Method for preparing composite transparent conductive electrode based on metal grid and metal nano-wire

A technology of transparent conductive electrodes and metal nanowires, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of single-variable metal grid structure difficulty and reduce light transmittance, and achieve excellent light transmittance and electrical conductivity. , the effect of easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

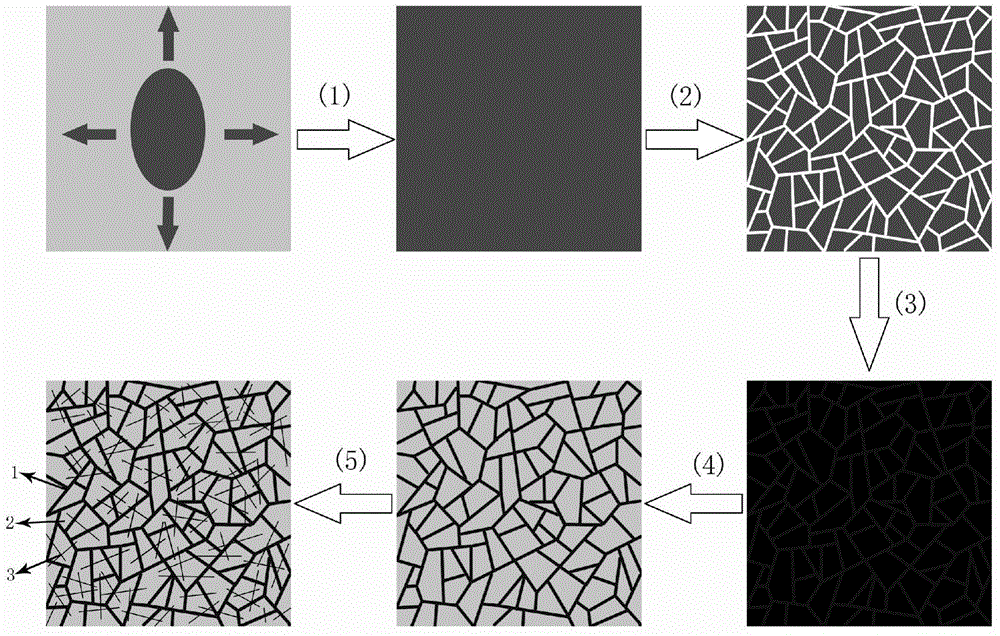

[0045] This embodiment provides a method for preparing a composite transparent conductive electrode based on metal grids and metal nanowires, such as figure 1 As shown, wherein (1) represents the deposition of the sacrificial layer template, (2) represents the formation of cracks in the sacrificial layer, (3) represents the metal film deposition, (4) represents the removal of the sacrificial layer template to form a metal mesh film, ( 5) represents the formation of a composite electrode: wherein: 1 represents a metal network wire, 2 represents a mesh, and 3 represents a metal nanowire.

[0046] The detailed process of each step is as follows:

[0047] (1) Preparation of sacrificial layer template

[0048] First, prepare the template solution: use egg white as the raw material, add deionized water (the volume ratio of deionized water to egg white is 1:3) to the egg white liquid, ultrasonically clean for 30 minutes, and leave to stand for 6 hours to remove the impurities in the...

Embodiment 2

[0059] This embodiment provides a method for preparing a composite transparent conductive electrode based on metal grids and metal nanowires, such as figure 1 Shown, wherein (1) deposition of sacrificial layer film; (2) heating film, forms the sacrificial layer template of crack; (3) deposition of metal film; (4) removes sacrificial layer template, forms metal mesh film; (5 ) to coat the metal nanowires to complete the preparation of the composite electrode.

[0060] The detailed process of each step is as follows:

[0061] (1) Preparation of sacrificial layer template

[0062]First, prepare the template liquid: use egg white as raw material, add deionized water (the volume ratio of deionized water to egg white is 1:4) to the egg white liquid, ultrasonically clean it for 40 minutes, leave it to stand for 8 hours, and remove the impurities in the lower layer. Obtain a transparent pale yellow template liquid; then, adopt the spin coating method to deposit a sacrificial layer t...

Embodiment 3

[0073] This embodiment provides a method for preparing a composite transparent conductive electrode based on metal grids and metal nanowires, such as figure 1 Shown, wherein (1) deposition of sacrificial layer film; (2) heating film, forms the sacrificial layer template of crack; (3) deposition of metal film; (4) removes sacrificial layer template, forms metal mesh film; (5 ) to coat the metal nanowires to complete the preparation of the composite electrode.

[0074] The detailed process of each step is as follows:

[0075] (1) Preparation of sacrificial layer template

[0076] First, prepare the template solution: use egg white as the raw material, add deionized water (the volume ratio of deionized water to egg white is 1:2) to the egg white liquid, ultrasonically clean it for 60 minutes, and leave it to stand for 10 hours to remove the impurities in the lower layer. A transparent light yellow template solution was obtained. Then, the sacrificial layer film was deposited o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com