Positive electrode sheet of lithium iron phosphate type lithium ion battery, and preparation method thereof

A lithium-ion battery and lithium iron phosphate technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of poor high-current discharge effect, short cycle life, and difficult to meet, and achieve improved discharge specific capacity and capacity, The effect of improving the cycle life and increasing the effective feeding amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

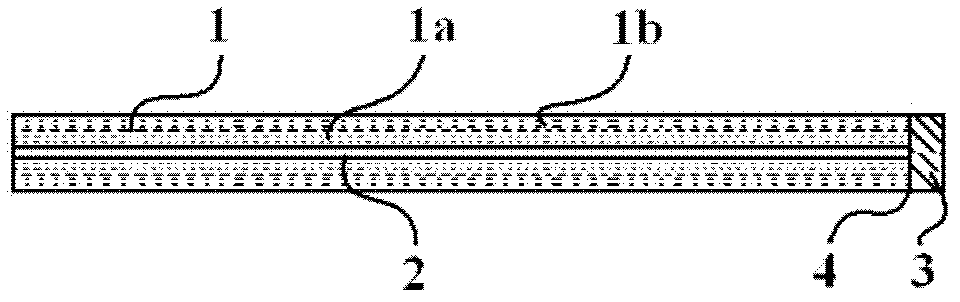

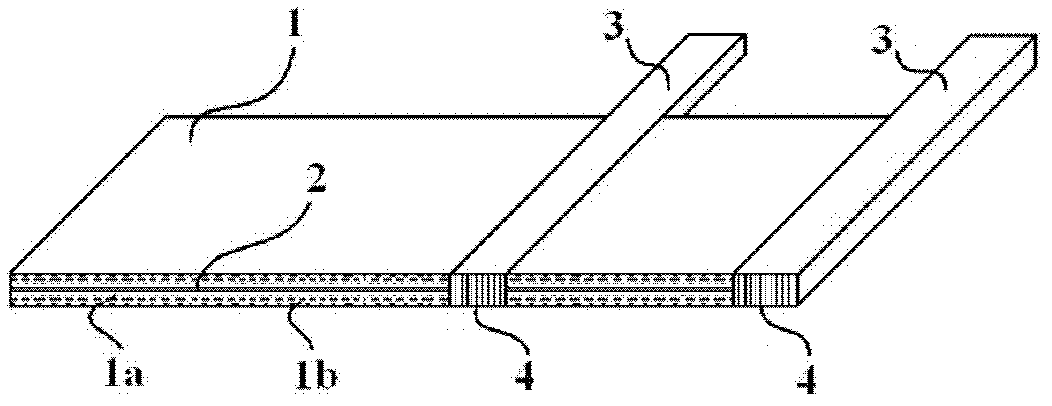

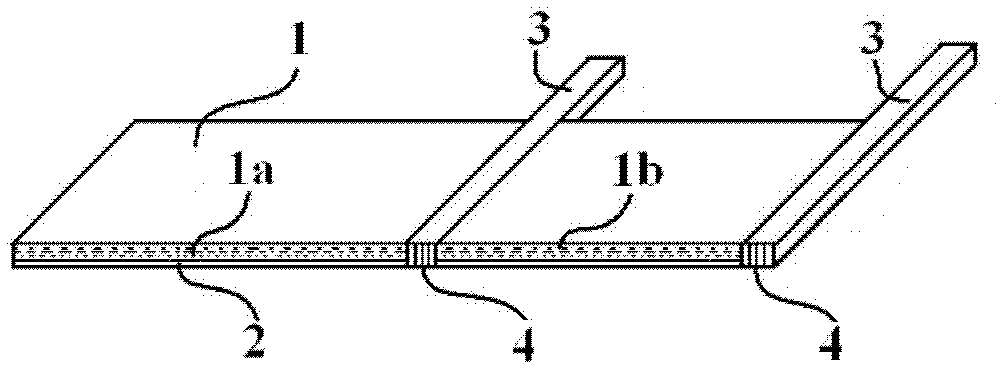

[0032] A lithium iron phosphate lithium ion battery cathode sheet, comprising a positive electrode active material coating 1 (a finer nanometer lithium iron phosphate positive electrode active material coating 1a, a thicker nanometer lithium iron phosphate positive electrode active material coating 1b), a set The fluid 2 and the tab 3 are formed, and a blank space 4 for spot welding the tab 3 is reserved at one end of the current collector 2 and the designed position. It is characterized in that: the positive electrode active material coating 1 is composed of nano-lithium iron phosphate positive electrode active material coating 1a, nano-lithium iron phosphate positive electrode active material slurry 1b, and the nano-lithium iron phosphate positive electrode active material slurry a is coated on the current collector 2 Above, the nano-lithium iron phosphate positive electrode active material slurry b is coated on the nano-lithium iron phosphate positive electrode active materi...

Embodiment 2

[0044] A kind of manufacture method of lithium iron phosphate type lithium ion battery positive pole sheet, its steps are:

[0045] A. Combine lithium iron phosphate cathode active materials with particle sizes of 1-20nm and 20-200nm with nano-carbon black (Super-C) conductive agent, polyvinylidene fluoride (PVDF) binder and N-methylpyrrolidone respectively (NMP) solvent, mixed according to the mass ratio of 85:4:4:90, ball milled for 5 hours under the condition of nitrogen protection, mixed evenly, and made into nano-lithium iron phosphate cathode active material slurry a and nano-lithium iron phosphate positive electrode active material slurry b;

[0046] B. The nano-lithium iron phosphate positive electrode active material slurry a prepared by the lithium iron phosphate with a particle size of 1 to 20 nm in step (A) is coated on both sides of the positive electrode current collector with a thickness of 0.01 mm through an intermittent coating process ( 2) On the aluminum fo...

Embodiment 3

[0055] A kind of manufacture method of lithium iron phosphate type lithium ion battery positive pole sheet, its steps are:

[0056] A. Combine lithium iron phosphate cathode active materials with particle sizes of 1-20nm and 20-200nm with nano-carbon black (Super-C) conductive agent, polyvinylidene fluoride (PVDF) binder and N-methylpyrrolidone respectively (NMP) solvent, mixed according to the mass ratio of 90:5:5:100, ball milled for 2 hours under the condition of nitrogen protection, mixed evenly, and made into nano-lithium iron phosphate cathode active material slurry a and nano-lithium iron phosphate positive electrode active material slurry b;

[0057] B. The nano-lithium iron phosphate positive electrode active material slurry a prepared by step (A) with a particle size of 1 to 20 nm lithium iron phosphate is coated on one side with a thickness of 0.085 mm on a positive electrode current collector ( 2) On the aluminum foil, dry at 65°C for 10 minutes, so that the posit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com