Patents

Literature

1238 results about "N-Methyl-2-pyrrolidone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

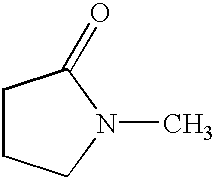

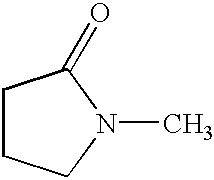

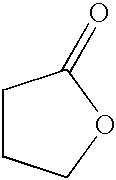

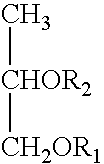

N-Methyl-2-pyrrolidone (NMP) is an organic compound consisting of a 5-membered lactam. It is a colorless liquid, although impure samples can appear yellow. It is miscible with water and with most common organic solvents. It also belongs to the class of dipolar aprotic solvents such as dimethylformamide and dimethyl sulfoxide. It is used in the petrochemical and plastics industries as a solvent, exploiting its nonvolatility and ability to dissolve diverse materials.

Electro-optic assemblies, and adhesives and binders for use therein

InactiveUS20090122389A1Lower volume resistivityLayered productsPolyureas/polyurethane adhesivesOrganic matterAdhesive materials

An electro-optic assembly comprises an adhesive layer and a layer of electro-optic material. The adhesive layer comprises a polymeric adhesive material and an ionic material having either its cation or its anion fixed to the polymeric adhesive material. The ionic material reduces the volume resistivity of the polymeric adhesive material and is not removed upon heating to 50° C. In a similar electro-optic assembly comprising an adhesive layer and a layer of electro-optic material, the adhesive layer comprises a polymeric adhesive material which has been subjected to dialysis or diafiltration to remove organic species having a molecular weight less than about 3,500, so that the adhesive material has a content of N-methylpyrrolidone not exceeding 500 ppm based upon the total weight of the adhesive layer and layer of electro-optic material.

Owner:E INK CORPORATION

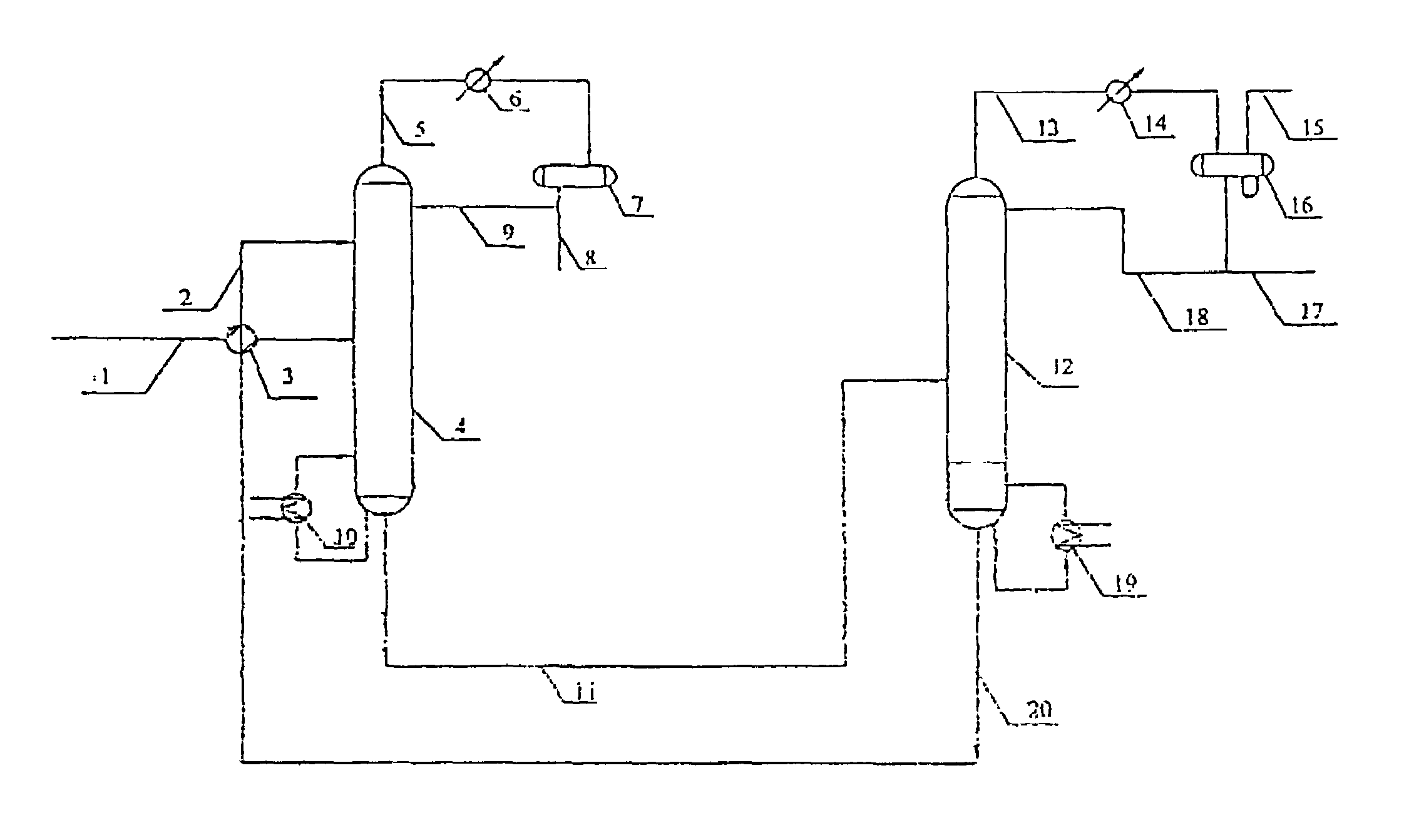

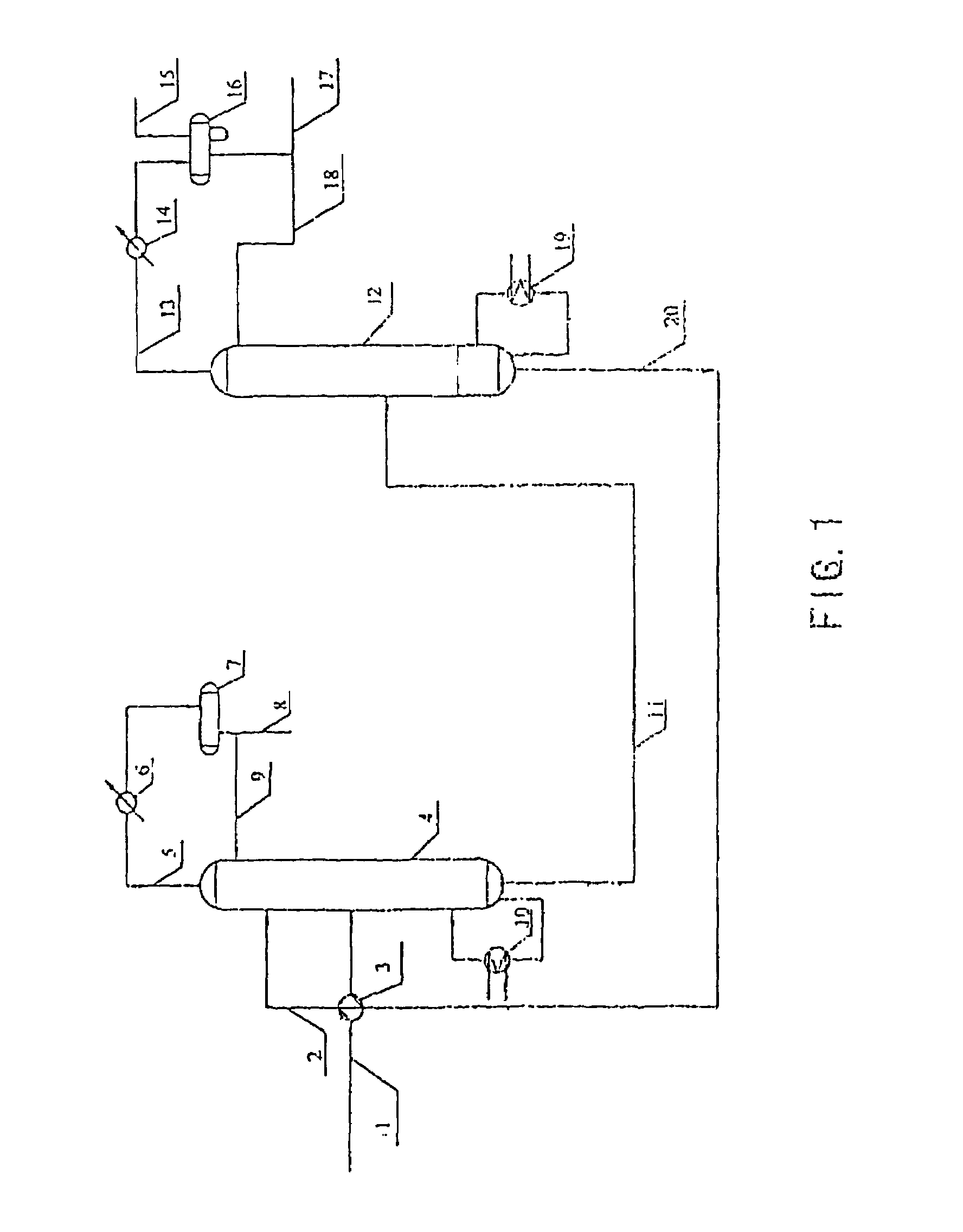

Method and apparatus for preparing purified terephthalic acid

InactiveUS6013835AOrganic compound preparationCarboxylic preparation by oxidationPolyester resinSide reaction

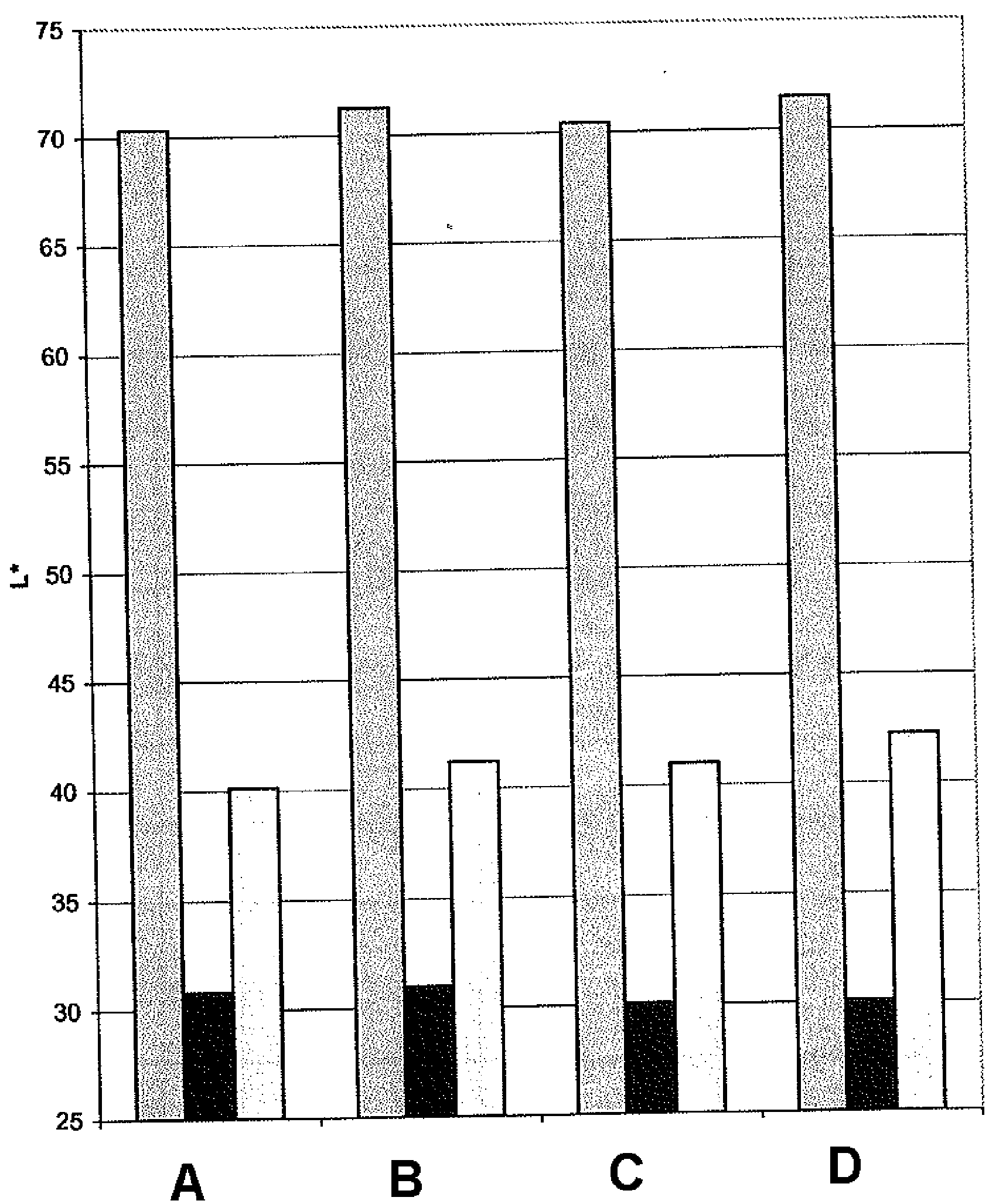

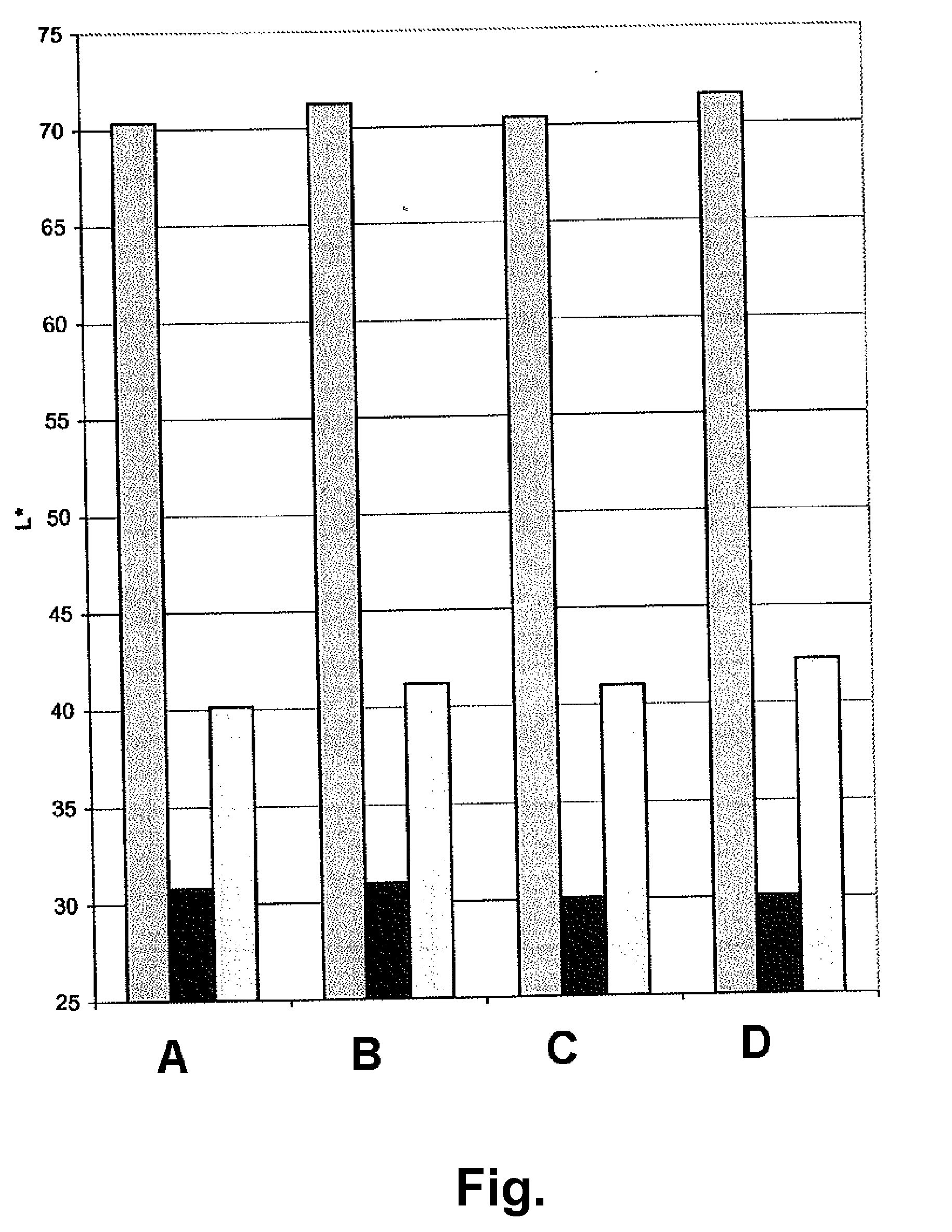

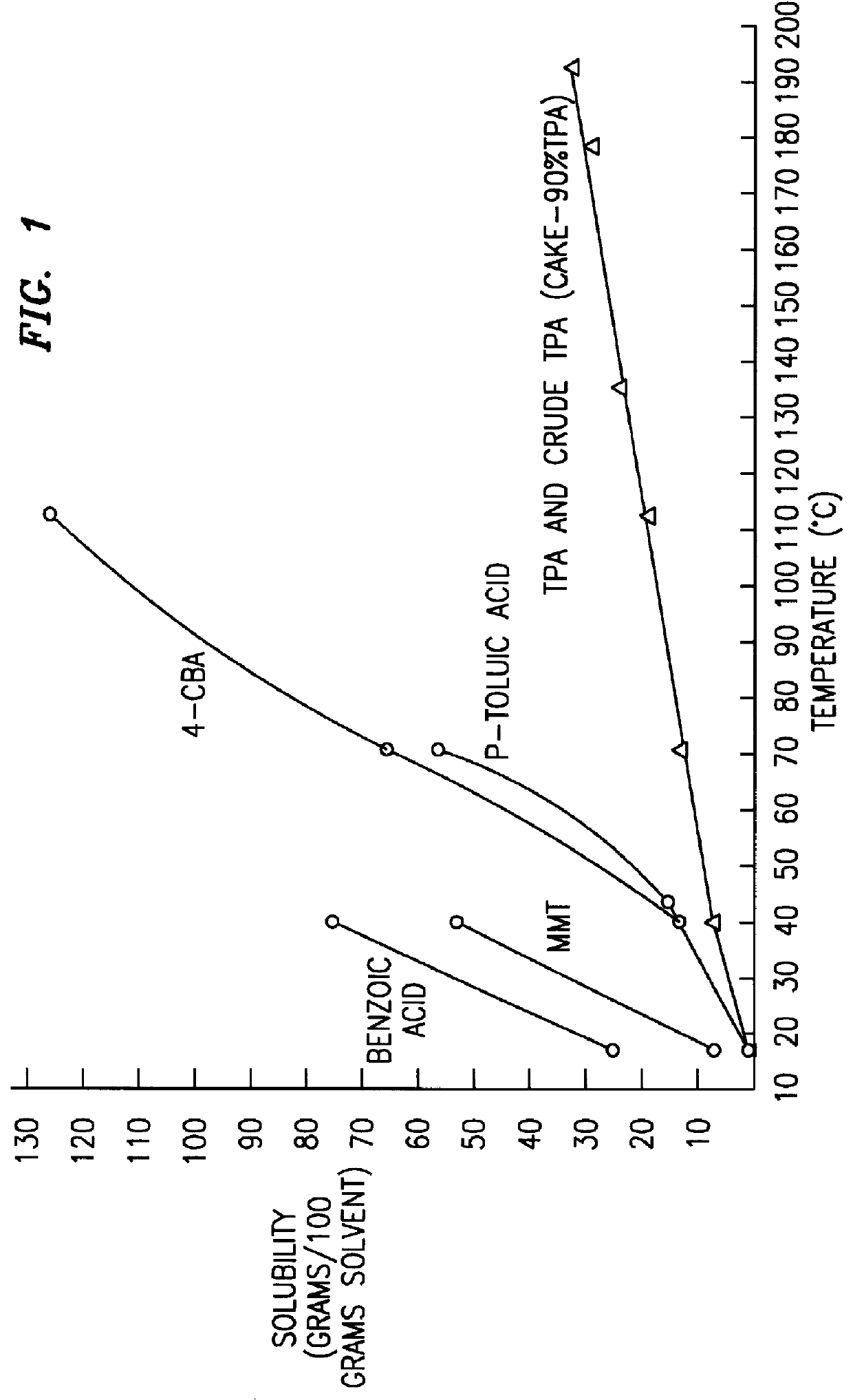

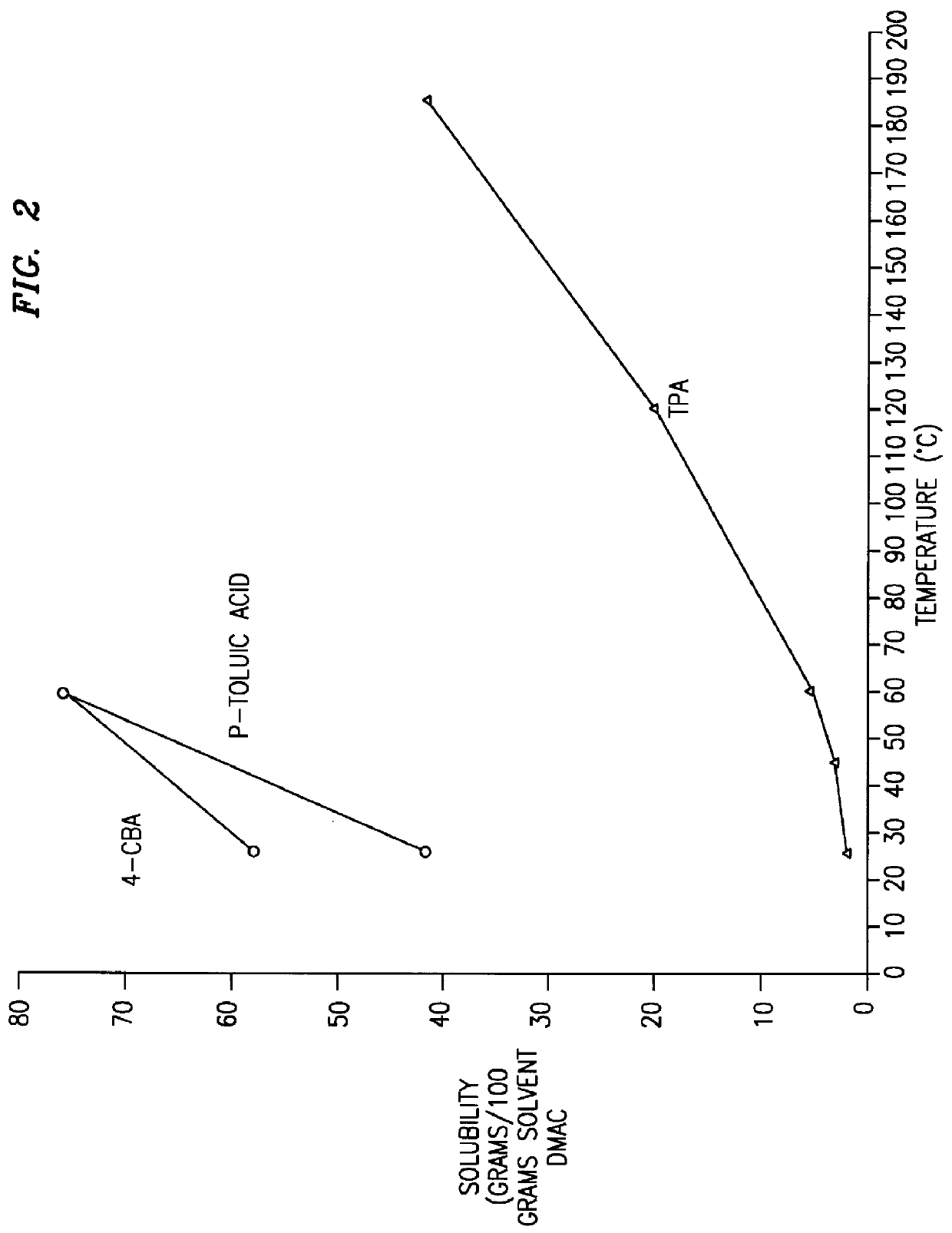

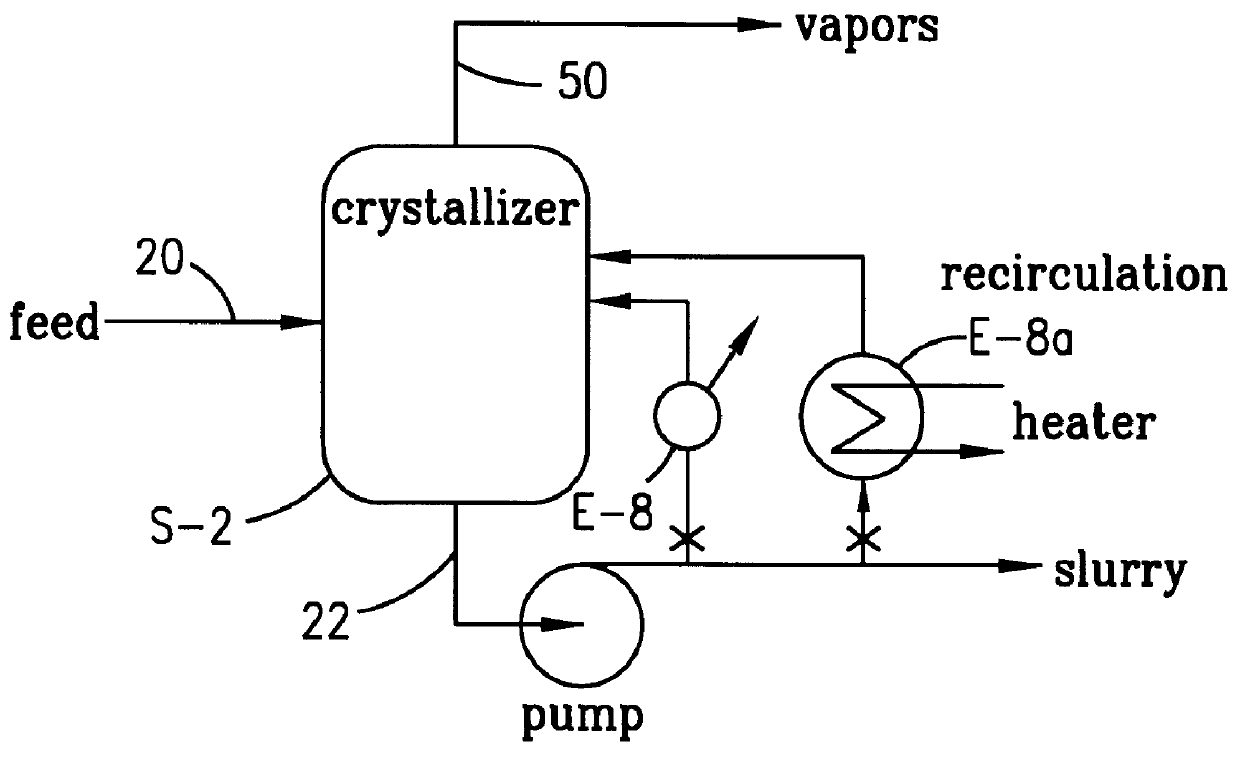

A method and apparatus for purifying crude terephthalic acid from a liquid dispersion thereof also containing impurities selected from unreacted starting materials, solvents, products of side reactions and / or other undesired materials is provided. The method comprises the steps of filtering the dispersion to form a crude terephthalic acid filter cake, dissolving the filter cake in a selective crystallization solvent at an elevated temperature to form a solution, crystallizing purified terephthalic acid from the solution in the crystallization solvent by reducing the pressure and temperature of the solution, and separating the crystallized purified terephthalic acid from the solution. According to the invention, the selective crystallization solvent is non-aqueous, non-corrosive and essentially non-reactive with terephthalic acid. Preferably, the selective crystallization solvent is N-methyl pyrrolidone. The method and apparatus produces purified terephthalic acid having a purity desired for use in forming polyester resin and other products at an economically attractive rate and at operating conditions of reduced severity which require a lower capital investment and simplified processing.

Owner:GTC TECHNOLOGY INC

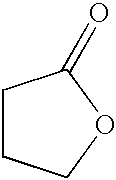

Ectoparasite control compositions

Provided are ectoparasite control compositions, a method of controlling an ectoparasite and uses of a composition for controlling an ectoparasite. The ectoparasite control compositions comprise a solvent and 1-methyl-2-nitro-3-[(3-tetrahydrofuryl)methyl]guanidine, wherein said solvent contains mainly N-methyl-2-pyrrolidone. The methods of controlling an ectoparasite, comprise applying to a host animal, an ectoparasite control composition which comprises a solvent and 1-methyl-2-nitro-3-[(3-tetrahydrofuryl)methyl]guanidine, wherein said solvent contains mainly N-methyl-2-pyrrolidone.

Owner:SUMITOMO CHEM CO LTD

Large scale process for polymerization of dapbi-containing polyaramid

A method for obtaining an aromatic polyamide crumb from an aromatic diamine and an aromatic diacid chloride, which aromatic polyamide comprises 5(6)-amino-2-(p-aminophenyl)benzimidazole terephthalamide units and has a relative viscosity ηrel of at least 3, by: (1) adding at least monomers (i)-(iii) in N-methyl pyrrolidone as solvent wherein (i) is 0-30 mole % para-phenylenediamine (PPD), (ii) is 20-50 mole % 5(6)-amino-2-(p-aminophenyl)benzimidazole (DABPI), (iii) is 49.05-50.05 mole % terephthaloyl dichloride (TDC), and optionally calcium chloride to obtain a CaCl2 / aromatic diamine molar ratio less than 0.5, and an aromatic diamine / aromatic diacid chloride ratio between 0.99 and 1.01; (2) mixing the monomers and the optional calcium chloride to a homogenous mixture having a monomer concentration of 5 to 12 wt %; followed by (3) adding calcium chloride to the homogeneous mixture to obtain a CaCl2 / aromatic diamine molar ratio 0.6-1.0; and (4) polymerizing the mixture.

Owner:TEIJIN ARAMID BV

Anti-inflammatory analgesic adhesive patch for external use

ActiveUS20120283671A1Promote absorptionLess irritatingAntipyreticAnalgesicsAdditive ingredientTackifier

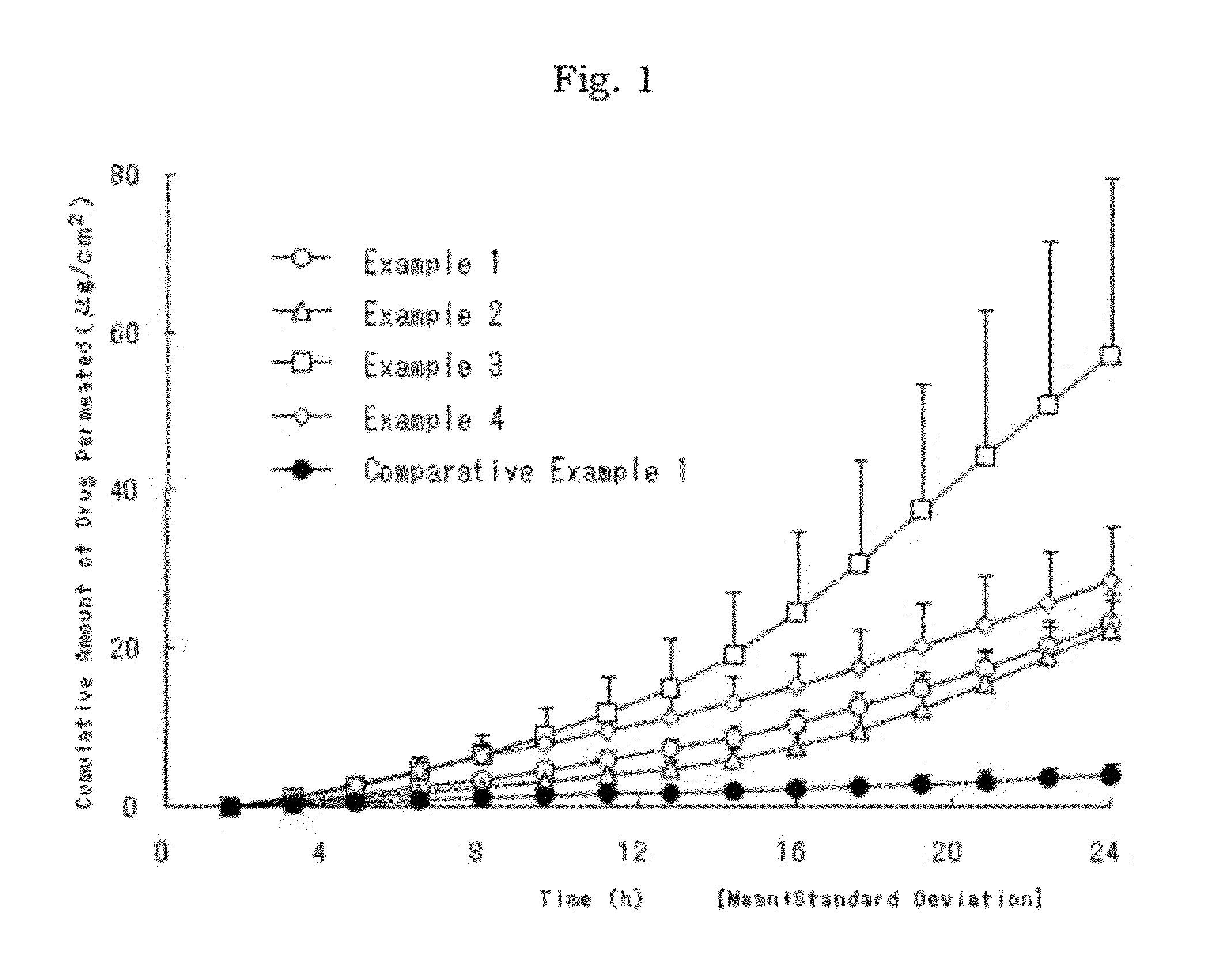

An external patch containing diclofenac hydroxyethylpyrrolidine prepared by laminating an adhesive layer on a backing, wherein said adhesive layer is characterized by comprising 5-50% by weight of styrene•isoprene•styrene block copolymer, 20-50% by weight of a tackifier resin, 5-70% by weight of a softening agent, and 0.5-20% by weight of one or more solubilizers selected from N-methyl-2-pyrrolidone, propylene glycol and dimethyl sulfoxide as essential ingredients, and 0.5-20% by weight of diclofenac hydroxyethylpyrrolidine as an active ingredient. The patch has excellent transdermal absorption, less skin-irritation and excellent stability of the drug.

Owner:TEIKOKU SEIYAKU KK TEIKOKU SEIYAKU CO LTD +1

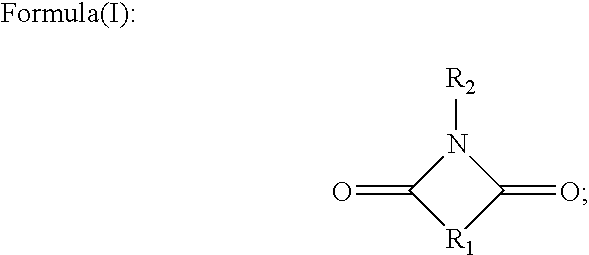

Process for producing cyclic compounds

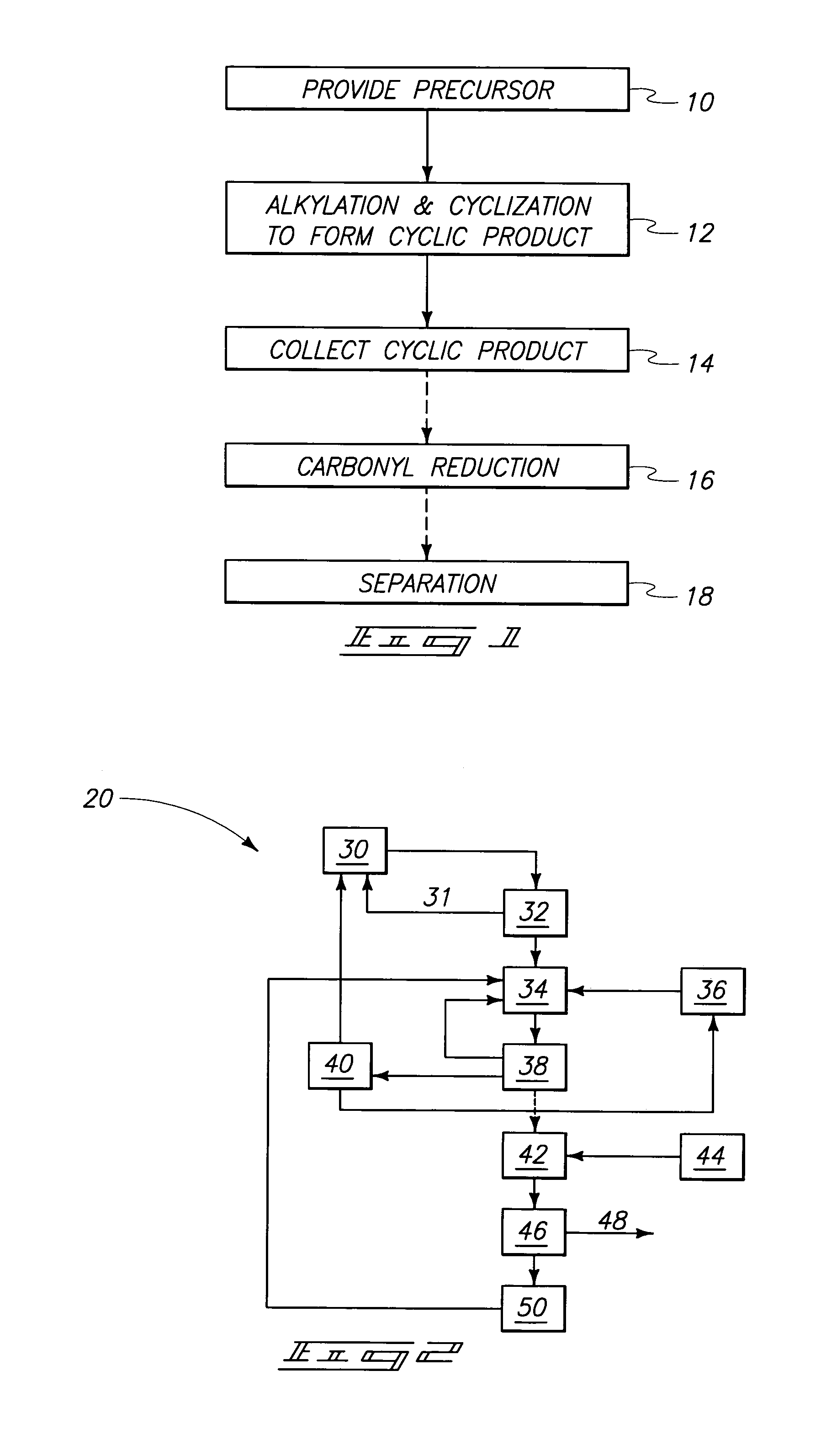

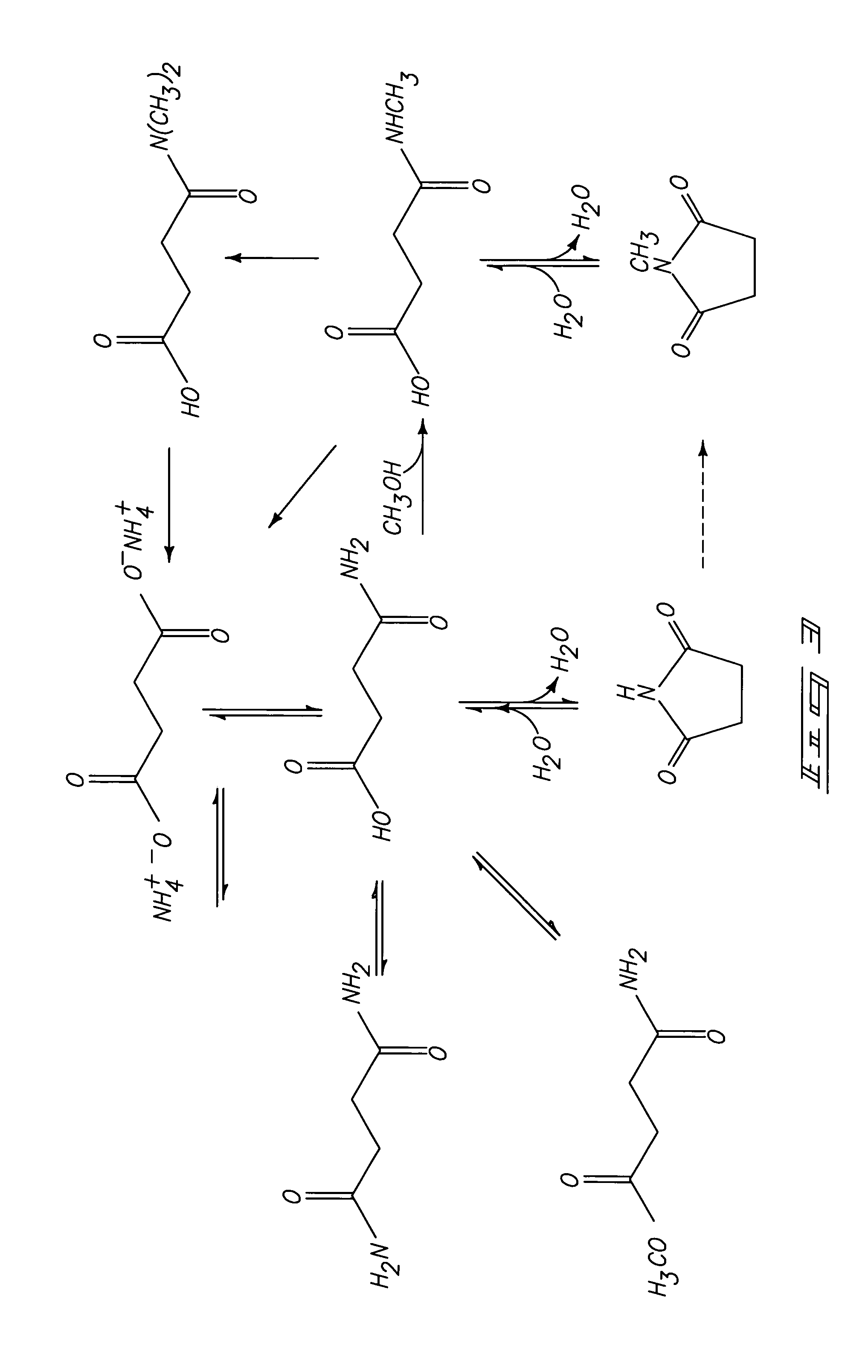

The invention includes methods of processing an initial di-carbonyl compound by conversion to a cyclic compound. The cyclic compound is reacted with an alkylating agent to form a derivative having an alkylated ring nitrogen. The invention encompasses a method of producing an N-alkyl product. Ammonia content of a solution is adjusted to produce a ratio of ammonia to di-carboxylate compound of from about 1:1 to about 1.5:1. An alkylating agent is added and the initial compound is alkylated and cyclized. The invention includes methods of making N-methyl pyrrolidinone (NMP). Aqueous ammonia and succinate is introduced into a vessel and ammonia is adjusted to provide a ratio of ammonia to succinate of less than 2:1. A methylating agent is reacted with succinate at a temperature of from greater than 100° C. to about 400° C. to produce N-methyl succinimide which is purified and hydrogenated to form NMP.

Owner:BATTELLE MEMORIAL INST

Manufacturing method of liquid crystal display device

InactiveUS6806925B2High affinityAvoid distractionStatic indicating devicesOptical filtersLiquid-crystal display2-Pyrrolidone

The irregularities of coloring concentration which is generated between dyed media when a color filter substrate which is prepared in a manufacturing method of a liquid crystal display device is manufactured by supplying ink to dyed media formed on a main surface of the color filter substrate using an ink jet method. In the present invention, as color filter ink which is supplied to the dyed media formed on the color filter substrate using the inkjet method, liquid which contains dye which colors the dyed media, solvent (for example, water) which has an affinity for the dye, a volatility-adjusting agent (for example, glycerin) which lowers the volatility of the ink to a level below the volatility of the solvent, and a dyeing-promoter agent (for example, N-methyl-2-pyrrolidone) which exhibits a higher affinity for the dye and the dyed media than the volatility adjusting agent. Then, the dyed media is colored with this ink.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

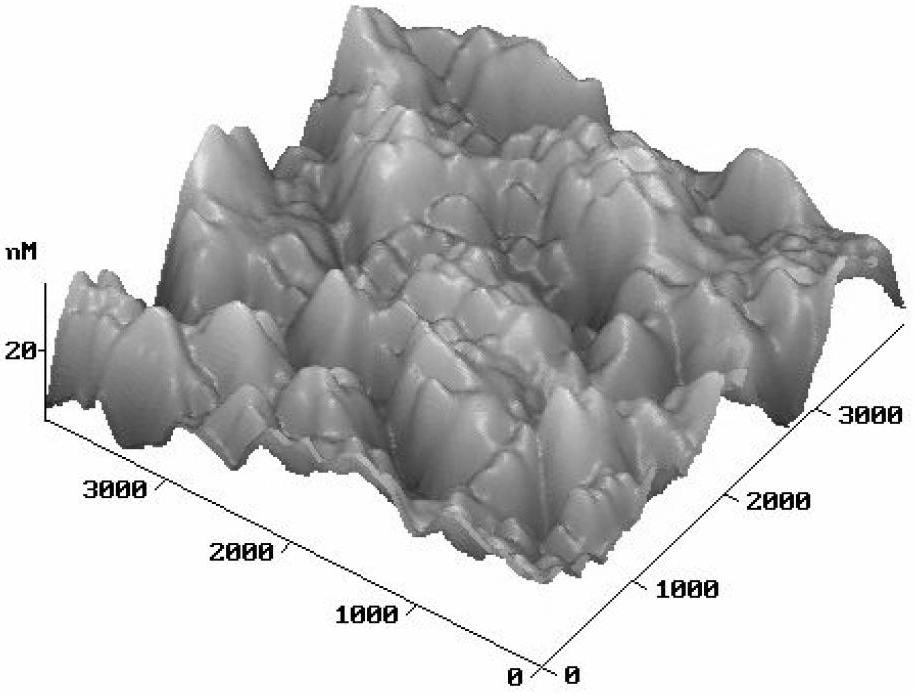

Preparation method for graphene oxide/polyvinylidene fluoride composite ultrafiltration membrane

InactiveCN102688707AImprove hydrophilicityStrong stain resistanceUltrafiltrationUltrafiltrationGlass sheet

The invnetion provides a preparation method for a graphene oxide / polyvinylidene fluoride composite ultrafiltration membrane and relates to the preparation method of the graphene oxide / polyvinylidene fluoride composite ultrafiltration membrane. The invention aims to solve the problem of poor hydrophilicity and stain resistance of the existing polyvinylidene fluoride ultrafiltration membrane. The method provided by the invention comprises the following steps of: 1. respectively adding graphene oxide, polyvinylpyrrolidone and polyvinylidene fluoride with N-methylpyrrolidone as solvent, heating and stirring to obtain casting membrane solution; 2. putting the casting membrane solution on a clean glass plate and scrapping to a certain thickness by a coating device, and then immersing distilled water, shedding and drying to obtain the graphene oxide / polyvinylidene fluoride composite ultrafiltration membrane. The preparation method provided by the invention can be applied to the fields of drinking water preparation, food industry, pharmaceutical industry, biotechnology, chemical process and environmental engineering.

Owner:HARBIN INST OF TECH

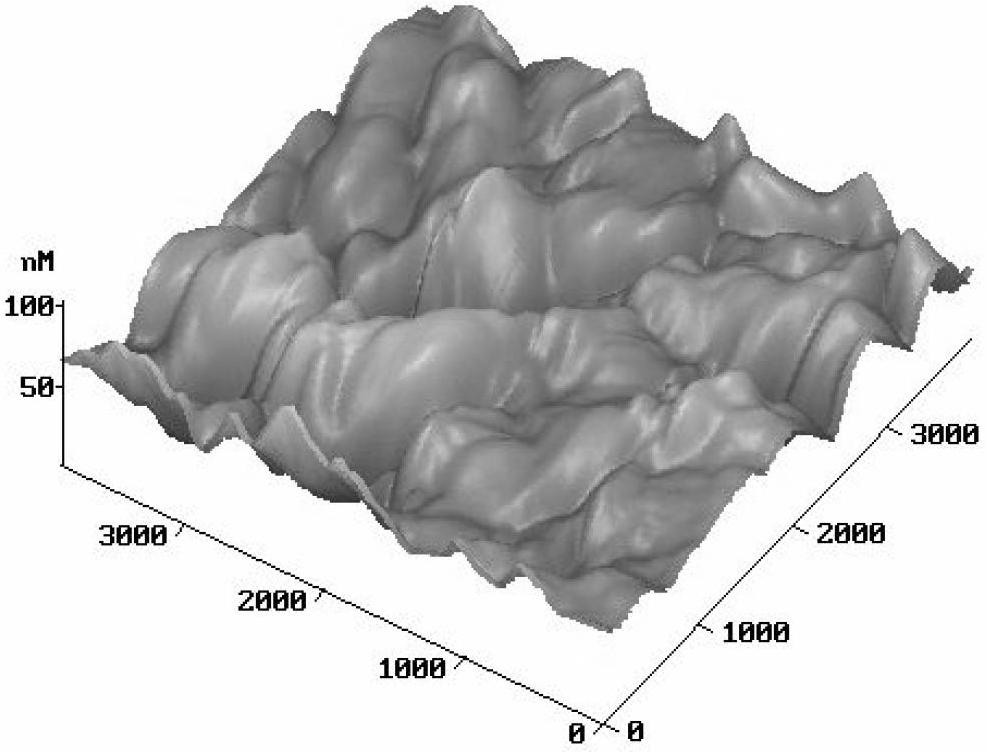

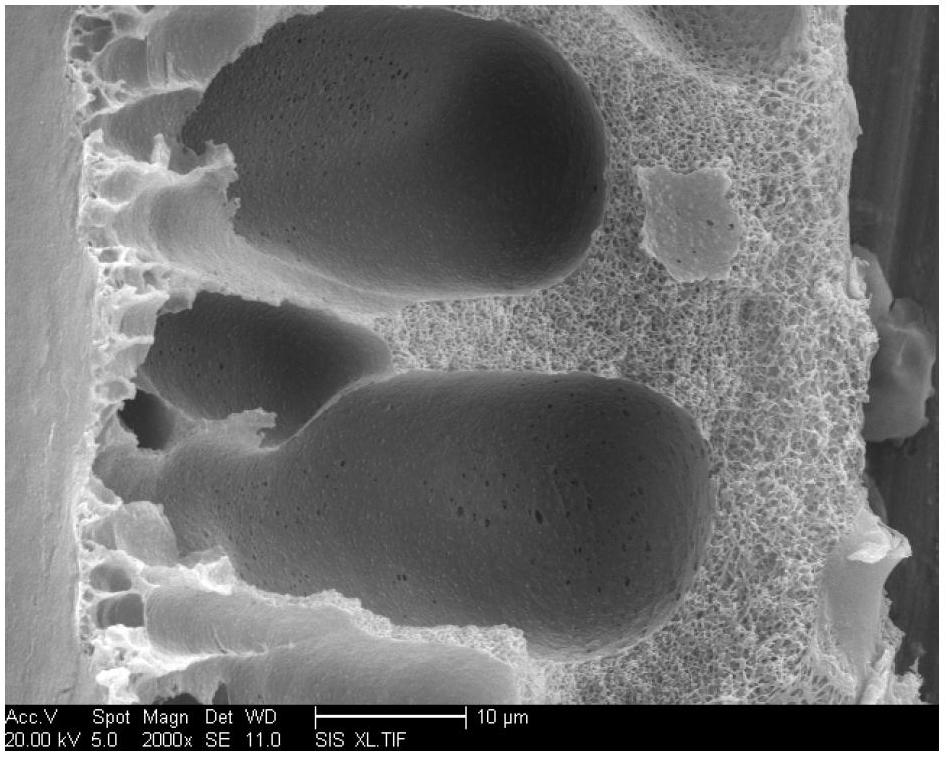

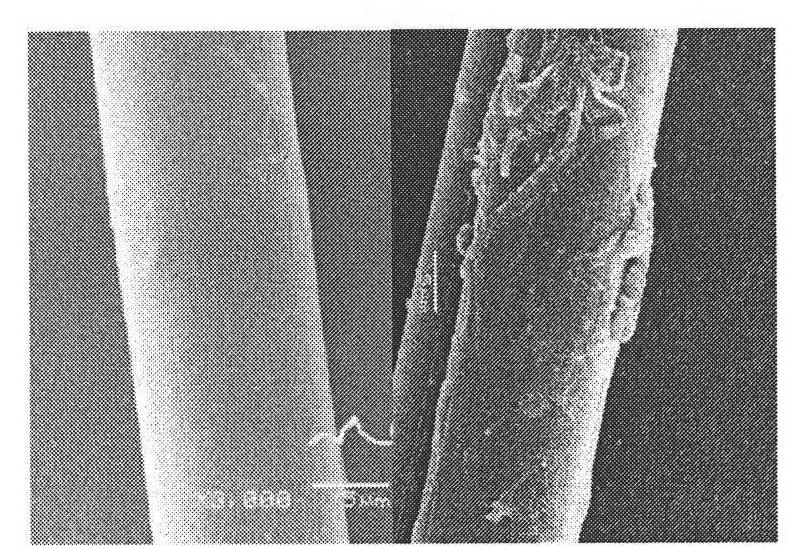

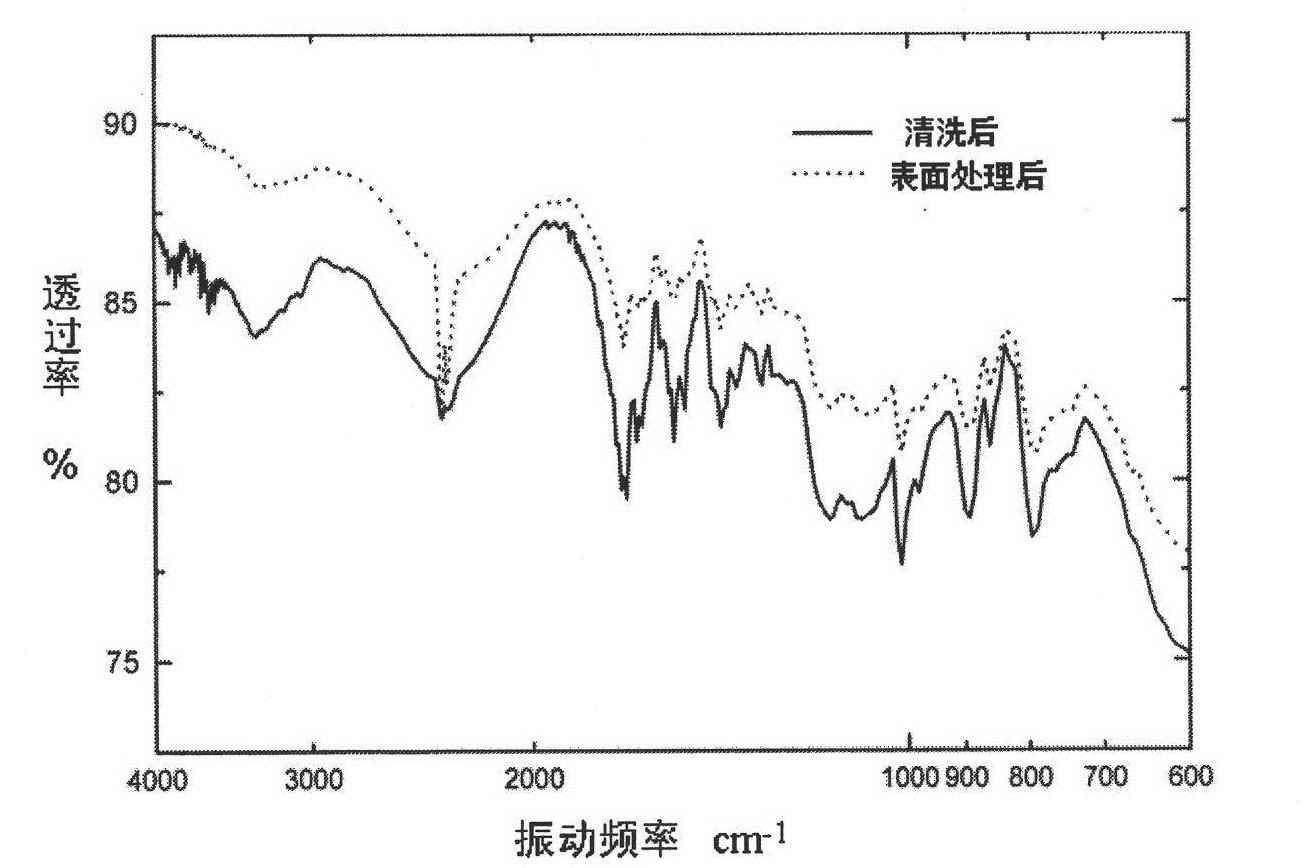

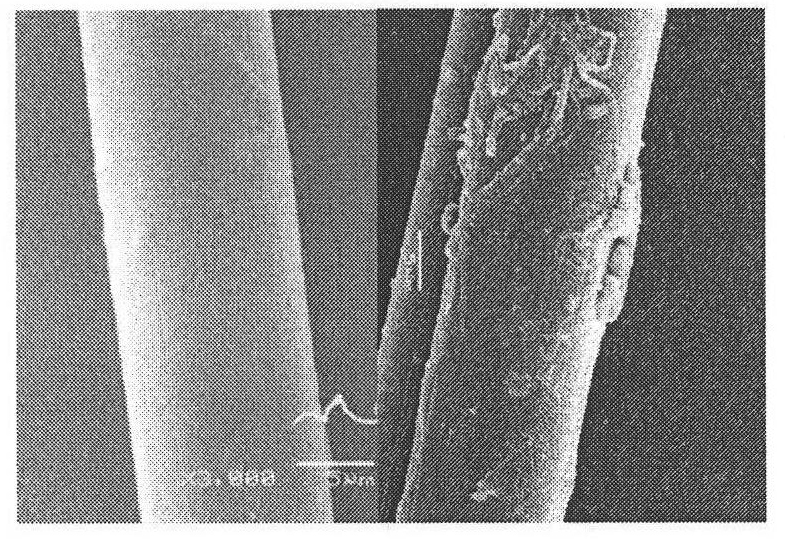

Method for modifying aramid fiber by using carbon nano tubes

InactiveCN101831800AImprove adhesionImprove mechanical propertiesPhysical treatmentFibre typesEpoxyResearch Object

The invention relates to a method for modifying aramid fiber by using carbon nano tubes, which comprises the following steps of: selecting an epoxy resin / aramid fiber composite material as a research object, selecting the carbon nano tubes as a surface modification material, forming free amino groups in a certain ratio on the aramid fiber by a chemical modification method, soaking the aramid fiber into N-methylpyrrolidone solution (NMP), and reacting the solution and the surface carboxylation carbon nano tubes with the aid of ultrasonic, wherein part of carbon nano tubes enter the interior of Kevlar fiber, and the other part of carbon nano tubes are fixed on the surface of the fiber through amido bonds formed by the carbon nano tubes and amino, thus, a aramid fiber complex inside and outside which the carbon nano tubes are doped is formed. Single fiber tensile test results and single fiber pull-out test results show that the mechanical property of the modified aramid fiber and the interface bonding strength with the epoxy resin are improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

High-performance flat-type cellulose acetate/graphene blend forward osmosis membrane

ActiveCN104474919APollution resistantImprove hydrophilicitySemi-permeable membranesCellulose acetateN-Methyl-2-pyrrolidone

The invention discloses a high-performance flat-type cellulose acetate / graphene blend forward osmosis membrane. 5 to 25 percent by weight of cellulose acetate, 1 to 15 percent by weight of additives, 0.01 to 2 percent by weight of graphene and mixed solvent of dimethylformamide, dimethylacetamide, or N-methylpyrrolidone and acetone are added into a dissolving tank according to a given sequence and are stirred and dissolved for 2 to 18 hours at the temperature of 5 to 75 DEG C to be uniformly mixed so as to prepare a forward osmosis membrane casting solution; the high-performance flat-type cellulose acetate / graphene blend forward osmosis membrane is prepared on a supporting material by adopting a phase inversion method. According to the forward osmosis membrane, 1M NaCl is used as a driving liquid, the deionized water is used as a raw material solution, the flux of pure water of the forward osmosis membrane is more than 21L / m<2> within the test time of one hour, and the salt flux in the reverse direction is less than 3.5g / m<2>.

Owner:UNIV OF JINAN

Manufacturing method of liquid crystal display device

InactiveUS20020054252A1High affinityAvoid distractionStatic indicating devicesOptical filtersLiquid-crystal display2-Pyrrolidone

The irregularities of coloring concentration which is generated between dyed media when a color filter substrate which is prepared in a manufacturing method of a liquid crystal display device is manufactured by supplying ink to dyed media formed on a main surface of the color filter substrate using an ink jet method. In the present invention, as color filter ink which is supplied to the dyed media formed on the color filter substrate using the inkjet method, liquid which contains dye which colors the dyed media, solvent (for example, water) which has an affinity for the dye, a volatility-adjusting agent (for example, glycerin) which lowers the volatility of the ink to a level below the volatility of the solvent, and a dyeing-promoter agent (for example, N-methyl-2-pyrrolidone) which exhibits a higher affinity for the dye and the dyed media than the volatility adjusting agent. Then, the dyed media is colored with this ink.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

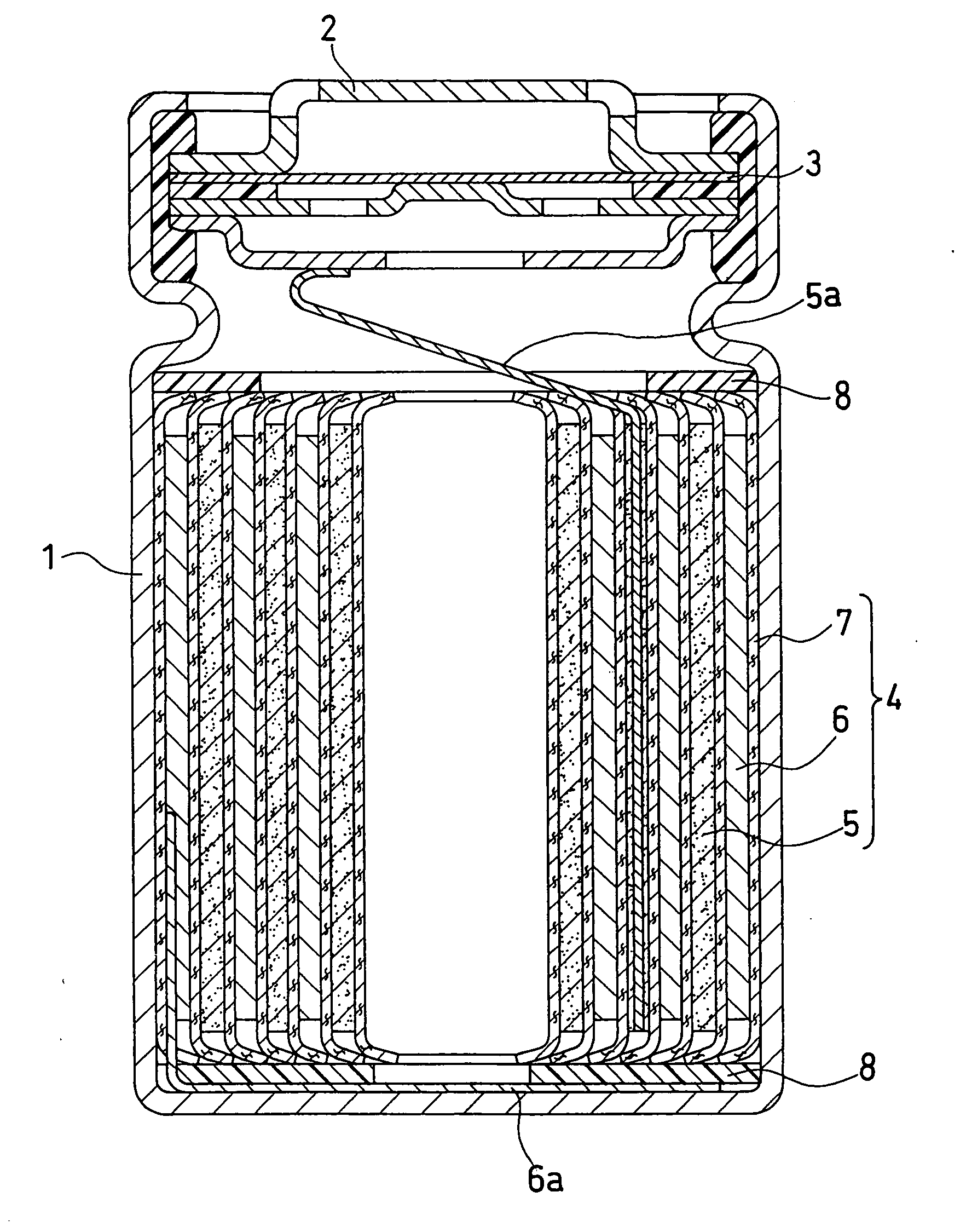

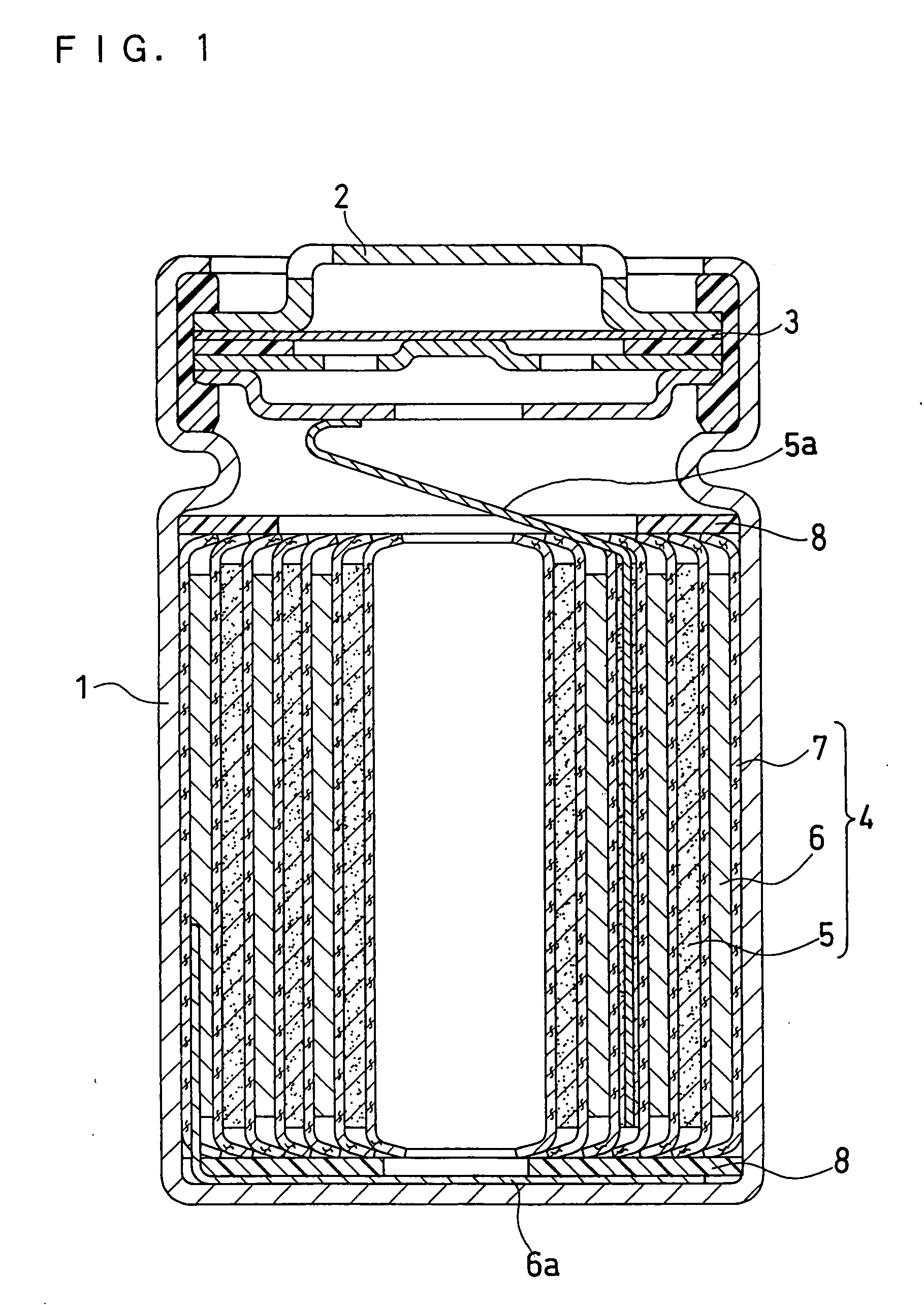

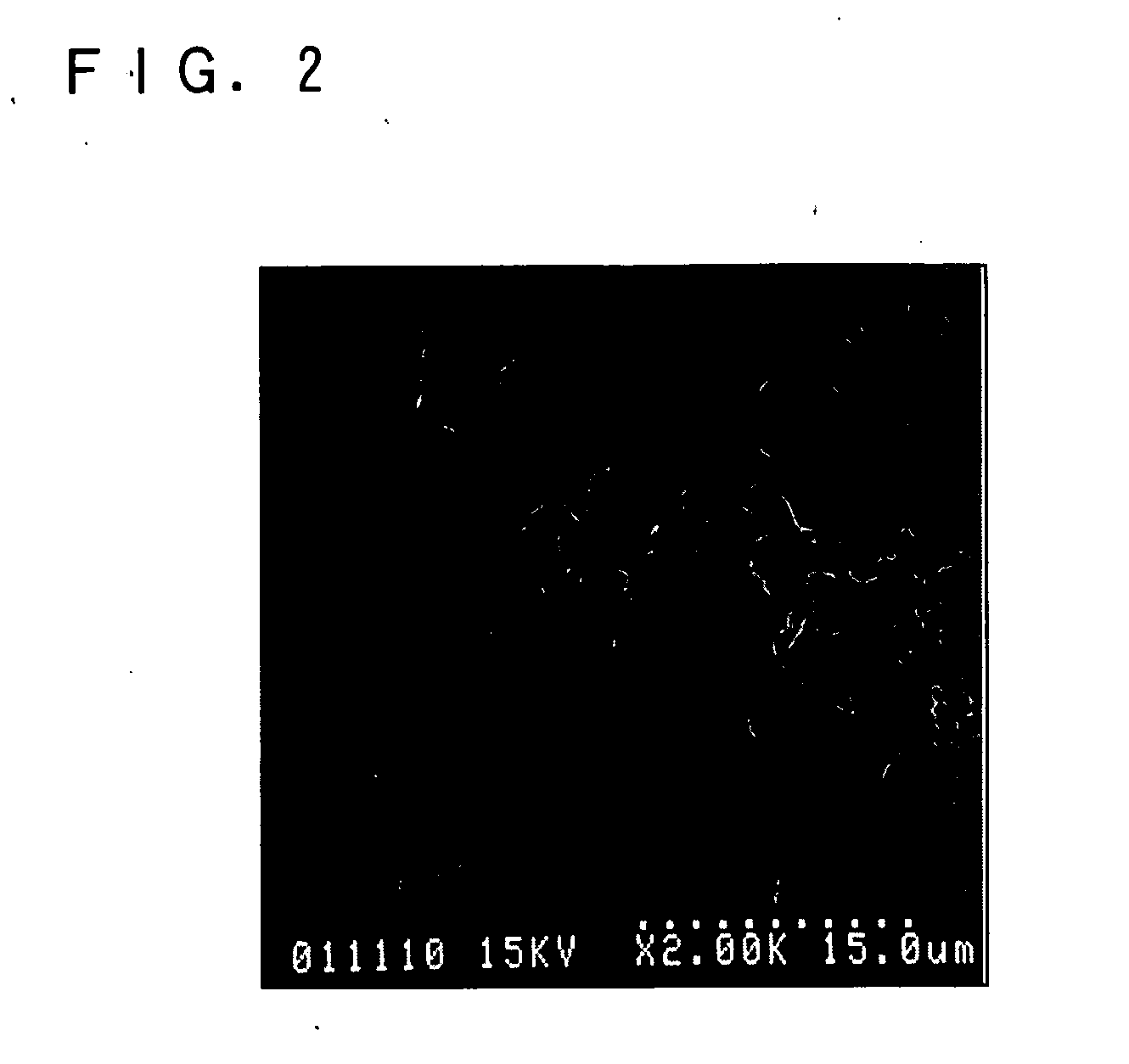

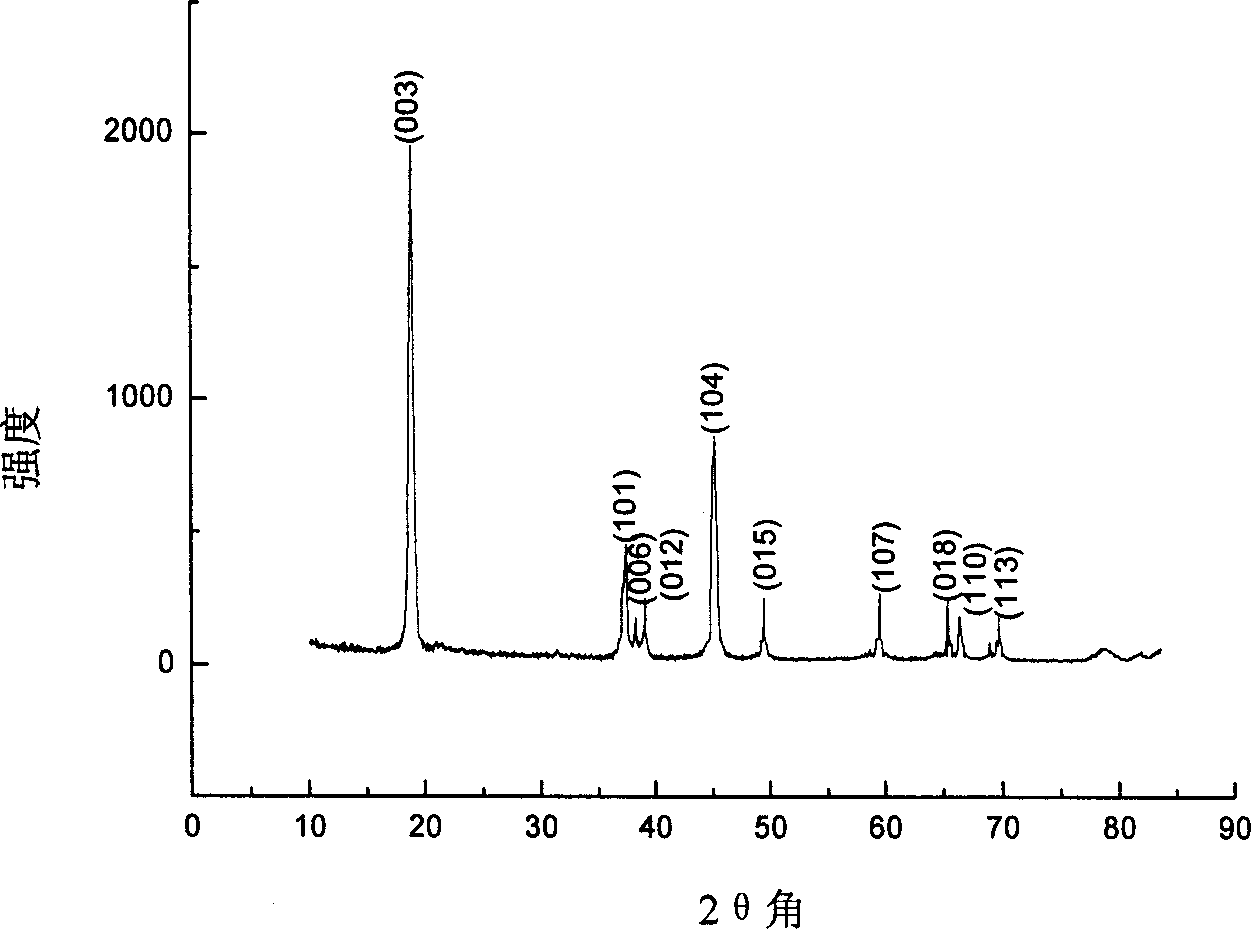

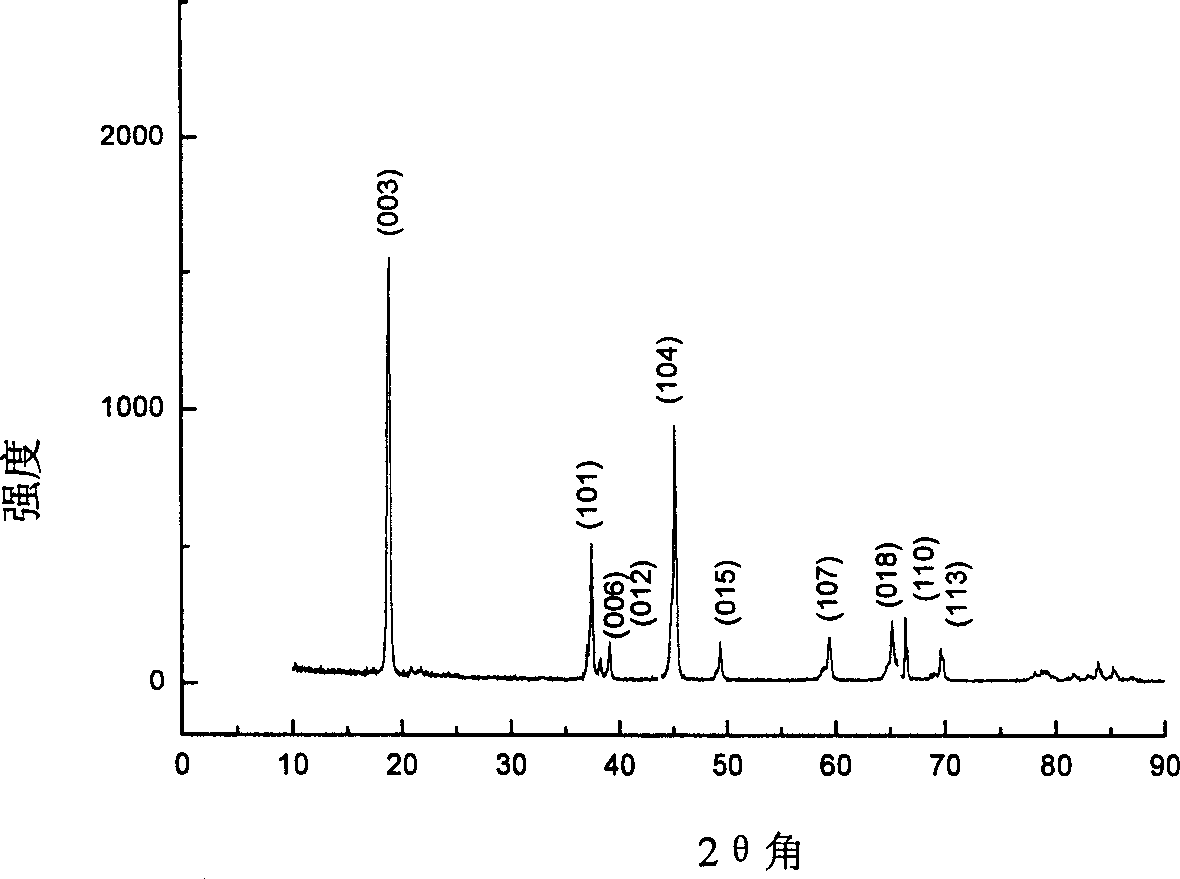

Positive electrode active material, non-aqueous electrolyte secondary battery containing the same and method for evaluating positive electrode active material

InactiveUS20050221182A1Maintain good propertiesHighly practicalOxygen/ozone/oxide/hydroxideAlkali metal oxidesABSORPTION BASEViscosity

A positive electrode active material powder for a non-aqueous electrolyte secondary battery, wherein an amount of a liquid reagent absorbed by the powder is 20 to 40 ml per 100 g of the powder when the liquid reagent is dibutyl phthalate, and the amount is 20 to 50 ml per 100 g of the powder when the liquid reagent is N-methyl-2-pyrrolidone or water, the absorption amount is a value measured using a device according to test method A or B regarding DBP absorption based on JIS K6217 (1997), and the measured value is an amount of the liquid reagent added until the viscosity of a mixture of the powder and the liquid reagent reaches a level corresponding to 70% of a maximum torque which is recorded when a change in the viscosity of a mixture of the powder and the liquid reagent is measured by a torque detecting device.

Owner:PANASONIC CORP

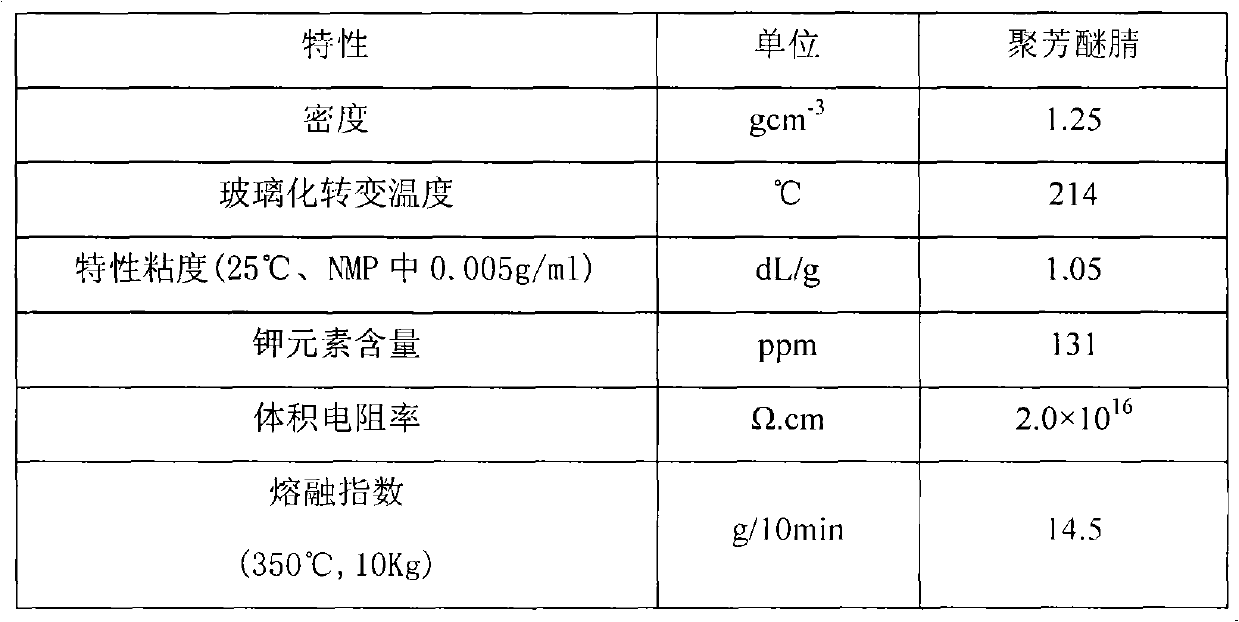

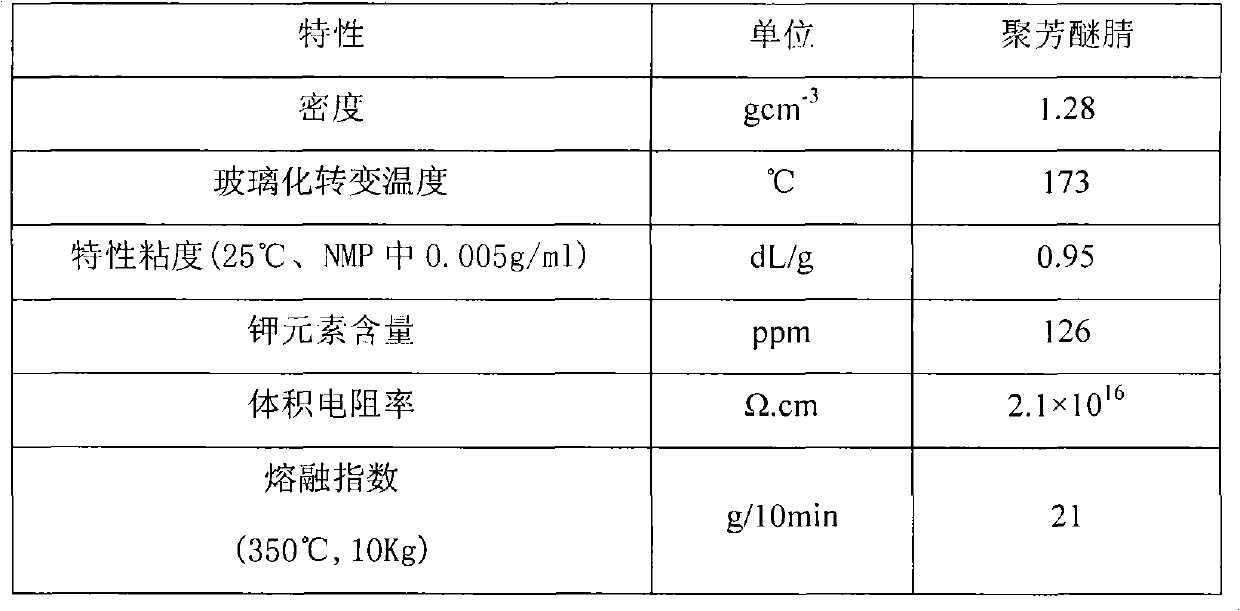

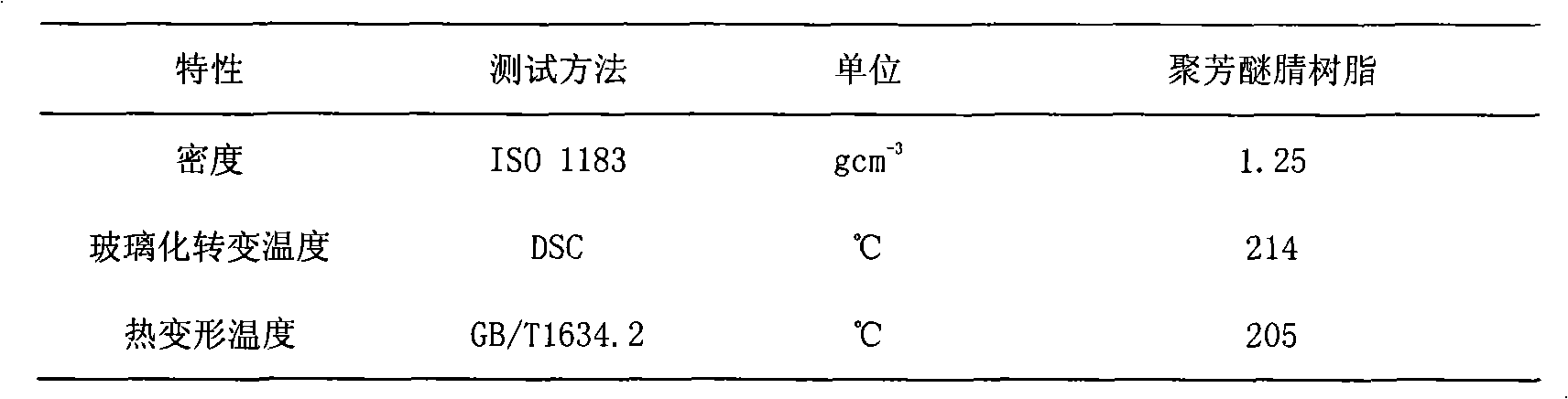

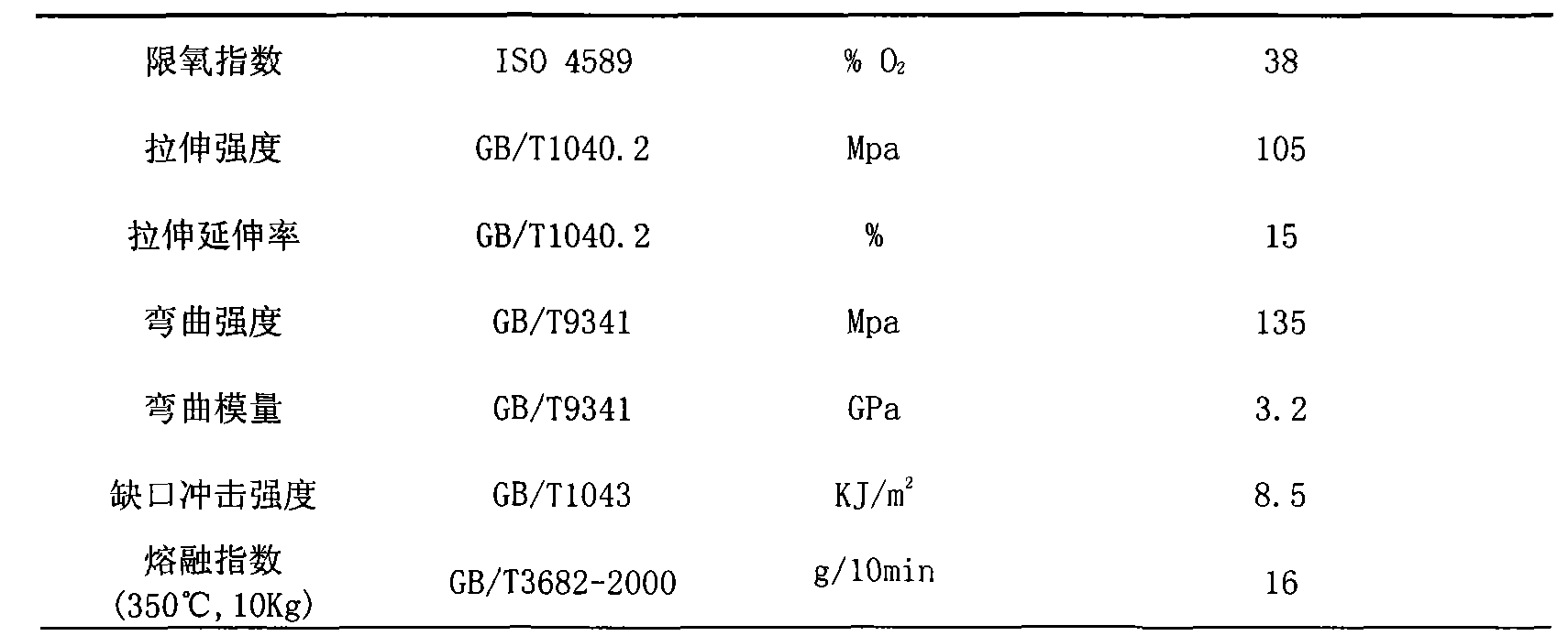

Method for preparing poly(arylene ether nitrile) resin powder

The invention discloses a method for preparing poly(arylene ether nitrile) resin powder, and belongs to the technical field of high polymer materials. 2,6-dichlorobenzonitrile and aromatic dihydric phenol are taken as raw materials, 1-methyl-2-Pyrrolidinone is taken as a solvent, anhydrous potassium carbonate or anhydrous sodium carbonate is taken as a catalyst, and methylbenzene or dimethylbenzene is taken as a dehydrating agent; and the method comprises the following steps of: performing reflux reaction at the temperature of between 130 and 160 DEG C for 2 to 4 hours in a reactor, slowly evaporating out water and the dehydrating agent, and raising the temperature to 180-200 DEG C until a macromolecular rod-climbing phenomenon happens; adding the solvent into the reactor, and diluting the reaction products to the mass concentration of 2 to 15 percent; and adding a precipitator into the reactor, continuously stirring, performing centrifugal solid-liquid separation, washing the solid in acidic boiling water, filtering and drying to obtain the poly(arylene ether nitrile) resin powder. The prepared poly(arylene ether nitrile) resin powder has the characteristics of superfine granularity (reaching 100-400 meshes), uniform granularity, high purity, stable performance, and excellent electrical property, and can be widely applied in the fields such as electronics, precision machines, aerospace, new energy and the like.

Owner:SICHUAN FEIYA NEW MATERIAL

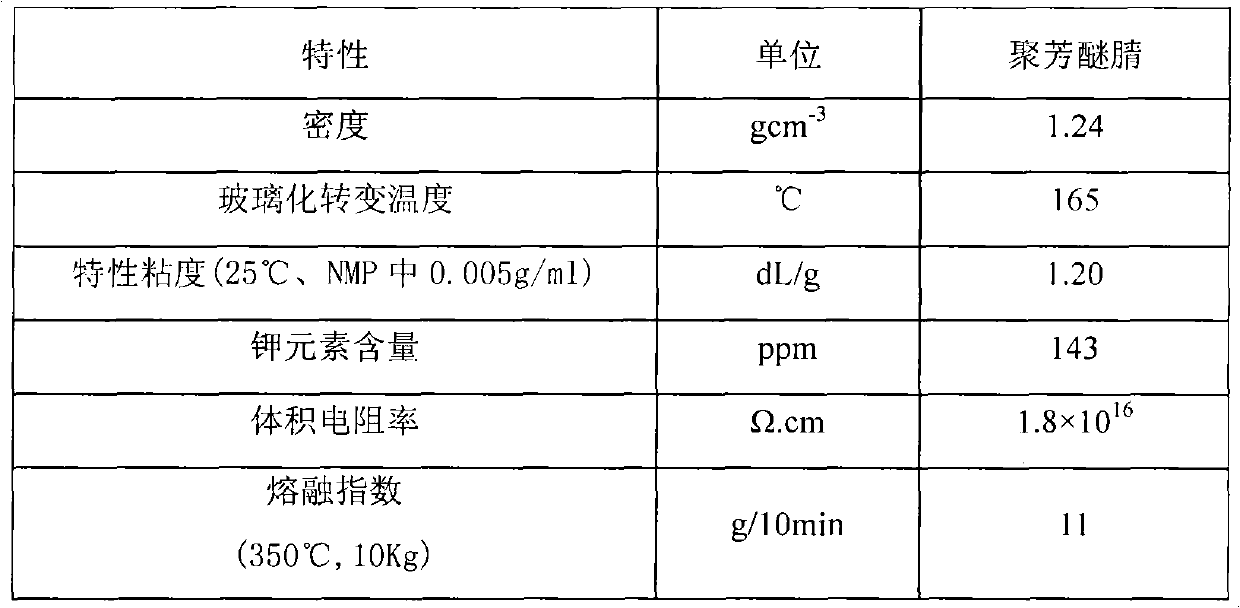

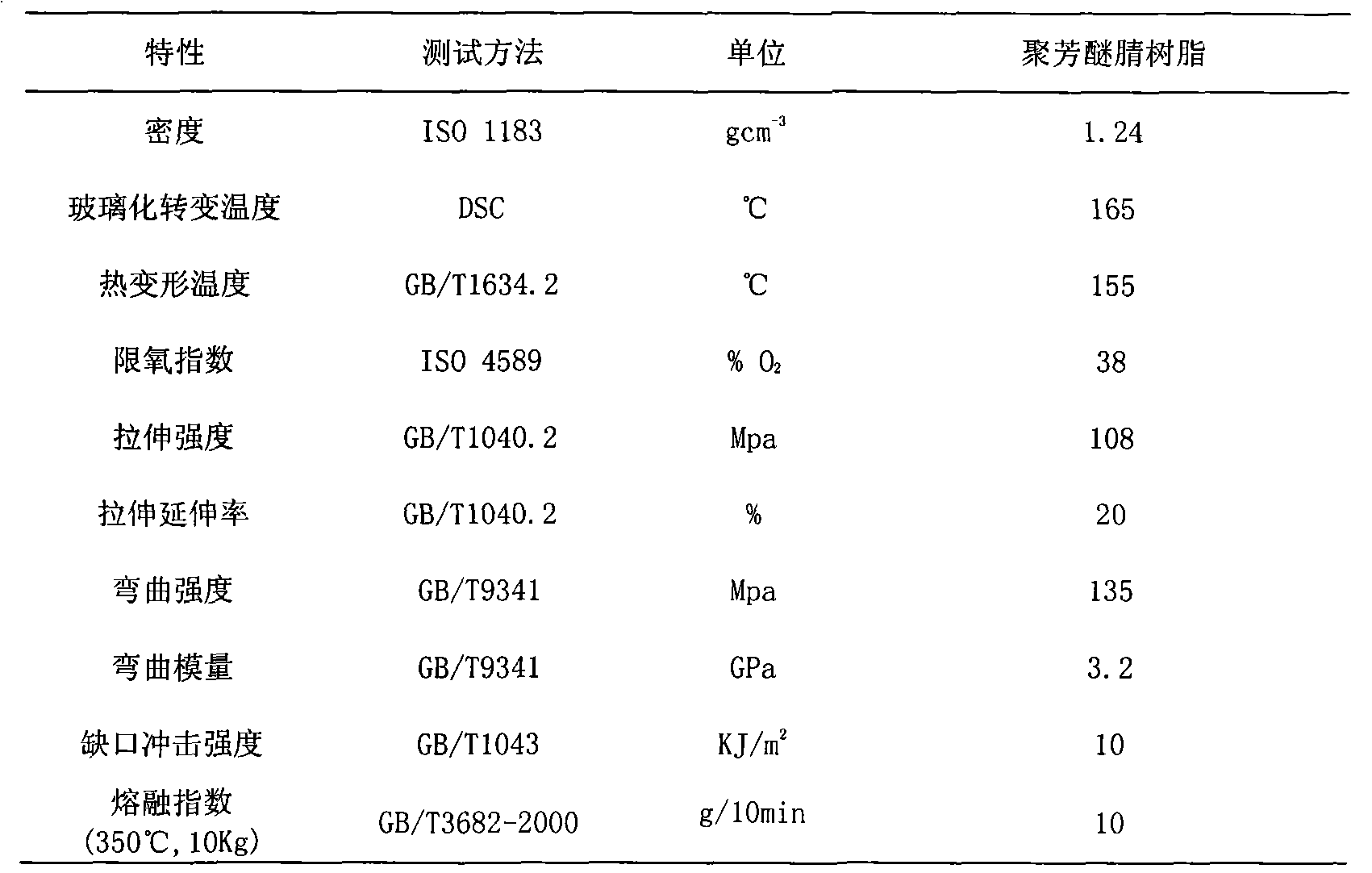

Method for preparing poly(arylene ether nitrile) resin

The invention discloses a method for preparing poly(arylene ether nitrile) resin, which belongs to the technical field of high polymer materials. The method comprises the following steps of: finishing a reaction in a reaction kettle under normal pressure under the actions of a catalyst and a dehydrating agent by taking 2,6-dichlorobenzonitrile and aromatic dicarboxylic phenol as raw materials and taking N-methyl pyrrolidone as a solvent; pressurizing and atomizing solution after dilution to a precipitating agent for precipitating; after heating, stirring and refluxing a precipitate and the precipitating agent to finish solvent extraction, performing solid-liquid separation by using a centrifugal machine; allowing liquid to enter a rectifying tower for rectifying and recovering the solvent; and drying solid after washing with boiling water to obtain the poly(arylene ether nitrile) resin of the invention. The method has the characteristics of easily implemented production conditions, and safe and environmentally-friendly production process. The poly(arylene ether nitrile) resin prepared by adopting the method of the invention has the characteristics of high purity and stable performance, and can be applied to the field of aerospace, electronics, machinery, medical treatment, chemical industry and the like.

Owner:SICHUAN FEIYA NEW MATERIAL

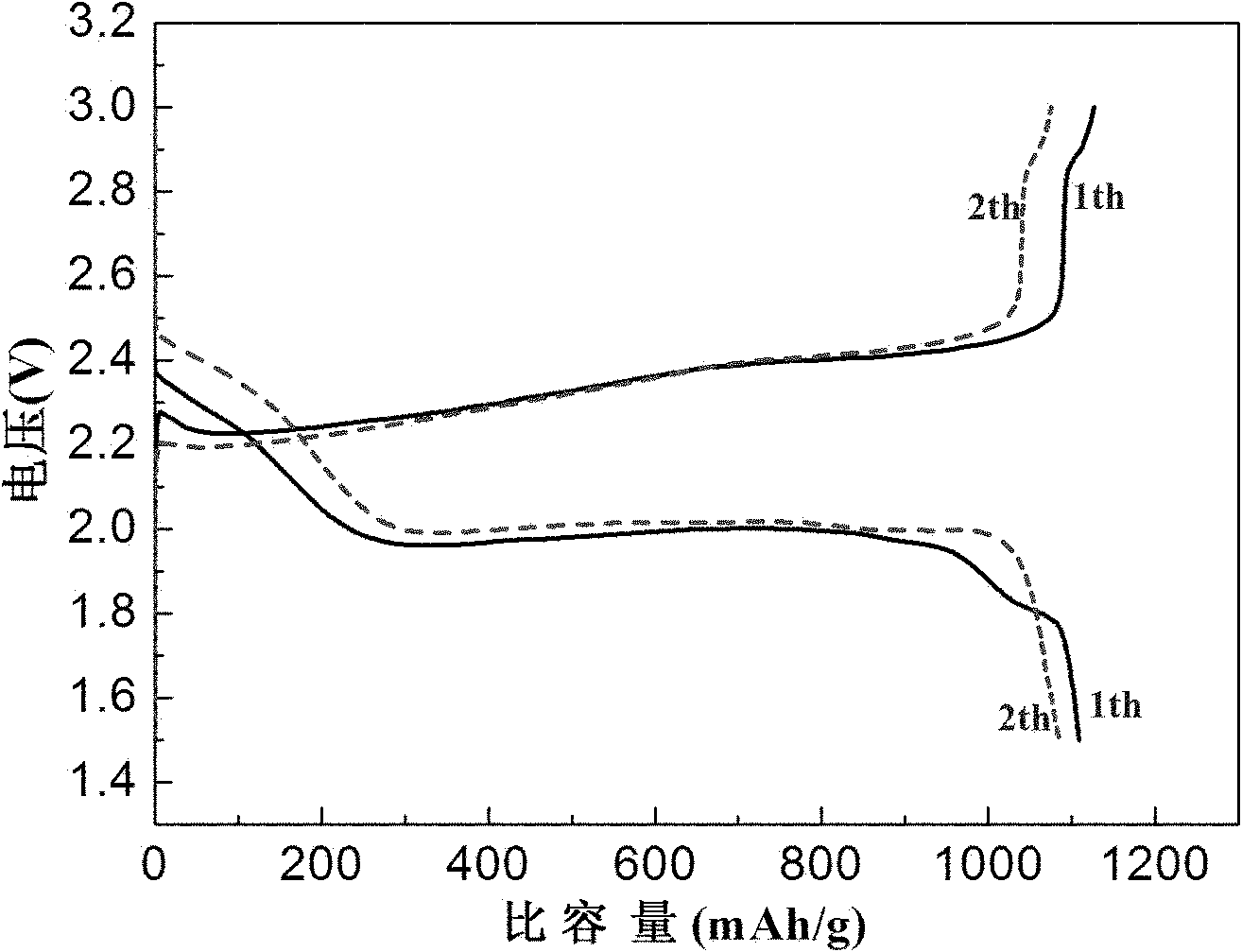

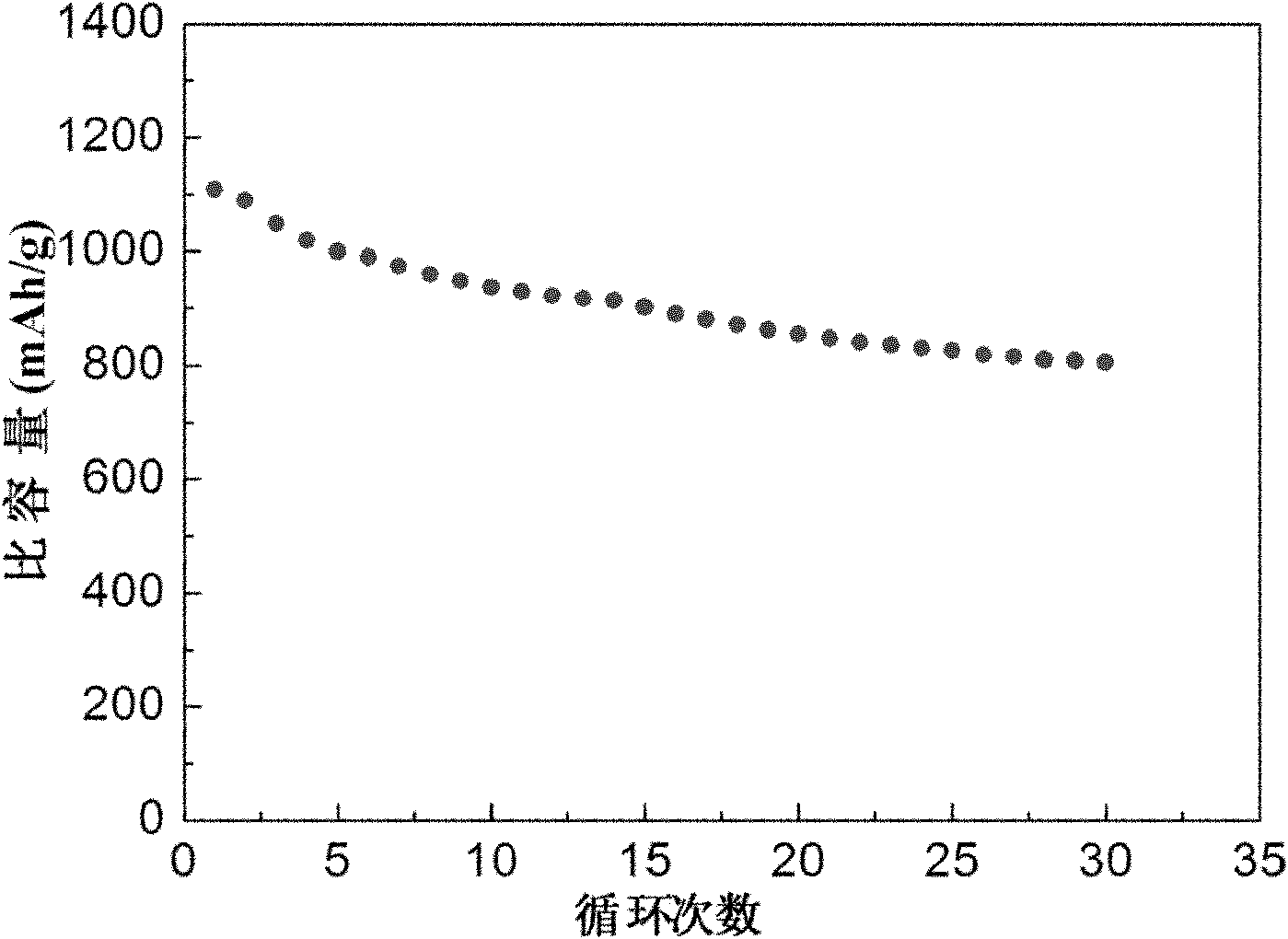

Porous nano carbon fiber material, lithium battery cathode material and cathode plate

ActiveCN102127828AEasy to operateAperture controllableFilament/thread formingSecondary cellsFiberCarbon fibers

The invention discloses a porous nano carbon fiber material, a lithium battery elemental sulfur / porous nano carbon fiber composite anode material and an anode plate which are prepared from the porous nano carbon fiber material. The lithium battery elemental sulfur / porous nano carbon fiber composite anode plate is prepared by using the method: (1) mixing lithium battery elemental sulfur / porous nano carbon fiber composite anode material shown by the right requirements 3 with acetylene black and an adhesive and uniformly stirring to obtain a mixture; and (2) adding an N-methyl pyrrolidone solution to the mixture obtained in the step (1), proportioning into paste and scraping the paste on a carbon-coated aluminum foil as a current collector and drying to obtain an elemental sulfur / porous nano carbon fiber composite anode plate. Lithium sulphur batteries made by utilizing the anode plate of the invention have greatly-improved cycle performance.

Owner:SOUTH CHINA NORMAL UNIVERSITY

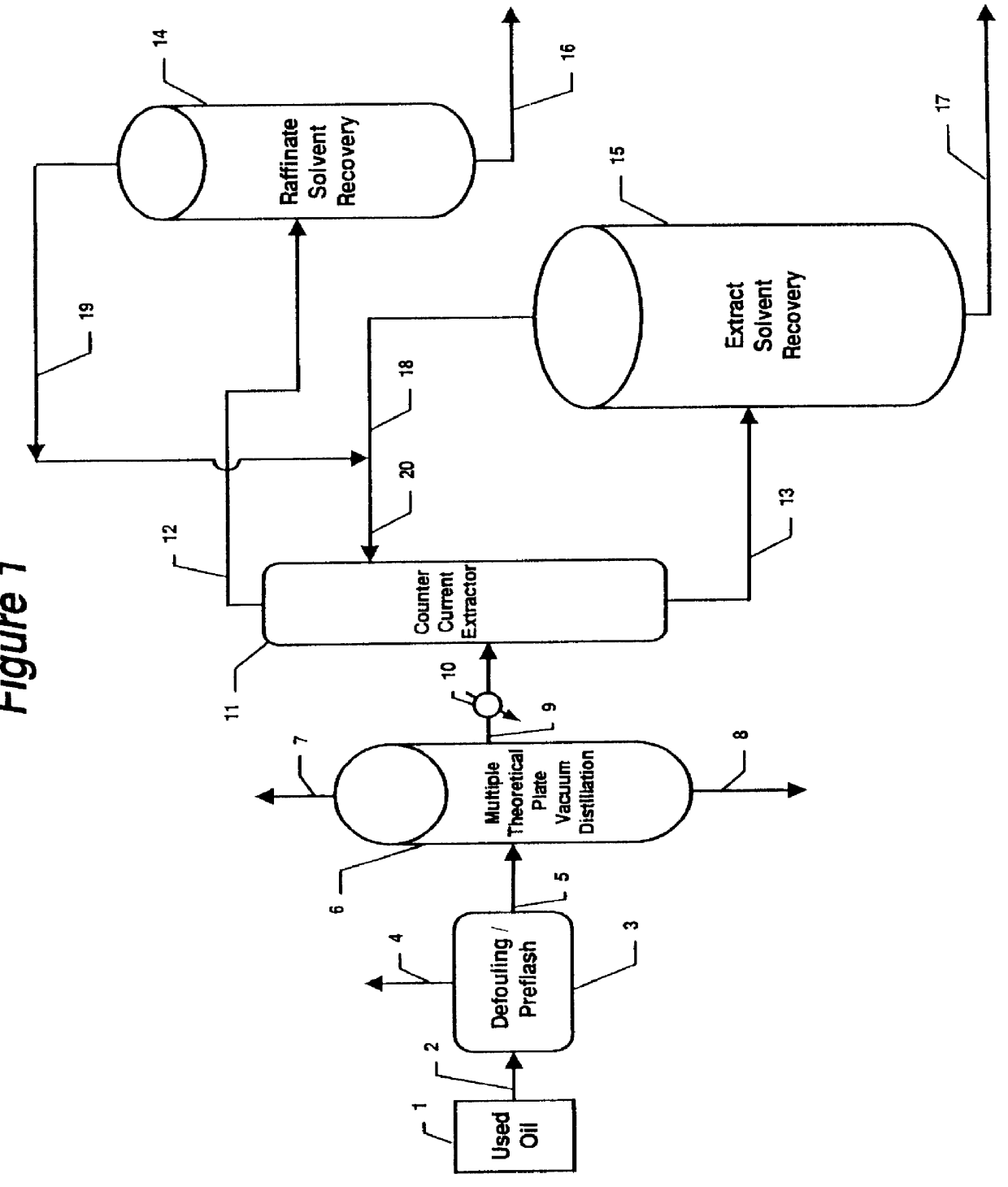

Method of rerefining waste oil by distillation and extraction

InactiveUS6117309AHigh yieldLower the volumeRefining with acid-containing liquidsLubricant compositionTheoretical plateDistillation

Owner:SARP

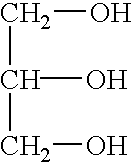

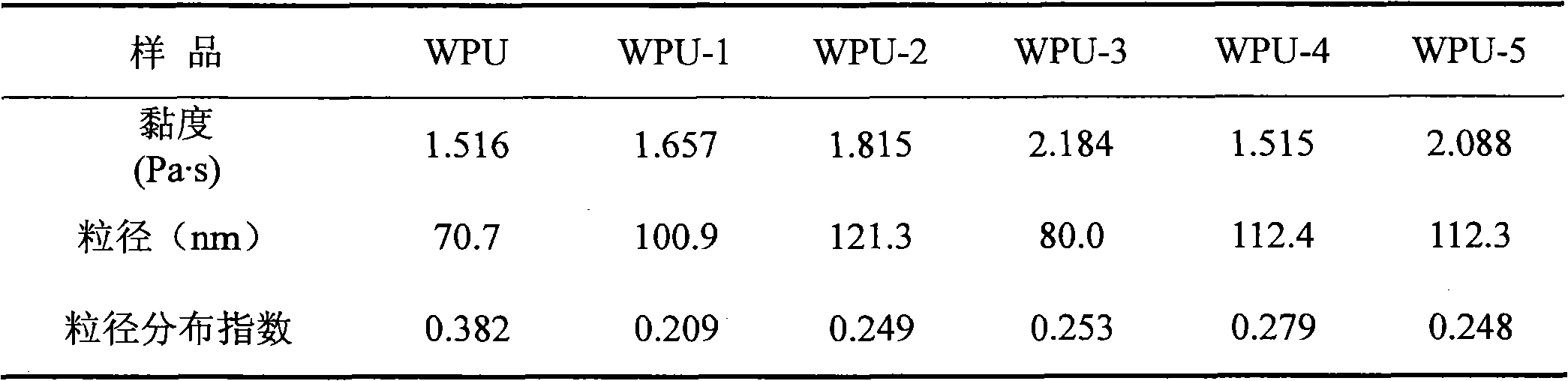

Method for preparing aqueous polyurethane/nano titanium dioxide hybrid material

The invention discloses a method for preparing an aqueous polyurethane / nano titanium dioxide hybrid material and relates to a preparation technology of a modified polyurethane emulsion. The method comprises the following steps of: (1) preparing TBT (Tributyltin) sol; (2) adding polyalcohol and isocyanate which are used as raw material monomers, adding a hydrophilic chain extender, heating up the system to 30-80 DEG C by using N-polyvinyl pyrrolidone as a solvent and then adding a catalyst; (3) after the mixture reacts of 1-6 hours, heating up the system to 60-100 DEG C; continuing to make the mixture react for 1-6 hours, and then cooling to 20-60 DEG C; adding triethylamine used as a salt forming agent, and making the mixture react for 10-60 minutes; dispersing with water by using ethanediamine as a chain extender to obtain an aqueous polyurethane emulsion; maintaining the temperature to 20-50 DEG C, adding a small quantity of gamma-epoxypropyl trimethoxy silane and stirring for 10-90 minutes; adding the TBT sol to the system and dropwise adding a small quantity of hydrochloric acid; and persistently stirring for 12-48 hours to obtain the aqueous polyurethane / nano titanium dioxide hybrid material. The properties such as the weather resistance, the mechanical property, the coating transparency, and the like of the hybrid material are greatly improved.

Owner:JIANGSU UNIV

Graphene/conductive polymer composite film and preparation method thereof

ActiveCN101798462AImprove conductivityImprove antistatic performanceOrganic conductorsCarbon-silicon compound conductorsConductive polymer compositeComposite film

The invention relates to a graphene / conductive polymer composite film and a preparation method thereof. The graphene / conductive polymer composite film comprises products prepared by the following reaction: 1) preparing graphite oxide from graphite by a chemical oxidation method; 2) adding an oxidant ammonium persulfate into monomer containing acid solution to prepare conductive polymer; 3) performing ultrasonic dispersion on the graphite oxide and the conductive polymer in N-methylpyrrolidone, adding a reducing agent, and stirring; 4) coating solution prepared by step 3) on the surface of a substrate to form a film, washing and drying; and 5) repeating the step 4) until the film has the required thickness. The graphene / conductive polymer composite film and the preparation method have the advantages that: 1) the formed graphene / conductive polymer composite film has good electric conduction and antistatic property, and has the conductivity between 1*10<-3> and 1*10<2>S / cm; 2) the conjugated structure of the grapheme and the conductive polymer ensures that the grapheme and the conductive polymer have high compatibility; 3) the composite film has controllable thickness; and 4) the preparation method has simple conditions and easy operation.

Owner:武汉工大科技园发展有限公司

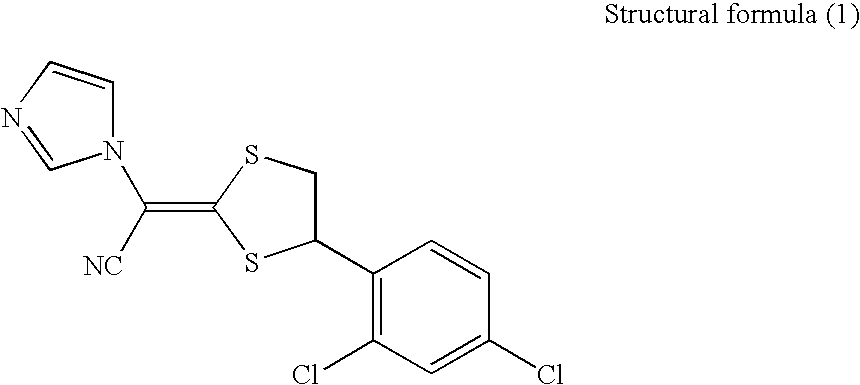

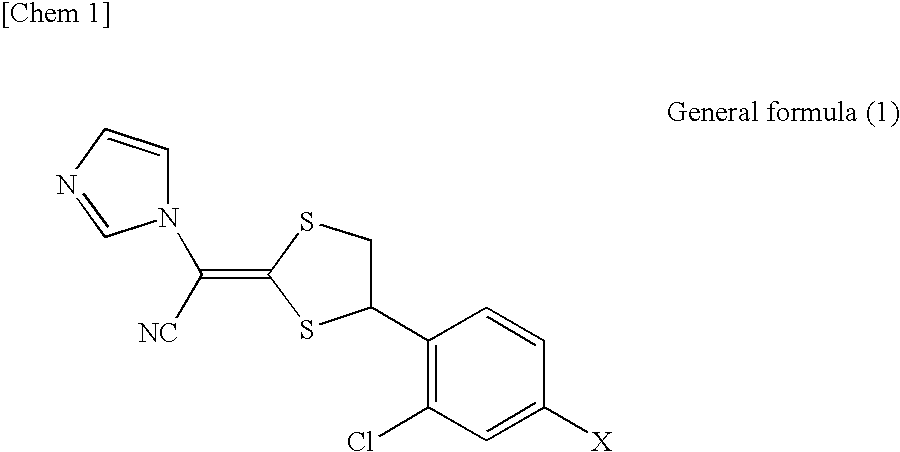

Pharmaceutical composition for external use

ActiveUS20090137651A1Decrease in optical purityLow purityBiocideOrganic active ingredientsMedicinePropylene carbonate

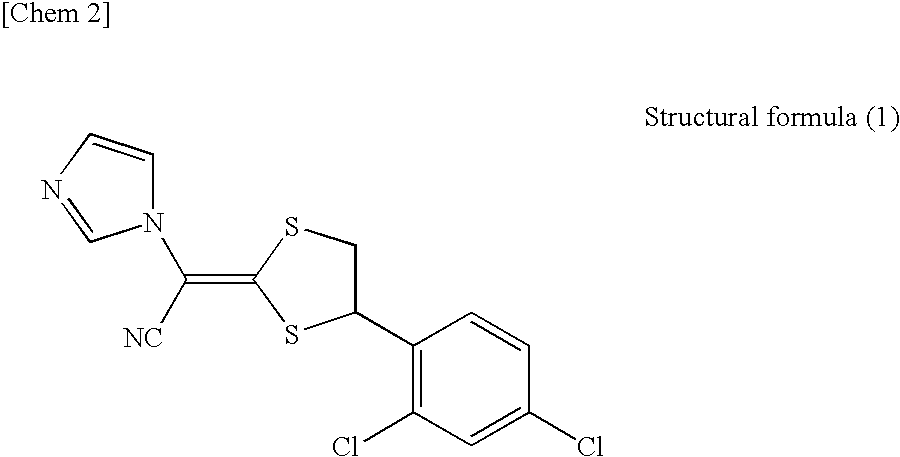

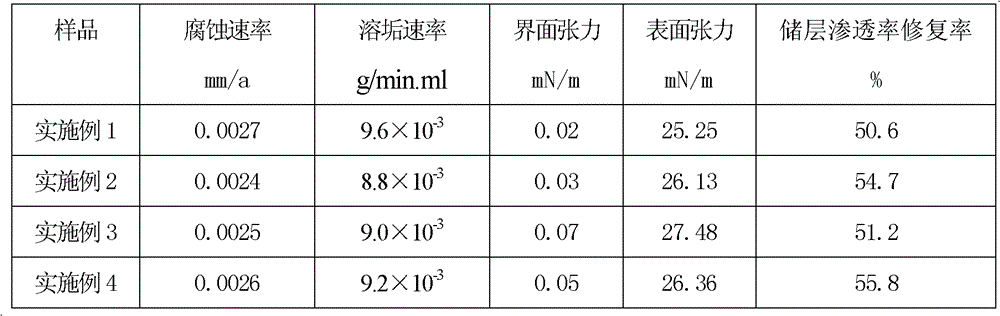

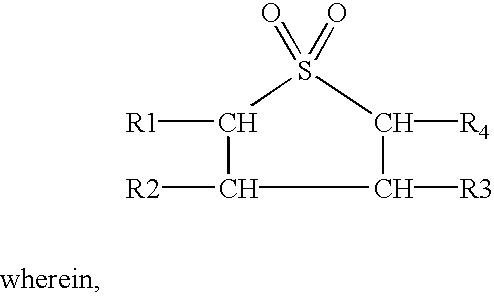

A pharmaceutical composition for external use, including: i) luliconazole represented by the following structural formula (1) and / or a salt thereof; and ii) one or two or more selected from N-methyl-2-pyrrolidone, propylene carbonate, and crotamiton.

Owner:NIHON NOHYAKU CO LTD +1

Blocking remover of gas well shaft

The invention relates to a blocking remover of a gas well shaft. The blocking remover comprises, by weight, 5-25% of an alcohol ether compound, 0.5-10% of a dispersant, 1-10% of a cleaning agent, and 0.5-5% of chelating agent, with the balance being a nitrogen-containing polar solvent, wherein the nitrogen-containing polar solvent is one selected from N,N dimethyl formamide, N,N dimethyl acetamide, and N-methyl pyrrolidone, the alcohol ether compound is one selected from glycol-ether, glycol-propyl ether, glycol-butyl ether, and diglycol-ether, the disperant whose micelle particle size is from 20nm to 100nm is a middle-phase microemulsion-type dispersant mixed by kerosene, water, a surfactant and a cosurfactant, the cleaning agent is one selected from allene diamine, acetonitrile and pentylamine, and the chelating agent is one selected from sodium citrate and EDTA. The blocking remover has the advantages that corrosivity is weak, that the speed of dissolving blockage is fast, that the product performance is stable in high temperatures, and that the blocking remover can reduce damages caused by water locking and fouling in areas close to gas wells, and can recover the permeability of storing layers.

Owner:PETROCHINA CO LTD

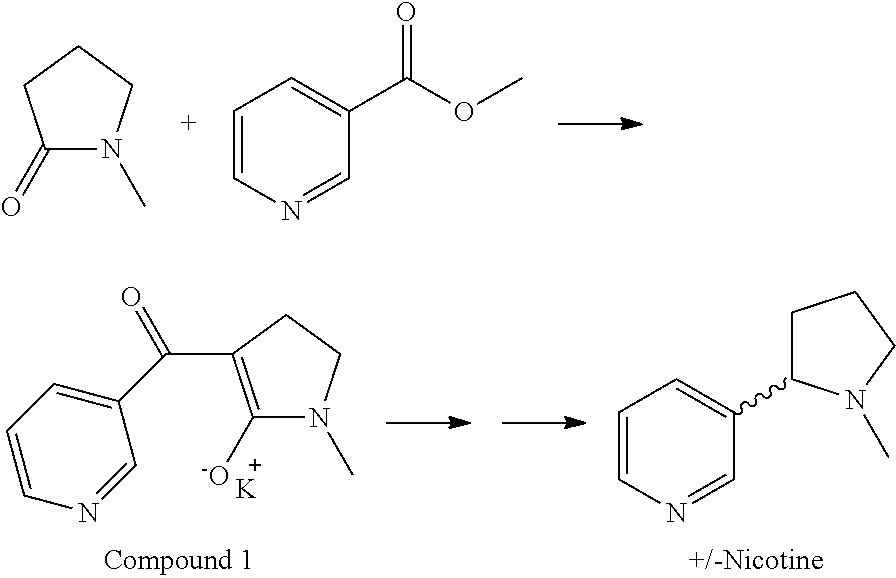

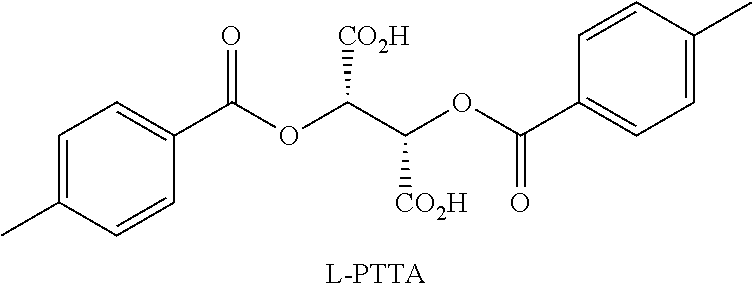

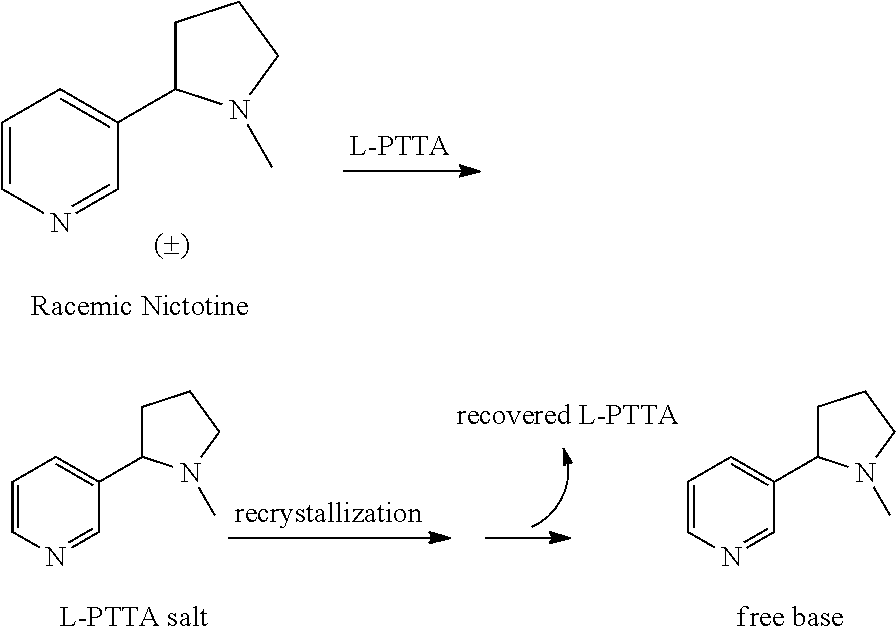

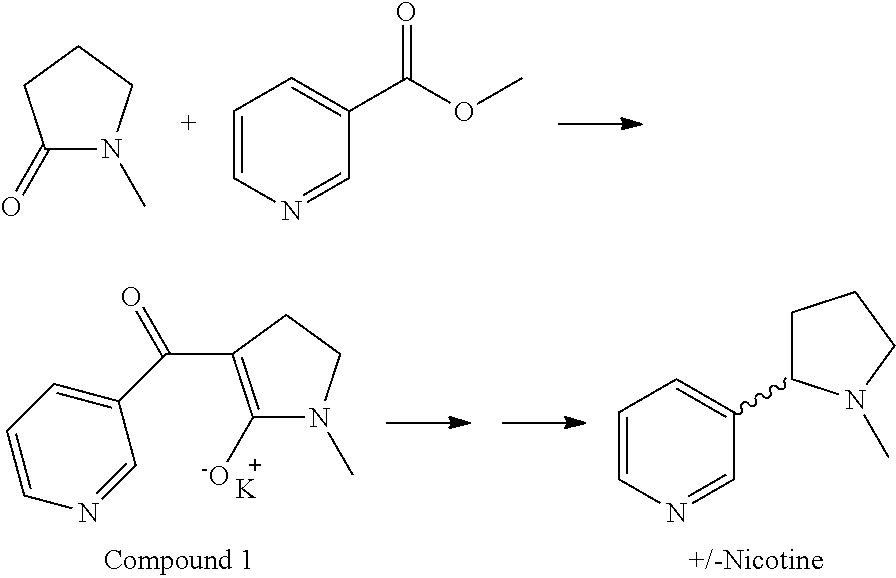

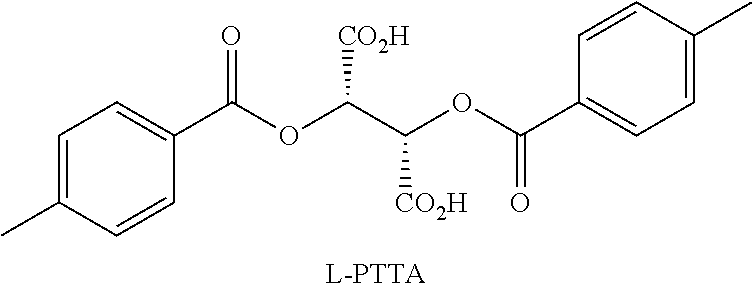

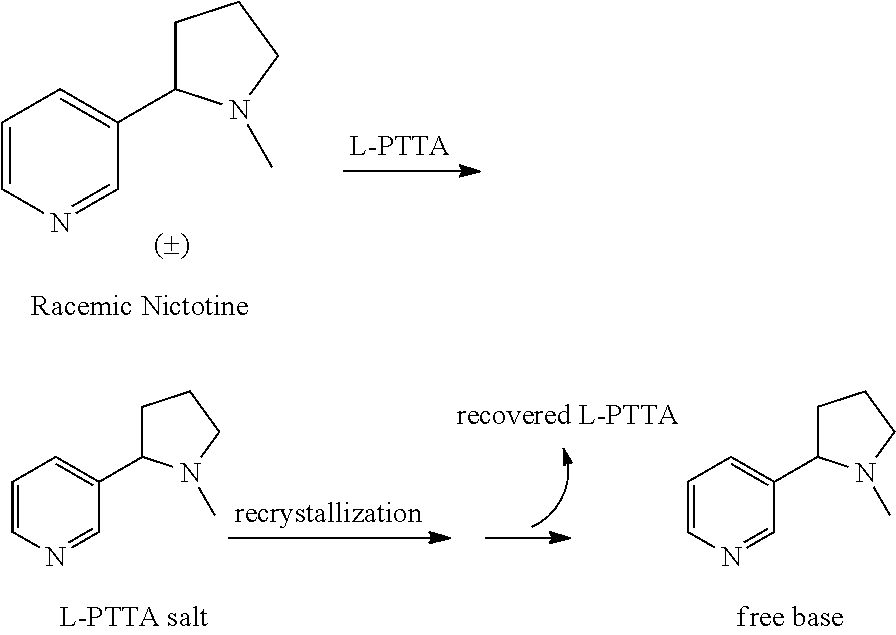

Synthesis and resolution of nicotine

The present disclosure generally relates to methods of preparing nicotine and resolving R,S nicotine to enrich the (S)(−) enantiomer. The method may comprise combining N-methyl-2-pyrrolidone or a salt thereof with a nicotinate compound in the presence of a solvent and a strong base to form 1-methyl-3-nicotinoyl-2-pyrrolidone or a salt thereof; and reducing the 1-methyl-3-nicotinoyl-2-pyrrolidone or salt thereof in solution with Na2S2O4 to produce racemic nicotine or salt thereof. Resolving the racemic nicotine (or other enantiomeric mixture) may comprise combining the nicotine with (−)-O,O′-di-p-toluoyl-L-tartaric acid (L-PTTA).

Owner:NJOY LLC

Production of LixCoO2 from recovering waste lithium ionic battery

InactiveCN1747224AHigh specific surface area of powderLarge specific surface areaReclaiming serviceable partsWaste accumulators reclaimingNitrateChloride

The method includes following steps: cut off batteries; separate anode materials, and cut the anode material into pieces; the anode pieces are steeped into N-Methyl-2-Pyrrolidone liquor, and are heated to separate activating material LiCoO2, and then acquire black powder. The black powder is putted into nitric acid solution or spirit of salt, and after filtering the nitric acid solution or chloride solution containing Co2+,Li+ ion is acquired. NH3íñN2O is added into Co2+,Li+ ion acidic solution, and meanwhile add surfactant; LiOH is added into suspension to adjust concentration of Li+ in suspension; the suspension is filtered and dried, then is sintered at 600-900 Deg C. to acquire LixCoO2 powder.

Owner:TIANJIN UNIV +1

High-performance flat plate type cellulose acetate/nano-titanium dioxide blended forward osmosis membrane

ActiveCN104474920AControl performancePollution resistantSemi-permeable membranesCellulose acetateN-Methyl-2-pyrrolidone

The invention discloses a high-performance flat plate type cellulose acetate / nano-titanium dioxide blended forward osmosis membrane, which is prepared by comprising the following steps: adding the following raw materials in percentage by weight: 7.0%-26.0% of cellulose acetate, 2.0%-16.0% of additives, 0.1%-5.0% of nano-titanium dioxide, 0.05%-0.1% of graphene, and a dimethylformamide or dimethylacetamide, N-methylpyrrolidine and acetone mixed solvent into a dissolving tank according to certain sequence, stirring and dissolving for 3-15h to be full and even at 25-90DEG C, thus obtaining blended forward osmosis membrane casting liquid; and preparing the high-performance flat plate type cellulose acetate / nano-titanium dioxide blended forward osmosis membrane on a supporting material by using a phase conversion method. According to the prepared forward osmosis membrane, 1M NaCl and deionized water are respectively taken as driving liquid and feed solution, the flux of pure water can reach more than 17.5L / m<2>.h during testing time of1h and the backward salt flux is less than 3.0g / m<2>.h.

Owner:UNIV OF JINAN

Synthesis and resolution of nicotine

The present disclosure generally relates to methods of preparing nicotine and resolving R,S nicotine to enrich the (S)(−) enantiomer. The method may comprise combining N-methyl-2-pyrrolidone or a salt thereof with a nicotinate compound in the presence of a solvent and a strong base to form 1-methyl-3-nicotinoyl-2-pyrrolidone or a salt thereof; and reducing the 1-methyl-3-nicotinoyl-2-pyrrolidone or salt thereof in solution with Na2S2O4 to produce racemic nicotine or salt thereof. Resolving the racemic nicotine (or other enantiomeric mixture) may comprise combining the nicotine with (−)-O,O′-di-p-toluoyl-L-tartaric acid (L-PTTA).

Owner:NJOY LLC

Process for separating aromatics by extractive distillation and a composite solvent used therein

InactiveUS7078580B2Improve solubilityWide boiling rangeDistillation purification/separationHydrocarbonsSulfolaneAlkalinity

This application relates to a composite solvent for separating aromatics by extractive distillation, comprising a main solvent, a solutizer and a modifier. Said solutizer is selected from any one or mixtures of any two of C8–C11 aromatics having different number of carbon atoms, the content of which is 3–39 wt %, and the number of carbon atoms of the lowest aromatic in the solutizer should be greater than that of the highest aromatic in the aromatics to be separated. When the solutizer is selected from any one of C8–C11 aromatics, the composite solvent contains 0.01–10.0 wt % of the modifier; when the solutizer is selected from mixtures of any two of C8–C11 aromatics having different number of carbon atoms, the composite solvent contains 0–10.0 wt % of the modifier. Said main solvent and modifier are independently selected from sulfolane derivatives, N-formyl morpholine, and N-methyl pyrrolidone, provided that the acidity and basicity of the modifier are opposite to those of the main solvent. When the composite solvent is used to recover aromatics by extractive distillation, it is possible to moderate the operation conditions of solvent recovery, increase the yield of aromatics, and make the separated aromatics to be neutral.

Owner:CHINA PETROCHEMICAL CORP +1

Positive electrode sheet of lithium iron phosphate type lithium ion battery, and preparation method thereof

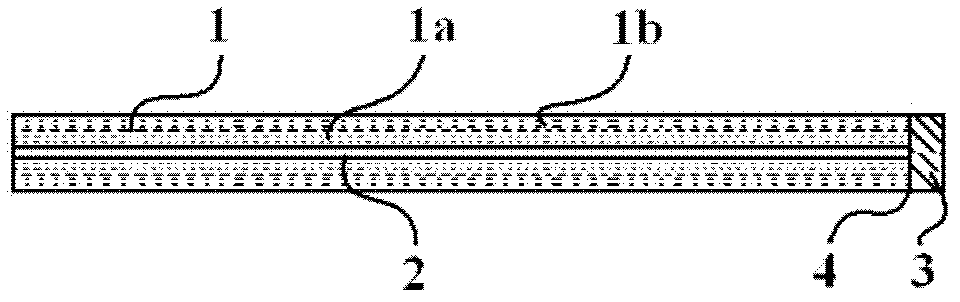

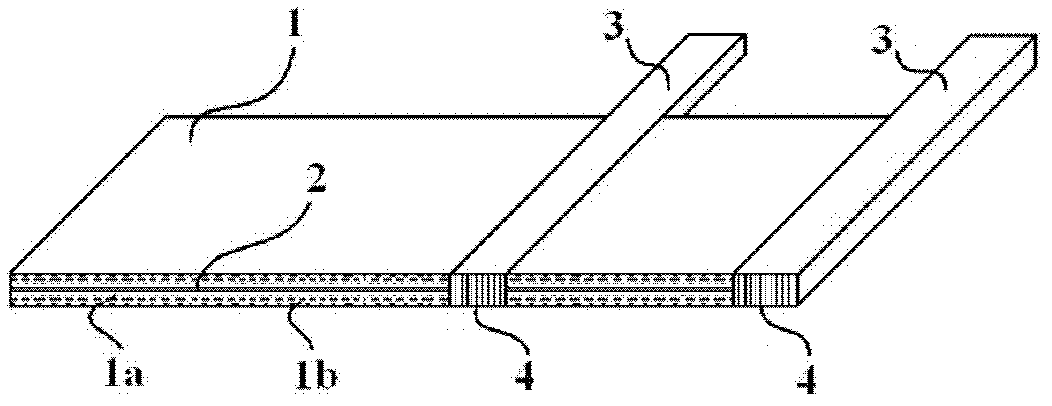

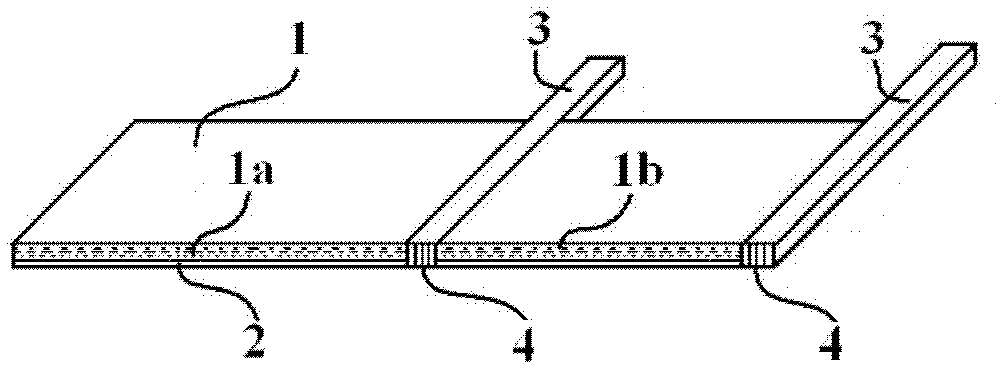

The present invention discloses a positive electrode sheet of a lithium iron phosphate type lithium ion battery, and a preparation method thereof. According to the present invention, a positive active material coating comprise a nano-lithium iron phosphate positive active material coating a and a nano-lithium iron phosphate positive active material coating b; nano-lithium iron phosphate positive active material slurry a is coated on a current collector; nano-lithium iron phosphate positive active material slurry b is coated on the nano-lithium iron phosphate positive active material coating a; electrode lugs are spot welded on reserved blank of the current collector. The method comprises the following steps that: A, a lithium iron phosphate positive active material is respectively mixed with a nano carbon black conductive agent, a polyvinylidene difluoride agglomerant and a N-methylpyrrolidone solvent according to the ratio to prepare the nano-lithium iron phosphate positive active material slurry a and the nano-lithium iron phosphate positive active material slurry b; B, the slurry prepared from the lithium iron phosphate are coated on a side or both sides of the current collector having a certain thickness to form the coatings; C, the positive electrode sheet having coatings is prepared. The lithium iron phosphate type lithium ion battery has characteristics of high capacity, high rate, good effect. With the positive electrode sheet provided by the present invention, the service life of the lithium ion battery is prolonged.

Owner:广州云通锂电池股份有限公司

Non-aqueous pharmaceutical composition

InactiveUS20090233912A1Free from irritationSolubility issueBiocideNervous disorderPropylene carbonatePropylene glycol

A composition for intranasal delivery of a drug comprising: includes: (i) the drug; and (ii) a non-aqueous vehicle containing (a) propylene glycol and at least one additional solvent selected from N-methylpyrrolidone, propylene carbonate, dimethyl sulfoxide and at least one propylene glycol fatty acid ester; (b) from about 40 to 100% by volume of N-methylpyrrolidone; or (c) from about 40 to 100% by volume of dimethyl sulfoxide (DMSO).

Owner:ARCHIMEDES DEVMENT

Preparation method for three-dimensional carbon nanotube/nitrogen-doped graphene/sulfur electrode slice

InactiveCN105609736AReduce Shuttle EffectImprove cycle lifeCell electrodesLi-accumulatorsSulfur electrodeCarbon nanotube

The invention provides a preparation method for a three-dimensional carbon nanotube / nitrogen-doped graphene / sulfur electrode slice. The preparation method comprises the following steps of (1) adding the carbon nanotube, graphite oxide and polyacrylonitrile to N-methyl pyrrolidone, performing an ultrasonic reaction, coating an aluminium foil with mixed paste, and performing vacuum drying to obtain the electrode slice; (2) putting the obtained electrode slice into a muffle furnace under ammonia gas protection, heating to 400-500 DEG C, and naturally cooling; and (3) enabling the electrode slice obtained in the step (2) to be fully inserted into a Na2S2O3 solution, and slowly adding hydrochloric acid to the solution in a dropwise manner until the PH value of the solution reaches 6.5-7.5, taking out the electrode slice, and drying the electrode slice to obtain a positive plate. The electrode slice prepared by the invention can be directly used for the positive electrode of a lithium-sulfur battery without requiring a conductive agent and a binder, so that the cost of the electrode is greatly lowered.

Owner:钟玲珑

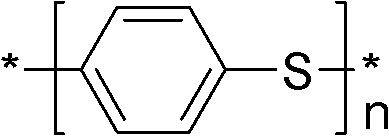

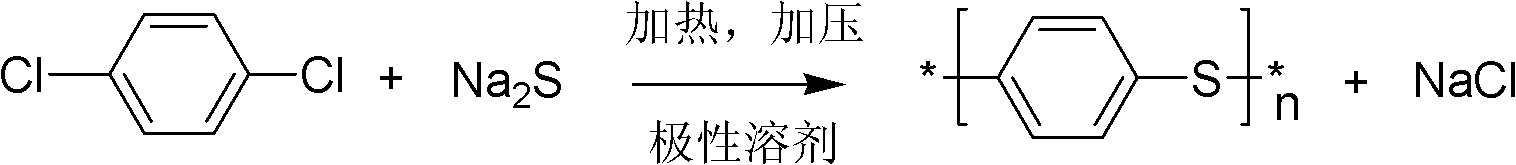

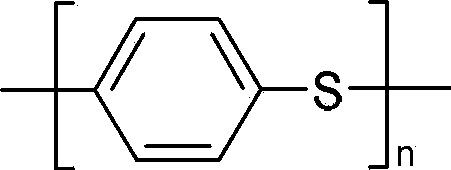

Method for synthesizing low-color high-purity fiber-grade polyphenylene sulfide resin

ActiveCN103073720AThe average molecular weight is largeMolecular distribution index is smallMonocomponent synthetic polymer artificial filamentFiberPolymer science

The invention discloses a method for synthesizing low-color high-purity fiber-grade polyphenylene sulfide resin. According to the invention, sodium sulfide and p-dichlorobenzene are adopted as raw materials; N-methyl pyrrolidone, N,N-dimethyl acetamide, and the like are adopted as solvents; under the existence of a basic salt, through a four-step method comprising pre-polymerization, polymerization, chain extension and end-capping, the high-purity low-color fiber-grade polyphenylene sulfide resin is synthesized. By adjusting process parameters, polyphenylene sulfide average molecular weight and distribution index can be effectively controlled. Also, purification process can be simplified, and metal ion embedding can be reduced. Resin slice color is reduced, resin processing stability is improved, and resin performance is improved.

Owner:CHINA PETROLEUM & CHEM CORP

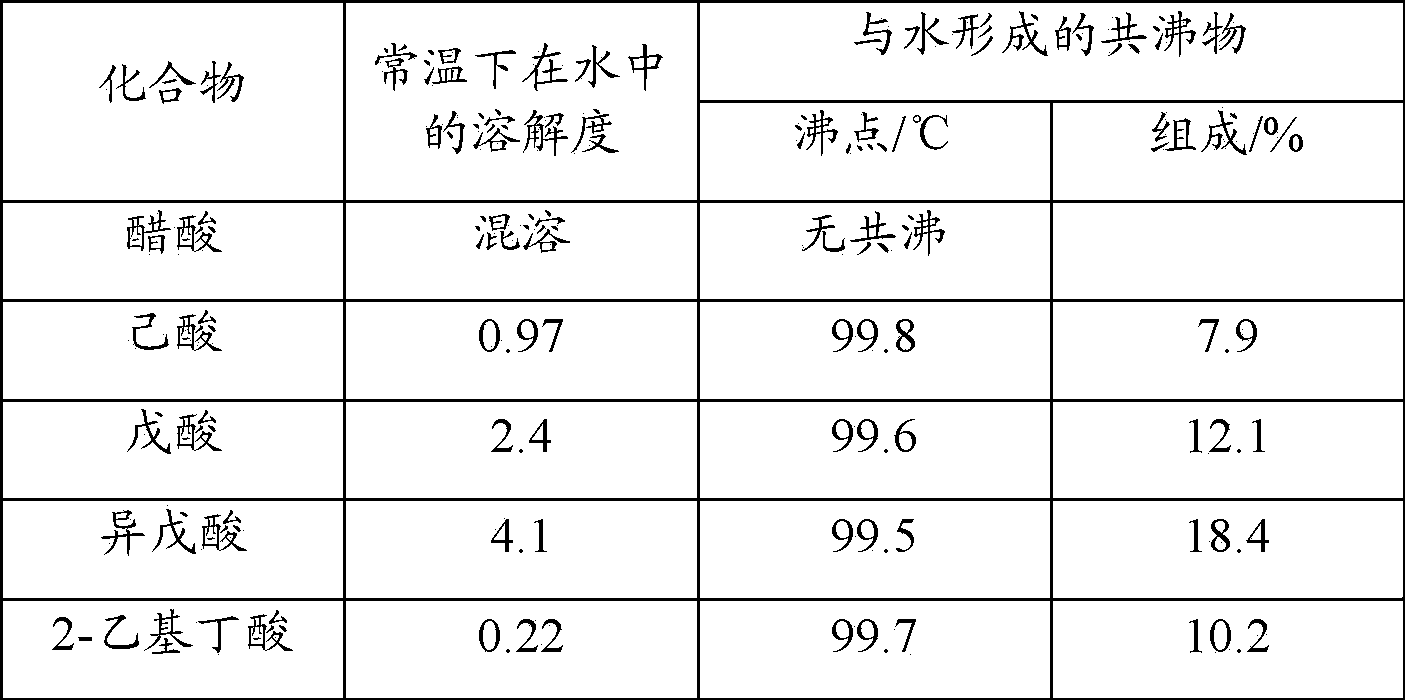

Synthesis method of fiber-grade polyphenylene sulfide (PPS) resin

Disclosed is a method for synthesizing a fibre-grade polyphenylene sulphide resin, comprising synthesizing via a polycondensation reaction by using a sodium hydrosulphide solution and p-dichlorobenzene as raw materials, N-methyl-2-pyrrolidone as a solvent, and a C5-C6 fatty acid salt formed by dehydration of a C5-C6 fatty acid and sodium hydroxide as an auxiliary for the polycondensation reaction. The reaction liquid is subjected to acidification and washing to obtain a white polyphenylene sulphide resin, the melt flow rate of the product is less than 125 g / 10 min, the weight-average molecular weight measured by GPC is greater than 4.2 × 104, and the whiteness is higher than 90, meeting the requirements of the fibre-grade polyphenylene sulphide resin. In the method of the present invention, the C5-C6 fatty acid salt used has good solubility in NMP and can better promote the polycondensation reaction, all of it enters a filtrate after reaction and filtration, and it is again converted into a free fatty acid through acidification with hydrochloric acid; and the C5-C6 fatty acid can co-boil with water, has low solubility in water, and can be recovered from the filtrate by the method of co-boiling with water, thereby avoiding the problem that both the auxiliary and sodium chloride are dissolved in water and cannot be separated and recovered.

Owner:ZHEJIANG NHU SPECIAL MATERIALS +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com