Patents

Literature

909 results about "Hexanoic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hexanoic acid, also known as caproic acid, is the carboxylic acid derived from hexane with the chemical formula CH3(CH2)4COOH. It is a colorless oily liquid with an odor that is fatty, cheesy, waxy, and like that of goats or other barnyard animals. It is a fatty acid found naturally in various animal fats and oils, and is one of the chemicals that give the decomposing fleshy seed coat of the ginkgo its characteristic unpleasant odor. It is also one of the components of vanilla. The primary use of hexanoic acid is in the manufacture of its esters for artificial flavors, and in the manufacture of hexyl derivatives, such as hexylphenols. Salts and esters of hexanoic acid are known as hexanoates or caproates.

Flavor enhancing methods

InactiveUS6287620B1Improve roundnessEnhances juicy characterMilk preparationDough treatmentKetopinic acidPropanoic acid

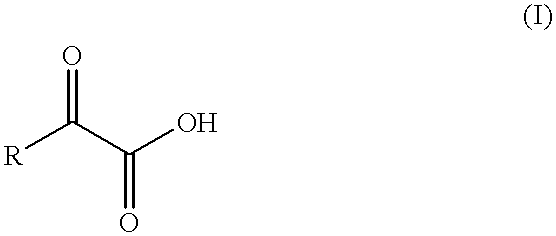

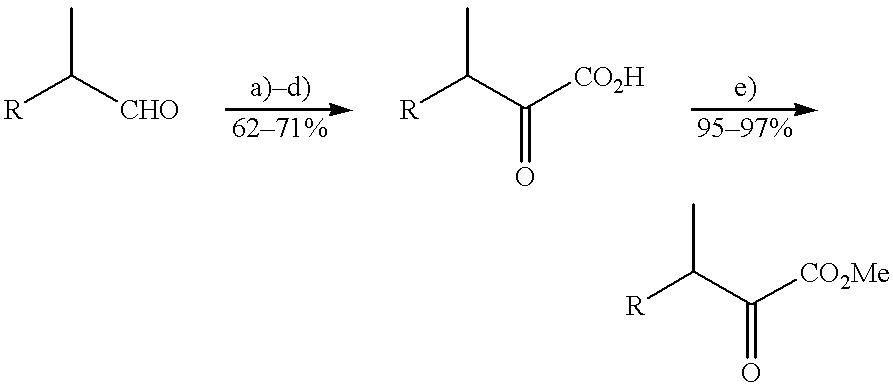

alpha-keto acids and certain precursors and derivatives thereof, particularly those selected from the group which consists of glyoxylic acid, 2-oxo-propanoic acid, 2-oxo-butanoic acid, 3-methyl-2-oxo butanoic acid, 3-methyl-2-oxo pentanoic acid, 4-methyl-2-oxo pentanoic acid, 3-hydroxy-2-oxo-propanoic acid, oxalacetic acid, 2-oxo-glutaric acid, 2-oxo-3-phenyl-propanoic acid, 3-(4-hydroxy-phenyl)-2-oxo-propanoic acid, 2-oxo-1H-indole-3-propanoic acid, 2-oxo-1H-imidazole-4-propanoic acid, 4-methylthio-2-oxo-butanoic acid, 3-mercapto-2-oxo-propanoic acid, 3-hydroxy-2-oxo-butanoic acid, 6-amino-2-oxo-hexanoic acid and 5-guanido-2-oxo-pentanoic acid, and precursors and derivatives thereof that are capable of being formed from or releasing said acids in the use medium, are useful as flavouring ingredients. Such ingredients are useful for preparing flavouring compositions and a wide variety of flavoured foodstuffs to which they impart greater creaminess and bulkiness so that they have heightened effect in the mouth and generally an enhanced mouthfeel. They are also useful for enhancing the sweetness of foods sweetened with natural or artificial sweeteners, and giving it a more natural character.

Owner:FIRMENICH SA

Process for preparing GAMM-hexalactone, products produced therefrom dan organoleptic uses of said products

A process for producing high yields of gamma -hexalactone and 2-pentanone from the corresponding hexanoic acid starting material is carried out with high amounts of oxygen and sugar in the presence of a mold microorganism. Fragrance compositions and foodstuff compositions are augmented and enhanced by the presence of the product compounds.

Owner:INTERNATIONAL FLAVORS & FRAGRANCES

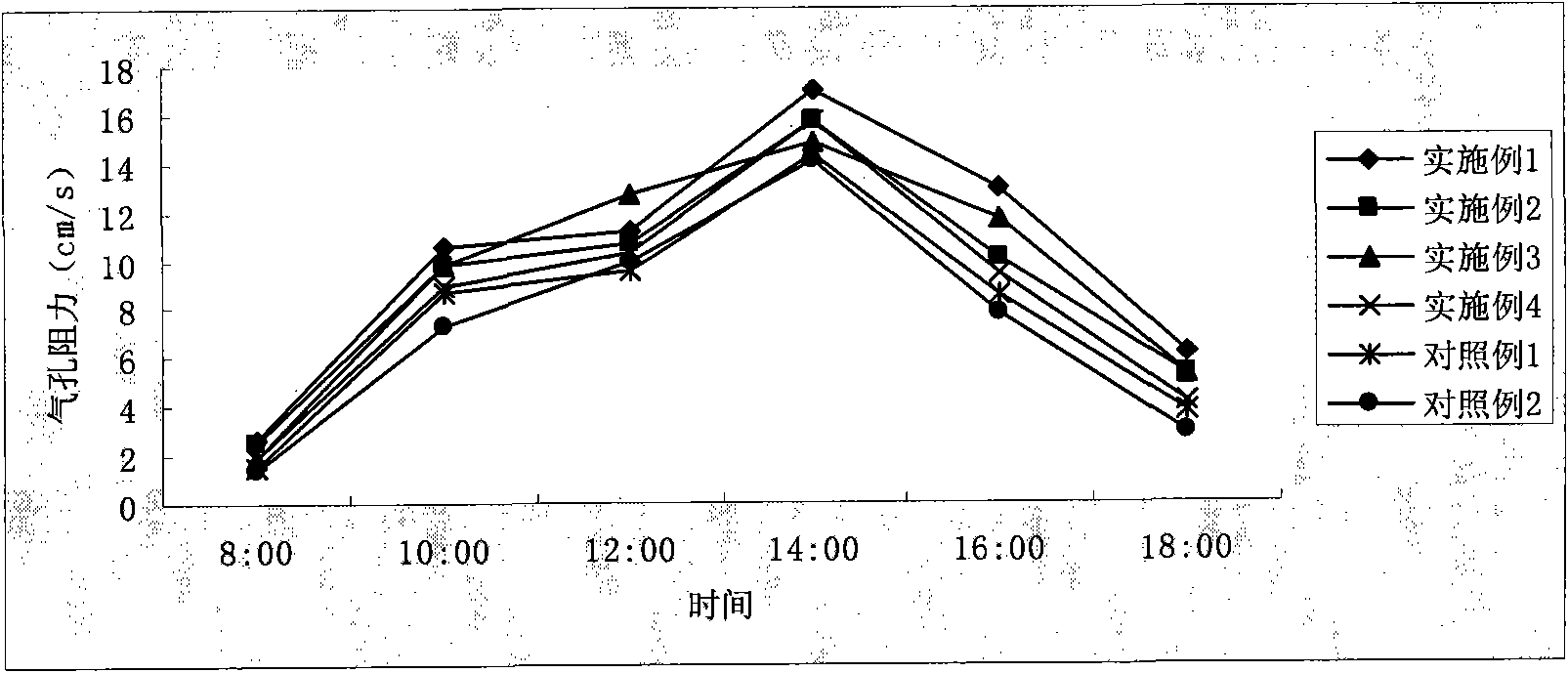

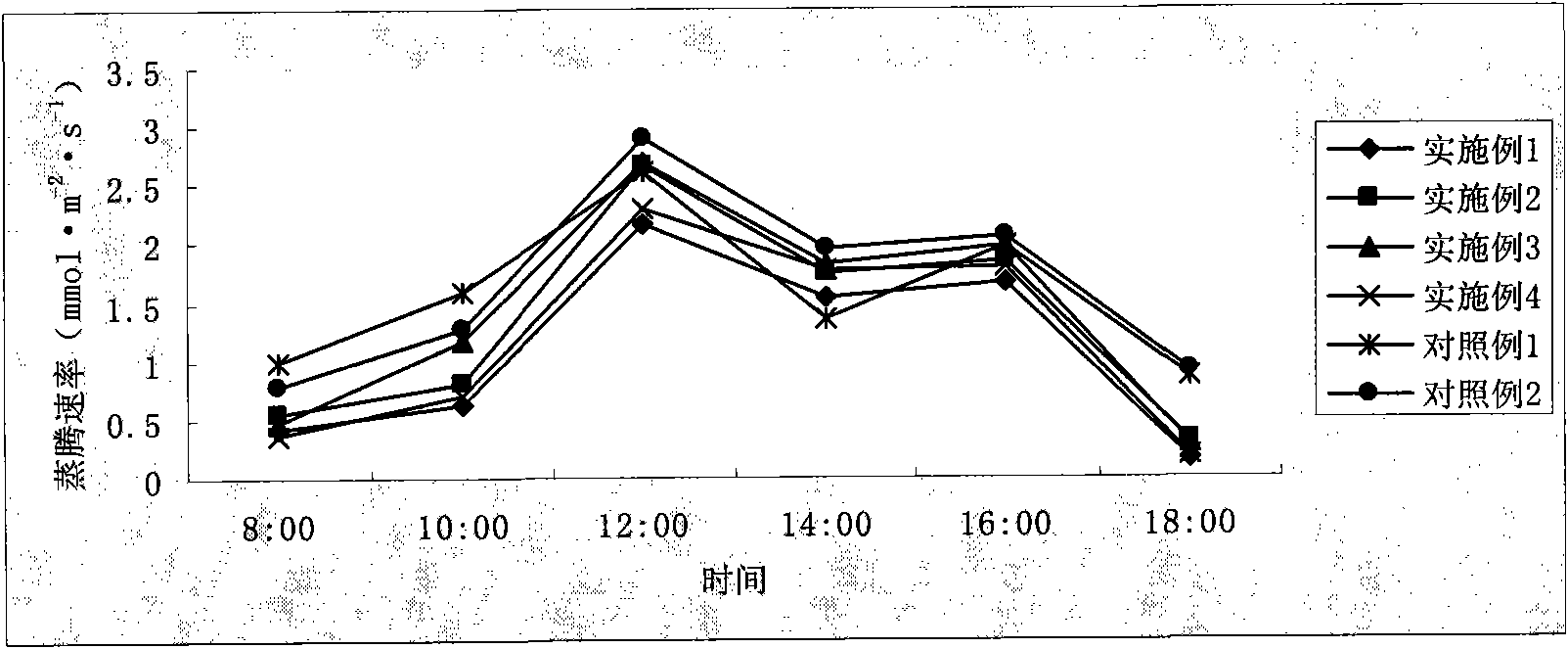

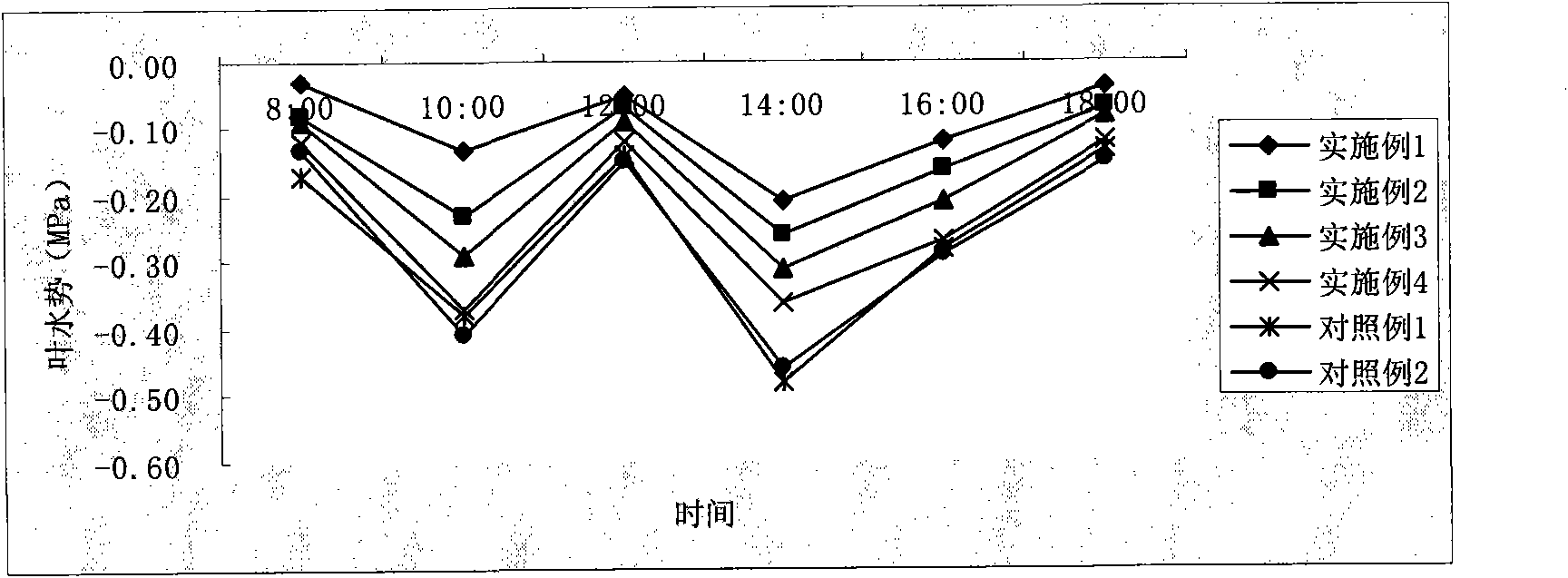

Antitranspirant foliar fertilizer and preparation method thereof

ActiveCN101913941AThe ratio is scientific and reasonableImprove solubilityFertilizer mixturesMicrobial agentMonopotassium phosphate

The invention discloses an antitranspirant foliar fertilizer and a preparation method thereof. The antitranspirant foliar fertilizer comprises the raw materials of copper sulfate, ethylene diamine tetraacetic acid, monopotassium phosphate, zinc sulfate, ferrous sulphate, manganese sulphate, ammonium molybdate, composite rare earth, boric acid, sodium dodecyl sulphonate, urea, fulvic acid, hexanoic acid 2-(diethylamino) ethyl ester, compound amino acid, magnesium sulfate, calcium nitrate, ethylene diamine tetraacetic acid, microbial agent, azone and ammonia water. The antitranspirant foliar fertilizer provides nutrient elements and microbial agents which are required by the growth of plants, the rare earth and amino acid and other beneficial elements, can promote the growth of the plants, improve the yield, the quality, the stress resistance of the plants and the absorbing and operating capabilities on trace elements, simultaneously can effectively reduce the transpiration of the plants and is applied to afforesting in arid regions.

Owner:SHENZHEN TECHAND ECOLOGY & ENVIRONMENT CO LTD

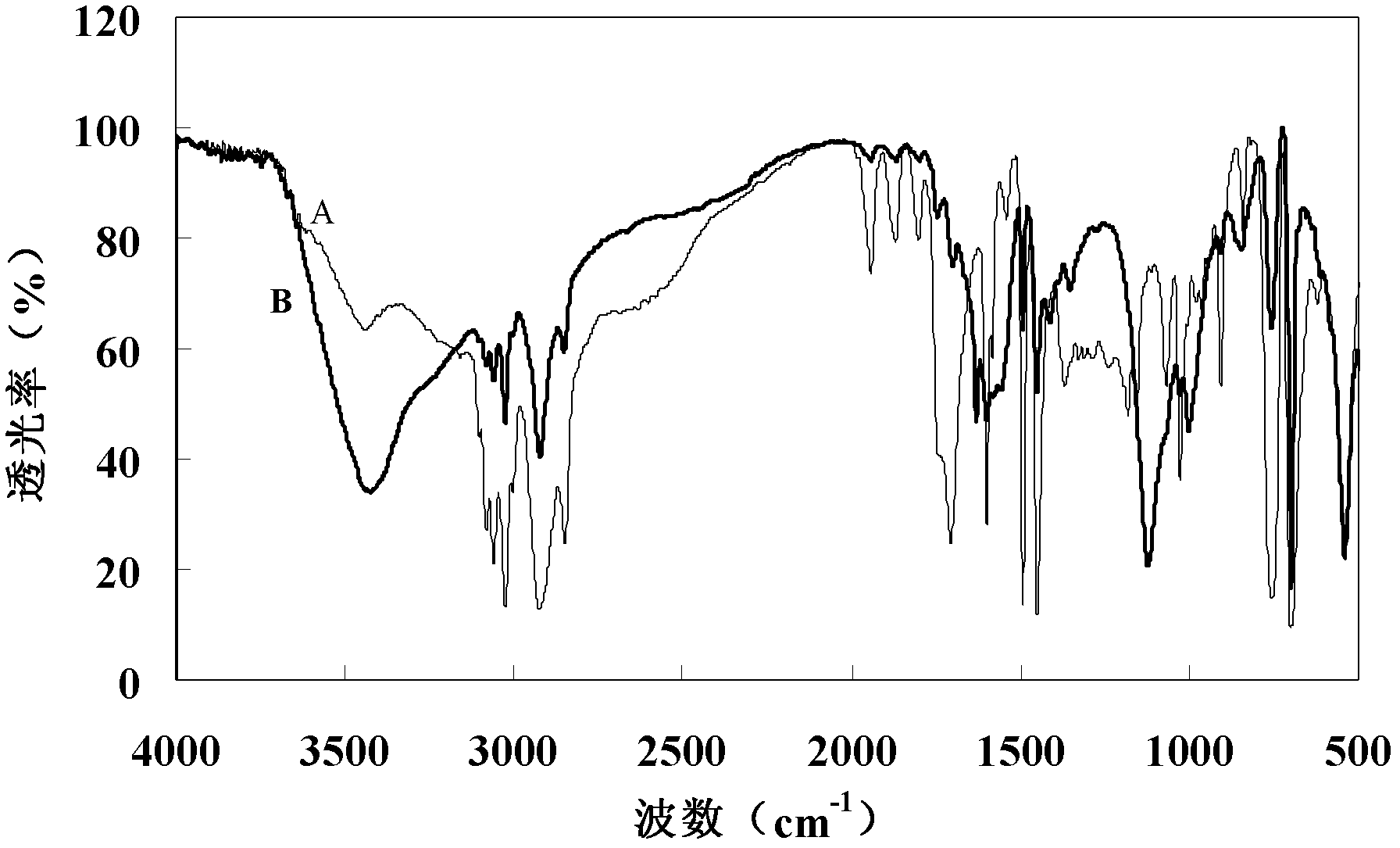

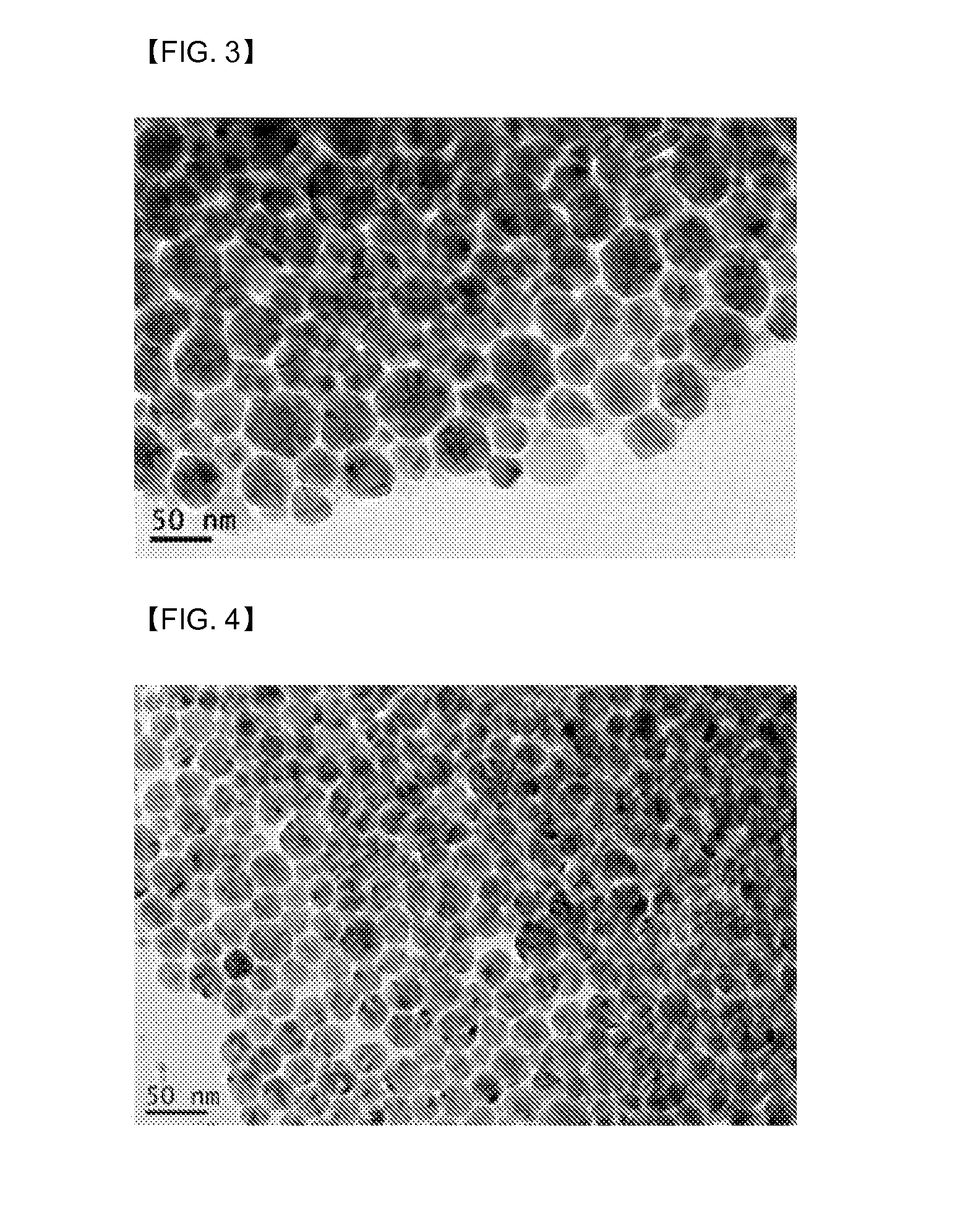

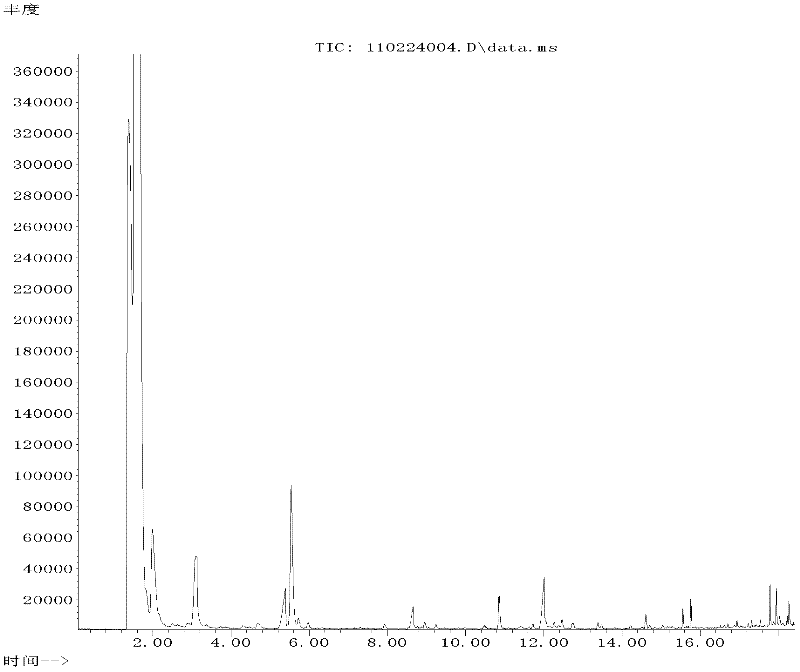

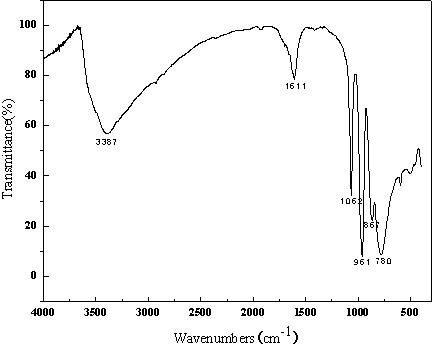

Preparation of antibacterial silver/chitosan nano fiber membrane

InactiveCN101297976AImprove mechanical propertiesRemain biodegradableSurgeryFilament/thread formingFiberStaphylococcus aureus

The invention discloses a preparation method of antibacterial silver / chitosan nano fibrous membranes, pertaining to the preparative technologies of nano composite fibrous membranes. The process of the method includes that a chitosan hexanoic acid solution, a silver nitrate aqoeous solution, a sodium borohydride water solution and an ethylene epoxide hexanoic acid solution are prepared and mixed to form compounded latex according to the volume ratios of the chitosan hexanoic acid solution and the silver nitrate aqoeous solution as well as an NaBH4 aqueous solution. The compounded latex and the ethylene epoxide hexanoic acid solution are mixed according to the volume ration to prepare a spinning solution, then the spinning solution is added into an injector in an electrostatic spinning device and electrostatic spinning is carried out to form the fibrous membrane. Crosslinking treatment is carried out to the fibrous membrane to obtain the antibacterial silver / chitosan nano fibrous membrane. The antibacterial silver / chitosan nano fibrous membrane of the invention has the advantages that the preparation process is simple; the prepared membrane material has broad-spectrum bactericidal property and comparatively high fatality rate to Bacillus coli, Bacillus subtilis, Staphylococcus aureus and Pseudomonas aeruginosa for 24 hours.

Owner:TIANJIN UNIV

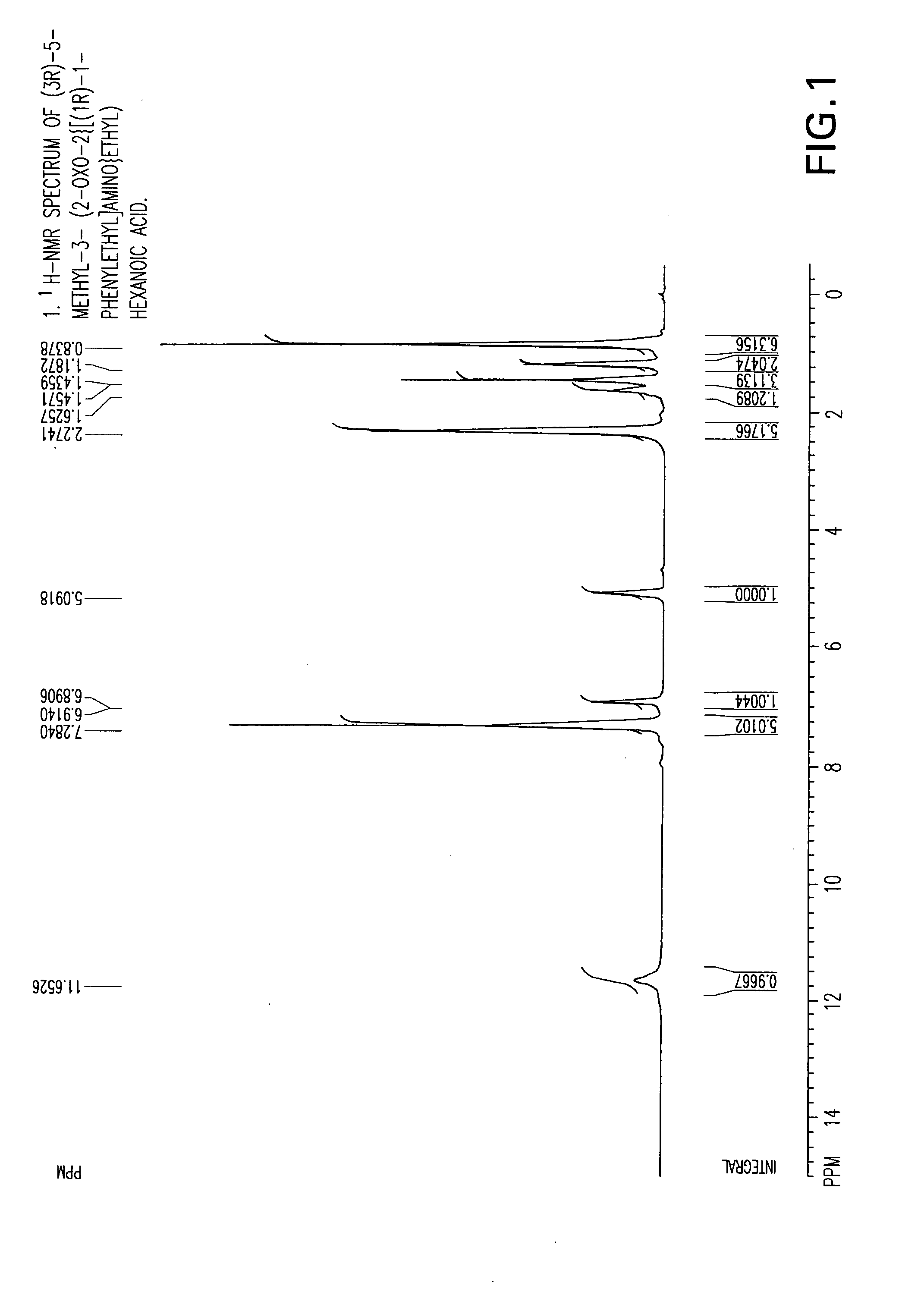

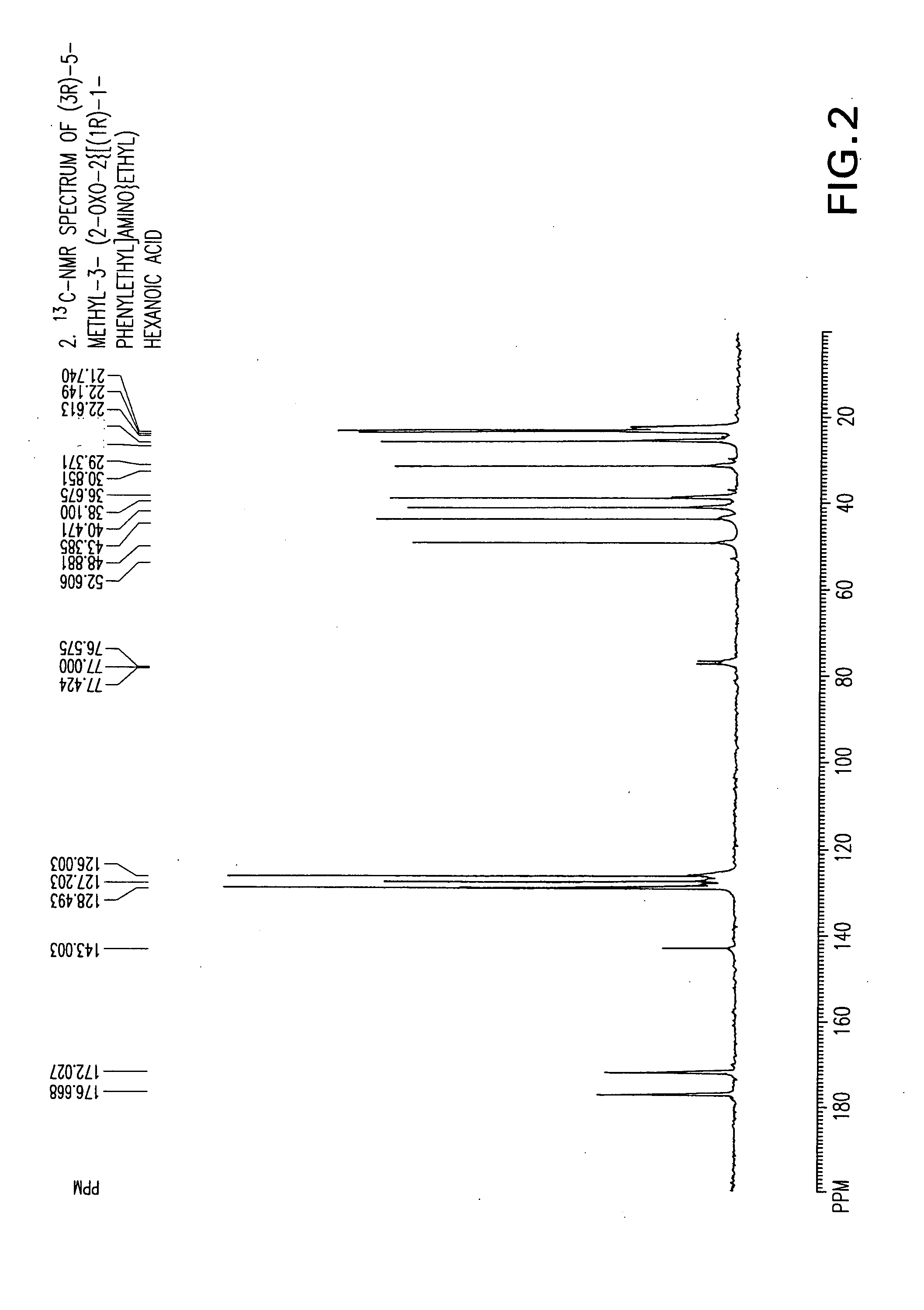

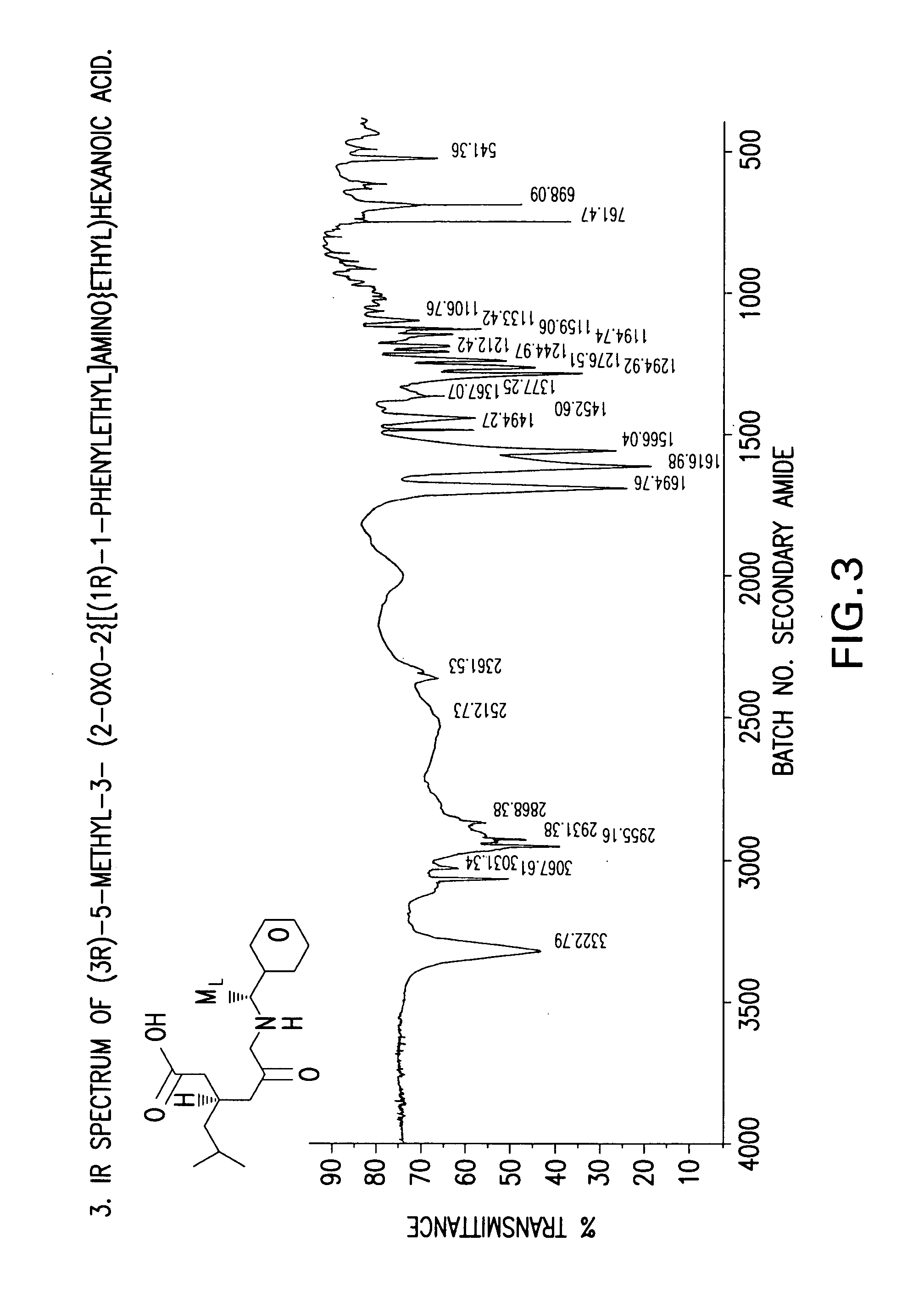

Chiral 3-carbamoylmethyl-5-methyl hexanoic acids, key intermediates for the synthesis of (S)-Pregabalin

The invention encompasses the synthesis of (S)-(+)-3-(aminomethyl)-5-methylhexanoic acid, (S)-Pregabalin, via the intermediate, (3R)-5-methyl-3-(2-oxo-2{[(1R)-1-phenylethyl]amino}ethyl)hexanoic acid.

Owner:TEVA PHARM USA INC

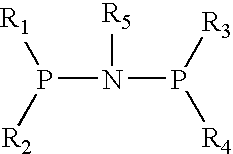

Catalyst composition for ethylene oligomerization and the use thereof

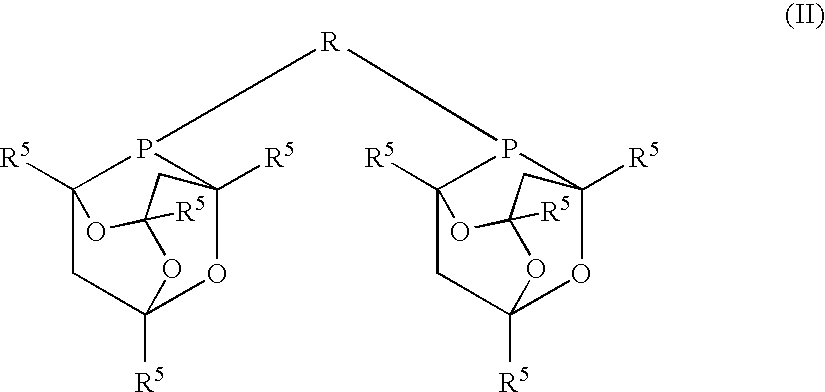

ActiveUS7786336B2High activityGood choiceOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbons from unsaturated hydrocarbon addition1-OcteneAluminoxane

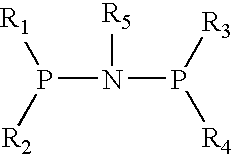

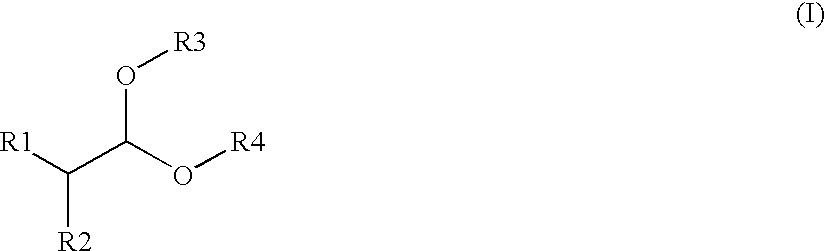

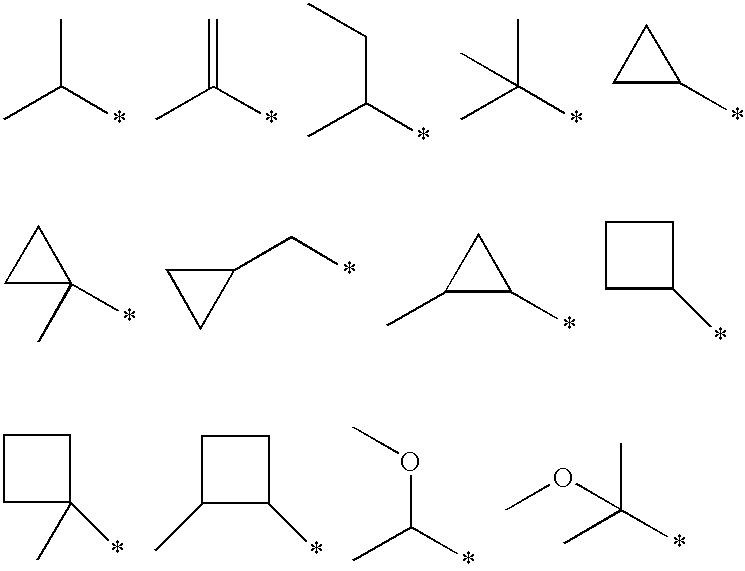

The present invention relates to a catalyst composition for ethylene oligomerization and the use thereof. Such catalyst composition includes chromium compound, ligand containing P and N, activator and accelerator; wherein the chromium compound is selected from the group consisting of acetyl acetone chromium, THF-chromium chloride and Cr(2-ethylhecanoate)3; general formula of the ligand containing P and N is shown as:in which R1, R2, R3 and R4 are phenyl, benzyl, or naphthyl. R5 is isopropyl, butyl, cyclopropyl, cyclopentyl, cyclohexyl or fluorenyl; the activatior is methyl aluminoxane, ethyl aluminoxane, propyl aluminoxane and / or butyl aluminoxane; the accelerator is selected from the group consisting of 1,1,2,2,-tetrachloroethane, 1,1,2,2-tetrabromoethane, 1,1,2,2-tetrafluoroethane, and compounds having a formula of X1R6X2, in which X1 and X2 are F, Cl, Br, I or alkoxyl, R6 is alkylene or arylene group; the molar ratio of chromium compound, ligand containing P and N, activator and accelerator is 1:0.5˜10:50˜3000:0.5˜10. After mixing the four components mentioned previously under nitrogen atmosphere for 10 minutes, they are incorporated to the reactor, or these four components are incorporated directly into the reactor. Then ethylene is introduced for oligomerization. Such catalyst can be used in producing 1-octene through ethylene oligomerization. It is advantageous in high catalysing activity, high 1-octene selectivity, etc. The catalytic activity is more than 1.0×106 g product·ma−1 Cr·h−1, the fraction of C8 linear α-olefin is more than 70% by mass.

Owner:PETROCHINA CO LTD

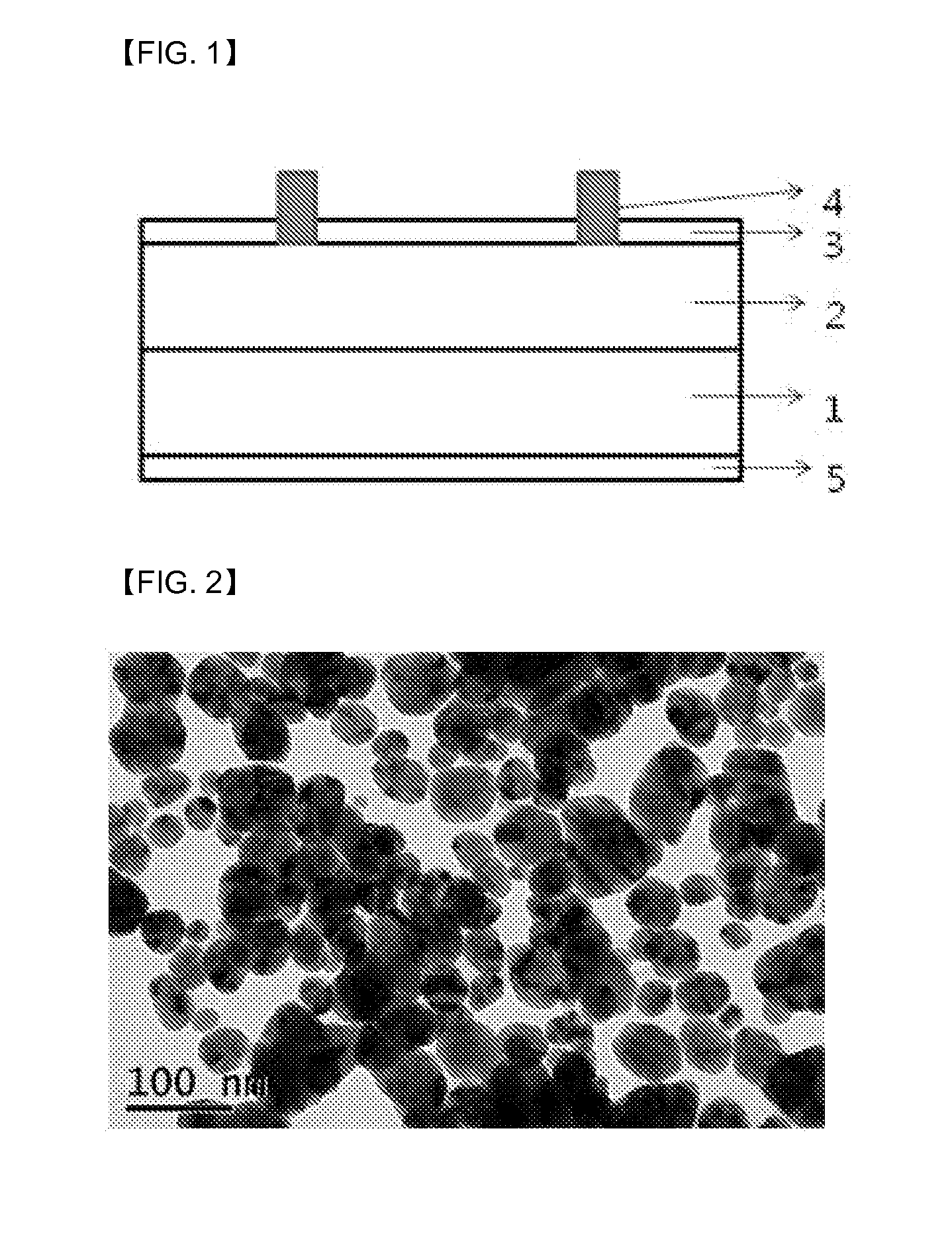

Metal delivery system for nanoparticle manufacture

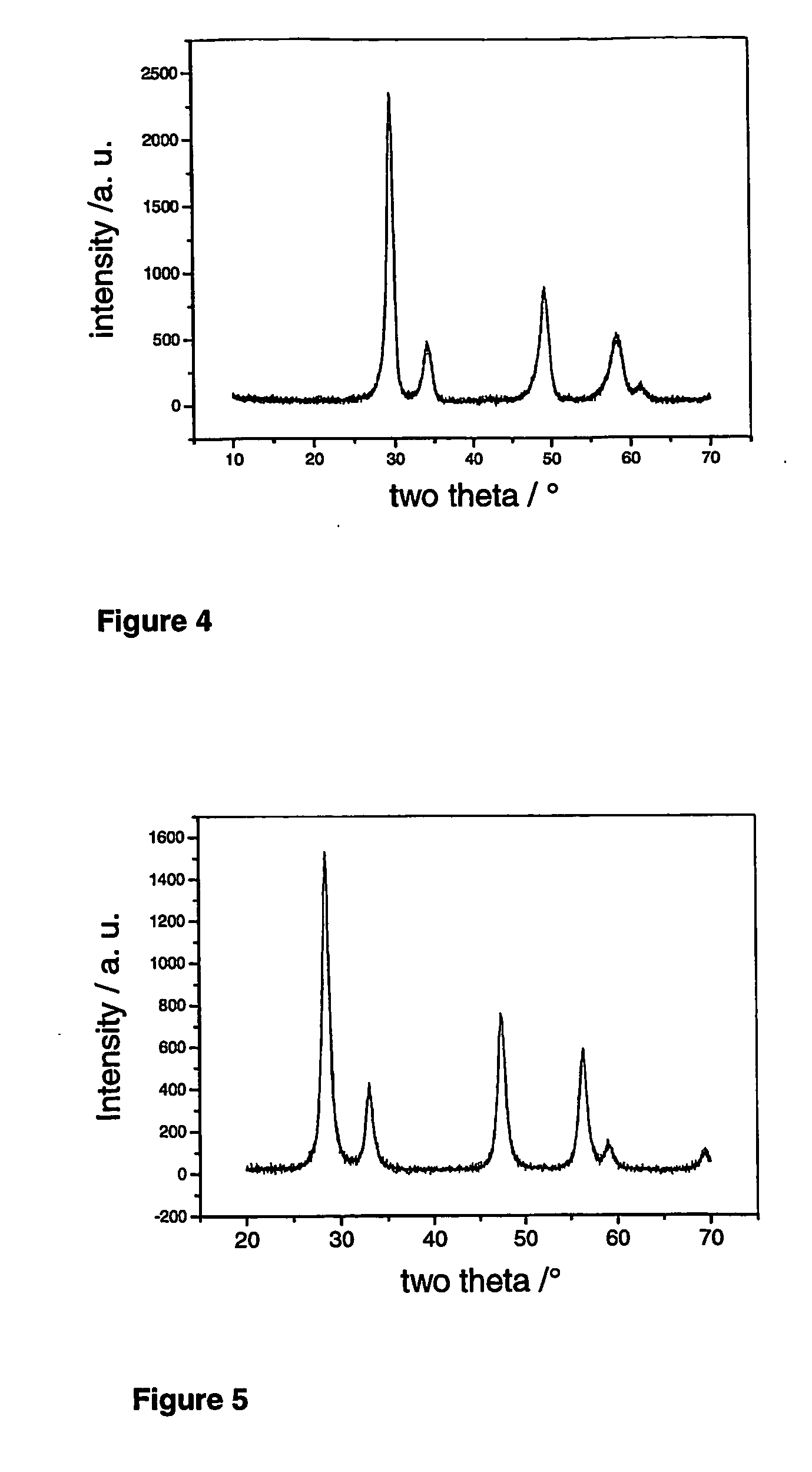

ActiveUS20060229197A1Improve productivityWell mixedRare earth metal oxides/hydroxidesMolten spray coating2-Ethylhexanoic acidMetallacarboxylic acid

Described is a method for the production of pure or mixed metal oxides, wherein at least one metal precursor that is a metal carboxylate with a mean carbon value per carboxylate group of at least 3, e.g. the 2-ethyl hexanoic acid salt, is formed into droplets and e.g. flame oxidized. The method is performed at viscosities prior to droplet formation of usually less than 40 mPa s, obtained by heating and / or addition of one or more low viscosity solvents with adequately high enthalpy.

Owner:ETH ZURICH THE SHORT NAME OF EID GENOSSISCHE TECHN HOCHSCHULE ZURICH

Plant growth regulator composite containing diethyl aminoethyl hexanoate and cycogan

InactiveCN101720762ANovel ideaImprove the effect of increasing productionBiocidePlant growth regulatorsSolventHexanoic acid

The invention discloses a plant growth regulator composite containing diethyl aminoethyl hexanoate and cycogan, which is characterized in that the plant growth regulator is liquid, powder or granula prepared by taking diethyl aminoethyl hexanoate (hexanoic acid 2-(diethylamino) ethyl ester) or salts thereof and the cycogan and adding with carriers or solvent, stabilizer and surfactant. The invention has the advantages of novel design, good effect in increasing yield for various crops and obviously-improved product quality, can effectively enhance stress resistance (such as lodging resistance, disease resistance, drought resistance, cold resistance, heat resistance, chemical injure resistance and the like), and has simple production technology, simple and convenient use and vast popularization and application prospect.

Owner:GUANGDONG GEOLONG BIOTECH

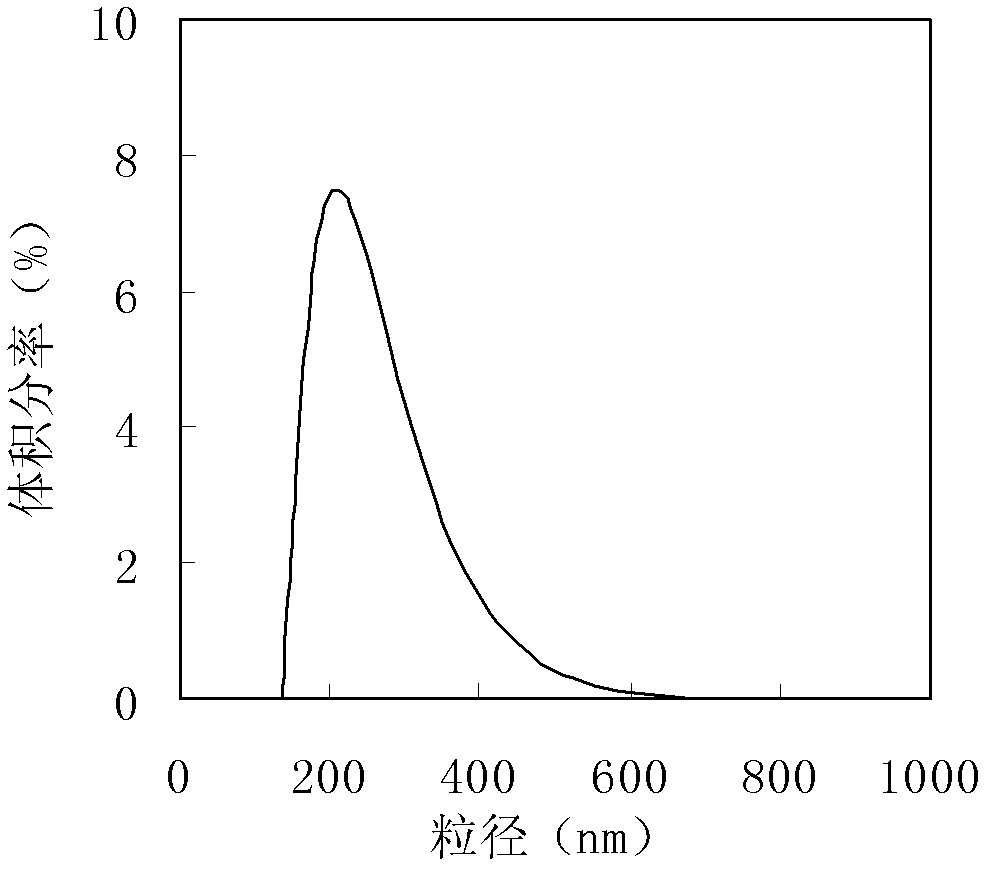

Nanometer carboxylated polystyrene microsphere with spacer arm and preparation method thereof

The invention relates to a nanometer carboxylated polystyrene microsphere with a spacer arm and a preparation method thereof. A nanometer carboxylated polystyrene microsphere A is prepared by taking styrene and acrylic acid as a mixed monomer, taking water as a reaction medium, taking potassium persulfate as an initiator and taking sodium dodecyl sulfate as an emulsifier with an emulsion polymerization method. In the presence of EDC (Ethylidene Dichloride) serving as a coupling agent and Sulfo NHS, 4-aminobutyric acid, 6-amidocaproic acid or 8-aminocaprylic acid is connected to the surface of the microsphere, so that the nanometer carboxylated polystyrene microsphere with the spacer arm is prepared. The spacer arm is introduced into the surface of the nanometer microsphere, so that the steric hindrance of a coupling macromolecule is lowered, the activity and utilization ratio of the macromolecule are increased, and a nonspecific interaction between the macromolecule and the polystyrene microsphere is reduced. Meanwhile, the grain diameter of the microsphere can be adjusted by adjusting the using amount of the emulsifier, the length of the space arm and surface density, so that the nanometer microsphere has a wide application prospect in the fields of immune diagnosis, solid phase extraction and the like when serving as a carrier as well as a template.

Owner:TIANJIN MEDICAL UNIV

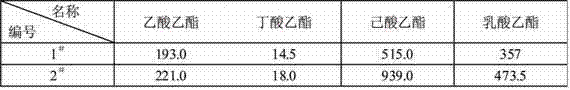

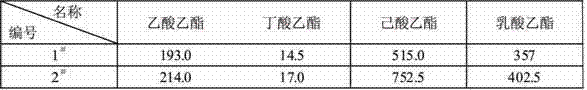

Method for making wine through grain of distiller of strong aromatic Chinese spirits by secondary fermentation and wine made by same

The invention discloses a method for making wine through grain of distiller of strong aromatic Chinese spirits by secondary fermentation, which comprises the following steps: utilizing strong aromatic Chinese grain of distiller as a substrate; adding yeast in the grain of distiller for piling fermentation; adding distillation tails, yellow water, esterase, acetic acid fermentation liquor and the like and stirring evenly; and then sealing by a plastic film for making the wine through the secondary fermentation. The invention fully utilizes a special culture medium, i.e. odour precursor and distilled grain remained in the grain of distiller to generate odour substances through the secondary fermentation of the grain of distiller. The grain of distiller is piled up after the yeast is added in, which aims to prompt the self-growth of the microorganism so as to lay a basis for esterification. The invention can also utilize the starch and the like in the grain of distiller so as to improve the utilization ratio of the distilled grain. The plastic film is used for sealed anaerobic fermentation after the piling fermentation so as to improve the production of the ester, and effectively avoid the discordant substance to body generated by microorganism in pit mud. The novel wine which is light on the palate and balance in fragrance is obtained by distillation under normal pressure after the fermentation.

Owner:LUZHOU LAOJIAO CO LTD +1

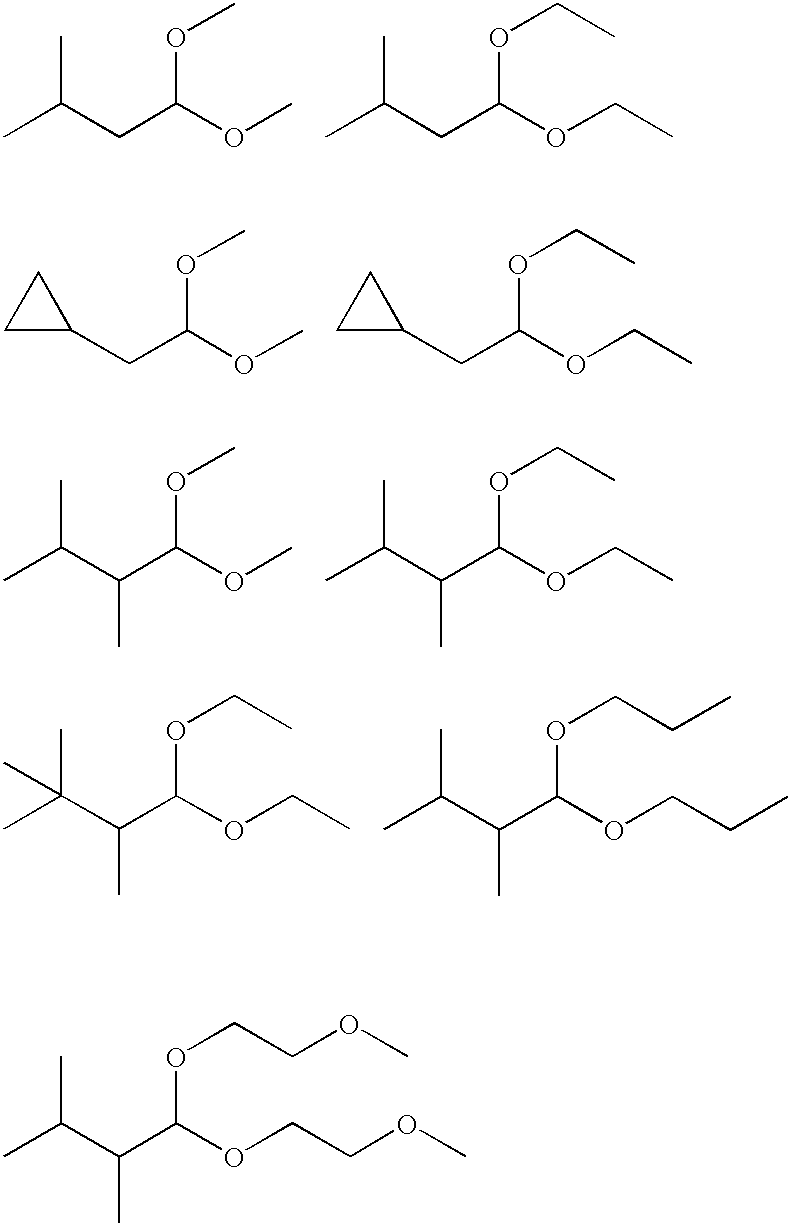

Use of low molecular weight acetal, alcohol, acylated alcohol and ester compounds to block or reduce odor of carboxylic acids

InactiveUS20030089885A1Avoid odorBlocking and reducing perceptionCosmetic preparationsOther chemical processesPropanoic acidFamily nursing

Low molecular weight acetal, alcohol, O-acylated alcohol and ester compounds are identified that block the odor of specific carboxylic acids especially propionic acid, butyric acid, isovaleric acid 3-methyl-2-hexenoic acid and hexanoic acid. These compounds exhibit surprisingly high odor blocking properties and are therefore useful additives to compositions such as: a) personal care products including underarm deodorant and antiperspirant, hair shampoo and conditioner, toilet soap, and skin lotion; b) fabric care products including laundry detergents, fabric conditioners, and fabric fresheners; c) pet care products including deodorant, shampoo, conditioner, and d) home care products including air fresheners, carpet fresheners, surface cleaners and hand wash dish detergent.

Owner:SENOMYX INC

A kind of cultivation method of caproic acid bacteria and liquid pit mud mixed bacterial solution

ActiveCN102260640ASolve agingSolve operational problemsBacteriaMicroorganism based processesBiotechnologyMicrobiology

The invention discloses a hexanoic acid bacterium and liquid pig mud bacterium mixed bacterial solution culture method, which comprises: culturing hexanoic acid bacteria in a hexanoic acid bacterium culture medium and liquid pig mud bacteria in a liquid pig mud culture medium separately; inoculating 1 percent of hexanoic acid bacterium strain and 9 percent of liquid pig mud bacterium strain into a Carlsberg flask, a stainless stain seed tank and a stainless stain fermentation tank in turn; and thus, obtaining the hexanoic acid bacterium and liquid pig mud bacterium mixed bacterial solution. The hexanoic acid bacterium and liquid pig mud bacterium mixed bacterial solution prepared by the method, when used for maintaining pig mud and culturing artificial pig mud, can solve the problem that the artificial addition of calcium matters into the pig mud promotes the aging of the pig mud and the problem of complex operation, low and instable quality in tank-type culture and also solve the problem of undesirable use effect of hexanoic acid bacteria and liquid pig mud bacteria, which are used alone.

Owner:SICHUAN MIANYANG FORGOOD DISTILLERY

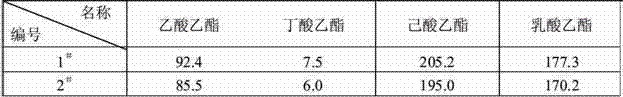

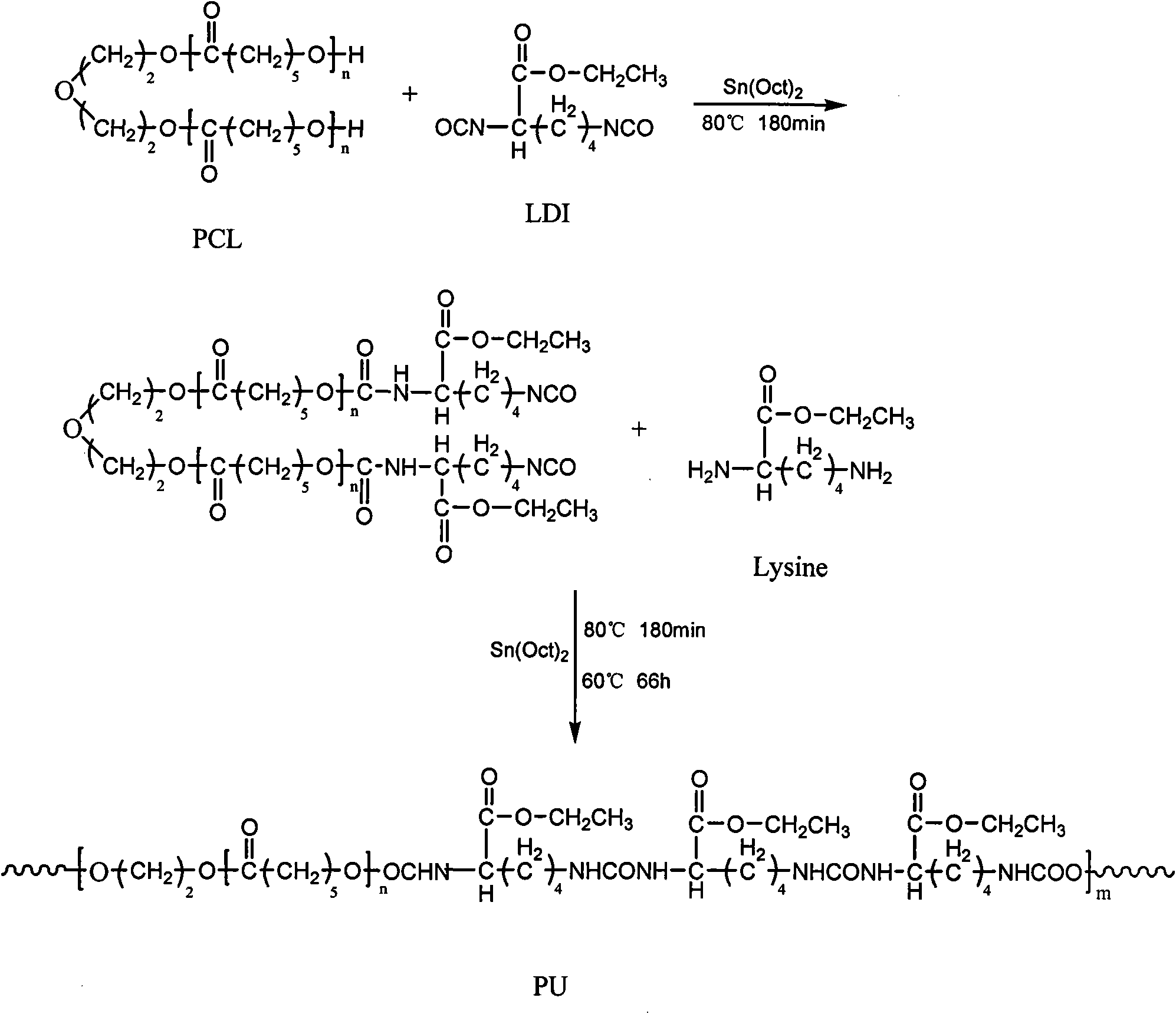

Degradable and nontoxic medical polyurethane material and preparation method thereof

The invention relates to a degradable and nontoxic medical polyurethane material and a preparation method thereof, belonging to the technial field of biomedical high polymer materials. Raw materials thereof adopt poly (epsilon-caprolactone) dibastic alcohol (PCL) as a soft segment and L-lysine ethyl ester diisocyanate (LDI-E) or L-lysine methyl ester diisocyanate (LDI-M) and chain extender L-lysine ethyl ester (Lysine-E) or L-lysine methyl ester (Lysine-M) as a hard segment, wherein the number-average molecular weight of the poly (epsilon-caprolactone) dibastic alcohol ranges from 500 to 5000.The polyurethane of the invention is degradable, and degradation products thereof are harmless to human bodies; as a great amount of carbamido is contained in the polyurethane, the mechanical property and the degradation property of the polyurethane are improved; and the degradation products are completely nontoxic, the degradation product of lysine can neutralize 6- hydroxyl hexanoic acid generated by soft segment degradation, the pH value of adjacent tissues can not be changed, and therefore the polyurethane prepared by the invention has favorable biocompatibility.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

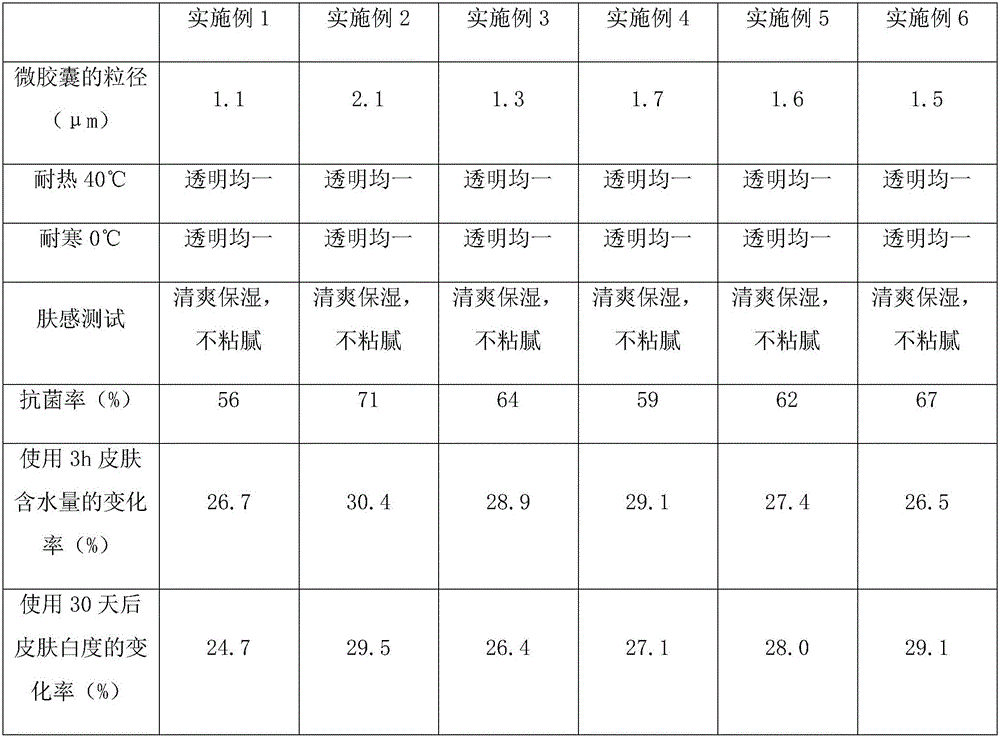

Herbaceous plant nutritive water based on emulsified microcapsule and preparation method of herbaceous plant nutritive water

InactiveCN105726456AGood skin tightening effectRich in nutrientsCosmetic preparationsToilet preparationsWater basedVegetable oil

The invention provides herbaceous plant nutritive water based on an emulsified microcapsule and a preparation method of the herbaceous plant nutritive water. The preparation method comprises the following specific steps: mixing hydrogenated vegetable oil, low erucic acid rapeseed oil , siloxane, microcrystalline wax and diglycerol, heating and uniformly stirring, and performing heat reservation and sterilization to obtain an oil phase; adding ethylene glycol, propylene glycol, glycine betaine, urea, poly-sodium glutamate, triethanolamine, caprylhydroxamic acid and hexylene glycol into deionized water, heating and uniformly stirring, performing heat preservation and sterilization to obtain a water phase; adding the oil phase into the water phase, performing heating, homogenization and low-speed stirring, adding cetyl ethyl hexanoate and stearic acid, then slowly adding PEG-40 hydrogenated castor oil and a microcapsule wall material, cooling, adding tremella, centella asiatica, polygonum cuspidatum, scutellaria baicalensis, tea leaves, glycyrrhiza glabra, female chrysanthemum, rosemary leaves, beer saccharomycete and grape fruit cell extract active components, and adding chondrus crispus extracts, bio-saccharide gum-1, diglycerol, palmitoyl tripeptide-1 and essence for mixing to obtain the herbaceous plant nutritive water based on the emulsified microcapsule.

Owner:广州市有喜化妆品有限公司

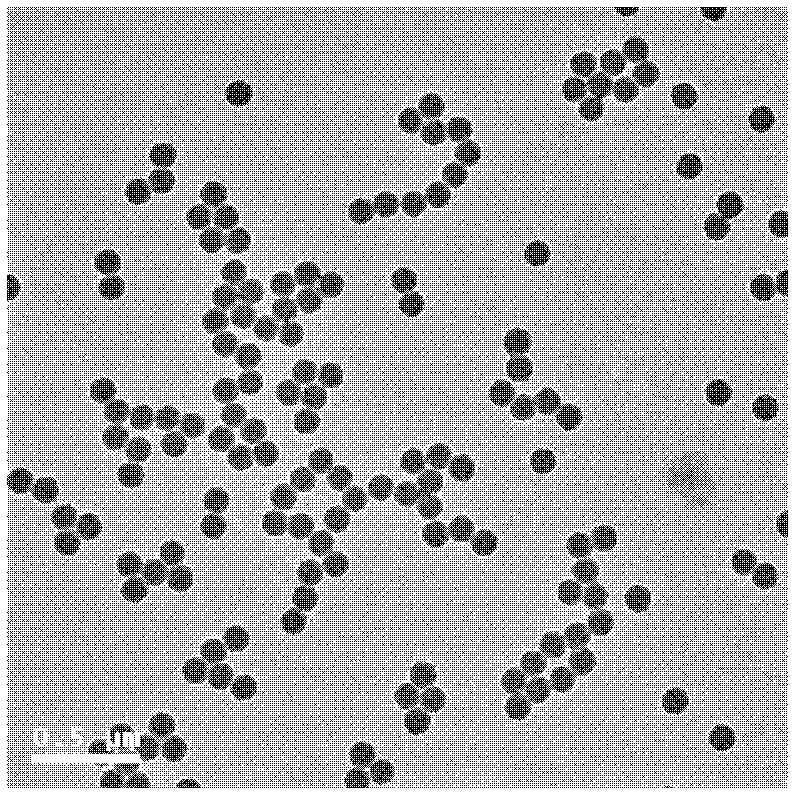

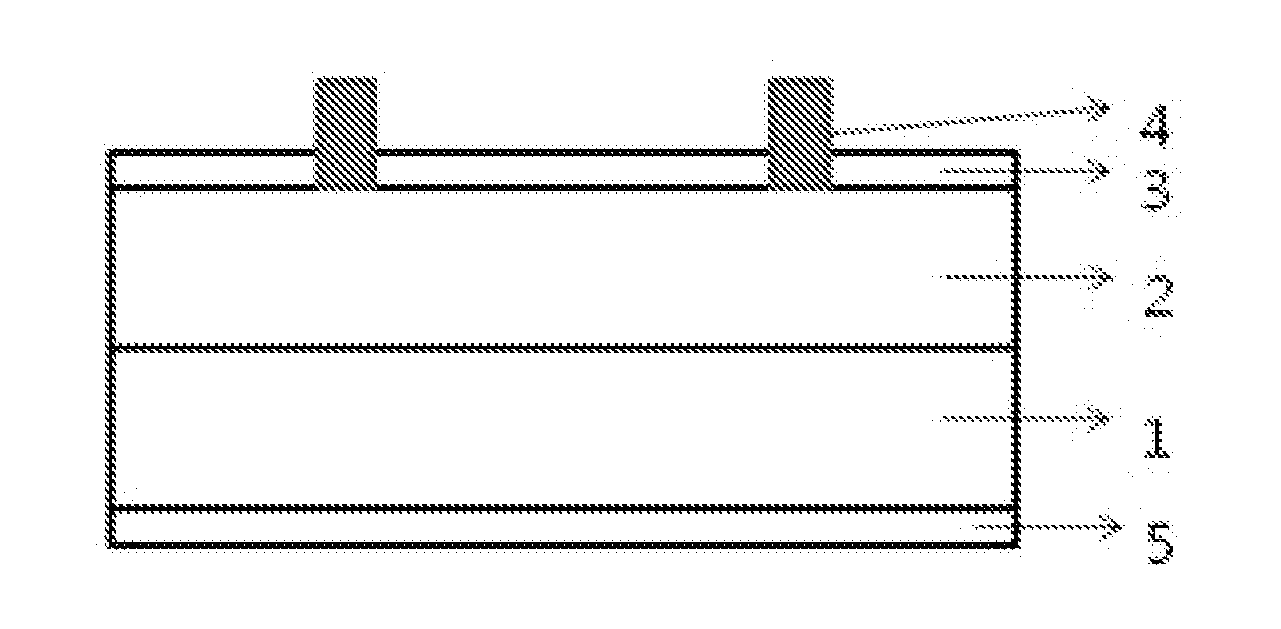

Paste composition for front electrode of solar cell and solar cell using the same

InactiveUS20140318618A1Decreased front electrode resistanceImprove battery efficiencyMaterial nanotechnologyLiquid surface applicatorsHexanoic acidSolar cell efficiency

The present invention relates to a paste composition for a front electrode of a solar cell comprising nano silver powder surface-treated with hexanoic acid, and a solar cell comprising a front electrode formed using the paste composition.According to the present invention, a front electrode is formed using a paste composition containing nano silver powder surface-treated with hexanoic acid, thereby decreasing resistance of a front electrode and broadening an area capable of absorbing light, to improve solar cell efficiency.

Owner:HANWHA CHEMICAL CORPORATION

Efficient multi-element compound fertilizer

InactiveCN101591202APromote stoutnessPromote absorptionSuperphosphatesAlkali orthophosphate fertiliserPhosphateInsect pest

The invention discloses an efficient multi-element compound fertilizer, which consists of hexanoic acid 2-(diethylamino) ethyl ester, polypeptide chelated potassium, polypeptide L-aspartate potassium, urea, potassium chloride, diammonium phosphate, calcium superphosphate, potassium dihydrogen phosphate, calcium-magnesium phosphate fertilizer, ammonium chloride, thiamine, zinc chloride, borax, ferrous sulphate, copper sulphate, manganese sulfate, sodium molybdate, cobalt chloride and silicon-manganese phosphate fertilizer. The efficient multi-element compound fertilizer has the advantages of promoting the growth of crops, improving the disease resistance of the crops, resisting falling, insect pests and frozen injury, improving the fertilizer effect, improving the soil, accelerating the growth of branches and leaves, reinforcing the photosynthesis, accelerating the growth of roots, enhancing the drought resistant capacity, improving the yield of the crops and improving the quality of fruits. The yield of grain crops is averagely increased by more than 26 percent, the yield of economic crops is averagely increased by more than 33 percent, and the yield of vegetable crops is averagely increased by more than 42 percent.

Owner:孙承环

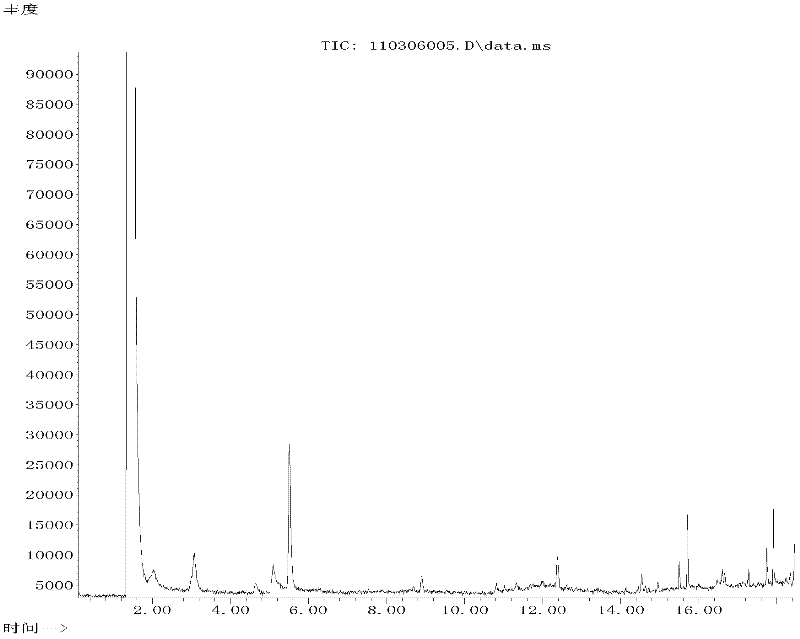

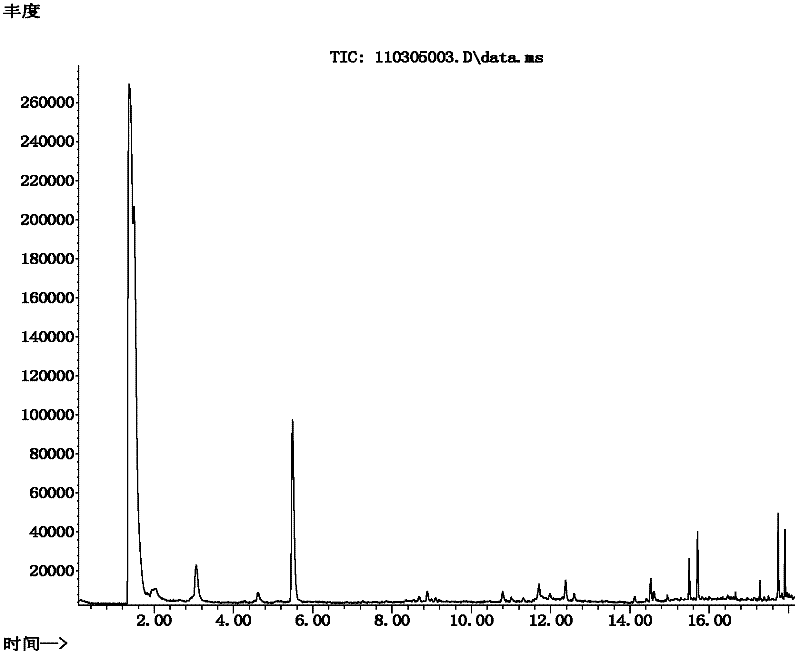

How to detect gutter oil

The invention discloses a method for detecting gutter oil. The method comprises: ①adding the oil sample to be tested into a headspace bottle, shaking the headspace bottle at a temperature of 40°C-150°C, and then balancing for 10min-120min; ②use The syringe absorbs the gas in the upper layer of the balanced headspace bottle and injects it into the gas chromatography-mass spectrometry instrument, and obtains the gas chromatography-mass spectrometry spectrum under the set chromatographic conditions and mass spectrometry conditions; Chromatography-mass spectrometry is used for qualitative analysis; when it is detected that the oil sample to be tested contains fatty acids, it is determined that the oil sample to be tested is waste oil or contains waste oil; the fatty acids are acetic acid, propionic acid, butyric acid, One or two or more of valeric acid and caproic acid. The method of the invention has good accuracy and is applicable to the detection of all waste oils.

Owner:同码信息科技(常州)有限公司

Process for the carbonylation of pentenenitrile

Processes to prepare 5-cyanovaleric acid or its ester are provided, by carbonylation of a pentenenitrile, wherein pentenenitrile is reacted with carbon monoxide and water and / or an alcohol in the presence of a catalyst system. The catalyst system contains:(a) a metal of Group VIII or a compound thereof and(b) a bidentate phosphine, arsine and / or stibine ligand, wherein the bidentate ligand has the general formula (I):R1R2-M1-R-M2-R3R4 (I) wherein M1 and M2 are independently P, As or Sb, R is a divalent organic bridging group, which bridging group comprises a chain of 3 to 5 atoms directly connecting the 2 phosphorus atoms, which chain consists of carbon atoms and optionally a nitrogen, oxygen or sulphur atom or a silano or dialkylsilicon group, which alkyl groups independently comprise from 1 to 4 carbon atoms, and R1–R4 represent the same or different optionally substituted tertiary alkyl groups,(c) an acid having a pKa less than 3, as measured at 18° C. in an aqueous solution.ε-caprolactam is also prepared by reduction of 5-cyanovaleric acid or ester obtained above to 6-aminocaproic acid or ester, and then cyclisation of the 6-aminocaproic acid or ester to ε-caprolactam.

Owner:SHELL OIL CO

Films and absorbent articles comprising a biodegradable polyhydroxyalkanoate comprising 3-hydroxybutyrate and 3-hydroxyhexanoate comonomer units

InactiveUS6027787AEasily processed into filmPromote degradationSynthetic resin layered productsBaby linensBiodegradable copolymersPolymer chemistry

The present invention relates to a film comprising a biodegradable copolymer, wherein the copolymer comprises at least two randomly repeating monomer units (RRMU) wherein the first RRMU monomer unit has the structure and the second RRMU has the structure wherein at least 50% of the RRMUs have the structure of the first RRMU. The present invention further relates to an absorbent article comprising a liquid pervious topsheet, a biodegradable liquid impervious backsheet comprising the above film, and an absorbent core positioned between the topsheet and the backsheet.

Owner:DANIMER IPCO LLC

External Preparation for Skin

InactiveUS20090081142A1Superior in affinity with skinExtended shelf lifeCosmetic preparationsToilet preparationsPolymer scienceMeth-

An external preparation for the skin containing isononyl 2-ethylhexanoate and / or 2-ethylhexyl 2-ethylhexanoate (i.e., component (a)); an oil-in-water emulsion type skin cosmetic composition containing the ingredient (a), (b) one or more ingredients selected from higher fatty acids and higher alcohols which are solid to semi-solid at an ordinary temperature (25° C.), (c) a homopolymer, copolymer, cross polymer, or mixture containing one or more ingredients selected from 2-acrylamide-2-methylpropane sulfonic acid and acrylic acid and its derivatives as constituent units and (d) one or more ingredients selected from nonionic surfactants having an HLB value of 9 or more; and an oil-in-water or a water-in-oil emulsion type sunscreen cosmetic composition containing (a) 2-ethylhexyl 2-ethylhexanoate and / or isononyl 2-ethylhexanoate, (b) an ultraviolet absorber, (c) an ultraviolet scatterer and (d) a silicone oil.

Owner:SHISEIDO CO LTD

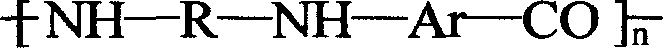

Thermosol of polyamide and preparation process thereof

Owner:CHINA PETROLEUM & CHEM CORP +1

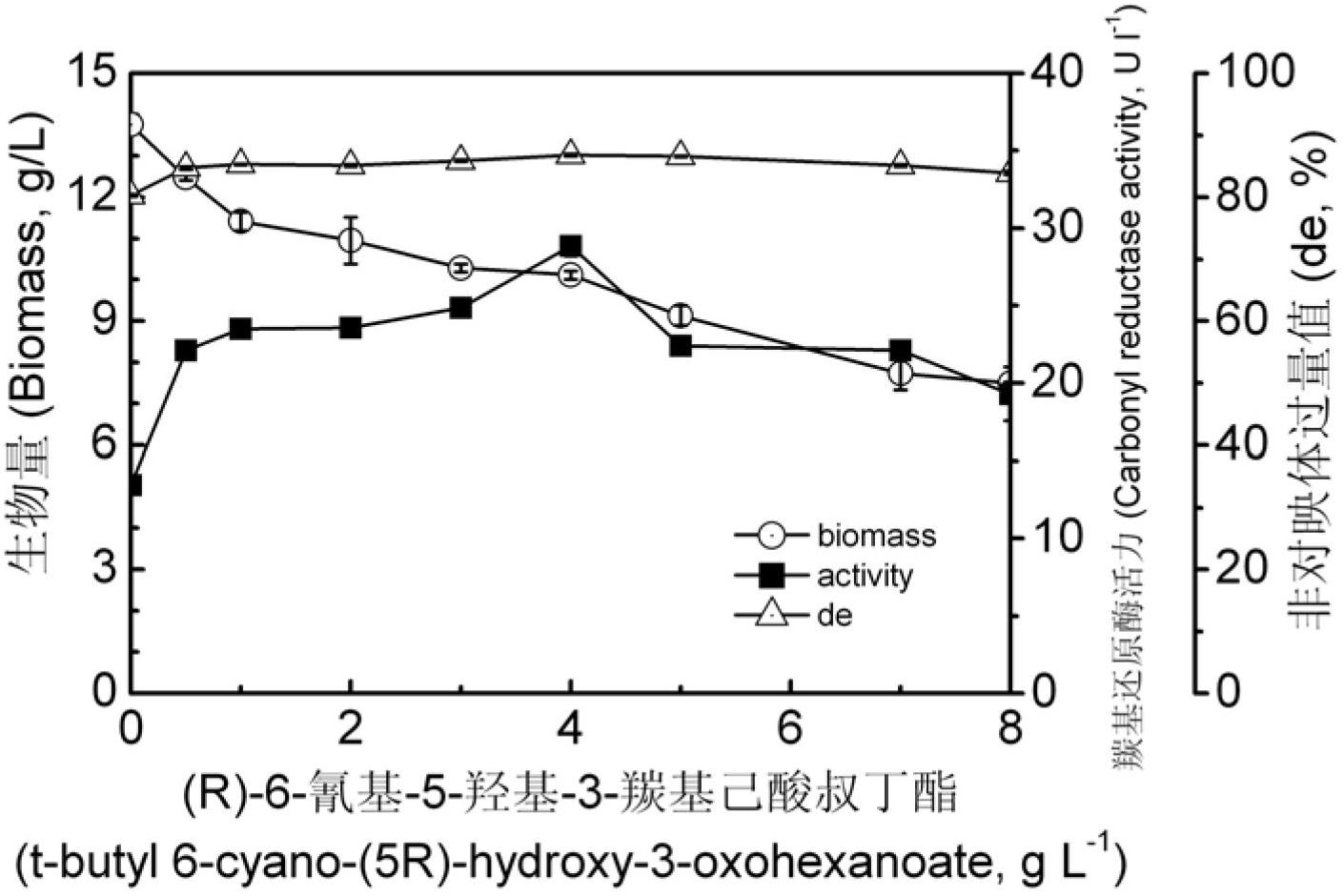

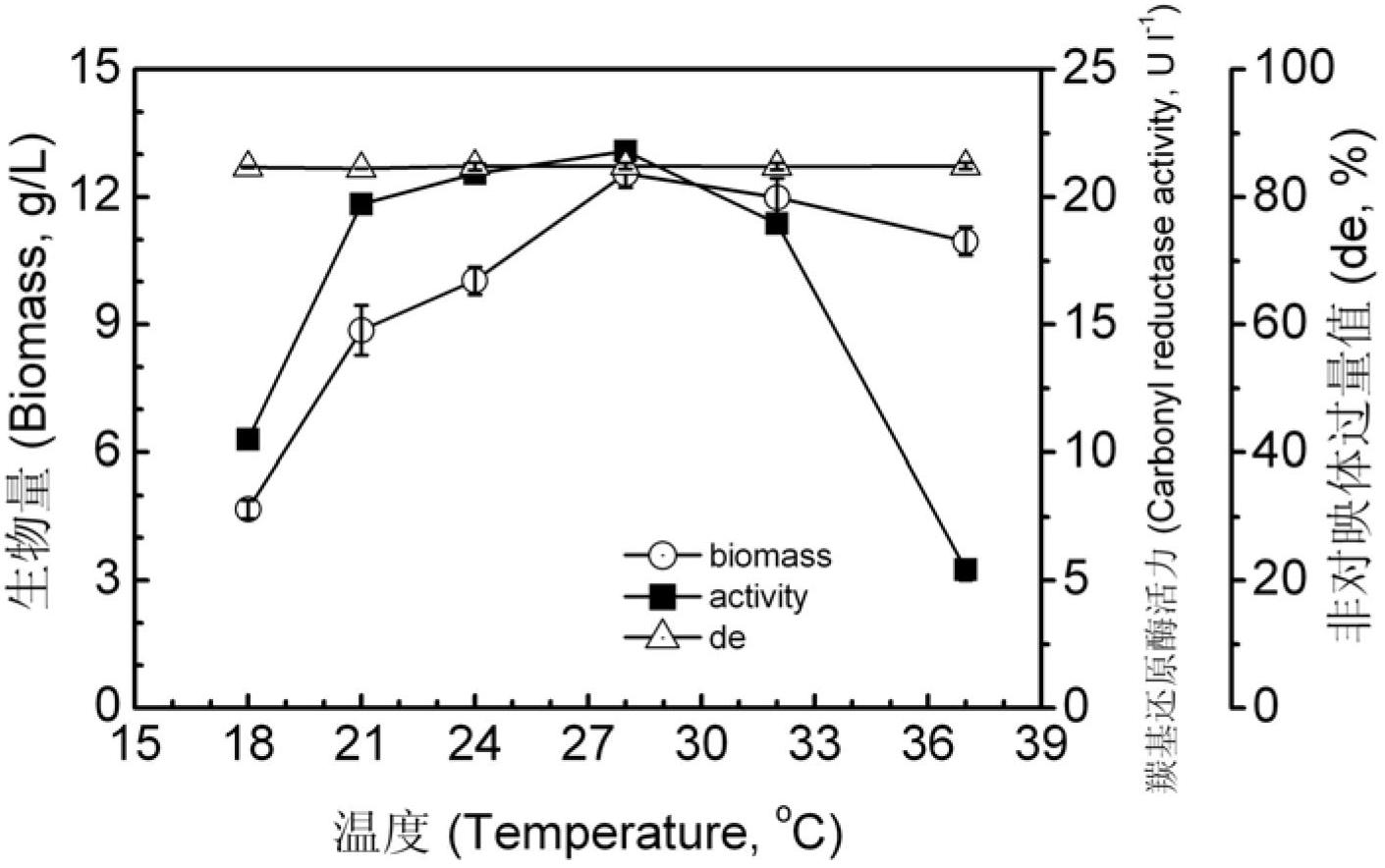

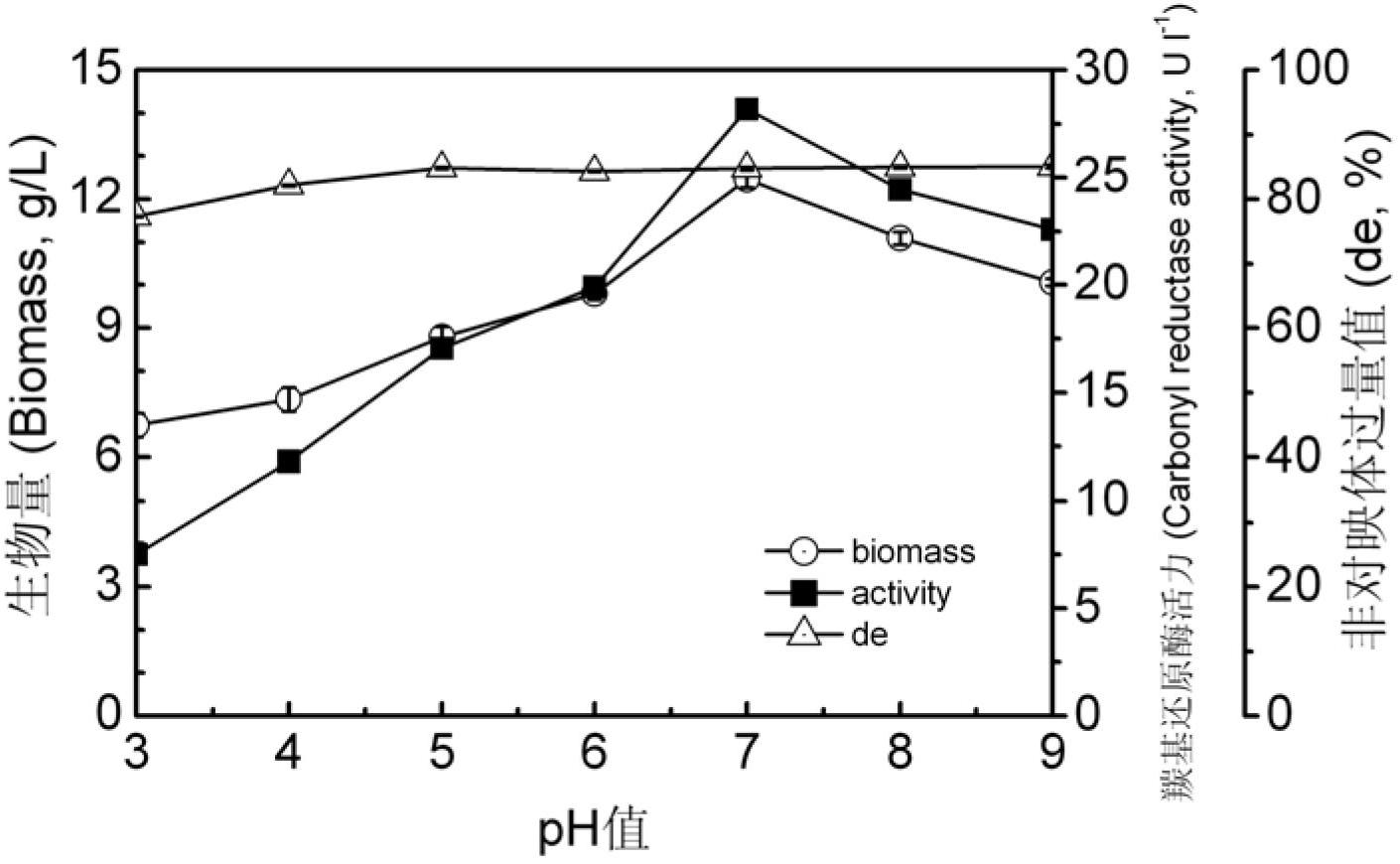

6- cyano-(3r, 5r)-dyhydroxyl hexanoic acid tert-butyl ester prepared by biological catalysis, and bacterial strain thereof

ActiveCN102643757AHigh stereoselectivityMild reaction conditionsFungiMicroorganism based processesCarbonyl ReductaseBacterial strain

The invention provides a Pichia guilliermondii X25 which is enriched and screened from soil, has high diastereoselectivity and is a carbonyl reductase active microbial new strain, and application of the Pichia guilliermondii X25 in preparation of 6-cyano-(3R, 5R)-dyhydroxyl hexanoic acid tert-butyl ester by biological asymmetric reduction (R)-6-cyano-5-hydroxyl-3-carbonyl hexanoic acid tert-butylester. The strain is preserved in China Center for Type Culture Collection (CCTCC), the address is Wuhan university, Wuhan, China, the post code is 430072, the CCTCC No. is M 2011386, and the preservation date is November11th,2011. The optical pure 6-cyano-(3R, 5R)-dyhydroxyl hexanoic acid tert-butyl ester prepared by using carbonyl reductase generated by the Pichia guilliermondii X25 to convert (R)-6-cyano-5-hydroxyl-3-carbonyl hexanoic acid tert-butyl ester is high in stereoselectivity, mild in reaction condition and environment-friendly.

Owner:ZHEJIANG UNIV OF TECH

Ketone reductase mutant and preparation method thereof

ActiveCN104342410ASignificantly high specific enzyme activityMild reaction conditionsBacteriaMicroorganism based processesSpecific enzymeWild type

The invention relates to a ketone reductase mutant and a preparation method thereof. The ketone reductase mutant comes from a saccharomyces cerevisiae wild type ketone reductase, is capable of converting 5-hydroxyl-3-oxohexanoate into corresponding cis 3,5-dihydroxylhexanoate, and has one or more mutants of I46V, S127N and Q144K. The ketone reductase mutant has obvious high specific enzyme activity which is improved by 2-100 times compared with that of the wild type ketone reductase, can be utilized to biologically catalyze 5-hydroxyl-3-oxohexanoate to product corresponding cis 3,5-dihydroxylhexanoate. The reaction conditions are mild, requirements on equipment are low, the production process does not need high temperature or cooling, and energy consumption is low. Because enzyme catalysis has efficient specific selectivity, the process of producing the statin medicine key intermediate cis 3,5-dihydroxylhexanoate, does not generate by-products, and purification is convenient. Additionally, the solvent employed in the reaction is mainly water, "three wastes (waste gas, waste water and industrial residue)" discharge is low, and the reaction is green and environment-friendly.

Owner:NANJING LANGEN BIOLOGICAL SCI & TECH

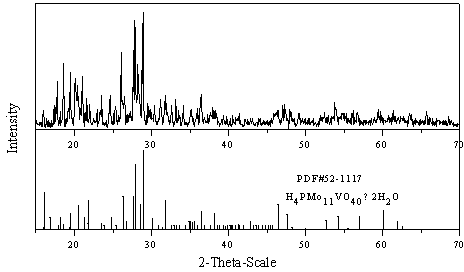

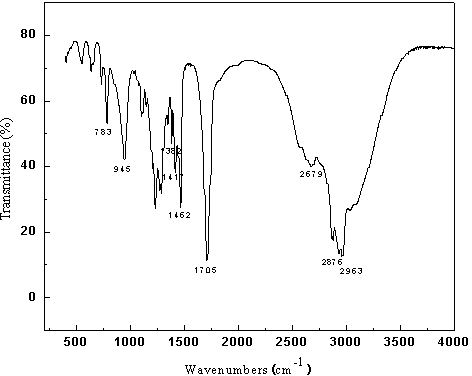

Method for preparing 2-ethyl hexanoic acid by catalytically oxidizing 2-ethylhexanal by molybdovanadophosphoric acid

InactiveCN102701944AStable chemical propertiesImprove thermal stabilityPhysical/chemical process catalystsOrganic compound preparation2-Ethylhexanoic acidReaction temperature

The invention discloses a method for preparing 2-ethyl hexanoic acid by catalytically oxidizing 2-ethylhexanal by molybdovanadophosphoric acid, and relates to a method for preparing a chemical preparation. The method comprises the following steps: weighing molybdovanadophosphoric acid and dissolving the molybdovanadophosphoric acid in distilled water at first and then in hydrochloric acid to prepare a catalyst solution; adding 2-ethylhexanal and the prepared catalyst in an ordinary-pressure reaction device, slowly heating and stirring the mixture, regulating oxygen flux, and starting to introduce oxygen when the temperature rises to the reaction temperature; after the reaction is ended, separating out the aqueous phase solution on the lower layer to obtain organic phase matter on the upper layer; and depressurizing and distilling the organic phase matter to obtain colorless transparent and pungent oily liquid, 2-ethyl hexanoic acid. By changing the ratio of molybdenum to vanadium of the catalyst and optimizing the reaction condition, the conversion rate of the 2-ethylhexanal reaches above 99%, and the selection and yield of the 2-ethyl hexanoic acid reach above 98% respectively.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Esterification method of pentaerythritol

ActiveCN104086417AIncrease in positive chargePromote esterification reactionOrganic compound preparationCarboxylic acid esters preparationOctanoic AcidsAfter treatment

The invention provides an esterification method of pentaerythritol, which comprises the following step: under the action of a tin catalyst, carrying out esterification reaction on pentaerythritol and saturated fatty acid to obtain pentaerythritol ester, wherein the saturated fatty acid is one or more of butyric acid, valeric acid, hexanoic acid, heptylic acid, octanoic acid, pelargonic acid and capric acid. The esterification method provided by the invention has the advantages of higher product yield, higher product quality, simple esterification after-treatment and low pollution. The experimental result indicates that the conversion rate of the esterification reaction is greater than 99.5%, and the hydroxyl value in the reaction product is lower than 1mg KOH / g.

Owner:CHINA PETROLEUM & CHEM CORP

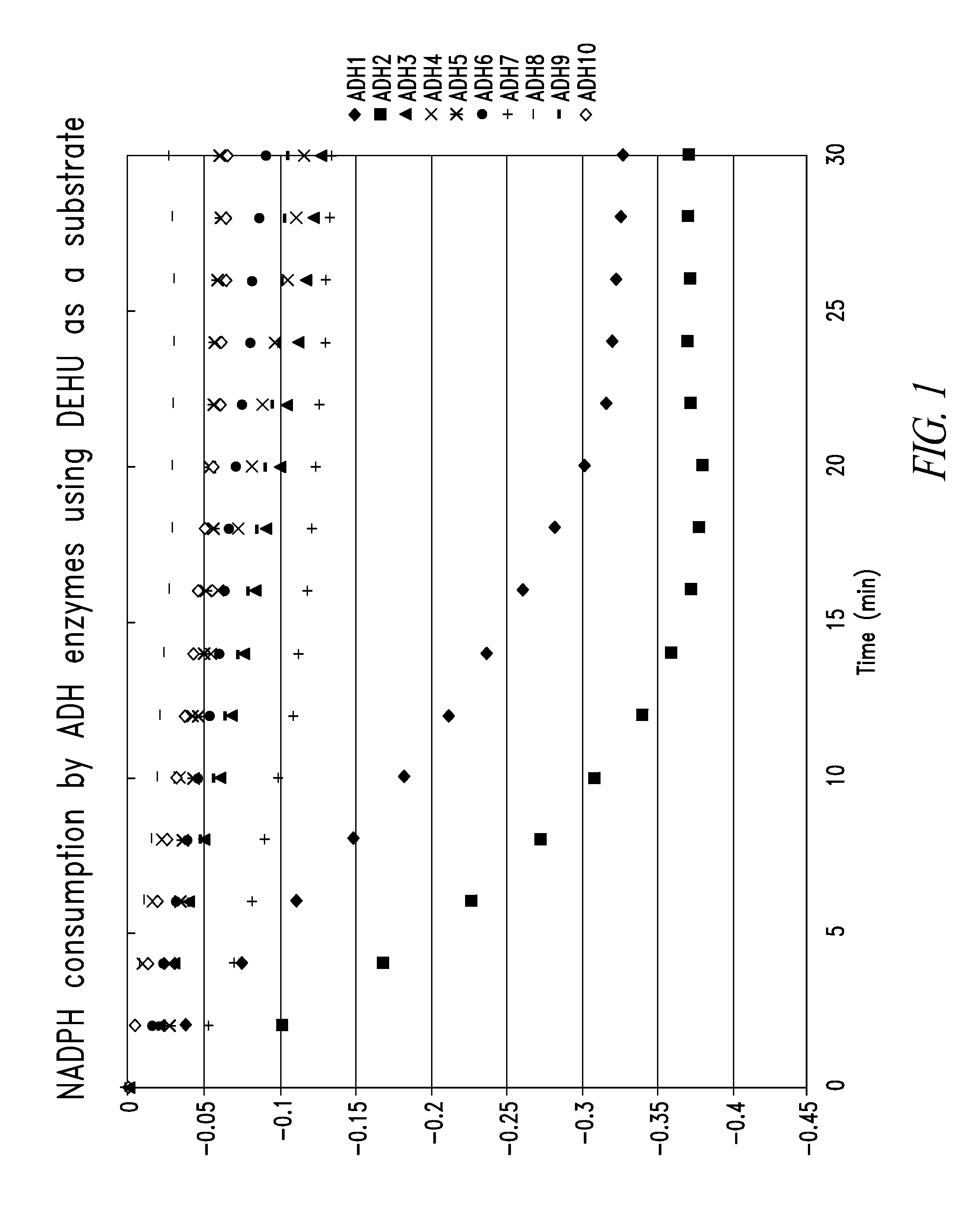

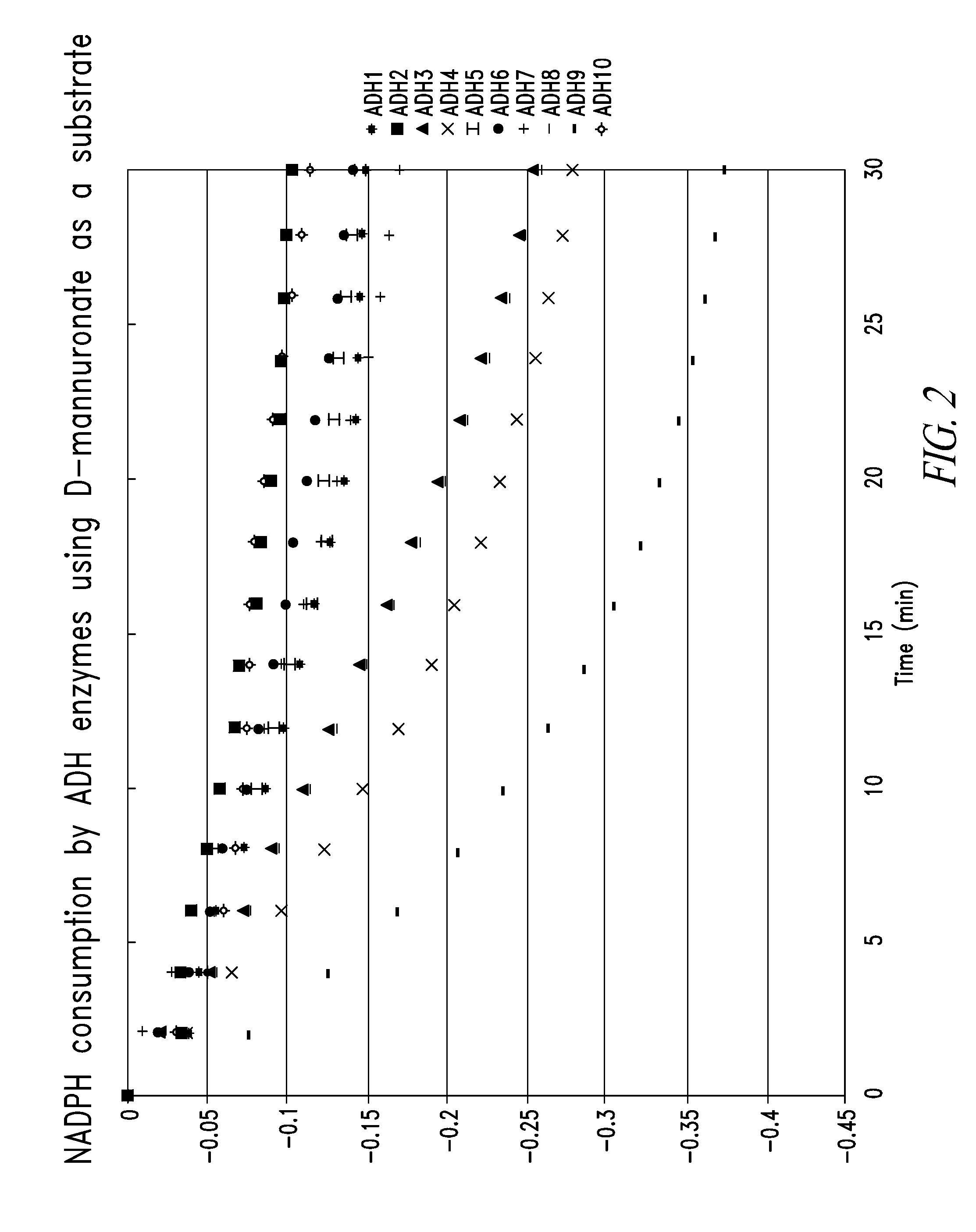

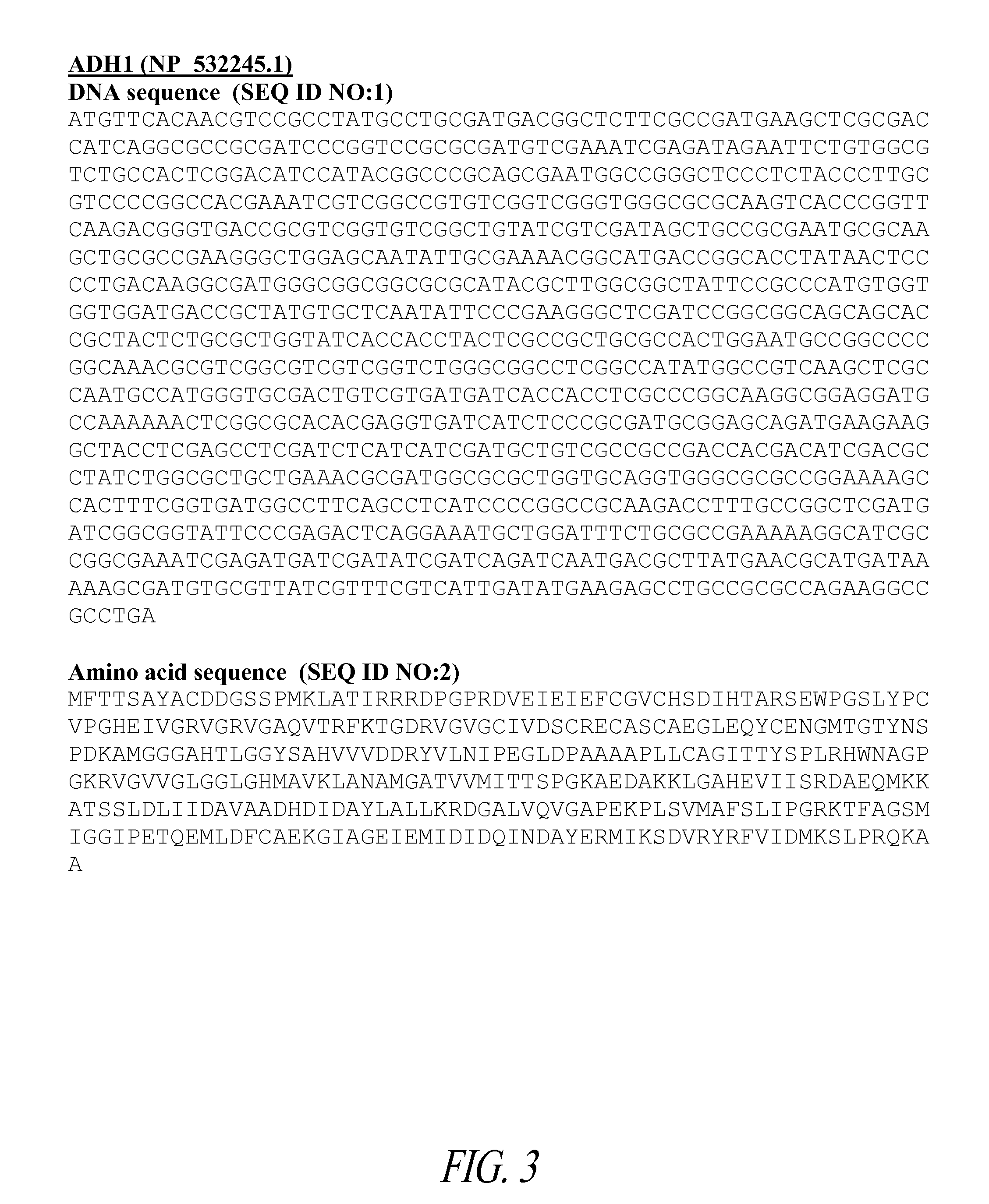

Isolated alcohol dehydrogenase enzymes and uses thereof

Bacterial polynucleotides and polypeptides are provided in which the polypeptides have a dehydrogenase activity, such as an alcohol dehydrogenase (ADH) activity, an uronate, a 4-deoxy-L-erythro-5-hexoseulose uronate (DEHU) ((4S,5S)-4,5 dihydroxy-2,6-dioxohexanoate) hydrogenase activity, a 2-keto-3-deoxy-D-gluconate dehydrogenase activity, a D-mannuronate hydrogenase activity, and / or a D-mannnonate dehydrogenase activity. Methods, enzymes, recombinant microorganism, and microbial systems are also provided for converting polysaccharides, such as those derived from biomass, into suitable monosaccharides or oligosaccharides, as well as for converting suitable monosaccharides or oligosaccharides into commodity chemicals, such as biofuels. Commodity chemicals produced by the methods described herein are also provided.

Owner:BIO ARCHITECTURE LAB

Production method of2-ethyl hexanoic acid

InactiveCN1410407AReduce contact timeHigh selectivityOrganic compound preparationCarboxylic compound preparationSolventOxygen

Owner:QILU PETRO CHEM - SINOPEC

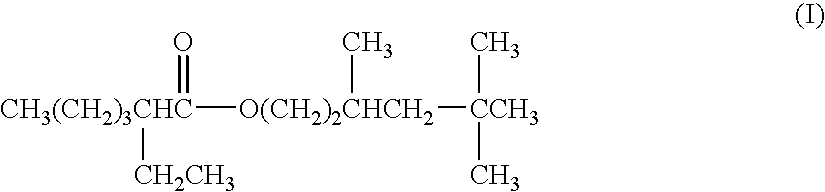

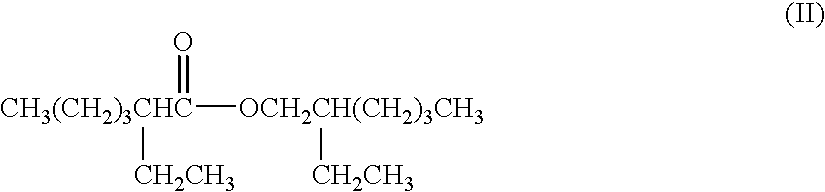

Intumescent Fireproofing Systems and Methods

InactiveUS20130331489A1Eliminate the potential for VOC releaseImprove performanceCoatingsEthyl groupFibre composition

Water-based intumescent fireproofing formulations are provided that exhibit excellent fireproofing properties while simultaneously significantly reducing and / or eliminating the potential for VOC release and exhibiting excellent hangability properties. The intumescent fireproofing formulation includes a coalescent that significantly reduces and / or eliminates the potential for VOC release and fiber constituents, e.g., fibers of greater than 0.2 mm in length. Exemplary coalescents have a boiling point of at least 180° C. and include bis(2-ethylhexanoate)triethyleneglycol, 2,2,4-trimethyl-1,3-pentanediolmono(2-methylproponate) and 2,2,4-trimethyl-1,3-pentanedioldi(2-methylpropanoate). Intumescent fireproofing formulations are also provided that include clay to further improve performance.

Owner:US MINERAL PRODS

Water-absorbing resin composition and process for production of the same

ActiveUS20100240808A1Superior deodorant property propertyAvoid poor antimicrobial propertiesGaseous substancesDeodrantsAlcoholEthyl butyrate

An object is to provide a water absorbent resin composition containing a water absorbent resin as a main component, with excellent deodorant property and antimicrobial property without impairing appearance and absorption characteristics of the water absorbent resin. The water absorbent resin composition according to the first aspect includes a water absorbent resin containing a polyacrylic acid (salt)-based water absorbent resin as a main component, and an extract of bamboo and an extract of tea. The water absorbent resin composition according to the second aspect includes a water absorbent resin containing a polyacrylic acid (salt)-based water absorbent resin as a main component, and at least two kinds of compounds selected from a group consisting of hexanoic acid (salt), ethyl butyrate, and 3-methyl-2-cyclopenten-1-one. In addition, the method for producing the water absorbent resin composition according to the third aspect includes the step of adding an alcoholic solution of an extract of bamboo, before or after polymerization of an unsaturated monomer containing an acrylic acid (salt) as a main component.

Owner:NIPPON SHOKUBAI CO LTD

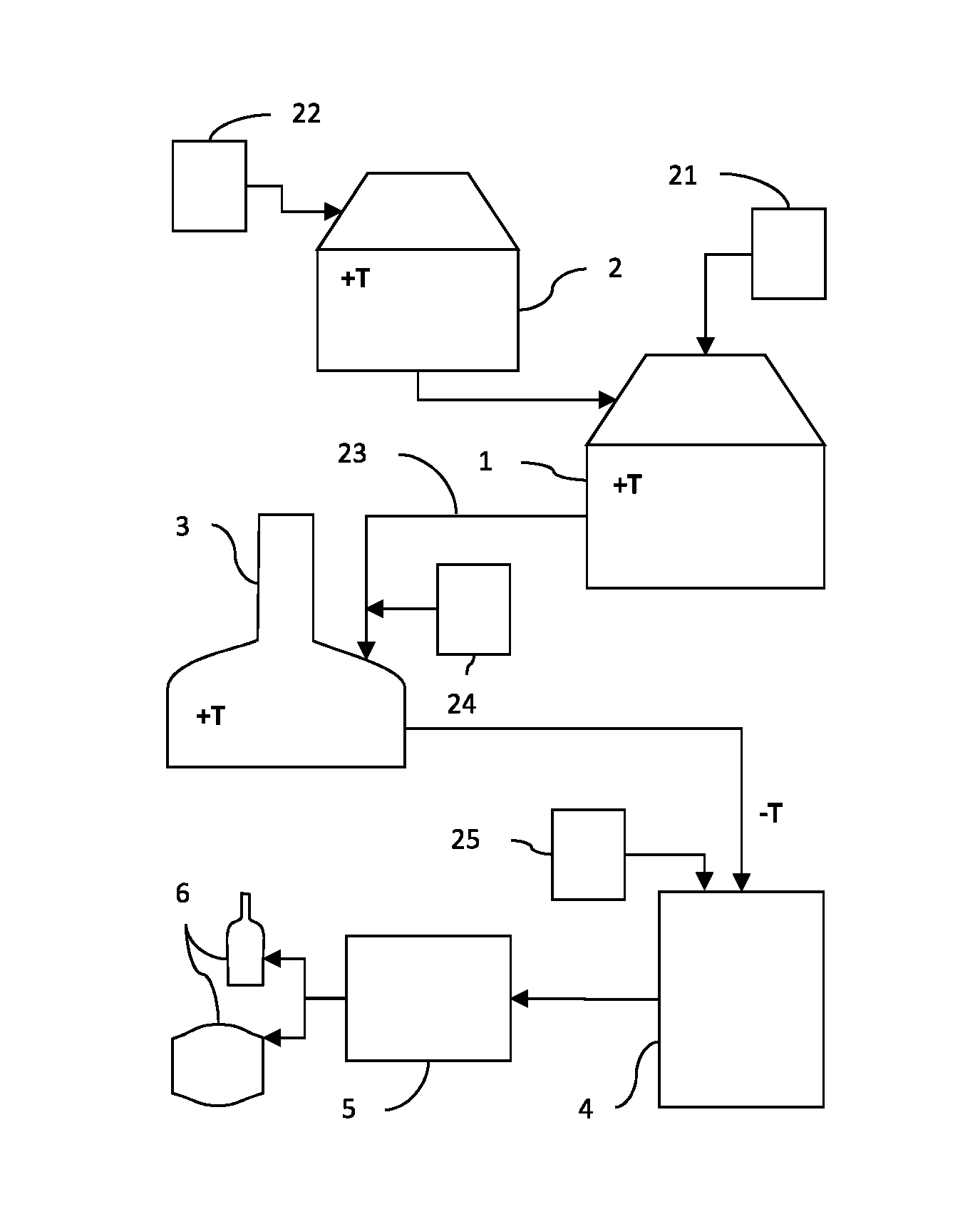

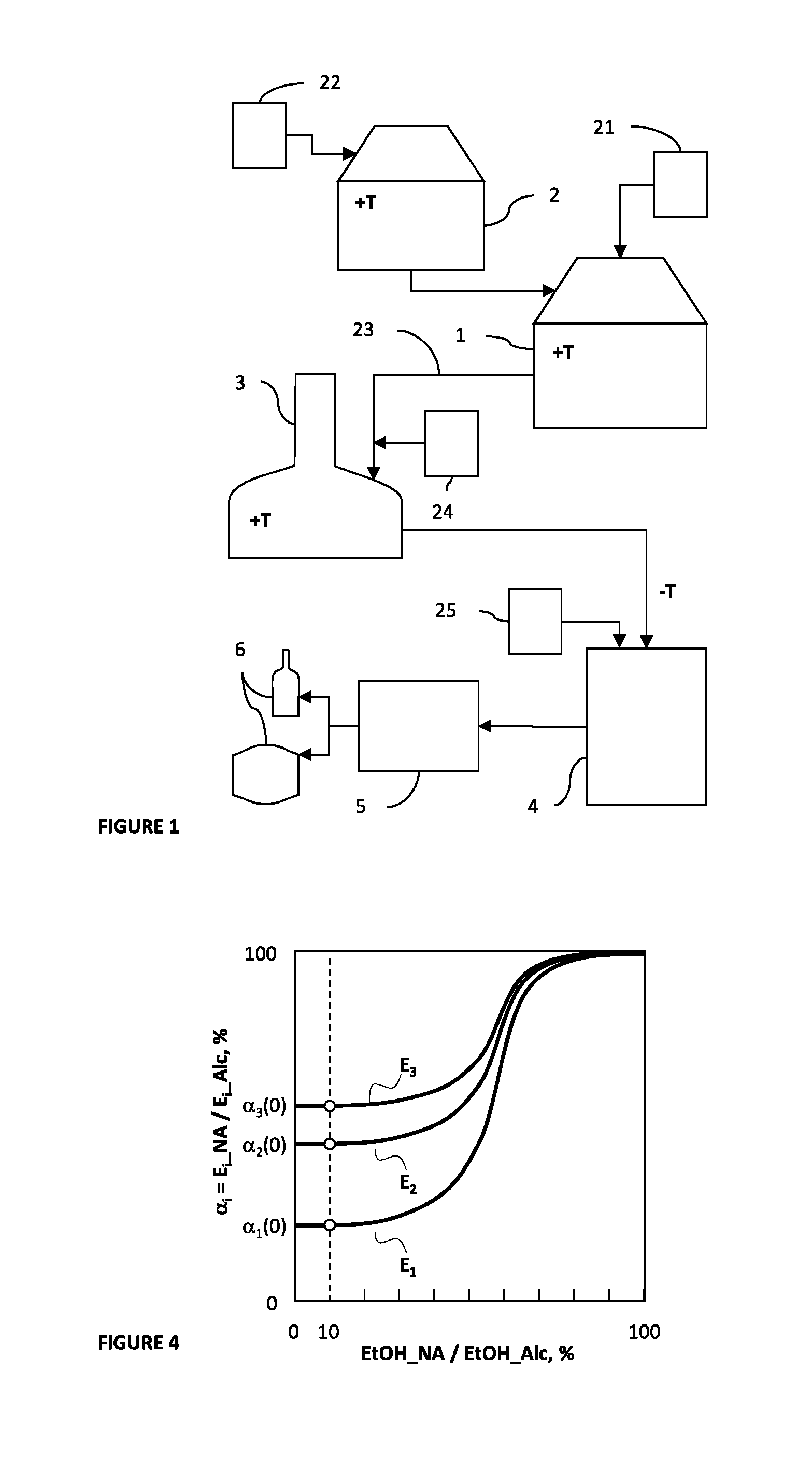

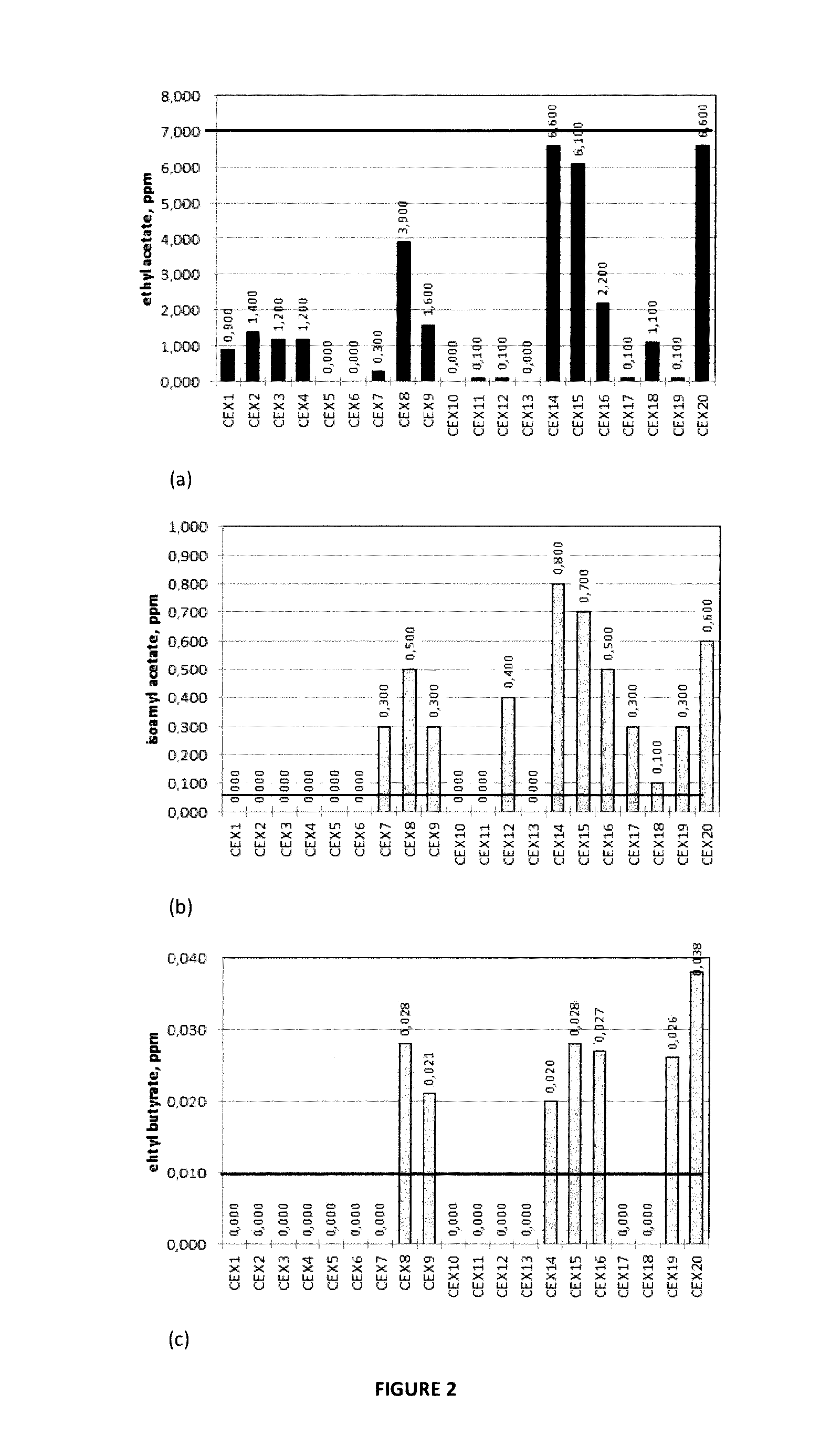

Low Alcohol or Alcohol Free Fermented Malt Based Beverage and Method for Producing It

An alcohol free or low alcohol fermented malt based beverage is disclosed. The malt based beverage has an alcohol content of not more than 1.0 vol. % preferably not more than 0.7 vol. % having an aroma profile close to the one of alcoholic lager beers. The beverage has 7.00-30.00 ppm ethyl acetate and 0.01-0.20 ppm ethyl butyrate. The beverage preferably has the esters 0.05-2.00 ppm isoamyl acetate; 0.01-0.10 ppm ethyl butyrate; and 0.01-0.05 ppm ethyl hexanoate. The beverage preferably has the higher alcohol 5.00-30.00 ppm (iso-)amyl alcohol. The (iso)amyl alcohol is defined as the sum of 3-methyl butanol and 2-methyl butanol.

Owner:ANHEUSER BUSCH INBEV SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com