Patents

Literature

209 results about "Metal oxide electrode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for manufacturing a nano-structured electrode of metal oxide

ActiveUS7084002B2Improve conductivityProtecting/adjusting hybrid/EDL capacitorHybrid capacitor electrodesElectrode potentialNanostructured metal

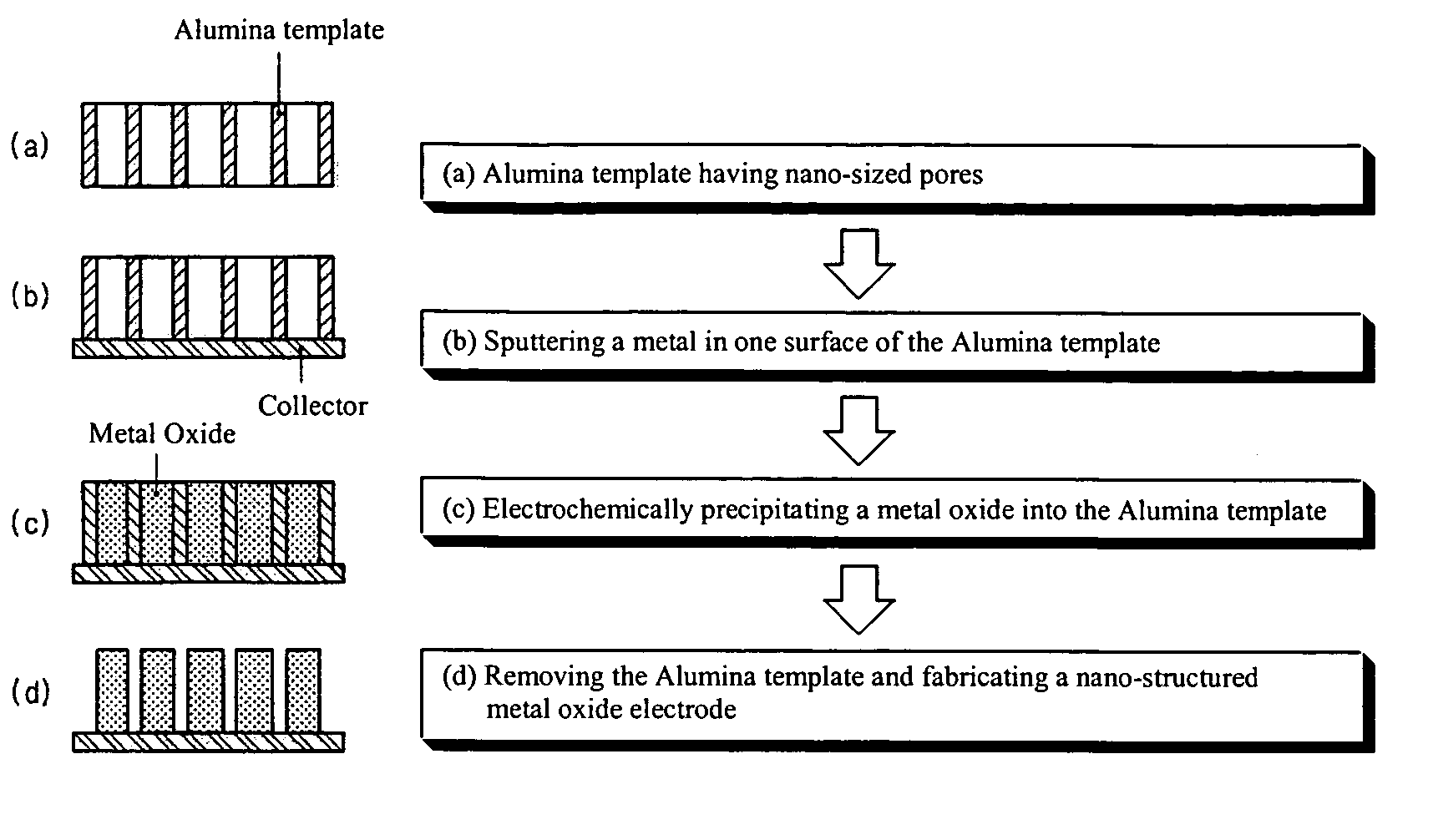

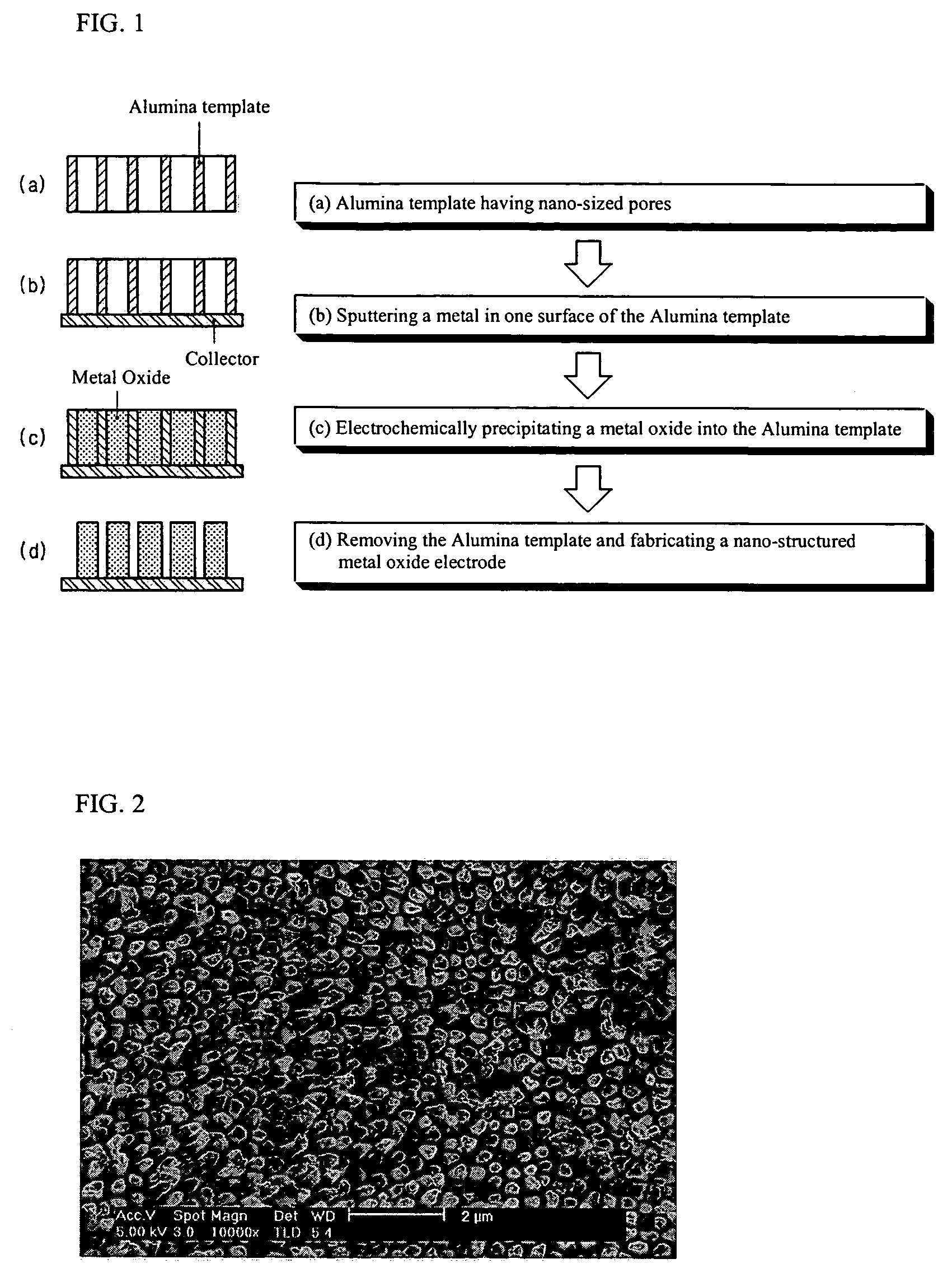

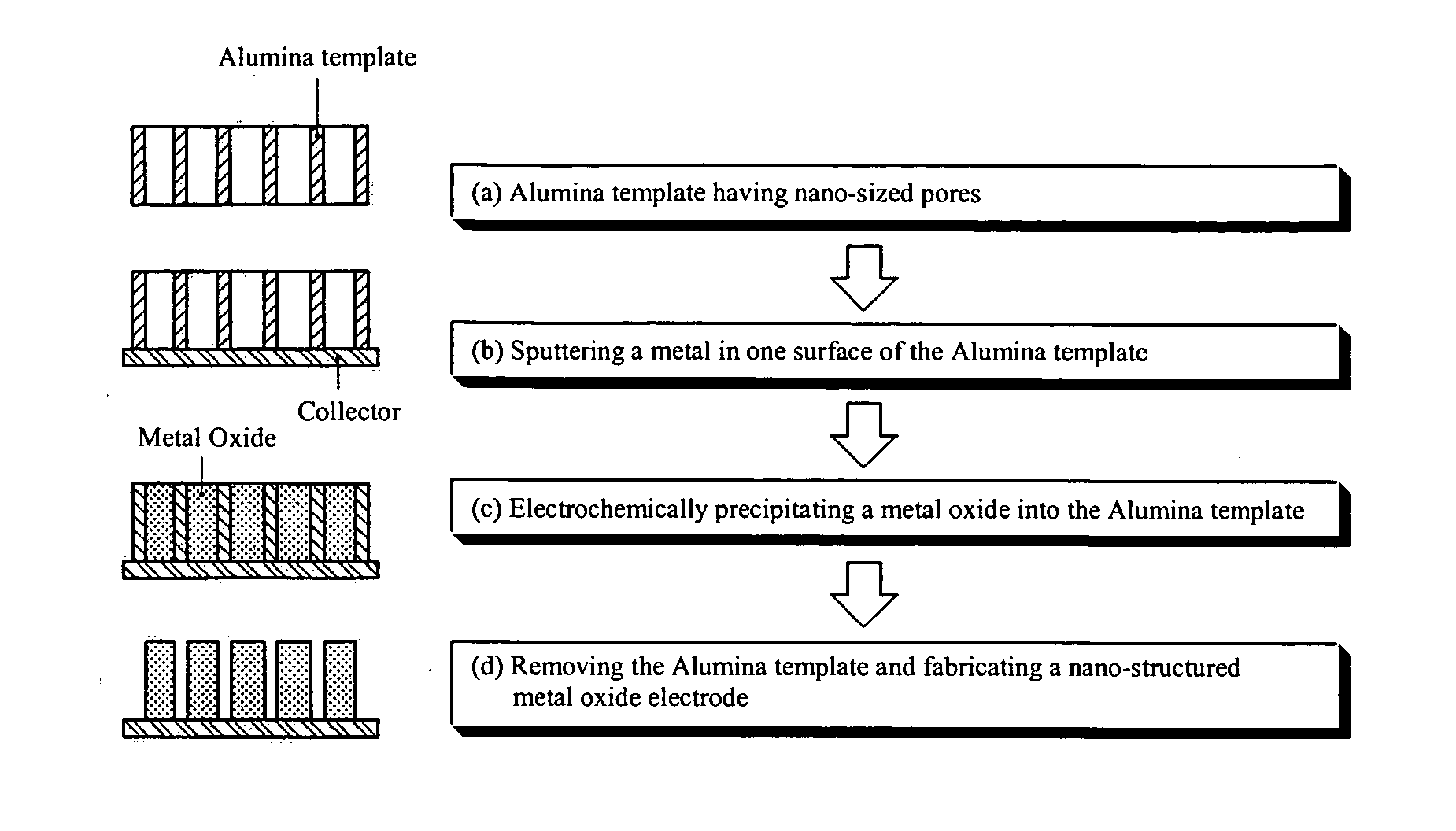

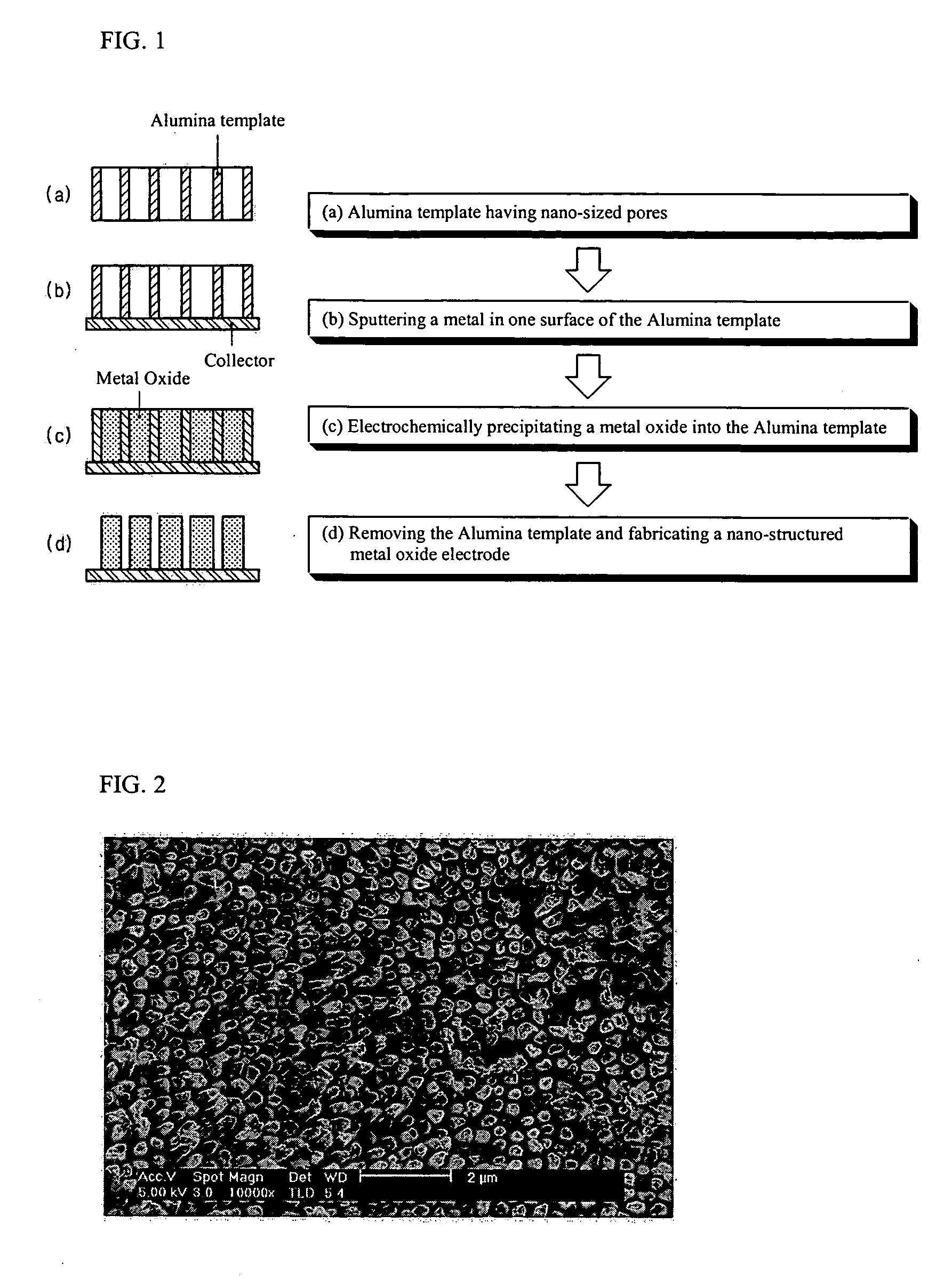

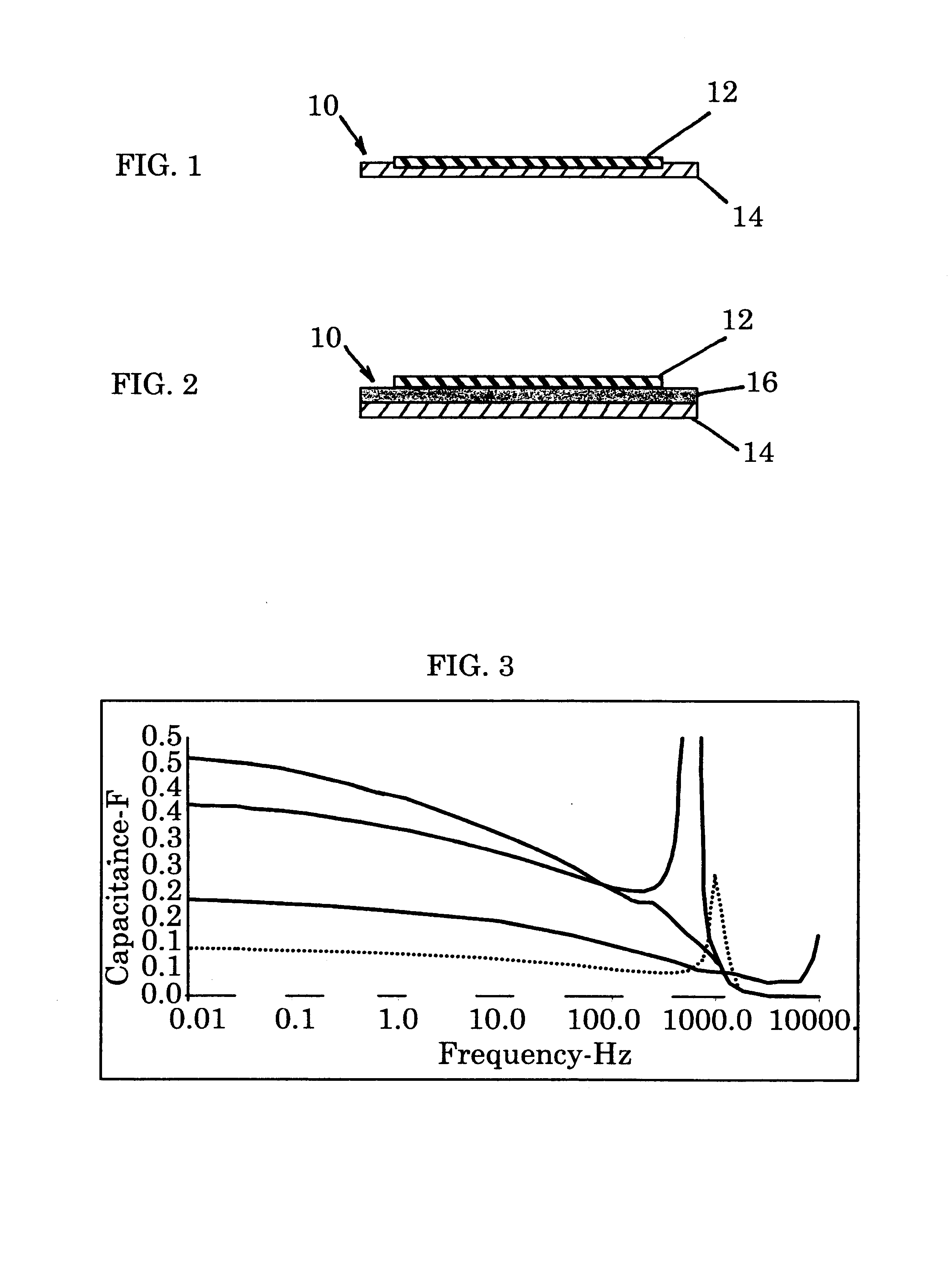

The present invention relates to a method for manufacturing a nano-structured metal oxide electrode, and in particular, to a method for manufacturing a metal oxide electrode having a few tens or hundreds of nanometers in diameter that is well adapted to an electrode of a supercapacitor using an alumina or polymer membrane having nano-sized pores as a template. Preferred methods for manufacturing a nano-structured metal oxide electrode comprises steps of preparing an alumina or polymer template having a plurality of nano-sized pores; sputtering a metal acting as a current collector with a few tens of μm of thickness in one surface of the alumina template; charging the template, after the sputtering step, by submerging it into a precipitation solution having a metal salt dissolved therein, and applying a static current or electrode electric potential thereby electrochemically precipitating a metal oxide in the nano-sized pores of the template; a step in which the composite of the alumina or polymer template and the metal oxide are contacted with a sodium hydroxide solution or other base to remove the alumina or polymer template; and an optional drying step to provide the nano-structured metal oxide electrode.

Owner:HYUNDAI MOTOR CO LTD +1

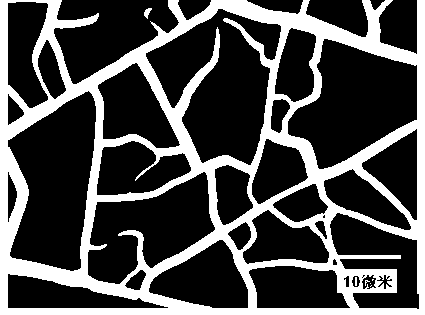

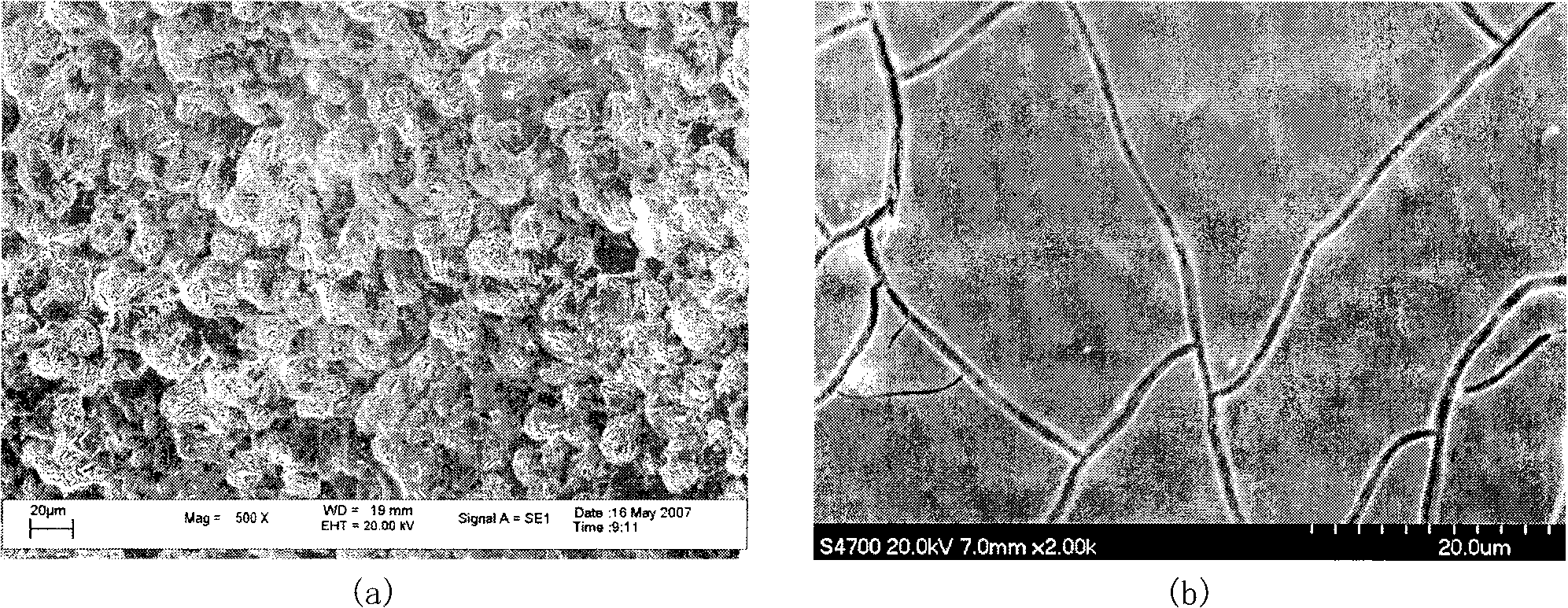

Method for preparing porous metal film transparent conducting electrode based on cracking template method

ActiveCN103227240AEasy to makeReduce usageFinal product manufactureSemiconductor devicesHYDROSOLMaterials science

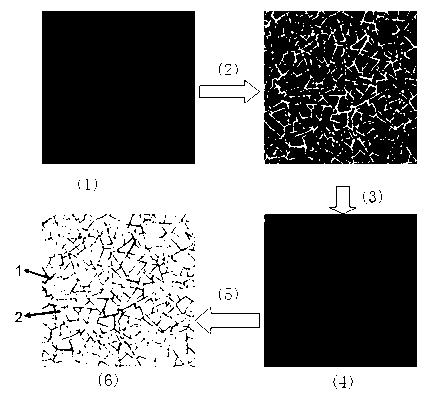

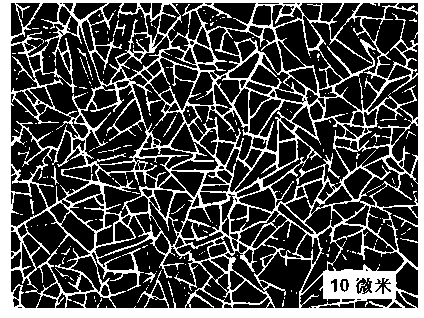

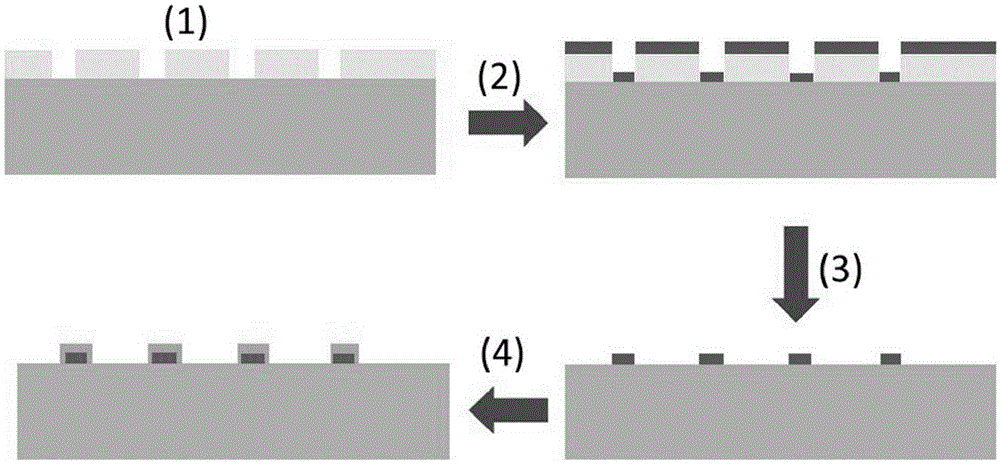

A method for preparing a porous metal film transparent conducting electrode based on a cracking template method comprises the following steps: (1) synthesizing cracking liquid: taking tetrabutyl titanate as a raw material to synthesize microcrystalline titanium dioxide collosol, and obtaining the cracking liquid, (2) fabricating a cracking template: uniformly depositing a cracking film on a substrate with the cracking liquid by a spin-coating method or a lifting method, controlling a temperature condition to allow the cracking film to be cracked naturally to form the cracking template, (3) depositing a metal film: depositing the dense metal film on the cracking template by a magnetron sputtering manner, and (4) removing the cracking template: removing the cracking template from the substrate, cleaning the surface, and forming the porous metal film transparent electrode on the substrate. The transparent conducting electrode prepared with the method has excellent photoelectric properties and higher mechanical and environmental stability; a preparation technology is simple; the resource consumption is low; the transparent conducting electrode is a favorable replacer of the traditional metal oxide electrode; the efficiency of a solar cell can be improved; and the cost can be lowered.

Owner:SOUTH CHINA NORMAL UNIVERSITY

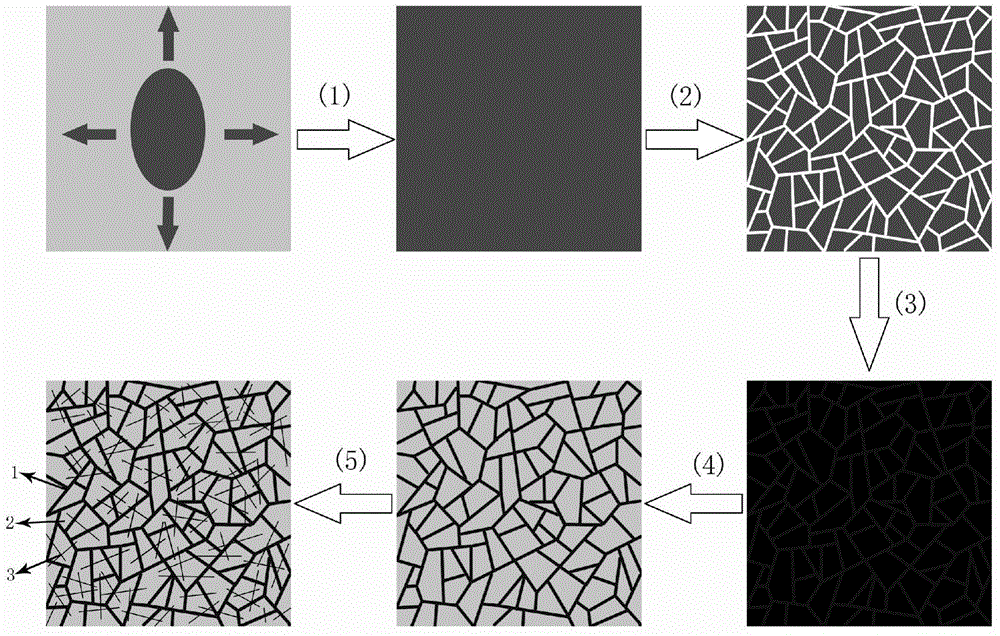

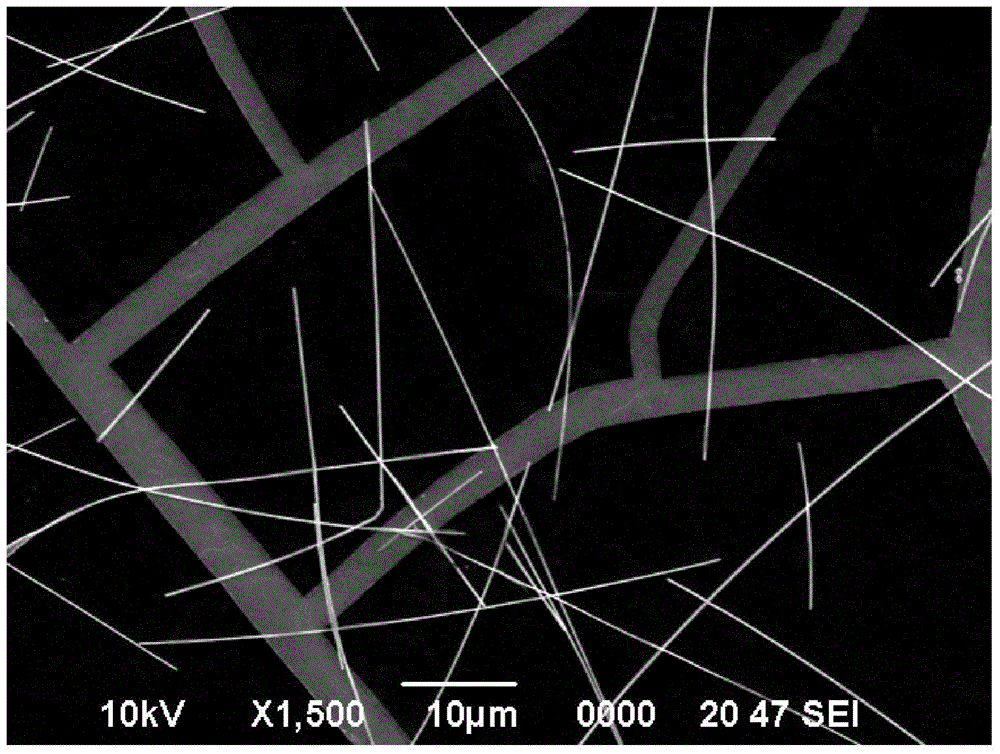

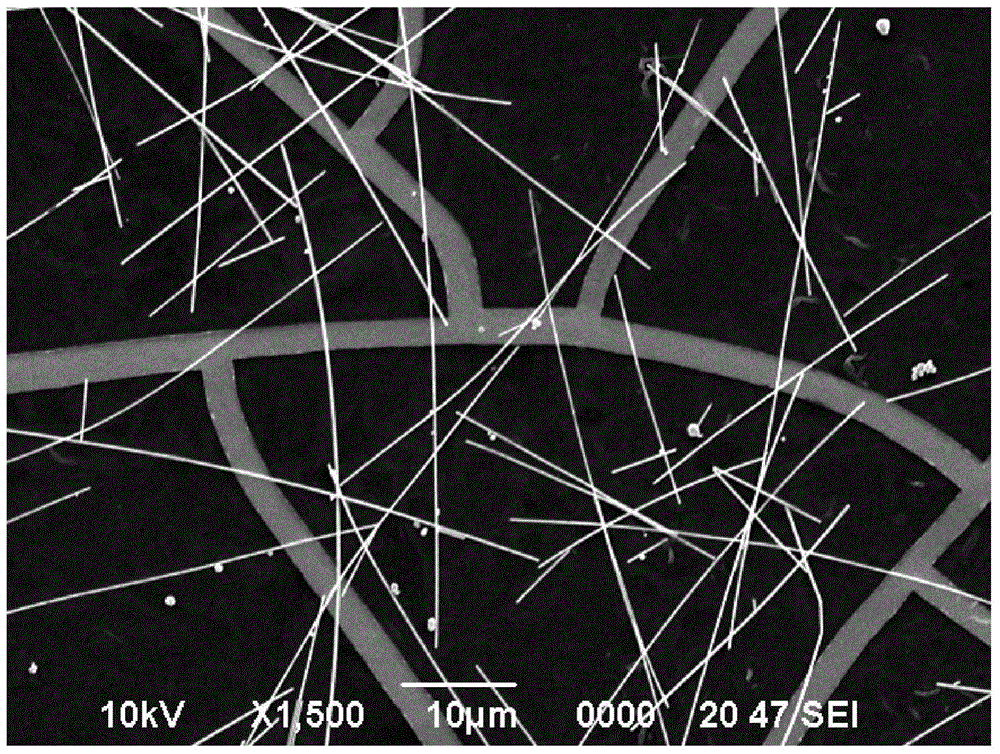

Method for preparing composite transparent conductive electrode based on metal grid and metal nano-wire

ActiveCN104681645AImprove conductivityEasy to prepareFinal product manufactureSemiconductor devicesNanowireResource consumption

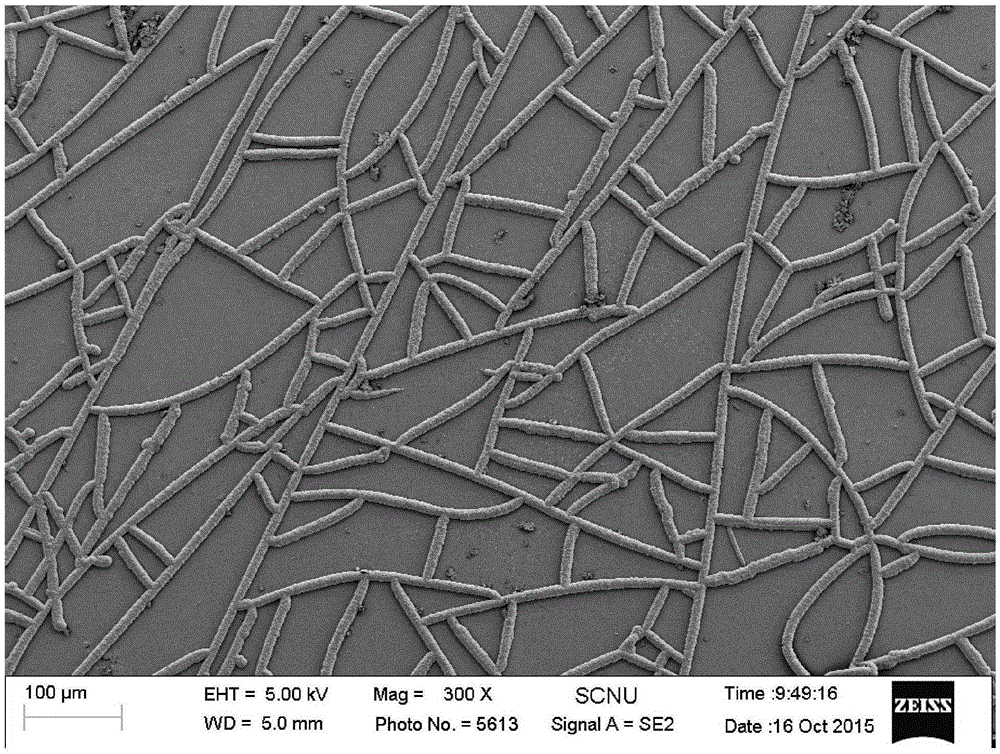

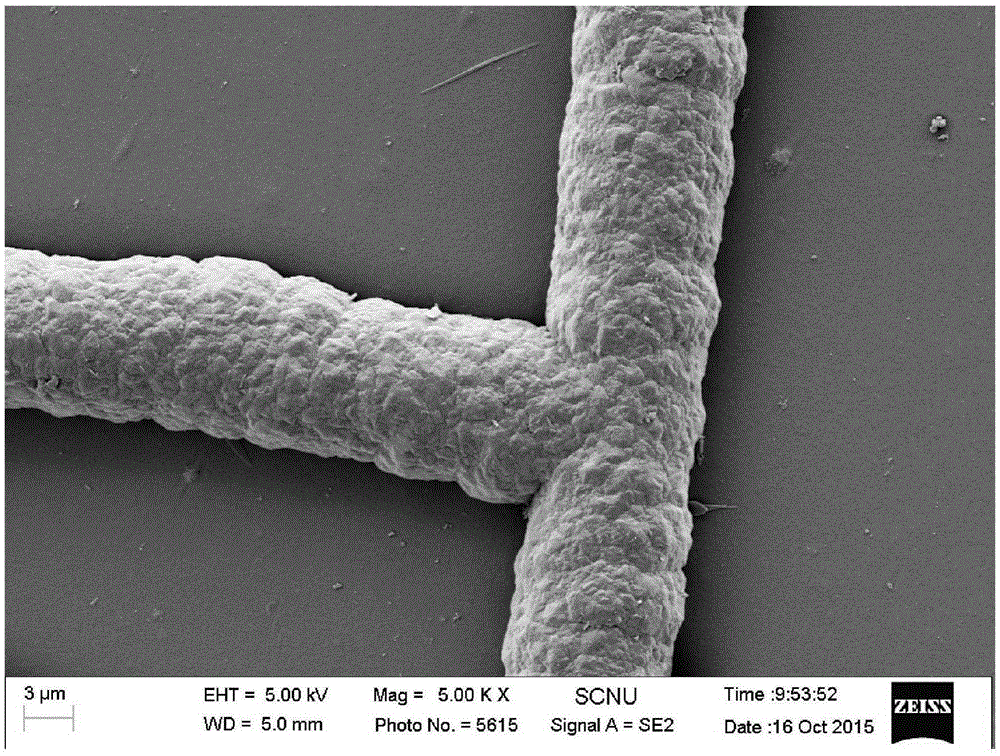

The invention discloses a method for preparing a composite transparent conductive electrode based on a metal grid and a metal nano-wire. The method comprises the following steps: (1) preparing a template solution; (2) manufacturing a sacrificial layer template; (3) depositing a metal thin film; (4) removing the sacrificial layer template; (5) synthesizing the metal nano-wire; and (6) coating the metal nano-wire to prepare the composite transparent conductive electrode. The composite transparent conductive electrode prepared by the method has excellent photoelectric property and environment stability; meanwhile, the electrode in a photoelectric device can be easily in contact with other functional layers; the preparation process is simple and the resource consumption is low; the composite transparent conductive electrode is a good substitute of a traditional metal oxide electrode, and the efficiency of a solar battery can be improved and the cost is reduced.

Owner:SOUTH CHINA NORMAL UNIVERSITY

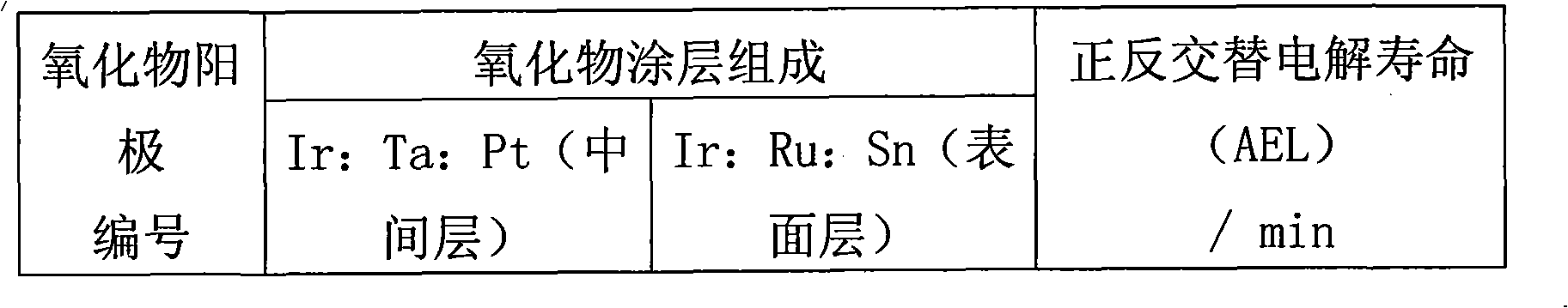

Preparation method for tantalum-contained interlayer metallic oxide electrode

InactiveCN102174704AImprove stabilityImprove protectionLiquid/solution decomposition chemical coatingElectrodesElectrolysisElectrochemistry

The invention belongs to the electrochemical technical field, and relates to a preparation method for a tantalum-contained interlayer metallic oxide electrode. The electrode is suitable for occasions including steel plate high-speed electroplating, seawater electrolysis marine life pollution and damage prevention devices, sodium hypochlorite electrolysis production devices, sewage treatment, cathode protection and the like in the electrochemistry industrial field. The main process comprises three steps, namely substrate pretreatment, tantalum-contained interlayer preparation and oxide coatingpreparation: firstly, a tantalum-contained interlayer is prepared on a titanium substrate by adopting a thermal decomposition method, and then a mixed metallic oxide electro-catalysis coating is prepared on the tantalum-contained interlayer; the mass percent purity of the metallic titanium substrate is larger than 99%; and the process is simple and convenient to carry out, the metallic oxide electrode with larger size or more complicated structure can be prepared, and the tantalum-contained interlayer can better protect the titanium substrate, delay the titanium substrate inactivation, improve the stability of the oxide electrode and prolong the service life.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

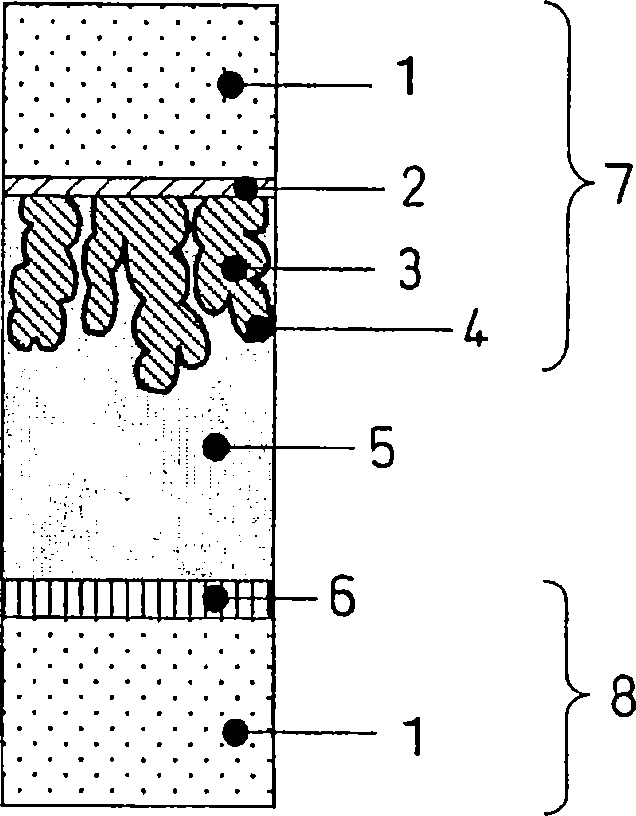

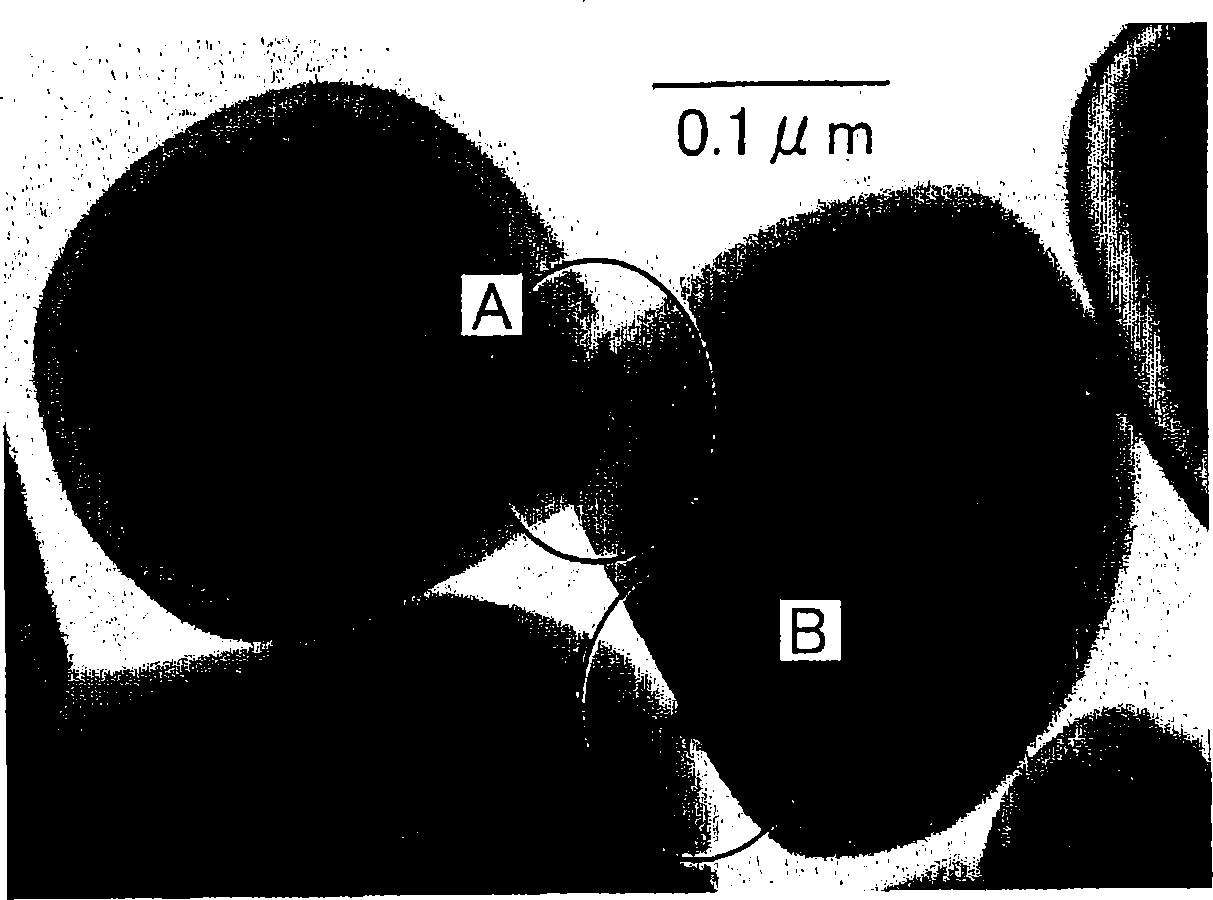

Metal Oxide Dispersion, Metal Oxide Electrode Film, and Dye Sensitized Solar Cell

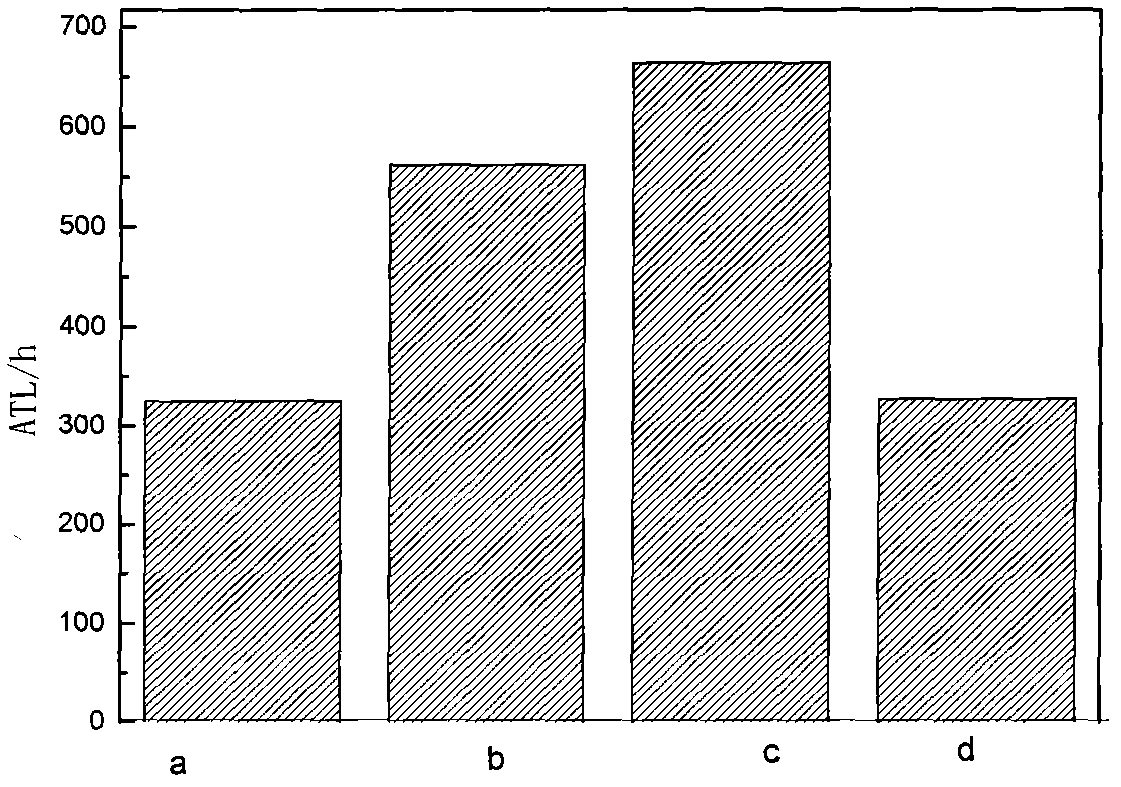

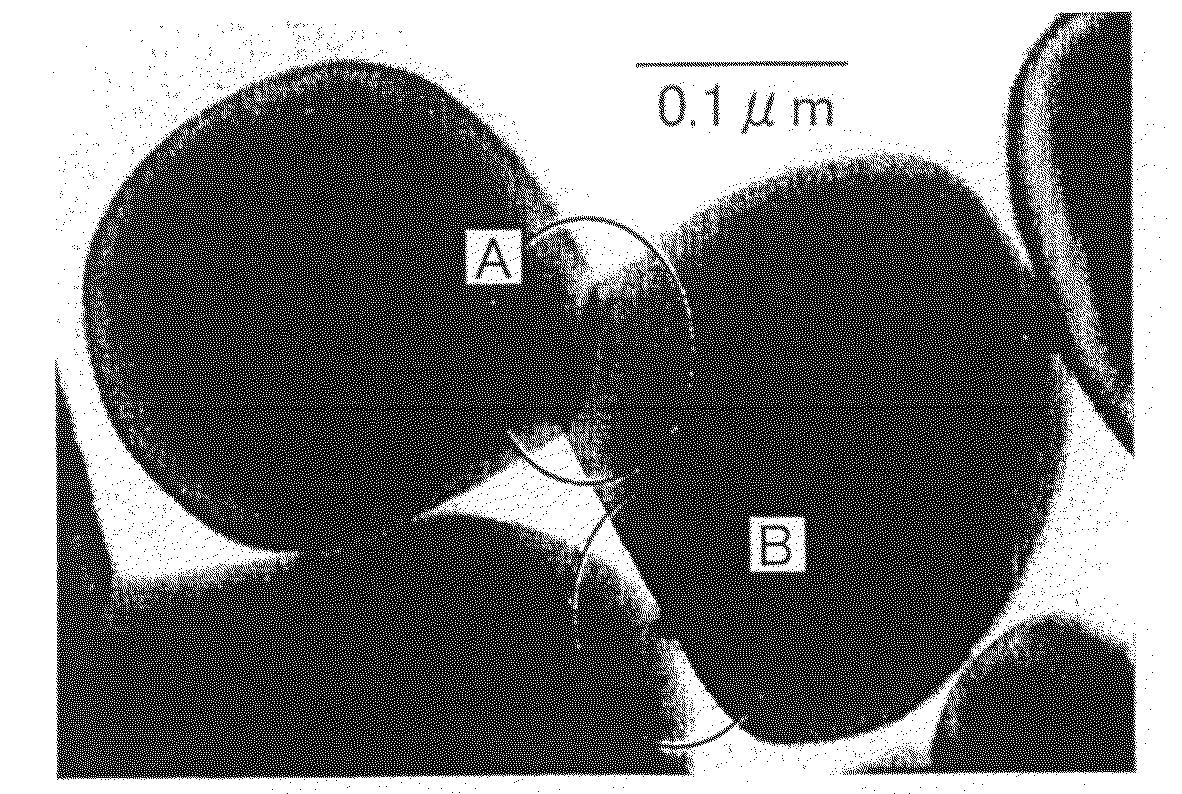

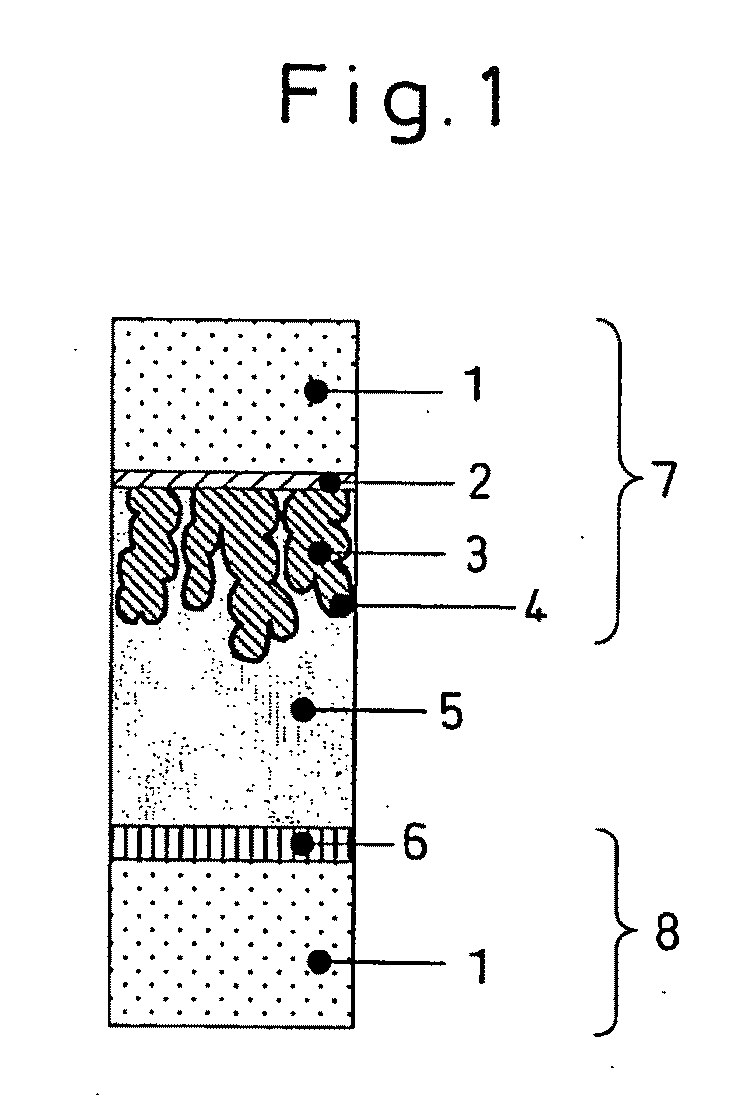

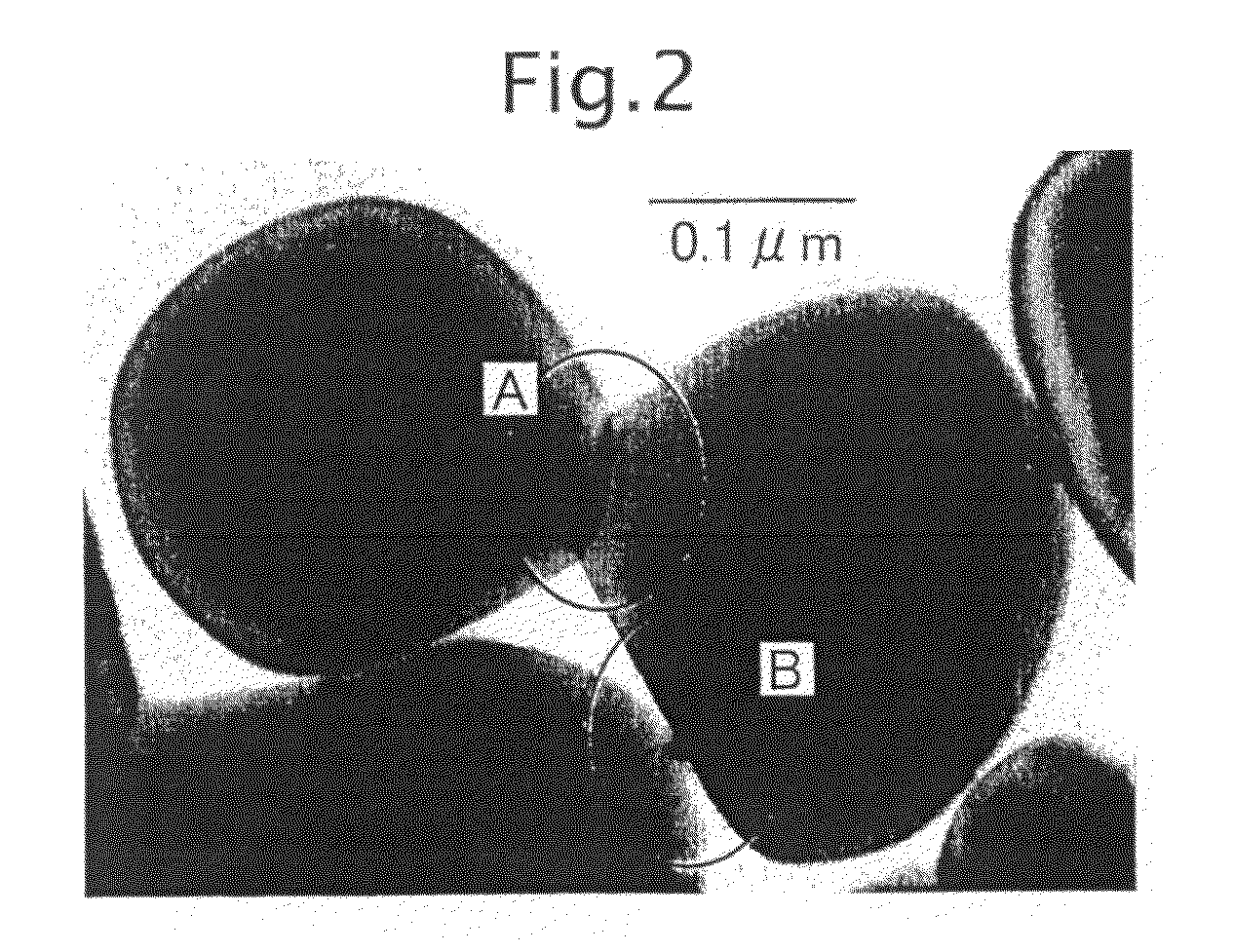

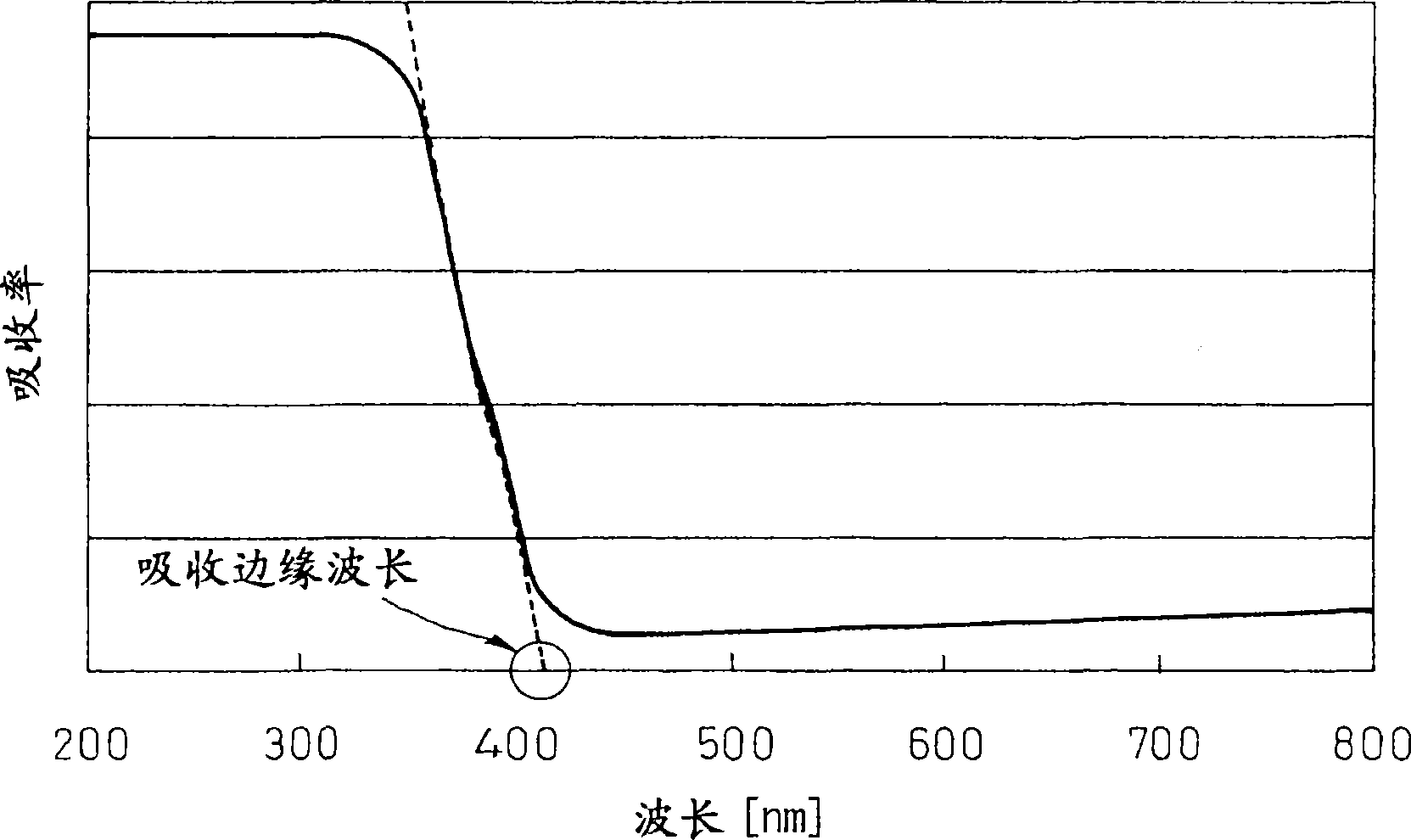

InactiveUS20090014062A1Degraded cell performanceFacilitates electron transferElectrolysis componentsLight-sensitive devicesNeck structureIndium tin oxide

A metal oxide dispersion comprising metal oxide particles with a necking structure, and a solvent, wherein the liquid droplet contact angle of the metal oxide dispersion to an ITO film (Indium-Tin Oxide type film) formed is from 0 to 60°. A metal oxide dispersion for the production of a dye-sensitized solar cell electrode, comprising Metal Oxide Particle Group F having a necking structure formed by m connected particles, Metal Oxide Particle Group G having only 0.2 m or less connected particles, and a solvent, and being formable into a film at 200° C. or less. A metal oxide electrode comprising an electrically conducting substrate having thereon a metal oxide layer comprising metal oxide particles bound by a binder, wherein the binder content is from 0.005 to 5 mass % based on the metal oxide film and the metal oxide layer has a pencil scratch strength of H or more according to JIS5600.

Owner:SHOWA DENKO KK

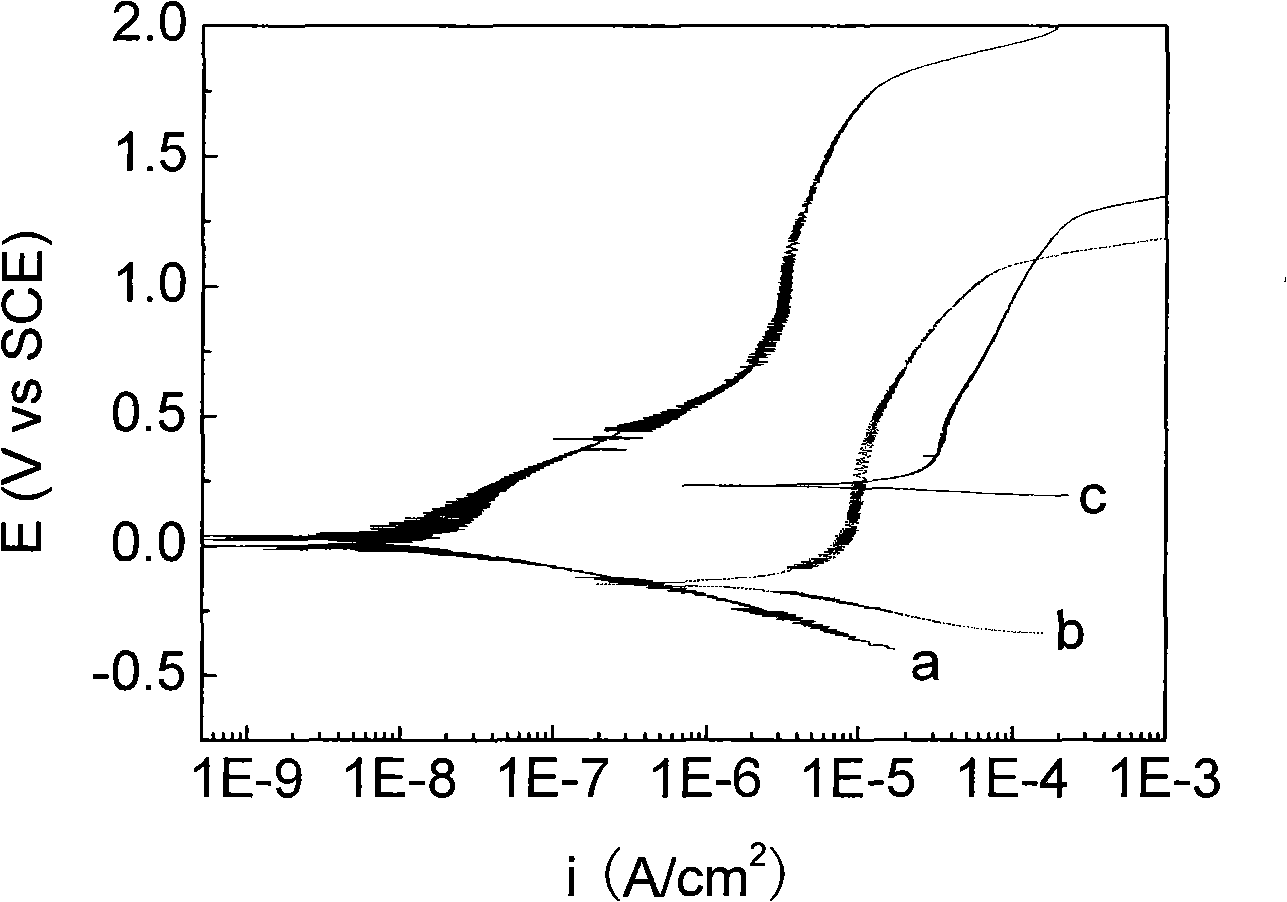

Electrochemical oxidation processing method for wastewater containing anthraquinone dye

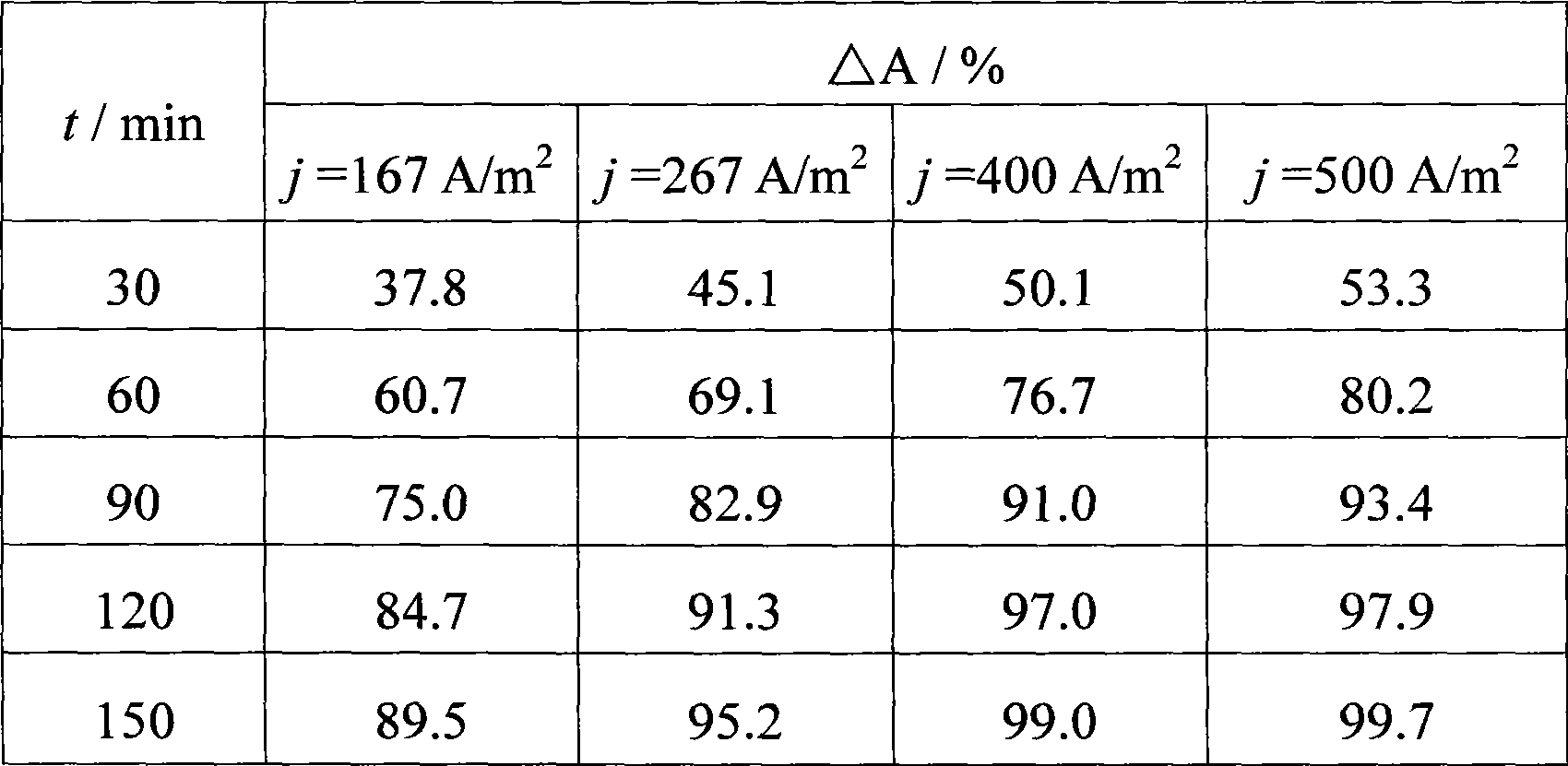

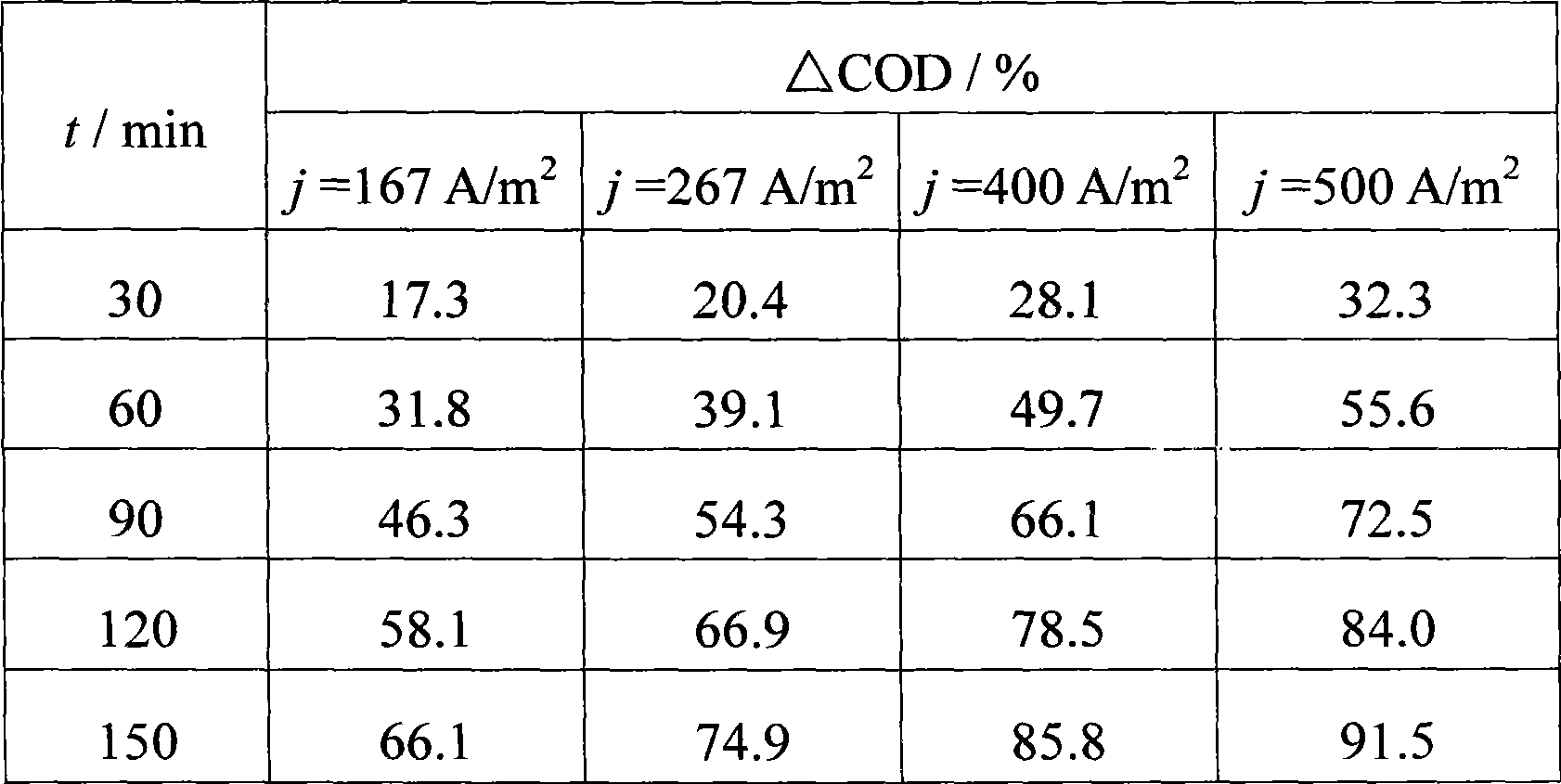

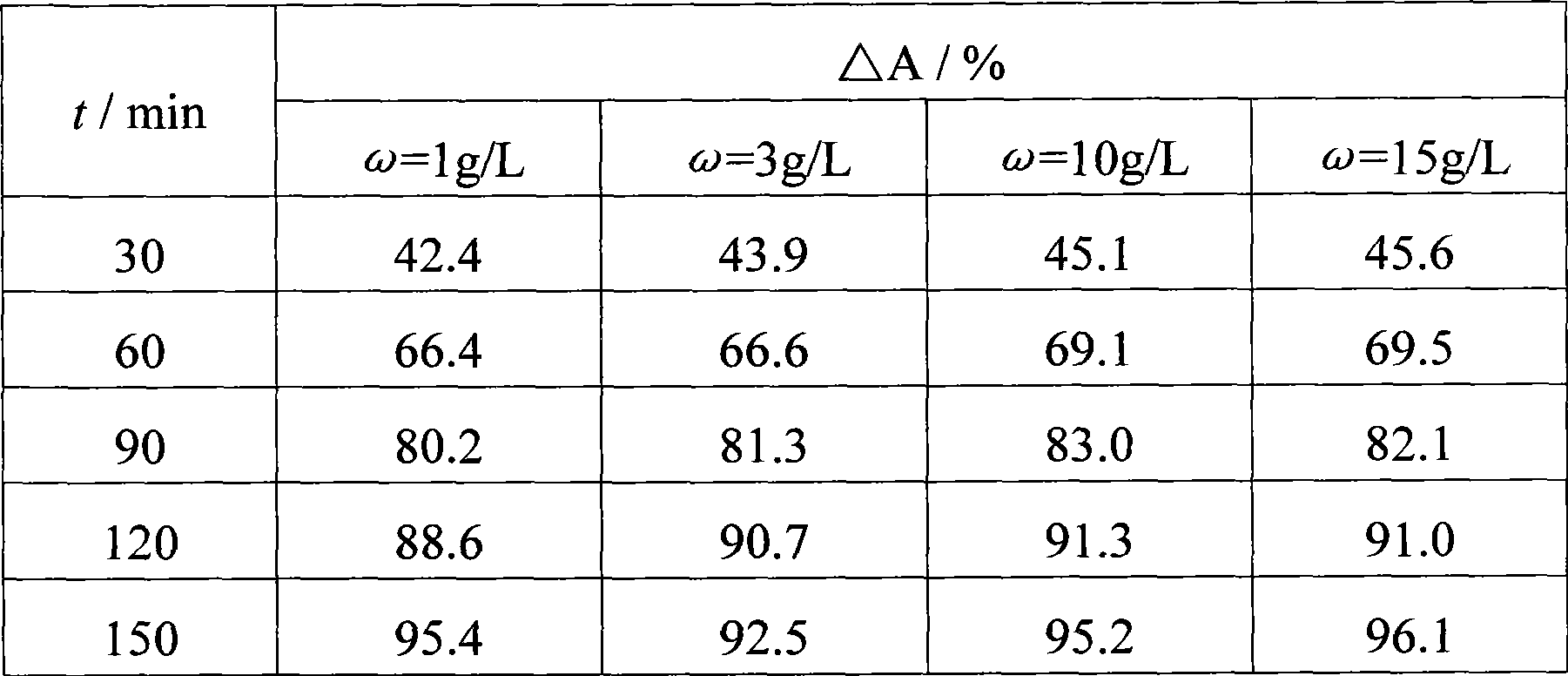

InactiveCN101508477AGood oxidative degradation abilityHigh drop rateWater contaminantsWater/sewage treatmentElectrochemical responseSupporting electrolyte

The invention provides a method for electrochemical oxidation treatment of waste water containing anthraquinone dye, and relates to the technical field of water treatment. In the method, a titanium-based metal oxide electrode is taken as an anode, copper or stainless steel is taken as a cathode, a flat plate or three-dimensional fixed bed is taken as an electrochemical reactor, under conditions of the current density of between 10 and 1,500A / m, the content of supporting electrolyte, namely Na2SO4 of between 1 and 20g / L and the temperature of the waste water of between 5 and 95 DEG C, the electrochemical oxidation treatment is performed. The method has the advantages of the degradation of the anthraquinone dye in a short time, quick reaction rate, good decolorization effect, high decrease rate of COD, simple technological flow, little equipment investment, easy operational control and easy industrialized application.

Owner:YANGZHOU UNIV

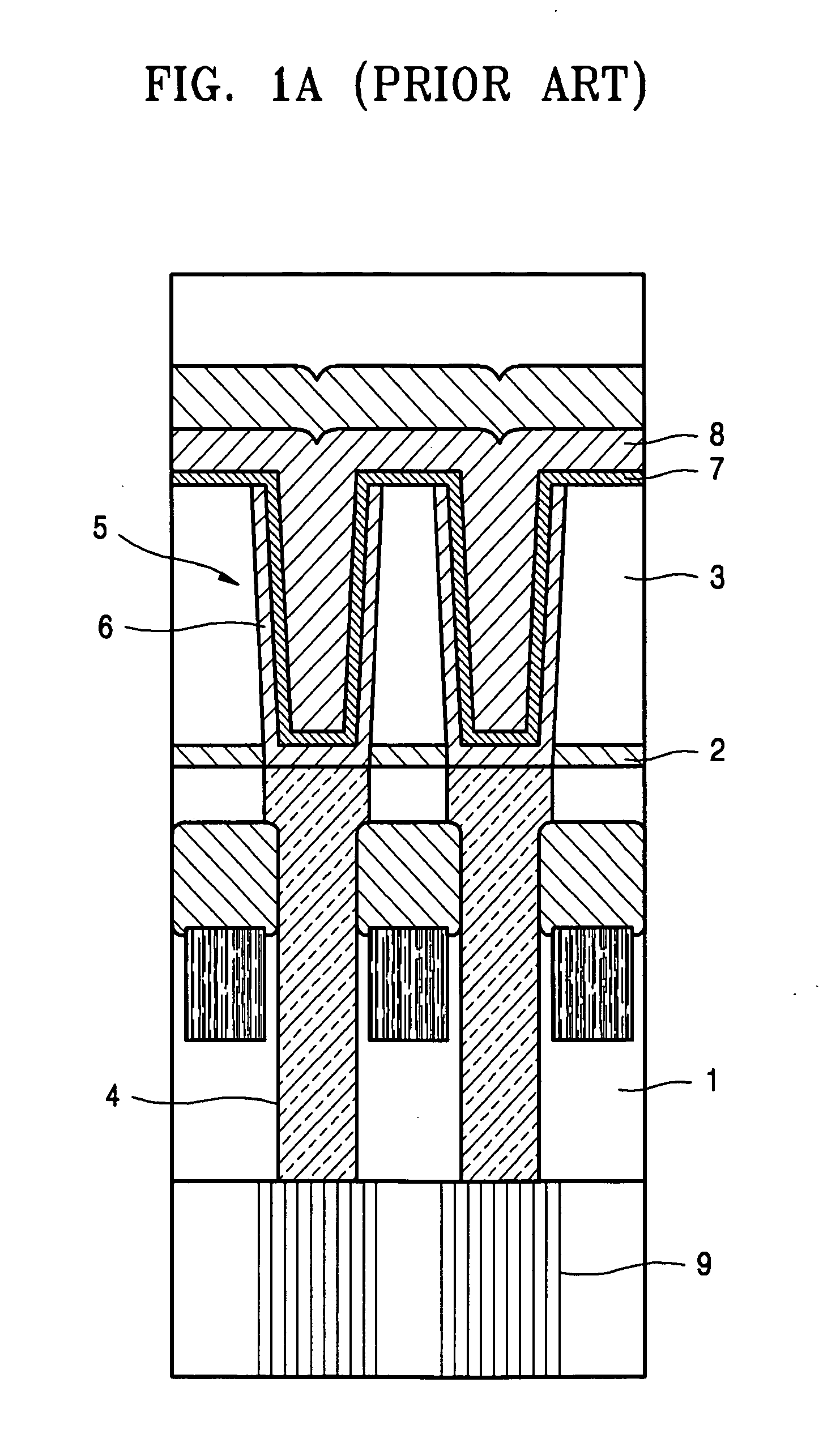

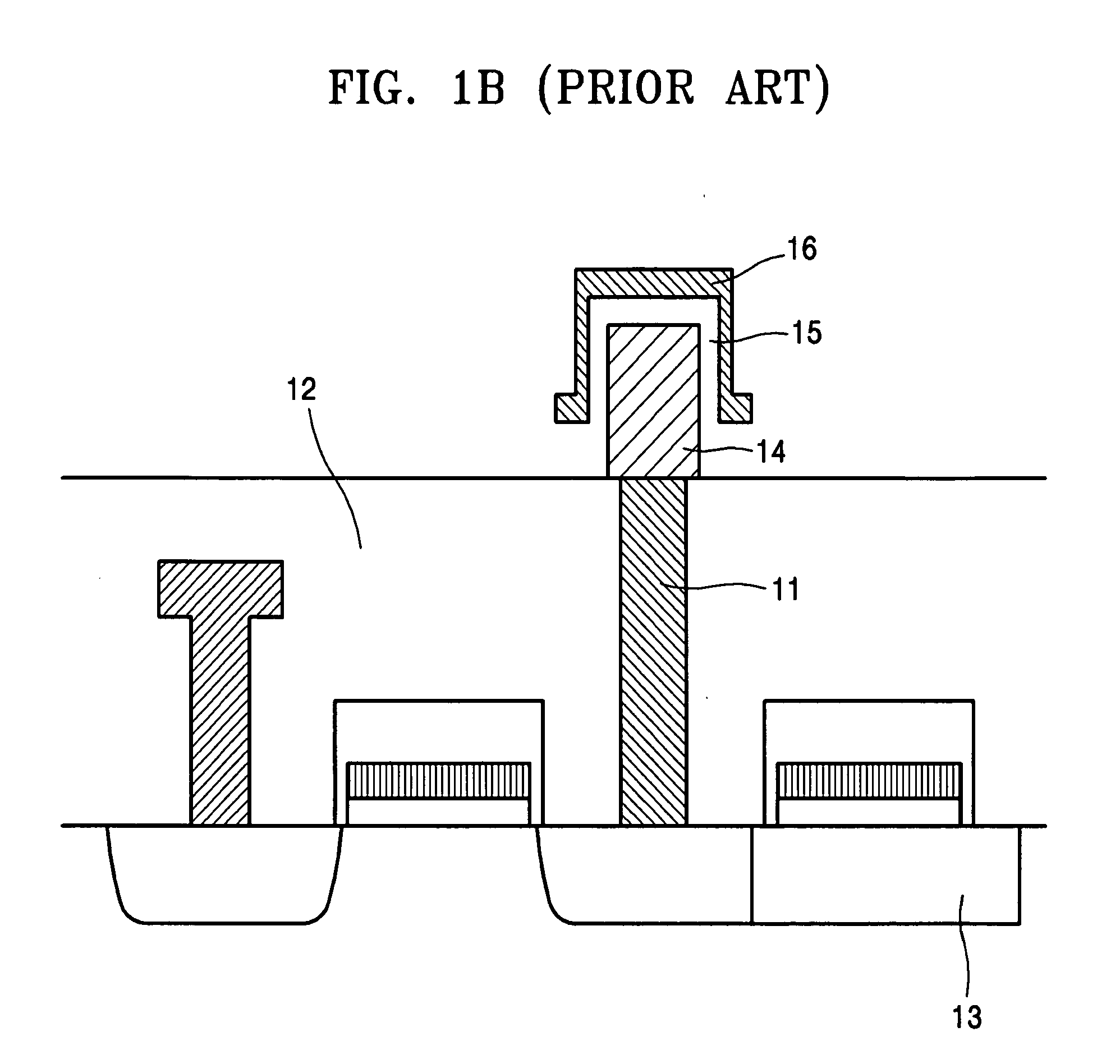

Method for manufacturing a nano-structured electrode of metal oxide

ActiveUS20050142898A1Improve conductivityProtecting/adjusting hybrid/EDL capacitorHybrid capacitor electrodesElectrode potentialNanostructured metal

The present invention relates to a method for manufacturing a nano-structured metal oxide electrode, and in particular, to a method for manufacturing a metal oxide electrode having a few tens or hundreds of nanometers in diameter that is well adapted to an electrode of a supercapacitor using an alumina or polymer membrane having nano-sized pores as a template. Preferred methods for manufacturing a nano-structured metal oxide electrode comprises steps of preparing an alumina or polymer template having a plurality of nano-sized pores; sputtering a metal acting as a current collector with a few tens of μm of thickness in one surface of the alumina template; charging the template, after the sputtering step, by submerging it into a precipitation solution having a metal salt dissolved therein, and applying a static current or electrode electric potential thereby electrochemically precipitating a metal oxide in the nano-sized pores of the template; a step in which the composite of the alumina or polymer template and the metal oxide are contacted with a sodium hydroxide solution or other base to remove the alumina or polymer template; and an optional drying step to provide the nano-structured metal oxide electrode.

Owner:HYUNDAI MOTOR CO LTD +1

Method for preparing high-performance metallic network transparent conducting electrode through metal plating method

ActiveCN105350043AEasy to prepareLow costApparatus for manufacturing conducting/semi-conducting layersElectrical resistance and conductanceResource consumption

The invention discloses a method for preparing a high-performance metallic network transparent conducting electrode through a metal plating method. The method includes the following steps: (1) a fracturing sacrificial layer template is prepared on a substrate; (2) a metallic conducting seed layer is deposited on the fracturing sacrificial layer template; (3) the fracturing sacrificial layer is removed to form a metallic conducting seed layer network; and (4) metal is continuously deposited on the metallic conducting seed layer through the metal plating method, a continuous metal network with the larger thickness and the lower resistance is formed, and therefore the high-performance metallic network transparent conducting electrode is prepared. The transparent conducting electrode is mainly obtained through the metal plating method, the metal plating method belongs to a chemical liquid phase method, the preparing process is simple, resource consumption is low, and the high-performance metallic network transparent conducting electrode is suitable for large-area continuous preparation. The prepared transparent conducting electrode has the extremely-low surface resistance and the better light transmittance; meanwhile, the mechanical property and the environmental stability are good, the transparent conducting electrode is a beneficial replacer of a traditional metallic oxide electrode, and it is expected that the method is used for industrialization of the large-area transparent conducting electrode.

Owner:SOUTH CHINA NORMAL UNIVERSITY

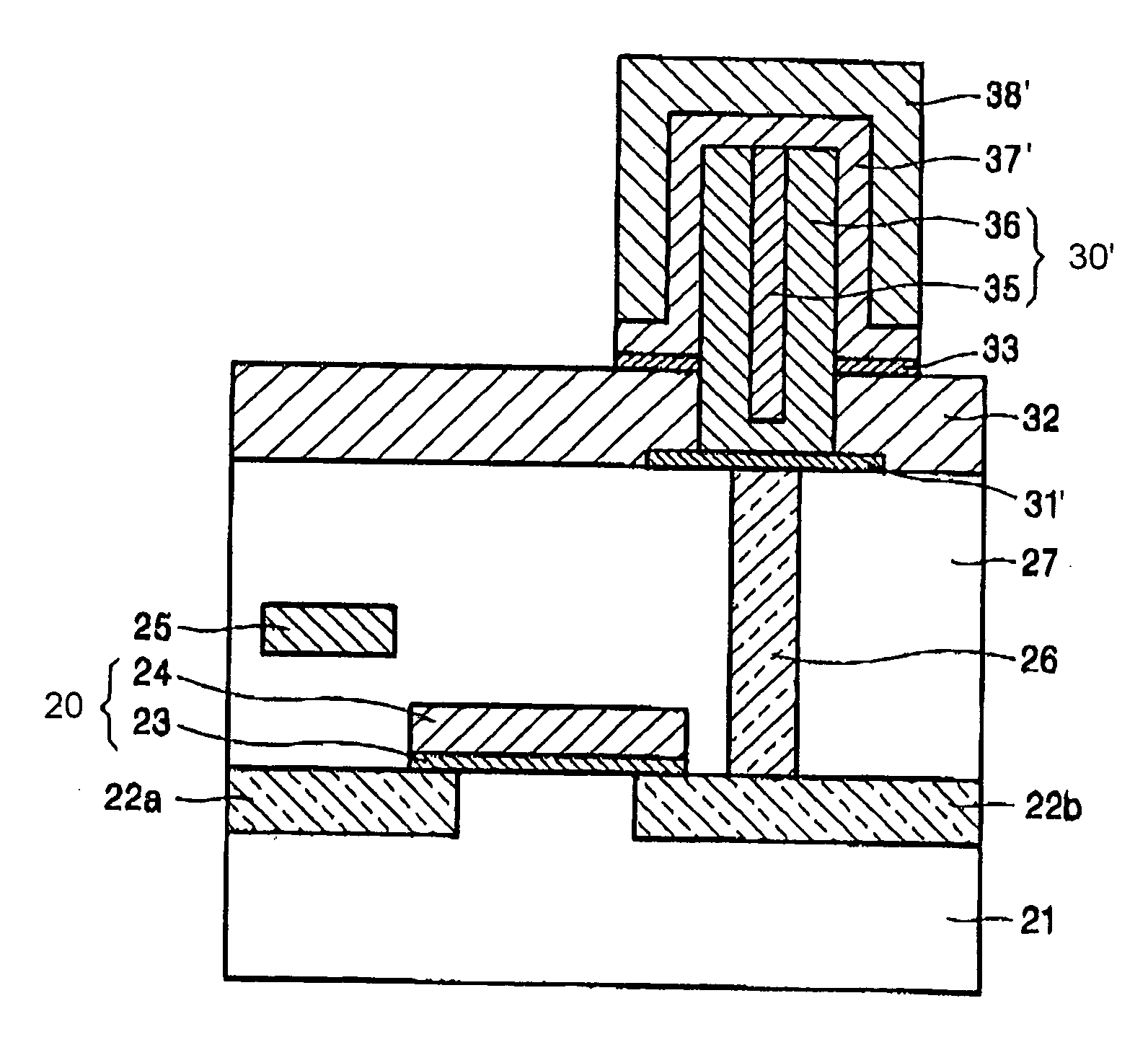

Capacitor of a memory device and fabrication method thereof

InactiveUS20060001070A1Excellent fatigue propertiesLow production costTransistorSolid-state devicesOptoelectronicsMetal electrodes

A capacitor of a memory device, and a method of fabricating the same, includes a lower electrode electrically coupled to a doping region of a transistor structure, the lower electrode having a metal electrode and a metal oxide electrode, a ferroelectric layer covering and extending laterally along the lower electrode, and an upper electrode formed on the ferroelectric layer.

Owner:SAMSUNG ELECTRONICS CO LTD

Technological method for treating carbolic acid waste water by electrochemical oxidation

InactiveCN1935679AExtended service lifeSimple processWater/sewage treatment by electrochemical methodsWater useElectrolysis

The invention discloses a process and method of electrolyzing and oxidizing phenol-containing waste water using Ti-base Sn-Sb metal oxide electrode as anode, belonging to water processing field. And the process uses Ti-base Sn-Sb metal oxide electrode as anode and Cu (or stainless steel) as cathode to electrolyze and oxidize the phenol-containing waste water, where the Ti-base Sn-Sb metal oxide anode is made from polymeric precursor by thermolysis. And it can fast degrade the phenol and the degradation intermediate product of the phenol-benzoquinone into aliphatic organic matters to be biochemically processed, thus able to largely raise follow-up biochemical processing efficiency. And it has simple process flow, strong operability, high current efficiency, and stable and reliable processing effect, easy to implement industrialized application.

Owner:YANGZHOU UNIV

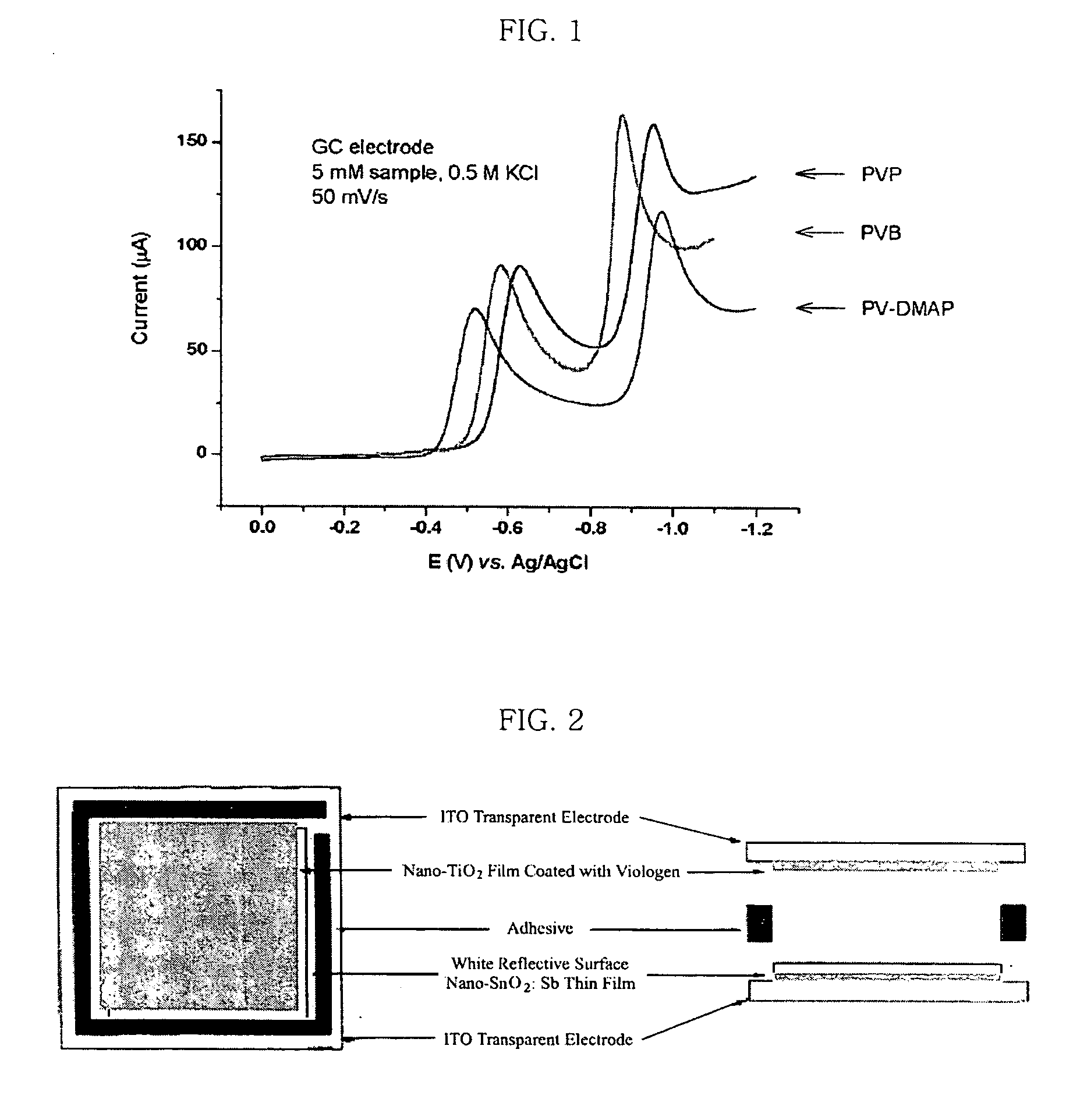

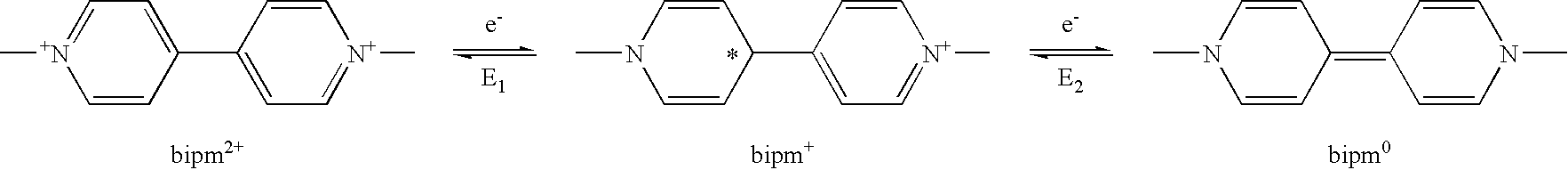

Electrochromic material with improved lifetime

ActiveUS20050179012A1High positive charge densityReduce aggregationPhotosensitive materialsDiffusing elementsPotential differenceOxidation-Reduction Agent

Disclosed are viologen derivatives as an electrochromic material having improved stability and lifetime, a metal oxide electrode including the same, and an electrochromic device using the viologen derivative as an electrochromic material. The viologen derivative includes a suitable regulator group capable of increasing ΔE that is a potential difference between E1 (potential at the first redox reaction) and E2 (potential at the second redox reaction). When ΔE increases, the mole fraction of viologen molecules present in the second reduction state decreases. Therefore, it is possible to lower the mole fraction of viologen molecules present in an irreversibly reduced state at an applied potential, thereby increasing the lifetime of an electrochromic material and an electrochromic device.

Owner:LG CHEM LTD

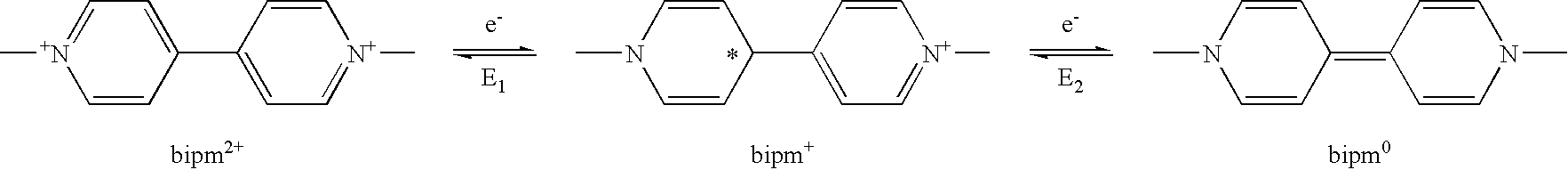

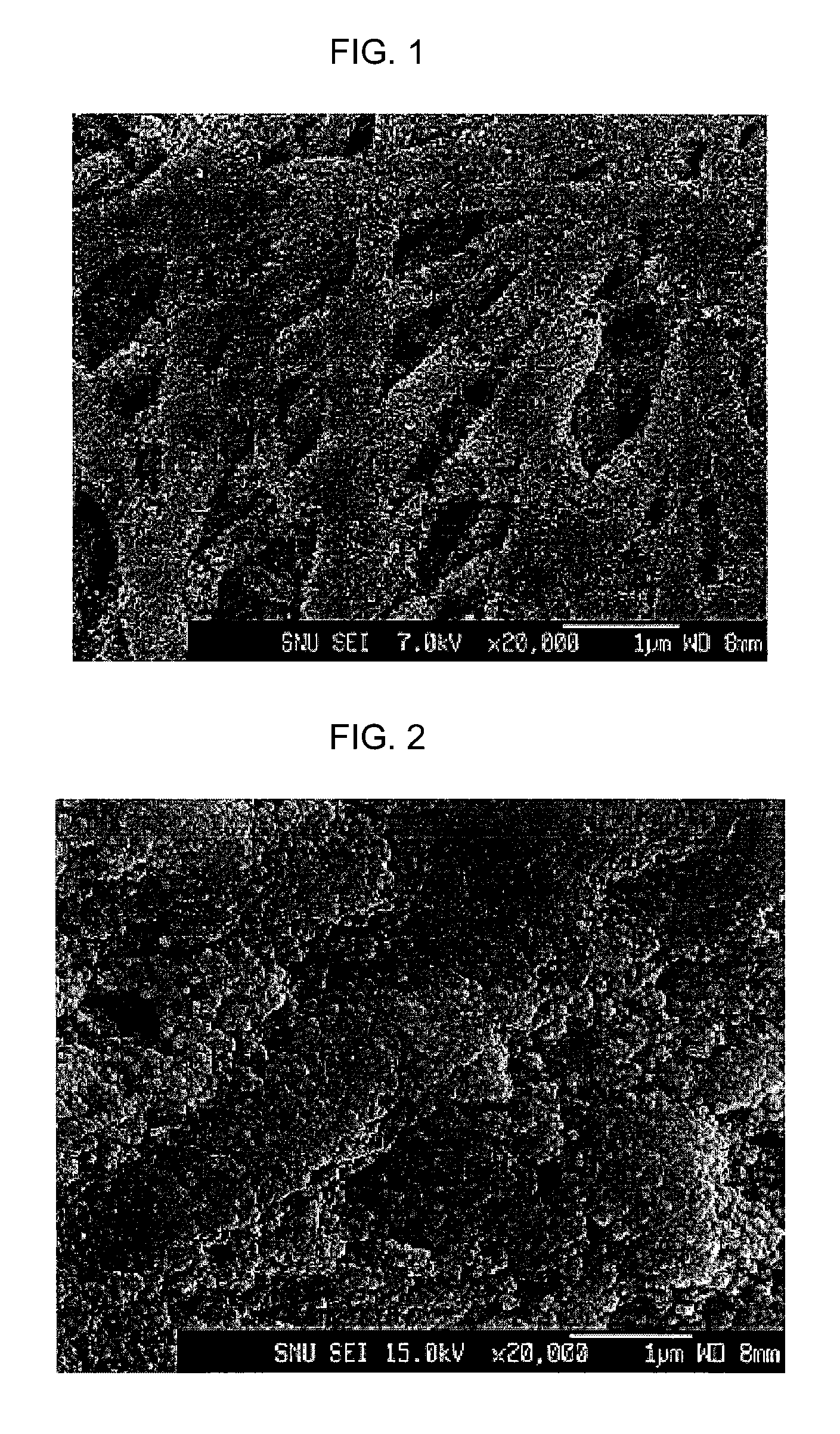

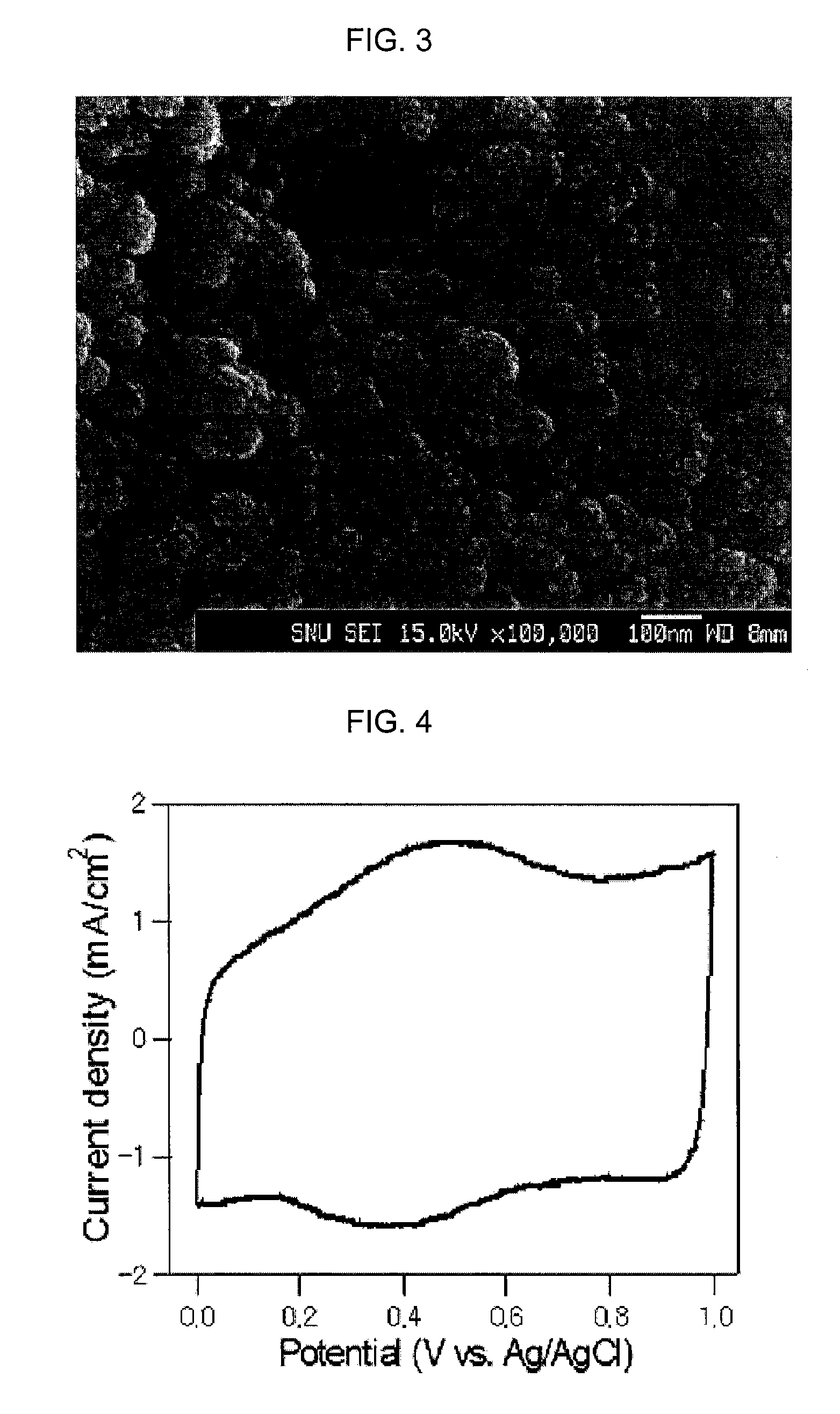

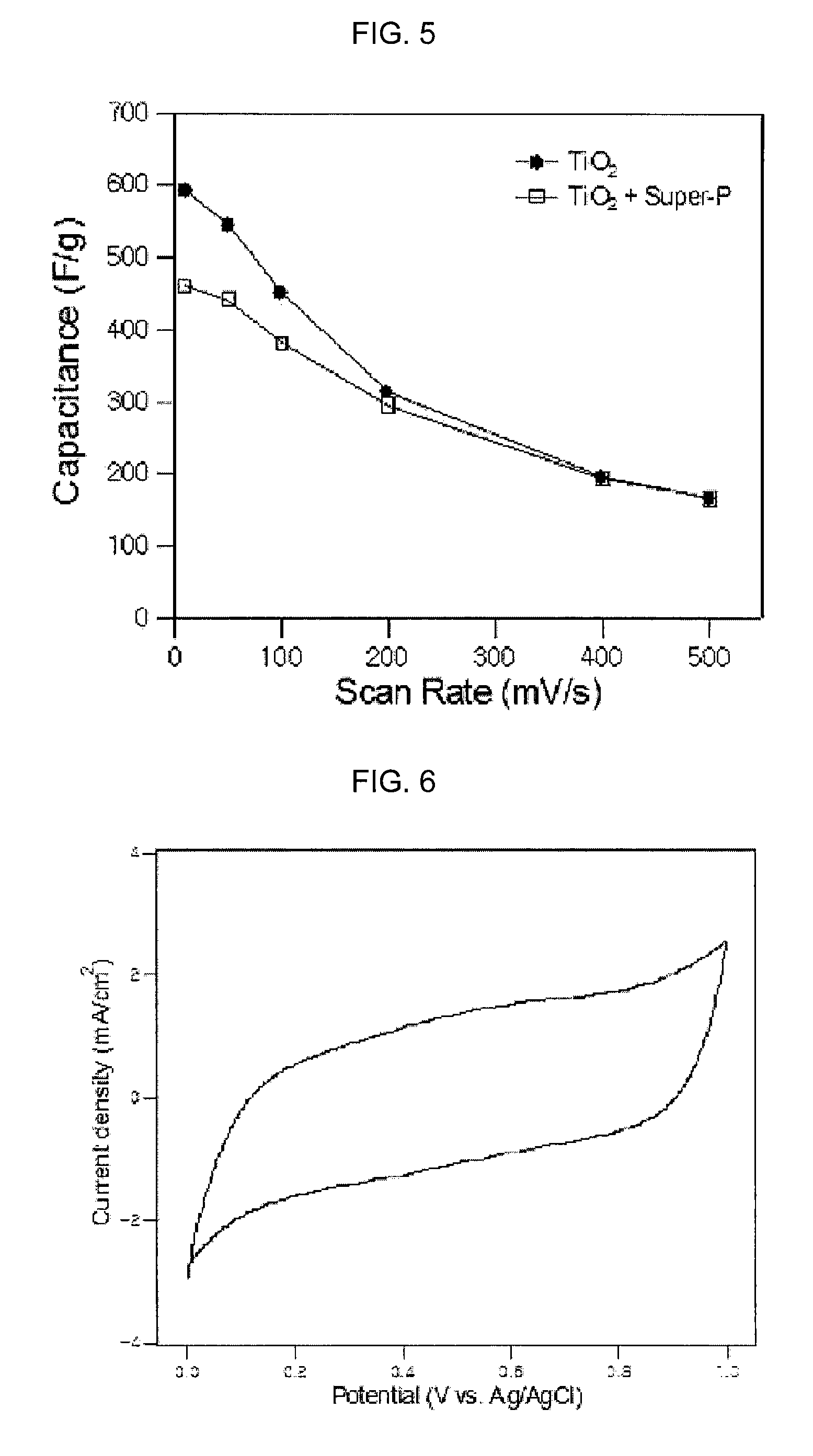

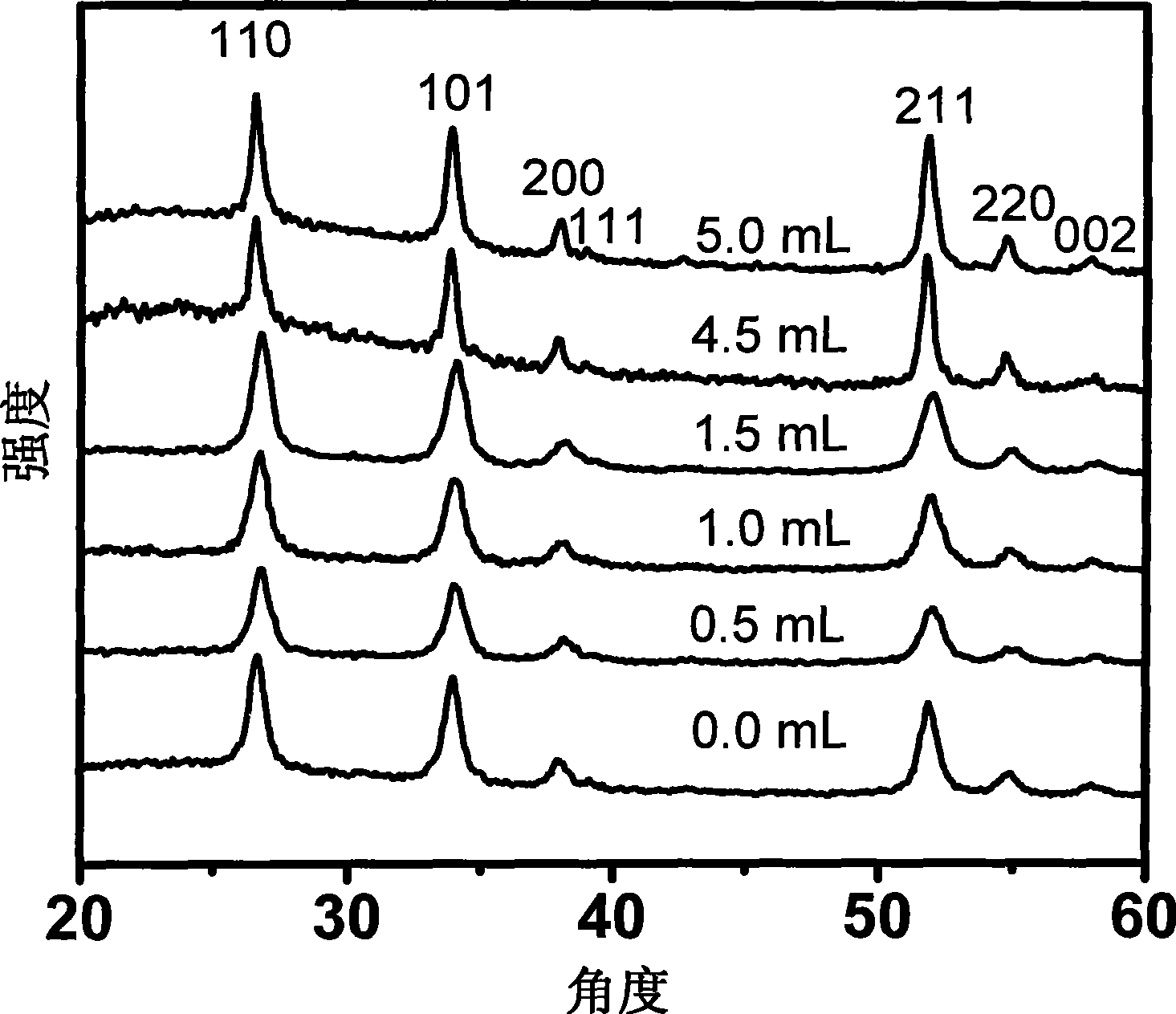

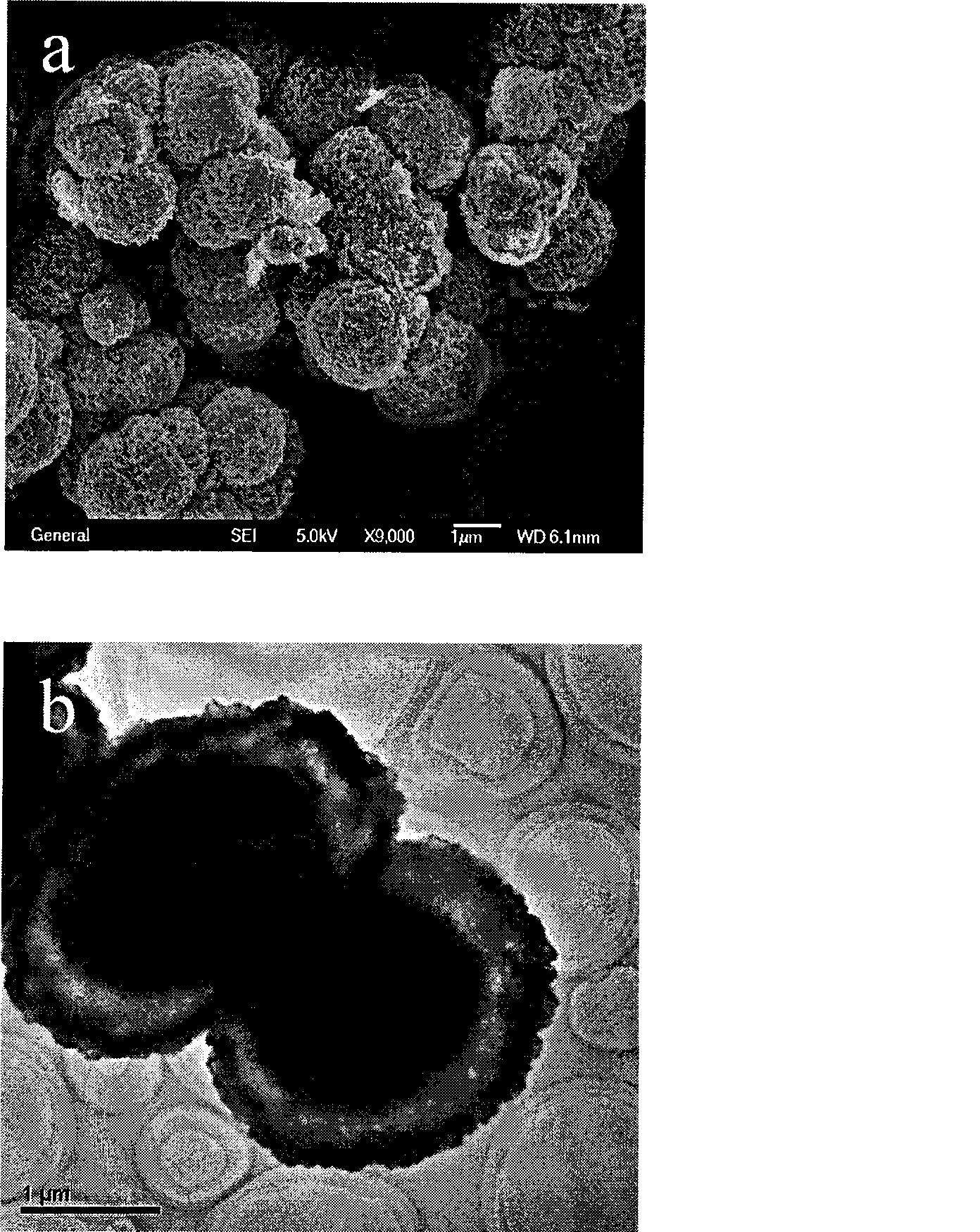

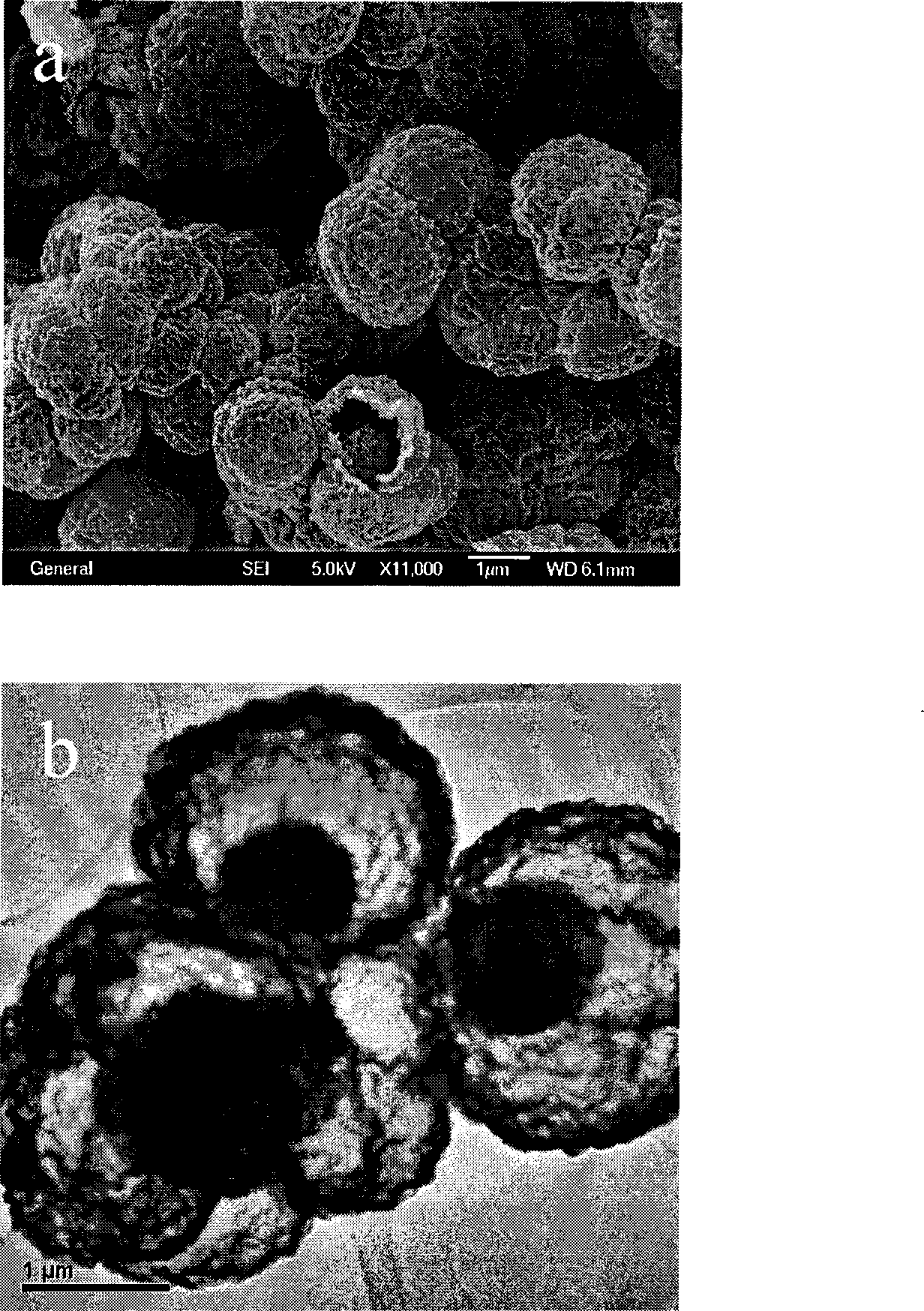

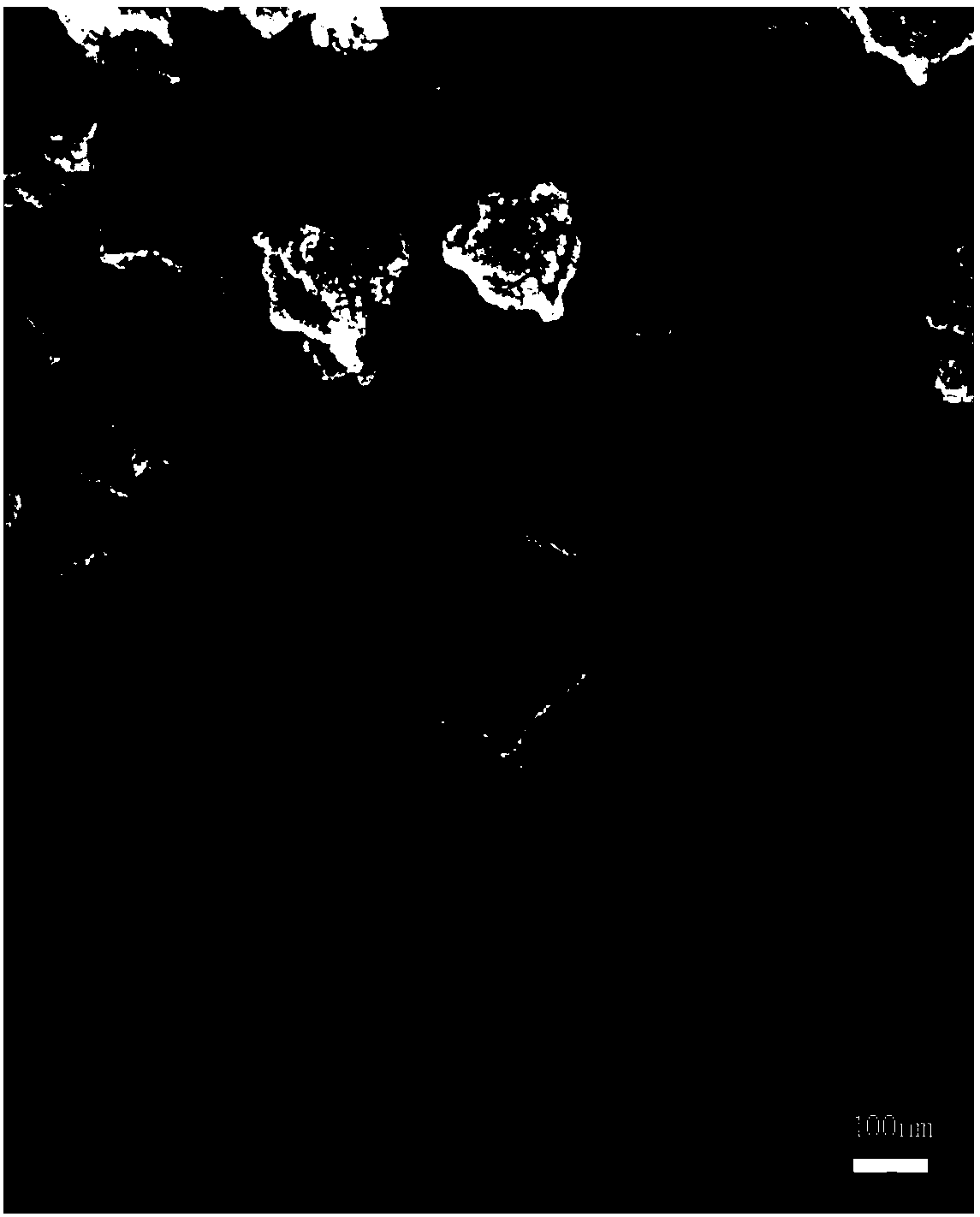

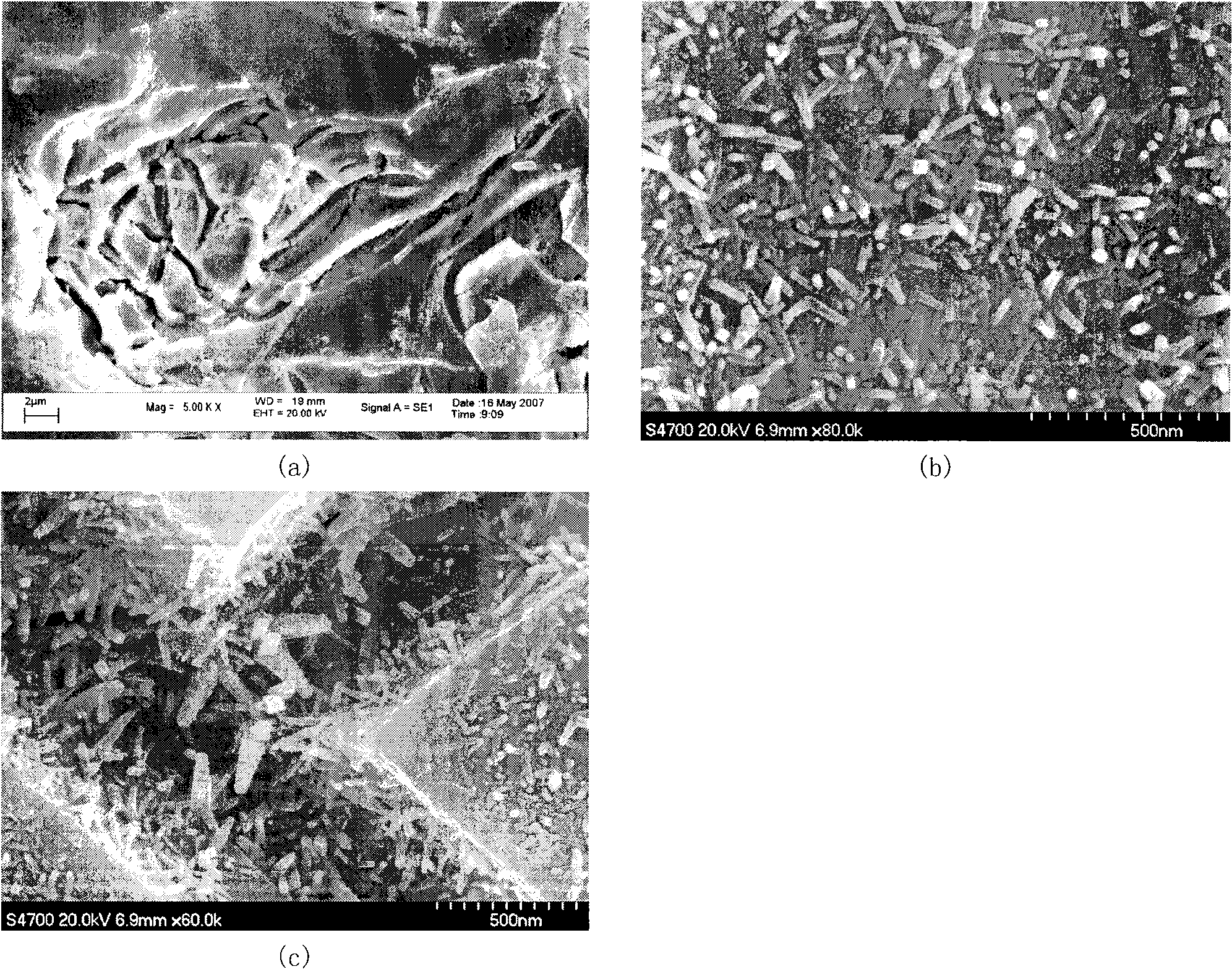

Metal oxide supercapacitor having metal oxide electrode coated onto titanium dioxide ultrafine fiber and method for preparing the same

InactiveUS20070095657A1Machining electrodesElectrolytic inorganic material coatingCapacitanceMaterials science

A supercapacitor having a metal oxide electrode and a method for preparing the same. The method comprises preparing a substrate composed of a current collector and a titanium dioxide ultrafine fiber matrix layer formed on the current collector, and electrochemically depositing a metal oxide thin film layer onto the substrate by a constant current potentiometry or a cyclic voltammetric method. Since the metal oxide is uniformly deposited on the substrate having a wide specific surface area with the titanium dioxide ultrafine fiber, a bonding material or a conductive particle need not to be added to the capacitor electrode. Therefore, a resistance of the capacitor electrode is prevented from being increased, and thus a capacitance of the capacitor electrode is prevented from being decreased.

Owner:KOREA INST OF SCI & TECH

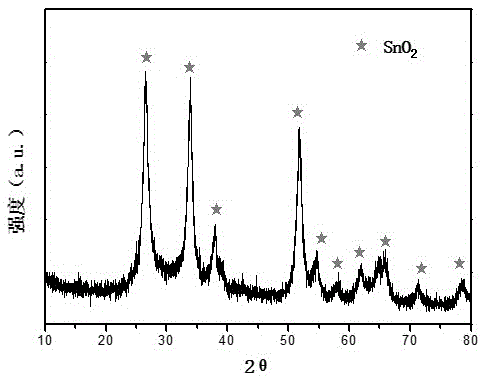

Process for producing nanostructured tin dioxide lithium ion battery negative pole material

InactiveCN101428847AControl structure sizeControl sizeCell electrodesTin oxidesTin dioxideSynthesis methods

The invention belongs to the preparation field of the anode material of a lithium ion battery, and in particular relates to a method for preparing metal oxide electrode material with a nanometer structure by utilizing the in-situ synthesis method. The internal structure and the dimension of a hollow micro-sphere obtained are controlled through adjusting the pH value of a system by utilizing hydrochloric acid. Raw materials in the invention are common and are easy to obtain; an organic solvent is not required during the preparation process; the preparation process is simple; the synthesis of template materials and the participation of a surface active agent are not required during the synthetic process; the requirements to the device are low, the time consumption is less and the preparation process is simple; and a main by-product during the preparation process is water and carbon dioxide and is environment-friendly. The raw materials used in the invention are common; and the preparation conditions are not restricted by areas. The hollow tin dioxide micro-spheres have higher application prospect in the filed of electrode material, catalyst carriers and the like. The method has the advantages of cheap and easily obtained raw materials, simple preparation process, and unrestricted preparation conditions by areas, and is suitable for massive industrial production.

Owner:JILIN UNIV

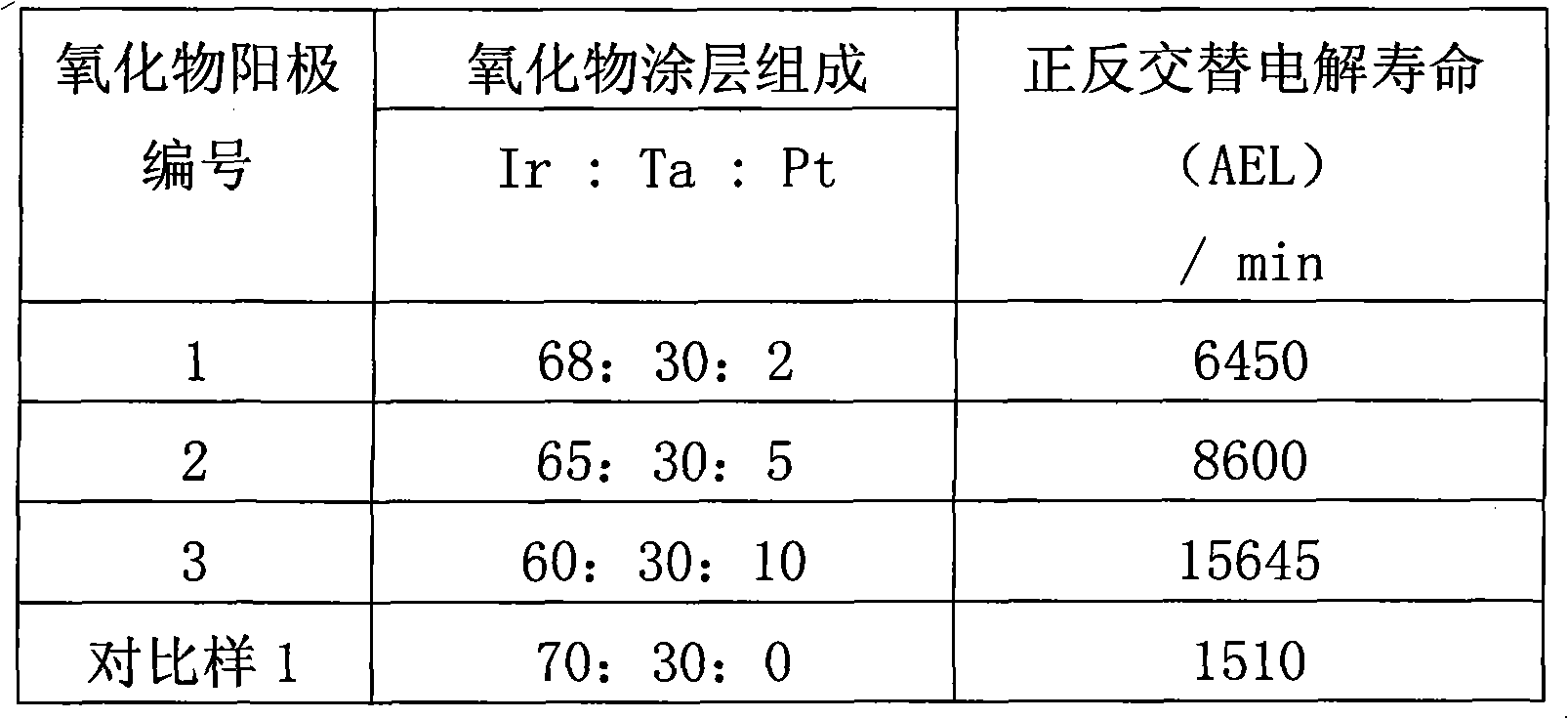

Positive and negative alternate electrolysis-resistance metal oxide electrode

ActiveCN101565833AExcellent resistance to positive and negative alternating electrolytic performanceImprove protectionWater/sewage treatment by electrochemical methodsLiquid/solution decomposition chemical coatingElectrolysisMechanical property

The invention relates to a positive and negative alternate electrolysis-resistance metal oxide electrode, which is suitable to be used in the field of electrochemical industry, such as high-speed steel plate plating, sea water electrolysis marine biofouling-resistance devices, sodium hypochlorite electrolysis production devices, sewage treatment, cathodic protection and other technical fields of electrochemistry. The positive and negative alternate electrolysis-resistance metal oxide electrode consists of a titanium substrate and a platinum-containing multielement mixed metal oxide coating formed on the titanium substrate by a pyrolytic process or a sol-gel method, wherein the mass percentage purity of the metal titanium substrate is over 99 percent; valve metal titanium has excellent mechanical property and machinability and is suitable for making electrode substrates, and the electrode titanium substrate is netty, platy, tubular or bar structural shapes; the platinum-containing multielement mixed metal oxide coating is IrO2-Ta2O5-PtOx, wherein the mole ratio of the Ir to Ta to Pt is (40-70):(20-40):(1-20); and the metal oxide electrode is obviously improved in positive and negative alternate electrolysis resistance and comprehensive performance, and is simple in structure and long in service life.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Thin-coat metal oxide electrode for an electrochemical capacitor

InactiveUS7167355B2High rateImprove bindingFixed capacitor electrodesHybrid capacitor electrodesThin metalMetal foil

An electrode for a capacitor is provided and includes a conductive metal foil layer and an electronically conductive intermediate layer disposed on the metal foil layer. A thin metal oxide ink coating is operatively printed on the intermediate layer and in one form includes a mixture of a carbon containing powder, a metal oxide powder, a conductive binder, a polar solvent and a dispersing agent.

Owner:T B KIM TECH INT

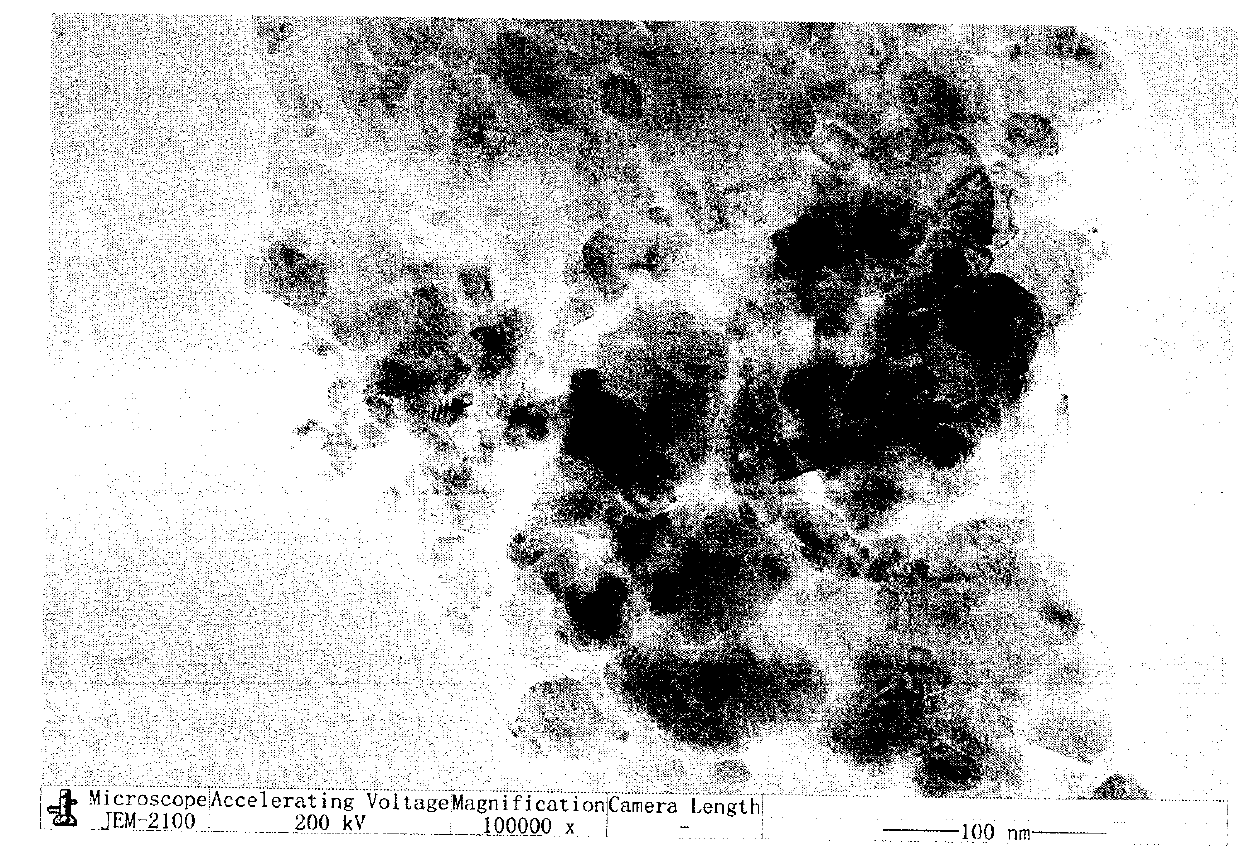

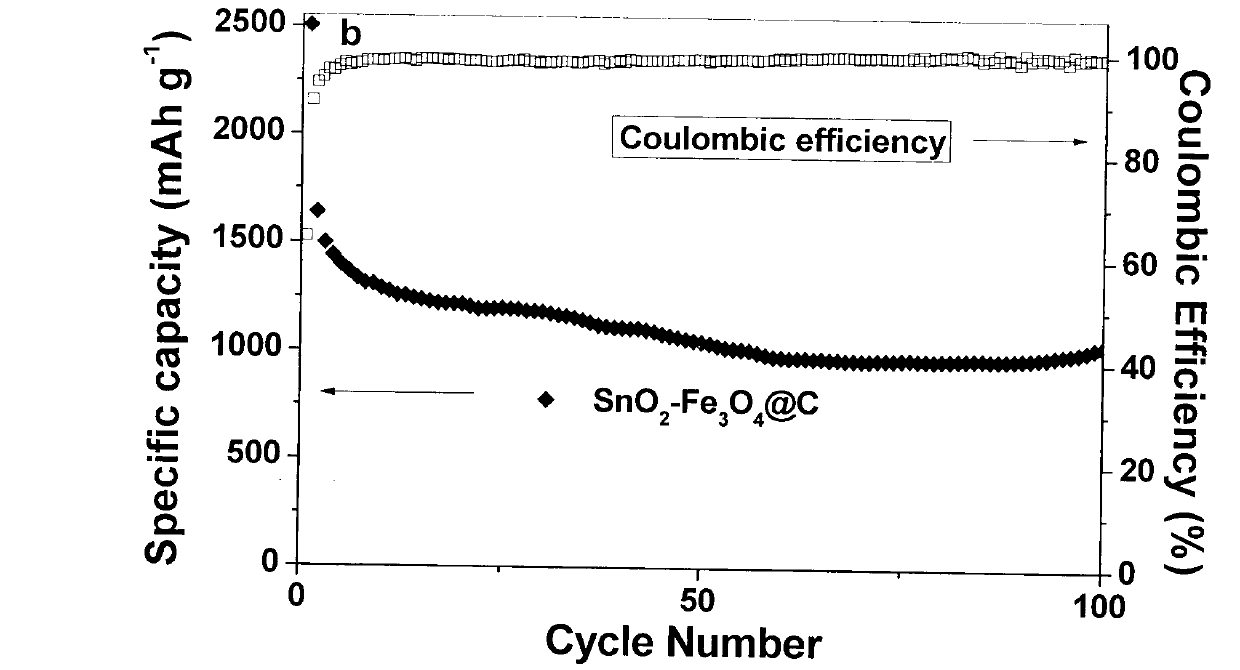

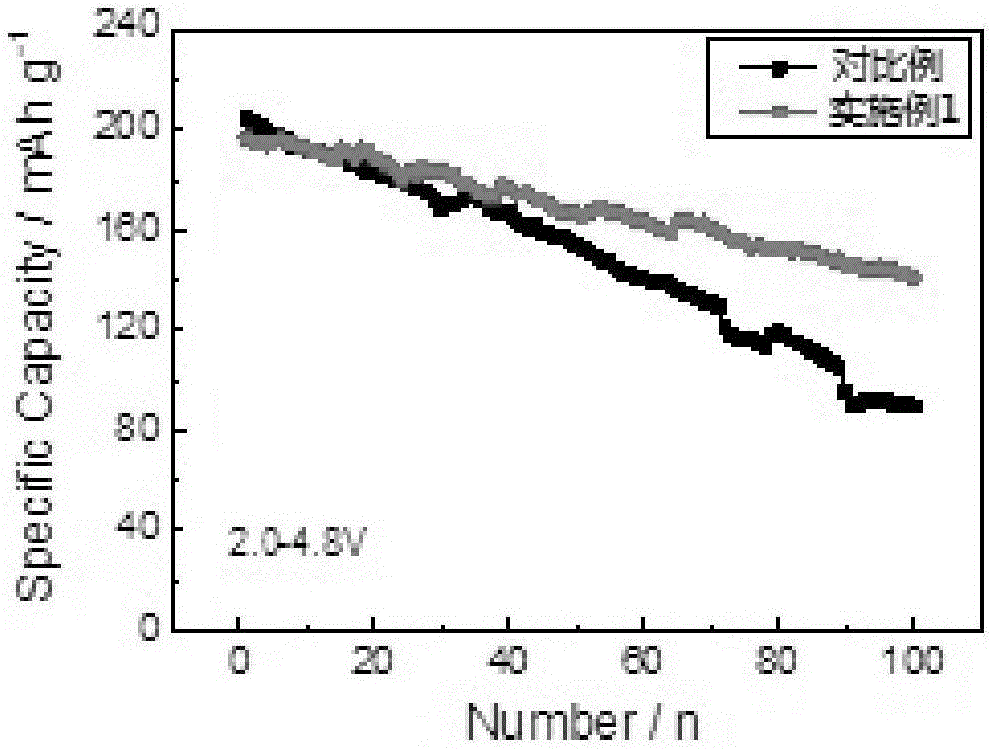

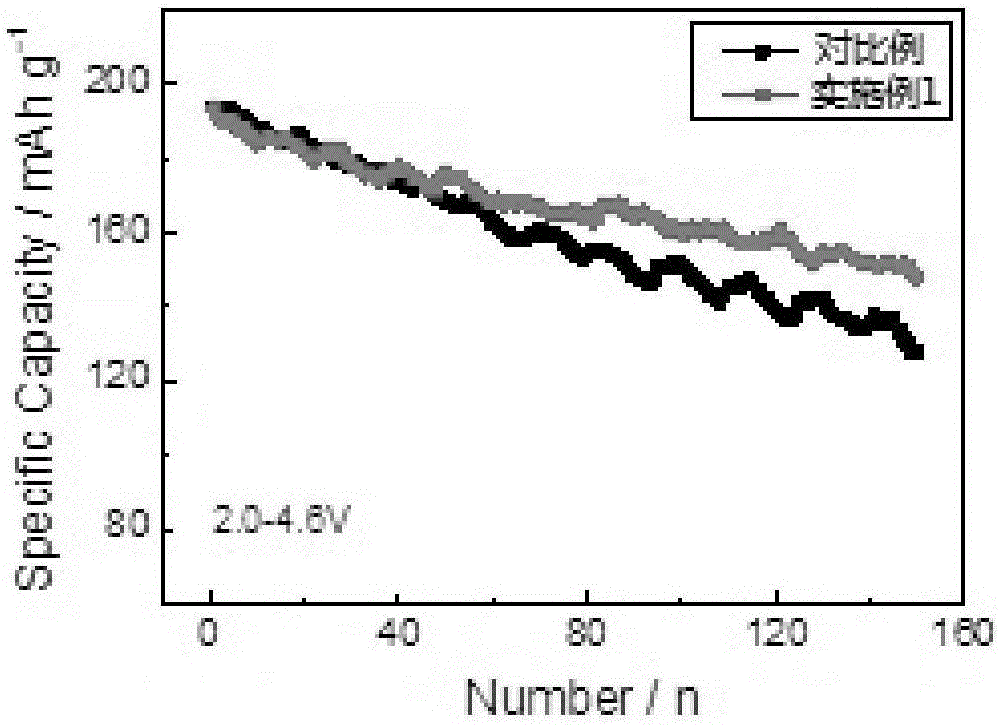

Preparation method for carbon coated composite metal oxide electrode material

The invention discloses a preparation method of a carbon coated stannic oxide (SnO2)-iron trioxide (Fe2O3) composite oxide material. During the preparation of the material, a polyaniline layer is introduced on the surface of a composite oxide by in-situ polymerization, and the carbon coated SnO2-Fe2O3 composite oxide material is obtained by a calcination method. The composite oxide material prepared by the method has the advantages of controllable particles, uniform thickness of a carbon layer; and the composite oxide material as a negative electrode material for a lithium ion battery has the characteristics of high lithium storage capacity and excellent cycling performance.

Owner:QINGDAO UNIV OF SCI & TECH

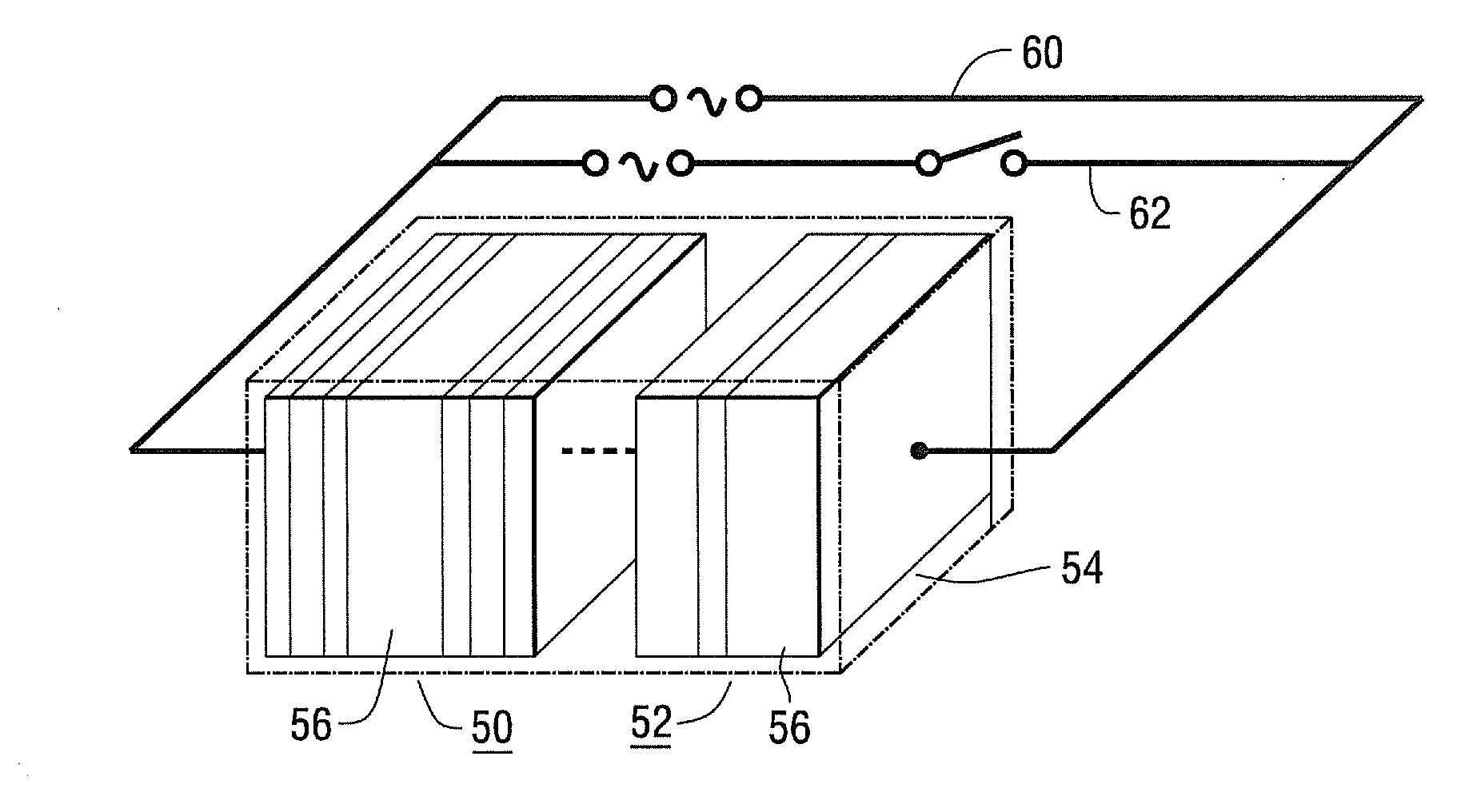

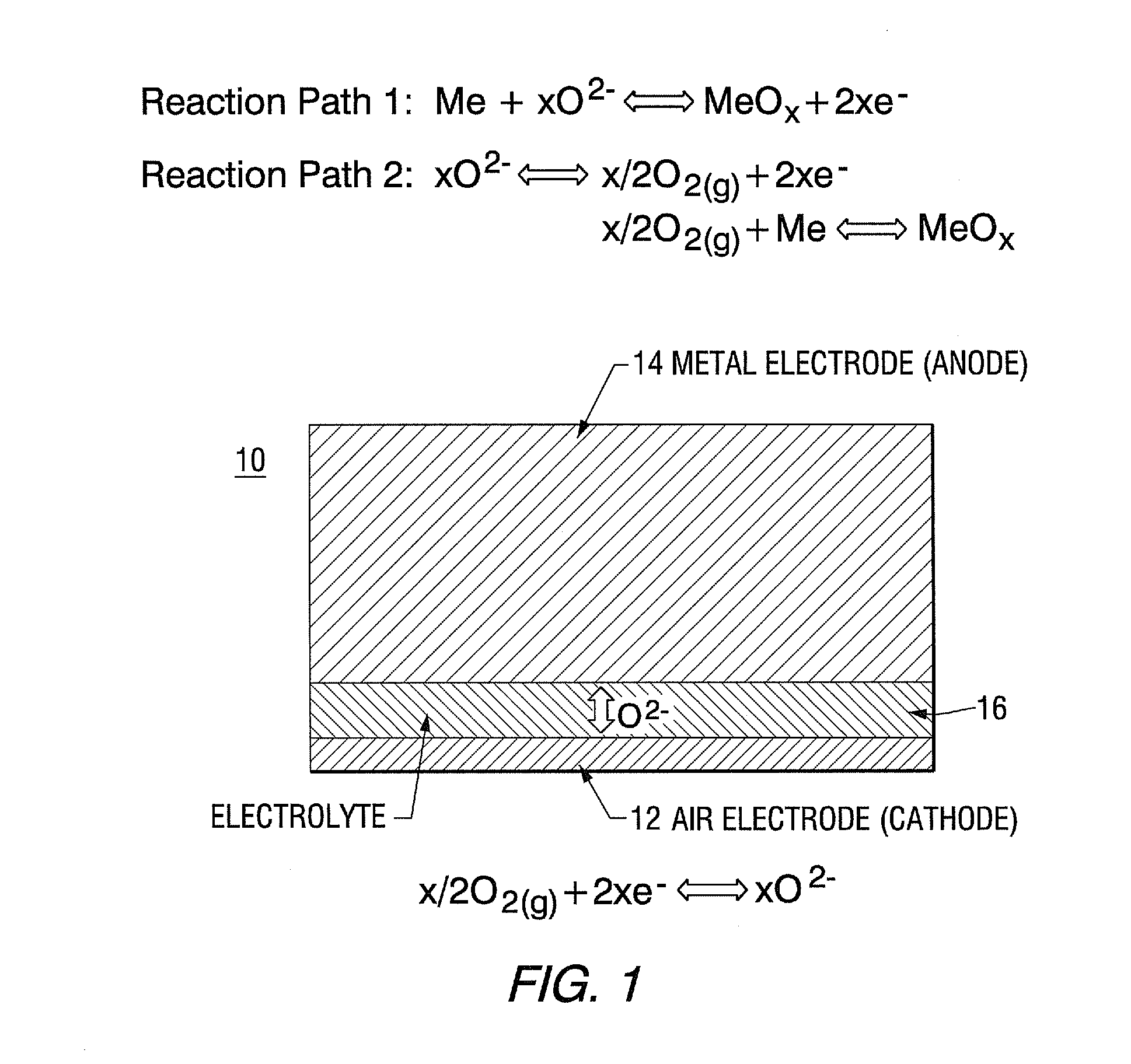

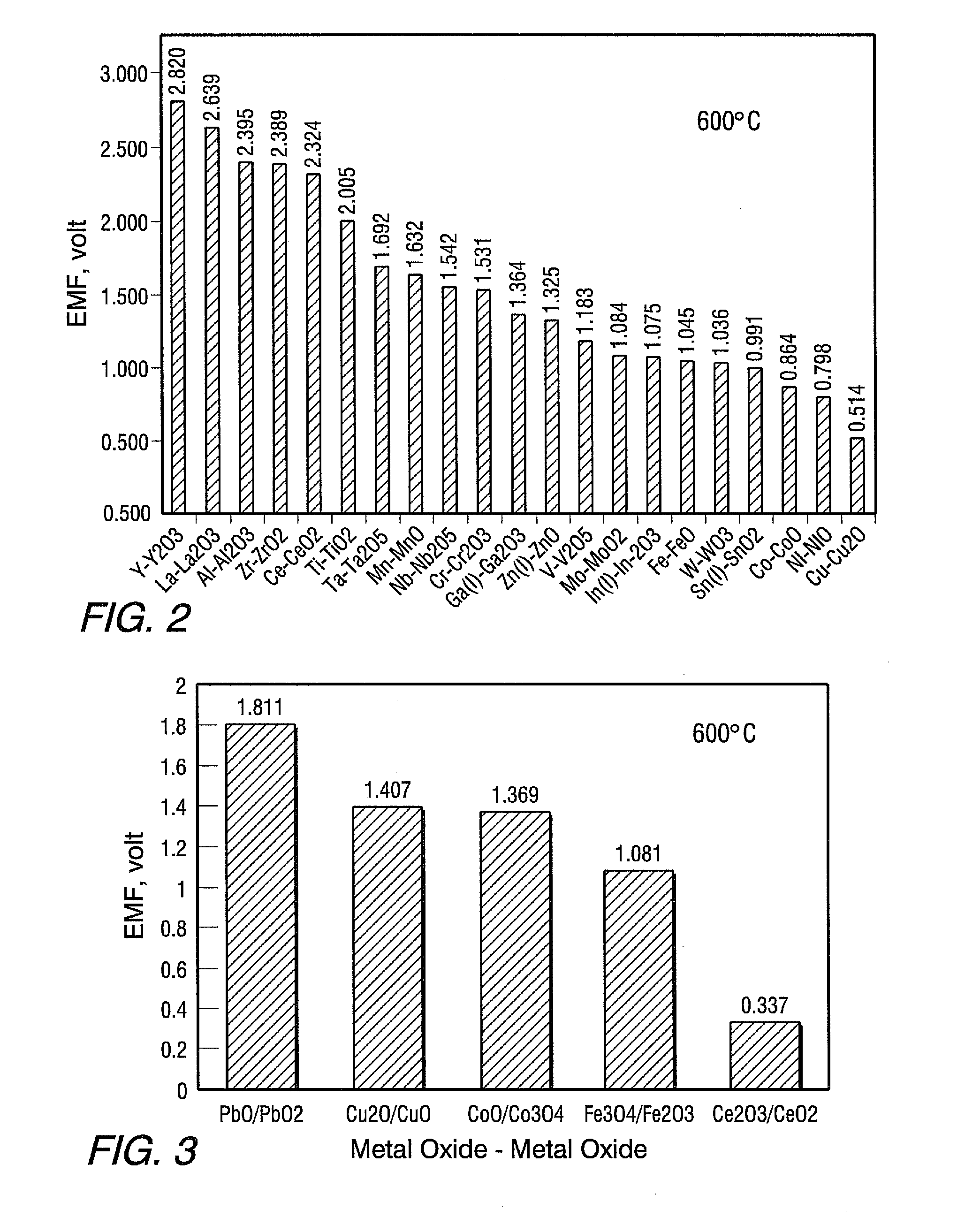

All solid state rechargeable oxide-ion battery (ROB) system

ActiveUS20120270088A1Energy efficiencyCost effectiveFuel and secondary cellsFinal product manufactureThermal energyAll solid state

An all solid state rechargeable oxide-ion (ROB) battery (30) has a thermal energy storage (TES) unit (20) between two oxide-ion cells (22, 24) with metal-metal oxide electrodes (34, 36, 40, 42) on opposite sides of an anion conducting solid electrolyte (32,38) where none of the electrodes is contact with air.

Owner:SIEMENS AG

Metal oxide dispersion, metal oxide electrode film, and dye sensitized solar cell

A metal oxide dispersion comprising metal oxide particles with a necking structure, and a solvent, wherein the liquid droplet contact angle of the metal oxide dispersion to an ITO film (Indium-Tin Oxide type film) formed is from 0 to 60 DEG . A metal oxide dispersion for the production of a dye-sensitized solar cell electrode, comprising Metal Oxide Particle Group F having a necking structure formed by m connected particles, Metal Oxide Particle Group G having only 0.2m or less connected particles, and a solvent, and being formable into a film at 200 DEG C or less. A metal oxide electrode comprising an electrically conducting substrate having thereon a metal oxide layer comprising metal oxide particles bound by a binder, wherein the binder content is from 0.005 to 5 mass% based on the metal oxide film and the metal oxide layer has a pencil scratch strength of H or more according to JIS5600.

Owner:SHOWA DENKO KK

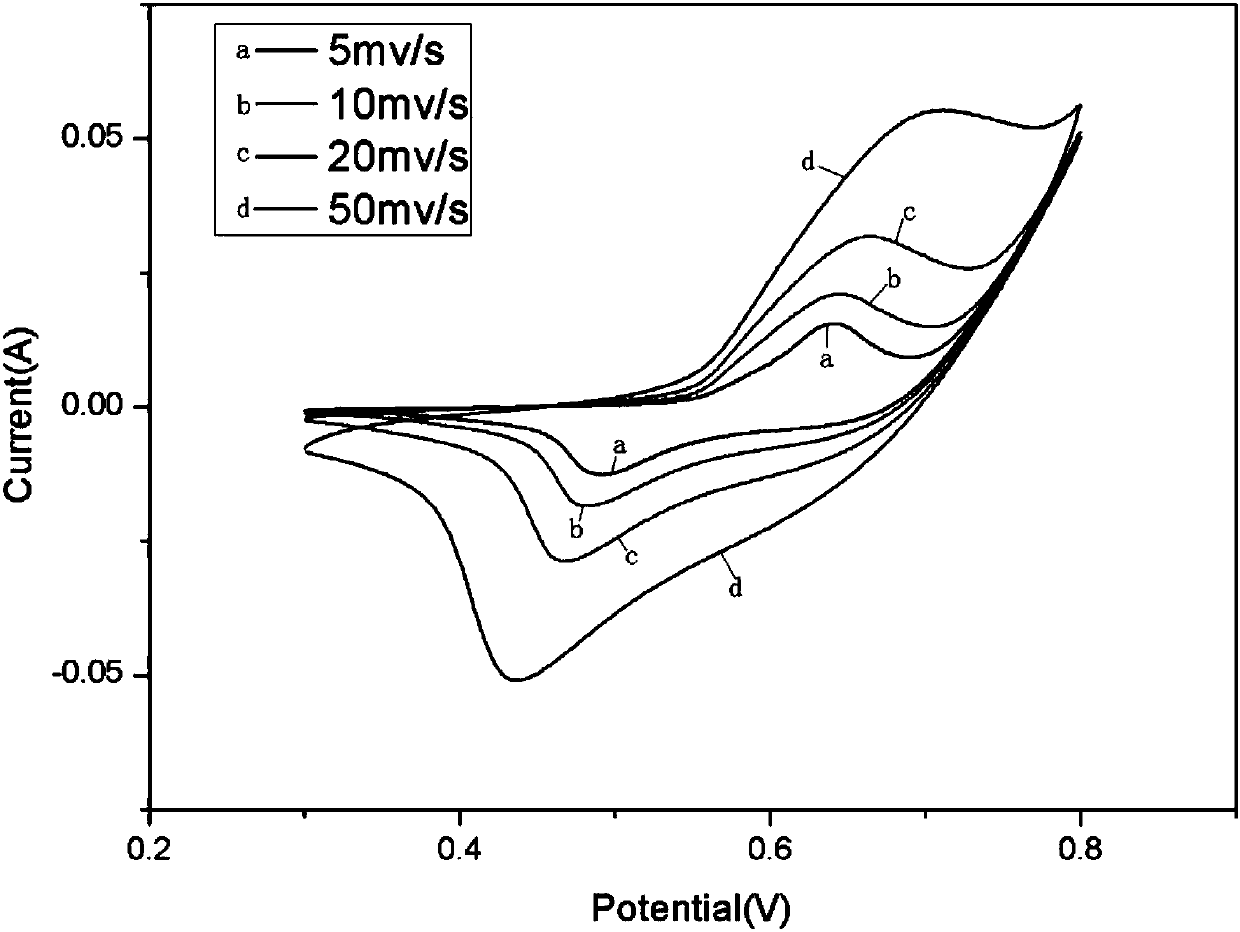

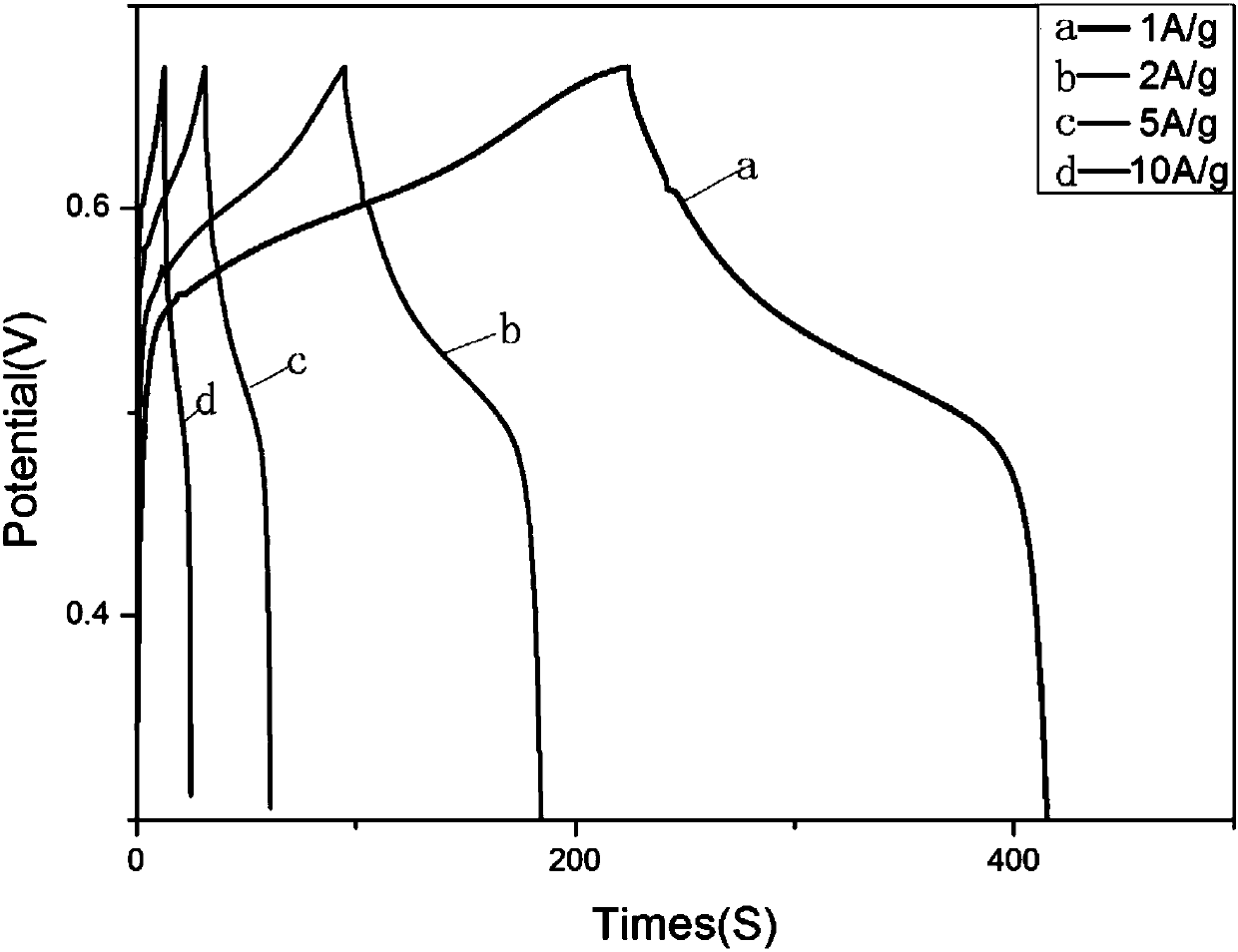

Polyhedron bimetallic oxide as well as preparation method and application thereof

InactiveCN107739023ASimple processMild conditionsOxygen/ozone/oxide/hydroxideIron oxides/hydroxidesCapacitanceAdhesive

The invention discloses a polyhedron bimetallic oxide as well as a preparation method and application thereof. The polyhedron bimetallic oxide is prepared by the following steps: with a zeolite imidazate skeleton structure material serving as a raw material, partially replacing metals in the zeolite imidazate skeleton structure material with a metal; heating for oxidation to obtain the polyhedronbimetallic oxide. Finally, mixed liquid is prepared by adopting the polyhedron bimetallic oxide as an active substance, carbon black as a conductive agent and polytetrafluoroethylene as an adhesive and adding a solvent N,N-dimethylpyrrolidone; the obtained mixed liquid is dropwise added to a nickel piece which is then dried to obtain a polyhedron bimetallic oxide electrode. The preparation methoddisclosed by the invention has the advantages of mild conditions, simple technology and controllable operation; when densities of the charge current and discharge current of the prepared polyhedron bimetallic oxide electrode are 1A / g in 1mol / L NaOH electrolyte respectively, the specific capacitance reaches 510F / g respectively; after 3,000 times of charging and discharging, the specific capacitanceis attenuated by 25%.

Owner:CHINA UNIV OF MINING & TECH

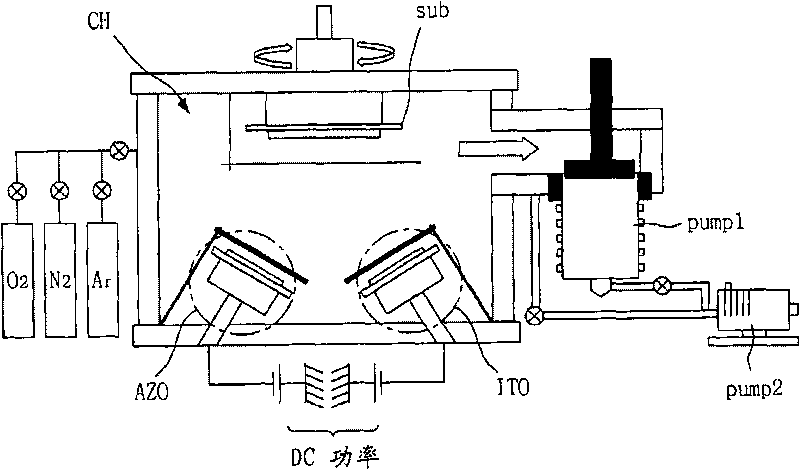

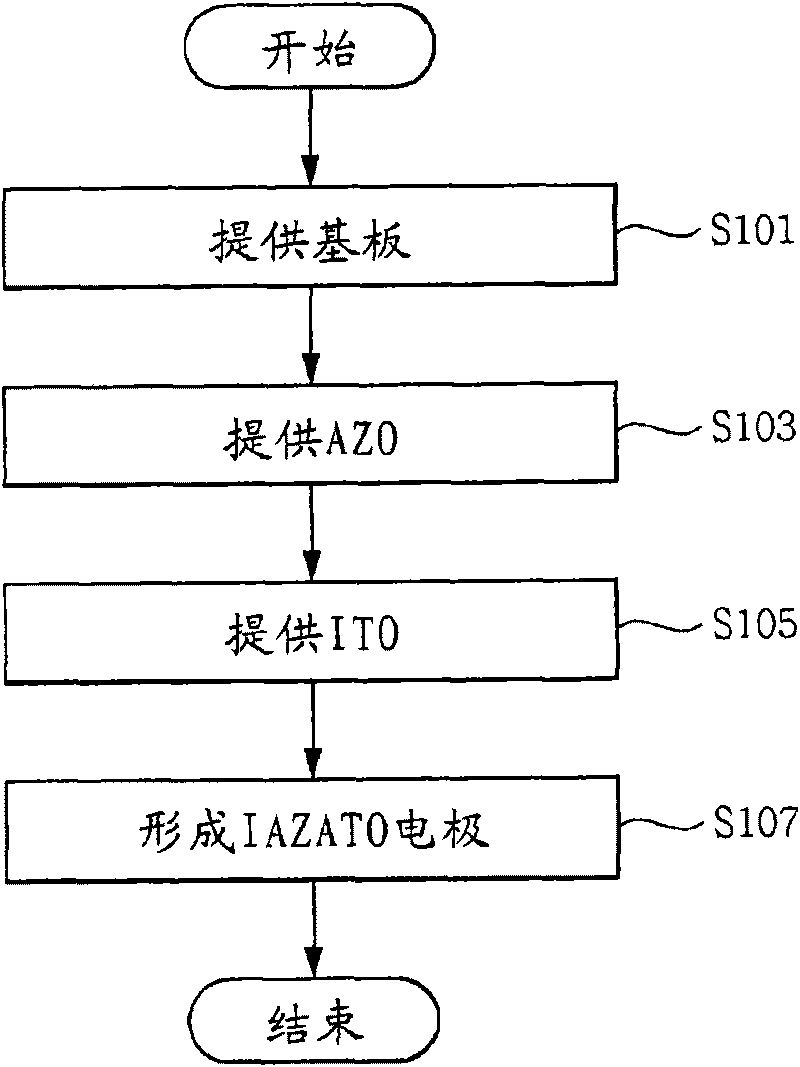

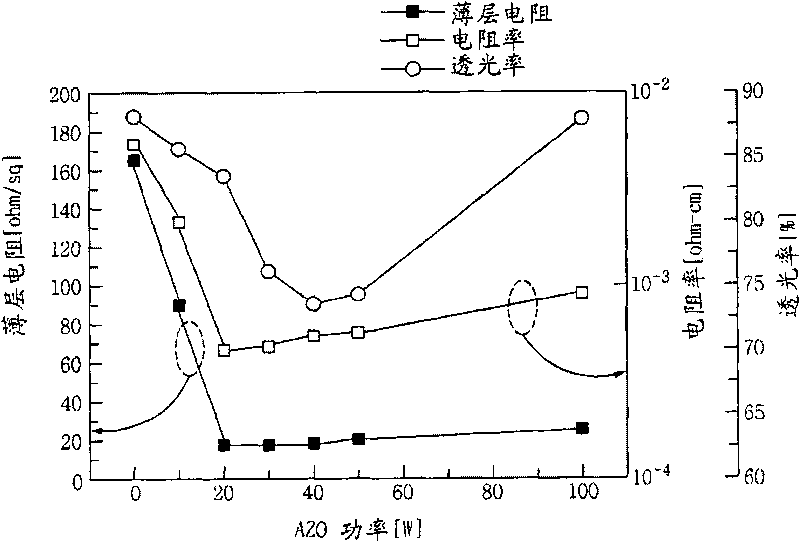

Method for manufacturing metal oxide electrode and organci light emitting display using the same

A method of manufacturing a metal oxide electrode and an organic light emitting diode (OLED) display using the same are provided. The method includes providing a substrate inside a chamber, providing Al2O3 doped ZnO (AZO) including zinc oxide (ZnO) and aluminum oxide (Al2O3) inside the chamber, providing indium tin oxide (ITO) including indium oxide (In2O3) and tin oxide (SnO2) inside the chamber, and applying a direct current (DC) power to a material including AZO and ITO to form an IAZTO electrode on the substrate.

Owner:LG DISPLAY CO LTD

Carbon nano-tube enhanced composite type metallic oxide electrode material and preparation thereof

The invention relates to a novel composite electrode material and a preparation method thereof, pertaining to the technical field of electrochemical electrode materials. Aiming at the problems of poor compactness of coating, low generating capacity and complex technology of the existing mixed metal oxides, the invention utilizes the high strength, good conductibitily, and the regulating effect to the traditional mixed metal oxide coating solution viscosity and leveling property of a carbon nano tube to prepare a composite mixed metal oxide electrode material with even and smooth appearance, compact microstructure, good mechanical property, good inoxidability, high generating capacity and reinforced carbon nano tube. The preparation process comprises the following steps: a mixed metal oxide precursor solution containing 0.1g / L to 5g / L of single-walled or multi-walled carbon nano tube that is processed with purification, short cutting and dispersion is coated on a conductive substrate surface which is roughened; the substrate is dried after being roasted at the temperature of 100 to 200 DEG C for 5 to 15min, sintered for 5 to 10min at the temperature of 400 to 600 DEG C; the coating and sintering steps are repeated till the required electrode coating thickness is reached; and finally the substrate is sintered for 50 to 150min at the temperature of 400 to 600 DEG C. As the coating solution velocity of the carbon nano tube is increased, the smoothness of the solution is improved, and the thickness and leveling property of the single-walled electrode coating are improved, the invention shortens the preparation time of electrode coatings with the same thickness, and leads the yield and production stability to be improved.

Owner:郭超

Preparation method of Ti-based nano-CeO2/PbO2 modified electrode

The invention relates to a preparation method of a rare earth oxide cerium oxide (Ce2O3) modified high catalytic activity Ti-based nano-PbO2 modified electrode material. One of the key issues involved is preparation of a rare earth cerium oxide (Ce2O3) modified lead electrode material. The invention employs an electrodeposition process and selects a rare earth oxide cerium oxide to modify a Ti / PbO2 metal oxide electrode. The method provided in the invention comprises: first, during preparation of a titanium-based PbO2 electrode, in an alkaline electroplating solution, conducting electroplating firstly at a high current density and then at a small current density to get a transition layer, i.e. an alpha-PbO2 layer, next, in an acidic electroplating solution, electroplating beta 3-PbO2 having catalytic activity on the well electroplated alpha-PbO2 layer, and finally in a dilute nitric acid solution containing rare earth cerium nitrate, employing a cyclic voltammetric electroplating process to modify a Ti / PbO2 electrode, thus obtaining the cerium oxide (Ce2O3)-doped and modified high catalytic activity Ti / PbO2-Ce2O3 modified electrode material.

Owner:HUAINAN NORMAL UNIV

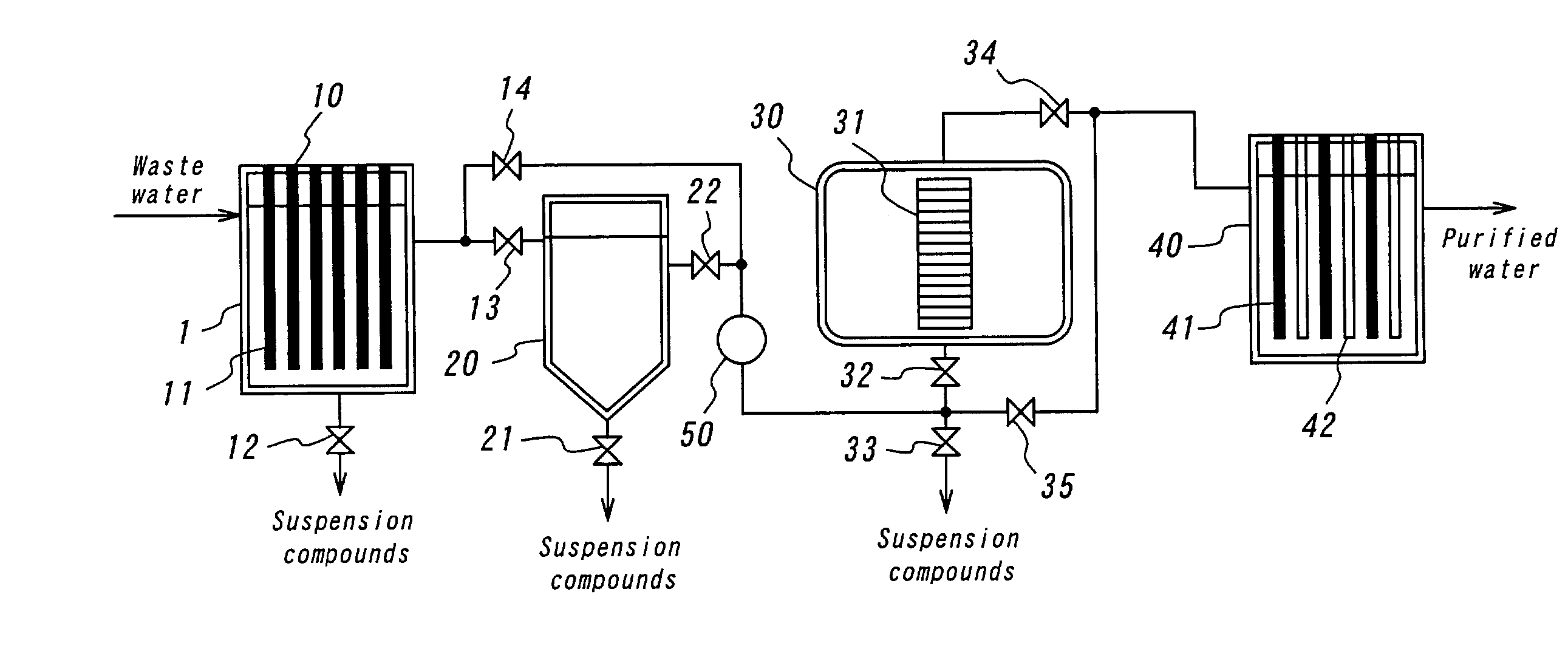

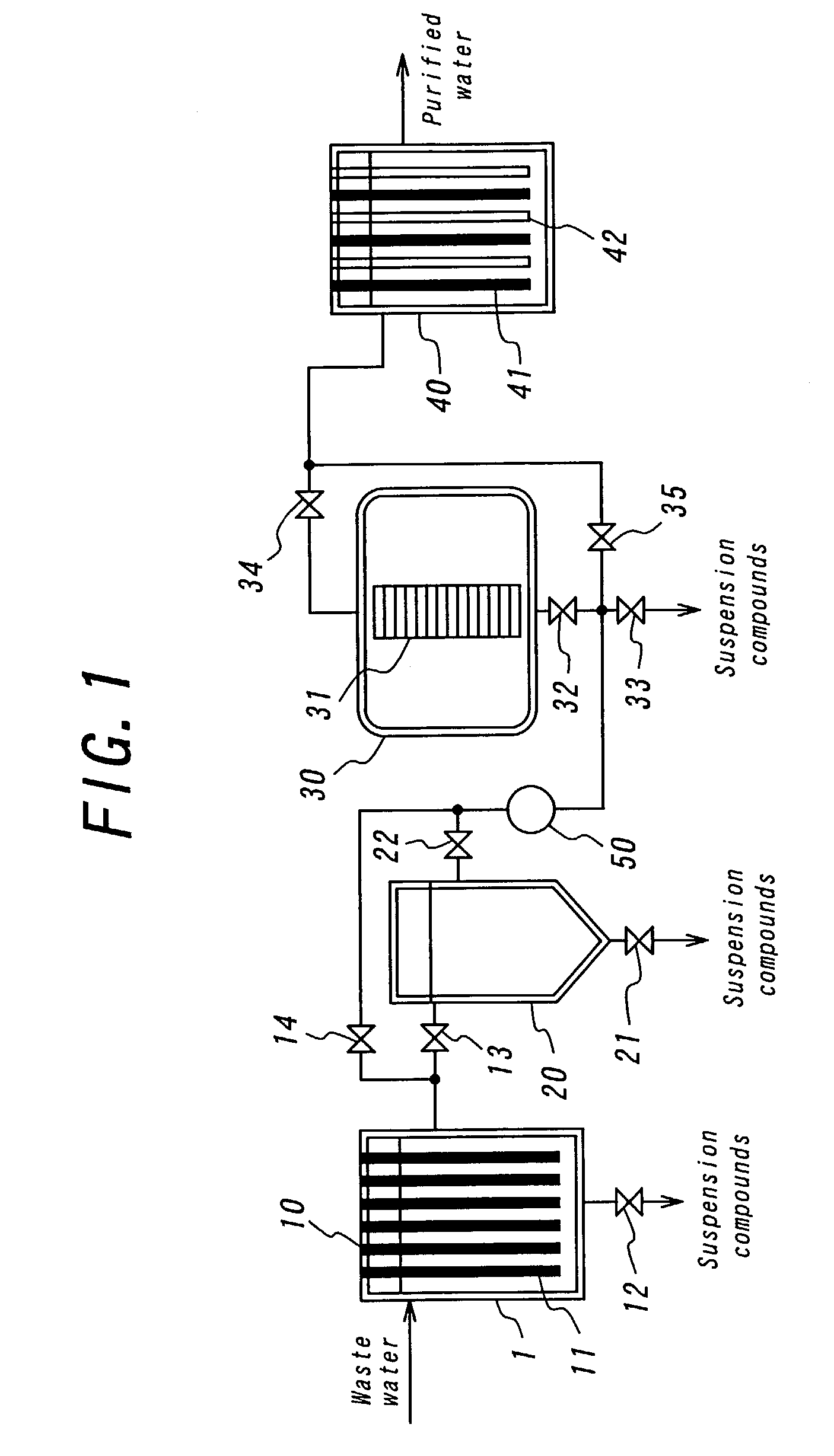

Apparatus for treating waste water and method for treating waste water

Waste water to be treated is introduced into a first electrolytic bath, and then, hydroxide iron particles are supplied into the waste water through the electrolysis reaction at iron electrodes. Impurities such as organic compounds, phosphoric compounds, persistent compounds and the like are physically absorbed onto the hydroxide iron particles. Then, the hydroxide iron particles (flocks) with absorbed impurities are discharged via a drain valve, to purify the waste water to some degree. The waste water is introduced into a second electrolytic bath with a water pump. In the second electrolytic bath, the remnant impurities in the waste water are chemically dissolved and removed through the oxidation reduction reaction between the surfaces of metallic oxide electrodes and the waste water.

Owner:JAPAN SOC FOR THE PROMOTION OF SCI

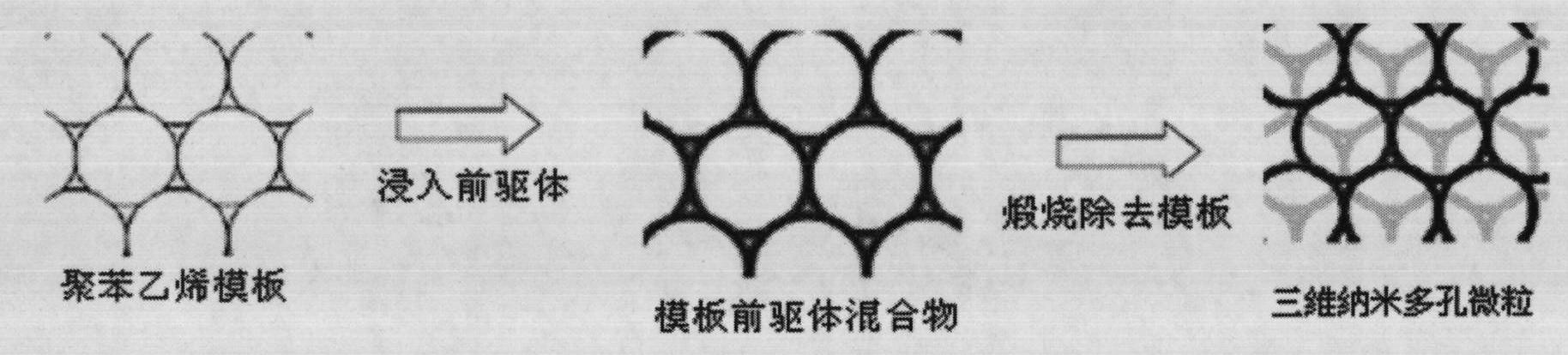

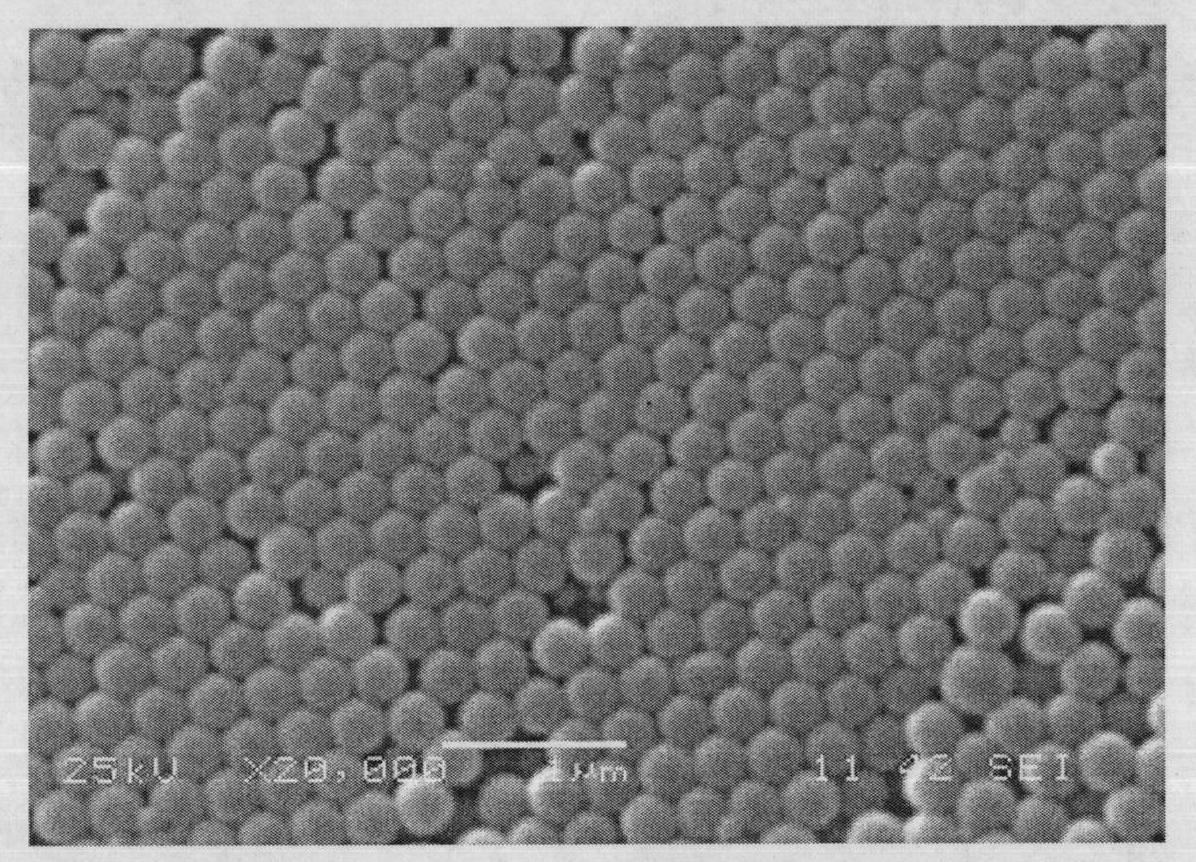

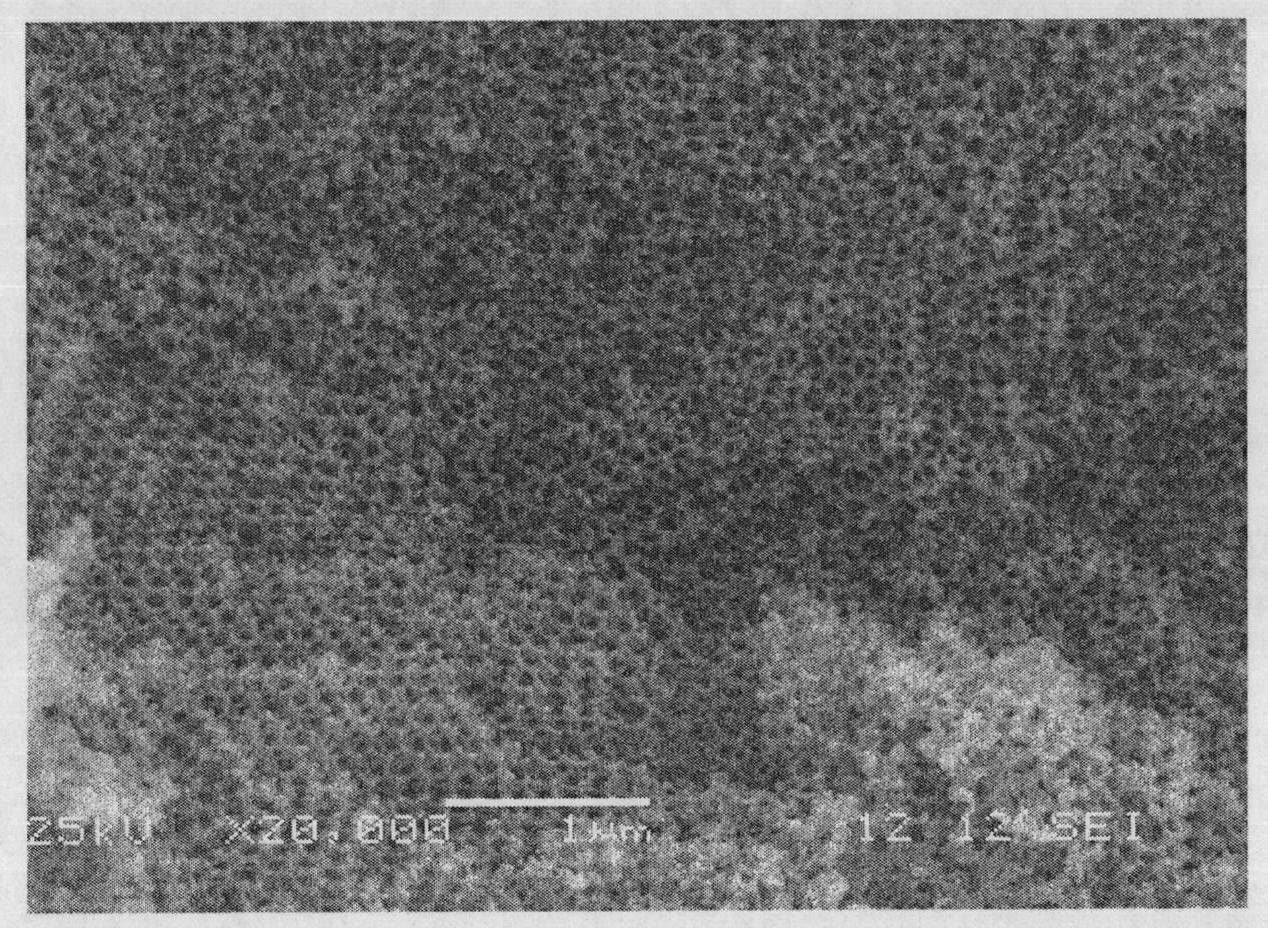

Three-dimensional nanoporous metal-oxide electrode material of lithium ion battery and preparation method thereof

InactiveCN101937989AShorten the diffusion pathIncrease the areaElectrode thermal treatmentNon-aqueous electrolyte accumulator electrodesElectrochemical responseMicrosphere

The invention relates to a preparation method of a three-dimensional nanoporous metal-oxide electrode material of a lithium ion battery, which comprises the following steps of: soaking a dried higher-molecular colloid crystal microsphere template for a period of time by using a metal salt solution as a precursor solution, filtering and drying to obtain a precursor-template compound; and preserving heat after heating the precursor-template compound to certain temperature at a low temperature-rise rate, and then cooling to room temperature. Preferably, the higher-molecular colloid crystal microsphere template is prepared by the following method comprising the following steps of: preparing a higher-molecular microsphere emulsion by a higher-molecular emulsion polymerization method, and then obtaining the higher-molecular colloid crystal microsphere template through coprecipitation or centrifugation. The invention also relates to the prepared metal-oxide electrode material. The three-dimensional nanoporous metal-oxide electrode material of the lithium ion battery improves the ionic electric conductivity of the cathode material of the lithium ion battery, shortens the diffusion path of lithium ions in the process of electrochemical reaction and greatly improves the rate discharge performance of the lithium ion battery, and the preparation method has unique design and simple and convenient operation and is suitable for large-scale popularization and application.

Owner:SHANGHAI ZHONGKE SHENJIANG ELECTRIC VEHICLE

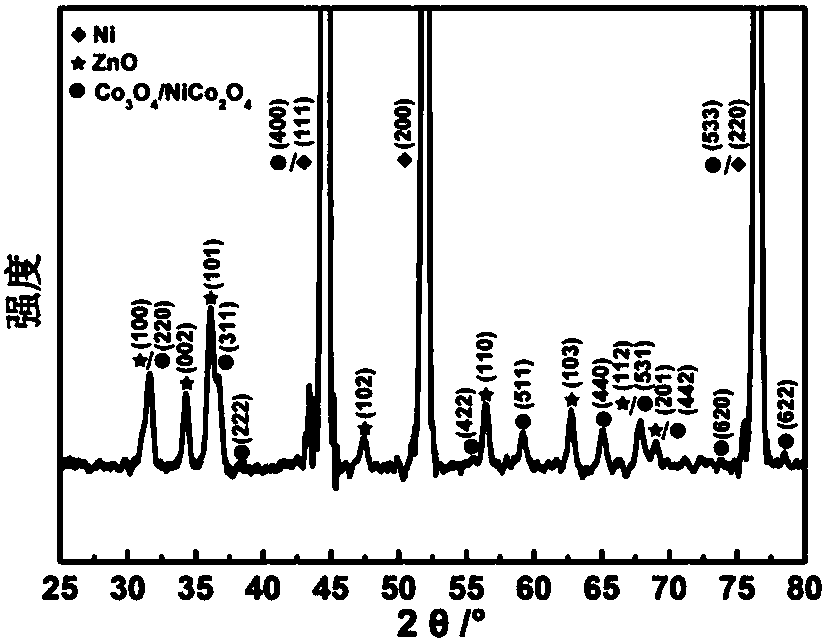

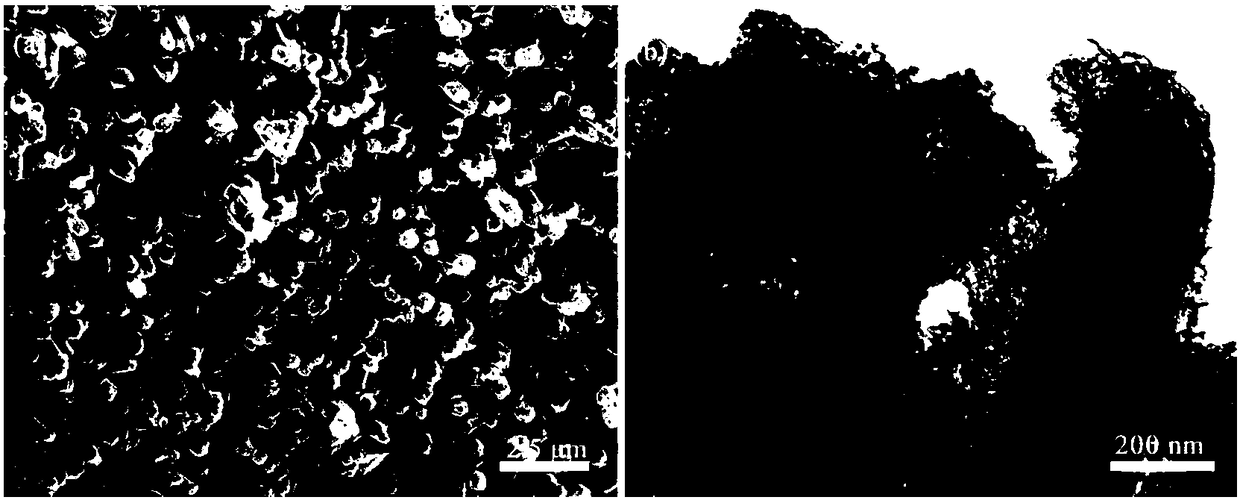

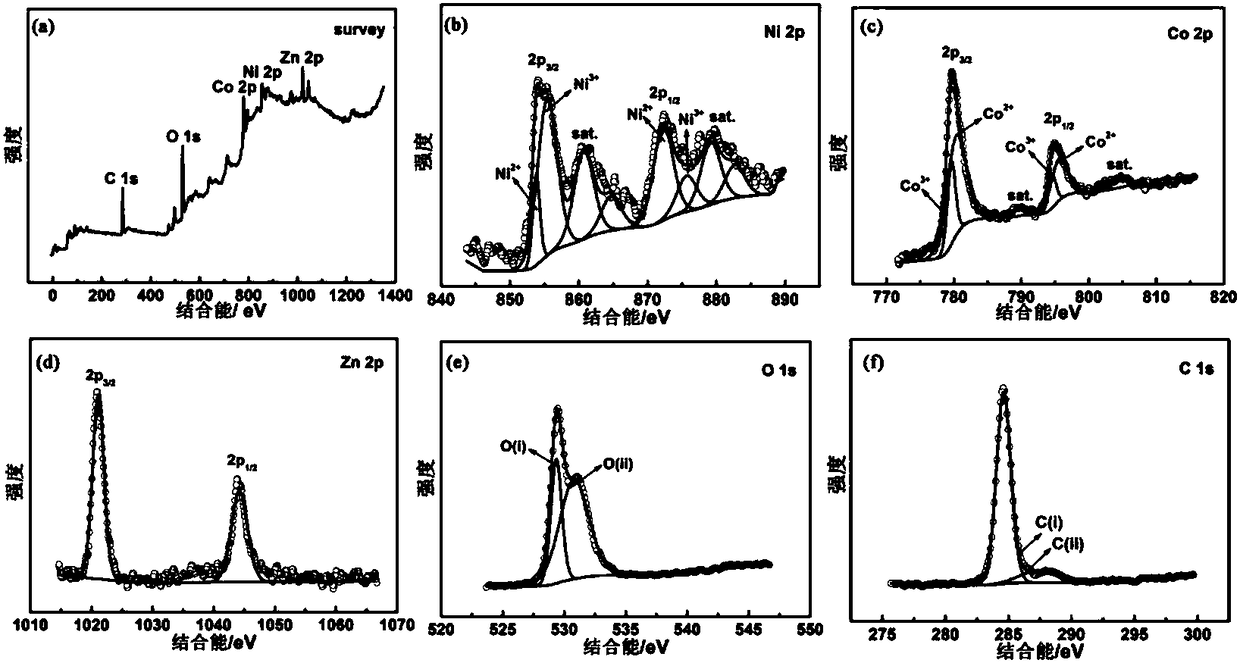

Preparation method of foam nickel-loaded composite nano metal oxide electrode material

ActiveCN108144620AHigh porosityAvoid technical issues that could lead to reunionsHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsPorosityNanoparticle

The invention discloses a preparation method of a foam nickel-loaded composite nano metal oxide electrode material, and aims to solve the technical problem that the existing preparation method of an existing electrode material has poor practicability. The preparation method disclosed by the invention is characterized in that In the technical scheme, foam nickel is adopted as a substrate, and ZnO nanowire and ZIFs -derived Co3O4 / NiCo2O4 doubel-shell nano cage structure nano particle material are loaded; ZnO / Co3O4 / NiCo2O4 / foam nickel is prepared in combination with the large specific surface area and quick electron transmission performance of ZnO as well as the high porosity and excellent catalytic performance of the ZIFs -derived Co3O4 / NiCo2O4 double-shell nano cage., ZnO / Co3O4 / NiCo2O4 / foamnickelwhich has the advantages of goodhigh electrocatalytic activity on H2O2, high sensitivity, low detection limit, wide detection range, goodhigh stability and the like, and avoids the technical problem of frequent agglomeration caused byof a powder modified electrode.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Process of preparing metal oxide electrode by polymeric precursor thermal decomposition method

The invention discloses a technique to preparing metallic oxide electrode with poly forerunner body thermal decomposition method, which comprise the following steps: preparing poly forerunner body solution with metallic element; multiple-coating poly forerunner body solution on ground-mass; thermal-decompositing; firing; getting the product; belonging to preparing technical domain of electric pole material; reacting polybasic carboxylic acid , polyatomic alcohol and metallic compound; getting the poly forerunner body solution; making the ground-mass as one of titanium, tantalum, niobium, zirconium and non-corrodible steel; This product possesses high electrocatalysis activity, good conductive property, long age and low cost, which can be used to electrochemical synthesis and negative pole protecting domains.

Owner:YANGZHOU UNIV

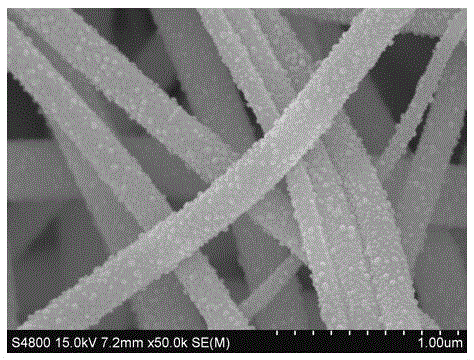

Method for preparing catalyst for electrical catalytic degradation of organic wastewater

InactiveCN105478102AEasy to operateImprove controllabilityWater contaminantsWater/sewage treatment by electrochemical methodsYarnFiber

The invention discloses a method for preparing a catalyst for electrical catalytic degradation of organic wastewater and relates to the technique for preparing a one-dimensional metallic oxide electrode catalyst for electrical catalytic degradation of organic wastewater. Metal salt, high-molecular polymer and organic solvent are mixed and stirred to form a spinning solution, electrostatic spinning is conducted to generate M / PVP composite fiber yarn, the yarn is subjected to heat treatment in the air to prepare a one-dimensional metallic oxide catalyst, and the prepared catalyst is made into an electrode through tablet pressing to serve as the positive pole for electrical catalysis of organic wastewater. The one-dimensional continuous filament-shaped metallic oxide can be prepared with the electrospinning method to be used as the electrode catalyst, has higher stability and conductivity compared with granules, and has a good catalysis effect in wastewater electro-catalysis as an electrocatalyst electrode.

Owner:YANGZHOU UNIV

Preparation method for titanium dioxide nanotube loaded with macroporous antimony tin oxide

The invention discloses a preparation method for a titanium dioxide nanotube loaded with a macroporous antimony tin oxide, relates to the technical field of preparation of metal oxide electrode materials and also relates to the technical field of treatment of phenolic waste water. The preparation method comprises the following steps: immersing the titanium dioxide nanotube filled with an antimony tin oxide into highly dispersed polystyrene microsphere alcohol liquor, drying and forming a film at a constant temperature to prepare the titanium dioxide nanotube loaded with an opal polystyrene template; and then, coating polymer precursor liquor on the opal polystyrene template of the titanium dioxide nanotube loaded with the opal polystyrene template, sintering at a high temperature to remove polystyrene microspheres to obtain an antimony tin oxide material with an inverse opal macroporous structure, which takes the titanium dioxide nanotube as a base body. According to the preparation method, a macroporous antimony tin oxide film material which is compact, uniform and ordered is prepared on the base body of the titanium dioxide nanotube by virtue of a polymer precursor process. The preparation method is convenient for industrial production and relatively low in cost.

Owner:YANGZHOU UNIV

Lithium ion battery additive, electrolyte and anode slurry

The invention belongs to the technical field of lithium ion batteries, and particularly discloses a lithium ion battery additive, electrolyte and anode slurry. The additive comprises one or more bismaleimide compound with a structure in a general formula I or general formula II. The electrolyte comprises electrolyte salt, a non-aqueous solvent and the additive. The anode slurry comprises an anode active material, a conductive agent, an adhesive and the additive. The structure of the additive contains a large number of unshared ion pairs and polar functional groups, the additive has strong interaction force with a metal oxide electrode material and a current collector, dispersity of metal oxide anode particles can be improved in the anode slurry, the bonding power between an electrode material coating and the current collector is remarkably improved, and the cycling performance is improved. The structure of the additive further contains a large number of double bonds, electrochemically oxidative polymerization can be realized under high voltage, a more stable SEI (solid electrolyte interface) film can be formed on the surface of the anode material, and exothermic auxiliary reaction of the anode material and the electrolyte at high temperature and under high voltage is effectively weakened.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

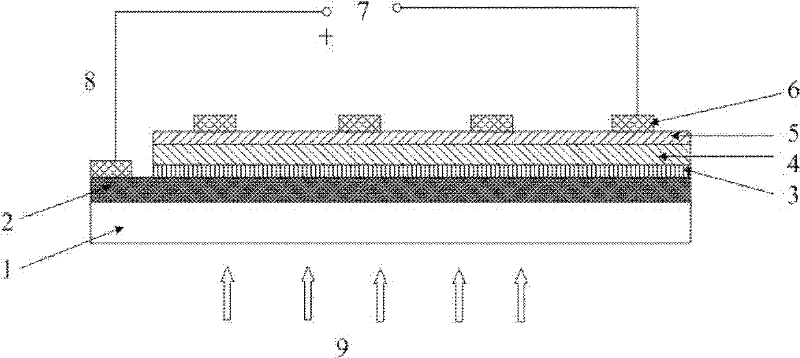

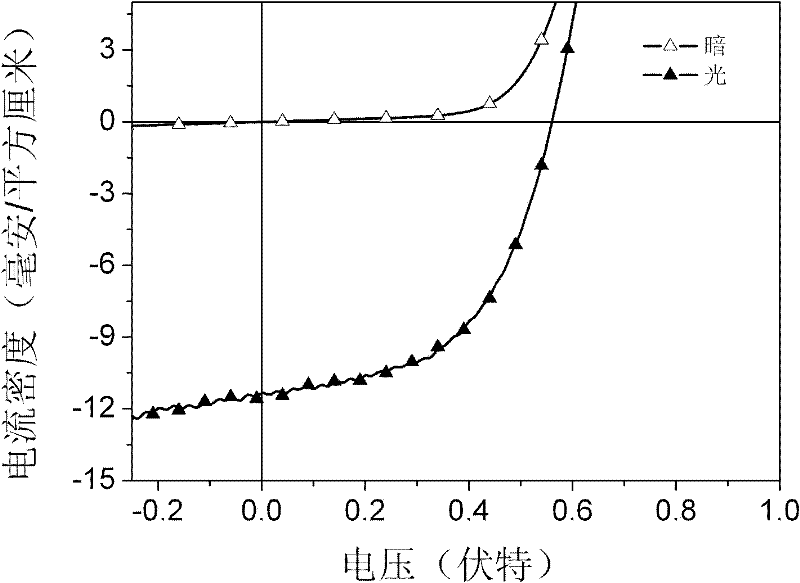

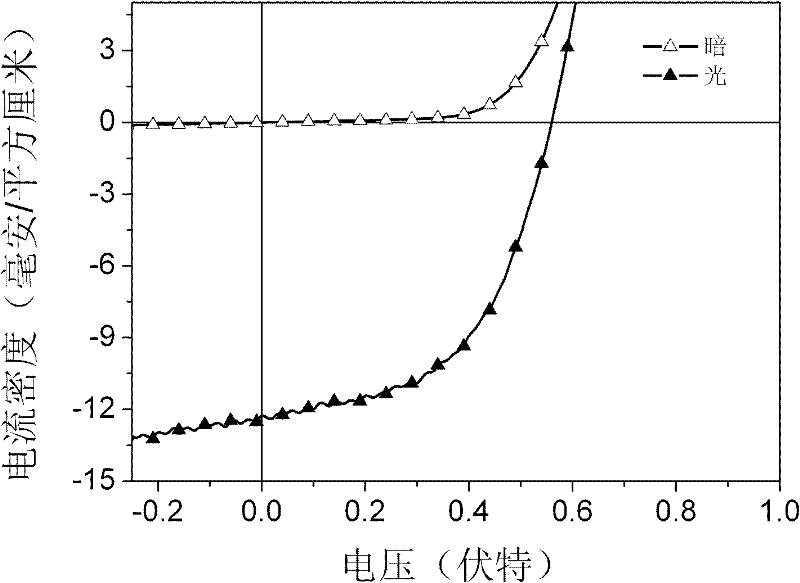

Polymer solar battery with inverted structure and fabrication method thereof

InactiveCN102201539AEfficient collectionImprove photoelectric conversion efficiencyFinal product manufactureSolid-state devicesSolar batteryElectron

The invention discloses a polymer solar battery with an inverted structure and a fabrication method thereof, belonging to the technical field of polymer solar battery. The polymer solar battery with an inverted structure comprises a substrate, a transparent conductive metal oxide electrode layer, an electron collection layer, a photovoltaic active layer, a hole collection layer and a high work function anode layer, which are sequentially stacked, wherein the electron collection layer is a titanium acetylacetonate membrane. The electron collection layer can be prepared by a spin coating method and can be introduced into the polymer solar battery with the inverted structure to achieve high-efficiency electron collection. Compared with TiO2 prepared by the traditional sol-gel method, the polymer solar battery with an inverted structure has the advantages of high photoelectric conversion efficiency, low cost, good experimental repeatability and the like, can be prepared by simple process and is suitable for large-scale industrial production.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com