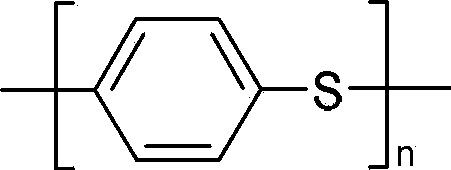

Synthesis method of fiber-grade polyphenylene sulfide (PPS) resin

A technology of polyphenylene sulfide resin and synthesis method, which is applied in the field of synthetic polyphenylene sulfide resin, can solve the problems of difficult recycling of sodium acetate and lithium chloride, etc., and achieve the reduction of "three wastes" treatment volume, production cost and recovery rate high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

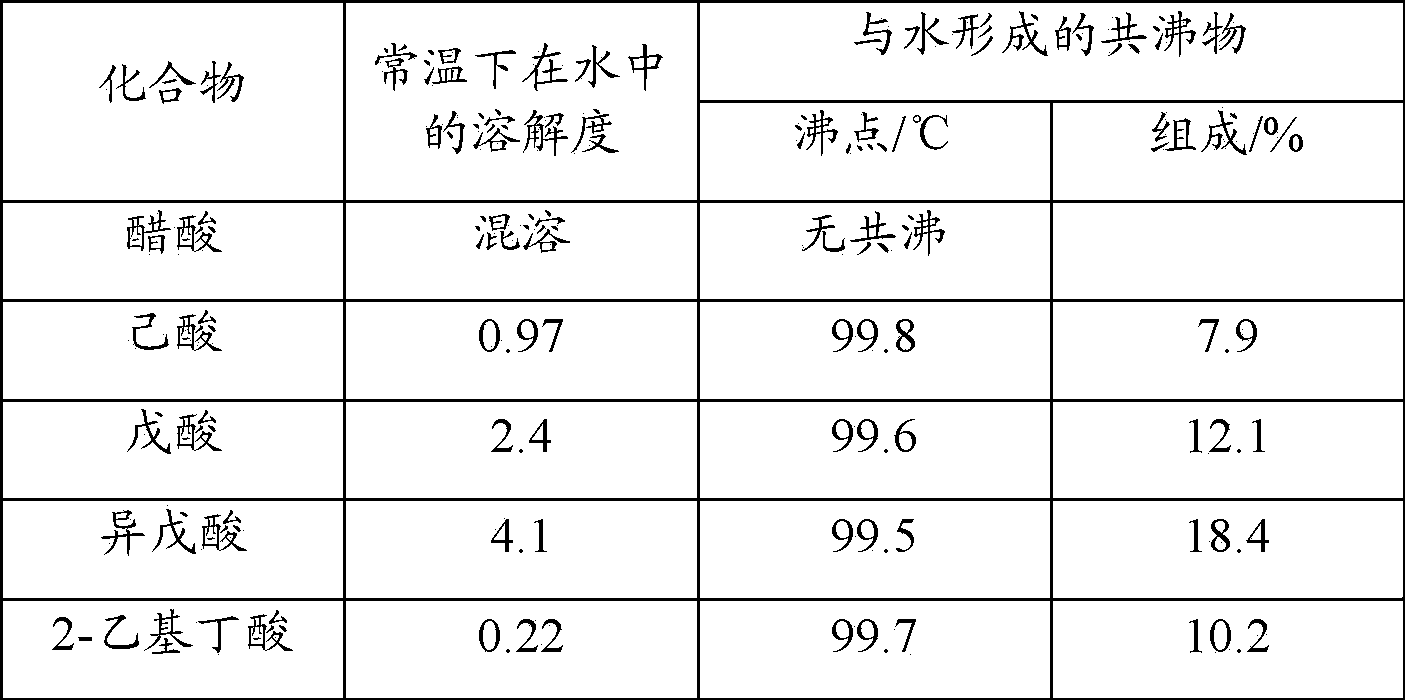

[0048] In the 100L reactor, add N-methyl-2-pyrrolidone (hereinafter referred to as NMP) 29.74Kg (300.0mol), 40% sodium hydroxide 13.0Kg (130.0mol) and hexanoic acid 3.485Kg (30.0mol), at 300rpm Under stirring speed and nitrogen protection, heat up to 120°C at a speed of 2.0°C / min, and keep warm for 1 hour; after the heat preservation is completed, heat up to 200°C at a speed of 2.0°C / min, and remove 8.74Kg of aqueous solution (water content 97.88%) , and then lower the temperature to 130°C. Add 40% sodium hydrosulfide 14.02Kg (100.0mol), NMP 4.09Kg (41.3mol), under the same stirring speed, heat up to 200°C at a speed of 1.5°C / min, remove 9.71Kg aqueous solution (water content 86.59%), After dehydration is completed, the temperature is lowered to 160°C. At this time, the amount of sulfur in the system was 99.0 mol, and the water content was 87.8 mol.

[0049]Add 14.55Kg (99.0mol) of p-dichlorobenzene (hereinafter referred to as PDCB) and 10.38Kg (104.8mol) of NMP into the abo...

Embodiment 2

[0053] In a 100L reactor, add 29.74Kg (300.0mol) of N-methyl-2-pyrrolidone (hereinafter referred to as NMP), 11.56Kg (130.0mol) of 45% sodium hydroxide and 3.485Kg (30.0mol) of 2-ethylbutyric acid ), under the stirring speed of 100rpm and nitrogen protection, with the speed of 1.0 DEG C / min, be warming up to 90 DEG C, be incubated 3 hours; Insulation finishes, be warming up to 180 DEG C with the speed of 1.0 DEG C / min, remove 7.12Kg aqueous solution ( water content 97.23%), then lower the temperature to 110°C. Add 40% sodium hydrosulfide 14.02Kg (100.0mol), NMP 4.09Kg (41.3mol), under the same stirring speed, heat up to 180°C at a speed of 0.7°C / min, remove 9.58Kg aqueous solution (water content 87.81%), After dehydration is completed, the temperature is lowered to 140°C. At this time, the amount of sulfur in the system was 99.1 mol, and the water content was 98.8 mol.

[0054] Add 14.63Kg (99.5mol) of p-dichlorobenzene (hereinafter referred to as PDCB) and 10.28Kg (103.8mol...

Embodiment 3

[0058] In the 100L reactor, add N-methyl-2-pyrrolidone (hereinafter referred to as NMP) 27.76Kg (280.0mol), 40% sodium hydroxide 11.0Kg (110.0mol) and valeric acid 1.021Kg (10.0mol), at 200rpm Under the stirring speed of 1.5 DEG C / min and under the protection of nitrogen, the temperature was raised to 100 DEG C at a speed of 1.5 DEG C / min, and the temperature was kept for 2 hours; after the heat preservation was completed, the temperature was raised to 190 DEG C at a speed of 1.5 DEG C / min, and 7.03Kg of aqueous solution (water content 97.52% ), and then lower the temperature to 110°C. Add 30% sodium hydrosulfide 18.69Kg (100.0mol), NMP 5.69Kg (57.5mol), under the same stirring speed, heat up to 190°C at a speed of 1.5°C / min, remove 14.88Kg aqueous solution (water content 87.95%), After dehydration is completed, the temperature is lowered to 150°C. At this time, the amount of sulfur in the system was 99.0 mol, and the water content was 96.3 mol.

[0059] Add 148.4Kg (101.0mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com