Patents

Literature

277 results about "Solar cell efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solar cell efficiency refers to the portion of energy in the form of sunlight that can be converted via photovoltaics into electricity by the solar cell. The efficiency of the solar cells used in a photovoltaic system, in combination with latitude and climate, determines the annual energy output of the system. For example, a solar panel with 20% efficiency and an area of 1 m² will produce 200 W at Standard Test Conditions, but it can produce more when the sun is high in the sky and will produce less in cloudy conditions or when the sun is low in the sky. In central Colorado, which receives annual insolation of 2000 kWh/m²/year, such a panel can be expected to produce 400 kWh of energy per year. However, in Michigan, which receives only 1400 kWh/m²/year, annual energy yield will drop to 280 kWh for the same panel. At more northerly European latitudes, yields are significantly lower: 175 kWh annual energy yield in southern England.

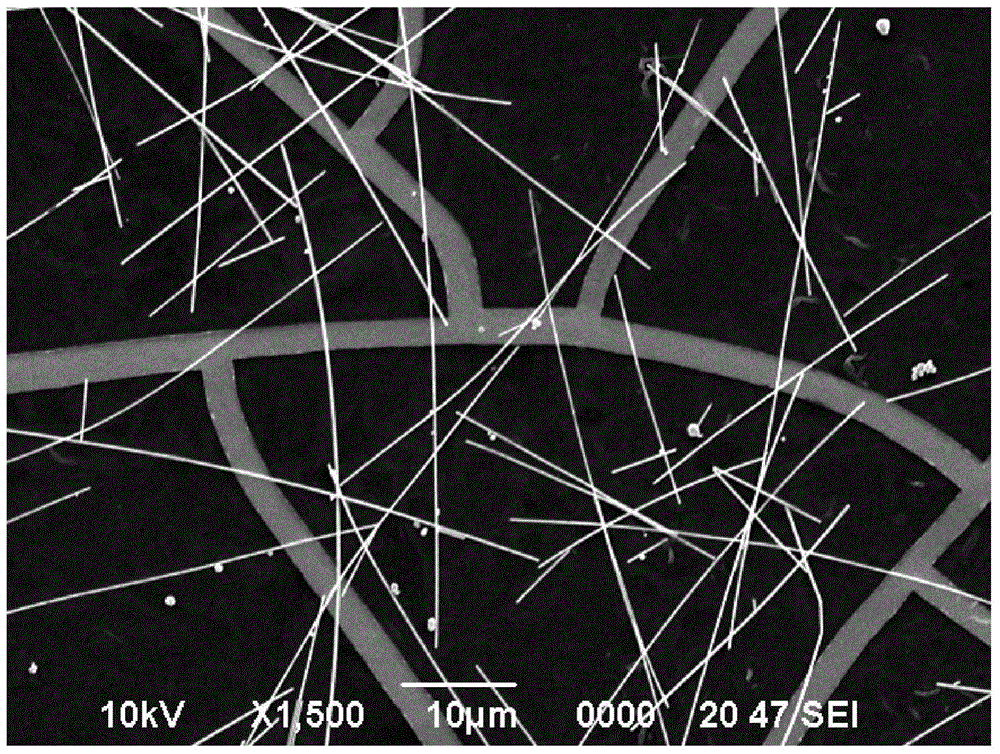

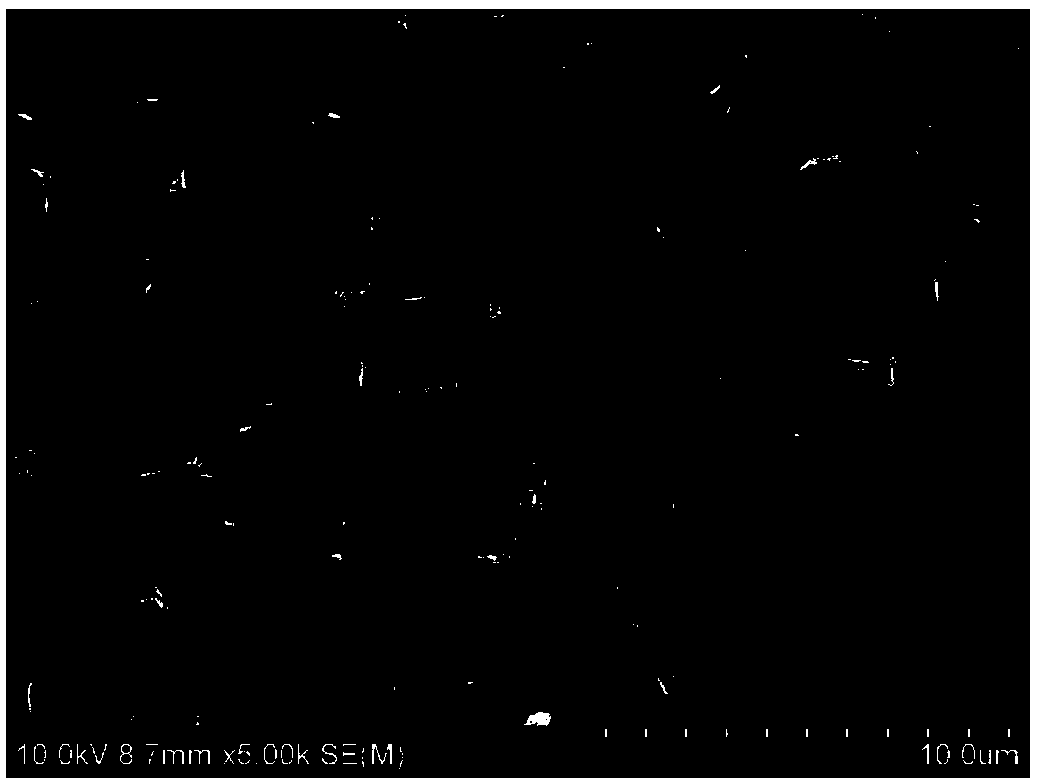

Method for preparing porous metal film transparent conducting electrode based on cracking template method

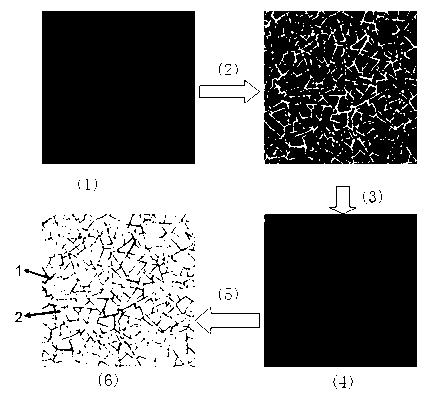

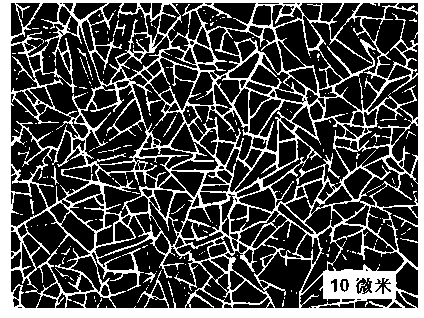

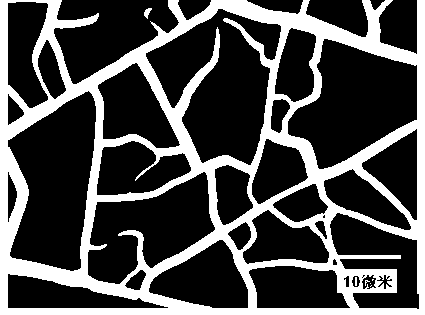

ActiveCN103227240AEasy to makeReduce usageFinal product manufactureSemiconductor devicesHYDROSOLMaterials science

A method for preparing a porous metal film transparent conducting electrode based on a cracking template method comprises the following steps: (1) synthesizing cracking liquid: taking tetrabutyl titanate as a raw material to synthesize microcrystalline titanium dioxide collosol, and obtaining the cracking liquid, (2) fabricating a cracking template: uniformly depositing a cracking film on a substrate with the cracking liquid by a spin-coating method or a lifting method, controlling a temperature condition to allow the cracking film to be cracked naturally to form the cracking template, (3) depositing a metal film: depositing the dense metal film on the cracking template by a magnetron sputtering manner, and (4) removing the cracking template: removing the cracking template from the substrate, cleaning the surface, and forming the porous metal film transparent electrode on the substrate. The transparent conducting electrode prepared with the method has excellent photoelectric properties and higher mechanical and environmental stability; a preparation technology is simple; the resource consumption is low; the transparent conducting electrode is a favorable replacer of the traditional metal oxide electrode; the efficiency of a solar cell can be improved; and the cost can be lowered.

Owner:SOUTH CHINA NORMAL UNIVERSITY

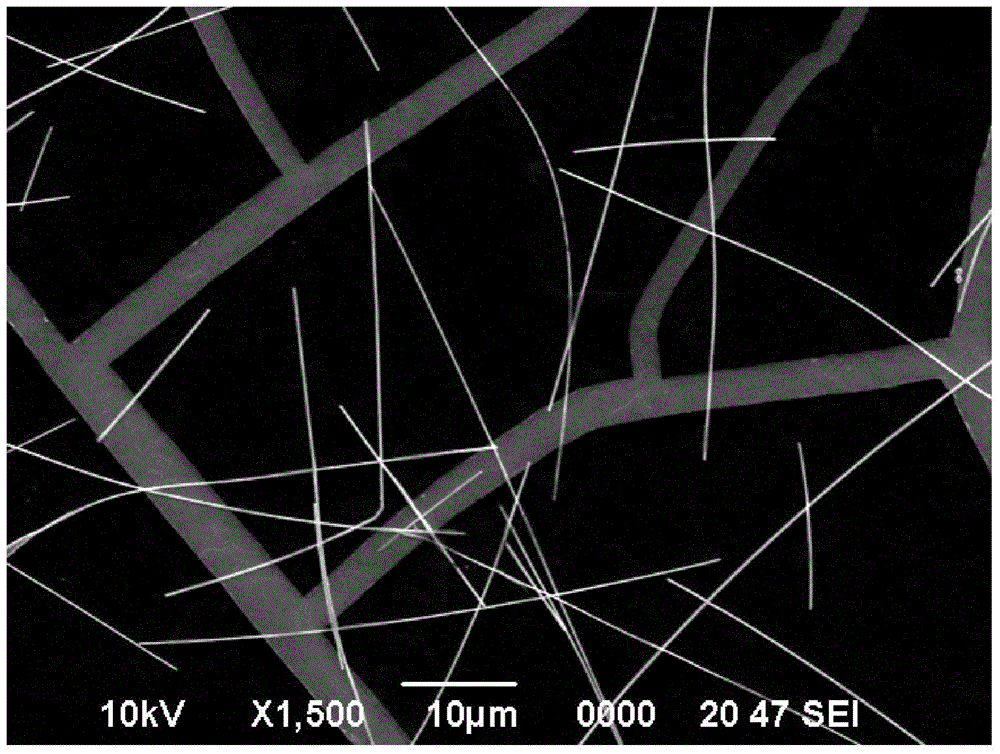

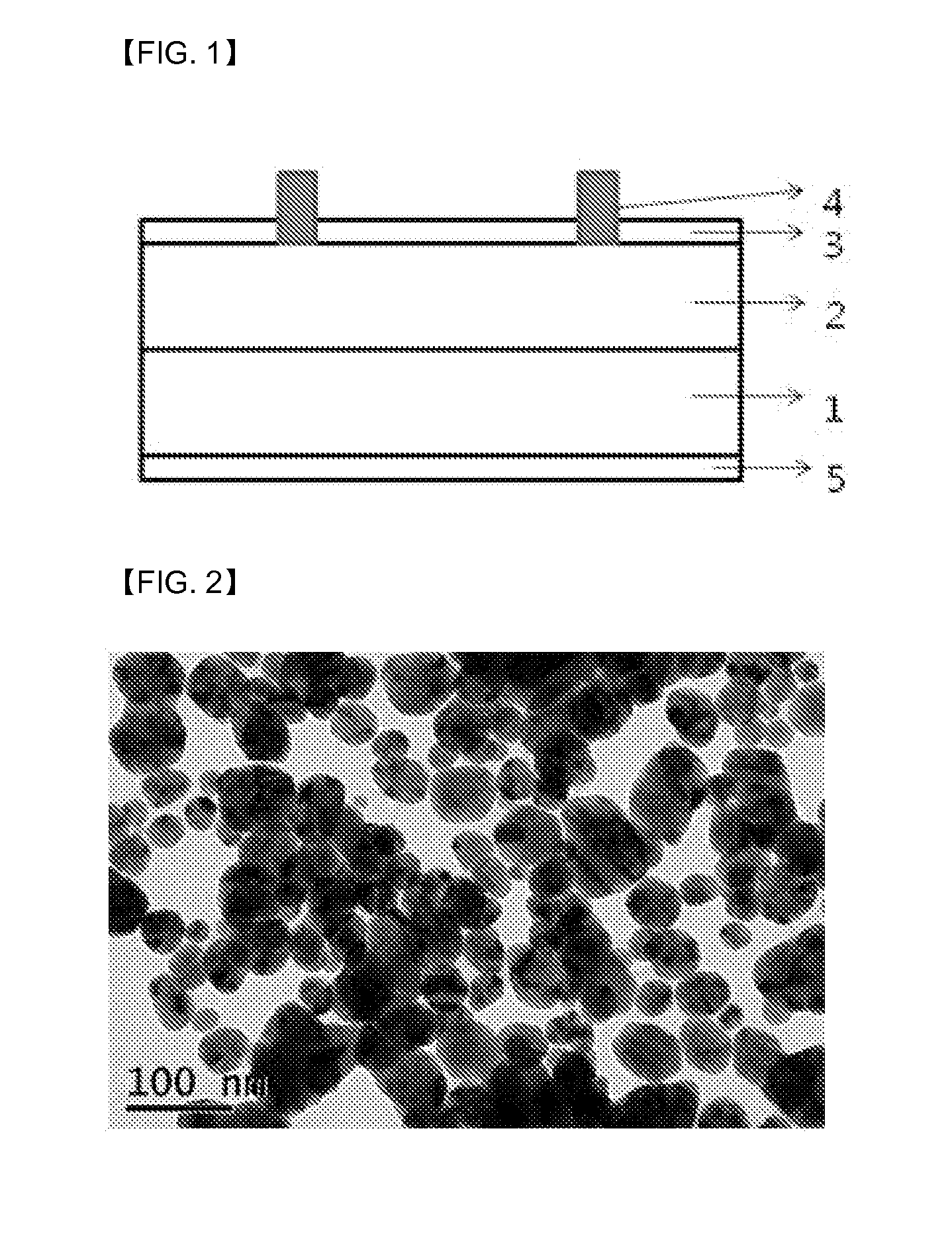

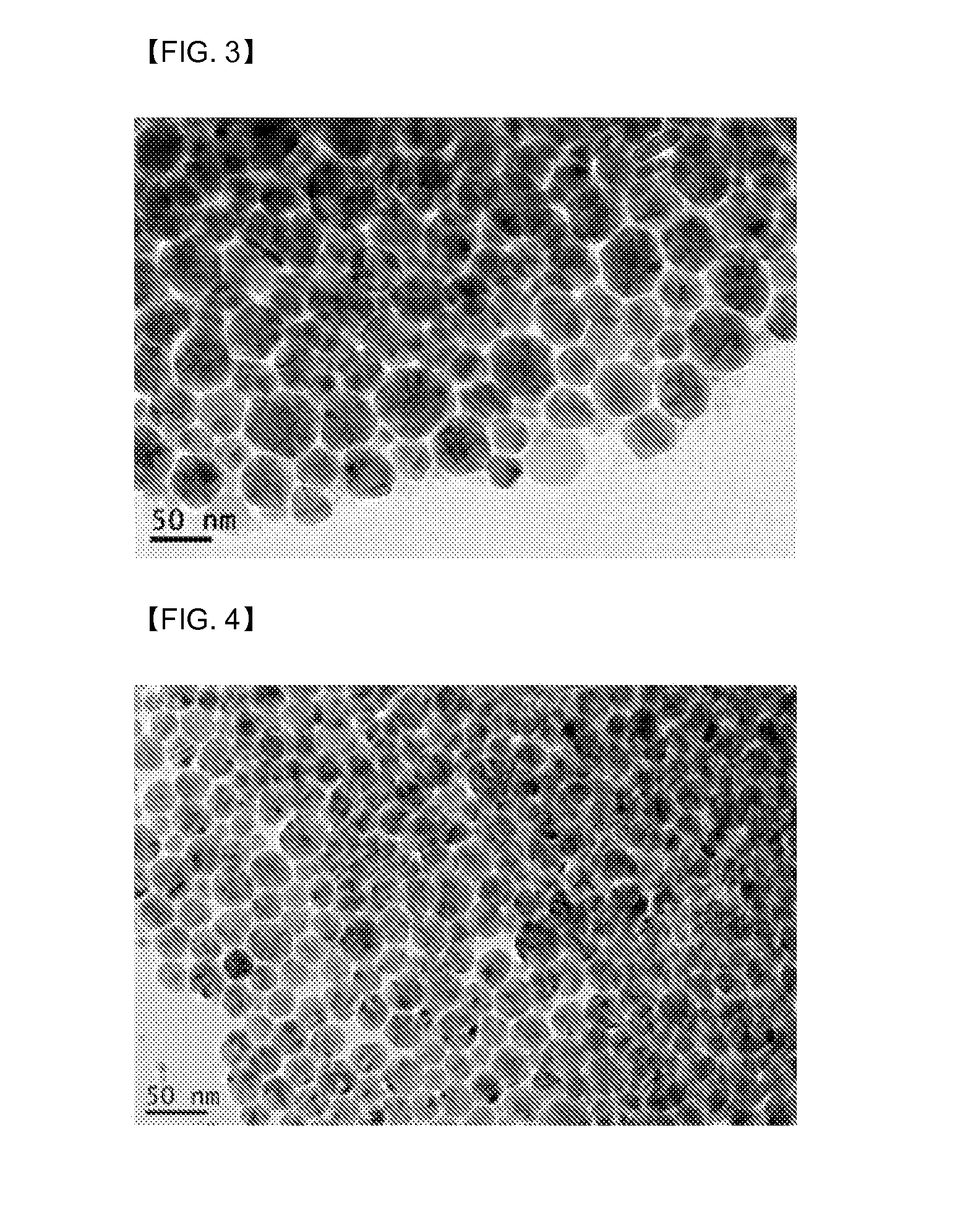

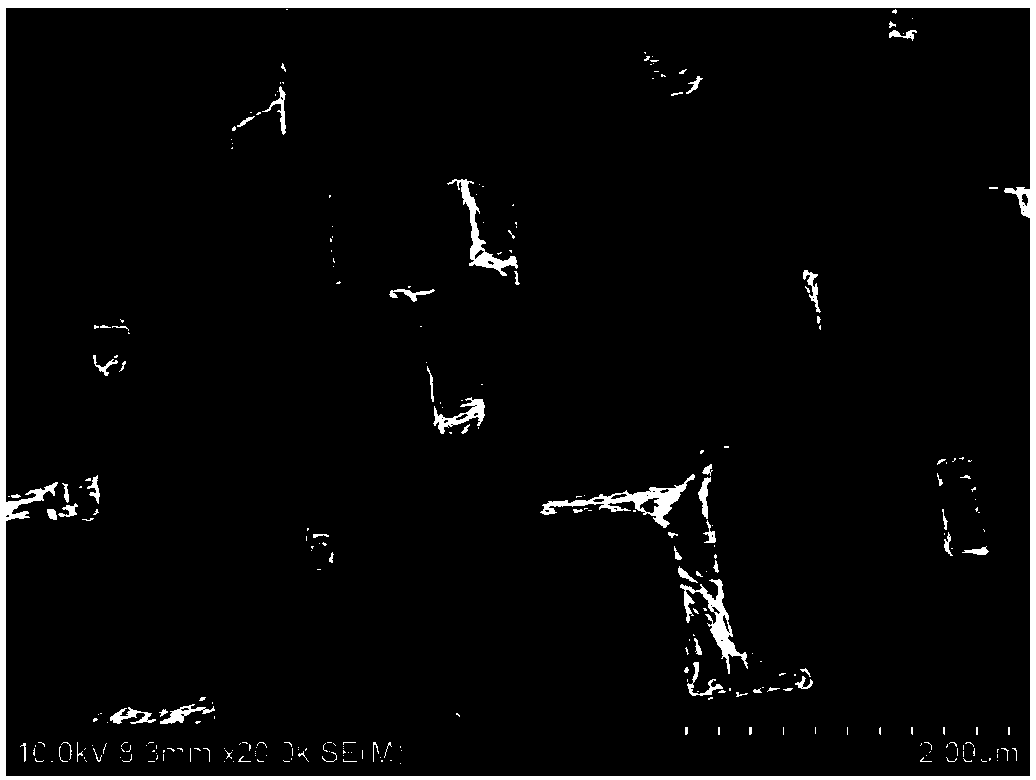

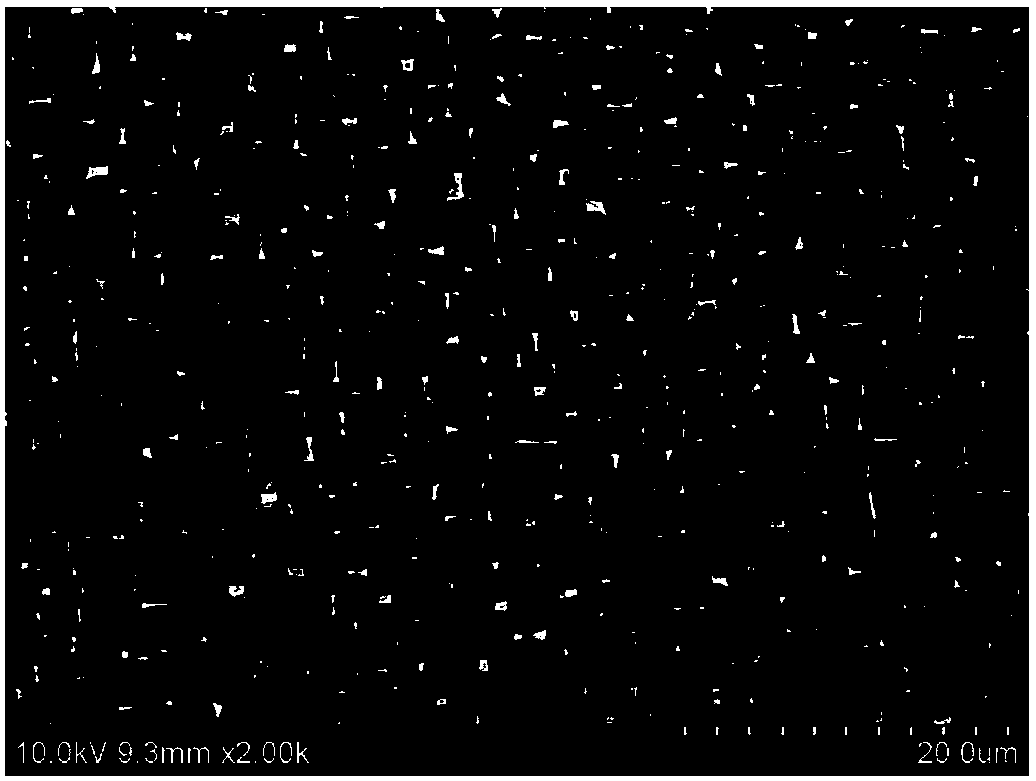

Method for preparing composite transparent conductive electrode based on metal grid and metal nano-wire

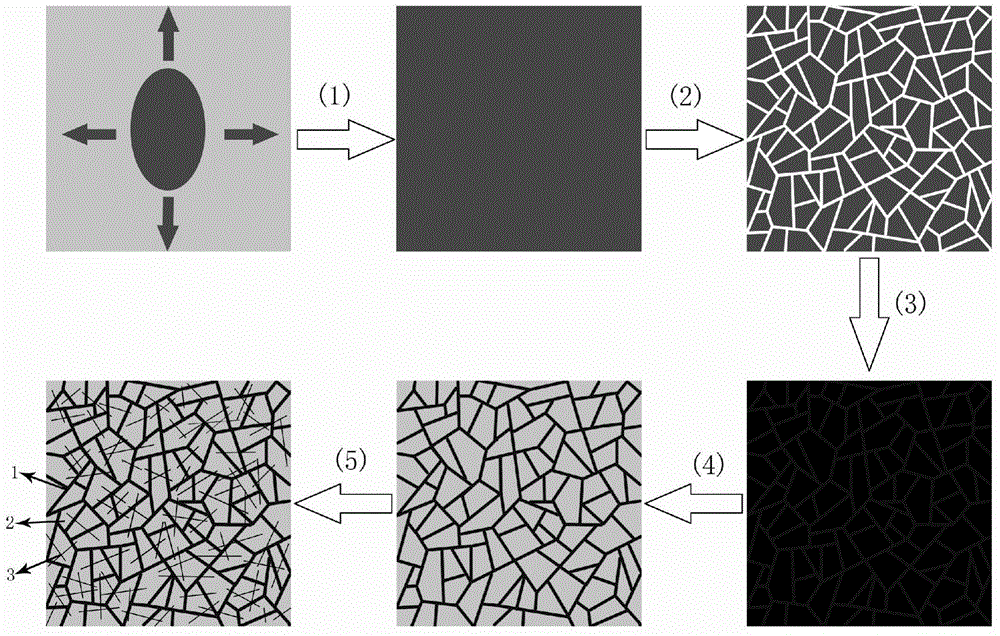

ActiveCN104681645AImprove conductivityEasy to prepareFinal product manufactureSemiconductor devicesNanowireResource consumption

The invention discloses a method for preparing a composite transparent conductive electrode based on a metal grid and a metal nano-wire. The method comprises the following steps: (1) preparing a template solution; (2) manufacturing a sacrificial layer template; (3) depositing a metal thin film; (4) removing the sacrificial layer template; (5) synthesizing the metal nano-wire; and (6) coating the metal nano-wire to prepare the composite transparent conductive electrode. The composite transparent conductive electrode prepared by the method has excellent photoelectric property and environment stability; meanwhile, the electrode in a photoelectric device can be easily in contact with other functional layers; the preparation process is simple and the resource consumption is low; the composite transparent conductive electrode is a good substitute of a traditional metal oxide electrode, and the efficiency of a solar battery can be improved and the cost is reduced.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Acidic texturing solution for etching solar cell silicon wafer, texturing method, solar cell silicon wafer and manufacturing method of solar cell silicon wafer

ActiveCN104195645AReduce reflectionIncrease the optical pathAfter-treatment detailsFinal product manufactureInverted pyramidFluoride

The invention discloses an acidic texturing solution for etching a solar cell silicon wafer, a texturing method, a solar cell silicon wafer and a manufacturing method of the solar cell silicon wafer. The acidic texturing solution comprises a copper ion source for providing 0.1-25mmol / L copper ions, a fluoride ion source for providing 0.5-10mol / L fluoride ions, and a 0.1-1.0mol / L oxidant for oxidizing copper into the copper ions. The surface of the silicon wafer is preferably textured by virtue of the acidic texturing solution and thus an independent, complete and compactly arranged micron-size inverted pyramid-shaped structure is formed on the surface of the silicon wafer at a relatively low temperature and a relatively short time. By adopting the inverted pyramid-shaped structure, the reflectivity of an incident light on the textured surface is reduced to 5%-15% such that the efficiency of the solar cell is improved. The inverted pyramid-shaped structure disclosed by the invention is not limited to the preparation of an HIT and a conventional diffusion cell and can be also applied in other solar cells and optoelectronic devices using a silicon substrate.

Owner:深圳市石金科技股份有限公司

Methods of texturing surfaces for controlled reflection

InactiveUS20130295712A1Semiconductor/solid-state device manufacturingPhotovoltaic energy generationRemote plasmaNanoparticle

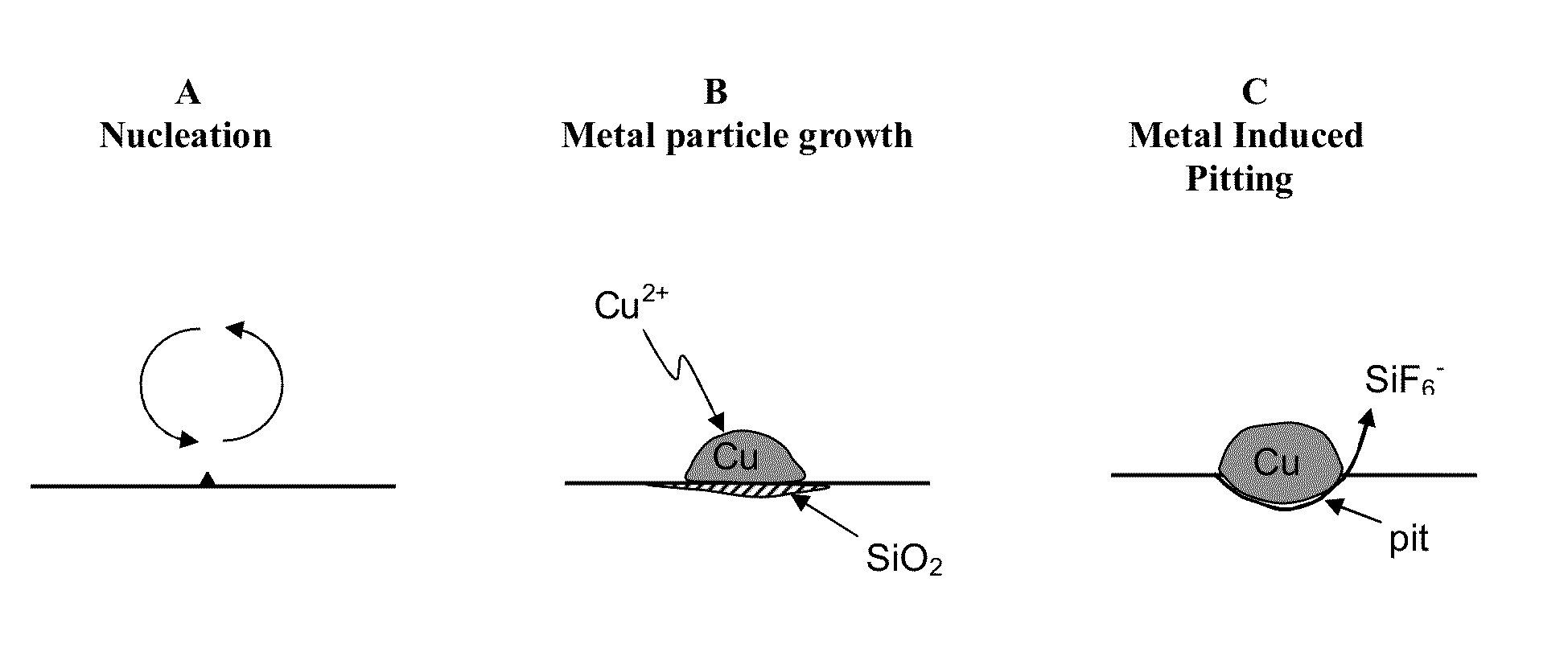

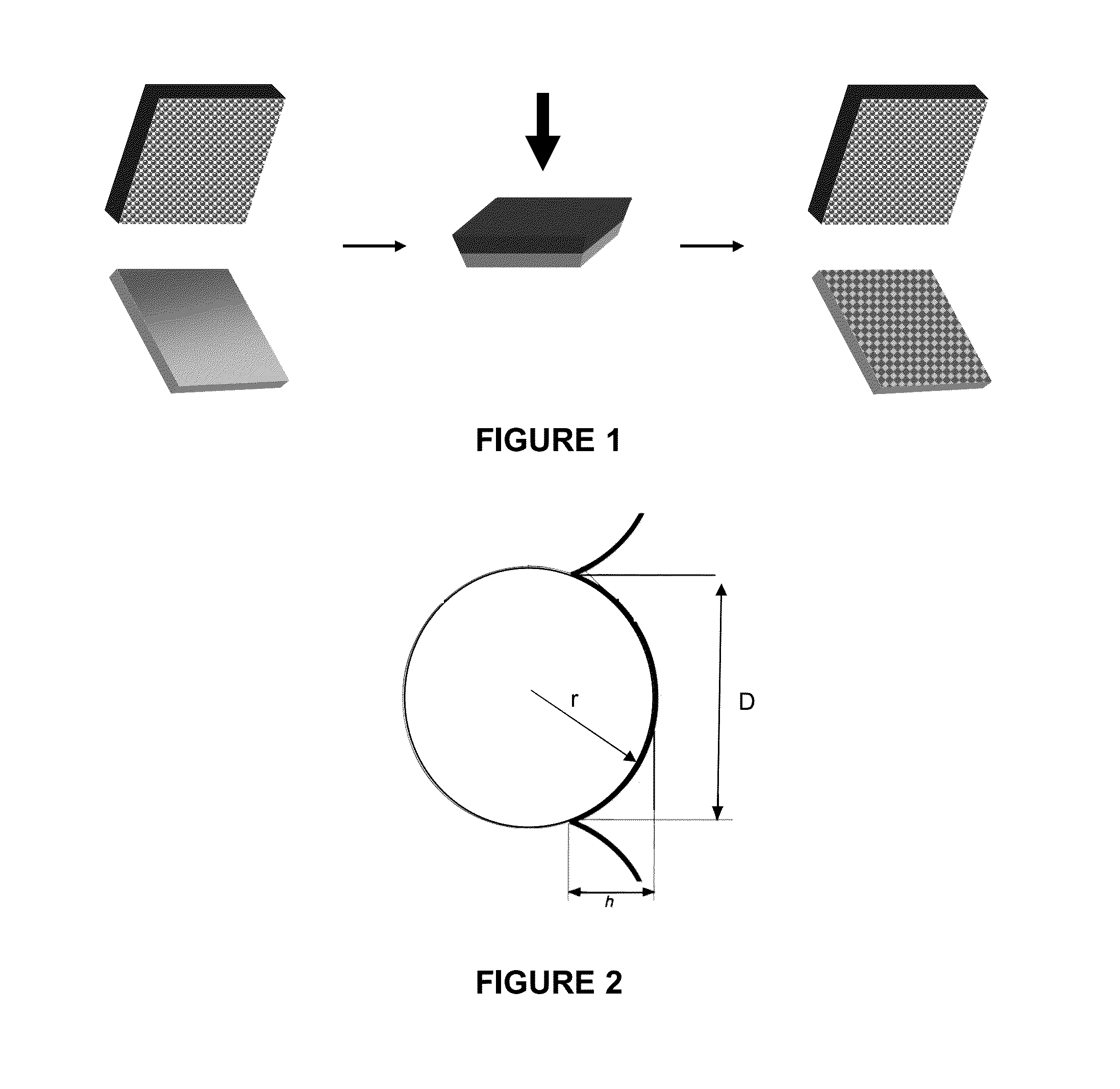

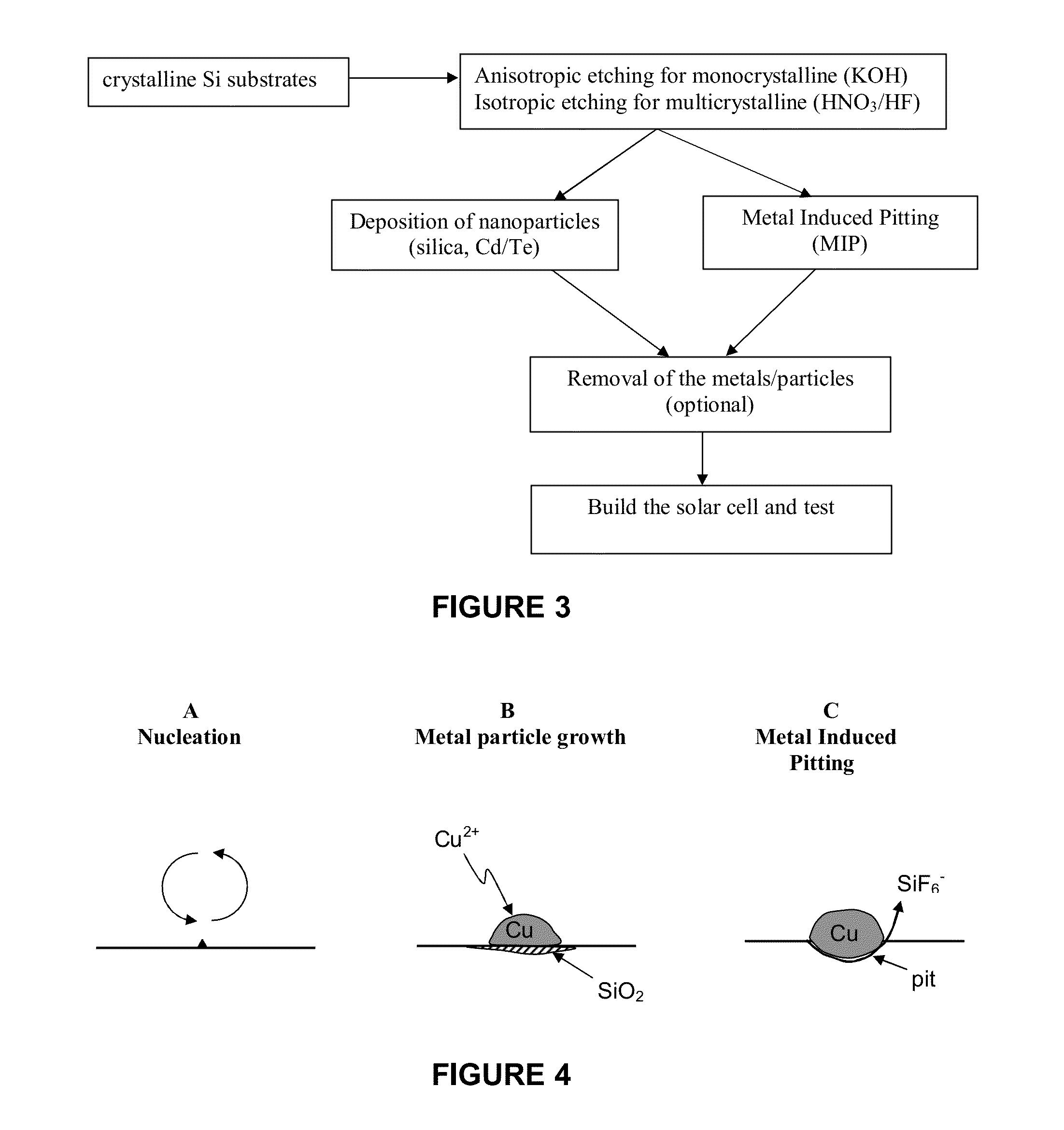

Novel methods for the texturing of photovoltaic cells is described, wherein texturing minimizes reflectance losses and hence increases solar cell efficiency. In one aspect, a microstamp with the mirror inverse of the optimum surface structure is described. The photovoltaic cell substrate to be etched and the microstamp are immersed in a bath and pressed together to yield the optimum surface structure. In another aspect, micro and nanoscale structures are introduced to the surface of a photovoltaic cell by wet etching and depositing nanoparticles or introducing metal induced pitting to a substrate surface. In still another aspect, remote plasma source (RPS) or reactive ion etching (RIE), is used to etch nanoscale features into a silicon-containing substrate.

Owner:ADVANCED TECH MATERIALS INC

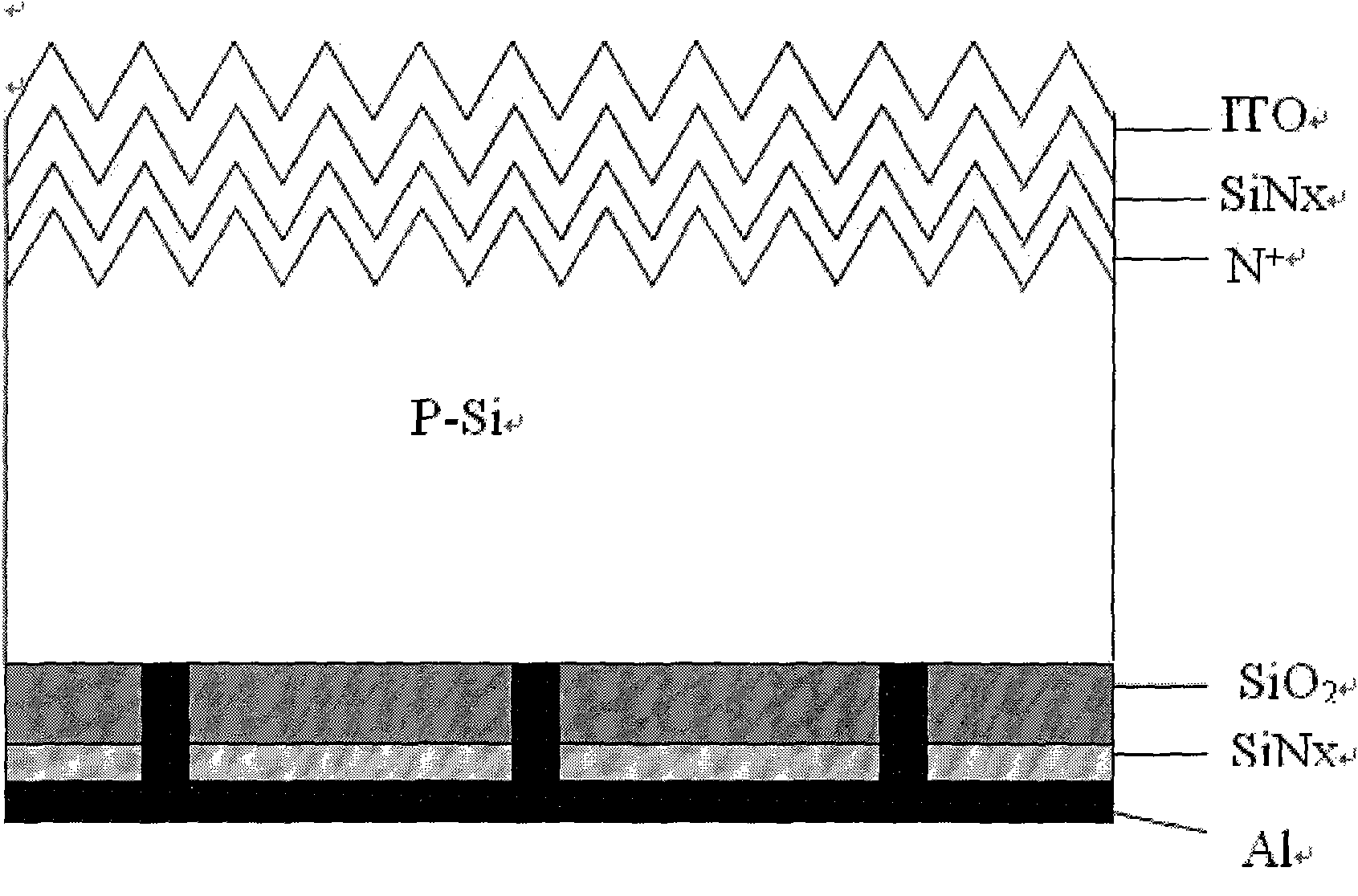

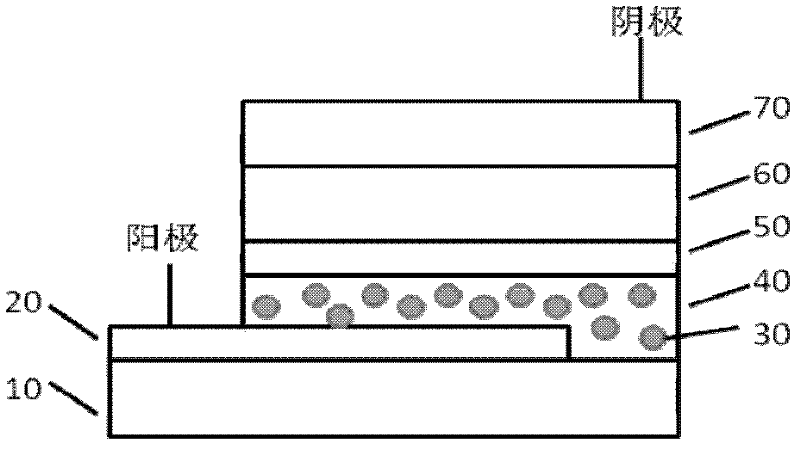

Preparation method of solar cell with buried charge layer

ActiveCN101882650AIncrease short circuit currentAvoid churnFinal product manufactureSemiconductor devicesCharge layerElectrode Contact

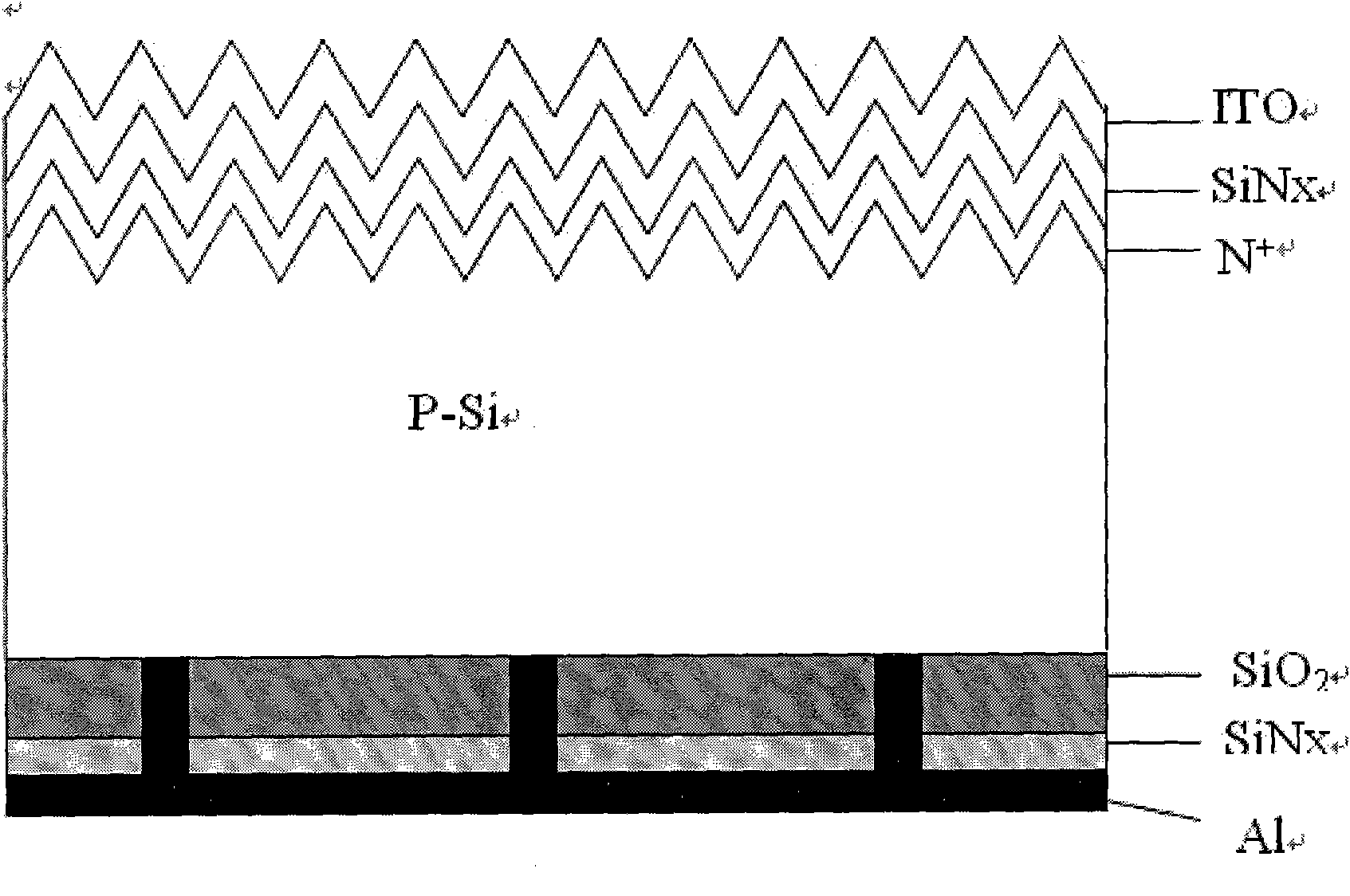

The invention relates to a monocrystalline silicon solar cell and a preparation method thereof, in particular to a monocrystalline silicon solar cell with a buried charge layer introduced into a passivating dielectric layer, and belongs to the technical field of the preparation of solar cell devices. The monocrystalline silicon solar cell is developed based on the preparation scheme of the general monocrystalline silicon solar cell and adopts a structure of partial back contact, and the preparation method is characterized by comprising the steps of: growing an SiO2 layer on the back of a solar cell by utilizing a thermal oxidation or atomic layer deposition technology, growing a layer of SiNx thin film by using PECVD (Plasma Enhanced Chemical Vapor Deposition), etching a back electrode contact area by using a laser grooving technology, then injecting electrons with a corona mode, and finally depositing an Al electrode with a vacuum evaporation mode. The invention can effectively improve the solar cell efficiency.

Owner:南通东湖国际商务服务有限公司

Paste composition for front electrode of solar cell and solar cell using the same

InactiveUS20140318618A1Decreased front electrode resistanceImprove battery efficiencyMaterial nanotechnologyLiquid surface applicatorsHexanoic acidSolar cell efficiency

The present invention relates to a paste composition for a front electrode of a solar cell comprising nano silver powder surface-treated with hexanoic acid, and a solar cell comprising a front electrode formed using the paste composition.According to the present invention, a front electrode is formed using a paste composition containing nano silver powder surface-treated with hexanoic acid, thereby decreasing resistance of a front electrode and broadening an area capable of absorbing light, to improve solar cell efficiency.

Owner:HANWHA CHEMICAL CORPORATION

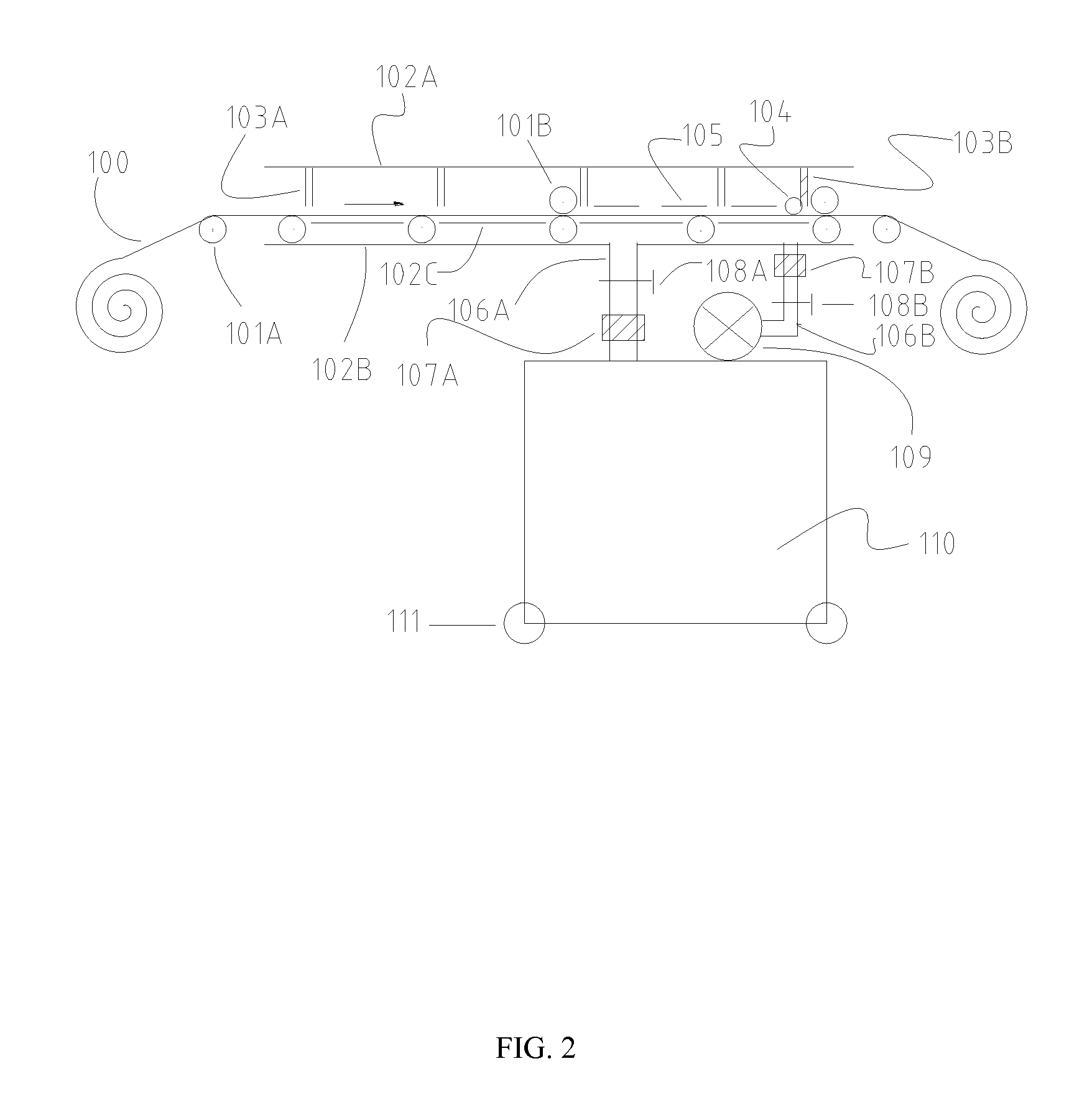

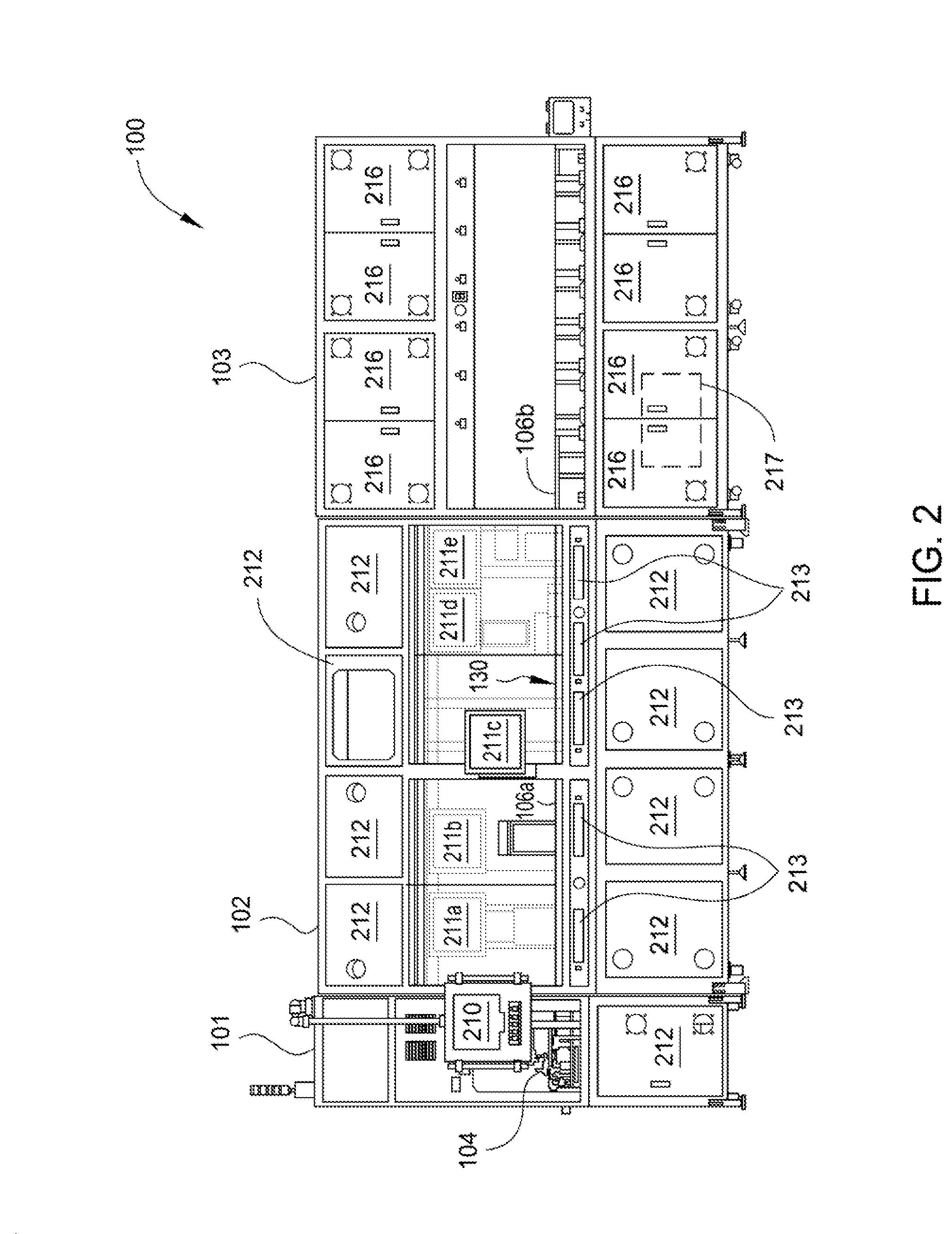

Production Line to Fabricate CIGS Thin Film Solar Cells via Roll-to-Roll Processes

InactiveUS20130224901A1Reduce manufacturing costImprove the quality of workLiquid surface applicatorsFinal product manufactureProduction lineModularity

An industrial production line is presented to fabricate CIGS thin film solar cells on continuous flexible substrates in roll-to-roll processes. It provides an entire solution including procedures and related equipments from starting blank substrates to completed solar cells that can be used to fabricate solar modules. This production line contains some core apparatuses, such as a modular electroplating system to deposit CIGS materials, a modular thermal reactor to annealing the CIGS films, and a chemical bath deposition reactor to coat CdS buffer layer, are recently invented by the present inventor. The present production line can be conveniently used to prepare the CIGS thin film solar cells with high efficiency but low cost.

Owner:WANG JIAXIONG

Passivated, dye-sensitized oxide semiconductor electrode, solar cell using same, and method

InactiveUS20060005877A1Improve efficiencyAvoid reorganizationElectrolytic capacitorsSolid-state devicesBattery cellSemiconductor

Disclosed is a dye-sensitized oxide semiconductor electrode comprising an electrically conductive substrate, an oxide semiconductor film provided on a surface of said electrically conductive substrate, and a sensitizing dye adsorbed on said film, wherein the oxide semiconductor film has been further treated with at least one silanizing agent comprising the partial structure R1—Si—OR2, wherein R1 and R2 are each independently alkyl groups, or R1 is an alkyl group and R2 is hydrogen or aryl. Also disclosed are solar cells comprising said electrode and a method for improving the efficiency of the solar cells. The solar cells exhibit improved efficiency and other beneficial properties compared to similar cells not having the passivated electrode.

Owner:GENERAL ELECTRIC CO

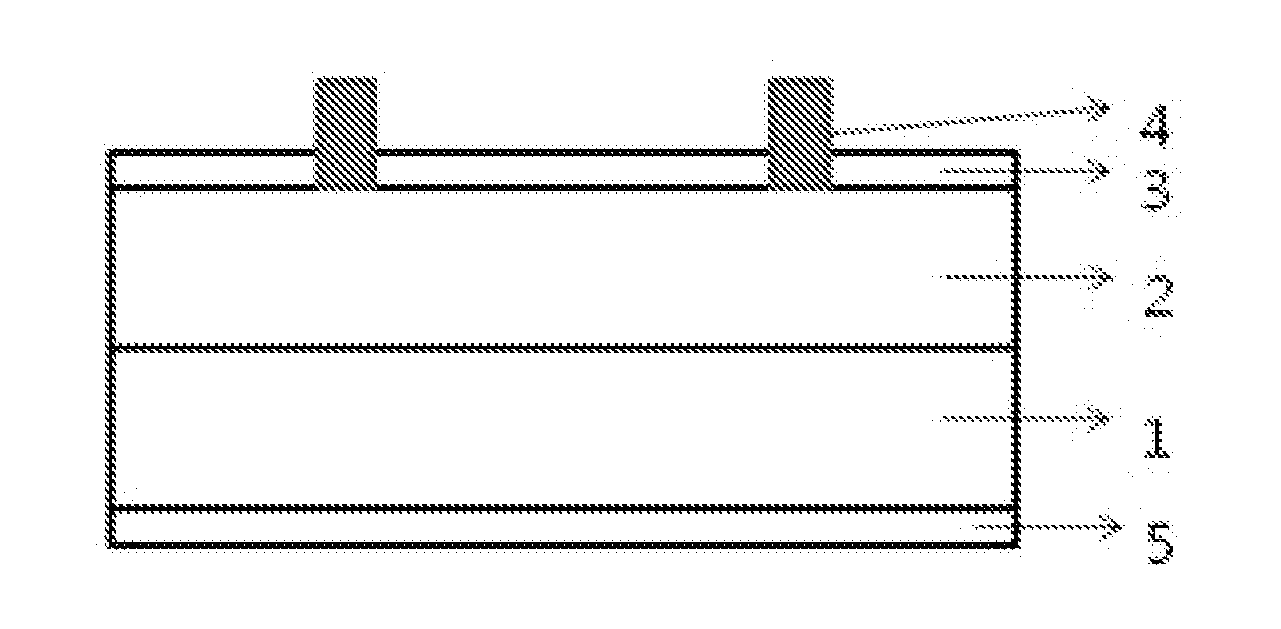

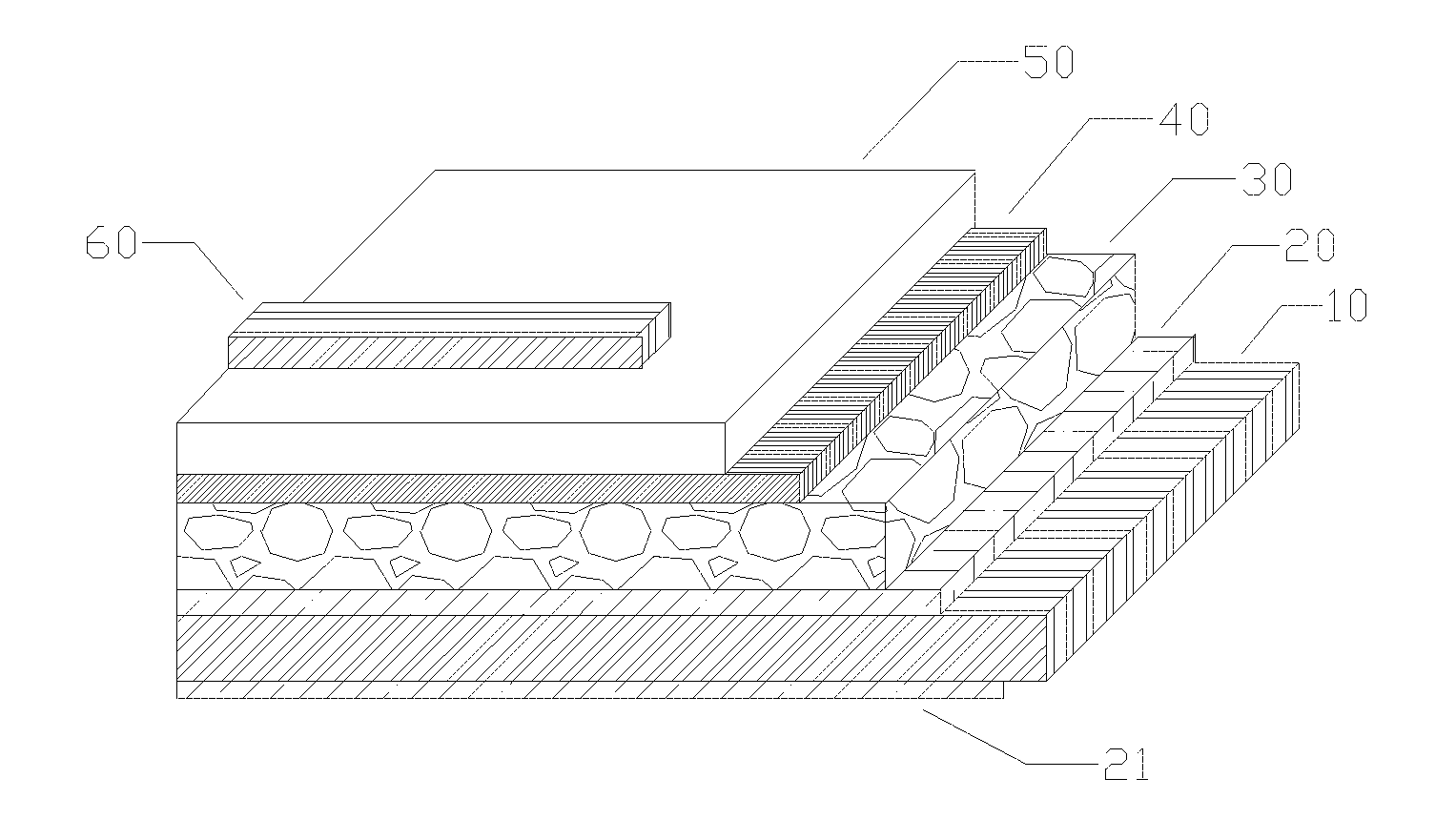

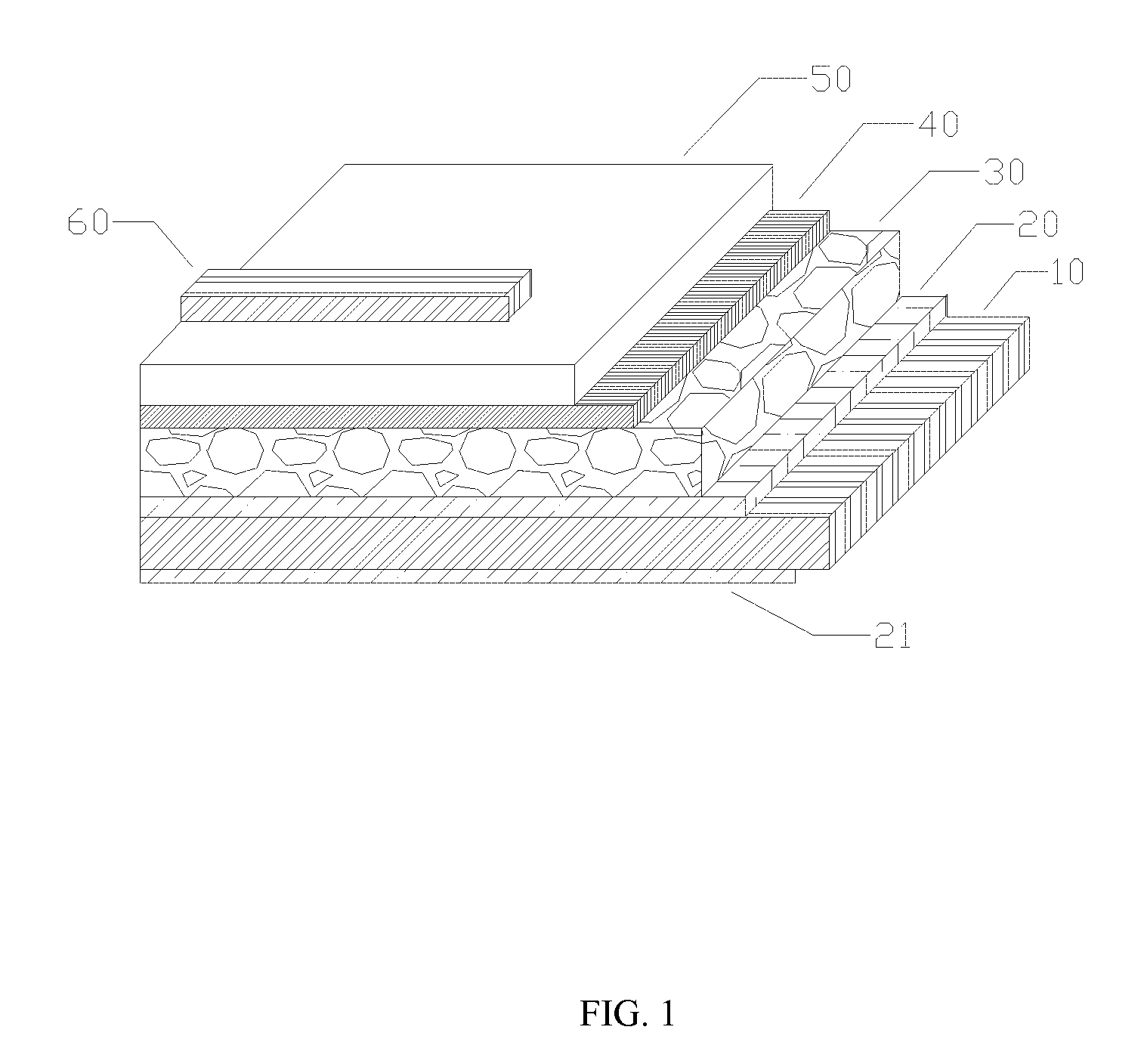

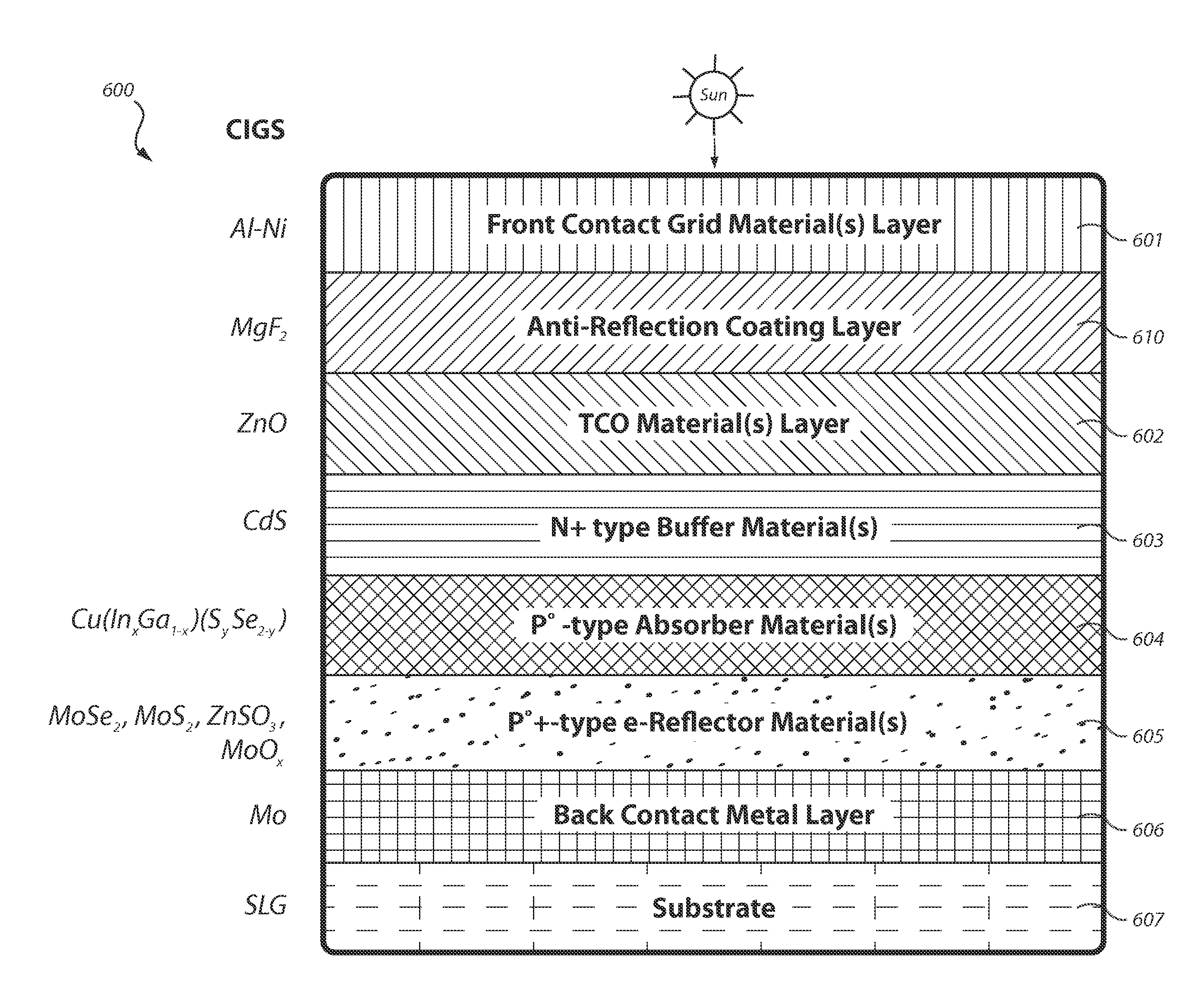

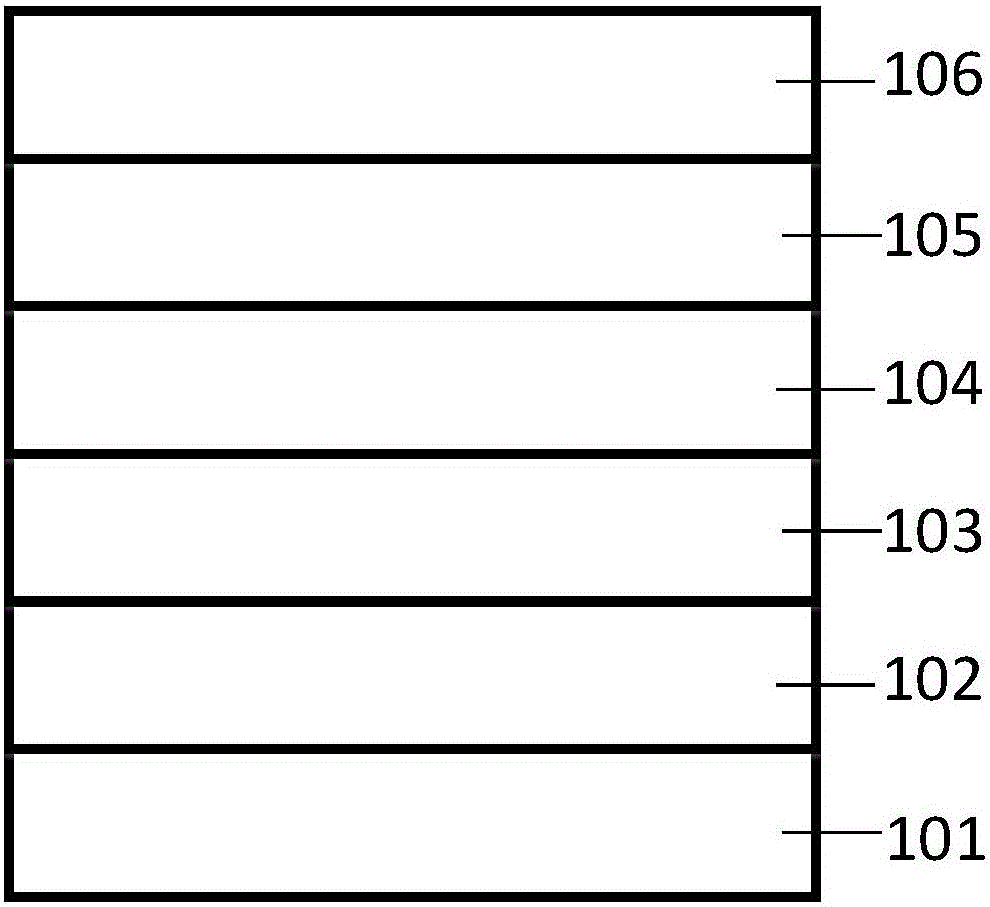

Back-Contact Electron Reflectors Enhancing Thin Film Solar Cell Efficiency

InactiveUS20140166107A1Semiconductor/solid-state device manufacturingPhotovoltaic energy generationAbsorbent materialContact layer

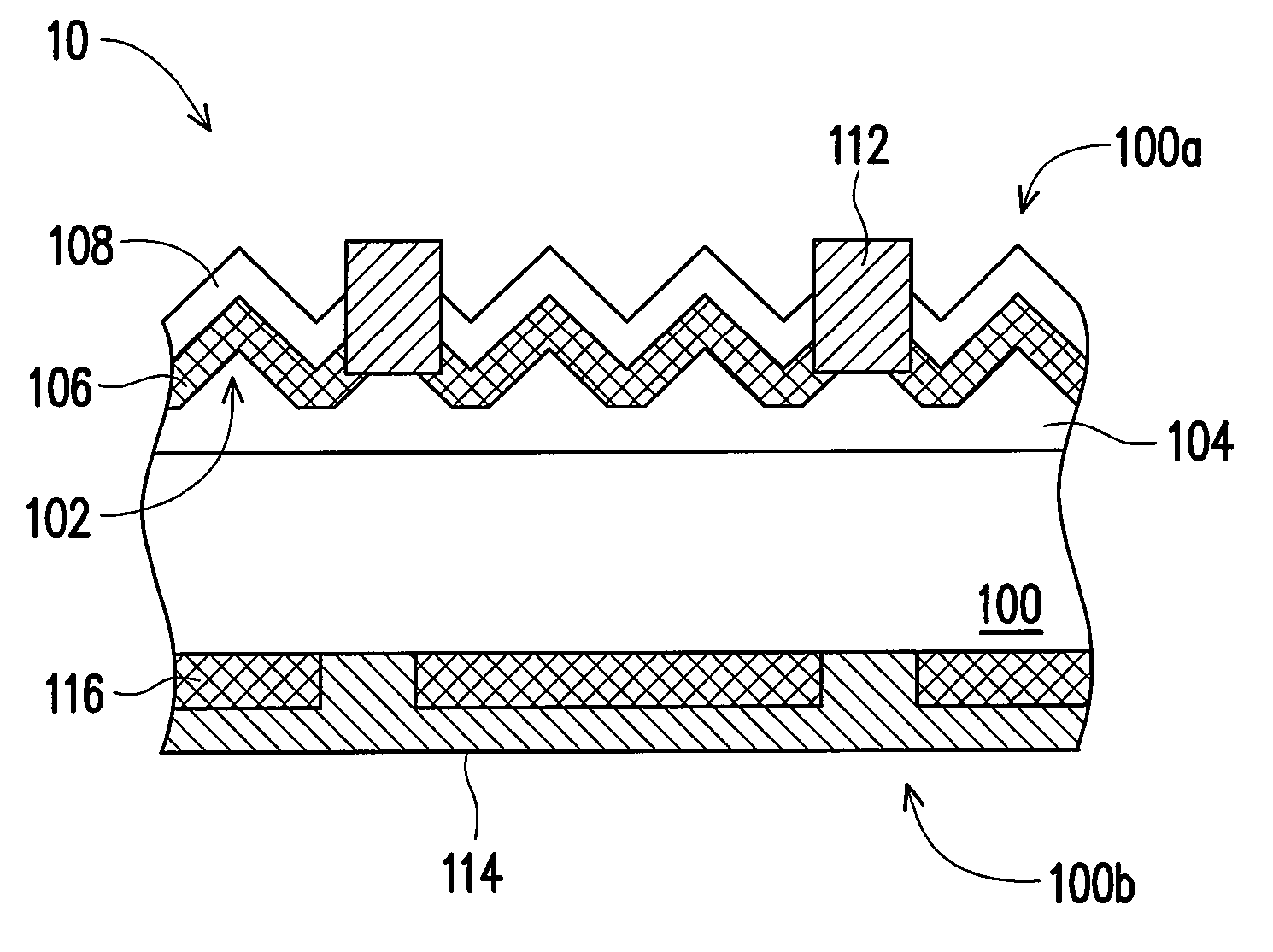

Methods for improving the efficiency of solar cells are disclosed. A solar cell consistent with the present disclosure includes a back contact metal layer disposed on a substrate. The solar cell also includes an electron reflector material(s) layer formed on the back contact metal layer and an absorber material(s) layer disposed on the electron reflector material(s) layer. In addition, the solar cell includes a buffer material(s) layer formed on the absorber material(s) layer wherein the electron reflector material(s) layer, absorber material(s) layer, and buffer material(s) layer form a pn junction within the solar cell. Furthermore, a TCO material(s) layer is formed on the buffer material(s) layer. In addition, the front contact layer is formed on the TCO material(s) layer.

Owner:INTERMOLECULAR

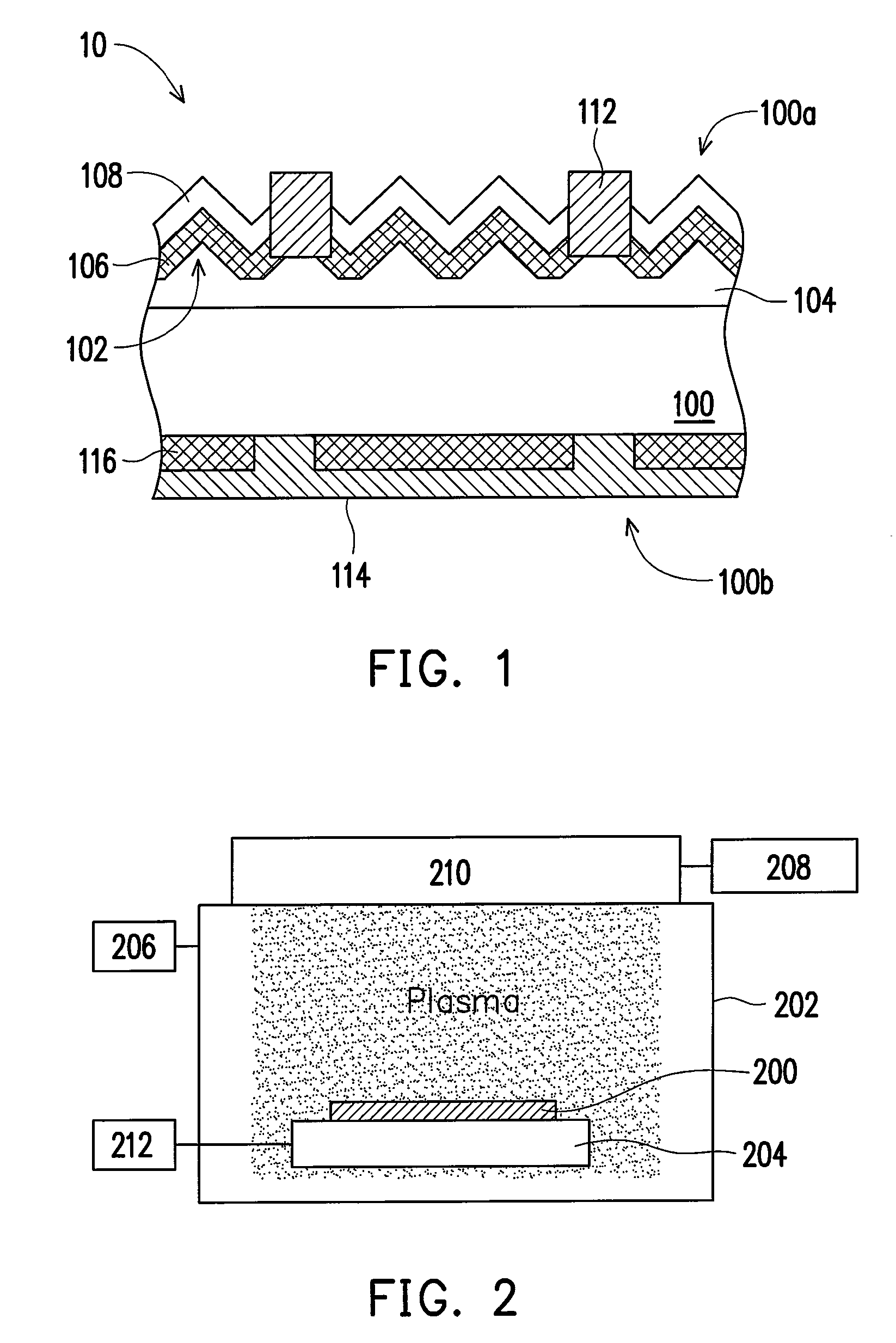

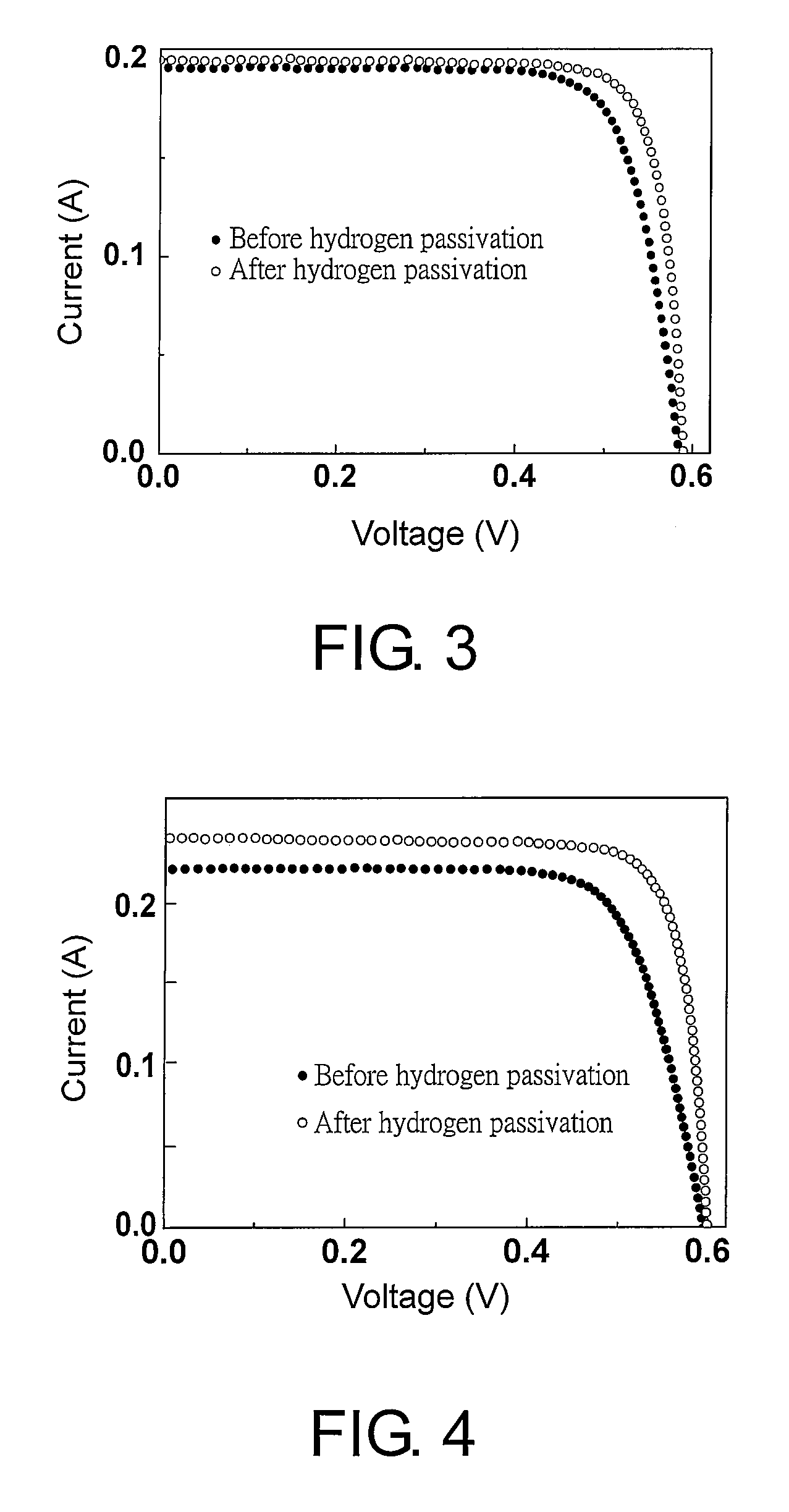

Method of fast hydrogen passivation to solar cells made of crystalline silicon

InactiveUS20090101202A1Improve performanceFast passivationFinal product manufacturePhotovoltaic energy generationCrystallographic defectHydrogen ion

A method of improving efficiency of solar cells made of crystalline silicon, including monocrystalline silicon, multicrystalline silicon and polycrystalline silicon is provided. In the method, a negative bias pulse is applied to solar cells at a predetermined voltage, a predetermined frequency, and a predetermined pulse width while immersing the solar cells in a hydrogen plasma. Hydrogen ions are attracted and quickly implanted into the solar cells. Thus, the passivation of crystal defects in the solar cells can be realized in a short period. Meanwhile, the properties of an antireflection layer cannot be damaged as proper operating parameters are used. Consequently, the serious resistance of the solar cells can be significantly reduced and the filling factor increases as a result. Further, the short-circuit current and the open-circuit voltage can be increased. Therefore, the efficiency can be enhanced.

Owner:IND TECH RES INST +1

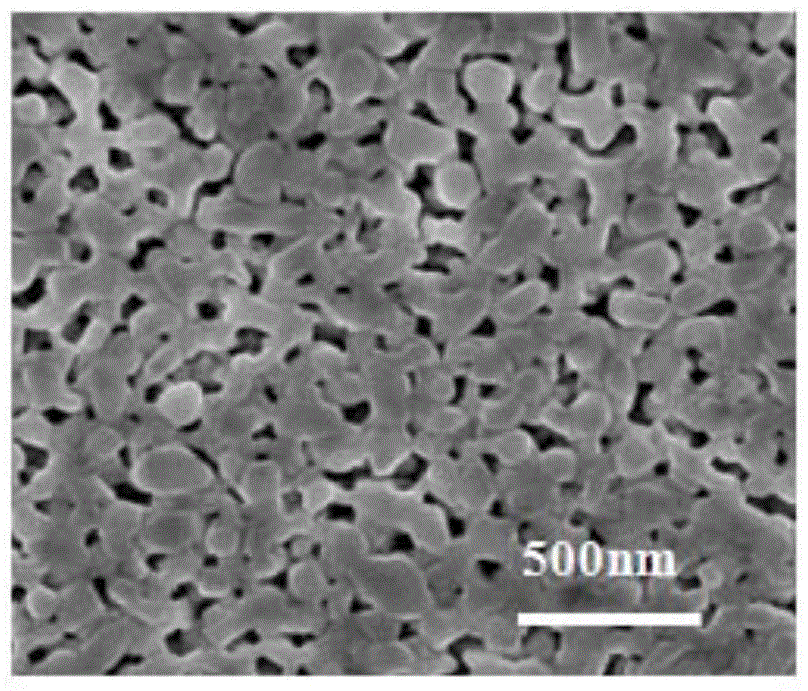

Preparation method of organic-inorganic perovskite solar battery

InactiveCN104518091AImprove uniformityImprove compactnessVacuum evaporation coatingSolid-state devicesGas phaseMetal particle

The invention discloses a preparation method of an organic-inorganic hybridization perovskite solar battery in a plane structure. The preparation method comprises the steps of selection and pretreatment of a transparent conduction substrate, magnetron sputtering of an n-type metal oxide layer or pulse laser preparation, preparation of an organic metal perovskite structure light absorption layer by a normal-pressure gas phase assistance solution method, preparation of a hole conduction layer structure, preparation of a metal alloy back electrode and the like. The method overcomes the problems of discontinuity, insufficient density, pinholes and the like of an n-type metal oxide film, an intermediate phase, pinholes, impure phases and the like of hydration organic metal halogen in a perovskite light absorption layer material, metal particle aggregation of the pure metal back electrode, layering of a hole layer and the like. The solar battery prepared by the method is high in efficiency, low in price, simple in technology, good in repeatability and suitable for mass production.

Owner:EAST CHINA NORMAL UNIV

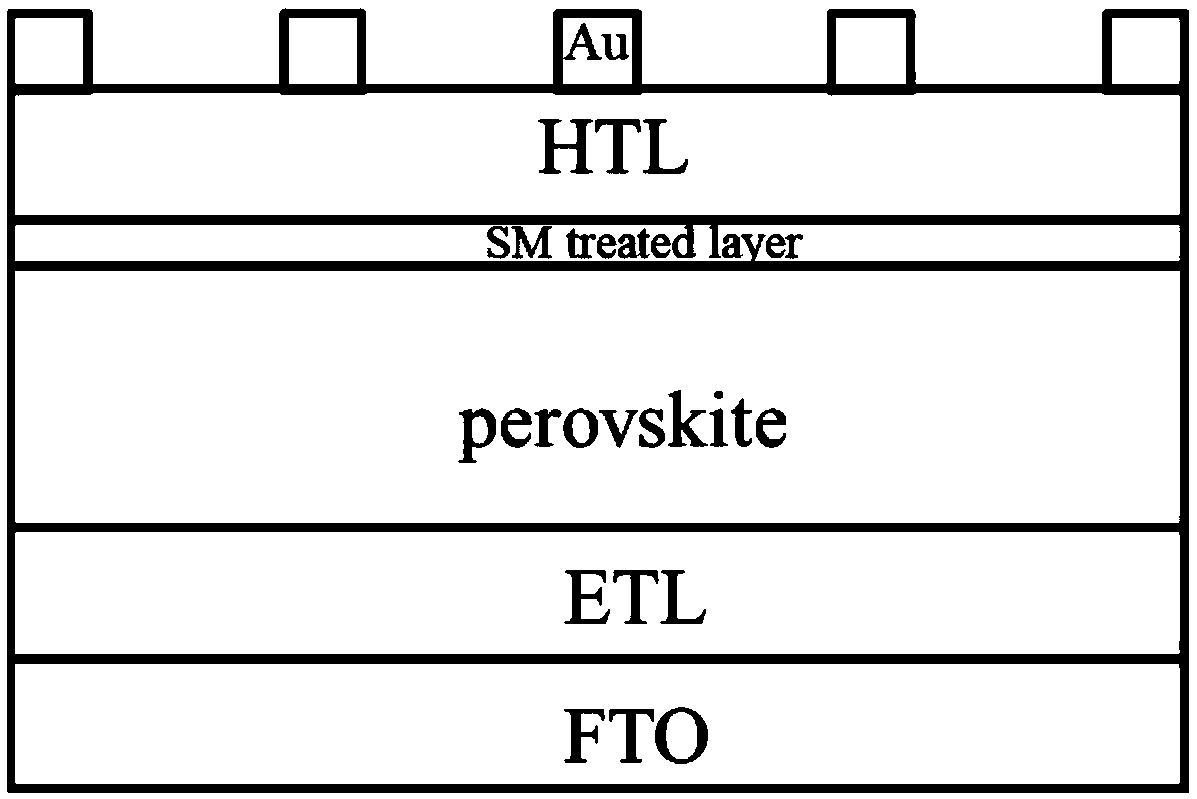

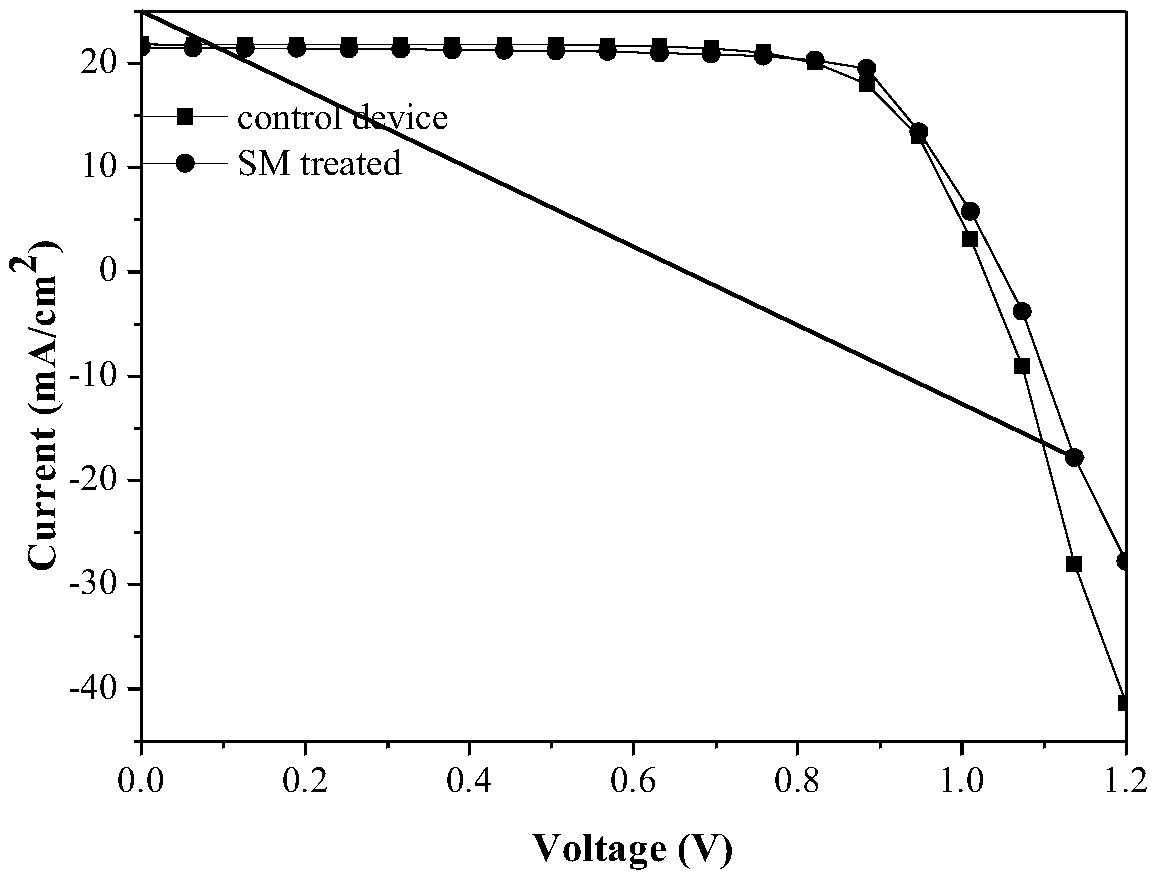

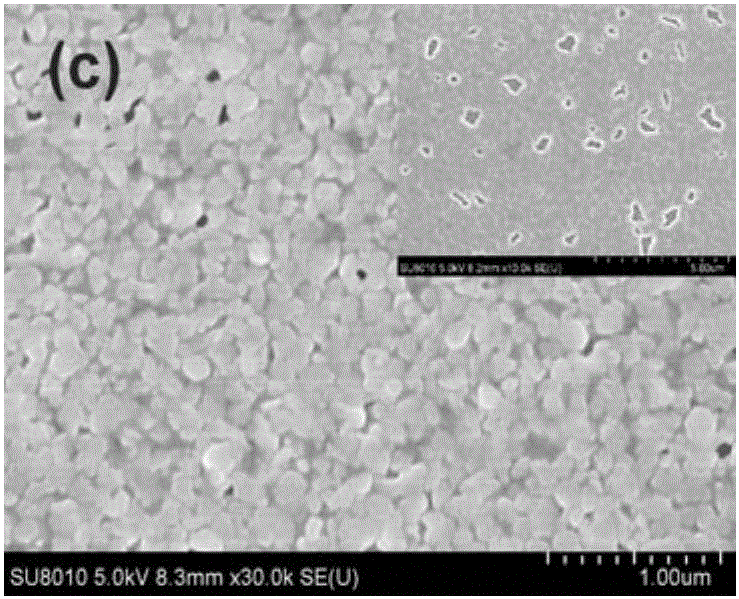

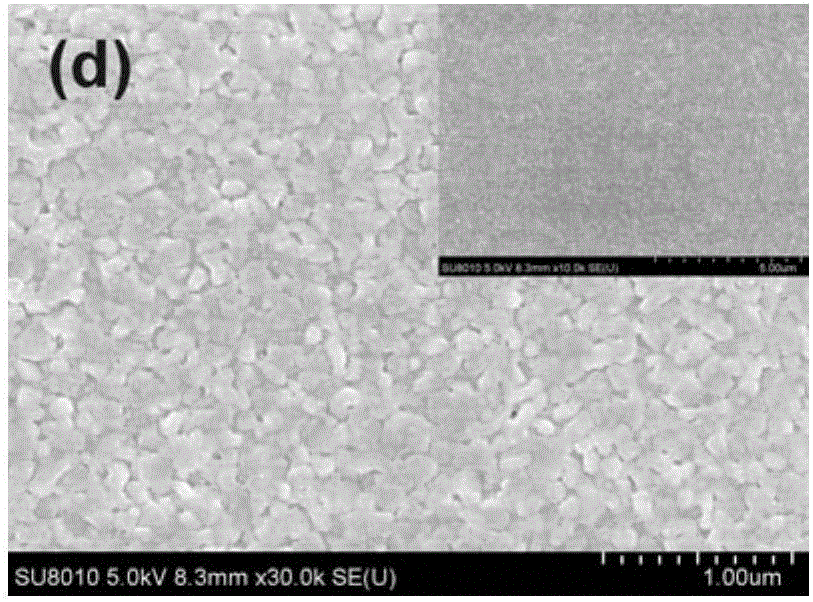

Method for improving efficiency and stability of perovskite solar cell, and perovskite solar cell

ActiveCN109545970ASolid-state devicesSemiconductor/solid-state device manufacturingAnti solventPerovskite solar cell

The invention discloses a method for improving efficiency and stability of a perovskite solar cell and the perovskite solar cell. By adding a small amount of hydrophobic organic micromolecules into ananti-solvent for preparing a perovskite light absorption layer, the efficiency of the perovskite solar cell and the stability of the perovskite solar cell in air under an unpackaged condition are improved. The perovskite solar cell provided by the invention is divided into a forwarding type and a reverse type according to different structures, and the perovskite light absorption layer is of an ABX3 structure. Results indicate that if the small molecules added into the anti-solvent are thiophene-containing structural units in the structure or conjugated small organic molecules containing any one atom of S, N and O element, the small molecules can play a role in reducing grain boundaries and surface defects of the perovskite layer in the two device structures, and finally achieve the purpose of improving the efficiency and stability of the perovskite solar cell.

Owner:南京烯勒光电科技有限公司

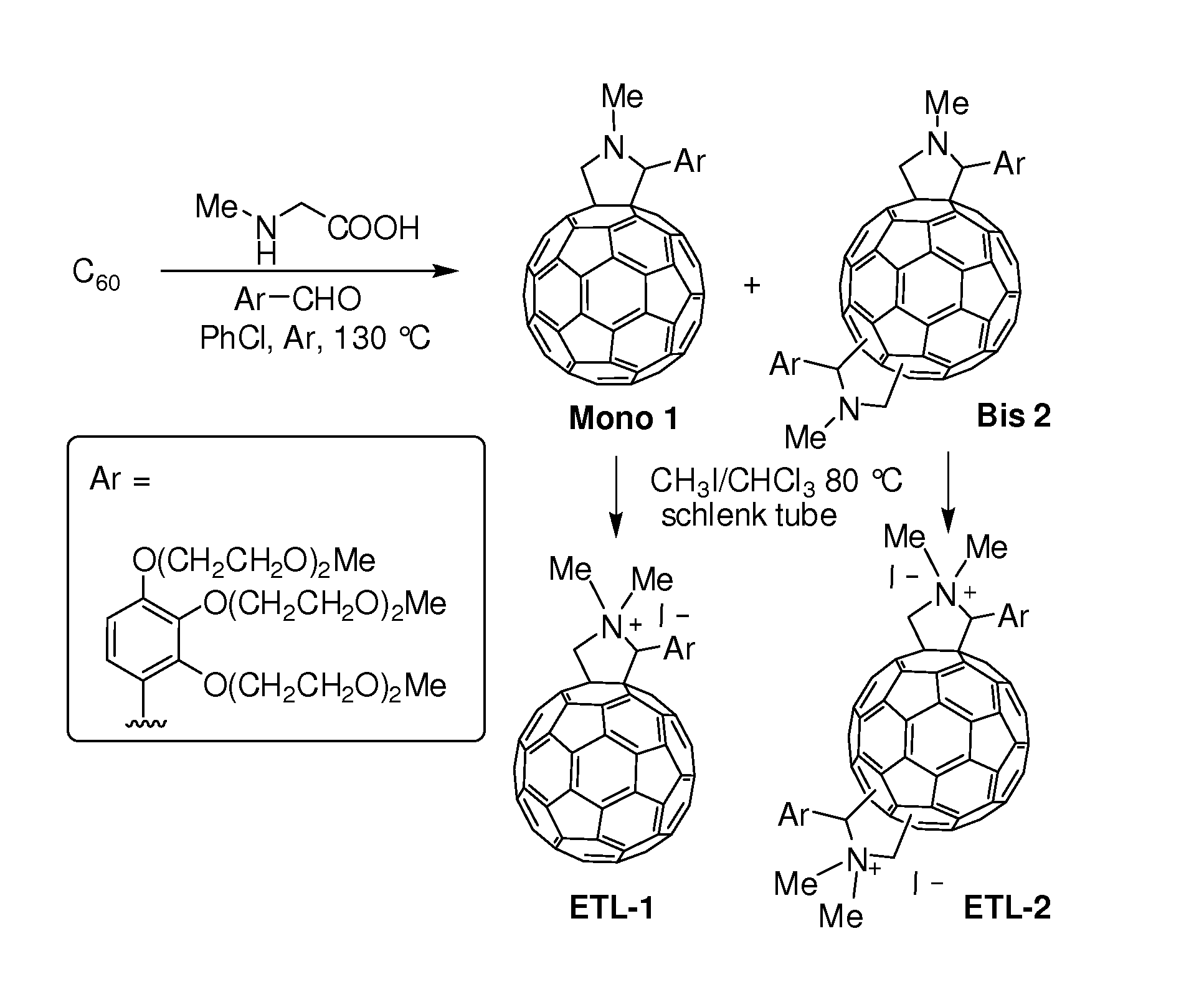

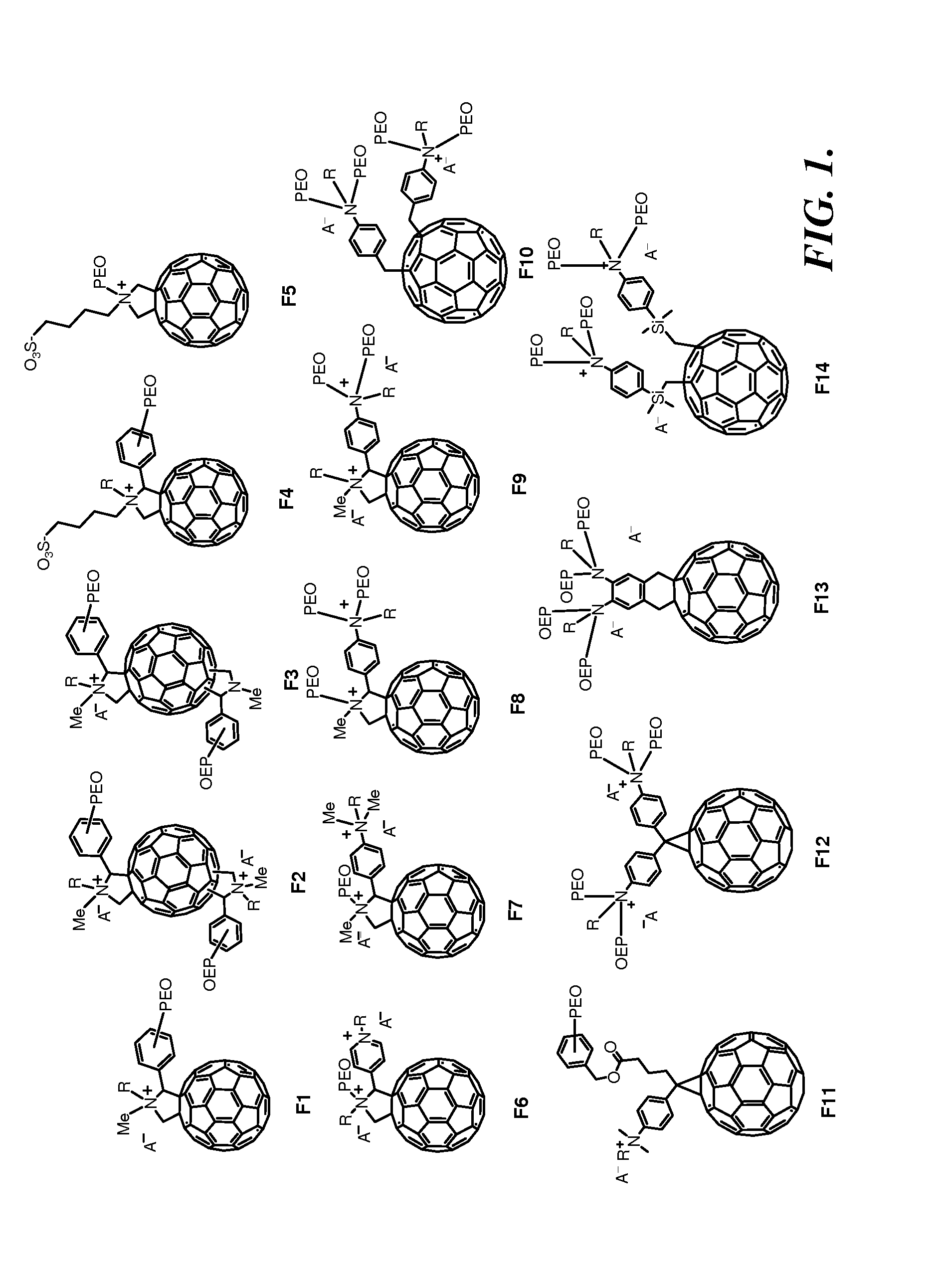

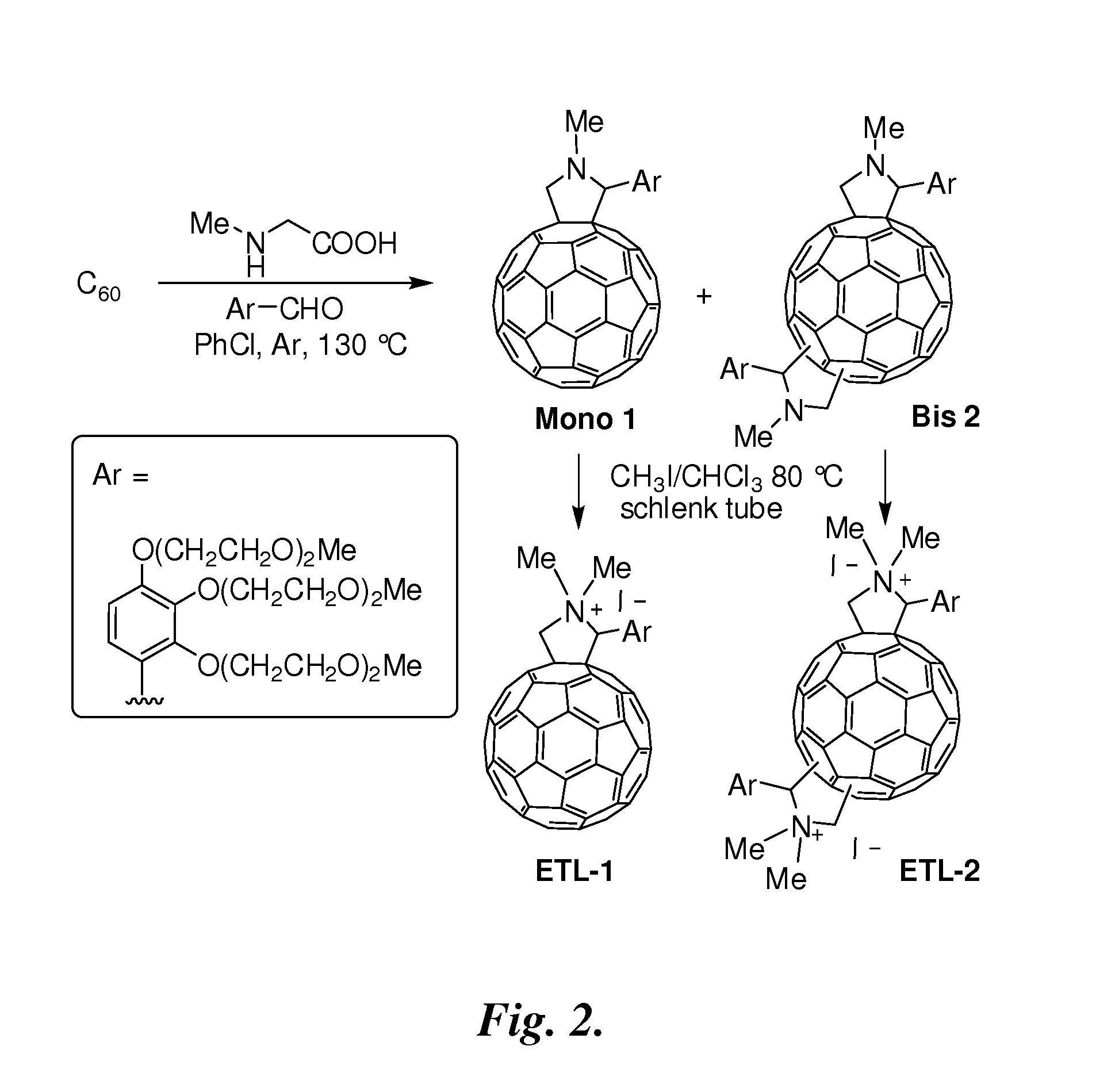

Fullerene surfactants and their use in polymer solar cells

ActiveUS20130160827A1Enhance solar cell efficiencyImprove battery efficiencyMaterial nanotechnologyOrganic chemistryActive agentSolar battery

Fullerene surfactant compounds useful as interfacial layer in polymer solar cells to enhance solar cell efficiency. Polymer solar cell including a fullerene surfactant-containing interfacial layer intermediate cathode and active layer.

Owner:UNIV OF WASHINGTON CENT FOR COMMERICIALIZATION

High-stability perovskite solar cell

InactiveCN105742504AImprove stabilityImprove efficiencySolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellLight emitting device

The invention provides a high-stability perovskite solar cell of a two dimensional-three dimensional composite perovskite structure, and relates to the field of solar cells and light emitting devices. The high-stability perovskite solar cell is characterized in that two-dimensional perovskite and three-dimensional perovskite are combined, the high stability of the two-dimensional perovskite and the high photoelectric conversion efficiency of the three-dimensional perovskite are fully utilized, and the stability is substantially improved without influencing the efficiency of the perovskite solar cell.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

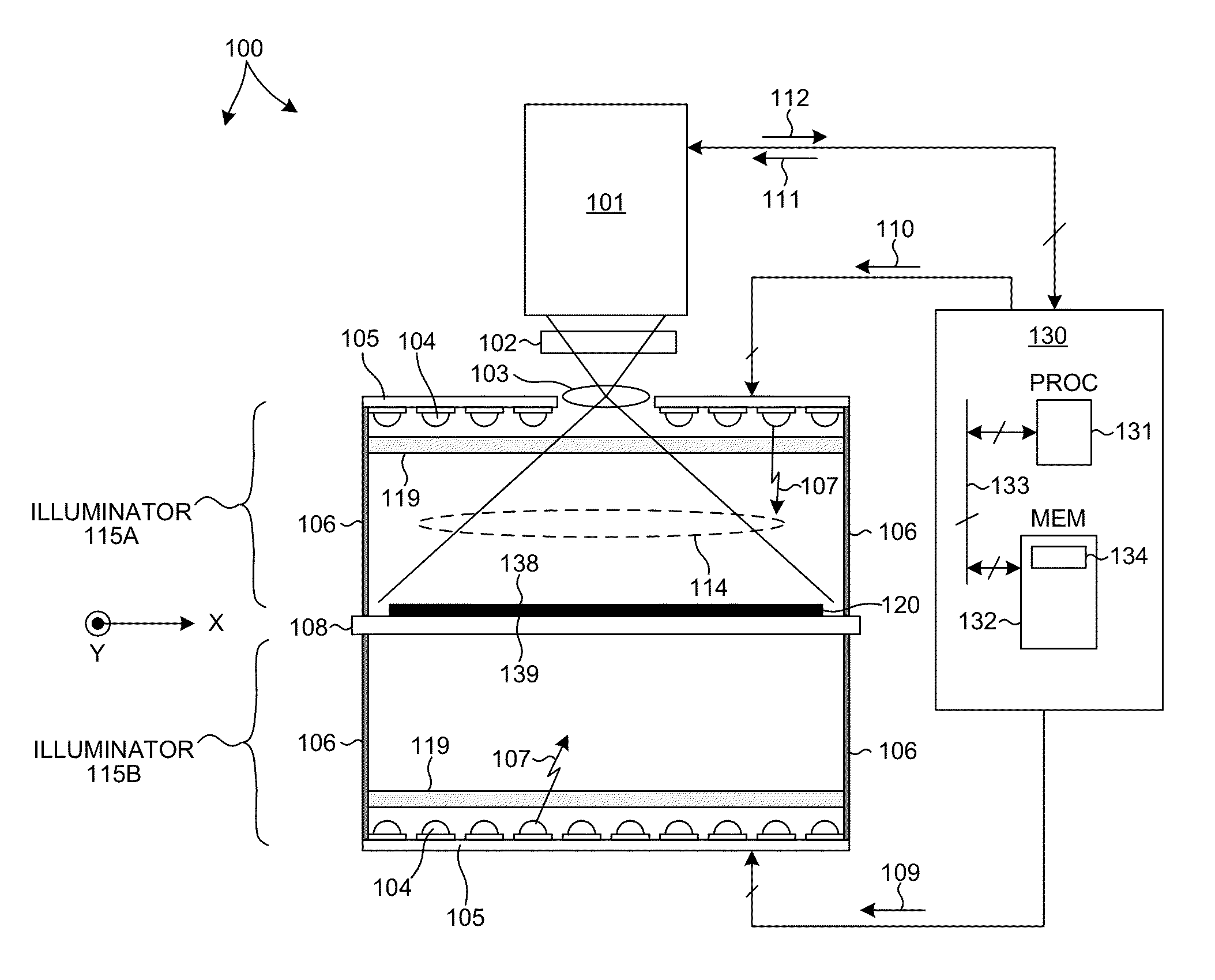

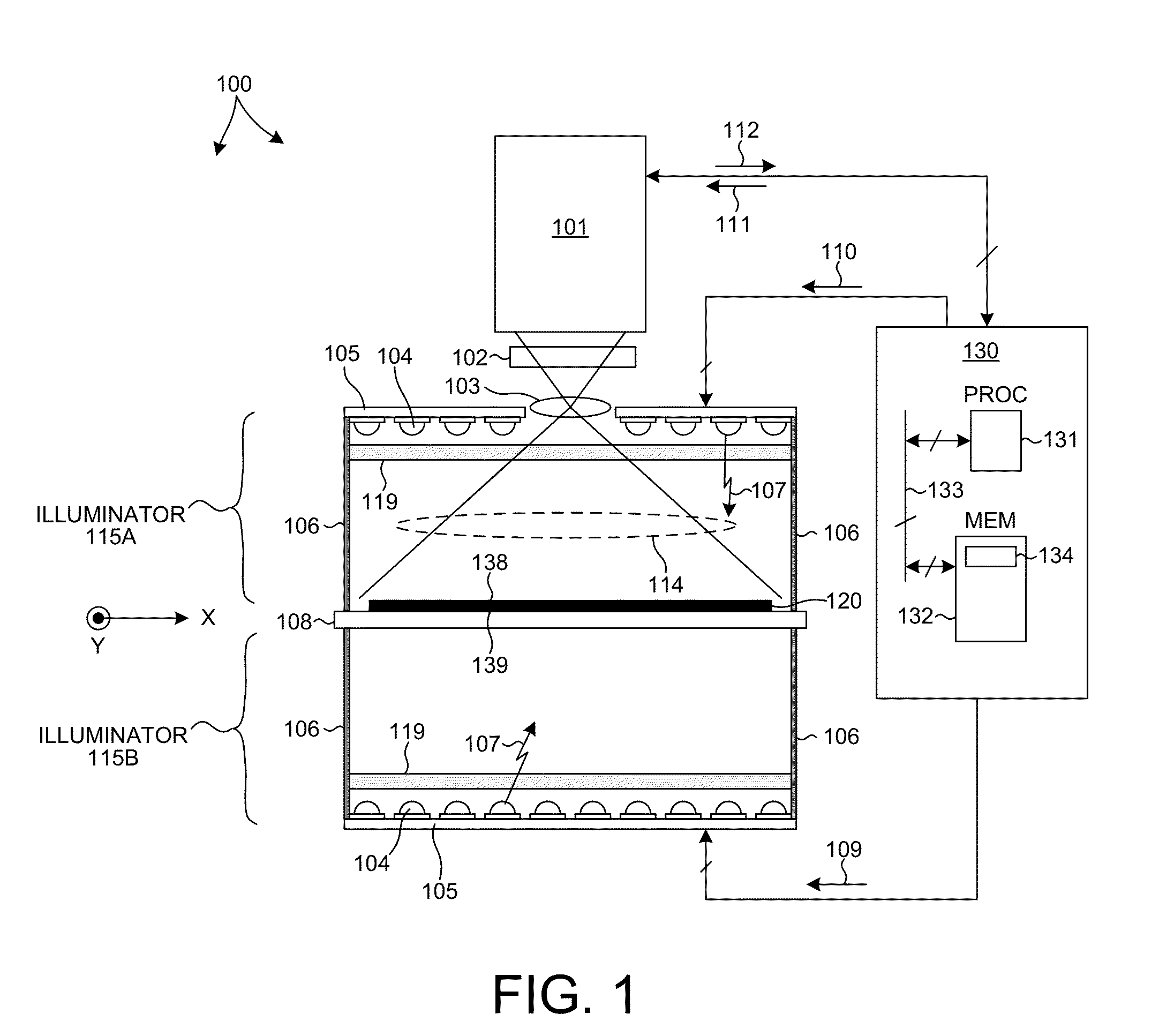

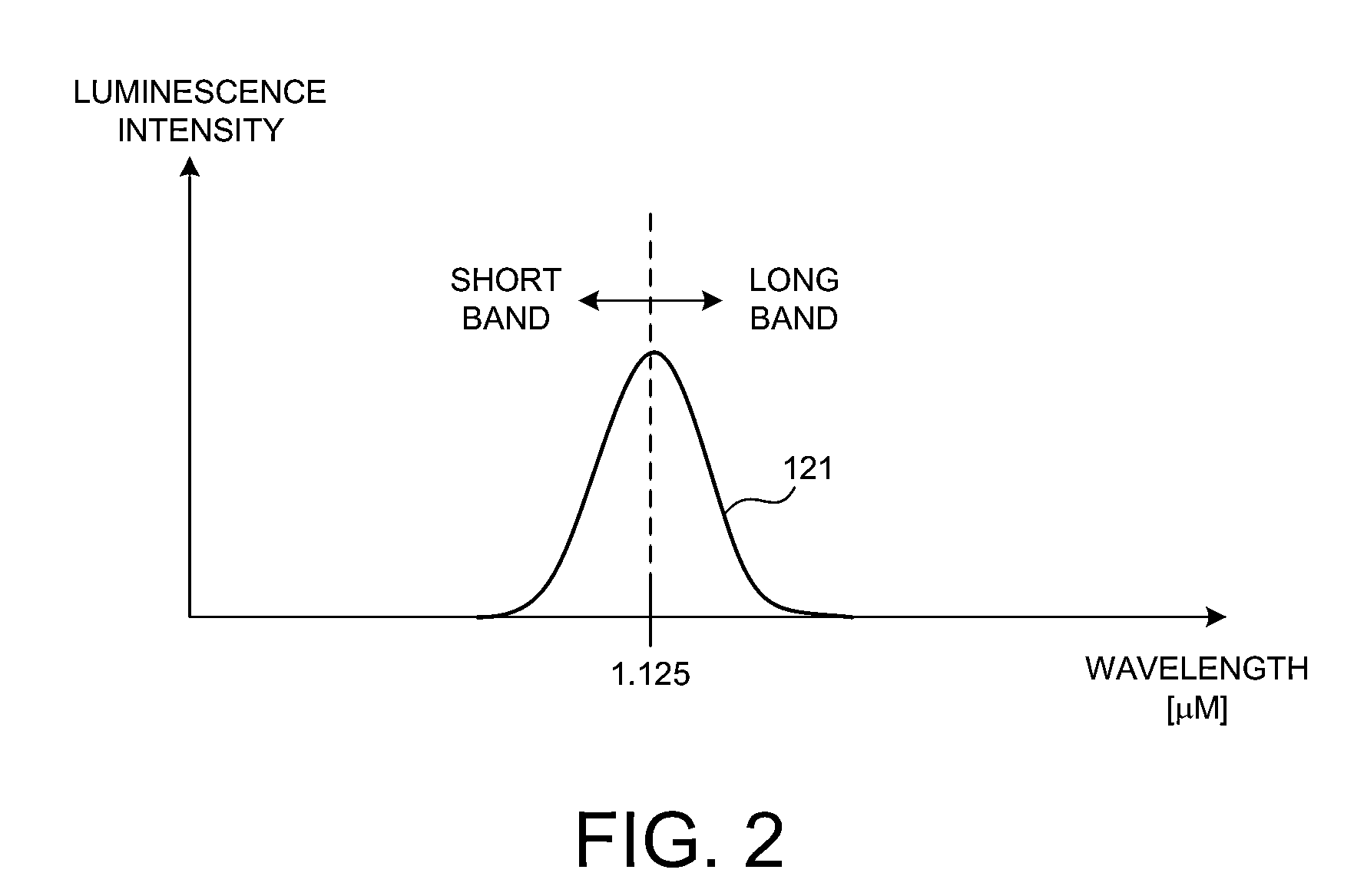

Solar Metrology Methods And Apparatus

InactiveUS20130048873A1Increase productionReduce manufacturing costPhotovoltaic monitoringLuminescent dosimetersDiffusionMetrology

Methods and apparatus are presented to measure the photoluminescence of incoming wafers and extract parameters such as minority carrier life time, diffusion length, and defect density that may be used to predict final solar cell efficiency. In some examples, illumination light is supplied to a side of an as-cut silicon wafer and the induced luminescence measured from the same side and the opposite side of the wafer is used to determine an indication of the minority carrier lifetime. In another example, the luminescence induced by two instances of illumination light of different wavelength is used to determine an indication of the minority carrier lifetime. In another example, the spatial distribution of luminescence intensity over an area surrounding a focused illumination spot is used to determine an indication of the minority carrier lifetime. Other apparatus useful to passivate the surface of a wafer for inspection are also presented.

Owner:KLA CORP

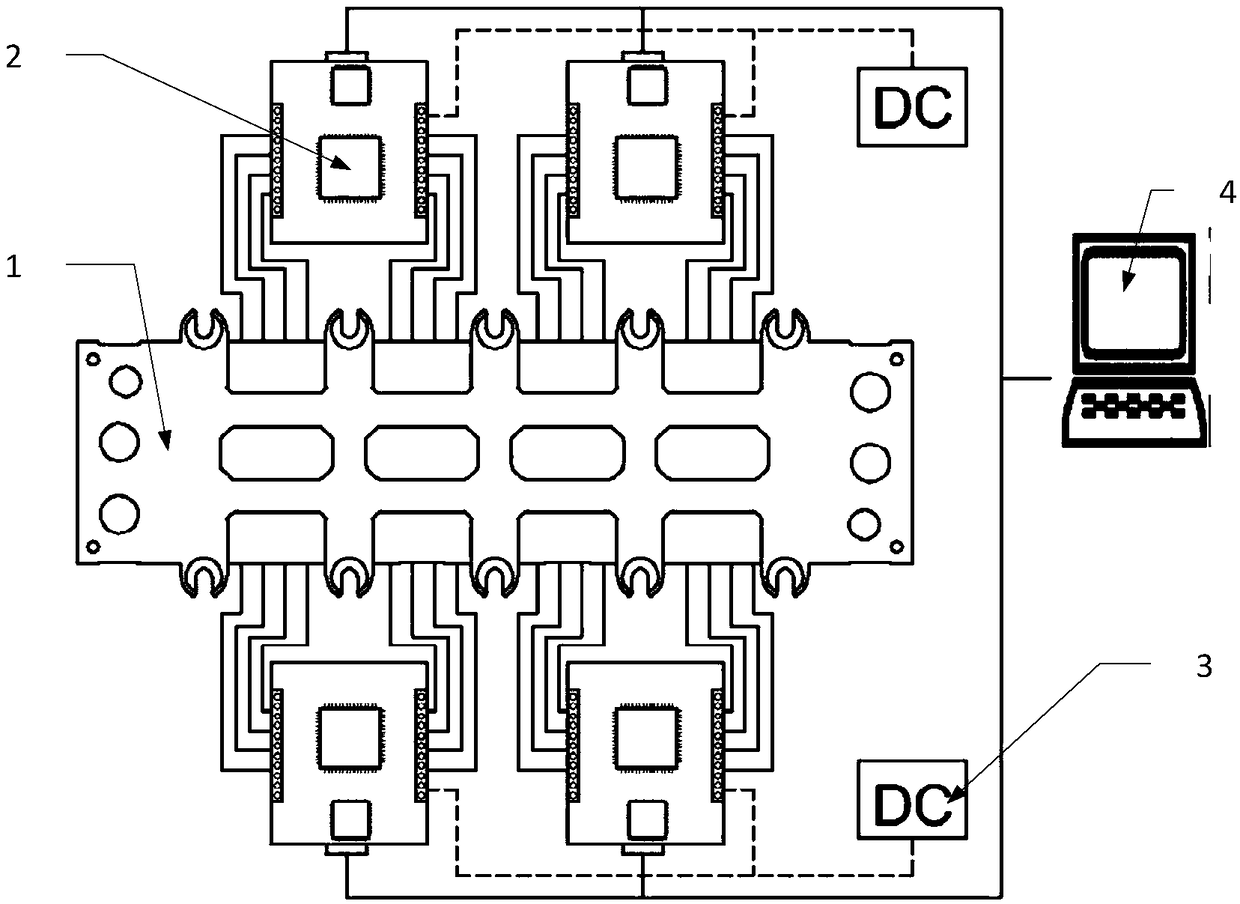

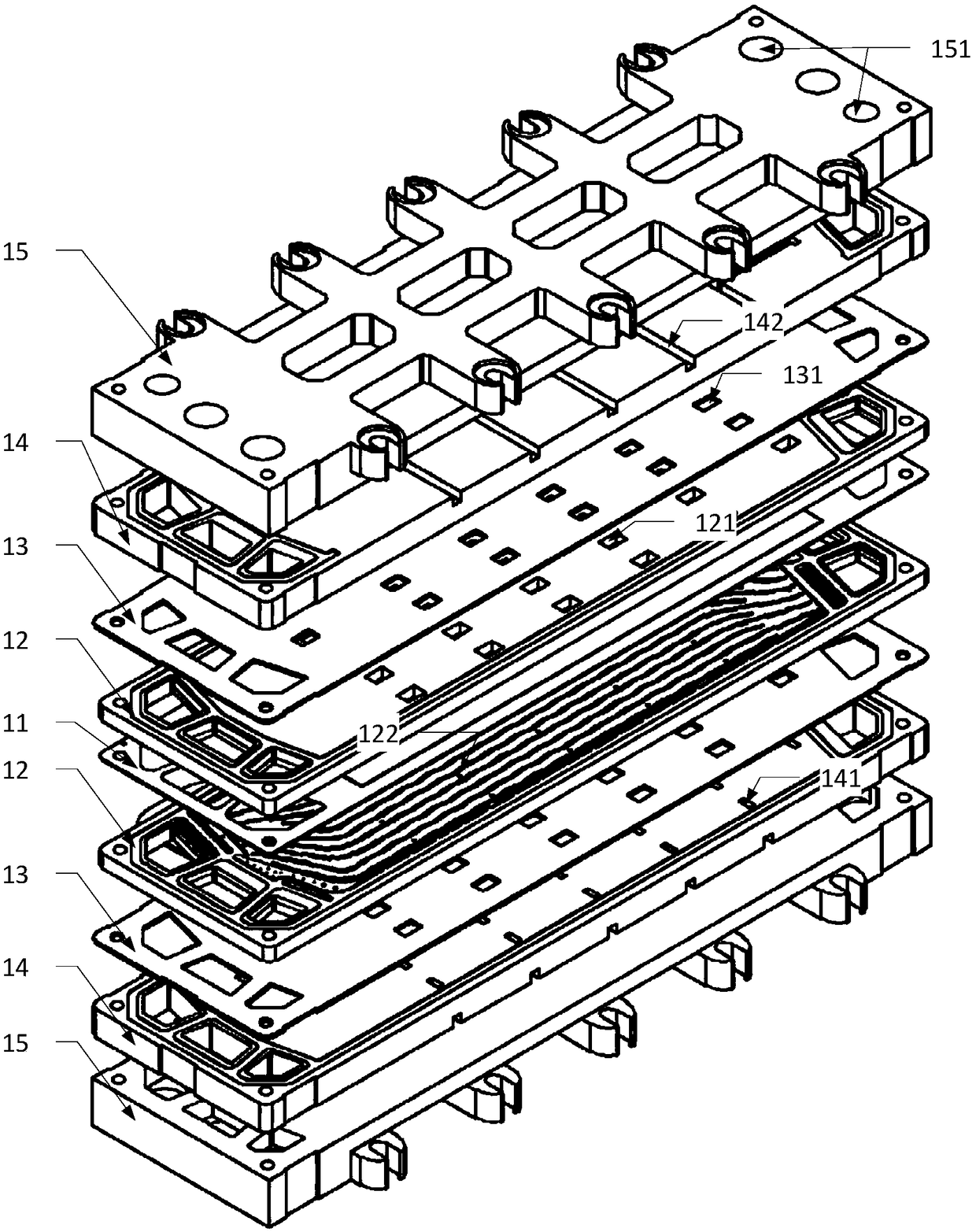

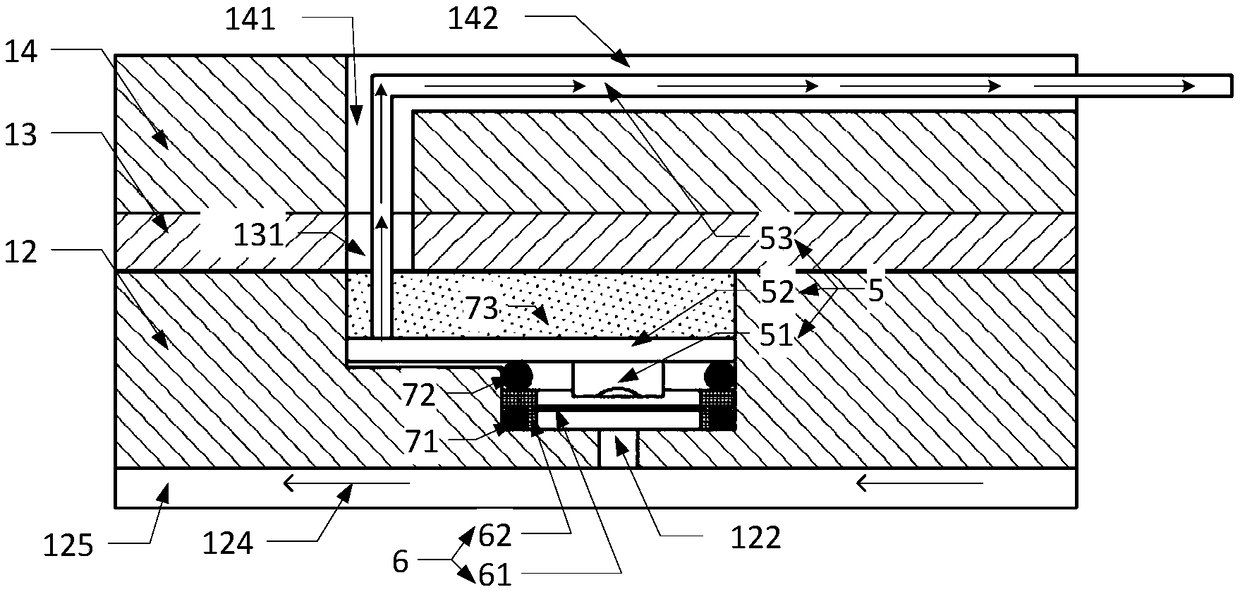

Fuel cell internal temperature and humidity online measurement system

ActiveCN108736049AJudging the moisture contentBest performance outputWater management in fuel cellsFuel cell controlFuel cellsFuel efficiency

The invention relates to a fuel cell internal temperature and humidity online measurement system. The system comprises a signal transceiving module connected with a fuel cell, a DC power supply connected with the signal transceiving module, a signal conversion record module, and a sensor module for detecting the temperature and humidity information of the internal cathode and anode reaction gas ofthe fuel cell. Compared with the prior art, the fuel cell internal temperature and humidity parameter can be online detected, the fuel cell internal moisture content is analyzed in real time. In theactual application, a cell control policy can be adjusted in real time according to a system diagnosis result, and the fuel cell efficiency and life are improved.

Owner:SHANGHAI JIAO TONG UNIV

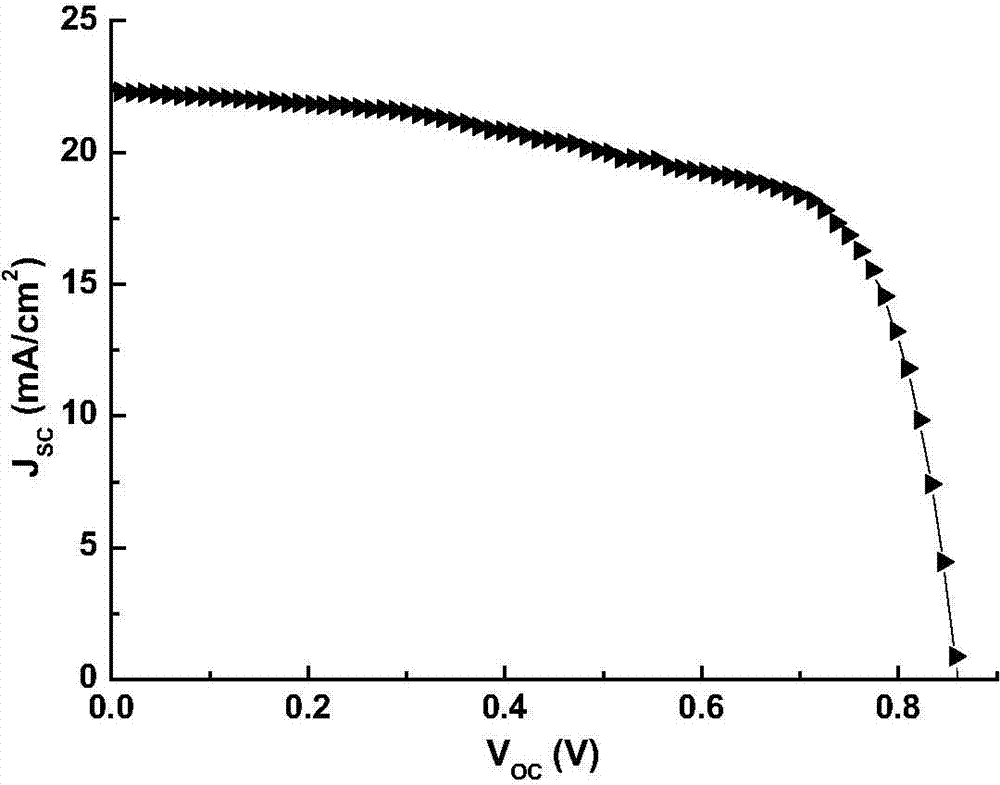

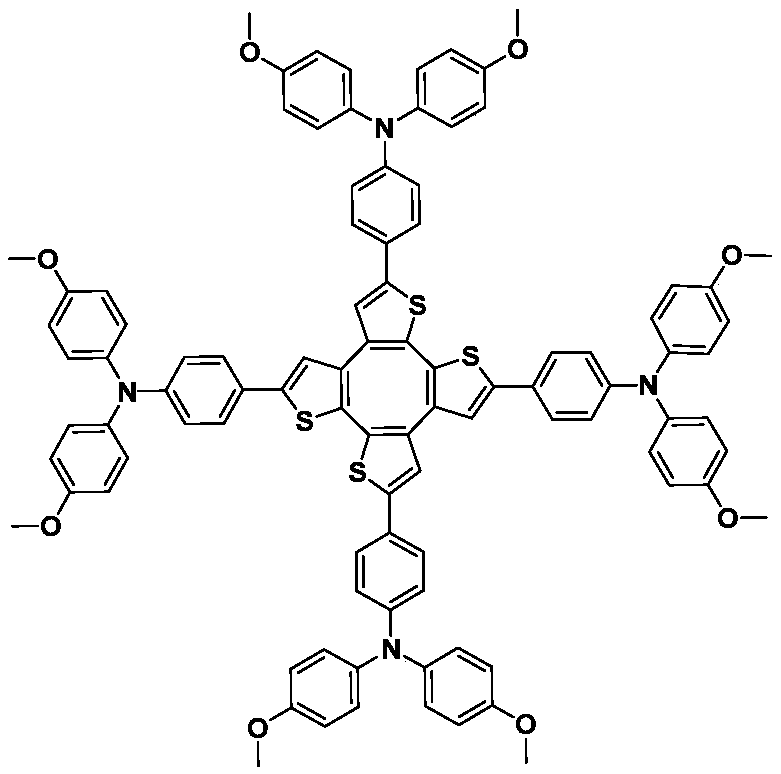

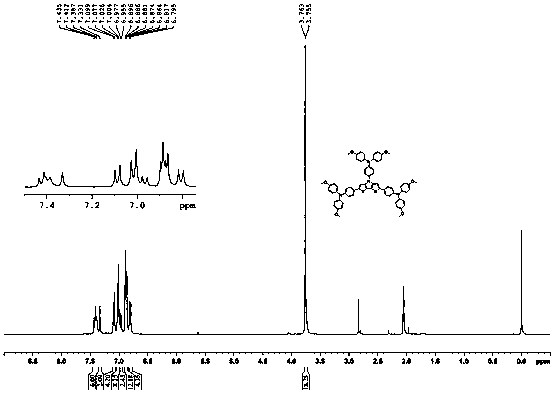

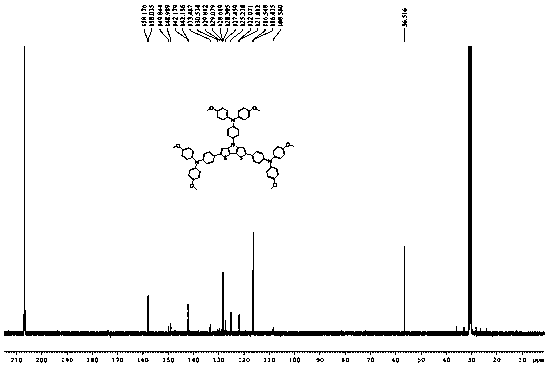

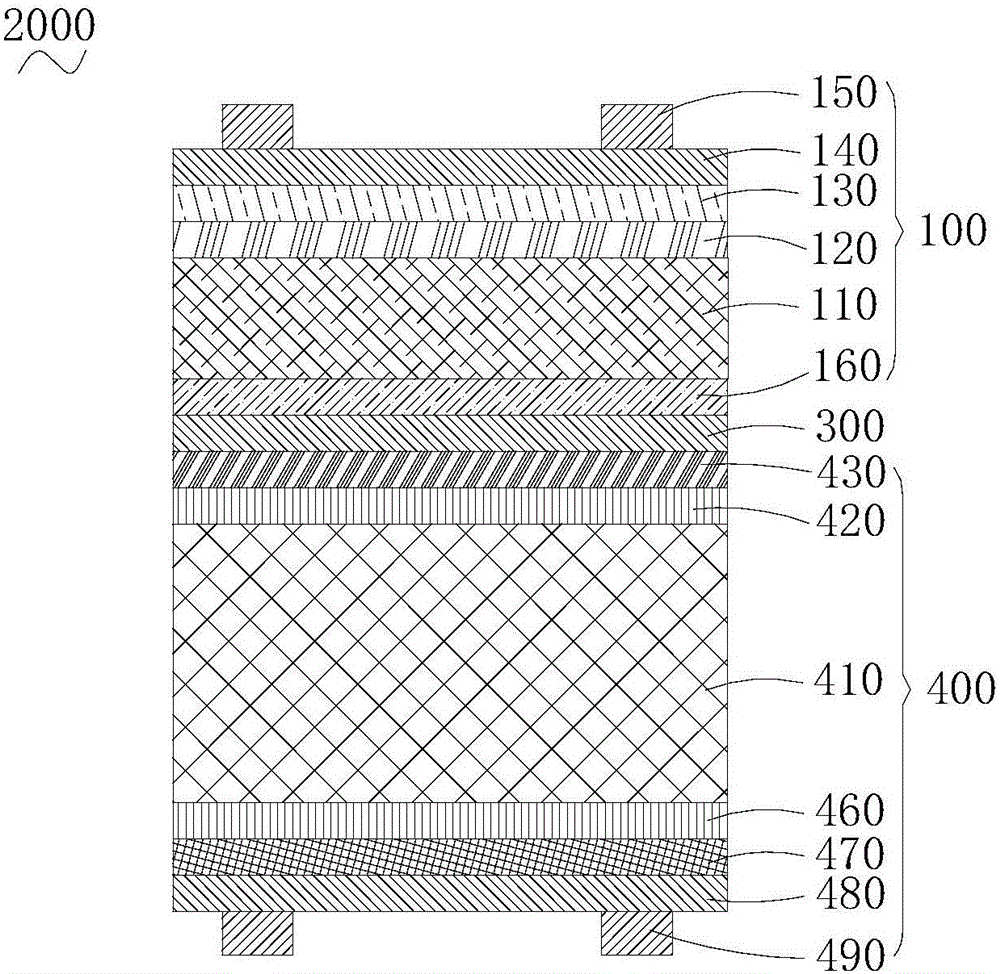

Organic cavity transmission material by using dithiophene pyrrole as core and preparation method and application thereof

InactiveCN107915744AThe synthetic route is simpleRaw materials are easy to getOrganic chemistrySolid-state devicesSolar batteryPhotocurrent

The invention discloses an organic cavity transmission material by using dithiophene pyrrole as a core and a preparation method and application thereof. The organic cavity transmission material by using the dithiophene pyrrole as the core has the advantages that the synthesis route is simple, the raw materials are easy to obtain, and the cost is low; the amorphous state is good, and the dissolvingproperty is excellent; proofed by testing results, when the organic cavity transmission material is applied into a perovskite solar battery, the short-circuiting photocurrent density of a battery device reaches 22.6mA cm<2>, the open-loop voltage is 1.01V, the filling factor is 0.71, the photoelectric conversion efficiency reaches 16.2%, and the practical meaning is realized for improving of theefficiency of the perovskite solar battery.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

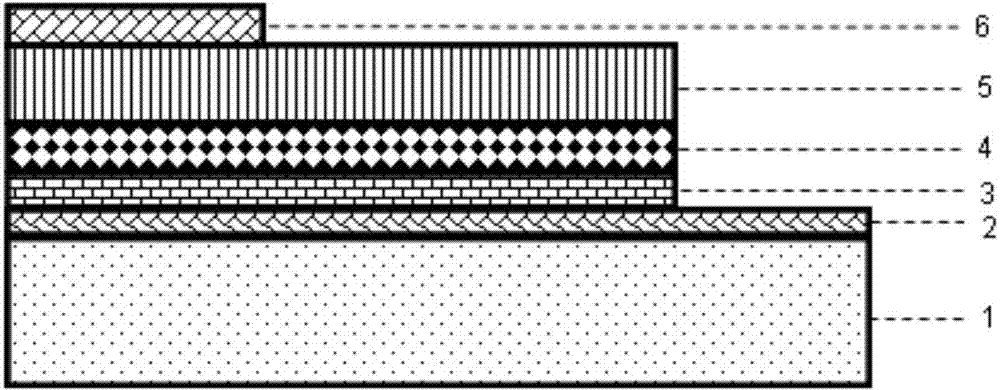

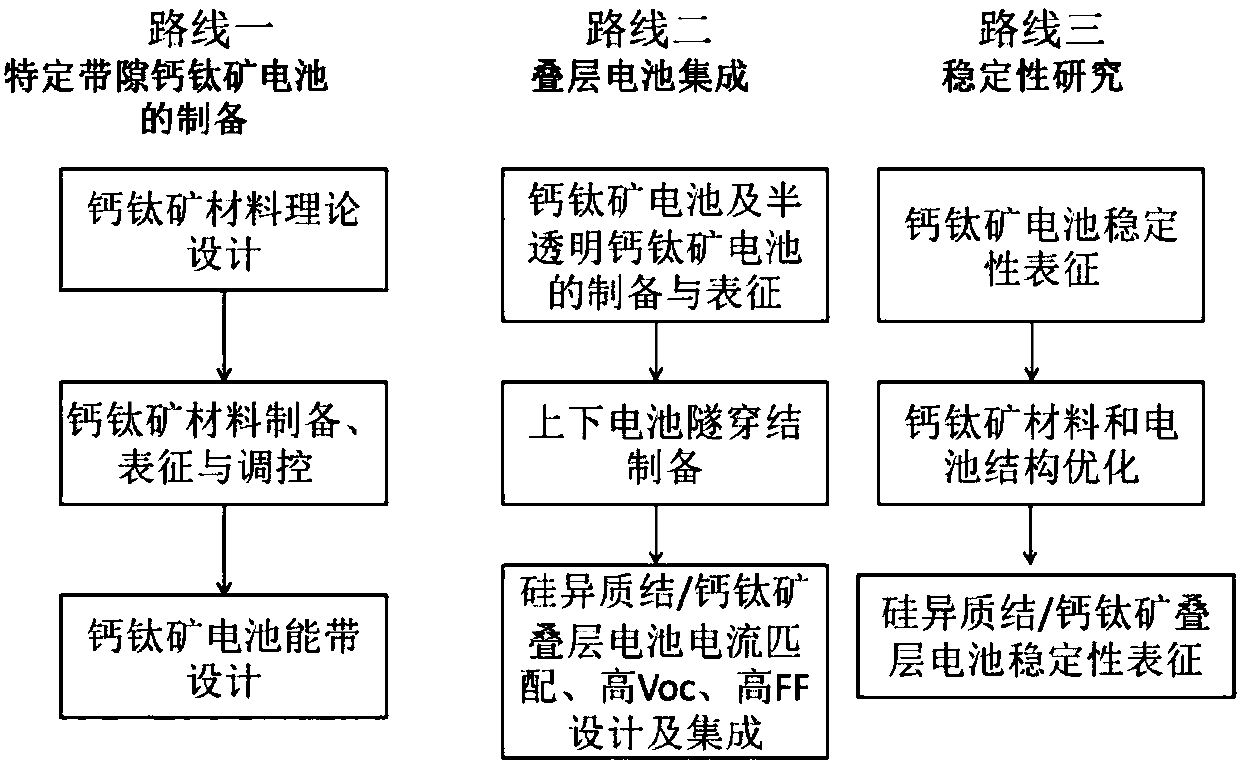

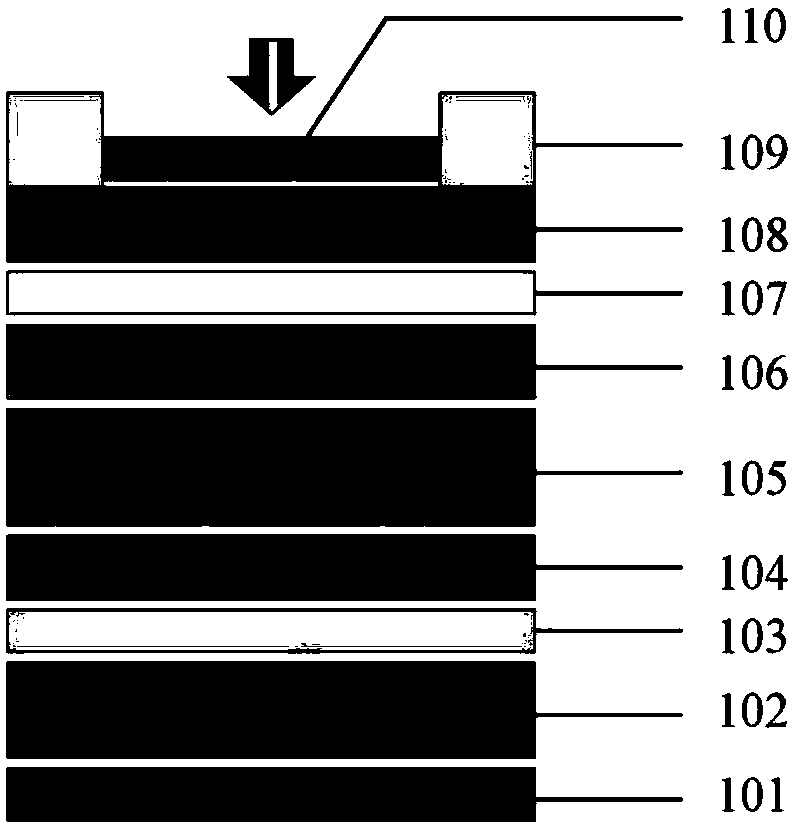

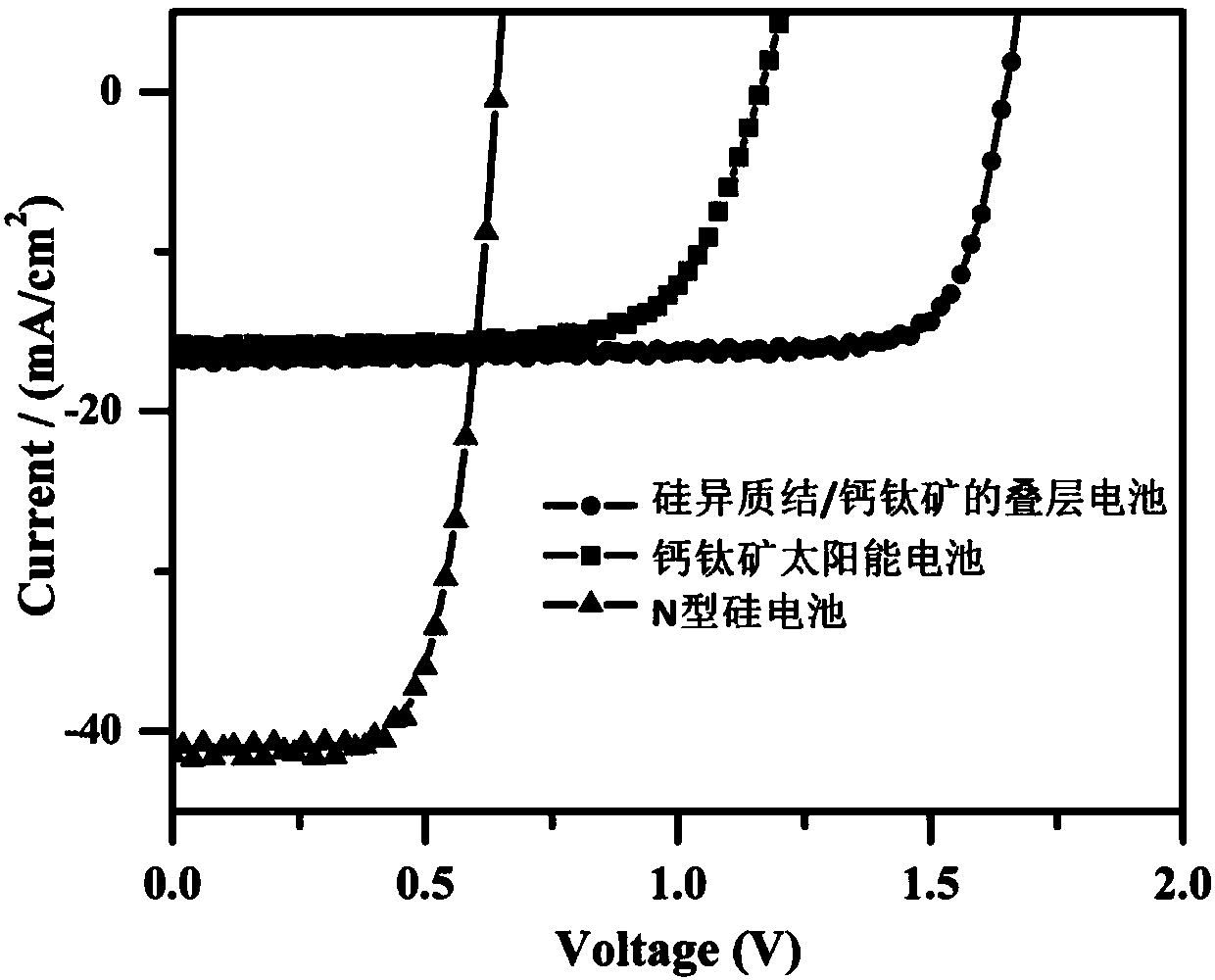

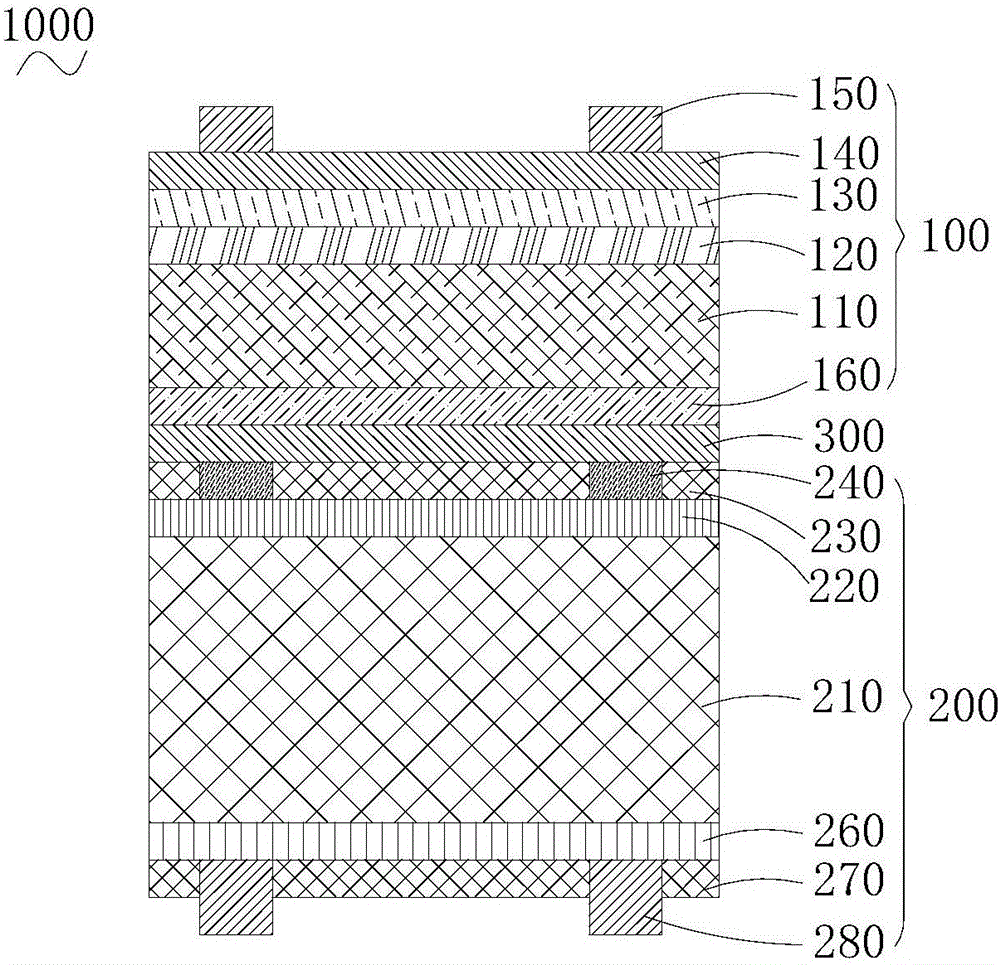

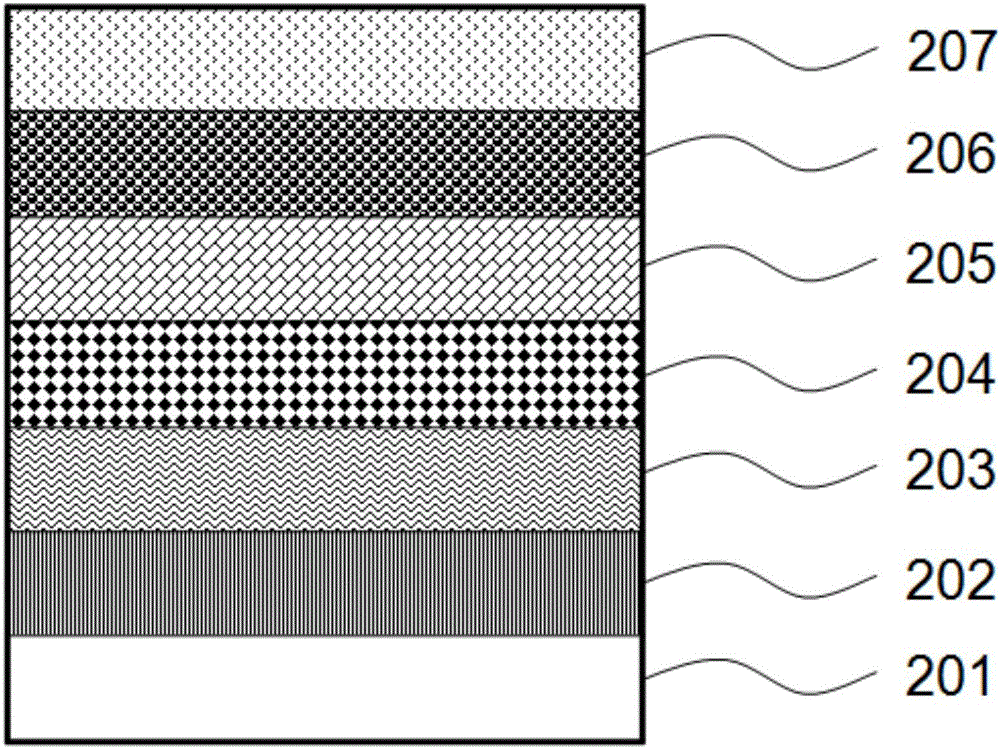

Silicon heterojunction/perovskite based double-electrode laminated solar cell

PendingCN109935690ASolid-state devicesSemiconductor/solid-state device manufacturingHeterojunctionMetal electrodes

The invention relates to a preparation method for a silicon heterojunction / perovskite based double-electrode laminated solar cell. Compared with a unijunction solar cell, the laminated solar cell canutilize medium-short wave photons in the sun spectrum more effectively to achieve a higher efficiency. The laminated solar cell based on silicon heterojunction / perovskite electrodes comprises a top wide-band-gap perovskite solar cell and a narrow-band-gap silicon cell, and also comprises an anti-reflecting layer, a transparent top electrode, a protective layer, a perovskite absorbing layer, an electron transmission layer, an intermediate layer, a Si heterojunction battery and a metal electrode successively from top to bottom. The tunnel junction and perovskite absorbing layer are prepared at low temperature. The silicon heterojunction / perovskite double-electrode laminated solar cell prepared by a simple low-cost solution method can reach the efficiency of 22.22% which is in a leading position domestically.

Owner:PEKING UNIV

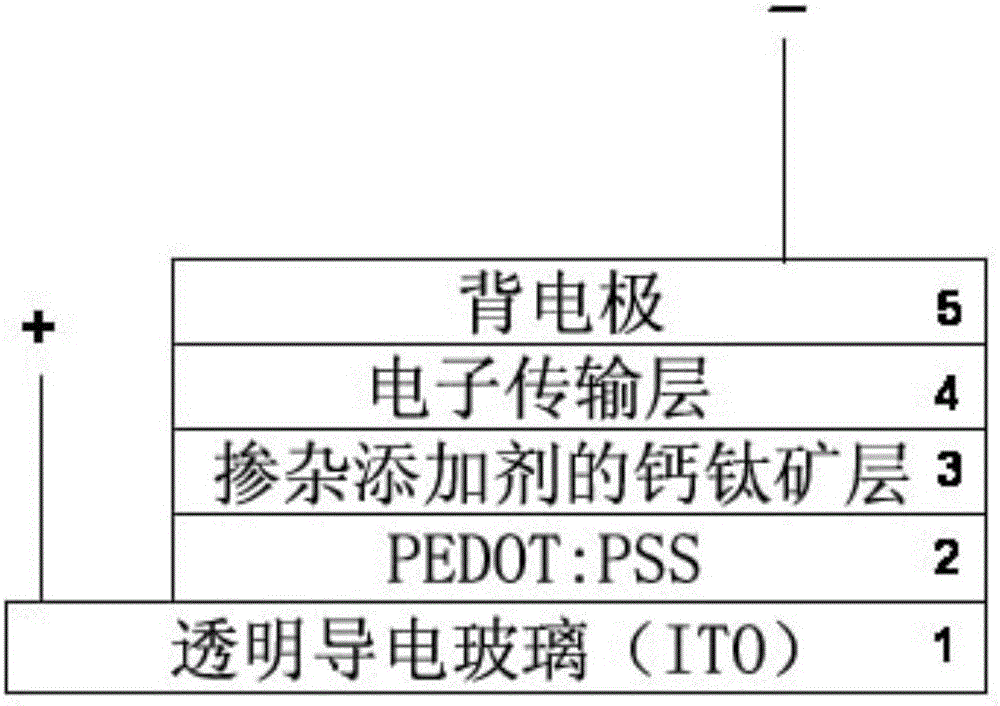

Method of improving perovskite solar cell efficiency by using ionic liquid additive

ActiveCN106816535AIncrease coverageGood lookingFinal product manufactureSolid-state devicesElectronic transmissionN dimethylformamide

The invention relates to a method of improving perovskite solar cell efficiency by using ionic liquid additive, and belongs to the organic optoelectronic technology field. The method comprises steps that (1) preparation of precursor mixed solution: lead acetate and methylammonium iodide are dissolved in an N,N-dimethylformamide solution to form the mixed solution; and 1-Ethylpyridinium chloride ionic liquid is adopted as the additive to prepare the precursor mixed solution; (2) preparation of a perovskite thin film: the precursor mixed solution is used to form a film by adopting a spin-coating technology, and is disposed on a conductive glass substrate provided with PEDOT:PSS, and annealing is carried out on a heating stage to acquire the perovskite thin film; (3) deposition of an electronic transmission layer: by adopting a thermal evaporation deposition way or a solution spin-coating way, the electronic transmission is deposited on the perovskite thin film; (4) evaporation deposition of a counter electrode: evaporation deposition of a metal aluminum electrode is carried out by adopting a vacuum evaporation film. The method has advantages of mild and controllable condition, simple preparation, low costs, and applicability in large-scale commercialized production.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

Tandem solar cell and manufacturing method thereof

InactiveCN106025087ASolid-state devicesSemiconductor/solid-state device manufacturingPower flowTandem solar cell

The invention relates to the field of solar cells, and particularly discloses a tandem solar cell, which comprises a top cell unit of a perovskite cell, a bottom cell unit of a silicon cell and a middle layer located between the top cell unit and the bottom cell unit. The chemical formula for the perovskite material in the perovskite cell is: [(NH2CHNH2)1-a(CH3NH3)a]Pb[I1-xBrx]3 or [(NH2CHNH2)1-bCsb]Pb[I1-xBrx]3, and 0.3< / =x< / =0.5, 0.3< / =a< / =0.5 and 0.1< / =b< / =0.5. According to the above tandem solar cell, band gaps of the top perovskite cell and the bottom silicon cell are matched, the problem of current matching between top and bottom cells can be well solved, and the cell efficiency can be improved. The invention also discloses a method of manufacturing the tandem solar cell.

Owner:SUZHOU GCLSI SCI & TECH IND APPL RES INST CO LTD +2

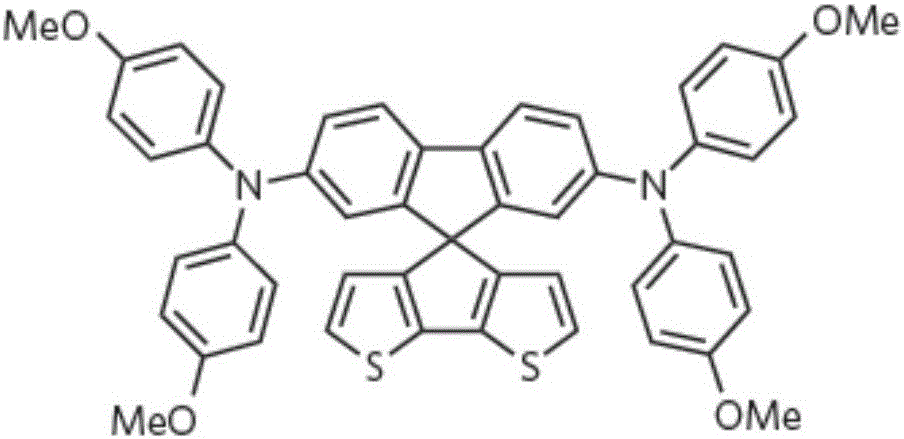

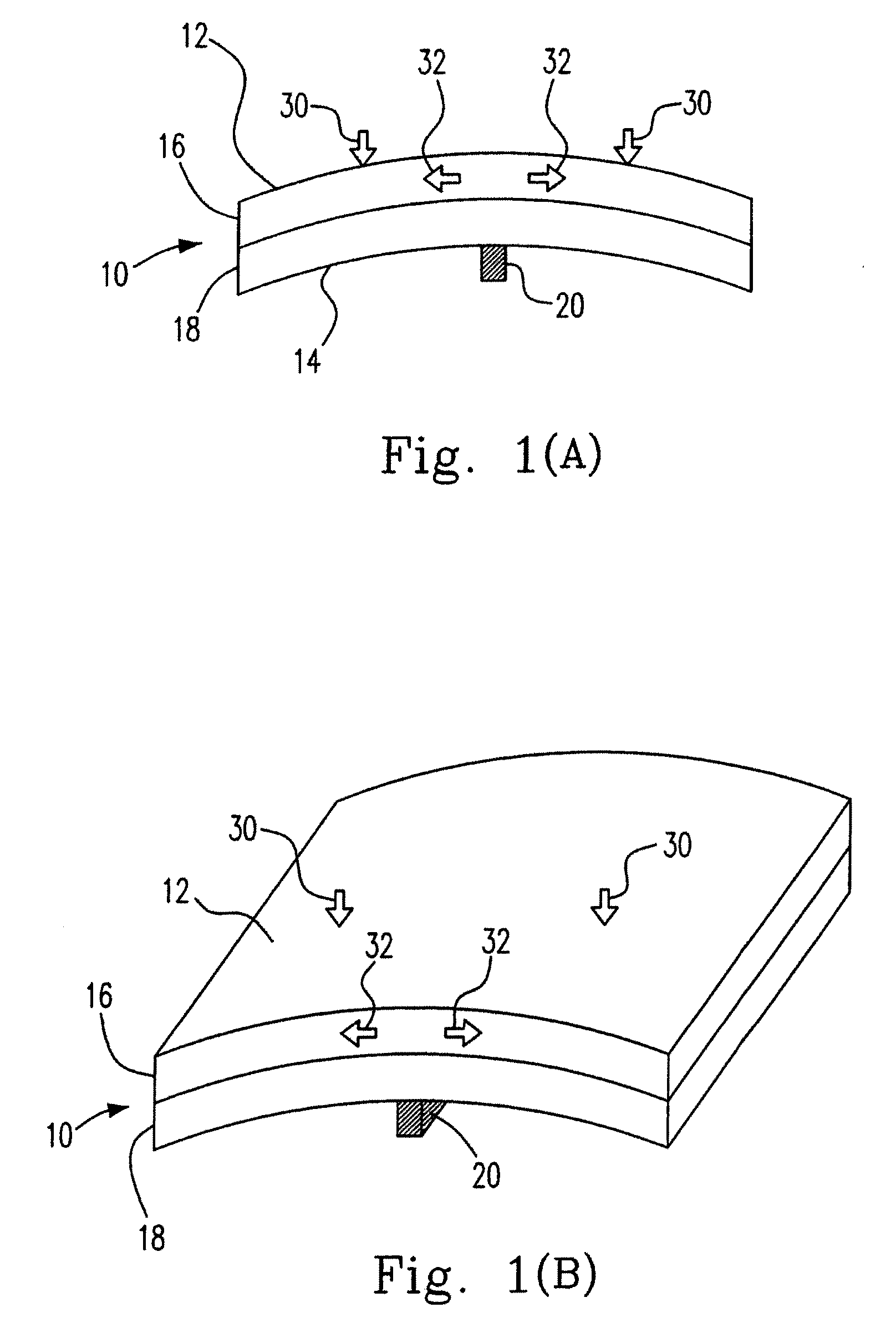

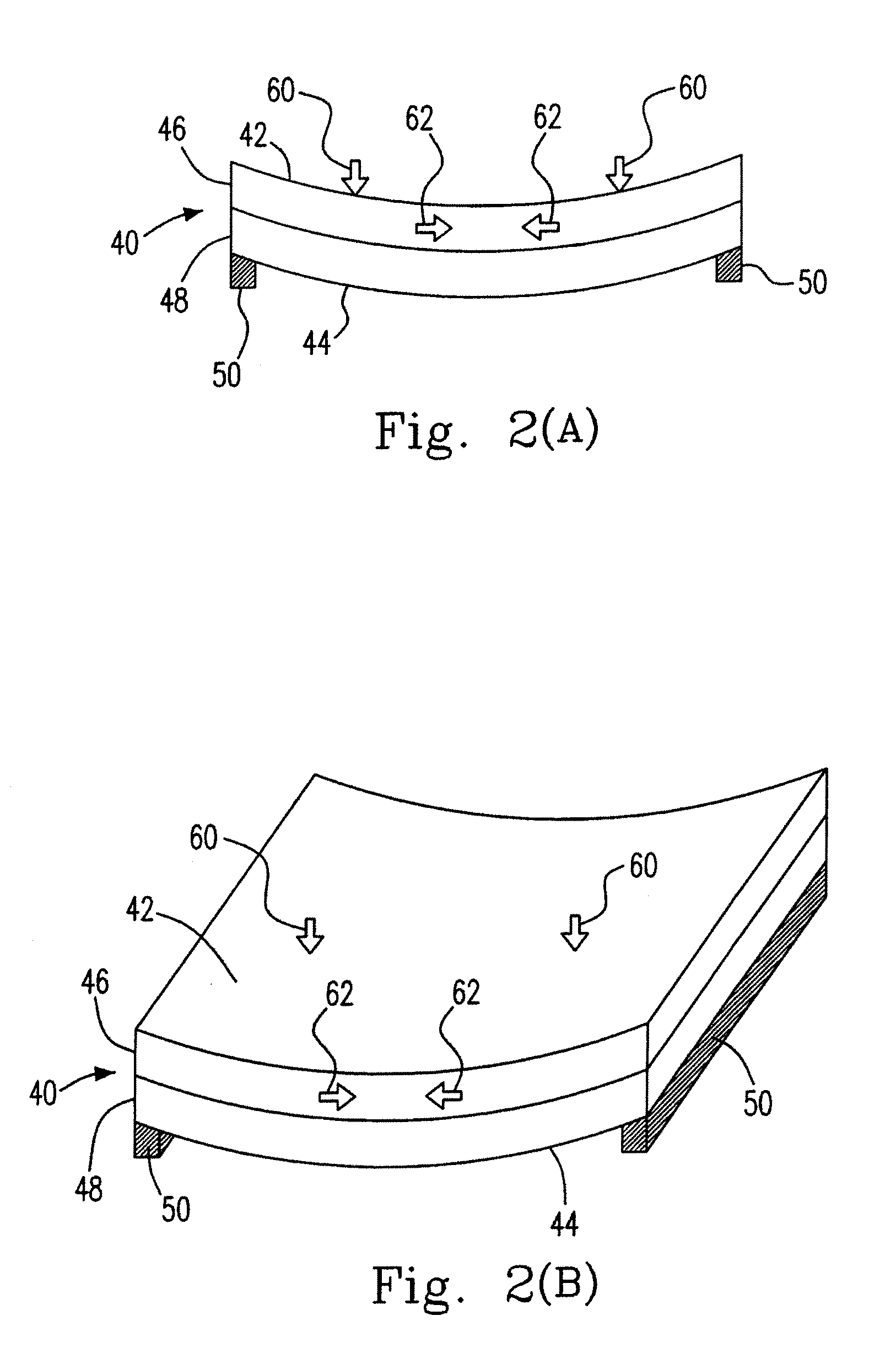

Structure And Method Of Solar Cell Efficiency Improvement By Strain Technology

InactiveUS20100024870A1Improve photoelectric conversion efficiencyGenerating tensionSemiconductor/solid-state device manufacturingPhotovoltaic energy generationEngineeringLattice constant

A structure and a method of the solar cell efficiency improvement by the strain technology are provided. The solar cell has a first surface and a second surfaces which at least a gasket is disposed thereon for supporting the solar cell and being the axle whiling stressing. The method includes the steps of: (a) applying at least a stress on the first surface; (b) generating a supporting force on the second surface; and (c) generating at least a strain in the solar cell. In addition, the present invention also includes a method involving a step of: (a) applying a mechanical stress to the solar cell; (b) generating a tension in the solar cell by at least two materials having different lattice constants; or (c) generating another tension in the solar cell by a shallow trench isolation filler, a high tensile / compressive stress silicon nitride layer and a combination thereof.

Owner:NAT TAIWAN UNIV

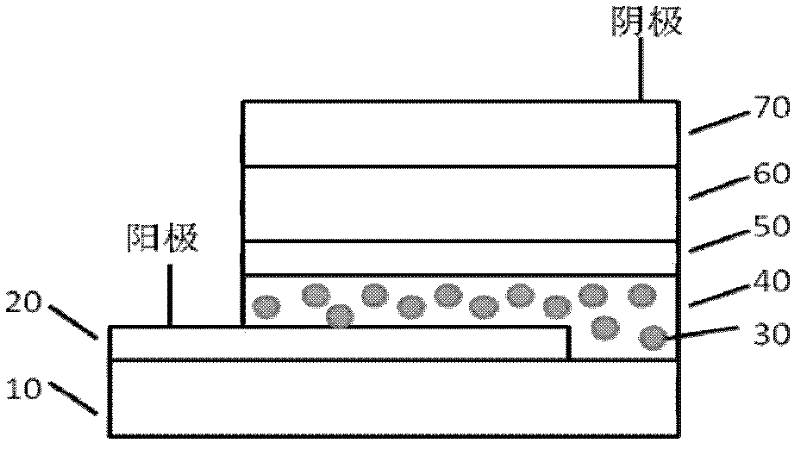

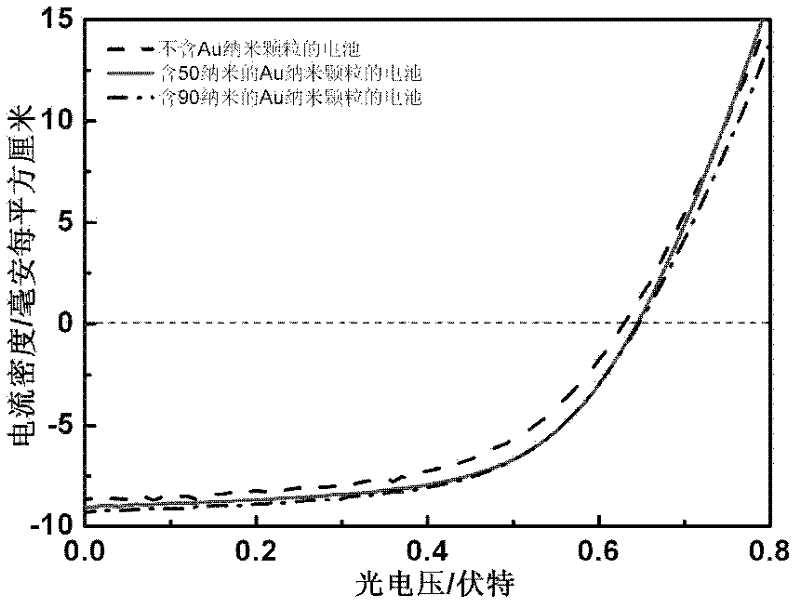

Method for increasing organic polymer solar cell efficiency

InactiveCN102394272AImprove efficiencyEnhanced light absorptionFinal product manufactureSolid-state devicesSurface plasmonNanoparticle

The invention discloses a method for increasing an organic polymer solar cell efficiency by using Au surface plasmon. Au nanoparticles with a certain size and concentration are mixed into a PEDOT: PSS hole transporting layer of the cell. The Au nanoparticles are synthesized through a wet chemical method. And chloroauric acid reacts with sodium citrate to obtain the Au nanoparticles which are dispersed in a water-soluble solvent. The Au nanoparticles are mixed with the PEDOT: PSS as a certain proportion and then mixture is spinningly coated on an ITO substrate. Annealing treatment is performed. The hole transporting layer containing the Au nanoparticles are prepared completely. Through using a local electric field enhancement effect of the Au nanoparticles, luminous absorption of the organic polymer solar cell can be increased and further a cell efficiency can be increased.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

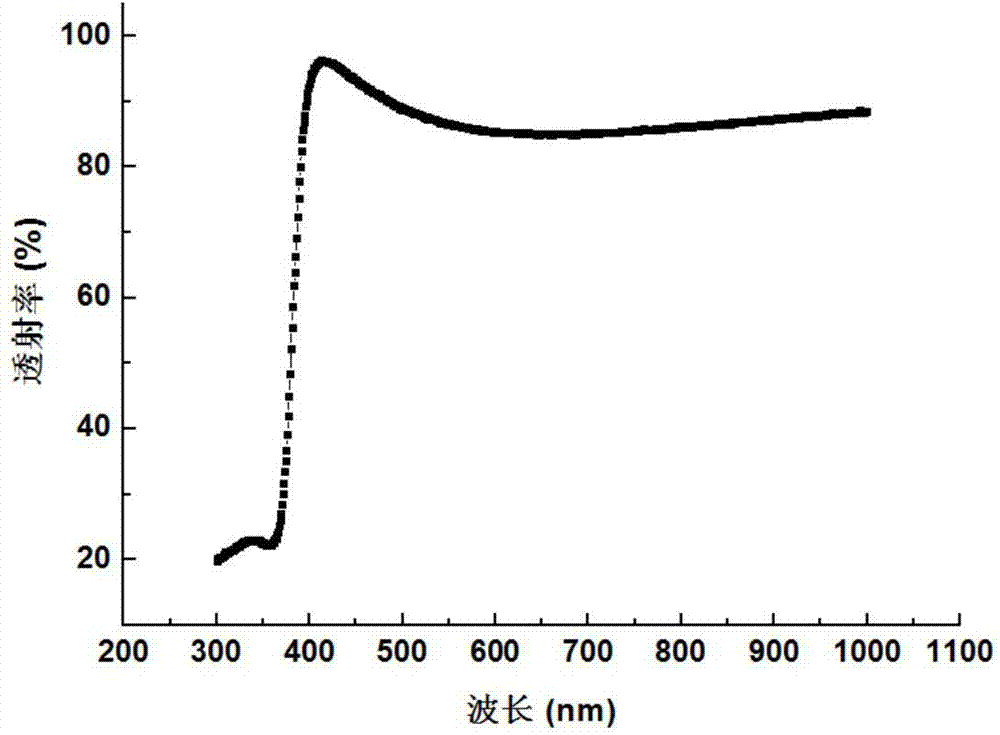

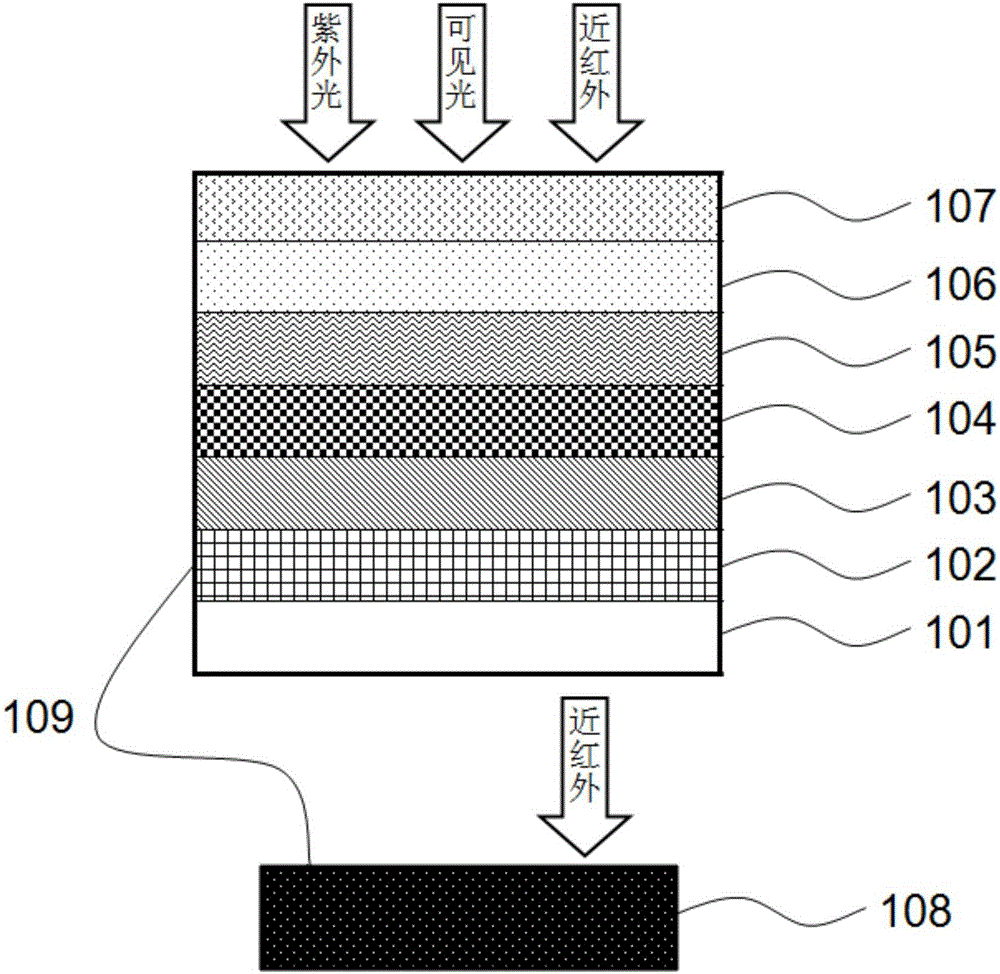

Efficient copper indium gallium selenide/perovskite series solar cell

InactiveCN106129053AImprove energy conversion efficiencyReduce lossesSolid-state devicesSemiconductor/solid-state device manufacturingHeterojunctionPerovskite solar cell

The invention provides an efficient copper indium gallium selenide / perovskite series solar cell. The four-terminal series solar cell comprises a semitransparent planar heterojunction perovskite solar cell and a copper indium gallium selenide (CIGS) solar cell which are connected in series. The series solar cell can overcome the shortcoming that the perovskite solar call cannot absorb near-infrared light; the efficient copper indium gallium selenide / perovskite series solar cell can effectively absorb ultraviolet light, visible light and near infrared light, so that the solar cell efficiency can be improved; and a new thought for the final commercialization of perovskite is provided.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

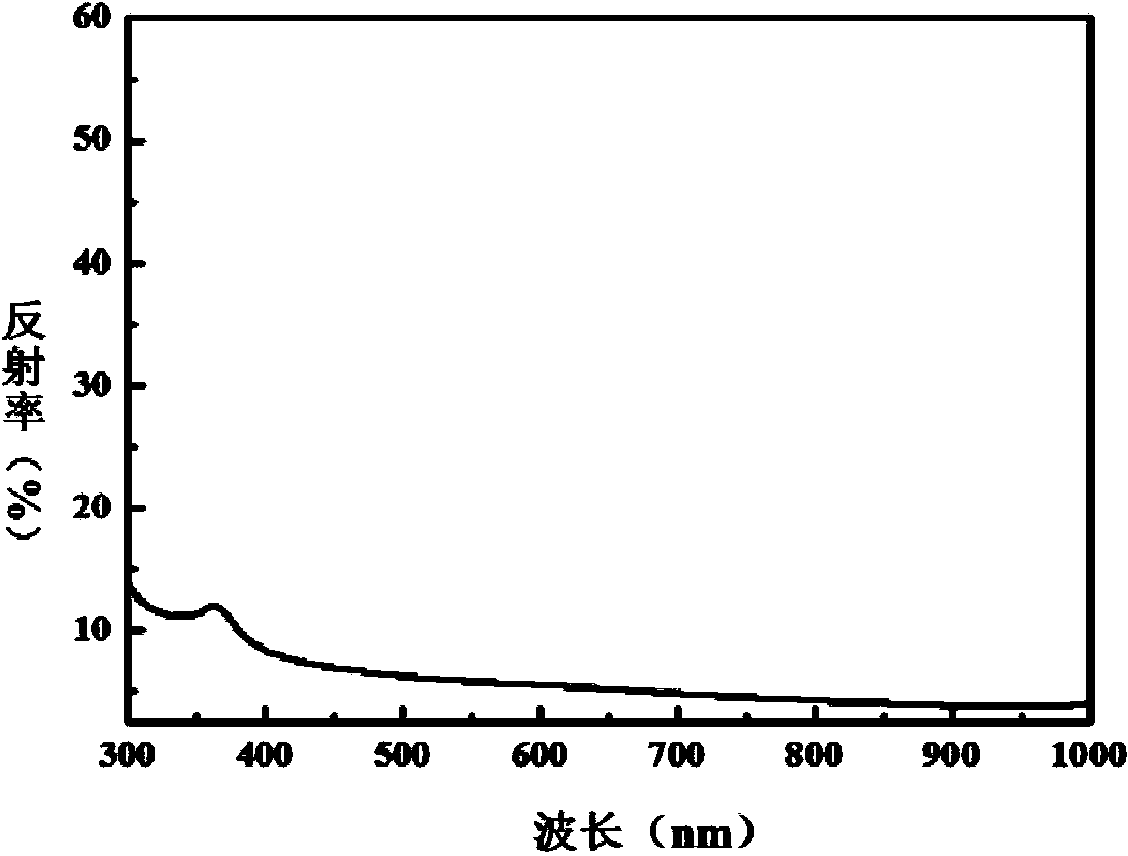

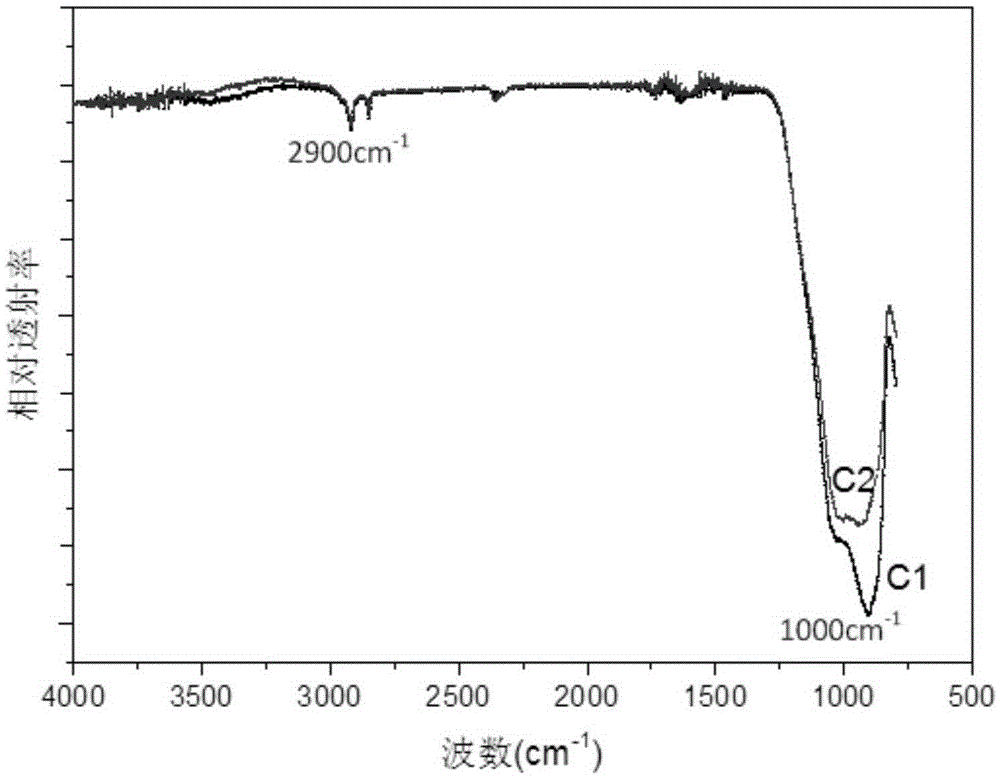

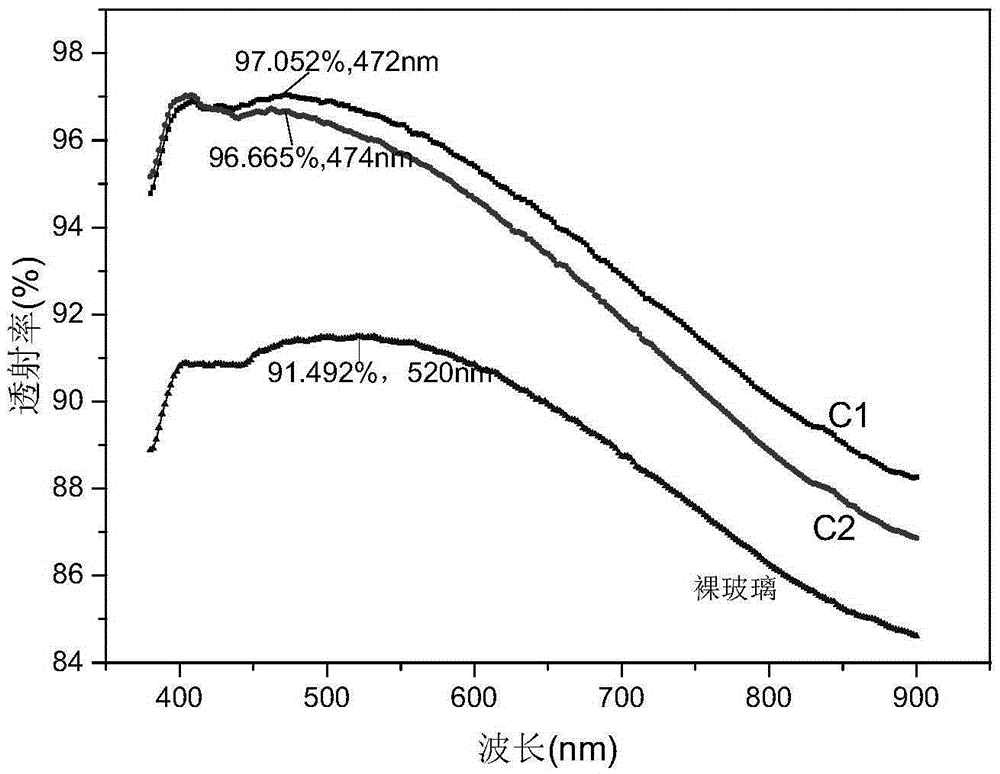

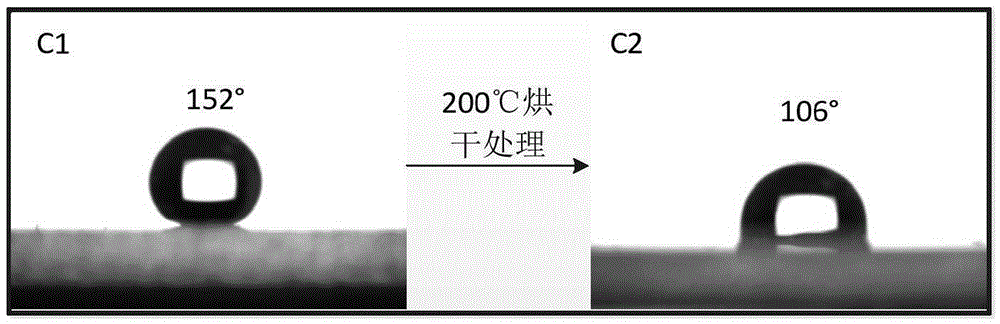

Super-hydrophobic high-transmittance SiO2 anti-reflecting thin film and preparation method thereof

The invention relates to a super-hydrophobic high-transmittance SiO2 anti-reflecting thin film and a preparation method thereof; a hybrid sol doped with trimethylchlorosilane is prepared by a sol-gel method; the surface of a glass slide is cleaned; a plating film is formed on the surface of the glass slide by a dip-coating method, and the super-hydrophobic high-transmittance SiO2 anti-reflecting thin film is obtained after the plating film is dried. Compared with the prior art, the preparation method has the advantages of simple manufacturing process and low cost, and the obtained sol has good uniformity and can be used for large-area film forming. Due to relatively high transmission, incident light transmission can be improved and the solar cell efficiency can be improved when the anti-reflecting thin film is used on a photovoltaic glass cover plate. Moreover, because the thin film has good hydrophobicity and has good self cleaning ability, the thin film is suitable for outdoor humid environments.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

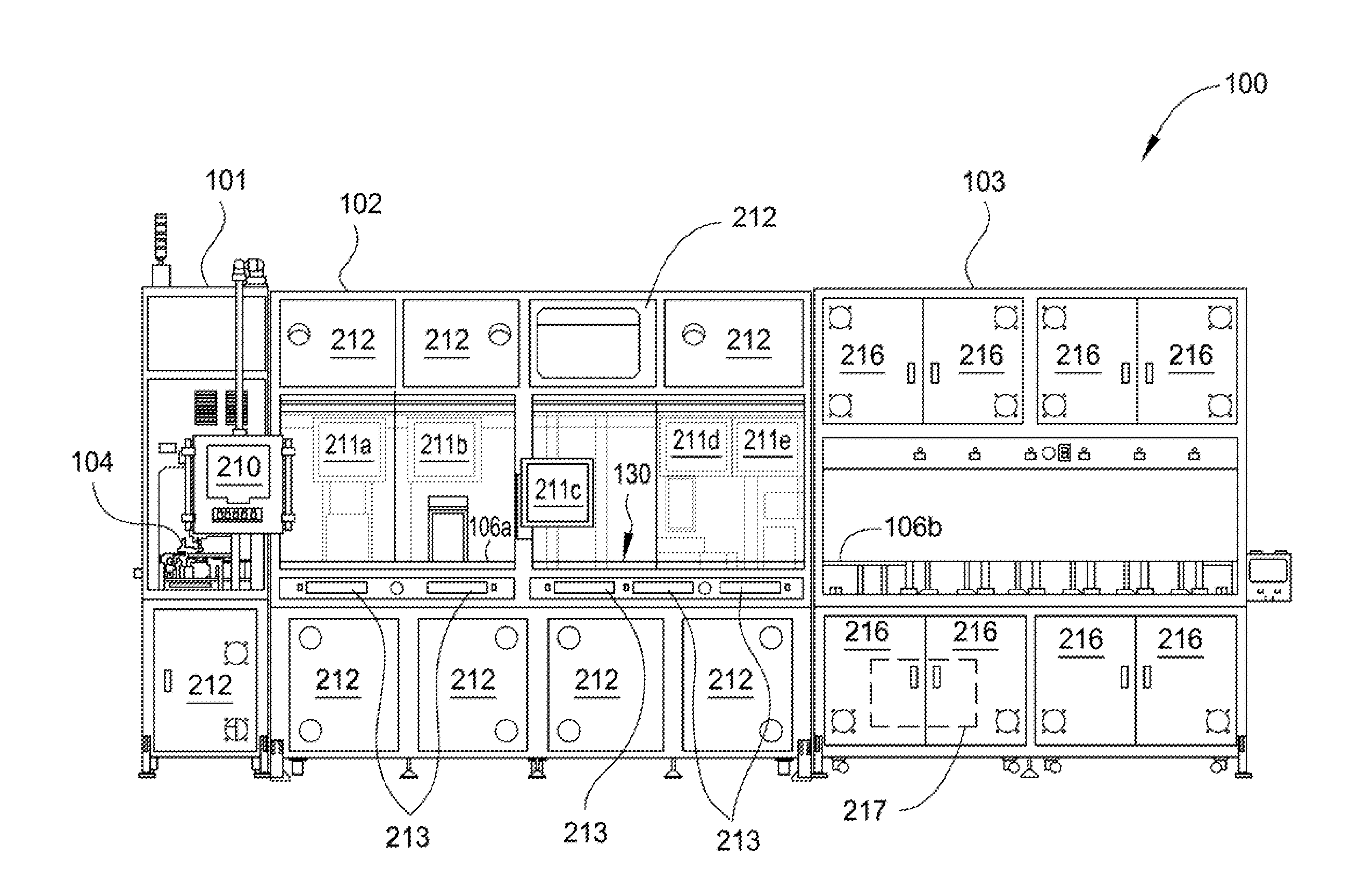

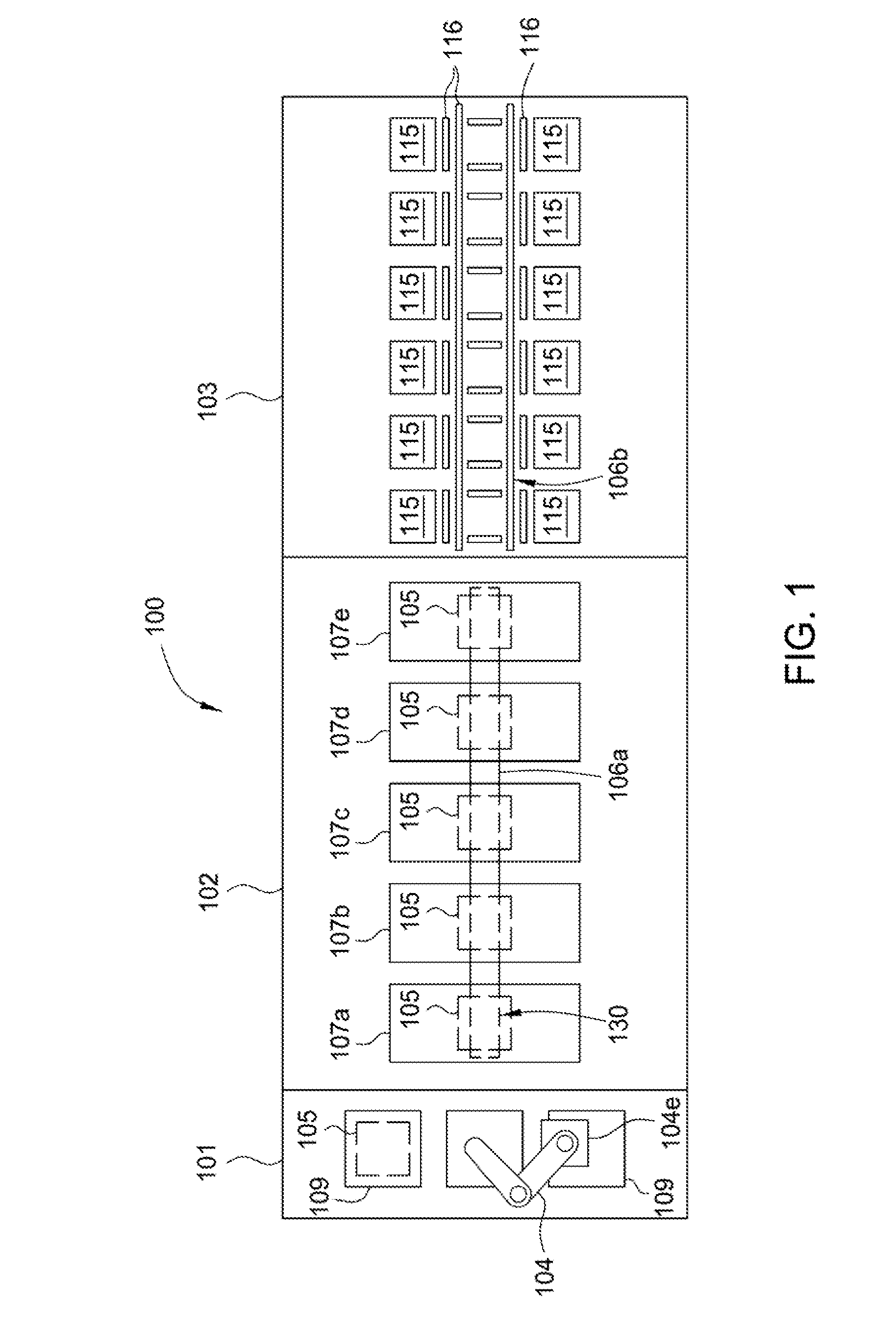

Linear inspection system

ActiveUS20150377796A1Photovoltaic monitoringSemiconductor/solid-state device testing/measurementMetrologyPhotoluminescence

Embodiments of the disclosure generally relate to comprehensive, expandable substrate inspection systems. The inspection systems include multiple metrology units adapted to inspect, detect, or measure one or more characteristics of a substrate, including thickness, resistivity, saw marks, geometry, stains, chips, micro cracks, crystal fraction, and photoluminescence. The inspection systems may be utilized to identify defects on substrates and estimate solar cell efficiency of a solar cell produced with the substrate, prior to processing a substrate into a solar cell. Substrates may be transferred through the inspection system between metrology units on a track or conveyor, and then sorted based upon inspection data.

Owner:APPLIED MATERIALS INC

Method for improving efficiency of perovskite solar cell

InactiveCN111599923APromote secondary growthIncrease the average particle sizeSolid-state devicesSemiconductor/solid-state device manufacturingPtru catalystHole transport layer

The invention provides a method for improving the efficiency of a perovskite solar cell. The method comprises the following steps: depositing a layer of lithium-magnesium heavily doped nickel oxide asa hole transport layer on an ITO glass substrate; then respectively spin-coating the surface with a perovskite precursor solution A and a doped precursor solution, wherein the perovskite precursor solution A is prepared by adding methylamine iodine and lead iodide into a DMF solvent and uniformly mixing, and the doped precursor solution is prepared by adding bismuth nitrate, potassium bromide anda guanidyl catalyst into a perovskite precursor solution B prepared from methylamine iodine, lead iodide and a DMF solvent. According to the method provided by the invention, a perovskite absorptionlayer with a double-layer structure is formed by adding a secondary growth process on the basis of an original crystal growth process, so that the carrier transfer efficiency in perovskite is effectively improved, and the photoelectric conversion efficiency of the solar cell is improved.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

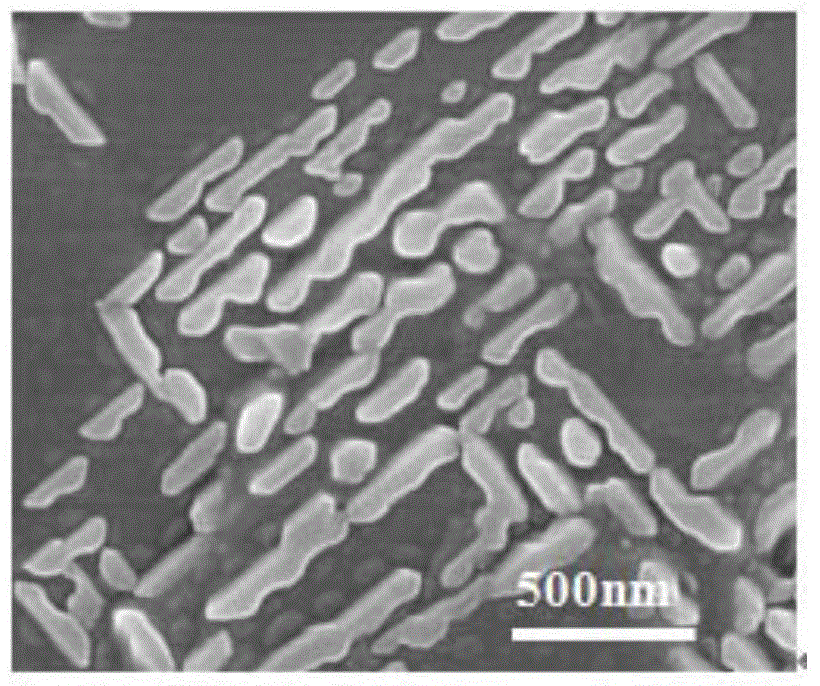

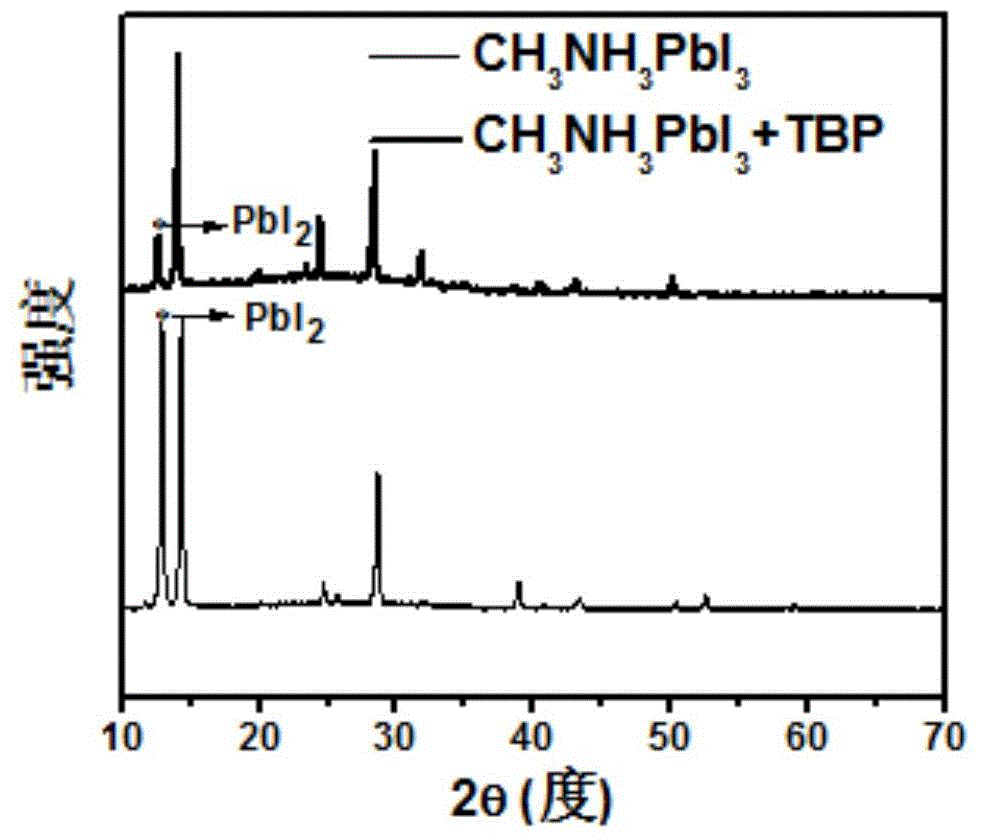

Method of improving efficiency of perovskite solar cell

ActiveCN104966763ALow costEasy to operateFinal product manufacturePhotovoltaic energy generationPerovskite solar cell4-tert-butylpyridine

The invention discloses a method of improving efficiency of a perovskite solar cell, which belongs to the technical field of solar cells. Organic micro-molecular 4-tert-butylpyridine serves as an additive and is added to a perovskite precursor solution according to a concentration of 0.4 to 0.8mol / L, a perovskite crystal film is made, and the cell is then made. The perovskite crystal film made by adopting the organic micro-molecular additive of the invention has a better quality, and the efficiency of the perovskite solar cell is significantly improved.

Owner:无锡暄时光电科技有限公司

High-refractive-index nano inorganic matter hybrid photovoltaic packaging material

InactiveCN106833406AHigh refractive indexImprove efficiencyNon-macromolecular adhesive additivesFilm/foil adhesivesWeather resistanceRefractive index

The invention discloses a high-refractive-index nano inorganic matter hybrid photovoltaic packaging material. The material comprises a packaging adhesive film substrate material, high-refractive-index nano inorganic matter and the like, the refractive index of the photovoltaic packaging material can be realized and adjusted by adding the high-refractive-index nano inorganic matter, refractive indexes of glass, the packaging material and a crystalline silicon cell piece are matched perfectly, the absorption of incident sunlight by a silicon wafer is optimized, and the efficiency of a solar cell is improved; the dispersibility of the high-refractive-index nano inorganic matter in a polymer is improved by coating the high-refractive-index nano inorganic matter; other additives are added to ensure that the insulativity, weather resistance and the like of the high-refractive-index nano inorganic matter hybrid photovoltaic packaging material meet the requirements of the photovoltaic packaging field.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

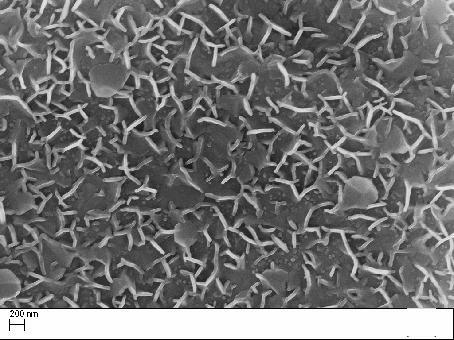

Method for preparing Al mixed with ZnO nanosheet array by adopting pulsed electromagnetic field

InactiveCN102693844ALower resistanceReduced band gapLight-sensitive devicesPhotovoltaic energy generationZinc nitrateZinc Acetate Dihydrate

The invention relates to a method for preparing Al mixed with ZnO nanosheet array by adopting a pulsed electromagnetic field, which is as follows: an FTO conductive sheet glass is placed in an ultrasonic cleaner for cleaning; the mixed solution I of zinc acetate, ethanol amine and ethylene glycol monomethyl ether is dripped on the conductive sheet glass, and is uniformly coated through a spin coater and heat treated to form a ZnO film thereon; the FTO conductive sheet glass coated with the ZnO film is put into a reaction kettle, the mixed solution II formed by aluminium nitrate, zinc nitrate and hexamethylene tetramine as well as deionized water is filled into the reaction kettle, the pulsed electromagnetic field treatment is applied to the reaction system in the reaction kettle, the kettle is moved to a constant temperature oven for hydrothermal reaction after the treatment, and the sediment on the surface of the glass is washed and dried after the hydrothermal reaction, so as to obtain the Al mixed with ZnO nanosheet array. The method is simple to operate, has low energy consumption, enables the orientation of the nanosheets to be identical, has higher verticality, enables the nanosheets to be neatly arrayed, has big specific surface area, facilitates electron transport when serving as the photoanode, and improves the efficiency of the dye sensitized solar cell.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

Normal temperature texturing method, silicon wafer prepared by texturing, solar battery piece and preparation method thereof

InactiveCN107919275AFinal product manufactureSemiconductor/solid-state device manufacturingReaction temperatureRoom temperature

The invention discloses an acid texturing liquid used for etching a solar battery silicon wafer, a texturing method, a solar battery piece and a manufacturing method thereof. The acid texturing liquidcomprises a copper ion source used for providing copper ions at the concentration of 20-150.0 mmol / L, a fluorine ion source used for providing fluorine ions at the concentration of 0.5-10.0 mol / L andan oxidizing agent at the concentration of 0.2-2.0 mol / L for oxidizing copper into copper ions. By adoption of the acid texturing liquid, the silicon wafer surface can be well textured, so that an independent, complete and tightly arranged inverted pyramid structure can be formed on the silicon wafer surface at the room temperature within extremely short time; by virtue of the structure, the reflectivity of incident light on the textured surface can be lowered to 4-12%, so that the solar battery efficiency is improved; and by adoption of the acid texturing liquid and the texturing method, production cost can be lowered, the reaction temperature can be lowered, the reaction time can be shortened, and production yield can be increased.

Owner:北京普扬科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com