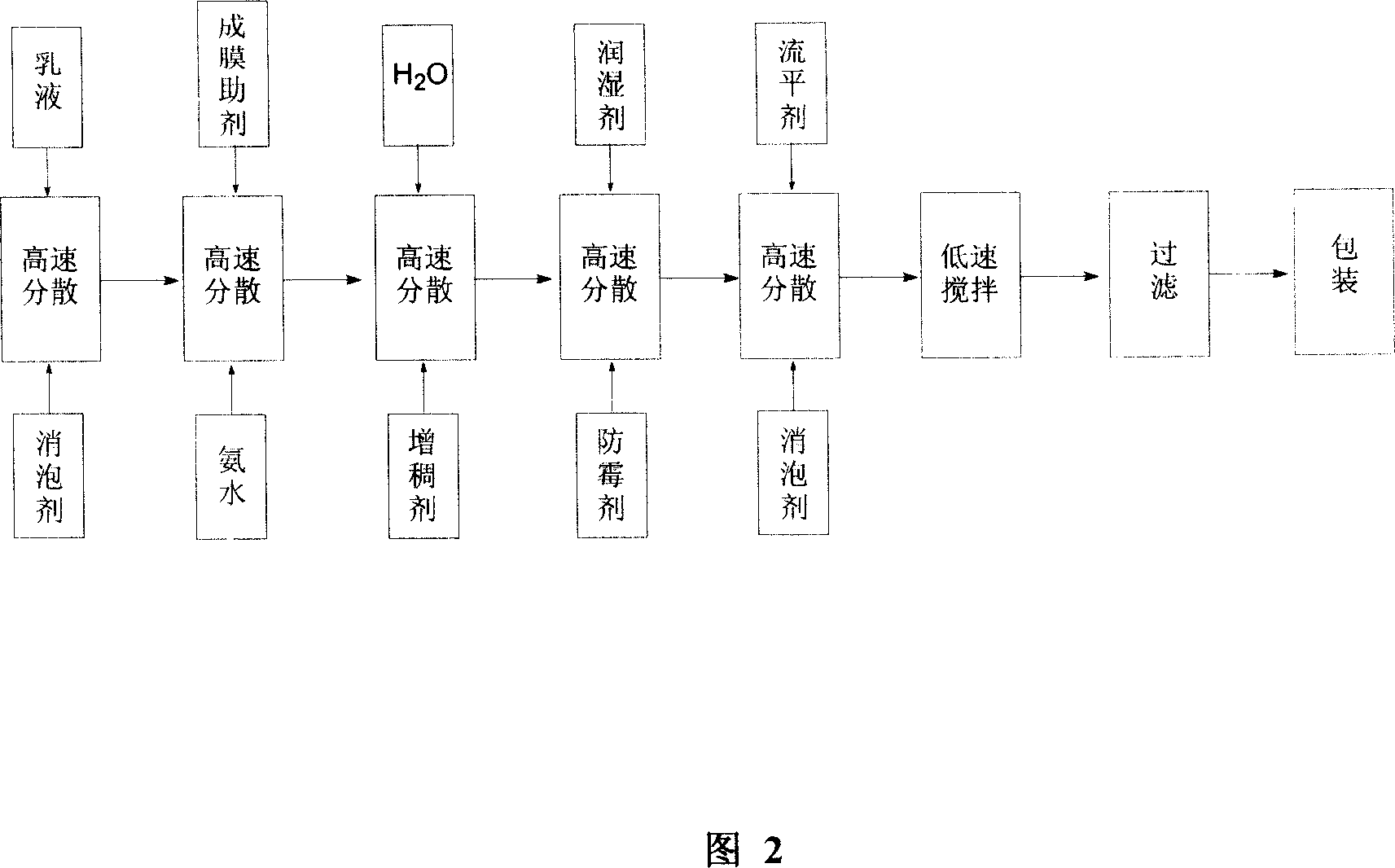

Method for preparing thermosetting acrylic ester emulsion coating under room temperature

The invention discloses a new making method of thermosetting acrylate emulsion paint under indoor temperature in the macromolecular synthesizing making industry, which comprises the following steps: (1). copolymerizing compound with at least two insaturated groups and olefinic monomer to form seed emulsion with crosslinking structure; (2) polymerizing emulsion to obtain core-case structural emulsion; (3) adding crosslinking agent in the emulsion to obtain the product under indoor temperature.

Owner:HUNAN UNIV OF TECH +1

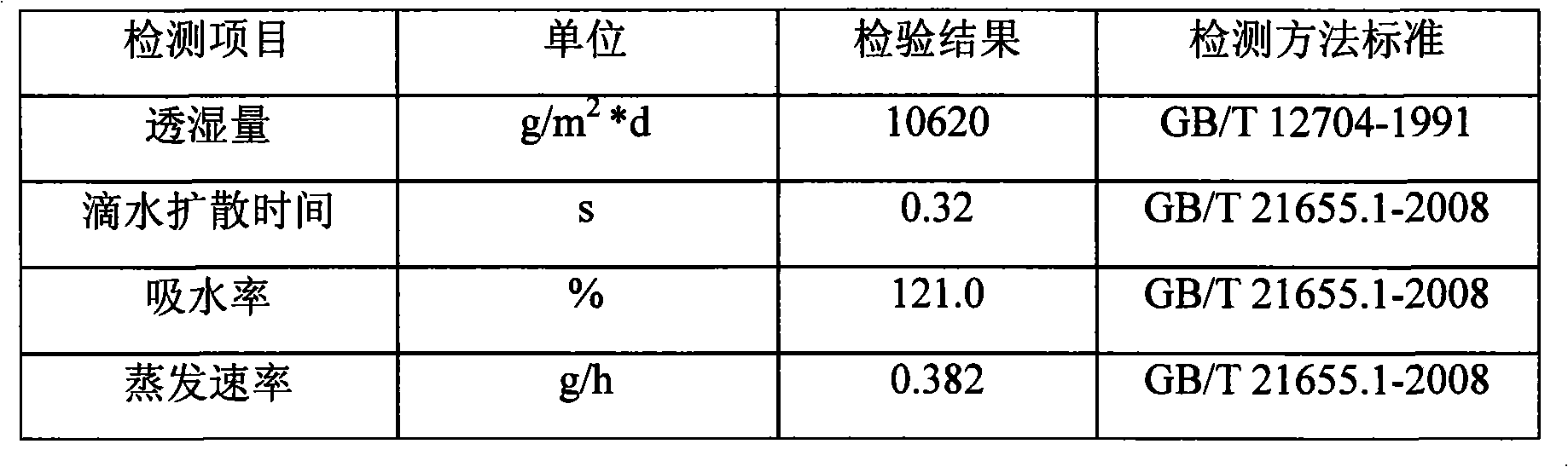

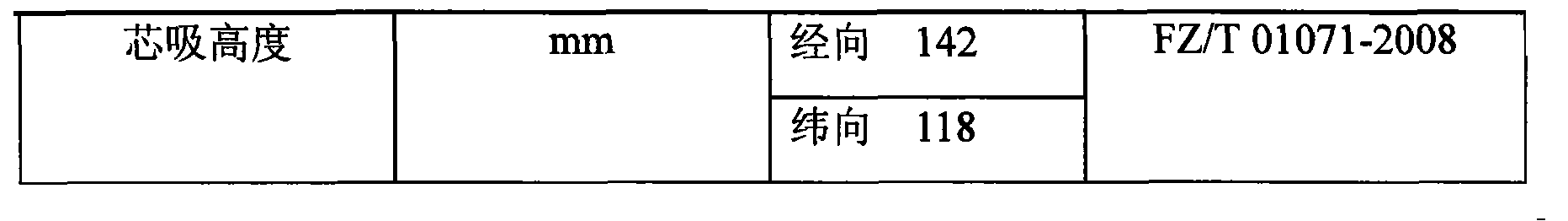

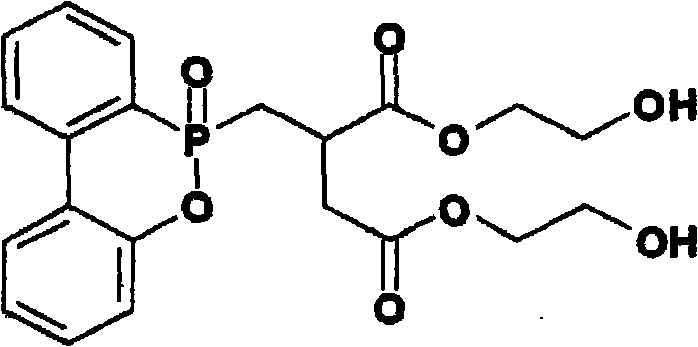

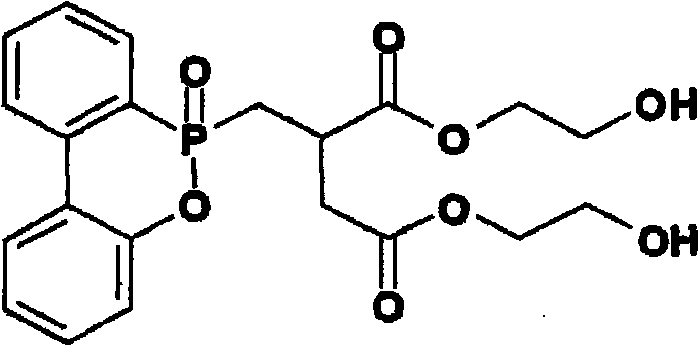

Uvioresistant, antibacterial and flame retardant terylene fiber, preparation method and application thereof

ActiveCN101629335AHas antibacterial propertiesThe composition ratio is scientific and reasonableMonocomponent polyesters artificial filamentProtective garmentFiberYarn

The invention discloses an uvioresistant, antibacterial and flame retardant terylene fiber, a preparation method and an application thereof. The terylene fiber comprises the following raw materials in percentage by weight: 1-10 percent of silver series antibacterial parent granule, 1-5 percent of uvioresistant parent granule and 85-98 percent of copolymerized type phosphorus flame retardant terylene fiber forming resin. The uvioresistant, antibacterial and flame retardant terylene fiber , the component proportions of which are scientific and reasonable, is prepared by the following steps: scientifically and organically combining the antibacterial silver series parent granules, the uvioresistant parent granules and the copolymerized type phosphorus flame retardant terylene fiber forming resin; preparing a pre-oriented yarn; and then elasticizing and deforming the pre-oriented yarn to produce low-elasticity deformed yarn; thus the terylene fiber has wide range of application. The preparation method of the uvioresistant, antibacterial and flame retardant terylene fiber has strong operability, reasonable process and high production efficiency and can realize industrial mass production.

Owner:微笑纺织科技(太仓)有限公司

Epoxy dry-hang glue and preparation method thereof

InactiveCN101712857AHigh strengthGood weather resistanceEpoxy resin adhesivesEpoxyWeather resistance

The invention discloses epoxy dry-hang glue and a preparation method thereof. The epoxy dry-hang glue comprises component A and component B, wherein in part by weight, the component A comprises 30 to 60 parts of epoxy resin, 5 parts of diluent, 40 to 60 parts of inorganic filler and 0.1 part of first color mixing material; the component B comprises 20 to 50 parts of phenolic compound modified amine hardener, 5 parts of diluent, 50 to 70 parts of inorganic filler, 3 parts of accelerant and 0.1 part of second color mixing material; the component A and the component B are mixed to form the epoxy dry-hang glue; and the using amount ratio of the component A to the component B is (1-5): 1. The epoxy dry-hang glue of the invention has no yellowing and oil spitting phenomena after solidification, and has the advantages of high strength and good weather resistance. The preparation method for the epoxy dry-hang glue has the advantages of simple steps, convenient operations, wide raw material sources and low manufacturing cost, is favorable for popularization and application, and can realize industrialized mass production.

Owner:江苏大力士投资有限公司

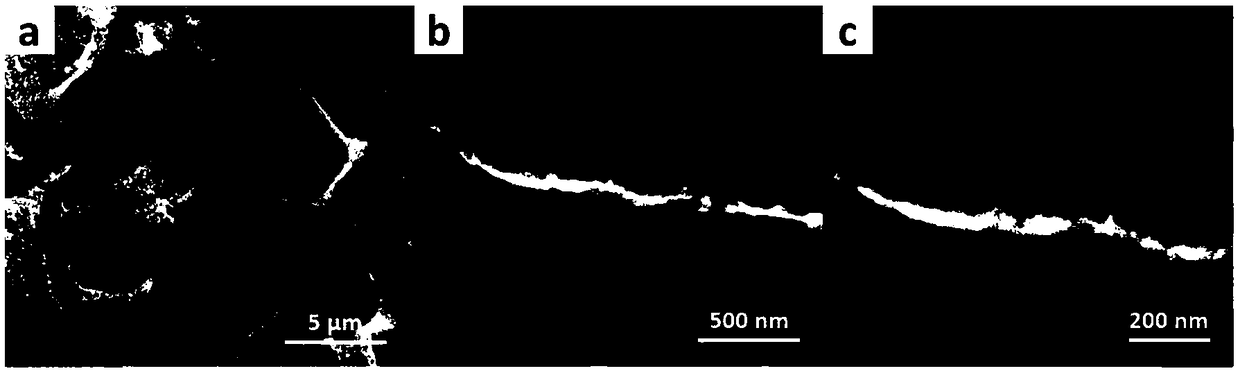

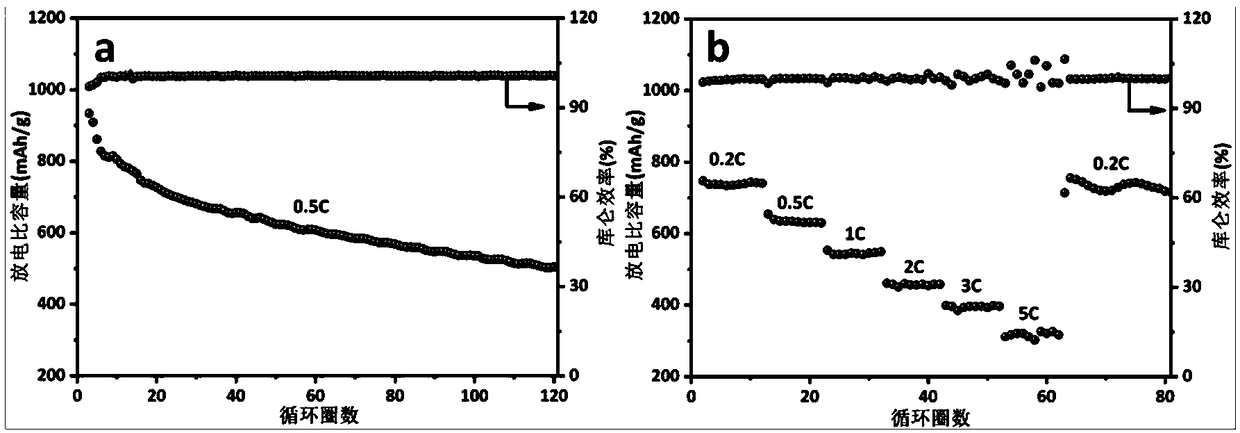

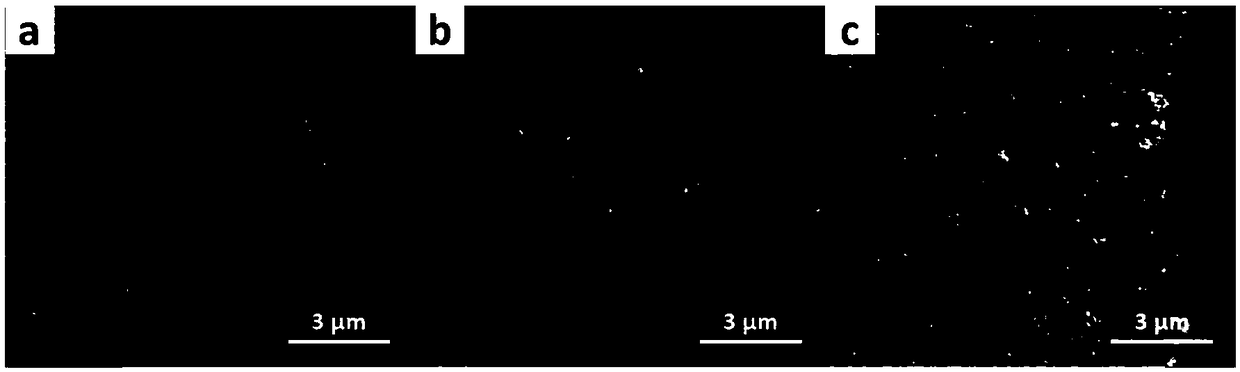

A method for prepare a nitrogen doped carbon nanotube three-dimensional composite material by in-situ growth of a small lay of titanium carbide

InactiveCN109167066AImprove conductivityAchieve controlled growthCell electrodesTetramethylammonium hydroxideFreeze-drying

The invention belongs to the technical field of preparation of nano-functional materials, in particular to a method for preparing a nitrogen doped carbon nanotube three-dimensional composite materialby in-situ growth of a few layers of titanium carbide, immersing ternary layered Ti3AlC2 ceramic powder in hydrofluoric acid solution, heating and stirring, centrifugally cleaning with ultrapure waterand absolute ethanol, drying to obtain two-dimensional layered titanium carbide nano-powder, adding it into tetramethylammonium hydroxide solution, heating and stirring, centrifuging with deionized water to obtain a few layers of titanium carbide nano-sheet dispersion; Adding cobalt salt into a dispersion of a few layers of titanium carbide nano-sheets for reaction, adding dicyandiamide, heatingand stirring until dicyandiamide is completely dissolved, freezing, and freeze-drying to obtain precursor powder; Nitrogen-doped carbon nanotubes (CNTs) three-dimensional composites were prepared by in-situ growth of a few layers of titanium carbide after grinding the precursor powder and heat treatment. A three-dimensional composite material is prepared by a simple pyrolysis method using a few layers of titanium carbide as a carrier, cobalt as a catalyst, dicyandiamide as a carbon and nitrogen source, and the electrochemical performance of the few layers of titanium carbide can be improved.

Owner:UNIV OF JINAN

Powder coating containing modified sepiolite powder and preparing method thereof

ActiveCN103059696AImproved surface levelingHigh gloss retentionPowdery paintsEpoxy resin coatingsLow-density polyethyleneEpoxy

The invention discloses a powder coating containing modified sepiolite powder and a preparing method thereof. The powder coating containing the modified sepiolite powder is composed of raw materials comprising modified epoxy resin, bisphenol S epoxy resin, linear low density polyethylene resin, modified sepiolite powder, polyethylene wax, film forming resin, polydimethylsiloxane, benzoin, silver powder, acrylic resin, superfine talcum powder, hexamine, 2,6-di-tert-butyl-4- dimethylamino methyl) phenol, n-butyl methacrylate and polyacrylamide. The powder coating is a green and environment-friendly coating, nontoxic and heat-resistant, contains no solvent, and discharges no volatile organic compound (VOC), and furthermore the modified sepiolite added in the powder coating enhances compatibility of the modified epoxy resin, the bisphenol S epoxy resin and the linear low density polyethylene resin, improves surface leveling of the powder coating, has high gloss retention, and enhances decorating performance of the powder coating, and therefore, an obtained finished product is high in pass percent, and industrialization mass production can be achieved.

Owner:CHUZHOU HONGYUAN SPRAYING

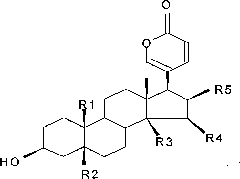

Composition with anti-tumor effect and application thereof in preparing medicament for treating tumor

InactiveCN101822832AImprove anti-tumor effectReduce cardiotoxicityAmphibian material medical ingredientsOrganic active ingredientsAntiarrhythmic effectToad Venom

The invention provides a composition with anti-tumor effect and application thereof. The composition consists of 0.01 to 10 weight parts of pure bufadienolide compound, extract rich in bufadienolide compound, raw toad venom or toad skin and 0.01 to 99.9 weight parts of medicament with anti-arrhythmic effect. The composition with the anti-tumor effect has the advantage that the match among the components is scientific and reasonable; multiple in vitro tumor cytotoxicity and in vivo tumor inhibiting experiments show that the composition provided by the invention has good anti-tumor effect and plays a role in synergy after combination; and cardiotoxic experiments show that the cardiotoxicity of the composition provided by the invention is obviously reduced, and the composition can reduce the cardiotoxicity caused by primary single use of the bufadienolide compound, the toad venom or the toad skin and plays a role in detoxifying. Therefore, the composition is safer and more effective to use, and is expected to develop a new generation anti-cancer medicament.

Owner:NANJING UNIVERSITY OF TRADITIONAL CHINESE MEDICINE

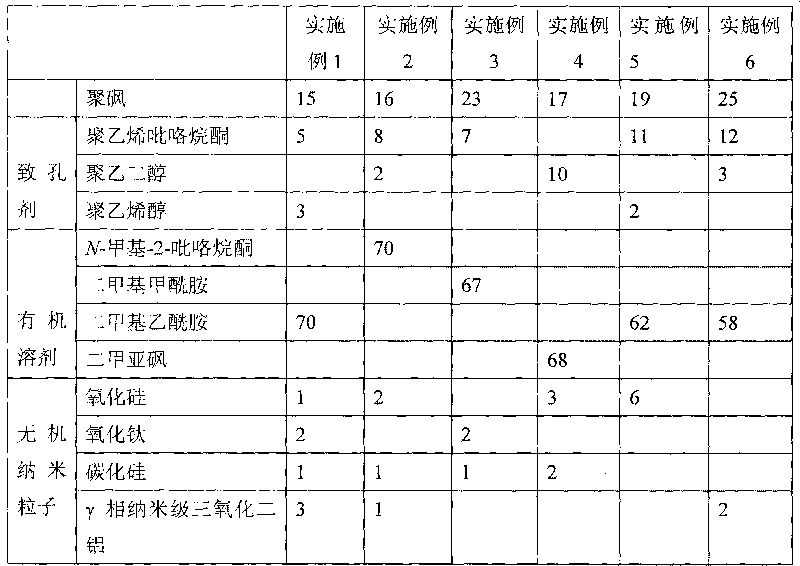

Blending modified hollow polysulfone fiber film, preparation method and application thereof

InactiveCN101711954AImprove featuresGood biocompatibilitySemi-permeable membranesSuction devicesFiberPolyethylene glycol

The invention relates to a blending modified hollow polysulfone fiber film which comprises the following components in percentage by weight: 3-40 percent of polysulfone, 0.5-20 percent of porogen, 50-90 percent of organic solvent and 0.5-20 percent of inorganic nano particles, wherein the inorganic nano particles are one or the mixture of more than two of silicon oxide nano particles, titanium oxide nano particles, silicon carbide nano particles and gamma-phase aluminium oxide nano particles; the viscosity-average molecular weight of the polysulfone is 40,000-200,000; the organic solvent is one of N-methyl-2-pyrrolidone, dimethyl acetamide or dimethyl sulfoxide; and the porogen is one or a mixture of any two of polyvinylpyrrolidone, polyethylene glycol and polyvinyl alcohol. The invention improves the surface property, the hydrophilic property and the mechanical strength of the film through modifying the hollow polysulfone fiber film, has simple film preparation process, and can realize industrial mass production.

Owner:江苏朗生生命科技有限公司

Energy-saving and environment-friendly powder coating and preparation method thereof

ActiveCN103045044AStrong surface levelingHigh gloss retentionRosin coatingsPolyether coatingsEpoxyFatty amine

The invention discloses an energy-saving and an environment-friendly powder coating and a preparation method thereof. The energy-saving and an environment-friendly powder coating comprises the following composition raw materials: modified epoxy resin, high-density polyethylene resin, an organosilicone levelling agent, film-forming resin, polydimethylsiloxane, fatty amine, zinc powder, methacrylic resin, nanoscale titanium dioxide, 4,4'-diamido-diphenyl sulphone, resorcinol, bis-tetradecyl alcohol ester and chlorcosane. The powder coating disclosed by the invention is a green and environment-friendly coating which is non-toxic, is high-temperature-resistant, does not contain a solvent and is free from VOC (volatile organic compounds) discharge, and the powder coating disclosed by the invention is strong in surface levelling property and high in gloss retention, thus decoration property is improved; and the prepared finished product is high in pass percent, and capable of realizing industrialized mass production.

Owner:CHUZHOU HONGYUAN SPRAYING

Method for producing fuel alcohol through alkaline method preprocessing plant fibre

InactiveCN101182551ASolve the shortage problemLow costBiofuelsLiquid carbonaceous fuelsSocial benefitsAlcohol

The invention relates to a method for pretreating the plant fiber with alkaline process to produce the fuel alcohol; the raw material of plant fiber is crushed and pretreated by sodium hydroxide solution to make the wood fiber residues; and then the residues are synchronously fermented by cellulase, xylanase and enzymolysis; the fermentation liquor is extracted and purified to get the alcohol. The invention can fully utilize the gramineous plant fiber and convert the waste into precious one; in this way, the invention is characterized by wide raw material sources, low price and cost; moreover, the invention is fit for industrial mass production and can substitute the method of burning alcohol industrial food raw materials. Therefore, the invention has obvious economic and social benefit.

Owner:HENAN TIANGUAN GRP

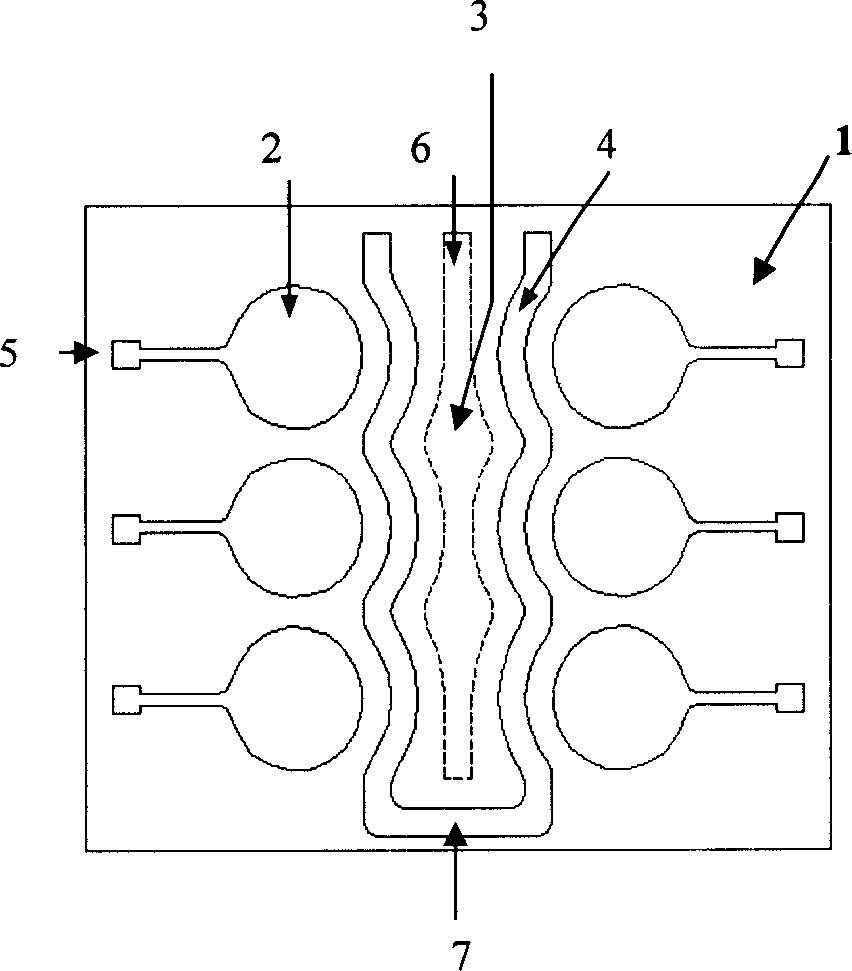

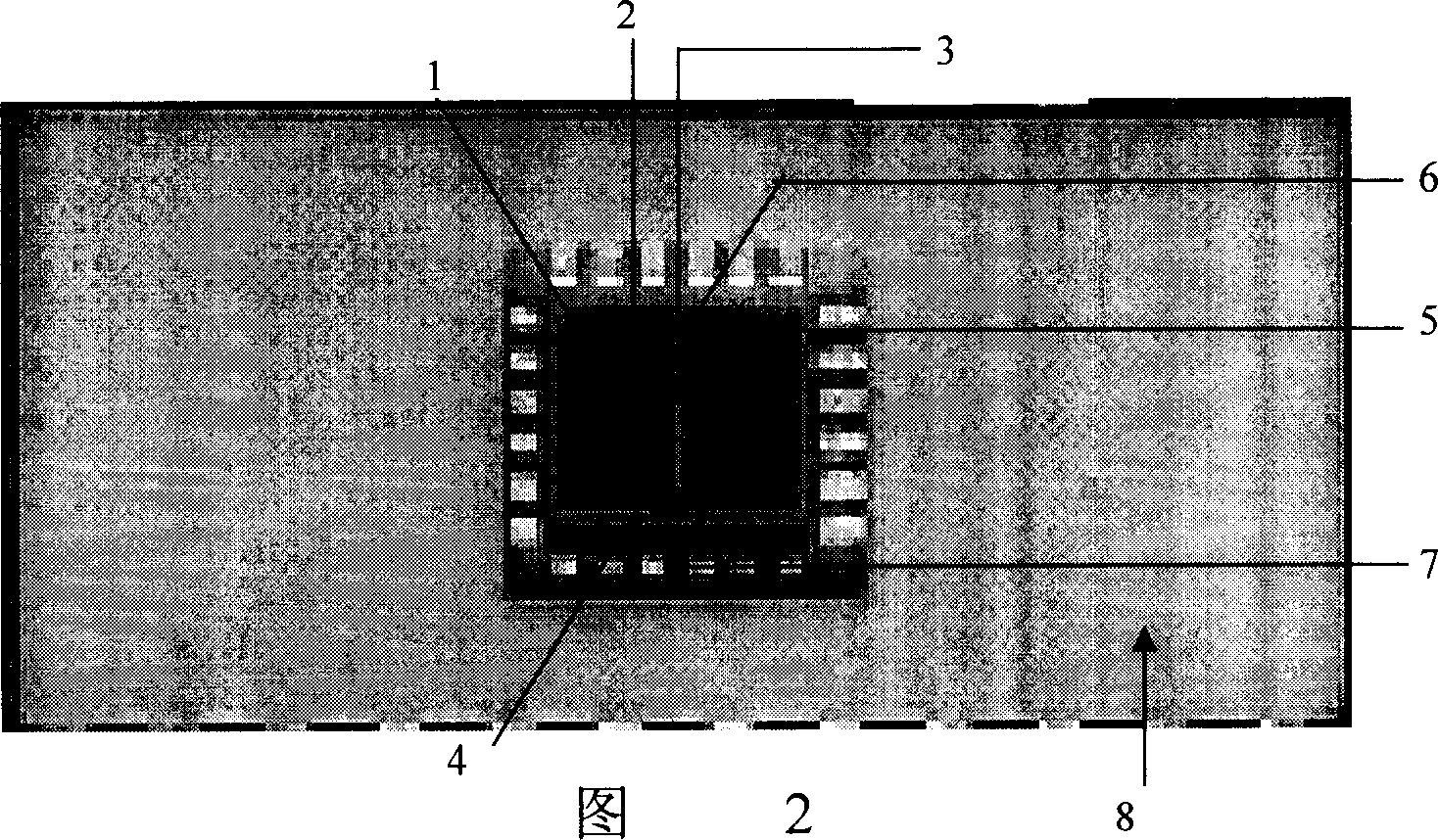

Electrode array microchip sensor, preparation method and application therefor

InactiveCN1865959AReduce manufacturing costAvoid the aforementioned problemsMaterial analysis by electric/magnetic meansBiological testingHigh fluxElectrode array

The related multi-channel array micro-chip sensor integrated tri-electrode system comprises: an electrode array micro-chip with a work electrode array, a counter electrode and a reference electrode; and a detection cell with area less than 50um. This invention improves detection sensitivity, accuracy and speed, reduces cost, and fit to wide application.

Owner:FUDAN UNIV +1

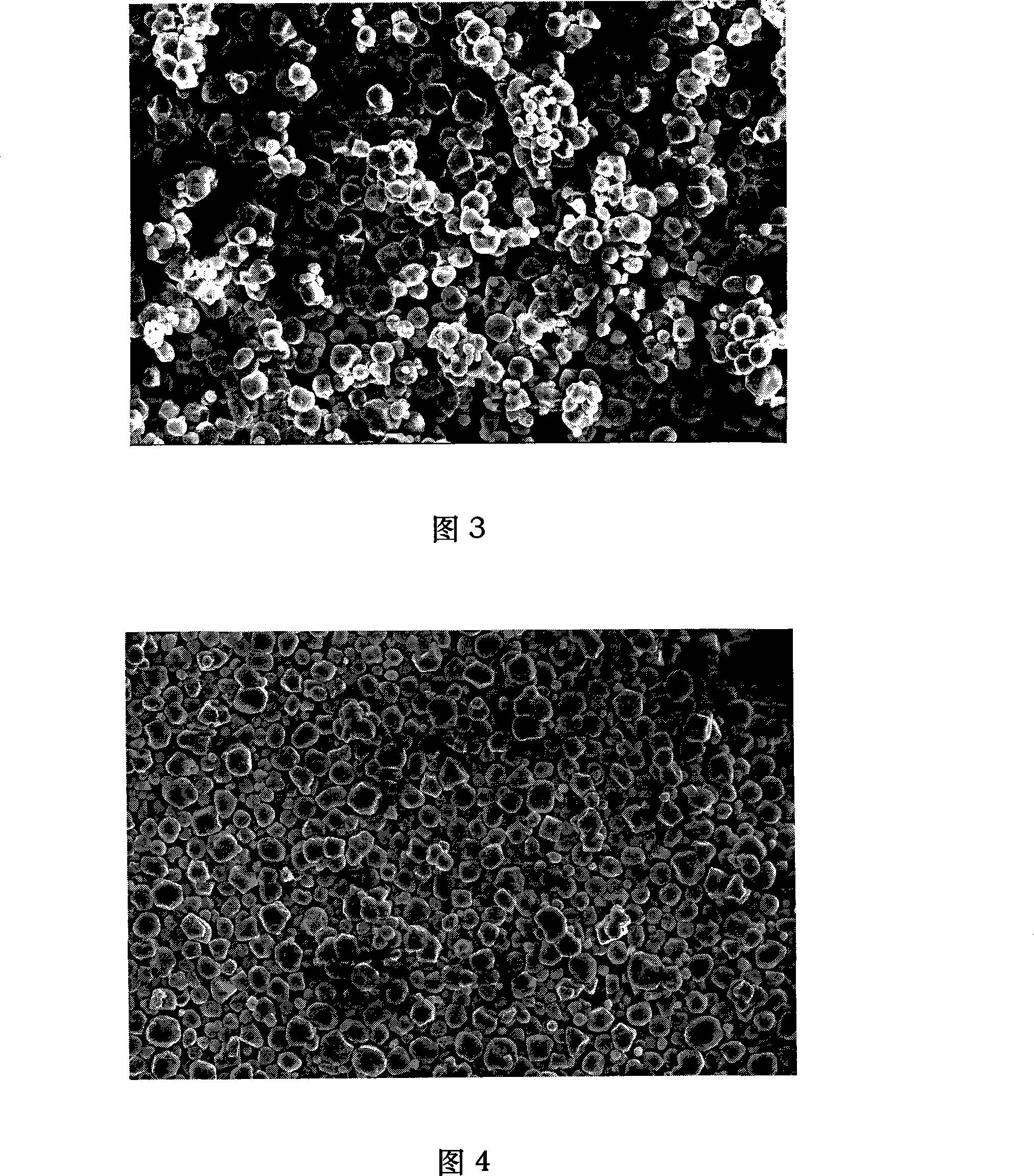

High-fluidity and strong-hydrophobicity starch and preparation method thereof

The invention discloses high flowing and strong hydrophobic starch and a preparation method thereof. The method comprises the following steps: the dry modification processing is performed to the starch by adopting the high-speed stirring equipment commonly used in the industry; a layer of hydrophobic film is wrapped on the surface of a starch granule, thereby obtaining the hydrophobic starch; simultaneously, a layer of flowing improver is wrapped on the surface of the hydrophobic starch granule, to ensure that the hydrophobic starch has good fluidity, thereby obtaining high flowing and strong hydrophobic starch granules. The technological process is simple, feasible, stable and reliable, the cost is low, the method has versatility, and the production can be operated under the prior production process and equipment condition, and the industrial large scale production can be realized. The modified starch prepared by adopting the method flows like water, floats on the water surface and cannot sink, has good fluidity as well as good hydrophobicity.

Owner:BEIHANG UNIV

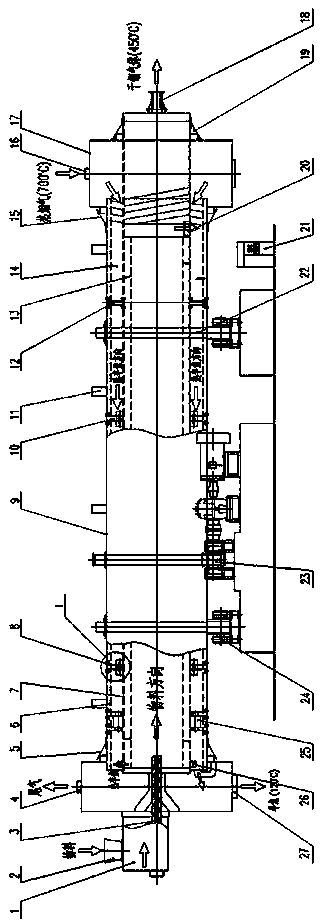

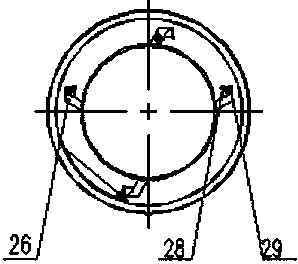

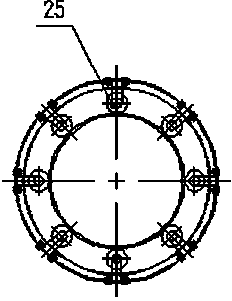

Multilayer rotary kiln based small granular material destructive distillation method

ActiveCN103952165ALow running costGuaranteed concentrationEnergy inputIndirect heating destructive distillationGranularityFlue gas

The invention relates to a multilayer rotary kiln based small granular material destructive distillation method. The method comprises the following steps: adding oil shale granules (with the granularity of 0-20mm) with the water content of below 5% to a bunker from a kiln head, sending to the inner cylinder of a rotary kiln by a spiral conveying device, heating the material in the inner cylinder to 500DEG C through the circulation of high temperature hot flue gas (with the temperature of 700DEG C) from a hot blast stove in an annular channel between an outer cylinder and the inner cylinder to pyrolyze the oil shale material in order to generate a destructive distillation gas and semicoke, and carrying out purifying recovery on the destructive distillation gas to obtain gas and shale oil; and adding the semicoke into the annular channel from the inner cylinder, allowing the semicoke to run along a direction opposite to the material running direction in order to carry out heat exchange of the material in the inner cylinder and absorb the waste heat of the semicoke, discharging parts of the semicoke from the stove, and adding a small amount of the semicoke to the inner cylinder for the mixing of the small amount of the semicoke with a normal temperature mixture in order to further utilize the waste heat of the semicoke. The method has the advantages of simple technology, low energy consumption, no pollution, high product quality, realization of the industrial large-scale production, and easy large-area popularization.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

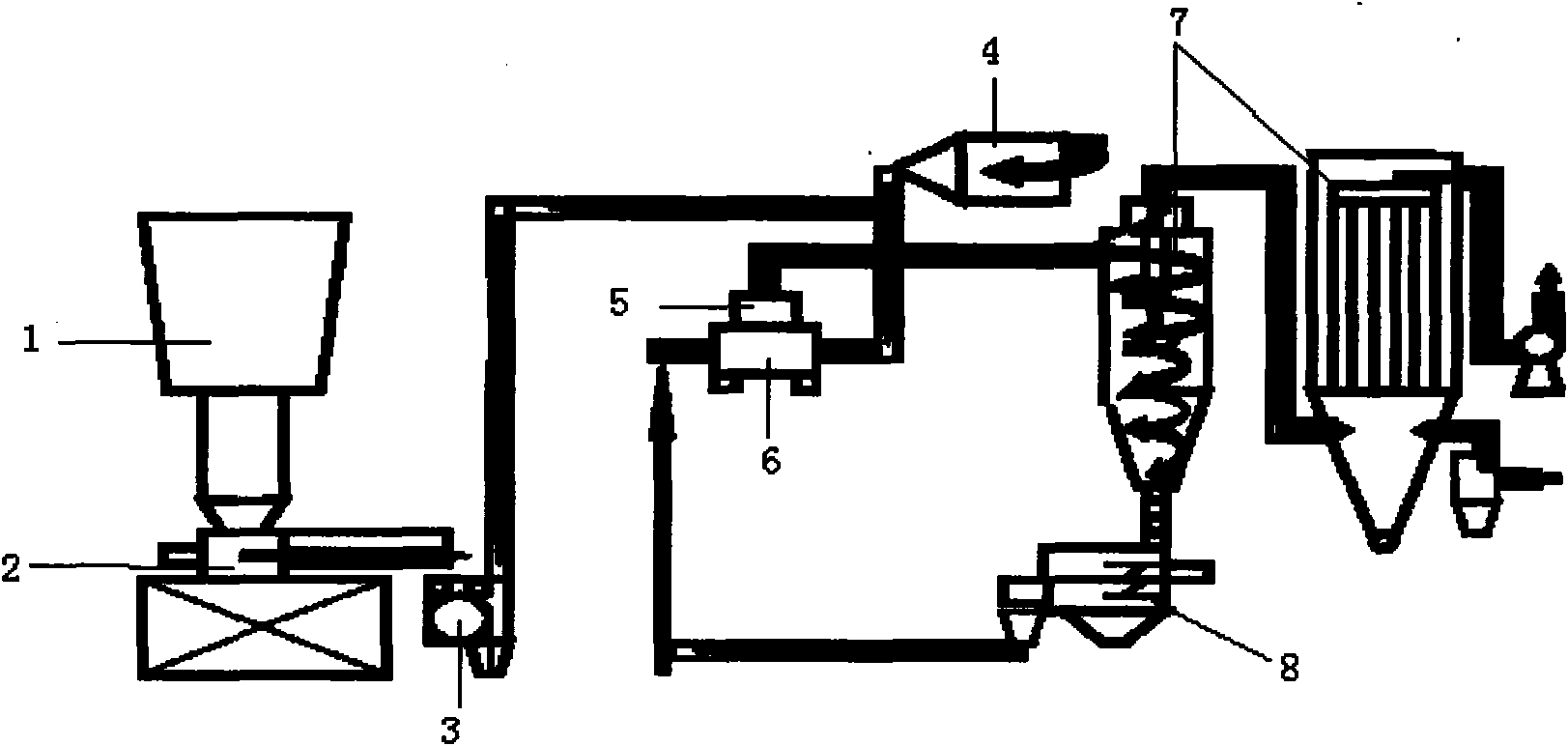

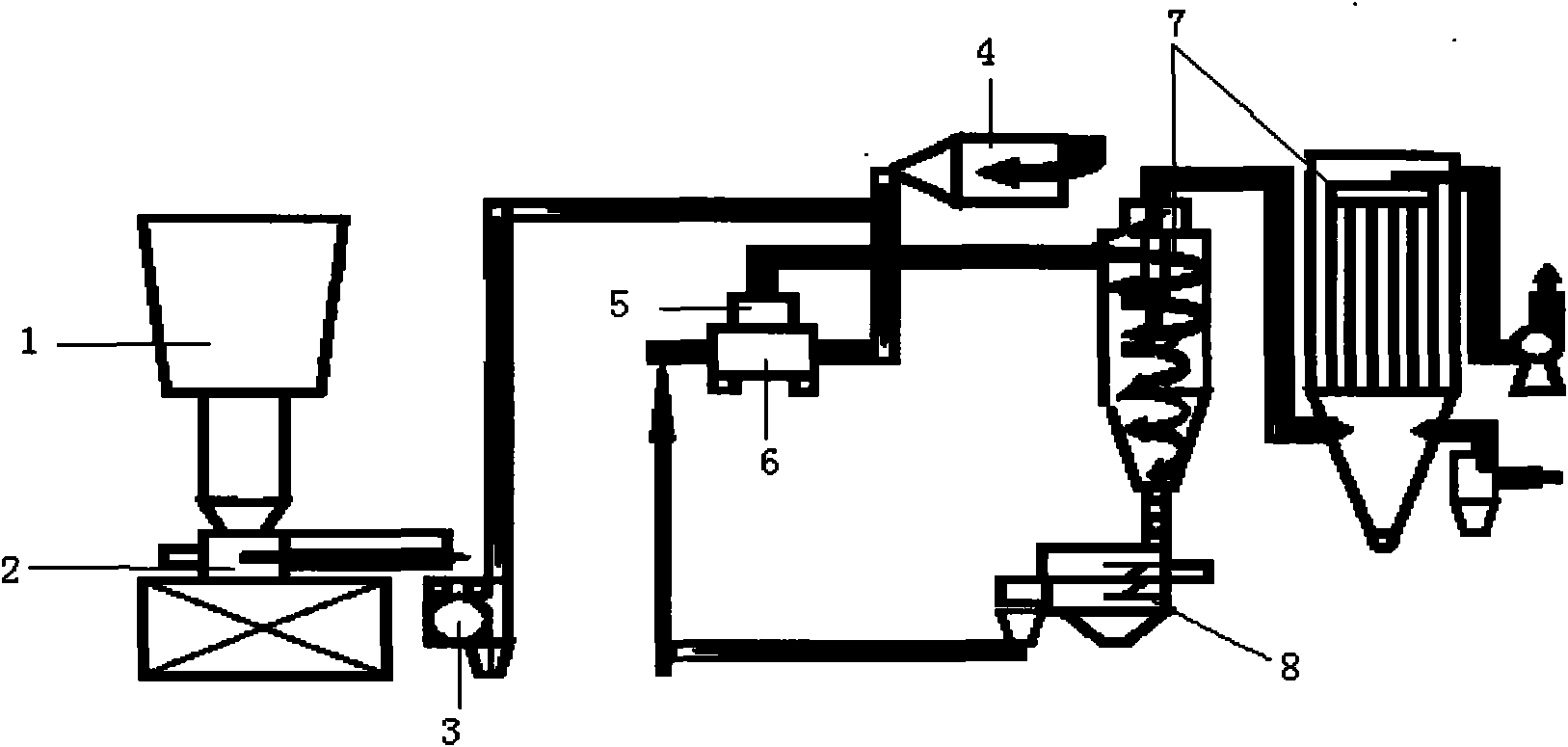

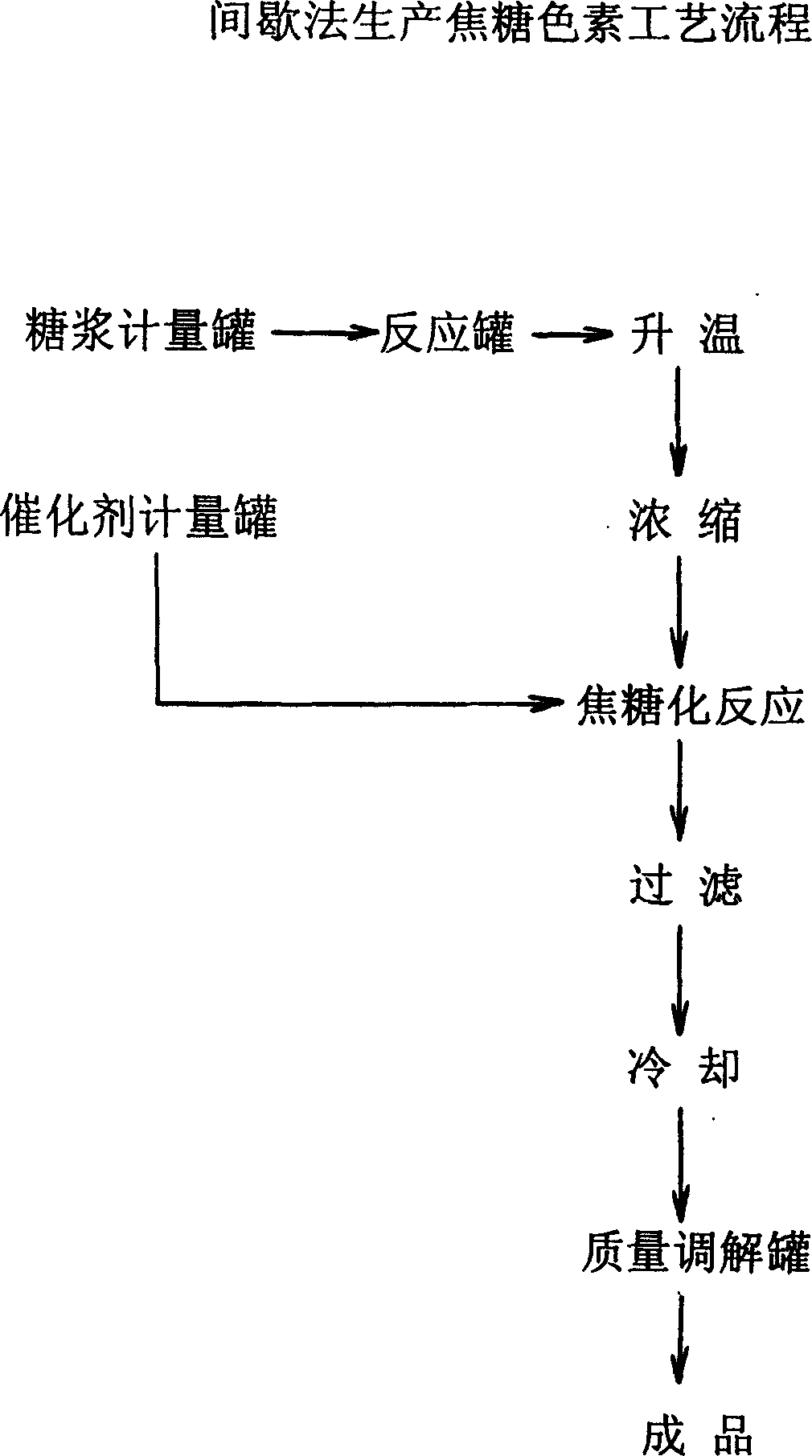

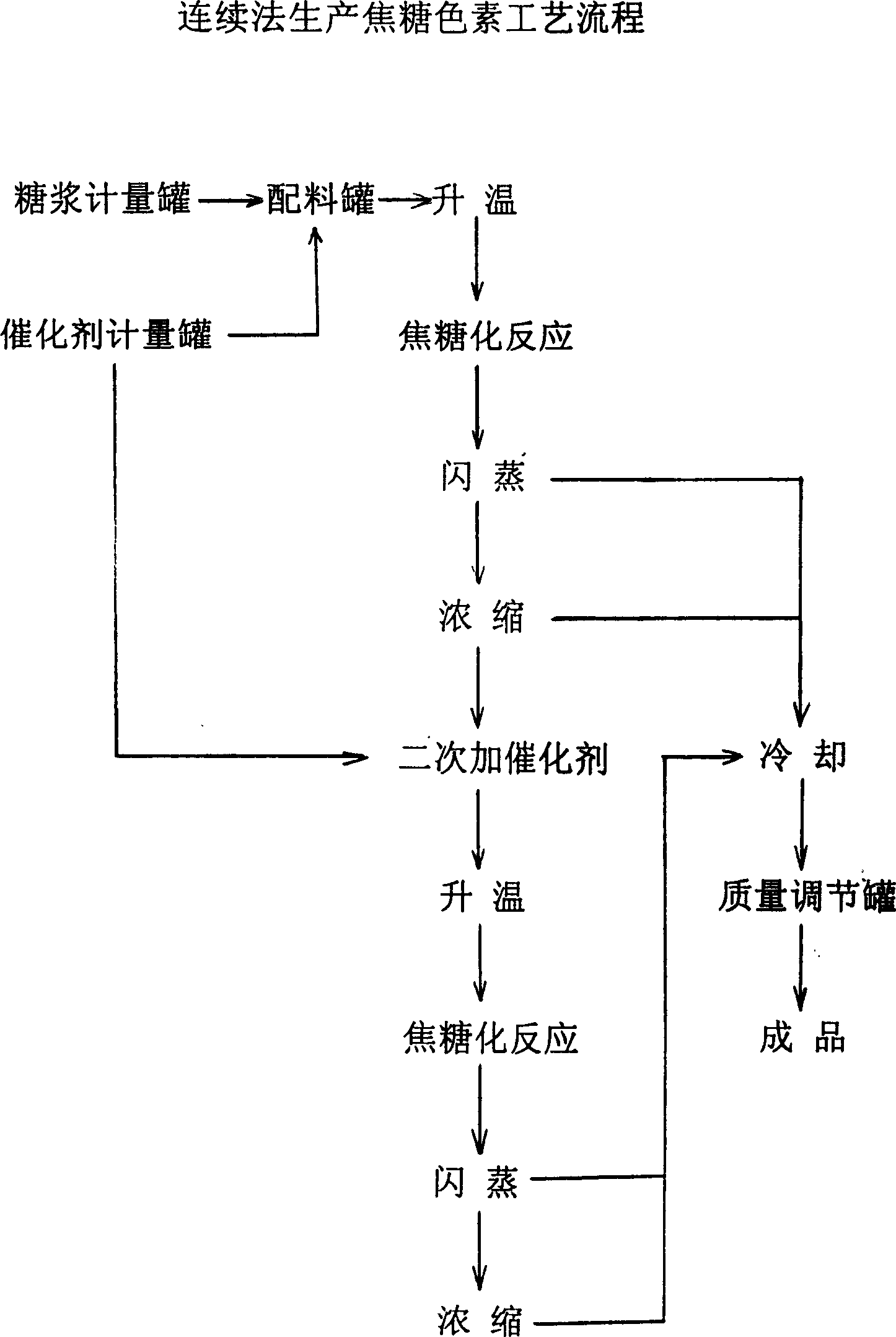

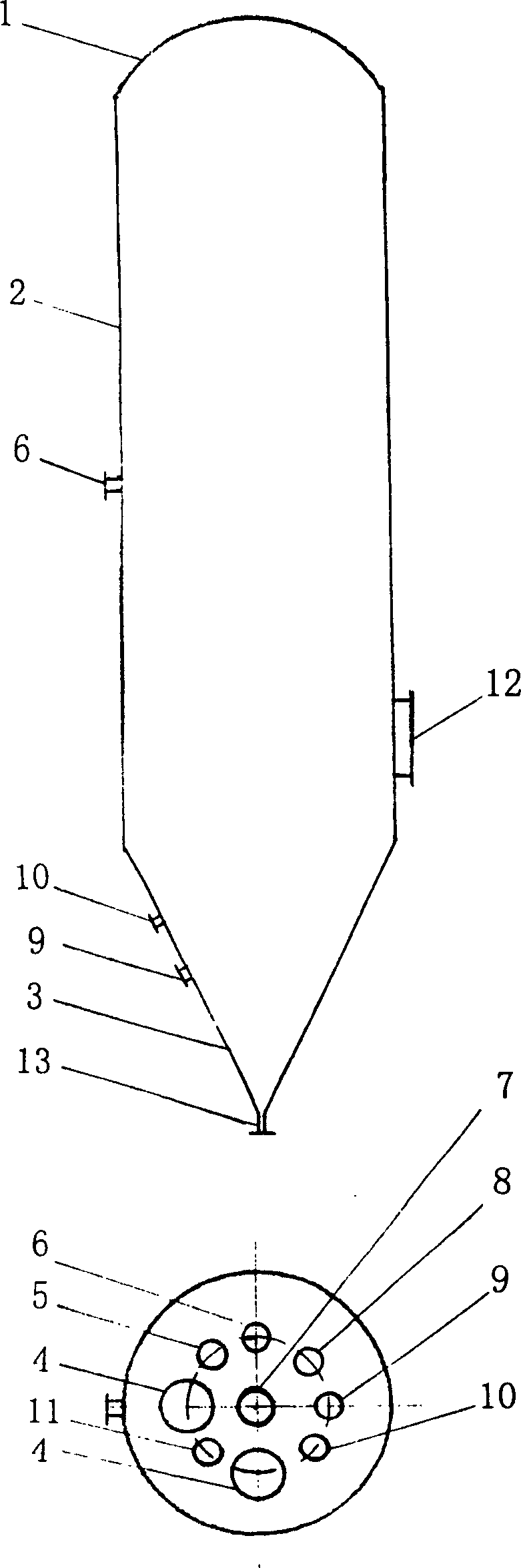

Process and apparatus for continuous manufacturing burnt sugar colouring matter

A process for continuous production of caramel pigment includes such steps as proportionally mixing catalyst with syrup, heating by heat exchanger for indirect heating and steam sprayer for direct heating, caramelizing reacting in reactor, cooling by flash evaporator, concentrating by evaporator, cooling by cooler, regulating quality in quality regulating tank, and storing in tank. Its advantages are high quality and output rate and low cost.

Owner:马荣昌

Powder coating containing modified attapulgite and preparation method of powder coating

ActiveCN103013296AImproved surface levelingHigh gloss retentionPowdery paintsEpoxy resin coatingsSolventCarbon black

The invention discloses a powder coating containing modified attapulgite and a preparation method of the powder coating. The powder coating consists of the following raw materials: modified epoxy resin, epoxidation polybutadiene resin, linear low-density polyethylene resin, modified attapulgite, polyethylene wax powder, film-forming resin, polydimethylsiloxane, high pigment carbon black, methacrylic acid resin, nanosilicon dioxide, triethylene tetramine, antioxygen DLTP (Dilauryl thiodipropionate), diphenylamine and trioctyl trimellitate. The powder coating is a green and environmental-friendly coating, has no toxicity, has high-temperature resistance, contains no solvent and has no VOC (Volatile Organic Compounds) emission; and furthermore, the modified attapulgite is added in the powder coating, so that the compatibility of the modified epoxy resin, the epoxidation polybutadiene resin and the linear low-density polyethylene resin is enhanced, the surface leveling of the powder coating is improved, the powder coating has the advantage of high gloss retention and the decorative property of the powder coating is enhanced; and the qualified rate of the finished product obtained by preparing is high and the industrial mass production can be realized.

Owner:CHUZHOU HONGYUAN SPRAYING

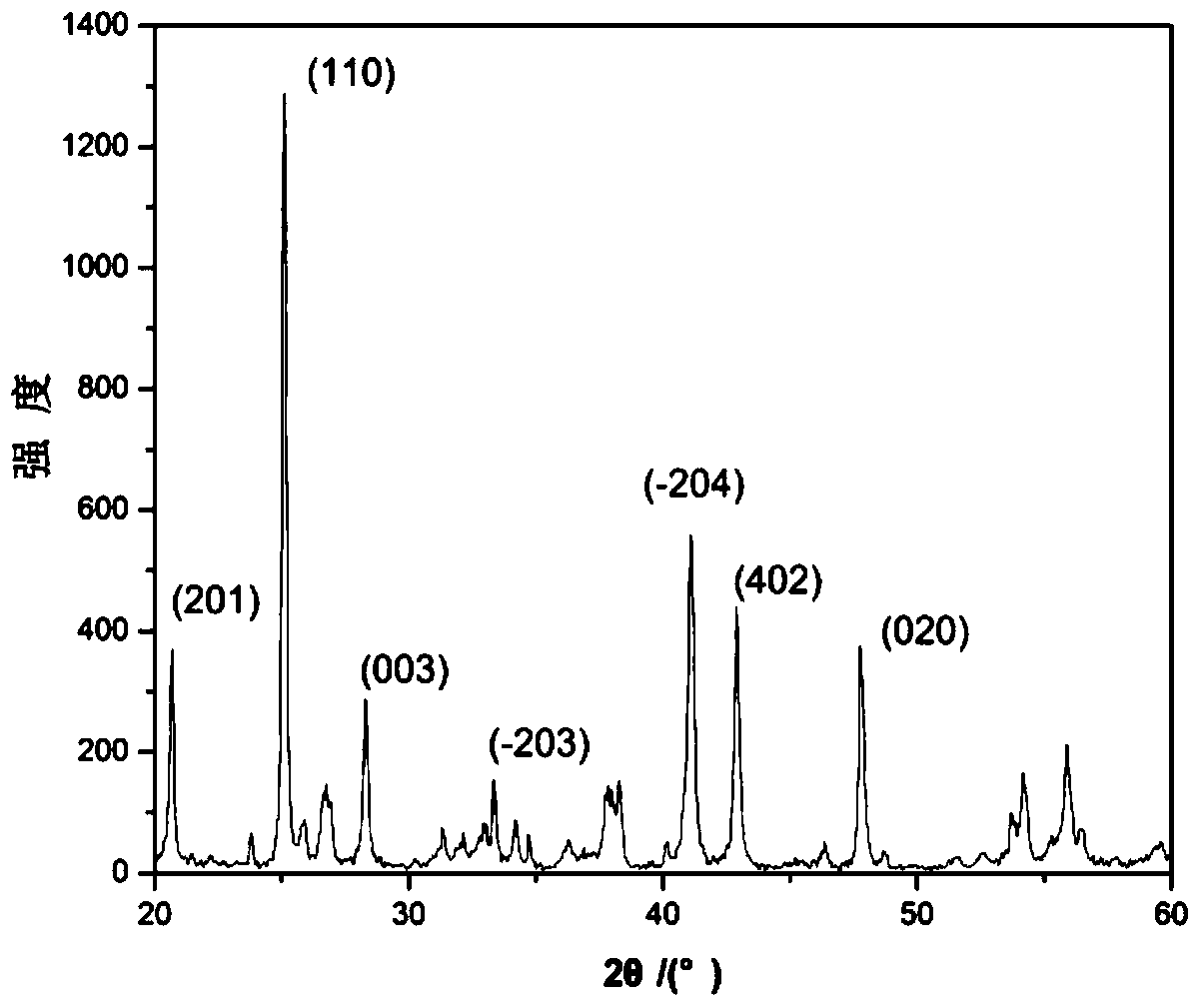

Preparation methods of Ti3O5 powder

ActiveCN103787409AEasy accessRealize industrialized mass productionTitanium oxides/hydroxidesSpray GranulationArgon atmosphere

The invention provides preparation methods of Ti3O5 powder. Three methods are provided, wherein the first method comprises the following steps of: (1) charging; (2) uniformly mixing raw materials by means of ball milling, and drying to obtained mixed powder for sintering; (3) sintering the mixed powder for sintering for 1 to 4 hours under a temperature of 1000 to 1400 DEG C in a vacuum or nitrogen or argon atmosphere. The second method comprises the following steps of: (1) charging; (2) performing ball milling, namely, performing dry ball milling for 2 to 6 hours through a ball mill at a rotating speed of 100 to 300 rotations per minute based on the ball-to-powder ratio of (8-40): 1, and then sieving and separating out milling ball bodies to obtain the mixed powder; (3) sintering mixed powder for 1 to 4 hours under a temperature of 700 to 1000 DEG C in a vacuum or nitrogen or argon atmosphere. The third method comprises the following steps of: (1) charging; (2) preparing a mixed solution with the raw materials through distilled water or deionized water, performing spray granulation with a spray dryer, and then drying; (3) sintering the particles for 1 to 4 hours under a temperature of 1000 to 1400 DEG C in a vacuum or nitrogen or argon atmosphere. With the adoption of the preparation methods, high-purity Ti3O5 powder can be obtained, the process is simplified, the cost is decreased, and mass industrial production is realized.

Owner:SICHUAN UNIV

Quick nano-copper particle preparation method

The invention belongs to the technical field of materials, and relates to a quick nano-copper particle preparation method. The method includes the following steps: (1) preparing ethanol water; (2) dissolving a reducing agent into the ethanol water to prepare a reducing agent solution; (3) with stirring, dissolving copper salt and a dispersing agent into the ethanol water in the step (1) to prepare a copper salt and dispersing agent solution; (4) heating the reducing agent solution to 25-28 DEG C, and under the conditions of stirring and ultrasonic wave, dropwise adding the copper salt and dispersing agent solution into the reducing agent solution heated to the temperature of 25-28 DEG C; (5) heating to the temperature of 25-28 DEG C, and reacting for 2-4h; (6) filtering and separating solid-phase precipitation, putting the solid-phase precipitation into a centrifuge for centrifugation, and drying and removing moisture in vacuum to obtain nano-copper particles with the surface coated with the dispersing agent. By the method, reaction time is saved, yield is increased, the prepared nano-copper particles can be used as additives to be applied to reusable lubricating oil with antifriction and self-repairing effect.

Owner:NORTHEASTERN UNIV

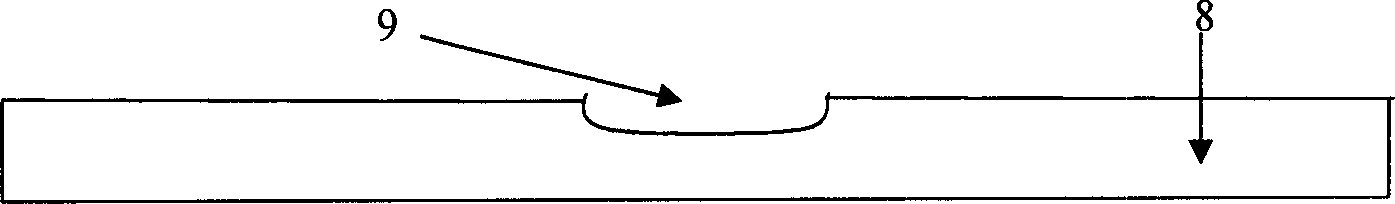

Rotor-type internal-compression oil-gas mixed transport pump unit

InactiveCN102206696ARealize industrialized mass productionMicroorganism based processesFermentationOrganic solventLiquid ratio

The invention relates to a rotor-type internal-compression oil-gas mixed transport pump unit, and belongs to the technical field of fluid transportation devices. The unit comprises a housing which supports a pair of conjugated rotors engaged with each other; the cavity in the housing is partitioned by the conjugated rotors into an inhalation chamber and a discharging chamber; the inhalation chamber is equipped with a fluid inlet, and the discharging chamber is equipped with a fluid outlet; the discharging chamber is partitioned into an engaging area and a discharging area by an isolating wall which is disposed between the conjugated rotors and the fluid outlet; at least one one-way valve is disposed at the isolating wall; when the one-way valve is closed, the engaging chamber is completely isolated from the discharging chamber are; when the one-way valve is opened, the engaging chamber is communicated with the discharging chamber. Even in a multiphase medium transporting process with an unstable gas-liquid ratio, the rotor-type internal-compression oil-gas mixed transport pump unit of the invention has the unique function of internally compressing the gas medium, pressurizing the gas to a discharging pressure so as to discharge the gas out of the pump; the invention can completely eliminate the gas blocking phenomenon, and can reliably realize the internal-compression transporting process of the transported multiphase medium.

Owner:ZHEJIANG XIANJU PHARMA

Bamboo charcoal, flame retardant and moisture conductive terylene fiber, preparation method and application thereof

InactiveCN101629333AImprove adsorption capacityImprove deodorizationFilament/thread formingMonocomponent copolyesters artificial filamentFire retardantMoisture

The invention discloses a bamboo charcoal, flame retardant and moisture conductive terylene fiber, a preparation method and an application thereof. The terylene fiber comprises the following raw materials in percentage by weight: 5-10 percent of active carbon parent granule and 90-95 percent of copolymerized type phosphorus flame retardant terylene fiber forming resin, wherein the cross section of the fiber is a profile cross section. The terylene fiber has good functions of adsorption, deodorization, bactriostasis and rot resistance and flame retardance, and because the cross section of the fiber is the profile cross section, the moisture conductive function of the fiber is also excellent, thus the terylene fiber has wide range of application. The preparation method of the bamboo charcoal, flame retardant and moisture conductive terylene fiber has strong operability, reasonable process and high production efficiency and can realize industrial mass production.

Owner:苏州金辉纤维新材料有限公司

High-solid terrace coating, preparation method and application thereof

InactiveCN101575477AAdd lessHarm reductionAnti-corrosive paintsFlooring insulationsPlasticizerReactive diluent

The invention discloses a high-solid terrace coating, a preparation method and application thereof. The coating is prepared from the following raw materials in percentage by weight: 50 to 55 percent of organosilicone modified epoxy resin; 15 to 30 percent of aliphatic amino resin, 4 to 10 percent of plasticizer, 5 to 10 percent of TiO2, 5 to 15 percent of pigment and filler, 4 to 5 percent of reactive diluent, 0.5 to 1.0 percent of defoaming agent, 0.5 to 1.0 percent of dispersant, and 0.2 to 0.5 percent of flatting agent 354. Experimental research shows that the high-solid terrace coating has good corrosion-resistant properties such as acid resistance and alkaline resistance as well as stronger toughness and mechanical property, no volatile solvent exists and the pigment and filler have small consumption in the raw materials of the high-solid terrace coating, and the high-solid terrace coating is an environment-friendly, nontoxic and good terrace coating. The preparation method of the coating has strong maneuverability, high production efficiency and low energy consumption, ensures that finished products obtained through the preparation have high qualification rate, and can realize industrialized large scale production.

Owner:WUXI YIBO COATING

Powder coating containing modified tree ash and preparation method of powder coating

ActiveCN103013279AImproved surface levelingImprove the decorative effectPowdery paintsEpoxy resin coatingsLow-density polyethyleneEpoxy

The invention discloses a powder coating containing modified tree ash and a preparation method of the powder coating. The powder coating consists of the following raw materials: modified epoxy resin, low-density polyethylene resin, phenolic resin, modified tree ash, organosilicone leveling agent, film-forming resin, polydimethylsiloxane, aliphatic amine, silver powder, acrylic resin, ultra-fine calcium carbonate, hexamethylenetetramine, catechol and simethicone. The powder coating is a green and environmental-friendly coating, has no toxicity, has high-temperature resistance, contains no solvent and has no VOC (Volatile Organic Compounds) emission; and furthermore, the modified tree ash is added in the powder coating, so that the compatibility of the modified epoxy resin, the low-density polyethylene resin and the phenolic resin is enhanced, the surface leveling of the powder coating is improved, the powder coating has the advantage of high gloss retention and the decorative property of the powder coating is enhanced; and the qualified rate of the finished product obtained by preparing is high and the industrial mass production can be realized.

Owner:CHUZHOU HONGYUAN SPRAYING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com