Blending modified hollow polysulfone fiber film, preparation method and application thereof

A hollow fiber membrane, blending modification technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc. Narrow distribution range, improved compressive resistance and mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

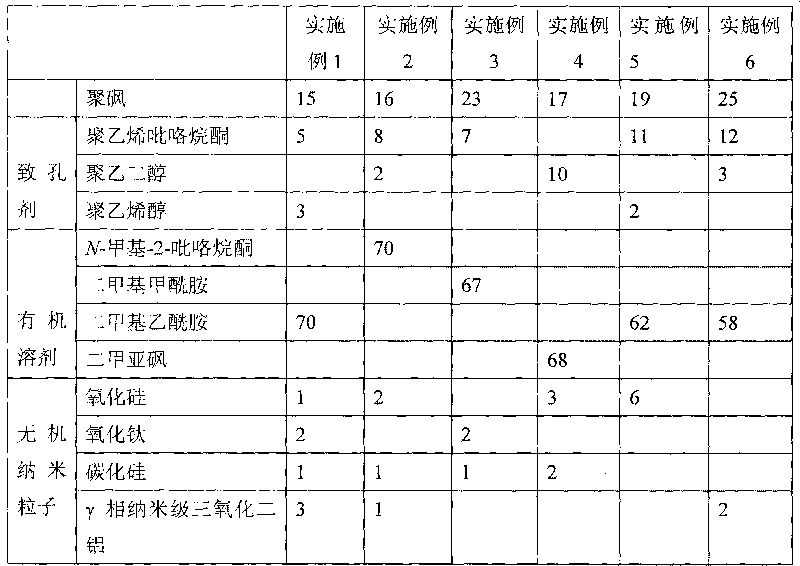

[0009] The blended modified polysulfone hollow fiber membrane of the present invention is composed of the following components by weight percentage: 15-25% polysulfone, 7-15% porogen, 55-70% organic solvent and 2-7% of inorganic nanoparticles, polysulfone in this system is 17-23%, porogen 8-10%, organic solvent is 62-68%, inorganic nanoparticles is 4-6%, the inorganic nano Particles are silicon oxide (SiO 2 ) nanoparticles, titanium oxide (TiO 2 ) nanoparticles, silicon carbide (SiC) nanoparticles, γ-phase nanoscale aluminum oxide (Al 2 o 3 ) of nanoparticles, or a mixture of two or more, and when it is a mixture of two or more, the ratio is not limited and can be used arbitrarily. The viscosity-average molecular weight of the polysulfone of the present invention is 40000-200000, and the best control of the viscosity-average molecular weight of the polysulfone is between 50000-100000, and the organic solvent of the present invention is N-methyl-2-pyrrolidone, dimethylacetam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com